EUROPEAN COMMISSION

DIRECTORATE-GENERAL

CLIMATE ACTION

Directorate C – Climate Strategy, Governance and Emissions from non-trading sectors

Unit C.2 – Governance and Effort Sharing

Guidance Document

The Monitoring and Reporting Regulation –

Guidance on Sampling and Analysis

MRR Guidance document No. 5,

Updated version of 7 October 2021

This document is part of a series of documents provided by the Commission services

for supporting the implementation of the “Monitoring and Reporting Regulation” (the

“MRR” or “M&R Regulation”) for the EU ETS (the European greenhouse gas Emission

Trading System). A new version of the MRR has been developed for the use in the 4

th

phase of the EU ETS, i.e. Commission Implementing Regulation (EU) 2018/2066 of 19

December 2018 in its current version

1

.

The guidance represents the views of the Commission services at the time of publica-

tion. It is not legally binding.

This guidance document takes into account the discussions within meetings of the in-

formal Technical Working Group on MRVA (Monitoring, Reporting, Verification and Ac-

creditation) under the WG III of the Climate Change Committee (CCC), as well as writ-

ten comments received from stakeholders and experts from Member States. This guid-

ance document was unanimously endorsed by the representatives of the Member

States of the Climate Change Committee by written procedure ending on 28

th

of Sep-

tember 2021.

All guidance documents and templates can be downloaded from the Commission’s web-

site at the following address:

https://ec.europa.eu/clima/policies/ets/monitoring_en#tab-0-1.

1

Updated by Commission Implementing Regulation (EU) 2020/2085 of 14 December 2020 amending and

correcting Implementing Regulation (EU) 2018/2066 on the monitoring and reporting of greenhouse gas

emissions pursuant to Directive 2003/87/EC of the European Parliament and of the Council; the

consolidated MRR can be found here:

https://eur-lex.europa.eu/legal-content/EN/TXT/?uri=CELEX%3A02018R2066-20210101.

Note: as some amendments to the MRR will start to apply on 1 January 2022 (see section 1.2 of GD 1

“What is new in the MRR”), they do not appear in the consolidated version in 2021. The complete

amendment can be found under https://eur-lex.europa.eu/eli/reg_impl/2020/2085/oj

2

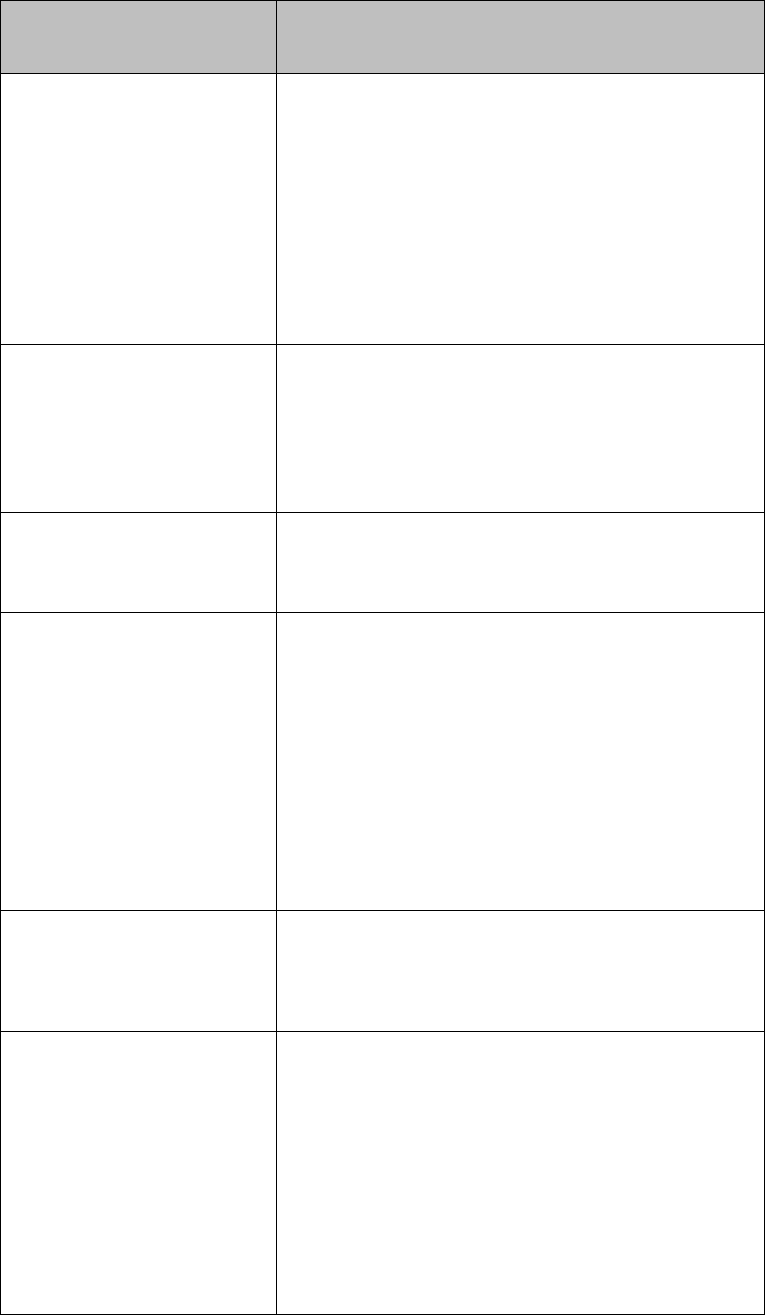

TABLE OF CONTENTS

1 INTRODUCTION ............................................................................ 4

1.1 About this document ................................................................................. 4

1.2 How to use this document ........................................................................ 4

1.3 Where to find further information ............................................................ 5

2 OVERVIEW .................................................................................... 8

2.1 Overview of this document....................................................................... 8

2.2 Calculation factors – Principles ............................................................... 8

2.3 General requirements for laboratory analyses .................................... 10

2.4 Procedures for analytical methods ....................................................... 11

3 SAMPLING PLAN ........................................................................ 13

3.1 Introduction to sampling ........................................................................ 13

3.2 Sampling plan requirements of the MRR .............................................. 18

3.3 Preparing a sampling plan...................................................................... 21

4 FREQUENCY OF ANALYSES ..................................................... 23

4.1 Minimum frequency of analyses (Annex VII of the MRR) .................... 23

4.2 The “1/3” rule ........................................................................................... 24

4.3 Incurrence of unreasonable costs ......................................................... 26

4.4 Analyses frequency for specific situations .......................................... 27

5 LABORATORIES ......................................................................... 28

6 ONLINE GAS ANALYSERS ......................................................... 31

7 ANNEX I: ACRONYMS AND LEGISLATION ............................... 32

7.1 Acronyms used ........................................................................................ 32

7.2 Legislative texts ....................................................................................... 32

8 ANNEX II: EXAMPLE FOR A SAMPLING PLAN TEMPLATE ..... 33

9 ANNEX III – FREQUENTLY ASKED QUESTIONS ...................... 38

9.1 Supplier data: What if the supplier does not provide sufficient

information for demonstrating compliance with the required tiers? . 38

9.2 Online gas analysers: What is the (initial) validation and how can it be

performed? ............................................................................................... 39

9.3 How can it be determined whether a sample taken is “representative”?

................................................................................................................... 40

9.4 How to proceed if the application of tier 3, i.e. analysis in accordance

with Articles 32 to 35, incurs unreasonable costs? ............................. 41

3

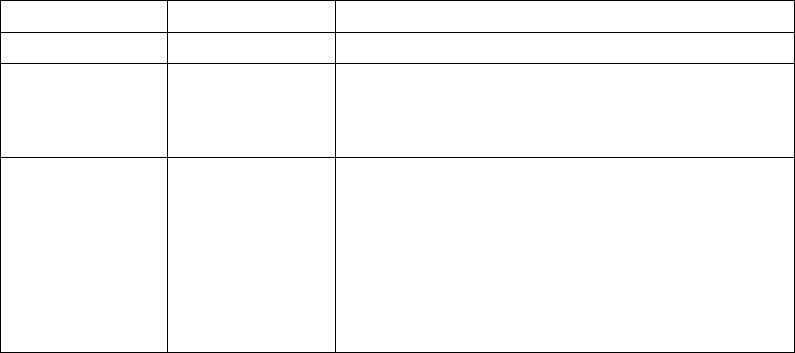

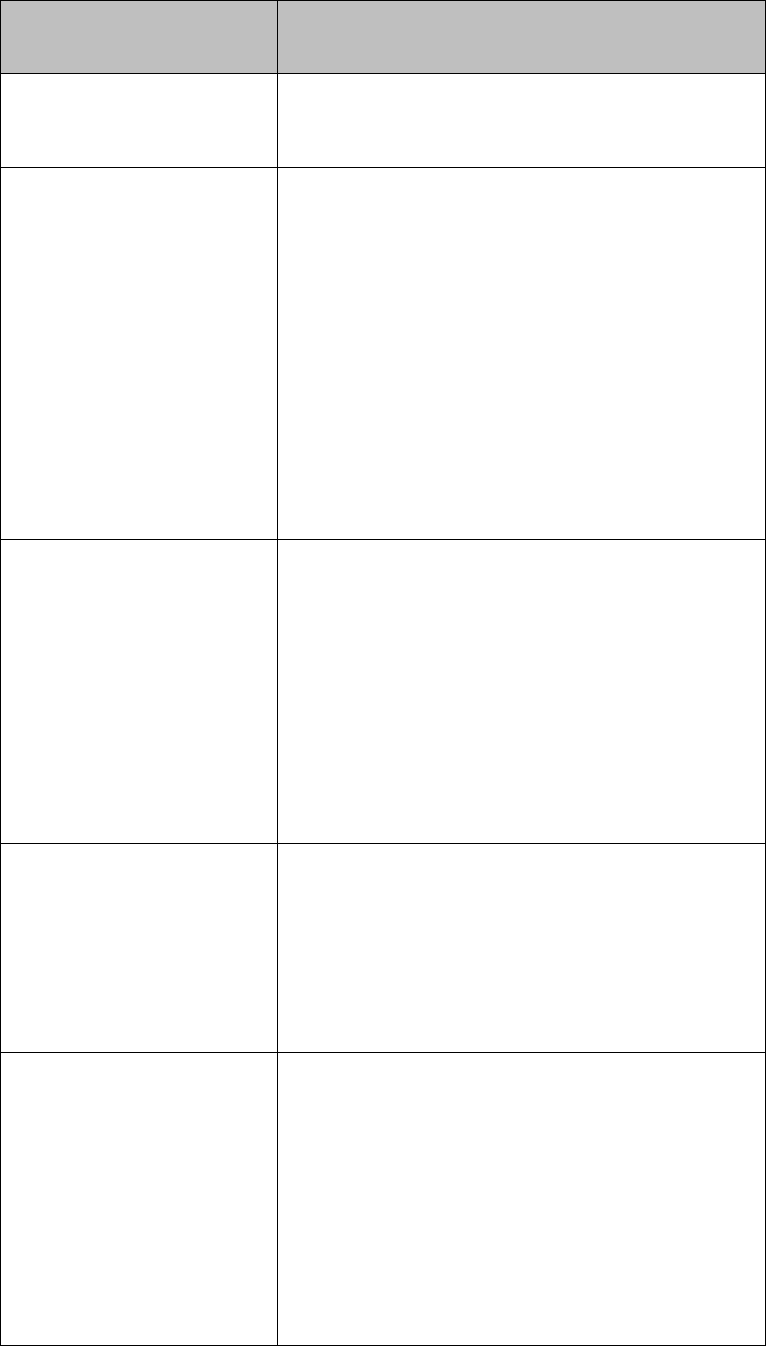

Version History

Date

Version status

Remarks

5 Oct 2012

published

Endorsed by CCC on 28 September 2012

27 November

2017

re-published

Correct reference to updated Annex VII of the MRR;

update of references to standard and legislation;

wording updates (e.g. chapter 5 on equivalence of la-

boratories)

