POWER FOCUS 6000

POCKET GUIDE

Release 2.3

Overview of the Power Focus 6000

and Tensor STR System

POCKET GUIDE TO POWER FOCUS 6000 SYSTEM

SYSTEM OVERVIEW ............................................................................................. 6

Power Focus 6000 Controller ......................................................................... 6

Intelligent Application Module (IAM) ............................................................. 7

Tensor STR Cable ............................................................................................ 7

Accessories And Communication Interfaces ................................................ 8

POWER FOCUS 6000 HARDWARE ...................................................................... 9

Power ............................................................................................................... 9

Line voltage ..................................................................................................... 9

Normal Environmental Conditions ................................................................ 9

Size and Weight .............................................................................................. 9

Display .............................................................................................................. 9

Communication ............................................................................................. 10

Audio .............................................................................................................. 10

Connections ................................................................................................... 10

IAM ..................................................................................................................11

POWER FOCUS 6000 SOFTWARE ..................................................................... 12

Menu Overview ............................................................................................. 12

Tightening Menu ........................................................................................... 12

Batch Sequence Menu .................................................................................. 12

Sources Menu ................................................................................................ 12

Tool Menu ...................................................................................................... 12

Virtual Station Menu ..................................................................................... 13

Controller Menu ............................................................................................ 13

Accessories Menu ......................................................................................... 13

Reports Menu ................................................................................................ 13

Settings Menu................................................................................................ 13

Basic Programming ....................................................................................... 14

Open Protocol ................................................................................................ 15

CONTENTS

POCKET GUIDE TO POWER FOCUS 6000 SYSTEM

FUNCTIONALITY MANAGEMENT SYSTEM ..................................................... 16

Introduction .............................................................................................. 16

Main benefits ............................................................................................ 16

Order and distribute licenses to customer portal ..................................... 17

Distribution from customer portal ............................................................ 17

FMS Server based .................................................................................... 18

FMS USB device/non network based ....................................................... 19

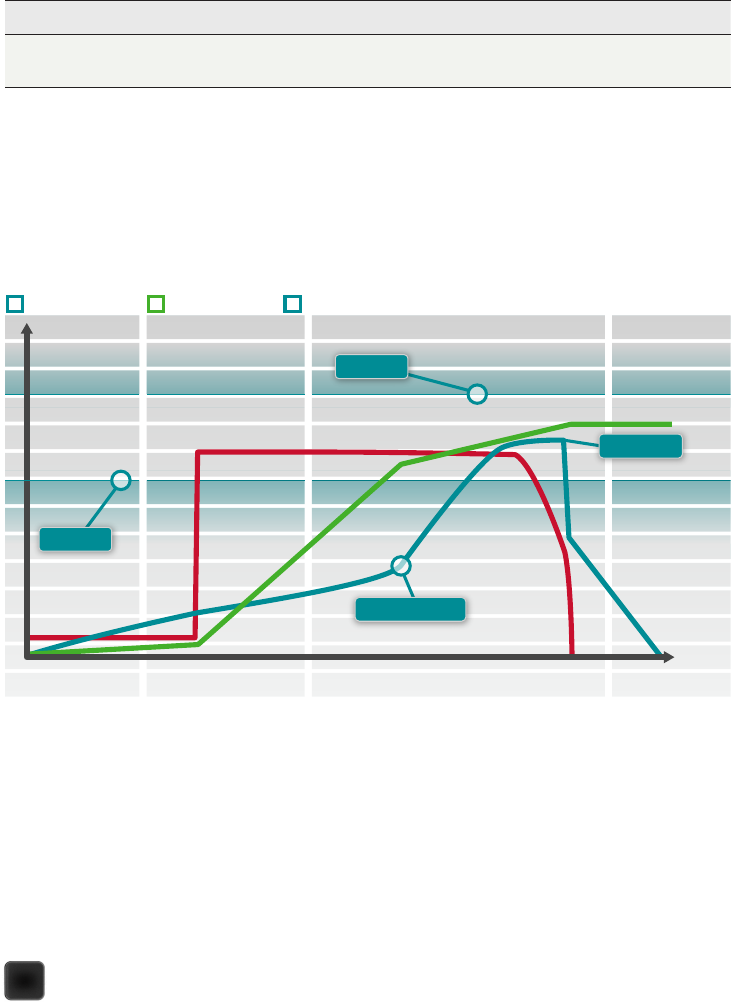

TIGHTENING STRATEGIES ................................................................................ 20

Turbo Tight

®

Tightening Strategy ................................................................. 20

Fine-tuning the Turbo Tight

®

Tightening strategy ....................................... 20

Reduced cycle times ................................................................................ 20

Reduced reaction force ........................................................................... 21

Easy set-up .............................................................................................. 21

Sustainability ................................................................................................ 22

How are cycle times reduced? ................................................................ 22

How is reaction force reduced? ............................................................... 22

How come set-up is so easy? .................................................................. 22

How does Turbo Tight

®

provide energy savings? ..................................... 22

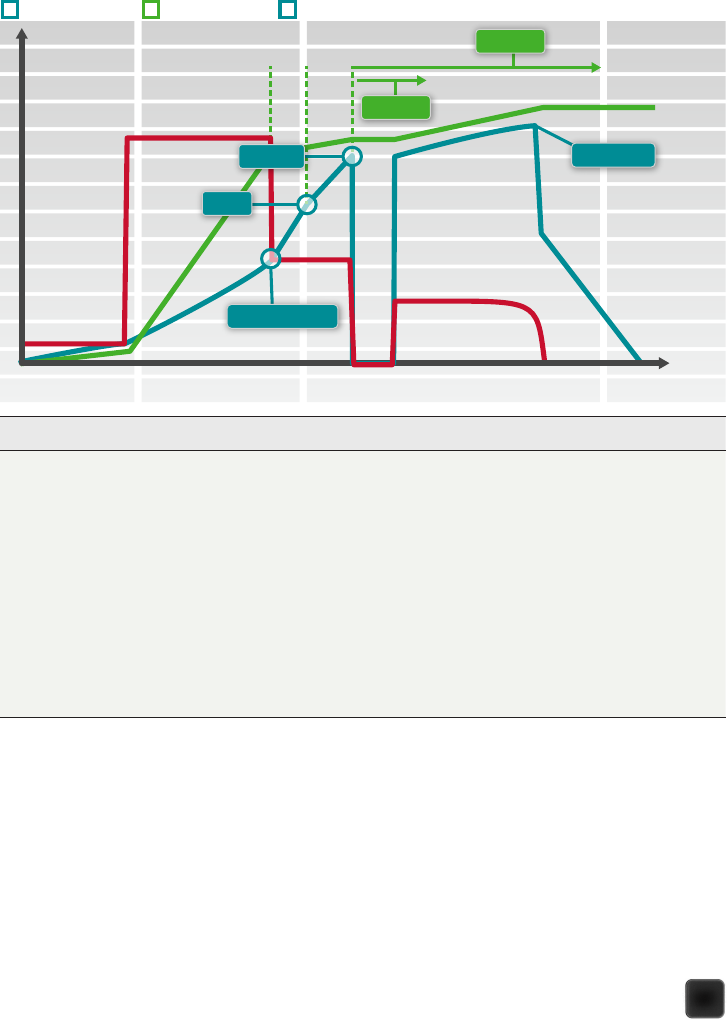

Two Step Tightening Strategy ...................................................................... 23

Fine-tuning the Two Step Tightening strategy ........................................... 23

Quick Step Tightening Strategy .................................................................... 24

Three Step Tightening Strategy ................................................................... 25

Rotate Strategy .............................................................................................. 26

Target Torque Limits ...................................................................................... 26

Target Angle Limits ....................................................................................... 27

Stop Stage ..................................................................................................... 28

Soft Stop ........................................................................................................ 29

POCKET GUIDE TO POWER FOCUS 6000 SYSTEM

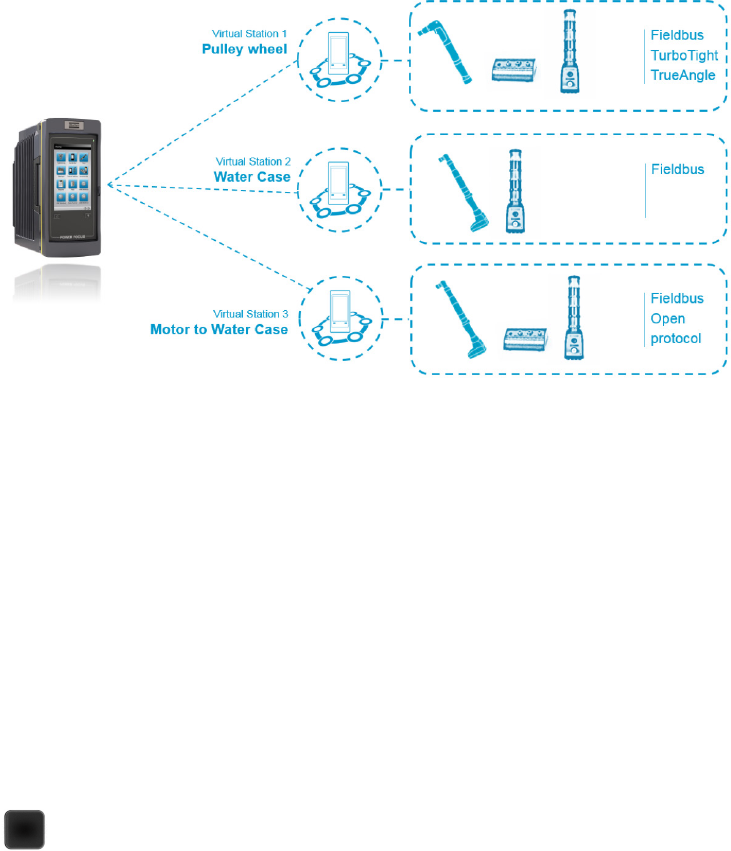

VIRTUAL STATIONS ............................................................................................ 30

Introduction ............................................................................................. 30

