User manual

COM OPEN PROTOCOL MDCv2/MDTC series

EN

60428-05/23

www.dogassembly.com

Manual COM OPEN PROTOCOL MDCv2/MDTC series 3 DOC.60428-05/23

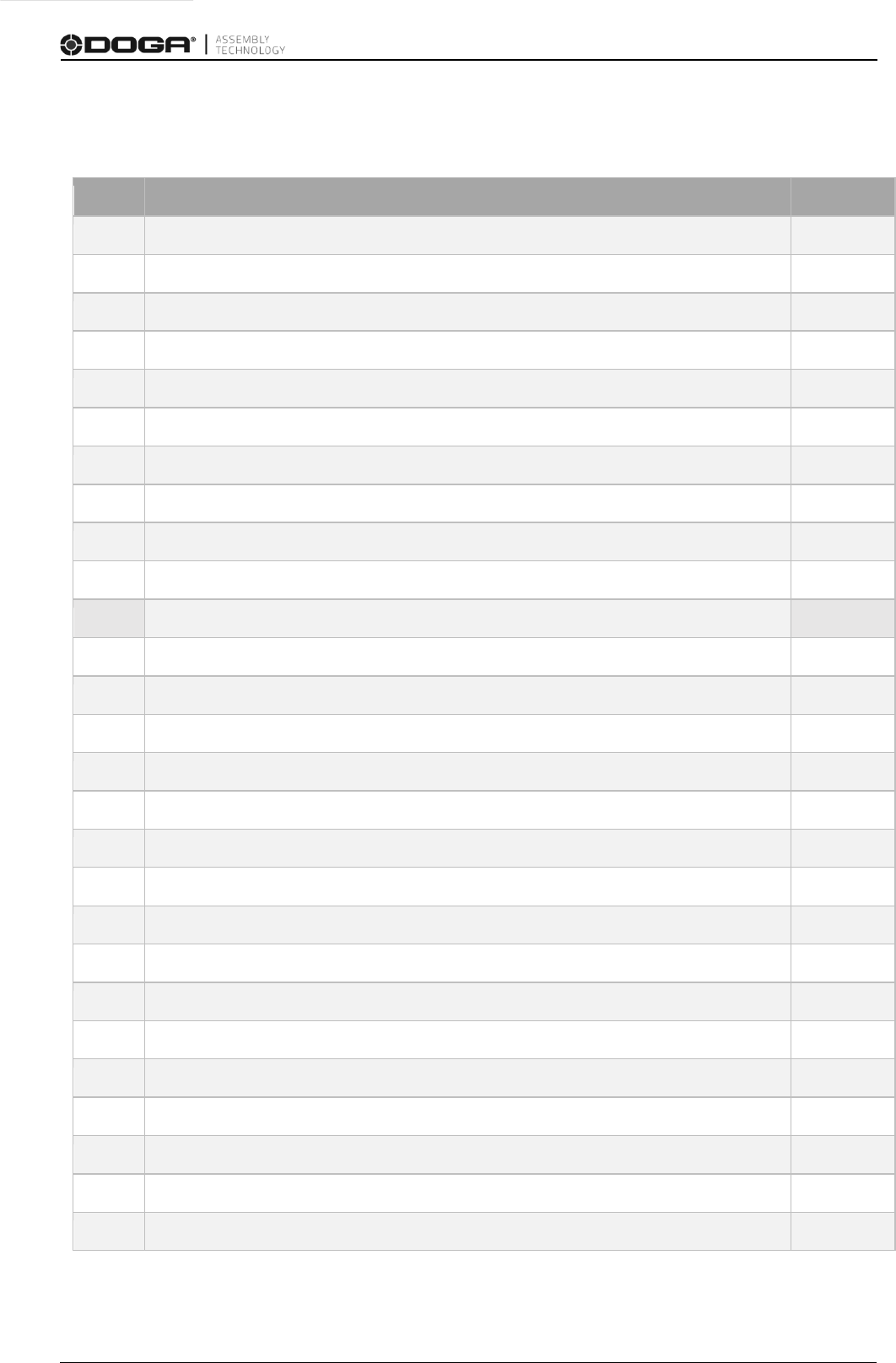

INDEX

1. Controller firmware version ............................................................ Erreur ! Signet non défini.

2. COMMUNICATION TYPE ........................................................................................................ 5

2.1 Serial Protocol ................................................................................................................. 5

2.2 Ethernet Protocol ............................................................................................................. 5

3. MESSAGE STRUCTURE ........................................................................................................ 6

3.1 Header ............................................................................................................................ 6

3.2 Serial message example ................................................................................................. 7

3.3 Ethernet message example ............................................................................................. 7

4. COMMUNICATION FLOW ....................................................................................................... 8

4.1 Serial Connection flow ..................................................................................................... 8

4.2 Ethernet Connection flow ................................................................................................. 8

4.3 Communication flow chart example ................................................................................. 9

5. Communication messages ..................................................................................................... 10

5.1 MID control type ............................................................................................................ 10

5.1.1 MID 0001 Communication start ................................................................................ 11

5.1.2 MID 0002 Communication start acknowledge .......................................................... 11

5.1.3 MID 0003 Communication stop ................................................................................ 12

5.1.4 MID 0004 Command error ....................................................................................... 12

5.1.5 MID 0005 Command accepted ................................................................................ 14

5.1.6 MID 0010 Parameter set ID (Preset number) upload request................................... 14

5.1.7 MID 0011 Parameter set ID (Preset number) upload reply ....................................... 15

5.1.8 MID 0012 Parameter set (Preset) data upload request ............................................ 15

5.1.9 MID 0013 Parameter set (Preset) data upload reply ................................................ 16

5.1.10 MID 0018 Select Parameter set (Preset).................................................................. 17

5.1.11 MID 0040 Tool data upload request ......................................................................... 18

5.1.12 MID 0041 Tool data upload reply ............................................................................. 18

5.1.13 MID 0042 Disable tool.............................................................................................. 21

5.1.14 MID 0043 Enable tool .............................................................................................. 21

5.1.15 M

ID 0060 Last tightening result data subscribe........................................................ 22

5.1.16 MID 0061 Last tightening result data ........................................................................ 23

5.1.17 MID 0062 Last tightening result data acknowledge .................................................. 28

5.1.18 MID 0063 Last tightening result data unsubscribe .................................................... 29

5.1.19 MID 0070 Alarm subscribe ....................................................................................... 29

5.1.20 MID 0071 Alarm ....................................................................................................... 30

5.1.21 MID 0072 Alarm acknowledge ................................................................................. 31

Manual COM OPEN PROTOCOL MDCv2/MDTC series 4 DOC.60428-05/23

5.1.22 MID 0073 Alarm unsubscribe ................................................................................... 31

5.1.23 MID 1000 Read parameter value ............................................................................. 32

5.1.24 MID 1001 Read parameter value acknowledge ....................................................... 32

5.1.25 MID 1002 Write parameter value ............................................................................. 33

5.1.26 MID 1003 Write parameter value acknowledge ........................................................ 33

5.1.27 MID 9999 Keep alive message ................................................................................ 34

5.2 Event message .............................................................................................................. 34

5.2.1 Event subscribe – unsubscribe messages ............................................................... 34

5.2.2 Event message acknowledge .................................................................................. 34

Manual COM OPEN PROTOCOL MDCv2/MDTC series 5 DOC.60428-05/23

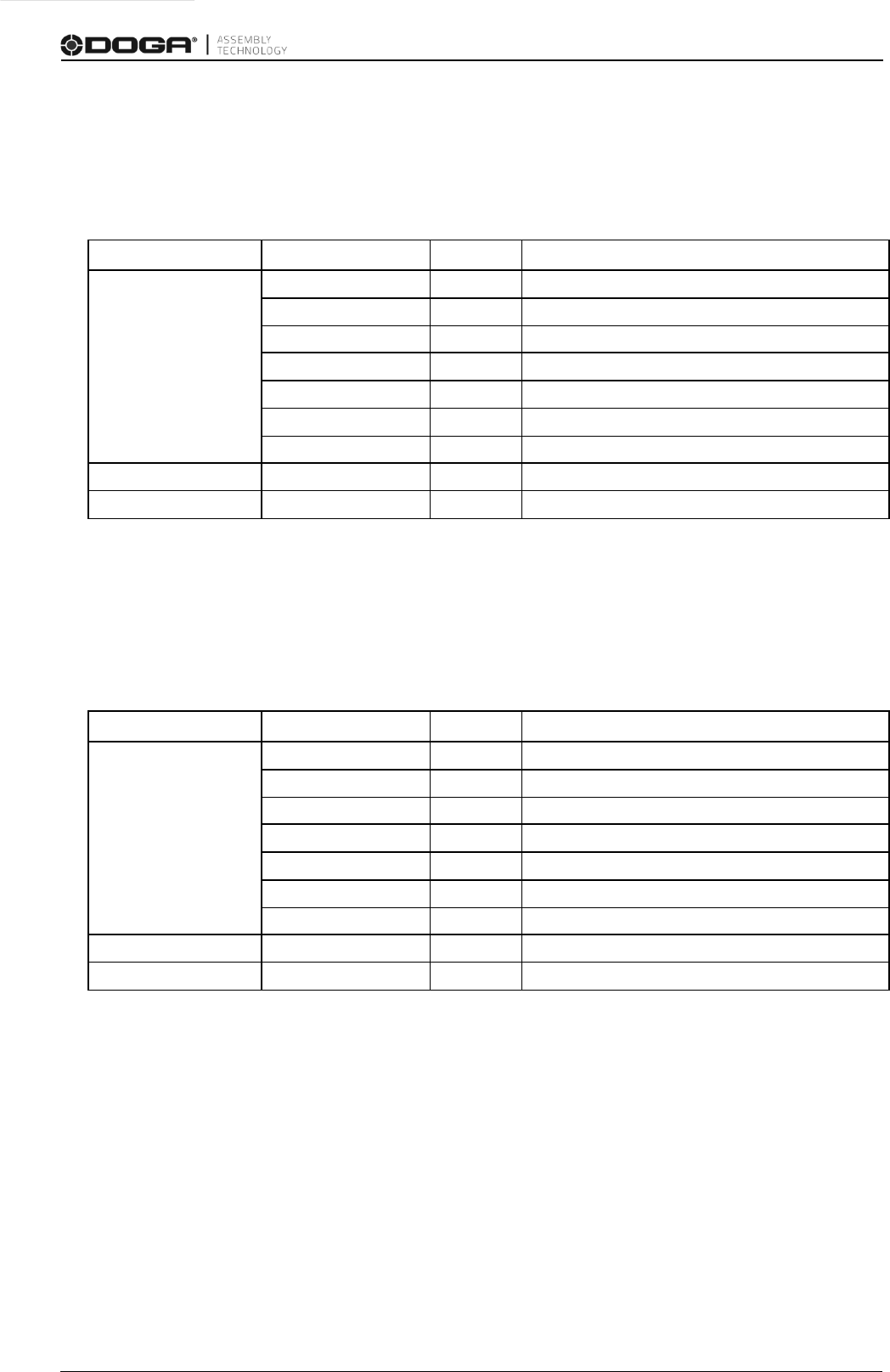

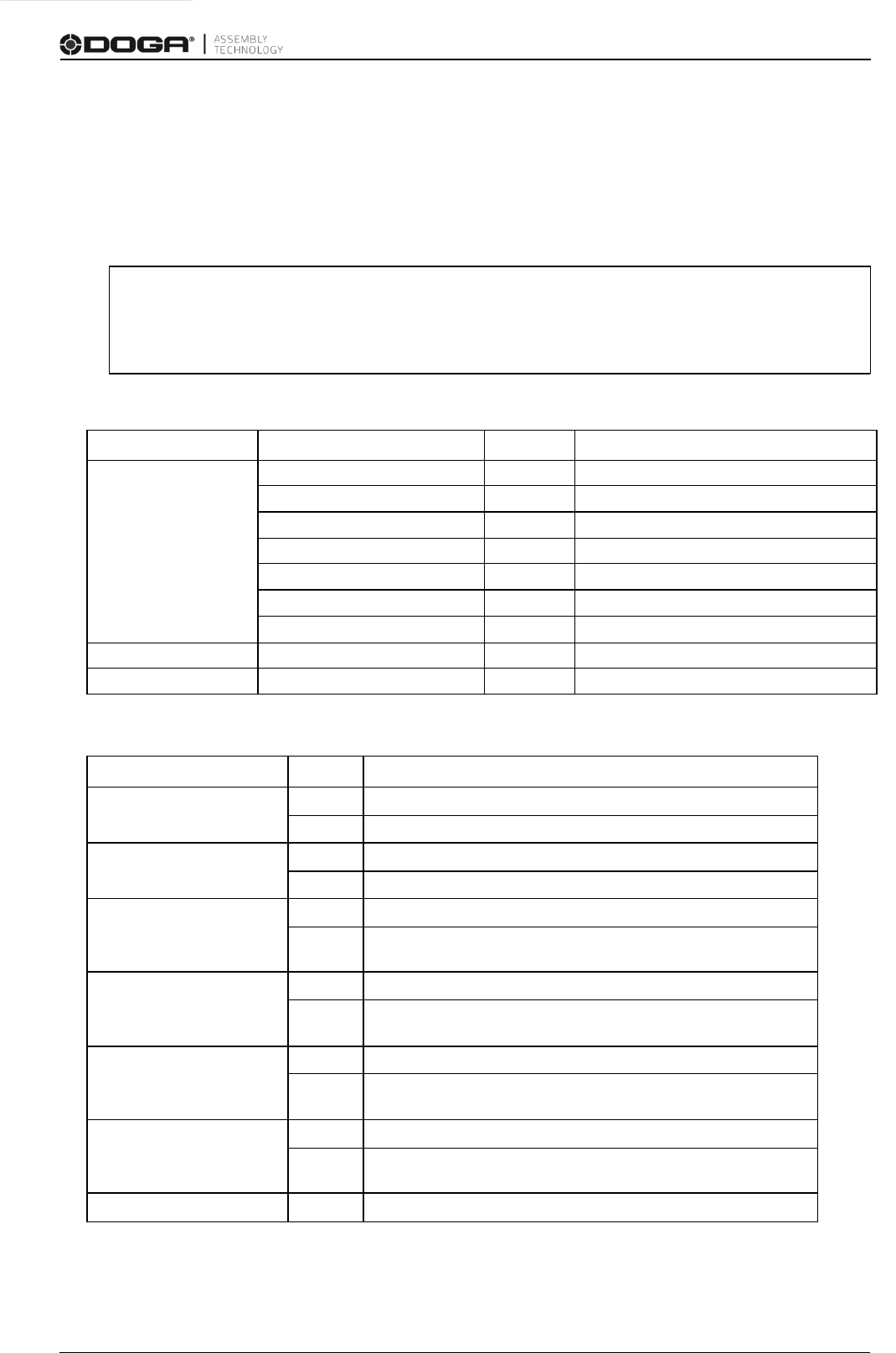

1. CONTROLLER FIRMWARE VERSION

Newer update MID40/41 applied since following firmware versions :

MDCv2 26 & 32 : MDC_v2.31.7_20230321.bin and newer

MDTC38 : MDTC_Normal_v1.31.5_230321.bin and newer

MDTC38 + : MDTC_Plus_v3.31.5_230321.bin and newer

2. COMMUNICATION TYPE

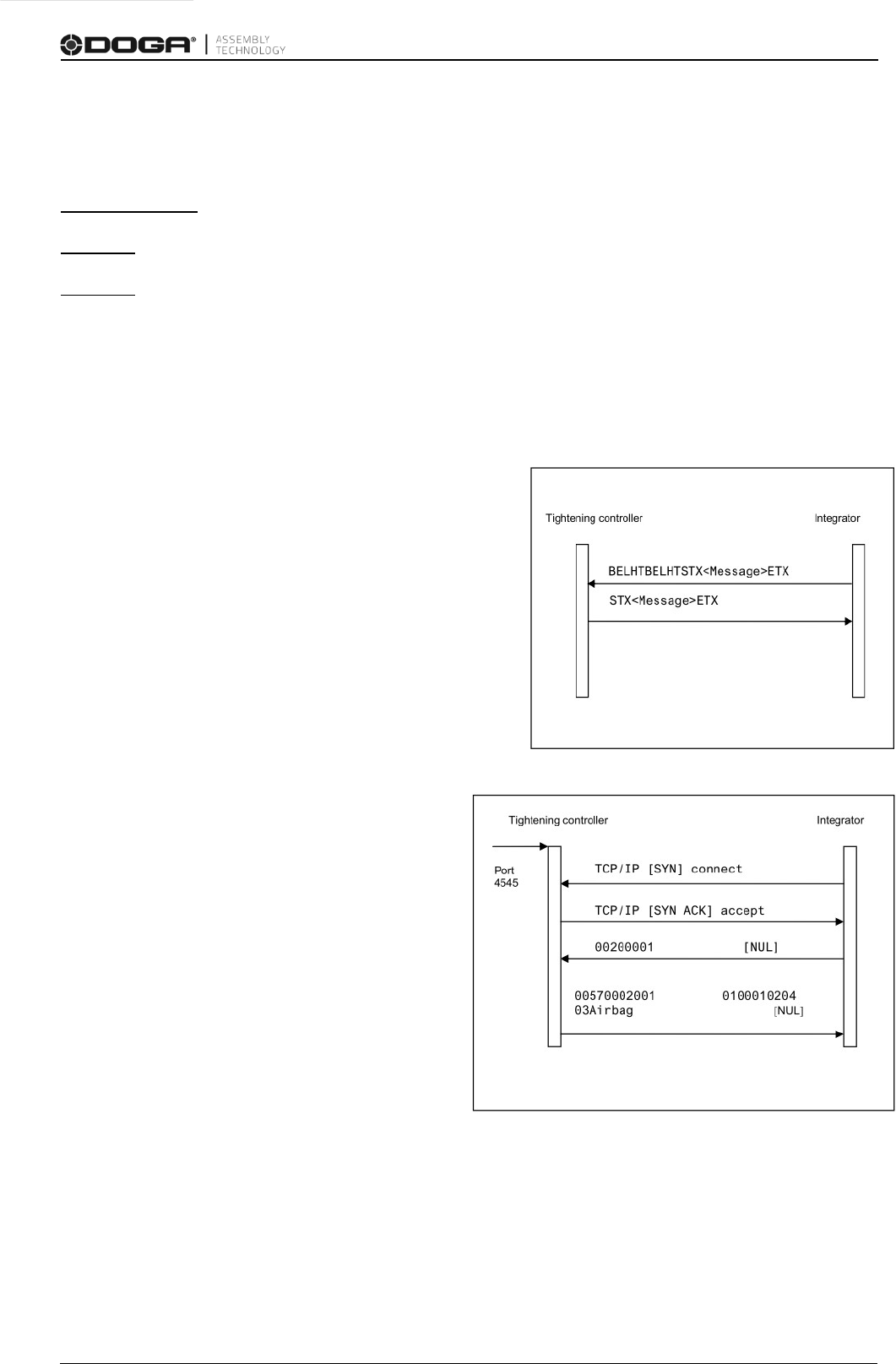

2.1 Serial Protocol

• Serial ASCII protocol

• Request message from Integrator to controller :

Add BEL(0x07), HT(0x09), BEL(0x07), HT(0x09)

as prefix.