7 October 2021

Updated version

endorsed by

CCC

Revision: move from MRR 2012 to MRR 2018, includ-

ing its revision in 2020, i.e. revision for use in the 4th

phase of the EU ETS

Clarification on the “1/3” rule in section 4.2

Clarification in chapter 6 on the relation between

online gas analysers and the provisions in Articles 33

to 35

Inclusion of Frequently Asked Questions

4

1 INTRODUCTION

1.1 About this document

This document is part of a series of guidance documents provided on specific topics of

monitoring and reporting under the EU ETS. While Guidance Document No. 1 provides

a general overview on monitoring and reporting of emissions from installations under

the EU ETS, this document (Guidance Document No. 5) explains in more detail the

requirements for laboratory analyses. It has been written to support the M&R Regulation

as well as the Guidance Document No. 1, by explaining its requirements in a non-legis-

lative language. However, it should always be remembered that the Regulation is the

primary requirement.

This document interprets the Regulation regarding requirements for installations. It

builds on guidance and best practice identified during earlier phases of the EU ETS.

It also takes into account the valuable input from the task force on monitoring and re-

porting established under the EU ETS Compliance Forum, and from the informal Tech-

nical Working Group on Monitoring, Reporting, Verification and Accreditation (TWG on

MRVA) of Member State experts established under the Working Group 3 (WG III) of the

Climate Change Committee.

1.2 How to use this document

Where article numbers are given in this document without further specification, they

always refer to the M&R Regulation (MRR) in its current version

2

.For acronyms, refer-

ences to legislative texts and links to further important documents, please see the An-

nex.

This document only refers to emissions starting from 2021 (with the exception of bio-

mass-related topics, which will apply in full only from 2022). A “New!” symbol (such as

on the margin here) indicates where changes to requirements compared to the MRR

2012 have taken place.

This symbol points to important hints for operators and competent authorities.

This indicator is used where significant simplifications to the general requirements of

the MRR are promoted.

The light bulb symbol is used where best practices are presented.

The small installation symbol is used to guide the reader to topics which are applicable

for installations with low emissions.

The tools symbol tells the reader that other documents, templates or electronic tools are

available from other sources (including those still under development).

The book symbol points to examples given for the topics discussed in the surrounding

text.

2

Implementing Regulation (EU) 2018/2066; The consolidated MRR can be found here:

https://eur-lex.europa.eu/eli/reg/2018/2066

small

5

1.3 Where to find further information

All guidance documents and templates provided by the Commission on the basis of the

M&R Regulation and the A&V Regulation can be downloaded from the Commission’s

website at the following address:

https://ec.europa.eu/clima/policies/ets/monitoring_en#tab-0-1

The following documents are provided

3

:

“Quick guides” as introduction to the guidance documents below. Separate docu-

ments are available for each audience:

Operators of stationary installations;

Aircraft operators;

Competent Authorities;

Verifiers;

National Accreditation Bodies.

Guidance document No. 1: “The Monitoring and Reporting Regulation – General

guidance for installations”. This document outlines the principles and monitoring

approaches of the MRR relevant for stationary installations.

Guidance document No. 2: “The Monitoring and Reporting Regulation – General

guidance for aircraft operators”.

Guidance document No. 3: “Biomass issues in the EU ETS”: This document dis-

cusses the application of sustainability criteria for biomass, as well as the require-

ments of Articles 38 and, 39 of the MRR. This document is relevant for operators of

installations as well as useful background information for aircraft operators.

Guidance document No. 4: “Guidance on Uncertainty Assessment”. This document

for installations gives information on assessing the uncertainty associated with the

measurement equipment used, and thus helps the operator to determine whether

he can comply with specific tier requirements.

Guidance document No. 4a: “Exemplar Uncertainty Assessment”. This document

contains further guidance and provides examples for carrying out uncertainty as-

sessments and how to demonstrate compliance with tier requirements.

Guidance document No. 5: “Guidance on Sampling and Analysis” (only for installa-

tions). This document deals with the criteria for the use of non-accredited laborato-

ries, development of a sampling plan, and various other related issues concerning

the monitoring of emissions in the EU ETS (this document).

Guidance document No. 5a: “Exemplar Sampling Plan”. This document provides

an example sampling plan for a stationary installation.

Guidance document No. 6: “Data flow activities and control system”. This document

discusses possibilities to describe data flow activities for monitoring in the EU ETS,

3

This list reflects the status at the time of writing this updated guidance. Further documents may be added

later.

6

the risk assessment as part of the control system, and examples of control activities.

It is relevant to installations as well as for aircraft operators.

Guidance document No. 6a: “Risk Assessment and control activities – examples”.

This document provides further guidance and an example for a risk assessment.

Guidance document No. 7: “Continuous Emissions Monitoring Systems (CEMS)”.

For stationary installations, this document gives information on the application of

measurement-based approaches where GHG emissions are measured directly in

the stack, and thus helps the operator to determine which type of equipment has to

be used and whether he can comply with specific tier requirements.

Guidance document No. 8: “EU ETS Inspections”. This document provides guid-

ance for competent authorities for carrying out inspections. It mainly focusses on

site-visit inspections of stationary installations.

The Commission furthermore provides the following electronic templates:

Template No. 1: Monitoring plan for the emissions of stationary installations

Template No. 2: Monitoring plan for the emissions of aircraft operators

Template No. 3: Monitoring plan for the tonne-kilometre data of aircraft operators

Template No. 4: Annual emissions report of stationary installations

Template No. 5: Annual emissions report of aircraft operators

Template No. 6: Tonne-kilometre data report of aircraft operators

Template No. 7: Improvement report of stationary installations

Template No. 8: Improvement report of aircraft operators

There are furthermore the following tools available for operators:

Unreasonable costs determination tool;

Tool for the assessment of uncertainties;

Frequency of Analysis Tool;

Tool for operator risk assessment.

The following MRR training material is available for operators:

Roadmap through M&R Guidance

Uncertainty assessment

Unreasonable costs

Sampling plans

Data gaps

Round Robin Test

Besides these documents dedicated to the MRR, a separate set of guidance documents

on the A&V Regulation is available under the same address.

All EU legislation is found on EUR-Lex: http://eur-lex.europa.eu/

The most important legislation is furthermore listed in the Annex of this document.

7

Also, competent authorities in the Member States may provide useful guidance on their

own websites. Operators of installations should in particular check if the competent au-

thority provides workshops, FAQs, helpdesks etc.

8

2 OVERVIEW

2.1 Overview of this document

Note: This document is only relevant for installations which determine calculation

factors by analyses, or – regarding the competence requirements of laboratories

– apply on-line gas analysers or continuous emission measurement systems

(CEMS).

This document provides an overview of the importance of sampling and analysis and

how this topic is treated in the MRR. In particular, the MRR uses the term “analyses in

accordance with Article 32 to 35” on several occasions where calculation factors are to

be determined by analysis (usually in the context of high tier approaches). Section 2.2

provides an introduction to this topic. Section 2.3 then gives a more detailed summary

of the MRR’s requirements for analyses, and explains also how those requirements

relate to situations where the MRR allows the use of “industry best practice”.

Chapter 3 gives guidance on the requirements of Article 33 for preparing a sampling

plan. Chapter 4 discussed how to determine the appropriate frequency of analyses

based on Article 35.

Thereafter the requirements for laboratories used to carry out analyses for the determi-

nation of calculation factors as laid down in Article 34 are elaborated in Chapter 5. This

focusses particularly on the possibilities to demonstrate equivalence to an accredited

service, if the laboratory is not accredited in accordance with EN ISO/IEC 17025.

Annex II supplements Chapters 3 and 4 by providing an example of a sampling plan

template.

2.2 Calculation factors – Principles

[This section is based on section 6.2 of Guidance Document 1 (general guidance for

installations). It is included here for reasons of completeness and to allow this to be read

as a self-standing document.]

Calculation factors are the focus of this paper. These factors are:

In the case of the standard methodology for combustion of fuels, or fuels used as

process input: Emission factors, net calorific values, oxidation factors and biomass

fractions;

In the case of the standard methodology for process emissions (in particular de-

composition of carbonates): Emission factors and conversion factors;

For mass balances: Carbon contents and, if applicable, the biomass fractions and

net calorific values.

The following formula shows how the calculation factors relate to the calculation of emis-

sions. The example relates to the most common case, i.e. emissions from the combus-

tion of fuels, using the standard calculation method in accordance with Article 24(1):

9

Example: Calculation-based monitoring of combustions of fuels

)1( BFOFEFNCVADEm

Where:

Em ...... Emissions [t CO

2

]

AD ....... Activity data (= fuel quantity) [t or Nm

3

]

Calculation factors:

NCV .... Net Calorific Value [TJ/t or TJ/Nm

3

]

EF ....... Emission factor [t CO

2

/TJ, t CO

2

/t or t CO

2

/Nm

3

]

OF ....... Oxidation factor [dimensionless]

BF ....... Biomass fraction [dimensionless]

According to Article 30(1) of the MRR, these factors can be determined by one of the

following principles:

a. from default values (see section 6.2.1 of guidance document No. 1); or

b. by laboratory analyses.