Setting up a Virtual Station ........................................................................ 31

Key Benefits .............................................................................................. 31

STR TOOL............................................................................................................. 32

Overview ........................................................................................................ 32

Models ............................................................................................................ 33

Tool Modules ................................................................................................. 33

Handle module ......................................................................................... 33

HMI ........................................................................................................... 33

Motor ........................................................................................................ 34

Torque transducer ..................................................................................... 34

Gears and Angle head ............................................................................... 34

ETT front part ............................................................................................ 34

Accessories (attached to the tool (ETV/ETD)) .............................................. 35

Certifications .................................................................................................. 36

EC declaration ................................................................................................ 36

Harmonized standards ............................................................................. 36

Other directives ........................................................................................ 36

IP 54 protection ........................................................................................ 37

Service/Maintenance Intervals ................................................................. 37

STR TOOL ACCESSORIES ................................................................................... 38

Local customization .................................................................................. 39

CONTENTS

POCKET GUIDE TO POWER FOCUS 6000 SYSTEM

CABLE MANAGEMENT ...................................................................................... 40

Use of a cable clamp bracket .................................................................... 41

Smaller bending radius for greater accessibility. ...................................... 43

Innovative ‘Cable Twist’ design ................................................................. 43

Centralized strain relief to prevent lead damage....................................... 44

FIELDBUS ............................................................................................................ 45

TOOL TALK 2 ........................................................................................................ 46

User Authentication .................................................................................. 46

Plant Structure .......................................................................................... 46

Multiple Controller Upgrade ..................................................................... 47

Controller Programming ............................................................................ 47

TOOLSNET 8 ....................................................................................................... 48

Simple setup in combination with Atlas Copco controllers ...................... 48

Simple Data Analysis ................................................................................ 48

Production Alarms .................................................................................... 49

Dashboard ................................................................................................ 49

Traceability ................................................................................................ 49

Tool Service Information ........................................................................... 50

POCKET GUIDE TO POWER FOCUS 6000 SYSTEM

6

SYSTEM OVERVIEW

The core Power Focus 6000 systems consist of the following parts:

• Power Focus 6000 controller

• Intelligent Application Module (IAM)

• Tensor STR tool

• Tensor STR cable

• Accessories and communication interfaces

In the image below you can see how these different parts fit together as a

system in a typical customer environment.

Power Focus 6000 Controller

Power Focus controllers are recognized around the

globe for their outstanding tightening capabilities. The

platform meets the need to enhance error-proofing,

connectivity and flexibility, and is the first to introduce

software ergonomics to the industry. This won the

Power Focus 6000 the prestigious Red Dot design

award in 2012. Learn more about the functionality

of the software or the hardware connections in the

respective chapter.

POCKET GUIDE TO POWER FOCUS 6000 SYSTEM

7

Intelligent Application Module (IAM)

The intelligent Application Module (IAM) stores all the

• Tightening results

• Events

• Configuration

• Logs

• Software

Carry all information in the palm of your hand and transfer it easy from one

controller to another. The module is located on the inside of the door to the

controller and is available in three different versions:

• IAM Critical control

• IAM Process control

• IAM Process+ control

For a complete overview of the included functionality please see respective

chapter.

The Atlas Copco Tensor STR tool is a complete tool designed to work with

optimal performance together with the Power Focus 6000 controller.

Tensor STR

This Tensor power tool is a result of years of research and development to

improve productivity and quality without compromising ergonomics. Major

ergonomics improvements have been made possible by using the latest and

greatest technology available.

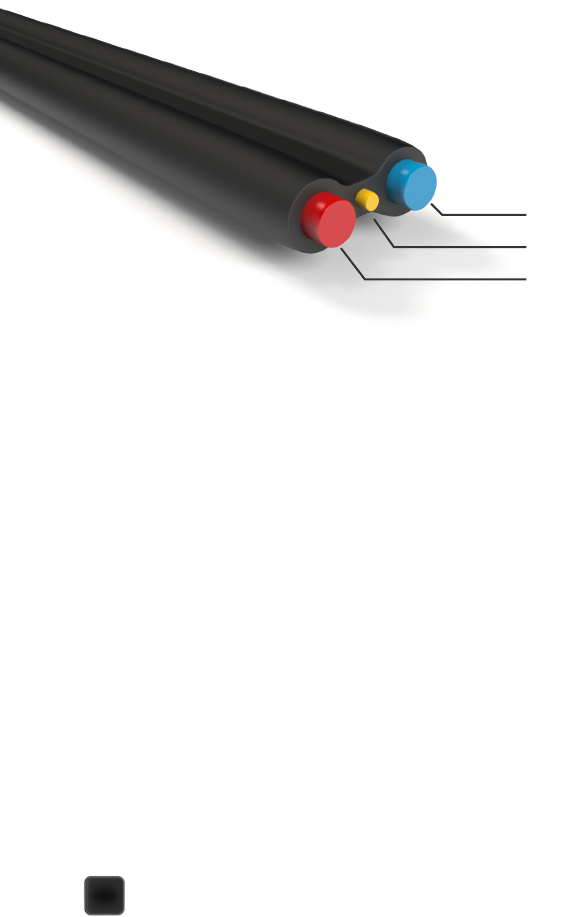

Tensor STR Cable

Atlas Copco has been producing assembly tool cables

since 1987 and has unrivaled experience in the

field. Flexibility and durability have steadily

improved since the introduction of the

company’s first generation cables,

resulting in today’s optimum

cable performance.

Atlas Copco’s flat-cable

design combines

maximum flexibility

(for access to difficult

applications) with

POCKET GUIDE TO POWER FOCUS 6000 SYSTEM

8

maximum durability.

Accessories And Communication Interfaces

The system connects perfectly to accessories and communication interfaces.

Most handheld tools are supported and the Power Focus 6000 system

has full connectivity with our QIF offerings and software products such as

ToolsNet 8 or ToolsNet 4000 and ToolsTalk 2.

The system also communicates with interfaces such as Fieldbus, Open

Protocol or customer specific protocols, creating a seamless integrated

solution in the customer environment.

POCKET GUIDE TO POWER FOCUS 6000 SYSTEM

9

POWER FOCUS 6000 HARDWARE

Power

Power Focus operates on a single-phase 115 or 230 VAC line voltage.

Power rating 1500 W

Line voltage

100-120 / 200-240 VAC (50-60 Hz) Power Focus has a function for sensing the

line voltage automatically. This means that the Power Focus automatically

switches to the voltage you connect to it.

Normal Environmental Conditions

The equipment is designed to be safe under the following conditions:

• Indoor use

• Altitude up to 2 000 m

• Maximum relative humidity 80% for temperatures

up to 31 °C decreasing linearly to 50% relative

humidity at 50 °C

Size and Weight

Height: 316 mm (14.44 inches)

Width: 146 mm (5.75 inches)

Depth: 293 mm (11.54 inches)

Weight: 10.8 kg (23.81 pounds)

Display

7” resistive touch screen display

480 x 800 pixels

LED back light

Back light lifetime 70 000 hours

316 mm

146 mm

293 mm

POCKET GUIDE TO POWER FOCUS 6000 SYSTEM

10

Communication

• W-LAN wireless networking; IEEE 802.11a/b/g/n

compatible

• Bluetooth 2.1 (3.0 ready) + EDR (Enhanced Data

Rate) wireless technology

• 10/100 Mb/s Ethernet (RJ-45 connector)

Audio

Mono speaker

Ambient Temperature

5...+50 °C (41...122 °F)

Transient over voltages typically present on the mains

supply.

Connections

• 2 x 2.0 High Speed USB ports

• 2 x 10/100 Ethernet ports

• 4 x digital inputs (24V -15% +20%)

• 4 x digital outputs (24V ±20%, 1A)

• 1 x I/O bus

• 1 x aux. input (24V ±10%, 0.5A min)

• 1 x aux. output (24V, 1.5A max)

• 1 x emergency stop circuit class 3

• 2 x comm. ports (daisy chain)

• 1 x fan power output connector

• 1 x remote start switch

• 1 x Anybus CC connector

• 1 x IAM connector

• 1 x tool cable connector

POCKET GUIDE TO POWER FOCUS 6000 SYSTEM

11

IAM

With a memory capacity of 8 GB the IAM (Intelligent Application Module)

stores all the data for the Power Focus 6000: Licenses, results, events,

configurations, controller Firmware and service logs.

If needed, this data is easily transferred to other Power Focus 6000 by simply

removing and inserting the IAM.

Firmware updates are secure, as old firmware is kept available. This allows

you to quickly switch back to old firmware if needed.

POCKET GUIDE TO POWER FOCUS 6000 SYSTEM

12

POWER FOCUS 6000 SOFTWARE

Menu Overview

The menus is intuitive and easy to use. Navigate in the controller interface

by either tapping on a menu item or swiping across the display to scroll

through items. The web interface is identical to the controller display,

enabling configuration and programming via a web-browser on a connected

computer.

Tightening Menu

The Tightening menu lists the tightening program(Pset)

available for configuration, stored on the controller.

Batch Sequence Menu

The Batch menu lists the batch programs (Batch sequences)

stored in the controller.