• Respose message from controller to Integrator :

Add STX (0x02) as prefix, ETX(0x03) as sufix.

2.2 Ethernet Protocol

• TCP/IP Protocol

• After TCP/IP connection confirmation,

Message can be delivered.

• There is no Prefix and sufix as like BEL, HT

in serial communication.

Manual COM OPEN PROTOCOL MDCv2/MDTC series 6 DOC.60428-05/23

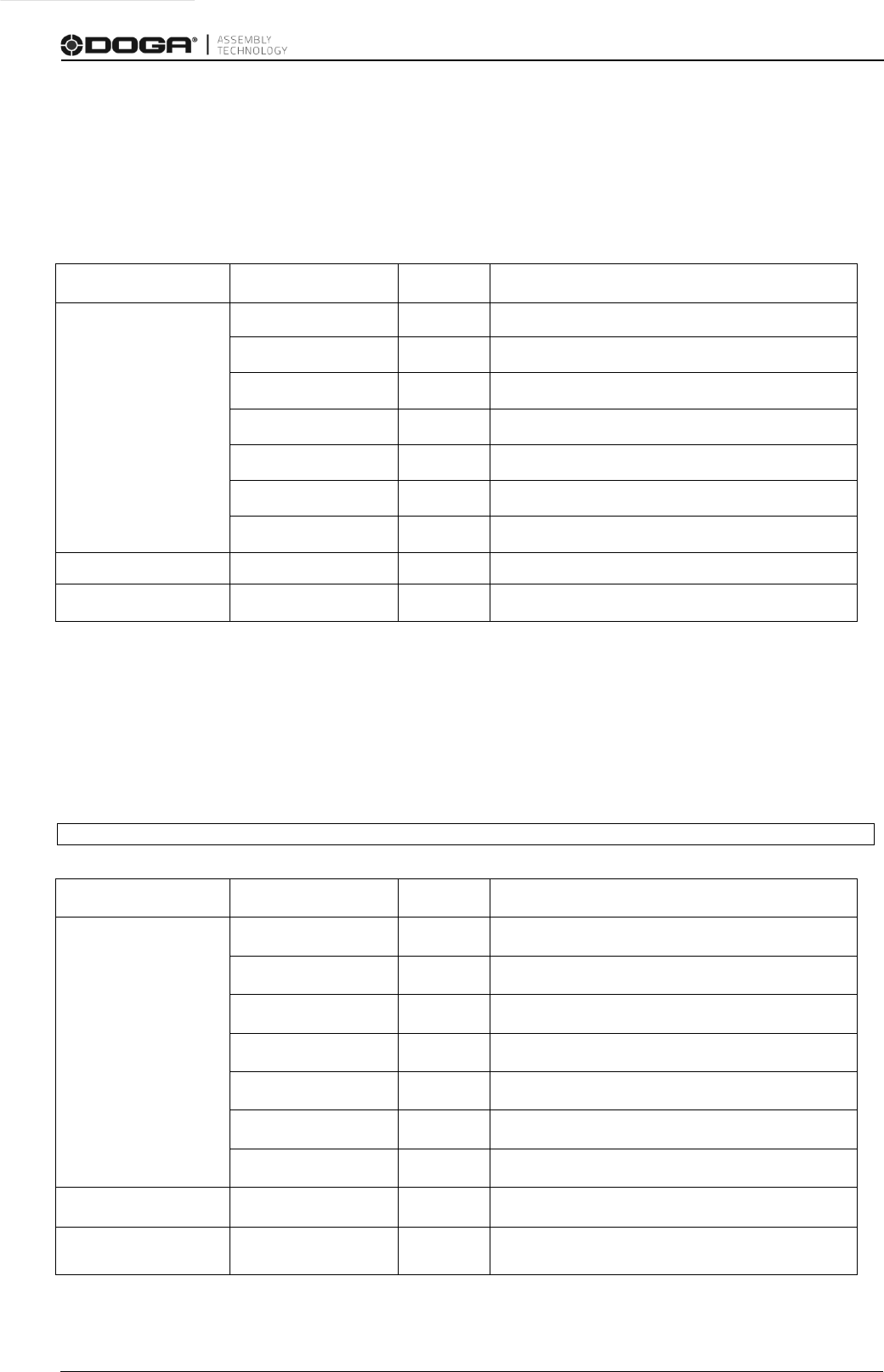

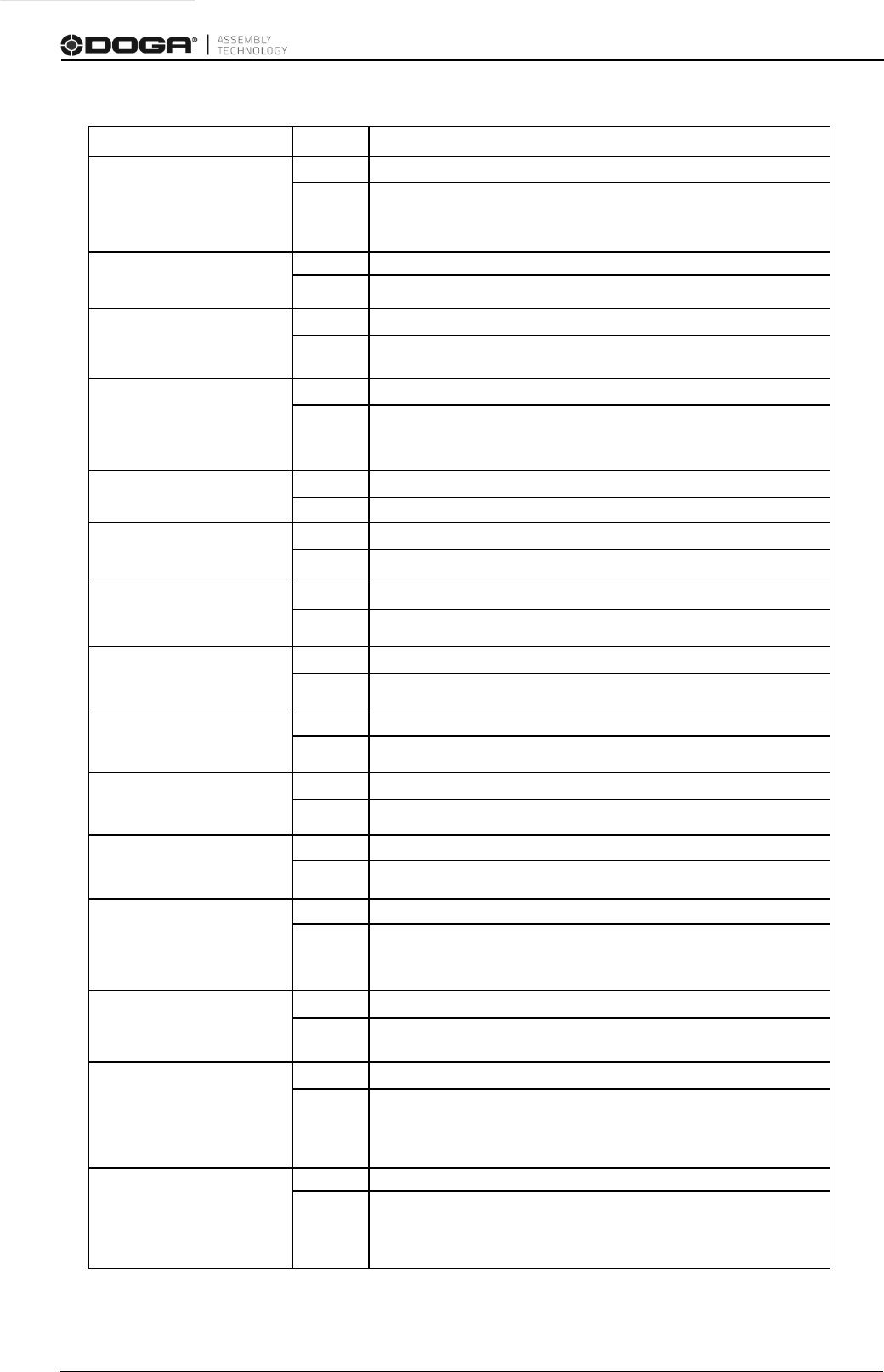

3. MESSAGE STRUCTURE

Header

Data Field Message End

Length

MID

Revision

No

ack

flag

Station

ID

Spindle

ID

Spare

---

NUL

(Hex 0x00)

20Byte

Max 1004Byte

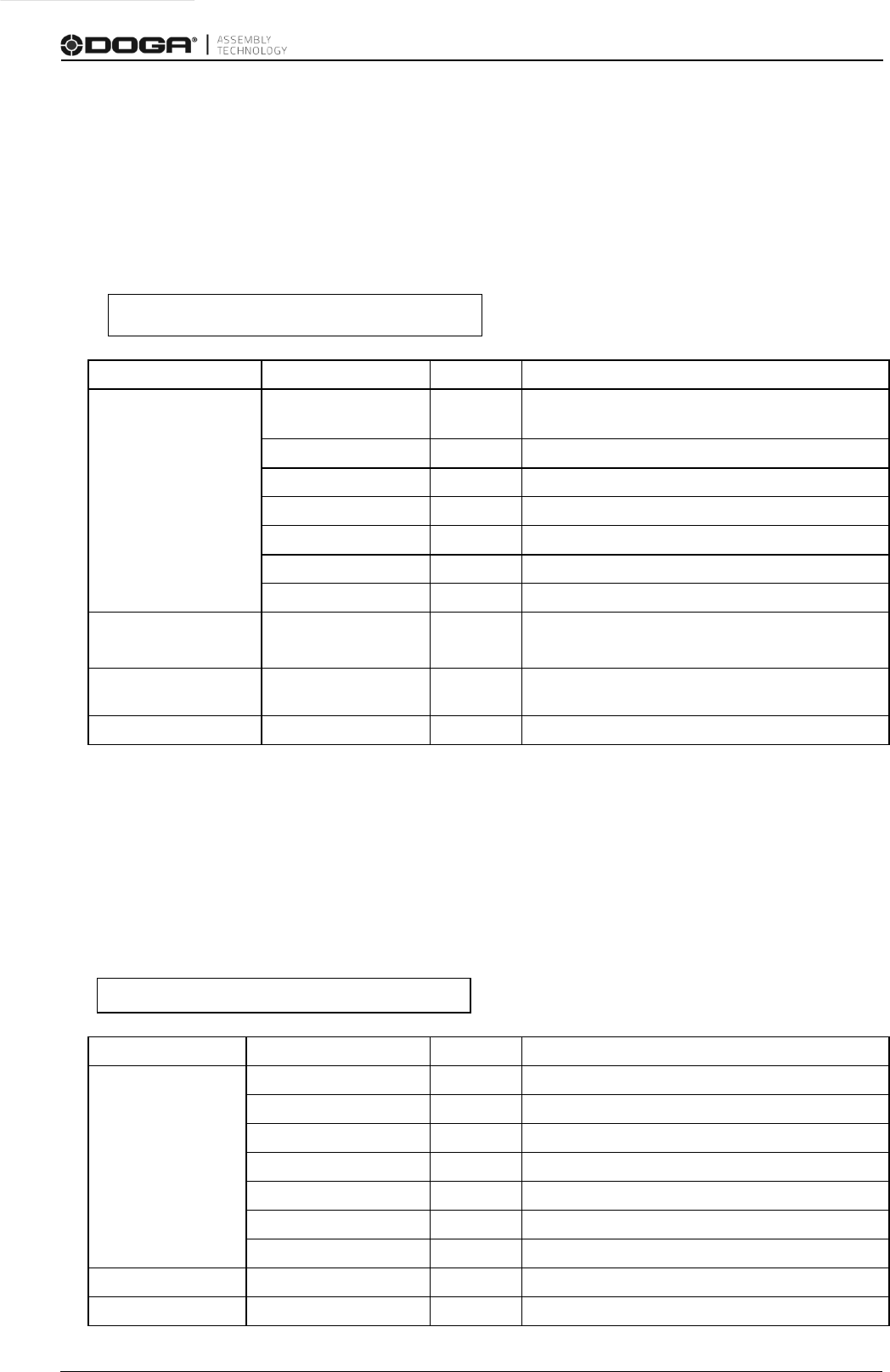

3.1 Header

Part Bytes

Comment

Length

4

Total length of message except prefix and sufix (BEL, HT, STX, ETX)

Range: 0000 ~ 9999

MID

4

Command message (Ex: Parameter save, Disable tool)

Range: 0001 ~ 9999

Revision

3

Message version

According to the MID, Data type and lenght is different.

No ack

flag

1

Require Ack message as a response ?

0: YES 1: NO

Station

ID

2

No use. Replace with 0x20(space)

Spindle

ID

2

Spare

4

Spare. No use. Replace with 0x20(space)

Note.

- The empty space Byte in Length and MID should be replaced with 0x30(0)

Manual COM OPEN PROTOCOL MDCv2/MDTC series 7 DOC.60428-05/23

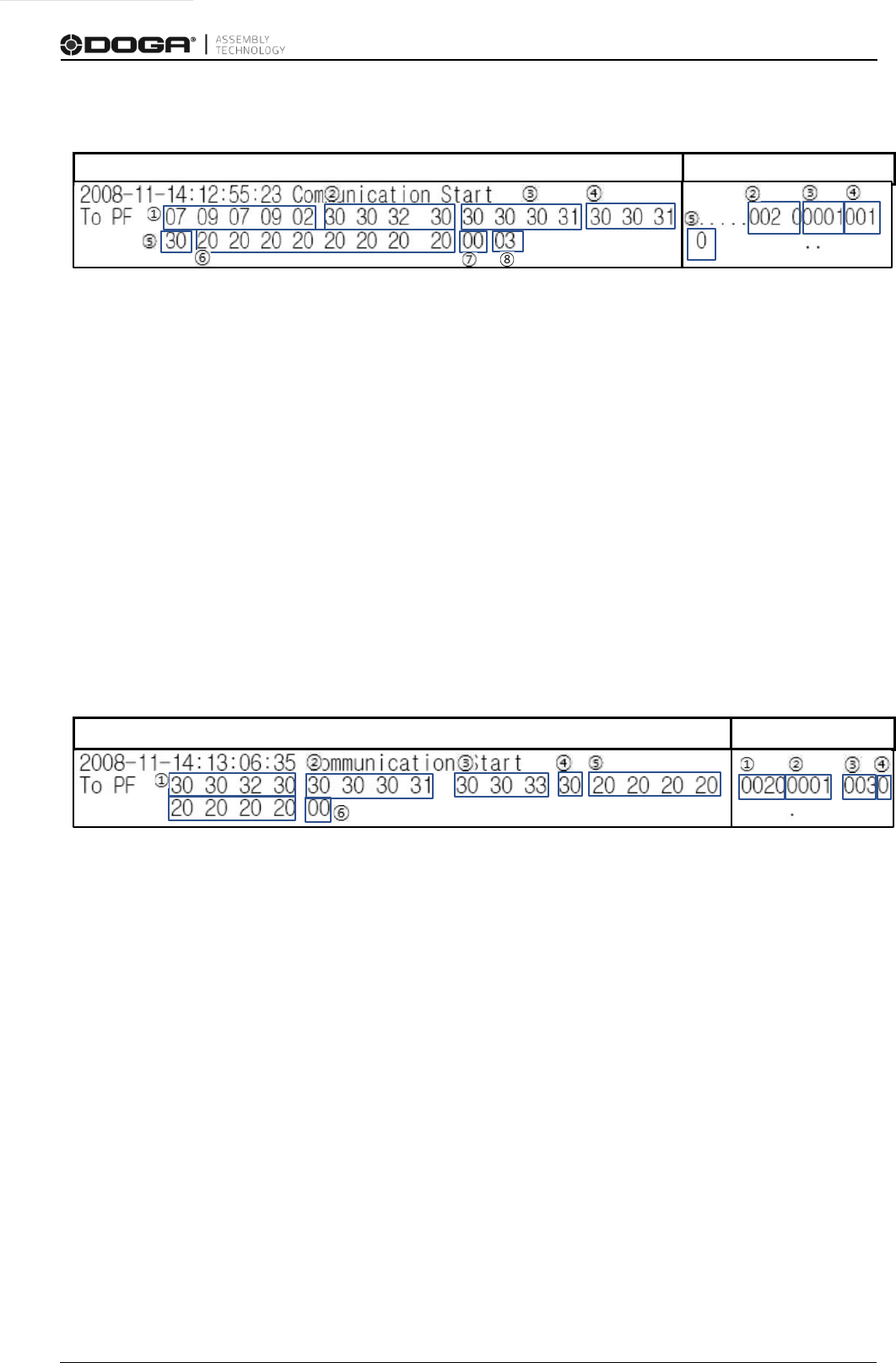

3.2 Serial message example

1. BEL, HT, BEL, HT, STX : Prefix of the message from Integrator to controller.

2. 0020(Decimal): Total message length is 20byte.

3. 0001(Decimal): MID (command) 1 is for communication start.

4. 001(Decimal): The current message version is 1

st

.

5. 0(Decimal): “0” requires ACK response.

6. 20 20…(hex): No use with Space(0x20).

7. 00(hex): NULL.

8. 03(hex): ETX. The end of Message.

3.3 Ethernet message example

1. 0020: Total message length is 20byte.

2. 0001: MID (command) 1 is for communication start.

3. 003: Revision. The current message version is 3

th

.

4. 0: No ack flag. “0” requires ACK response.

5. 20 20…(hex): No use with Space(0x20).