The applicable tier will determine which of these options is used. Lower tiers allow for

default values, i.e. for values which are kept constant throughout the years, and updated

only when more accurate data becomes available. The highest tier defined for each

parameter in the MRR is usually the laboratory analysis, which is more demanding, but

of course more accurate. The result of the analysis is valid for each batch from which

the sample has been taken, while a default value is usually an average or conservative

value determined on the basis of big quantities of that material. For example, emission

factors for coal as used in national inventories might be applicable to a country-wide

average of several (or even many) coal types as used also in energy statistics, while an

MRR analysis will be valid for the particular batch analysed (one coal type).

Important note: In all cases, the operator must ensure that activity data and all calcu-

lation factors are used consistently. Where a fuel’s quantity is determined in the wet

state before entering the boiler, the calculation factors must also refer to the wet state.

Where analyses are carried out in the laboratory from the dry sample, the moisture must

be taken into account appropriately, for arriving at calculation factors applicable for the

wet material.

Operators must also be careful not to mix up parameters of inconsistent units. Where

the amount of fuel is determined per volume, also the NCV and/or emission factor must

refer to volume rather than mass

4

.

With respect to biomass source streams, the operator has to determine the biomass

fractions only for mixed fuels or materials. For the biomass fraction of all other fuels or

materials, the operator may use either a default value of 100% where the fuel or material

consists exclusively of biomass, or a default value of 0% for fossil fuels or material.

However, Article 38(5) stipulates that the operator may only apply an emission factor of

4

See section 4.3.1 of guidance document No. 1

10

zero (i.e. a biomass fraction of 100%) for biomass if he can demonstrate that biofuels,

bioliquids and biomass fuels used for combustion comply with the sustainability and the

greenhouse gas emissions saving criteria of the RES Directive

5

. For further guidance

on biomass related topics, please see section 6.3.5 of Guidance Document 1 and Guid-

ance Document 3.

2.3 General requirements for laboratory analyses

Where the MRR refers to determination “in accordance with Article 32 to 35”, this

means that a parameter must be determined by (chemical) laboratory analyses. The

MRR imposes relatively strict rules for such analyses, in order to ensure valid and com-

parable results at a high quality level. In particular, the following points need consider-

ation:

The laboratory must demonstrate its competence. This is achieved by one of the

following approaches:

An accreditation in accordance with EN ISO/IEC 17025, where the analysis

method required is within the accreditation scope; or

Demonstrating that the criteria listed in Article 34(3) are satisfied. This is con-

sidered reasonably equivalent to the requirements of EN ISO/IEC 17025. Note

that this approach is allowed only where use of an accredited laboratory is

shown to be technically not feasible or involving unreasonable costs.

The way samples are taken from the material or fuel to be analysed is considered

crucial for receiving representative results.

6

Therefore, operators have to develop

sampling plans in the form of written procedures (see Chapter 3) and get them

approved by the competent authority. Note that this applies also where the operator

does not carry out the sampling himself, but treats it as an outsourced process.

Analytical methods usually have to follow international or national standards

7

.

Note that the above is usually related to the highest tiers for calculation factors. There-

fore, these rather demanding requirements are rarely applicable to smaller installations.

In particular operators of installations with low emissions may use “any laboratory that

is technically competent and able to generate technically valid results using the relevant

analytical procedures, and that provides evidence for quality assurance measures as

referred to in Article 34(3)”. In fact, the minimum requirements would be that the labor-

atory demonstrates that it is technically competent and “capable of managing its per-

sonnel, procedures, documents and tasks in a reliable manner”, and that it demon-

strates quality assurance measures and corrective actions, if needed, for calibration and

5

For this purpose, the “RED II” (Directive (EU) 2018/2001 of the European Parliament and of the Council of

11 December 2018 on the promotion of the use of energy from renewable sources (recast)) will have to be

used from 1 January 2022. In 2021, the RED I (Directive 2009/28/EC) still applies. For more details, see

guidance document No. 3.

6

Question 4.3 of the FAQ document may provide further helpful information on how to determine whether a

sample is “representative”. The FAQs can be downloaded under the following link: https://ec.eu-

ropa.eu/clima/sites/clima/files/ets/monitoring/docs/faq_mmr_en.pdf

7

For the use of standards, Article 32(1) defines the following hierarchy: “The operator shall ensure that any

analyses, sampling, calibrations and validations for the determination of calculation factors are carried out

by applying methods based on corresponding EN standards.

Where such standards are not available, the methods shall be based on suitable ISO standards or national

standards. Where no applicable published standards exist, suitable draft standards, industry best practice

guidelines or other scientifically proven methodologies shall be used, limiting sampling and measurement

bias.”

small

11

test results

8

. However, it is in the operator’s interest to receive reliable results from the

laboratory. Therefore, operators should strive to comply with the requirements of Article

34 to the highest degree feasible.

Furthermore, it is important to note that the MRR, in the activity specific requirements

of Annex IV, allows the use of “industry best practice guidelines” for some lower tiers.

In some cases, this is the lowest tier where no default values are applicable. In such

cases, where despite approval to apply a lower tier methodology analyses are still re-

quired, it may not be appropriate or possible to apply Articles 32 to 35 in full. However,

the competent authority should deem the following as minimum requirements:

Where the use of an accredited laboratory is technically not feasible or would lead

to unreasonable costs, the operator may use any laboratory that is technically com-

petent and able to generate technically valid results using the relevant analytical

procedures, and that provides evidence for quality assurance measures and cor-

rective actions, if needed, as referred to in Article 34(3).

The operator should submit a sampling plan in accordance with Article 33.

The operator should determine the frequency of analysis in accordance with Article

35.

2.4 Procedures for analytical methods

Annex I of the MRR requires that a monitoring plan shall contain, if applicable, a list of

the analytical methods to be used for the determination of all relevant calculation factors

for each source streams, and a description of the written procedures for those analyses.

How such procedures can be described in the monitoring plan is shown by the following

example.

Example of the required MP summary for an analysis procedure:

Item according to

Article 12(2)

Possible content (examples)

Title of procedure

Analysis of NCV of solid and liquid fuels.

Reference for proce-

dure

Solid fuels: ANA 1-1/UBA; Liquid fuels: ANA 1-2/UBA; Compari-

son by external (accredited) laboratory: ANA 1-3/ext

Diagram reference

(where applicable)

N.A.

Brief description of

procedure

Bomb calorimeter method is used. Appropriate amount of sample

is based on experience from earlier measurements of similar ma-

terials.

Samples are used in dry state (dried at 120°C for at least 6h).

NCV is corrected for moisture content by calculation.

Solid fuels: as in standard. Liquid fuels: Only slightly adapted from

standard; samples are not dried.

Post or department

responsible for the

procedure and for any

data generated

Company's Laboratory - Head of department. Deputy: HSEQ man-

ager.

8

Examples for such measures are given in Article 34(3), point (j): regular participation in proficiency testing

schemes, applying analytical methods to certified reference materials, or inter-comparison with an

accredited laboratory.

12

Location where rec-

ords are kept

Hardcopy: Laboratory Office, shelf 27/9, Folder identified “ETS 01-

ANA-yyyy” (where yyyy is the current year).

Electronically: “P:\ETS_MRV\labs\ETS_01-ANA-yyyy.xls”

Name of IT system

used (where applica-

ble).

Internal log of the lab (MS Access database): sample numbers

and origin/name of sample are tracked together with the results.

List of EN or other

standards applied

(where relevant)

EN 14918:2009 with modifications for using also for non-biomass

and liquid fuels.

13

3 SAMPLING PLAN

3.1 Introduction to sampling

“Frequency of Sampling” versus “Frequency of Analyses”

The MRR refers to “Frequency of Analyses” in Article 35 (see chapter 4). Depending on

the specific situation the resulting requirement in the approved monitoring plan for the

operator may be e.g. that the minimum frequency of analyses of the emission factor of

a certain source stream is four times a year.

This term “Frequency of Analyses” must not be confused with the “Frequency of Sam-

pling”, i.e. the frequency of taking samples or increments from a batch or delivery of a

fuel or material. In general, a lot more samples/increments than four have to be taken

over the year to obtain representative results. This Chapter 3 and its sections only deal

with the frequency of taking samples.

The following example should help to clarify.

Example: A coal firing plant is burning 500,000 tonnes of coal a year. In accordance

with Annex VII (also see section 4.1), the operator is required as a minimum to analyse

every 20,000 tonnes of coal. This will at least result in 25 different laboratory samples

that are analysed each year. The main objective of the sampling plan, which also in-

cludes the frequency of sampling, is to prepare (at least) 25 laboratory samples that are

representative for each of the 20,000 tonne batches. In order to have representative

laboratory samples more than just one sample/increment will have to be taken from

each 20,000 tonne batch.

Sampling is a very important task wherever something is to be analysed in a laboratory.

It is crucial to develop and apply a reproducible methodology (the sampling plan) which

ensures that the sample taken is representative of the whole batch or delivery from

which the sample is taken. The sampling plan describes the overall aims and objectives;

it includes specific and practical instructions on what is going to be sampled, how it will

be sampled, at what frequency, what the sample will be analysed for and by whom. It

covers all steps from drawing the sample until the sample is being analysed. An appro-

priate sampling plan provides transparency to all users and will not only improve the

reliability of the results and the level of assurance; it may also help to reduce costs for

analyses and verification.

The complexity of the sampling plan will to a large extent depend on the degree of

heterogeneity of the fuel or material. In general, it might be useful in complex cases to

put some effort into the preparation of an elaborate sampling plan. However, it should

also be noted that the use of highly heterogeneous materials is not a very common

practice in EU ETS installations. Therefore, few installations will have to develop so-

phisticated sampling plans. In many cases it may happen that sampling used for other

purposes (such as quality or process control) can be used (as it is) without further ad-

aptation, as the examples show.

The development of a sampling plan is explained in section 3.3. Sampling is more com-

plicated the more heterogeneous the material is. For a very homogeneous material (e.g.

a liquid fuel which is homogenised in a tank by stirring) a simple sample of 50 ml may

well be representative for the whole 500 tonnes in the tank. At the other end of the

14

spectrum, some waste fractions (e.g. electronic scrap) may consist of items each be-

yond 50 kg mass, while a laboratory analysis usually needs only samples of some grams

or even in some cases micrograms (µg).