Sources Menu

The Sources menu lists hardware accessories or functions

controlling the selection of a tightening program, for example

a Pset or a batch sequence. This is also where you configure

scanners you may be using with your tools.

Tool Menu

The Tool menu gives you access to information about the

connected tool, perform tool calibration, motor tuning, and set

up tool maintenance.

POCKET GUIDE TO POWER FOCUS 6000 SYSTEM

13

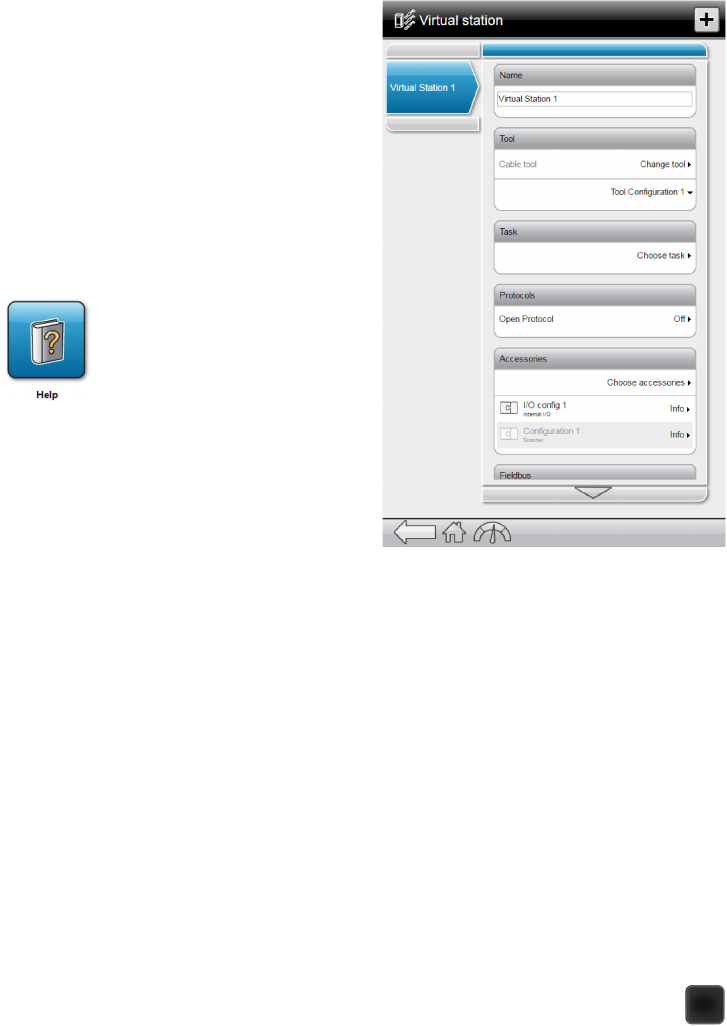

Virtual Station Menu

Tools and accessories are connected to the controller but

assigned to a virtual station. The task selection is also done in

the virtual station.

Controller Menu

The Controller menu makes sure you can administer and install

new controller software, view information about the hardware

devices installed on the controller, and export or import

configurations and reports.

Accessories Menu

The Accessories menu enables you to configure the internal

I/Os and the hardware accessories that can be used with

the controller such as I/O Expander, Stacklight, Operator

Panel, Socket selector and Scanner. The Scanner can also be

configured via other menus, such as the Sources menu.

Reports Menu

The Reports menu gives you access to historical tightening

results, events, and NOK ratio.

Settings Menu

The Settings menu is where you can set up the

controller on a LAN, configure PIN, language date and

time. This is also where you set torque unit to be used,

set tool alarms, configure Wi-Fi channels for wireless

tools, as well as configure how to display events.

POCKET GUIDE TO POWER FOCUS 6000 SYSTEM

14

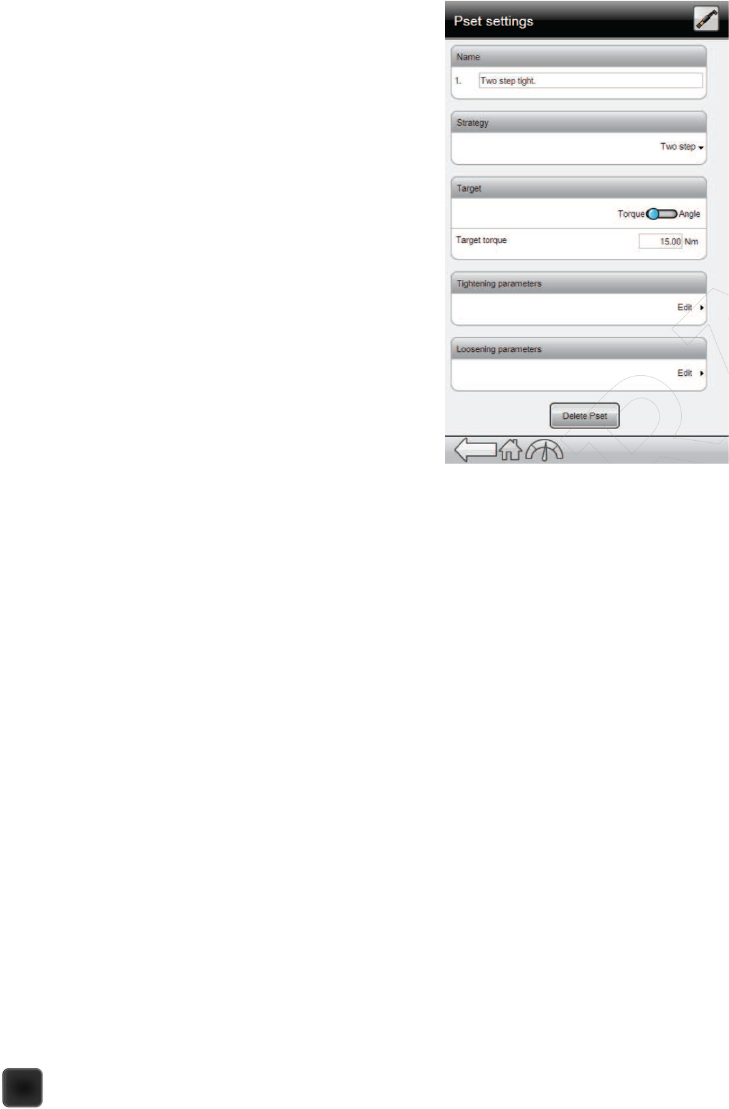

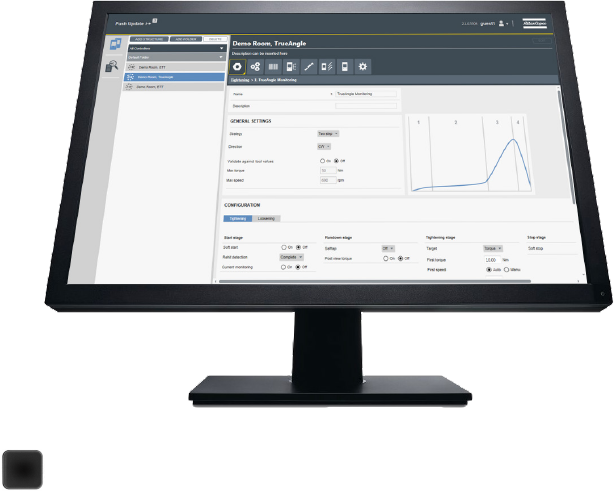

Basic Programming

The power focus 6000 tightening programs

need parameters such as target torque or

target angle to be set in order to perform a

tightening. Other settings – soft start, self

tap, and torque compensation – are optional,

just as setting which tightening strategy

to use. Monitor the tightening progress

by adding limits for torque, or specified

tightening angle.

In the general Pset settings you can set up

and manage the Psets by naming them and

making general tightening settings. Choose

tightening strategy, manual or quick prog

mode, and set the Pset target value.

To the right you can see a configured Pset

named Two step tight that uses a two step

tightening strategy set to the Target torque of

15 Nm

By clicking on “two step” in the strategy

box you can change strategy from two step

to TurboTight etc. Find more configuration

options by clicking on edit under tightening

parameters or loosing parameters.

For more information regarding

programming please use the power focus

6000 configuration guide with detailed

information on each menu item and the

configuration.

POCKET GUIDE TO POWER FOCUS 6000 SYSTEM

15

Open Protocol

The Power Focus 6000 enables communication

trough open protocol. The Atlas Copco Open

Protocol is a standard communication protocol

developed to facilitate communication

between our controllers and external parties in

the customer’s production processes.

Open Protocol is an interface for building

applications for remote control or data

subscription of controllers. It is platform

independent and can be implemented

on Linux, PLC, printers, and all Windows

platforms. The Open Protocol supports

Ethernet connection with the Power Focus

6000.

An Open Protocol message consists of

three parts; header, data field and message

end. Depending on type of communication,

a package includes the message and an

encapsulation before and after.

The MID, or message ID, is represented by a

four digit number (for example MID 0062 for

Vehicle ID Number upload). Each MID can have several revisions. Usually

a new revision is created when more data is included and the length of

the message needs to be increased. MID revisions are added to ensure

backwards compatibility.

For a full overview of what information, or MIDs (Message IDs) and

revisions, are supported with the Power Focus 6000 please see the Open

Protocol Appendix (picture above) provided in the Marketing and Support

Web Portal. The main value with Open Protocol is to provide a standard

and easy-to-use communication protocol. It can be set up in minutes and

integrated with your production processes in your plant. Through the years

“Open Protocol” has become an industry standard to communicate with

tightening equipment on assembly lines.