6. 00(hex): NULL

A

)

SCII (Hex

D

ecimal

A

SCII (Hex)

D

ecimal

Manual COM OPEN PROTOCOL MDCv2/MDTC series 8 DOC.60428-05/23

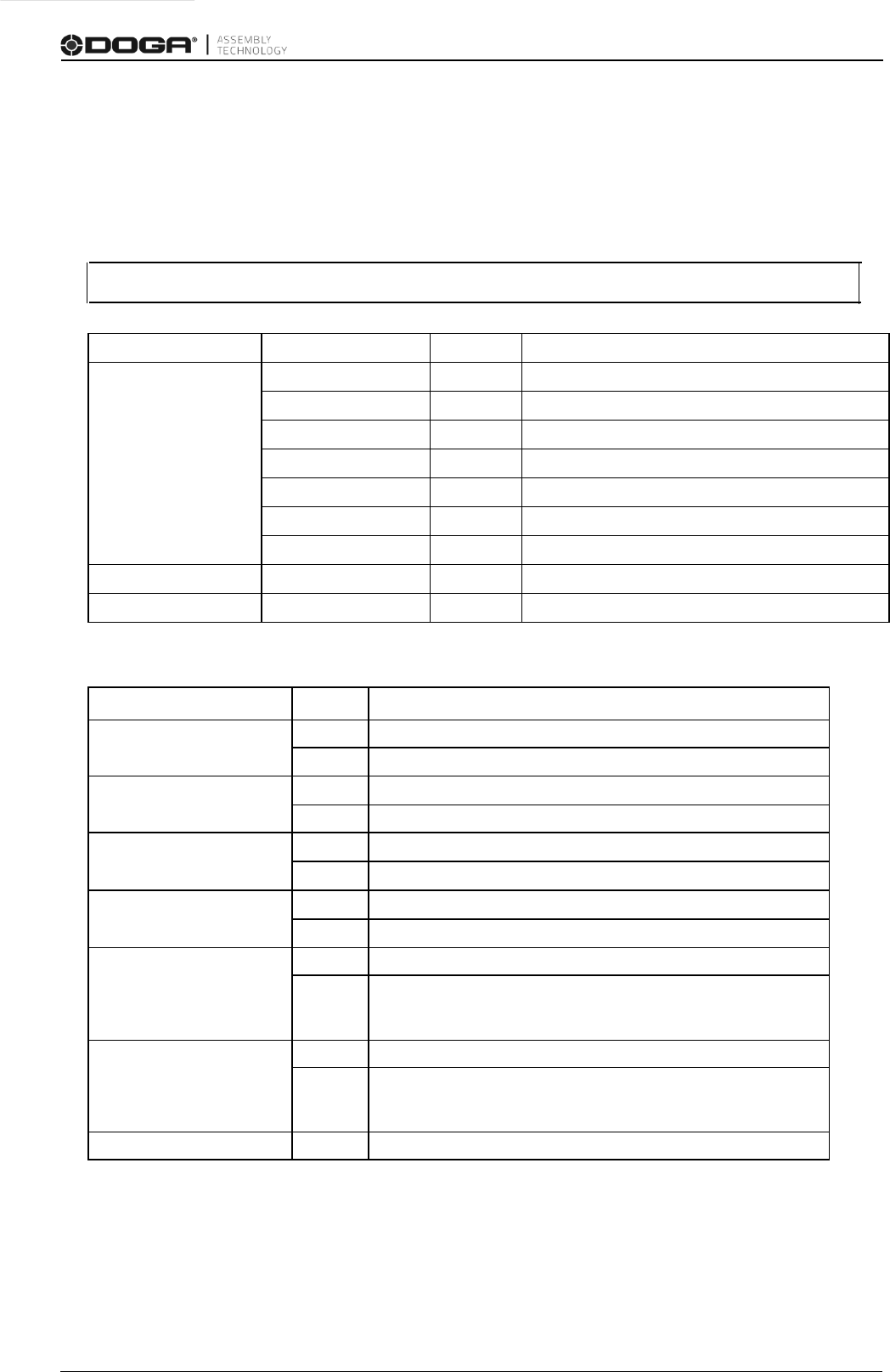

4. COMMUNICATION FLOW

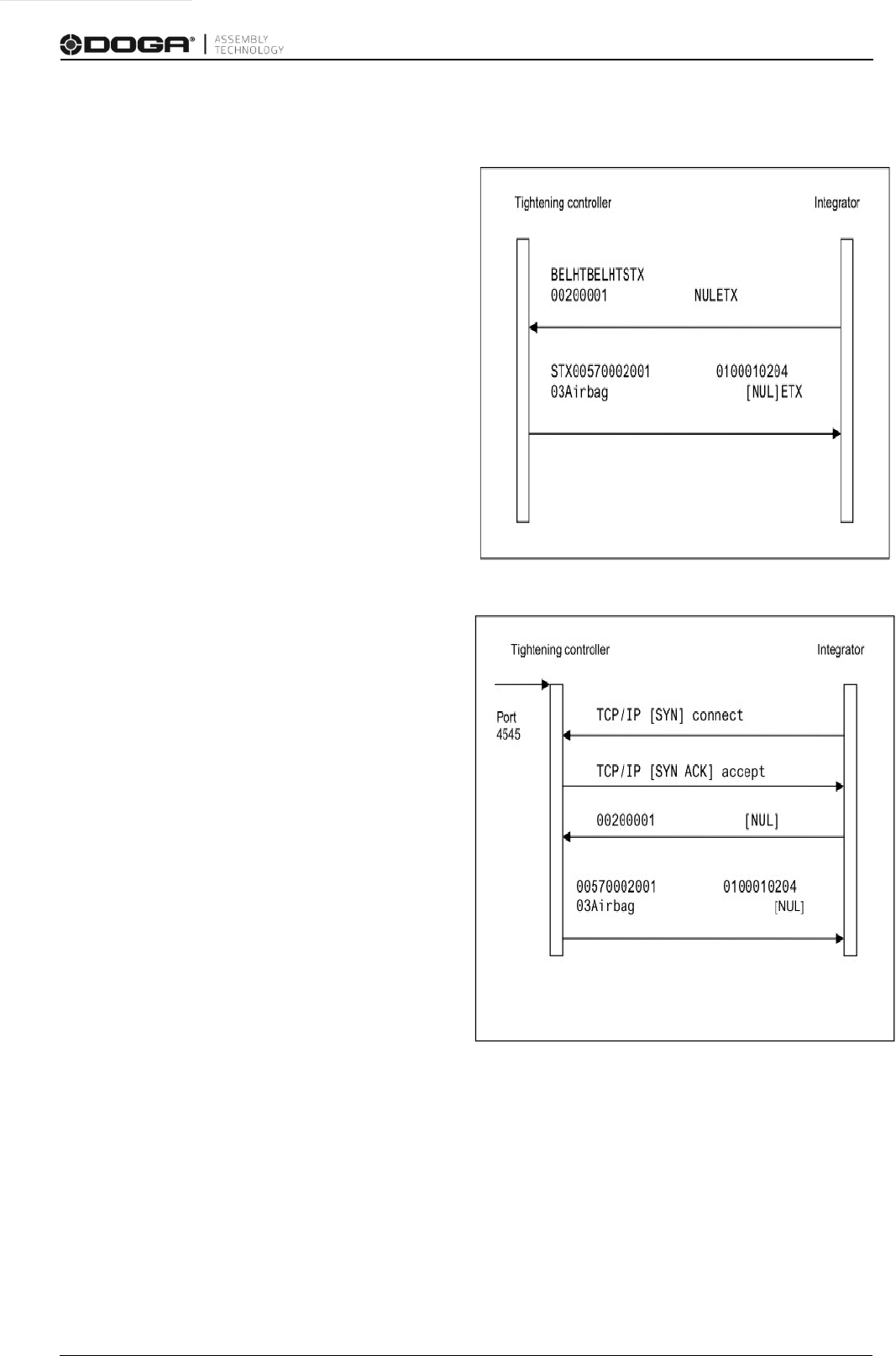

4.1 Serial Connection flow

1. Integrator send MID 0001 message to

controller for communication start.

2. Controller response with MID 0002 ACK

message which means communication

start.

4.2 Ethernet Connection flow

1. Integrator request TCP connection to

Controller.

2. Controller response TCP accept

message.

3. Integrator send MID 0001 message to

controller for communication start.

4. Controller response with MID 0002 ACK

message which means communication

start.

