Specification

Open Protocol

Atlas Copco Industrial Technique AB

9836 4415 01

Specification Release 2.8.0

Copyright Atlas Copco Industrial Technique AB

Note! This manual can be altered without further notice.

For further information log in to Atlas Copco www.atlascopco.com

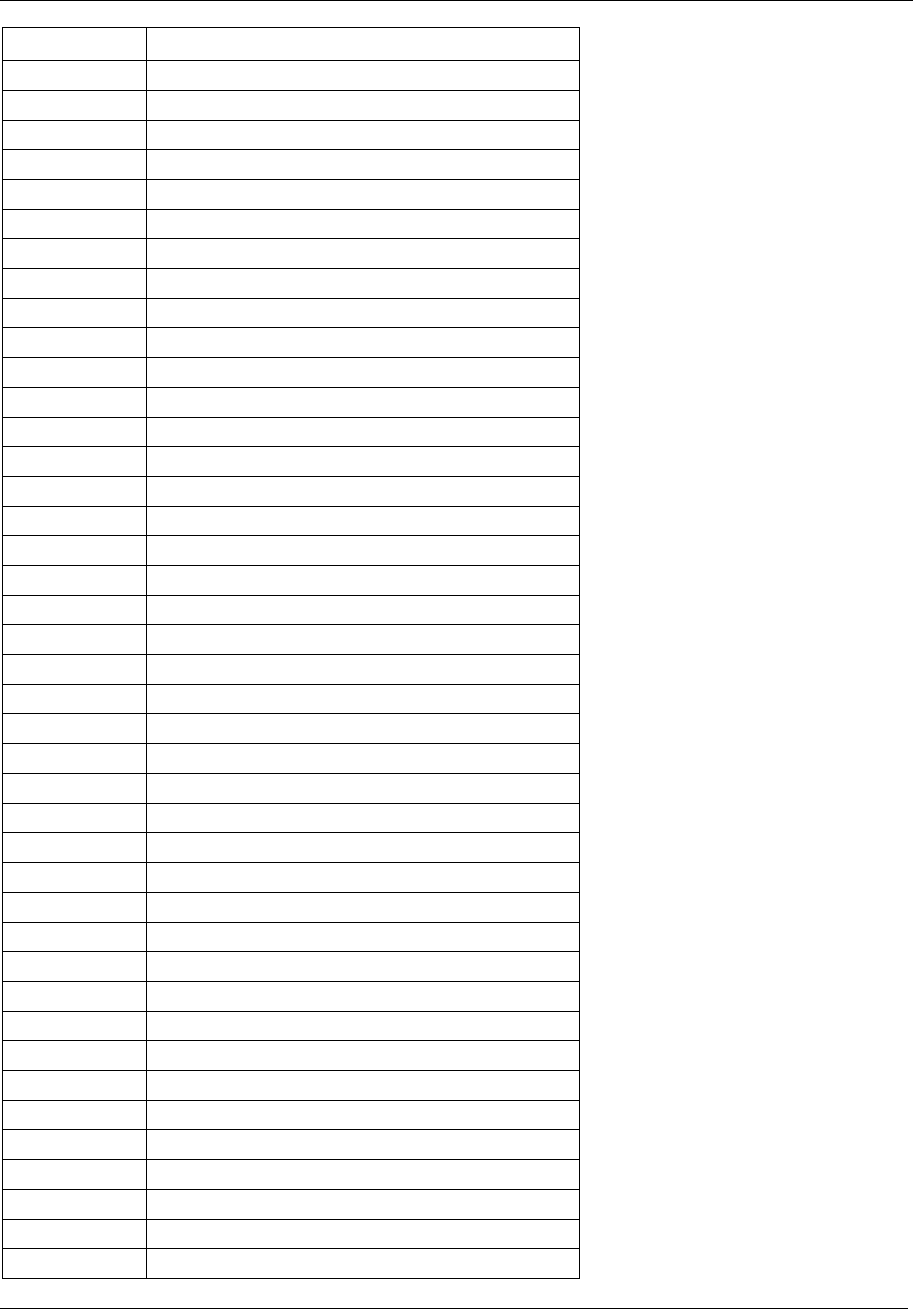

Contents

1 (285)

1 Introduction ............................................................................................................ 11

1.1 Revision history ................................................................................................. 11

1.2 Referenced documents ..................................................................................... 16

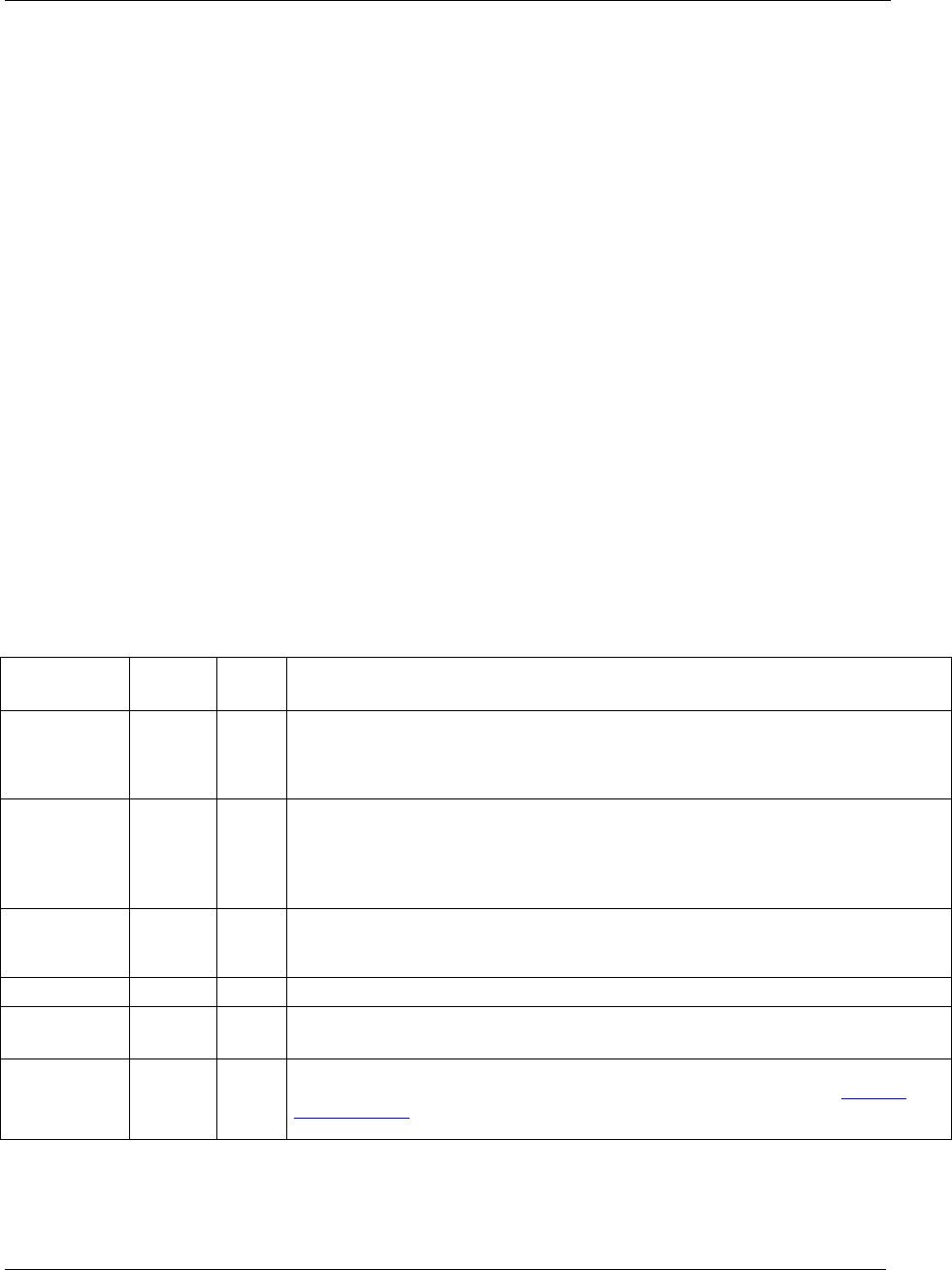

1.3 Protocol and Specification Versioning ............................................................... 16

1.4 Terminology ....................................................................................................... 18

2 Using Open Protocol ............................................................................................. 21

2.1 Communication ................................................................................................. 21

2.1.1 Ethernet protocol ................................................................................................................................... 21

2.1.2 Serial protocol ........................................................................................................................................ 22

2.2 Message structure ............................................................................................. 25

2.2.2 Header ................................................................................................................................................... 26

2.2.3 New MID numbers use from OP 2.0 ...................................................................................................... 27

2.2.4 MID with both ASCII and binary data from OP 2.0 ................................................................................. 28

2.2.5 Sequence number functionality from OP spec. 2.0 ................................................................................ 28

2.2.6 Message linking functionality from OP spec 2.0 .................................................................................... 30

2.3 Static Data Field use ......................................................................................... 30

2.3.1 Static Data field implementation rules .................................................................................................... 31

2.4 Variable data field use from OP spec 2.0 .......................................................... 32

2.4.1 Message End ......................................................................................................................................... 33

3 Implementation guidelines and Communication ................................................ 34

3.1 Application Startup messages exchange ........................................................... 34

3.2 Message acknowledging methods .................................................................... 34

3.2.1 Application Level acknowledging method .............................................................................................. 34

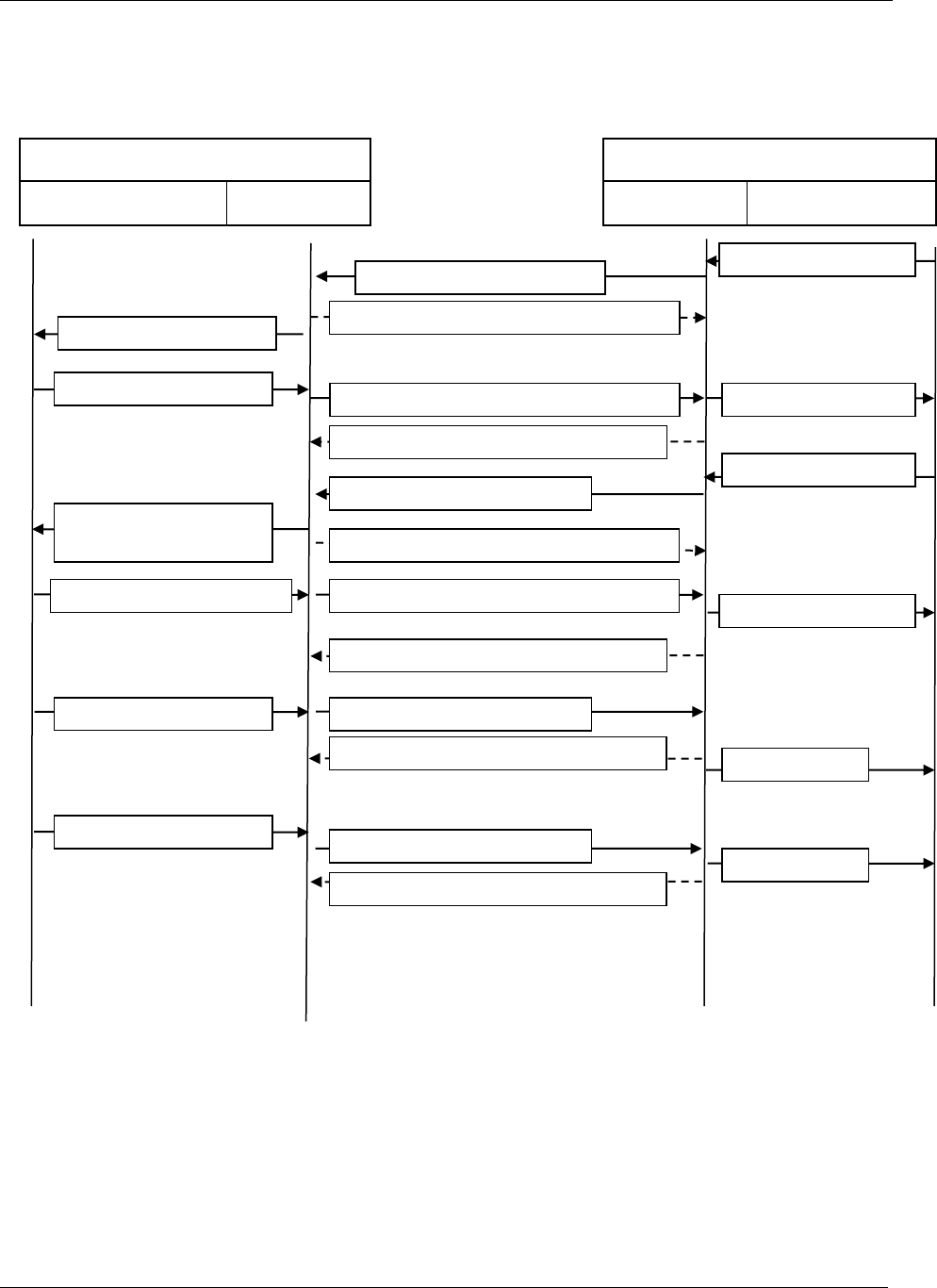

3.2.2 Link Level acknowledging method from OP spec. 2.0 ........................................................................... 36

3.3 Establishing contact ........................................................................................... 41

3.3.1 Ethernet connection ............................................................................................................................... 41

3.3.2 Serial connection ................................................................................................................................... 42

3.3.3 Serial connection with 3964R ................................................................................................................ 43

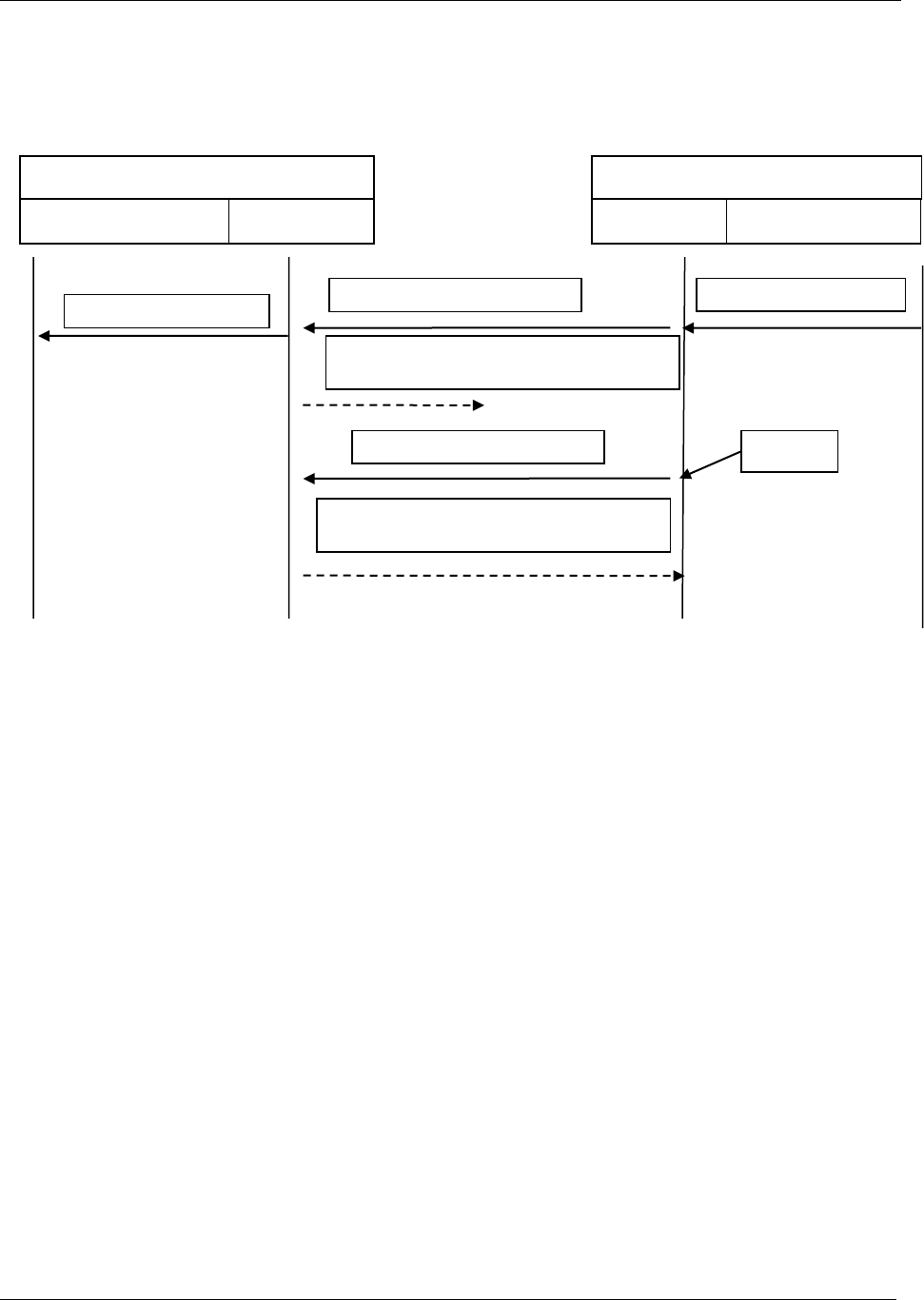

3.3.4 Session control connections .................................................................................................................. 44

3.4 Starting a subscription ....................................................................................... 45

3.5 Sending a request ............................................................................................. 47

3.6 Sending a command .......................................................................................... 48

3.7 CCS ruled production message sequences ...................................................... 49

3.7.1 General Job/Work order selection rules ................................................................................................. 49

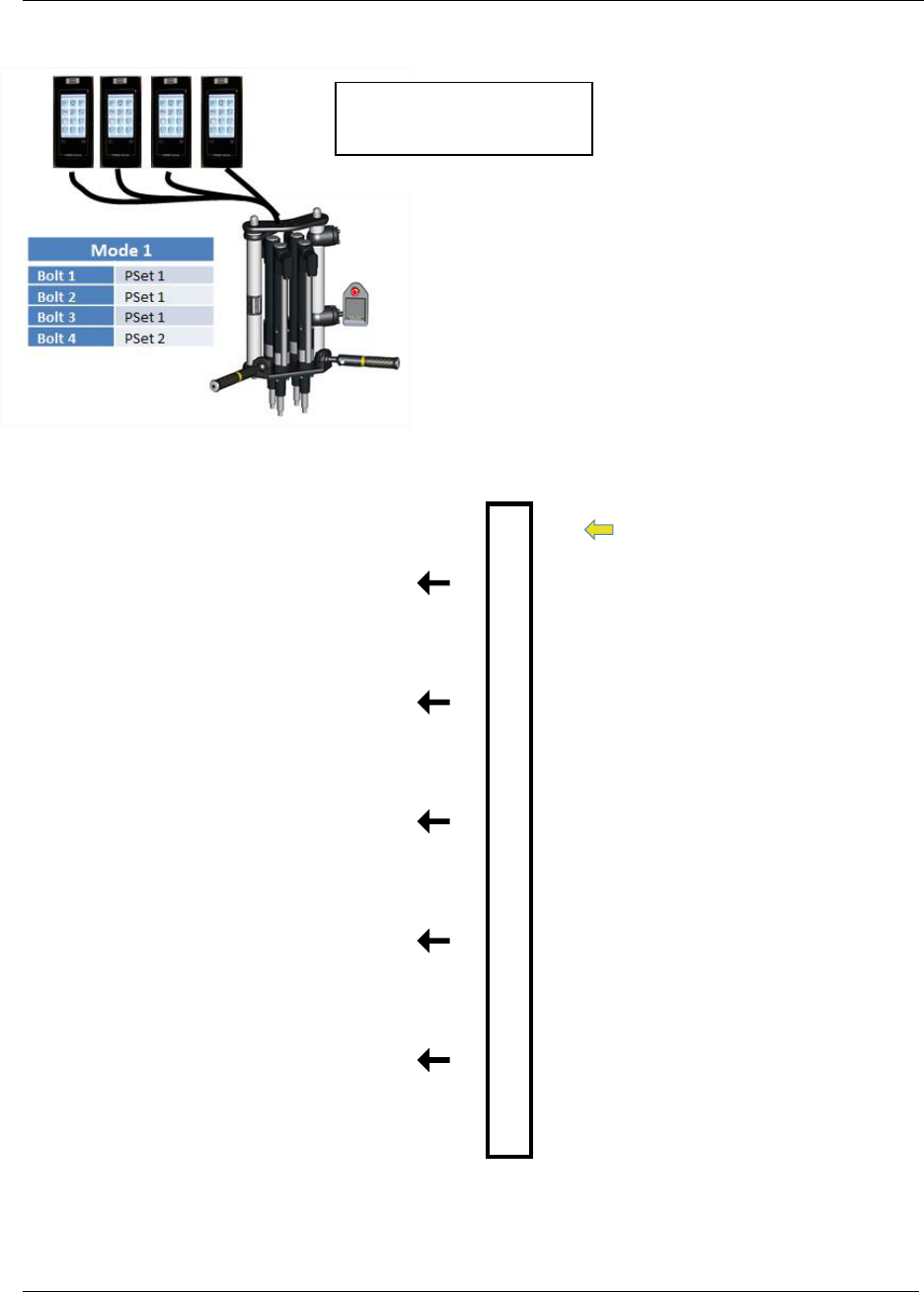

3.7.2 Production Control by Pset selection and tightening .............................................................................. 51

3.7.3 Production control by Job selection and tightening ................................................................................ 55

3.8 Message End determination methods ............................................................... 58

3.9 Version 2.0 implementation description ............................................................. 58

3.9.1 Startup ................................................................................................................................................... 58

3.9.2 Link level acknowledging ....................................................................................................................... 58

3.9.3 Generic Application data request ........................................................................................................... 58

3.9.4 Generic Application data subscription .................................................................................................... 59

3.9.5 Data field variable parameter pattern ..................................................................................................... 59

4 Message categories ............................................................................................... 61

4.1 Application Request and Request reply messages ........................................... 61

4.1.1 Generic Request message .................................................................................................................... 61

4.2 Application Command and Command reply messages ..................................... 61

4.3 Application Subscription Messages ................................................................... 62

4.3.1 Event data Subscribe/ Unsubscribe messages...................................................................................... 62

4.3.2 Subscribed data messages ................................................................................................................... 62

4.3.3 Subscribed data message acknowledge ............................................................................................... 62

4.3.4 Generic Subscription/Unsubscription messages.................................................................................... 62

4.3.5 Subscription/Unsubscription messages handling when sequence numbering and Link level

acknowledging is used. ....................................................................................................................................... 62

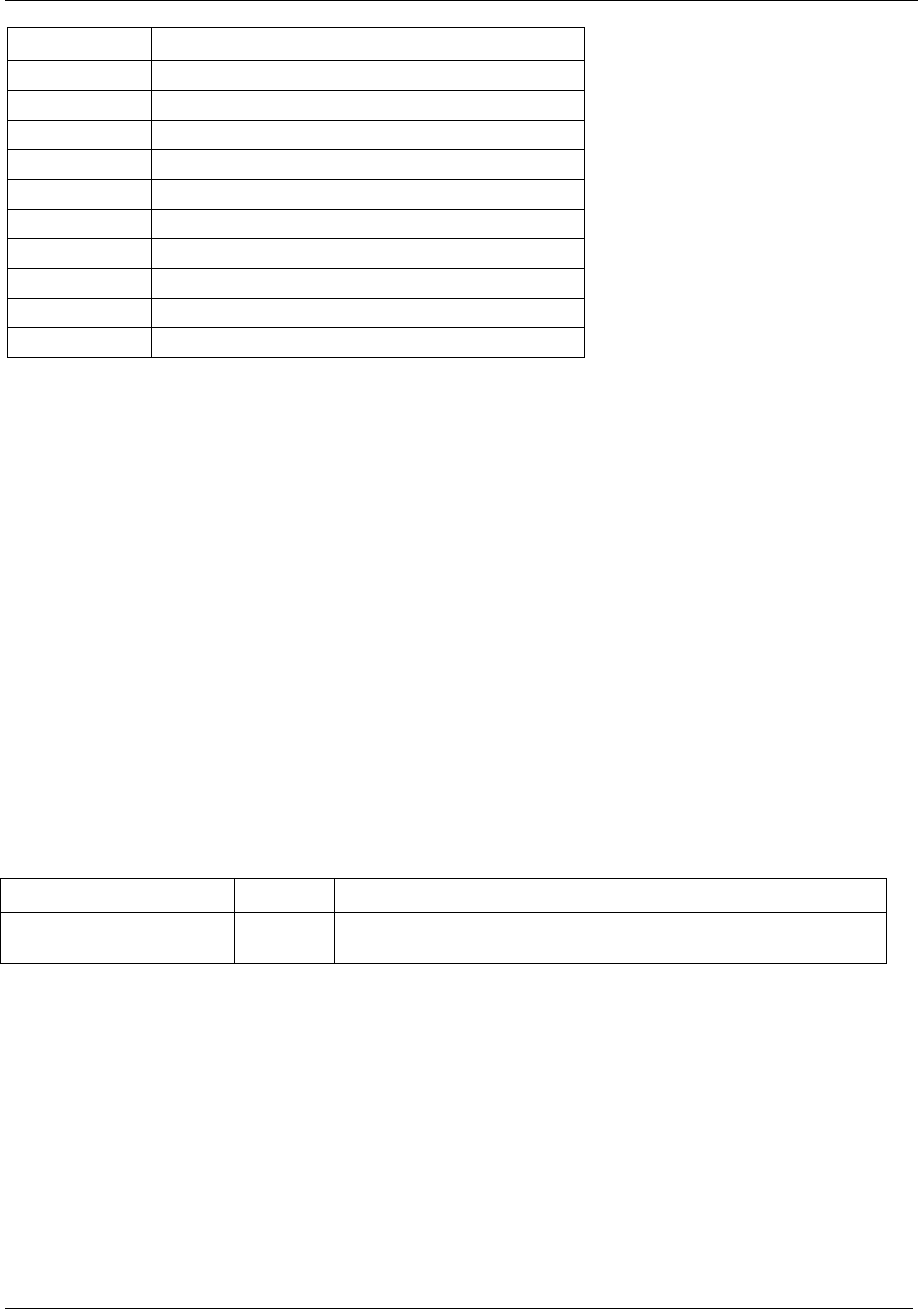

Contents

2 (285)

4.4 Programming control ......................................................................................... 63

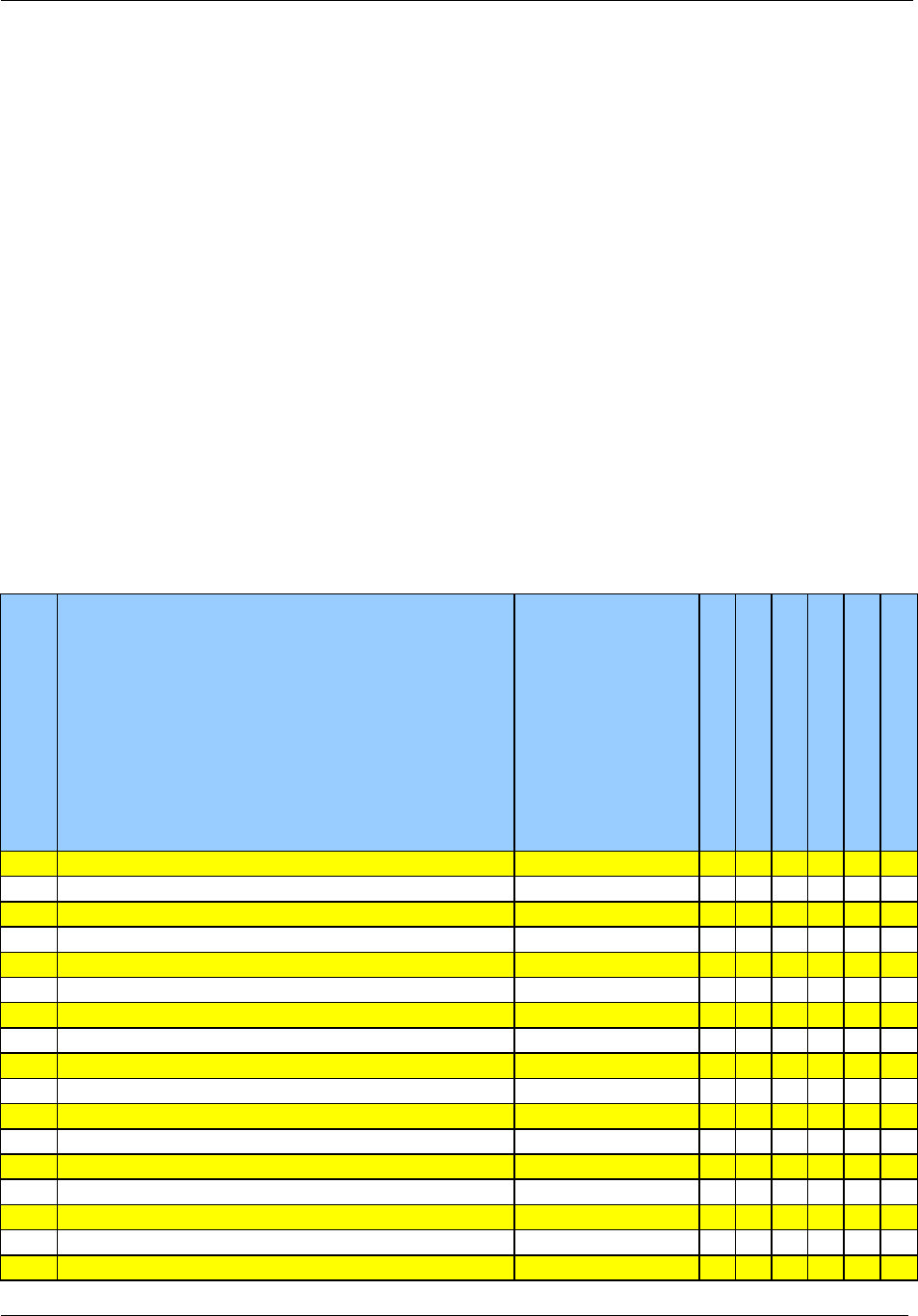

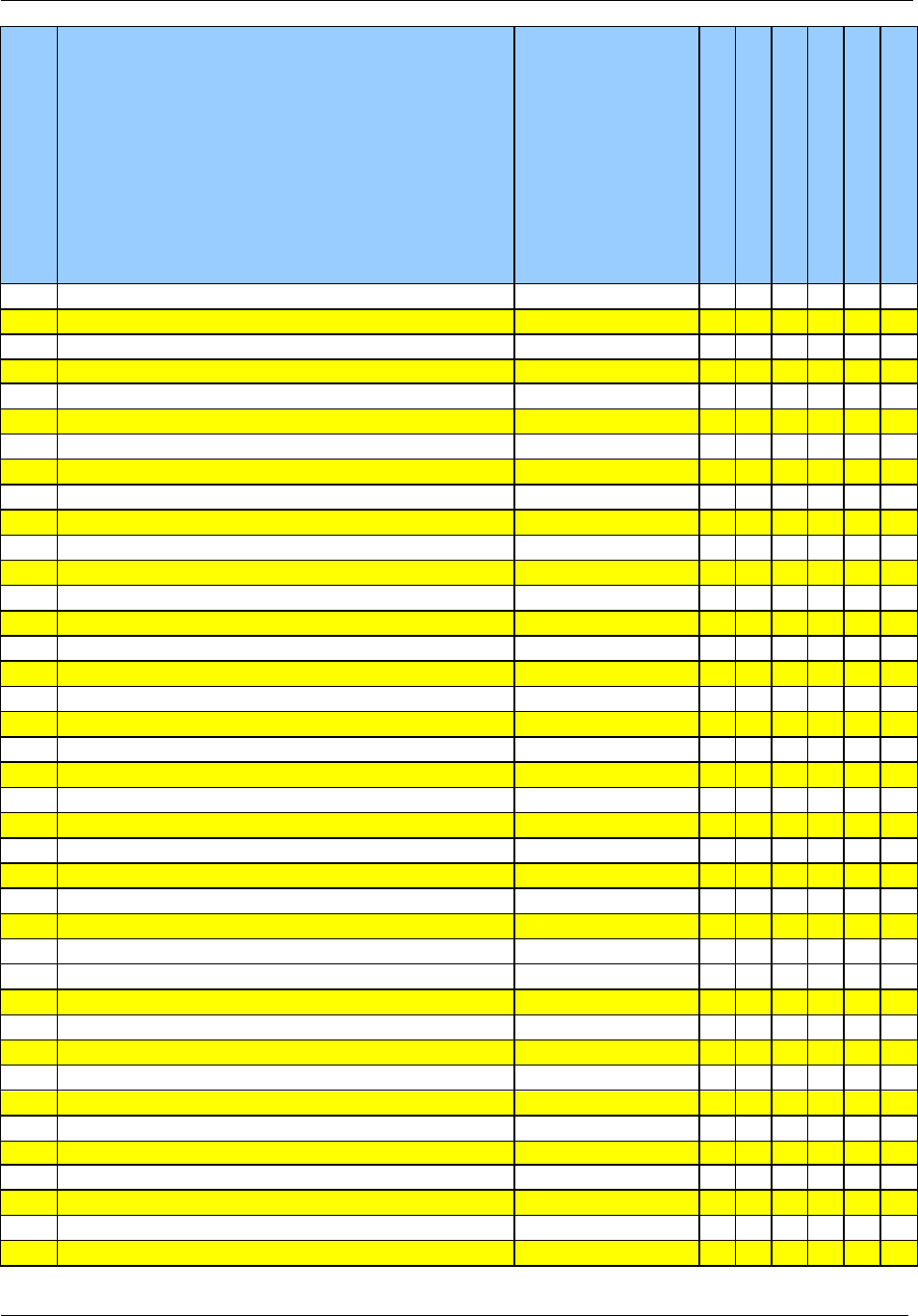

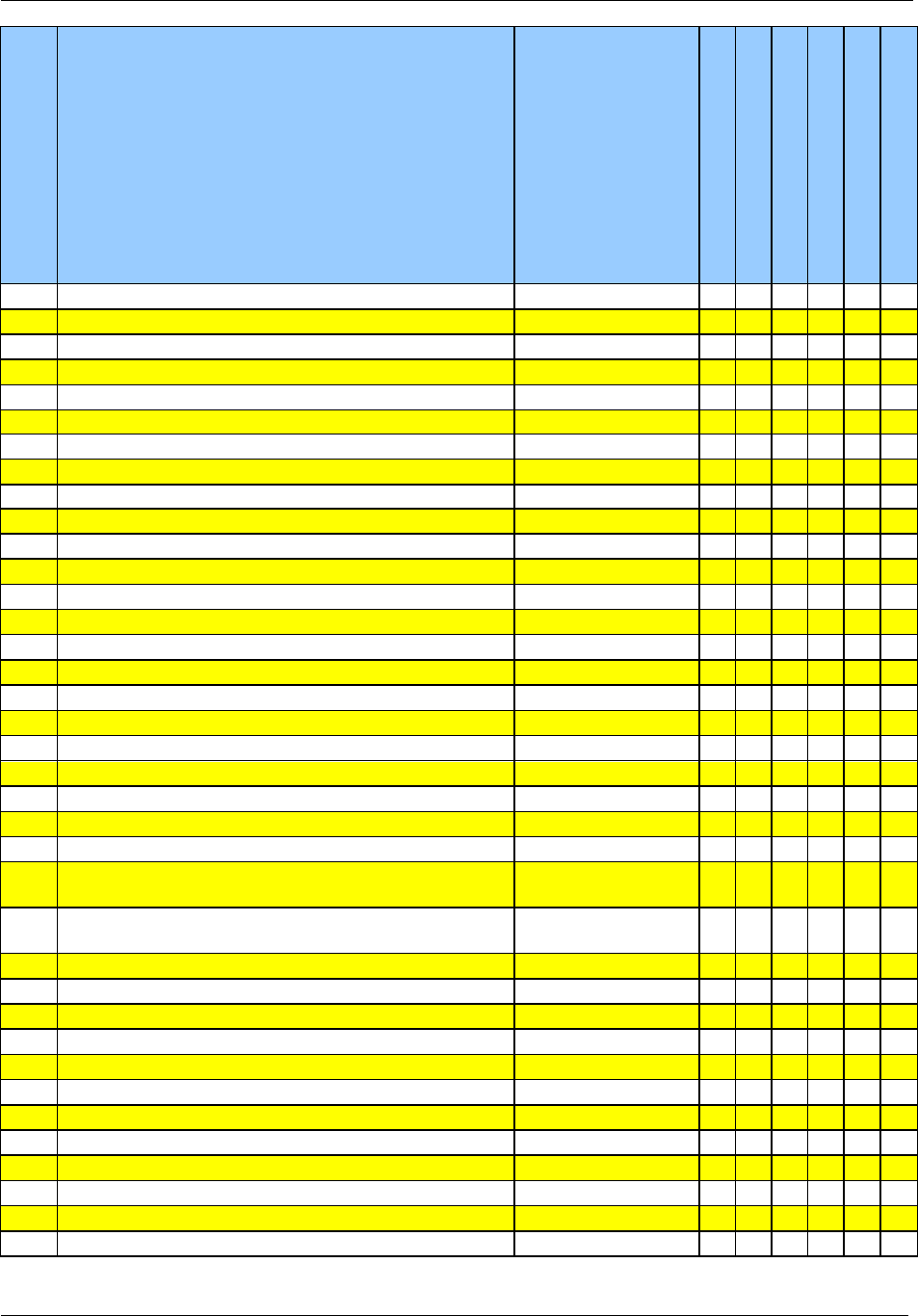

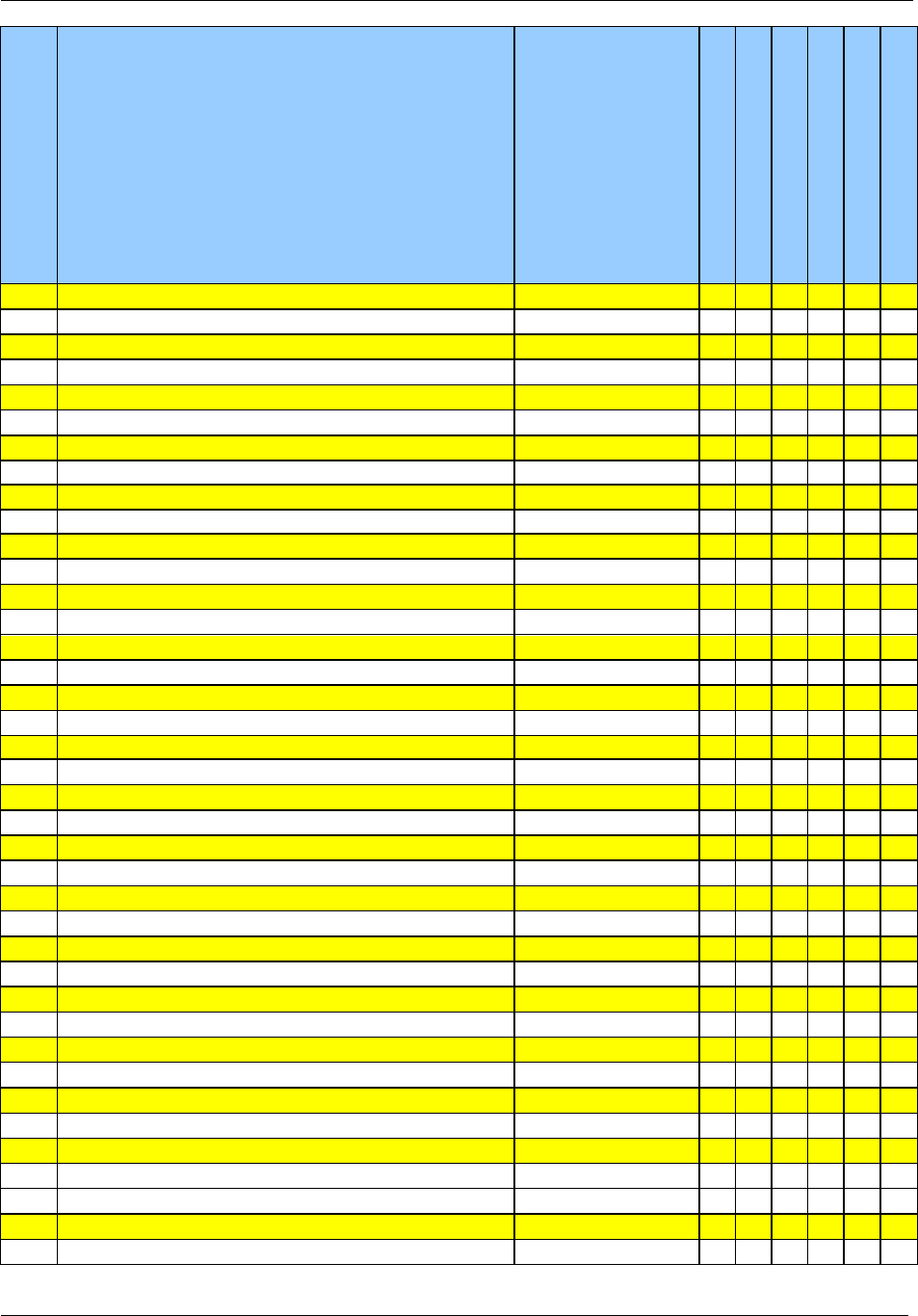

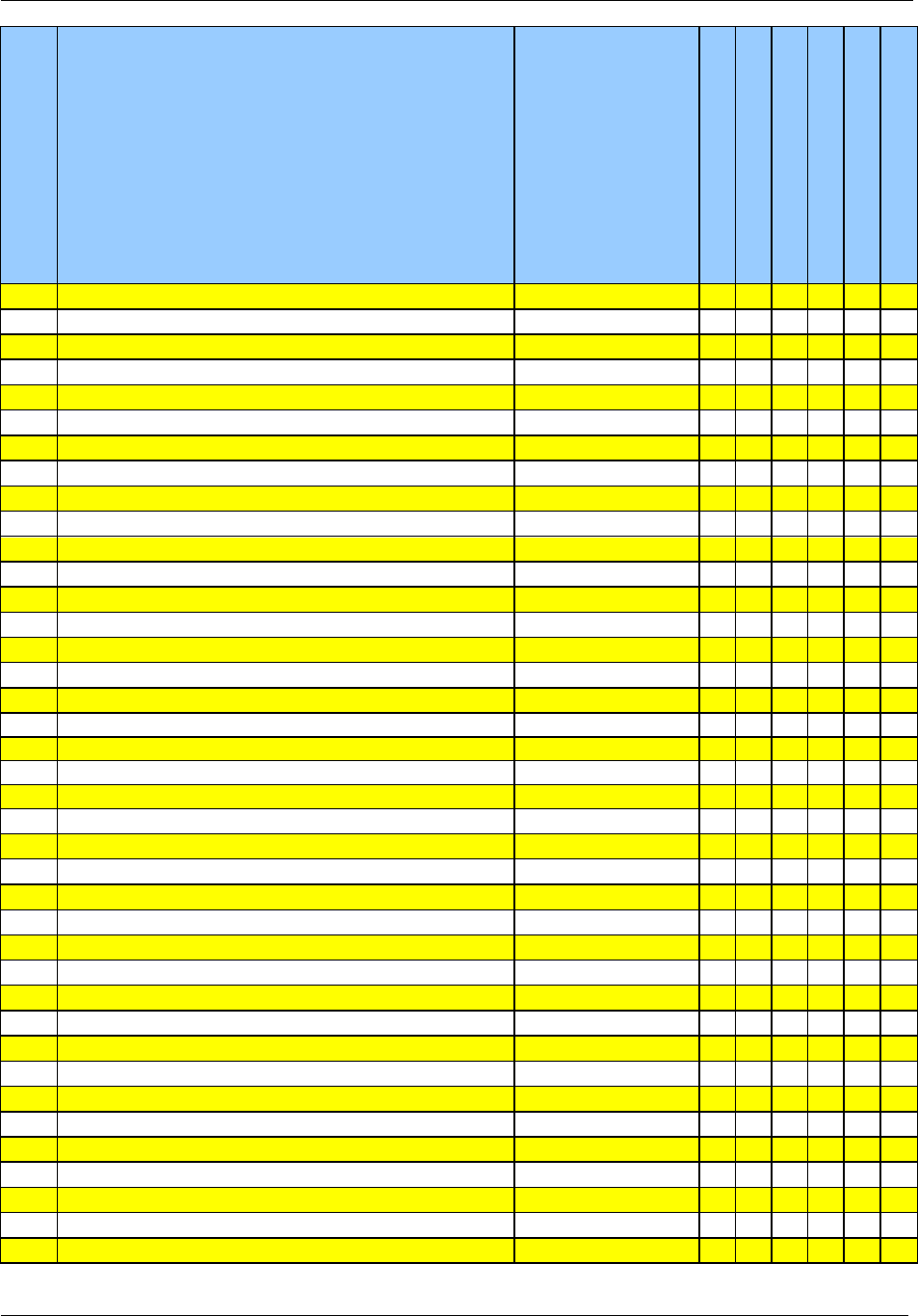

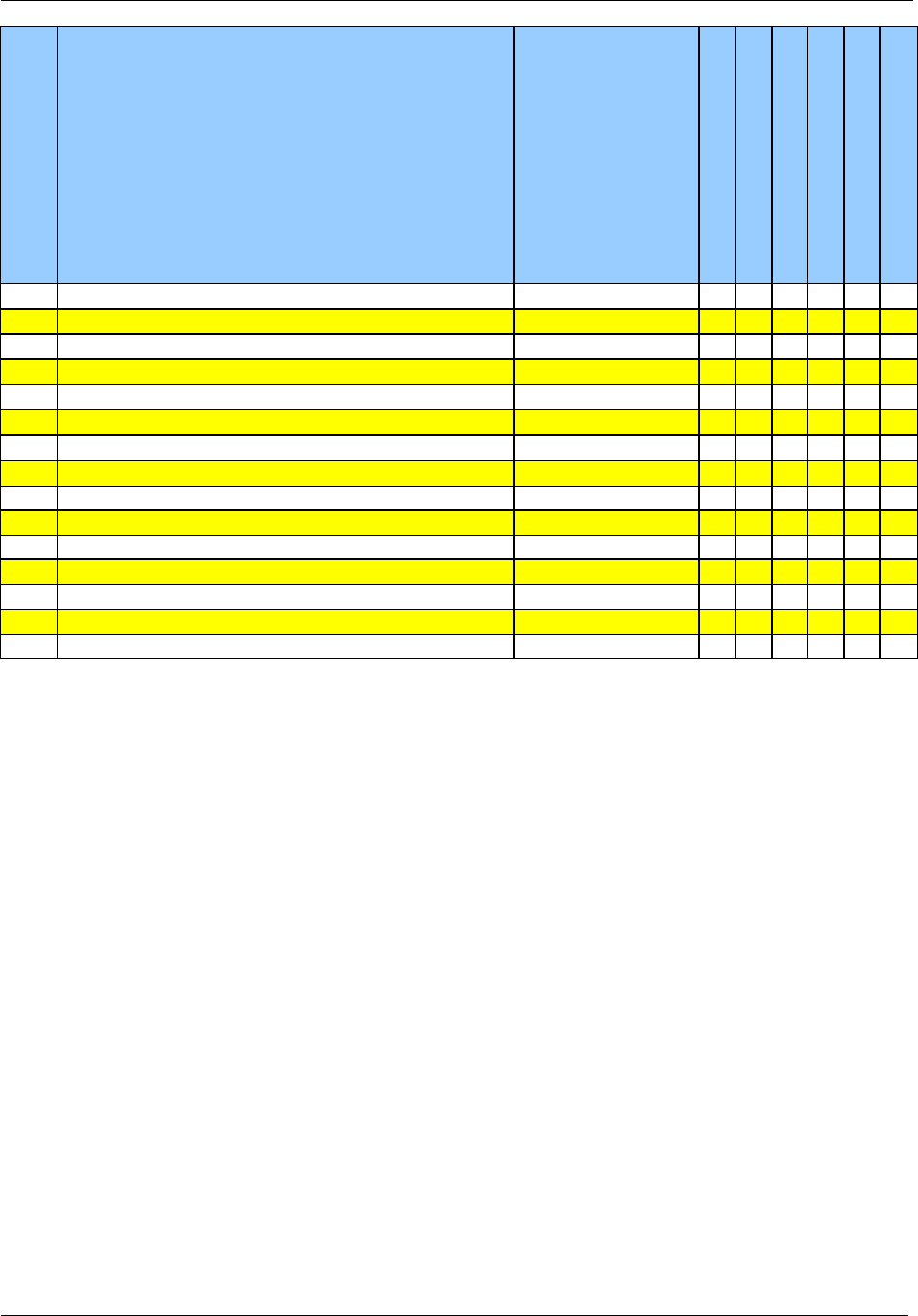

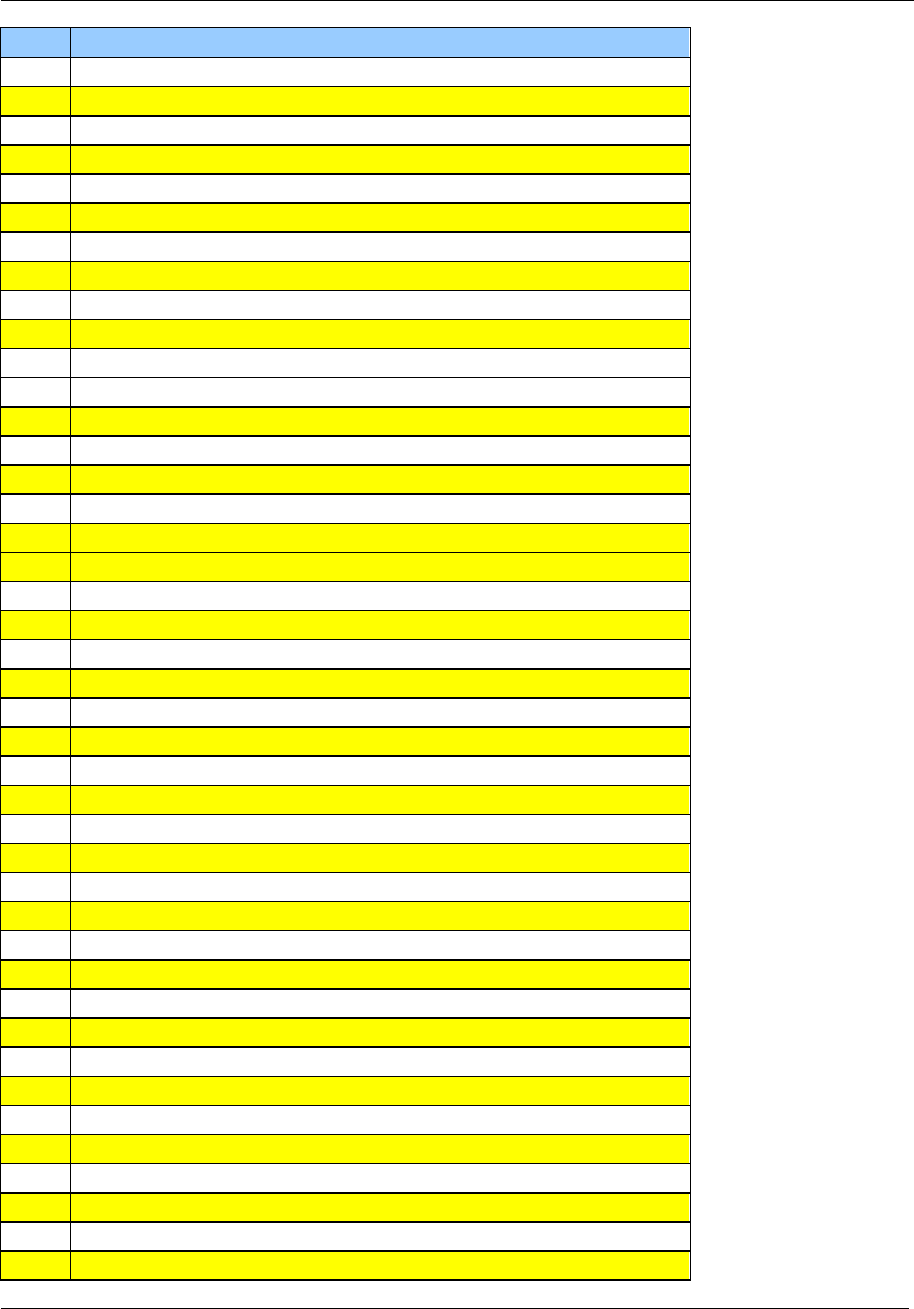

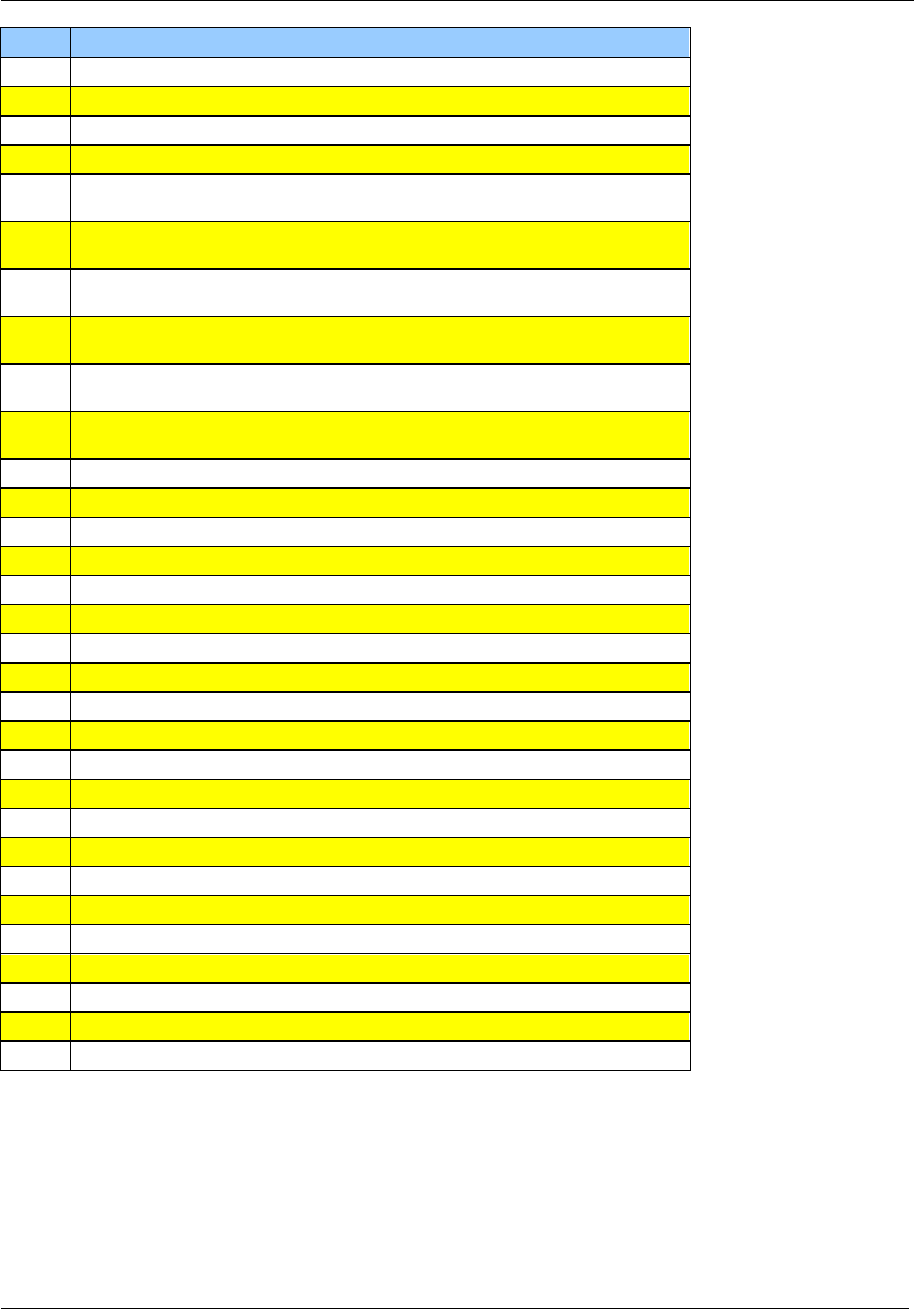

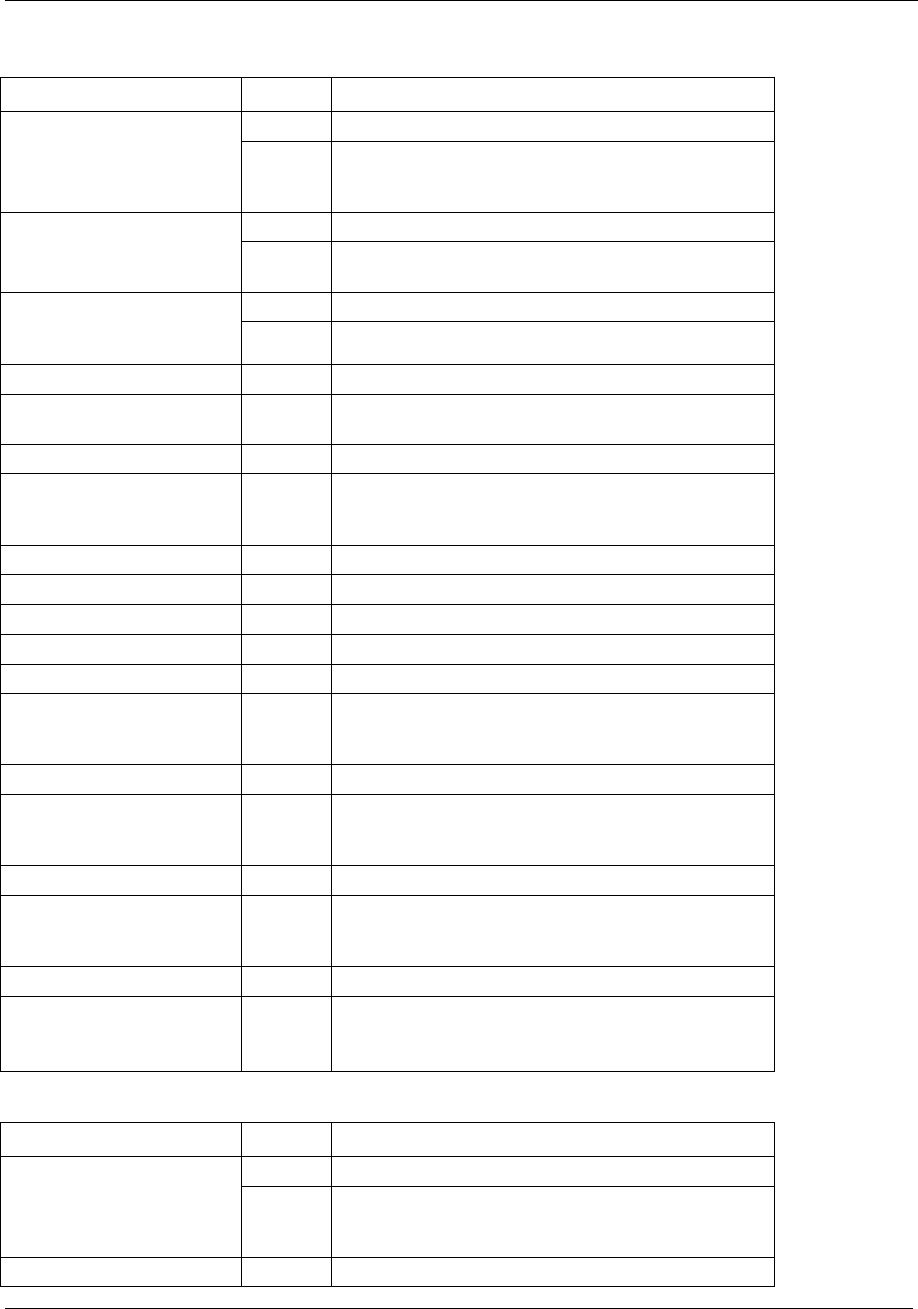

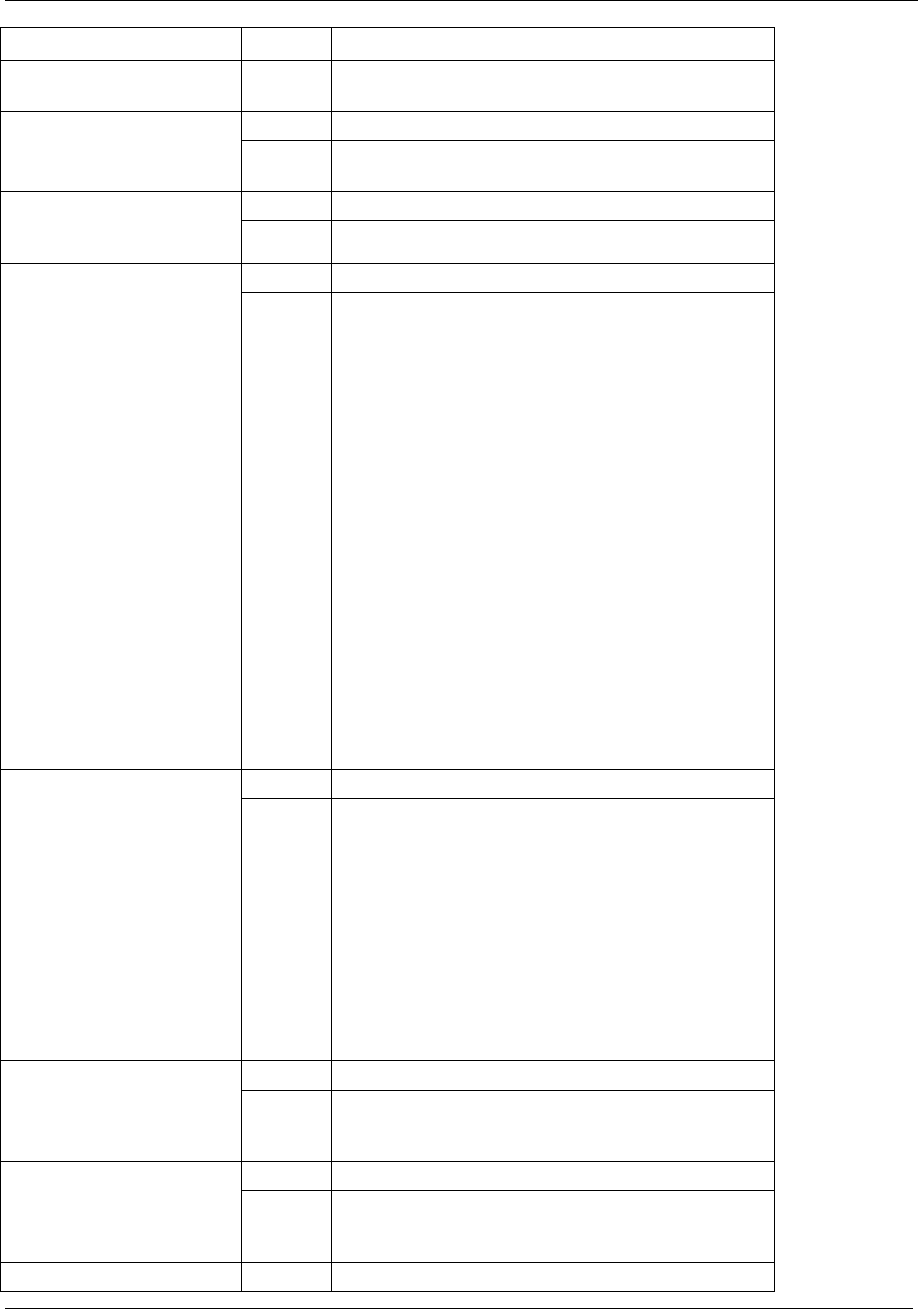

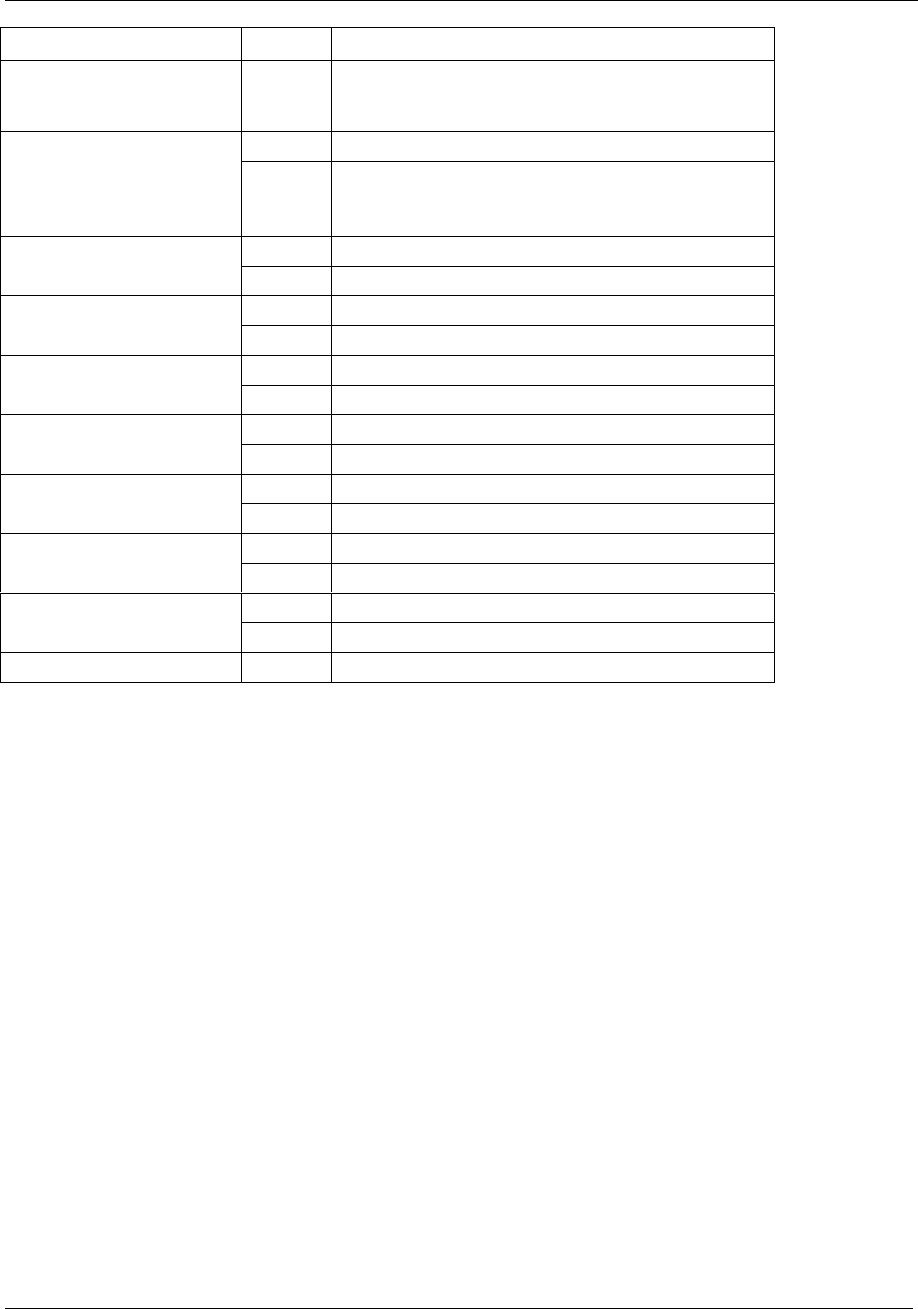

4.5 Message list ...................................................................................................... 63