POCKET GUIDE TO POWER FOCUS 6000 SYSTEM

16

FUNCTIONALITY MANAGEMENT SYSTEM

Introduction

Atlas Copco Functionality Management System (FMS) is our new licensing

platform and it is a completely new way of delivering and administering

functionality available on Power Focus 6000 controllers. FMS is meant as

a way to simplify the way that functionality is added and removed from a

controller based on the actual needs on a station.

The customer portal is used for activating controller functionality, for getting

an overview of previous purchase orders and to map available features

to a USB license device or a functionality management system server. All

features that has been purchased is easily available from the customer

portal. This gives traceability of the functionality that has been bought and

also easy access in case a license has been lost.

Main benefits

• Flexible rebalancing

• Customizable and upgradable

• Instant delivery

• Trial licences

POCKET GUIDE TO POWER FOCUS 6000 SYSTEM

17

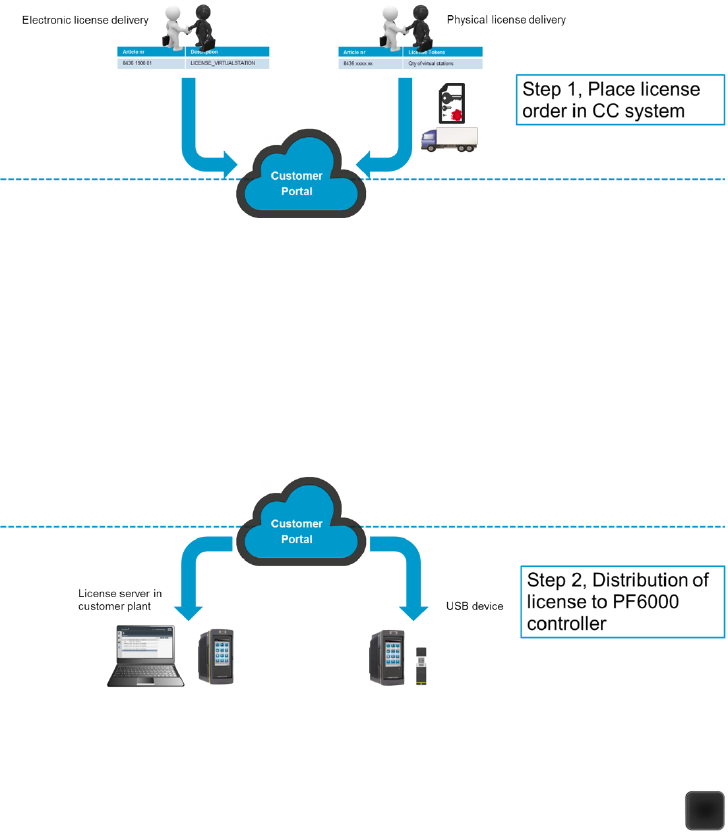

Order and distribute licenses to customer portal

There are two ways to distribute features and licenses to the customer

portal, electronic or physical delivery. The electronic delivery is made

automatically once the order is put in the local CC system and the features

is automatically linked to the customer account in the customer portal. The

physical delivery is carried out from PTD as a physical license paper from

PTD and a manual registration is required to link the features to the account

in the customer portal.

Distribution from customer portal

Once the licenses and features are delivered and linked to the customer

portal there are two ways to distribute the features to the controllers; a

server based solution (electronic way) and a non-network required solution

(physical way). The network based solution is meant for production facilities

where it is needed to re-balance and move functionality quickly and

efficiently between virtual stations. The physical way is the FMS USB license

device solution and is perfect for customers where an IP-based network is

not available and the need for rebalancing is not as big.

POCKET GUIDE TO POWER FOCUS 6000 SYSTEM

18

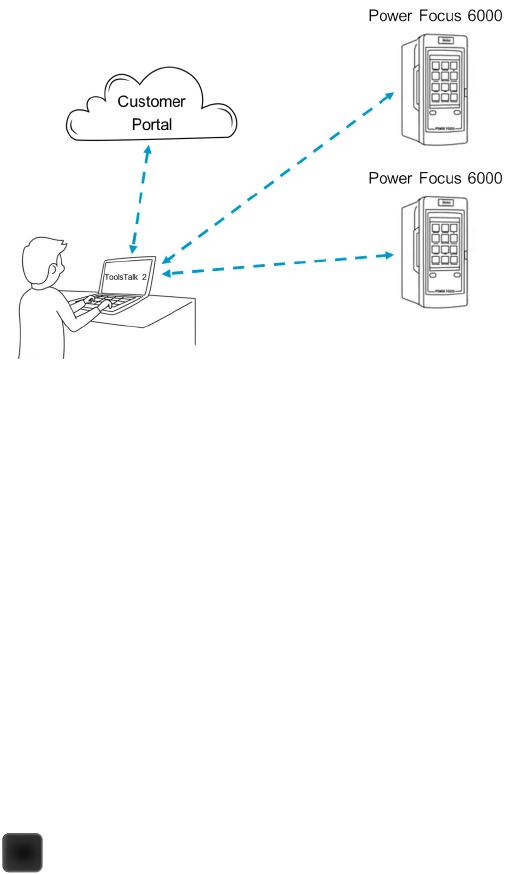

FMS Server based

The Atlas Copco FMS functionality is built into ToolsTalk from start making

it the best way to distribute virtual stations and features to the individual

controllers. ToolsTalk is also the best way of managing and programming

multiple controllers.

Start by uploading the capability request, received from Customer Portal, to

ToolsTalk in order to make the licenses available for distribution. After this is

done it is a very straight forward process to and features to the Power Focus

6000.

POCKET GUIDE TO POWER FOCUS 6000 SYSTEM

19

FMS USB device/non network based

The FMS USB license device is a great option for customers that do not

have the controllers networked and do not have any need for ToolsTalk

and plant level management of their controllers. With the Atlas Copco

USB license device it is possible to load and distribute virtual stations and

features to individual controllers.

After the USB device has been registered on the Atlas Copco customer

portal and the capability file has been downloaded, move the license file

to the USB device. The USB device will be used for transporting the virtual

stations and features to the controller. Plug in the USB to the controller that

needs to have additional virtual stations and features. After the device has

been inserted an icon will appear on the top right of the controller screen

or in the webHMI and by pressing this icon it is possible to add more virtual

stations and/or features to the controller.

When adding a virtual station and/or feature to the controller this means

that the amount of available functionality on the USB device will go down

based on what is added to the controller.

If a virtual station or a feature needs to be moved from a controller to

another one just plug in the same USB stick as the one that was used to add

it originally and move it back to the USB device. Now the device contains

this functionality and it can be moved to a different virtual station.

POCKET GUIDE TO POWER FOCUS 6000 SYSTEM

20

TIGHTENING STRATEGIES

Select tightening strategy by choosing the method for applying clamping

force (or preload) to the joint. Different joints require different strategies for

applying the desired clamping force and to minimize unwanted in-service

effects.

The Turbo Tight

®

strategy enables the option to use Manual programming or

Quick prog, see section Strategy. The Quick step, Two step, and Three step

strategies enable the choice of tightening towards a Target torque or a Target

angle value, see section Target.

All tightening strategies require that you set either Target torque or Target

angle value.

Turbo Tight

®

Tightening Strategy

Turbo Tight

®

is the default tightening strategy, designed to perform a very

fast and ergonomic tightening based on the tool’s maximum speed (Tool

max speed). This strategy only requires Target torque to be set in order to

perform the tightening. Depending on the joint properties, for example if the

joint is very stiff or very soft, a different tightening strategy might be needed.

Note! The Turbo Tight

®

strategy is only available when using the Tensor STR

tools.

Fine-tuning the Turbo Tight

®

Tightening strategy

If the Turbo Tight

®

strategy gives unwanted results, we recommend you to

take look at how the Rundown complete is set.

A Rundown complete set too high could give the Turbo Tight

®

strategy too

little time to work on the needed calculations in the Tightening step, and

result in an overshoot. The ambition should be to set the Rundown complete

as close to snug as possible. A Rundown speed set too high could also cause

the Turbo Tight

®

not to have enough time to work on the needed calculations

in the Tightening step resulting in an overshoot. This is even more important

if the joint is very stiff.

Reduced cycle times

Turbo Tight

®

optimizes the tightening speed to achieve the fastest possible

tightening maintaining reliable accuracy. The results are:

• Possibility to remove bottlenecks,

• Possibility to rebalance assembly lines due to increased

cycle rate,

• Less heat development, a cooler tool during operation.

POCKET GUIDE TO POWER FOCUS 6000 SYSTEM

21

Reduced reaction force

With optimized tightening speed, the torque builds up faster,

reducing the amount of force transmitted to the operator’s hand.

The results are:

• Reduced operator fatigue and risk of injury,

• Improved operator comfort during tightening,

Reduced need for reaction absorbing devices in certain situations, giving

less cost and reduced tool weight.

Easy set-up

Turbo Tight

®

is designed to be extremely easy to set up. In most cases, you

just need to set the target torque and you’re ready to go. Exceptions are

discussed in the following chapters. In such cases please contact your local

Atlas Copco Tools representative for support. The results are:

• Time savings during set-up,

• Less time and money spent on training,

Work rotation enabled.

POCKET GUIDE TO POWER FOCUS 6000 SYSTEM

21

POCKET GUIDE TO POWER FOCUS 6000 SYSTEM

22

Sustainability

Using Turbo Tight

®

results in shorter tightening cycles. This in turn

means less heat development and a cooler tool. It also helps to reduce

energy consumption with 10 % and prolong tool lifetime in high-cycle

environments. In general the losses during a tightening can be reduced by

speeding up the tightening phase, but remember: the big savings come

from standby.