Manual COM OPEN PROTOCOL MDCv2/MDTC series 9 DOC.60428-05/23

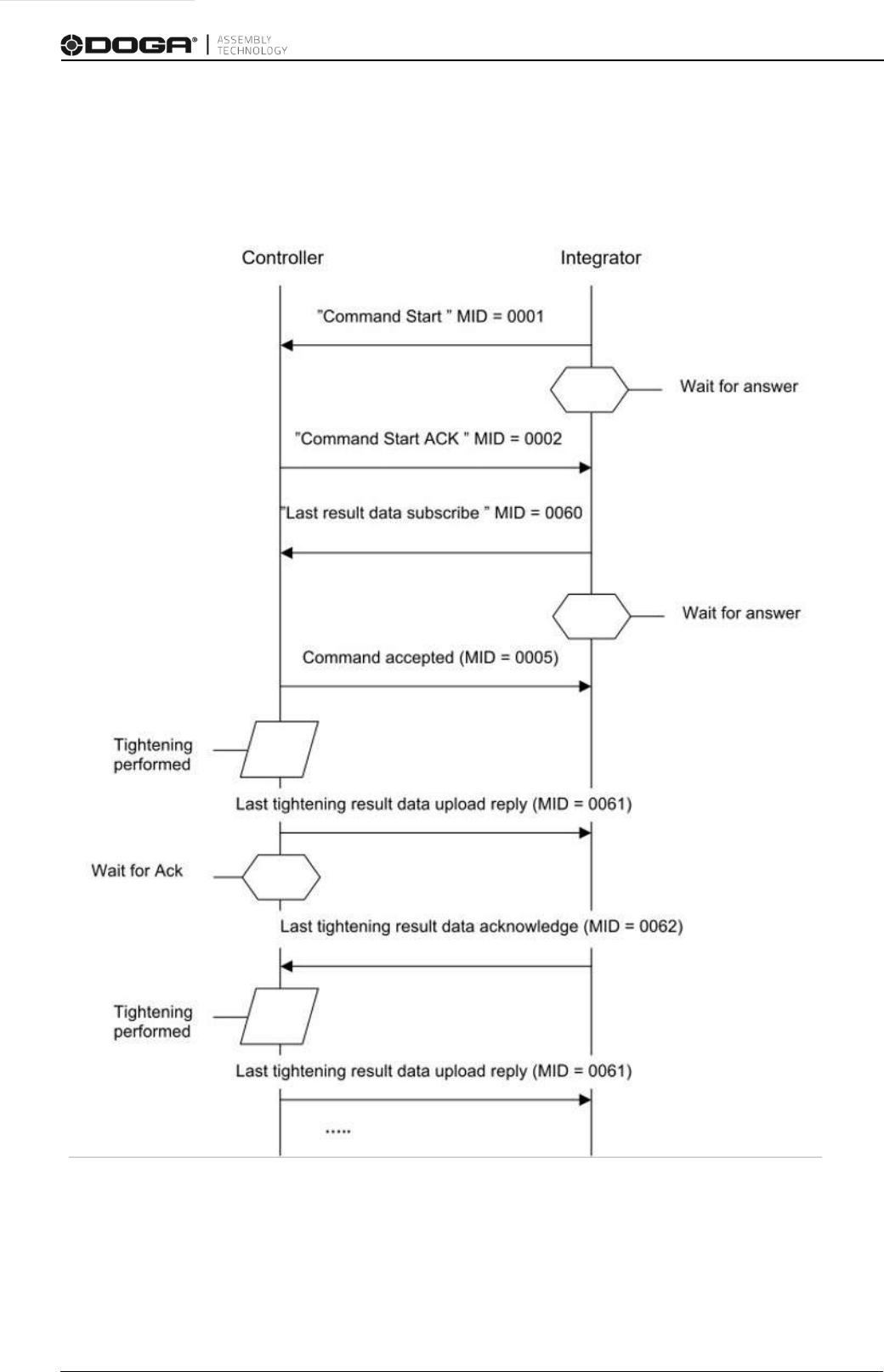

4.3 Communication flow chart example

Ex) Establish a connection and set result subscription

Manual COM OPEN PROTOCOL MDCv2/MDTC series 10 DOC.60428-05/23

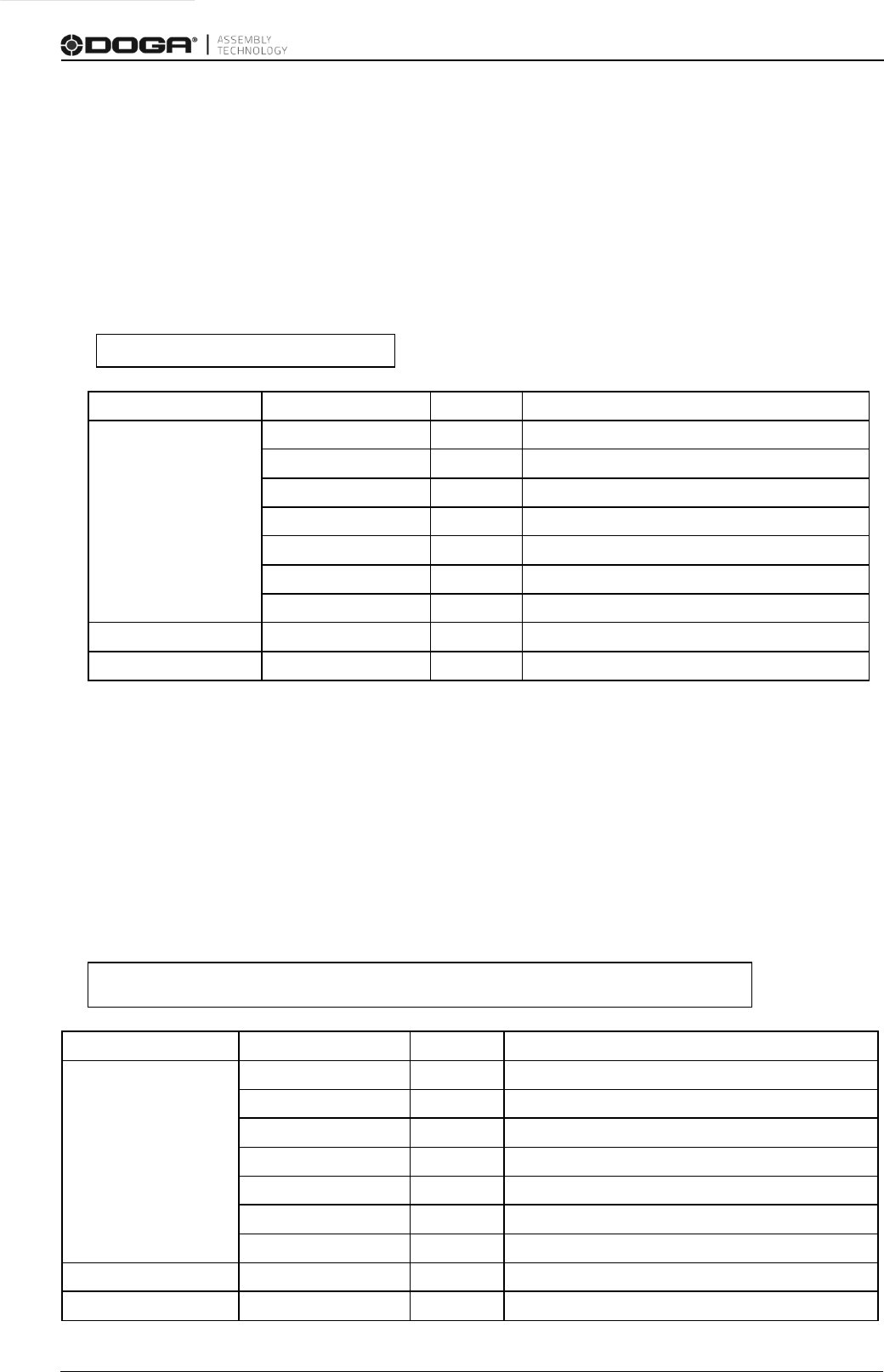

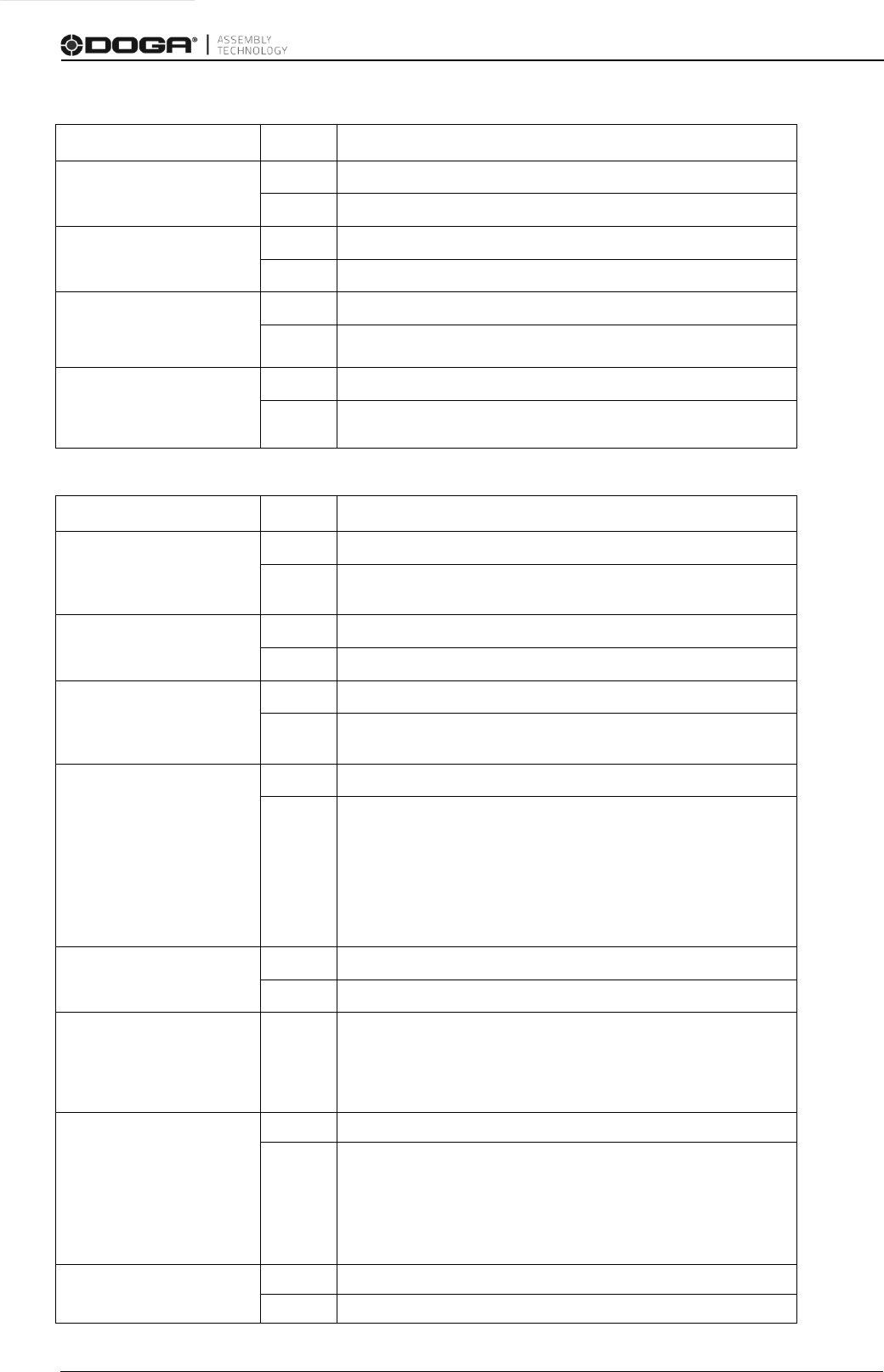

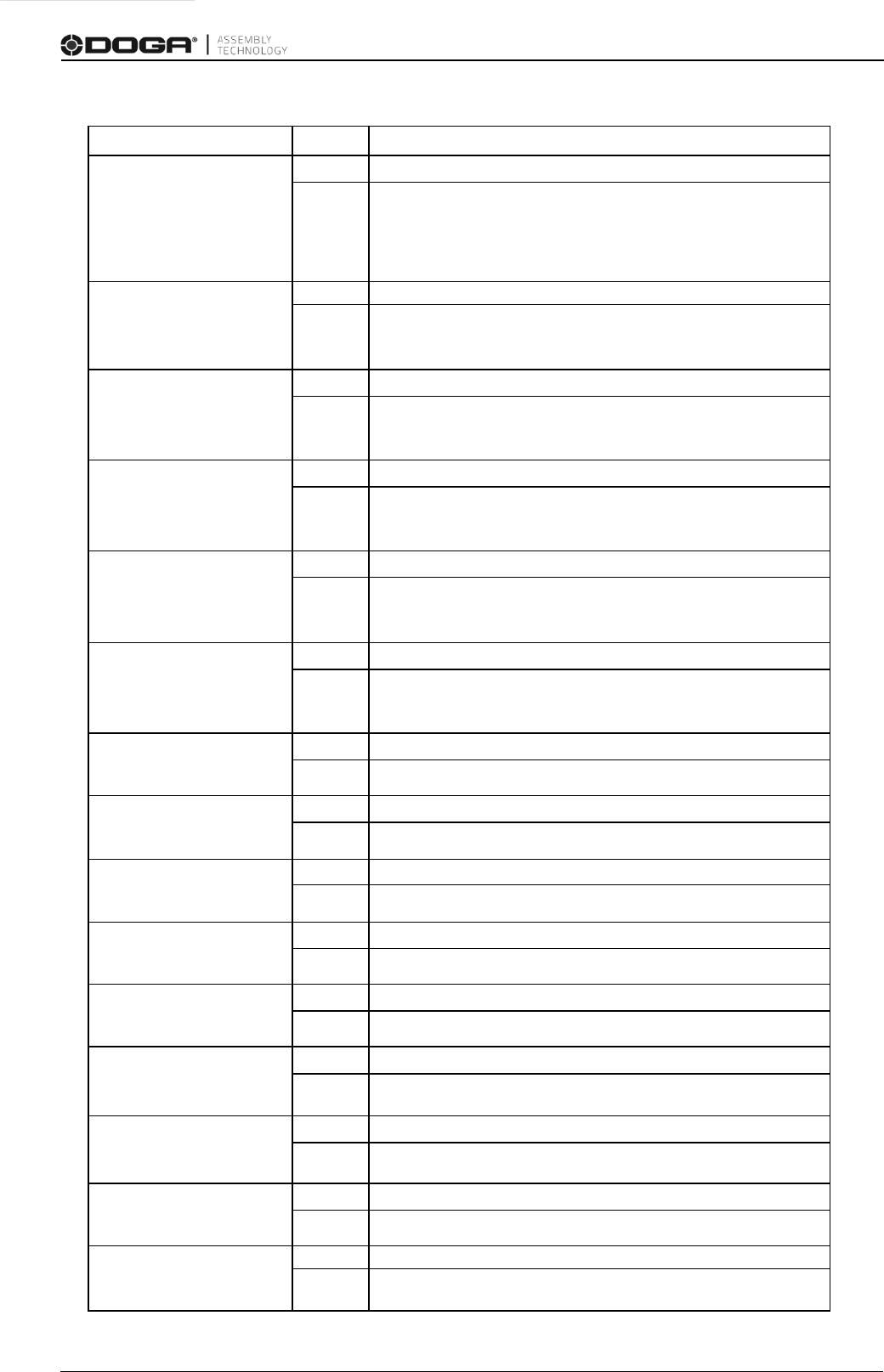

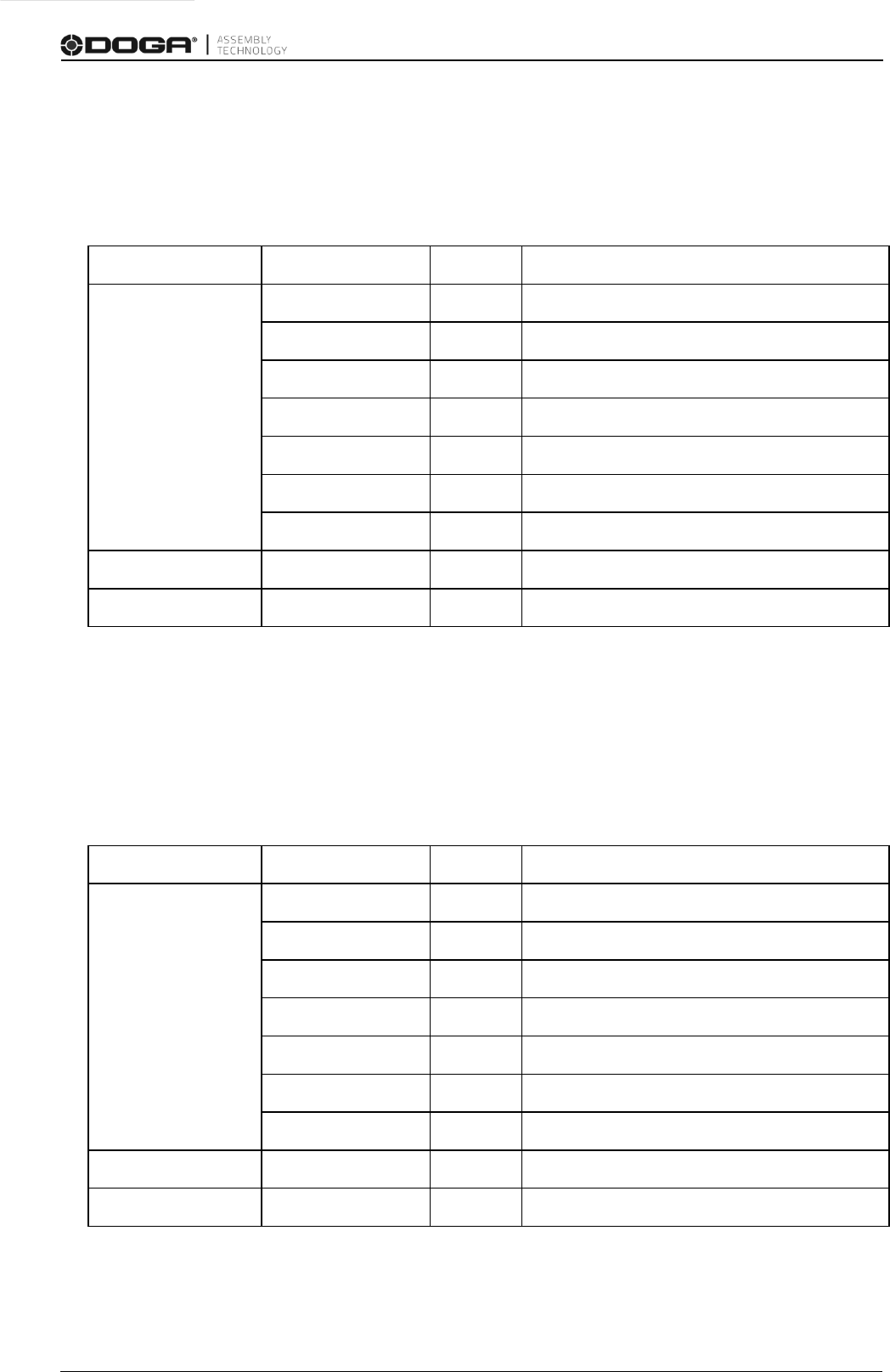

5. Communication messages

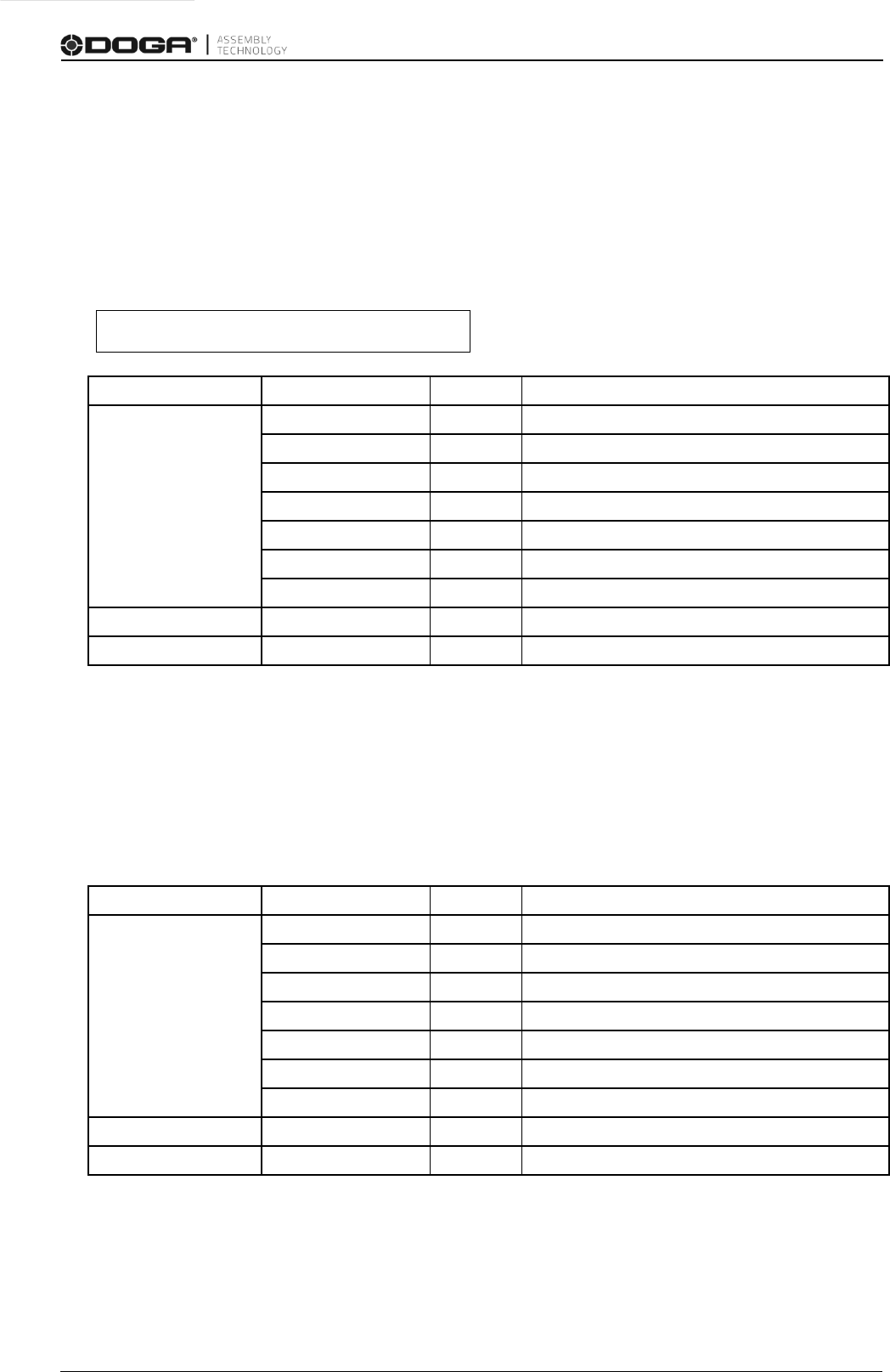

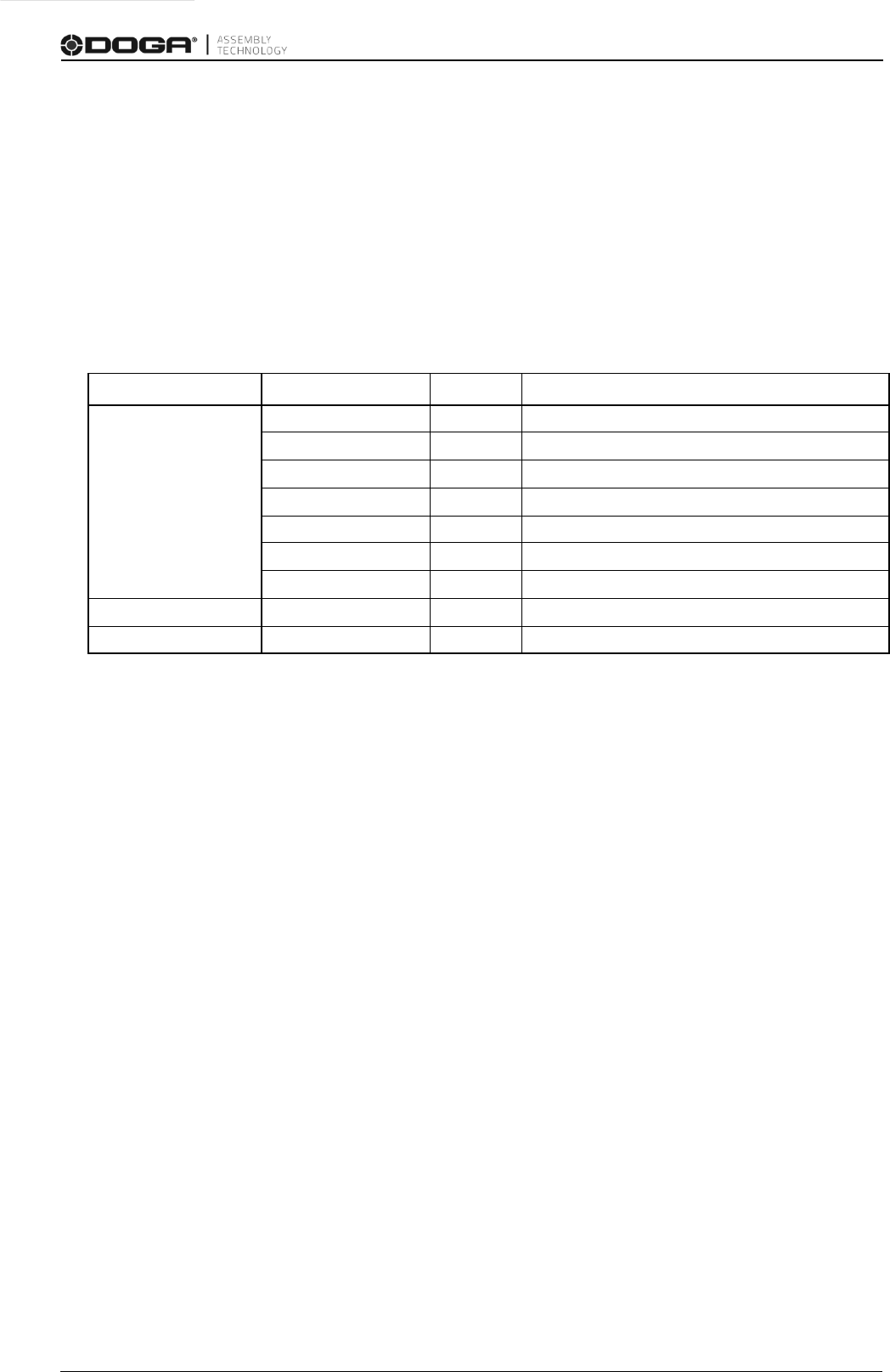

5.1 MID control type

ID

Description

Sent by

0001

Communication start

Integrator

0002

Communication start acknowledge

Controller

0003

Communication stop

Integrator

0004

Command error

Controller

0005

Command accepted

Controller

0010

Parameter set ID(Preset number) upload request

Integrator

0011

Parameter set ID(Preset number) upload reply

Controller

0012

Parameter set(Preset) data upload request

Integrator

0013

Parameter set(Preset) data upload reply

Controller

0018

Select Parameter set(Preset)

Integrator

0040

Tool data upload request

Integrator

0041

Tool data upload reply

Controller

0042

Disable Tool

Integrator

0043

Enable Tool

Integrator

0060

Last tightening result data subscribe

Integrator

0061

Last tightening result data

Controller

0062

Last tightening result data acknowledge

Integrator

0063 Last tightening result data unsubscribe Integrator

0070

Alarm subscribe

Integrator

0071

Alarm

Controller

0072

Alarm acknowledge

Integrator

0073

Alarm unsubscribe

Integrator

1000

Read Parameter value

Integrator

1001

Read Parameter value acknowledge

Controller

1002

Write parameter value

Integrator

1003

Write parameter value acknowledge

Controller

9999

Keep alive open protocol communication

Integrator

Manual COM OPEN PROTOCOL MDCv2/MDTC series 11 DOC.60428-05/23

5.1.1 MID 0001 Communication start

This message enables the communication. The controller does not respond to any other

command before this

� Message sent by: Integrator

� Answers: MID 0002 Communication start acknowledge or

MID 0004 Command error, Client already connected or MID revision unsupported

Example: Communication start with call for

MID 0002 Communication start acknowledge

revision 3.

00200001003

NUL

Message part

Parameter

Byte

Value

Header

Length

1-4

0020

MID

5-8

0001

Revision of MID 0002

9-11

Range: 001

No Ack flag

12

N/A

Station ID

13-14

N/A

Spindle ID

15-16

N/A

Spare

17-20

N/A

Data field

N/A

0

N/A

Message end

21

NUL

5.1.2 MID 0002 Communication start acknowledge

When accepting the communication start the controller sends as reply, a

Communication start acknowledge. This message contains some basic information

about the controller, such as cell ID, channel ID, and name.