The aim of every sampling exercise is that the final sample in the laboratory is as rep-

resentative of the whole delivery period or batch of fuel or material as possible. It is a

statistical exercise to determine how many “increments” (smaller samples which are

combined into a bigger sample) must be picked from a batch, and how big the incre-

ments must be, in order to obtain a reasonably representative “composite sample”. The

increments must be considerably bigger than the particle size, and the locations of sam-

pling should be spread over the whole area to be sampled. The number of increments

must be high enough to allow a meaningful average.

Example 1: An installation is burning clay delivered by storage tanks on trucks.

To determine the properties of this source stream, e.g. the EF, each delivery is

sampled and treated according to industry best practise.

Example 2: A power plant is firing coal. Sampling is done by an automatic sam-

pler from the onsite coal stockpile.

In both examples, the provision of a written procedure for the sampling plan may

well be an exercise of documenting what is already being done in the past rather

than implementing any new process steps.

Example 3: A cement clinker producing installation is exclusively firing petcoke.

The operator intends to additionally burn waste tyres and other solid recovered

fuels.

In this case, the operator is well advised to carefully study relevant standard doc-

uments (see below) to prepare a transparent sampling plan accompanied by the

underpinning procedure. The accredited laboratory that will be engaged for the

analyses may also be consulted for the purpose of preparing an appropriate sam-

pling approach.

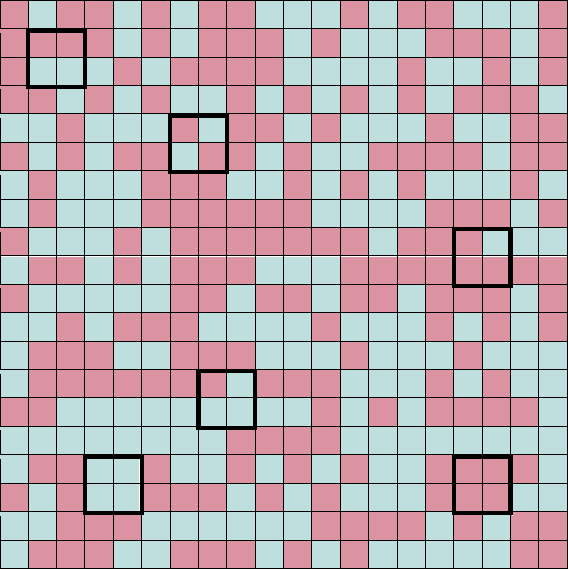

Example:

Figure 1 shows a population that consists of a physical mixture of two compo-

nents that are different in the one material property of interest (indicated by the

two different colours), e.g. the NCV. The average value of the property of the

population is of interest. It is assumed that only increments sizes of 2x2 boxes

(bold frames) can be taken.

This example should help the understanding that even rather simple cases re-

quire some effort to prepare an appropriate sampling plan providing representa-

tive results after analyses.

Although in the population there are as many green boxes as red ones, each

2x2 increment may contain different numbers of green and red ones. Due to this

problem where, in practice, the material may not show visible differences, one

of the main tasks of a sampling plan would be to determine the number of incre-

ments necessary to obtain sufficiently representative overall results (i.e. to have

an equal number of green and red boxes for analysis).

15

Figure 1: Example of a random two-component mixture with highly uniform particle size

distribution. The bold squares illustrate possible samples to be taken.

Furthermore, sampling often requires several consecutive steps of picking increments

from a pile, mixing these to a new sample, reducing the particle size, taking new

(smaller) samples, mixing again and reducing the size etc., until a final laboratory sam-

ple can be obtained. As indicated at the beginning, this process needs more effort the

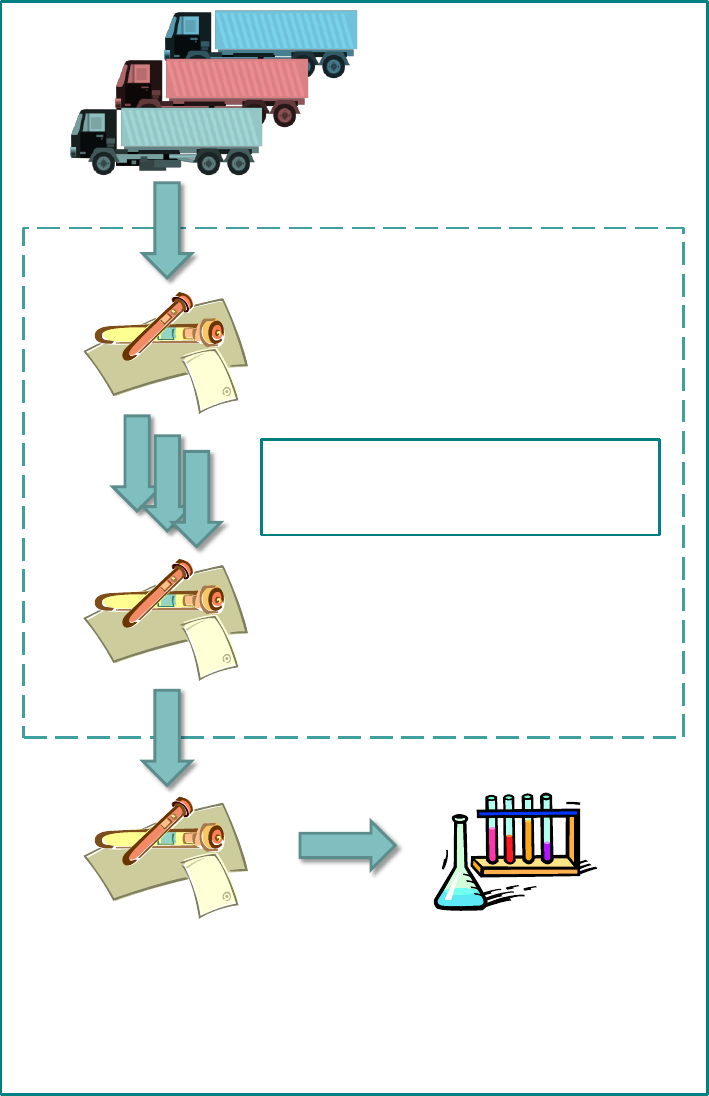

more heterogeneous a material is and the bigger the individual particles are. Figure 2

shows an example of a flow chart to help understand the role of sampling in the deter-

mination of calculation factors. Figure 3 shows a more detailed example of a sampling

plan.

16

Figure 2: Example of a flow sheet for sampling and analyses

(Composite) sample: e.g. increment or

sample taken from every truck delivery

(1 g to 100 kg scale)

Storage, mixing, sub-sampling, (particle

size reduction) and homogenisation of the

samples in installation‘s own laboratory

Final (sub)-sample : e.g. laboratory

sample analysed on the analytical

device (µg to mg scale)

the (weighted) average of all

analytical values in the reporting

period will be used for the

determination of the calculation factor

Mixed samples: combined samples

from several different trucks and from

different points in time

Process steps within the

boundaries of the sampling plan

Sample in accredited laboratory

Truck deliveries in the reporting

period

Transfer to accredited

laboratory

17

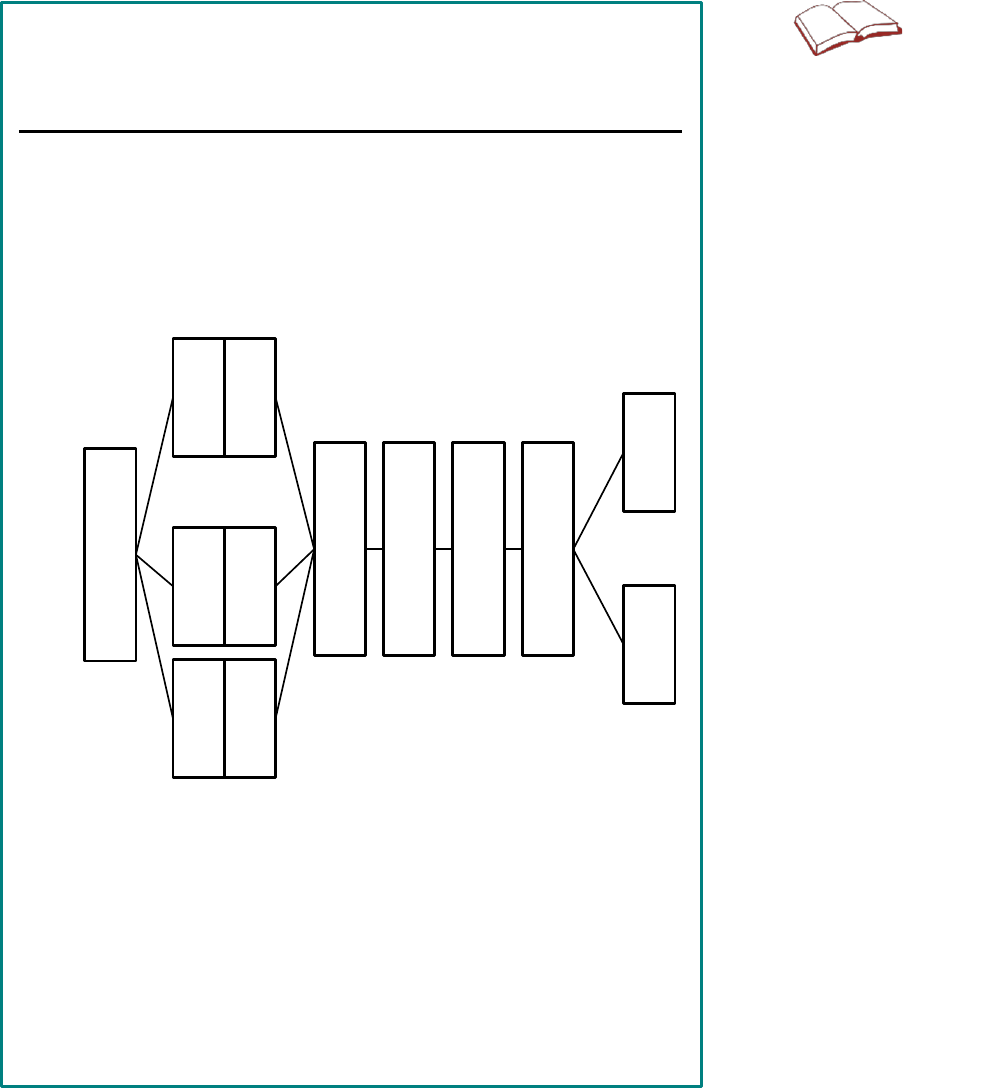

Figure 3. Example of a sampling plan flow sheet for the determination of the carbonate

content of clay

25,000 kg

Delivered amount

per truck

60 kg

30 kg

15 kg

1 kg

1 g 1 g

Increments

Combined samples

Sub-sample 1

Sub-sample 2

Sub-sample delivered

to laboratory

Analytical sample analysed

by the laboratory

1

5 kg

2

5 kg

12

5 kg

…

Grinding, mixing, dividing

Grinding, mixing, dividing

Dividing

Grinding, mixing, dividing

50 mm

50 mm

5 mm

1 mm

1 mm

0.06 mm

Particle

size

Treatment

18

Generally, all standards containing provisions for preparing sampling plans are suitable,

in particular those related to the specific type of source stream, e.g. coal. The following

standards and technical reports may be considered when preparing a sampling plan, in

particular for more complex cases:

EN 932-1: Tests for general properties of aggregates - Part 1: Methods for sam-

pling

EN ISO 10715: Natural gas - Sampling guidelines

ISO 13909-2: Hard coal and coke -- Mechanical sampling -- Part 2: Coal -- Sam-

pling from moving streams

EN 14899: Characterization of waste – Sampling of waste materials – Frame-

work for the preparation and application of a sampling plan

CEN/TR 15310: Characterization of waste – Sampling of waste materials

This technical report consisting of five parts assists and supple-

ments EN 14899

EN 15442: Solid recovered fuels – Methods for sampling

EN 15443: Solid recovered fuels – Methods for the preparation of the laboratory

sample

EN 14778: Solid biofuels - Sampling

Some of these standards and technical reports focus on waste materials. However, solid

waste materials are often very heterogeneous. Therefore, the approaches for preparing

a sampling plan related to waste materials presented in the standards and technical

reports can be considered to cover even the most complex non-waste cases as well. In

the absence of a suitable standard for the specific fuel, considerable simplifications may

be possible if the fuel or material is more homogeneous.

In some cases, analytical results may show that the heterogeneity of the fuel or material

significantly deviates from the information on heterogeneity on which the original sam-

pling plan for that specific fuel or material has been based. In such cases, Article 33(2)

requires the operator to adapt the relevant elements of the sampling plan. Those adap-

tations shall be in agreement with the laboratory carrying out the analysis for the re-

spective fuel or material (see Chapter 5) and subject to the approval of the competent

authority.

An example for a sampling plan template can be found in Annex II.

3.2 Sampling plan requirements of the MRR

For putting the above into practice in a practical and consistent manner, Article 33 re-

quires the operator to submit a sampling plan to the competent authority for approval

for each fuel or material for which calculation factors are to be determined by analyses.

If only tiers using default values or purchasing records are applied for the determination

of calculation factors, this requirement (and consequently this guidance document) is

not relevant.

19

The sampling plan shall be in form of a written procedure containing the following infor-

mation:

Methodologies for the preparation of samples

Responsibilities

Locations

Frequencies

Quantities

Methodology for the storage and transport of samples.

Furthermore, the MRR contains provisions that the sampling plan has to be updated

regularly if any changes of source streams or of the properties of source streams occur

over time. This is achieved by requiring that the operator puts in place a procedure

attached to the monitoring plan related to the revision of the appropriateness of the

sampling plan.

The ultimate goal of a sampling plan in the MRR is to ensure that samples analysed are

representative for the relevant batches and that the cumulated results of analytical val-

ues thereof allow the determination of representative calculation factors, e.g. that sam-

pling and analysis of the carbon content

9

of a source stream is representative for that

material over the whole reporting period.

In many cases, the requirement to have a sampling plan and an underpinning procedure

in place does not impose any additional requirements to current practice at the installa-

tion. In any case, the MRR requires that relevant elements of the sampling plan shall be

agreed with the laboratory carrying out the analysis for the respective fuel or material,

and evidence of that agreement shall be included in the sampling plan. This is in partic-

ular relevant in cases of rather heterogeneous material having properties that vary spa-

tially and temporally.

In some cases, sampling itself may be carried out by a third party, e.g. the fuel/material

supplier. In such a case, it is still the operator’s responsibility to demonstrate compliance

with the requirements in the MRR for sampling plans. This may be achieved by obtaining

information and evidence about the sampling plan by the third party

10

. In any event, the

operator is responsible for correct sampling defined in an appropriate sampling plan in

accordance with Article 33 regardless whether sampling or analysis is carried out by the

operator or by third parties.

9

As pointed out in section 6.3.1 of Guidance document No. 1, the emission factor is based on the carbon

content of a fuel or material. Carbon content is the primary object of analysis.

10

See FAQ 1 in section 9.1)

20

Example for a relatively simple sampling plan procedure:

Item according to Article 12(2)

Possible content (examples)

Title of the procedure

Sampling Plan for waste oil

Traceable and verifiable reference for

identification of the procedure

ETS 01-SP

Post or department responsible for imple-

menting the procedure and the post or

department responsible for the manage-

ment of the related data (if different)

Head of the waste department of the installa-

tion’s laboratory

11

Brief description of the procedure

12

1000 ml samples are taken from each

truck’s storage tank (about 250 trucks a

year).

Responsible person makes arrangement

that sampling is supervised (weekly spot

checks) by the responsible shift manager or

a representative nominated by the man-

ager.

Samples are collected in tight bottles clearly

marked with date and time, fuel supplier ID,

and name of the person who took the sam-

ple.

Samples are stored in room LA-007 of the

laboratory (at room temperature).

When 10 samples have been collected,

they are mixed and homogenised to give “a

composite sample”. This results in approxi-

mately 6 composite samples each quarter.

Once per quarter the composite samples

are sent to the accredited laboratory identi-

fied in the Monitoring plan.

Location of relevant records and infor-

mation

Hardcopy: Laboratory Storage Room, shelf

27/9, Folder identified “ETS 01-SP”.

Electronically:

“P:\ETS_MRV\Analyses\ETS_01-SP.xls”

Name of the computerised system used,

where applicable

N.A. (Normal network drives)

List of EN standards or other standards

applied, where relevant

EN 14899

11

Note that this is the installation’s own laboratory and not the accredited laboratory used to carry out the

analyses.

12

This description is required to be sufficiently clear to allow the operator, the competent authority and the

verifier to understand the essential parameters and operations performed.

21

3.3 Preparing a sampling plan

The following section outlines a step-by-step approach for preparing a sampling plan,

including a brief description of the steps. This approach is taken from CEN/TR 15310-

1.

1. Specify the objective of the Testing Programme

This should be a general statement on the overall purpose and this is an essential

first step. However, it will usually be at a rather high-level and too non-specific to

lead directly to detailed instructions for a sampling plan.

In most cases, this objective will simply be something like “to determine the average

carbon content” or “to determine the average emission factor of a material over the

whole reporting period”.

2. Develop the Technical Goals from the objective

(a) Define the population to be sampled

Population is a statistical term for defining the total volume of material or fuel

about which information is required through sampling. This should be one of the

first steps. In the most general case, the population will refer to the total amount

of material or fuel consumed within a reporting period. Sub-populations may,

for example, be defined as single batches (e.g. each delivery, or as a volume

as given by the analysis frequency in Annex VII of the MRR) or as fuel con-

sumed each month in case of a continuous source stream.

(b) Assess variability

Variability can be distinguished between

Spatial variability

This term refers to the heterogeneity of a material depending on the loca-

tion, e.g. the heterogeneity within one single batch.

Temporal variability

This term takes into account changes of properties over time, e.g. the var-

iability of the net calorific values between a batch consumed in March and

a batch consumed in November.

(c) Select the sampling approach

This can be distinguished between

Probabilistic sampling

This means that each element within the population to be assessed has an

equal chance of being selected. This approach is therefore preferable to

obtain representative results and eliminates one source for committing sys-

tematic errors.

Judgmental sampling

Due to practical or costs reasons a probabilistic sampling is not always

possible. Judgmental sampling will result in sampling sub-populations, e.g.

due to technical reasons only samples from the top of a storage tank are

being taken.

(d) Identify the scale

The scale defines the minimum quantity of material below which variations are

judged to be unimportant.

(e) Choose the required statistical approach

The relevant statistical parameters will be the mean values as well as the stand-

ard deviation. Although only the mean value over the whole reporting value is

22

to be reported and no specific uncertainty thresholds are mentioned in the MRR

for those mean values, the deviation provides information about the appropri-

ateness of the sampling plan to improve the level of assurance.

(f) Choose the desired reliability

Reliability refers to “bias”, “precision” and “confidence”. Choices must be made

on the confidence level, and to the extent that random and systematic errors in

sampling can be minimised.

3. Determine the practical instructions

(a) Choose the sampling pattern

The sampling pattern defines when, where and how samples are selected.

(b) Determine the increment/sample size

An increment is the amount of material that is obtained through one single sam-

pling action. It is not analysed as an individual unit, but is combined with other

increments to form a composite sample. A simple “sample” is defined as a lot

that is analysed individually.

The increment/sample size should depend on properties like heterogeneity or

particle size.

(c) Determine the use of composite or individual samples

This selection depends inter alia on costs and the statistical parameters. As in

general the mean value will be of particular interest, usually composite samples

will be used.

4. Determine required number of samples

This is a statistical exercise taking into account any standard deviations between

increments, samples, composites etc. This point is relevant for the reliability of re-

sults but also for cost-efficiency.

After all relevant decisions have been made the sampling plan can be put down on

paper. At least the following elements should be covered:

Who is responsible for each step?

Where and when are samples taken?

How are the samples taken? E.g. it might be necessary to first clean pipes where

residues from previous samples might still be contained, etc.

Which instruments are used, if relevant? Describe automatic sampling equipment,

but also describe the tools for manual sampling. It might also be important how

samples can be picked out from sufficiently deep in a pile of several metres height.

How will the identity of the samples be ensured?

How are the samples stored (dry, cool, dark, inert atmosphere, etc.)?

How and when are increments combined?

When are the samples analysed, are remaining samples stored after analysis, etc.?

As further help for the development of a sampling plan, the Annex of this document

contains an example of a template for a sampling plan.

23

4 FREQUENCY OF ANALYSES

According to Article 35 the operator has to consider the following options when deter-

mining the minimum frequency of analyses:

Applying the minimum frequency for relevant fuels and materials listed in Annex

VII of the MRR (see Table 1 in section 4.1);

Analysis frequencies different from those listed in that table may be allowed where

the operator demonstrates one of the following:

Based on historical data, any variation in the analytical values for the respec-

tive fuel or material does not exceed 1/3 of the uncertainty value to which the

operator has to adhere with regard to the activity data determination of the

relevant fuel or material (see section 4.2);

Applying the minimum frequency listed in Table 1 would incur unreasonable

costs (see section 4.3);

Where an installation operates for part of the year only, or where fuels or ma-

terials are delivered in batches that are consumed over more than one calen-

dar year, the competent authority may agree with the operator a more appro-

priate schedule for analyses. However, this approach has to result in a com-

parable uncertainty as the approach based on the “1/3” rule presented above

(see section 4.4).