How are cycle times reduced?

Turbo Tight

®

controls the motor speed to achieve the fastest possible

tightening without excessive overshoot. Comparing it to a traditional Two

Step strategy, Turbo Tight

®

runs faster for a longer period.

How is reaction force reduced?

Turbo Tight

®

uses the tool’s mass moment of inertia to reduce the reaction

force transmitted to the operator. The increased control of the motor in

combination with the fast dynamic regulation enables the tool to minimize

the reaction force from the tightening.

How come set-up is so easy?

Turbo Tight

®

is a strategy that controls the motor speed based on the actual

torque rate and the remaining torque of the joint. Since all these parameters

are dynamically calculated during the tightening, the only user input

required is the target torque.

How does Turbo Tight

®

provide energy savings?

Atlas Copco has been ISO 14001 certified since 2010, ensuring the planning,

execution, control and optimization of continuous improvement processes

for all Atlas Copco Industrial Technique products. If we compare the energy

consumption of a Power Focus 4000 running a Tensor ST tool with a Two

Step set-up, with the energy consumption of a Power Focus 600/6000

running a Tensor ES/STR tool with Turbo Tight

®

, we get the following result.

POCKET GUIDE TO POWER FOCUS 6000 SYSTEM

23

Target Speed

Pause Time

Target Torque

First Torque

Rundown Complete

First Speed

Start Stop

TIME

TORQUE/TIME ANGLE/TIME SPEED/TIME

Rundown Tightening

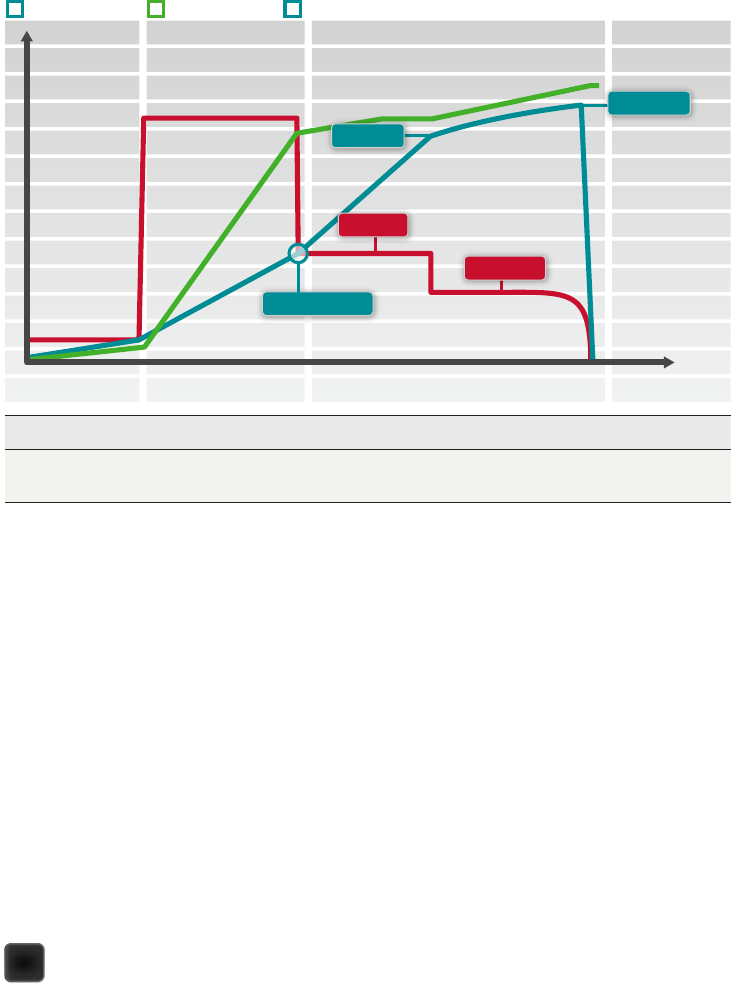

Two Step Tightening Strategy

The two step tightening strategy is very similar to the Quick step strategy

with the exception that it adds a small time delay between the first step and

the final step, to further counteract short-term relaxation effects in the joint.

Fine-tuning the Two Step Tightening strategy

When the First target is reached the tool will make an immediate stop for a

specified time before it continues with the final step. The First torque value

and the Pause time should be chosen to improve ergonomics for hand-held

tools.

Parameter Description Default Value

First torque Target torque for the first step

First speed Target speed for the first step

Pause time Time between first and second step 50ms

POCKET GUIDE TO POWER FOCUS 6000 SYSTEM

24

Quick Step Tightening Strategy

Quick step tightening strategy is used to reduce the joint’s preload scatter by

adding an initial step with a given torque and speed, and then reducing the

target speed in the final step.

Start Stop

TIME

TORQUE/TIME ANGLE/TIME SPEED/TIME

Rundown Tightening

Rundown Complete

Target Speed

First Speed

First Torque

Target Torque

Parameter Description Default Value

First torque Target torque for the first step

First speed Target speed for the first step

POCKET GUIDE TO POWER FOCUS 6000 SYSTEM

25

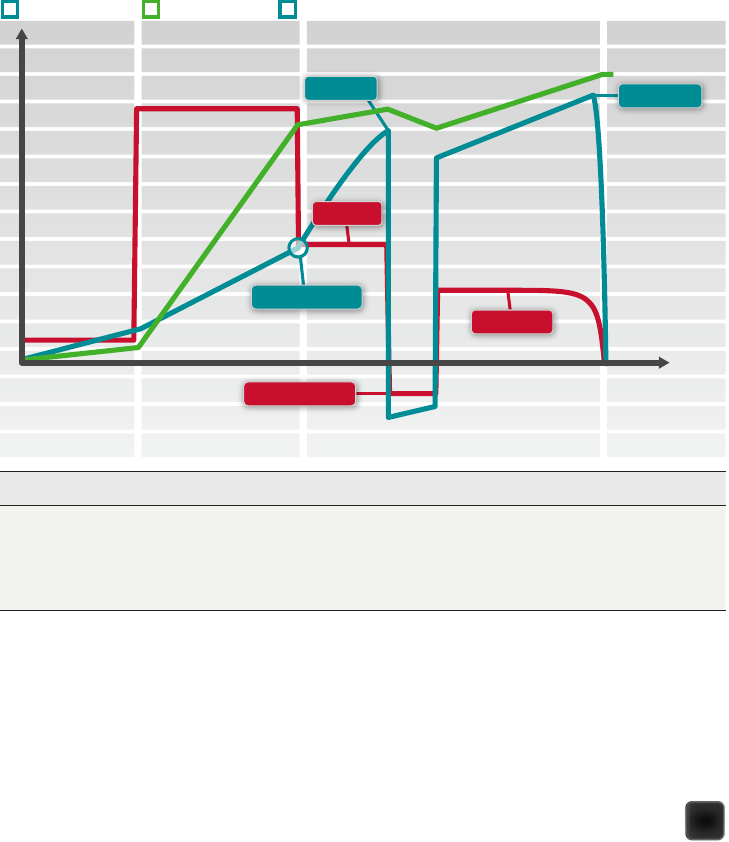

Three Step Tightening Strategy

The three step tightening strategy adds a loosening step between the

first step and the final step to overcome short-term relaxation effects due

to embedment, and reduce preload scatter. This is sometimes called to

condition the joint. This can be useful in, for example, joints with many

adjoining surfaces and will have greater effect on new parts than on reused

ones due to the smoothening of surfaces which will reduce embedment.

Conditioning the joint is done by tightening the first step to a given torque,

First torque, and then releasing the load by turning the nut a specified

Conditioning angle and then retightening the nut to its Target torque.

Target Speed

Conditioning Speed

Target Torque

First Torque

Rundown Complete

Start Stop

TIME

TORQUE/TIME ANGLE/TIME SPEED/TIME

Rundown Tightening

First Speed

Parameter Description Default Value

First torque Target torque for the first step

First speed Target speed for the first step

Conditioning speed Target speed during the conditioning step

Conditioning angle Angle to turn the socket during the conditioning step 180°

POCKET GUIDE TO POWER FOCUS 6000 SYSTEM

26

Rotate Strategy

The rotate strategy is primarily a strategy for testing and demo purposes.

When letting the tool rotate in free air, it will turn the socket to the specified

angle using the lowest torque possible.

Target Torque Limits

By setting the Target torque limits is it possible to discard a tightening,

should the torque result not fall within the specified torque limits. A Torque

set too high can cause the bolt to deform or break as a result of passing the

yield point. Not enough torque can end up with the clamping force not being

enough to withstand the forces for which the joint is designed.

Parameter Description Default Value

Target speed Target speed for the Rotate Strategy

Target angle Angle to turn the spindle 360°

Start Stop

TIME

TORQUE/TIME ANGLE/TIME SPEED/TIME

Rundown Tightening

Target Torque

Max Torque

Rundown Complete

Min Torque

POCKET GUIDE TO POWER FOCUS 6000 SYSTEM

27

Target Angle Limits

With Target angle limits set, it is possible to monitor if the nut is turned to

the desired angle during the tightening.

Start Stop

TIME

TORQUE/TIME ANGLE/TIME SPEED/TIME

Rundown Tightening

Target Torque

Angle max

Angle min

Torque

First target

Rundown Complete

Parameter Description Default Value

Angle limits Choose the section of the tightening in degrees, where to

monitor the angle.