� Message sent by: Controller

� Answer: None

Example, revision 1: The connected controller belongs to cell 1, the channel ID is

1 and the name is Airbag1

00570002

010001020103Airbag1

NUL

Message part

Parameter

Byte

Value

Header

Length

1-4

Rev 1: 0057

MID

5-8

0002

Revision

9-11

Range: 001

No Ack flag

12

N/A

Station ID

13-14

N/A

Spindle ID

15-16

N/A

Spare

17-20

N/A

Data field

Controller information

21-length

See Table 1

Message end

Rev 1: 58

NUL

Manual COM OPEN PROTOCOL MDCv2/MDTC series 12 DOC.60428-05/23

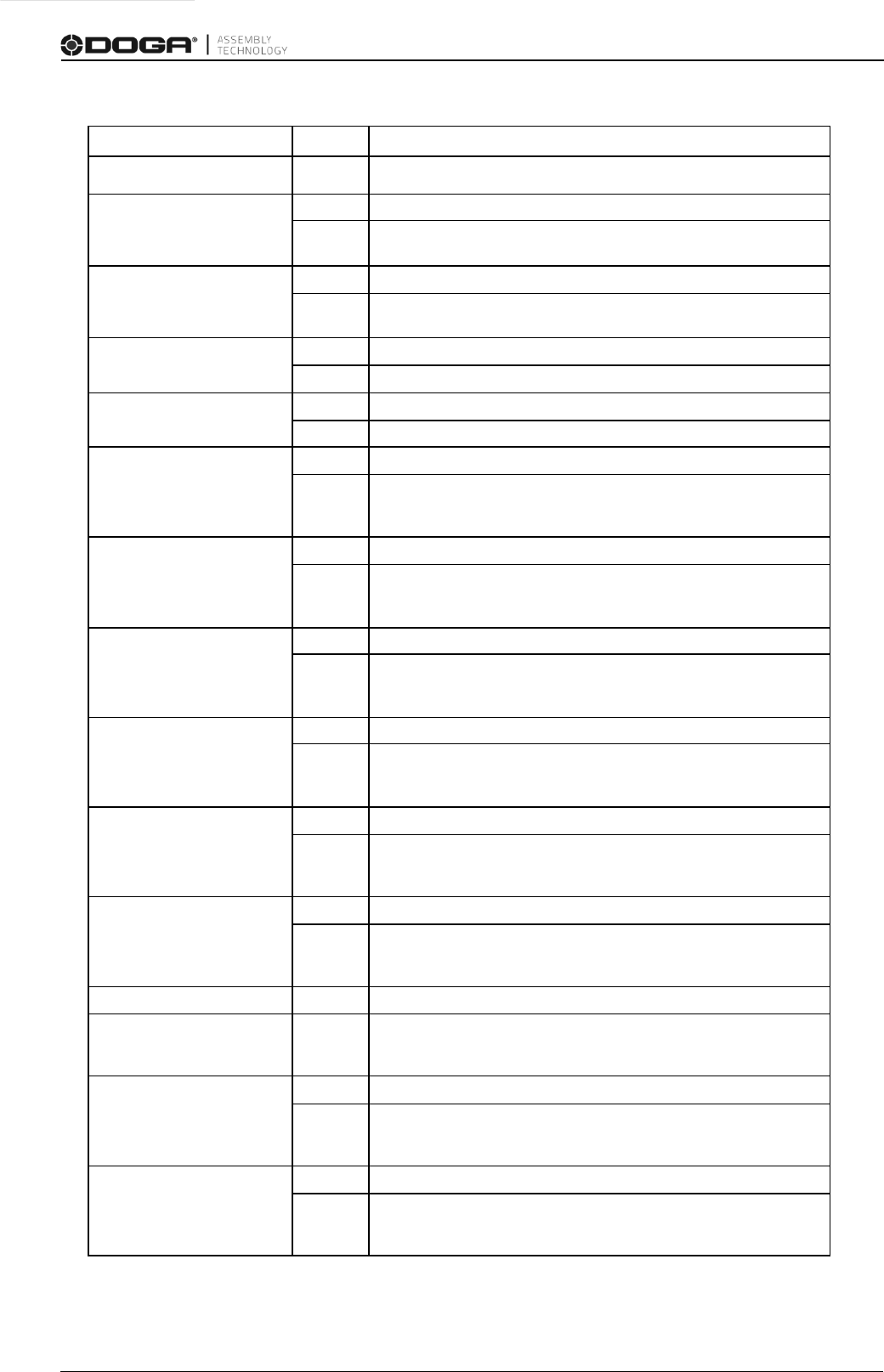

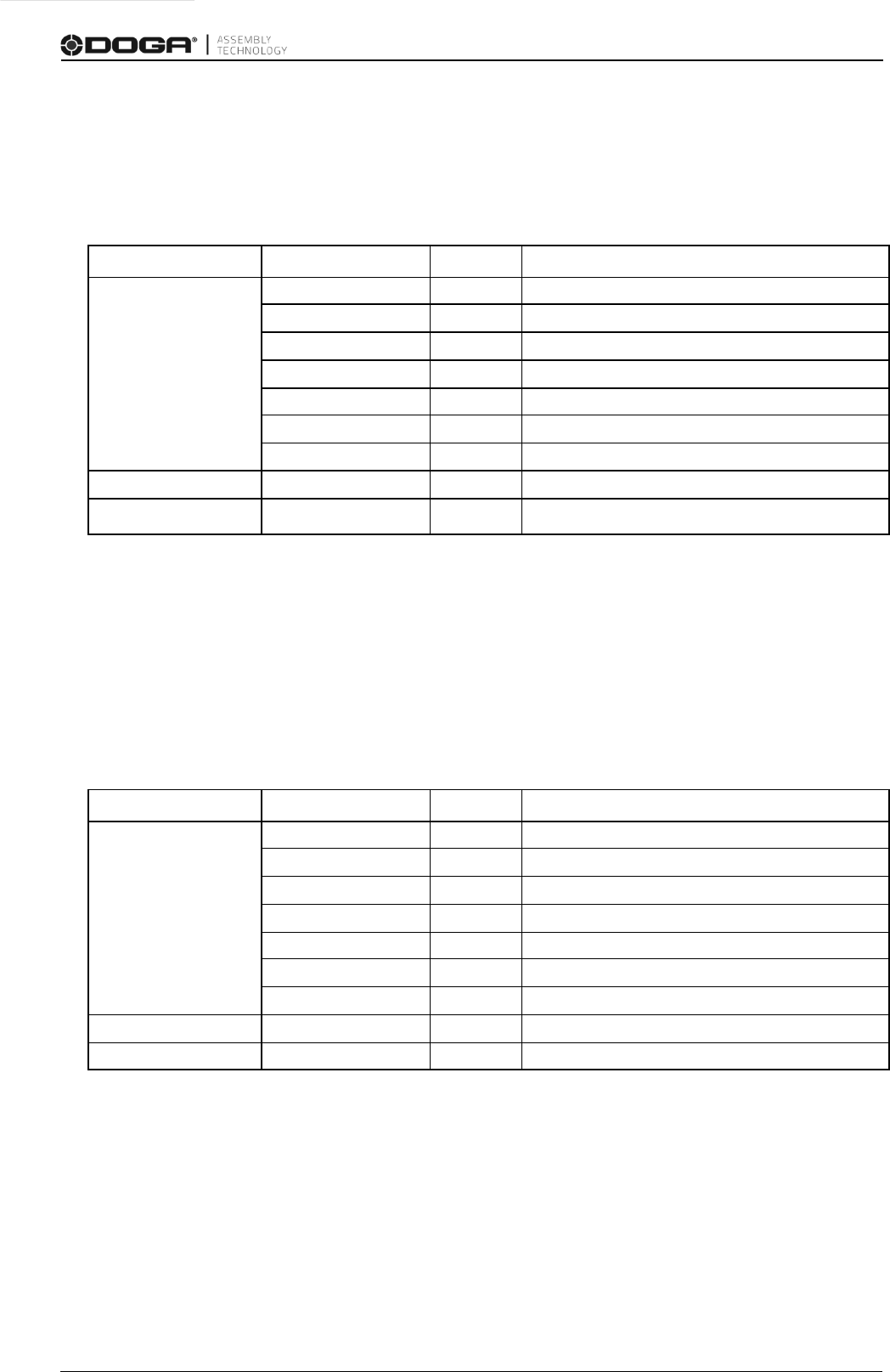

Table 1 MID 0002 Revision 1

Parameter

Byte

Value

Cell ID

21-22

01

23-26

The cell ID don’t use. (Fill with 0x30)

Channel ID

27-28

02

29-30

The channel ID don’t use. (Fill with 0x30)

Controller Name

31-32

03

33-57

The controller name is 25 bytes long and specified by 25 ASCII

characters

5.1.3 MID 0003 Communication stop

This message disables the communication. The controller will stop to respond to any commands

except for

MID 0001 Communication start after receiving this command.

� Message sent by: Controller:

� Answer: MID 0005 Command accepted

Message part

Parameter

Byte

Value

Header

Length

1-4

0020

MID

5-8

0003

Revision

9-11

00-01

No Ack flag

12

N/A

Station ID

13-14

N/A

Spindle ID

15-16

N/A

Spare

17-20

N/A

Data field

N/A

N/A

Message end

21

NUL

5.1.4 MID 0004 Command error

This message is used by the controller when a request for any reason has not been

performed. The data field contains the message ID of the message request that failed

as well as an error code.

� Message sent by: Controller:

� Answer: None

Example: The request

MID 0018 Select parameter set failed, the parameter set number was not

present in the controller.

00260004

001802NUL

Manual COM OPEN PROTOCOL MDCv2/MDTC series 13 DOC.60428-05/23

Message part

Parameter

Byte

Value

Header

Length

1-4

0026

MID

5-8

0004

Revision

9-11

Range: 000-001

No Ack flag

12

N/A

Station ID

13-14

N/A

Spindle ID

15-16

N/A

Spare

17-20

N/A

Data field

MID and error code

21-26

see Table 2.

Message end

27

NUL

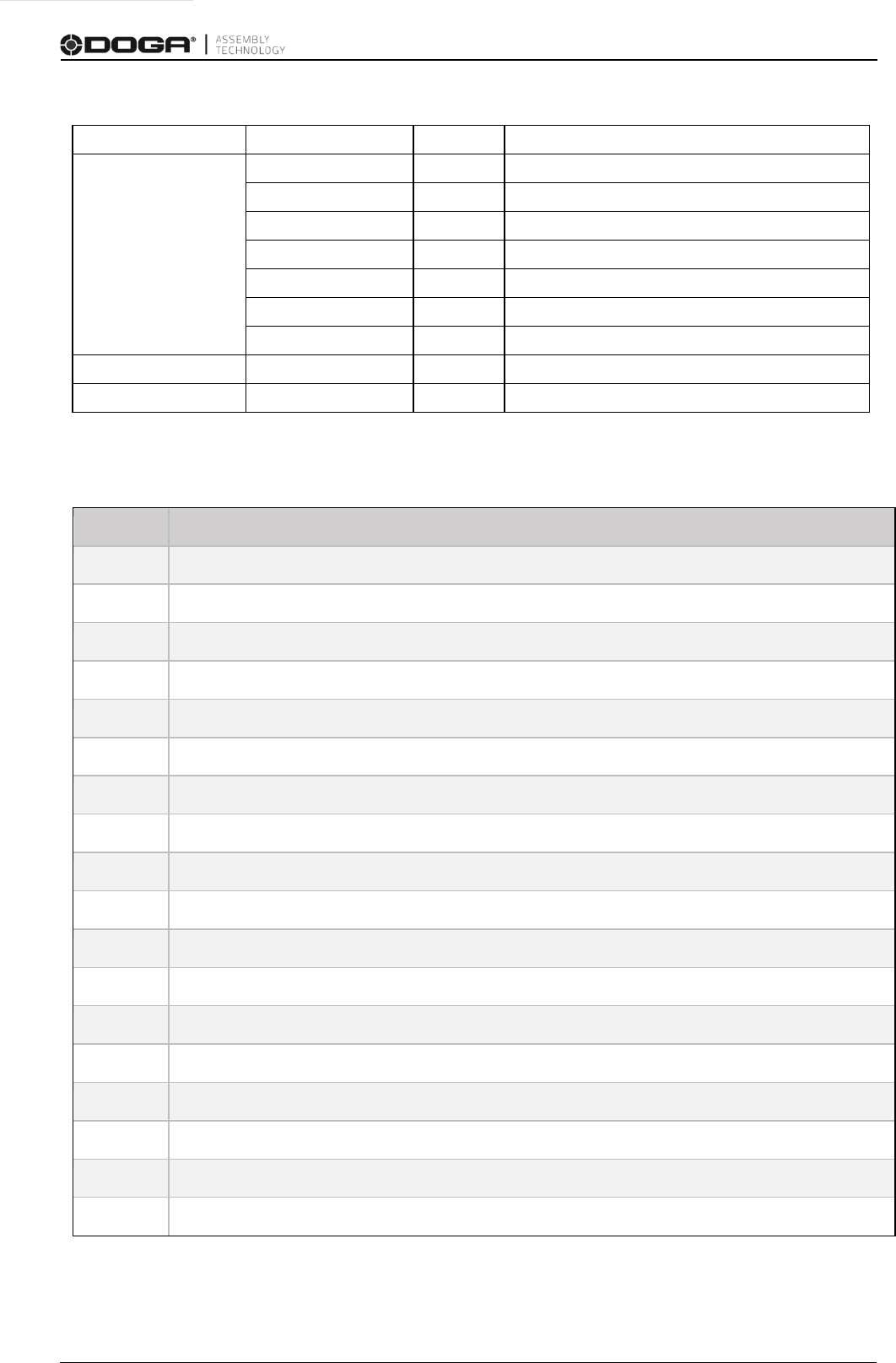

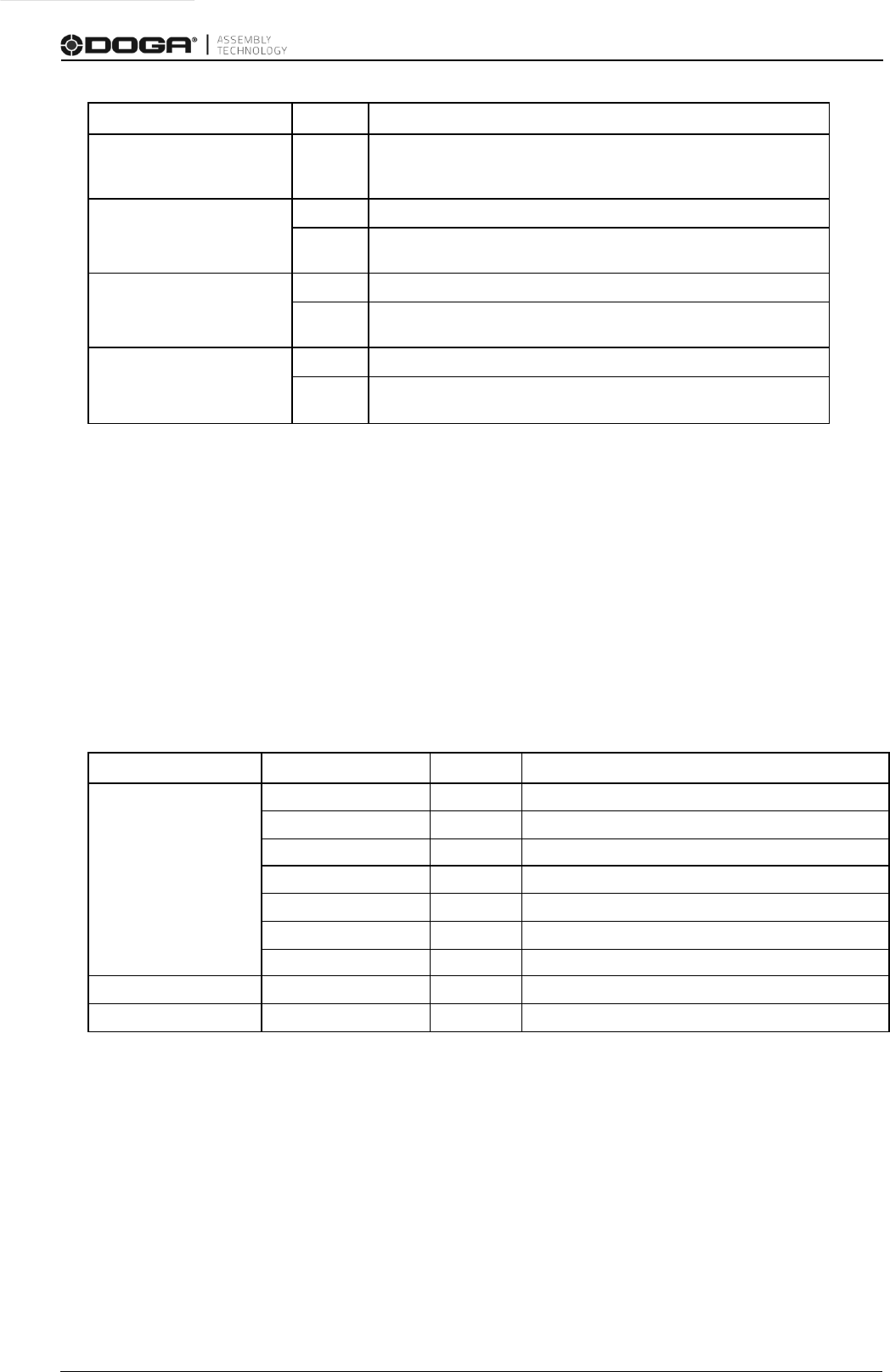

Table 2 MID 0004 Data field (Error code description)

ID

Description

00

No Error

01

Invalid data

02

Parameter set : ID not present

03

Parameter set : can not be set.

04

Parameter set : not running

09

Last tightening result subscription already exists

10

Last tightening result subscription does not exist

11

Alarm subscription already exists

12

Alarm subscription does not exist

13

Parameter set selection subscription already exists

14

Parameter set selection subscription does not exist

16

Connection rejected protocol busy

58

No alarm present

79

Command failed

96

Client already connected

97

MID revision unsupported

98

Controller internal request timeout

99

Unknown MID

Manual COM OPEN PROTOCOL MDCv2/MDTC series 14 DOC.60428-05/23

5.1.5 MID 0005 Command accepted

This message is used by the controller to confirm that the latest request sent by the

integrator was accepted. The data field contains the MID of the request accepted.

� Message sent by: Controller.

� Answer: None.

Example: The request

MID 0018 Select parameter set is accepted.