4.1 Minimum frequency of analyses (Annex VII of the MRR)

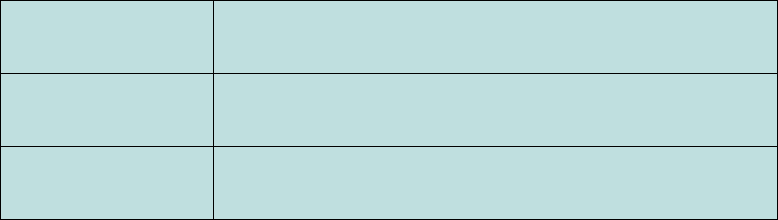

Table 1 lists the minimum frequency of analyses for relevant fuels and materials as laid

down in Annex VII of the MRR.

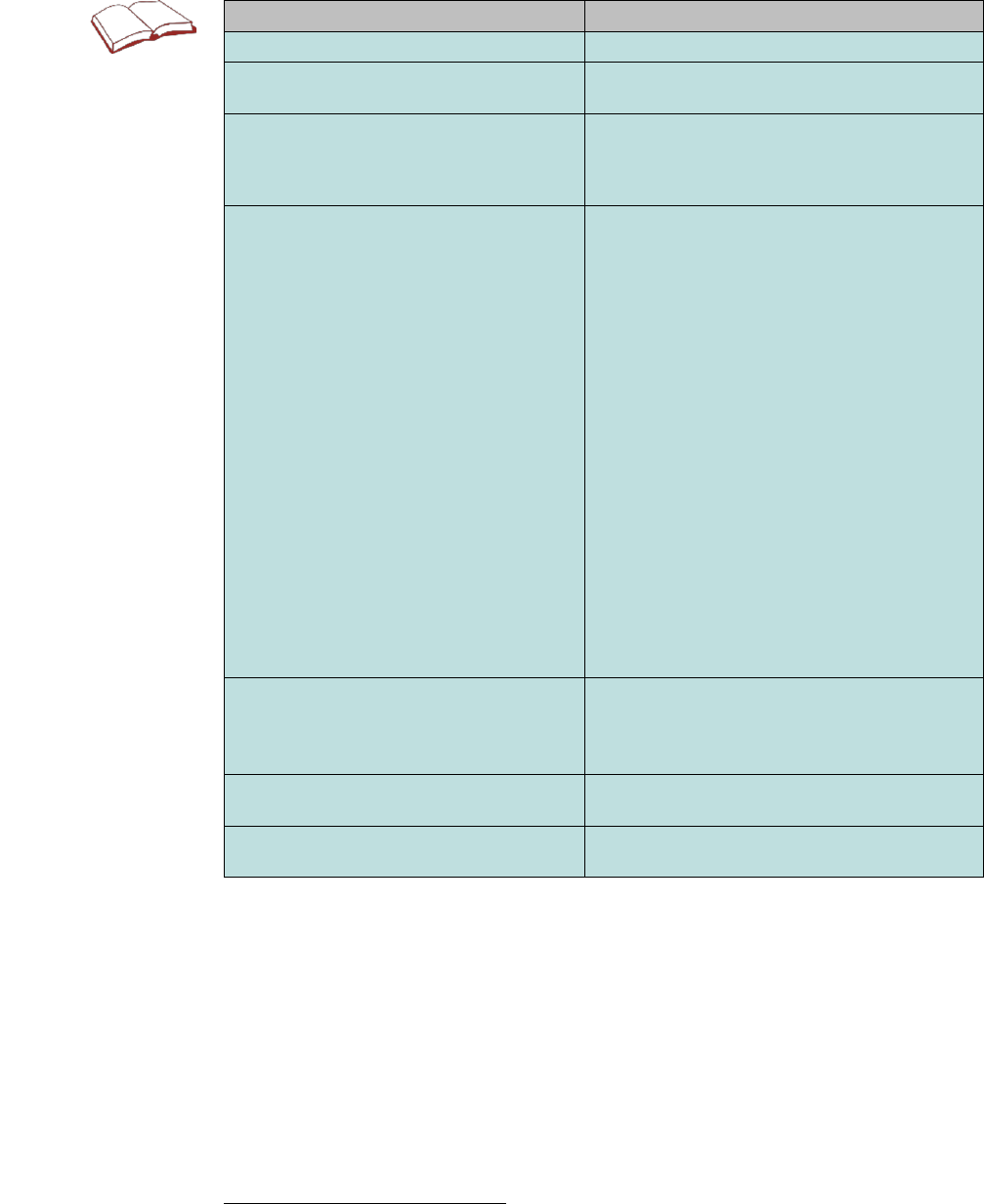

Table 1: Minimum frequency of analyses

Fuel/material

Minimum Frequency of Analyses

Natural gas

At least weekly

Other gases, in particular synthesis gas

and process gases such as refinery

mixed gas, coke oven gas, blast-fur-

nace gas, convertor gas, oilfield and

gasfield gas

At least daily - using appropriate procedures at

different parts of the day

Fuel oil (for example light, medium,

heavy fuel oil, bitumen)

Every 20,000 tonnes and at least six times a

year

Coal, coking coal, coke, petroleum

coke, peat

Every 20,000 tonnes and at least six times a

year

Other fuels

Every 10,000 tonnes of fuel and at least four

times a year

Untreated solid waste (pure fossil or

mixed biomass/fossil)

Every 5,000 tonnes and at least four times a

year

Liquid waste, pre-treated solid waste

Every 10,000 tonnes and at least four times a

year

Carbonate minerals (including lime-

stone and dolomite)

Every 50,000 tonnes and at least four times a

year

24

Fuel/material

Minimum Frequency of Analyses

Clays and shales

Amounts of material corresponding to 50,000

tonnes of CO

2

and at least four times a year

Other materials (primary, intermediate

and final product)

Depending on the type of material and the vari-

ation, amounts of material corresponding to

50,000 tonnes of CO

2

and at least four times a

year

4.2 The “1/3” rule

An operator may apply a different frequency to that listed in Table 1 (see section 4.1) if

any variation in the analytical values

13

for the respective fuel or material does not exceed

1/3 of the uncertainty value to which the operator has to adhere with regard to the ac-

tivity data determination of the relevant fuel or material. The determination of this varia-

tion has to be based on historical data, including analytical values for the respective

fuels or materials in the reporting period immediately preceding the current reporting

period.

Any variation in the analytical value may be determined as the overall uncertainty of

uncorrelated input quantities (see Annex III of Guidance Document 4 on Uncertainty):

n

nn

xxx

xuxuxu

u

...

)(...)()(

21

22

22

2

11

total

where:

u

i

.......... relative uncertainty of the analytic value of sample i

x

i

.......... sample size of sample i

Under the assumptions that the uncertainty of the analytic value of each sample is the

same and all sample sizes are similar, the formula simplifies to:

n

u

n

n

uu

i

i

total

where:

n .......... number of analysed samples

If the total uncertainty related to the analytic values is known (in most cases it is a direct

result of the standard deviation of the analytical values) the required minimum number

of samples can be determined as:

13

The term ‘variation of the analytical values’ in this section comprises all of the following three elements: 1)

the variation of the actual value over time, 2) the analytical error to determine the value and 3) the sampling

and any further errors. No distinction is made as to which of those contributes the most to the historic variation

observed. Further background information can be found in the training material on sampling, which can be

downloaded from:

https://ec.europa.eu/clima/sites/default/files/ets/monitoring/docs/sampling_training_material_en.pdf

25

2

total

2

u

u

n

i

This approach has been successfully implemented in an Excel based tool provided by

the Netherlands. It can be downloaded from https://ec.europa.eu/clima/poli-

cies/ets/monitoring_en#tab-0-1

Example:

A category B installation is burning heavy fuel oil. In the monitoring plan the heavy

fuel oil is listed as a major source stream to be monitored by a calculation-based

approach. The MRR (and approved monitoring plan) requires it to meet tier 4 (±1.5%)

for activity data and to determine the calculation factors emission factor (EF) and net

calorific value (NCV) by laboratory analyses in accordance with Articles 32 to 35. The

“1/3” rule requires that the uncertainty related to the determination of the calculation

factors does not exceed 0.5% (This u

total

is the input parameter for determining the

number of samples).

Table 1 (see section 4.1) would require analysing at least six times a year. From

historic analyses the operator demonstrates that the uncertainty related to the deter-

mination of the NCV is 1.00%. The following table displays the results from historic

samples.

# of sample

NCV [GJ/t]

1

42,28

2

42,41

3

42,35

4

42,68

5

42,44

6

42,4

7

42,68

8

42,6

9

42,02

10

42,33

11

42,41

12

42,2

average

42.4

Uncertainty u

i

1.00%

The uncertainty is determined as the standard deviation of the data series (0.45%)

multiplied by the Student t-factor for 12 values and a 95% confidence interval

(=2.201). The application of this factor is required because uncertainty as defined in

26

Article 3(6)

14

always refers to a confidence interval of 95%. The minimum frequency

of analysis to meet the requirements of the “1/3” rule is then calculated by:

4

%5.0

%0.1

2

2

n

Therefore, in this case, the operator may be allowed to apply a lower frequency of

analysis of four times per year instead of six times for NCV determination. For the

emission factor a similar test can be carried out whether these requirements are ful-

filled with 4 samples per year as well.

It is important to note that the “1/3” rule also offers the operator an option to deviate

from carrying out analyses in accordance with Article 32 to 35. The MRR, in the defini-

tion of tiers for calculation factors in Annex II, under specific situations allows the use of

the empirical correlation as specified for Tier 2b in sections 2.1 and 3.1 of Annex II to

be regarded as Tier 3. However, in such cases the uncertainty of that empirical correla-

tion may not exceed 1/3 of the uncertainty value to which the operator has to adhere

with regard to the activity data determination of the relevant fuel or material. The oper-

ator has to demonstrate to the satisfaction of the competent authority that he complies

with this provision.

4.3 Incurrence of unreasonable costs

An operator is also allowed to deviate from applying the minimum requirements for fre-

quency of analyses in Table 1 (see section 4.1) or applying minimum frequency of anal-

yses resulting from the “1/3” rule if he can demonstrate they would incur unreasonable

costs.