Off: No limits are checked.

From Rundown complete: The monitoring window is set from

when the Rundown complete torque is reached.

From Torque: The monitoring window is set from when the

specified torque value is reached. Torque must be greater than

First torque.

From First target: The monitoring is set from when First target

is reached. This option is not available if TurboTight is chosen.

Target speed

<From torque> Torque value from where angle limits are set Target speed

Angle min Angle value for lower angle limit 90°

Angle max Angle value for upper angle limit 720°

POCKET GUIDE TO POWER FOCUS 6000 SYSTEM

28

Torque Compensation

By using torque compensation, the actual clamping force applied to the joint

can be better determined and the scatter in the applied clamping force can

be reduced.

The torque compensation point is set by using a previously specified angle

from Rundown complete and then calculating a value for the torque used

during rundown. When creating the preload in the bolt, this is compensated

for by adding the torque value calculated in the torque compensation point,

to the Target torque.

Stop Stage

The Stop stage terminates the tightening so that the socket can be released.

Parameter Description Default Value

Torque compensation Enables adjusting Target torque for torque used in the

rundown stage.

Off: No compensation made.

On: Manually sets the Torque compensation point.

Off

POCKET GUIDE TO POWER FOCUS 6000 SYSTEM

29

Soft Stop

Soft stop makes the tightening stop in a more ergonomic fashion. Avoiding

the tool to stop within the time interval of 50-300 ms, since it is known to

create an uncomfortable stop.

Parameter Description Default Value

Soft stop Turns the soft stop on or off.

Off: No soft stop is used.

On: Soft stop is activated. When target torque is reached the

tool speed is immediately decreased to 75%. Then the speed

is decreased to zero in at most 40 ms.

Off

POCKET GUIDE TO POWER FOCUS 6000 SYSTEM

30

VIRTUAL STATIONS

Introduction

The Virtual Station is the enabler of your assembly. It controls the tool,

the communication and the accessories in your assembly station.

Controlling multiple tools, working with virtual station gives you less cable

management, less network connections and less hardware components.

You will gain increased flexibility with increased rebalancing speed in your

production.

The Virtual Station keeps all information about your assembly process,

giving you an instant overview of what is going on in the production.

Tool Control:

Making sure your tool

is performing correct

tightenings for your

assembly.

• Pset selection

• VIN handling

• Batch sequence

control

Communication

Control:

Communicating for

easy and seamless

integration with your

production systems.

• Open Protocol

• Fieldbus

• Customer Protocols

Accessory Control:

Taking care of multiple

accessories per virtual

station.

• Stacklight

• Socket selector

• Digital I/O

POCKET GUIDE TO POWER FOCUS 6000 SYSTEM

31

Setting up a Virtual Station

In every IAM there is at least one

Virtual Station included. More virtual

stations can be added using the

FMS function in ToolsTalk2 or by pre-

configured IAMs.

When an additional virtual station has

been added a plus sign will appear

in the in right corner in the Virtual

Station menu. When all Virtual Stations

available has been added the plus sign

will disappear.

In the help menu there is information

on how to configure and setup the

Virtual Station. All the help material

can be downloaded in PDF from the

controller using the WebHMI.

Key Benefits

• Easy to set up

• QIF accessories connected in total

• The same accessory can’t be repeated in the same Virtual Station

(i.e. 2 stacklights on the same Virtual Station)

• Works with existing accessories (socket selectors, stacklight, operator

panel, etc.)

• Copy-Paste psets, Virtual Station configurations (ToolsTalk 2)

• 1 job in different Virtual Stations

• Excellent user interface

• Excellent graphical concept and very easy to configure

• Less wiring complexity

POCKET GUIDE TO POWER FOCUS 6000 SYSTEM

32

STR TOOL

Overview

Tensor STR tools can be powered by the Power Focus 4000 and the Power

Focus 6000 controllers. The full capacity of the tool is available when

controlled by the Power Focus 6000.

When running on a Power Focus 4000:

• Tools are generally running on a slightly lower max

speed around 90% of maximum.

• Turbo Tight

®

is not available when running on a

Power Focus 4000.

• When connecting the ETT tool to a Power Focus

4000 the front trigger can only be programmed to

act as a safety trigger.

• When connecting STR tools to Power Focus 4000

the ST tool cable should be used.

The tool has been designed for a very high level of reliability and durability.

Heat transfer has been improved a lot compared to previous generations.

The heat is more efficiently transferred over the tool, keeping the hot areas

cooler. This increases the life length of grease and in the long run the

internal mechanical parts. IP54 classification (ETV and ETD) is another factor

that highly contributes to the increased durability, since the tool is better

sealed and protected for intrusion of dust and fluids.

ETV and ETD are the full featured STR tools. ETT is missing the IP

classification and gyroscope. ETP is of an older base design but offers the

same level of connectivity and accuracy as the most recent tools.

POCKET GUIDE TO POWER FOCUS 6000 SYSTEM

33

Models

Tool Modules

The STR concept uses modules to increase quality and flexibility. Different

modules are combined with new models and all the motors have the same

diameter so modules can be interchangeable between different sizes.

Due to matching electronics and hardware tested as a separate unit, the

module concept also makes it easier to replace parts. All electronic modules

use connectors to make assembly and service fast and simple, no soldering

required.

Handle module

The handle module is common for all STR ETV and ETD models. It includes

the main electronic board, the board and its components are molded into

plastics for extra protection. The module also carries the vibrator, which can

be programmed to give feed back to the operator.

The gyroscope is another key component in the handle as it can sense

movements of the tool down to 1 degree.

The cable connection has a new generation of pins and sleeves that

increases the wear resistance considerably compared to previous

generations.

The trigger is easily removed for better accessibility during cleaning.

HMI

The HMI module is where the tool and operator interact with each other. The

module has LED lights – yellow, green or red. There is also a blue LED and

a tightening direction indicator. The reverse ring is lockable and the module

also includes a speaker that can send sound signals to the operator.

The standard HMI and EHMI is available with or without a button on the

reverse ring.

ETD ETV

ETPETT

POCKET GUIDE TO POWER FOCUS 6000 SYSTEM

34

Motor

In the STR ETV/ETD range all motors have the same diameter. More

powerful motors are made longer.

Focus has been to increase the robustness of the motor. For example the

bearing houses are made stronger and in Aluminum. A new insulation

system has made it possible for the intermediate shaft to be made with

fewer parts and without plastic material.

Motor rotation speed is higher than on ST tools when running with a Power

Focus 6000.

RFID tag is included in the motor module. It will be determined at a later

point what will be included in the chip.

Torque transducer

The torque transducer is a delicate part that should not be replaced if faulty.

The transducer shows a very accurate reading from 100% down to 20% of

the nominal torque. STR range is improved so that disturbance from the

motor has less effect on the signal, making the reading more exact resulting

in an improved tool accuracy.

Gears and Angle head

Planet gears and angle gears are all made of a special steel that is specially

developed for Atlas Copco.

The angle head gears are spiral cut for maximum accuracy and durability,

larger angle heads are prepared for attaching a reaction plate.

ETT front part

The ETT front part differs from other tools in how the transducer is placed

after the angle gear and attached to the output shaft. This gives the ETT tools

an accuracy of 2,5% over 3s.

POCKET GUIDE TO POWER FOCUS 6000 SYSTEM

35

Accessories (attached to the tool (ETV/ETD))

The tool has two connections for accessories, making it possible to combine

a number of different combinations of helpful accessories.

Accessory Function

Lever trigger 135deg

Trigger that is offset for alternative grip, acting as

“button”.

Lever trigger?

Same as lever trigger 135 deg but straight, acting as

“button”

Button Button for sending impulse on st bus.

Headlight Lamp to illuminate tolls work area.

2D scanner Scanning 2d codes (3d > qr)

Selector ring (button) Button on ring, acting as “button”

Tool leds Led card with leds to send operator feedback.

Ehmi Display with 3 buttons

Tls tag

POCKET GUIDE TO POWER FOCUS 6000 SYSTEM

36

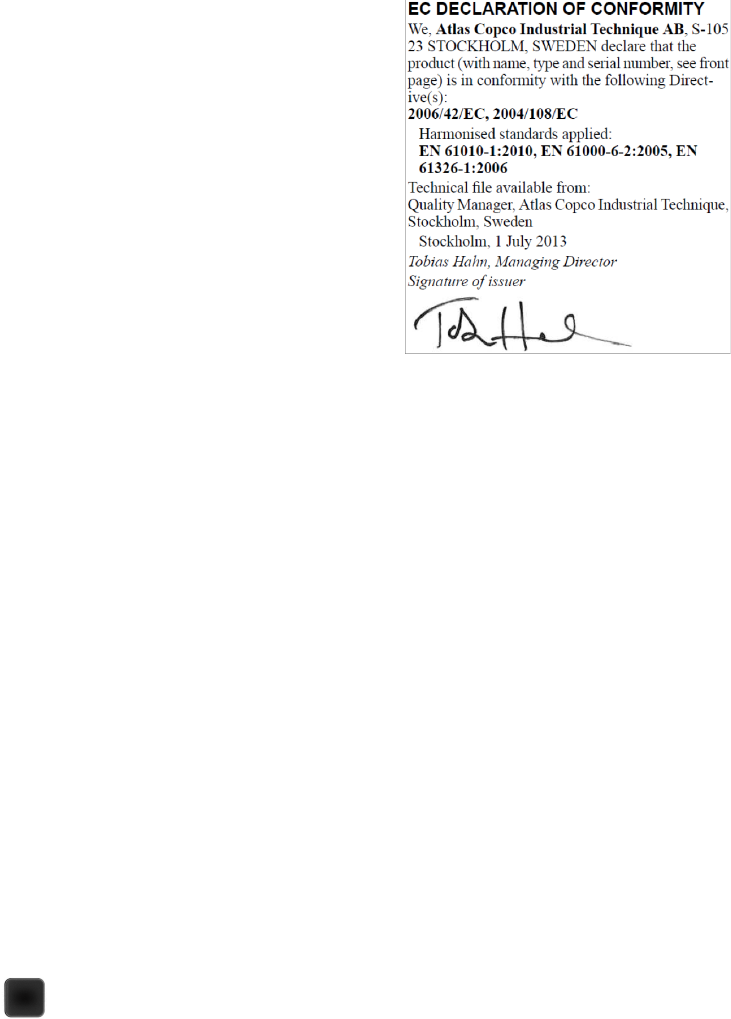

Certifications

EC declaration

EC declaration can be found in the

Safety information appended to

the product. The declaration states

responsible manufacturer and shows

European product directives and

harmonized standards.