00240005

0018NUL

Message part

Parameter

Byte

Value

Header

Length

1-4

0024

MID

5-8

0005

Revision

9-11

Range: 000-001

No Ack flag

12

N/A

Station ID

13-14

N/A

Spindle ID

15-16

N/A

Spare

17-20

N/A

Data field

MID accepted

21-24

Four ASCII digits

Message end

25

NUL

5.1.6 MID 0010 Parameter set ID (Preset number) upload request

A request to get the valid parameter set IDs from the controller.

� Message sent by: Integrator

� Answer: MID 0011 Parameter set ID upload reply

Message part

Parameter

Byte

Value

Header

Length

1-4

0020

MID

5-8

0010

Revision, MID 0011

9-11

Range: 000-001

No Ack flag

12

N/A

Station ID

13-14

N/A

Spindle ID

15-16

N/A

Spare

17-20

N/A

Data field

N/A

N/A

Message end

21

NUL

Manual COM OPEN PROTOCOL MDCv2/MDTC series 15 DOC.60428-05/23

5.1.7 MID 0011 Parameter set ID (Preset number) upload reply

The transmission of all the valid parameter set IDs of the controller. The data field

contains the number of valid parameter sets currently present in the controller, and the

ID of each parameter set present.

� Message sent by: Controller

� Answer: None

Example: parameter set 1 and 2 are present in the controller.

00290011

002001002NUL

Message part

Parameter

Byte

Value

Header

Length 1-4

Length depends on the number of parameter sets. 23

+ number of parameter sets x3

MID

5-8

0011

Revision

9-11

Range: 000-001

No Ack flag

12

N/A

Station ID

13-14

N/A

Spindle ID

15-16

N/A

Spare

17-20

N/A

Data field, part 1

The number of

parameter sets in the

controller

21-23

Three ASCII digits. Range: 001-015

Data field, part 2

The ID of each

parameter set present

24 -

Three ASCII digits for each parameter set

Message end

Length +1

NUL

5.1.8 MID 0012 Parameter set (Preset) data upload request

Request to upload parameter set data from the controller.

� Message sent by: Integrator

� Answer: MID 0013 Parameter set data upload reply, or

MID 0004 Command error, Parameter set not present

Example: Request to upload parameter set data for parameter set 1.

00230012

001NUL

Message part

Parameter

Byte

Value

Header

Length

1-4

0023

MID

5-8

0012

Revision, MID 0013

9-11

Range: 001

No Ack flag

12

N/A

Station ID

13-14

N/A

Spindle ID

15-16

N/A

Spare

17-20

N/A

Data field

Parameter set ID

21-23

Three ASCII digits. Range: 001-015

Message end

24

NUL

Manual COM OPEN PROTOCOL MDCv2/MDTC series 16 DOC.60428-05/23

5.1.9 MID 0013 Parameter set (Preset) data upload reply

Upload of parameter set data reply. The following tables show the revisions available:

� Message sent by: Controller

� Answer: None

Example: Upload parameter set data for parameter set 1 called Airbag 1.

01040013 0100102Airbag1 031040305001200

0600150007001400080036009007201000480NUL

Message part

Parameter

Byte

Value

Header

Length

1-4

0104

MID

5-8

0013

Revision

9-11

Range: 001

No Ack flag

12

N/A

Station ID

13-14

N/A

Spindle ID

15-16

N/A

Spare

17-20

N/A

Data field

Parameter set data

21-104

See Table 3

Message end

105

NUL

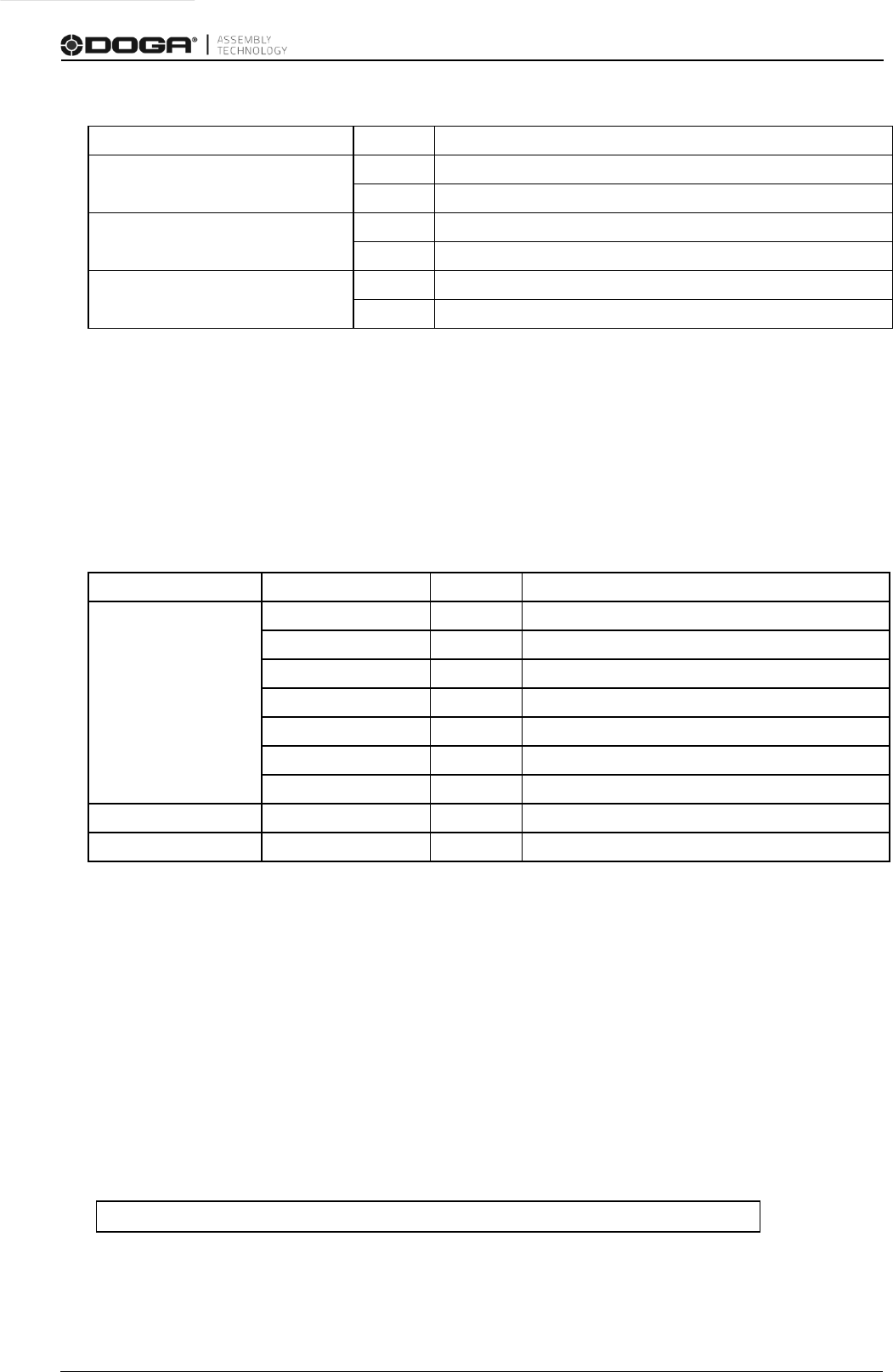

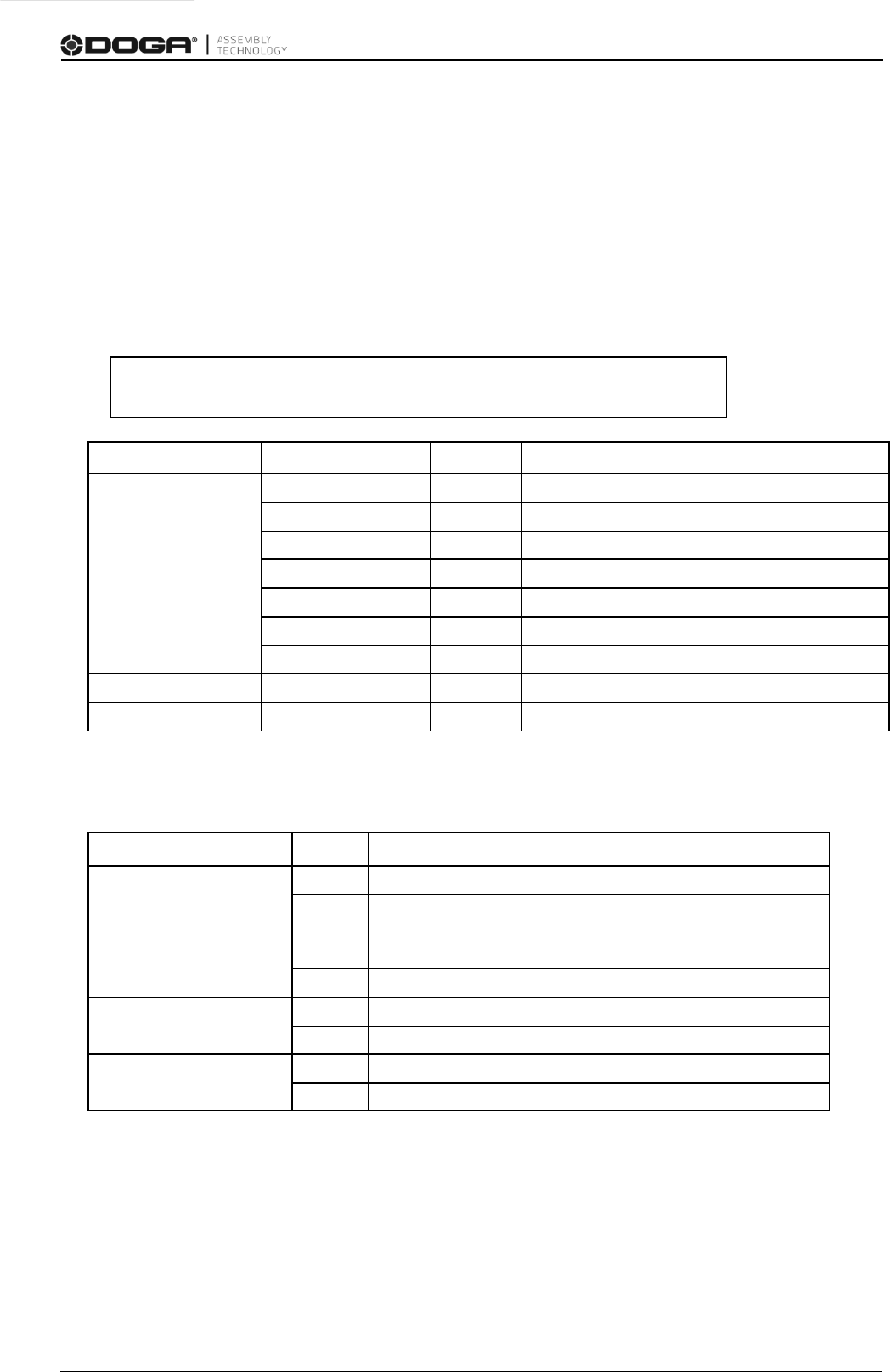

Table 3 MID 0013 Revision 1

Parameter

Byte

Value

Parameter set ID

21-22

01

23-25

Three ASCII digits, range 001-015

Parameter set name

26-27

02

28-52

Parameter set name don’t use.

Rotation direction

53-54

03

55

1=CW, 2=CCW

Batch size

56-57

04

58-59

The batch size doesn’t use. (Fill with 0x30)

Torque min

60-61

05

62-67

The torque min limit is multiplied by 100 and sent as an integer

(2 decimals truncated). It is six bytes long and is specified by six

ASCII digits.

Torque max

68-69

06

70-75

The torque max limit is multiplied by 100 and sent as an integer

(2 decimals truncated. It is six bytes long and is specified by six

ASCII digits.

Torque final target

76-77

07

Manual COM OPEN PROTOCOL MDCv2/MDTC series 17 DOC.60428-05/23

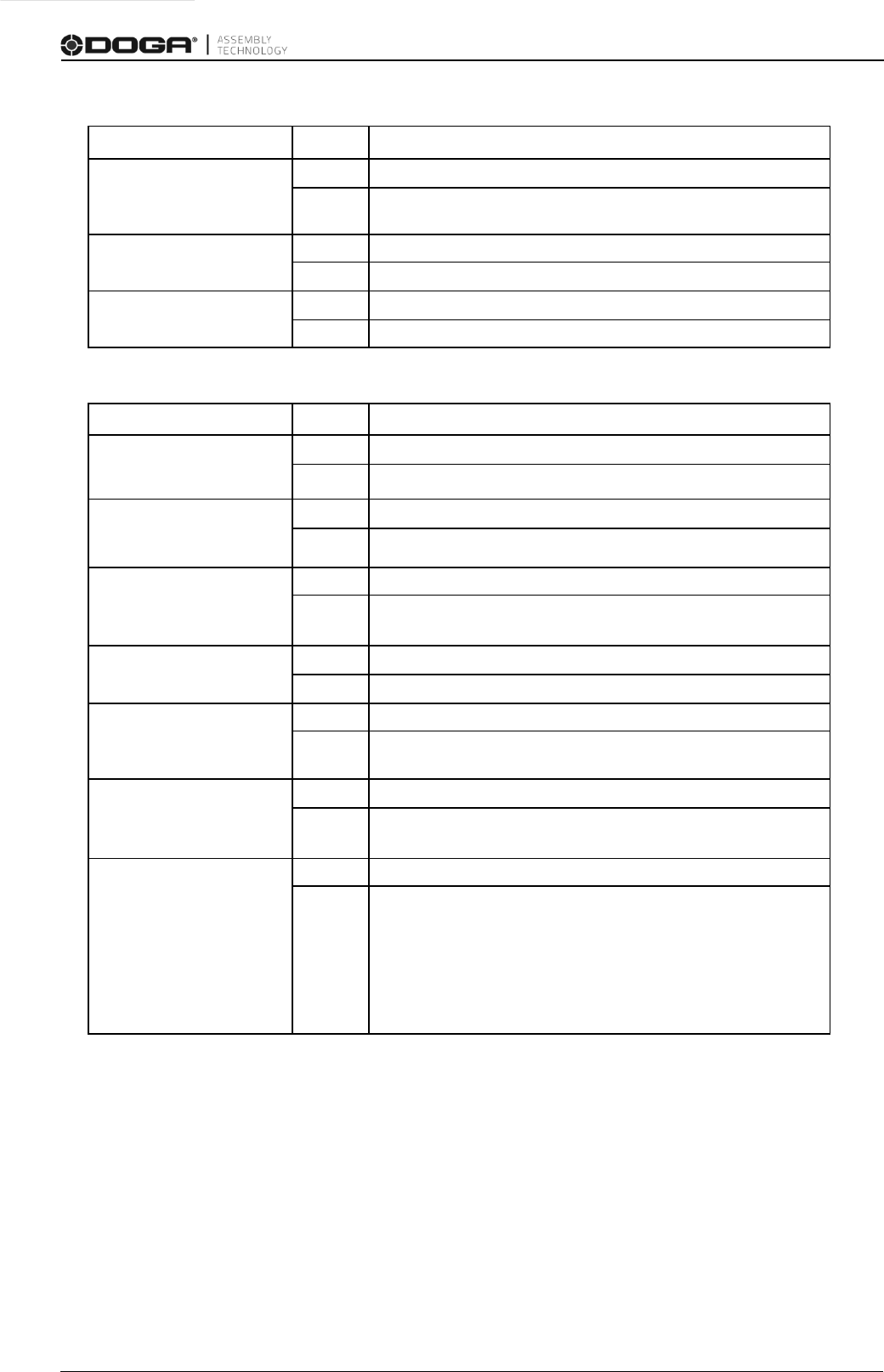

Parameter

Byte

Value

Torque final target

78-83

The torque final target is multiplied by 100 and sent as an integer

(2 decimals truncated). It is six bytes long and is specified by six

ASCII digits.

Angle min

84-85

08

86-90

The angle min value is five bytes long and is specified by five ASCII

digits. Range: 00000-99999.

Angle max

91-92

09

93-97

The angle max value is five bytes long and is specified by five

ASCII digits. Range: 00000-99999.

Final Angle Target

98-99

10

100-104

The target angle is specified in degrees. 5 ASCII digits. Range:

00000-99999.

5.1.10 MID 0018 Select Parameter set (Preset)

Select a parameter set.

� Message sent by: Integrator

� Answer: MID 0005 Command accepted or

MID 0004 Command error, Parameter set can not be set

The Pset will then be automatically selected when the operator chooses the correct socket

from the selector.

Subscription of the currently selected Pset via MID 0014 will show when the operator has

selected the correct Pset.

Message part

Parameter

Byte

Value

Header

Length

1-4

0023

MID

5-8

0018

Revision

9-11

Range : 000-001

No Ack flag

12

N/A

Station ID

13-14

N/A

Spindle ID

15-16

N/A

Spare

17-20

N/A

Data field

Parameter set ID

21-23

Three ASCII digits, range 001-015

Message end

24

NUL

Manual COM OPEN PROTOCOL MDCv2/MDTC series 18 DOC.60428-05/23

5.1.11 MID 0040 Tool data upload request

A request for some of the data stored in the tool. The result of this command is the transmission of the tool

data.

Message sent by: Integrator

Answer:

MID 0041 Tool data upload reply

Message part

Parameter

Byte

Value

Header

Length

1-4

0020

MID

5-8

0040

Revision, MID 0041

9-11

Range: 000-004

No Ack flag

12

N/A

Station ID

13-14

N/A

Spindle ID

15-16

N/A

Spare

17-20

N/A

Data field

N/A

N/A

Message end

21

NUL

5.1.12 MID 0041 Tool data upload reply

Upload of tool data from the controller.