Article 18(1) defines costs as unreasonable if they exceed the benefit. The benefit shall

be calculated by multiplying an improvement factor by a reference price of 20 euro per

allowance and costs shall include an appropriate depreciation period based on the eco-

nomic lifetime of the equipment. Article 18(3) defines this improvement factor as 1% of

the average annual emissions of the respective source streams in the three most recent

reporting periods. For further guidance on unreasonable costs, please see section 4.6.1

of Guidance Document 1 (General Guidance for Installations).

Example: The heavy fuel oil source stream above emits about 40,000 tonnes of CO

2

annually. The costs for the analyses have to exceed the benefit in order to be re-

garded as unreasonable. If the costs are lower they are not unreasonable:

IFAEmPC

14

Article 3(6): ‘uncertainty’ means a parameter, associated with the result of the determination of a quantity,

that characterises the dispersion of the values that could reasonably be attributed to the particular quantity,

including the effects of systematic as well as of random factors, expressed in per cent, and describes a con-

fidence interval around the mean value comprising 95% of inferred values taking into account any asymmetry

of the distribution of values;

27

where:

C ......... Costs [€/year]

P ......... specified allowance price = 20 € / t CO

2(e)

AEm .... Average emissions from related source stream(s) [t CO

2(e)

/year]

IF ......... improvement factor = 1%

It is assumed that one analysis costs 1,000 €. As the benefits are 8,000 € / year (20

x 40,000 x 1%) the costs for six analyses per year cannot be regarded as unreason-

able.

Question 4.4 of the FAQ document

15

may provide further helpful information on how to

proceed if the application of tier 3, i.e. analysis in accordance with Articles 32 to 35,

incurs unreasonable costs. Furthermore, the Commission has published a tool (“Unrea-

sonable costs determination tool”) on the MRVA website (see link in section 1.3).

4.4 Analyses frequency for specific situations

Article 35(2) gives the operator another option to deviate from the minimum frequency

listed in Annex VII of the MRR (see section 4.1). However, this option may only be

applied in either of the following situations:

an installation operates for part of the year only;

fuels or materials are delivered in batches that are consumed over more than

one calendar year.

In these special situations, the competent authority may agree with the operator a more

appropriate schedule for analyses. Nonetheless, it has to be assured that the approach

the operator and the competent authority agree upon will result in an uncertainty com-

parable to an uncertainty achieved if the approach based on the “1/3” rule were used

(see section 4.2).

15

https://ec.europa.eu/clima/sites/clima/files/ets/monitoring/docs/faq_mmr_en.pdf

28

5 LABORATORIES

Pursuant to Article 34 all analyses for the determination of calculation factors shall be

carried out by laboratories that are accredited for the relevant analytical methods in

accordance with EN ISO/IEC 17025. However, operators may deviate from this require-

ment if it can be demonstrated to the satisfaction of the competent authority that access

to accredited laboratories is technically not feasible or would incur unreasonable costs.

In this case also non-accredited laboratories may be used provided that they meet the

requirements listed in Article 34(3). Those requirements are considered appropriate to

demonstrate competence equivalent to accreditation in accordance with EN ISO/IEC

17025.

The equivalent requirements concern the quality management and technical compe-

tence of the laboratory, and should be demonstrated in the form of procedures attached

to the monitoring plan.

With respect to quality management, the operator may demonstrate the competence

by an accredited certification of the laboratory in conformity with EN ISO/IEC 9001, or

other certified quality management systems that cover the laboratory. In the absence of

such certified quality management systems, the operator shall provide other appropriate

evidence that the laboratory is capable of managing in a reliable manner its

personnel,

procedures,

documents and

tasks.

With respect to technical competence, the operator shall provide evidence that the

laboratory is competent and able to generate technically valid results using the relevant

analytical procedures. Article 34(3) lists the topics on which evidence is to be provided.

Table 2 lists elements which the competent authority should take into account when

assessing an operator’s proposed evidence on the laboratory he uses.

Note: Article 47(7) allows operators of installations with low emissions to use any labor-

atory to determine calculation factors by analyses that is technically competent and able

to generate technically valid results using the relevant analytical procedures. Evidence

only needs to be provided for the quality assurance measures referred to in point j of

Table 2.

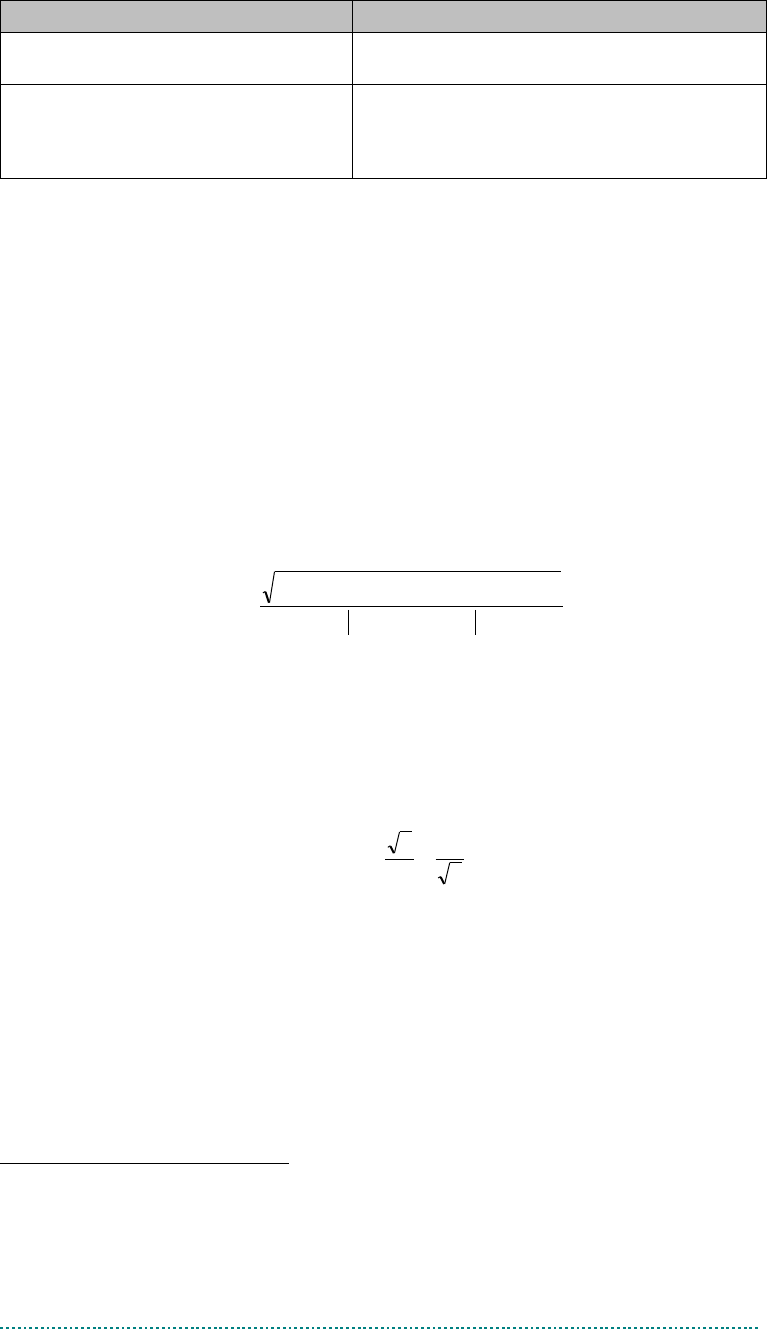

Table 2: Elements for demonstrating equivalent technical competence to an accreditation for

laboratories

Element of Article 34(3), on

which competence needs to

be demonstrated

Important elements for the competent authority to

assess (non-exhaustive)

(a) Management of the per-

sonnel’s competence for the

specific tasks assigned

Is the personnel executing the sampling and analysis

authorised for their job by the management?

Can the competence of the personnel be proven by

records of their education, training and experience?

Is an adequate procedure for training and supervision

of personnel implemented (especially for new person-

nel)?

29

Element of Article 34(3), on

which competence needs to

be demonstrated

Important elements for the competent authority to

assess (non-exhaustive)

(b) suitability of accommoda-

tion and environmental condi-

tions

Is the building and the laboratory area sufficiently

heated / air-conditioned, safe, secure and clean for

the purpose?

Is access to and use of areas affecting the quality of

the tests and/or calibrations controlled and are

measures taken to ensure good housekeeping?

Are environmental conditions monitored, controlled

and recorded as required by the relevant specifica-

tions, methods and procedures, or where they influ-

ence the quality of the results, and are tests and cali-

brations stopped when the environmental conditions

jeopardise the results?

(c) selection of analytical

methods and relevant stand-

ards

Is an adequate procedure in use to ensure that the lat-

est valid edition of a standard is used?

Is the procedure for the selection of a method docu-

mented and is the procedure actually used for the se-

lection of appropriate methods?

Is the reporting of deviations from the standardised

method ensured?

(d) where applicable, manage-

ment of sampling and sample

preparation, including control

of sample integrity

Are adequate procedures for representative sampling

of substances, materials or products implemented?

Are deviations from the required sampling procedures

recorded?

(e) where applicable, develop-

ment and validation of new

analytical methods or applica-

tion of methods not covered

by international or national

standards

Note: These requirements only apply if the operator’s

monitoring plan requires analyses which are not yet es-

tablished, or where no standards are available.

When non-standard methods are used, are these

methods well described?

Are the methods used for the determination of the cal-

culation factor(s) validated?

Where new methods are used or developed, at least

the following performance characteristics must be

known or be determined: sensitivity of the method, re-

peatability and/or reproducibility, cross-sensitivity

against interference from the matrix of the sample/test

object.

(f) uncertainty estimation

Does the procedure for the estimation of the uncer-

tainty include all components of uncertainty?

Are previous experiences and the results of the valida-

tion of the applied method included in the estimation

of the uncertainty?

(g) management of equip-

ment, including procedures for

calibration, adjustment,

maintenance and repair of

equipment, and record keep-

ing thereof

Are records maintained of each item of equipment and

its software?

Does the laboratory apply procedures for safe han-

dling, transport, storage, use and planned mainte-

nance of the measuring equipment to ensure proper

functioning?

Is there a scheme for calibration and maintenance of

the equipment and its software implemented?

Can the state of calibration be proven with certifi-

cates?

Is there an adequate procedure to ensure that calibra-

tion factors are correctly implemented in time?