European product directives – This

is the European Union product

legislation. The directives contain high

(and low) level requirements on the

product and procedures that relate to

the product during its life-cycle. The

requirements mainly concerns safety.

The directives applicable to STR are:

2006/42/EC – The machinery directive

2004/108/EC – The EMC directive

(ElectroMagnetic Compatibility)

1994/9/EC- The ATEX directive (Explosive Atmosphere)

Harmonized standards

The directives set out high level product requirements. These may be

difficult to interpret. A harmonized standard is generally a safety standard

that has been approved by the European Union authorities as compliant

with a product directive. In practice, the standards are used as the means for

complying with the law. E.g.

EN 61010-1:2010 Safety requirements for electrical equipment for

measurement, control and laboratory use - Part 1: General requirements.

EN 61000-6-2:2005 Electromagnetic compatibility (EMC) - Part 6-2: Generic

standards - Immunity for industrial environments.

En 61326-1:2006 Electrical equipment for measurement, control and

laboratory use- EMC requirements Part 1: General requirements.

Other directives

The EC declaration concerns directives required for CE marking. However,

there is more legislation that needs to be considered. E.g.

Information concerning Restriction of Hazardous Substances (RoHS) - This

product and its information, meets the requirements of the RoHS Directive

(2011/65/EU).

POCKET GUIDE TO POWER FOCUS 6000 SYSTEM

37

Information concerning Waste of Electrical and Electronic Equipment (WEEE)

- This product and its information, meets the requirements of the WEEE

Directive (2012/19/EU), and must be handled according to the directive.

IP 54 protection

The STR tools are certified for IP protection level 54. The level of protection

will prevent foreign particles and fluids from entering the tool. This will make

the tool more durable than previous generations, due to less contamination

of internal parts.

IP54 – The first number marks the protection level for dust. Level 5 = “Ingress

of dust is not entirely prevented, but it must not enter in sufficient quantity

to interfere with the satisfactory operation of the equipment; complete

protection against contact (dust proof)”. The second number states the

protection level for water intrusion. Level 4 = “Water splashing against the

enclosure from any direction shall have no harmful effect”.

Note! ETT and ETP STR tools are not IP tested and do not meet IP54

requirement.

Service/Maintenance Intervals

Overhaul and preventive maintenance is recommended at regular intervals

once per year or after maximum 250.000 tightening depending on which

comes first. More frequent overhaul may be needed if the machine is used

in heavy-duty operations.

POCKET GUIDE TO POWER FOCUS 6000 SYSTEM

38

STR TOOL ACCESSORIES

The STR tool can utilize two different accessories at a time.

The accessories consist of two halves, upper and lower and can be

combined in different ways, for example a scanner and headlight can

be put together on the front bus.

Used for reading bar codes or QR codes, connects to one of

the tool bus slots.

Button for sending instructions from the operator connects to

one of the tool bus slots.

Used to illuminate the work piece, connects to one of the tool

bus slots.

Suspension that allows the tool to rotate, used when attach-

ing the tool to a balancer.

POCKET GUIDE TO POWER FOCUS 6000 SYSTEM

39

Mounting Bracket Used for fixturing the tool

Protection Cover

Protection to avoid scratches caused by the tool in sensitive

applications.

Trigger that is offset for alternative grip connects to one of

the tool bus slots.

Shorter lever that can be used as a safety trigger connects to

one of the tool bus slots.

EHMI, small display that can show information about the

tightening and also acts as a Pset selector connects to one of

the tool bus slots.

Local customization

The tools can easily be fine-tuned to fit the operator preferences or the

application by adding tools accessories. The standardized sizes, fits a wide

range of Atlas Copco tools.

POCKET GUIDE TO POWER FOCUS 6000 SYSTEM

40

CABLE MANAGEMENT

Cables are used in conjunction with all Atlas Copco tools and assembly

equipment, including: hand held tools, fixtured hand tools or when spindle

”motors only” are provided for incorporation into various types of machine

automation.

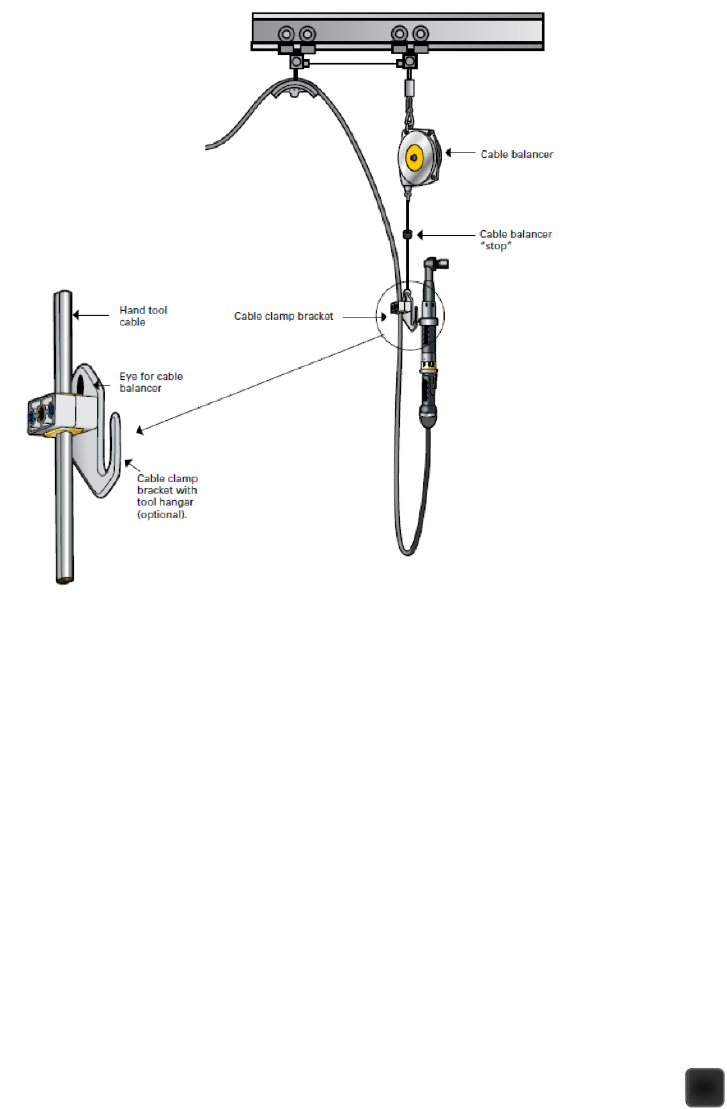

As with many industrial systems, cables are a main failure point – especially

in applications where the cables are subject to repetitive motion. Atlas

Copco has the knowledge to help the customer find effective solutions to

their facilities unique cable needs.

In the case of fastening equipment, cables connect the following functions:

• Power supply

• Controller

• Nutrunner

• Accessory

With a proper cable management

you will increase the life of

the cable and reduce the risk

operators falling over them. In

example, using a cable balancer

helps to manage the excess cable

when the tool and cable are not

extended.

POCKET GUIDE TO POWER FOCUS 6000 SYSTEM

41

Use of a cable clamp bracket

This clamp bracket can be attached to a hand tool cable and then be attached

to a cable balancer. When located properly on the tool cable, the cable

balancer will keep the cable off the floor. A hook is provided as a place to

“rest” the tool and may be used with or without a cable balancer to “rest”

the tool when the cable is spread over the cable shoe.

POCKET GUIDE TO POWER FOCUS 6000 SYSTEM

42

Types of cables available

Various types of cables are available from Atlas Copco to suit all kinds of

applications, as illustrated below.

Tensor STR cable

Tensor STR cable has the same functionality but

different interfaces towards the controller.

However, they have the same interface

towards the tool.

Tensor S Extension Cable.

Tensor S Extension Cable with loop. The

cable loop makes cable even more flexible

if the tool is used in small circles.

Tensor ST Spiral Cable.

Tensor S Extension Cable for

fixtured applications.

Tensor S Cable with 90°connector.

Angle connection cables for

applications where space does not

allow the use of normal cables.

Cable cover for workpiece surface protection.

Tensor S Tool Cable.

Tensor ST Tool Cable

POCKET GUIDE TO POWER FOCUS 6000 SYSTEM

43

Flat cable for greater durability

Atlas Copco has been producing assembly

tool cables since 1987 and has unrivaled

experience in the field. Flexibility and

durability have steadily improved since the

introduction of the company’s first-generation

cables, resulting in today’s optimum cable

performance. Atlas Copco’s flat-cable design

combines maximum flexibility (for access

to difficult applications) with maximum

durability. No other manufacturer can offer

such a powerful combination of flexibility and

performance.