Message sent by: Controller

Answer: None

Example: Tool data

00810041 01C341212 02548796 032001-05-07:13:24:5404670919 NUL

Message part

Parameter

Byte

Value

Header

Length

1-4

Revision 1: 0081

Revision 2: 0156

MID

5-8

0041

Revision

9-11

Range: 000-004

No Ack flag

12

N/A

Station ID

13-14

N/A

Spindle ID

15-16

N/A

Spare

17-20

N/A

Data field

Tool data

21-length

See Table 31,Table 32, Table 33

Message end

N/A

Rev 1: 82

Rev 2: 157

NUL

Manual COM OPEN PROTOCOL MDCv2/MDTC series 19 DOC.60428-05/23

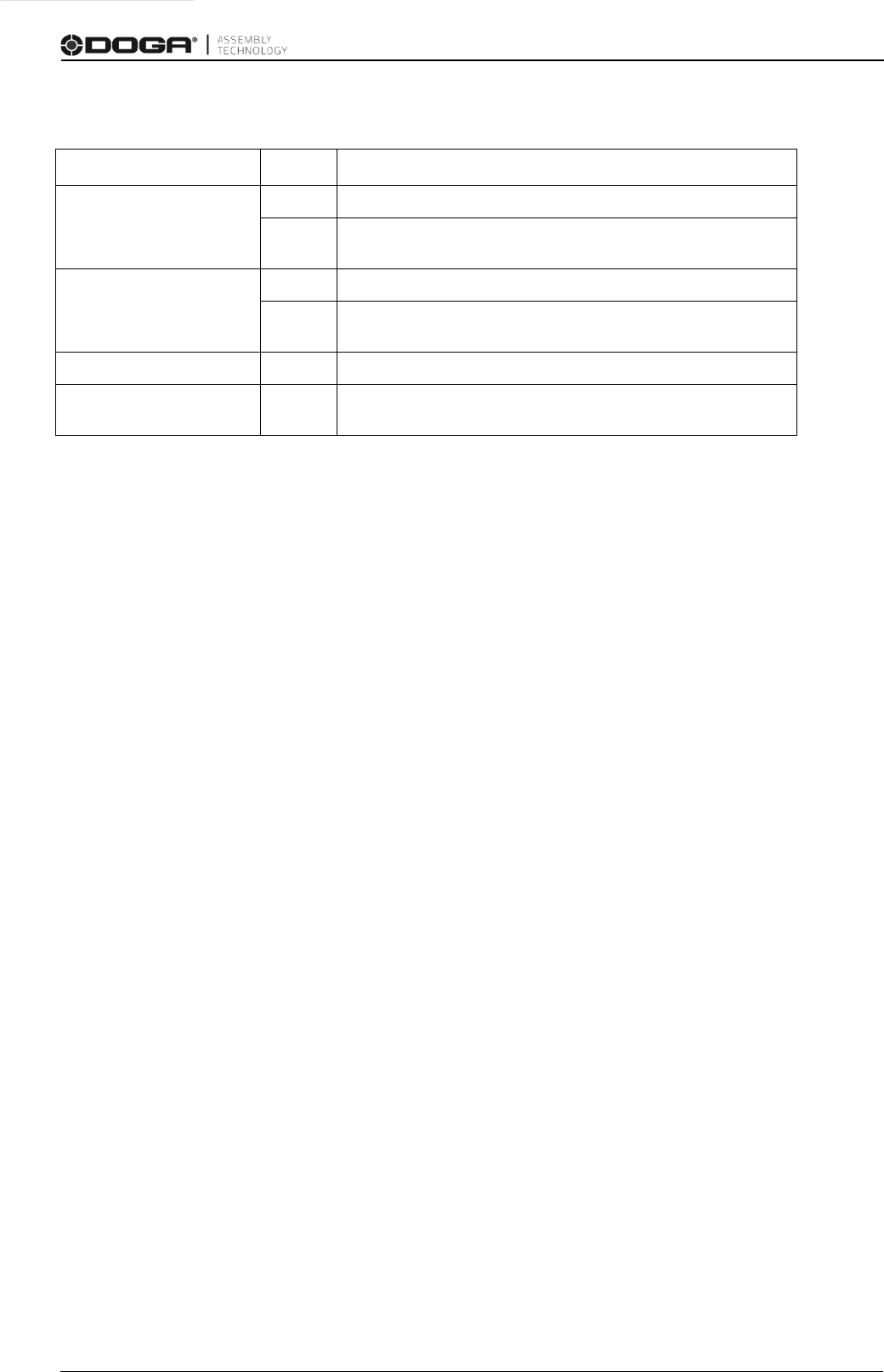

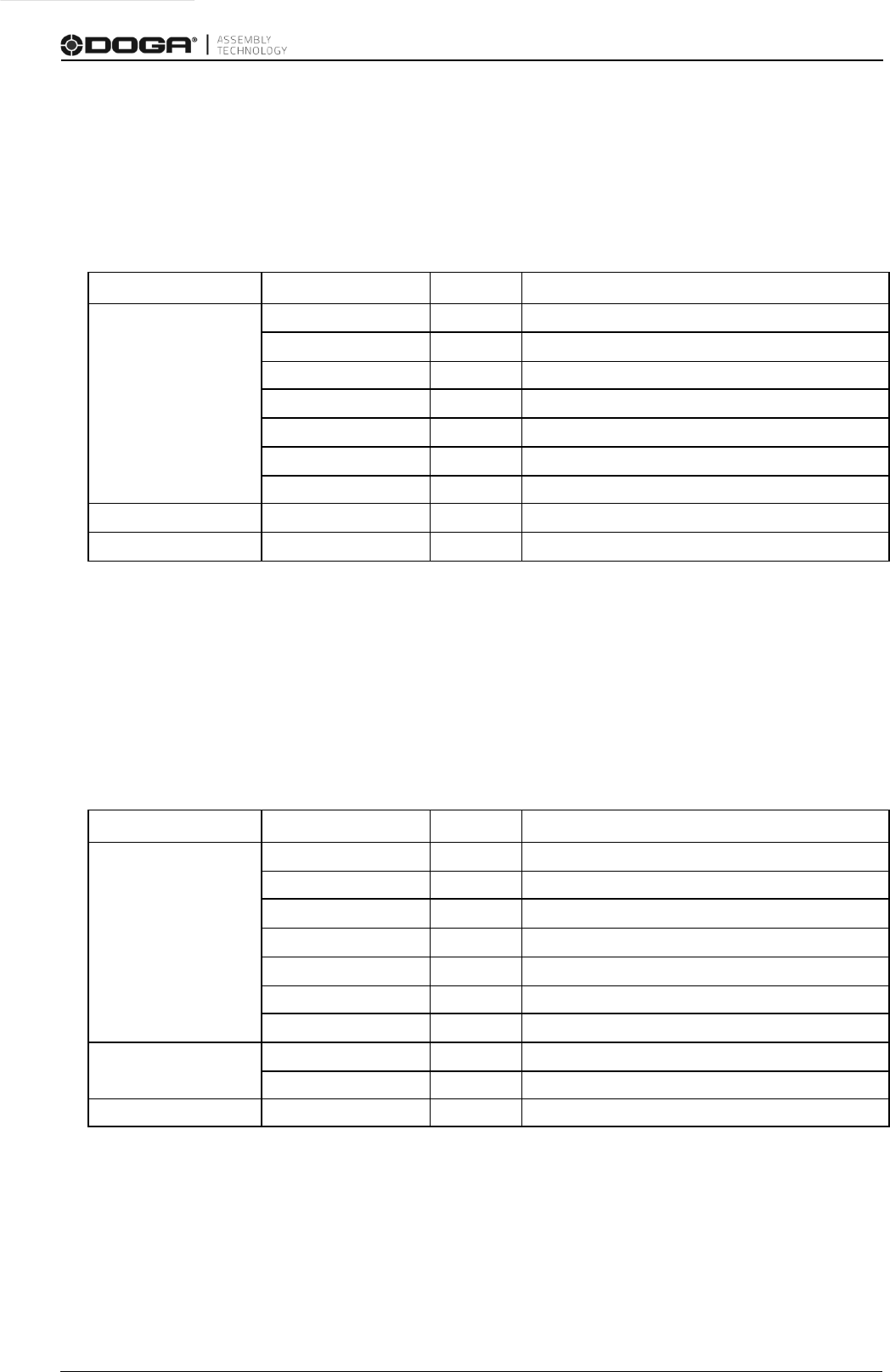

Table 31 MID 0041 Tool data, revision 1

Parameter

Byte

Value

Tool serial number

21-22

01

23-36

14 ASCII characters

Tool number of tightening

37-38

02

39-48

10 ASCII digits. Max 4294967295 - N.A. on MD tools

Last calibration date

49-50

03

51-69

19 ASCII characters. YYYY-MM-DD:HH:MM:SS

N.A. on MD/MDT tools

Controller serial number =

Ford. RBU Serial = Normal

70-71

04

72-81

10 ASCII characters

N.A. on MD/MDT tools

Table 32 MID 0041 Tool data, additions for revision 2

Parameter

Byte

Value

Calibration value

82-83

05

84-89

The tool calibration value is multiplied by 100 and sent as an

integer (2 decimals truncated). Six ASCII digits.

Last service date

90-91

06

92-110

YYYY-MM-DD:HH:MM:SS - N.A. on MD/MDT tools

Tightenings since service

111-112

07

113-122

The number of tightenings since last service is specified by 10

ASCII digits. Max 4294967295. - N.A. on MD tools

Tool type

123-124

08

125-126

The tool type is specified by 2 ASCII digits:

00=No Tool, 01=S-tool, 02=DS-tool, 03=Ref. transducer,

04=STtool, 05=EP-tool, 06=ETX-tool, 07=SL-tool, 08=DL-tool,

09=IRC Offline, 10=STB-tool, 11=QST-tool, 12=STT-tool,

13=STwrench,

14 = ES-tool

30 = MD (Doga)

31= MDT (Doga)

Motor size

127-128

09

129-130

The motor size is specified by 2 ASCII digits,

range 00-99.

00 = no motor, 01-99 = motor size xx in Atlas Copco

nomenclature, or motor size = 10xx in Atlas Copco nomenclature

(certain numbers correspond to 2 different motor sizes, for

example 62 for both motor size 62 and motor size 1062)

Open end data

131-132

10

133-135

The open end data is specified by 3 ASCII digits.

The first digit represents the “use open end”: 1=true, 0=false.

The second digit indicates the tightening direction: 0=CW,

1=CCW.

The third digit indicates motor rotation: 0=normal, 1=inverted.

N.A. on MD/MDT tools

Controller software version

136-137

11

138-156

The software version is specified by 19 ASCII characters.

Manual COM OPEN PROTOCOL MDCv2/MDTC series 20 DOC.60428-05/23

Table 33 MID 0041 Tool data, additions for revision 3

Parameter

Byte

Value

Tool max torque

157-158

12

159-164

The tool max toque value is multiplied by 100 and sent as an

integer (2 decimals truncated). Six ASCII digits.

Gear ratio

165-166

13

167-172

The gear ratio value is multiplied by 100 and sent as an integer (2

decimals truncated). Six ASCII digits.

Tool full speed

173-174

14

175-180

The tool full speed value is multiplied by 100 and sent as an

integer (2 decimals truncated). Six ASCII digits.

Manual COM OPEN PROTOCOL MDCv2/MDTC series 21 DOC.60428-05/23

5.1.13 MID 0042 Disable tool

Disable tool .

� Message sent by: Integrator

� Answer: MID 0005 Command accepted

Message part

Parameter

Byte

Value

Header

Length

1-4

0020

MID

5-8

0042

Revision

9-11

Range: 000-001

No Ack flag

12

N/A

Station ID

13-14

N/A

Spindle ID

15-16

N/A

Spare

17-20

N/A

Data field

N/A

N/A

Message end

21

NUL

5.1.14 MID 0043 Enable tool

Enable Tool.

� Message sent by: Integrator

� Answer: MID 0005 Command accepted

Message part

Parameter

Byte

Value

Header

Length

1-4

0020

MID

5-8

0043

Revision

9-11

Range: 000-001

No Ack flag

12

N/A

Station ID

13-14

N/A

Spindle ID

15-16

N/A

Spare

17-20

N/A

Data field

N/A

N/A

Message end

21

NUL

Manual COM OPEN PROTOCOL MDCv2/MDTC series 22 DOC.60428-05/23

5.1.15 MID 0060 Last tightening result data subscribe

Set the subscription for the result tightenings. The result of this command will be the

transmission of the tightening result after the tightening is performed (push

function). The MID revision in the header is used to subscribe to different revisions

of

MID 0061 Last tightening result data upload reply.

� Message sent by: Integrator

� Answer: MID 0005 Command accepted or

MID 0004 Command error, Last tightening subscription already exists or

MID revision not supported

Message part

Parameter

Byte

Value

Header

Length

1-4

0020

MID

5-8

0060

Revision of MID 0061

9-11

Range: 001

No Ack flag

12

0=Ack needed, 1=No ack needed

Station ID

13-14

N/A

Spindle ID

15-16

N/A

Spare

17-20

N/A

Data field

N/A

N/A

Message end

N/A

21

NUL

Manual COM OPEN PROTOCOL MDCv2/MDTC series 23 DOC.60428-05/23

5.1.16 MID 0061 Last tightening result data

Upload the last tightening result. The following tables show the revisions available:

� Message sent by: Controller

� Answer: MID 0062 Last tightening result data acknowledge

Example:

MID 0061 Last tightening result data upload reply, revision 1

Message part

Parameter

Byte

Value

Header

Length

1-4

Revision 001(0231), 002(0385)

MID

5-8

0061

Revision

9-11

Range: 001

No Ack flag

12

0=Ack needed, 1=No ack needed

Station ID

13-14

N/A

Spindle ID

15-16

N/A

Spare

17-20

N/A

Data field

Tightening data

21-length

Se

e Table 4

Message end

Rev 1: 232

NUL

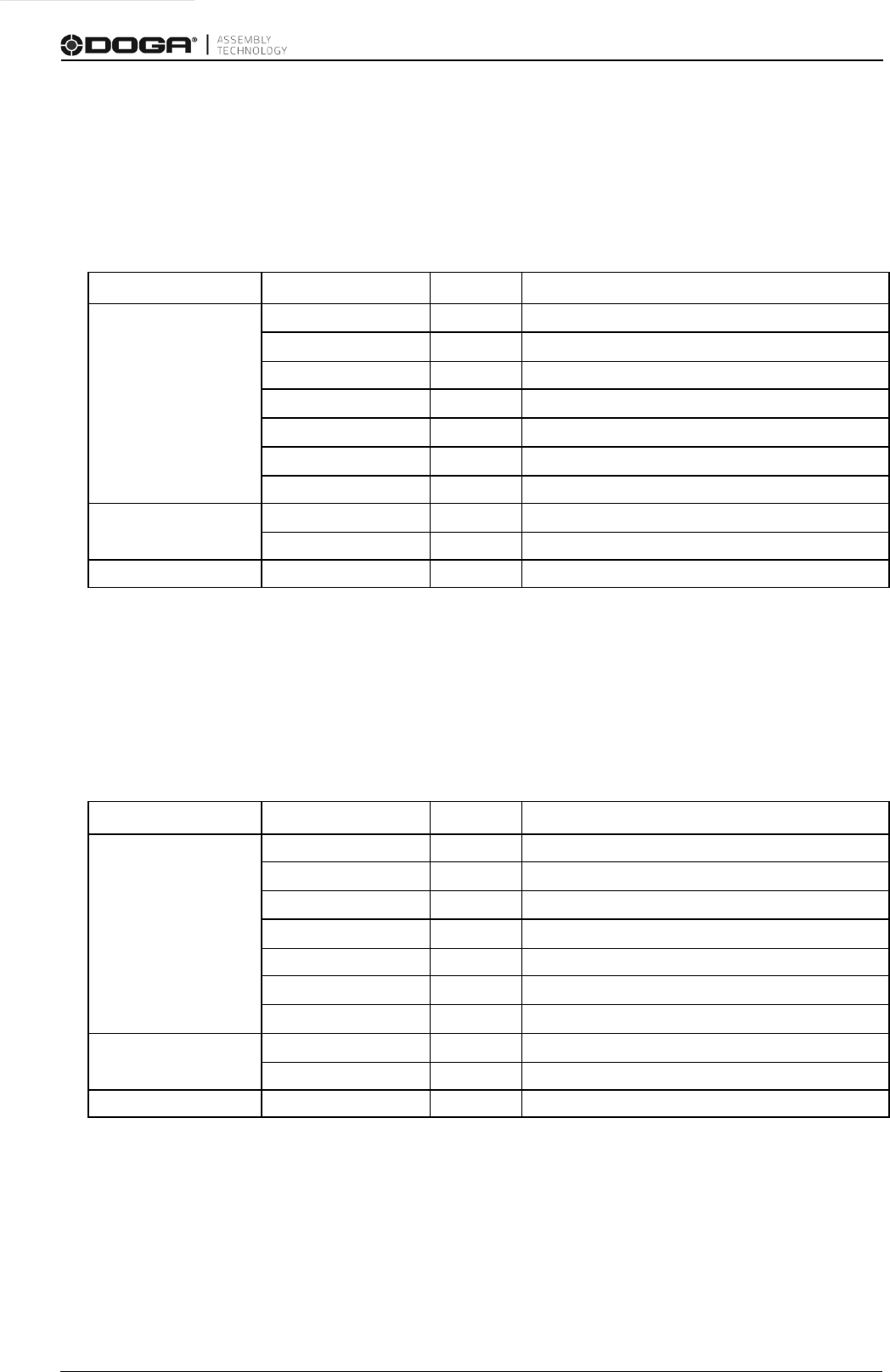

Table 4 MID 0061 Revision 1

Parameter

Byte

Value

Cell ID

21-22

01

23-26

The cell ID don’t use. (Fill with 0x30)

Channel ID

27-28

02

29-30

The channel ID don’t use. (Fill with 0x30)

Torque controller Name

31-32

03

33-57

The controller name is 25 bytes long and is specified by 25 ASCII

characters. (ex: 0000…003201)

VIN Number

58-59

04

60-84

The VIN number don’t use. (Fill with 0x30)

Job ID

85-86

05

87-88

The Job ID don’t use. (Fill with 0x30)

Parameter set ID

89-90

06

91-93

The parameter set ID is three bytes long and specified by three

ASCII digits. Range: 000-999.

Batch size

94-95

07

04

KPOL3456JKLO

897

05000600307000008000009010011112000840

130014001400120015000739160000017099991800000

010001020103

airbag

7

023100610010

Manual COM OPEN PROTOCOL MDCv2/MDTC series 24 DOC.60428-05/23

Parameter

Byte

Value

Batch size

96-99

The batch size doesn’t use. (Fill with 0x30)

Batch counter

100-101

08

102-105

The batch counter information doesn’t use. (Fill with 0x30)

Tightening Status

106-107

09

108

The tightening status is one byte long and specified by one ASCII

digit. 0=tightening NOK, 1=tightening OK.

Torque status

109-110

10

111

0=Low, 1=OK, 2=High

Angle status

112-113

11

114

0=Low, 1=OK, 2=High

Torque Min limit

115-116

12

117-122

The torque min limit is multiplied by 100 and sent as an integer (2

decimals truncated). It is six bytes long and is specified by six

ASCII digits.

Torque Max limit

123-124

13

125-130

The torque max limit is multiplied by 100 and sent as an integer (2

decimals truncated). It is six bytes long and is specified by six

ASCII digits.