4.6 Implemented Messages from the list ................................................................. 68

5 All messages .......................................................................................................... 69

5.1 Application Link Communication messages ...................................................... 69

5.1.1 MID 9998 Communication acknowledge error ....................................................................................... 69

5.1.2 MID 9997 Communication acknowledge ............................................................................................... 69

5.2 Application Communication messages .............................................................. 70

5.2.1 MID 0001 Application Communication start ........................................................................................... 70

5.2.2 MID 0002 Application Communication start acknowledge ..................................................................... 70

5.2.3 MID 0003 Application Communication stop ........................................................................................... 73

5.2.4 MID 0004 Application Communication negative acknowledge .............................................................. 74

5.2.5 MID 0005 Application Communication positive acknowledge ................................................................ 77

5.2.6 MID 0006 Application data message request ........................................................................................ 77

5.2.7 MID 0008 Application data message subscription ................................................................................. 79

5.2.8 MID 0009 Application Data Message unsubscribe ................................................................................ 80

5.3 Application Parameter Set Messages................................................................ 81

5.3.1 MID 0010 Parameter set ID upload request .......................................................................................... 81

5.3.2 MID 0011 Parameter set ID upload reply ............................................................................................... 82

5.3.3 MID 0012 Parameter set data upload request ....................................................................................... 82

5.3.4 MID 0013 Parameter set data upload reply ........................................................................................... 83

5.3.5 MID 0014 Parameter set selected subscribe ......................................................................................... 85

5.3.6 MID 0015 Parameter set selected ......................................................................................................... 86

5.3.7 MID 0016 Parameter set selected acknowledge.................................................................................... 88

5.3.8 MID 0017 Parameter set selected unsubscribe ..................................................................................... 88

5.3.9 MID 0018 Select Parameter set ............................................................................................................. 88

5.3.10 MID 2504 Select Parameter set, Dynamic Job Included ................................................................... 88

5.3.11 MID 2505 Select Parameter set dynamically. .................................................................................... 89

5.3.12 MID 0019 Set Parameter set batch size ............................................................................................ 90

5.3.13 MID 0020 Reset Parameter set batch counter .................................................................................. 91

5.3.14 MID 0021 Lock at batch done subscribe ........................................................................................... 91

5.3.15 MID 0023 Lock at batch done upload Acknowledge .......................................................................... 92

5.3.16 MID 0024 Lock at batch done unsubscribe ....................................................................................... 93

5.3.17 MID 0025 Parameter user set download request .............................................................................. 93

5.3.18 MID 2500 Tightening Program Message download ........................................................................... 94

5.3.19 MID 2501 Tightening Program Message Upload............................................................................. 102

5.4 Application Mode MIDs .................................................................................... 104

5.4.1 Functionality......................................................................................................................................... 104

5.4.2 MID 2600 Mode ID upload request ...................................................................................................... 106

5.4.3 MID 2601 Mode ID upload reply .......................................................................................................... 106

5.4.4 MID 2602 Mode data upload request ................................................................................................... 106

5.4.5 MID 2603 Mode data upload reply ....................................................................................................... 106

5.4.6 MID 2604 Mode selected ..................................................................................................................... 107

5.4.7 MID 2605 Mode selected acknowledge ............................................................................................... 108

5.4.8 MID 2606 Select Mode ........................................................................................................................ 108

5.5 Application Job messages ............................................................................... 109

5.5.1 MID 0030 Job ID upload request ......................................................................................................... 109

5.5.2 MID 0031 Job ID upload reply ............................................................................................................. 109

5.5.3 MID 0032 Job data upload request ...................................................................................................... 111

5.5.4 MID 0033 Job data upload reply .......................................................................................................... 112

5.5.5 MID 0034 Job info subscribe ............................................................................................................... 115

5.5.6 MID 0035 Job info ................................................................................................................................ 115

5.5.7 MID 0036 Job info acknowledge .......................................................................................................... 120

5.5.8 MID 0037 Job info unsubscribe ........................................................................................................... 120

5.5.9 MID 0038 Select Job ........................................................................................................................... 120

5.5.10 MID 0039 Job restart ....................................................................................................................... 120

5.6 Application Tool messages .............................................................................. 122

5.6.1 MID 0040 Tool data upload request ..................................................................................................... 122

5.6.2 MID 0041 Tool data upload reply ......................................................................................................... 122

Contents

3 (285)

5.6.3 MID 0042 Disable tool ......................................................................................................................... 125

5.6.4 MID 0043 Enable tool .......................................................................................................................... 125

5.6.5 MID 0044 Disconnect tool request ....................................................................................................... 126

5.6.6 MID 0045 Set calibration value request ............................................................................................... 126

5.6.7 MID 0046 Set primary tool request ...................................................................................................... 126

5.6.8 MID 0047 Tool Pairing handling........................................................................................................... 127

5.6.9 MID 0048 Tool Pairing status............................................................................................................... 128

5.6.10 MID 0700 Tightening data download status .................................................................................... 129

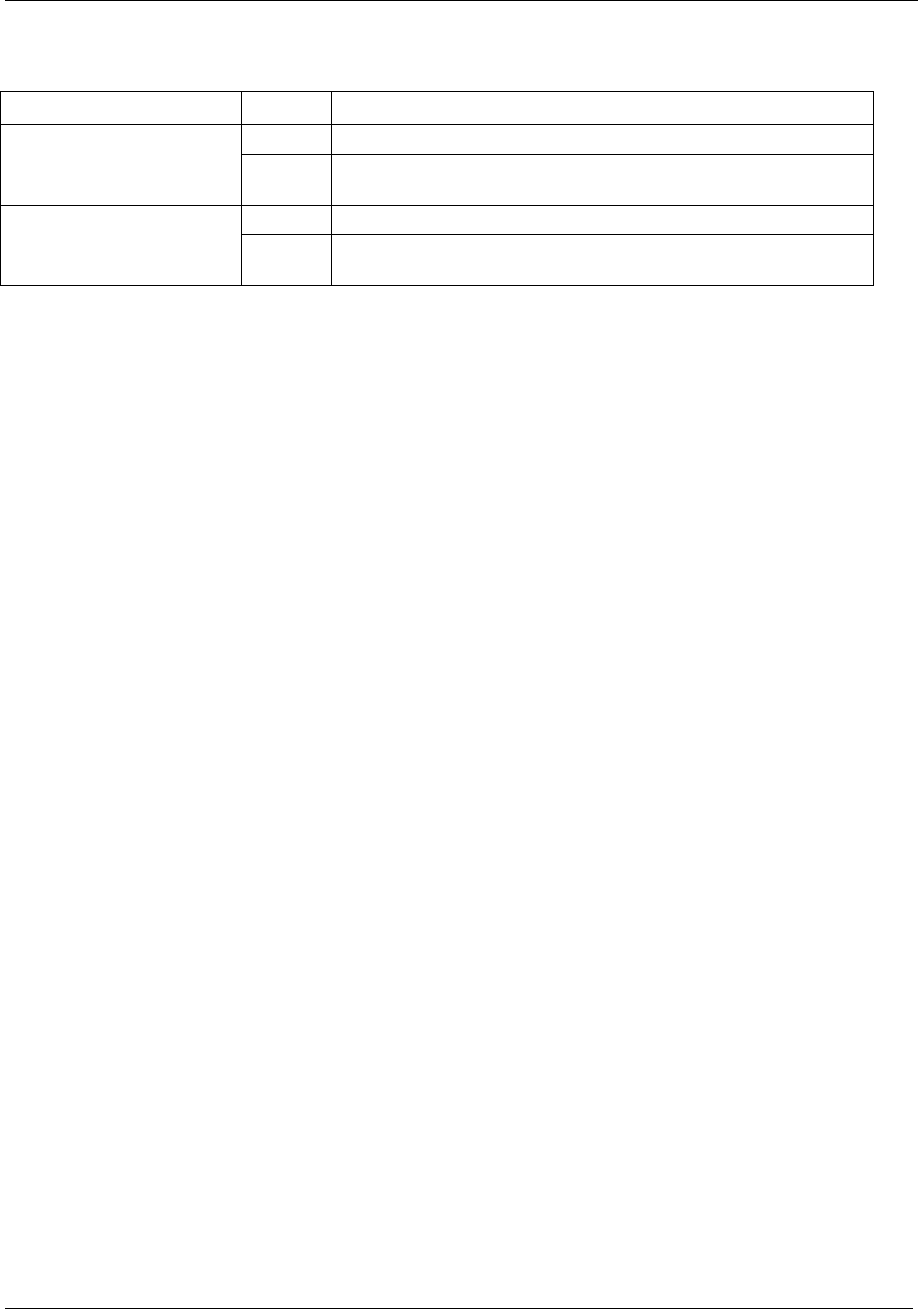

5.7 Application VIN Messages ............................................................................... 130

5.7.1 MID 0050 Vehicle ID Number download request ................................................................................. 130

5.7.2 MID 0051 Vehicle ID Number subscribe .............................................................................................. 130

5.7.3 MID 0052 Vehicle ID Number .............................................................................................................. 131

5.7.4 MID 0053 Vehicle ID Number acknowledge ........................................................................................ 132

5.7.5 MID 0054 Vehicle ID Number unsubscribe .......................................................................................... 132

5.8 Application Tightening result messages .......................................................... 133

5.8.1 MID 0060 Last tightening result data subscribe ................................................................................... 133

5.8.2 MID 0061 Last tightening result data ................................................................................................... 133

5.8.3 MID 0062 Last tightening result data acknowledge ............................................................................. 145

5.8.4 MID 0063 Last tightening result data unsubscribe ............................................................................... 145

5.8.5 MID 0064 Old tightening result upload request .................................................................................... 146

5.8.6 MID 0065 Old tightening result upload reply ........................................................................................ 146

5.9 Application result messages with variables ..................................................... 153

5.9.1 MID 1201 Operation result Overall data .............................................................................................. 154

5.9.2 MID 1202 Operation result object data ................................................................................................ 157

5.9.3 MID 1203 Operation result data acknowledge ..................................................................................... 158

5.9.4 Examples ............................................................................................................................................. 159

5.10 Application Alarm messages ........................................................................ 163

5.10.1 MID 0070 Alarm subscribe .............................................................................................................. 163

5.10.2 MID 0071 Alarm .............................................................................................................................. 163

5.10.3 MID 0072 Alarm acknowledge......................................................................................................... 165

5.10.4 MID 0073 Alarm unsubscribe .......................................................................................................... 165

5.10.5 MID 0074 Alarm acknowledged on controller .................................................................................. 166

5.10.6 MID 0075 Alarm acknowledged on controller acknowledge ............................................................ 166

5.10.7 MID 0076 Alarm status .................................................................................................................... 166

5.10.8 MID 0077 Alarm status acknowledge .............................................................................................. 167

5.10.9 MID 0078 Acknowledge alarm remotely on controller ..................................................................... 168

5.11 Application Time messages ......................................................................... 169

5.11.1 MID 0080 Read time upload request ............................................................................................... 169

5.11.2 MID 0081 Read time upload reply ................................................................................................... 169

5.11.3 MID 0082 Set Time ......................................................................................................................... 169

5.12 Application Multi-spindle status messages ................................................... 170

5.12.1 MID 0090 Multi-spindle status subscribe ......................................................................................... 170

5.12.2 MID 0091 Multi-spindle status ......................................................................................................... 170

5.12.3 MID 0092 Multi-spindle status acknowledge ................................................................................... 172

5.12.4 MID 0093 Multi-spindle status unsubscribe ..................................................................................... 172

5.12.5 Application Multi-spindle result messages ....................................................................................... 172

5.12.6 MID 0100 Multi-spindle result subscribe .......................................................................................... 172

5.12.7 MID 0101 Multi-spindle result .......................................................................................................... 173

5.12.8 MID 0102 Multi-spindle result acknowledge .................................................................................... 179

5.12.9 MID 0103 Multi spindle result unsubscribe ...................................................................................... 179

5.13 Application PowerMACS result data ............................................................ 180

5.13.1 MID 0105 Last PowerMACS tightening result data subscribe ......................................................... 180

5.13.2 MID 0106 Last PowerMACS tightening result Station data ............................................................. 181

5.13.3 MID 0107 Last Power MACS tightening result Bolt data ................................................................. 187

5.13.4 MID 0108 Last Power MACS tightening result data acknowledge ................................................... 195

5.13.5 MID 0109 Last Power MACS tightening result data unsubscribe .................................................... 195

5.14 Application User interface messages ........................................................... 196

5.14.1 MID 0110 Display user text on compact .......................................................................................... 196

5.14.2 MID 0111 Display user text on graph .............................................................................................. 196

5.14.3 MID 0113 Flash green light on tool .................................................................................................. 197

Contents

4 (285)

5.15 Application Job messages, advanced .......................................................... 198

5.15.1 MID 0120 Job line control info subscribe ......................................................................................... 198

5.15.2 MID 0121 Job line control started .................................................................................................... 198

5.15.3 MID 0122 Job line control alert 1 ..................................................................................................... 198

5.15.4 MID 0123 Job line control alert 2 ..................................................................................................... 198

5.15.5 MID 0124 Job line control done ....................................................................................................... 199

5.15.6 MID 0125 Job line control info acknowledge ................................................................................... 200

5.15.7 MID 0126 Job line control info unsubscribe ..................................................................................... 200

5.15.8 MID 0127 Abort Job ........................................................................................................................ 200

5.15.9 MID 0128 Job batch increment ........................................................................................................ 200

5.15.10 MID 0129 Job batch decrement ...................................................................................................... 201

5.15.11 MID 0130 Job off ............................................................................................................................. 202

5.15.12 MID 0131 Set Job line control start ................................................................................................. 202

5.15.13 MID 0132 Set Job line alert 1 .......................................................................................................... 203

5.15.14 MID 0133 Set Job line alert 2 .......................................................................................................... 203

5.15.15 MID 0140 Execute dynamic Job request ......................................................................................... 203

5.16 Application Multiple identifiers messages ..................................................... 207

5.16.1 MID 0150 Identifier download request ............................................................................................. 207

5.16.2 MID 0151 Multiple identifier and result parts subscribe ................................................................... 207

5.16.3 MID 0152 Multiple identifier and result parts ................................................................................... 207

5.16.4 MID 0153 Multiple identifiers and result parts acknowledge ............................................................ 208

5.16.5 MID 0154 Multiple identifier and result parts unsubscribe ............................................................... 208

5.16.6 MID 0155 Bypass Identifier ............................................................................................................. 209

5.16.7 MID 0156 reset latest Identifier ........................................................................................................ 209

5.16.8 MID 0157 reset all Identifiers ........................................................................................................... 209

5.17 Application I/O Interface ............................................................................... 210

5.17.1 MID 0200 Set externally controlled relays ....................................................................................... 210

5.17.2 MID 0210 Status externally monitored inputs subscribe .................................................................. 211

5.17.3 MID 0211 Status externally monitored inputs .................................................................................. 212

5.17.4 MID 0212 Status externally monitored inputs acknowledge ............................................................ 212

5.17.5 MID 0213 Status externally monitored inputs unsubscribe .............................................................. 212

5.17.6 MID 0214 IO device status request ................................................................................................. 213

5.17.7 MID 0215 IO device status reply ..................................................................................................... 213

5.17.8 MID 0216 Relay function subscribe ................................................................................................. 224

5.17.9 MID 0217 Relay function ................................................................................................................. 224

5.17.10 MID 0218 Relay function acknowledge ........................................................................................... 225

5.17.11 MID 0219 Relay function unsubscribe ............................................................................................. 226

5.17.12 MID 0220 Digital input function subscribe ....................................................................................... 226

5.17.13 MID 0221 Digital input function ........................................................................................................ 226

5.17.14 MID 0222 Digital input function acknowledge .................................................................................. 228

5.17.15 MID 0223 Digital input function unsubscribe ................................................................................... 228

5.17.16 MID 0224 Set digital input function .................................................................................................. 229

5.17.17 MID 0225 Reset digital input function .............................................................................................. 229

5.18 Application PLC user data messages .......................................................... 230

5.18.1 MID 0240 User data download ........................................................................................................ 231

5.18.2 MID 0241 User data subscribe ........................................................................................................ 232

5.18.3 MID 0242 User data ........................................................................................................................ 232

5.18.4 MID 0243 User data acknowledge .................................................................................................. 233

5.18.5 MID 0244 User data unsubscribe .................................................................................................... 233

5.18.6 MID 0245 User data download with offset ....................................................................................... 233

5.19 Application Selector messages .................................................................... 235

5.19.1 MID 0250 Selector socket info subscribe ........................................................................................ 235

5.19.2 MID 0251 Selector socket info......................................................................................................... 235

5.19.3 MID 0252 Selector socket info acknowledge ................................................................................... 235

5.19.4 MID 0253 Selector socket info unsubscribe .................................................................................... 236

5.19.5 MID 0254 Selector control green lights ........................................................................................... 236

5.19.6 MID 0255 Selector control red lights ............................................................................................... 237

5.19.7 MID 1900 Selector socket info......................................................................................................... 238

5.19.8 MID 1901 Selector socket control .................................................................................................... 240

5.20 Application Tool Location System messages ............................................... 242

Contents

5 (285)

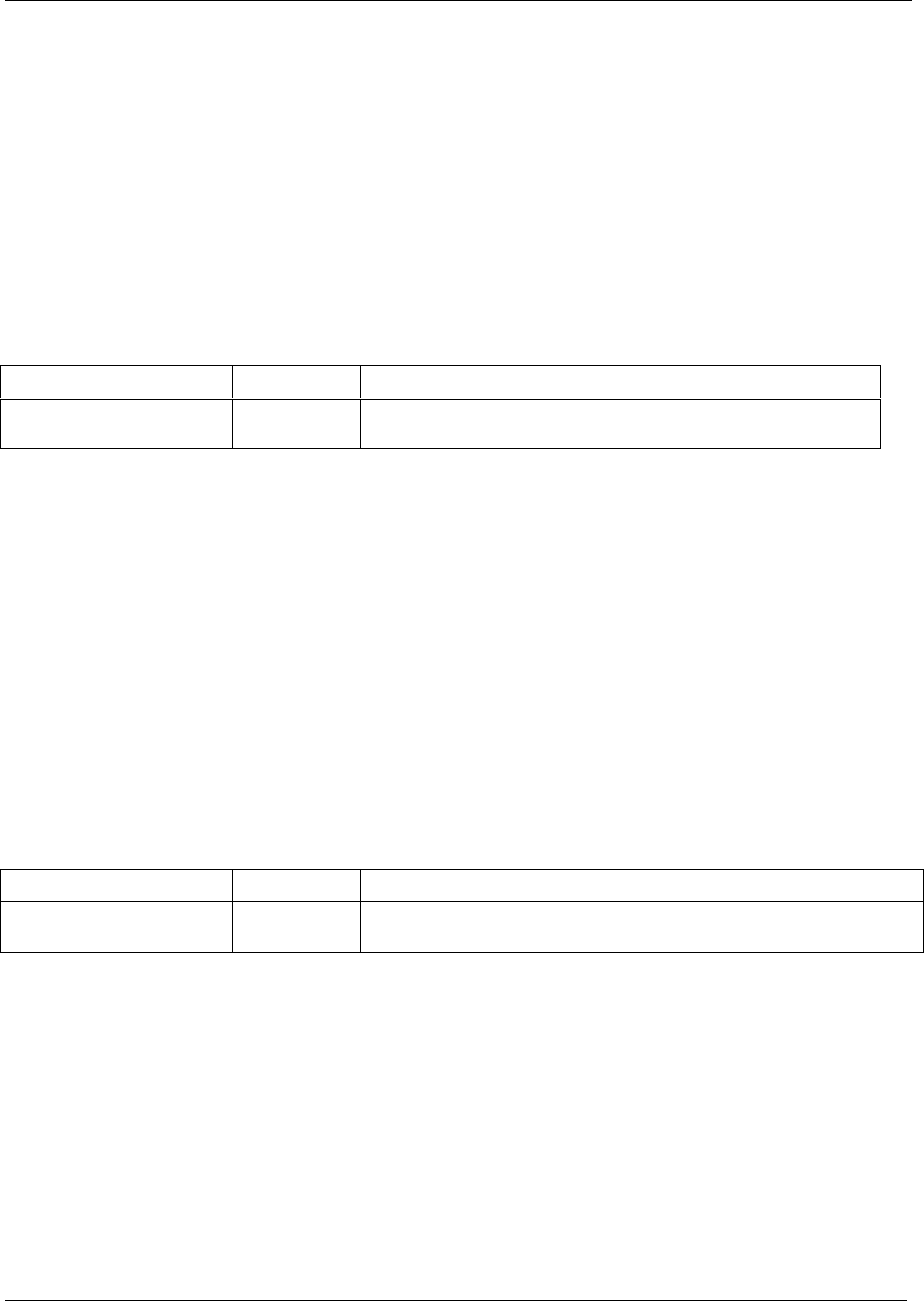

5.20.1 MID 0260 Tool tag ID request ......................................................................................................... 242

5.20.2 MID 0261 Tool tag ID subscribe ...................................................................................................... 242

5.20.3 MID 0262 Tool tag ID ...................................................................................................................... 242

5.20.4 MID 0263 Tool tag ID acknowledge ................................................................................................ 243

5.20.5 MID 0264 Tool tag ID unsubscribe .................................................................................................. 243

5.20.6 MID 0265 External Tool tag ID and status ....................................................................................... 244

5.21 Application Controller messages .................................................................. 245

5.21.1 MID 0270 Controller reboot request ................................................................................................ 245

5.21.2 MID 2100 Device command. ........................................................................................................... 245

5.22 Statistic messages ....................................................................................... 247

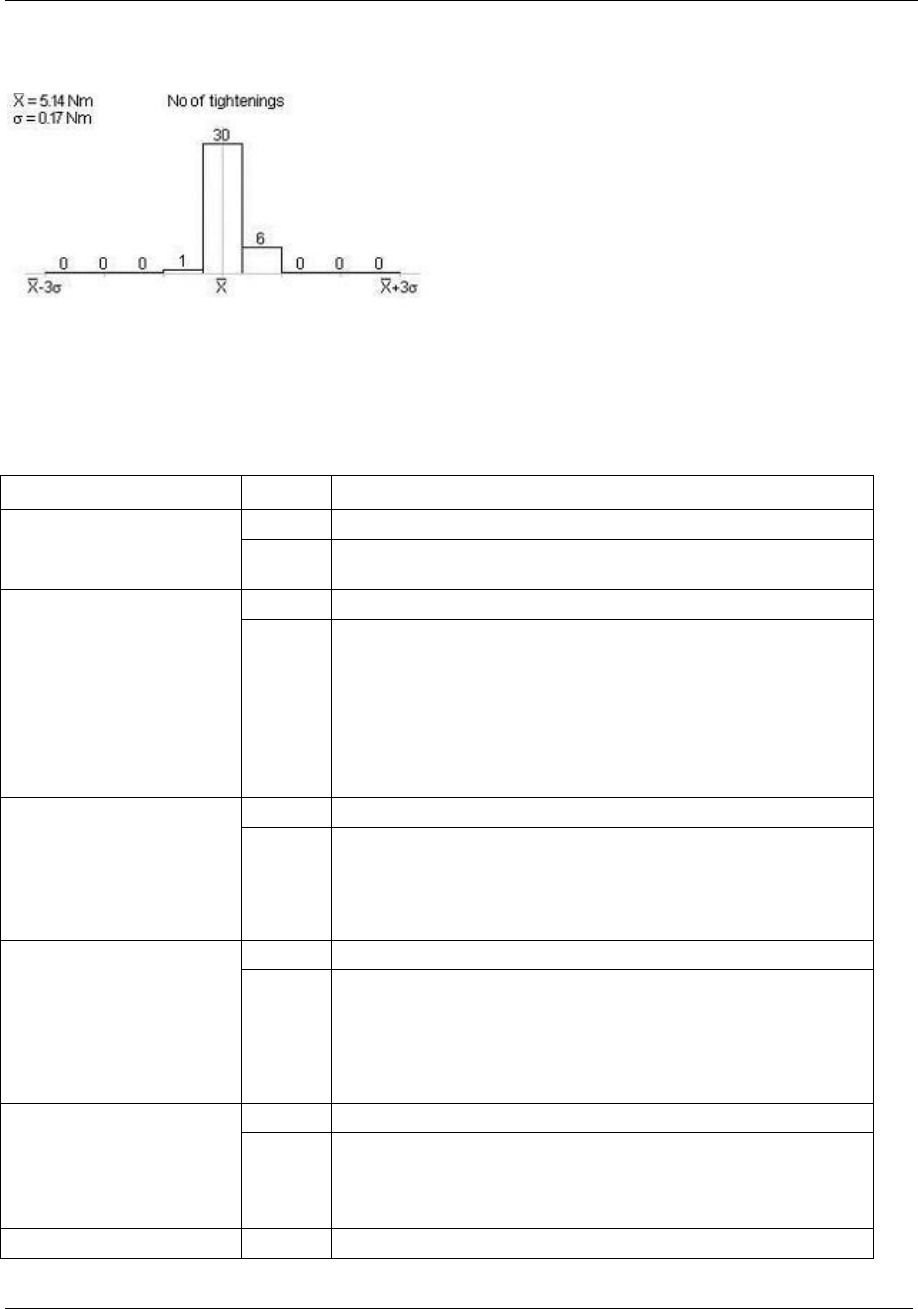

5.22.1 MID 0300 Histogram upload request ............................................................................................... 247

5.22.2 MID 0301 Histogram upload reply ................................................................................................... 247

5.23 Application Automatic/Manual mode messages ........................................... 250

5.23.1 MID 0400 Automatic/Manual mode subscribe ................................................................................. 250

5.23.2 MID 0401 Automatic/Manual mode ................................................................................................. 250

5.23.3 MID 0402 Automatic/Manual mode acknowledge ........................................................................... 250

5.23.4 MID 0403 Automatic/Manual mode unsubscribe ............................................................................. 251

5.23.5 MID 0410 AutoDisable settings request .......................................................................................... 251

5.23.6 MID 0411 AutoDisable settings reply .............................................................................................. 251

5.24 Application Open Protocol Commands Disabled .......................................... 253

5.24.1 MID 0420 Open Protocol commands disabled subscribe ................................................................ 253

5.24.2 MID 0421 Open Protocol commands disabled ................................................................................ 253

5.24.3 MID 0422 Open Protocol commands disabled acknowledge .......................................................... 254

5.24.4 MID 0423 Open Protocol commands disabled unsubscribe ............................................................ 254

5.25 Application MID 8000, MID 8001 .................................................................. 255

5.26 Application Motor tuning ............................................................................... 255

5.26.1 MID 0500 Motor tuning result data subscribe .................................................................................. 255

5.26.2 MID 0501 Motor tuning result data .................................................................................................. 255

5.26.3 MID 0502 Motor tuning result data acknowledge ............................................................................ 255

5.26.4 MID 0503 Motor tuning result data unsubscribe .............................................................................. 256

5.26.5 MID 0504 Motor tuning request ....................................................................................................... 256

5.27 Application Tightening result messages ....................................................... 257

5.27.1 MID 0900 Trace curve data message ............................................................................................. 257

5.27.2 MID 0901 Traces Plot Parameters Message ................................................................................... 263

5.28 Application Keep alive message .................................................................. 265

5.28.1 MID 9999 Keep alive message ........................................................................................................ 265

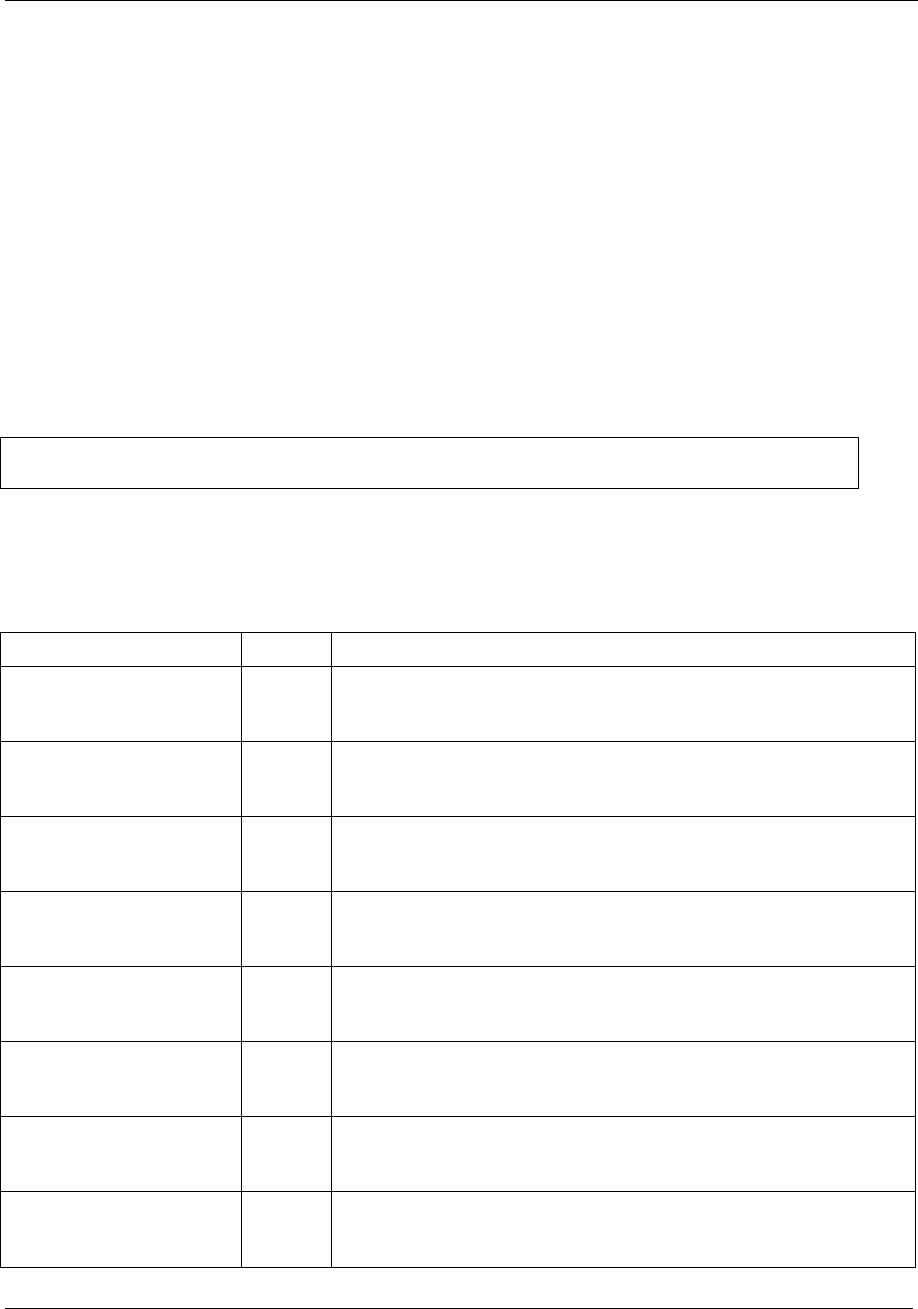

6 Unit /Parameter ID/Data Type definitions ........................................................... 266

6.1 Data Type definitions ....................................................................................... 266

6.2 Trace Plotting type figures definitions .............................................................. 267

6.3 Unit types definitions ....................................................................................... 267

6.4 Parameter ID numbers .................................................................................... 270

6.5 Systems Unique Parameter ID number series ................................................ 283

Contents

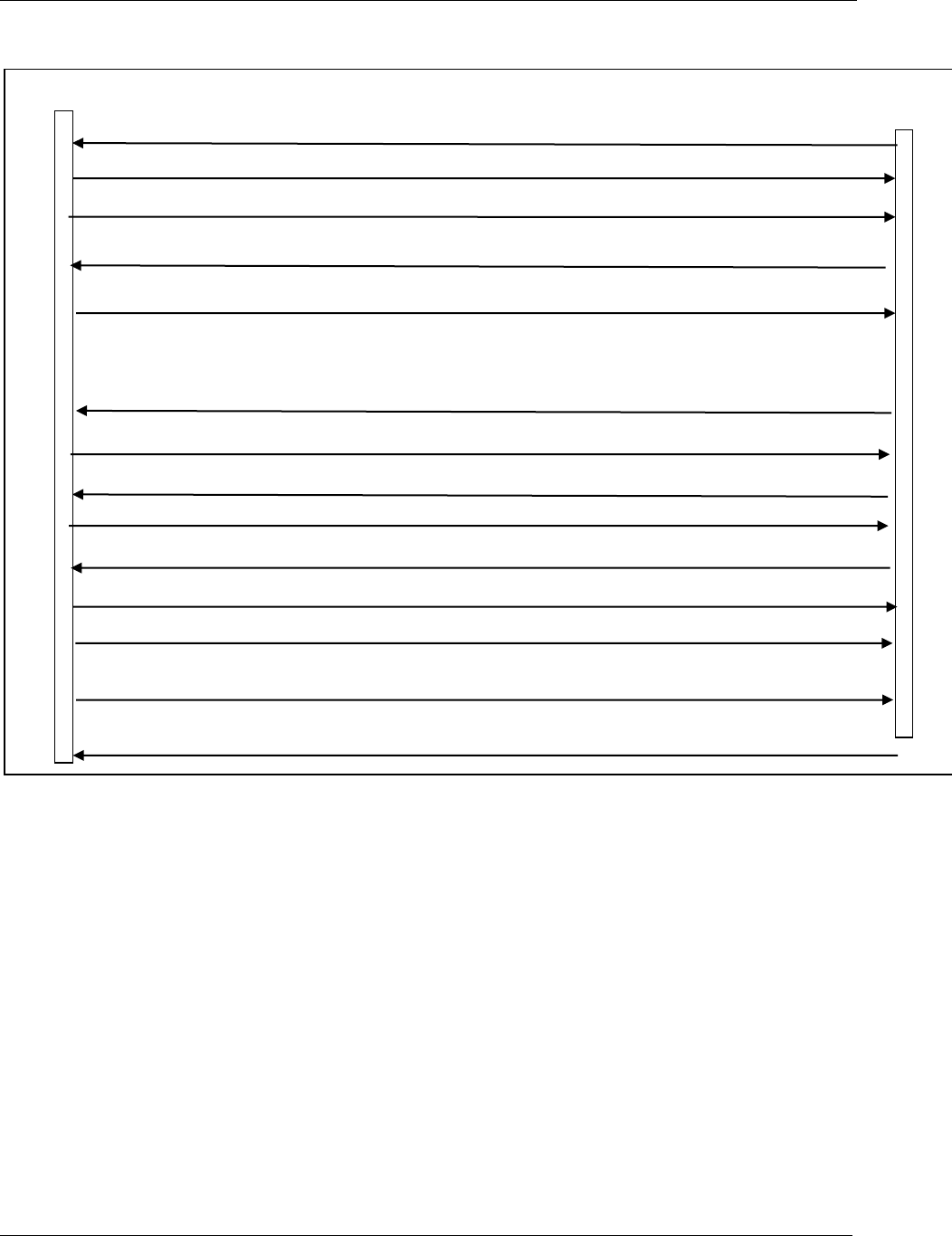

6 (285)

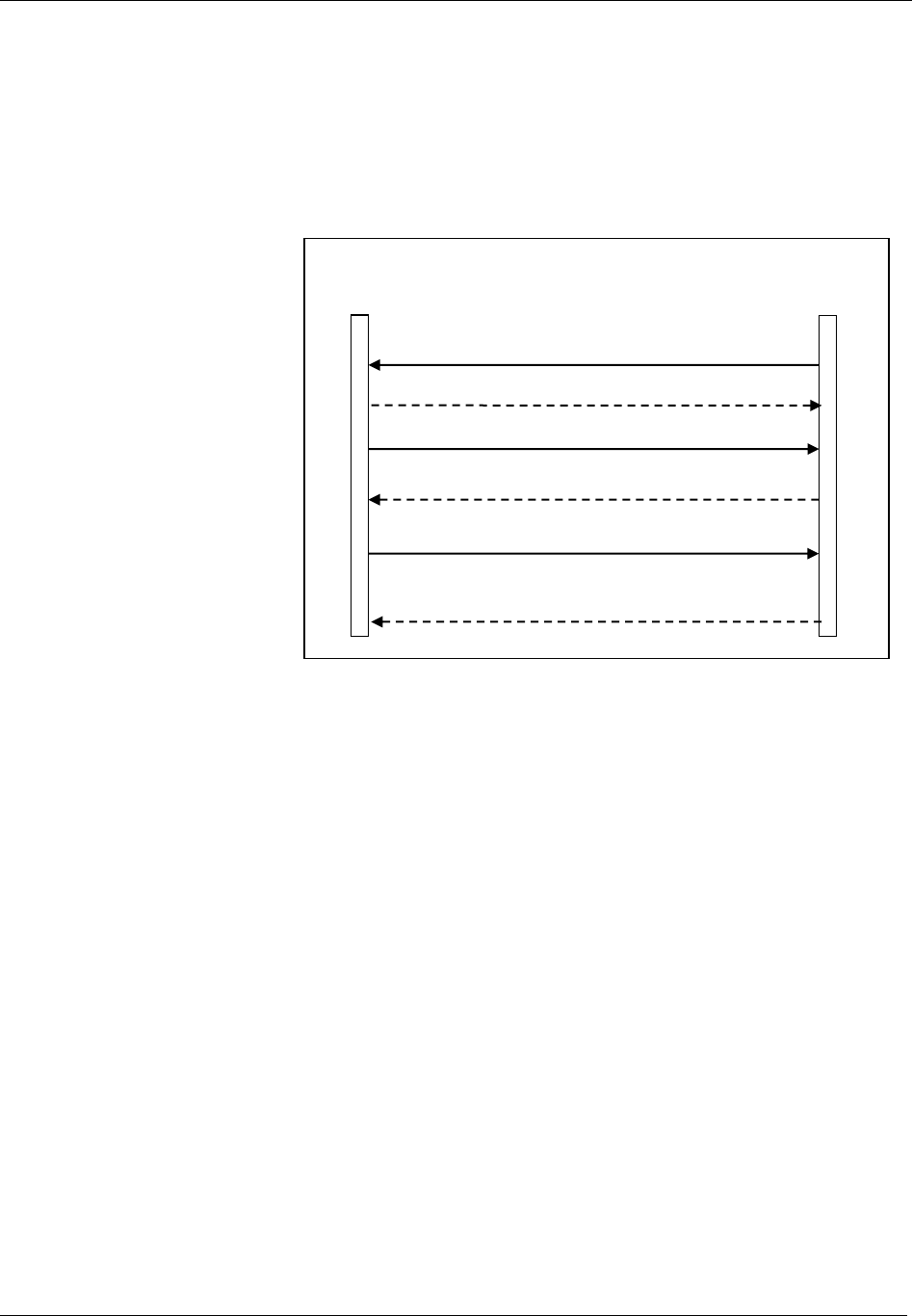

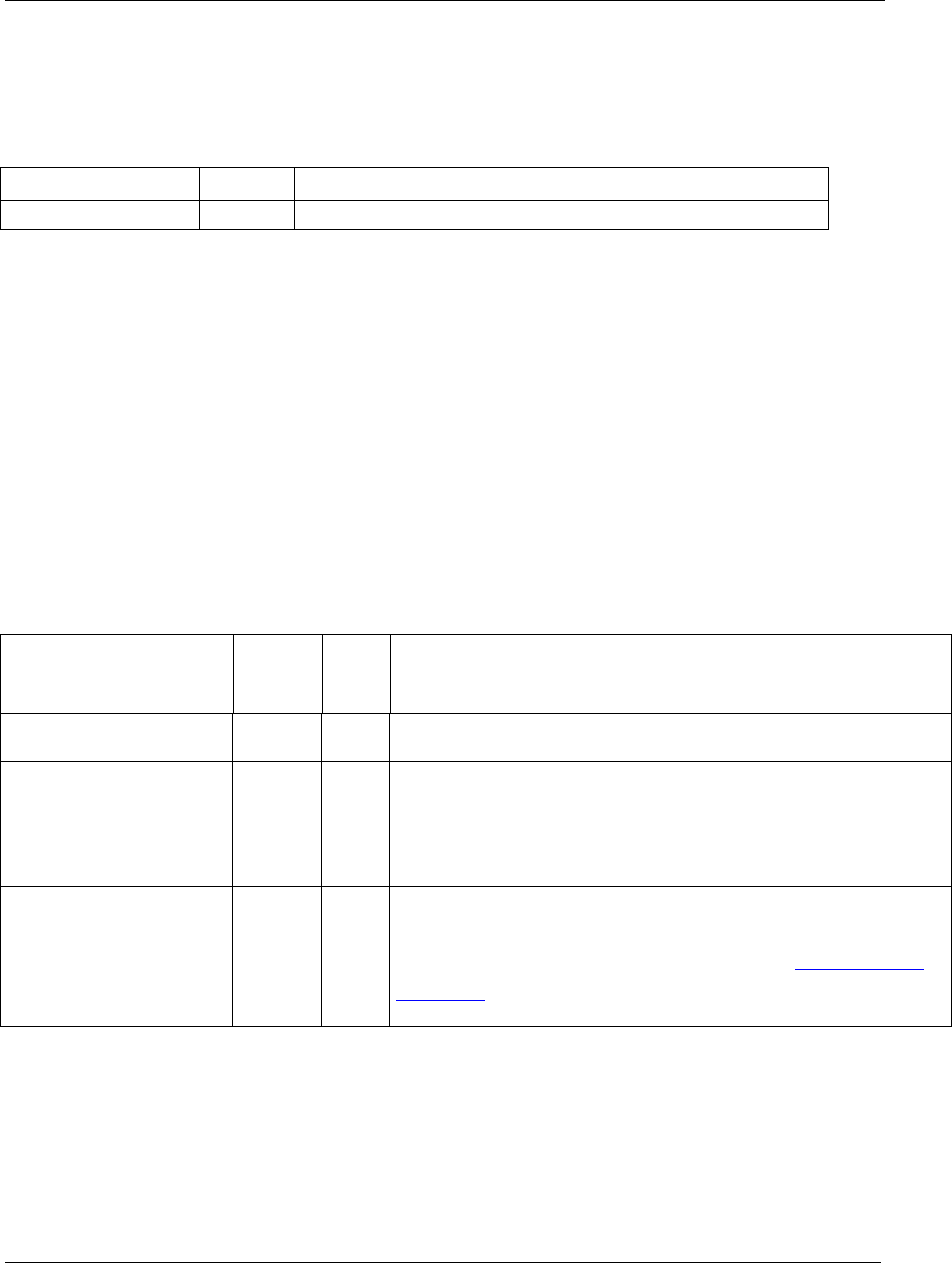

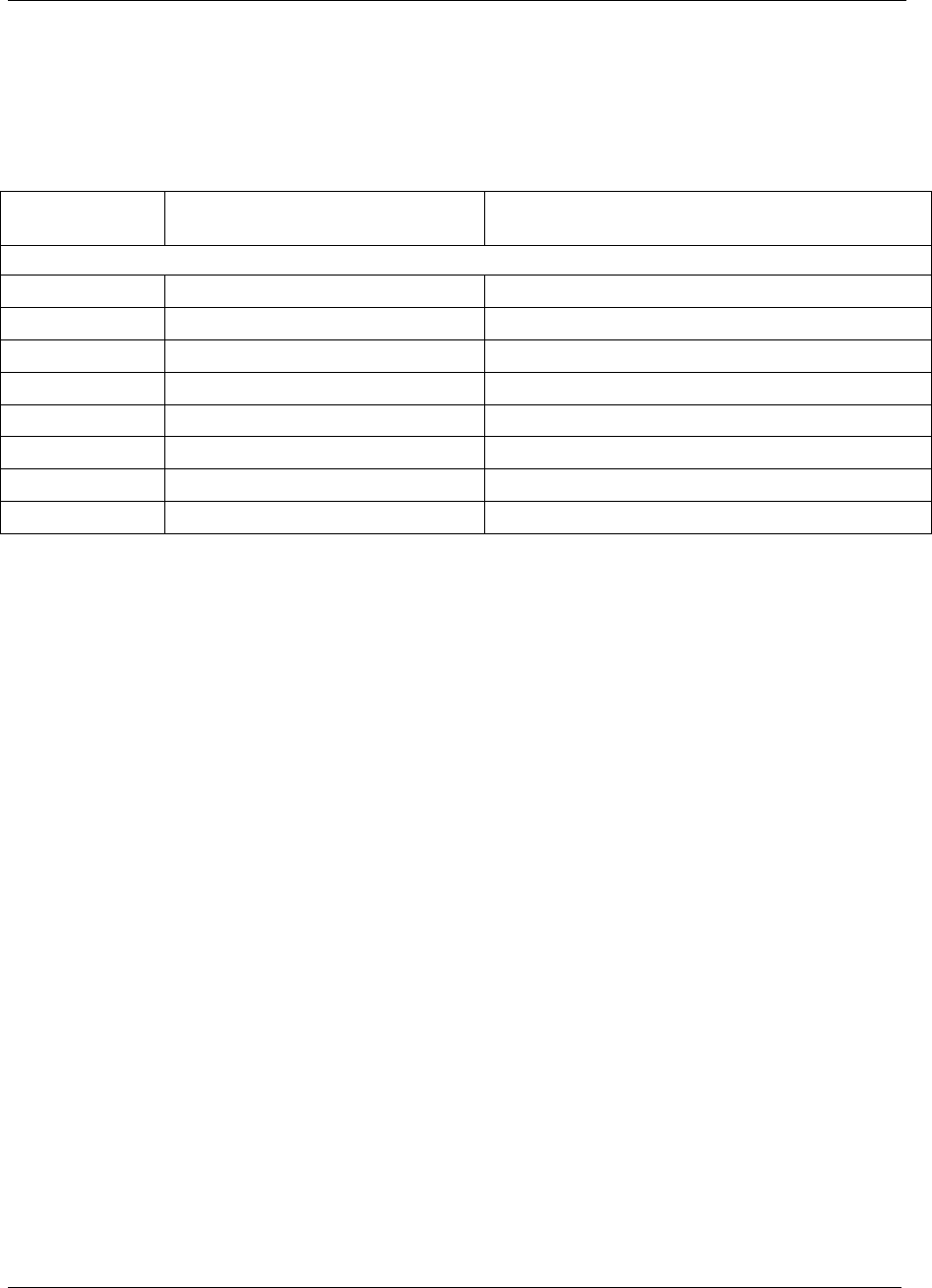

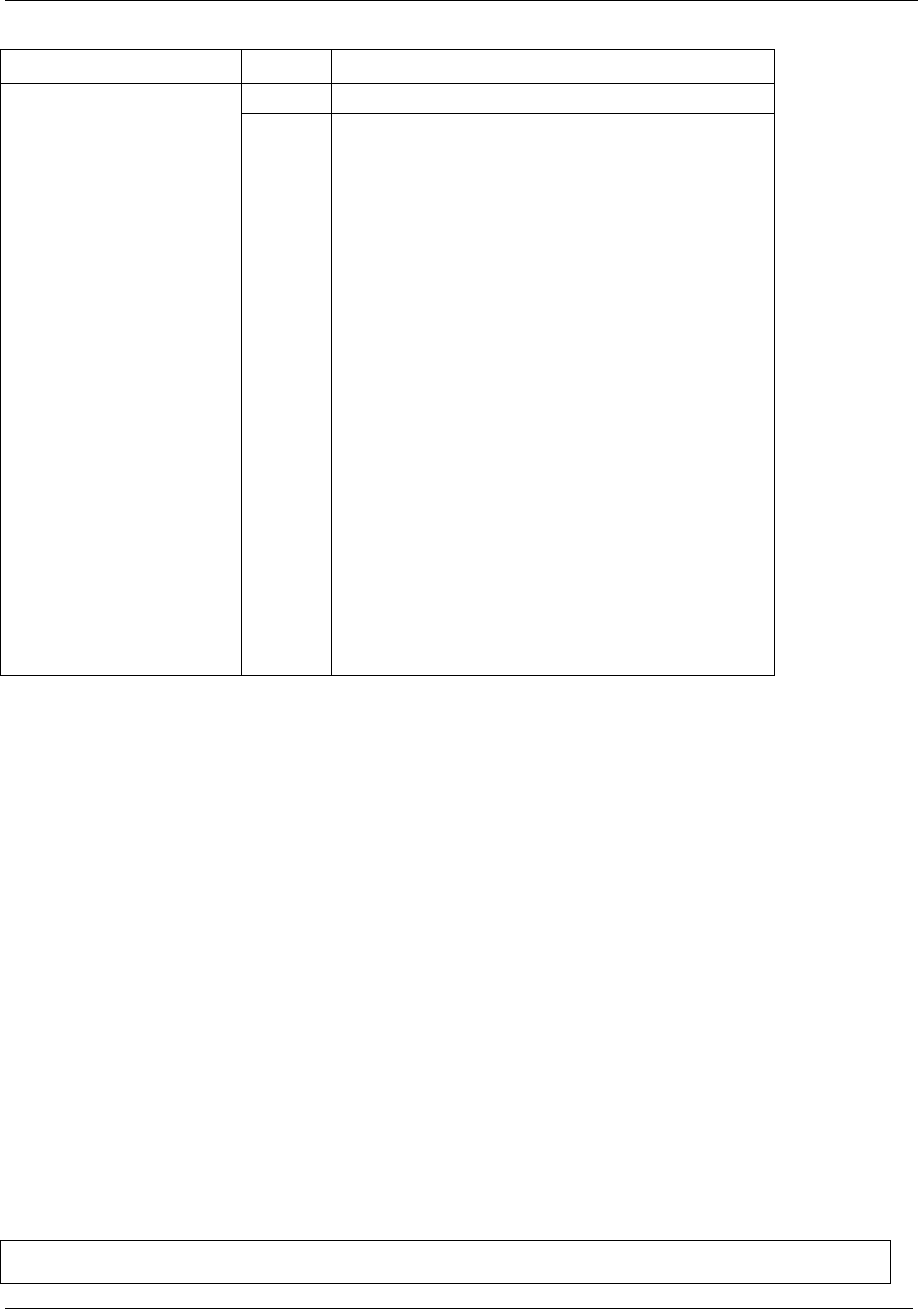

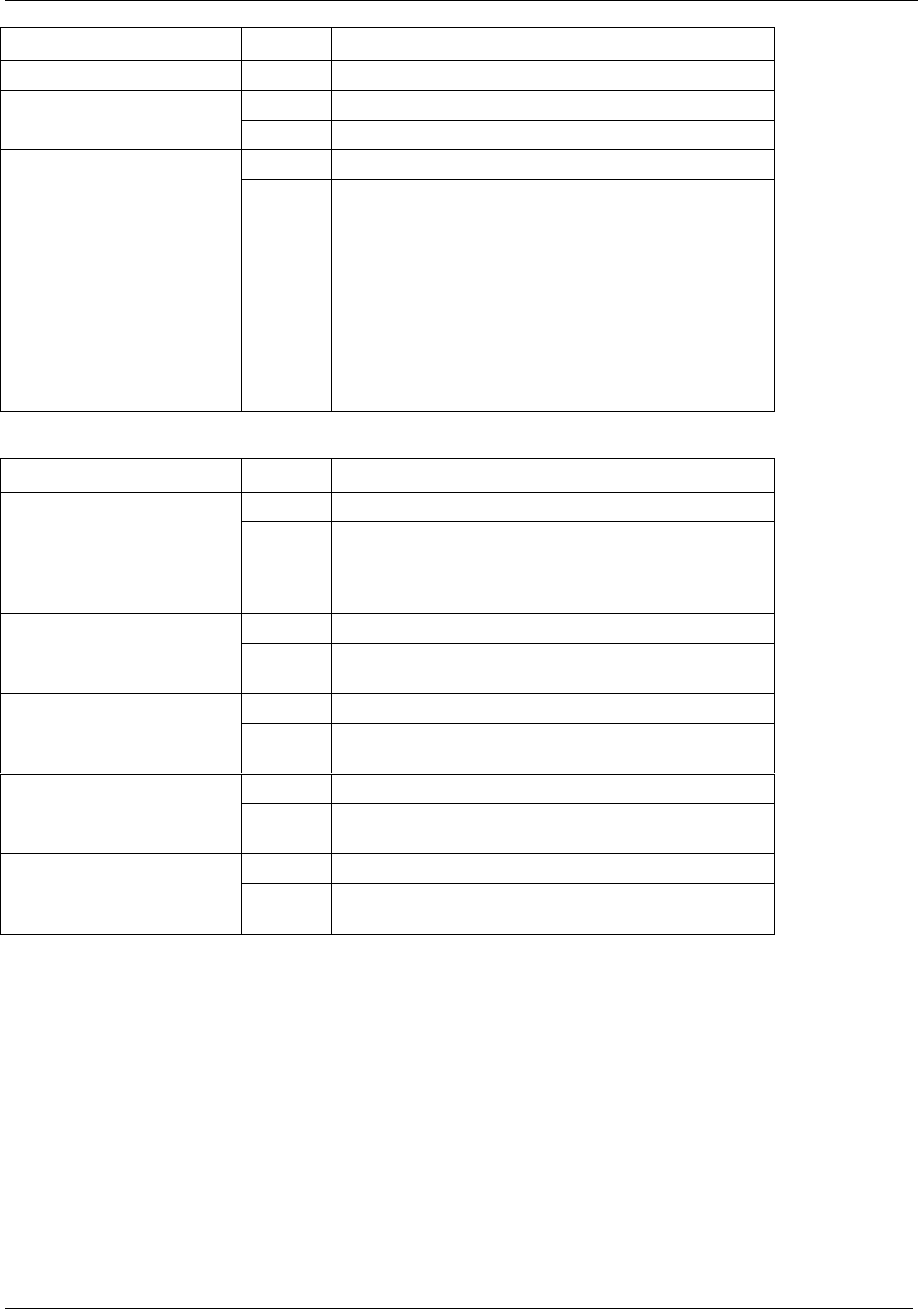

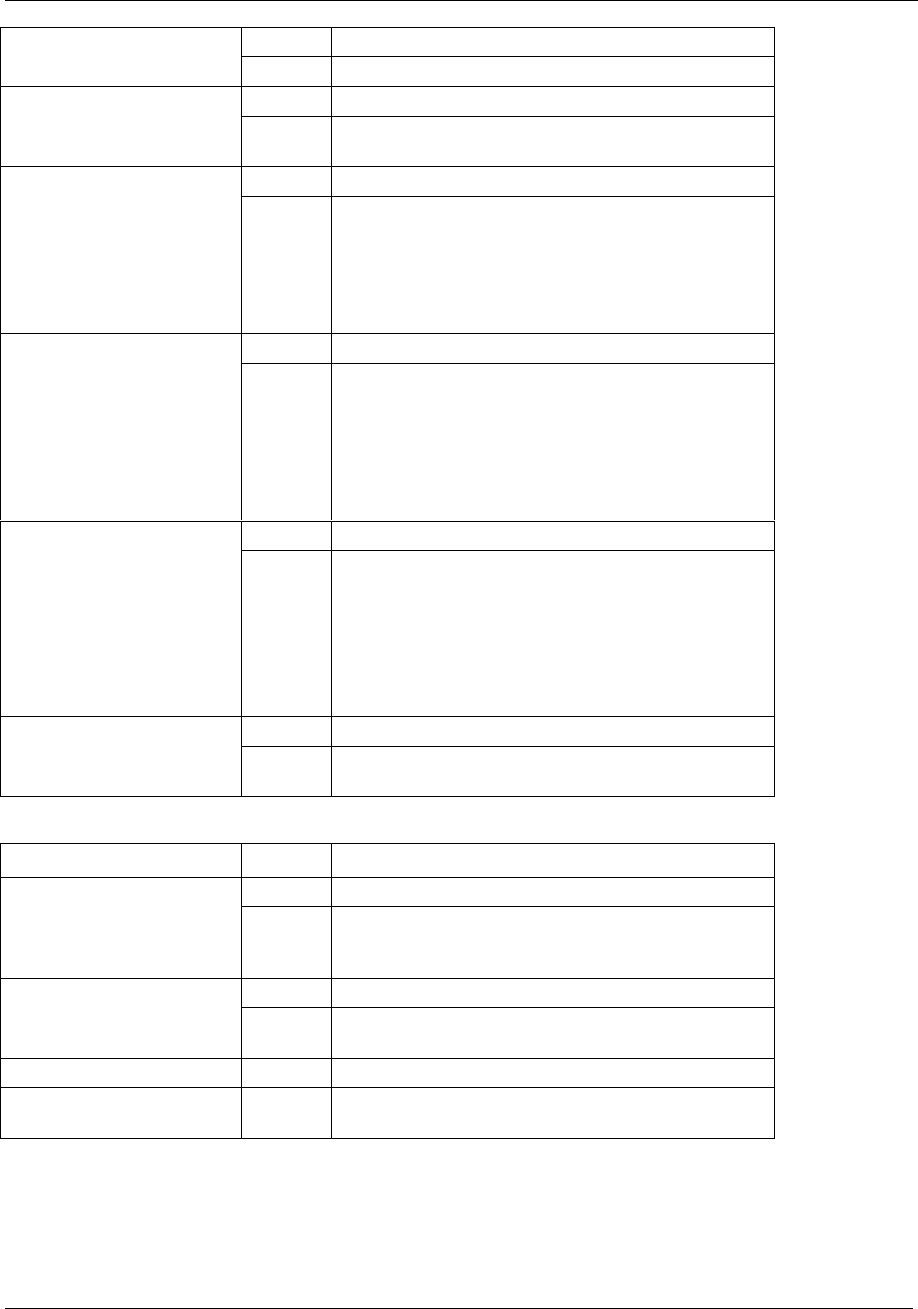

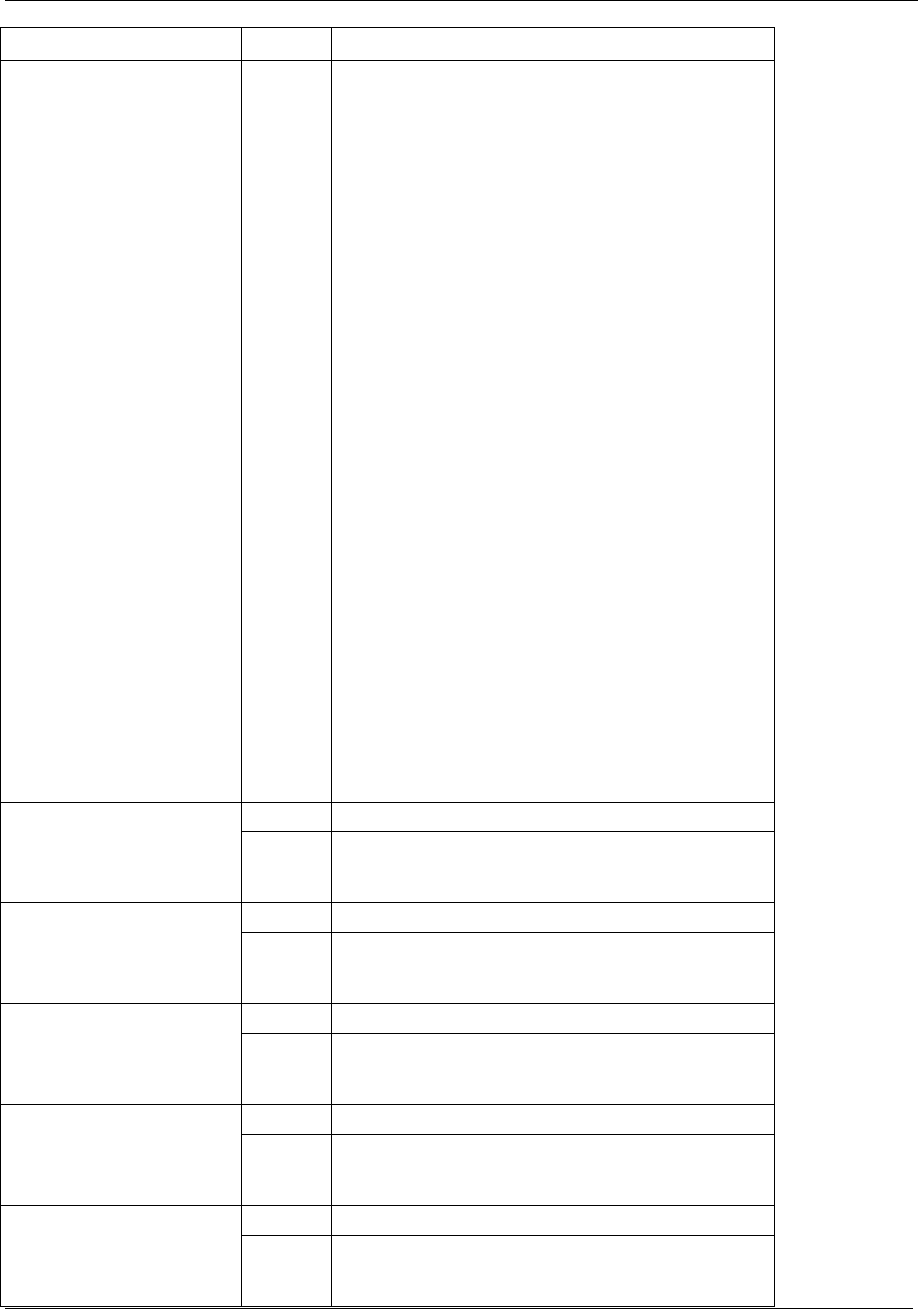

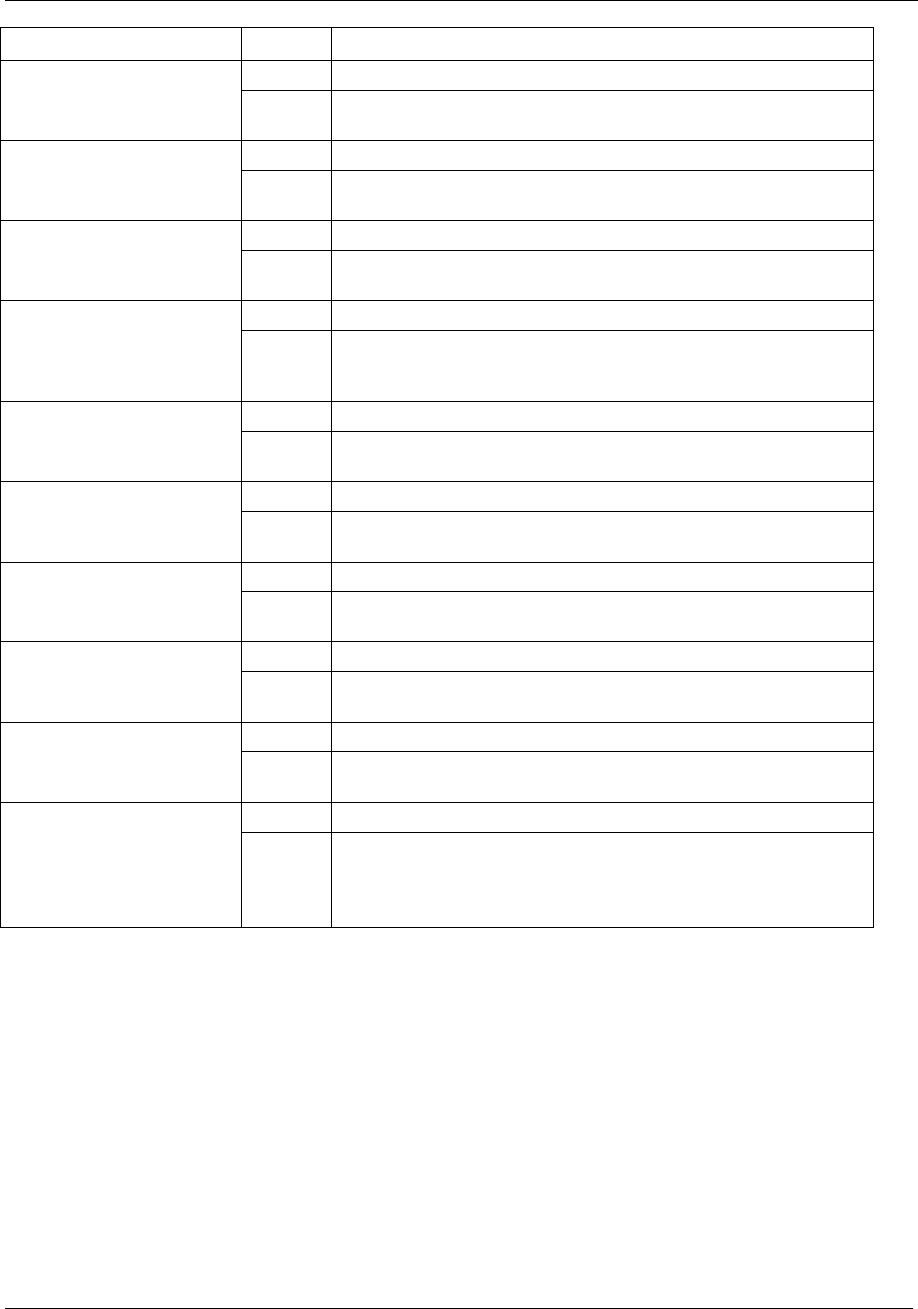

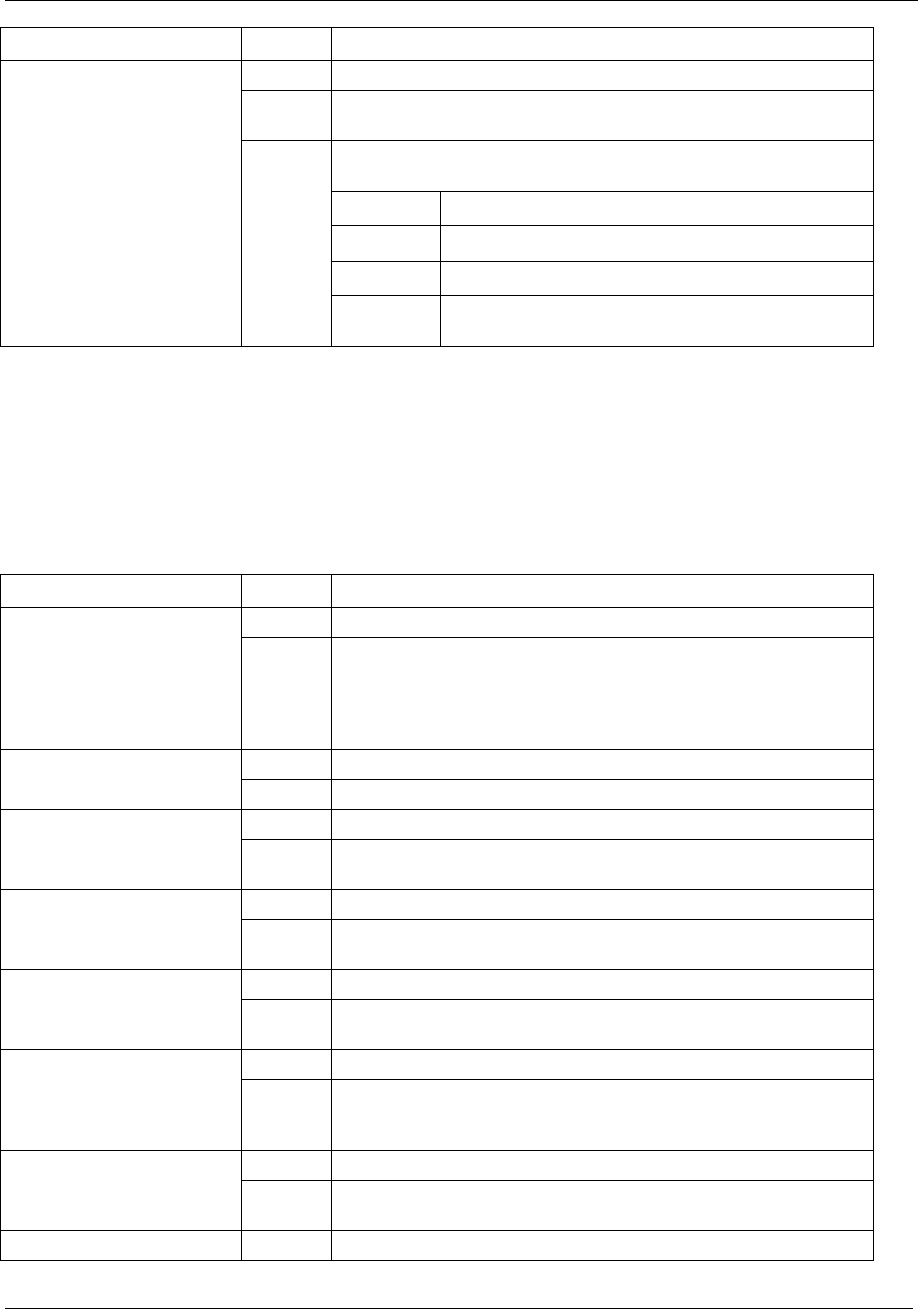

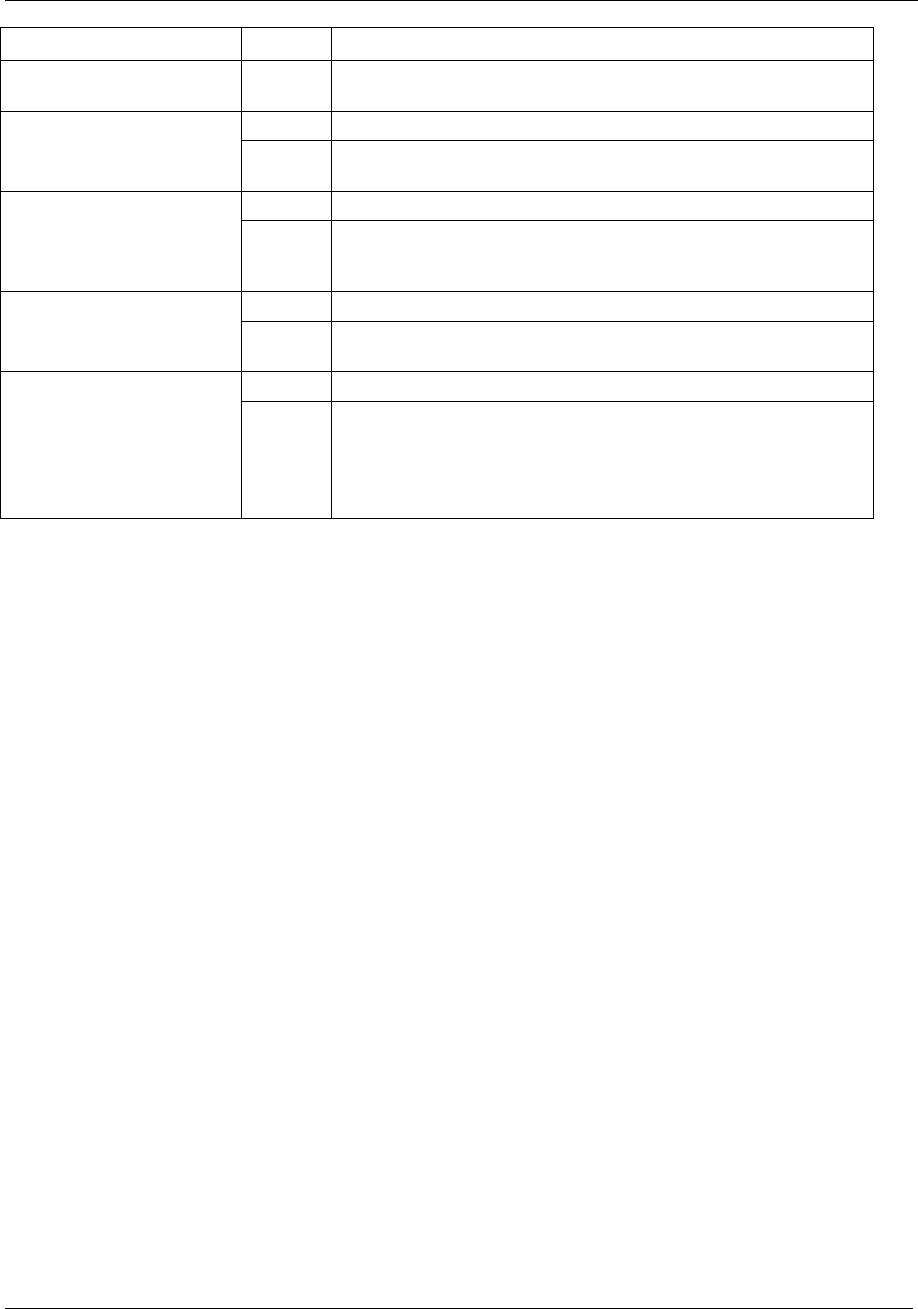

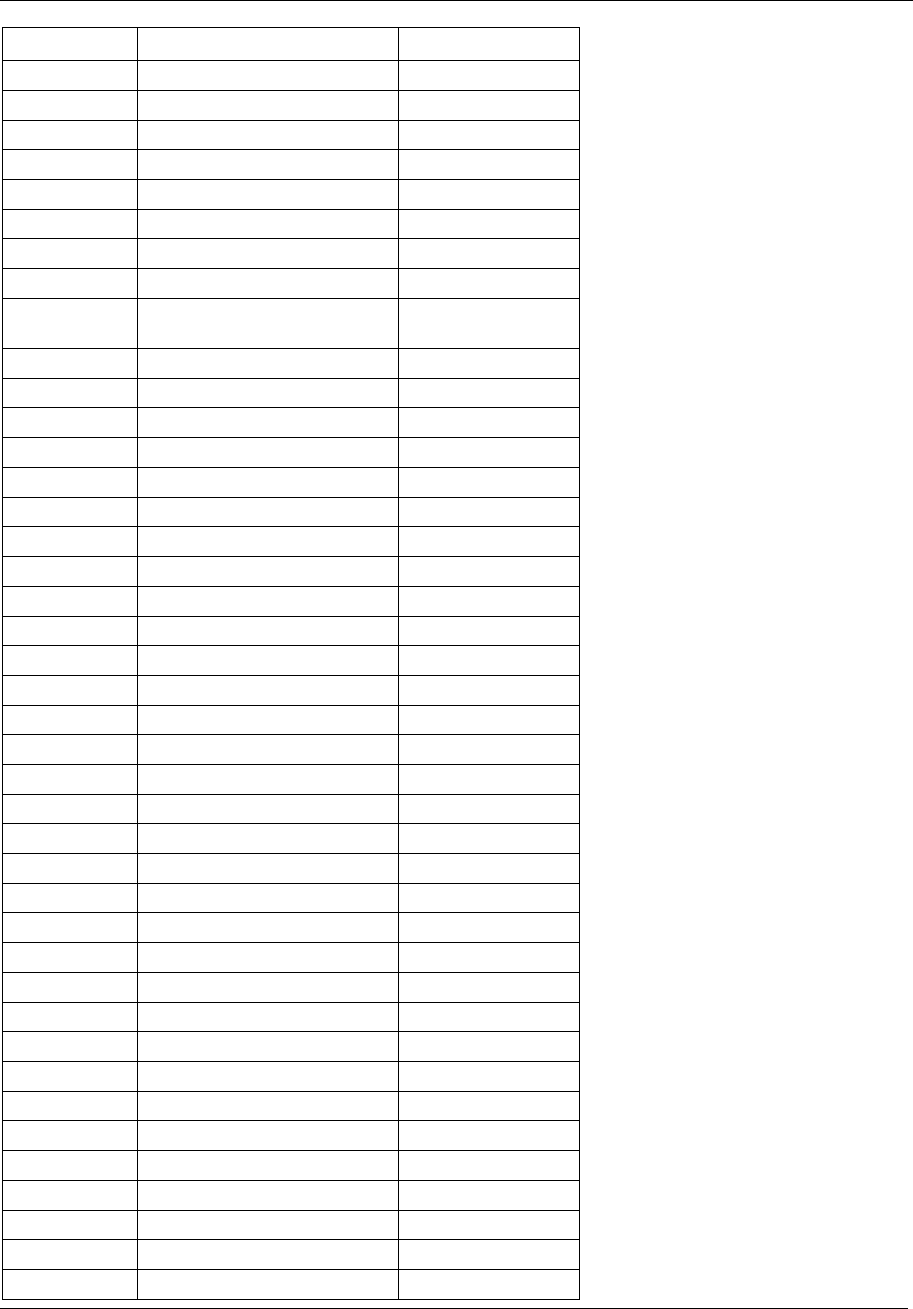

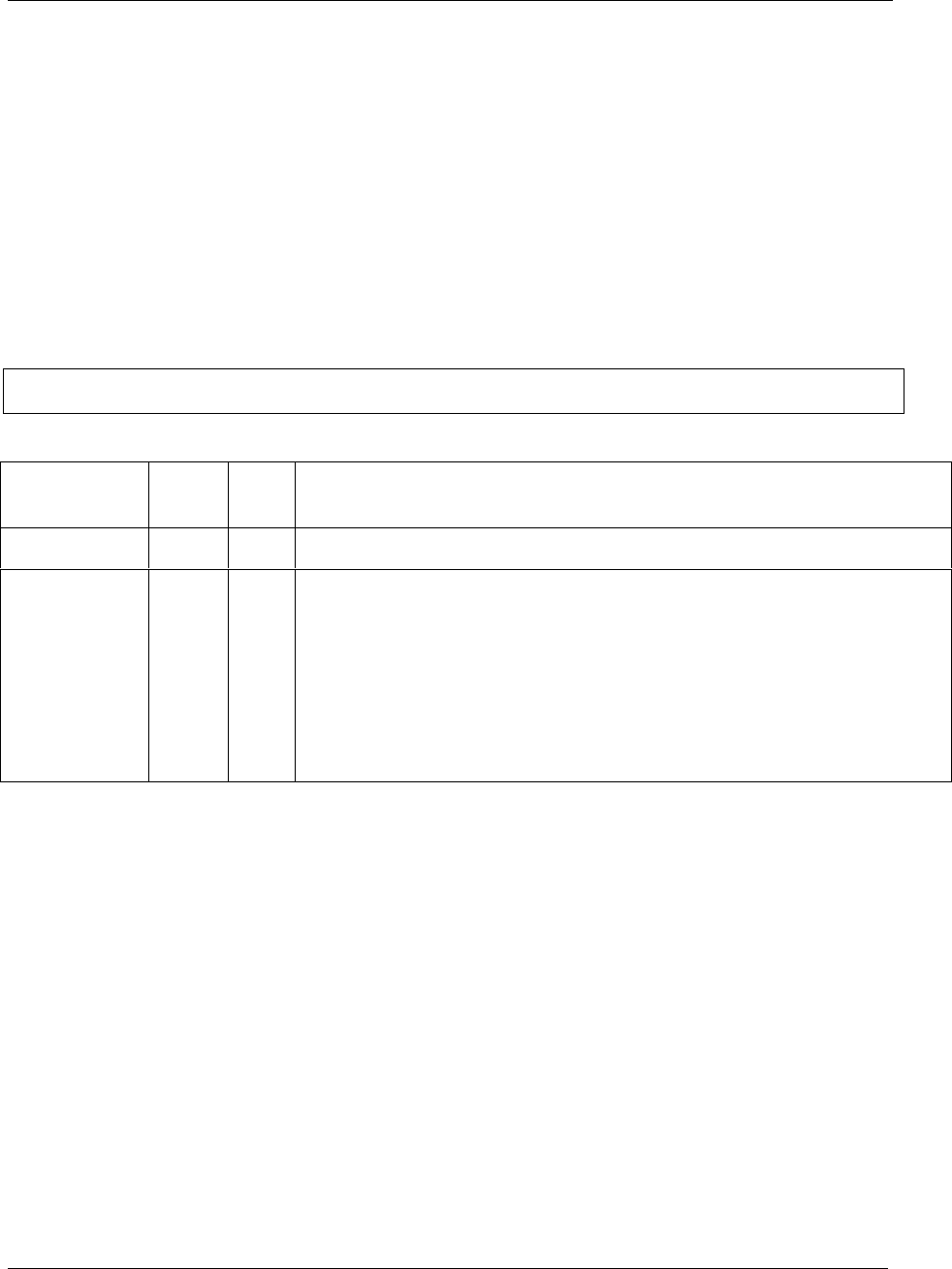

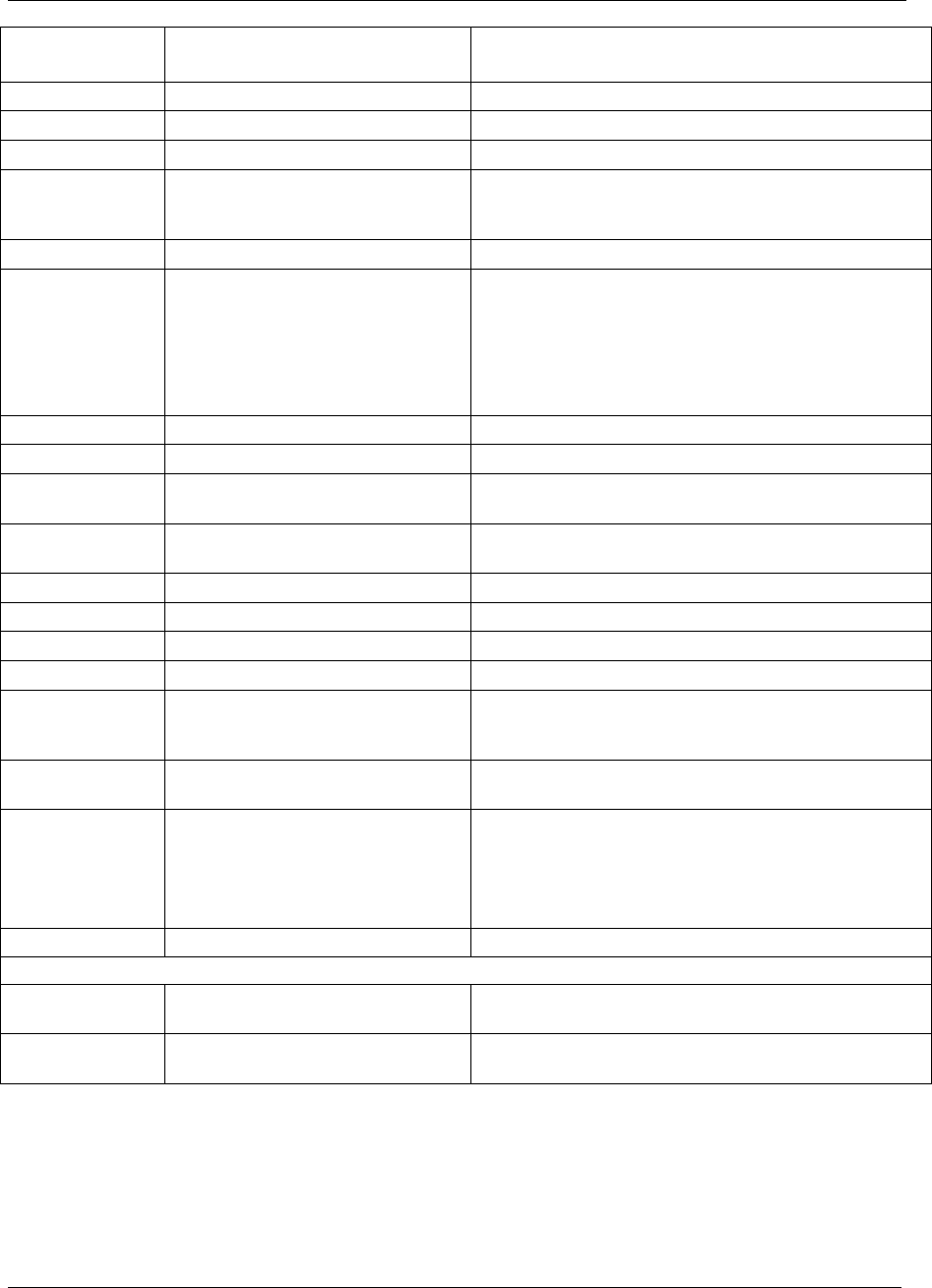

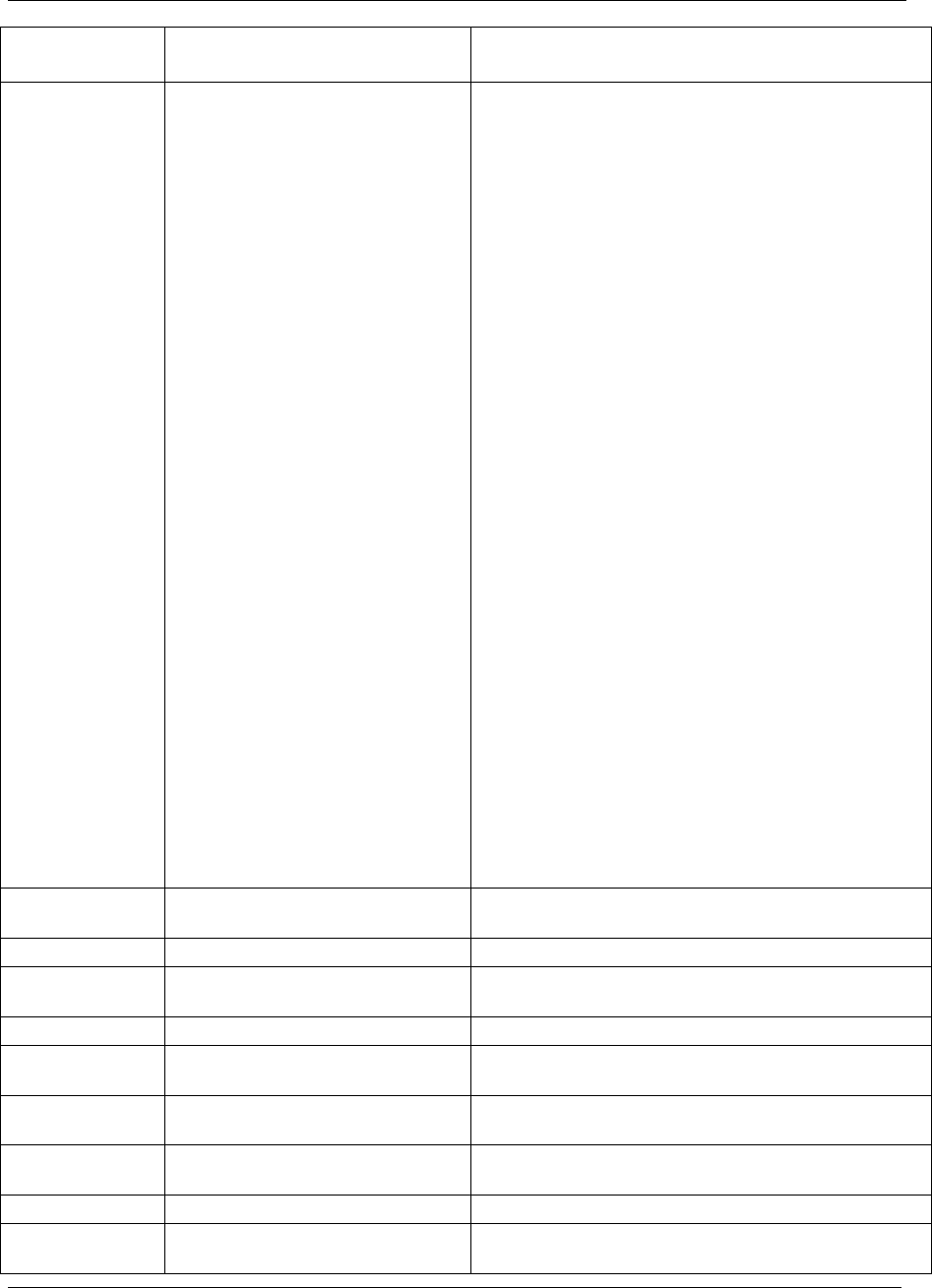

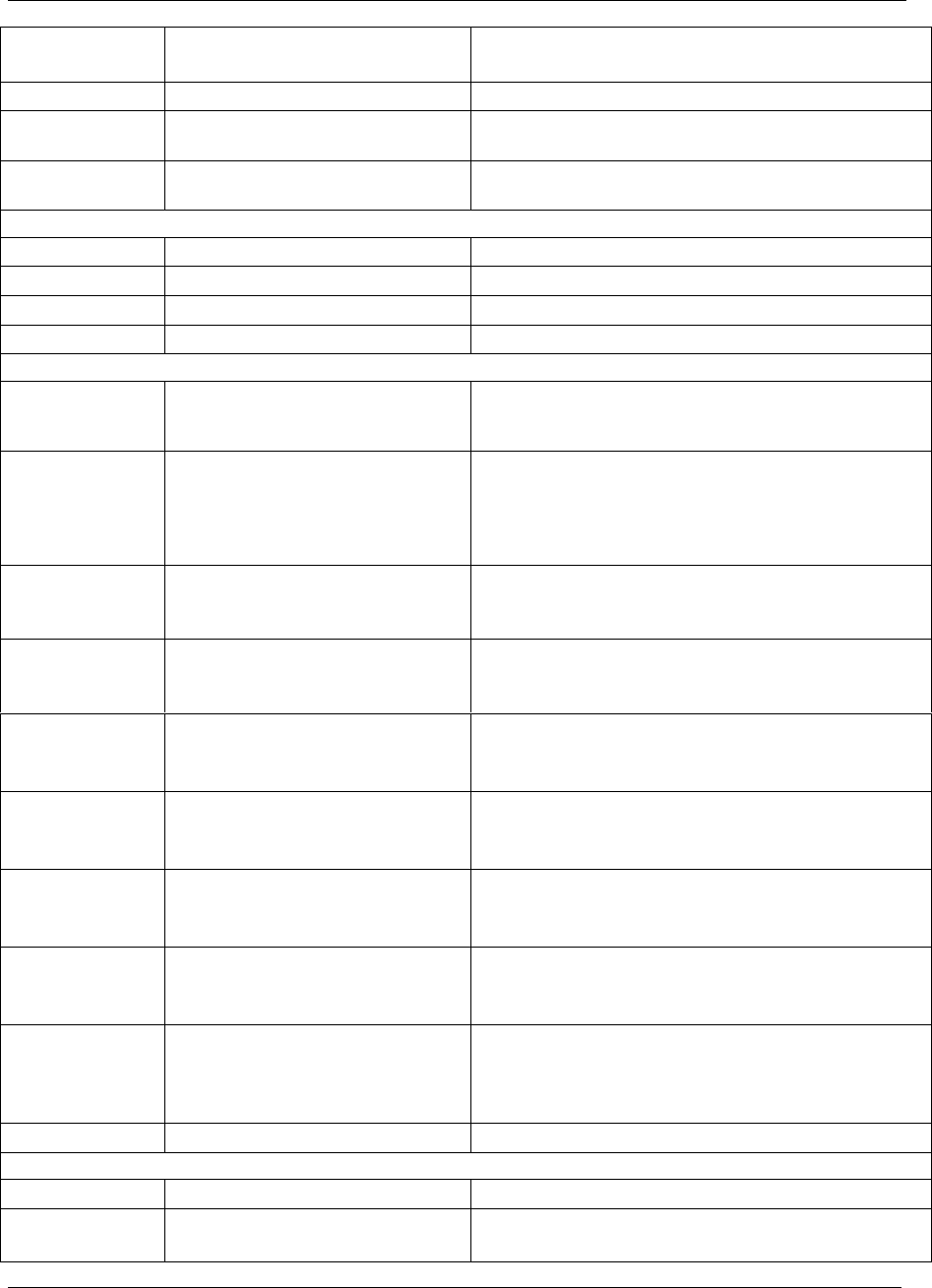

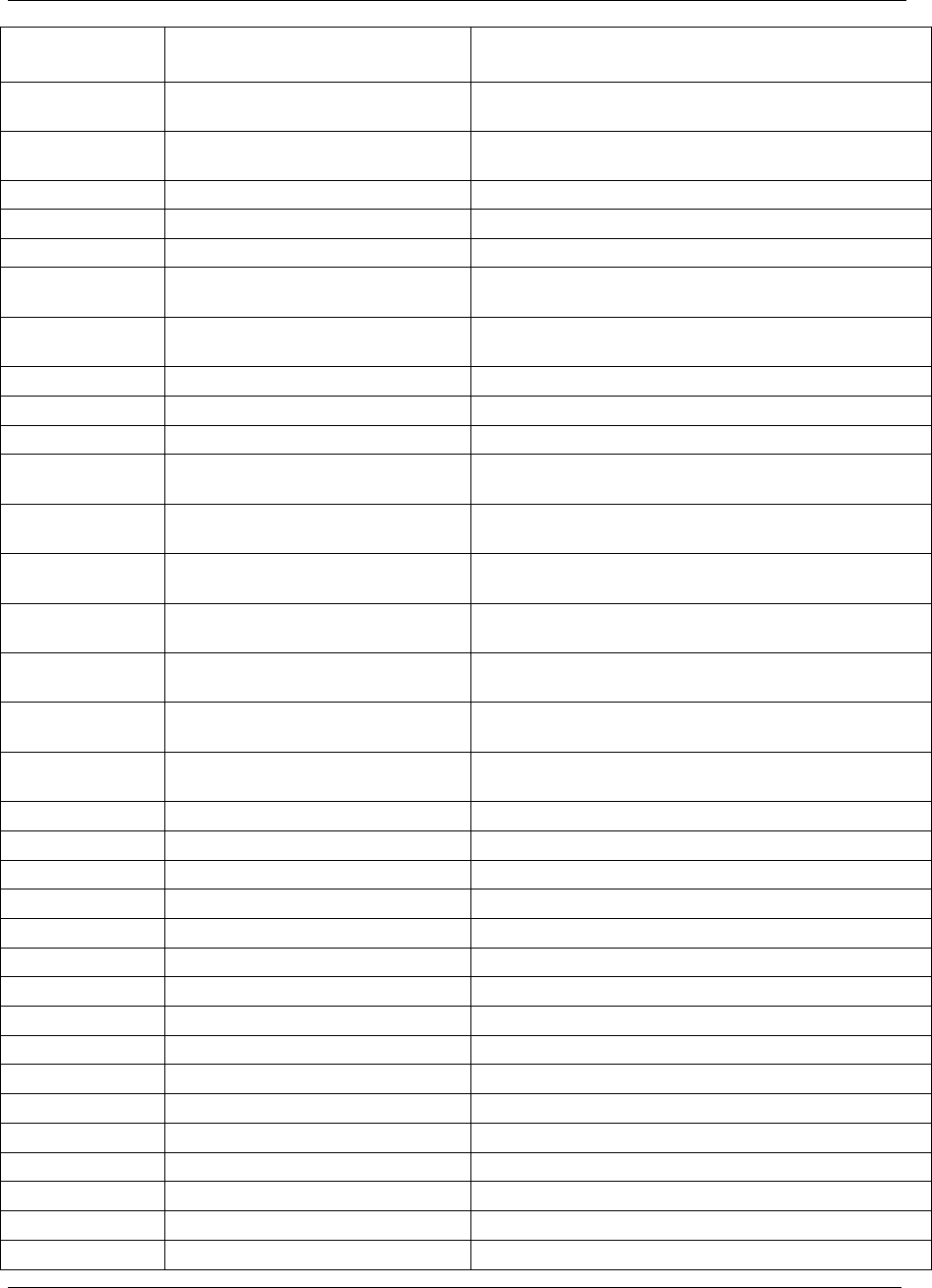

Figure 1 Open Protocol in the network, example .......................................................................................................... 11

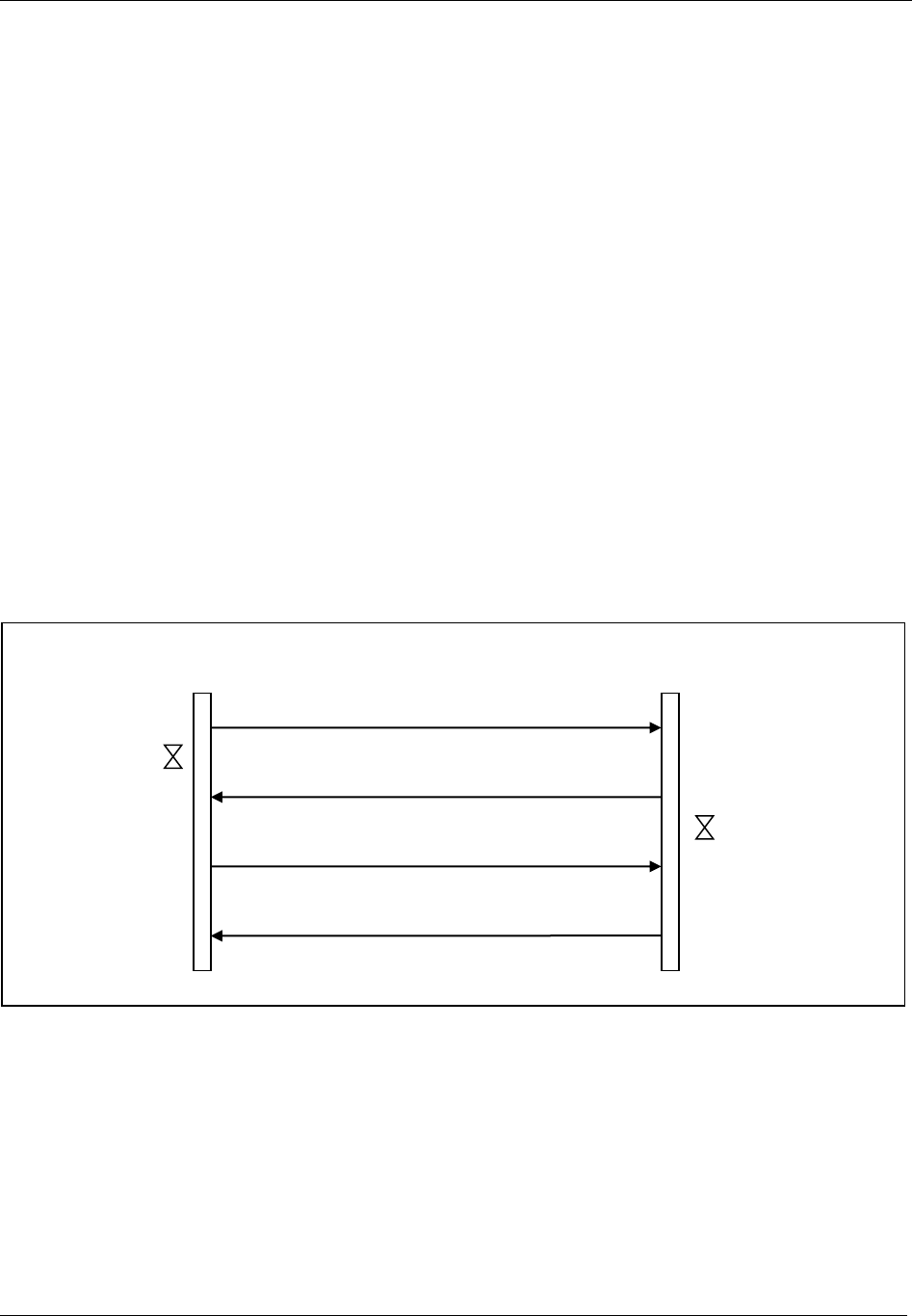

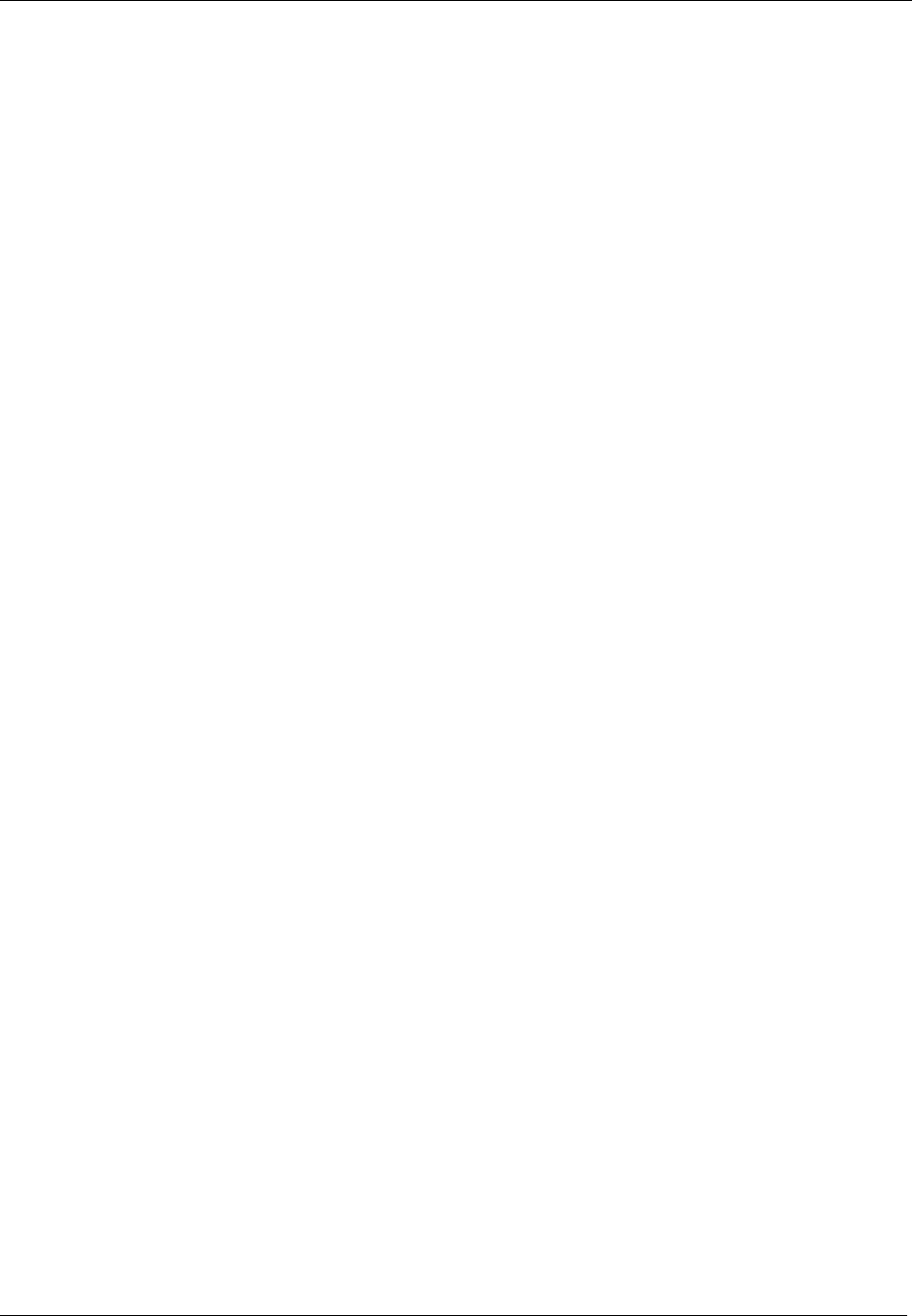

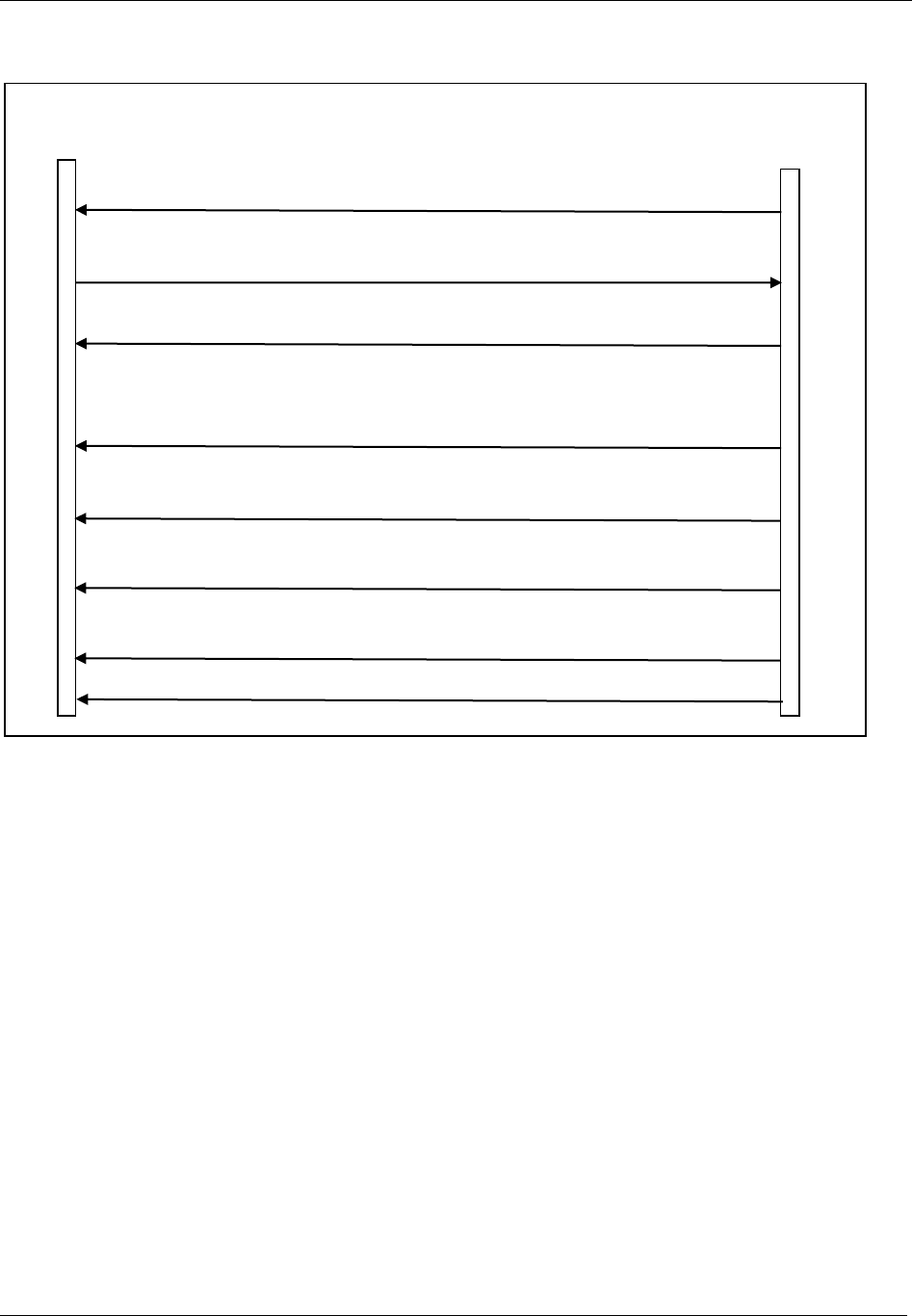

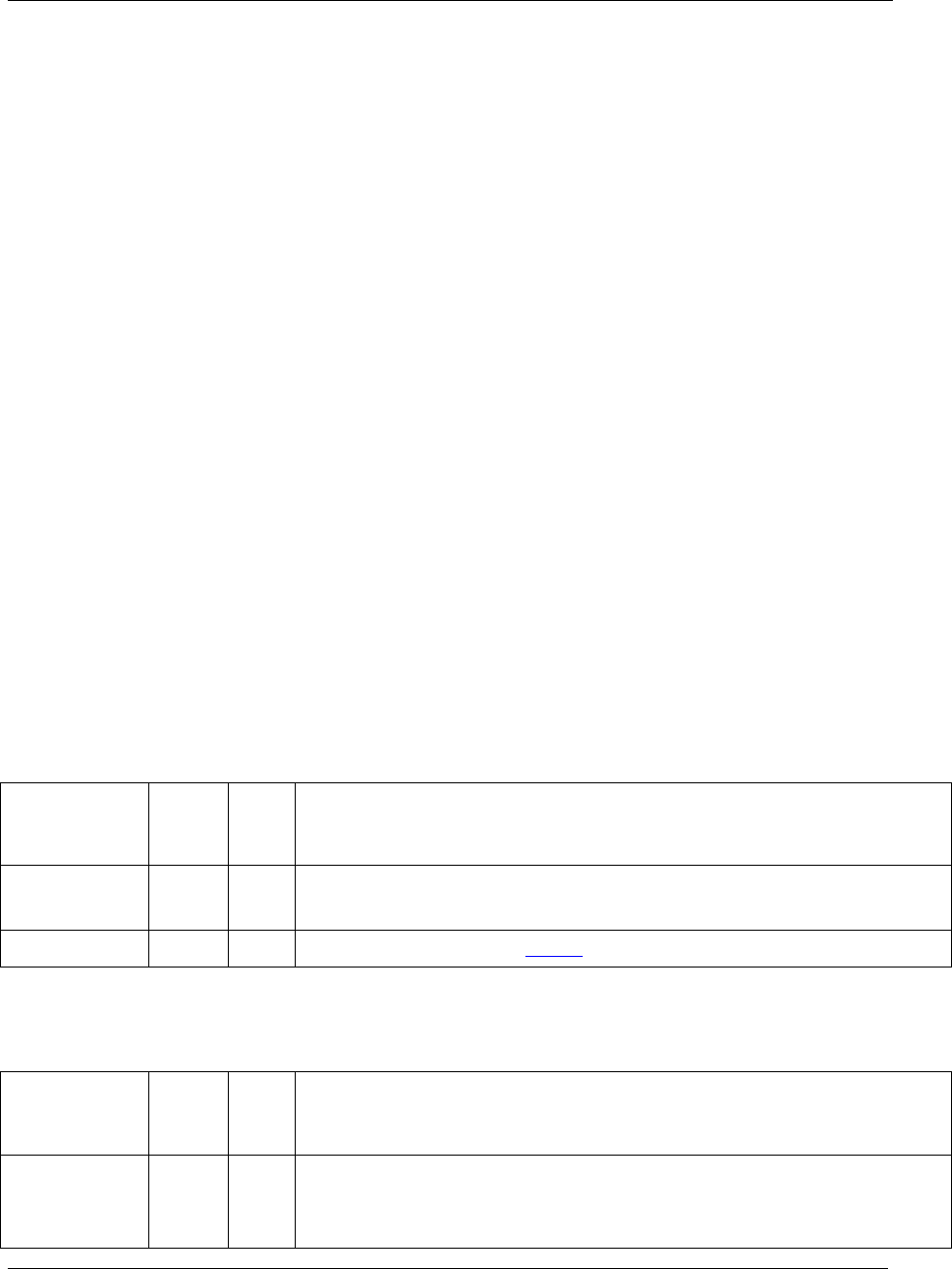

Figure 2 Communication structure ................................................................................................................................ 21

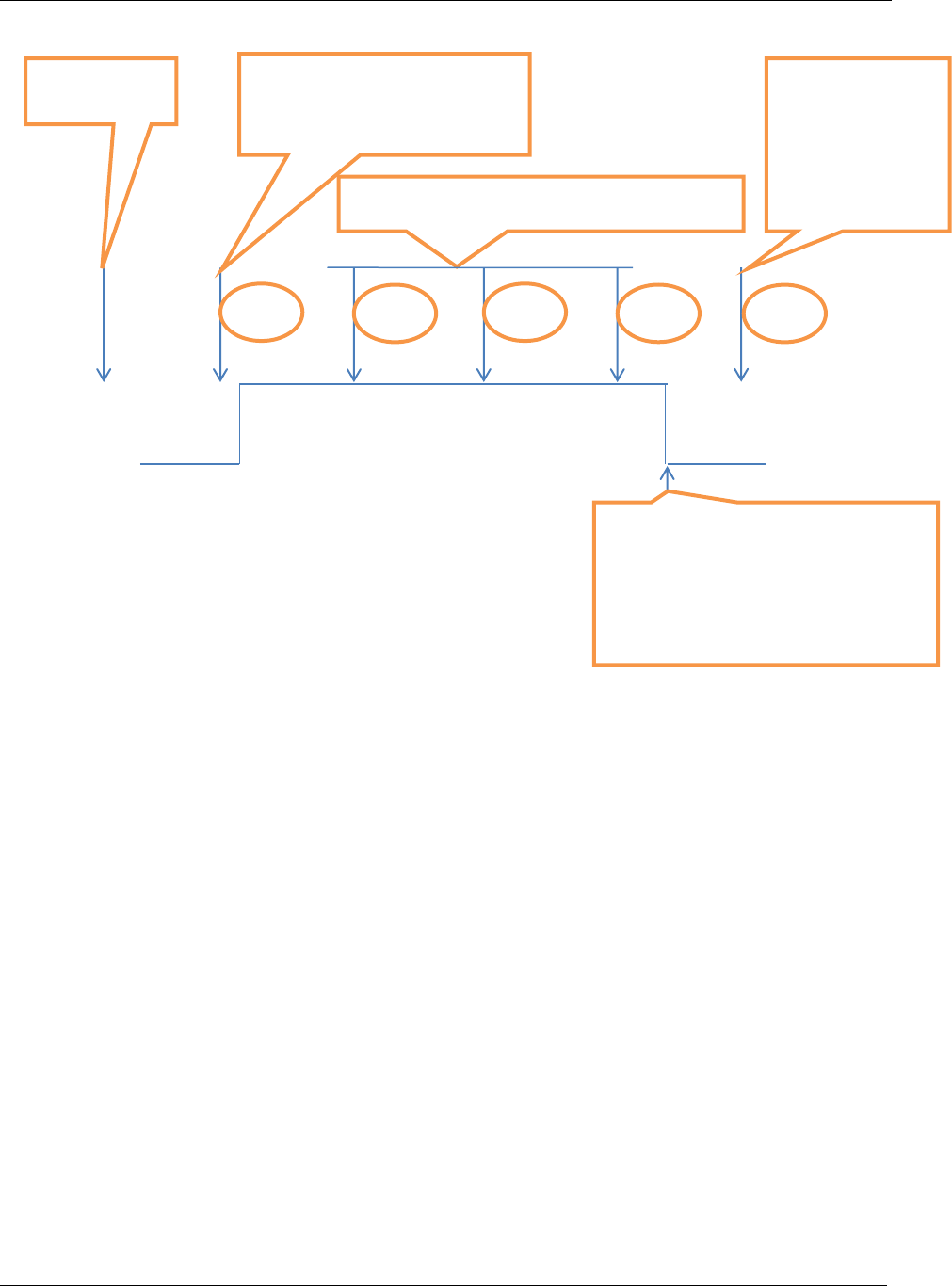

Figure 3 Serial communication protocol ....................................................................................................................... 22

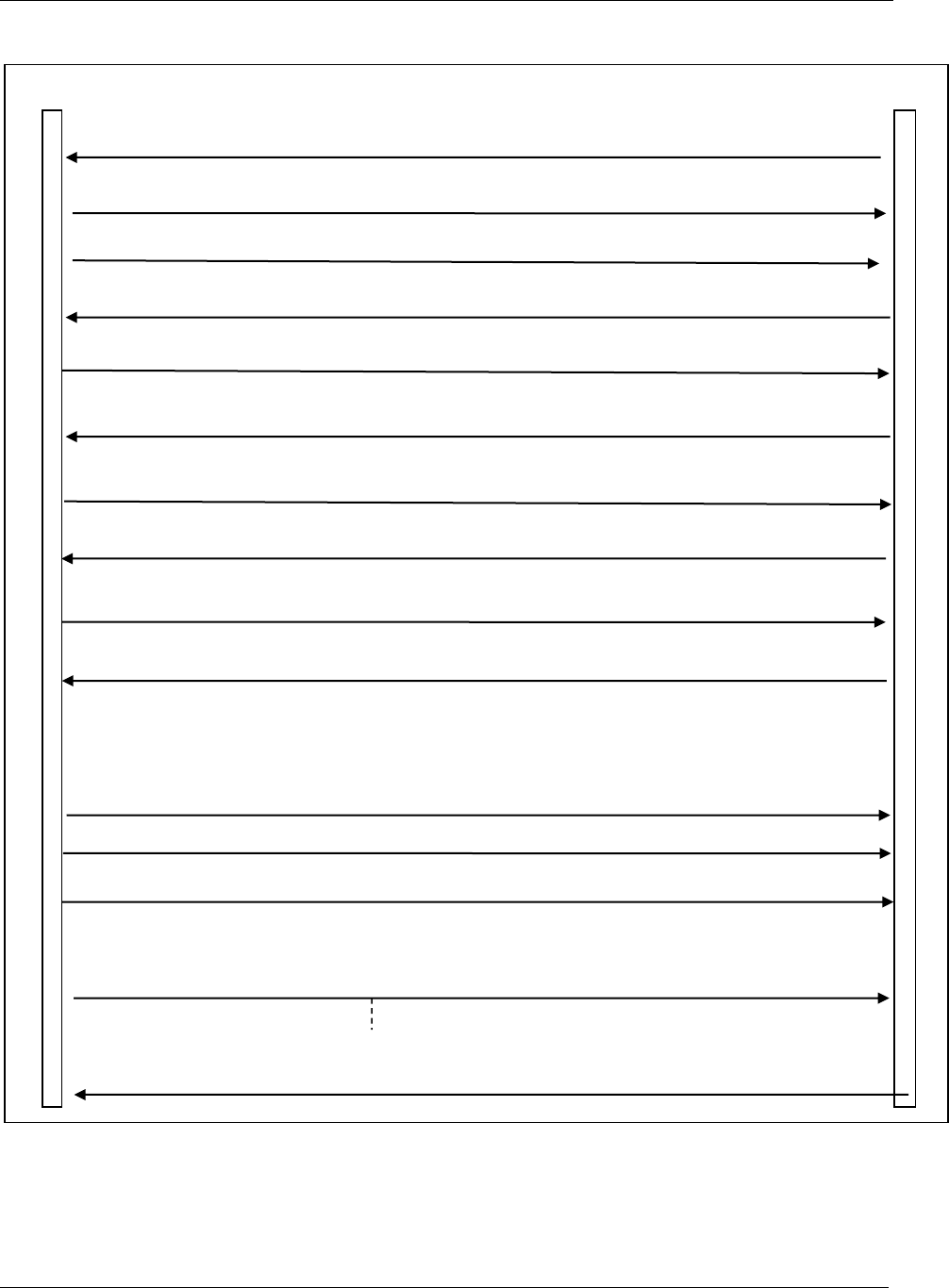

Figure 4 Integrator sending serial communication protocol with 3964R handshake ..................................................... 23

Figure 5 Controller sending serial communication protocol with 3964R handshake ..................................................... 23

Figure 6 Message example with byte number .............................................................................................................. 25

Figure 7 Message example without byte number ......................................................................................................... 25

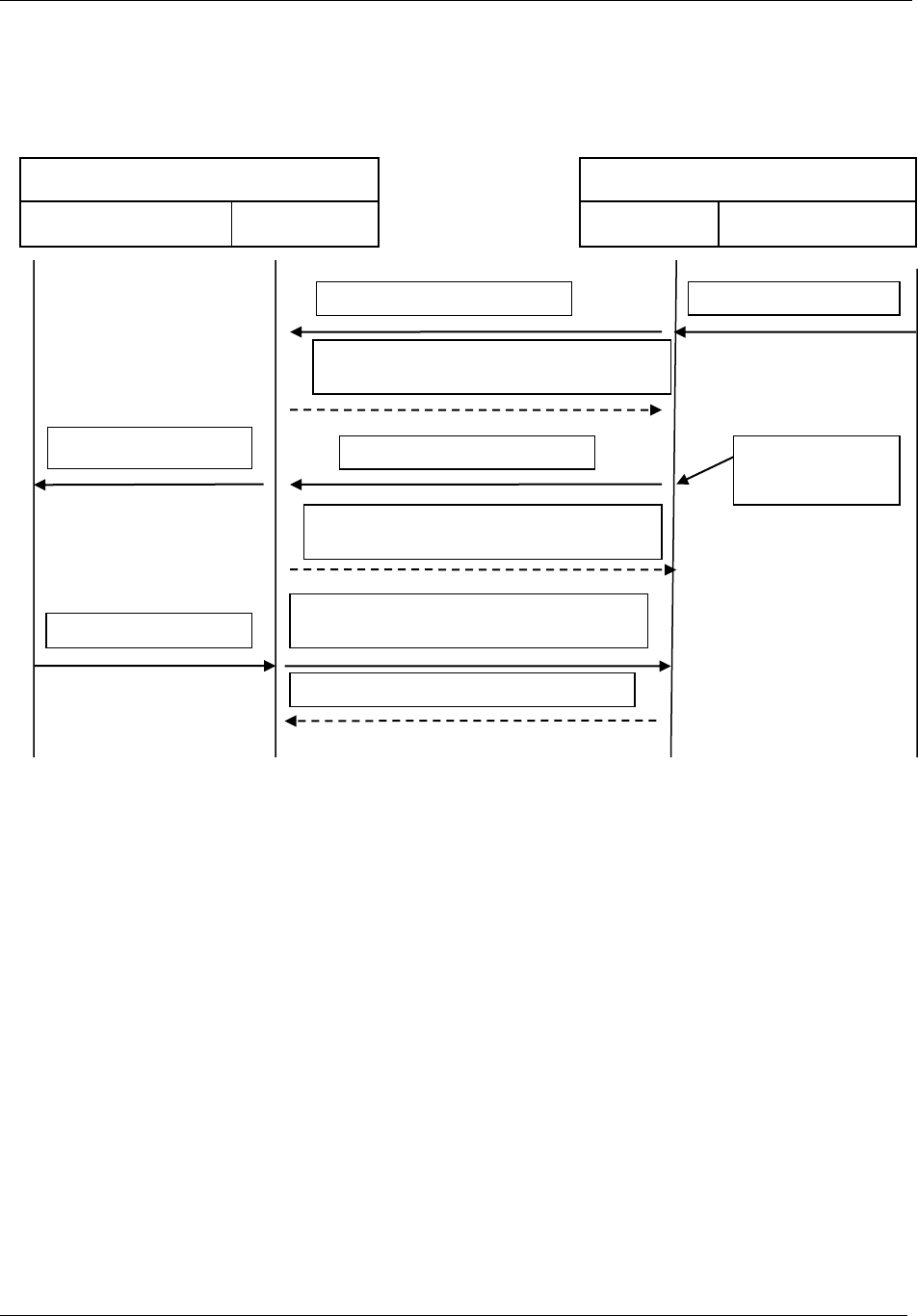

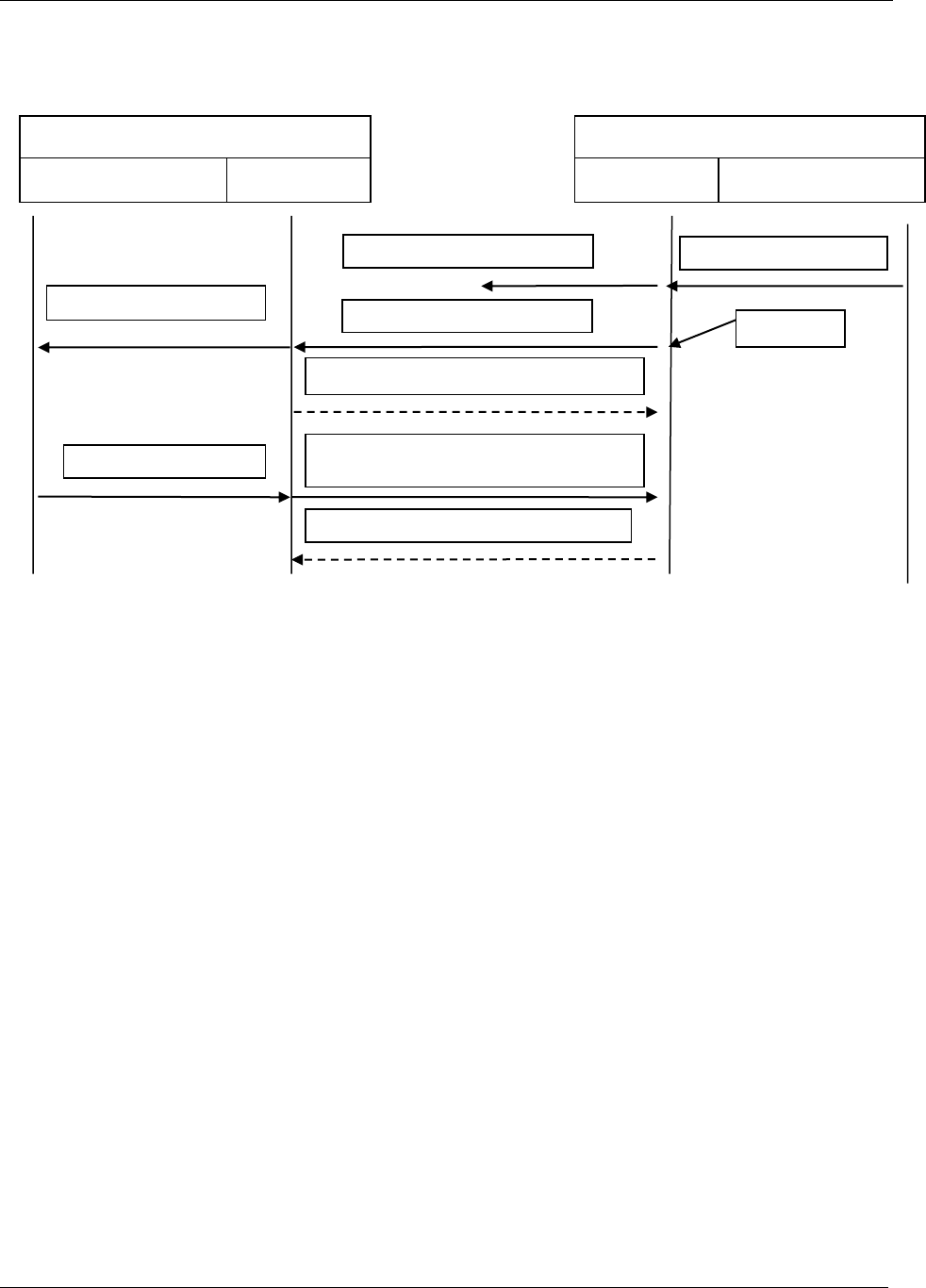

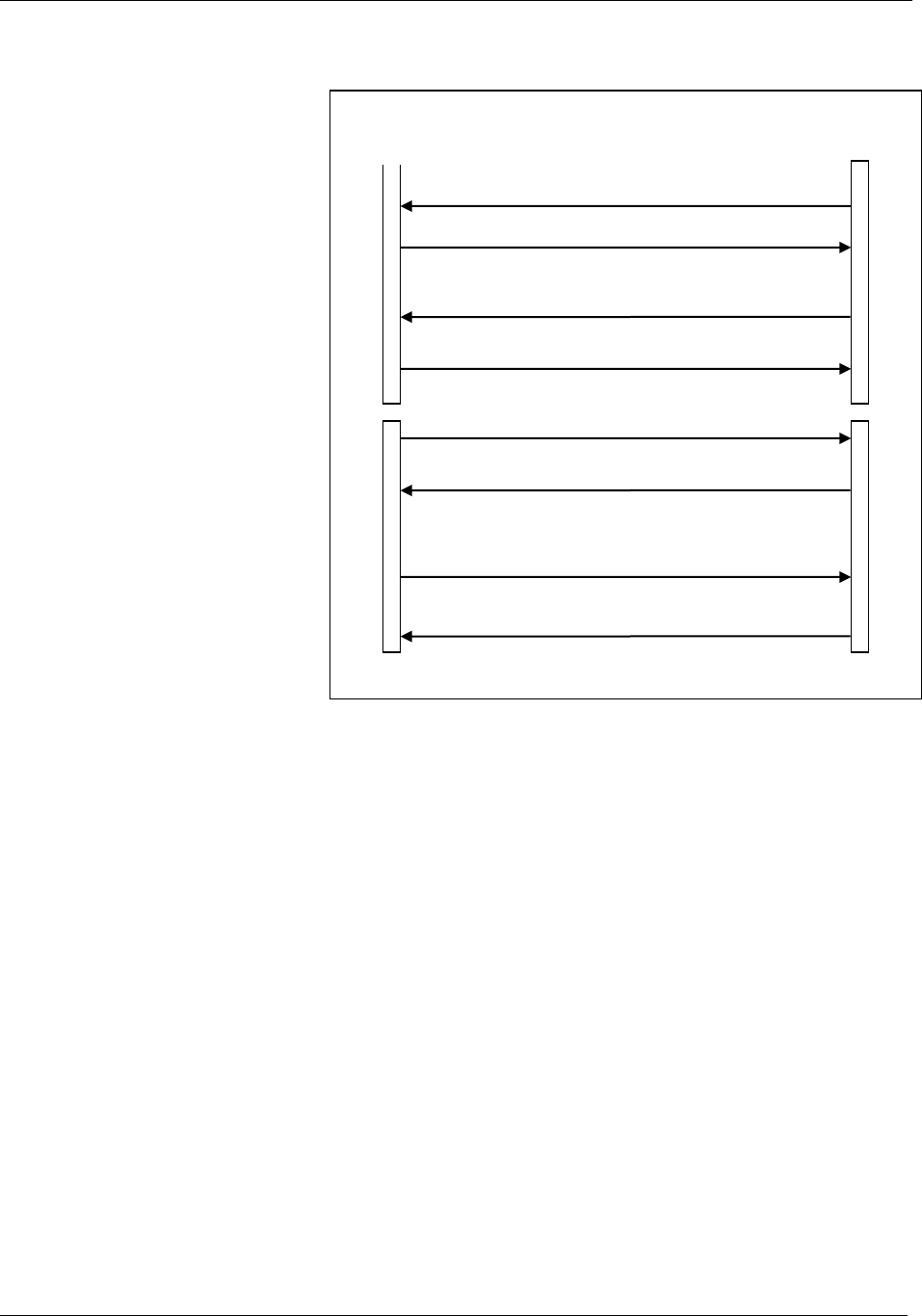

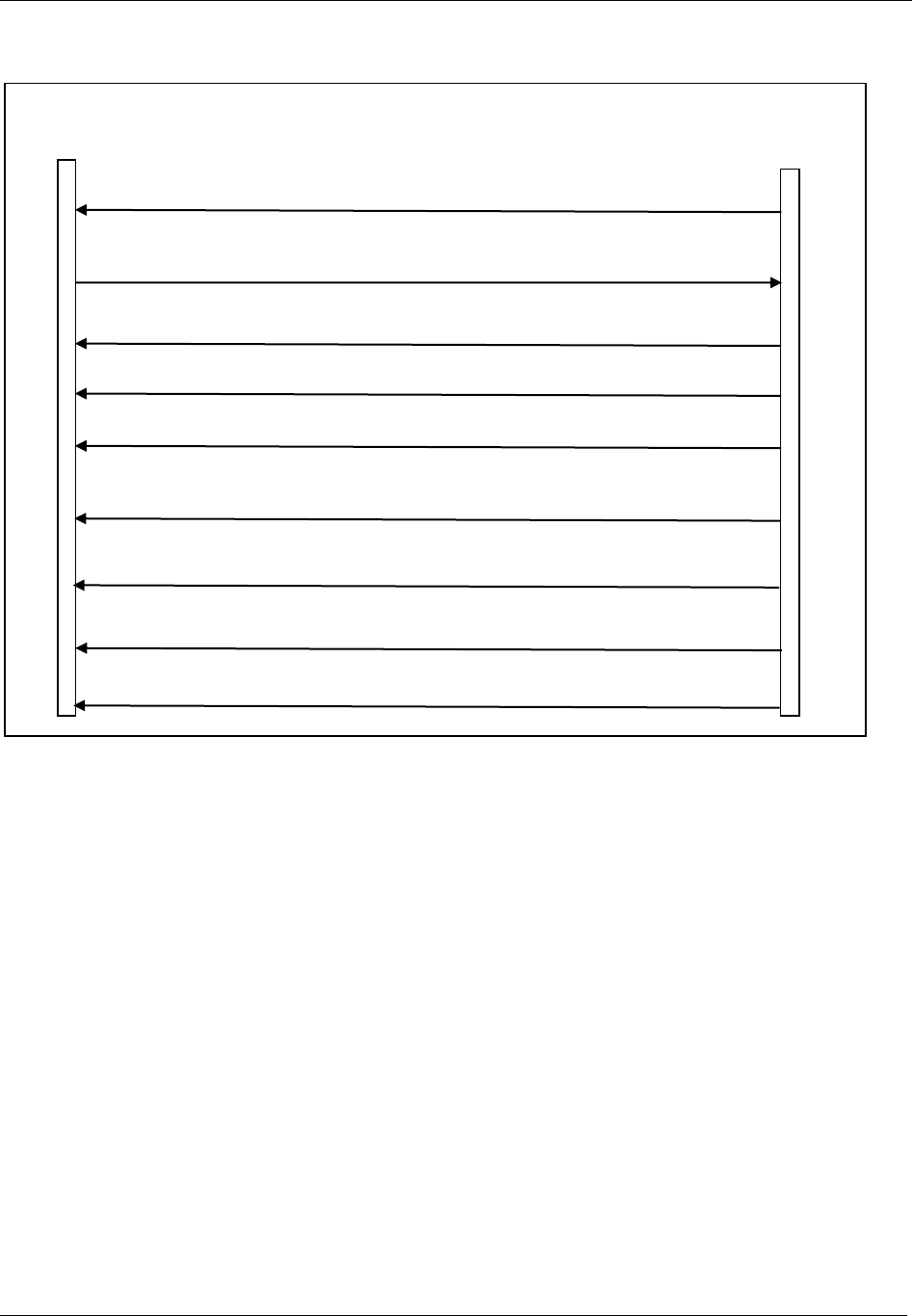

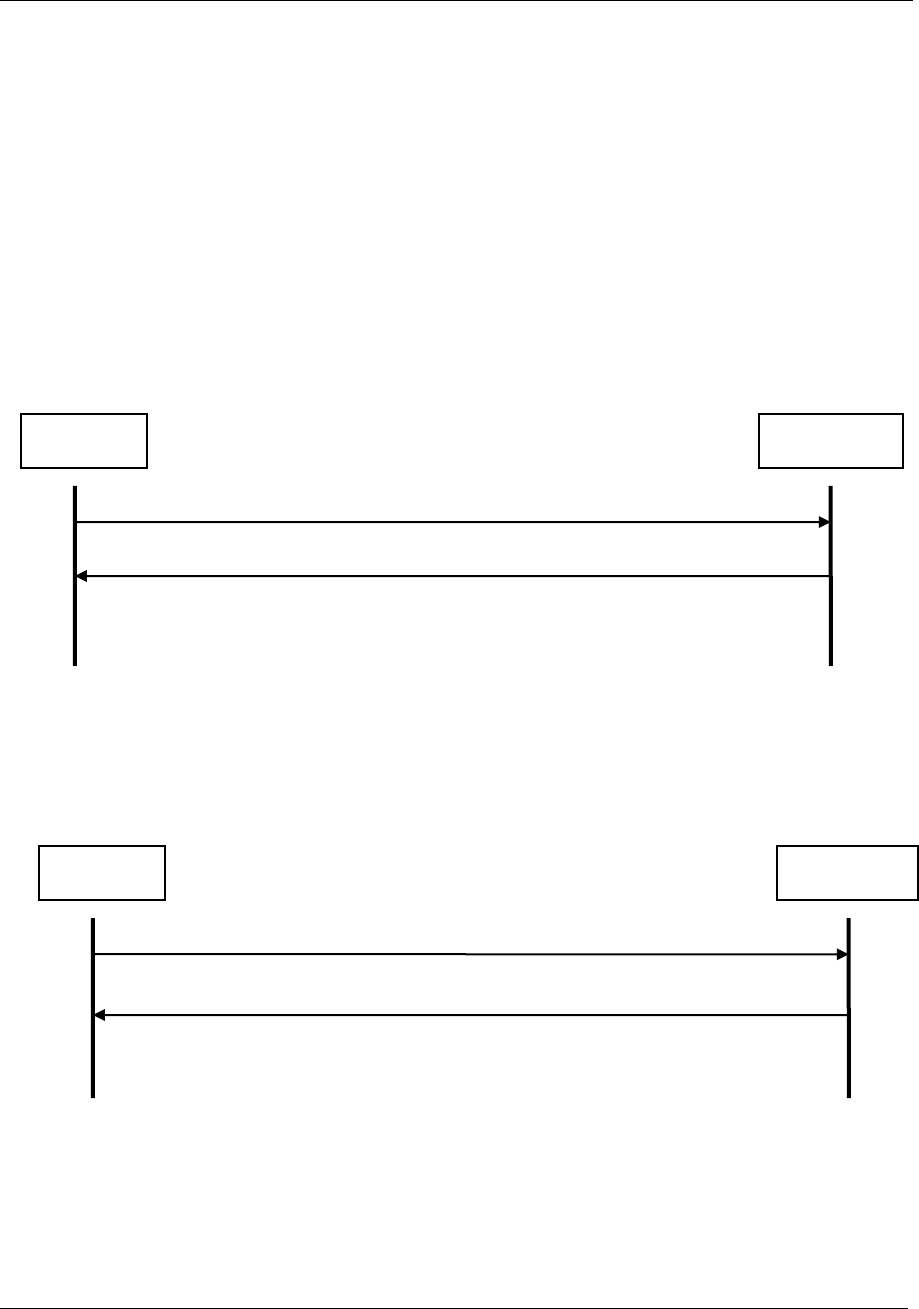

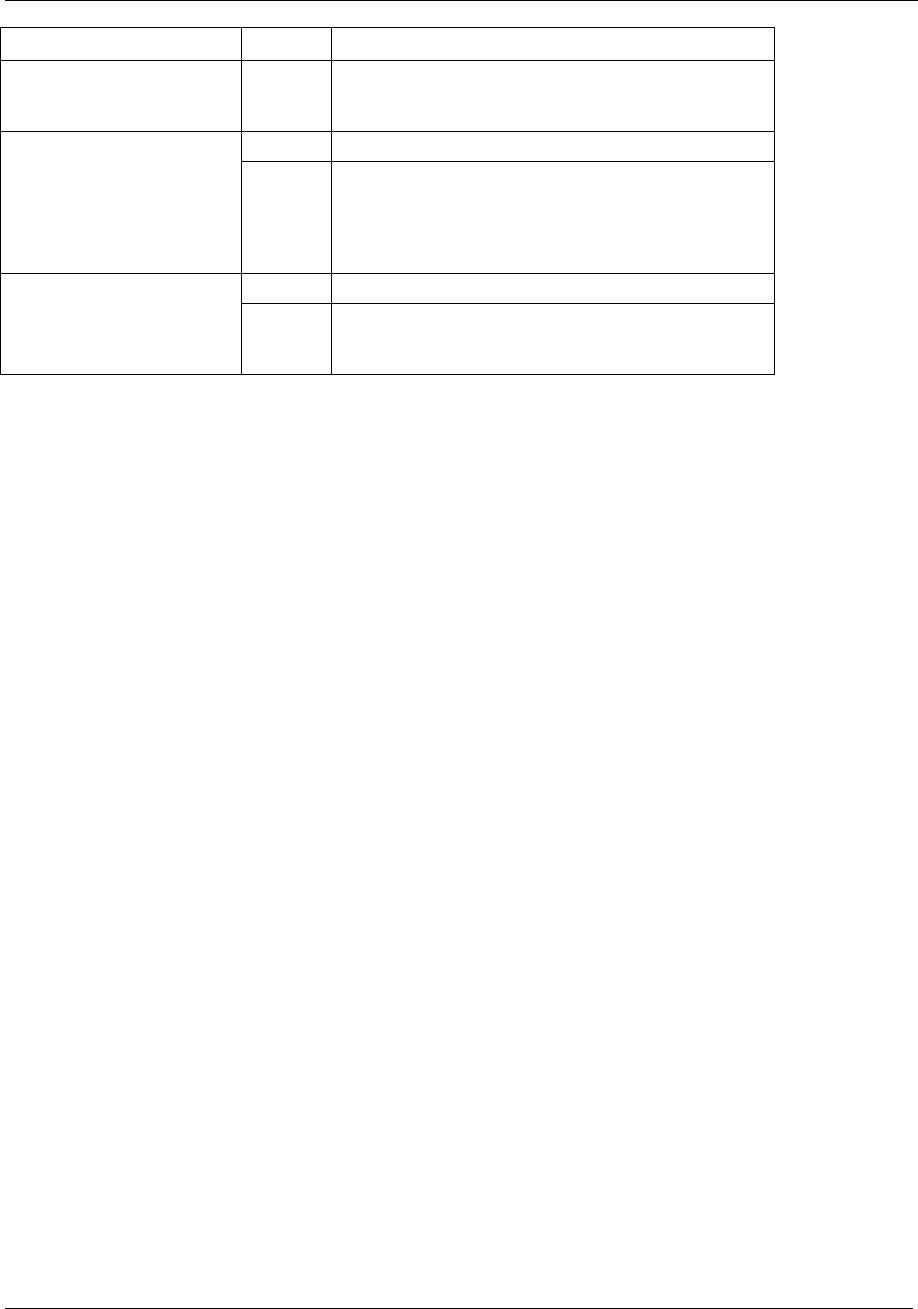

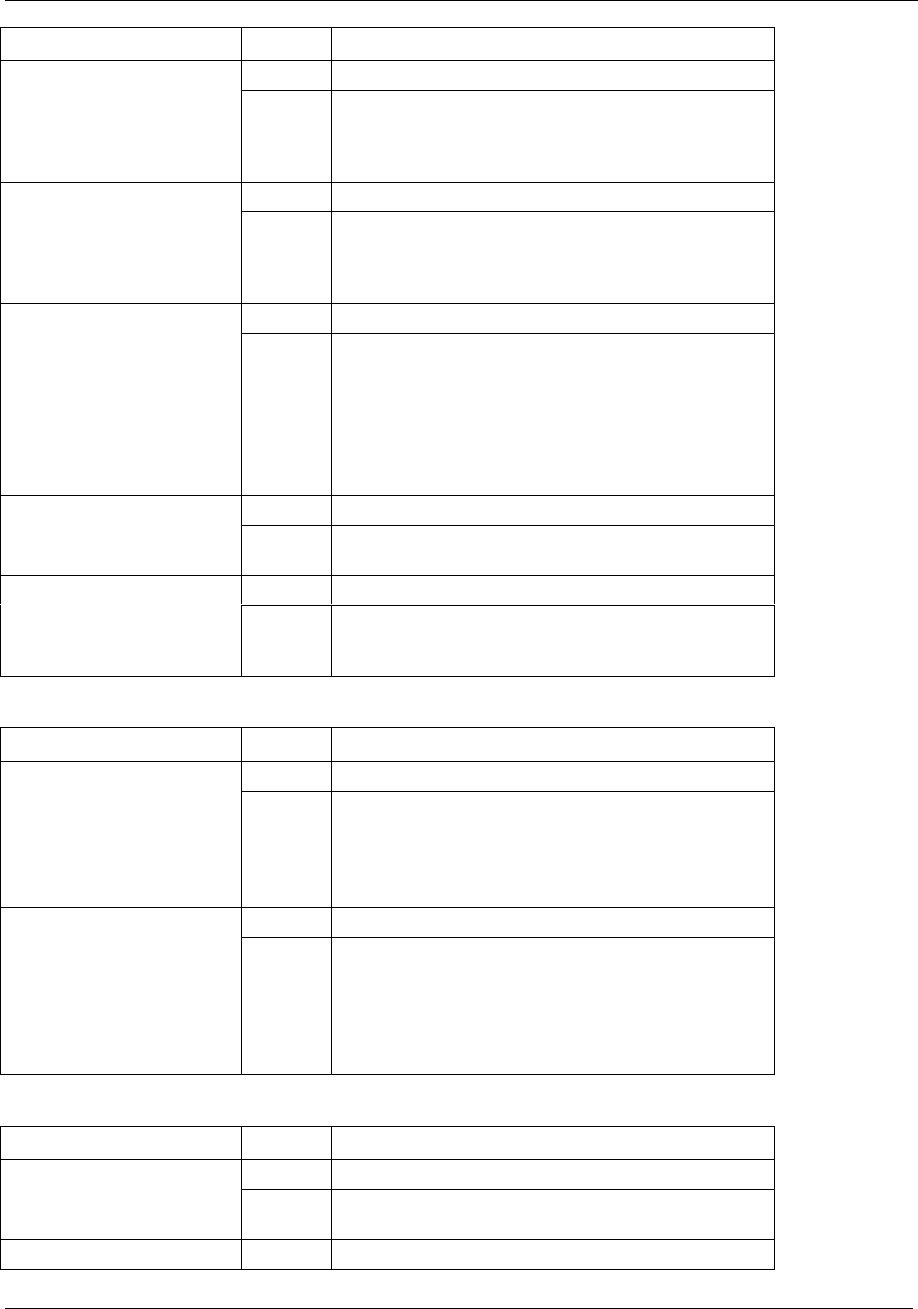

Figure 8 Normal communication ................................................................................................................................... 37

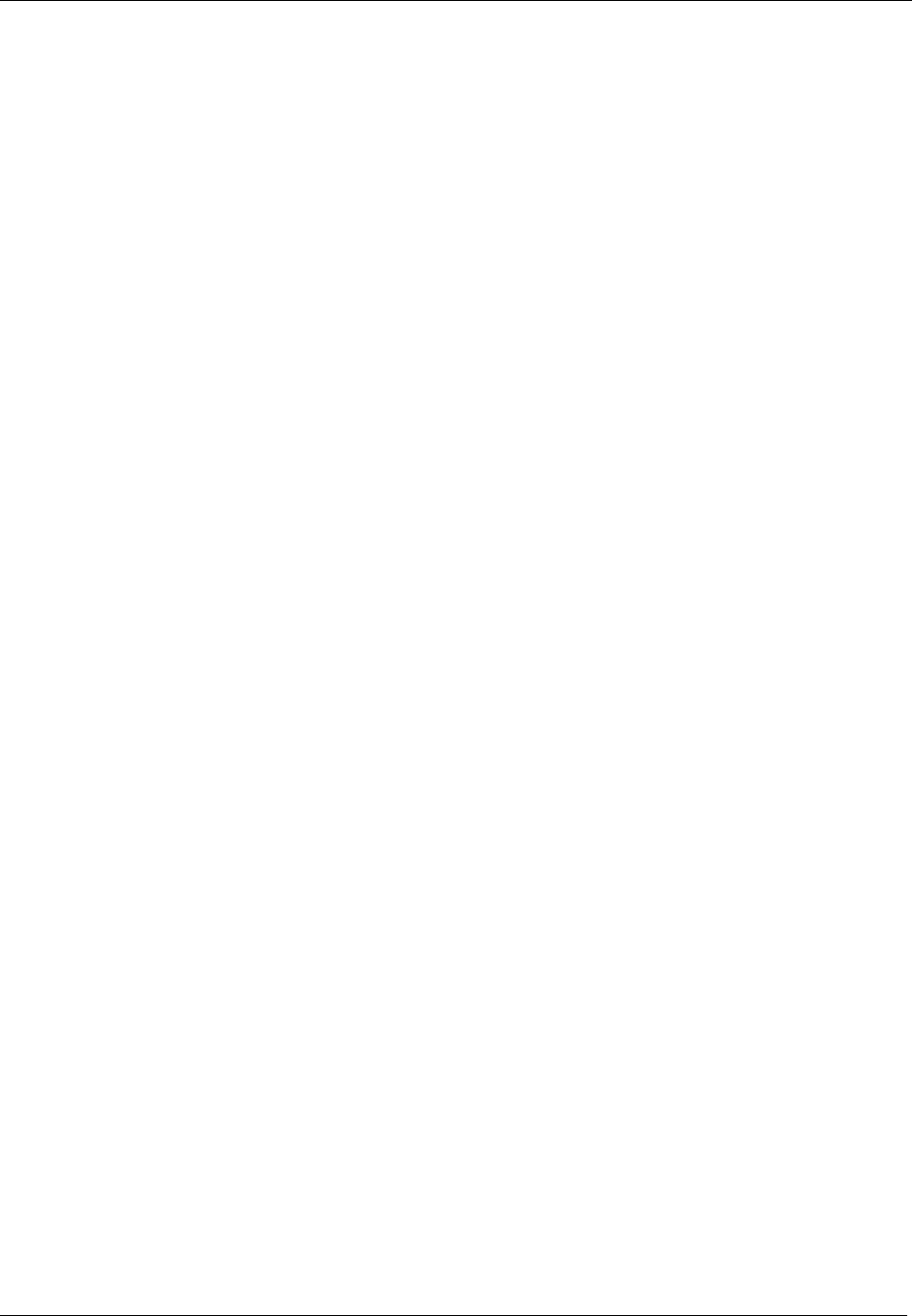

Figure 9 No Acknowledge received ............................................................................................................................. 38

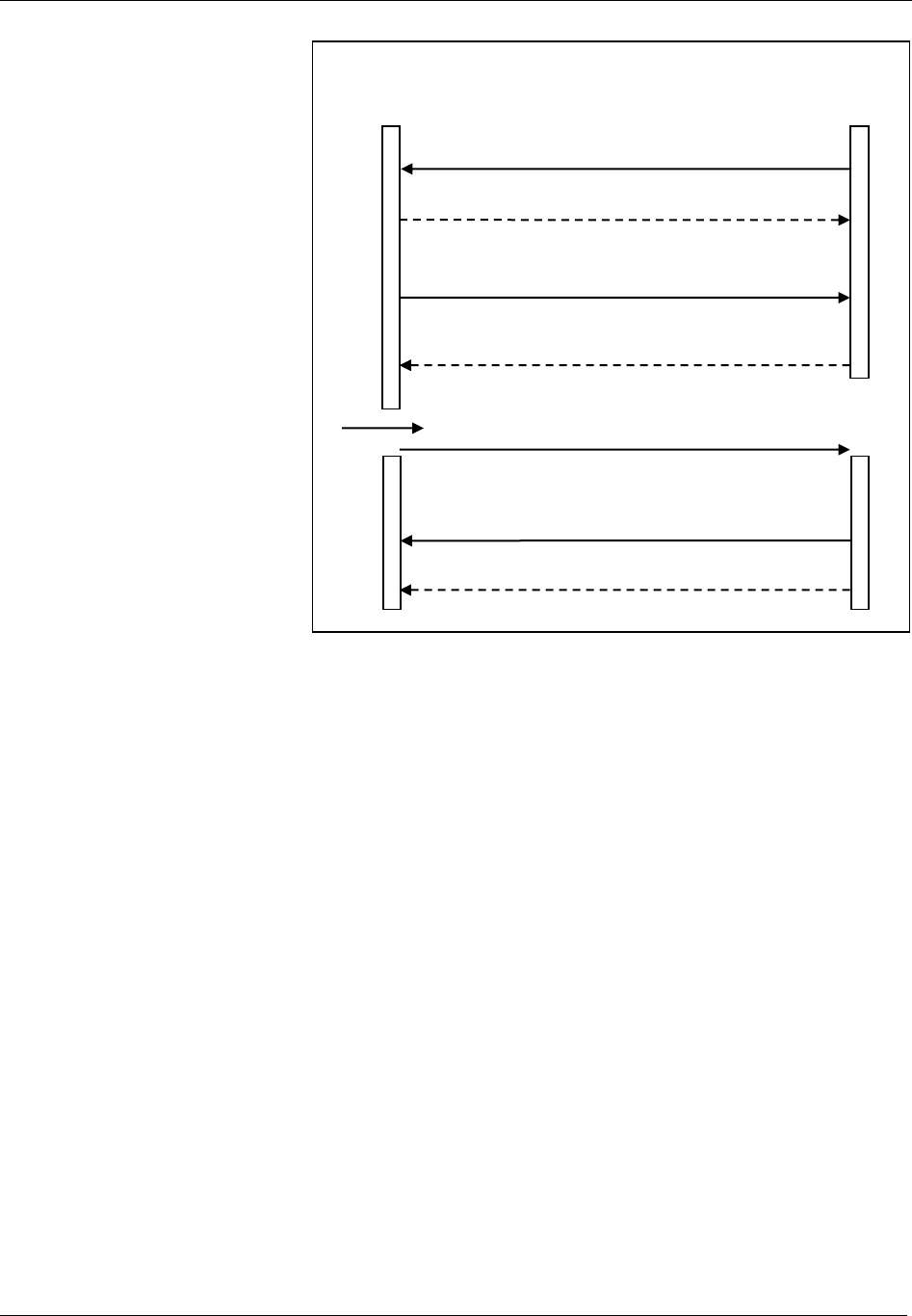

Figure 10 Wrong sequence numbering ....................................................................................................................... 39

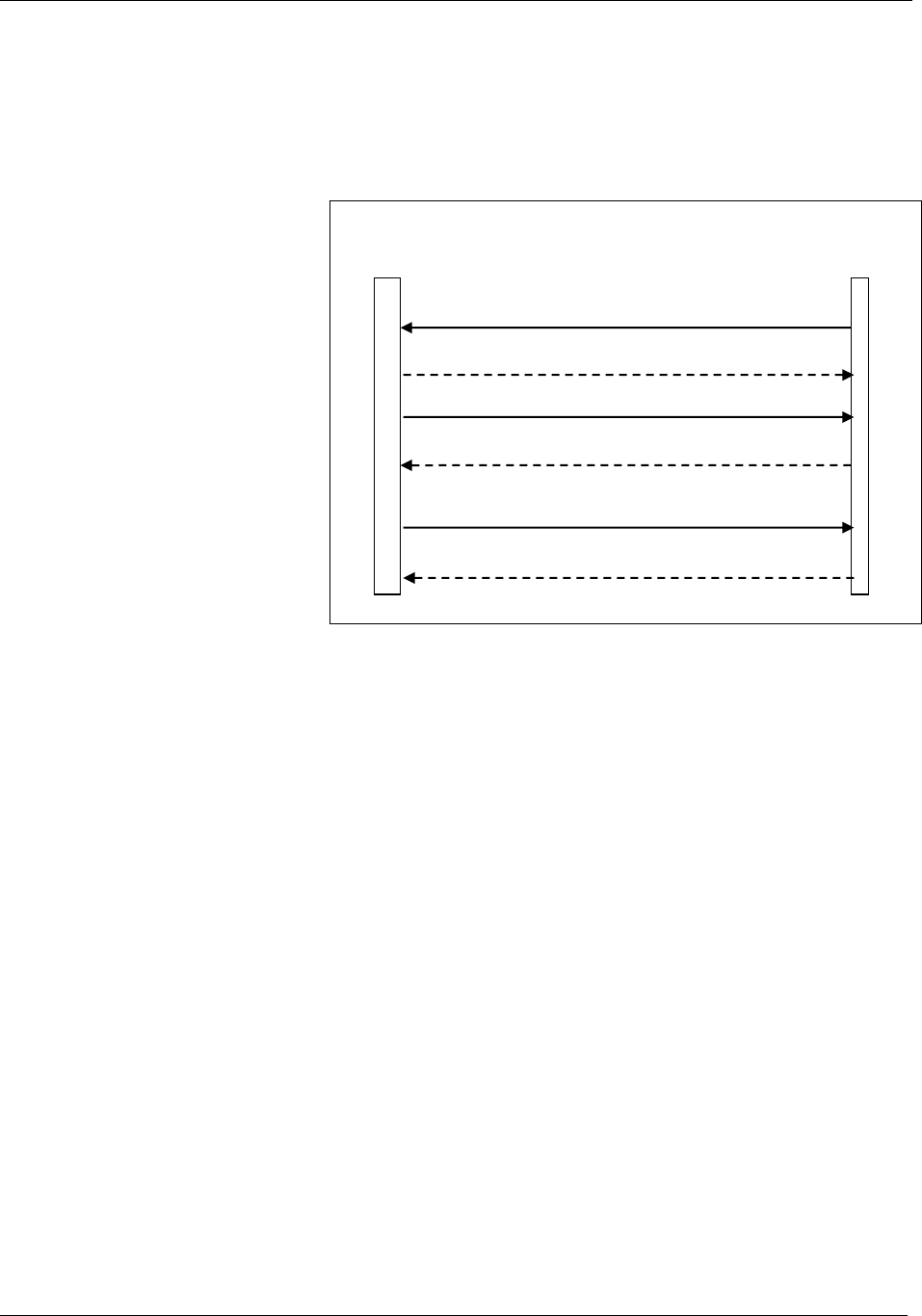

Figure 11 Transmission broken .................................................................................................................................... 40

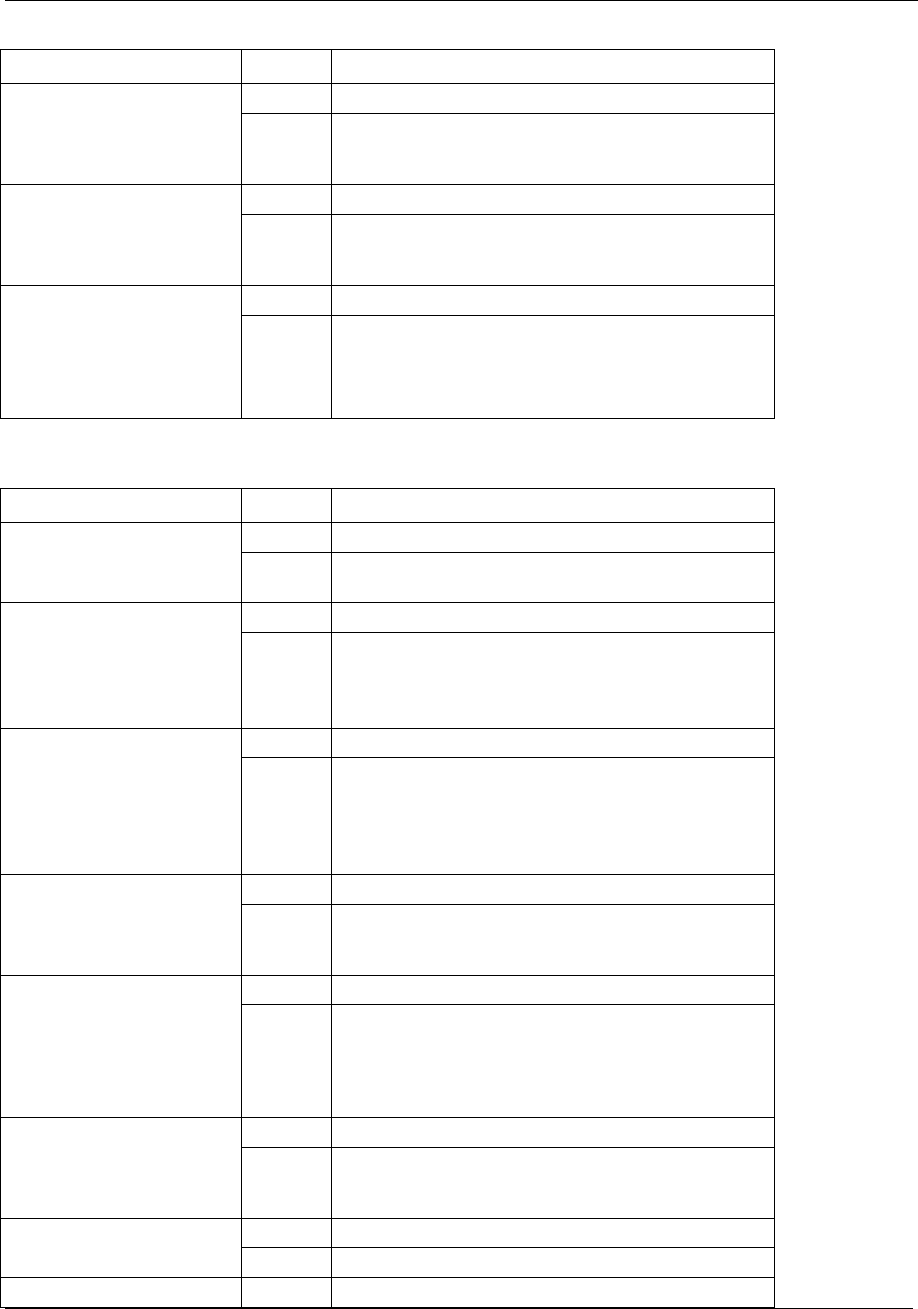

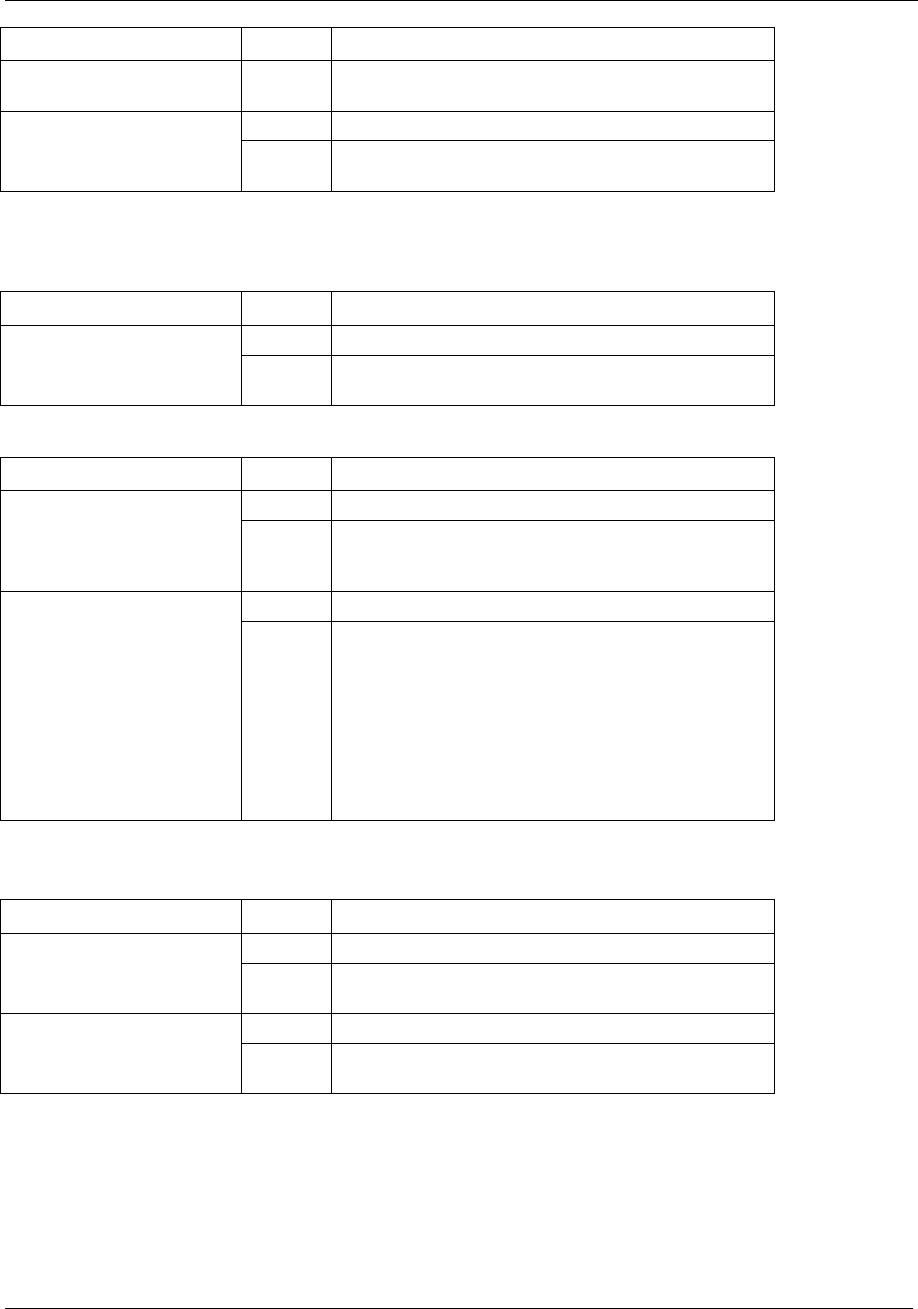

Figure 12 Ethernet connection example ....................................................................................................................... 41

Figure 13 Serial connection example ........................................................................................................................... 42

Figure 14 Serial connection with 3964R, example........................................................................................................ 43

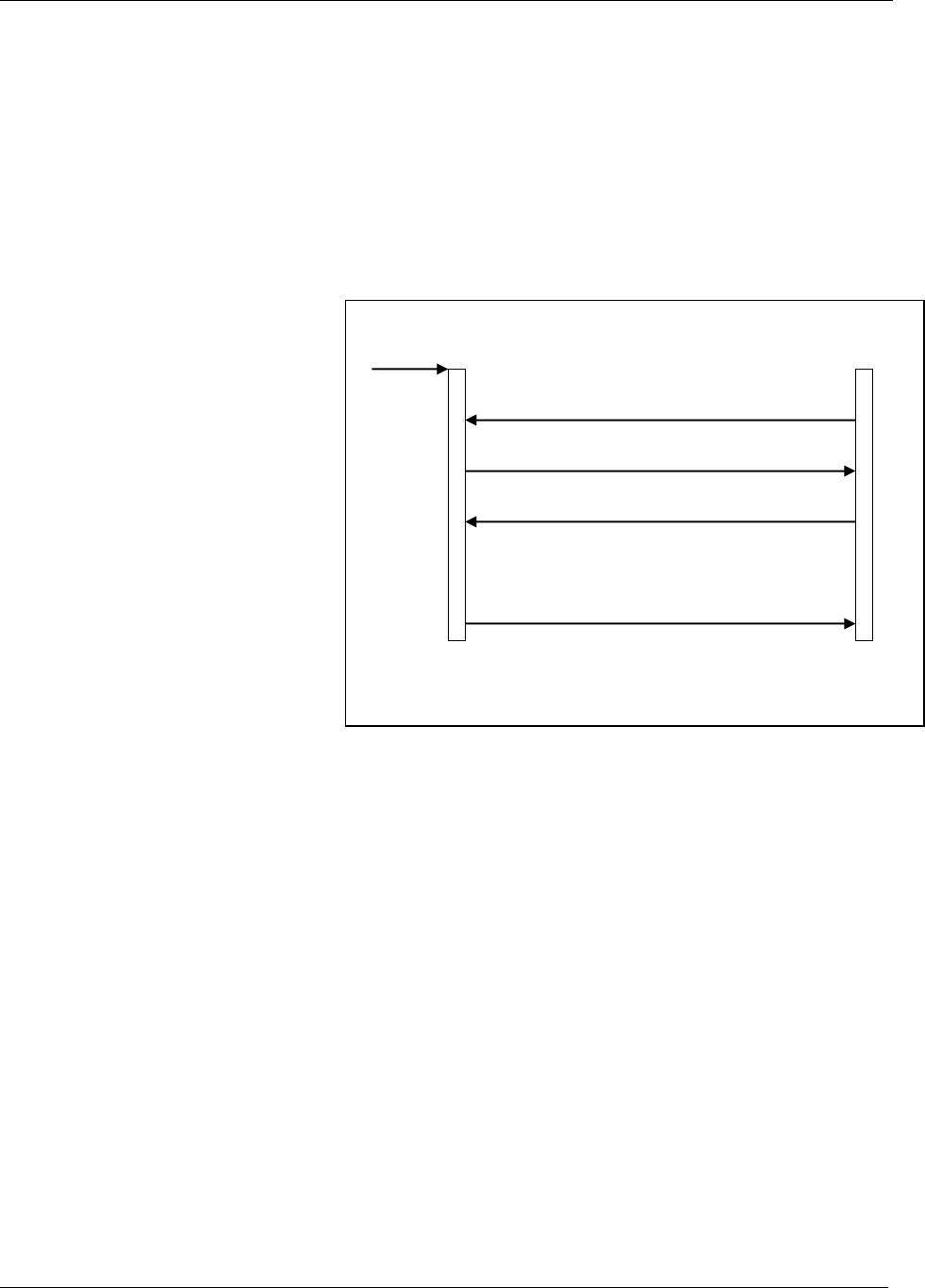

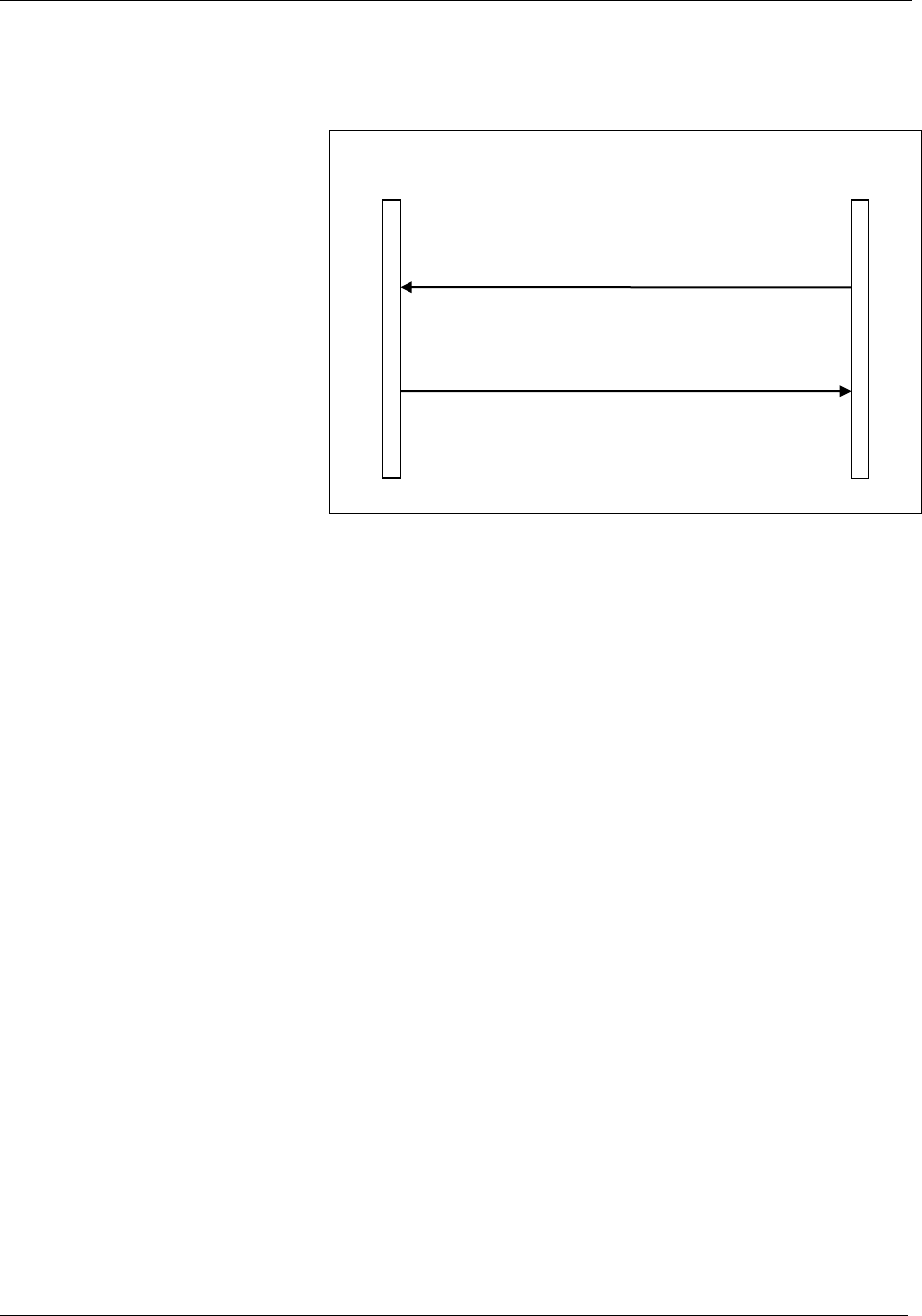

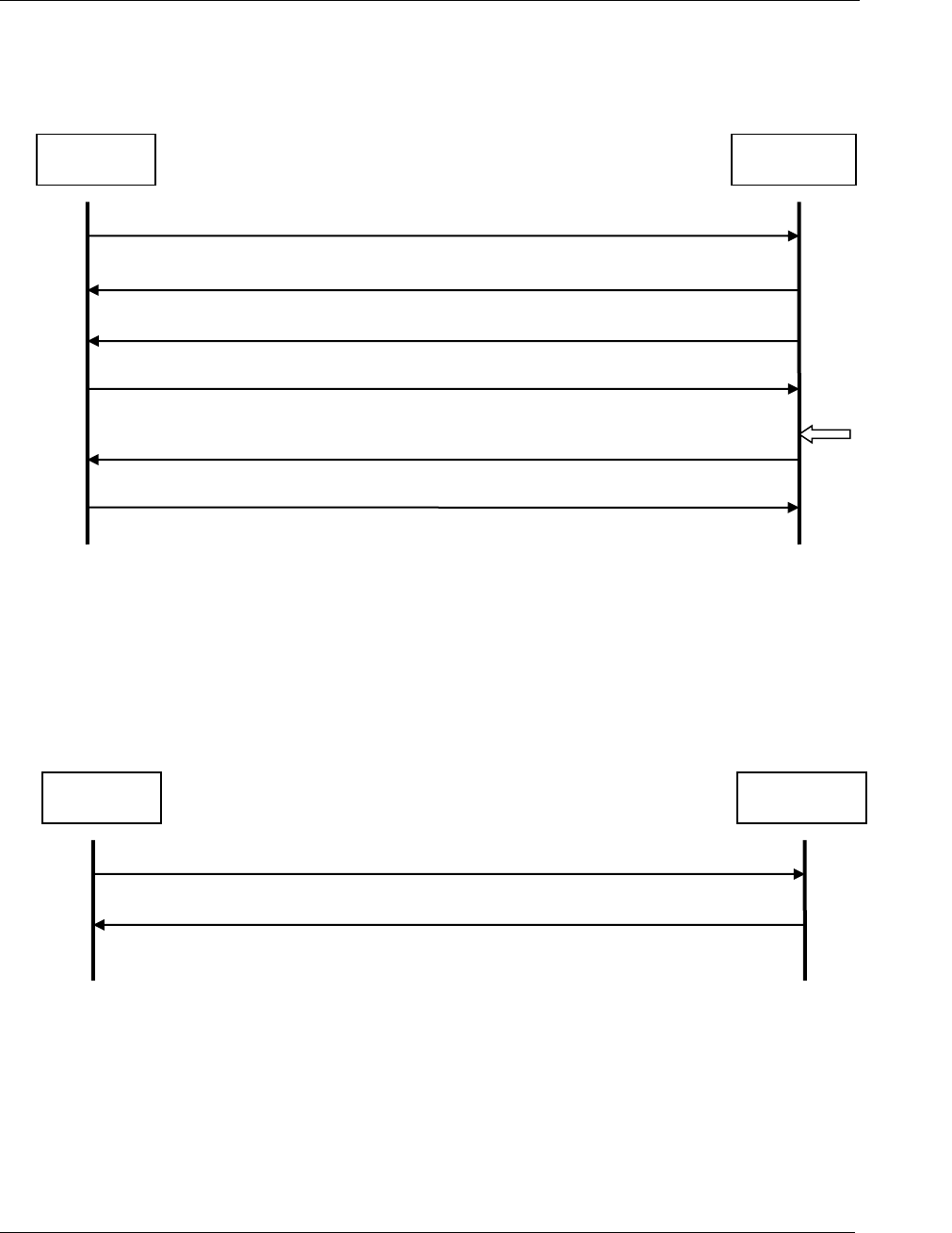

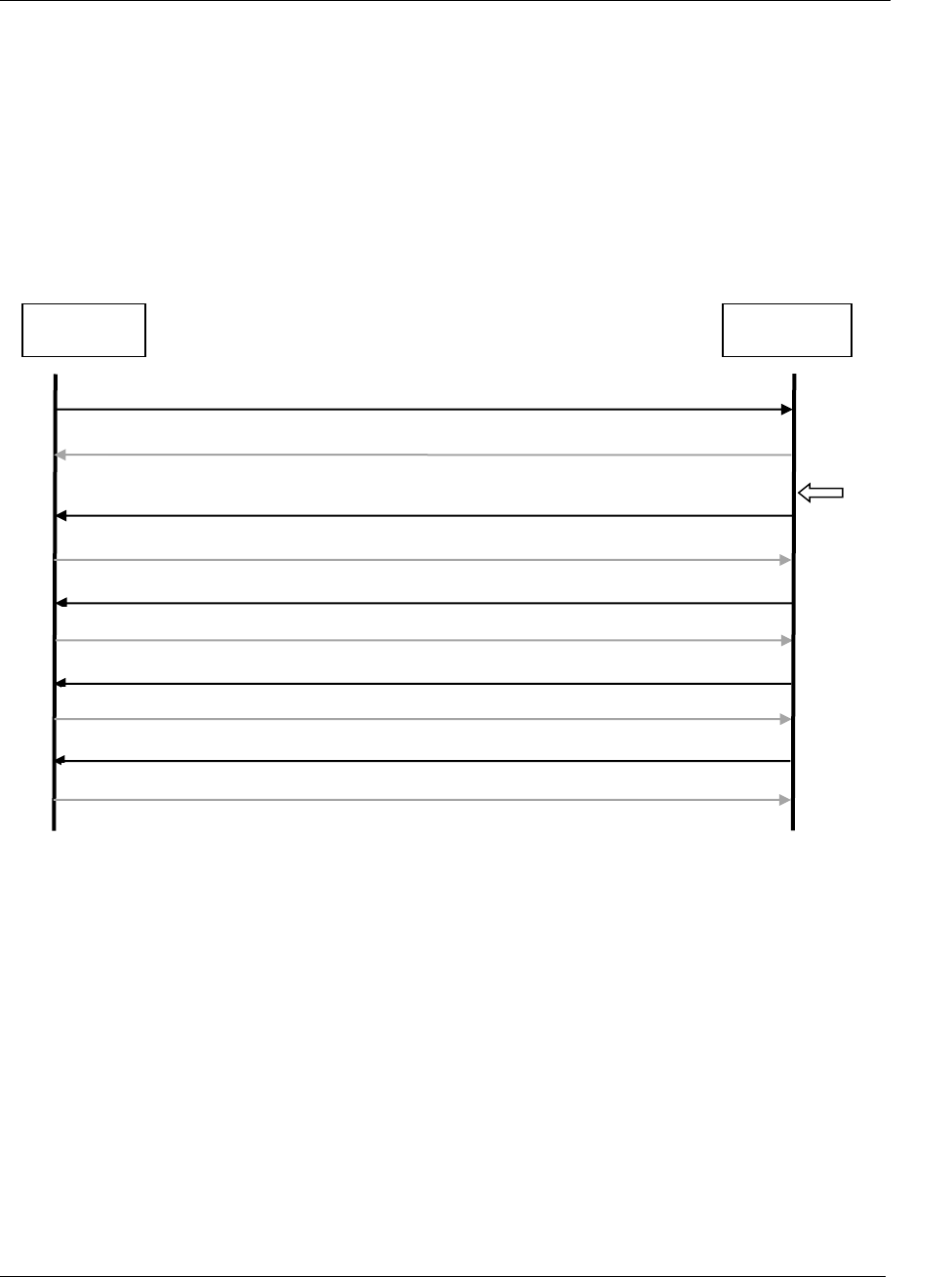

Figure 15 Starting a subscription ................................................................................................................................. 46

Figure 16 Sending a request ........................................................................................................................................ 47

Figure 17 Send a command ......................................................................................................................................... 48

Figure 18 Production startup Pset selection ................................................................................................................ 53

Figure 19 Running production at Pset selection .......................................................................................................... 54

Figure 20 Production startup at Job selection............................................................................................................... 56

Figure 21 Running production at Job selection............................................................................................................. 57

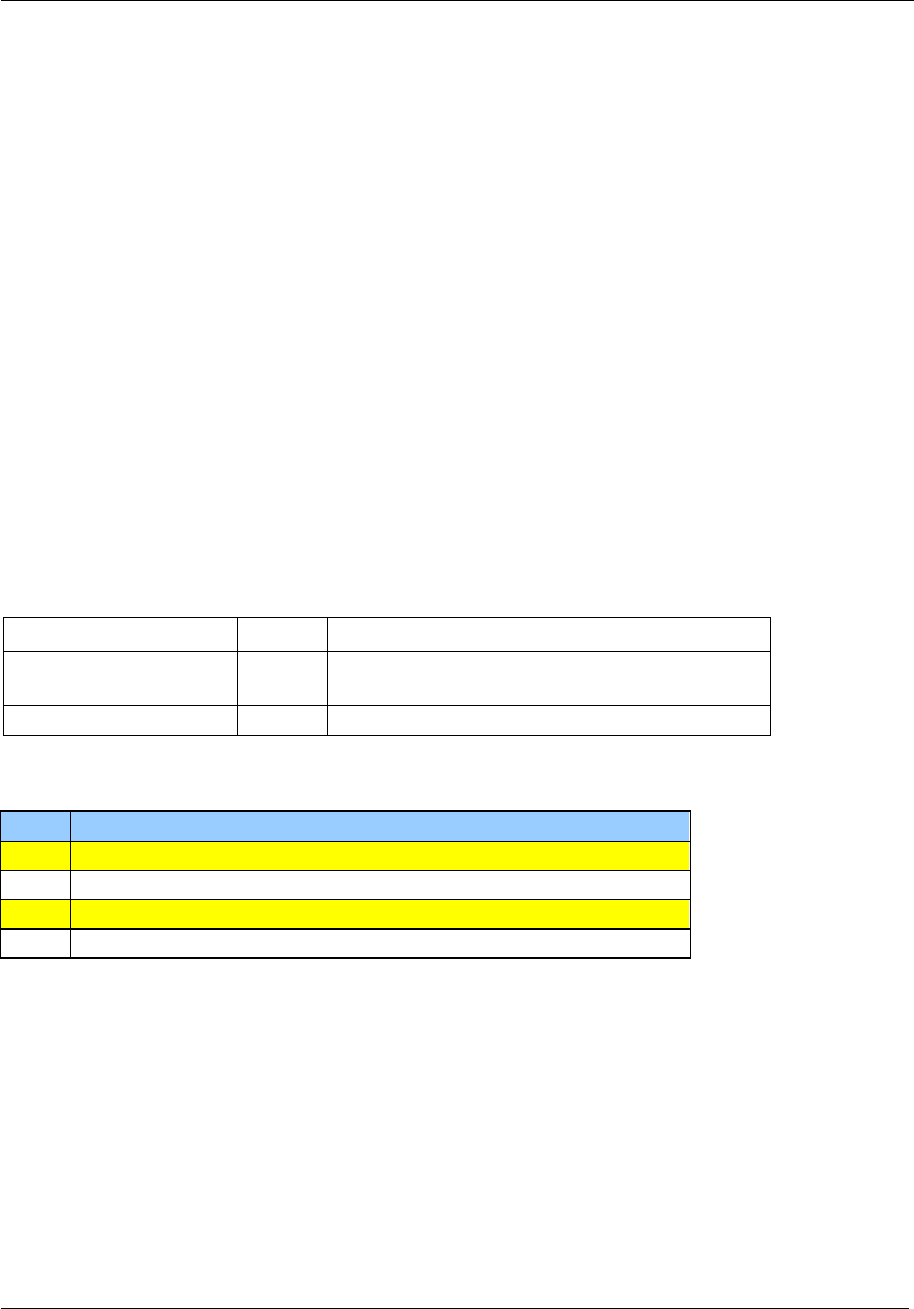

Figure 22 Histogram example..................................................................................................................................... 248

Contents

7 (285)

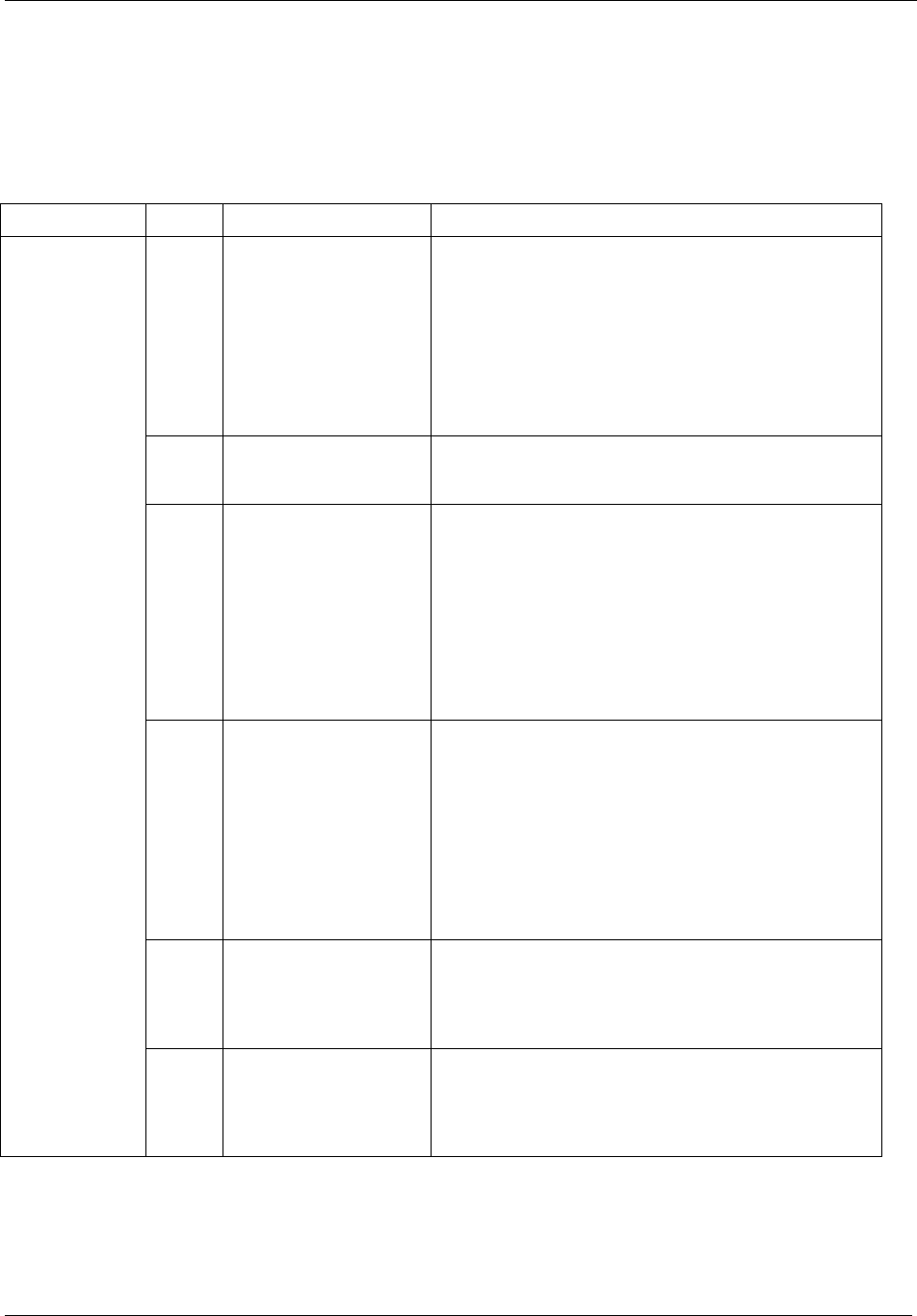

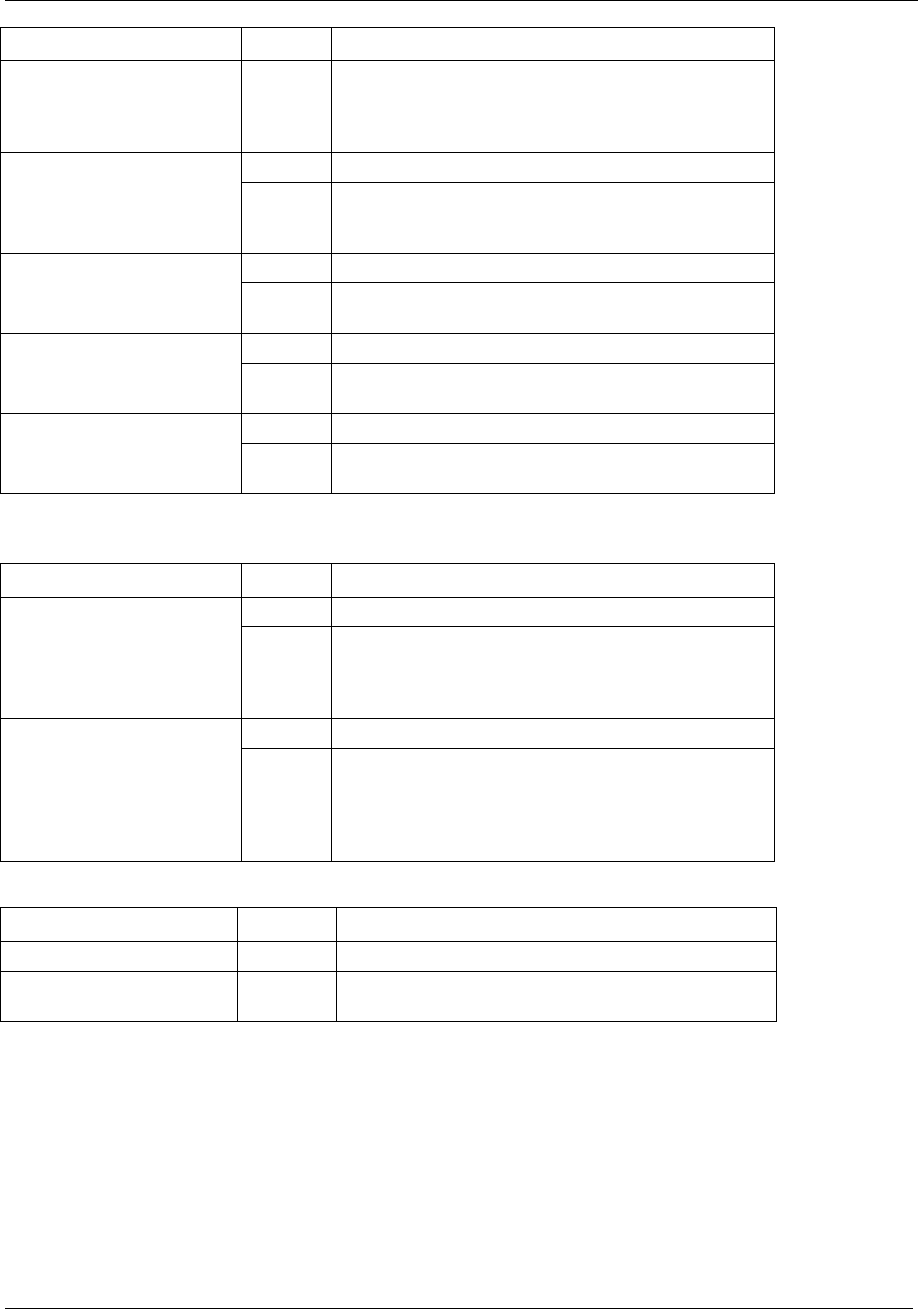

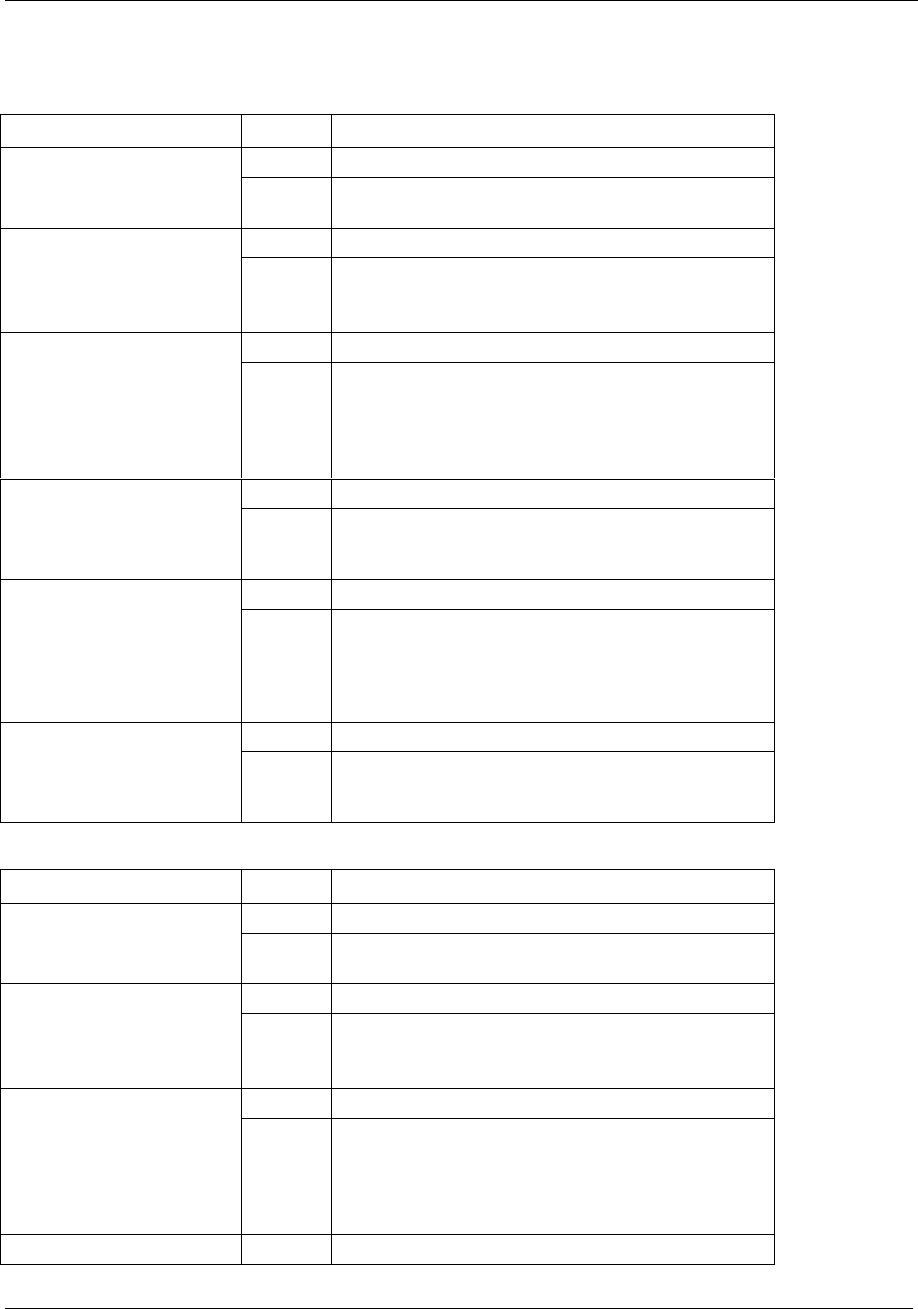

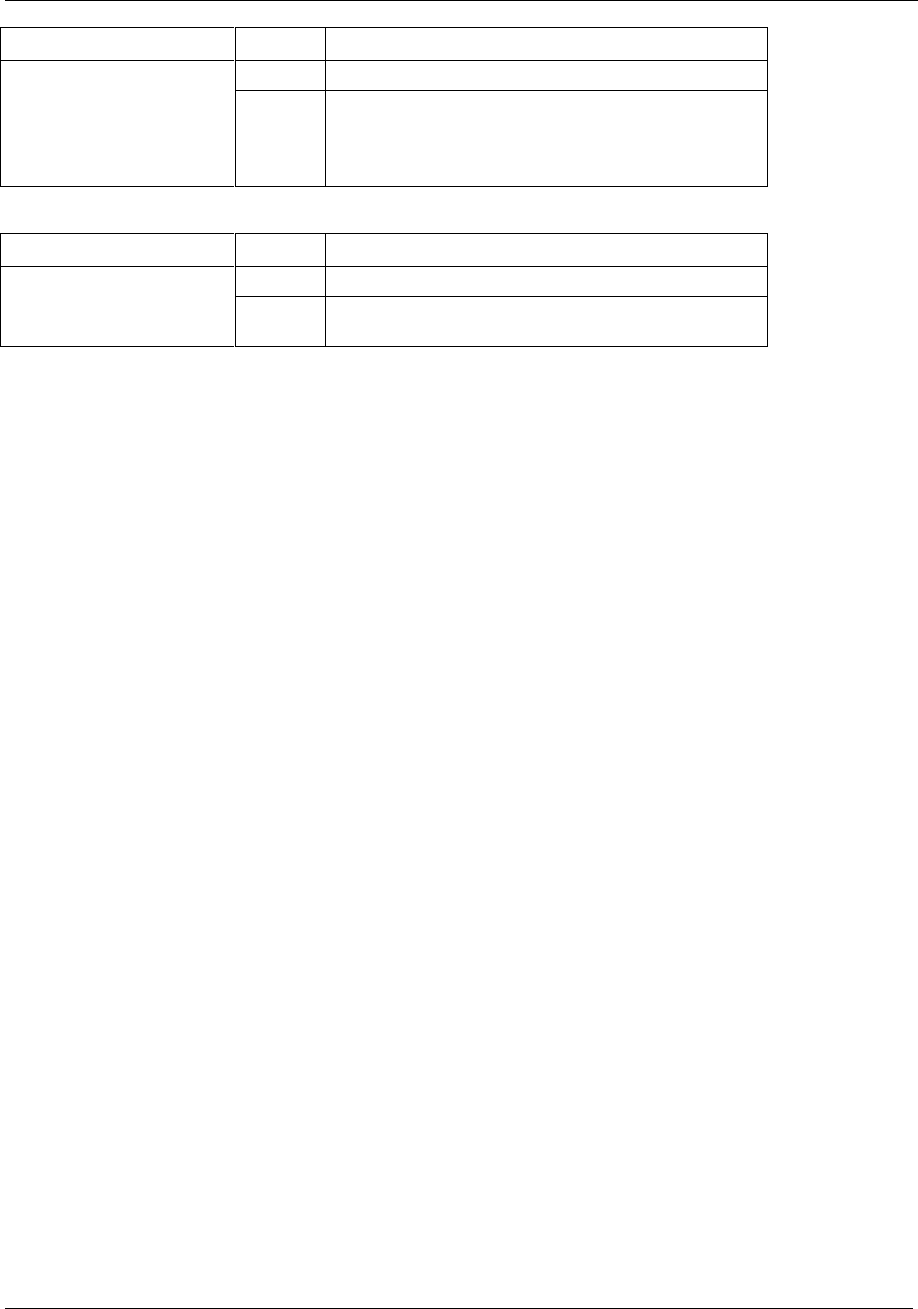

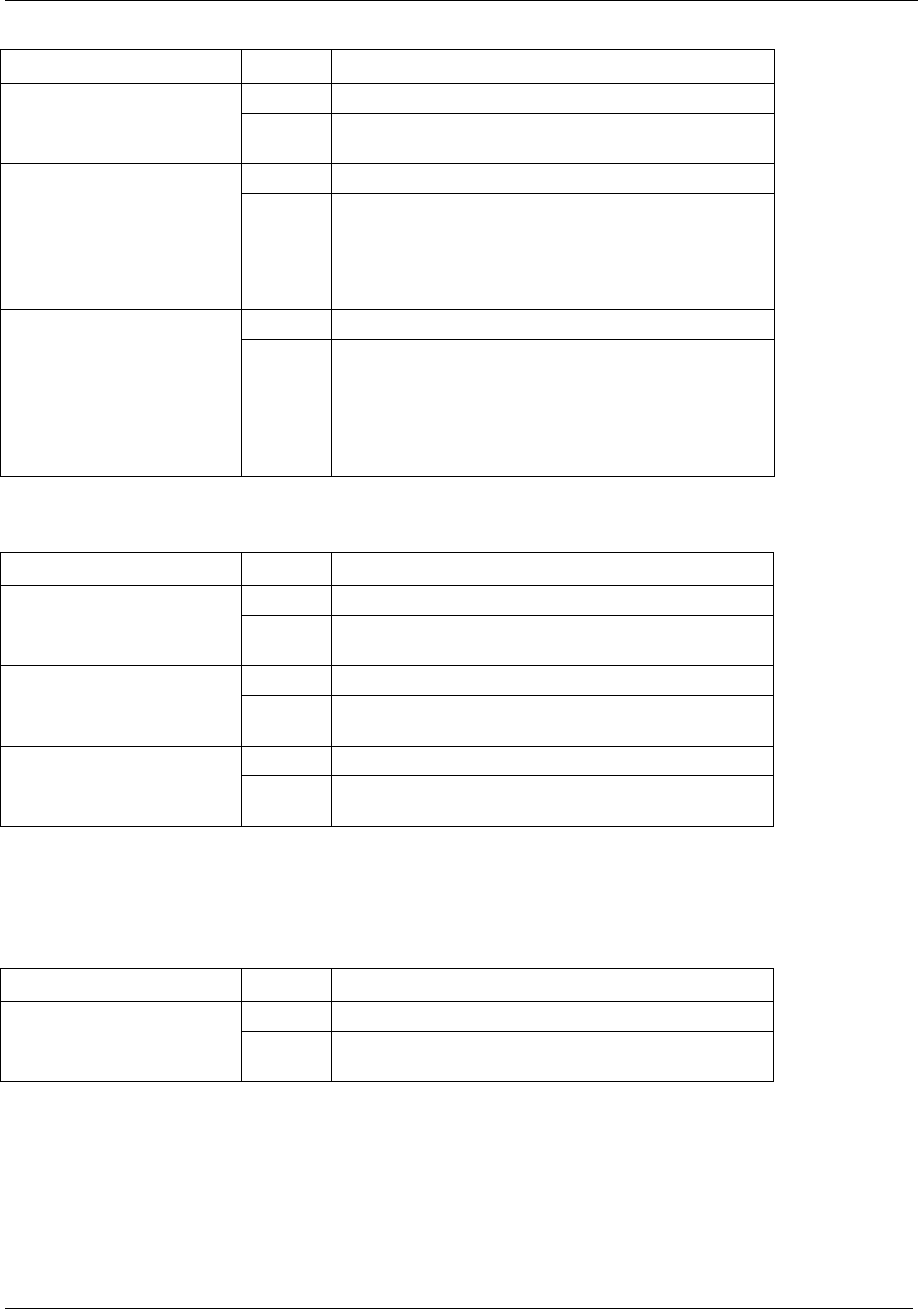

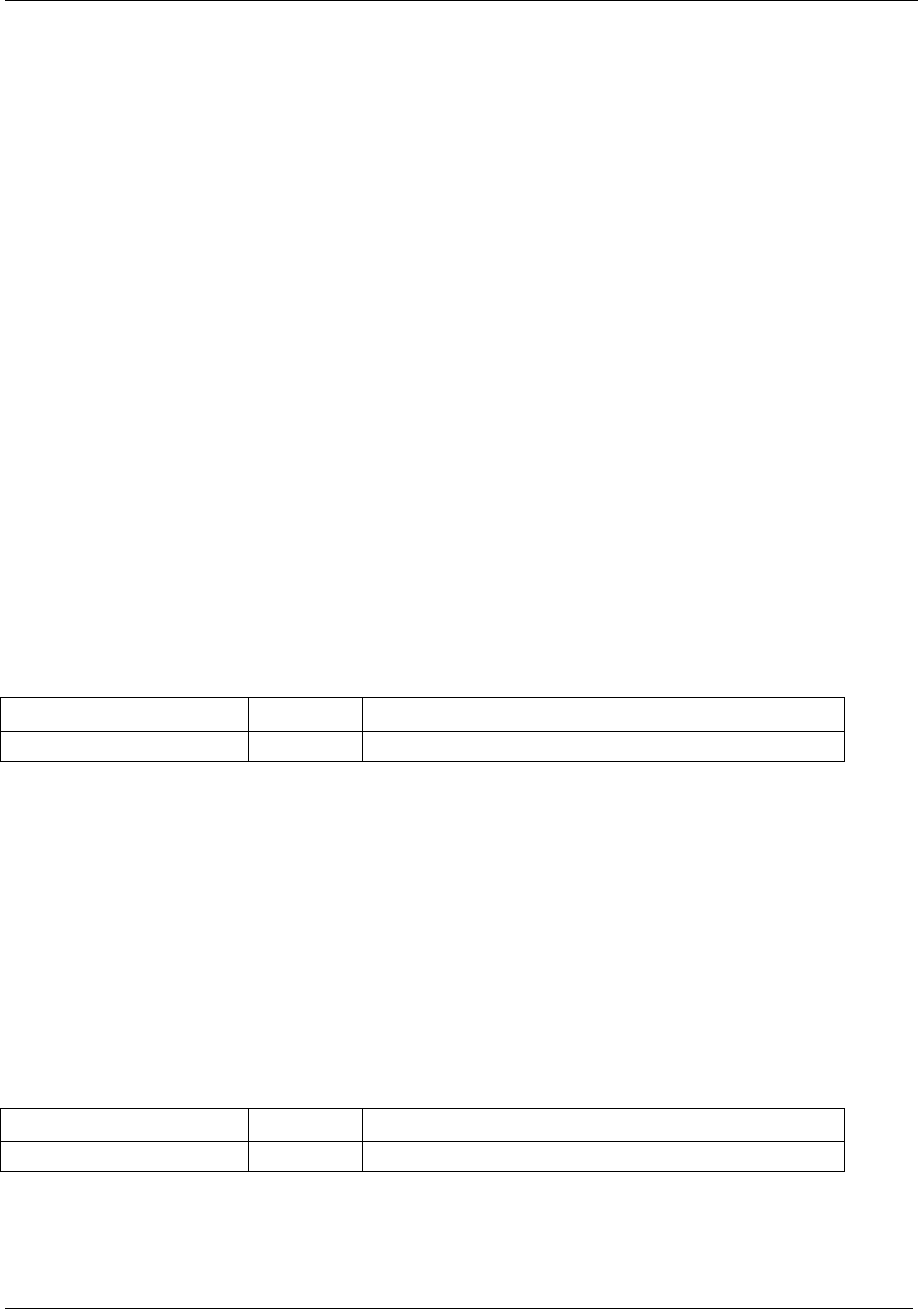

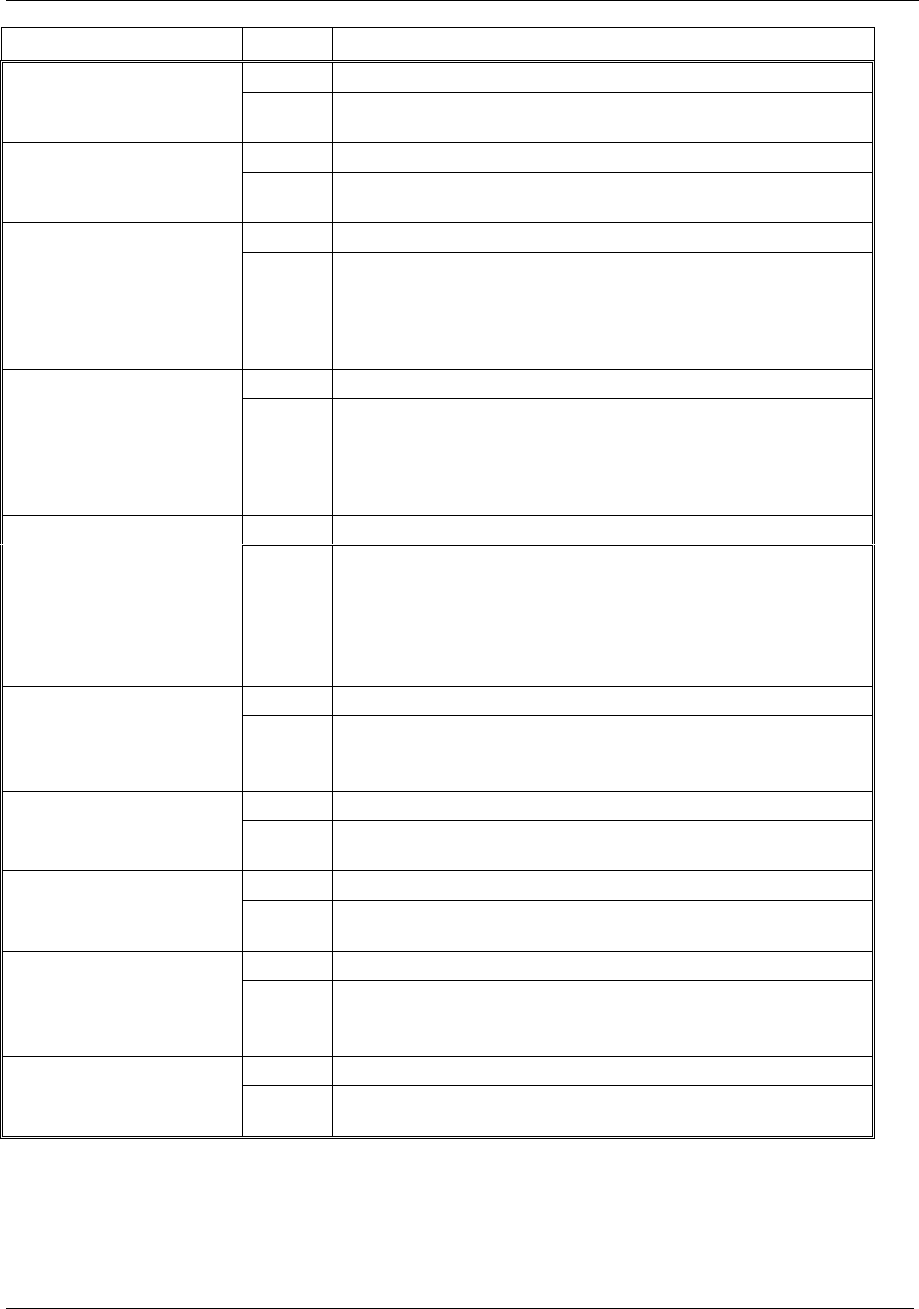

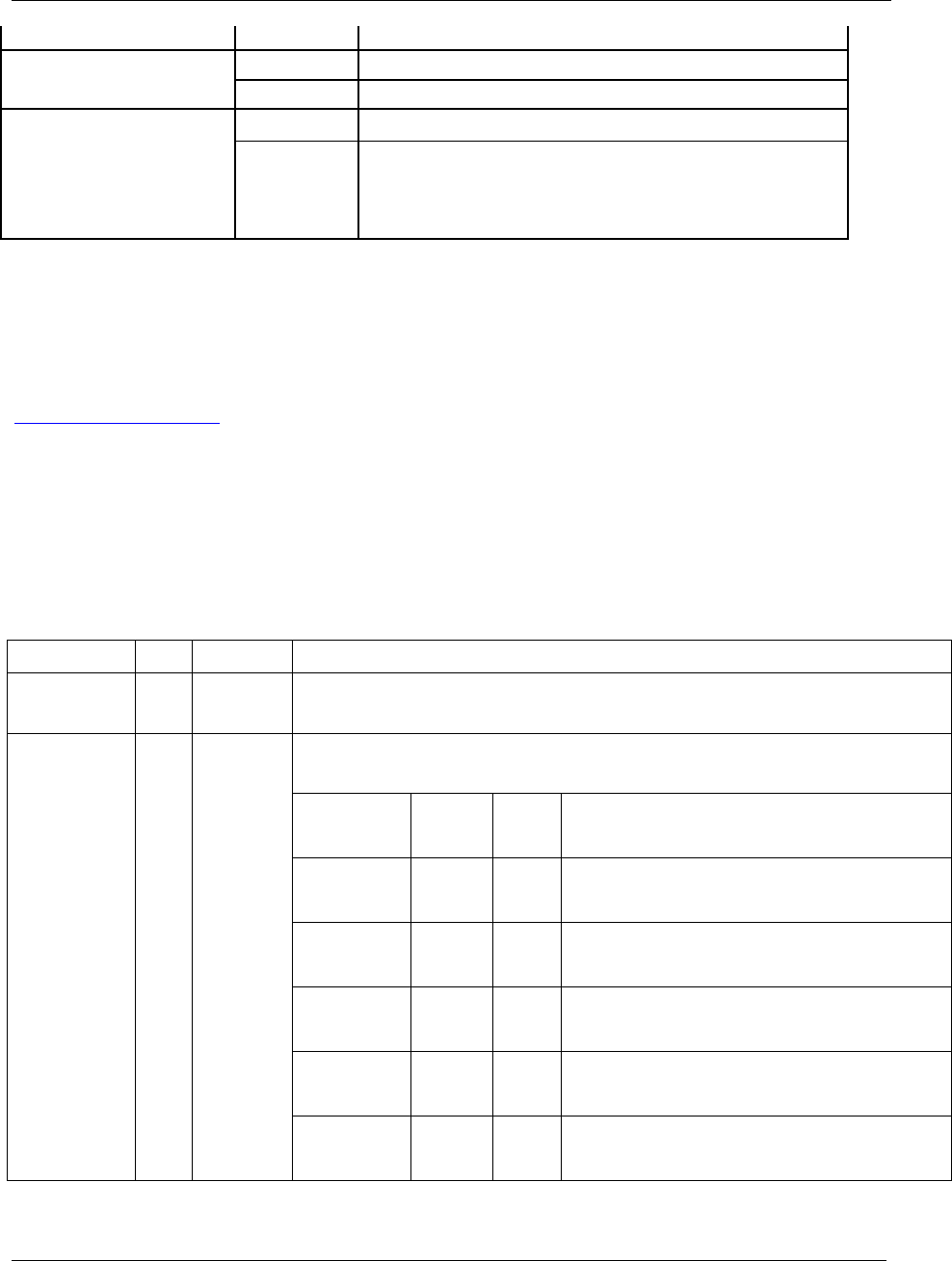

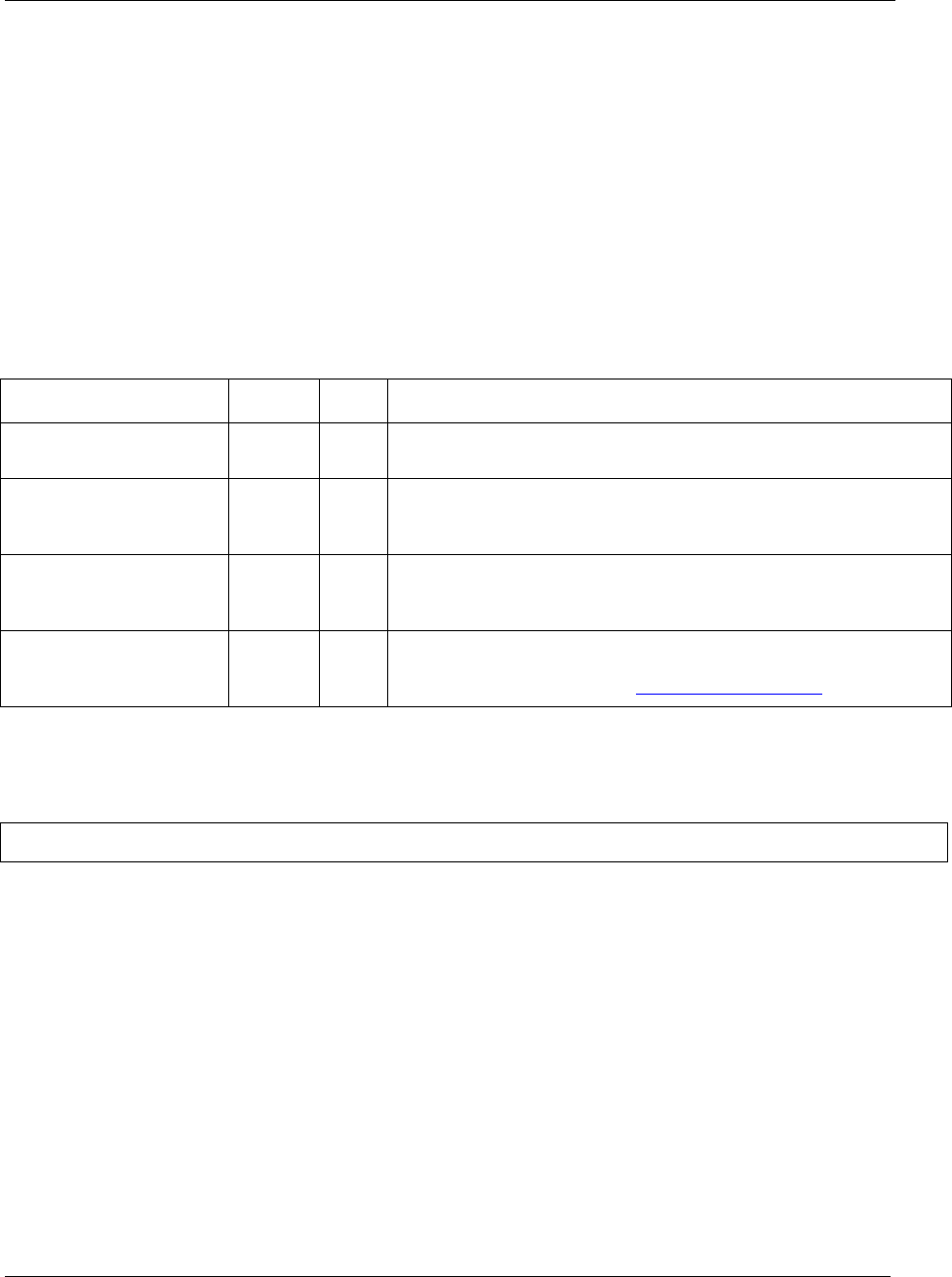

Table 1 Header content ................................................................................................................................................ 26

Table 2 Message with binary data contents ................................................................................................................. 28

Table 3 Data field content ............................................................................................................................................. 30

Table 4 Variable Data field content ............................................................................................................................... 32

Table 5 Message end content ...................................................................................................................................... 33

Table 6 Messages using the variable parameter pattern .............................................................................................. 59

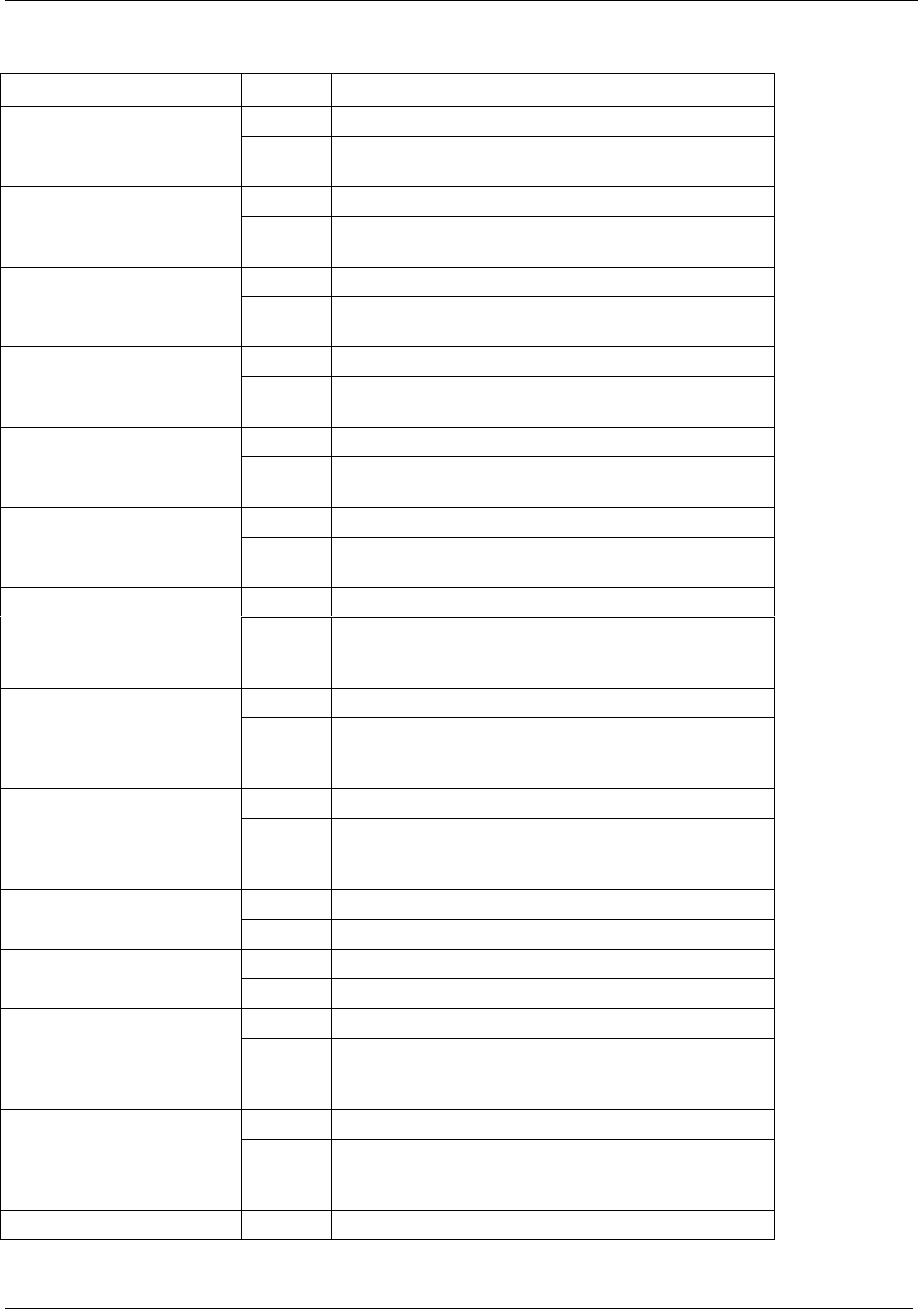

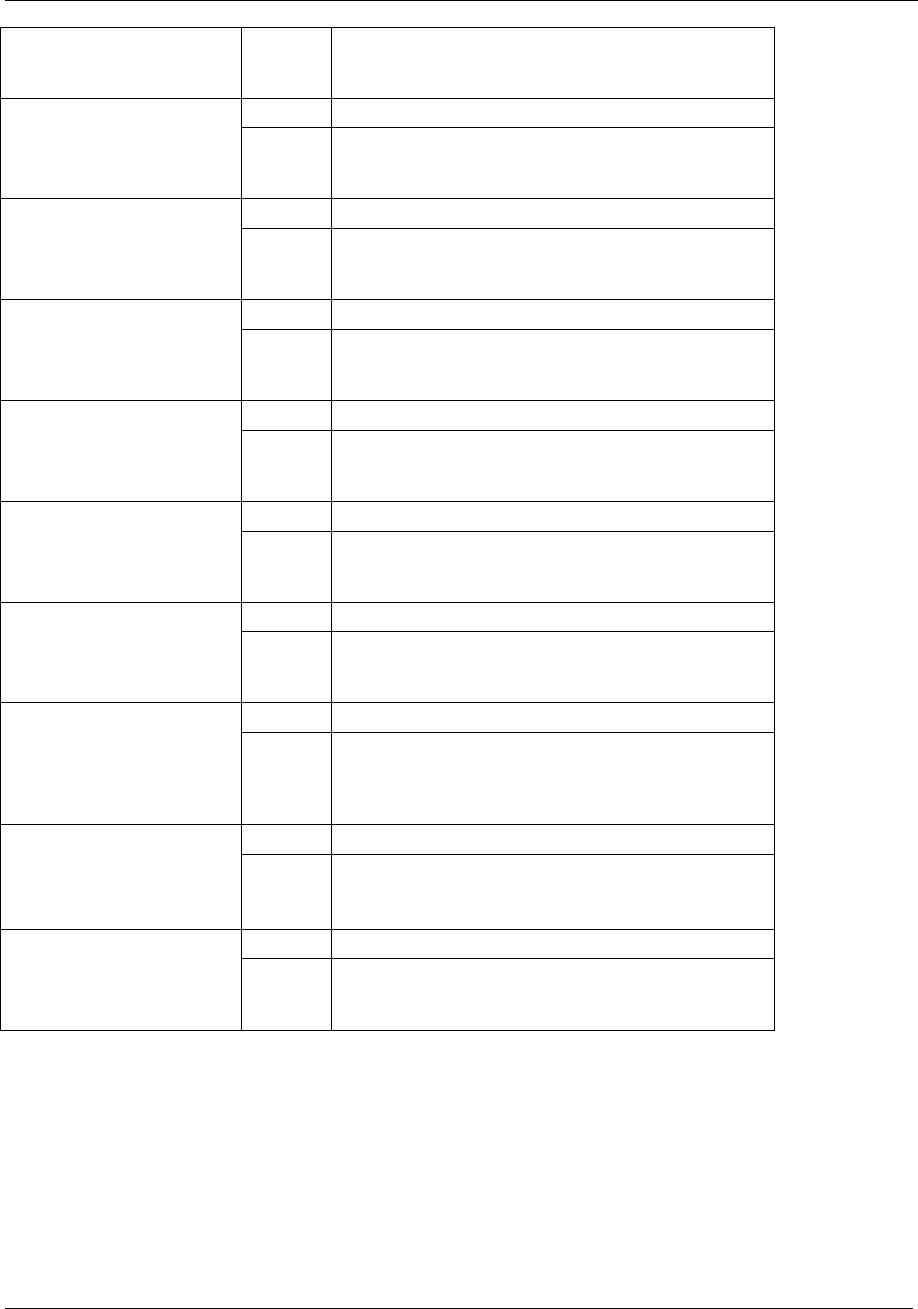

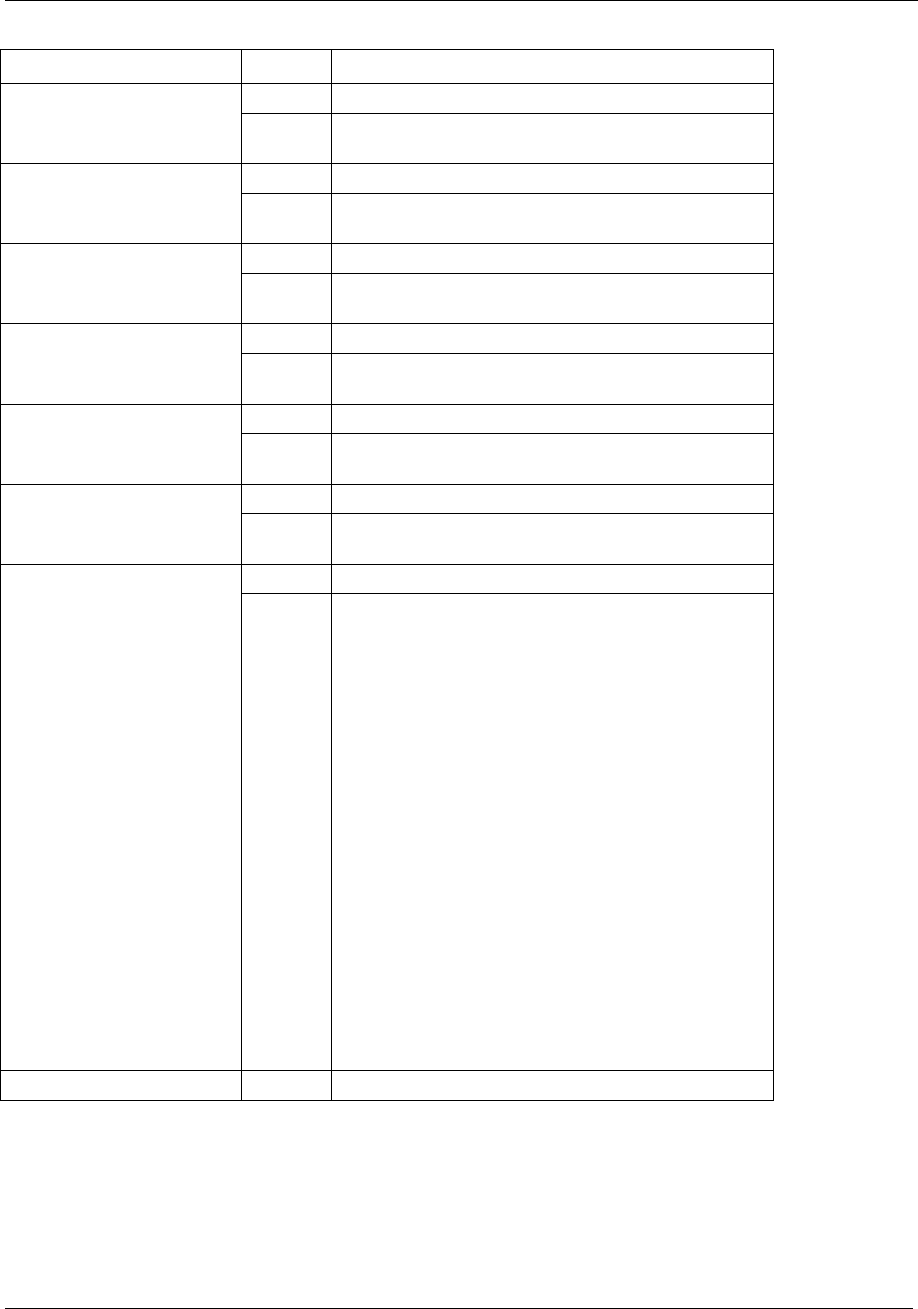

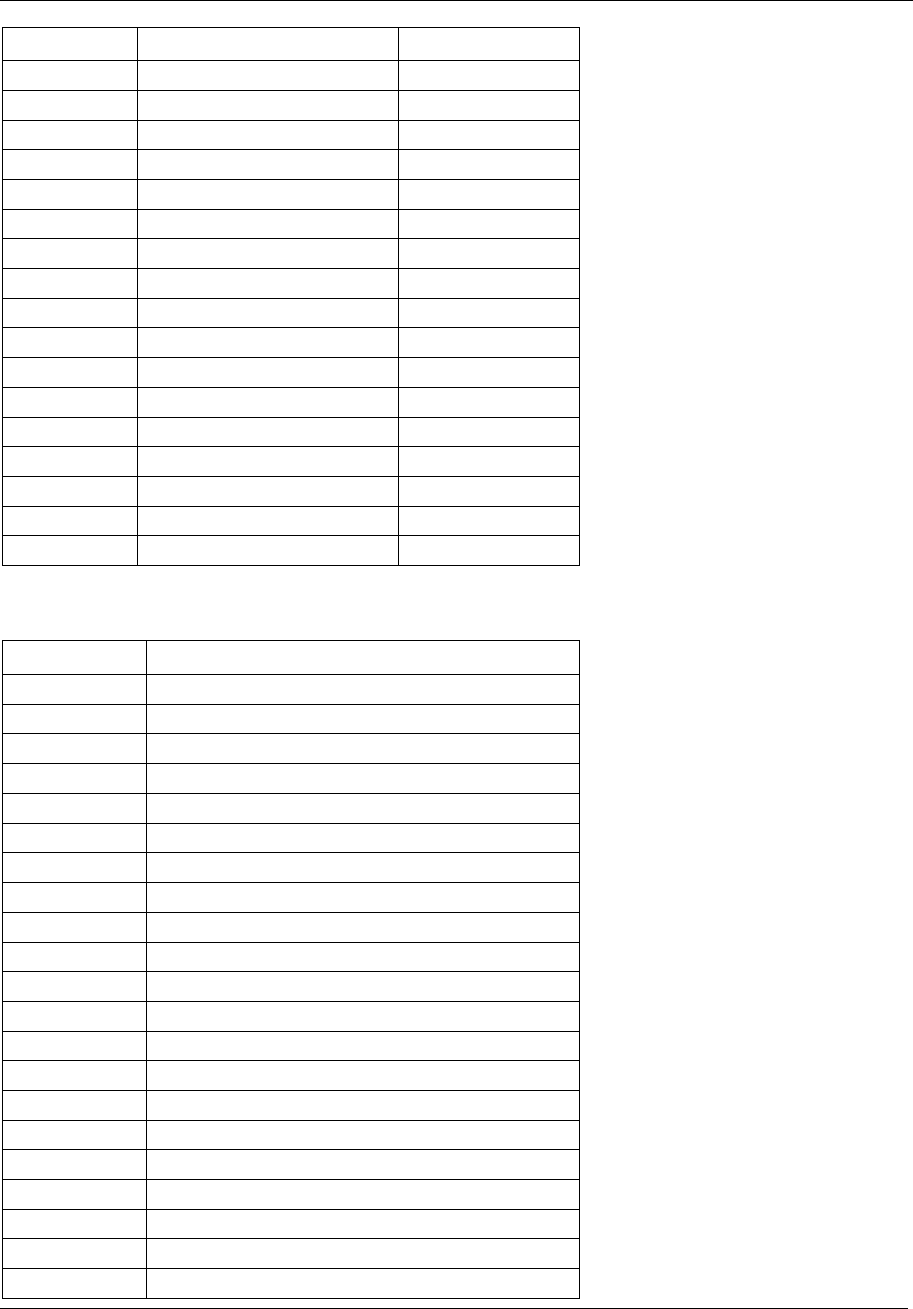

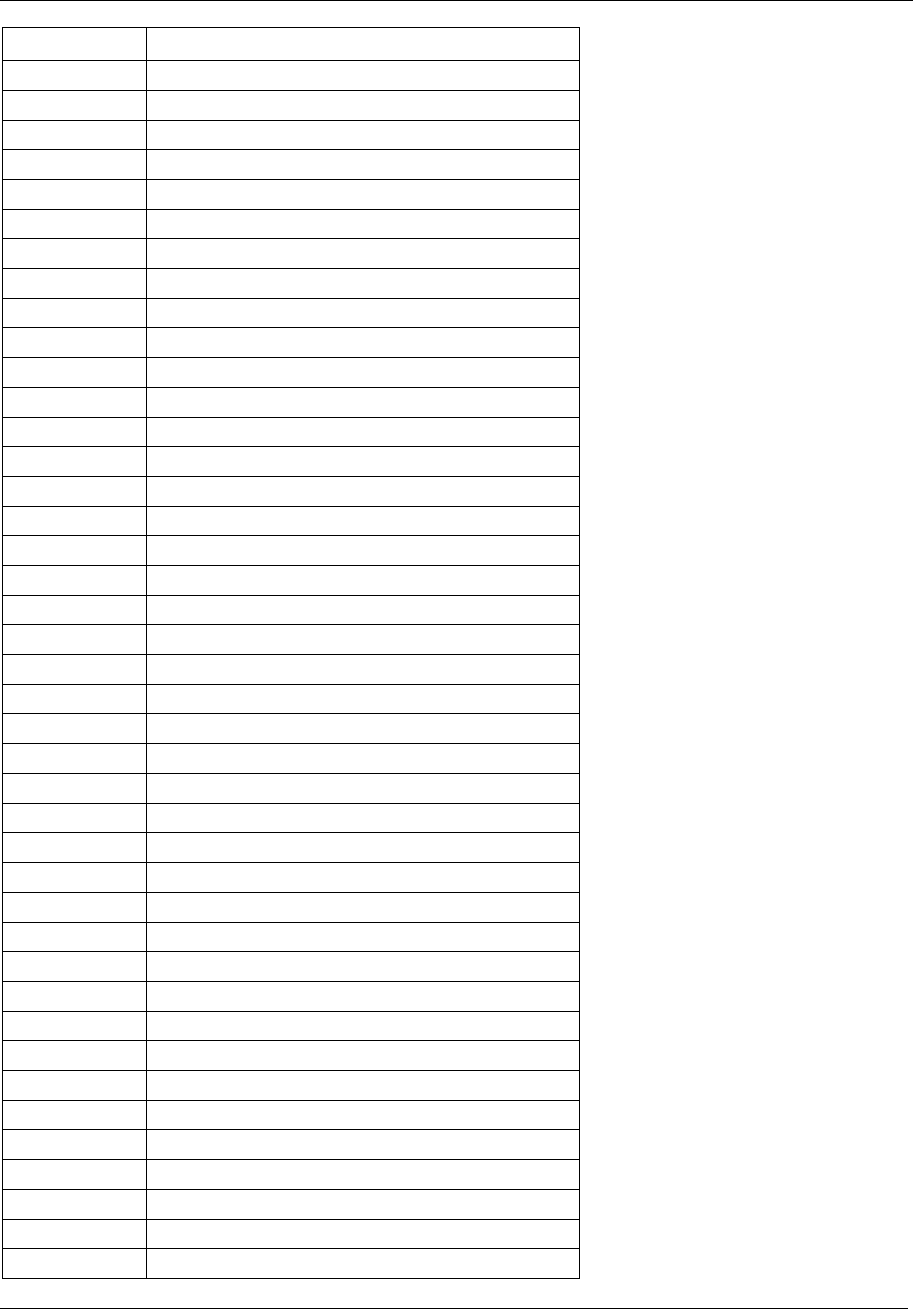

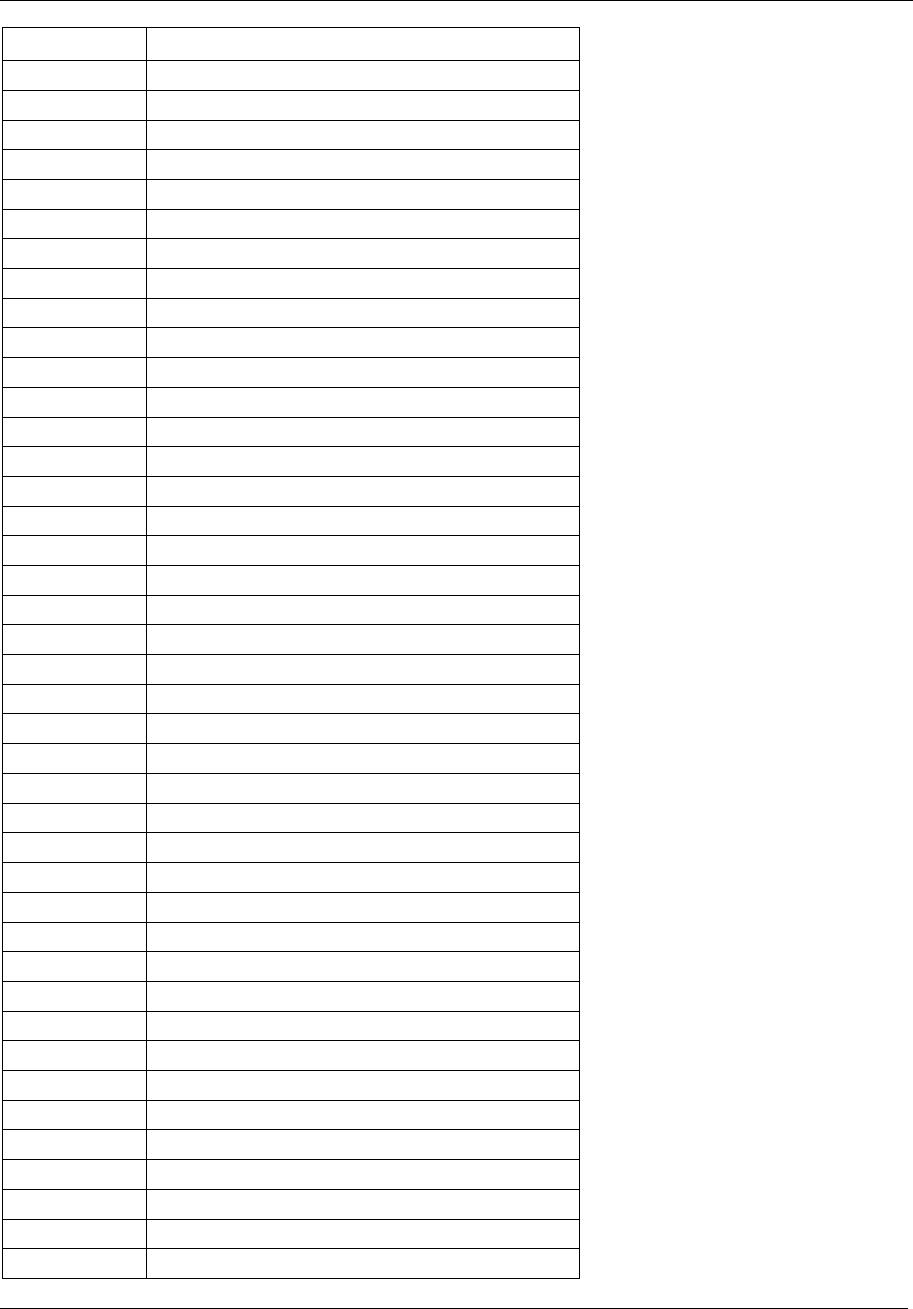

Table 7 Available messages ......................................................................................................................................... 63

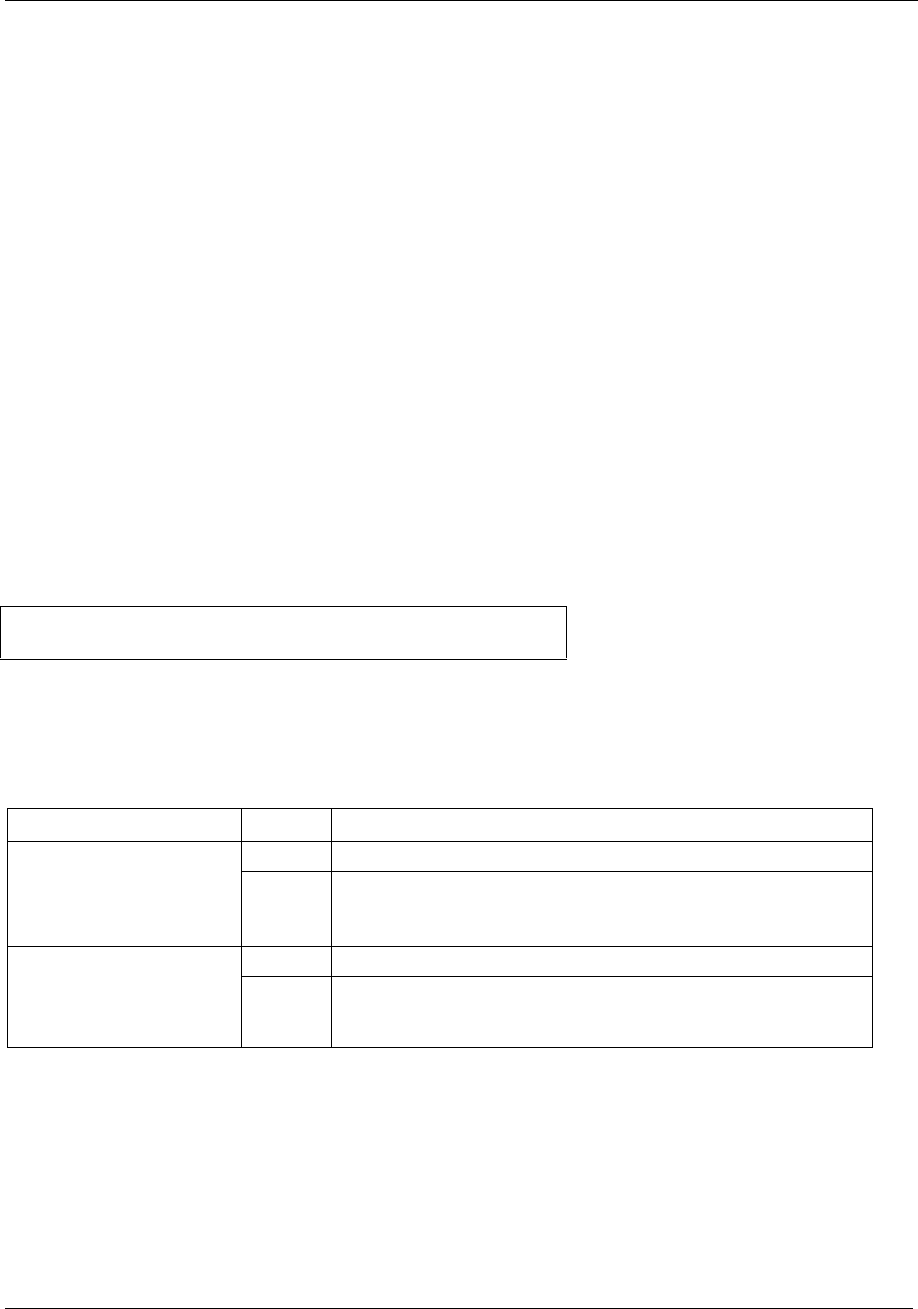

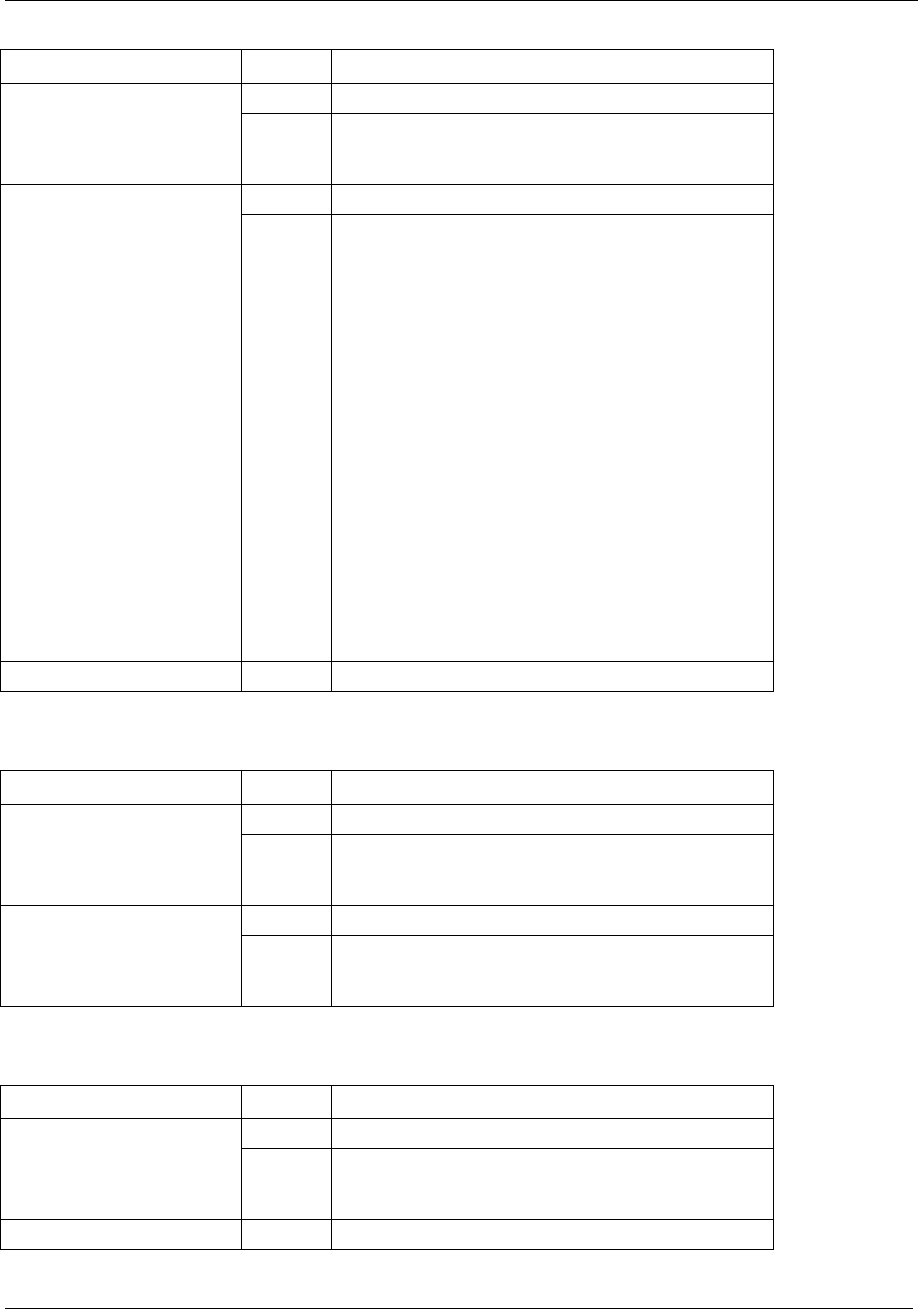

Table 8, MID 9998 Rev 1 .............................................................................................................................................. 69

Table 9 Error code description...................................................................................................................................... 69

Table 10, MID 9997 Rev 1 ............................................................................................................................................ 70

Table 11 MID 0002 Revision 1 ..................................................................................................................................... 71

Table 12 MID 0002 Additions for revision 2 .................................................................................................................. 71

Table 13 MID 0002 Additions for revision 3 .................................................................................................................. 71

Table 14 MID 0002 Additions for revision 4 .................................................................................................................. 71

Table 15 MID 0002 Additions for revision 5 .................................................................................................................. 72

Table 16 MID 0002 Additions for revision 6 .................................................................................................................. 72

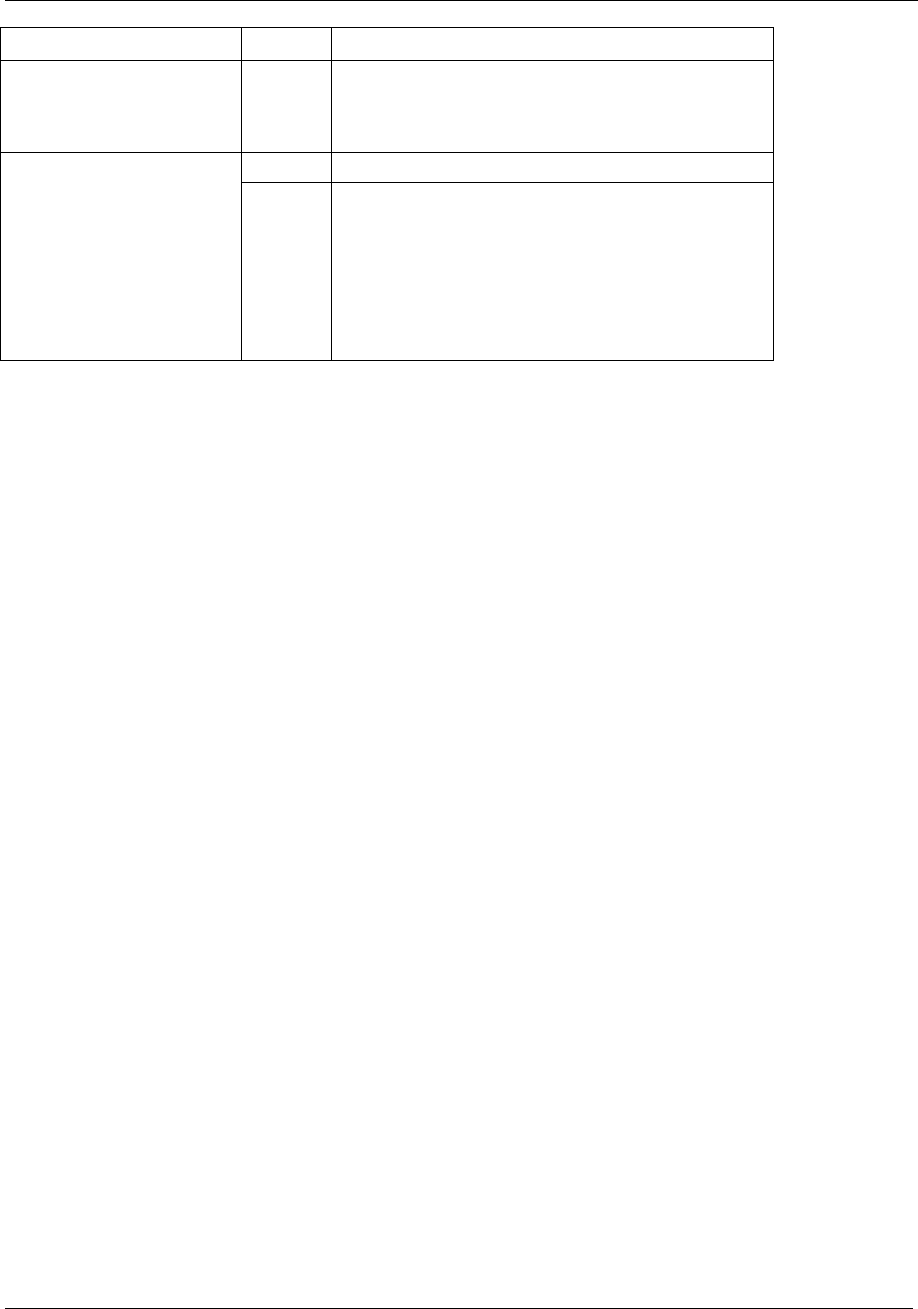

Table 17 MID 0004 Rev 1 ............................................................................................................................................. 74

Table 18 Error code description.................................................................................................................................... 74

Table 19 MID 0005 Rev 1 ............................................................................................................................................. 77

Table 20 MID 0006, revision 1 ...................................................................................................................................... 78

Table 21 MID 0008, revision 1 ...................................................................................................................................... 79

Table 22 MID 0009, revision 1 ...................................................................................................................................... 80

Table 23 MID 0011 Rev 1 ............................................................................................................................................. 82

Table 24 MID 0012 Rev 1 and Rev 2 ........................................................................................................................... 83

Table 25 MID 0012 Rev 3 and Rev 4 ........................................................................................................................... 83

Table 26 MID 0013 Revision 1 ..................................................................................................................................... 83

Table 27 MID 0013 additions for revision 2 .................................................................................................................. 84

Table 28 MID 0013 Revision 3 and 4 ........................................................................................................................... 84

Table 29 MID 0015 Revision 1 ..................................................................................................................................... 86

Table 30 MID 0015 Revision 2 ..................................................................................................................................... 86

Table 31 MID 0018 Revision 1 ..................................................................................................................................... 88

Table 32 MID 2504 Revision 1 ..................................................................................................................................... 89

Table 33 MID 0019 Revision 1 ..................................................................................................................................... 90

Table 34 MID 0020 Revision 1 ..................................................................................................................................... 91

Table 35 MID 0022 Revision 1 ..................................................................................................................................... 92

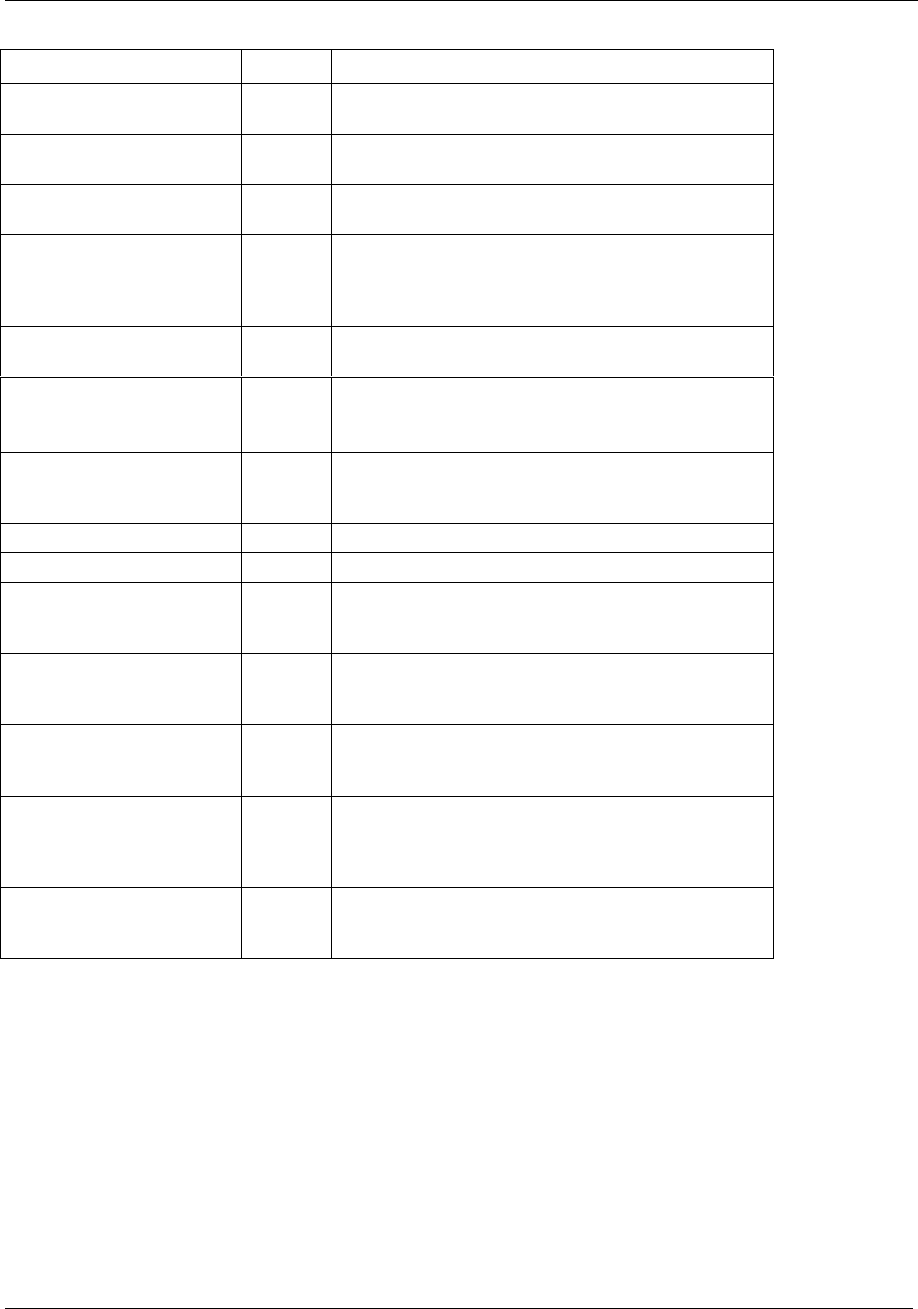

Table 36 Node specification ......................................................................................................................................... 96

Table 37 Available node types...................................................................................................................................... 97

Table 38 Example parameters for PF4000 ................................................................................................................... 97

Table 39 Example parameters for PM4000 ................................................................................................................ 100

Table 40 MID 2501 Request extra data ...................................................................................................................... 102

Table 41 MID 2501 Subscription extra data ............................................................................................................... 102

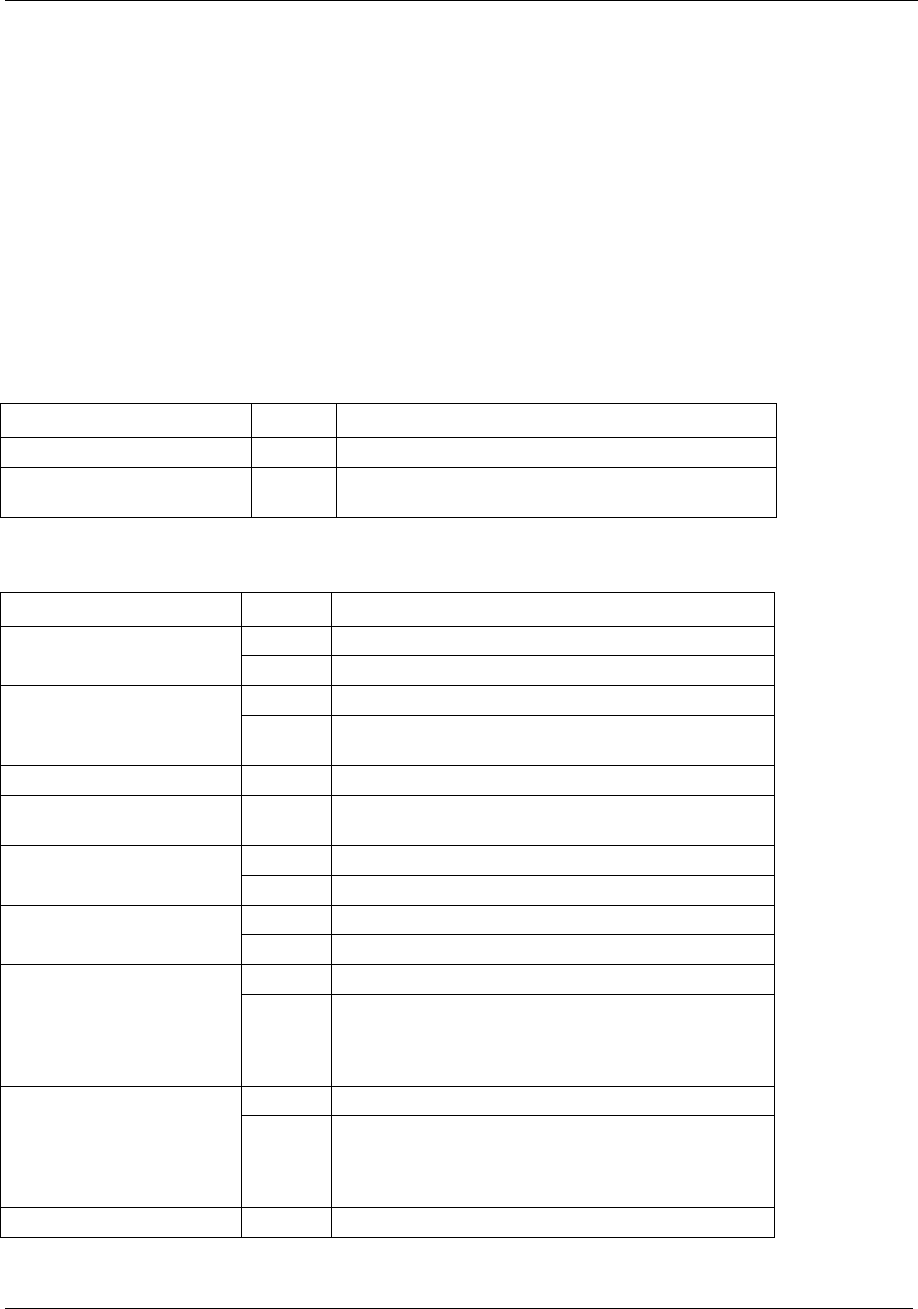

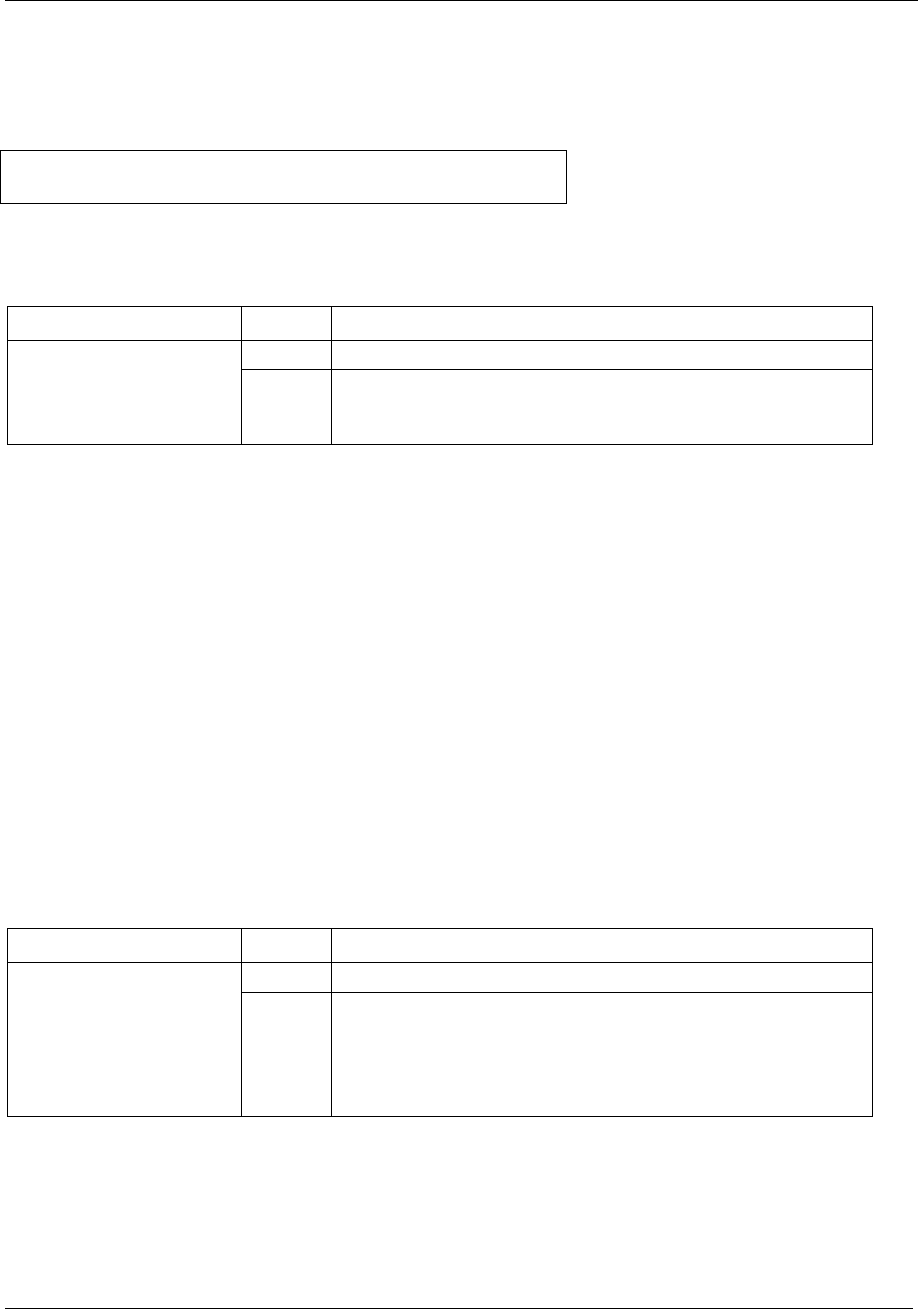

Table 42 MID 2601 data, revision 1 ............................................................................................................................ 106

Table 43 MID 2602 data, revision 1 ............................................................................................................................ 106

Table 44 MID 2603 data, revision 1 ............................................................................................................................ 107

Table 45 MID 2604, revision 1 .................................................................................................................................... 107

Table 46 MID 2606 data, revision 1 ............................................................................................................................ 108

Table 47 MID 0031 Revision 1 ................................................................................................................................... 109

Table 48 MID 0031 Revision 2 ................................................................................................................................... 109

Table 49 MID 0032 Revision 1 ................................................................................................................................... 111

Table 50 MID 0032 Revision 2 and 3 ......................................................................................................................... 111

Table 51 MID 0033 Job data Revision 1 ..................................................................................................................... 112

Table 52 MID 0033 Job data Revision 2 ..................................................................................................................... 113

Table 53 MID 0033 Job data Revision 3 ..................................................................................................................... 115

Table 54 MID 0035 Job info Revision 1 ...................................................................................................................... 116

Table 55 MID 0035 Job info Revision 2 ...................................................................................................................... 116

Table 56 MID 0035 Job info Revision 3 ...................................................................................................................... 118

Table 57 MID 0035 Job info Revision 4 ...................................................................................................................... 118

Table 58 MID 0035 Job info Revision 5 ...................................................................................................................... 119

Table 59 MID 0038 Job ID, revision 1 ........................................................................................................................ 120

Table 60 MID 0038 Job ID, revision 2 ........................................................................................................................ 120

Table 61 MID 0039 Revision 1 ................................................................................................................................... 121

Contents

8 (285)

Table 62 MID 0039 Revision 2 ................................................................................................................................... 121

Table 63 MID 0041 Tool data, revision 1 .................................................................................................................... 122

Table 64 MID 0041 Tool data, additions for revision 2 ............................................................................................... 122

Table 65 MID 0041 Tool data, additions for revision 3 ............................................................................................... 123

Table 66 MID 0041 Tool data, additions for revision 4 ............................................................................................... 123

Table 67 MID 0041 Tool data, additions for revision 5 ............................................................................................... 124

Table 68 MID 0045 Calibration data ........................................................................................................................... 126

Table 69 MID 0046 Primary tool, revision 000-001 ..................................................................................................... 127

Table 70 MID 0047 Tool Pairing handling, revision 000-001 ...................................................................................... 127

Table 71 MID 0048 Tool Pairing status Revision 000-001 .......................................................................................... 128

Table 72MID 0700 Data ............................................................................................................................................. 129

Table 73 MID 0050 Revision 1 ................................................................................................................................... 130

Table 74 MID 0052 Identifier data, revision 1 ............................................................................................................. 131

Table 75 MID 0052 Identifier data, additions for revision 2 ......................................................................................... 131

Table 76 MID 0061 Revision 1 ................................................................................................................................... 134

Table 77 MID 0061 Revision 3 ................................................................................................................................... 141

Table 78 MID 0061 Revision 4 ................................................................................................................................... 141

Table 79 MID 0061 Revision 5 ................................................................................................................................... 141

Table 80 MID 0061 Revision 6 ................................................................................................................................... 142

Table 81 MID 0061 Revision 7 ................................................................................................................................... 142

Table 82 MID 0061 Revision 998 ............................................................................................................................... 142

Table 83 MID 0061 Light, revision 999 ....................................................................................................................... 144

Table 84 MID 0064 Revision 1 ................................................................................................................................... 146

Table 85 MID 0065 Revision 1 ................................................................................................................................... 147

Table 86 MID 0065 Revision 2 ................................................................................................................................... 147

Table 87 MID 0065 Revision 3 ................................................................................................................................... 151

Table 88 MID 0065 Revision 4 ................................................................................................................................... 151

Table 89 MID 0065 Revision 5 ................................................................................................................................... 152

Table 90 MID 0065 Revision 6 ................................................................................................................................... 152

Table 91 MID 0065 Revision 7 ................................................................................................................................... 152

Table 92 MID 1201, Subscription “Extra data” field included in MID 0008, rev 001. ................................................... 154

Table 93 MID 1201 Data, revision 1 ........................................................................................................................... 156

Table 94 MID 1202, revision 1 .................................................................................................................................... 157

Table 95 MID 0071 Alarm data revision 0-1 ............................................................................................................... 163

Table 96 MID 0071 Alarm data revision 2 .................................................................................................................. 163

Table 97 MID 0074 Revision 1 ................................................................................................................................... 166

Table 98 MID 0076 Alarm status data Rev 1 .............................................................................................................. 166

Table 99 MID 0076 Alarm status data Rev 2 .............................................................................................................. 167

Table 100 MID 0081 Revision 1 ................................................................................................................................. 169

Table 101 MID 0082 Revision 1 ................................................................................................................................. 169

Table 102 MID 0091 Multi-spindle status data............................................................................................................ 170

Table 103 MID 0100 Revision 2 ................................................................................................................................. 172

Table 104 MID 0100 Revision 3, 4 and 5 ................................................................................................................... 173

Table 105 MID 0101 Multi-spindle result data, Revision 1, 2 and 3 ............................................................................ 173

Table 106 MID 0101 Multi-spindle result data, Revision 4 .......................................................................................... 176

Table 107 MID 0101 Multi-spindle result data, Revision 5 .......................................................................................... 178

Table 108 MID 0105 Revision 2, 3 and 4 ................................................................................................................... 181

Table 109 MID 0106 Last tightening result Station data, revision 1,2 and 3 ............................................................... 181

Table 110 MID 0106 Last tightening result Station data, revision 4 ............................................................................ 184

Table 111 MID 0107 Last tightening result Bolt data, revision 1,2 and 3 .................................................................... 188

Table 112 MID 0107 Last tightening result Bolt data, revision 4 ................................................................................. 191

Table 113 MID 0108 Revision 1-4 .............................................................................................................................. 195

Table 114 MID 0110 Revision 1 ................................................................................................................................. 196

Table 115 MID 0110 Graphic text display ................................................................................................................... 197

Table 116 MID 0129 Revision 2 ................................................................................................................................. 201

Table 117 MID 0130 Revision 1 ................................................................................................................................. 202

Table 118 MID 0140 Dynamic Job data revision 1 ..................................................................................................... 204

Table 119 MID 0140 Dynamic Job data revision 999 ................................................................................................. 206

Table 120 MID 0150 Revision 1 ................................................................................................................................. 207

Table 121 MID 0152 Multiple identifier and result parts data, Revision 1 ................................................................... 208

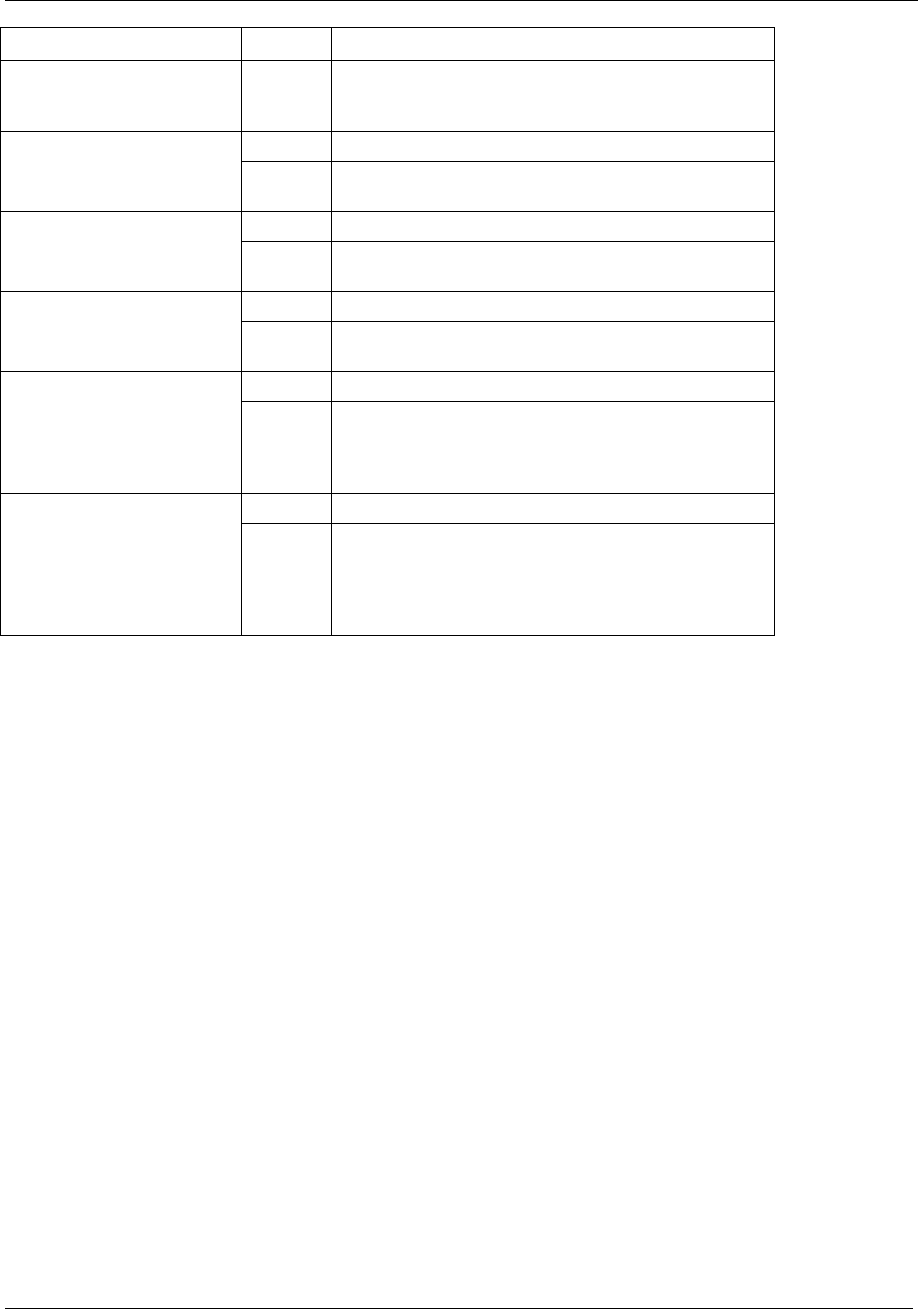

Table 122 MID 0200 Relay status revision 1 .............................................................................................................. 210

Table 123 MID 0211 Digital input status revision 1 ..................................................................................................... 212

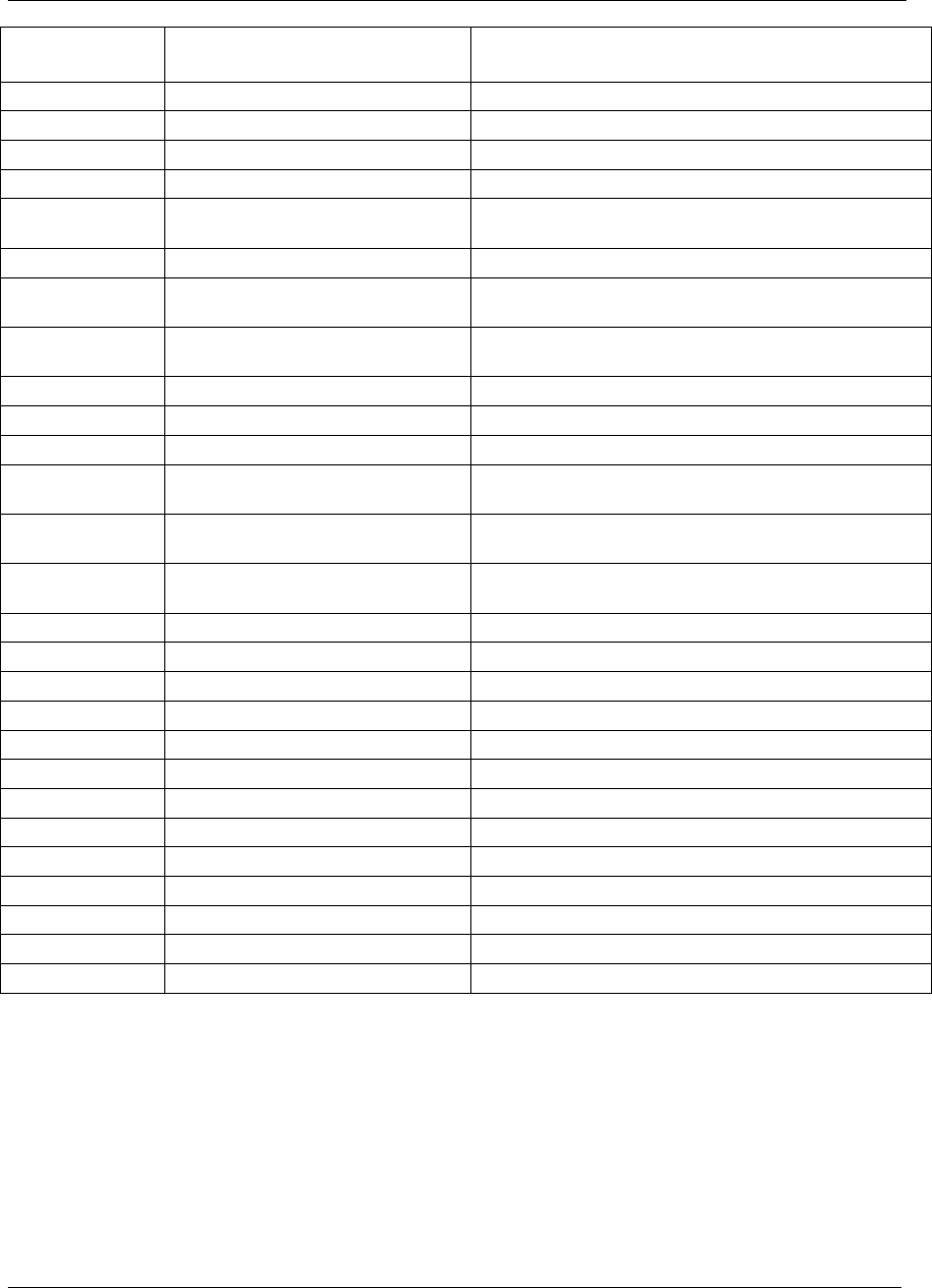

Contents

9 (285)

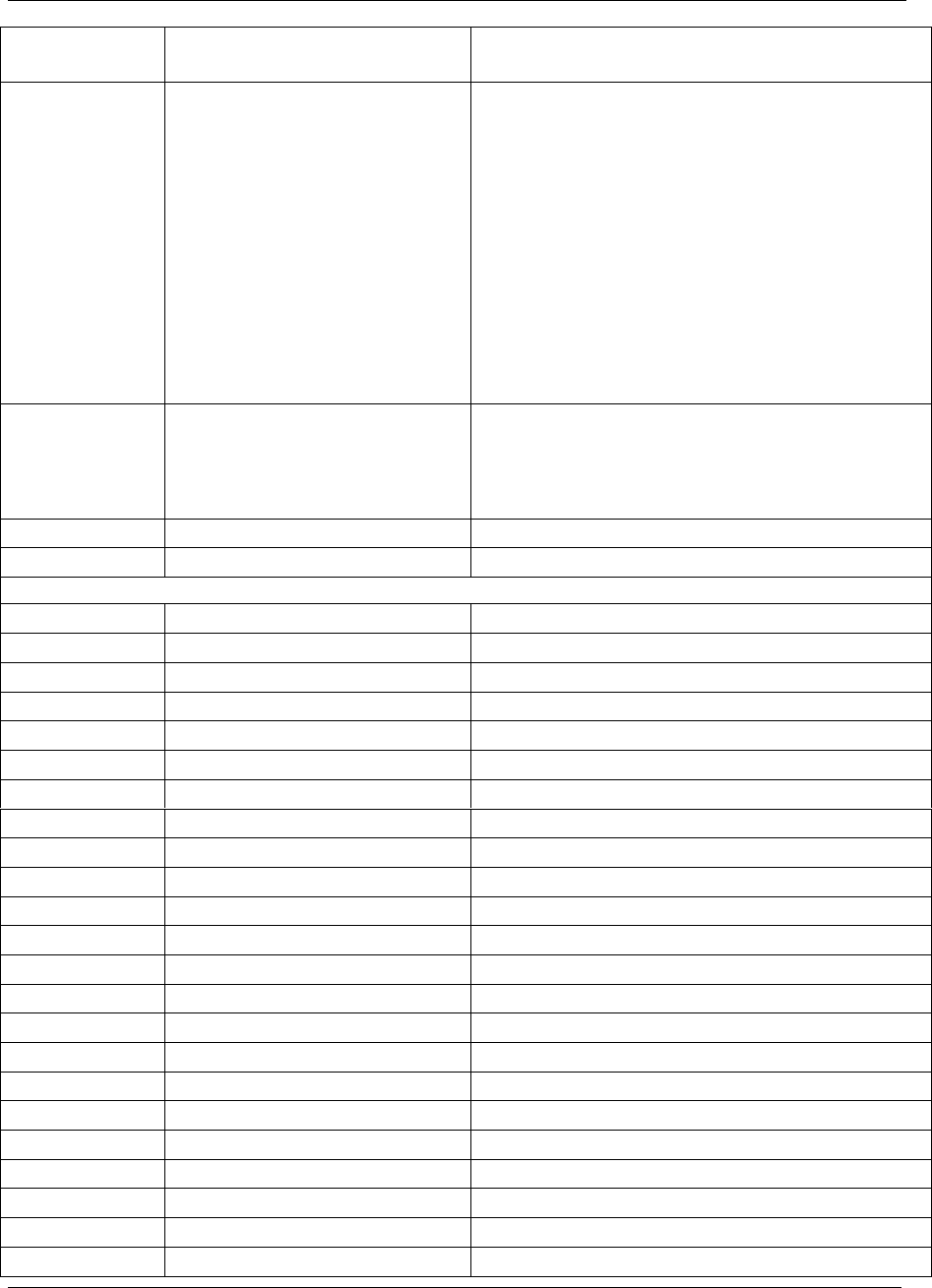

Table 124 MID 0214 Revision 1 and 2 ....................................................................................................................... 213

Table 125 MID 0215 Revision 1 ................................................................................................................................. 214

Table 126 MID 0215 Revision 2 ................................................................................................................................. 214

Table 127 MID 0215 Relay number ............................................................................................................................ 215

Table 128 MID 0215 DigIn number ............................................................................................................................. 220

Table 129 MID 0216 Revision 1 ................................................................................................................................. 224

Table 130 MID 0217 Relay no and status Revision 1 ................................................................................................. 225

Table 131 MID 0219 Revision 1 ................................................................................................................................. 226

Table 132 MID 0220 Revision 1 ................................................................................................................................. 226

Table 133 MID 0221 Digital input no and status Revision 1 ....................................................................................... 227

Table 134 MID 0223 Revision 1 ................................................................................................................................. 228

Table 135 MID 0224 Revision 1 ................................................................................................................................. 229

Table 136 MID 0225 Revision 1 ................................................................................................................................. 229

Table 137 Example 1 input ......................................................................................................................................... 230

Table 138 Example 1 output ....................................................................................................................................... 230

Table 139 MID 0240 Revision 1 ................................................................................................................................. 231

Table 140 MID 0242 Revision 1 ................................................................................................................................. 232

Table 141 MID 0245 User data download with offset, revision 1 ................................................................................ 233

Table 142 MID 0251 Selector socket data Revision 1 ................................................................................................ 235

Table 143 MID 0254 Selector green lights revision 0, 1 ............................................................................................. 236

Table 144 MID 0254 Selector green lights revision 2 ................................................................................................. 236

Table 145 MID 0255 Selector red lights revision 0, 1 ................................................................................................. 237

Table 146 MID 0255 Selector red lights revision 2 ..................................................................................................... 237

Table 147 MID 0262 TLS ST Tool Tag Identity Revision 1 ......................................................................................... 242

Table 148 MID 0265 External TLS Tool Tag Identity and status Revision 1 ............................................................... 244

Table 149 Definition of required and optional parameters of MID 2100 ...................................................................... 246

Table 150 Available Generic Commands ................................................................................................................... 246

Table 151 MID 0300 Parameter set and histogram type Revision 1 ........................................................................... 247

Table 152 MID 0301 Histogram data Revision 1 ........................................................................................................ 248

Table 153 MID 0401 Revision 1 ................................................................................................................................. 250

Table 154 MID 0411 Revision 1 ................................................................................................................................. 252

Table 155 MID 0421 Revision 1 ................................................................................................................................. 253

Table 156 MID 501Motor tuning result data Revision 1 .............................................................................................. 255

Table 157 MID 900 Data field, revision 1 .................................................................................................................... 257

Table 158 Extra data field for subscription MID 900, revision 1 .................................................................................. 260

Table 159 Extra data field for unsubscription MID 900, revision 1 .............................................................................. 262

Table 160 MID 901 data field, revision 1 .................................................................................................................... 263

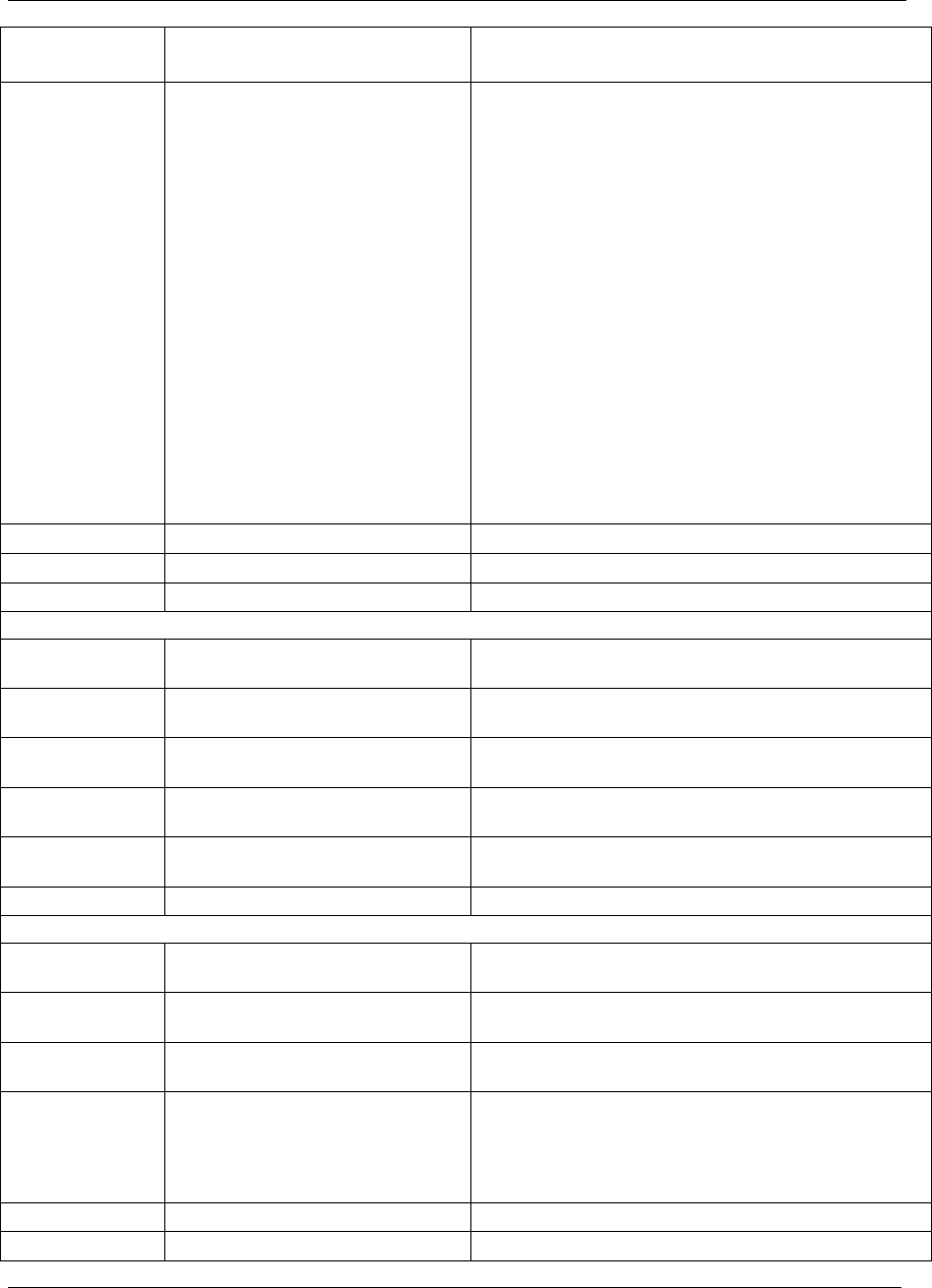

Table 161 Data type definitions .................................................................................................................................. 266

Table 162 Unit type definitions ................................................................................................................................... 267

Table 163 Parameter IDs definitions common ............................................................................................................ 270

Table 164 Parameter IDs definitions system unique .................................................................................................. 283

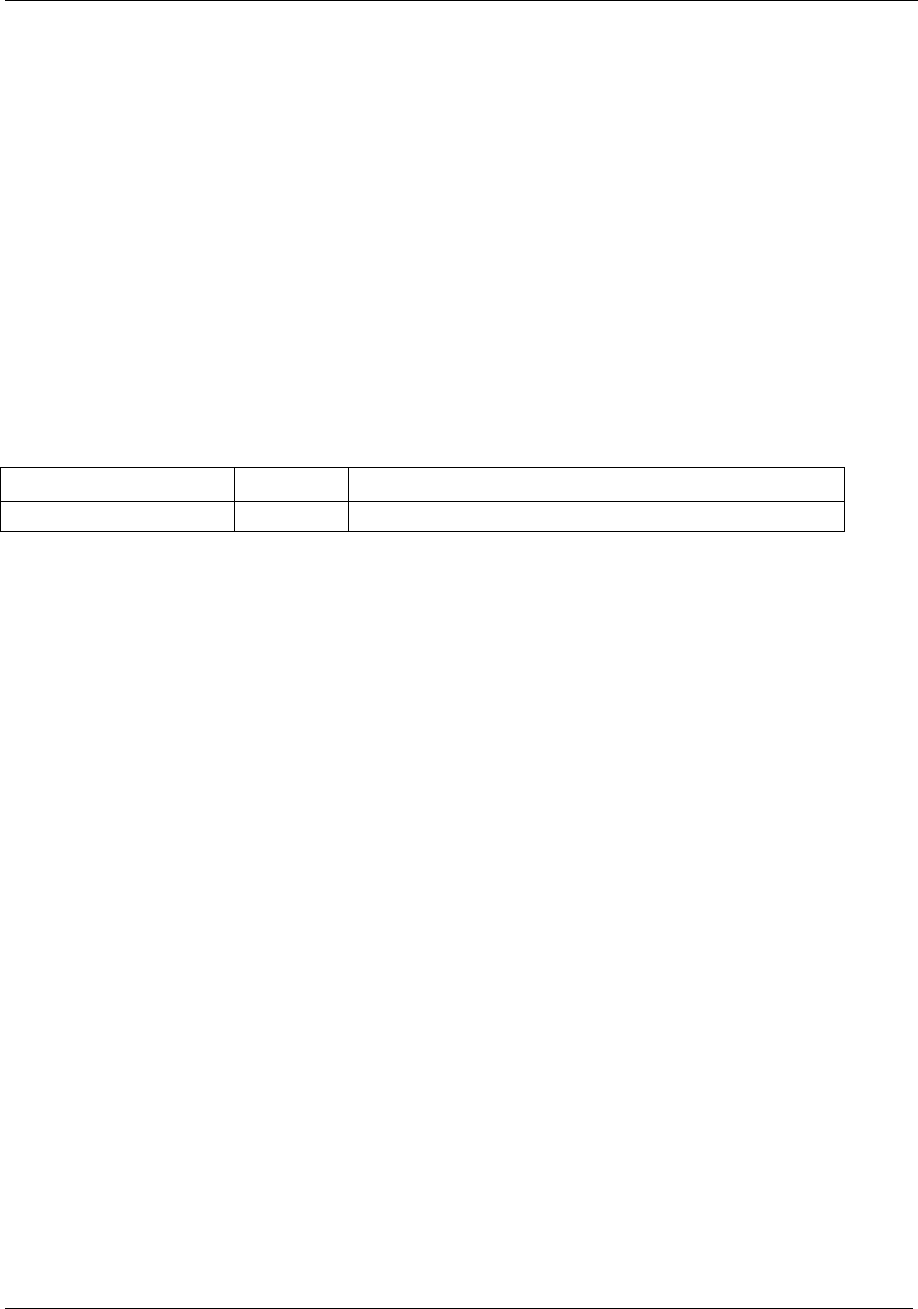

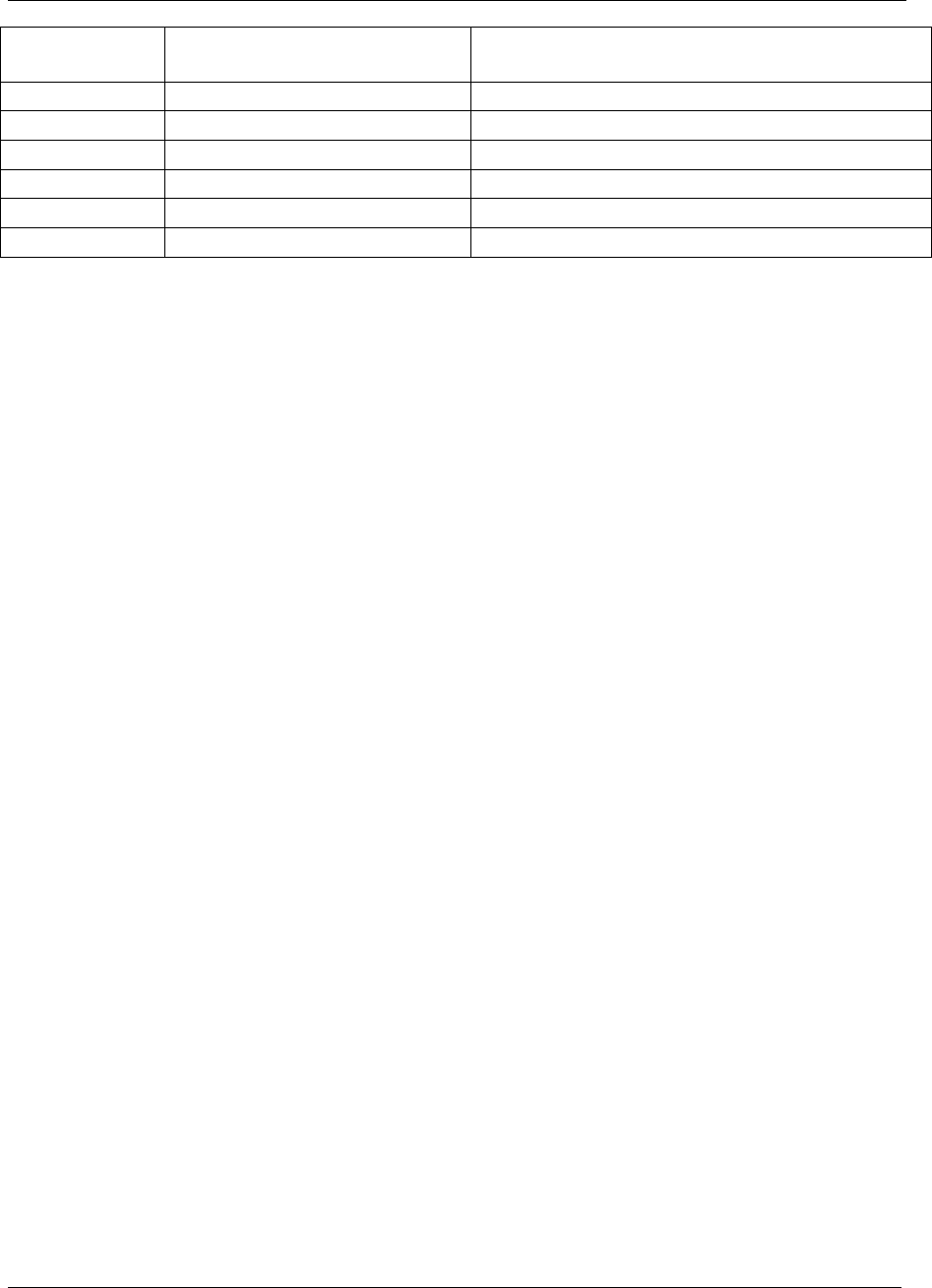

Introduction

7 (285) 2.1

1 Introduction

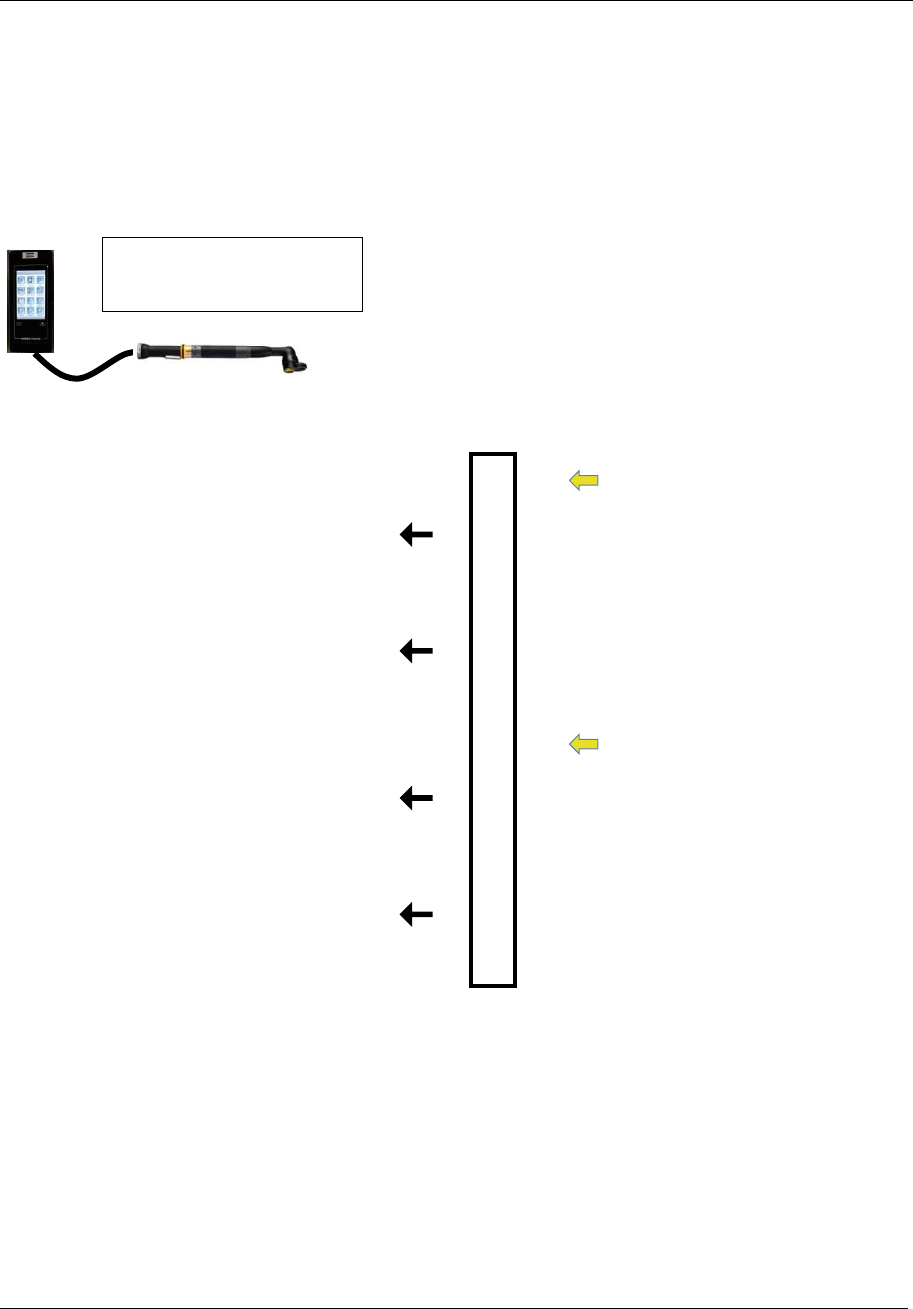

Open Protocol is an interface for building applications for remote control or data subscription of

controllers. It is platform independent and can be implemented on Linux, PLC, printers, and all Windows

platforms for example.

The Open Protocol supports both serial and Ethernet connection.

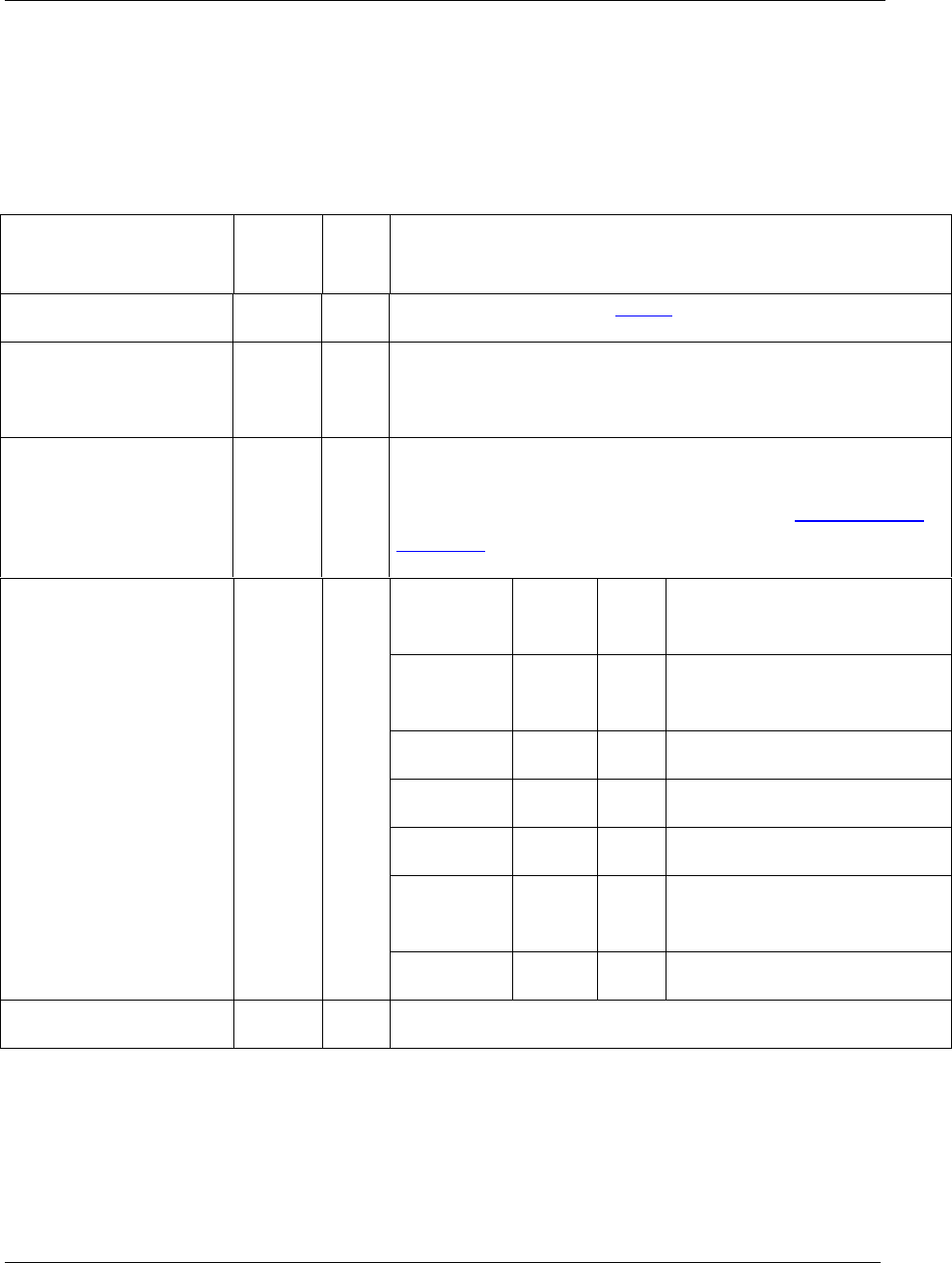

Figure 1 Open Protocol in the network, example

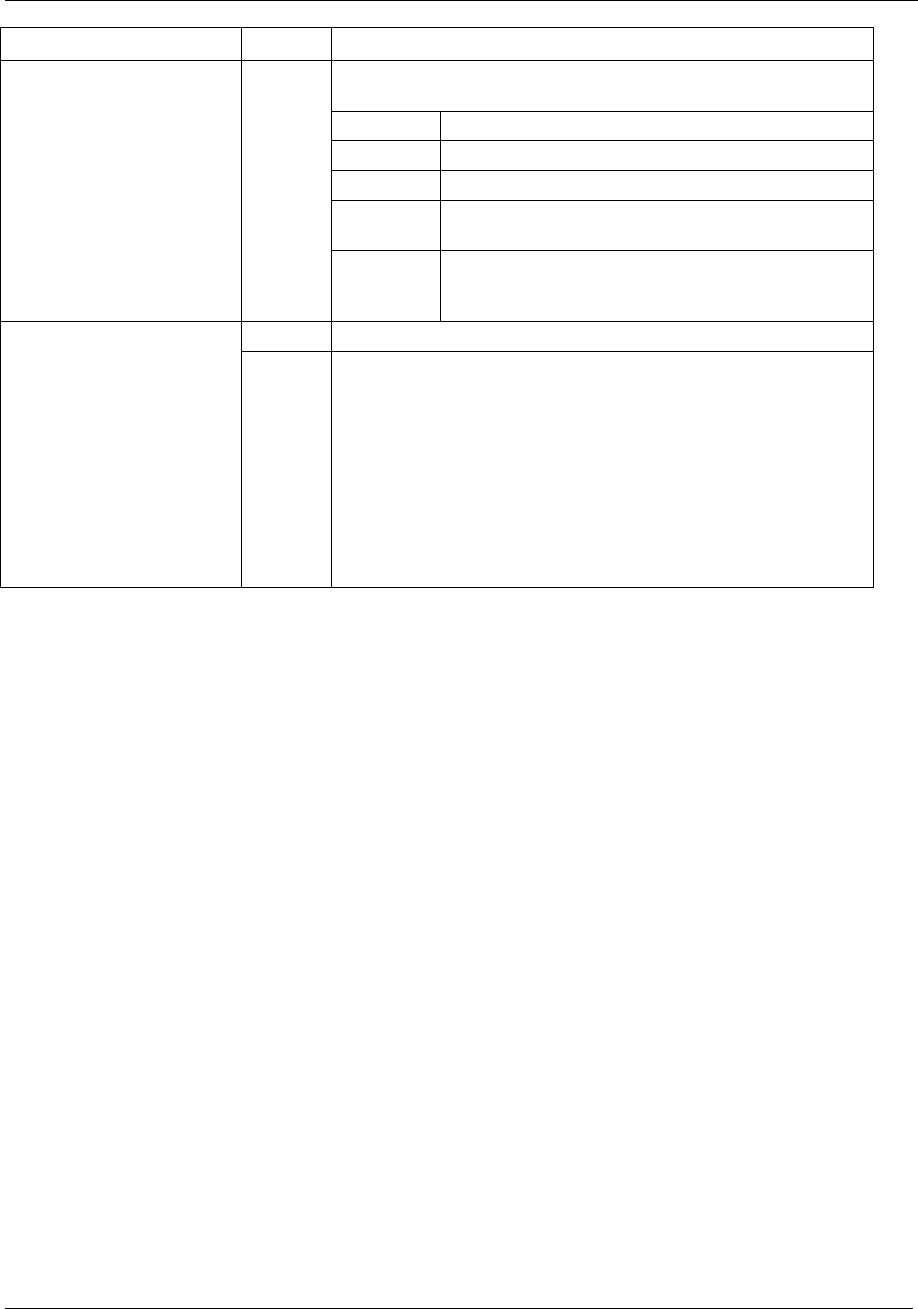

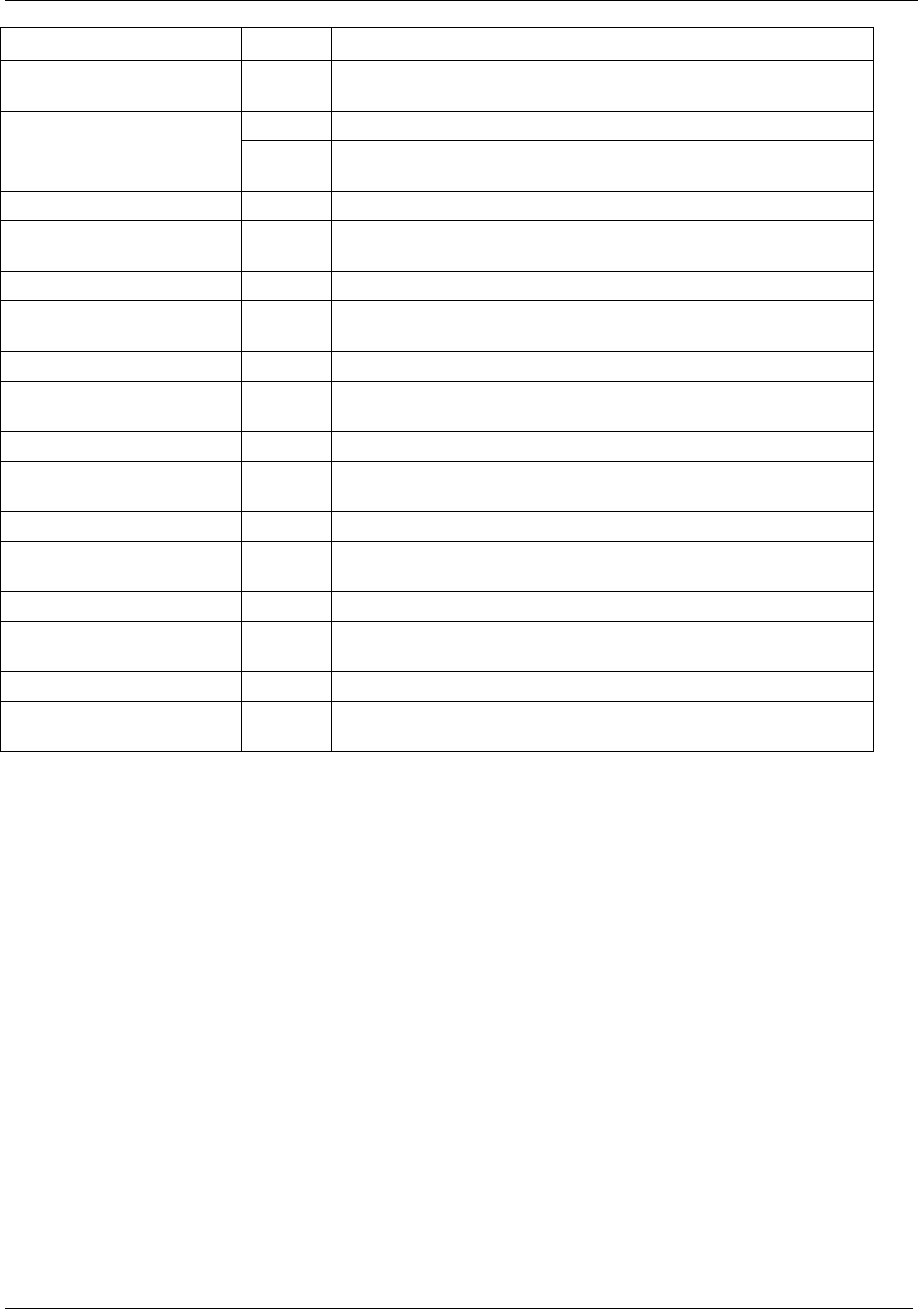

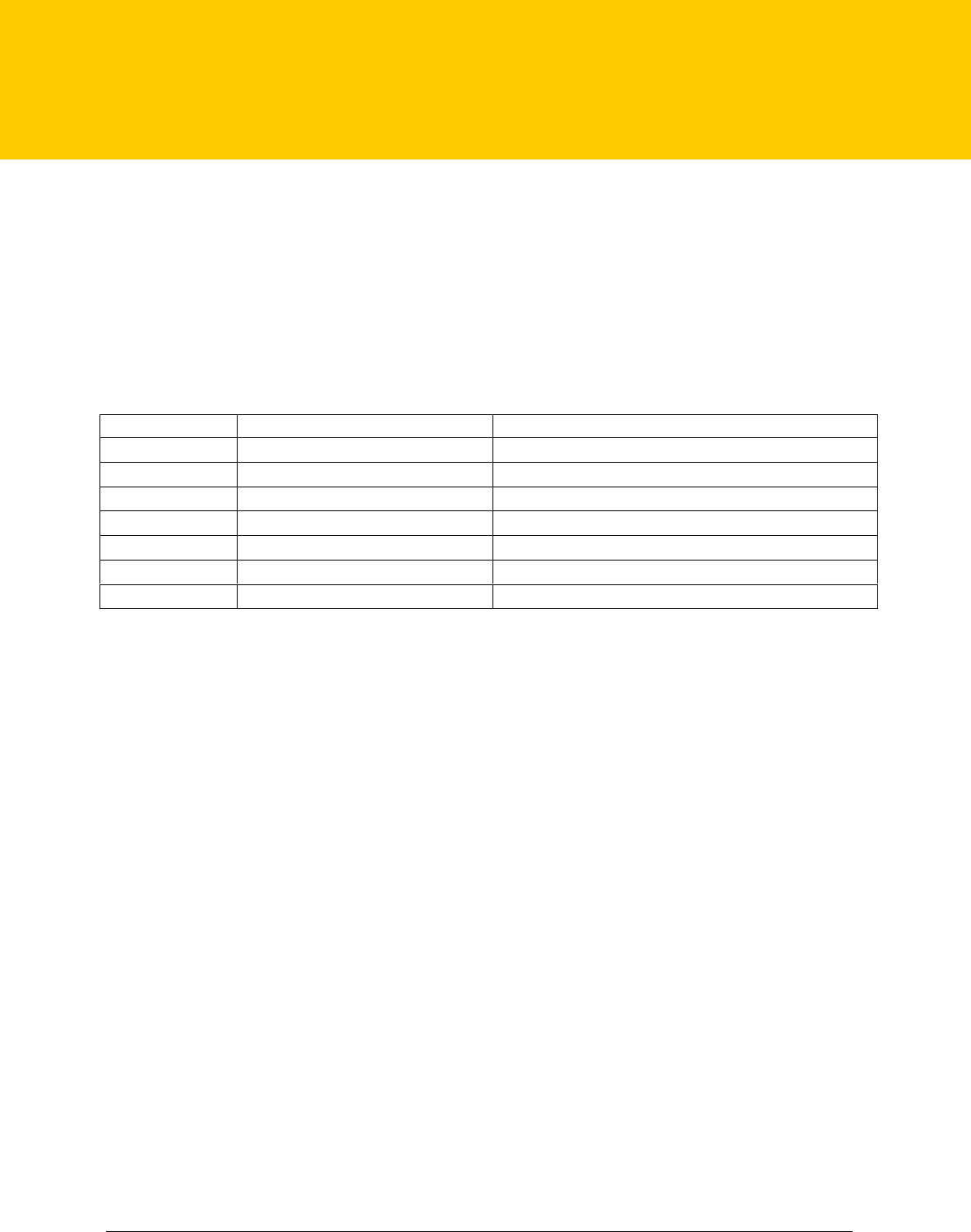

1.1 Revision history

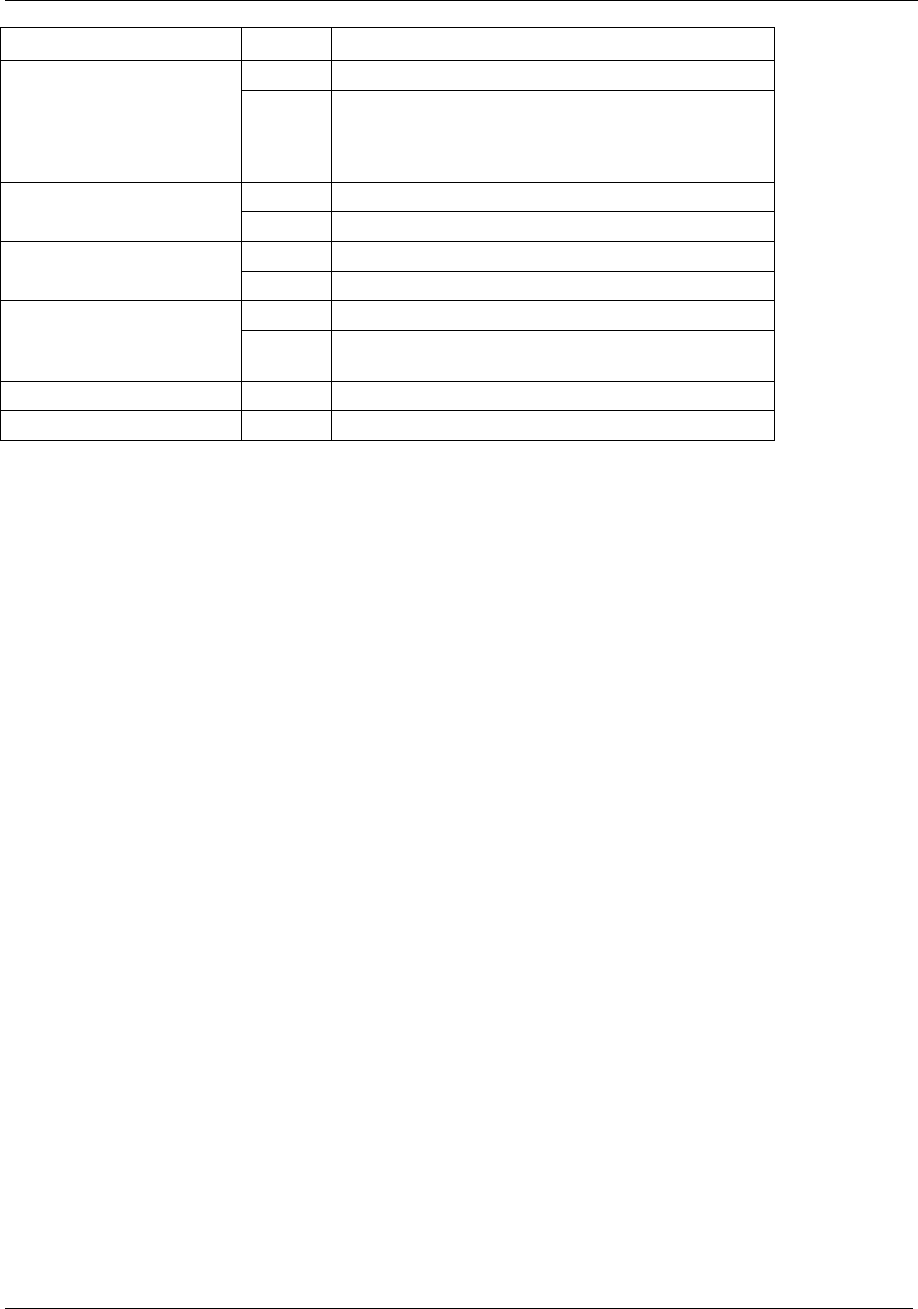

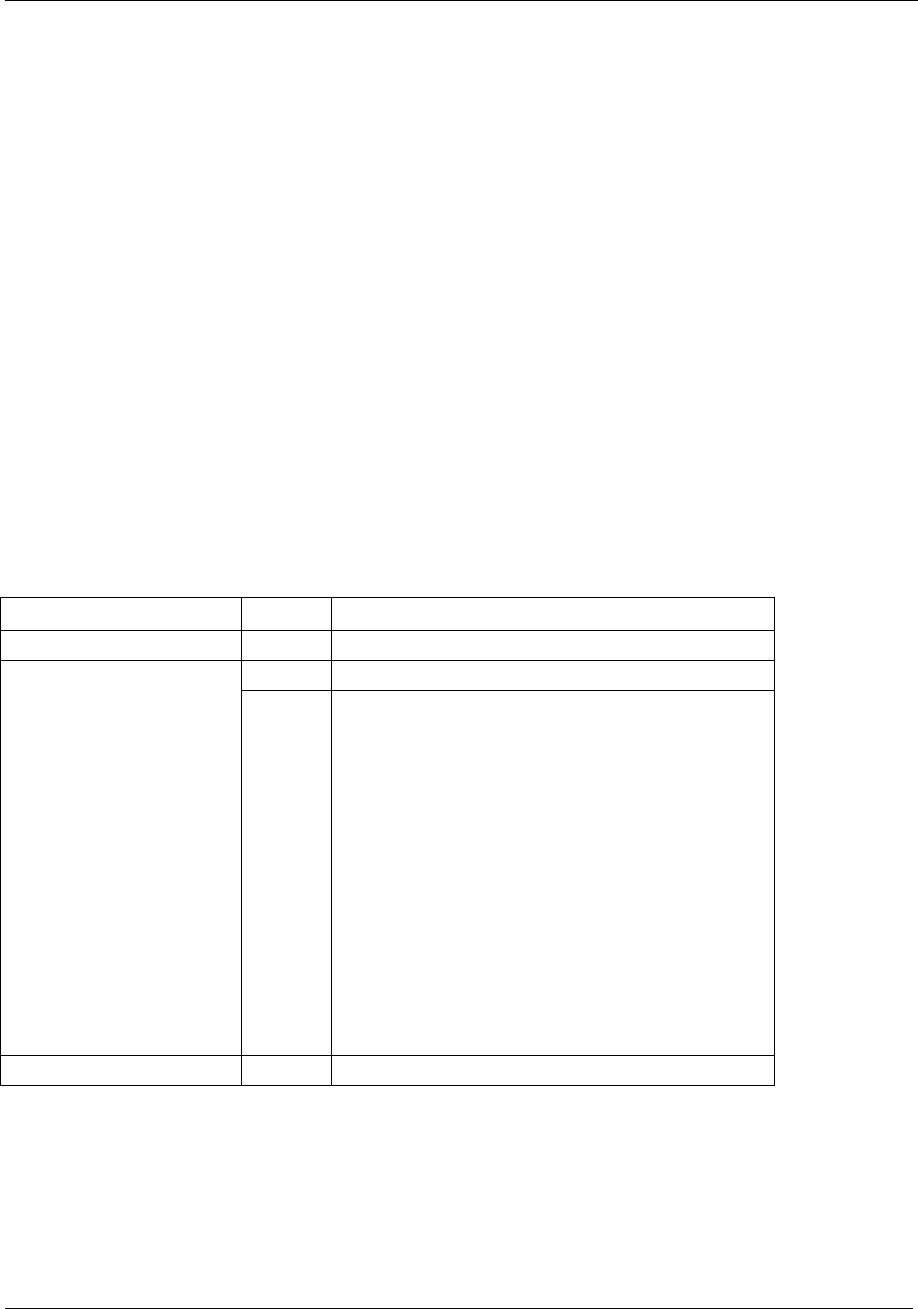

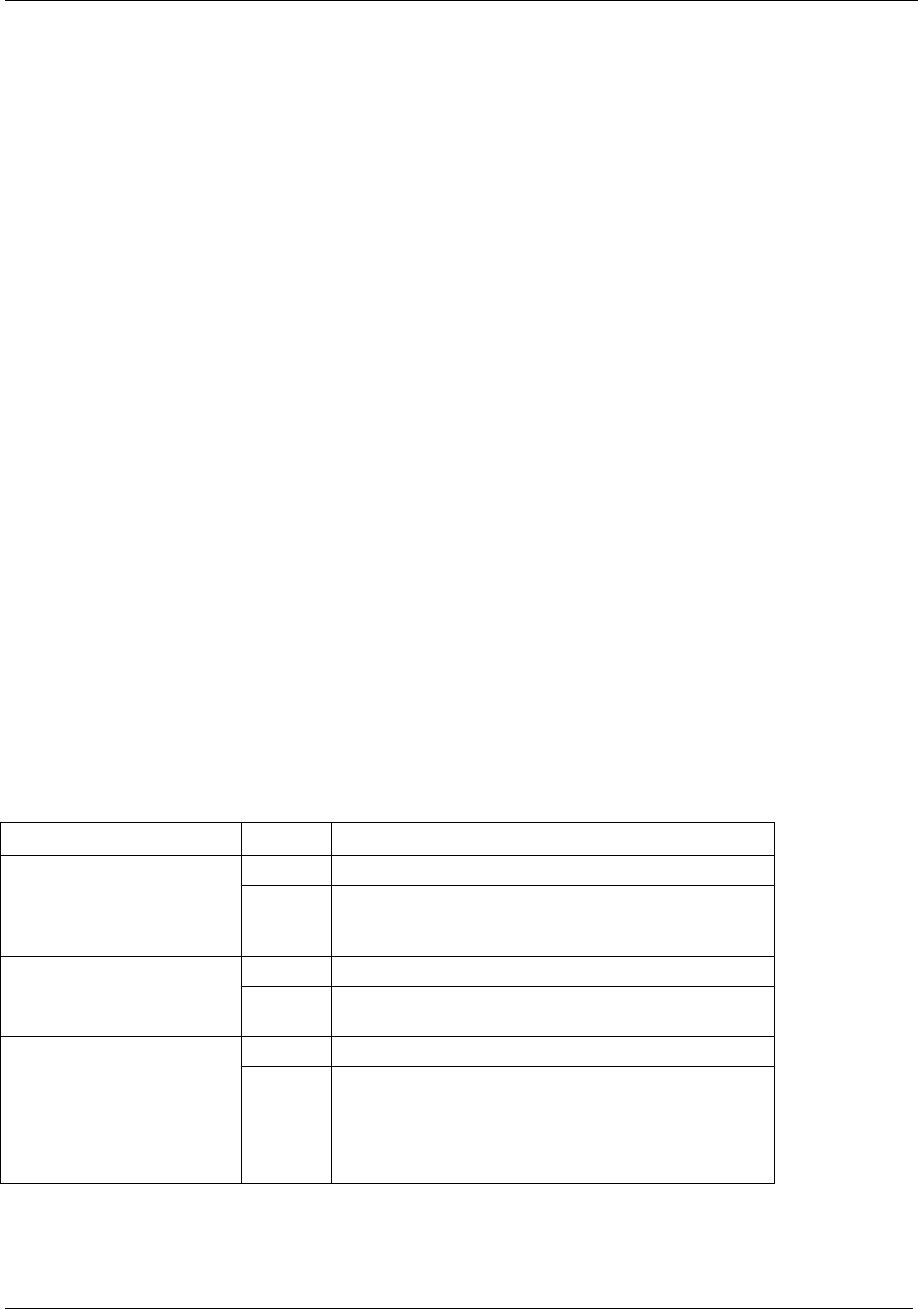

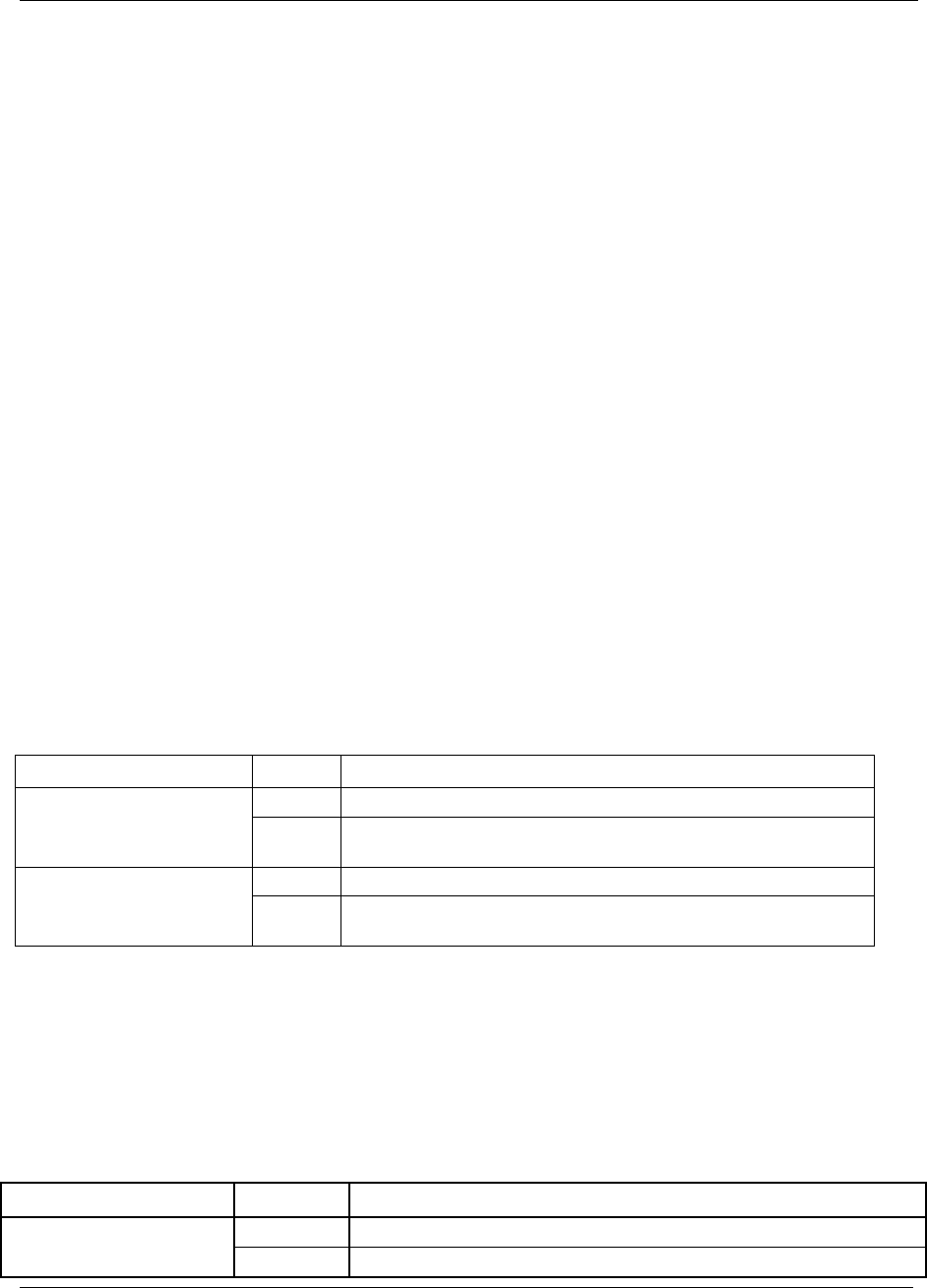

The changes since release 1.2 revision 14 are:

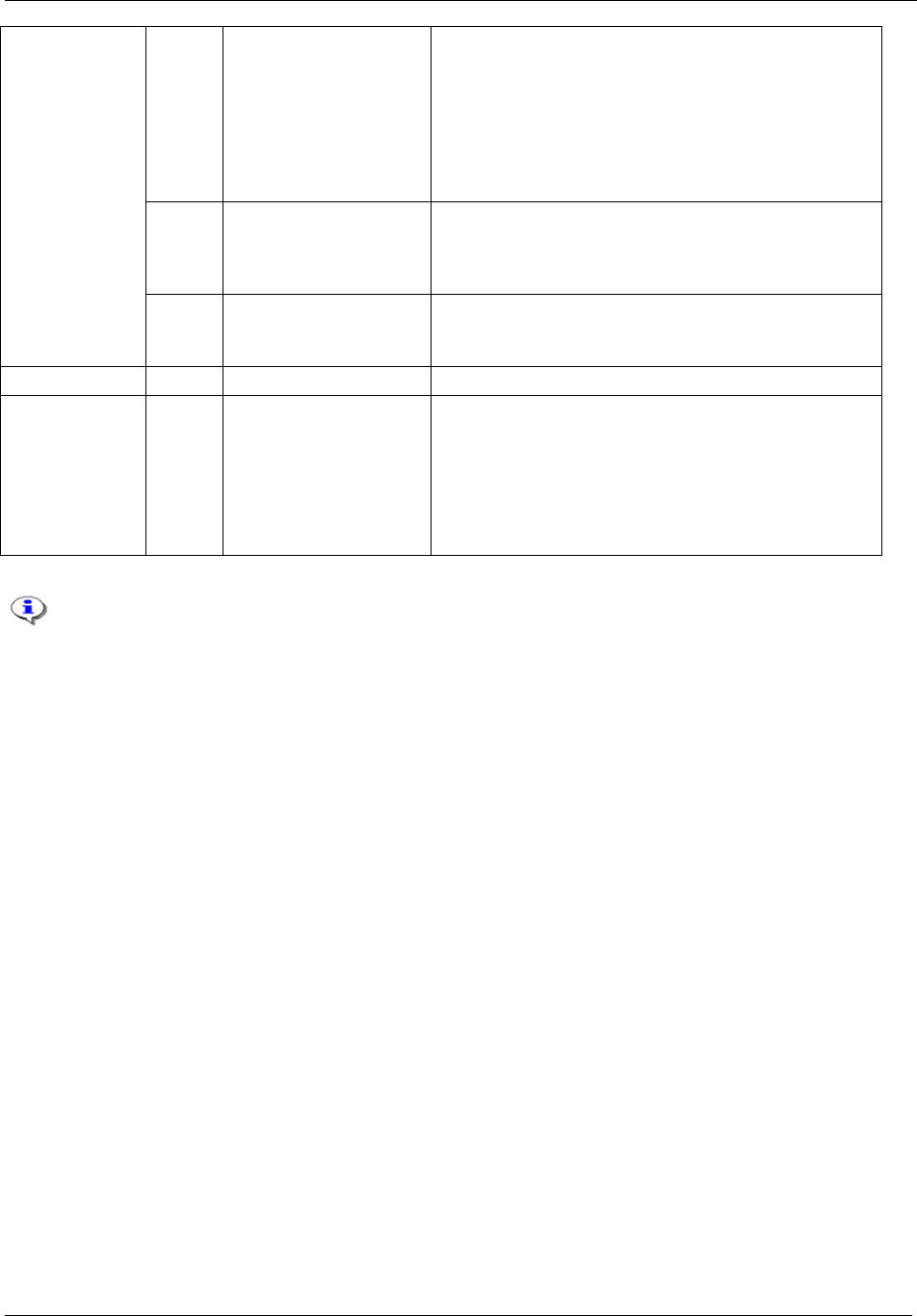

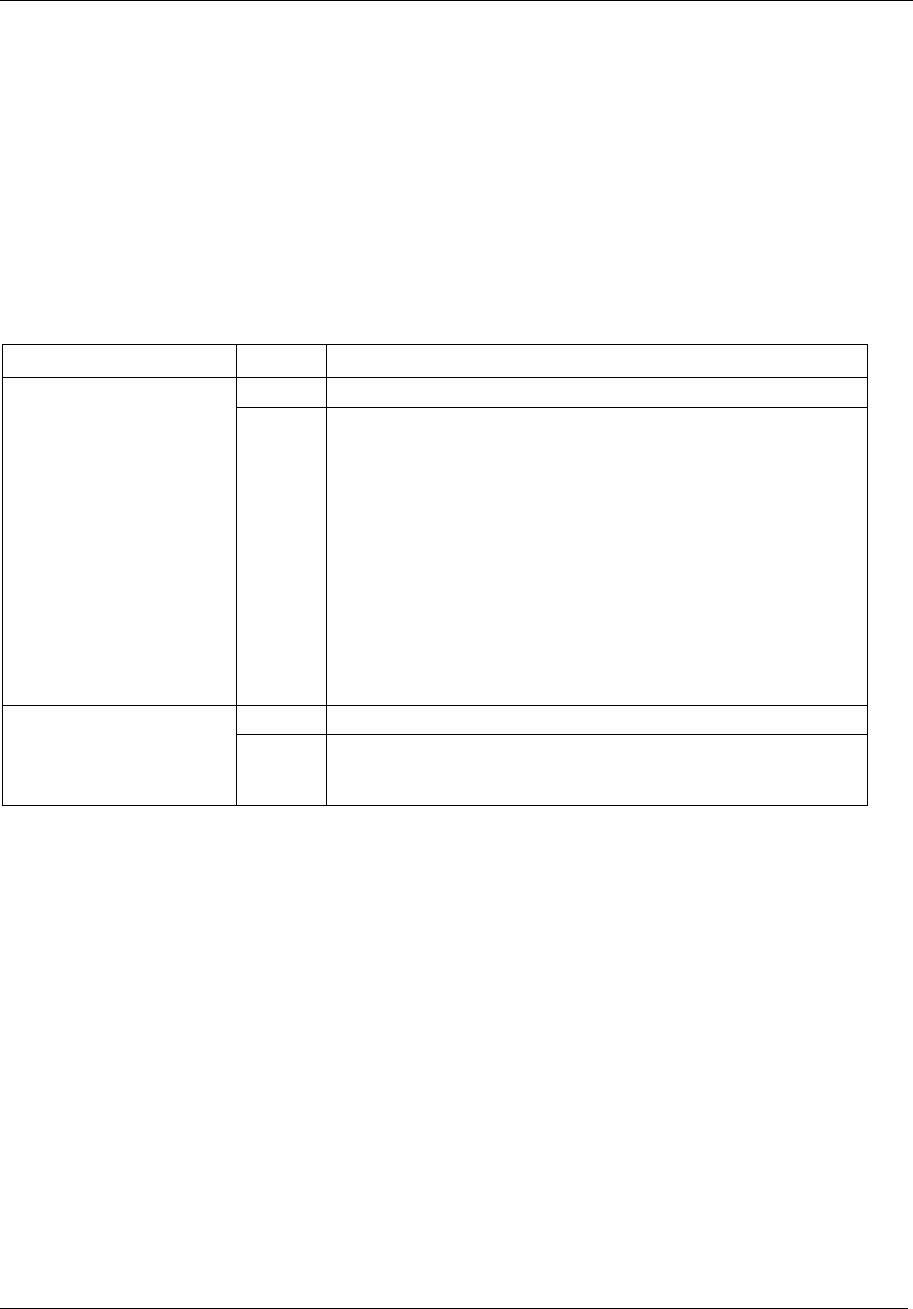

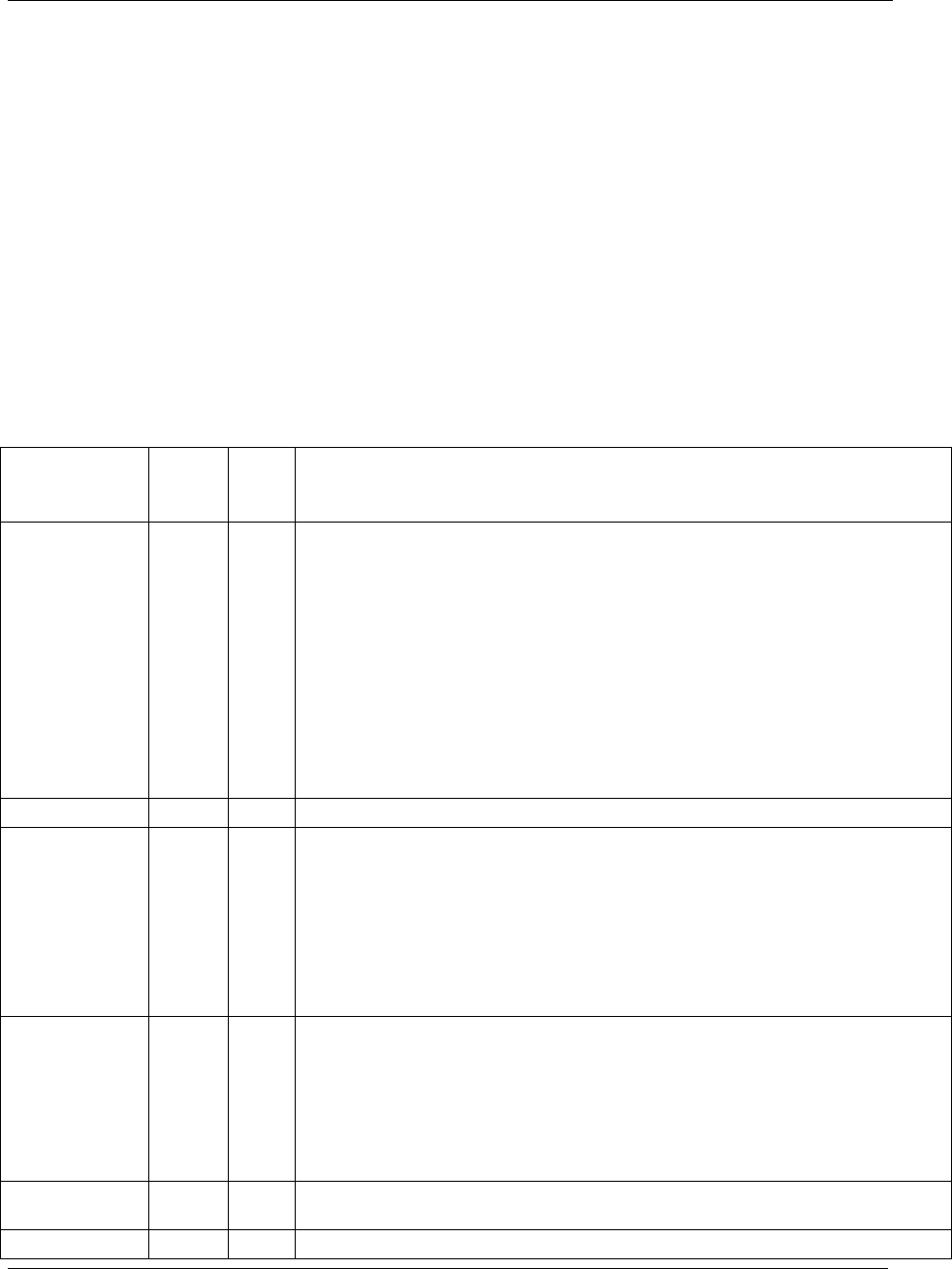

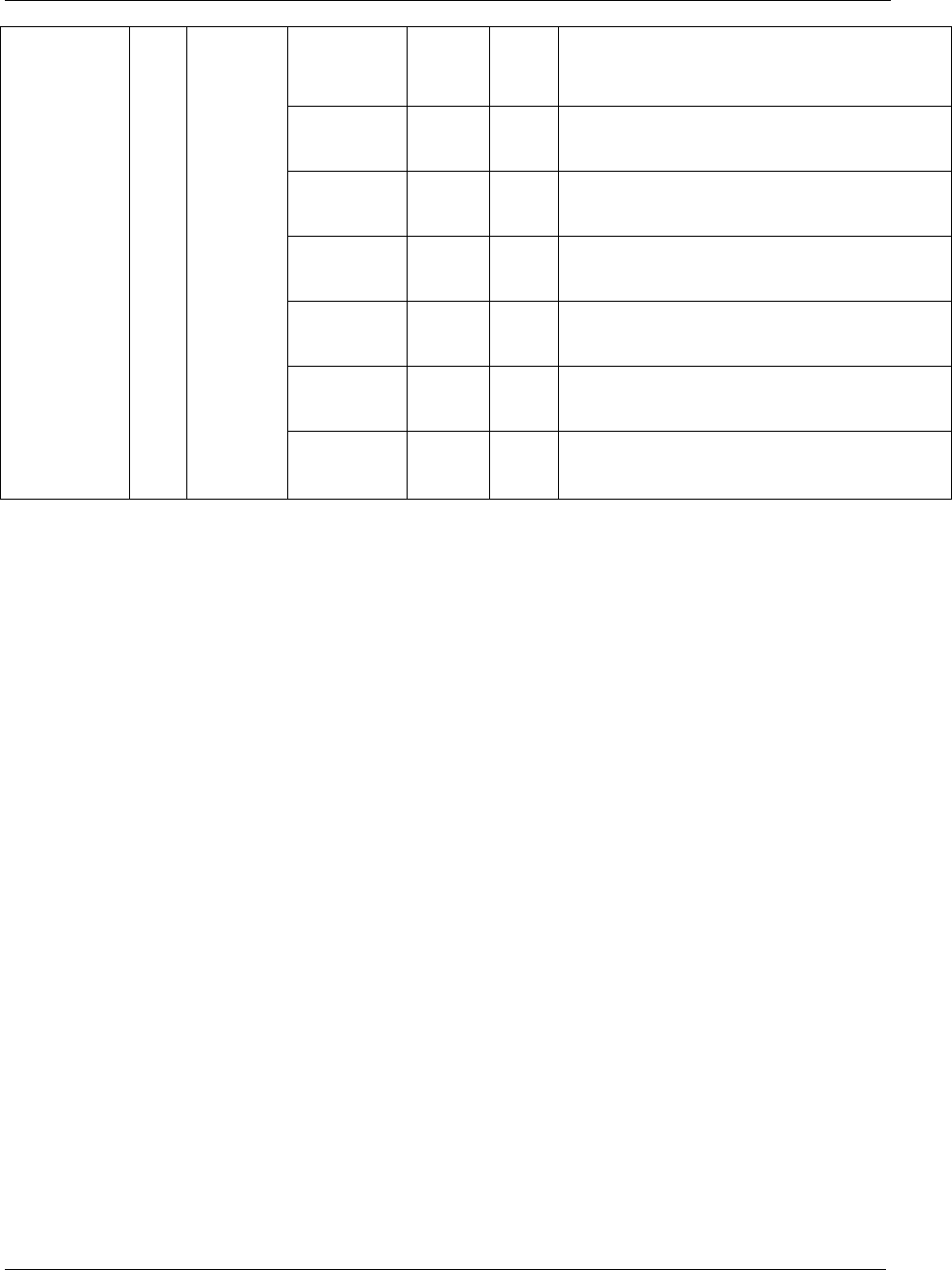

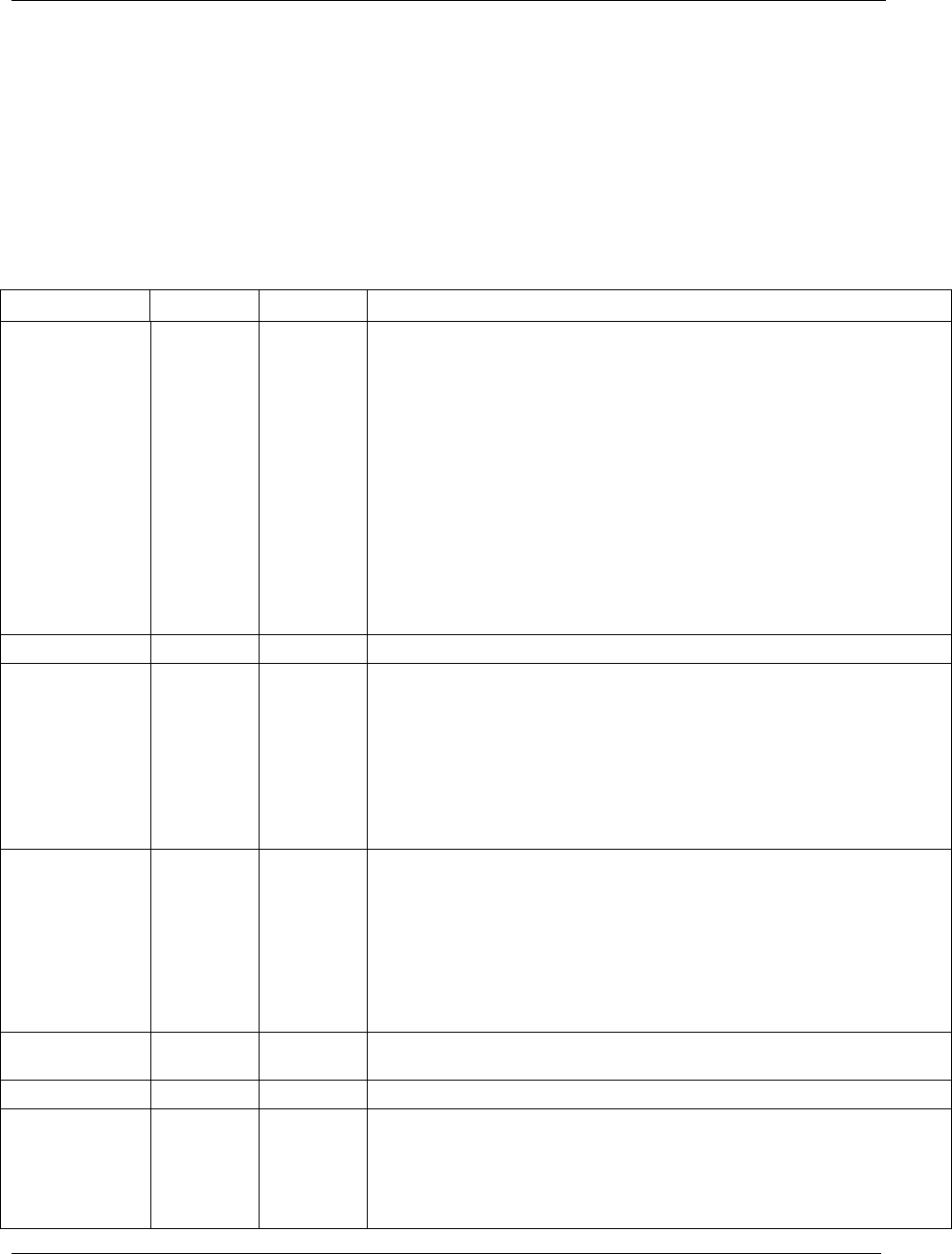

Version

Date

Author

Change

1.3.0

2011-06-15

Björn Johansson

Initial.

Added revision 1, 2 and 3 for MID 0100.

Added revision 3 MID 0105.

Corrected the header contains Table 1 Station is

two digits, corresponding to the rest of the

document, the Spindle ID starts at byte 15 and

spare at 17.

Added revision 4 for MID 0035. Corrected the

revision range in MID 0035 and MID 0034

Correction of Identifier length in MID 151 to 100

More thoroughly description of MID 0022

concerning the messages exchanges

Introduction

12 (285)

Version

Date

Author

Change

Added Revision 3 documentation for MID 32.

Corrected the description of MID 411.

Created a Ford special appendix due to DR 2104.

Ford special rev 2 of MID11 and MID 61 now

documented 2011-06-09 BJ

Corrections done to all headers Revision fields

from N/A to the real value.

Added rules for Revision Handling 2011-06-14 /BJ.

Updated the revision to 1.3.0 due to new MID

revisions created. 2011-06-15

1.3.2

2011-09-07

Björn Johansson

Clarification of MID 122-123 due to DR2789.

1.3.3

2011-09-15

Björn Johansson

Corrected the MID 33 description due to DR 2917,

DR2918.

1.3.4

2011-10-03

Björn Johansson

Corrected the MID129 description due to DR2965.

1.3.5

2011-10-11

Björn Johansson

Corrected the Ackflag doc. in the headers for all

MID subscription messages. DR3009

1.3.6

2011-10-

20

Björn Johansson

Added changes for the new product PowerMACS

Press RM

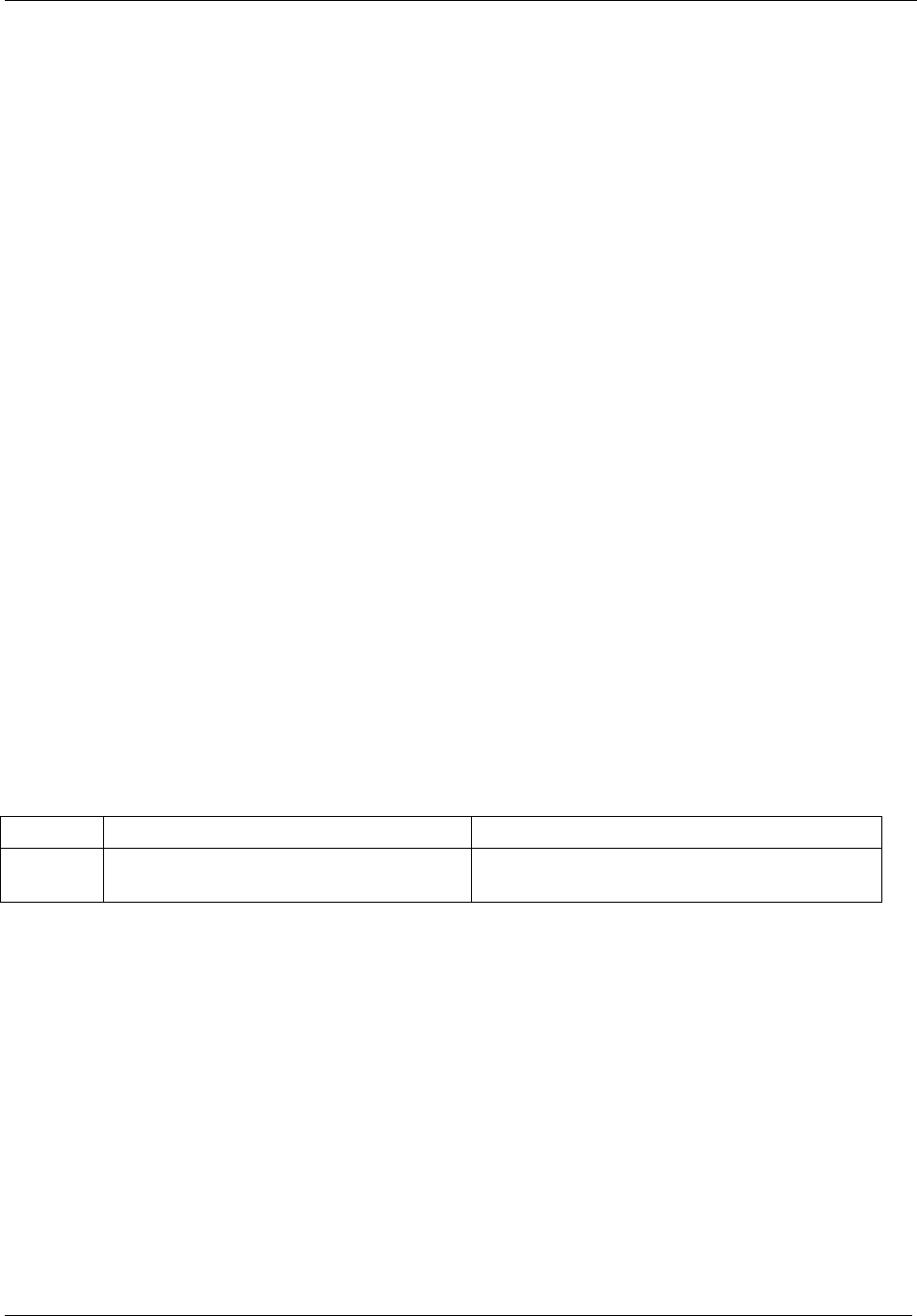

1.4.2

2011-11-14

Björn Johansson

Corrections done for MID 0033. Aligned with DIM

revision

1.4.3

2011-11-14

Björn Johansson

Corrections done for MID 65 DR 2941

1.4.4

Björn Johansson

Explanation for MID 33 Rev 3 added DR 3057

1.4.5

Björn Johansson

Updating table 73 due to DR 3114

1.4.6

Björn Johansson

Updated rev number to DIM rev number

1.5.0

2012-01-26

Björn Johansson

New revision 002 for MID 0010/0011 for

transmission of number of stages for each

Pset/Mset and a new revision 005 for MID

0040/0041 for transmission of tool model according

to W 10.8 DR 3281.

1.5.1

2012-01-27

Björn Johansson

New revision for the document 1.5.1 Padding for

Tool Model in Rev. 5 of MID 41 changed to spaces

BJ W10.8 DR 3281.

Using Open Protocol

13 (285)

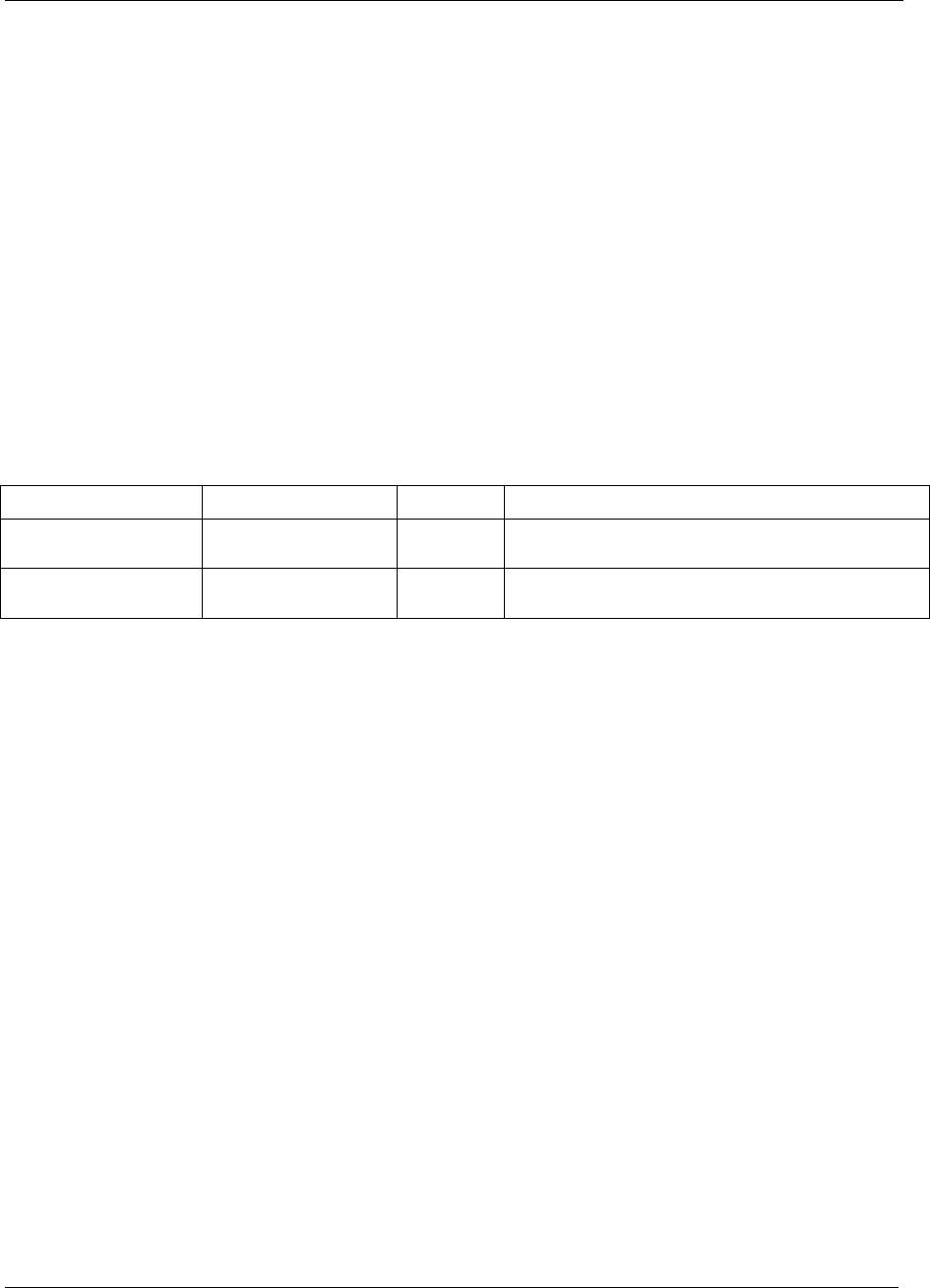

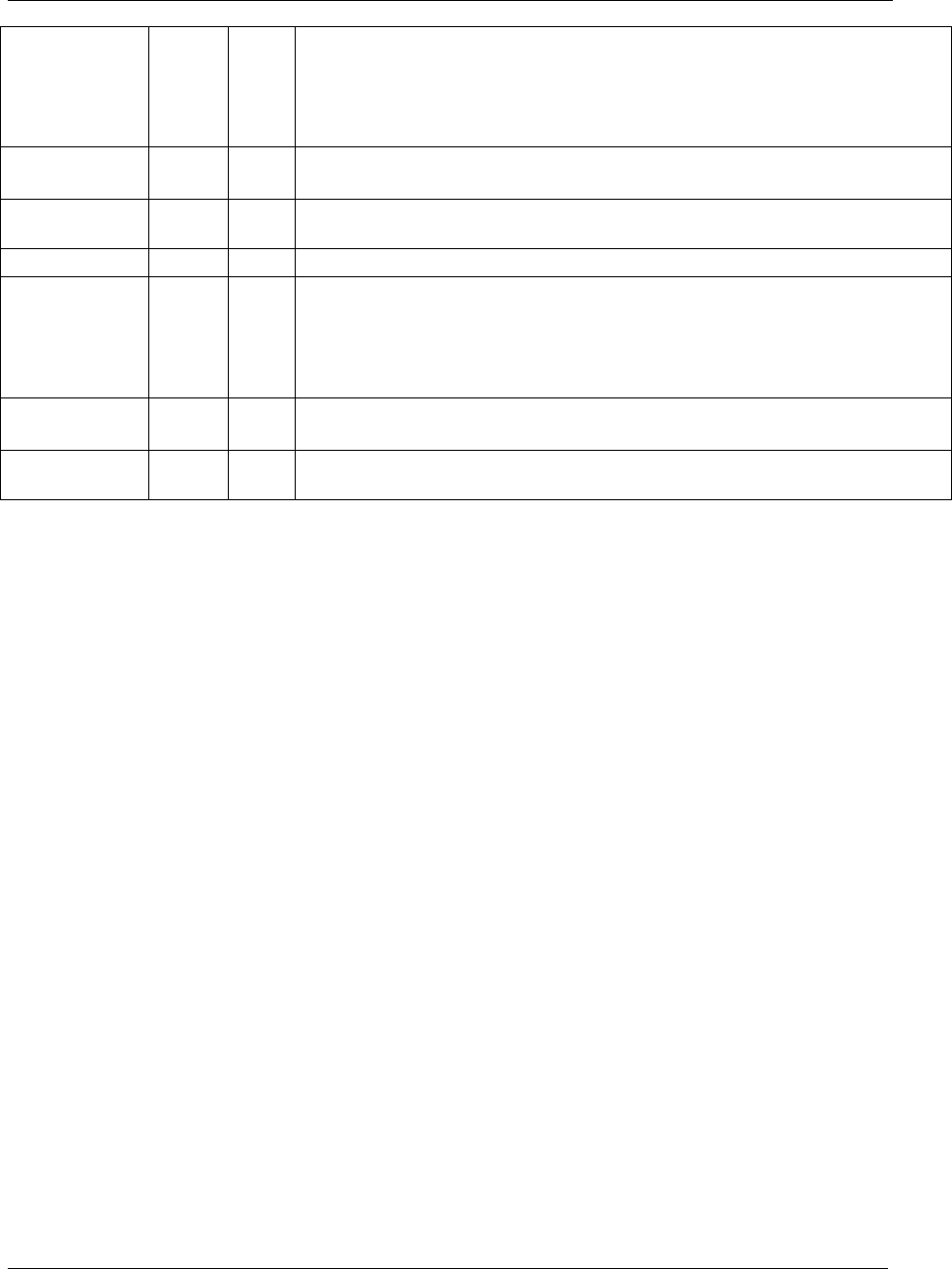

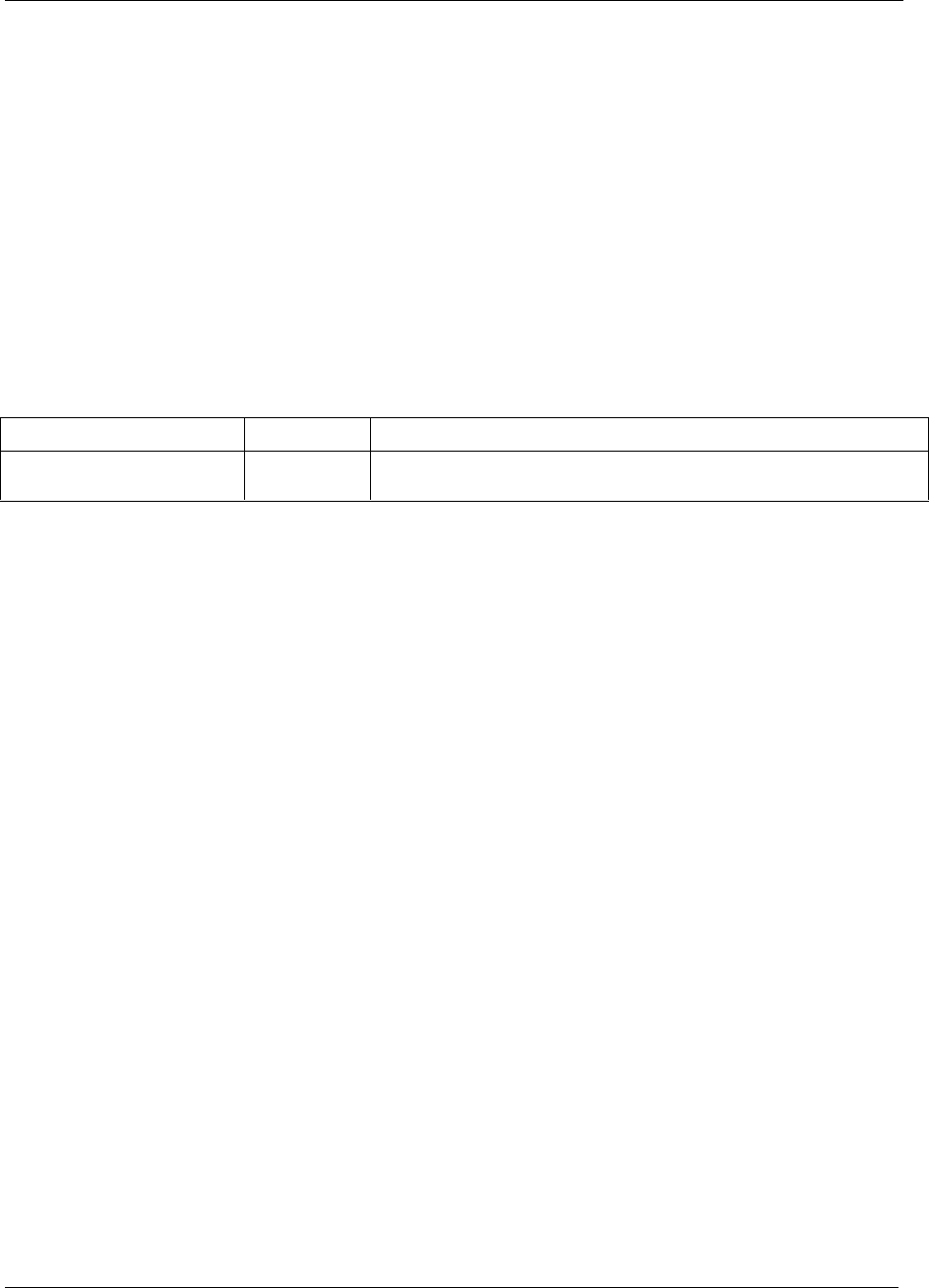

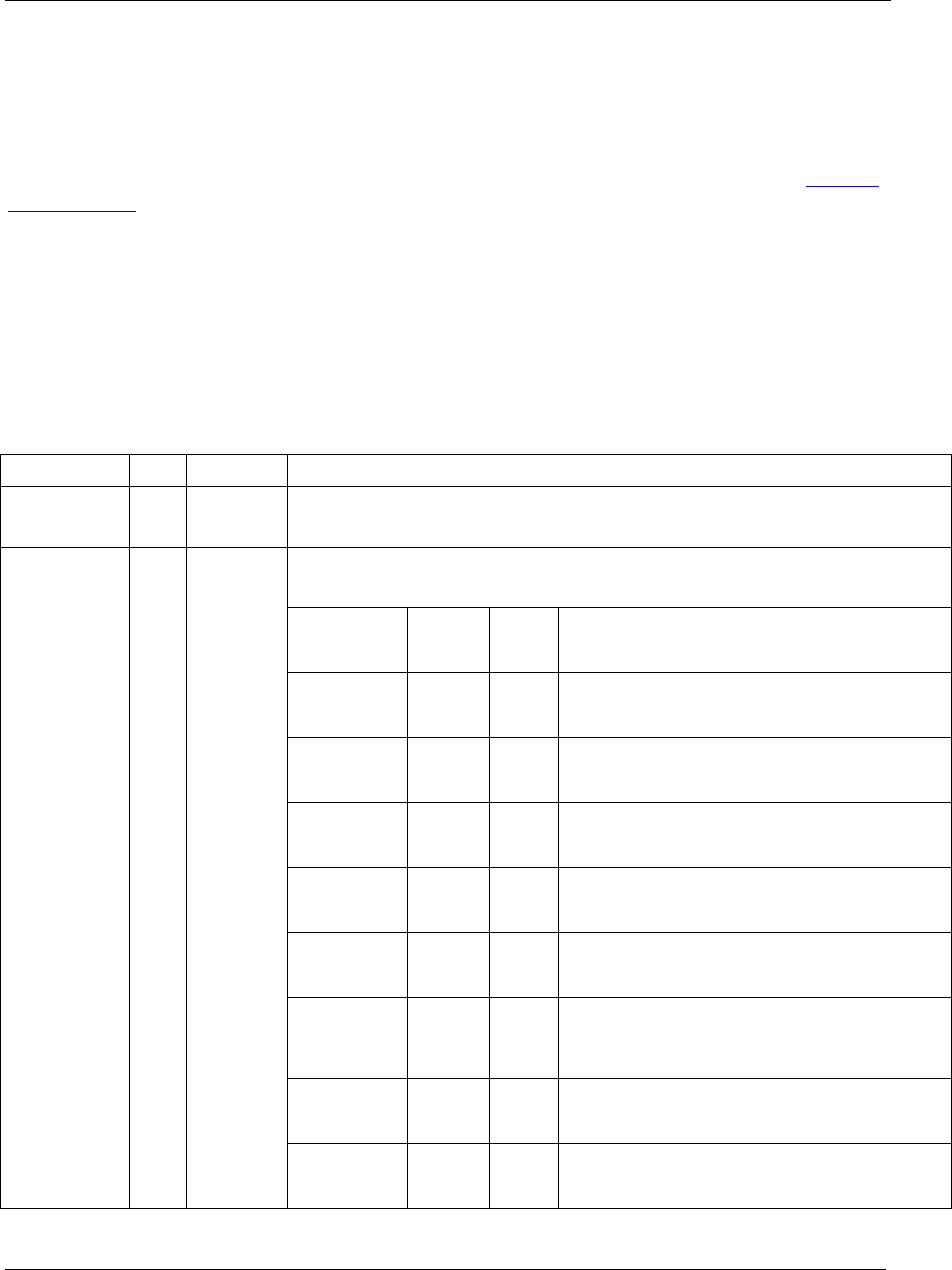

Version

Date

Author

Change

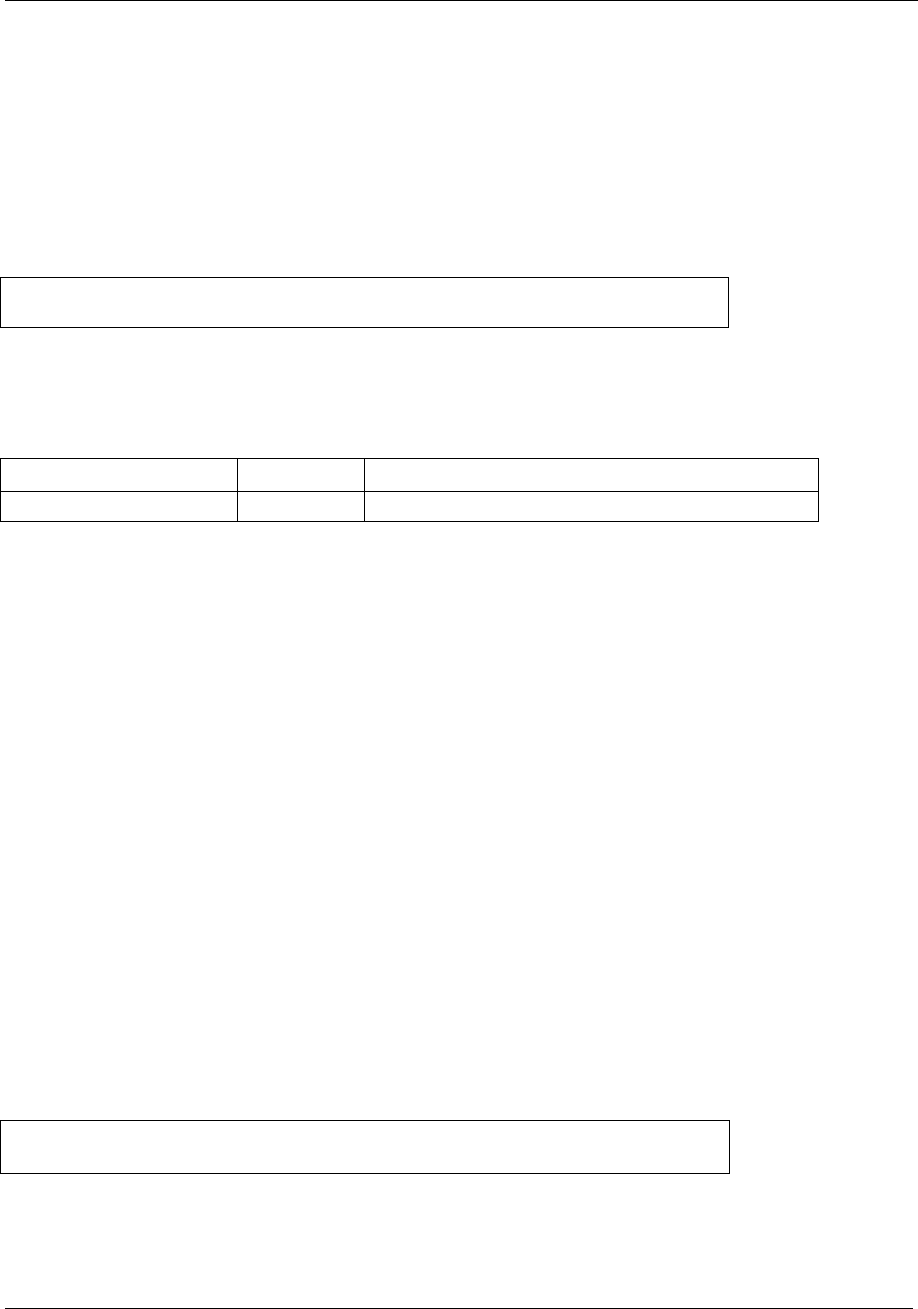

1.5.2

2012-01-27

Björn Johansson

New rev. for document 1.5.2. MID 41 length

corrected.

1.5.3

2012-09-19

Björn Johansson

New rev. 1.5.3 According to DR 3457 in PF project

W10.9

1.6.0

2012-09-21

Björn Johansson

New release 1.6.0 due to introducing PF6000

product. New chapter added for data field

implementation

The appendix 6.3 Product MID and revision

support table changed to include PF6000 product.

In the appendix a table is added for PF6000

parameter support

In each MID description tables a column is added

for marking of product parameters support or not

The following MID/Revisions has been

changed/added:

MID 0060/0061 new revision 7

MID 0012/0013 new revision 4. See Toyota

appendix

MID 0025 new revision 2. See Toyota appendix

MID 0070/0071 new revision 2

New MIDs 0500-0504 for tool motor tuning

1.6.1

2012-10-11

Björn Johansson

New Revision 1.6.1.

Introducing wireless tool pairing

New MID 0047 added for Start, Abort and get

Pairing Status

New MID 0048 added for Pairing status reporting

New error codes for MID 0004, 61-68

Adding a new unit, Ncm, in parameter 48 in MID

61/Revision 3 and upwards, MID 45 and MID 65.

Ncm = a symbol for the newton centimeter, a

metric unit of torque equal to 0.01 newton meter or

about 1.416 12 inch ounces (in·oz) in traditional

English units.

Introduction

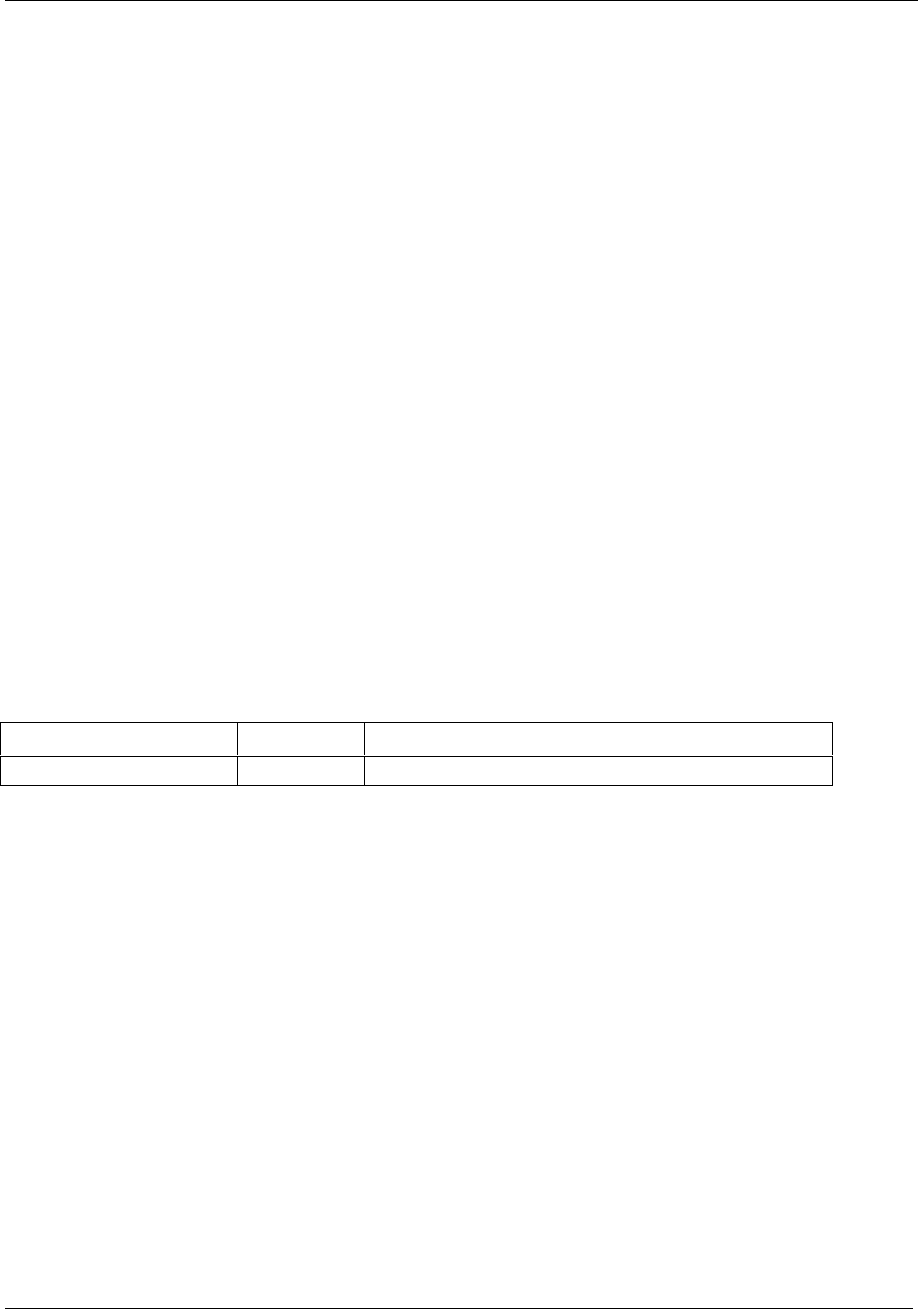

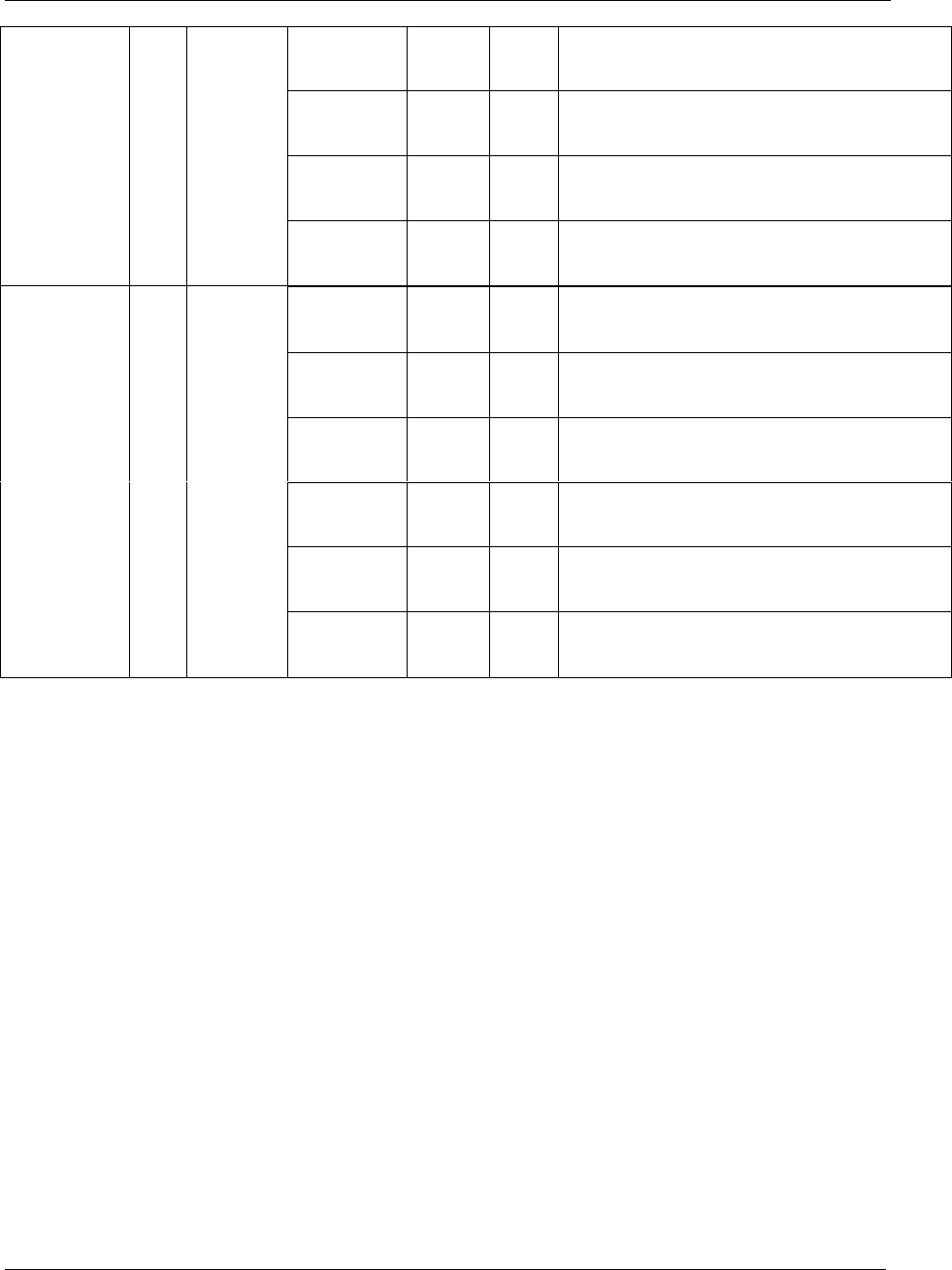

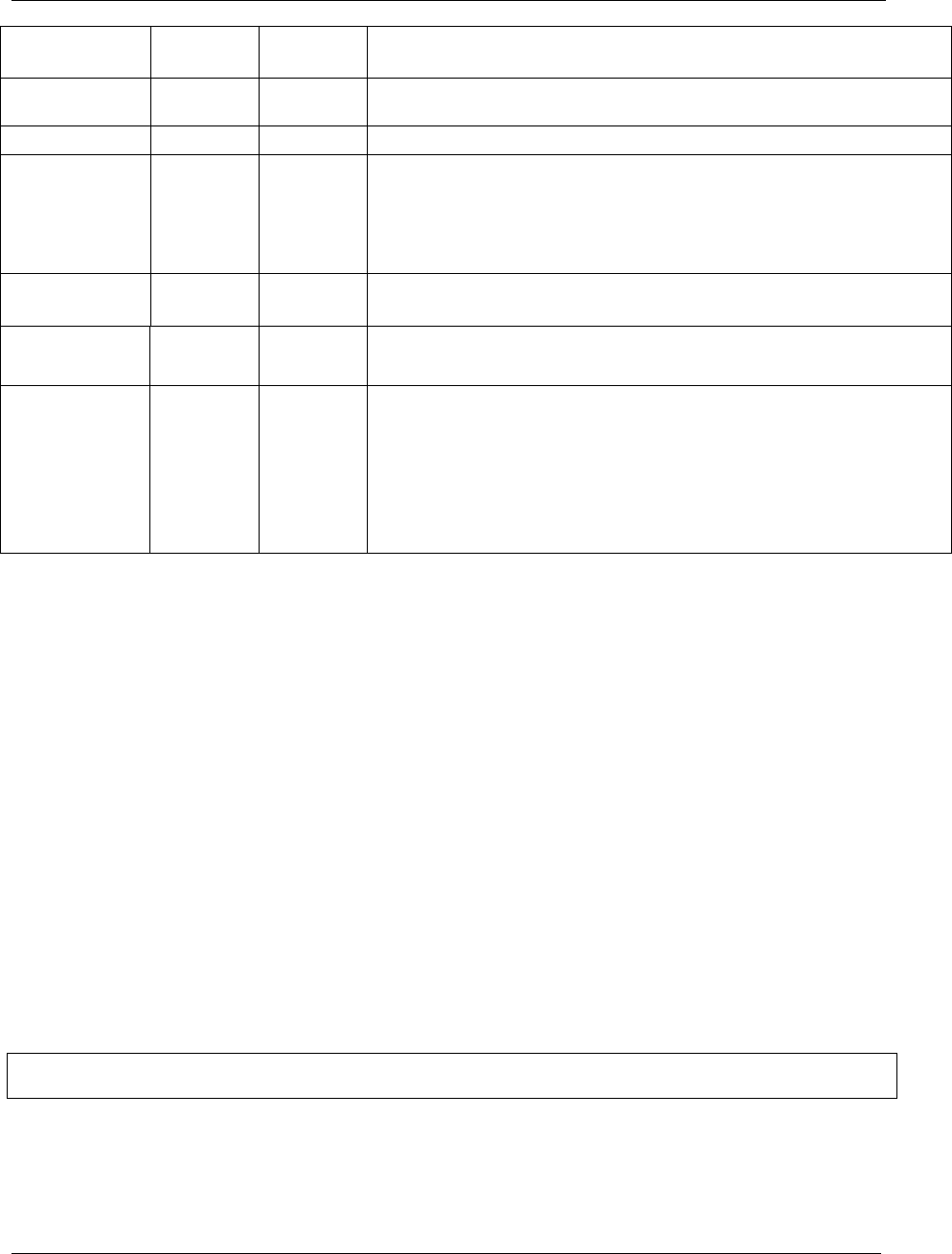

14 (285)

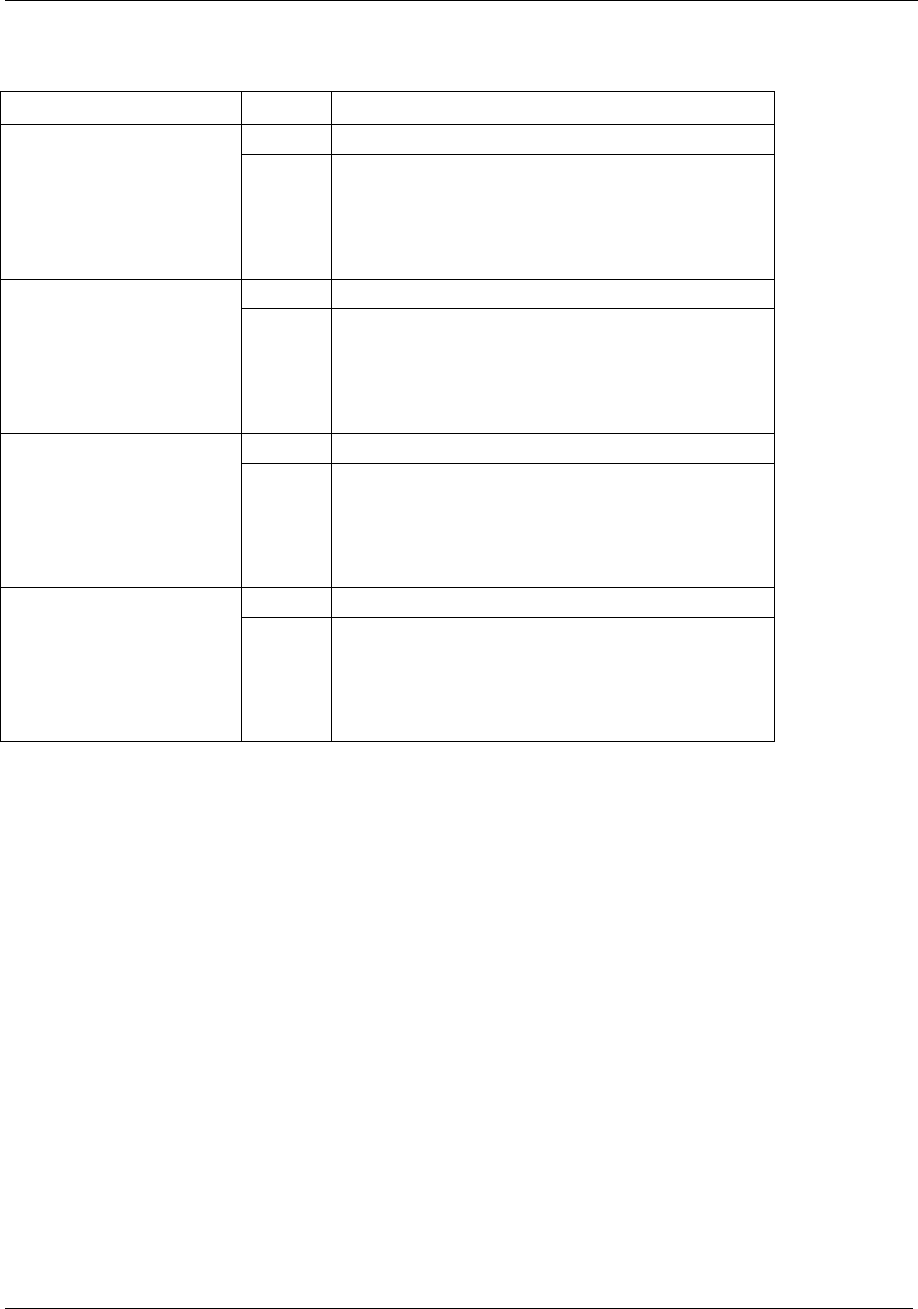

Version

Date

Author

Change

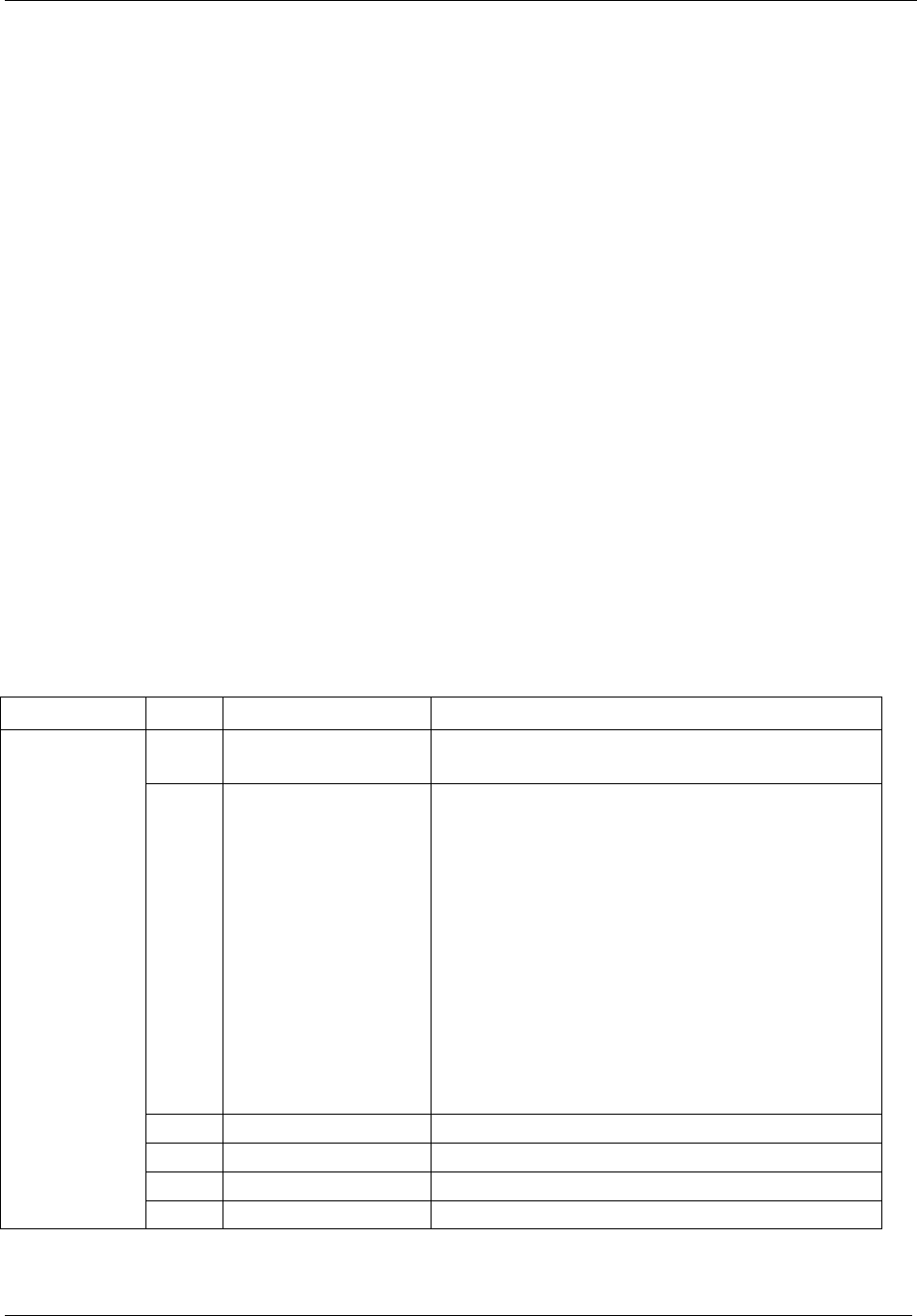

1.6.2

2012-12-20

Björn Johansson

Some corrections of 1.6.1 BJ

1.6.3

2012-12-20

Björn Johansson

Added relays for the PLUS protocol, the

“PLUS Protocol not active” and ”PLUS No

tightening”.

The “Not supported by” column removed. It is

up to each project to provide documentation of

which MIDs, Revisions and parameters that are

supported according to decision in the Open

Protocol committee

Hence a new document shall be created to

handle the support issue and the specialties

described today in the Appendix chapter 6.

This will be done to the next release of OP and

OPIT.

1.6.4

Björn Johansson

Revision 4 of MID 0010/0011 added Appendix

removed. Moved to product specific documents

1.6.5

2014-01-20

Björn Johansson

Document rewritten and added with an

“Implementation Guideline” chapter.

New MID 0245 add, PLC download data for

PowerMACS.

Message Linking functionality description added.

Sequence number use and functionality description

added inclusive the MID 9997 and MID 9998

description.

Common generic subscription/unsubscription MIDs

0008 and 0009 description added.

Common generic application data request MID

0006 added.

MID number allocation rules chapter added. To be

used for new MIDs in the future.

New pattern for variable data parameter use added.

New MIDs 1201, 1202, and 1203 added that uses

the new pattern for variable parameter.

New group of MIDs for so called Mode selection

handling added MIDs, MIDs 2600-2606.

New MIDs 0900 for Traces and MID 0901 for Plot

parameters on Traces added.

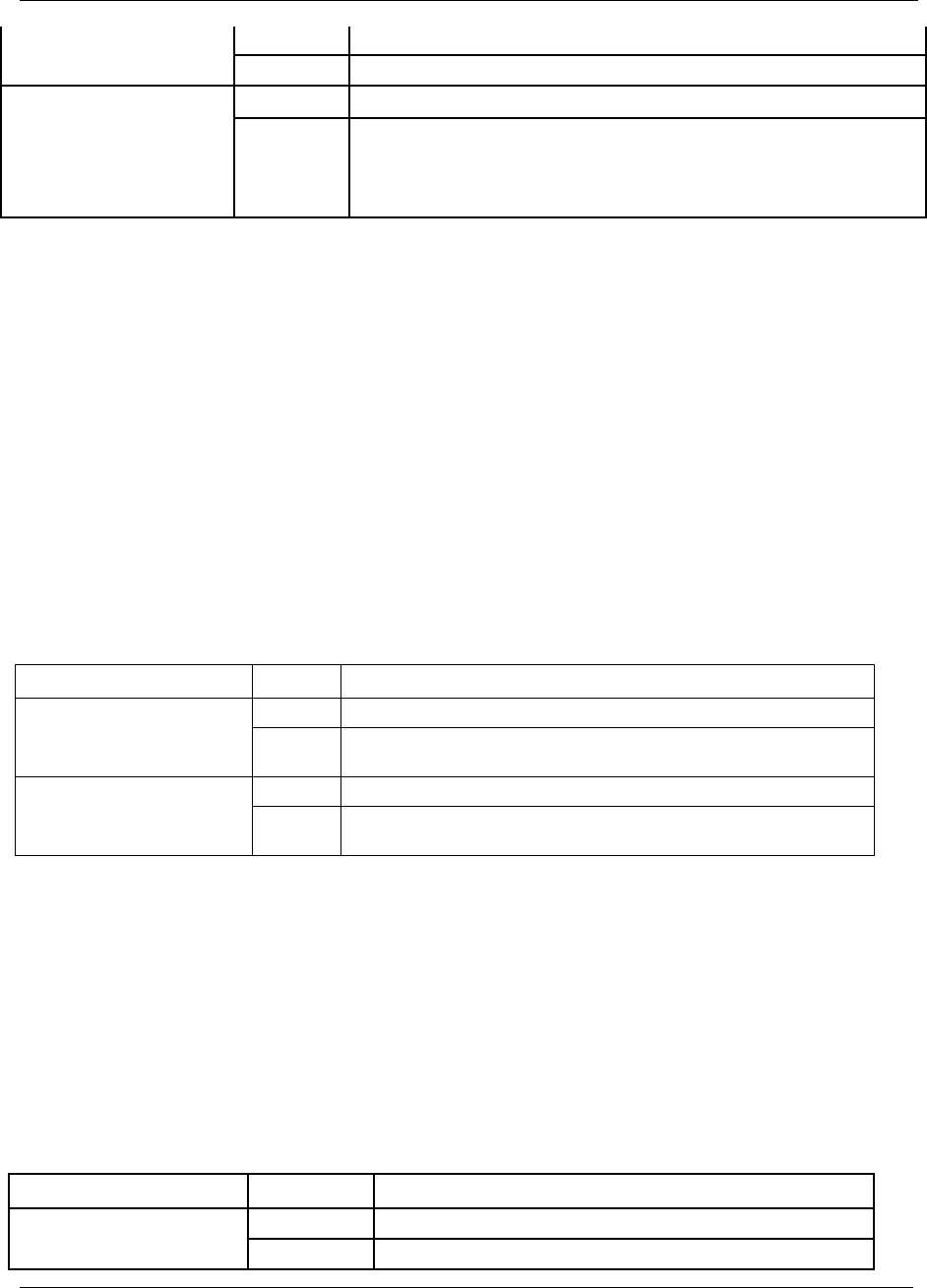

2.0

2014-03-20

Björn Johansson

New MIDs 02500 and 02501 added Program

upload and download. Revision upgraded due to all

Using Open Protocol

15 (285)

Version

Date

Author

Change

the new protocol basic functionality added also in

1.6.5

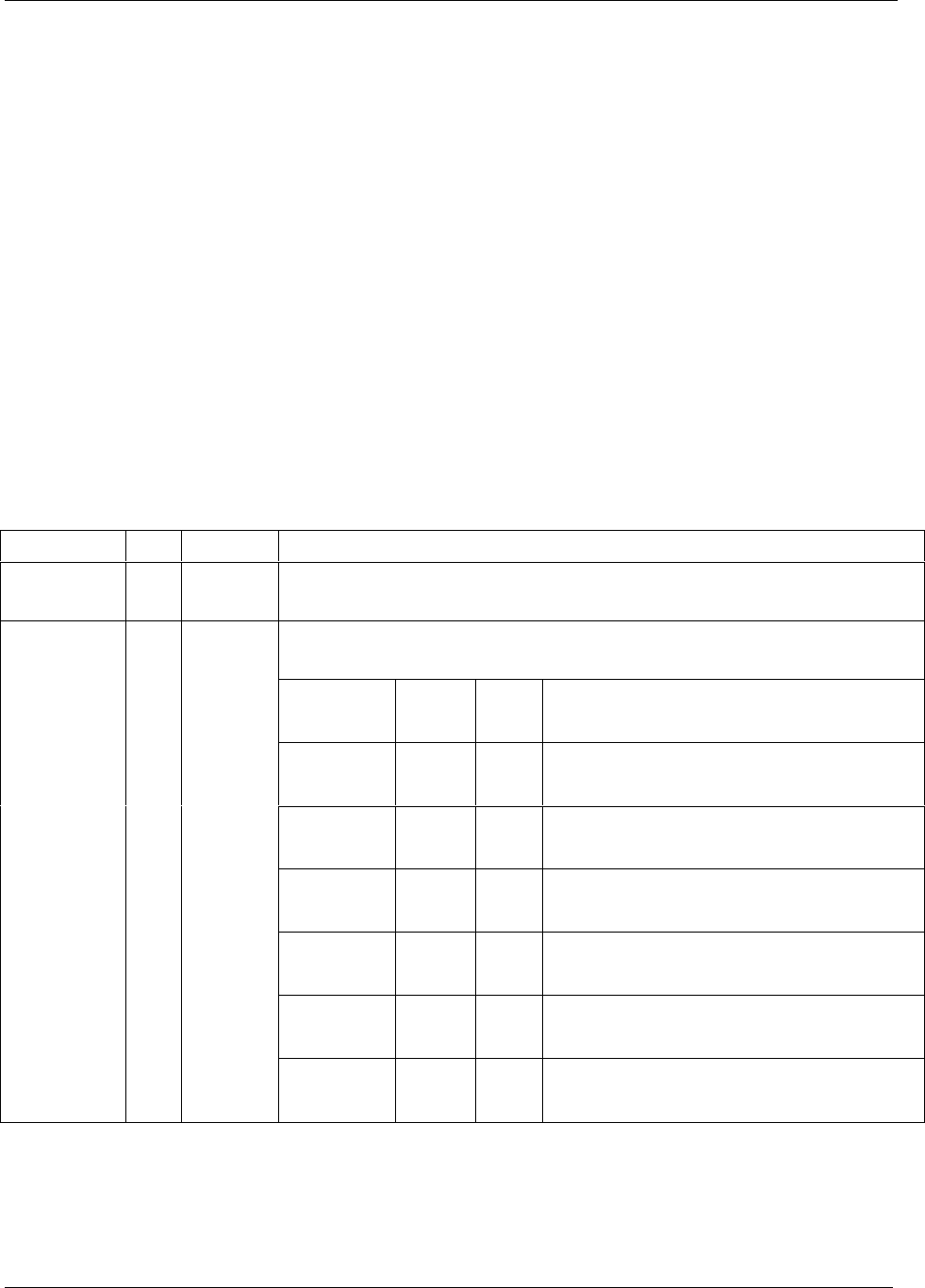

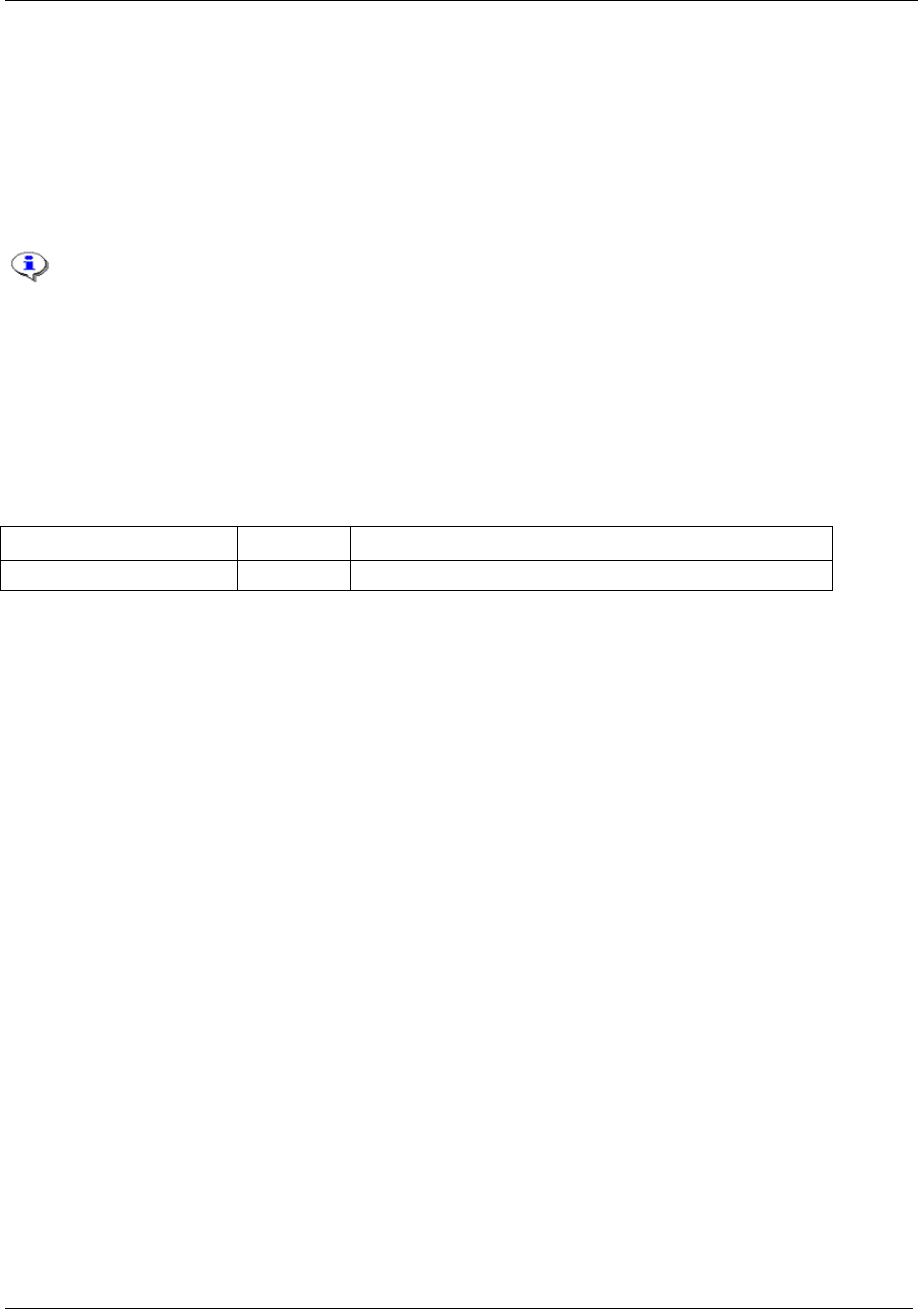

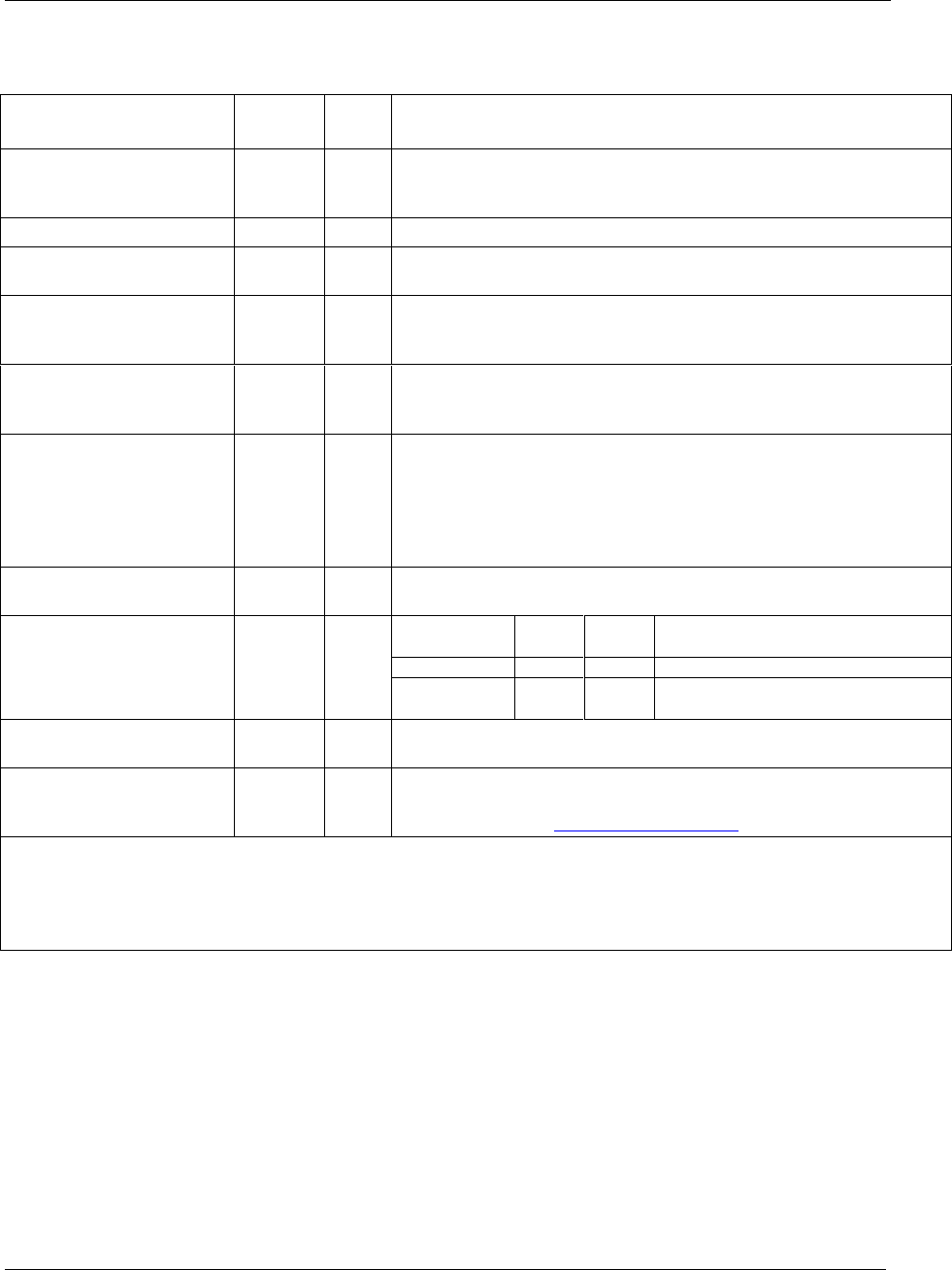

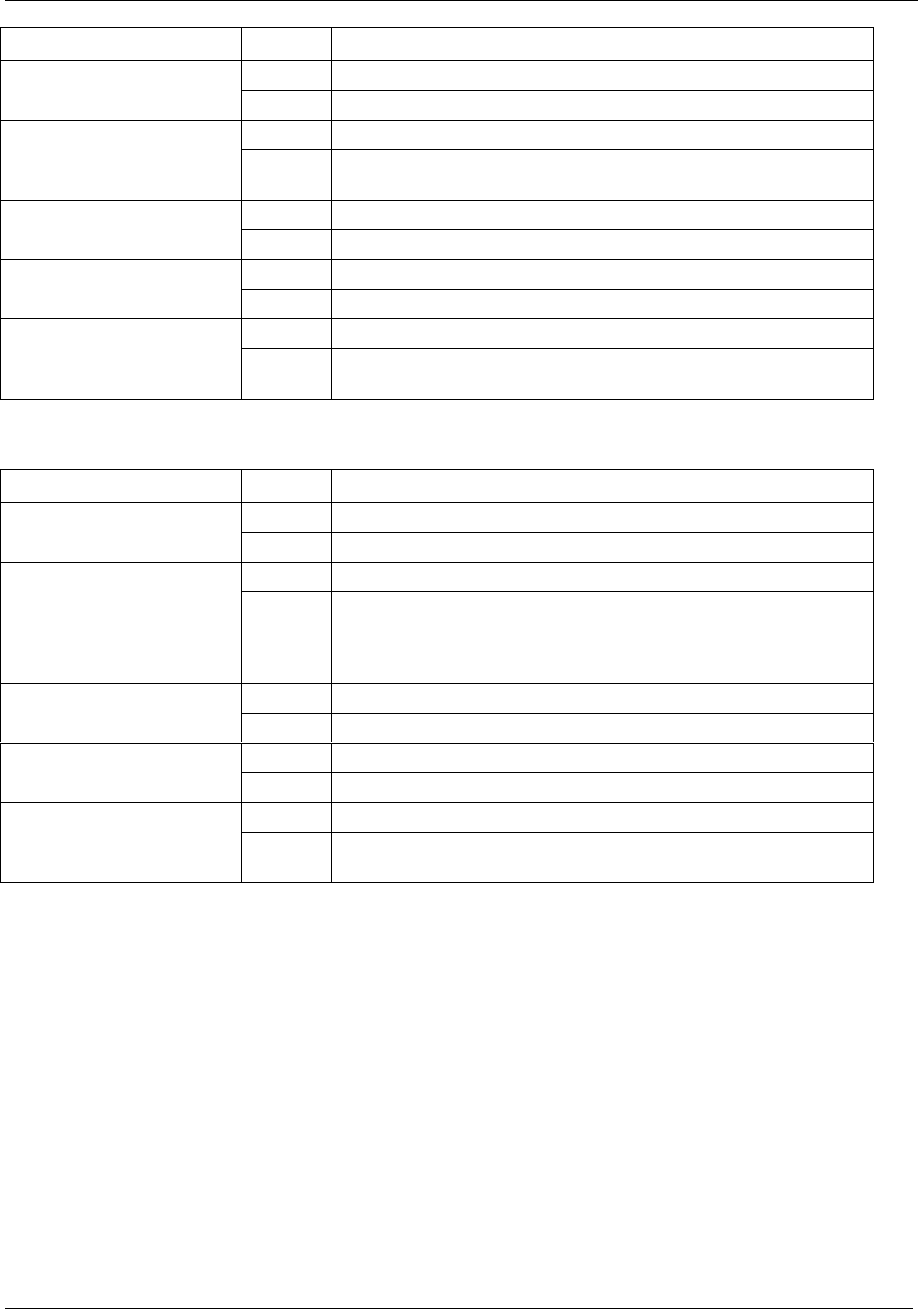

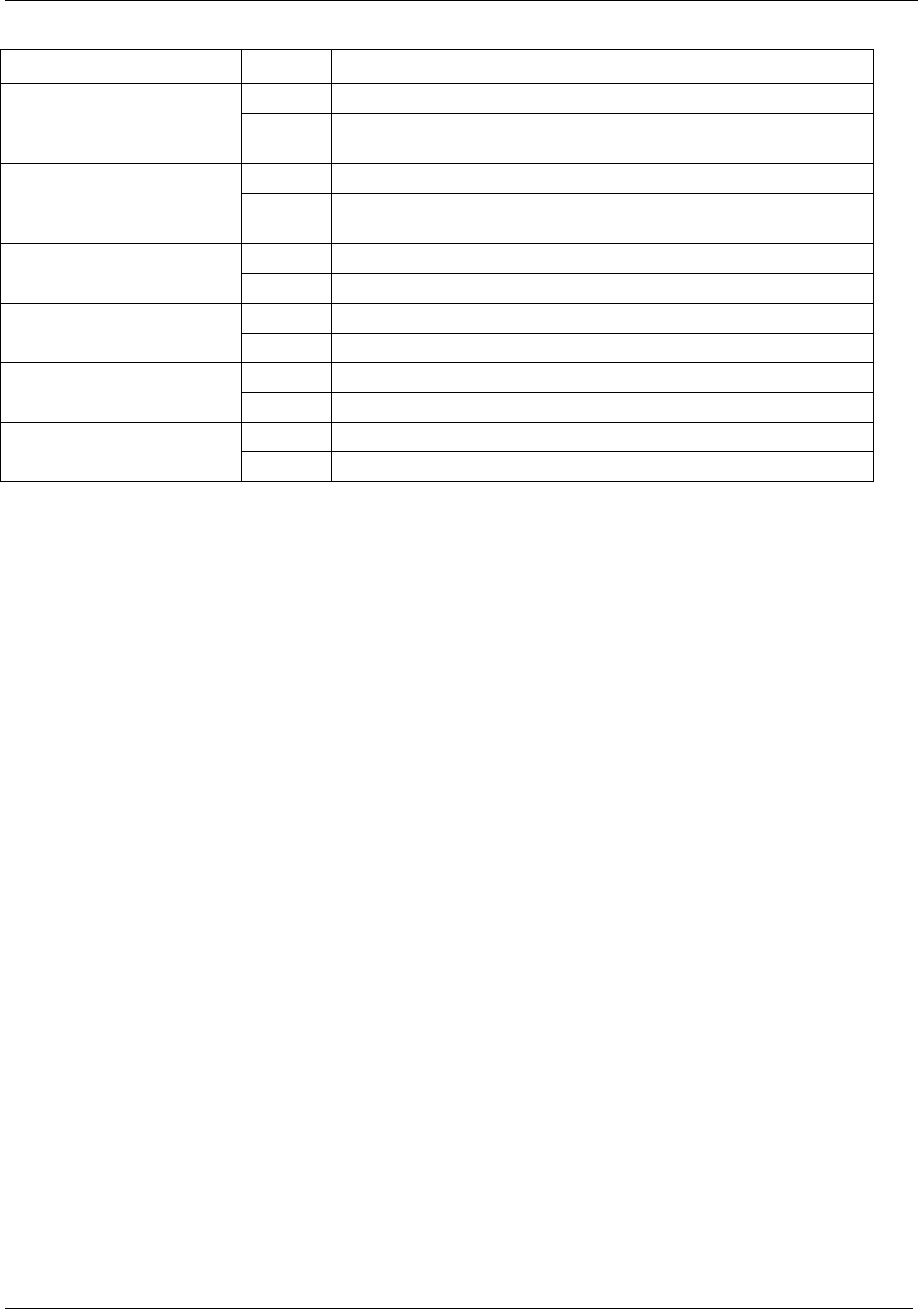

2.1

2014-05-20

Björn Johansson

Corrections done of PID numbers 01001-01033

2.2

2014-06-22

Björn Johansson

Added MID 2505 for Pset dynamic selection.

Added PIDs 00030-00031.

Added new PIDs 02215, 02216, 02217 and 02218

for 4 stage tightening, used in MID 900.

2.3

2015-03-30

Björn Johansson

Added MID 700 for Tightening data download

status for radio connected Tools. Added new PIDs

04000-04002 for that purpose.

Also more specification text for clarifying of the

Tool pairing functionality with MID 0047, 0048

2.4

2015-05-19

Björn Johansson

Added Digin functions 136 and 137

2.5

2015-06-16

Björn Johansson

Change the subscription extra data for results

supporting historical data

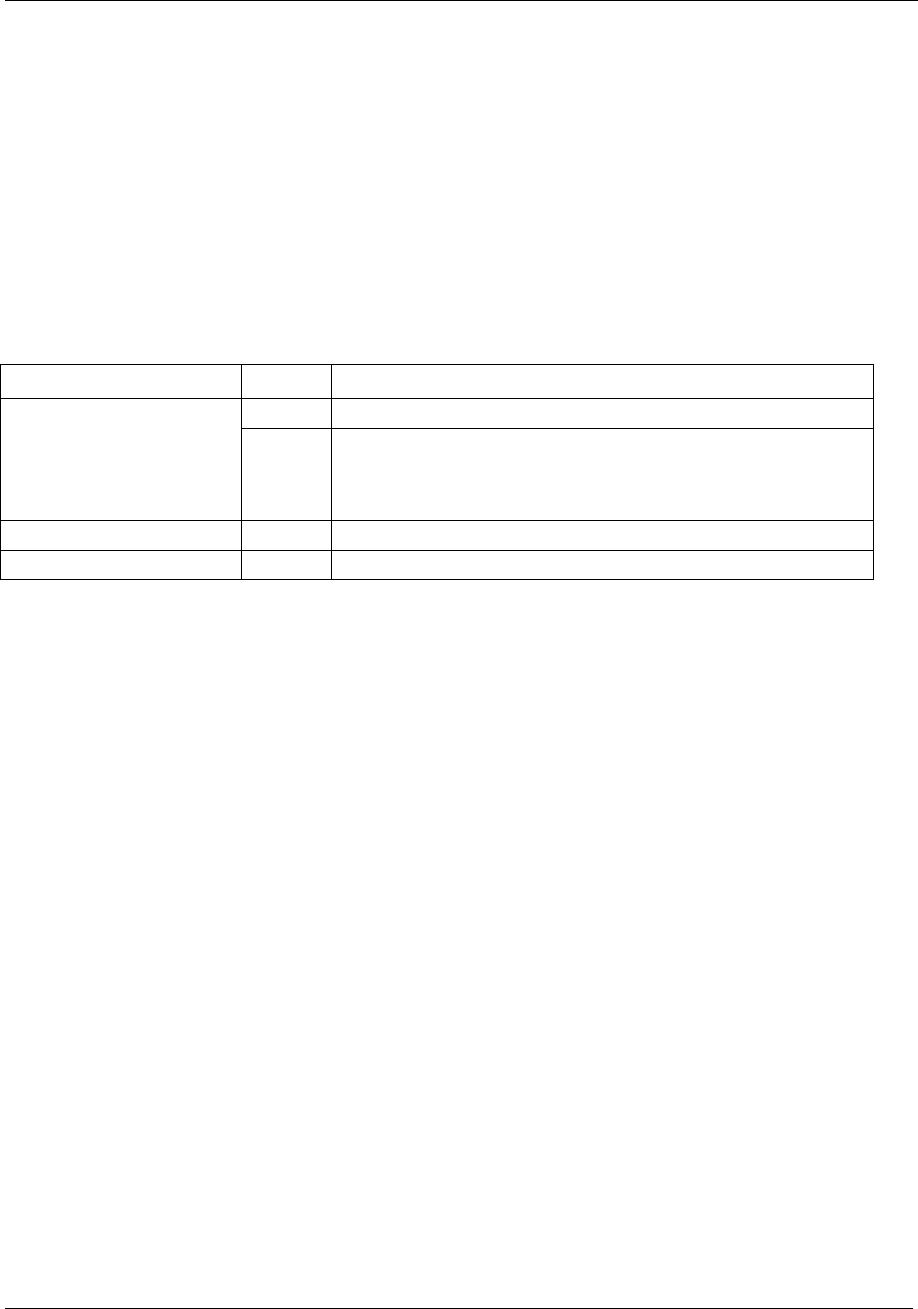

2.6

2015-09-21

Björn Johansson

1. Clarification of generic subscription

answers/acknowledging

2. Correction of MID 61 Rev. 7 length. Jira issue

OPC 38

3. Subscriptions on Results Mid 1201 and 1202

and Traces MID 900 and 901 possible to get as

snap time, snap Id, latest and from Id or Time to

latest. Added PIDs 00050-00053 for that purpose.

MID 0071 added with Error text in revision 2

Added PIDS for tuning.

Added subscription for Pset upload at change.

2.7

2016-02-02

Björn Johansson

Added controller information in Revision 6 of

MID 0002 about Station Id and Station Name for

PF 6000. Used by PF 4000 for Cell Id and Cell

Name.

Also added a Client Id.

Added new revision 2 for MIDs 0254, 0255

Selector Control.

Added spec., for MID 1900 and MID 1901 which

use the variable pattern and shall substitute the

use of MID 0254, 0255 and belonging

subscription and stop subscription and

acknowledging by using the generic MID 0008,

MID 0009 subscription, stop subscription.

Added PIDs 01508, 01509 for Job reference Mac

and Job start time.

Corrected MID 900 description by adding PID

Introduction

16 (285)

Version

Date

Author

Change

02214 coefficient for multiplication of the 16 bit

trace values as alternative to PID 02213

Added a chapter for Session control functionality

2.7.1

20160601

Björn Johansson

Corrections made after review

2.8.0

20170201

John-Eric Ericsson

Added revision 5 of MID 0035

Removed all header definitions for all MIDs and

refer to the specification in its own section

Added revision 5 of MID 0101

Added MID 2100, Device command