Smaller bending radius for greater accessibility.

Atlas Copco engineers its tool cables to withstand consistent and long-

term flexing. Cable size (diameter) is the most

critical factor in terms of flex life. The best

way to reduce fatigue affecting the internal

cable conductors is to keep cable thickness to

a minimum. Atlas Copco’s flat-cable design is

just under half the thickness of a comparable

“round” cable, offering an exponential gain

in flex life. When it comes to durability and

flexibility, the Atlas Copco cable is unique.

Innovative ‘Cable Twist’ design

The most critical area for an assembly tool cable is at the point of maximum

flex – generally close to the tool connection point. Atlas Copco’s “Cable

Twist” design spreads the flex load over a greater distance, to minimize flex

in the critical area. This patented flat-cable “twist” design is unique to Atlas

Copco.

Round

Flat

Tensor Round

POCKET GUIDE TO POWER FOCUS 6000 SYSTEM

44

Centralized strain relief to prevent lead damage

The flat-cable design features a Kevlar-reinforced core, to absorb the

tensile loads to which cables can be subjected in tough applications. When

subjected to high tensile loads, this centralized load-relief Kevlar core also

prevents cable leads being damaged or compressed. For maximum signal

integrity, the flat cable design also ensures optimum separation of high and

low voltage conductors.

For more information regarding cable management please look in the cable management

pocket guide (9833 1640 01). In this pocket guide you will find more information regarding cable

management for fixtured and hand held tools and check points before, during an

Low

Kevlar

High

POCKET GUIDE TO POWER FOCUS 6000 SYSTEM

45

FIELDBUS

Fieldbus is an industrial network system

for real-time distributed control. It is a way

to connect instruments in a manufacturing

plant, for example Power Focus controllers.

Fieldbus works on a network structure which

typically allows daisy-chain, star, ring, branch,

and tree network topologies. The fieldbus

requires only one communication point at

the controller level, and allows hundreds of

analog and digital points to be connected at

the same time. This reduces both the length

of the cable required and the number of

cables required. Furthermore, since devices

that communicate through fieldbus require a

microprocessor, multiple points are typically

provided by the same device. Some fieldbus

devices now support control schemes such

as PID control on the device side instead of

forcing the controller to do the processing.

The Power Focus 6000 currently (release 2.1)

supports three different fieldbus types:

• DeviceNet

• EtherNet/IP

• ProfiNetIO

You can set up the fieldbus parameters using Tool Talk 2. For a full overview

of how this is done, please see the user guide for Tool Talk 2.

In short, the value of using a fieldbus communication is to have a real-time

control over multiple controllers in a standardized way in your production

plant.

Please note that there are a couple of fieldbus types available in the Power

Focus 4000 that are not yet implemented on the Power Focus 6000 platform.

POCKET GUIDE TO POWER FOCUS 6000 SYSTEM

46

TOOL TALK 2

Tool Talk 2 is developed from the ground up, to support the new multi-

controller concept delivered in the Power Focus 6000. When the old version

of ToolsTalk was a software tool to configure a single controller

– Tool Talk 2 takes controller programming to a whole new level by making it

easy to manage and program multiple controllers.

User Authentication

Tool Talk 2 supports user authentication in the application from the start.

This functionality makes sure that no one, except approved users, can make

changes to controllers and tightening programs. The second benefit of this

is that customers have full traceability of changes to tightening programs

in the application. Every change to a tightening program is logged in the

application, making it possible to see all the changes that have been made

to a program during its life cycle and also exactly which user that made the

change. If a problem occurs in production it is easy to identify the person

that made the change and by this it is possible to find the reason for the

change.

• Full change traceability of tightening programs

• Ensure that only approved users can make changes

to tightening programs

• Know which user is making changes on a controller

Plant Structure

The plant structure in ToolsTalk 2 makes it possible to organize all Power

Focus 6000 controllers into a structure that resembles the structure in the

plant. This makes it quicker and easier to administer controllers throughout

production.

• Organize controllers according to the layout in the

plant

• Quickly find controllers and tightening programs

that needs to updated

• Get an overview that everything is running as it

should

POCKET GUIDE TO POWER FOCUS 6000 SYSTEM

47

Multiple Controller Upgrade

ToolsTalk 2 leverages on the dual memory area functionality of the Power

Focus 6000, by making it possible to upgrade multiple controllers at

once just by one click. When doing an upgrade ToolsTalk 2 loads the new

controller firmware into the Power Focus 6000 controller but it does not

activate the new software until you are ready. When then time has come to

use the new software, it is possible to make the switch from ToolsTalk 2. It

also increases safety since you can switch back to the previous version of

the software just as easily if needed.

• Upgrade multiple controllers directly from the

application

• See exactly which software that is running on all

controllers in production

• Switch between software versions running on

the controller by selecting the desired preloaded

software versions.

Controller Programming

ToolsTalk 2 makes controller programming easier than ever before. All the

tightening parameters are available from a single view, creating a great

overview of the complete setup. When setting up or updating a tightening

program in ToolsTalk 2 all the changes are saved locally in the database of

the application, meaning no changes are stored on the controller initially.

This makes it possible to make all the needed changes before saving

anything to the controller. Thanks to this all the parameters can be adjusted

and verified before actually saved on the controller.

ToolsTalk 2 also saves all version of the tightening programs in its database,

making it possible to go back to a previous version of a program in case

there are any problems or concerns with an update that has been made.

• Great overview of all tightening parameters

• Possibility to setup all parameters before saving on

the controller

• Easily go back to a previous version of a program

POCKET GUIDE TO POWER FOCUS 6000 SYSTEM

48

TOOLSNET 8

ToolsNet 8 is the next generation data collection and production analysis

software from Atlas Copco. In order to achieve the highest value in the

application the whole web application was rebuilt from scratch, making it

possible to leverage on new modern technologies. In the base ToolsNet 8

still has the reliable data collection that has been developed by Atlas Copco

for almost 15 years.

With the new additions of the dashboard, statistical center and the tool

center we make sure the value of the product is increased to an even higher

level.

Reliable Data Collection

Collecting data is easy when using an Atlas Copco controller in combination

with ToolsNet 8. After ToolsNet 8 is installed just set the IP-address of the

ToolsNet 8 server in the controller and it immediately starts sending over

tightening results. ToolsNet 8 also supports competitor tools through

ToolsNet 8 Open Protocol. With Open Protocol it is important to check with the

competitor regarding what functionality they have implemented on their side.

Simple setup in combination with Atlas Copco controllers

Data buffers both on the controller itself but also on the ToolsNet 8

application server in case the database goes down which ensure high

security.

Simple Data Analysis

In ToolsNet 8 the reports have been further enhanced, meaning more of the

daily work and analysis can be done directly in ToolsNet 8.

• Possibility to filter directly in the reports

• All users can choose what fields they want to see in

their reports

• Possibility to group data directly from the reports

• Save favorite reports which increases the efficiency

when working with the application

• Export reports to Excel for further analysis

• Get detailed information about tightening results

• Simple access to all traces

POCKET GUIDE TO POWER FOCUS 6000 SYSTEM

49

Production Alarms

ToolsNet 8 makes it simple to setup alarms based on specific controller

events in production. All the events that are available in the Power Focus

and the PowerMACS controller can be setup as events in the notification

center of ToolsNet 8. After it has been setup, an email will go out to the

configured receiver as soon as there is an event, making it possible to

cut down response times and thereby reducing the time it will take to fix

production problems.

• Reducing down-time thanks to direct notification

about production problems

• Simple setup of notification means customers will

use it

Alarms based on statistical trends. Find material problems or process

problems automatically.

Dashboard

The dashboard gives a direct overview of the production in the plant. Every

user can configure the dashboard in a way that best suits their needs. For

example, if a user wants to focus on statistics it is possible to setup multiple

widgets showing SPC data in real-time for specific applications making it

easier to catch problems related to material or process problems.

Available dashboard widgets are:

• Top NOK applications: Shows the applications with

the highest failure rate for a configured part of the

tool structure.

• Running SPC: Shows the real-time X-bar and range

charts for a configured application.

• Tool maintenance: Shows the tools that need service

or calibration, from all the Power Focus tools in

production (currently only support Power Focus

W10.6+ and W14 controllers).

• Latest results: Shows an overview of the latest results

from the chosen part of the of the tool structure.

Traceability

ToolsNet 8 greatly increases the traceability in our customer’s production.

With the application it is possible to find a specific product and ensure that

all tightening have been done correctly by for example analysis the traces.

• Get all results based on a time interval

• Get all results based on a specific VIN number

• Find statistical deviations based on all tightening results.

POCKET GUIDE TO POWER FOCUS 6000 SYSTEM

50

Tool Service Information

ToolsNet 8 automatically collects information about all the tools in

production making it possible to find tools that have not been serviced in a

long time or tools in need of calibration. You can also find information about

software version of connected tools and the number of rundowns that have

been performed since the last service.

• Keep service log of all tools in production

• Get statistics on how a tool is performing on a

specific application

• Find information about tool software versions

• Get information about last service and calibration

of a specific tool

• Locate to which controller a tool is currently

connected by serial number

• Manage custom tool serial numbers in the plant

POCKET GUIDE TO POWER FOCUS 6000 SYSTEM

51

COMMITTED TO SUSTAINABLE PRODUCTIVITY

www.atlascopco.com

9833 2074 01 2016:1