Torque final target

131-132

14

133-138

The torque final target is multiplied by 100 and sent as an integer

(2 decimals truncated). It is six bytes long and is specified by six

ASCII digits.

Torque

139-140

15

141-146

The torque value is multiplied by 100 and sent as an integer (2

decimals truncated). It is six bytes long and is specified by six

ASCII digits.

Angle Min

147-148

16

149-153

The angle min value in degrees. Each turn represents 360

degrees. It is five bytes long and specified by five ASCII digits.

Range: 00000-99999.

Angle Max

154-155

17

156-160

The angle max value in degrees. Each turn represents 360

degrees. It is five bytes long and specified by five ASCII digits.

Range: 00000-99999.

Final Angle

161-162

18

target

163-167

The target angle value in degrees. Each turn represents 360

degrees. It is five bytes long and specified by five ASCII digits.

Range: 00000-99999.

Angle

168-169

19

170-174

The turning angle value in degrees. Each turn represents 360

degrees. It is five bytes long and specified by five ASCII digits.

Range: 00000-99999.

Time stamp

175-176

20

177-195

Time stamp don’t use. (Fill with 0x30)

Manual COM OPEN PROTOCOL MDCv2/MDTC series 25 DOC.60428-05/23

Parameter

Byte

Value

Date/time of last change in

parameter set settings

196-197

21

198-216

Time stamp for the last change in the current parameter set

settings don’t use.

Batch status

217-218

22

219

The batch status doesn’t use. (Fill with 0x30)

Tightening ID

220-221

23

222-231

The tightening ID don’t use. (Fill with 0x30)

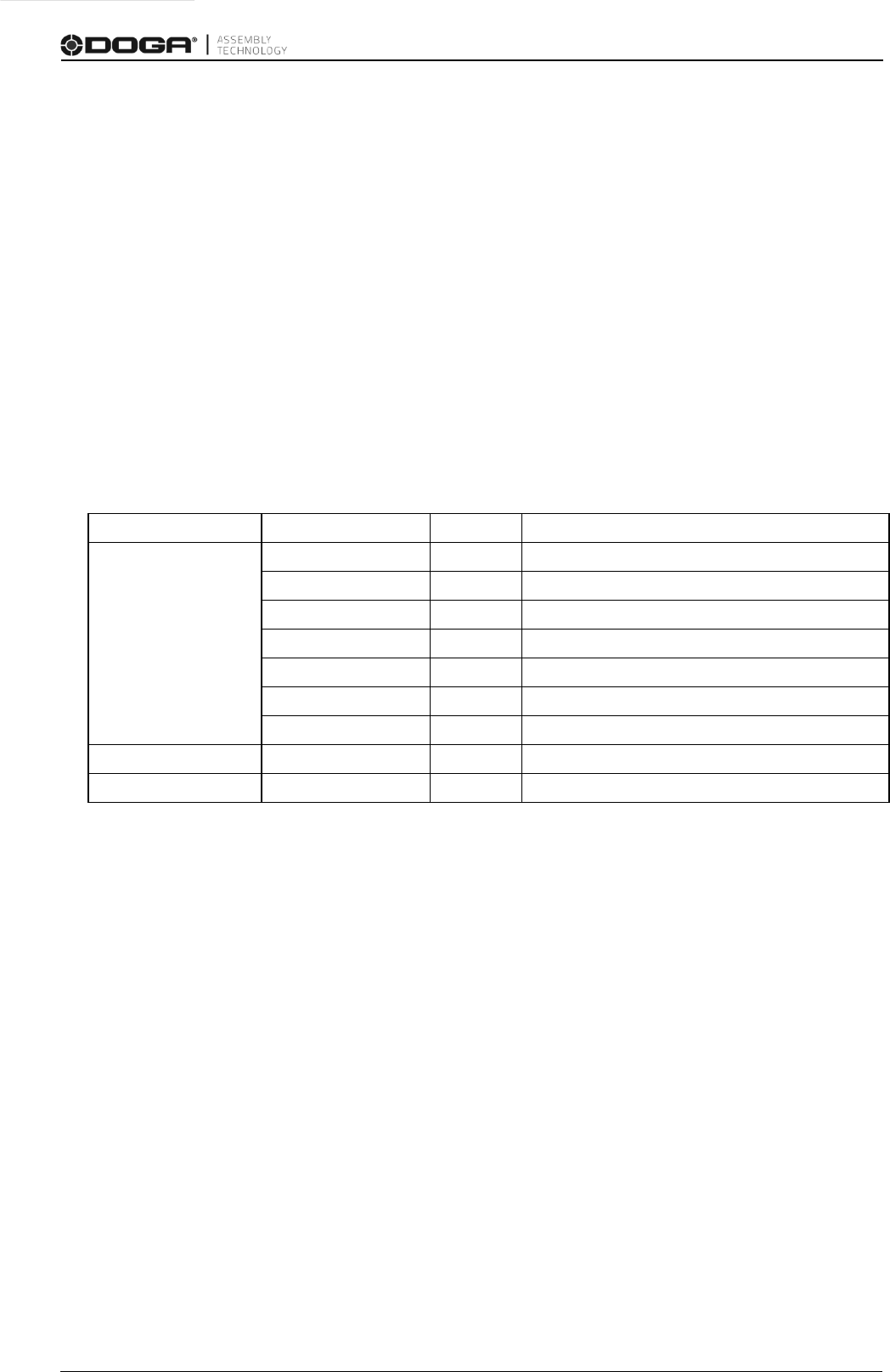

MID 0061 Revision 2

Parameter

Byte

Value

Cell ID

21-22

01

23-26

The cell ID don’t use. (Fill with 0x30)

Channel ID

27-28

02

29-30

The channel ID don’t use. (Fill with 0x30)

Torque controller Name

31-32

03

33-57

The controller name is 25 bytes long and is specified by 25 ASCII

characters. (ex: 0000…003201)

VIN Number

58-59

04

60-84

The VIN number don’t use. (Fill with 0x30)

Job ID

85-86

05

87-88

The Job ID don’t use. (Fill with 0x30)

Parameter set ID

89-90

06

91-93

The parameter set ID is three bytes long and specified by three

ASCII digits. Range: 000-999.

Strategy

96-97

07

98-99

The strategy currently run by the controller. It is two bytes long and

specified by two ASCII digits. Range: 00-99.

The corresponding strategies are :

02=Torque control / angle monitoring,

04=Angle control / torque monitoring

Manual COM OPEN PROTOCOL MDCv2/MDTC series 26 DOC.60428-05/23

Parameter

Byte

Value

Strategy options

100-101

08

102-106

Five bytes long bit field.

Bit 0 Torque

Bit 1 Angle

Batch size

107-108

09

109-112

The batch size doesn’t use. (Fill with 0x30)

Batch counter

113-114

10

115-118

The batch counter information doesn’t use. (Fill with 0x30)

Tightening Status

119-120

11

121

The tightening status is one byte long and specified by one ASCII

digit.

0 = tightening NOK, 1 = tightening OK.

Batch status

122-123

12

124

The batch status doesn’t use. (Fill with 0x30)

Torque status

125-126

13

127

0=Low, 1=OK, 2=High

Angle status

128-129

14

130

0=Low, 1=OK, 2=High

Rundown angle status

131-132

15

133

Not use

Current Monitoring Status

134-135

16

136

Not use

Selftap status

137-138

17

139

Not use

Prevail Torque monitoring

status

140-141

18

142

Not use

Prevail Torque

compensat

e status

143-144

19

145

Not use

Tightening error status

146-147

20

148-157

Not use

Torque Min limit

158-159

21

160-165

The torque min limit is multiplied by 100 and sent as an integer (2

decimals truncated). It is six bytes long and is specified by six

ASCII digits.

Torque Max limit

166-167

22

168-173

The torque max limit is multiplied by 100 and sent as an integer (2

decimals truncated). It is six bytes long and is specified by six

ASCII digits.

Manual COM OPEN PROTOCOL MDCv2/MDTC series 27 DOC.60428-05/23

Parameter

Byte

Value

Torque final target

174-175

23

176-181

The torque final target is multiplied by 100 and sent as an integer

(2 decimals truncated). It is six bytes long and is specified by six

ASCII digits.

Torque

182-183

24

184-189

The torque value is multiplied by 100 and sent as an integer (2

decimals truncated). It is six bytes long and is specified by six

ASCII digits.

Angle Min

190-191

25

192-196

The angle min value in degrees. Each turn represents 360

degrees. It is five bytes long and specified by five ASCII digits.

Range: 00000-99999.

Angle Max

197-198

26

199-203

The angle max value in degrees. Each turn represents 360

degrees. It is five bytes long and specified by five ASCII digits.

Range: 00000-99999.

Final Angle Target

204-205

27

206-210

The target angle value in degrees. Each turn represents 360

degrees. It is five bytes long and specified by five ASCII digits.

Range: 00000-99999.

Angle

211-212

28

213-217

The turning angle value in degrees. Each turn represents 360

degrees. It is five bytes long and specified by five ASCII digits.

Range: 00000-99999.

Rundown angle Min

218-219

29

220-224

Not use

Rundown angle Max

225-226

30

227-231

Not use

Rundown angle

232-233

31

234-238

Not use

Current Monitoring Min

239-240

32

241-243

Not use

Current Monitoring Max

244-245

33

246-248

Not use

Current

Monitoring

Value

249-250

34

251-253

Not use

Selftap min

254-255

35

256-261

Not use

Selftap max

262-263

36

264-269

Not use

Selftap torque

270-271

37

272-277

Not use

Manual COM OPEN PROTOCOL MDCv2/MDTC series 28 DOC.60428-05/23

Parameter

Byte

Value

Prevail torque monitoring

min

278-279

38

280-285

Not use

Prevail torque monitoring

max

286-287

39

288-293

Not use

Prevail torque

294-295

40

296-301

Not use

Tightening ID

302-303

41

304-313

Not use

Job sequence number

314-315

42

316-320

Not use

Sync tightening ID

321-322

43

323-327

Not use

Tool serial number

328-329

44

330-343

Not use

Time stamp

344-345

45

346-364

Not use

Date/time of last change in

parameter set settings

365-366

46

367-385

Not use

5.1.17 MID 0062 Last tightening result data acknowledge

Acknowledgement of last tightening result data.

� Message sent by: Integrator

� Answer: None

Message part

Parameter

Byte

Value

Header

Length

1-4

0020

MID

5-8

0062

Revision

9-11

Range: 001-006, 998-999

No Ack flag

12

N/A

Station ID

13-14

N/A

Spindle ID

15-16

N/A

Spare

17-20

N/A

Data field

N/A

N/A

Message end

N/A

21

NUL

Manual COM OPEN PROTOCOL MDCv2/MDTC series 29 DOC.60428-05/23

5.1.18 MID 0063 Last tightening result data unsubscribe

Reset the last tightening result subscription.

� Message sent by: Integrator

� Answer: MID 0005 Command accepted or

MID 0004 Command error, Last tightening result subscription does not exist

Message part

Parameter

Byte

Value

Header

Length

1-4

0020

MID

5-8

0063

Revision

9-11

Range: 001-006, 998-999

No Ack flag

12

N/A

Station ID

13-14

N/A

Spindle ID

15-16

N/A

Spare

17-20

N/A

Data field

N/A

N/A

Message end

N/A

21

NUL

5.1.19 MID 0070 Alarm subscribe

A subscription for the alarms that can appear in the controller.

� Message sent by: Integrator

� Answer: MID 0005 Command accepted or

MID 0004 Command error, Alarm subscription already exists

Message part

Parameter

Byte

Value

Header

Length

1-4

0020

MID

5-8

0070

Revision

9-11

Range: 000-001

No Ack flag

12

0=Ack needed, 1=No ack needed

Station ID

13-14

N/A

Spindle ID

15-16

N/A

Spare

17-20

N/A

Data field

N/A

N/A

Message end

N/A

21

NUL

Manual COM OPEN PROTOCOL MDCv2/MDTC series 30 DOC.60428-05/23

5.1.20 MID 0071 Alarm

An alarm has appeared in the controller. The current alarm is uploaded from the

controller to the integrator.

� Message sent by: Controller

� Answer: MID 0072 Alarm acknowledge

Example: MID 0071. Alarm E404 appeared on June 12, 2008. The controller and

the tool have ready status.

00530071

01E404021031042008-06-

02:10:14:26NUL

Message part

Parameter

Byte

Value

Header

Length

1-4

0053

MID

5-8

0071

Revision

9-11

Range: 000-001

No Ack flag

12

0=Ack needed, 1=No ack needed

Station ID

13-14

N/A

Spindle ID

15-16

N/A

Spare

17-20

N/A

Data field

Alarm data

21-53

See Table 5

Message end

N/A

54

NUL

Table 5 MID 0070 Alarm data

Parameter

Byte

Value

Error code

21-22

01

23-26

The error code is specified by 4 ASCII characters. The error code

begins with E and is followed by three digits. Example E851.

Controller ready status

27-28

02

29

Controller ready status 1=OK, 0=NOK

Tool ready status

30-31

03

32

Tool ready status 1=OK, 0=NOK

Time

33-34

04

35-53

Time stamp don’t use. (Fill with 0x30)

Manual COM OPEN PROTOCOL MDCv2/MDTC series 31 DOC.60428-05/23

5.1.21 MID 0072 Alarm acknowledge

Acknowledgement for

MID 0071 Alarm.

� Message sent by: Integrator

� Answer: None

Message part

Parameter

Byte

Value

Header

Length

1-4

0020

MID

5-8

0072

Revision

9-11

Range: 000-001

No Ack flag

12

N/A

Station ID

13-14

N/A

Spindle ID

15-16

N/A

Spare

17-20

N/A

Data field

N/A

N/A

Message end

N/A

21

NUL

5.1.22 MID 0073 Alarm unsubscribe

Reset the subscription for the controller alarms.

� Message sent by: Integrator

� Answer: MID 0005 Command accepted or

MID 0004 Command error, Alarm subscription does not exist

Message part

Parameter

Byte

Value

Header

Length

1-4

0020

MID

5-8

0073

Revision

9-11

Range: 000-001

No Ack flag

12

N/A

Station ID

13-14

N/A

Spindle ID

15-16

N/A

Spare

17-20

N/A

Data field

N/A

N/A

Message end

N/A

21

NUL

Manual COM OPEN PROTOCOL MDCv2/MDTC series 32 DOC.60428-05/23

5.1.23 MID 1000 Read parameter value

Read parameter value of parameter address.

� Message sent by: Integrator

� Answer: MID 1001 Read parameter value ack or MID 4 Error, Data invalid

Message part

Parameter

Byte

Value

Header

Length

1-4

0024

MID

5-8

1000

Revision

9-11

Range 000-001

No Ack flag

12

N/A

Station ID

13-14

N/A

Spindle ID

15-16

N/A

Spare

17-20

N/A

Data field

Parameter address

21-24

Range 0000 - parameter size (0874)

Message end

N/A

25

NUL

5.1.24 MID 1001 Read parameter value acknowledge

Acknowledgement of Read parameter value.

� Message sent by: Controller

� Answer: None

Message part

Parameter

Byte

Value

Header

Length

1-4

0029

MID

5-8

1001

Revision

9-11

Range 000-001

No Ack flag

12

N/A

Station ID

13-14

N/A

Spindle ID

15-16

N/A

Spare

17-20

N/A

Data field

Parameter address

21-24

Range 0000 - parameter size (0874)

Parameter value

25-29

Range 00000 - 99999

Message end

N/A

30

NUL

Manual COM OPEN PROTOCOL MDCv2/MDTC series 33 DOC.60428-05/23

5.1.25 MID 1002 Write parameter value

Write parameter value to controller.

� Message sent by: Integrator

� Answer: MID 1003 Write parameter value ack or MID 4 Error, Data invalid

Message part

Parameter

Byte

Value

Header

Length

1-4

0029

MID

5-8

1002

Revision

9-11

Range 000-001

No Ack flag

12

N/A

Station ID

13-14

N/A

Spindle ID

15-16

N/A

Spare

17-20

N/A

Data field

Parameter address

21-24

Range 0000 - parameter size (0874)

Parameter value

25-29

Range 00000 - 99999

Message end

N/A

30

NUL

5.1.26

MID 1003 Write parameter value acknowledge

Acknowledgement of Write parameter value.

� Message sent by: Controller

� Answer: None

Message part

Parameter

Byte

Value

Header

Length

1-4

0029

MID

5-8

1003

Revision

9-11

Range 000-001

No Ack flag

12

N/A

Station ID

13-14

N/A

Spindle ID

15-16

N/A

Spare

17-20

N/A

Data field

Parameter address

21-24

Range 0000 - parameter size (0874)

Parameter value

25-29

Range 00000 - 99999

Message end

N/A

30

NUL

Manual COM OPEN PROTOCOL MDCv2/MDTC series 34 DOC.60428-05/23

5.1.27 MID 9999 Keep alive message

The integrator sends a keep alive to the controller. The controller should only mirror

and return the received keep alive to the integrator.

The controller has a communication timeout equal to 15s. This means that if no

message has been exchanged between the integrator and the controller for the last

15s, then the controller considers the connection lost and closes it.

In order to keep the communication alive the integrator must send a keep alive to the

controller with a time interval lower than 15s.

Note: An inactivity timeout is suggested to integrator i.e. if no message has been

exchanged (sent or received) during the last 10s, send a keep alive.

� Message sent by: Integrator

� Answer: The same message mirrored by the controller.

Message part

Parameter

Byte

Value

Header

Length

1-4

0020

MID

5-8

9999

Revision

9-11

Range 000-001

No Ack flag

12

N/A

Station ID

13-14

N/A

Spindle ID

15-16

N/A

Spare

17-20

N/A

Data field

N/A

N/A

Message end

N/A

21

NUL

5.2 Event message

The controller can spontaneously send messages to the integrator after an event such as a

tightening or an alarm. This service is only enabled after a subscription event message.

5.2.1 Event subscribe – unsubscribe messages

The subscription is made with the subscribe - unsubscribe message. The subscription can be

cancelled at any time by the integrator by sending an unsubscribe message.

5.2.2 Event message acknowledge

The integrator should acknowledge the event messages by sending the corresponding acknowledge

MID. If no acknowledge is received before the response timeout the controller will re-send the

message up to three times. After three attempts the controller will consider the connection as lost.

Manual COM OPEN PROTOCOL MDCv2/MDTC series 35 DOC.60428-05/23

Manual COM OPEN PROTOCOL MDCv2/MDTC series 36 DOC.60428-05/23

© DOGA | DOC.60428-05/23