30

Element of Article 34(3), on

which competence needs to

be demonstrated

Important elements for the competent authority to

assess (non-exhaustive)

(h) management and control

of data, documents and soft-

ware

Is an adequate procedure for checking calculations

and data transfer on a regular basis implemented and

are the corrective actions in case of encountered mis-

takes specified?

(i) management of calibration

items and reference materials

Is there a programme and procedure for calibration

concerning the handling of the reference standards, or

for regular purchase of new standards?

Are the reference materials used, where possible,

traceable to international standards?

Are adequate procedures for intermediate checking of

the calibration status documented and implemented

on a regular basis?

Are procedures implemented for safe handling,

transport, storage and use of reference standards and

reference materials?

Are procedures implemented for safe transportation,

receipt, handling, protection, storage, retention and/or

disposal of calibration items?

Is a system used, which enables unambiguous identi-

fication of calibration items and reference materials?

(j) quality assurance for cali-

bration and test results, in-

cluding regular participation in

proficiency testing schemes,

applying analytical methods to

certified reference materials,

or inter-comparison with an

accredited laboratory

Does the laboratory apply procedures to monitor the

validity of the test and calibration results?

Are the results of these checks recorded, stored and,

where practicable, statistically evaluated?

Does the laboratory participate in inter-laboratory com-

parison or proficiency testing programmes?

If the laboratory participates in inter-laboratory com-

parison or proficiency testing programmes, how will

appropriate corrective action be taken in case differ-

ences are observed between laboratories?

Which other measures has the laboratory imple-

mented for quality assurance of calibration and test re-

sults?

(k) management of out-

sourced processes

Only relevant where processes are outsourced (e.g. cali-

bration of instruments, analyses by external laboratories

etc.)

Does the laboratory have a procedure implemented

which guarantees that the purchased services and

supplies are within the required specifications?

Are the required specifications included in each order

and is each delivery checked against those require-

ments?

(l) management of assign-

ments, customer complaints,

and ensuring timely corrective

action

Is the laboratory willing to cooperate with customers in

clarifying the customer's request, in monitoring the la-

boratory’s performance in relation to the work per-

formed and in seeking feedback from its customers?

Does the laboratory have a procedure for handling

complaints, non-conformities in the application of the

methods and mistakes in data handling and calcula-

tion methods, including keeping a documentation

thereof?

Does this procedure include an analysis of the source

of errors or complaints, and identification of corrective

actions as well as the timely implementation of the

corrective actions?

31

6 ONLINE GAS ANALYSERS

Gaseous fuel or material streams may contain organic carbon substances that give rise

to emissions and vary in composition over time. The most common gaseous source

stream is natural gas which might exhibit fluctuating composition depending on the

Member State or region the installation is situated. There are analytical methods based

on chromatographic separation of these substances and subsequent detection of each

substance. The most common detectors are e.g. the flame ionisation detector (FID)

16

or the mass spectrometry detector. These allow determination of the composition of the

gas online and thus calculation of relevant parameters such as NCV or EF

17

.

Article 32(2) requires the operator to obtain the competent authority’s approval for the

use of equipment where online gas chromatographs or extractive or non-extractive gas

analysers are used to determine emissions. To obtain approval the relevant information

might best be addressed by using a procedure describing the equipment, the method

used for sampling and analysis and the relevant standards. The use of these systems

is limited to the determination of composition data of gaseous fuels and materials. As

minimum quality assurance measures, the MRR requires that the operator shall ensure

that an initial validation and annually repeated validations of the instrument are per-

formed

18

.

It is recommended that the operator meets the requirements of EN ISO 9001 and that

calibration services and the suppliers of calibration gases are accredited in accordance

with EN ISO/IEC 17025. Also, where applicable, the initial and annually repeated vali-

dation of the instrument should be carried out by a laboratory accredited in accordance

with EN ISO/IEC 17025.

The following standards may be considered:

EN ISO 10723: Natural gas – Performance evaluation for on-line analytical systems;

EN 12619: Stationary source emissions – Determination of the mass concen-

tration of total gaseous organic carbon – Continuous flame ionisa-

tion detector method;

EN ISO 6976: Natural gas – Calculation of calorific values, density, relative density

and Wobbe index from composition;

ISO 6974: Natural gas – Determination of composition and associated uncer-

tainty by gas chromatography – Part 6: Determination of hydrogen,

helium, oxygen, nitrogen, carbon dioxide and C1 to C8 hydrocar-

bons using three capillary columns;

16

The detection principle of the FID is the oxidation/ionisation of substances. As CO

2

is fully oxidised carbon

the FID is insensitive to CO

2

. Therefore this detector is not suitable to detect inherent CO

2

which should be

part of the fuels emission factor according to Article 48.

17

Note that Articles 33 to 35 still apply here as well, subject to the tiers required, the technical feasibility and

no incurrence of unreasonable costs. For instance, this means that the sampling frequency would have to

follow the provisions in Article 35 and Annex VII. It should furthermore often easily be possible to demon-

strate that using an accredited laboratory (Article 34) would incur unreasonable costs.

18

For more information on the initial validation see FAQ No.2, section 9.2.

32

7 ANNEX I: ACRONYMS AND LEGISLATION

7.1 Acronyms used

CA .............. Competent Authority

CEMS ......... Continuous Emission Measurement System

EF ............... Emission factor

EU ETS ...... EU Emission Trading Scheme

GD .............. Guidance Document

MP .............. Monitoring Plan

MRR ........... Monitoring and Reporting Regulation (M&R Regulation)

MRV ........... Monitoring, Reporting and Verification

MRVA ......... Monitoring, Reporting, Verification and Accreditation

MS .............. Member State(s)

NCV............ Net calorific value

7.2 Legislative texts

EU ETS Directive: Directive 2003/87/EC of the European Parliament and of the Council

of 13 October 2003 establishing a system for greenhouse gas emission allowance trad-

ing within the Community and amending Council Directive 96/61/EC, as amended.

Download of the consolidated version:

https://eur-lex.europa.eu/eli/dir/2003/87/2020-01-01

M&R Regulation: Commission Implementing Regulation (EU) No. 2018/2066 of 19 De-

cember 2018 on the monitoring and reporting of greenhouse gas emissions pursuant to

Directive 2003/87/EC of the European Parliament and of the Council and amending

Commission Regulation (EU) No. 601/2012. Download under: https://eur-lex.eu-

ropa.eu/eli/reg_impl/2018/2066/oj and latest amendment under:

https://eur-lex.europa.eu/eli/reg_impl/2020/2085/oj

A&V Regulation: Commission Implementing Regulation (EU) No. 2018/2067 of 19 De-

cember 2018 on the verification of data and on the accreditation of verifiers pursuant to

Directive 2003/87/EC of the European Parliament and of the Council, as amended.

Download of consolidated version:

https://eur-lex.europa.eu/eli/reg_impl/2018/2067/2021-01-01

RES Directive (RED II): Directive (EU) 2018/2001 of the European Parliament and of

the Council of 11 December 2018 on the promotion of the use of energy from renewable

sources (recast). Download under:

https://eur-lex.europa.eu/eli/dir/2018/2001/oj

33

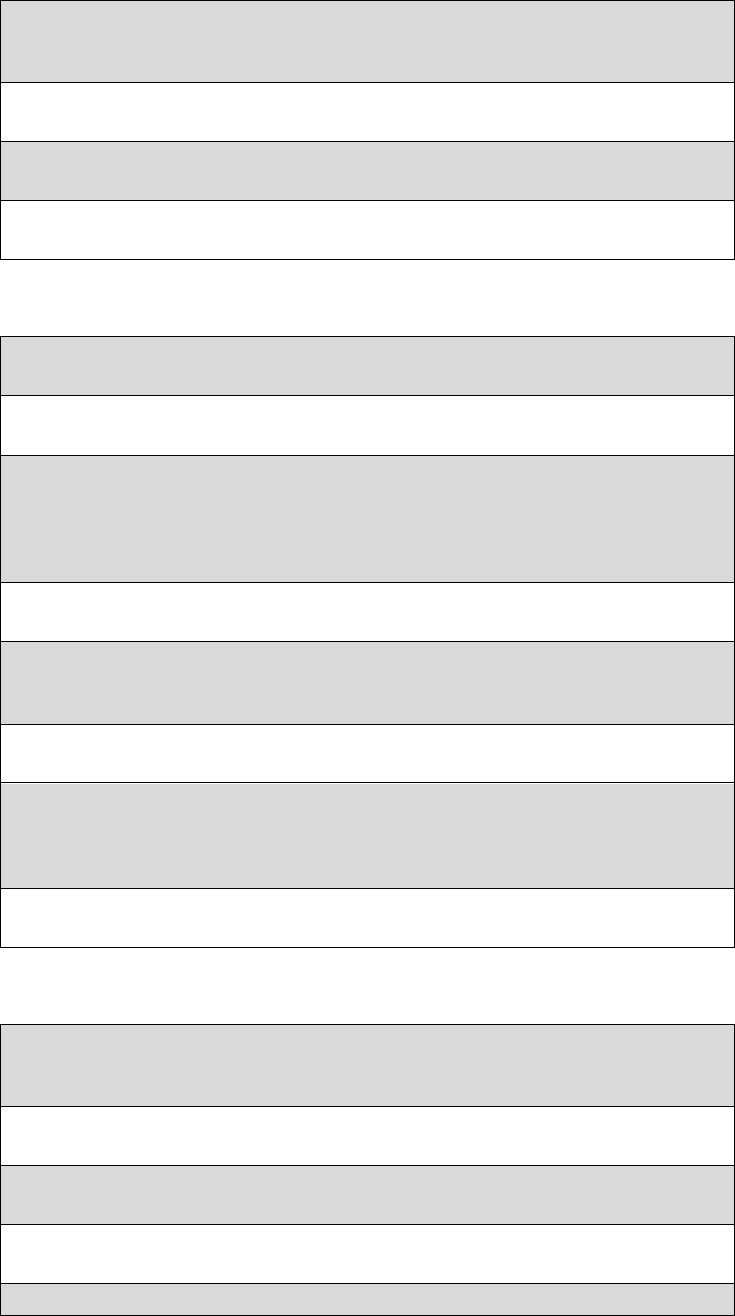

8 ANNEX II: EXAMPLE FOR A SAMPLING PLAN

TEMPLATE

1. General information

Operator name:

Installation ID:

Fill in the installation ID (as used by your competent authority)

Title of sampling plan:

Reference of procedure:

2. Responsibilities

Sampling plan completed by:

Fill in the name of the author of the sampling plan

Post or department responsible for sampling:

Fill in the name of the post or department responsible for the actual sampling

Post or department responsible for sampling data: