User guide

Power Focus 3000/3100/3102/4000

Control and Drive unit for TENSOR Electric Nutrunners

Atlas Copco Tools & Assembly Systems

9836 3123 01

Software Release W7.0

Edition 1

2007-04

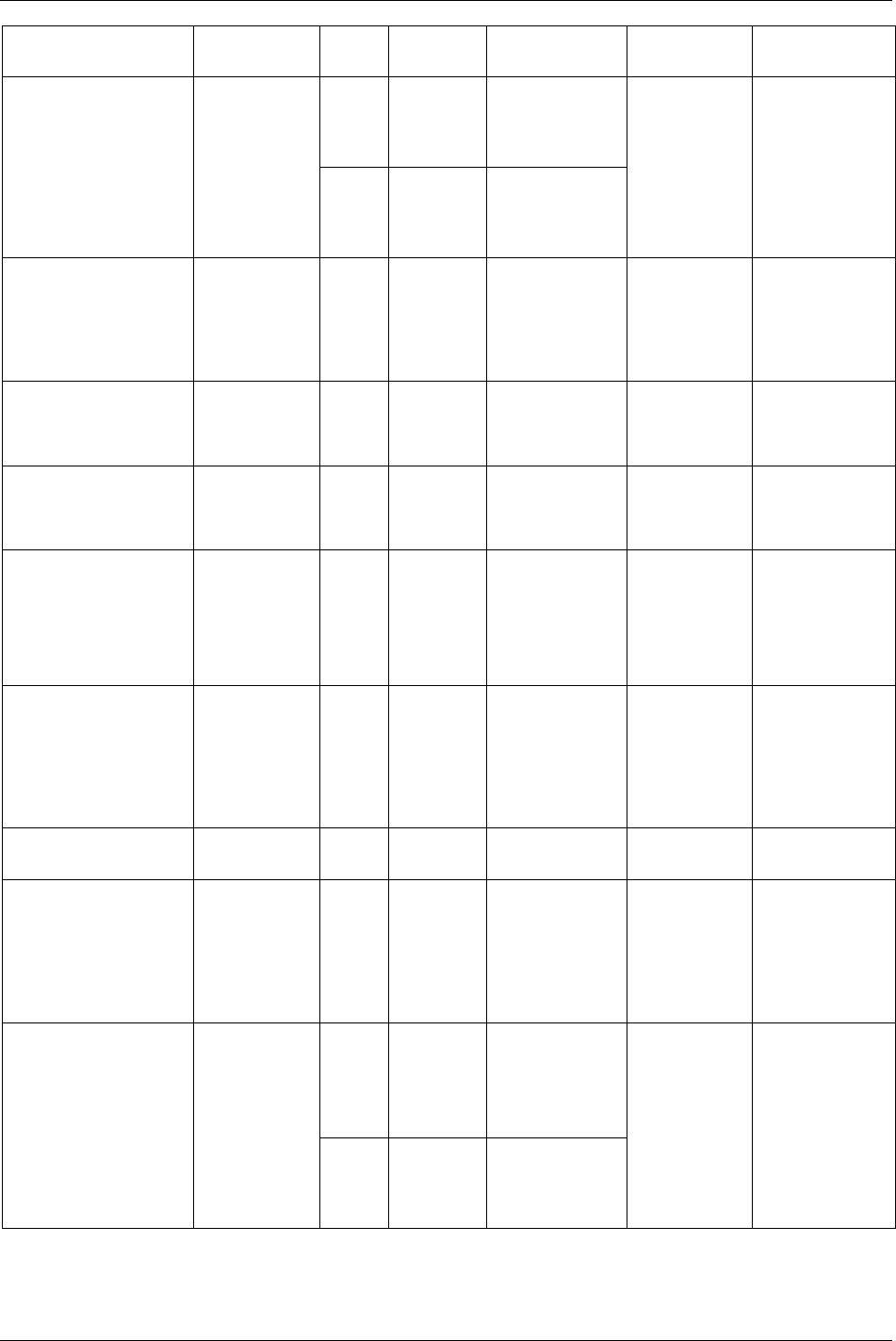

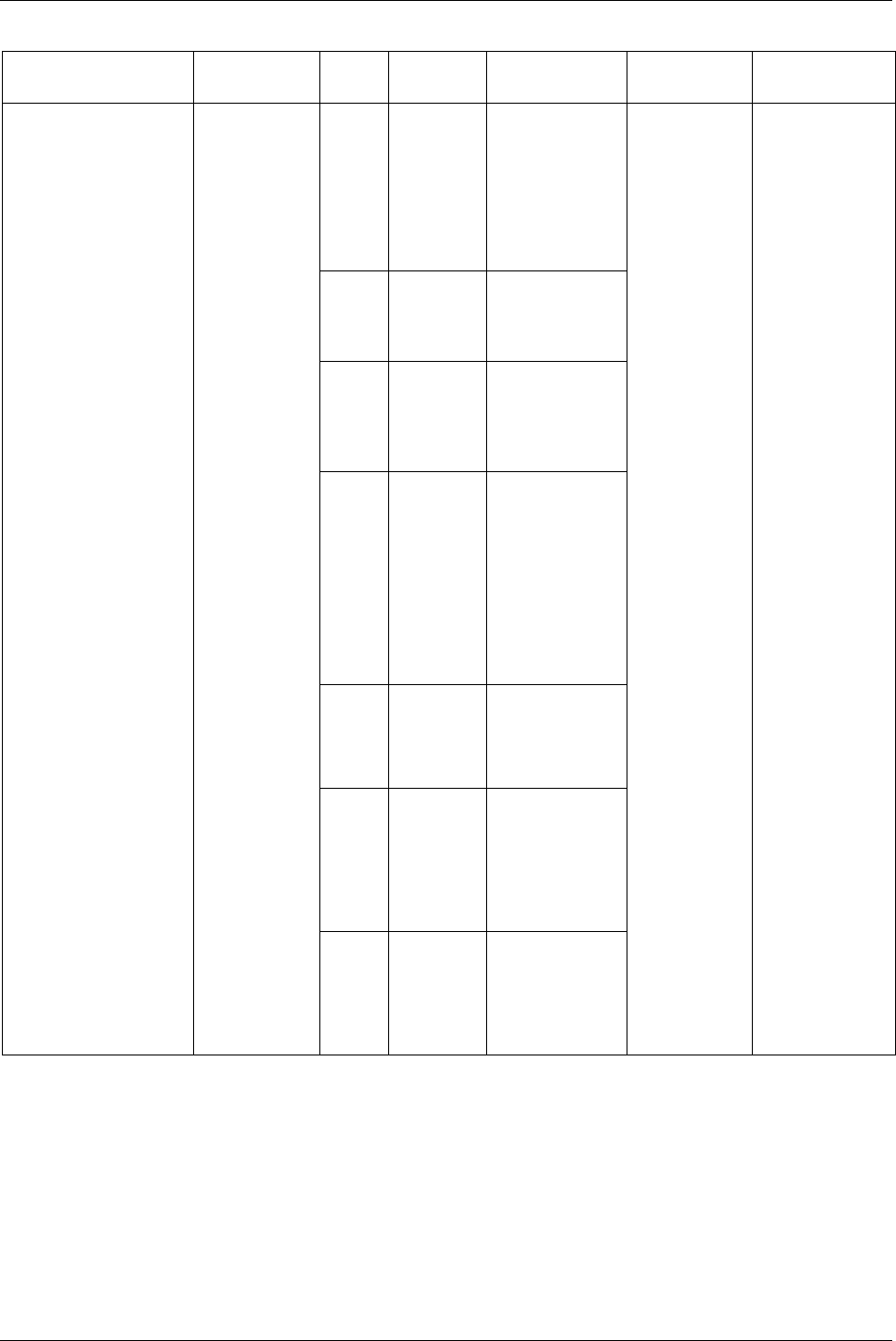

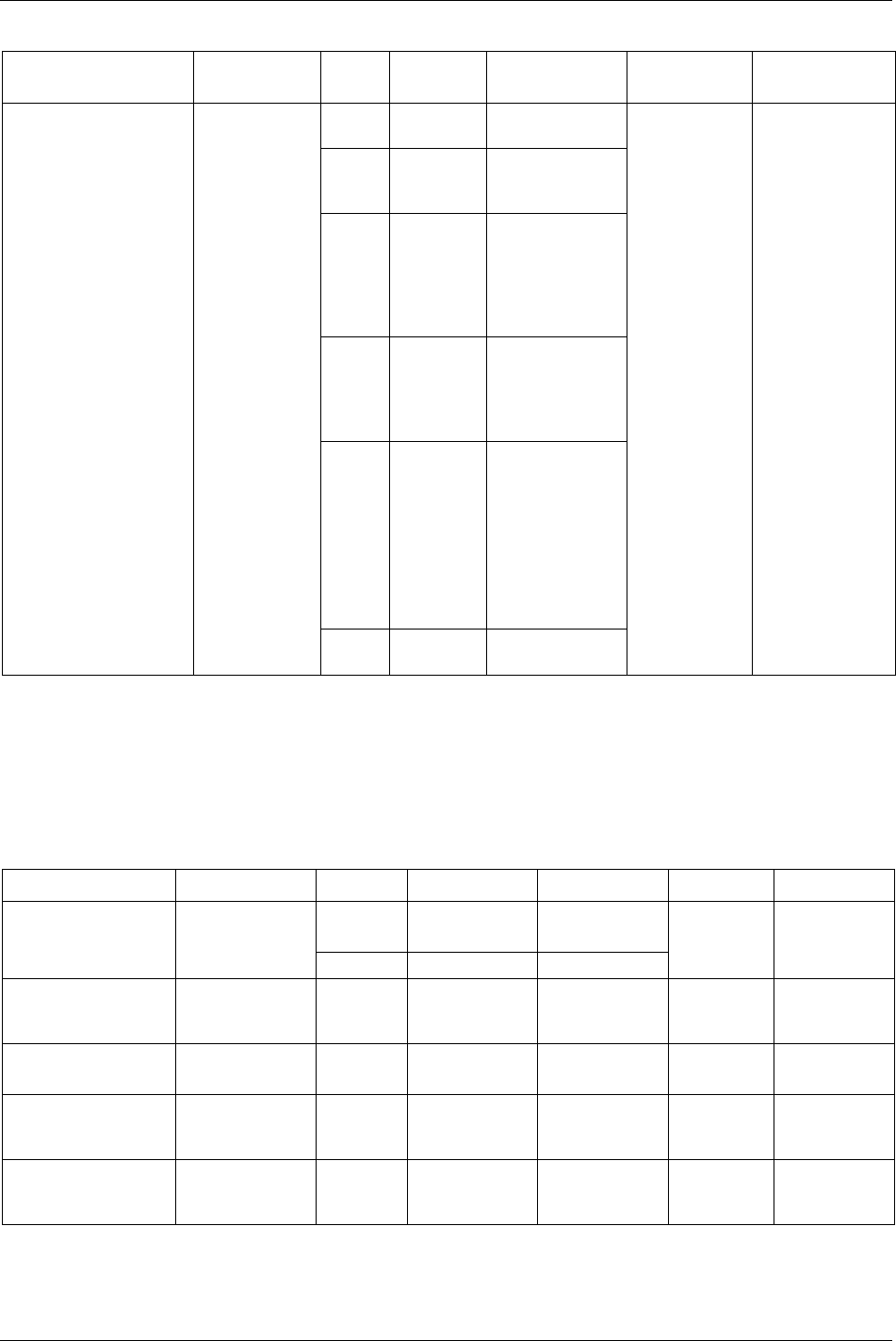

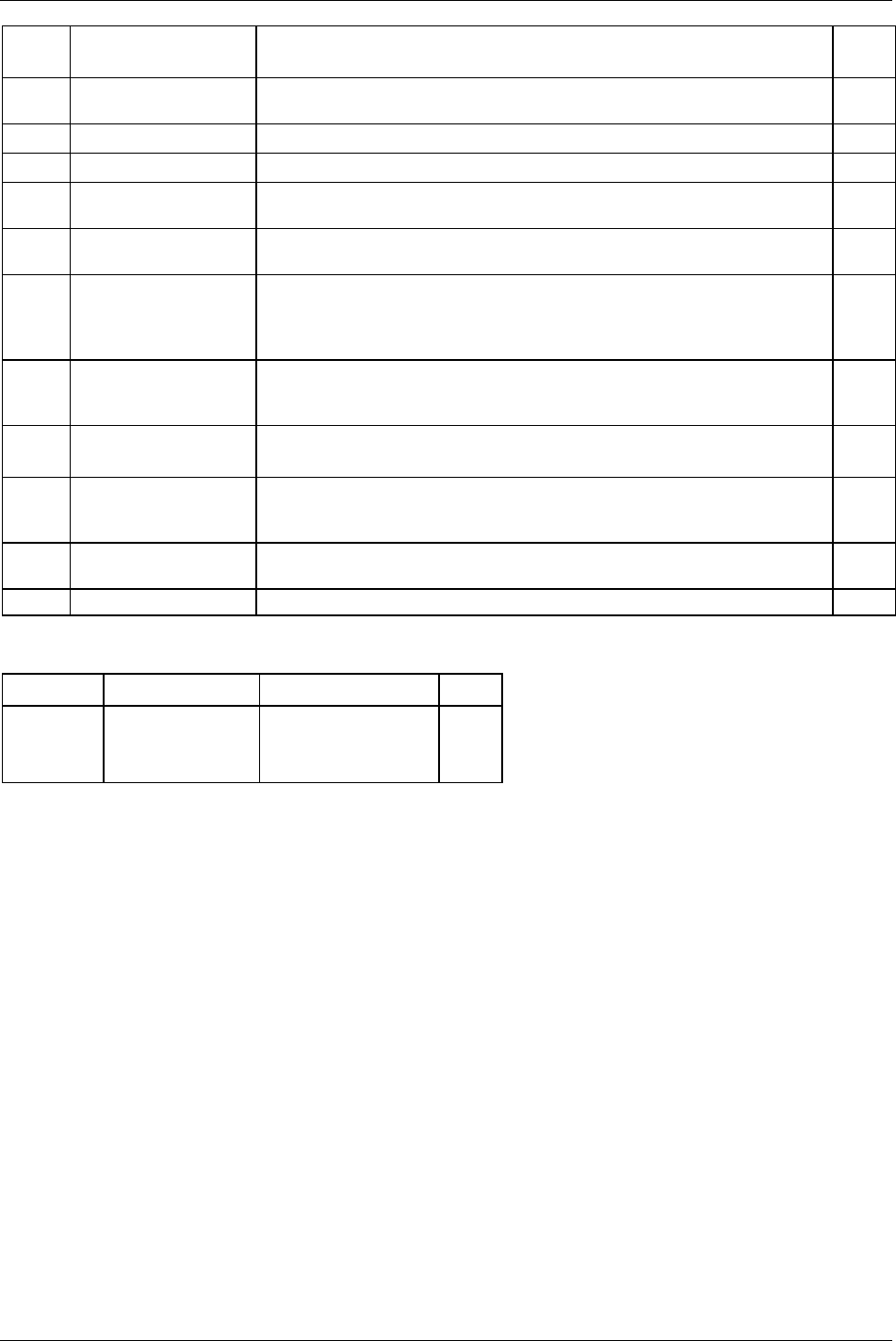

Contents

9836 3123 01 3 (330)

Contents

1 General safety instructions................................................................................11

1.1 Work area .................................................................................................................11

1.2 Electrical safety.........................................................................................................11

1.3 Personal safety.........................................................................................................12

1.4 Service......................................................................................................................12

2 Abbreviations ......................................................................................................13

3 Introduction to Power Focus..............................................................................15

3.1 PF 4000 ....................................................................................................................15

3.1.1 Logic Configurator ...................................................................................................16

3.1.2 SynchroTork ............................................................................................................16

3.1.3 Yield control.............................................................................................................16

3.2 PF 3000/3100/3102 ..................................................................................................17

3.3 ToolsTalk PF.............................................................................................................17

3.4 ToolsNet ...................................................................................................................18

3.5 Factory Overview......................................................................................................18

3.6 Event Monitor............................................................................................................19

3.7 API............................................................................................................................19

3.8 RBU ..........................................................................................................................19

3.9 Cell............................................................................................................................20

3.10 Job............................................................................................................................20

3.11 Sync..........................................................................................................................20

3.12 Communication.........................................................................................................20

3.13 Accessories ..............................................................................................................21

3.14 Nutrunners................................................................................................................23

3.15 ACTA 3000 ...............................................................................................................23

4 Getting started with ToolsTalk PF .....................................................................25

4.1 Overview...................................................................................................................26

4.1.1 Menu list ..................................................................................................................27

4.1.2 Selection panel........................................................................................................28

4.1.3 Toolbar.....................................................................................................................29

4.1.4 PF Map ....................................................................................................................30

4.2 Settings.....................................................................................................................32

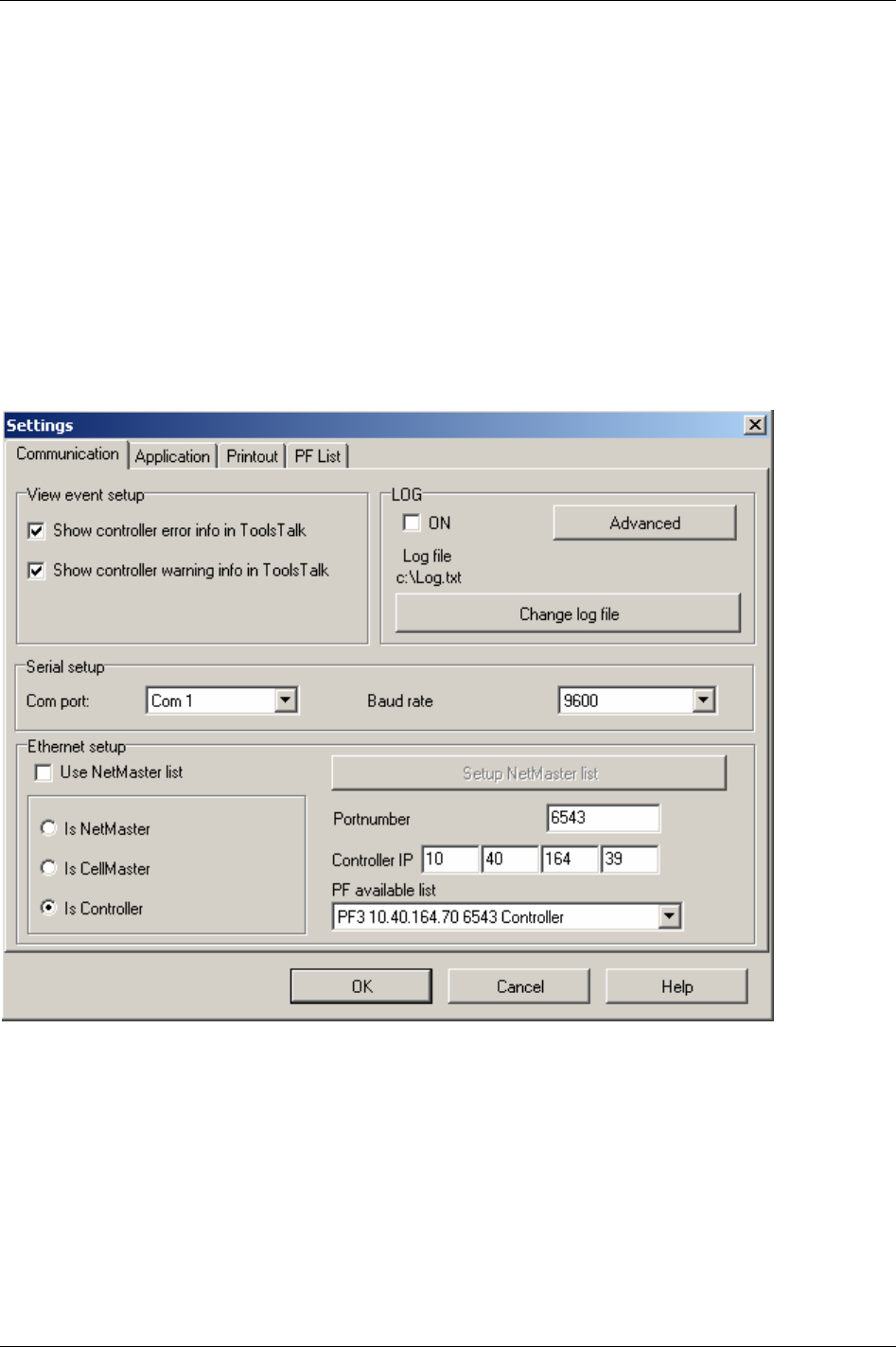

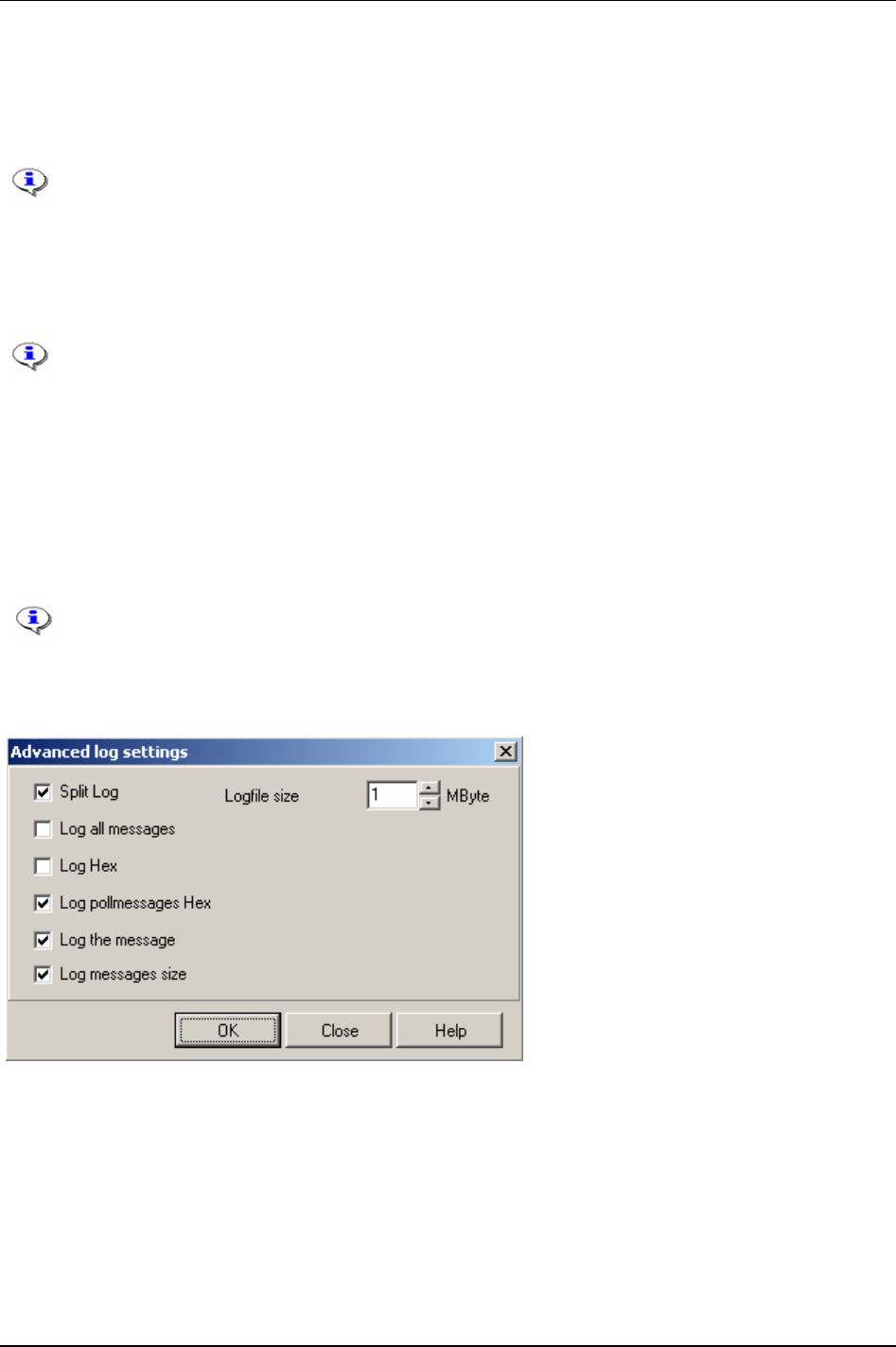

4.2.1 Communication........................................................................................................32

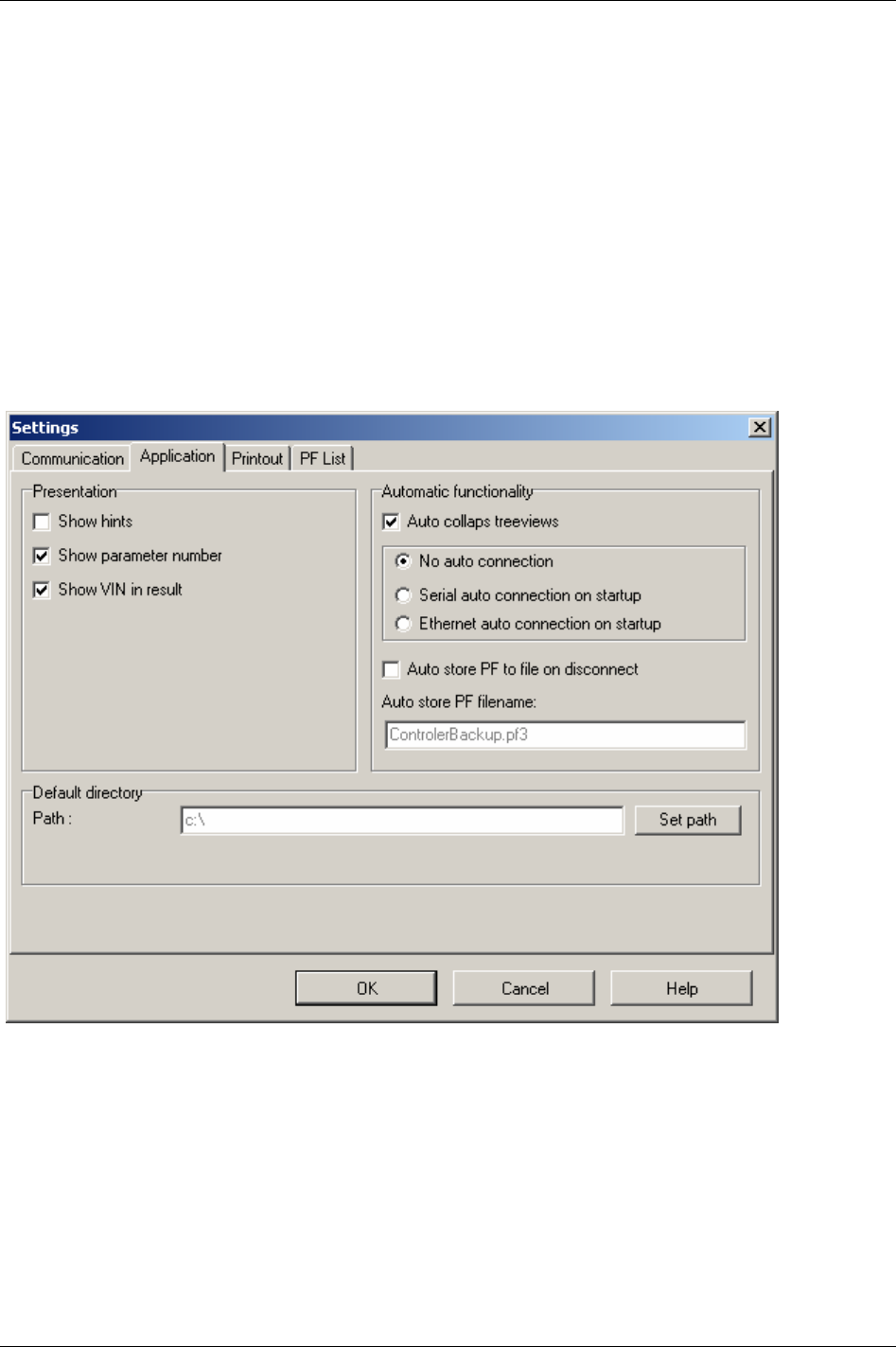

4.2.2 Application ...............................................................................................................34

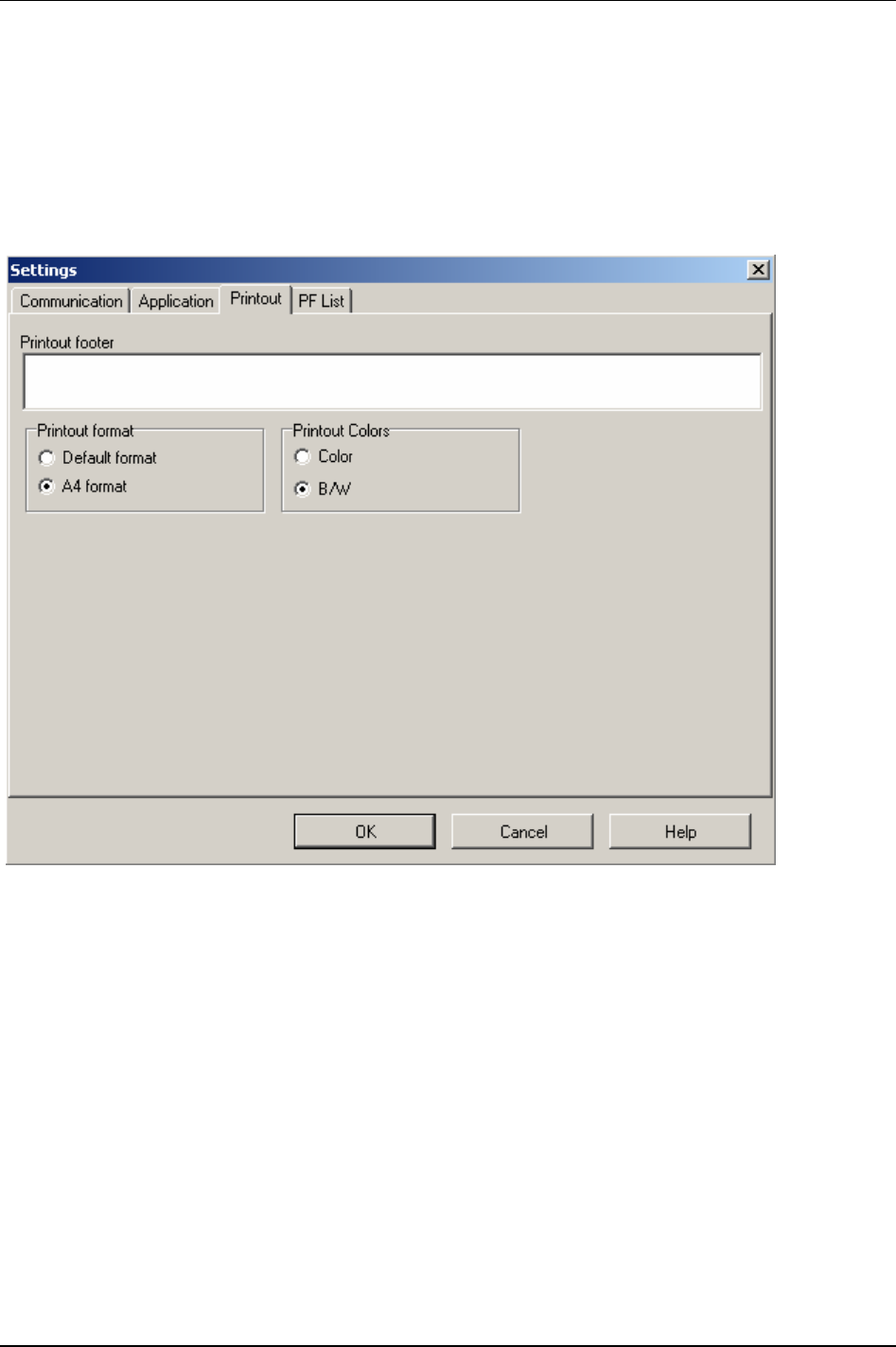

4.2.3 Printout ....................................................................................................................35

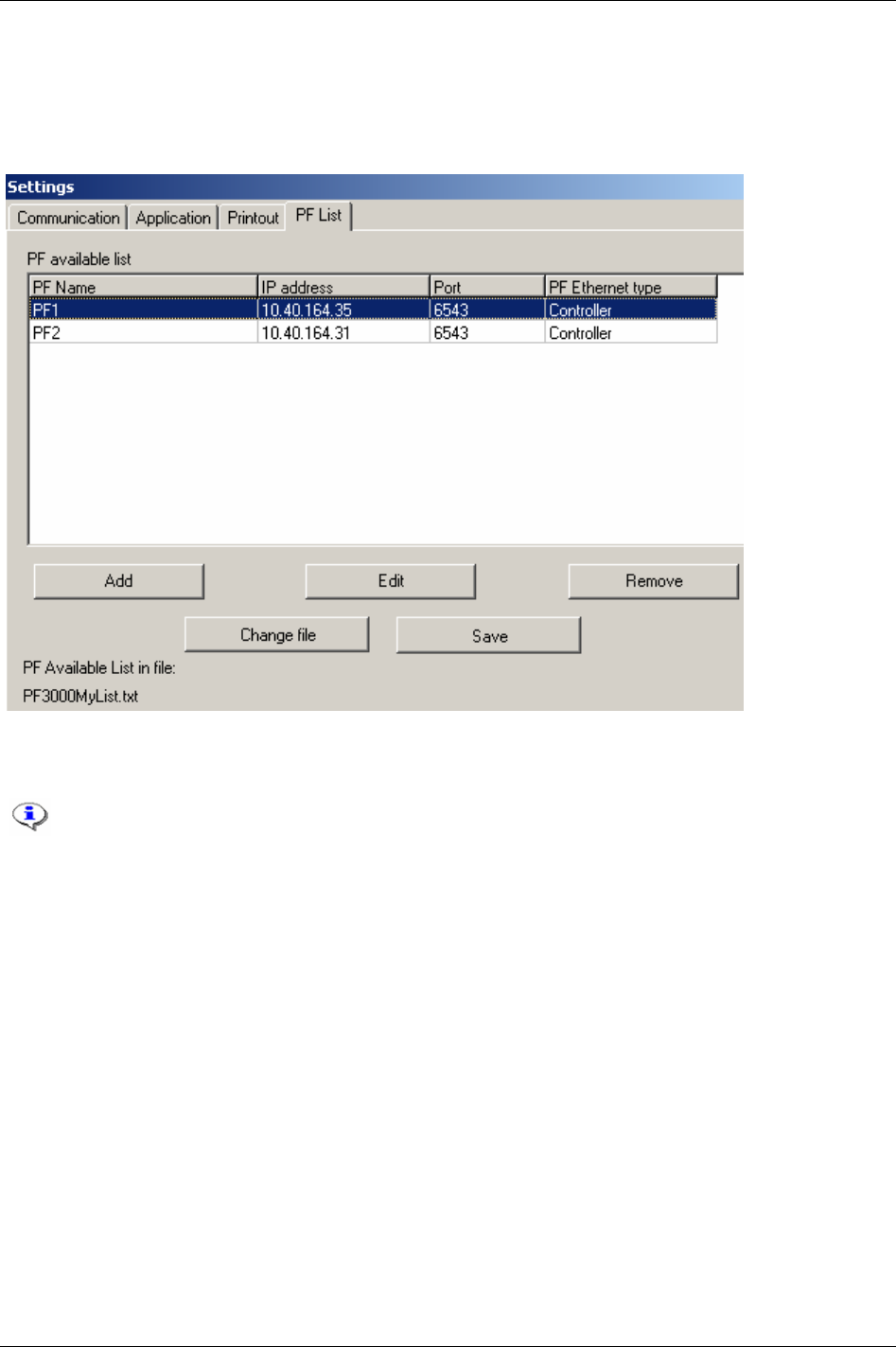

4.2.4 PF List......................................................................................................................36

4.3 Connecting a PF.......................................................................................................36

4.3.1 Ethernet connection.................................................................................................36

4.3.2 Serial connection.....................................................................................................37

4.3.3 USB connection.......................................................................................................37

4.3.4 To connect...............................................................................................................37

4.3.5 To disconnect ..........................................................................................................37

4.4 Storing programming on file......................................................................................37

4.5 Offline .......................................................................................................................38

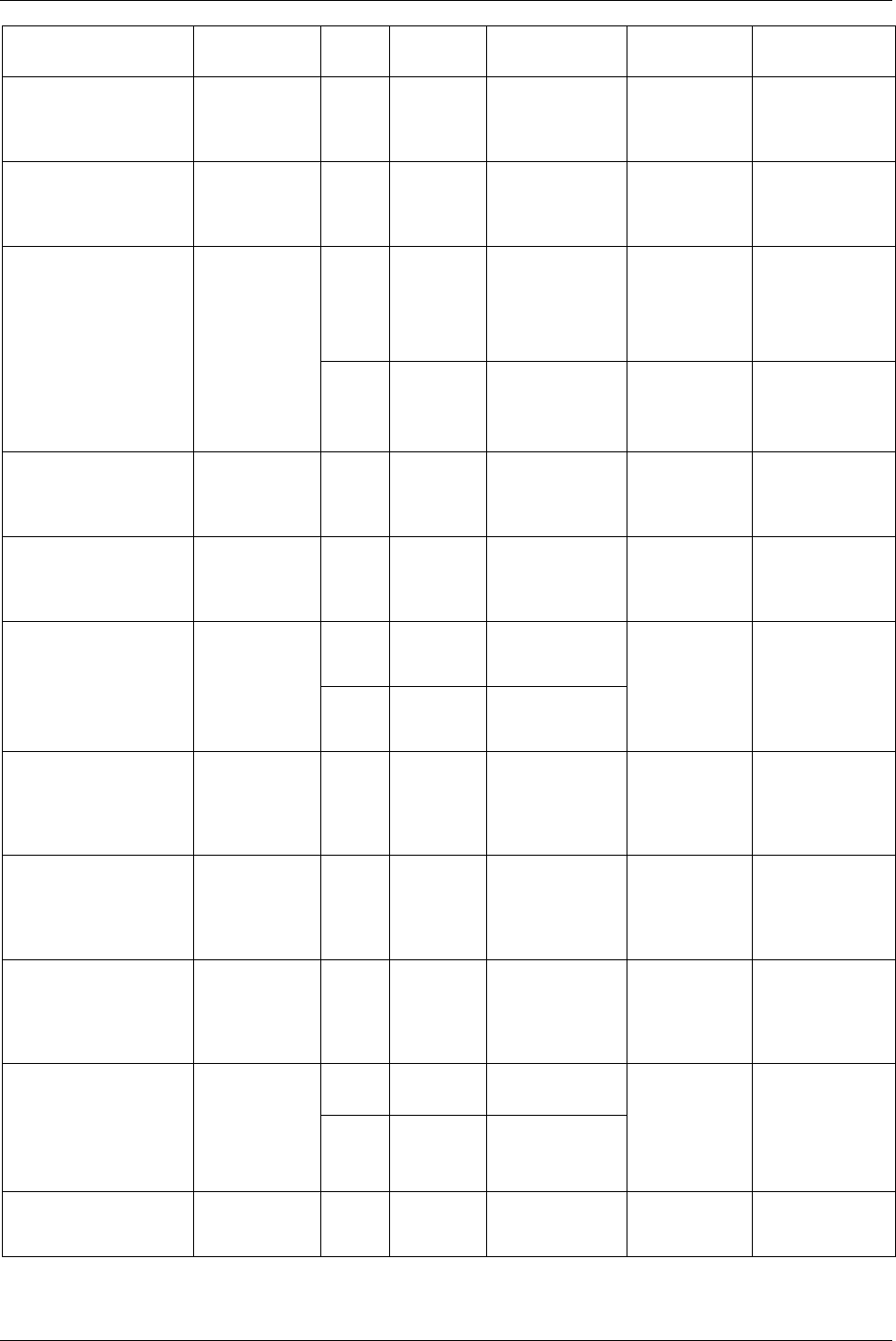

Contents

4 (330) 9836 3123 01

4.5.1 Configuring a tool offline......................................................................................... 39

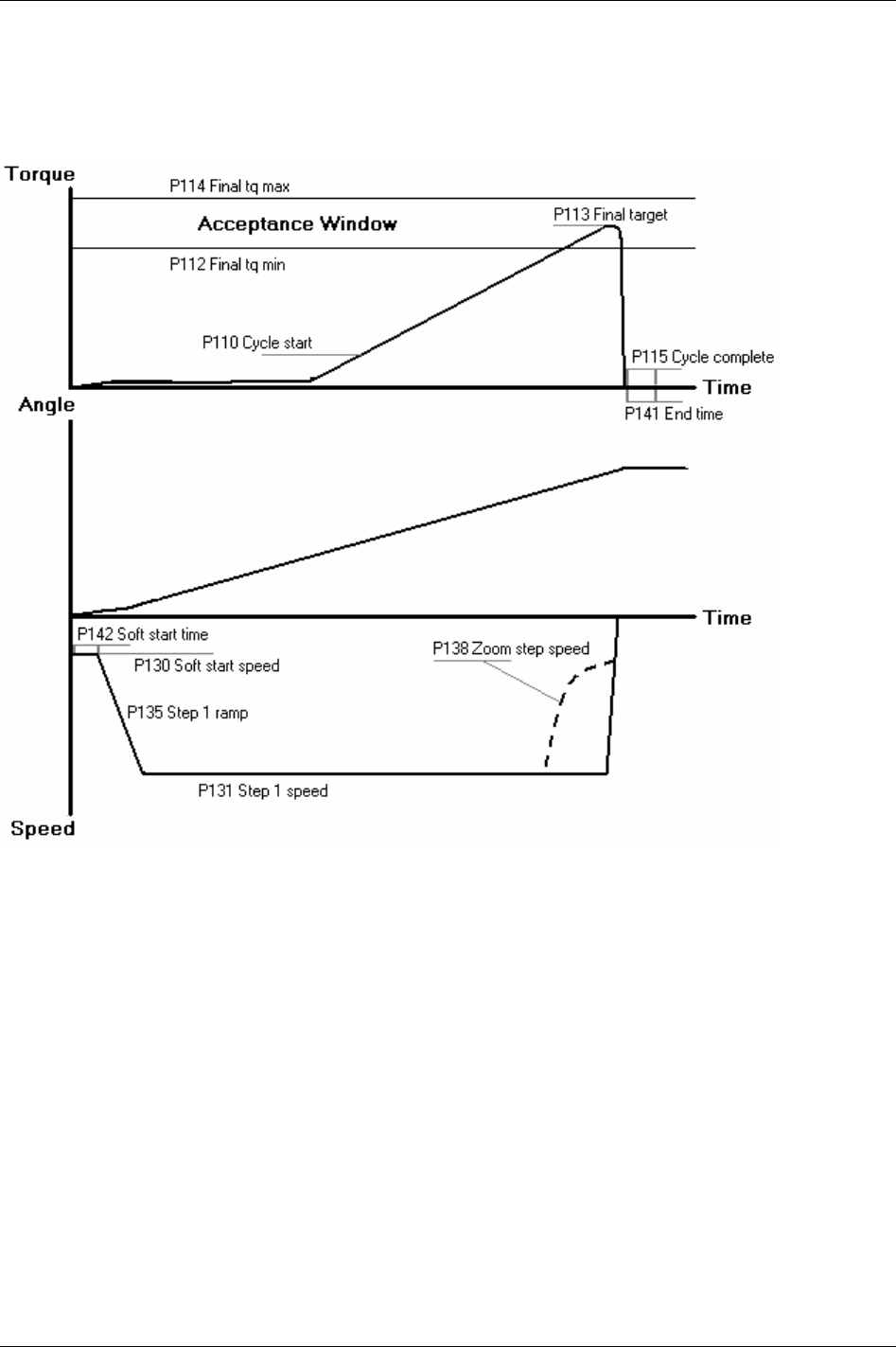

5 Pset ......................................................................................................................41

5.1 Create new Pset/Open Pset.....................................................................................41

5.2 Programming............................................................................................................42

5.2.1 Control strategies.................................................................................................... 44

5.2.2 Tightening strategies .............................................................................................. 47

5.2.3 Control options........................................................................................................ 52

5.2.4 Rehit detection........................................................................................................ 52

5.2.5 Autoset.................................................................................................................... 53

5.2.6 Quick programming ................................................................................................ 54

5.2.7 Programming help .................................................................................................. 55

5.3 Programming +.........................................................................................................55

5.4 Pset setup ................................................................................................................60

5.5 Statistic programming...............................................................................................61

5.6 Running a Pset.........................................................................................................61

6 Multistage ............................................................................................................63

6.1 Create new Multistage/Open Multistage ..................................................................64

7 Job........................................................................................................................65

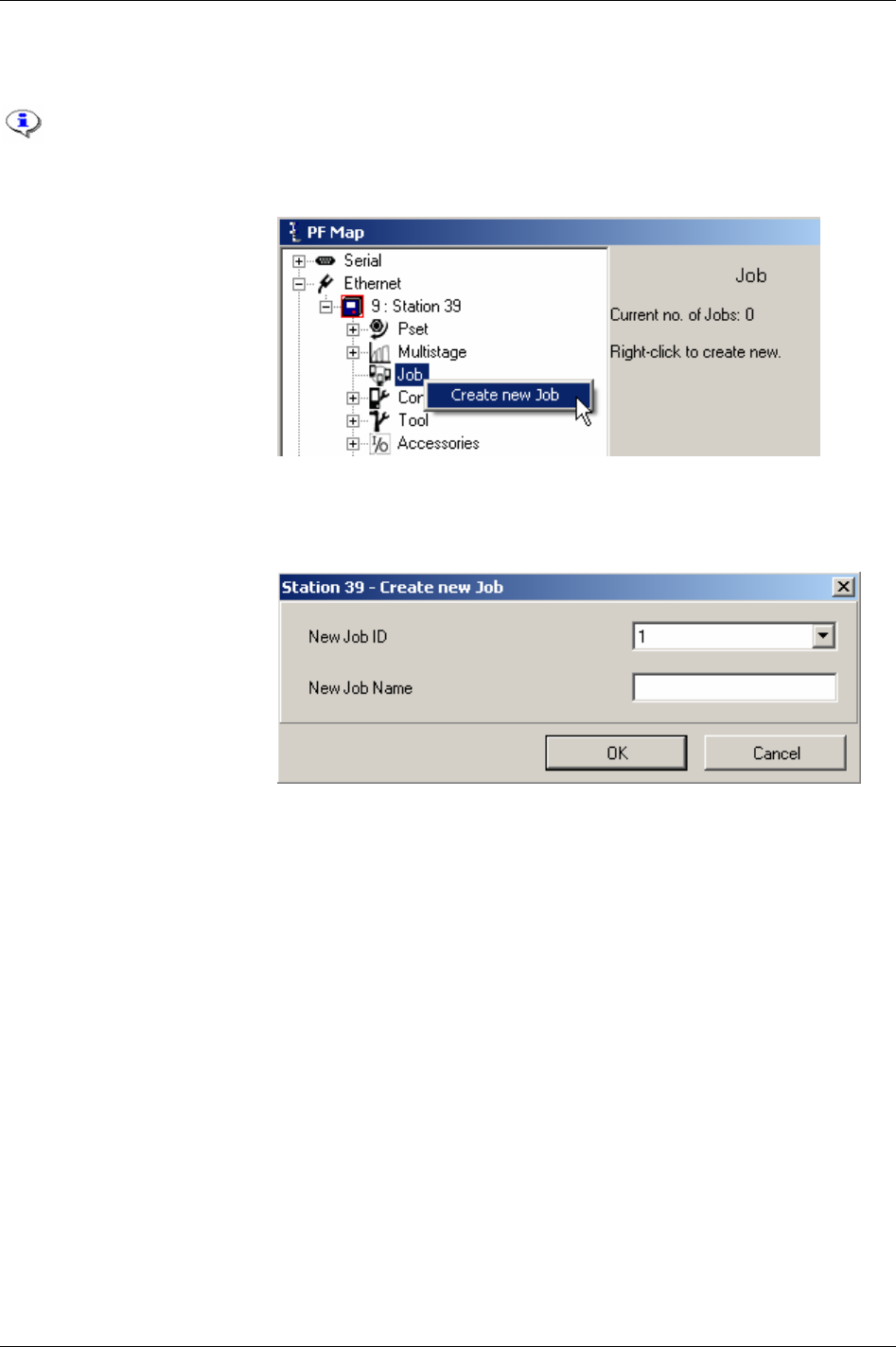

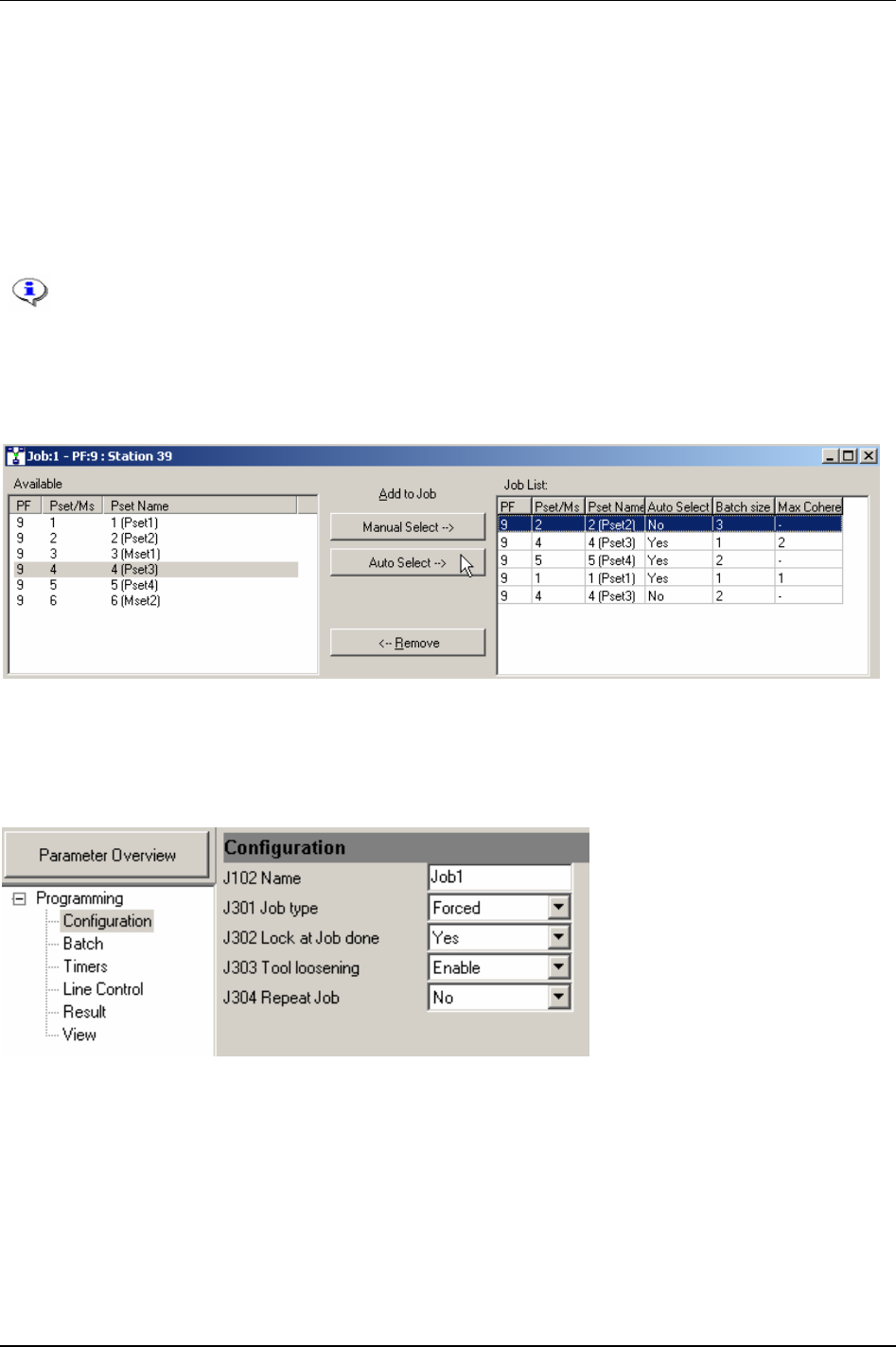

7.1 Create a Job group...................................................................................................67

7.2 Create new Job ........................................................................................................68

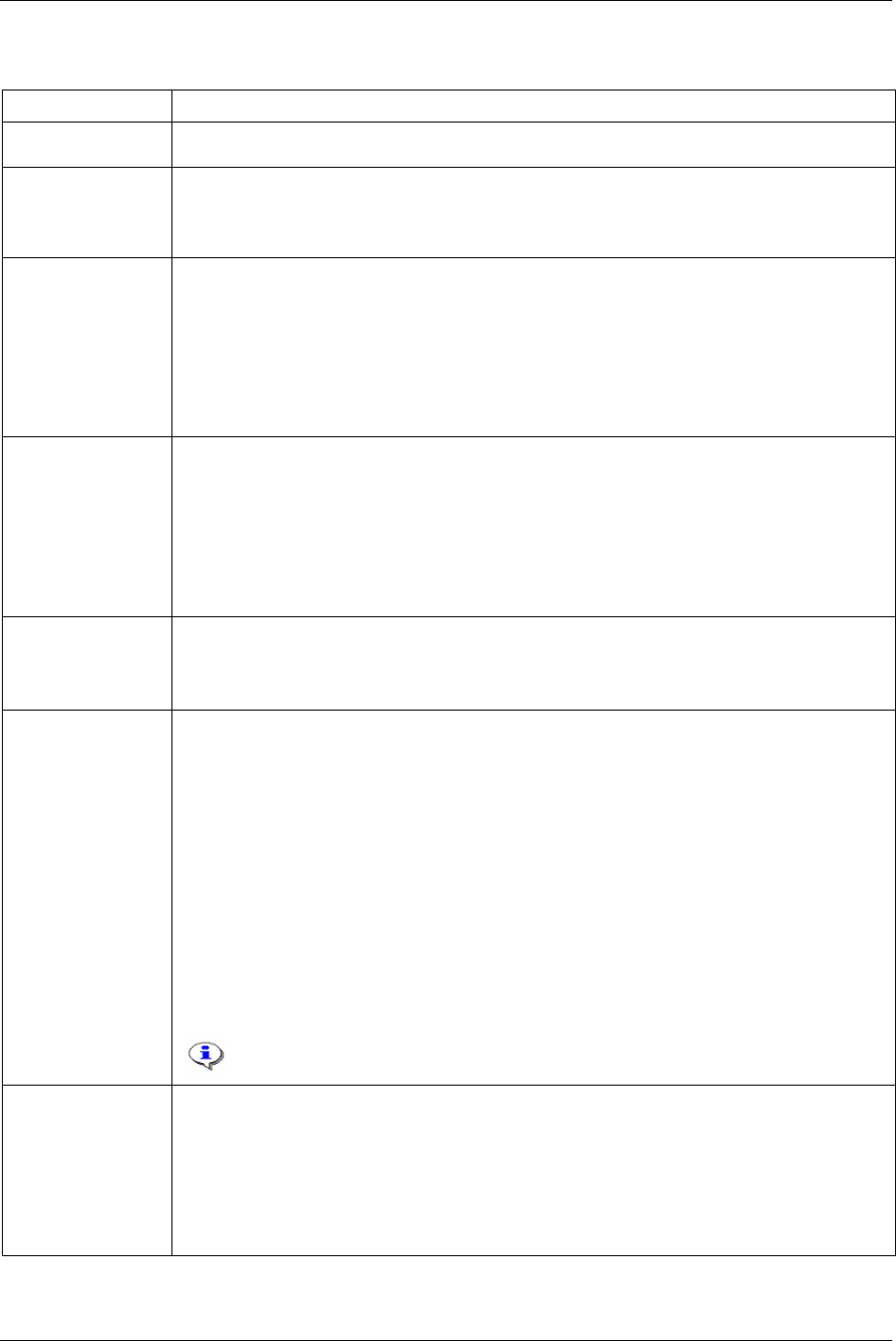

7.3 Select Job.................................................................................................................70

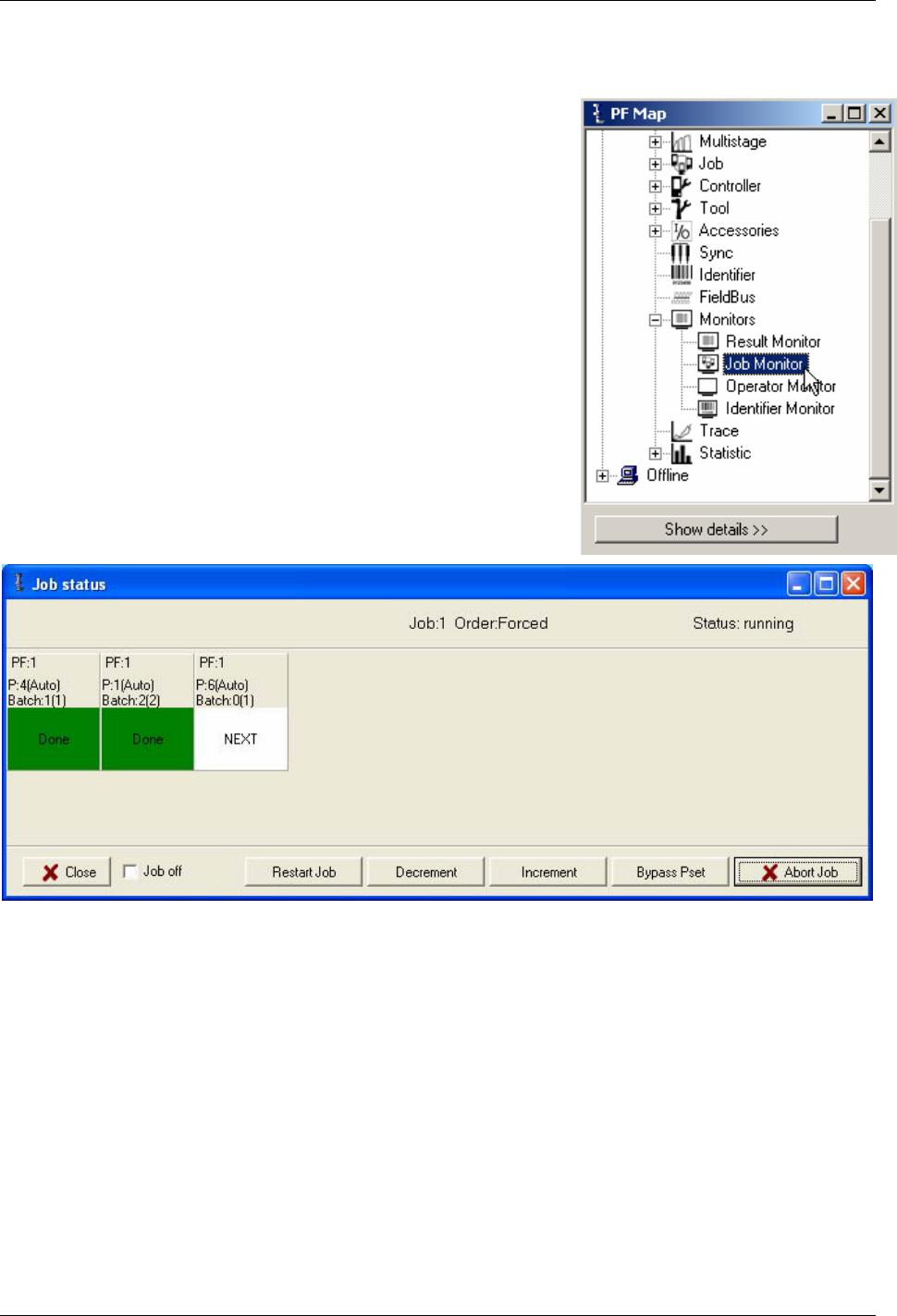

7.3.1 Functions in the Job monitor................................................................................... 72

7.4 Unlock the tool..........................................................................................................73

8 Controller.............................................................................................................75

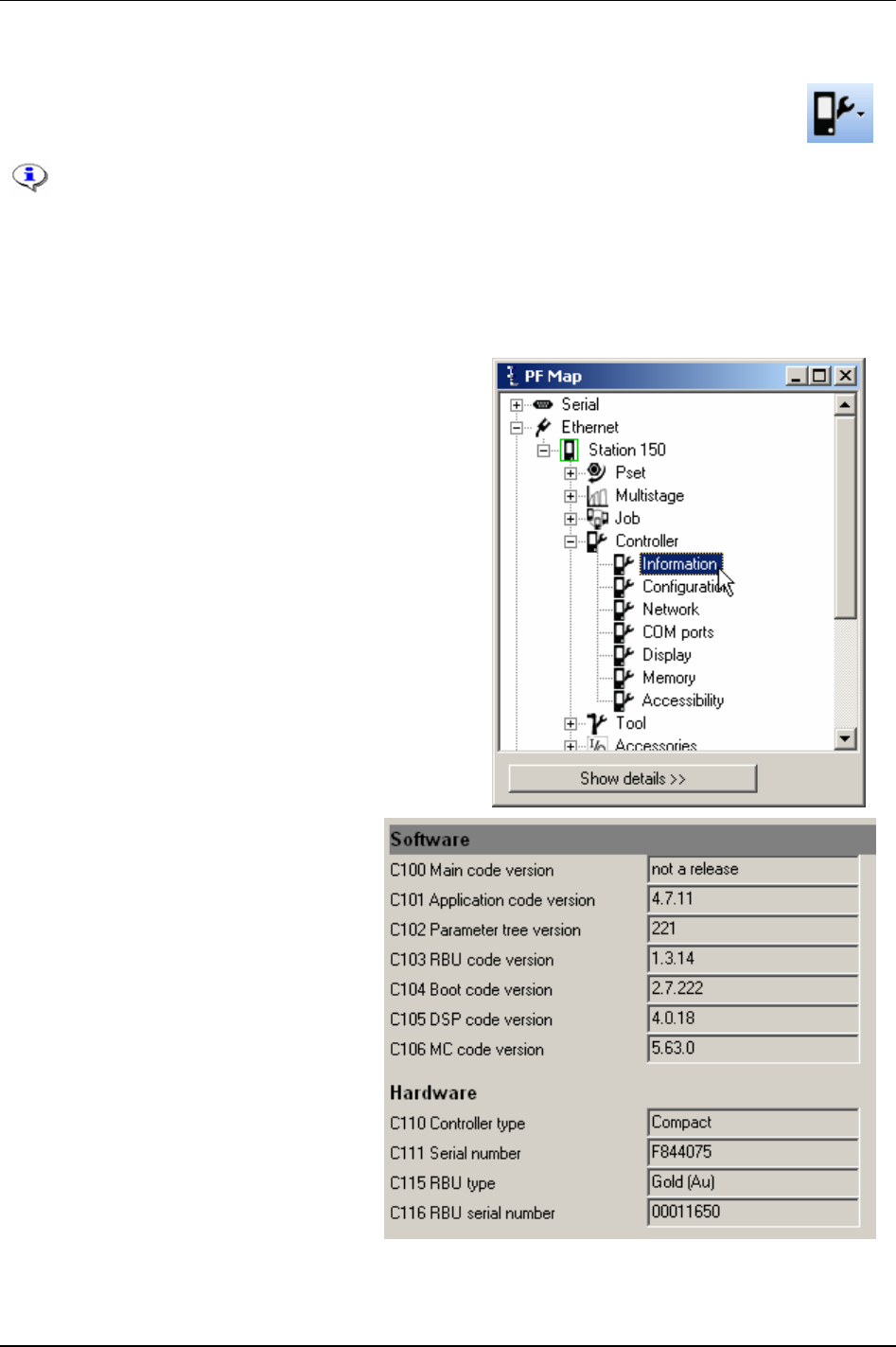

8.1 Information ...............................................................................................................75

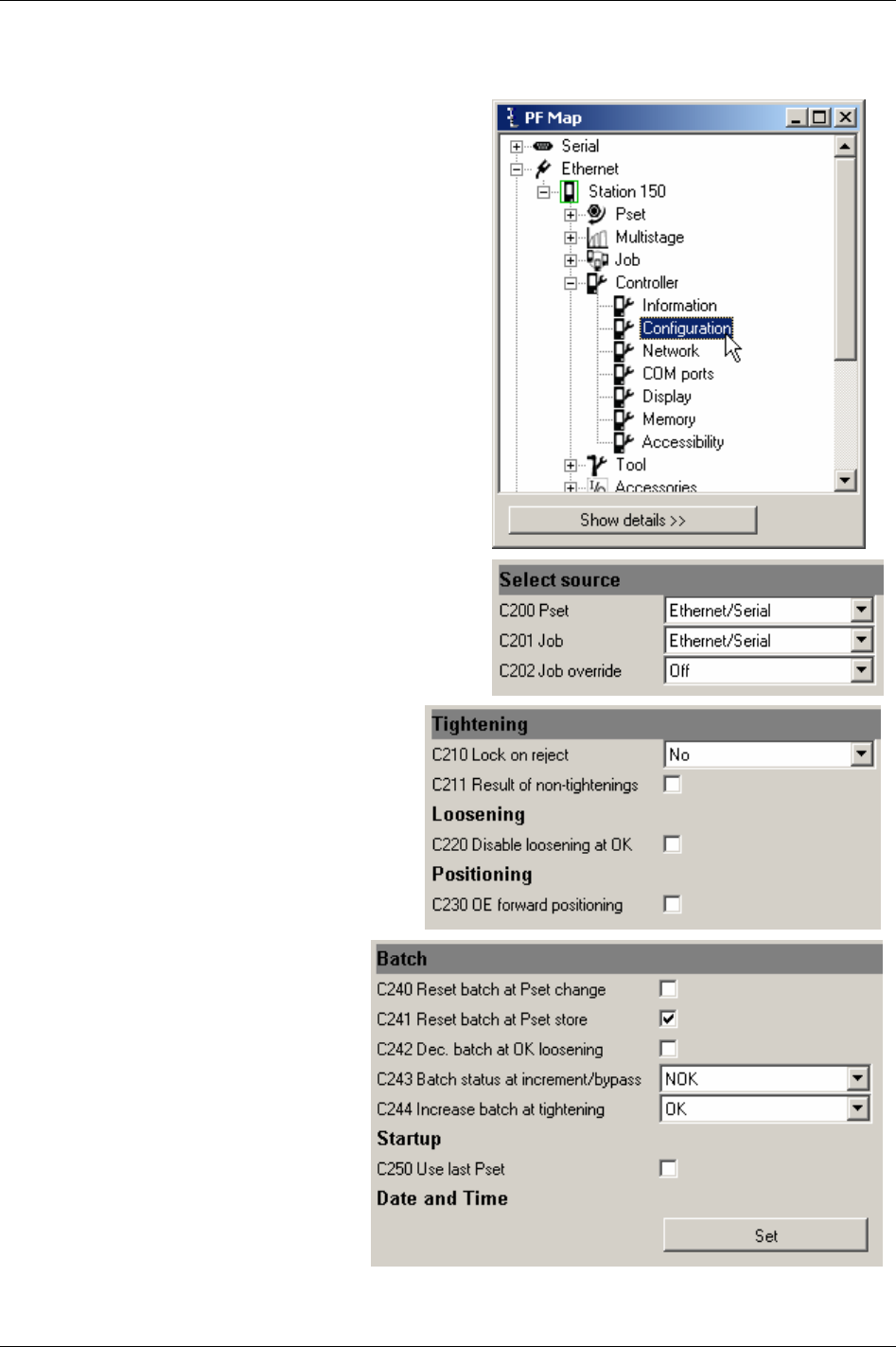

8.2 Configuration............................................................................................................76

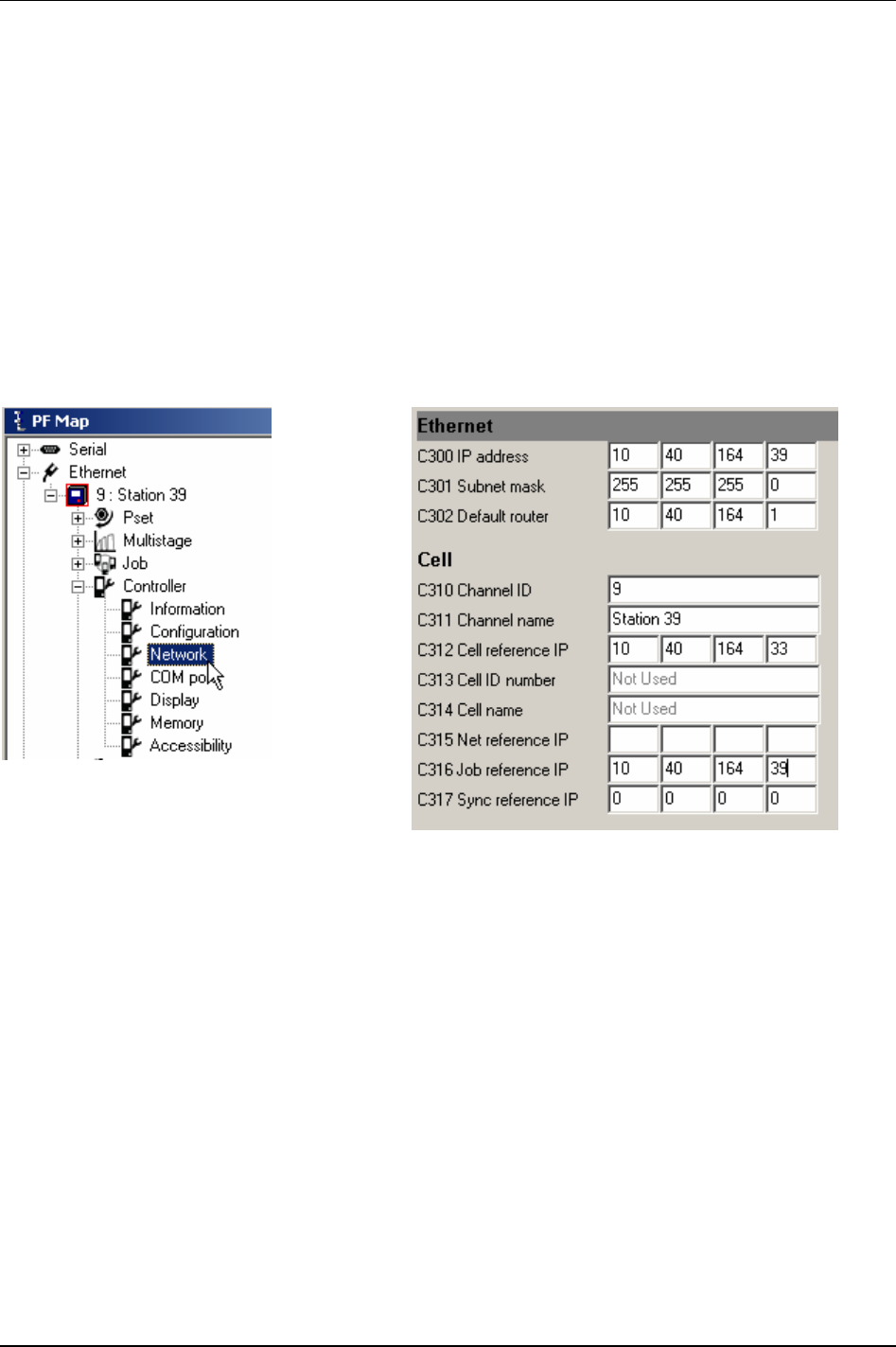

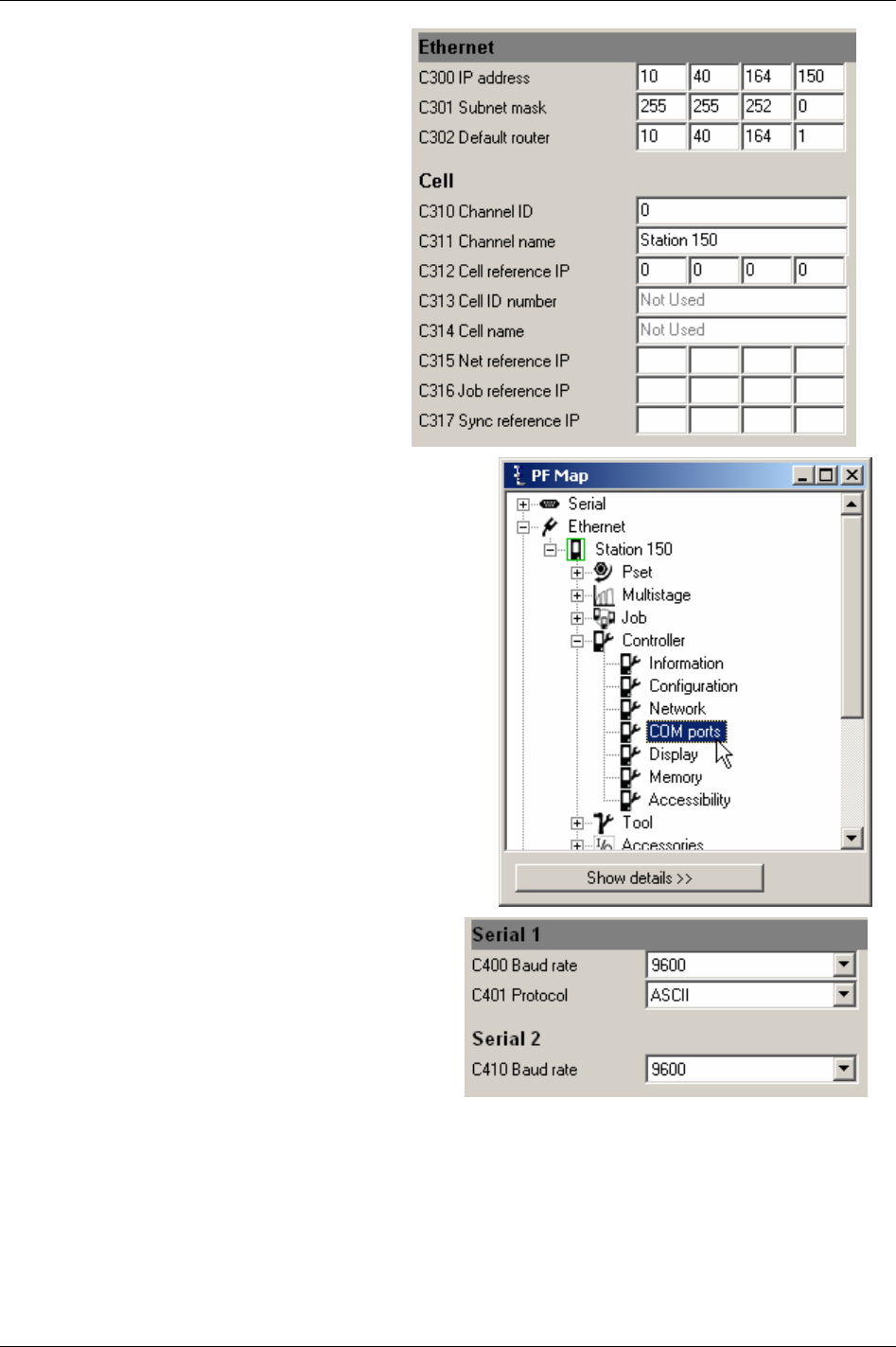

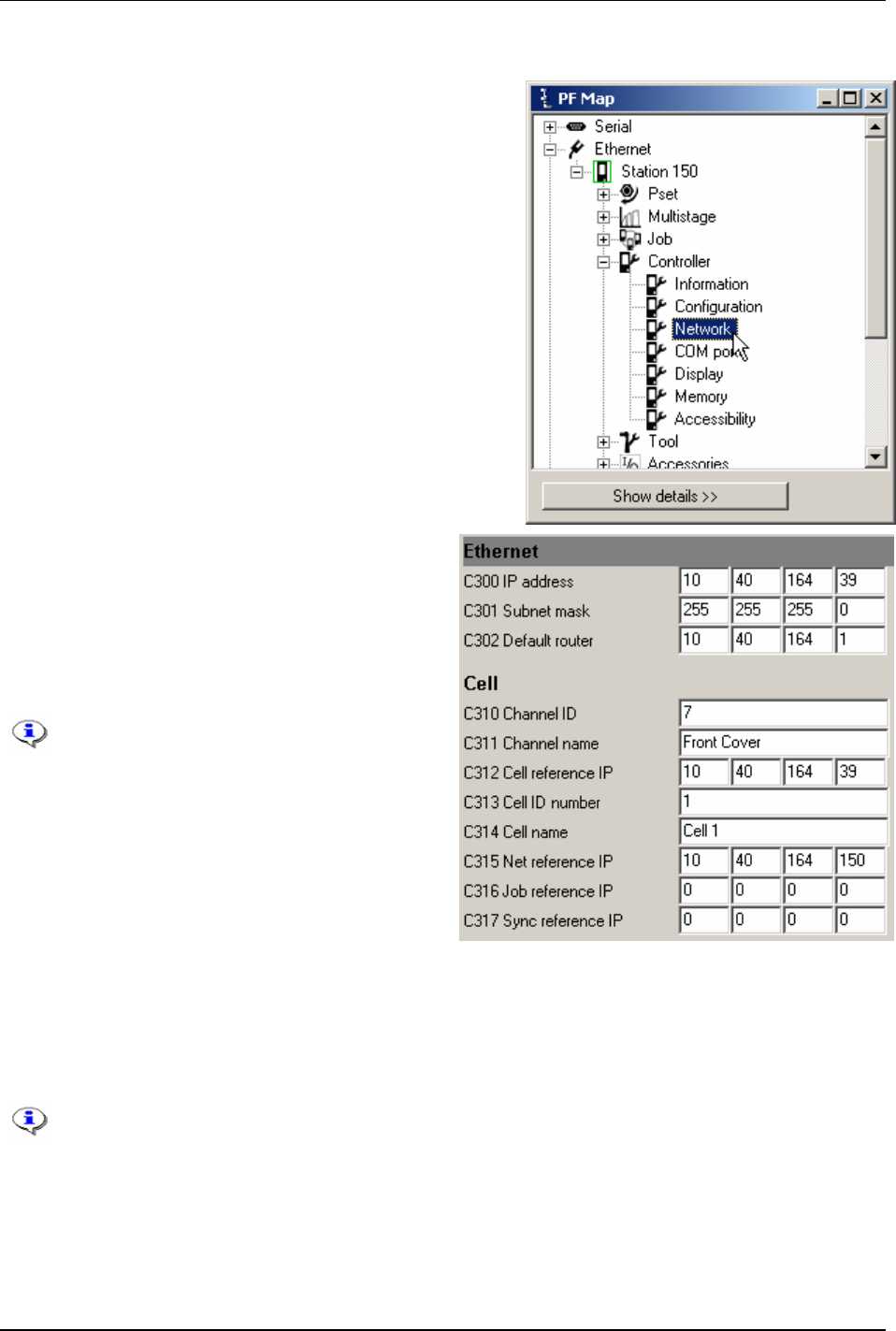

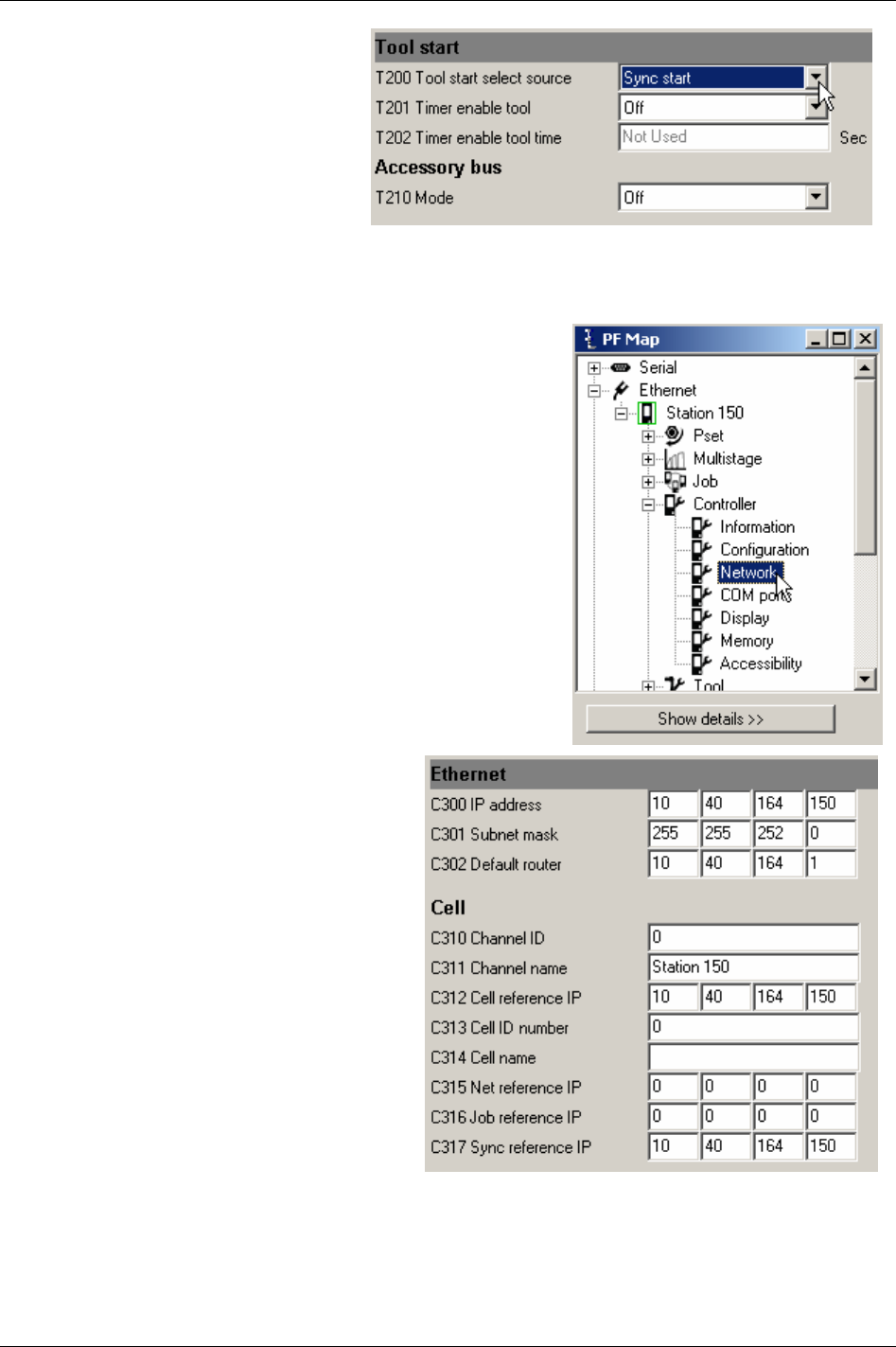

8.3 Network ....................................................................................................................77

8.3.1 Cell and Net............................................................................................................ 79

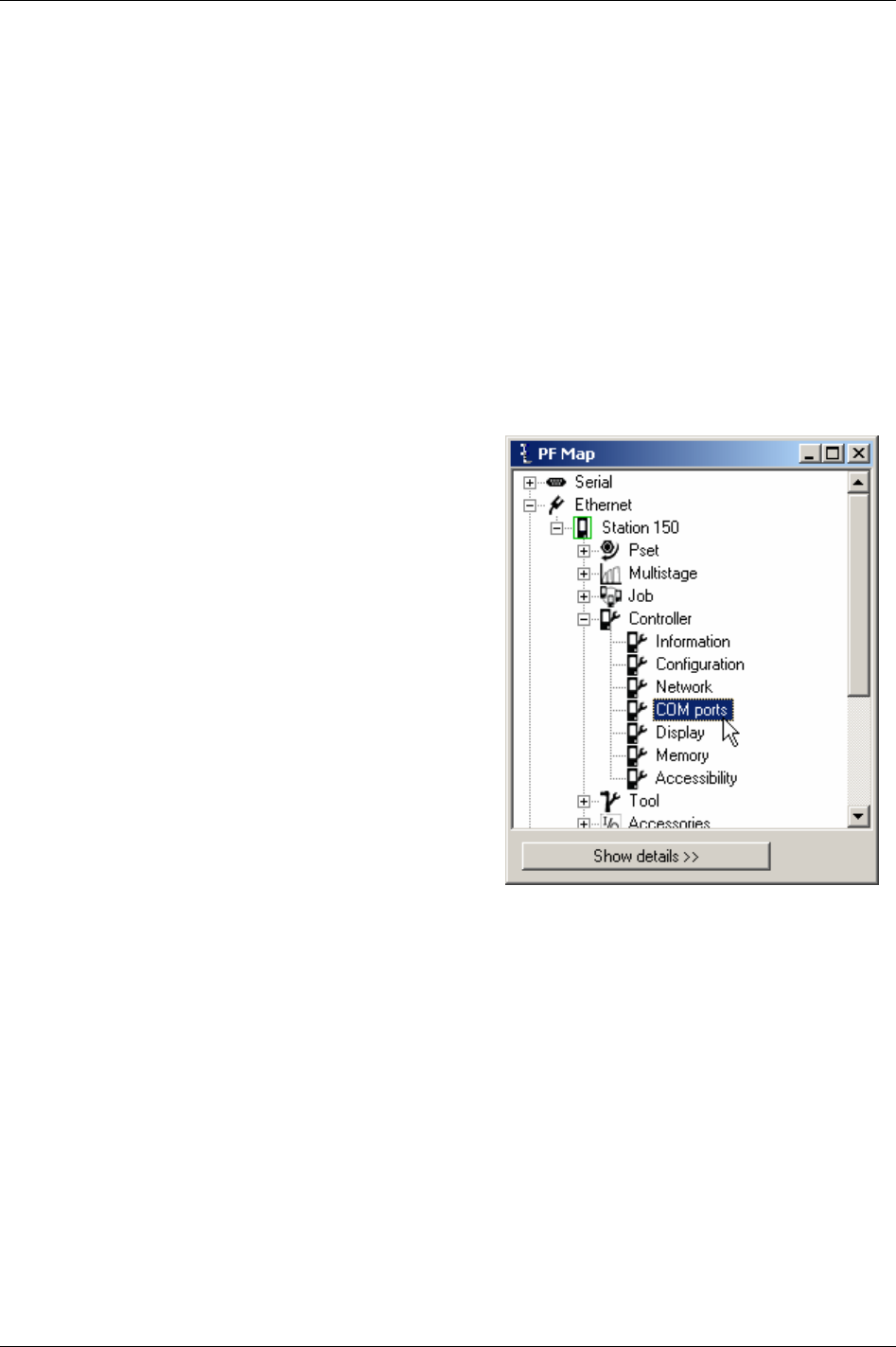

8.4 COM ports................................................................................................................84

8.5 Display......................................................................................................................85

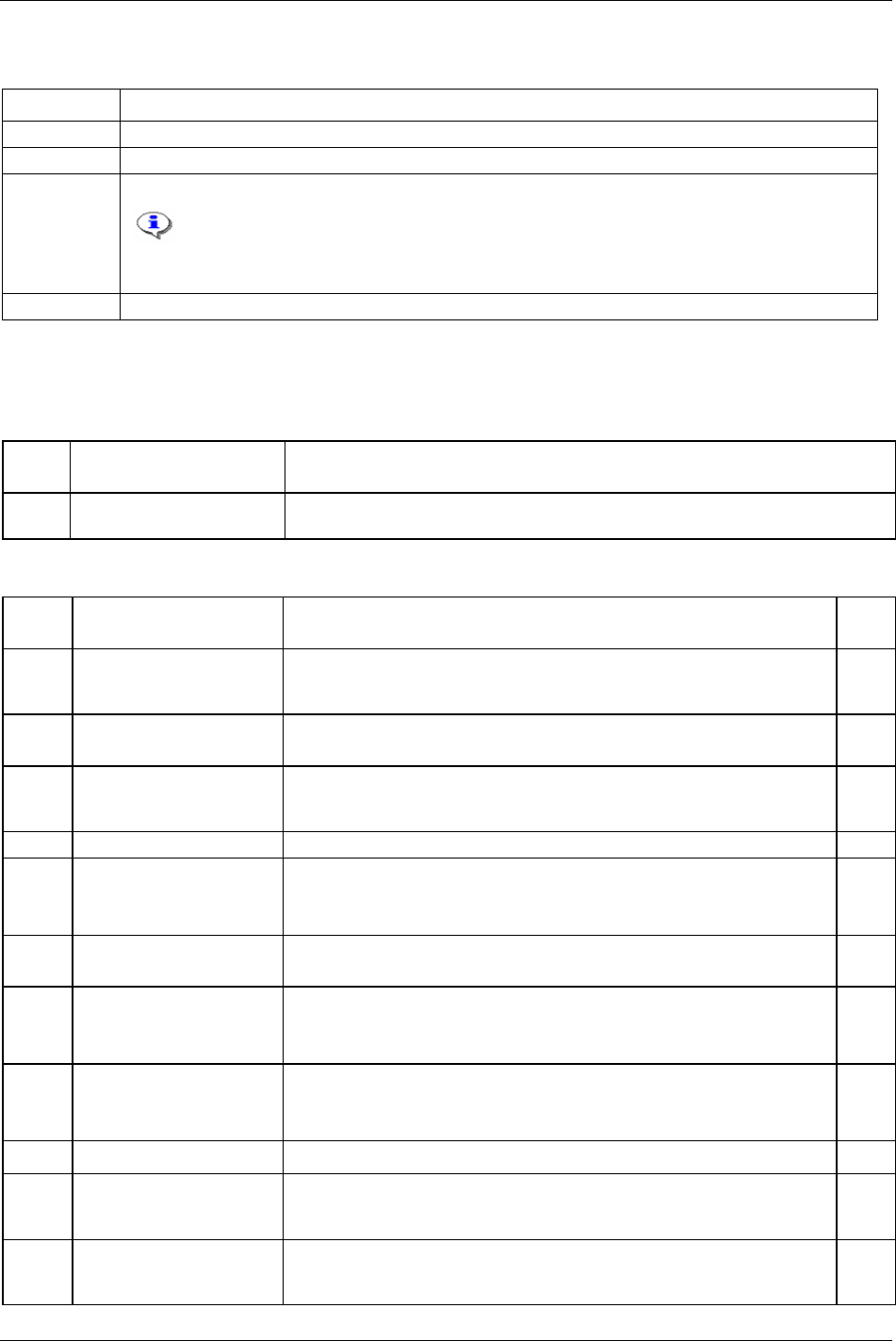

8.6 Memory ....................................................................................................................86

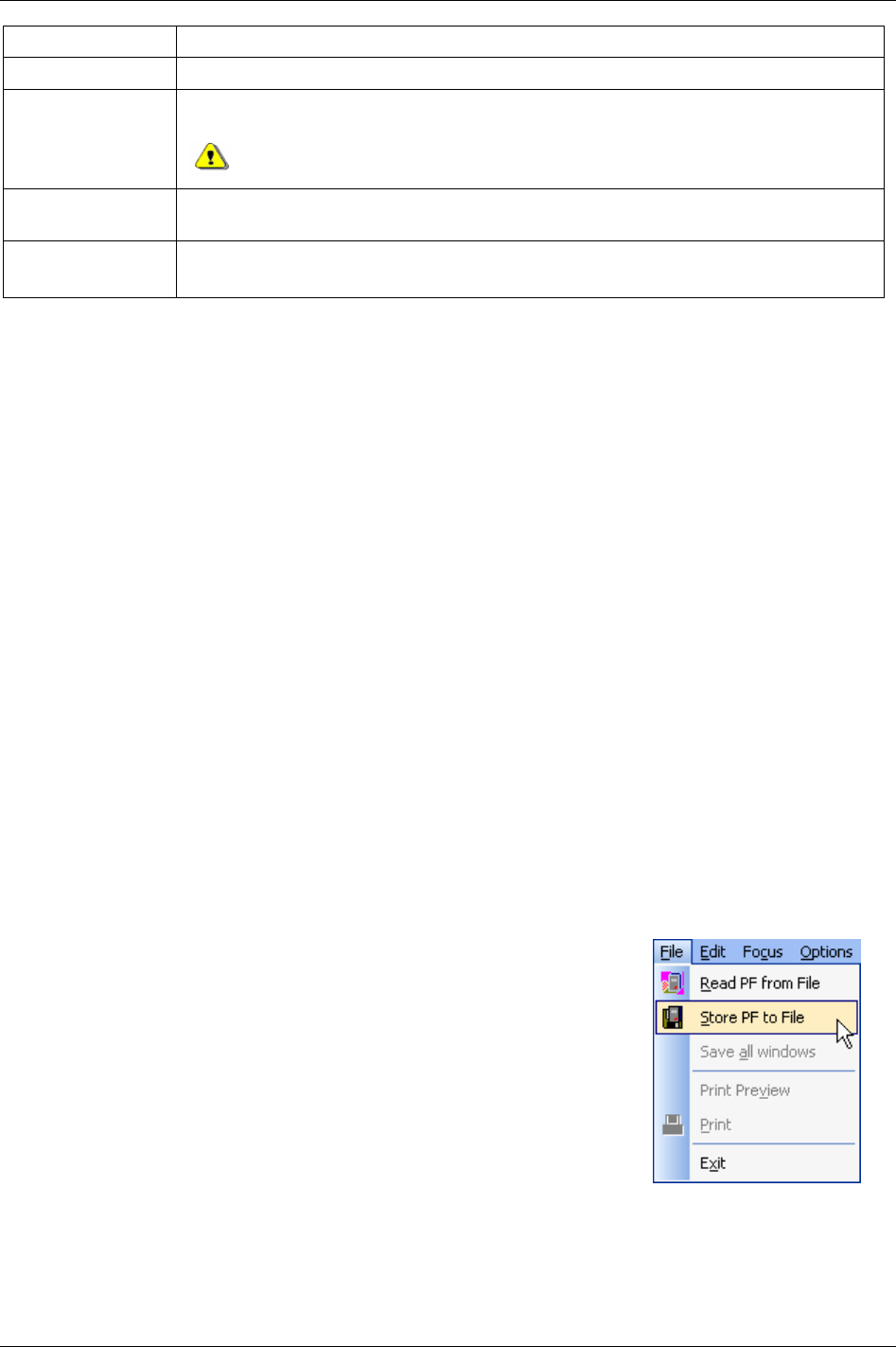

8.6.1 Store PF to file........................................................................................................ 86

8.6.2 Read PF from file.................................................................................................... 88

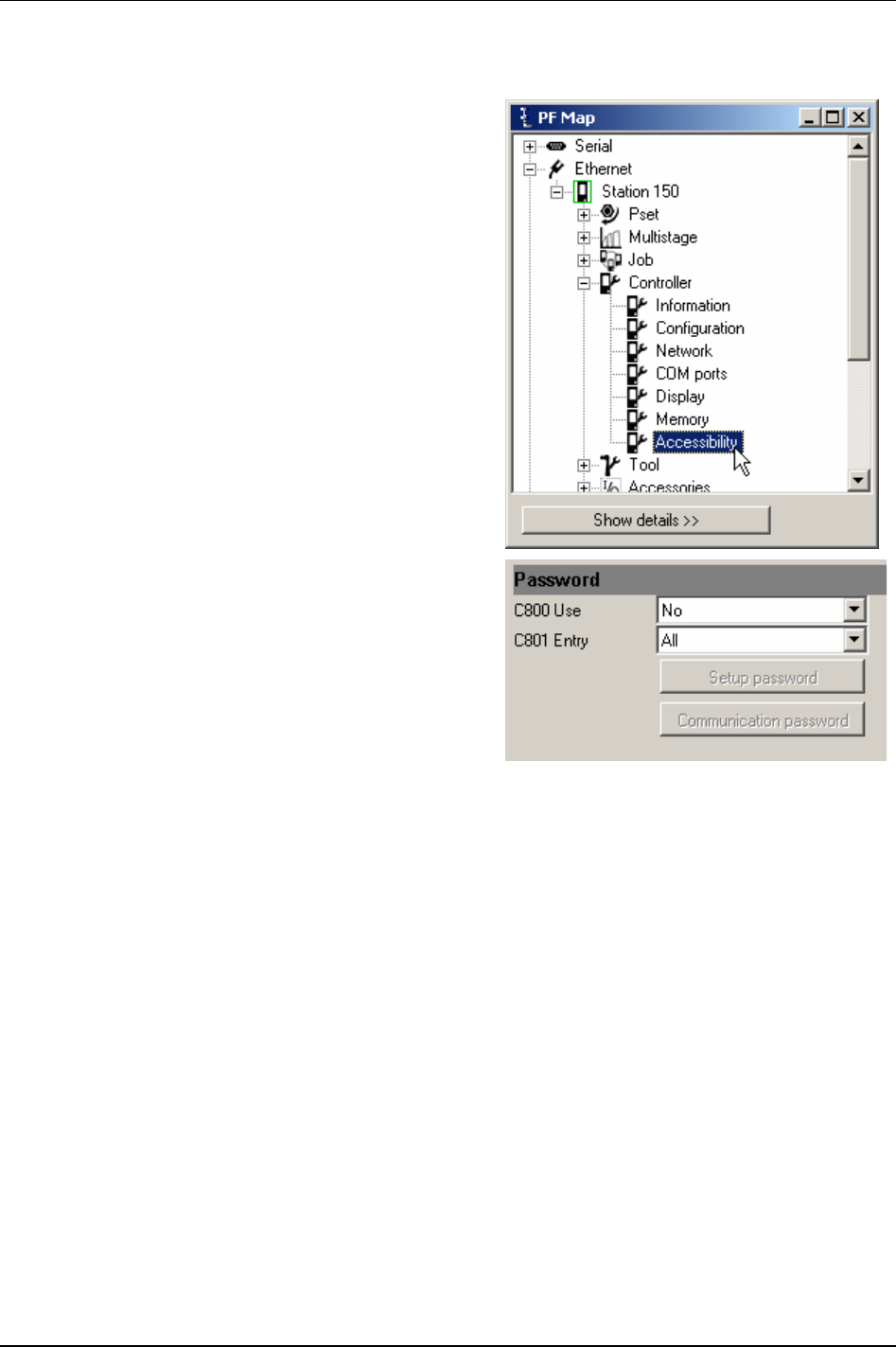

8.7 Accessibility..............................................................................................................89

9 Tool ......................................................................................................................91

9.1 Tool information........................................................................................................91

9.2 Tool configuration.....................................................................................................92

9.3 Tool diagnostic .........................................................................................................99

9.4 Tool maintenance...................................................................................................100

9.4.1 Motor tuning.......................................................................................................... 101

9.4.2 Disconnect tool ..................................................................................................... 102

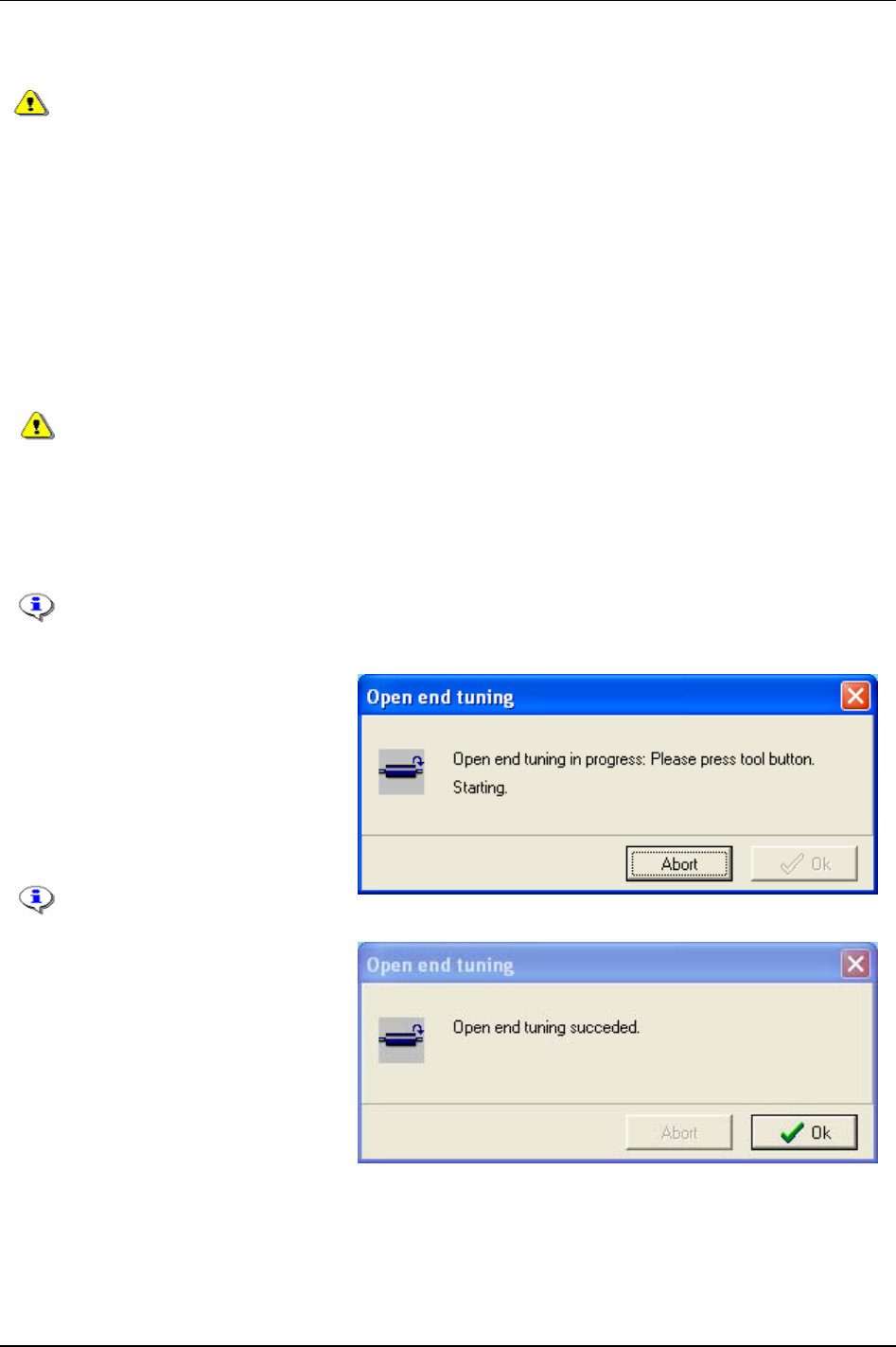

9.4.3 Open end tuning ................................................................................................... 103

9.4.4 Tool lock functionality ........................................................................................... 104

10 Accessories.......................................................................................................109

10.1 Digital I/O................................................................................................................109

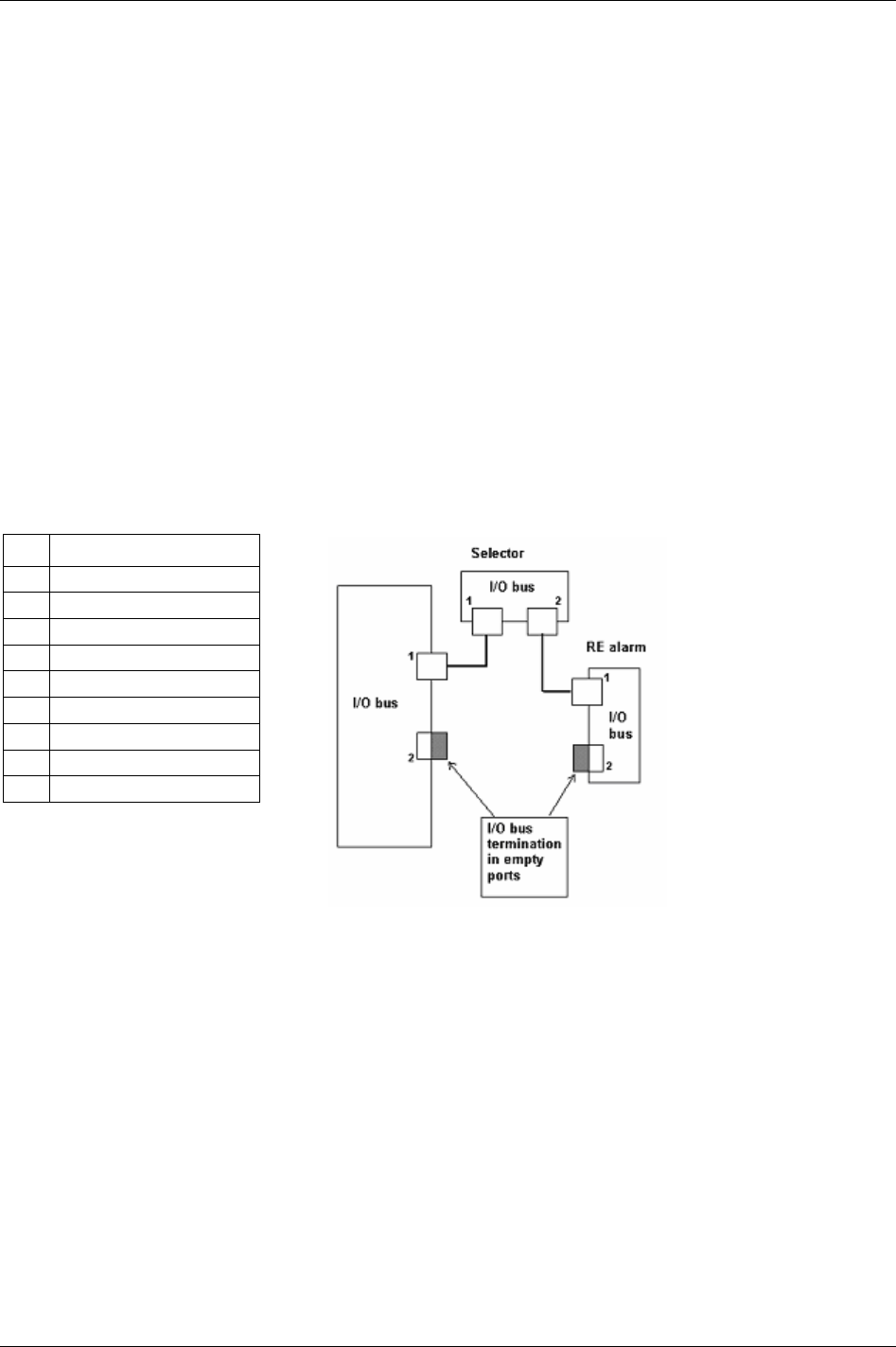

10.2 I/O bus....................................................................................................................111

10.3 Tool bus..................................................................................................................115

Contents

9836 3123 01 5 (330)

10.4 Printer .....................................................................................................................118

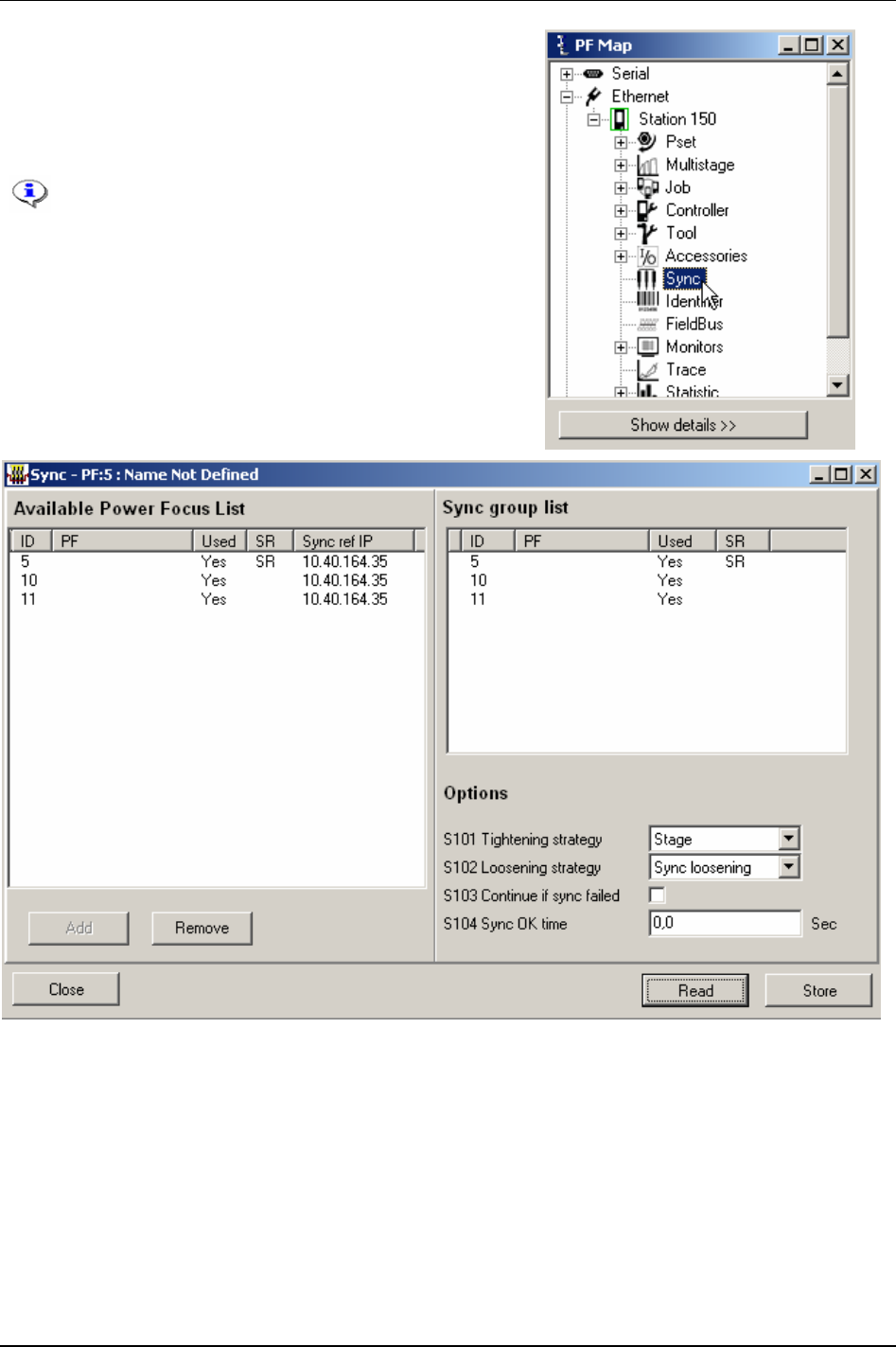

11 Sync ...................................................................................................................119

11.1 Hardware configuration...........................................................................................120

11.2 Sync members configuration ..................................................................................121

11.3 Sync reference configuration..................................................................................122

11.4 Running a Sync group ............................................................................................124

11.5 Troubleshooting......................................................................................................124

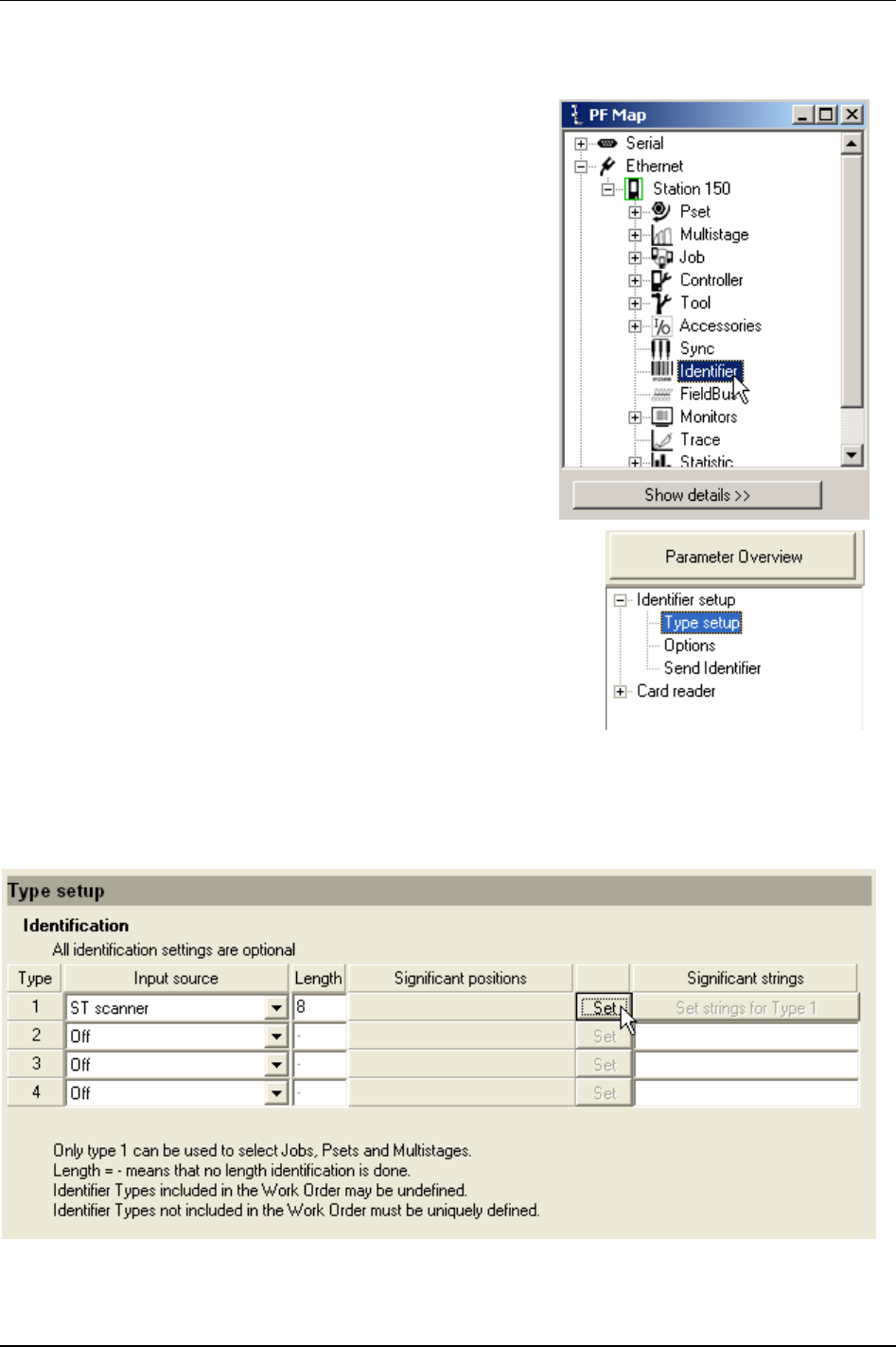

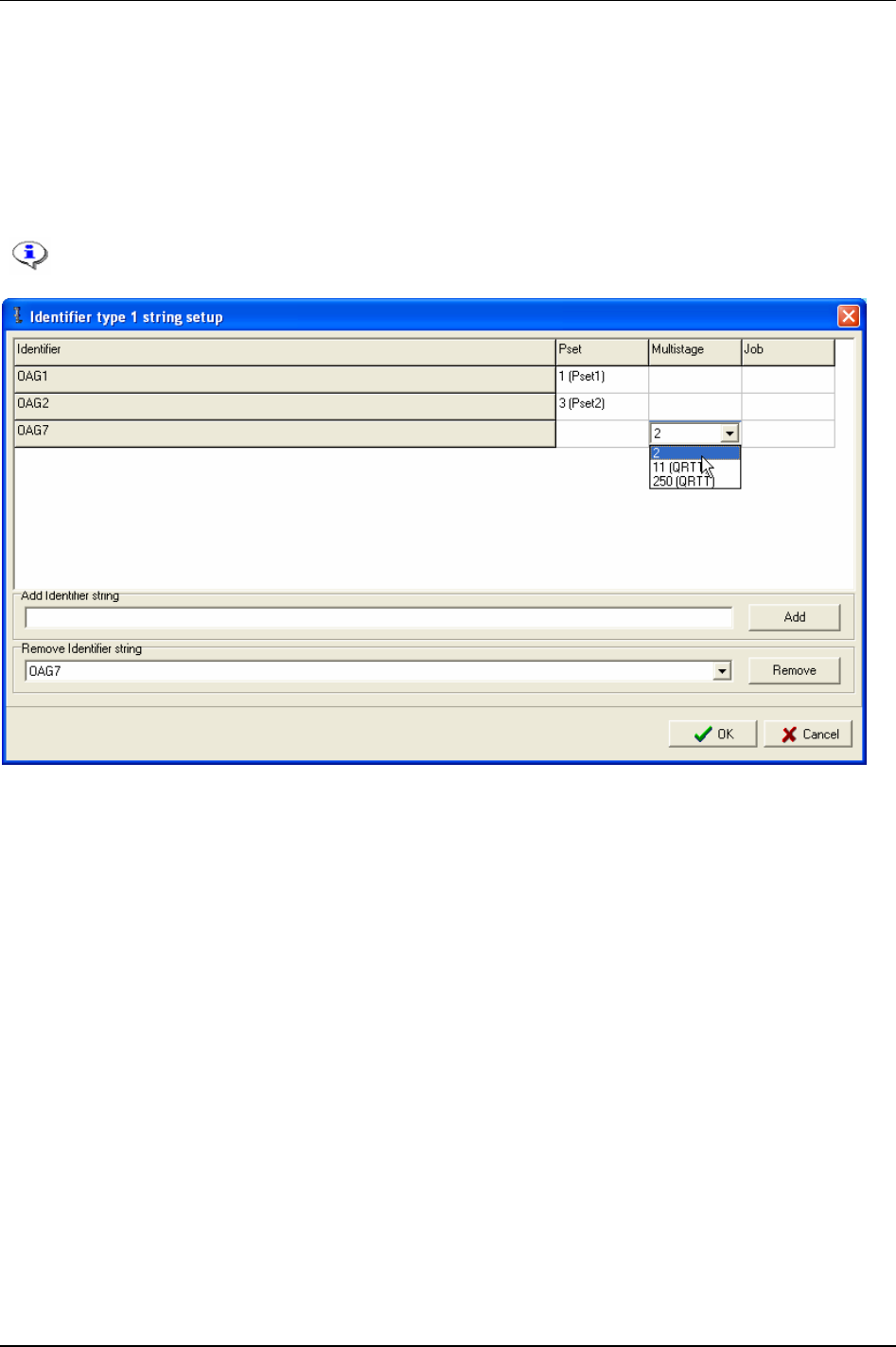

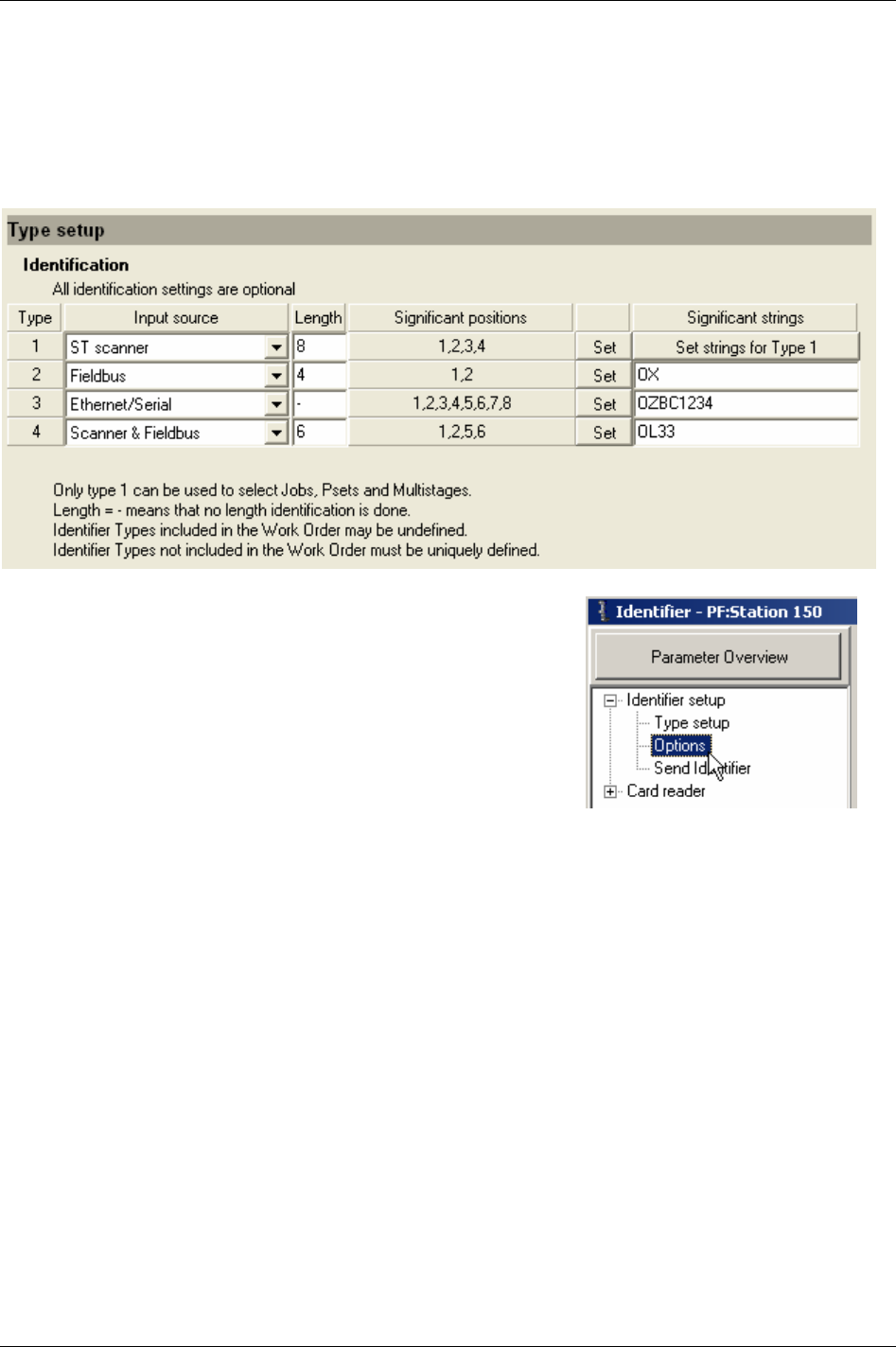

12 Identifier.............................................................................................................125

12.1 Single Identifier.......................................................................................................126

12.2 Multiple Identifier.....................................................................................................126

12.2.1 Work order.............................................................................................................126

12.3 Identifier types and work order ...............................................................................127

12.3.1 Result parts............................................................................................................132

12.3.2 Identifier monitor....................................................................................................134

12.3.3 Functions in identifier monitor................................................................................135

13 Field bus ............................................................................................................137

13.1 General setup .........................................................................................................137

13.2 From PF setup and to PF setup..............................................................................140

13.2.1 View Field bus information ....................................................................................141

13.2.2 Field bus modes ....................................................................................................141

13.2.3 Store to file and read from file ...............................................................................141

13.3 Field bus selector....................................................................................................142

13.4 Disable Field bus carried signals............................................................................142

13.5 Field bus configuration appendix............................................................................143

13.5.1 Bitmap select (Endian mode) ................................................................................143

13.5.2 Field bus data types ..............................................................................................143

13.5.3 Field bus selector configuration.............................................................................146

13.5.4 Items from PF........................................................................................................148

13.5.5 Items to PF ............................................................................................................159

13.5.6 ProfiBus-DP...........................................................................................................165

13.5.7 DeviceNet ..............................................................................................................168

13.6 InterBus/InterBus2MB.............................................................................................171

13.6.1 ModBusPlus...........................................................................................................173

13.6.2 EtherNet/IP ............................................................................................................176

13.6.3 ControlNet..............................................................................................................179

13.6.4 Profibus-IO.............................................................................................................180

13.6.5 FL-Net....................................................................................................................181

14 Logic Configurator............................................................................................183

14.1 Process description (an example) ..........................................................................183

14.2 Logic operators and function blocks .......................................................................184

14.2.1 Abbreviations.........................................................................................................184

14.2.2 Logic gates ............................................................................................................185

14.2.3 Function blocks......................................................................................................186

14.3 Logic Configurator setup.........................................................................................189

14.3.1 Simulation..............................................................................................................194

15 Monitors.............................................................................................................195

15.1 Result Monitor.........................................................................................................195

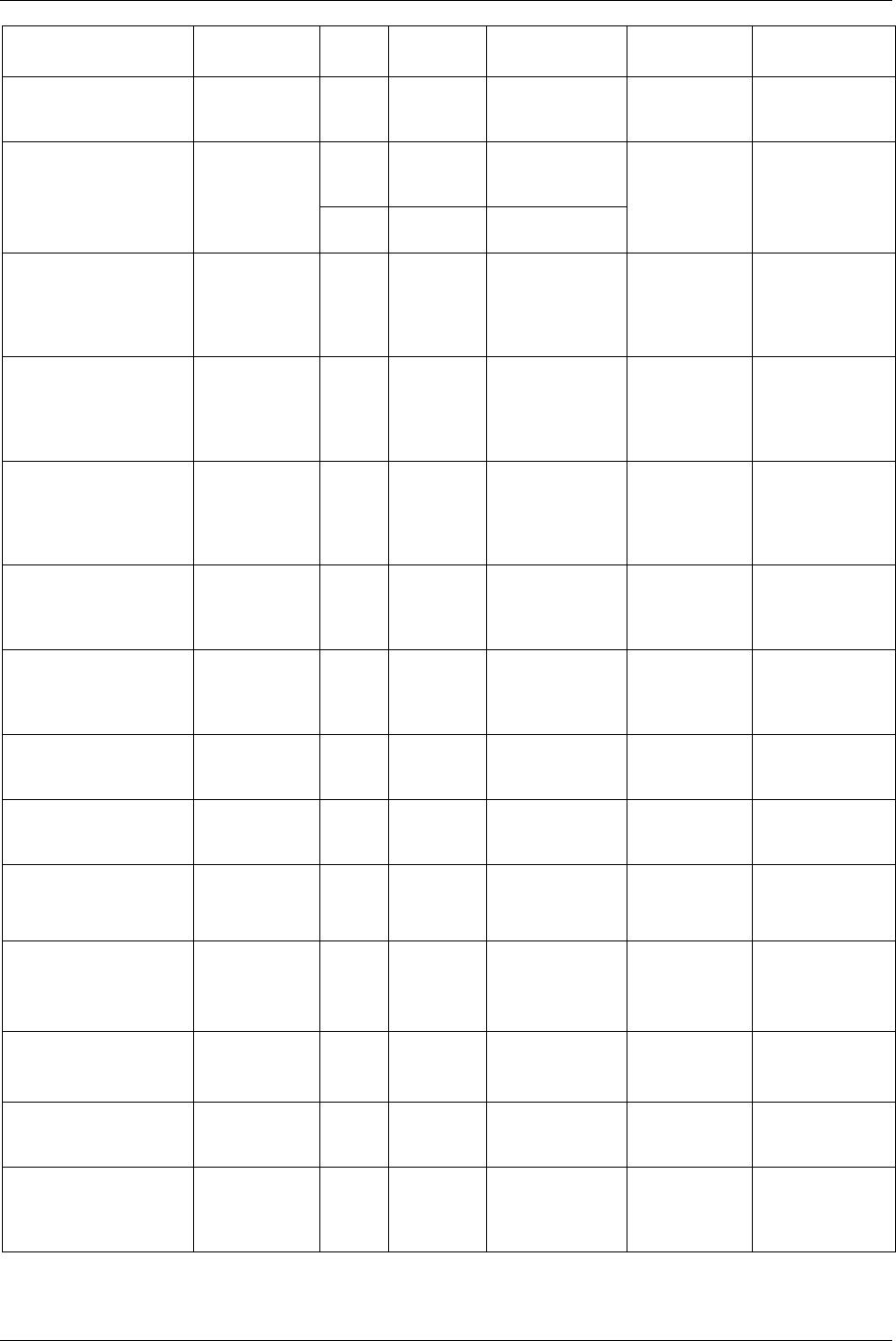

Contents

15.2 Job Monitor.............................................................................................................197

15.3 Operator Monitor ....................................................................................................198

15.3.1 Picture Monitor...................................................................................................... 201

15.4 Identifier Monitor.....................................................................................................202

15.5 Get all results .........................................................................................................203

16 Trace ..................................................................................................................205

17 Statistic..............................................................................................................207

17.1 Statistic in Power Focus.........................................................................................207

17.1.1 Statistical process control (SPC).......................................................................... 208

17.1.2 Statistic alarm ....................................................................................................... 208

17.1.3 Trend deviation alarm........................................................................................... 209

17.1.4 Calculation of UCL and LCL ................................................................................. 209

17.1.5 Calculation of

X

and

R

...................................................................................... 209

17.1.6 Calculation formulas ............................................................................................. 209

17.1.7 Constants for calculation of SPC variables .......................................................... 211

18 Connecting devices ..........................................................................................213

18.1 Printer.....................................................................................................................213

18.2 Serial RS232 #1 .....................................................................................................213

18.3 Serial RS232 #2 .....................................................................................................213

18.4 EtherNet/IP.............................................................................................................214

18.5 RBU........................................................................................................................214

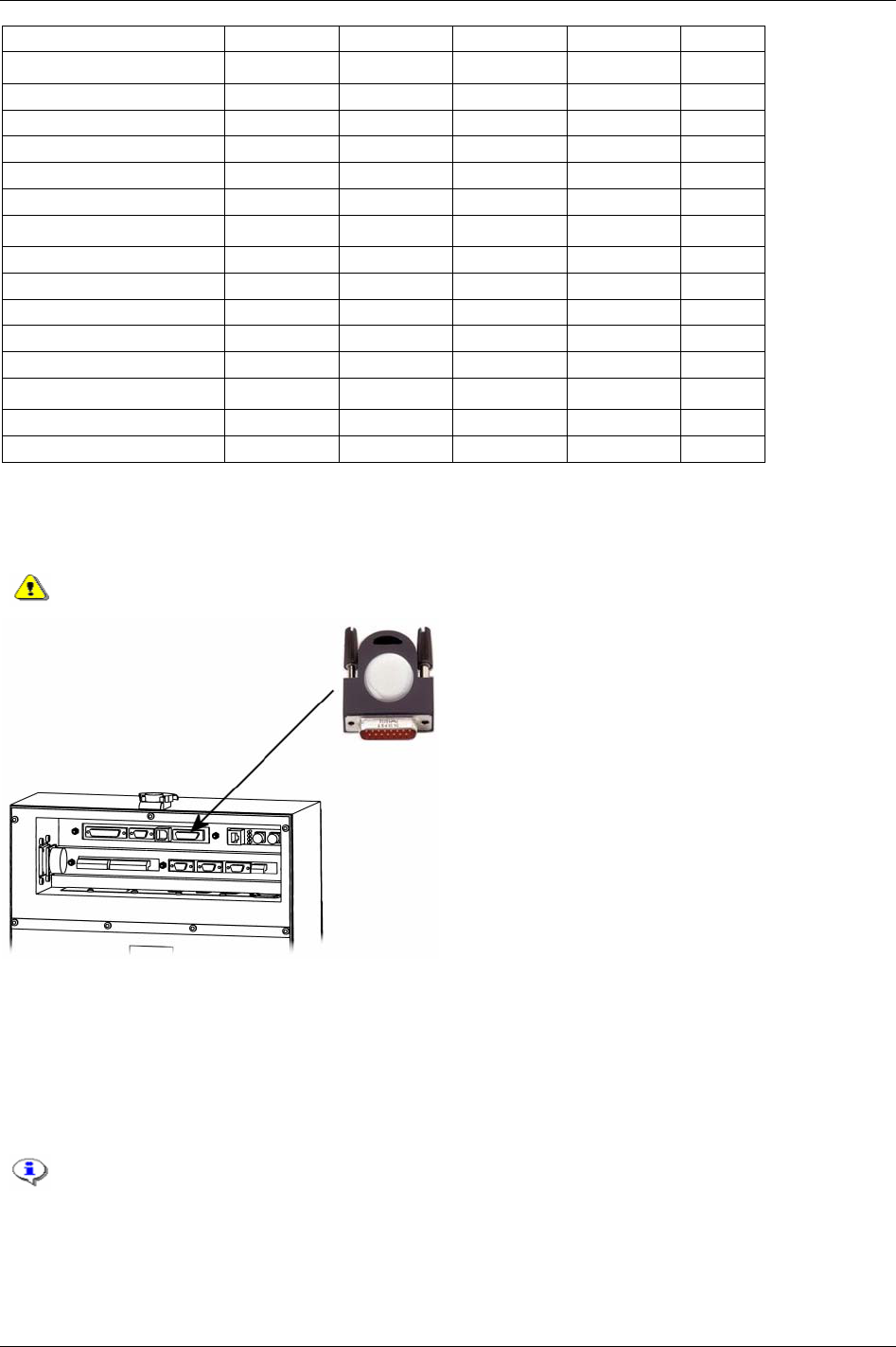

18.5.1 Tool connector (S tools)........................................................................................ 214

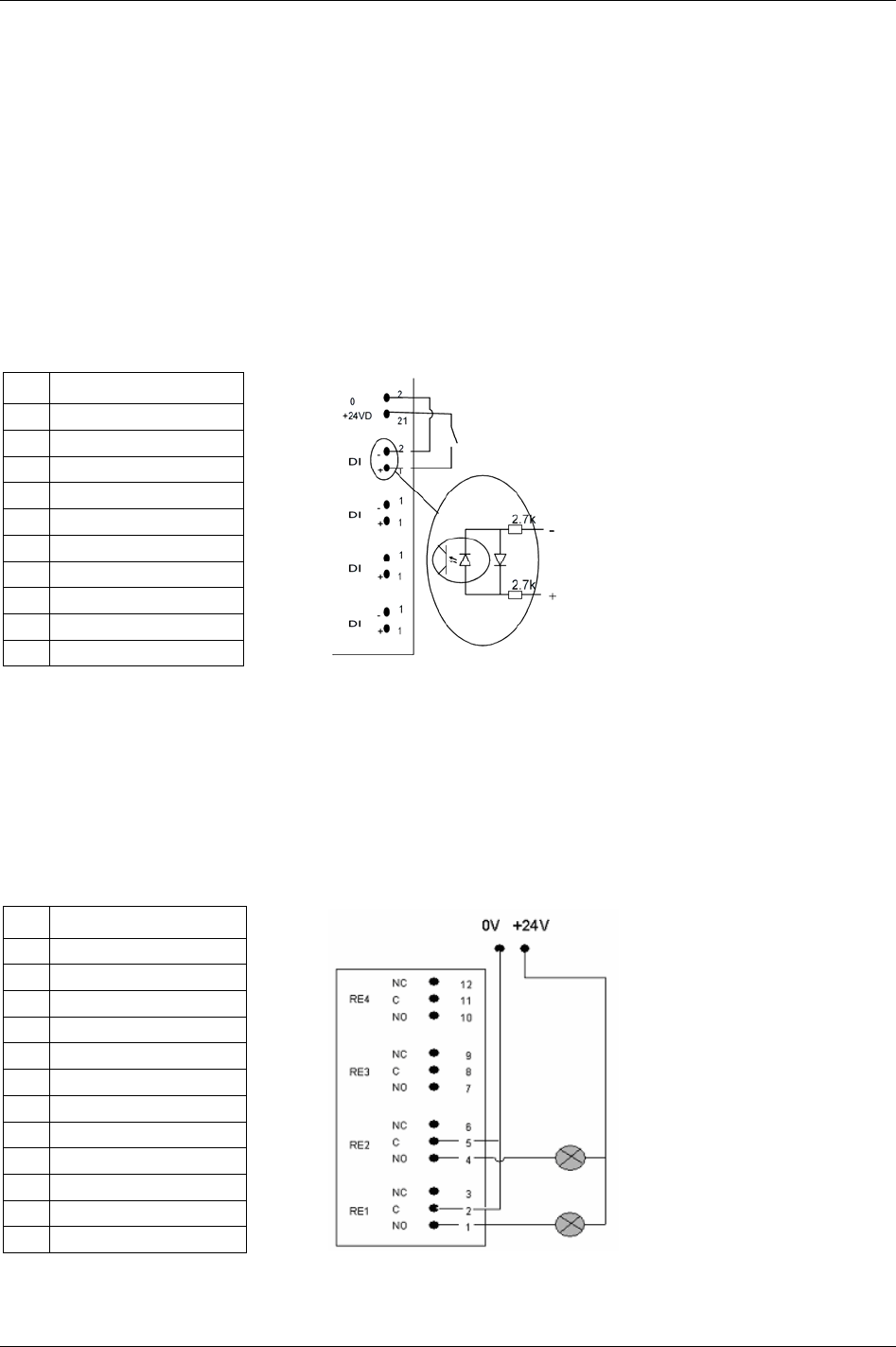

18.6 Digital inputs...........................................................................................................215

18.7 Digital outputs (relays)............................................................................................215

18.8 I/O bus #1...............................................................................................................216

18.9 I/O bus #2...............................................................................................................216

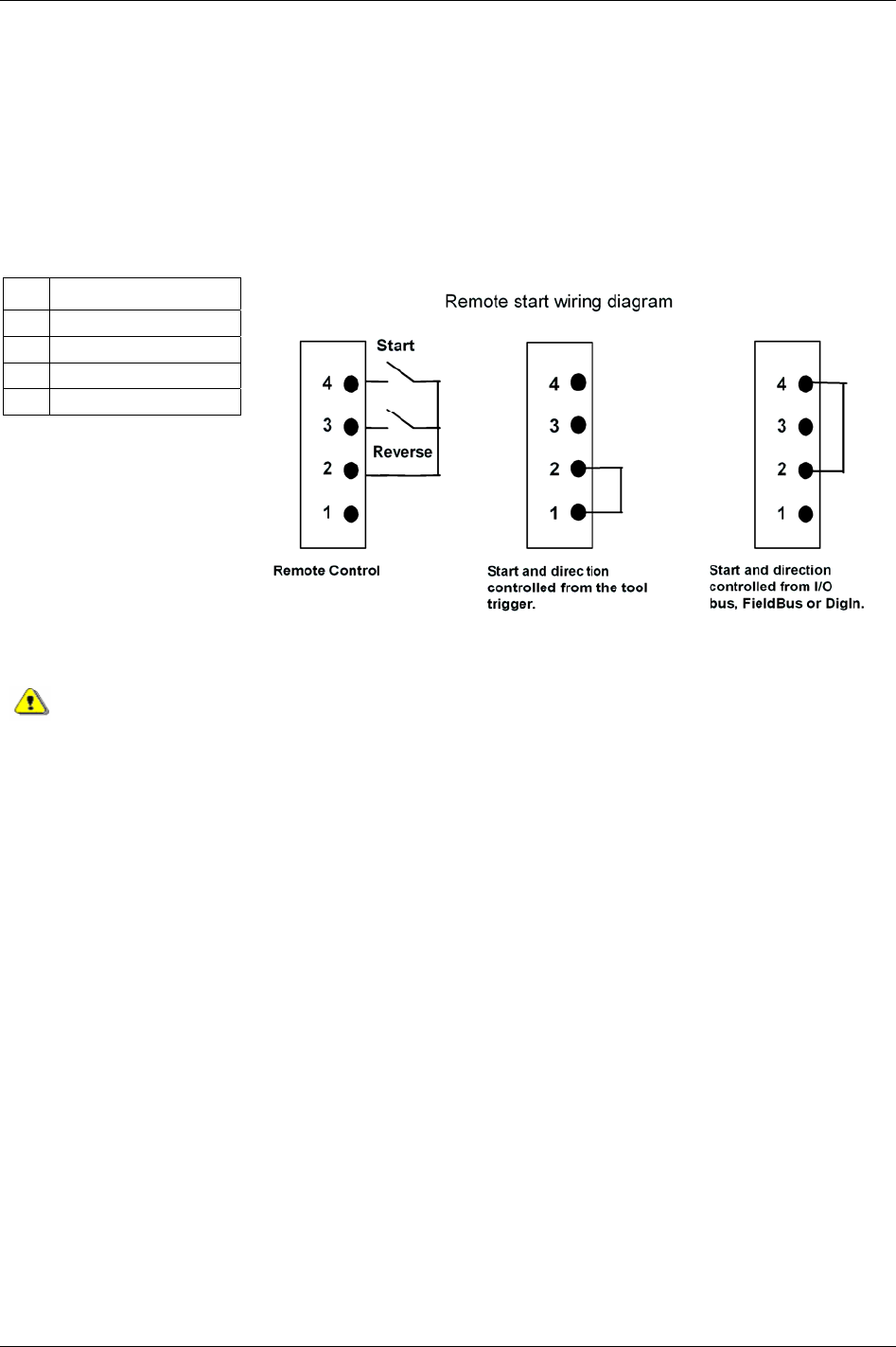

18.10 Remote start connector..........................................................................................217

18.11 Main power connector............................................................................................217

19 RBU ....................................................................................................................219

19.1 RBU functionality....................................................................................................220

19.2 Connecting the RBU...............................................................................................221

19.3 Start-up instructions ...............................................................................................221

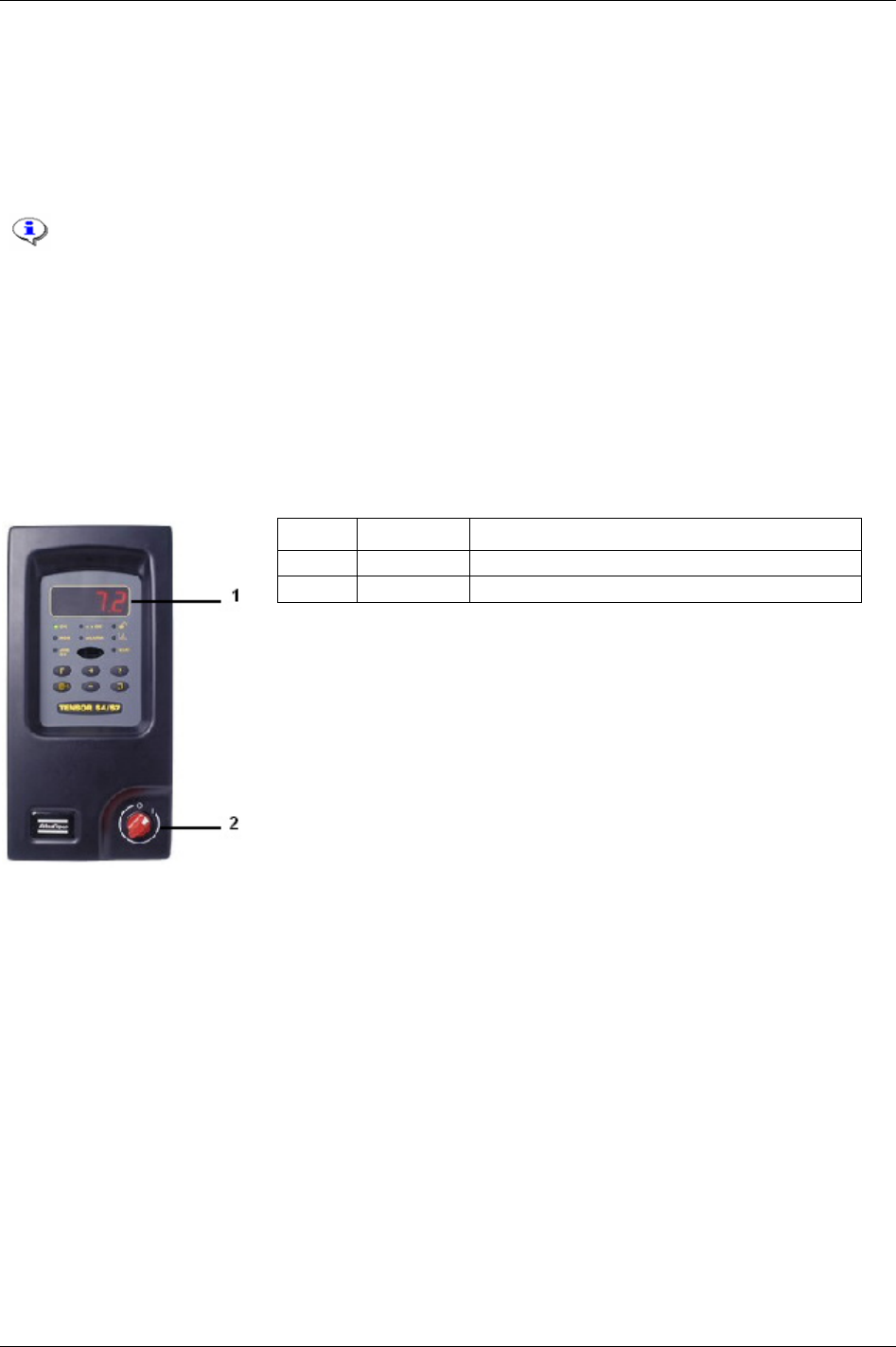

20 PF 3000 Compact user interface......................................................................223

20.1 Front panel .............................................................................................................223

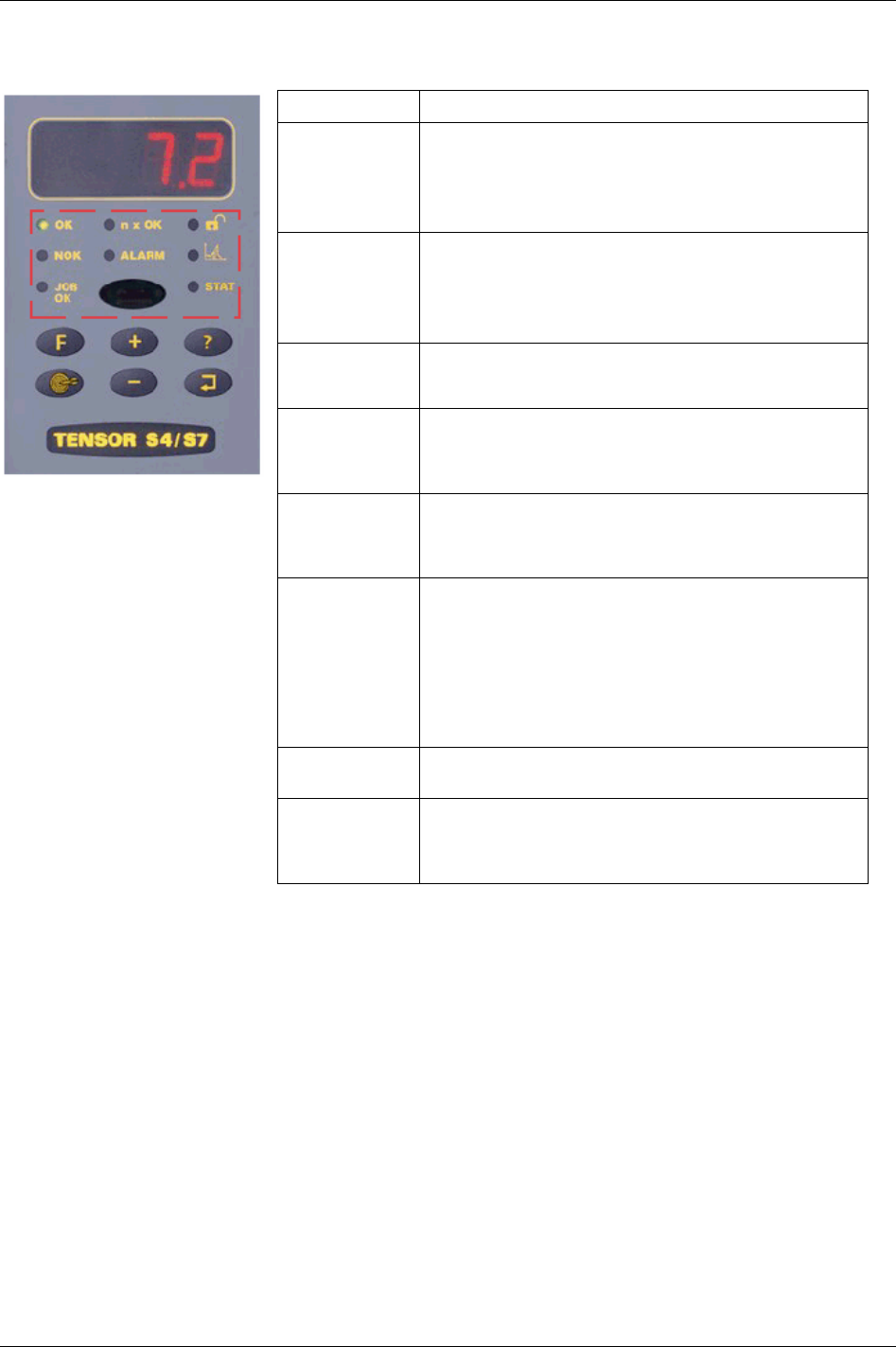

20.1.1 Indicator lights....................................................................................................... 224

20.1.2 Keypad.................................................................................................................. 225

21 Tensor tools.......................................................................................................229

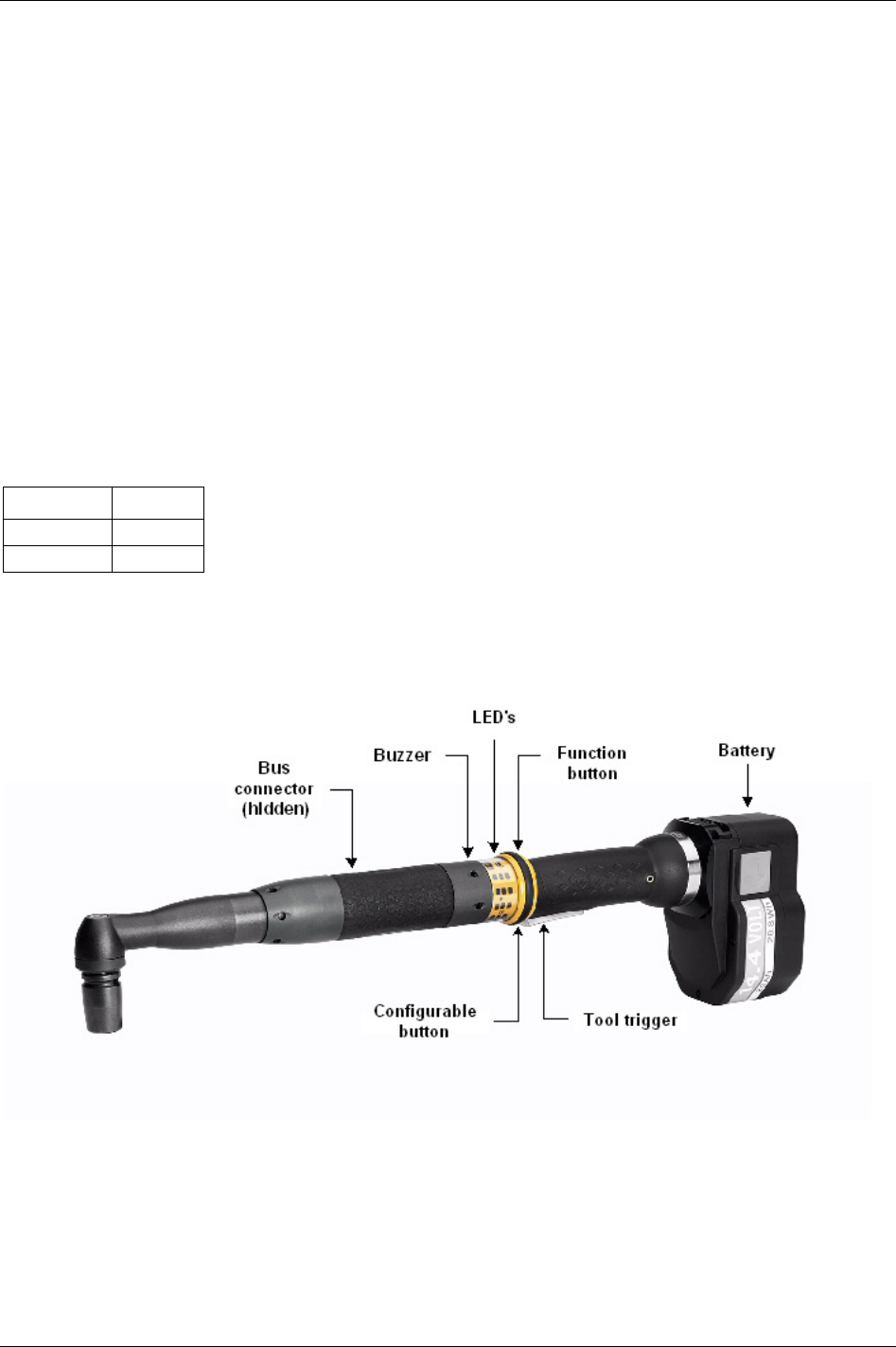

21.1 Tensor STB ............................................................................................................229

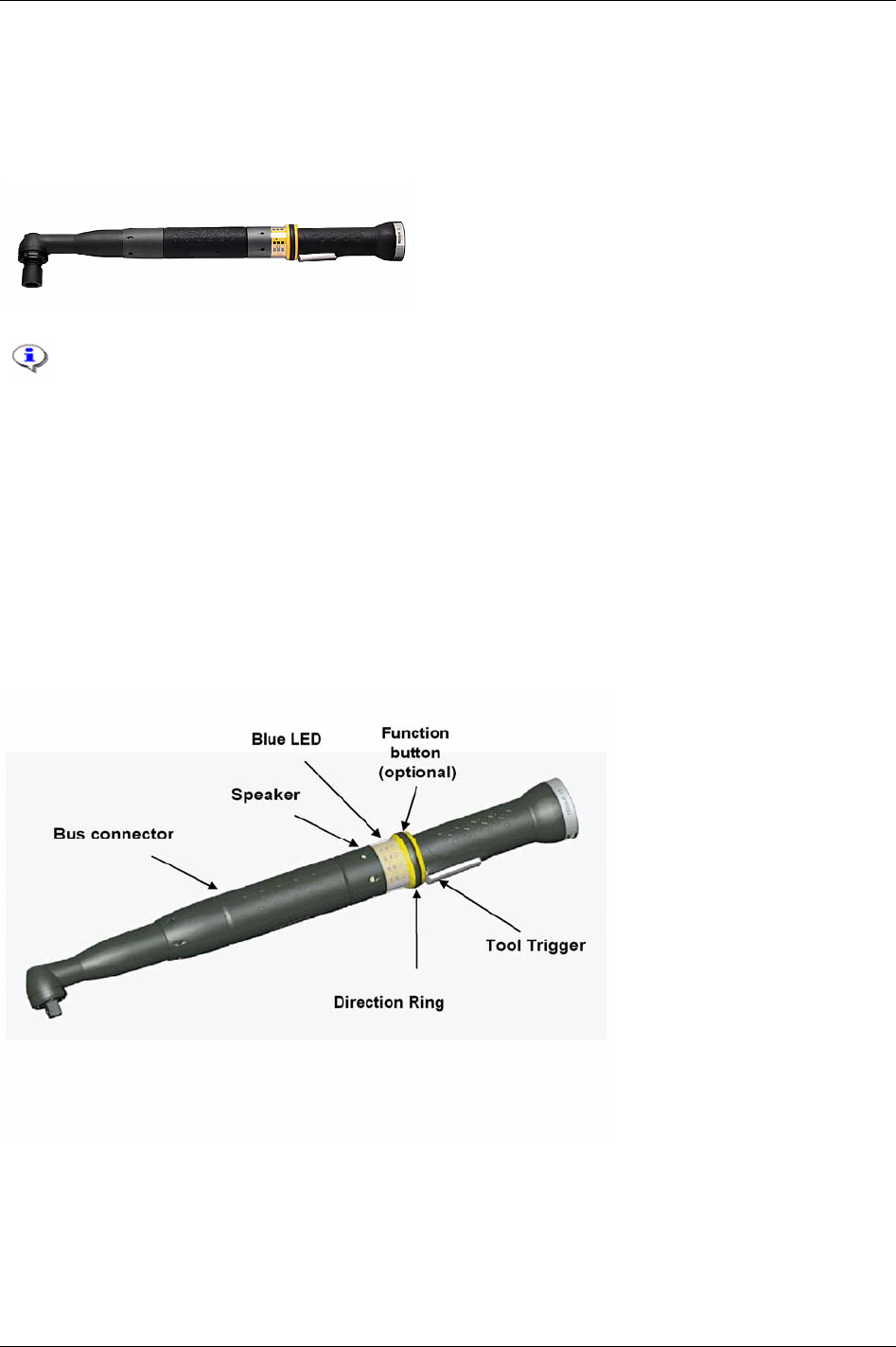

21.1.1 Tool functionality................................................................................................... 230

21.1.2 System setup........................................................................................................ 233

21.1.3 Crossover Ethernet cable connection................................................................... 234

21.2 Tensor ST...............................................................................................................235

21.3 Tensor SL...............................................................................................................236

21.4 Tensor S.................................................................................................................237

21.5 Tensor DS ..............................................................................................................238

21.6 Tensor ETX ............................................................................................................239

6 (330) 9836 3123 01

Contents

9836 3123 01 7 (330)

21.7 Tools with open end................................................................................................240

21.7.1 Start-up instruction ................................................................................................240

21.8 Tool accessories.....................................................................................................241

21.8.1 ST scanner ............................................................................................................241

21.8.2 ST GPIO ................................................................................................................241

21.8.3 ST selector.............................................................................................................241

21.8.4 ST/SL cable...........................................................................................................241

22 Quick reference guide ......................................................................................243

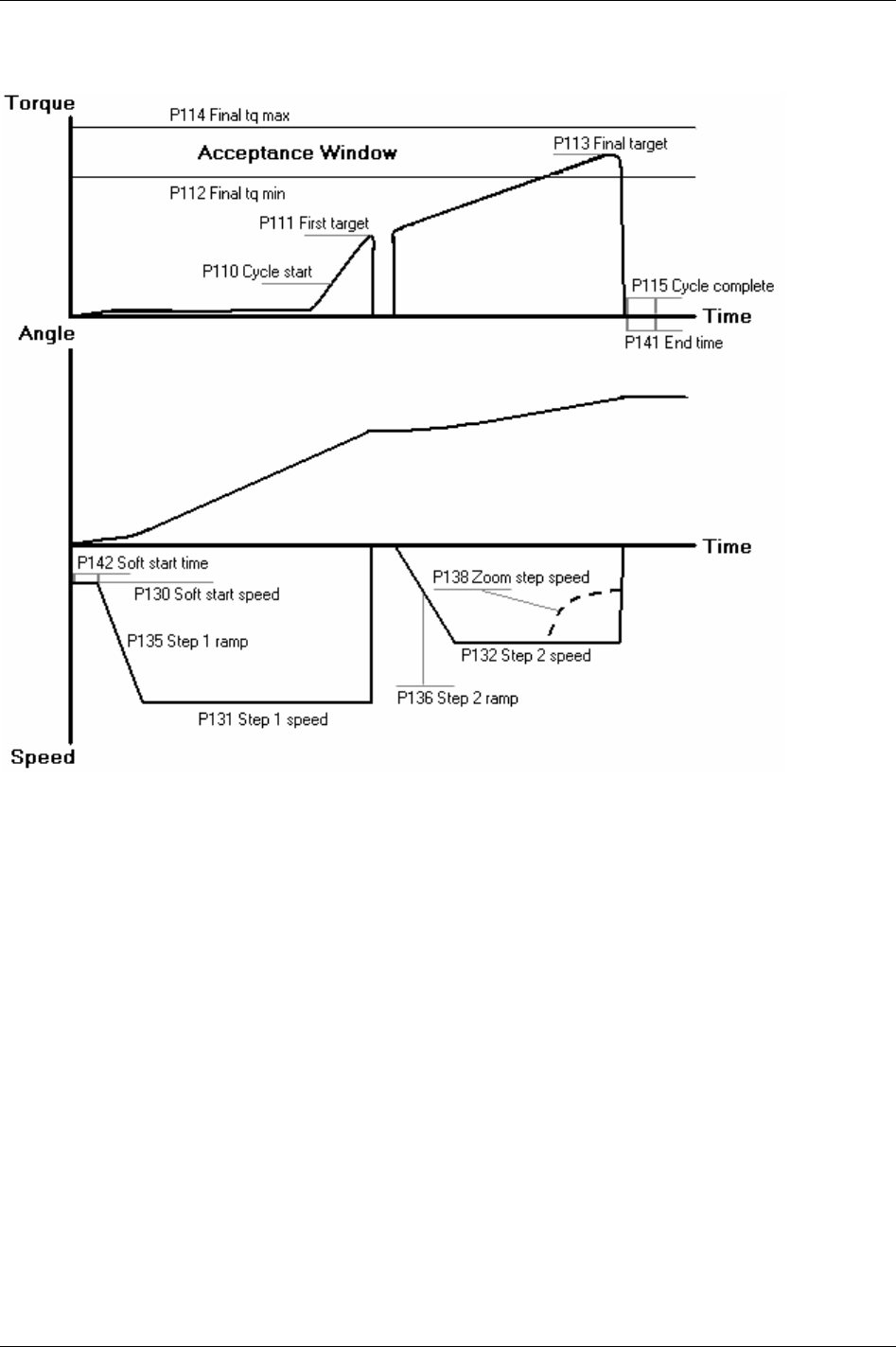

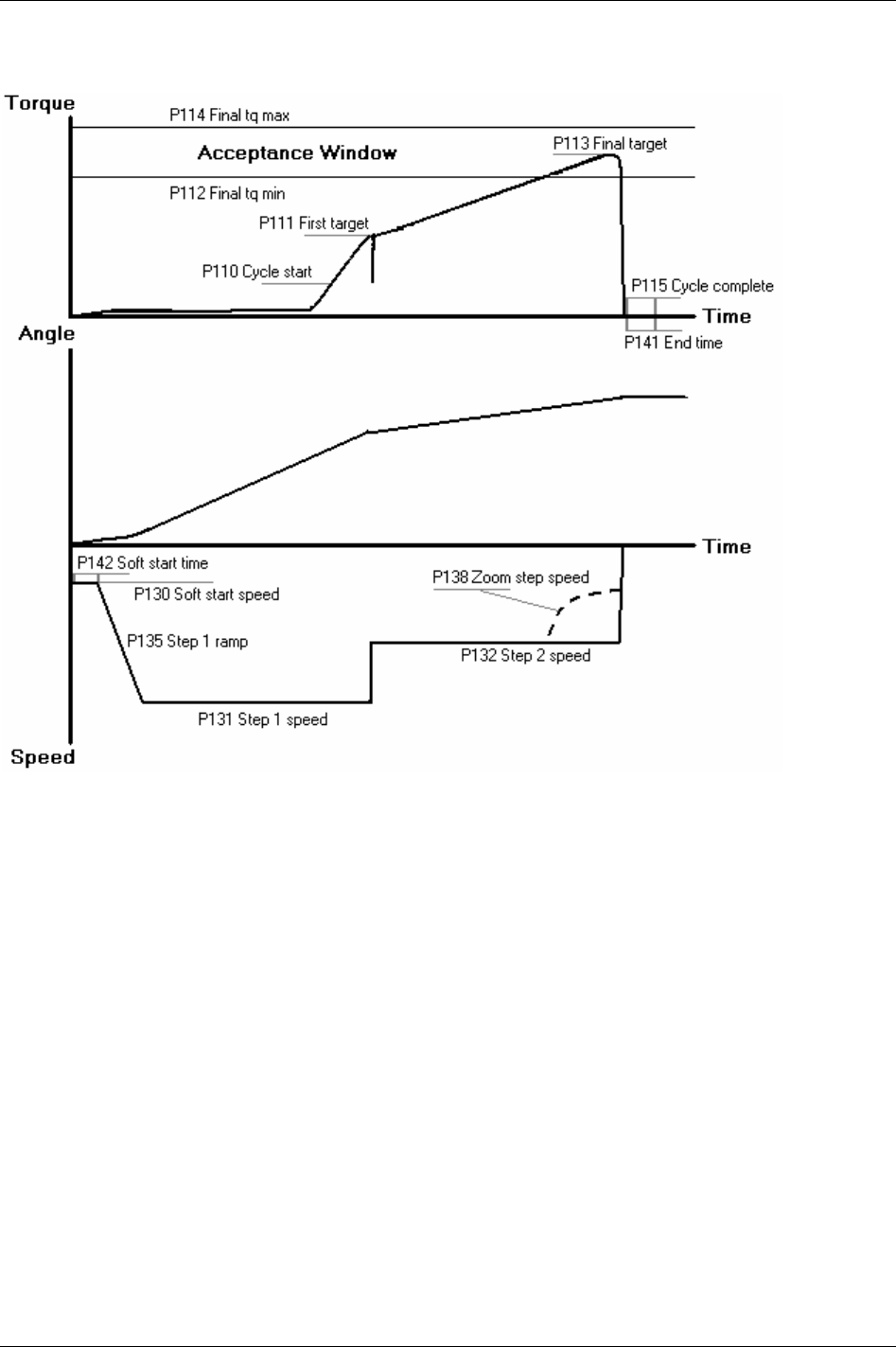

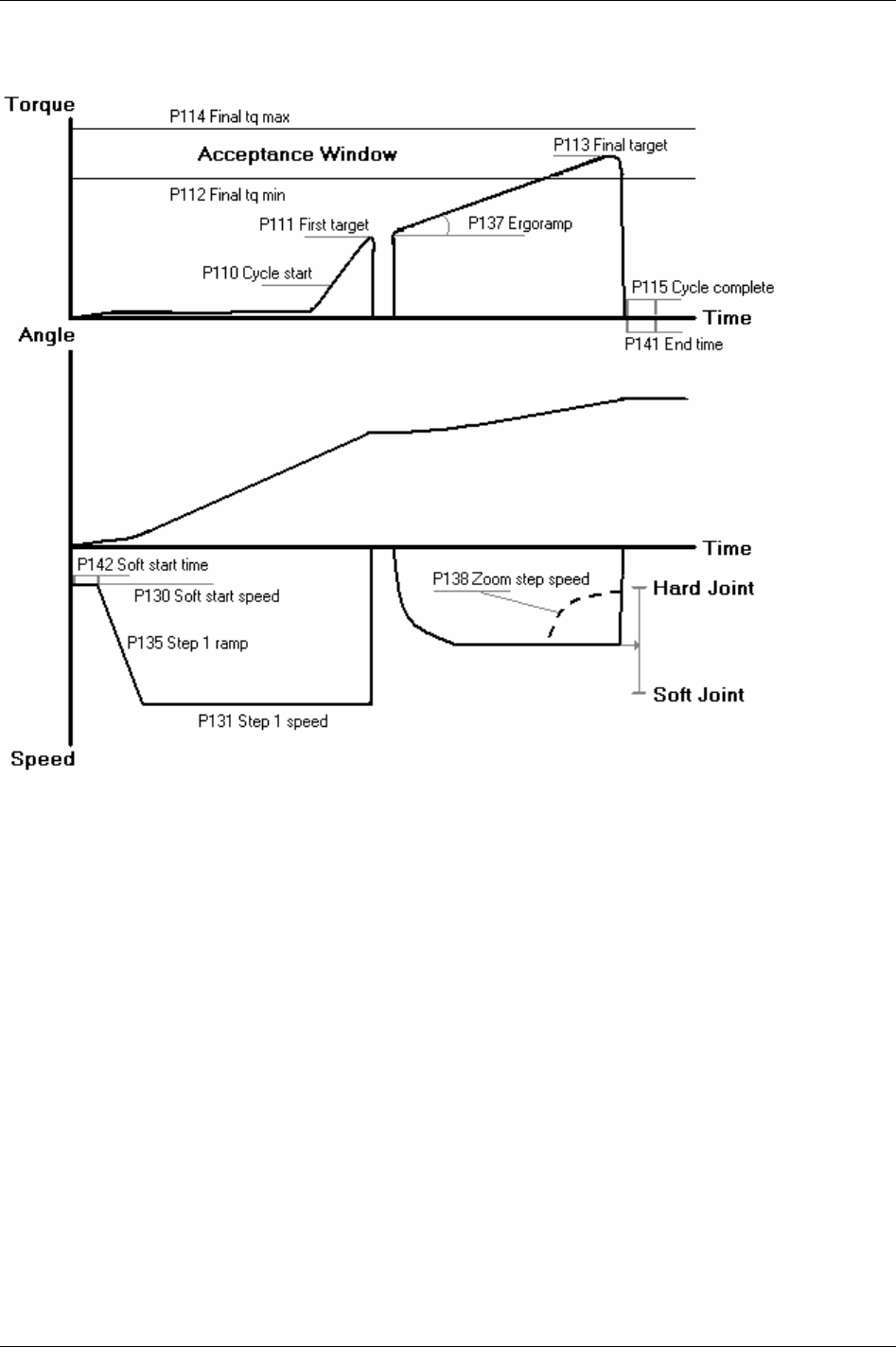

22.1 Tq con.....................................................................................................................244

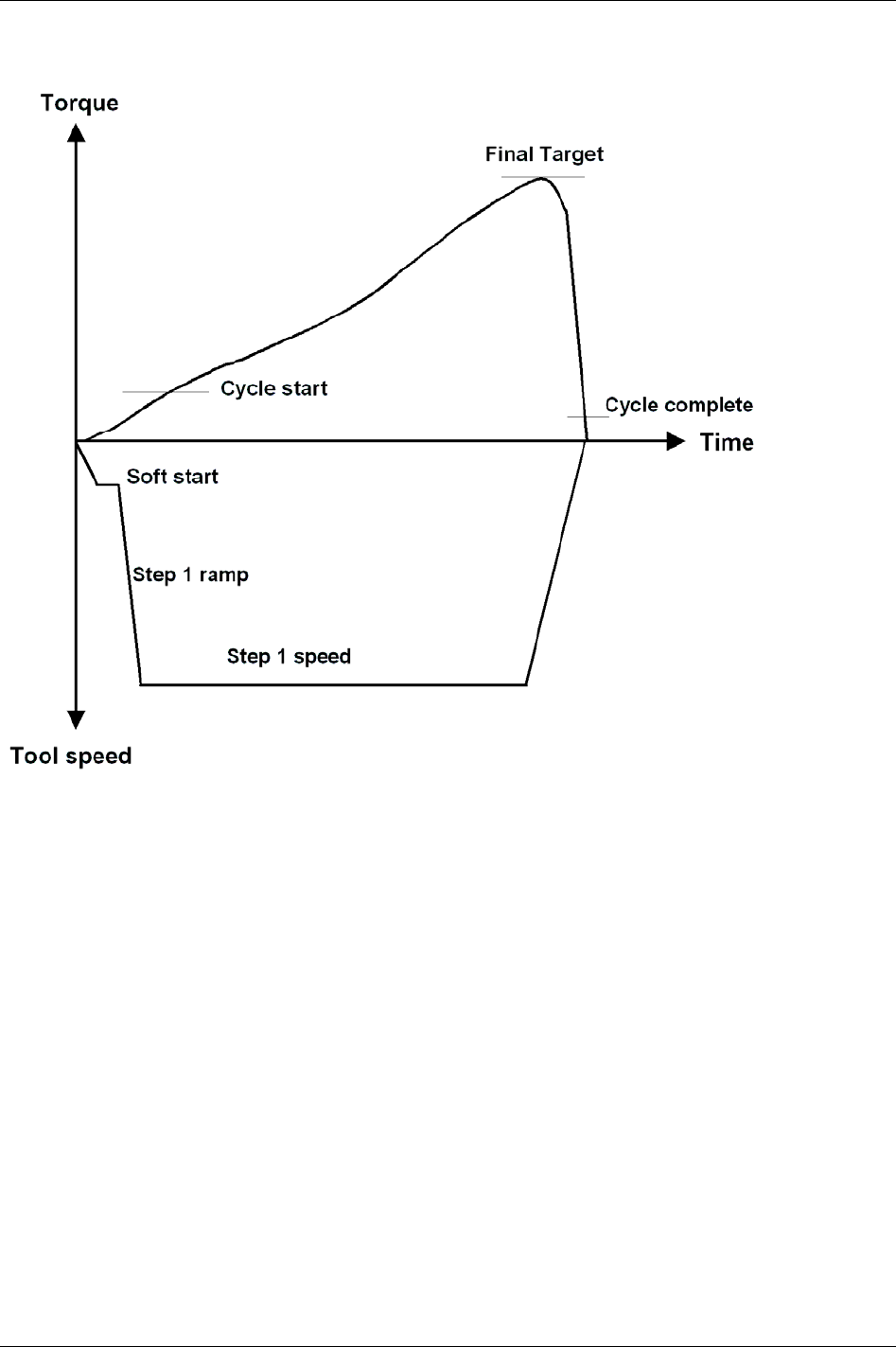

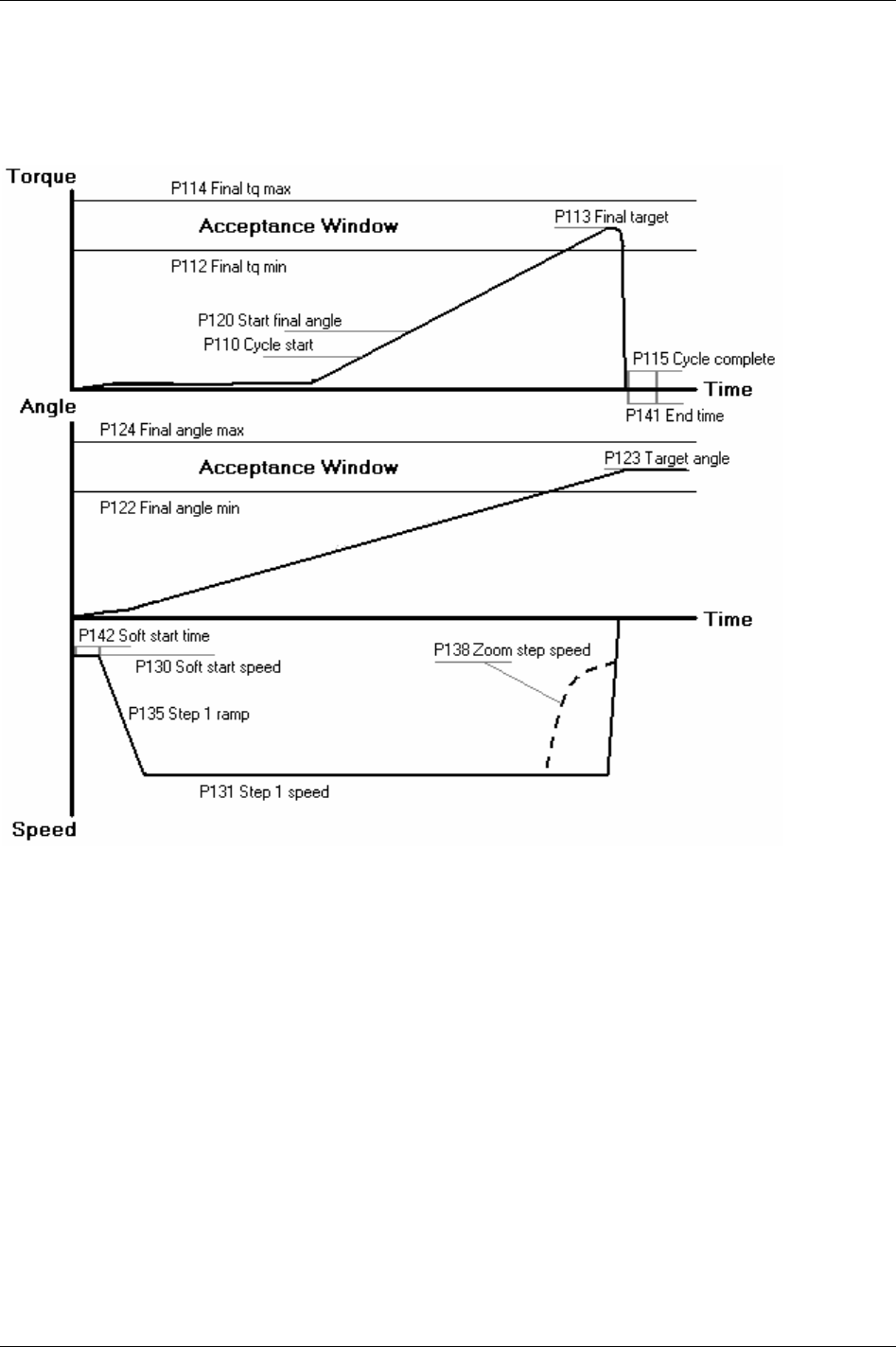

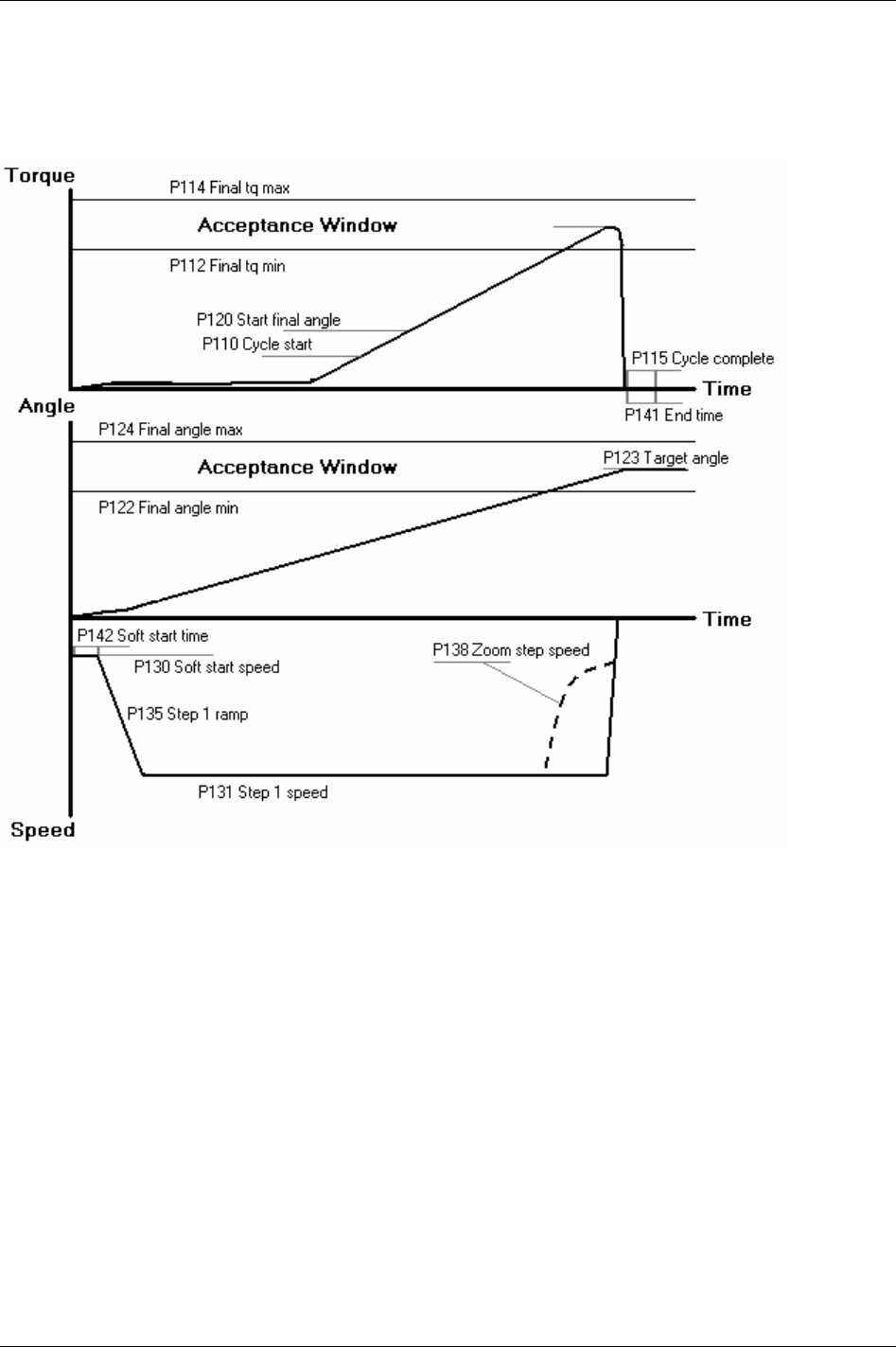

22.1.1 One stage ..............................................................................................................244

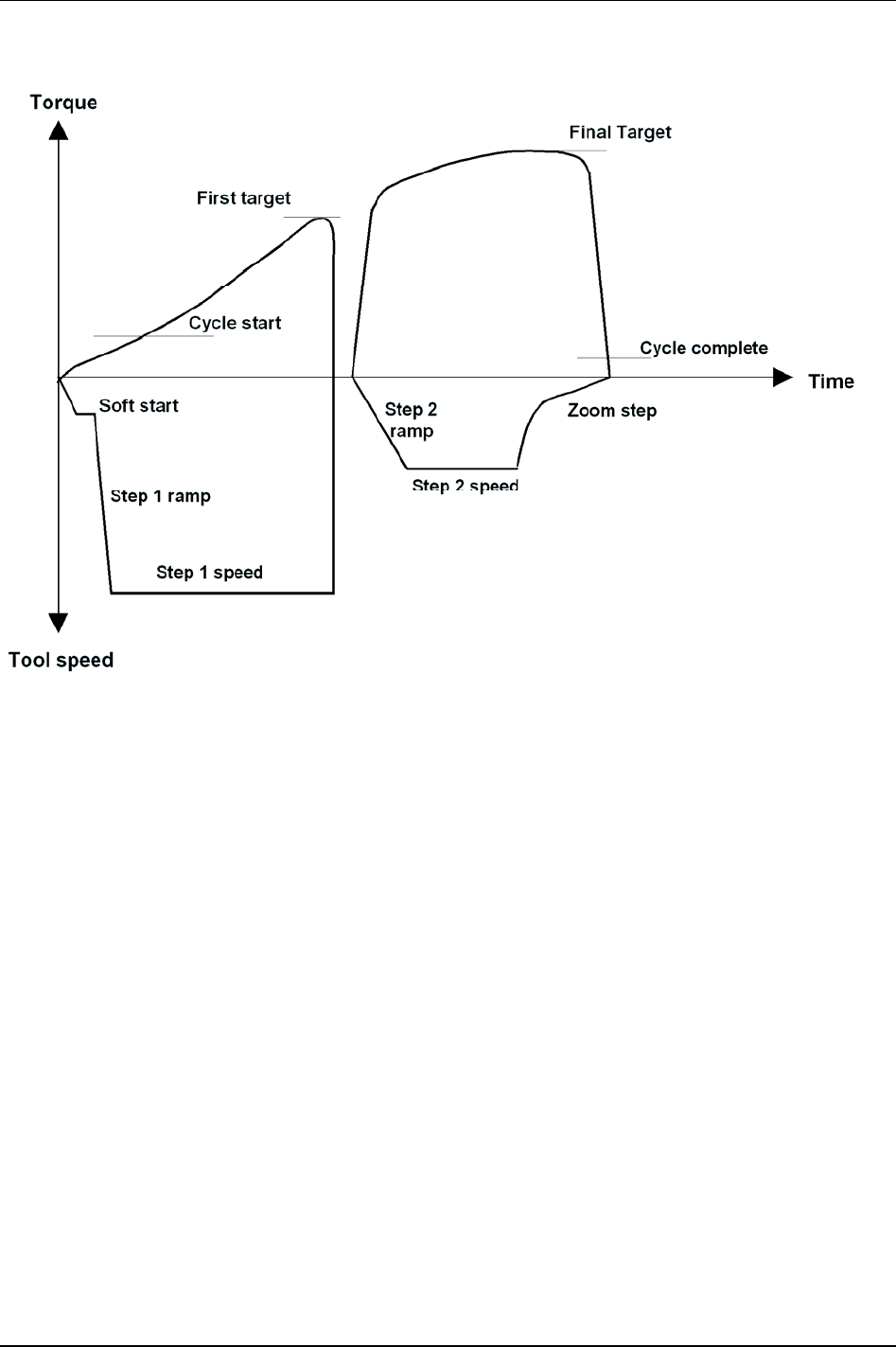

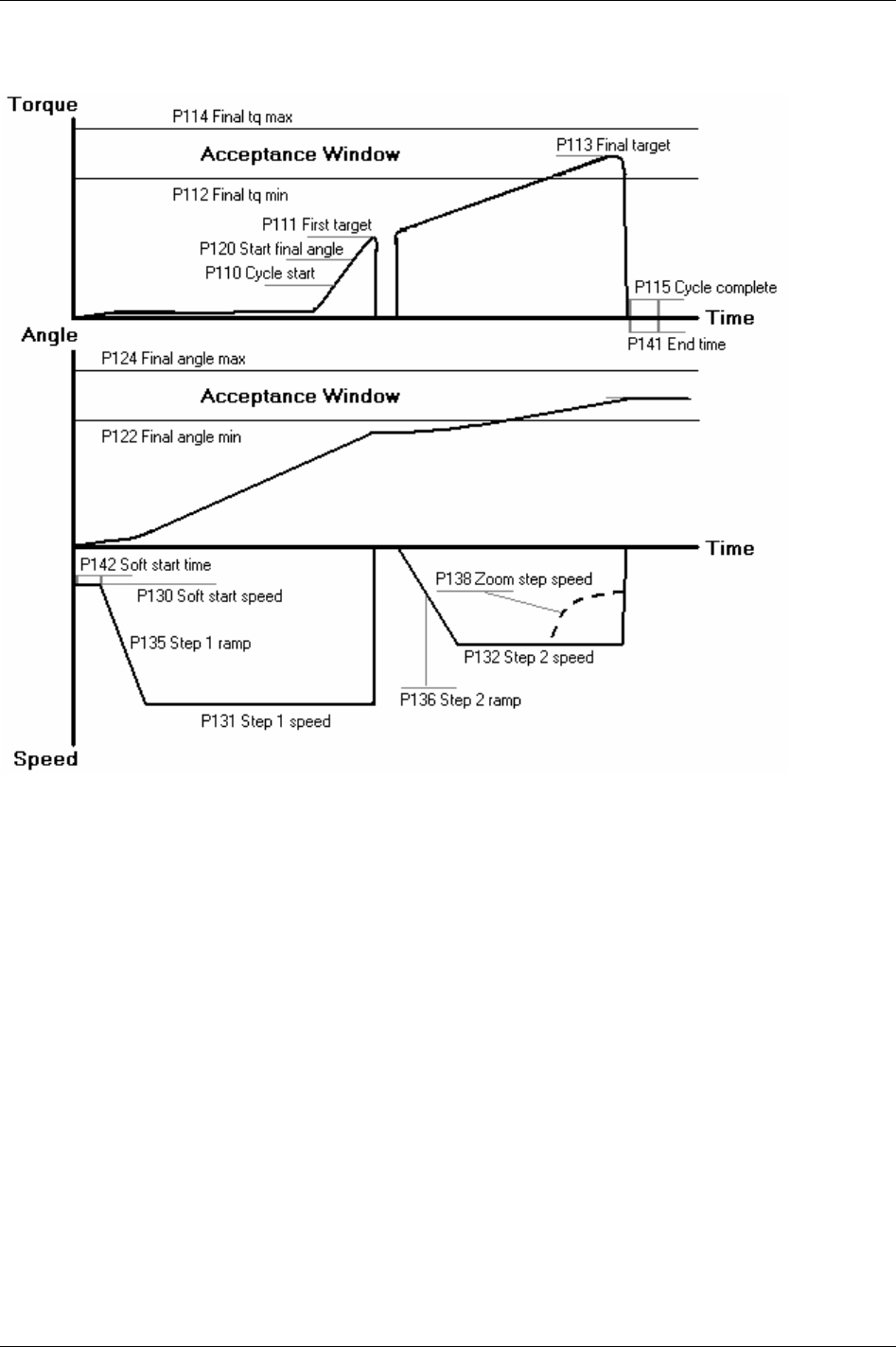

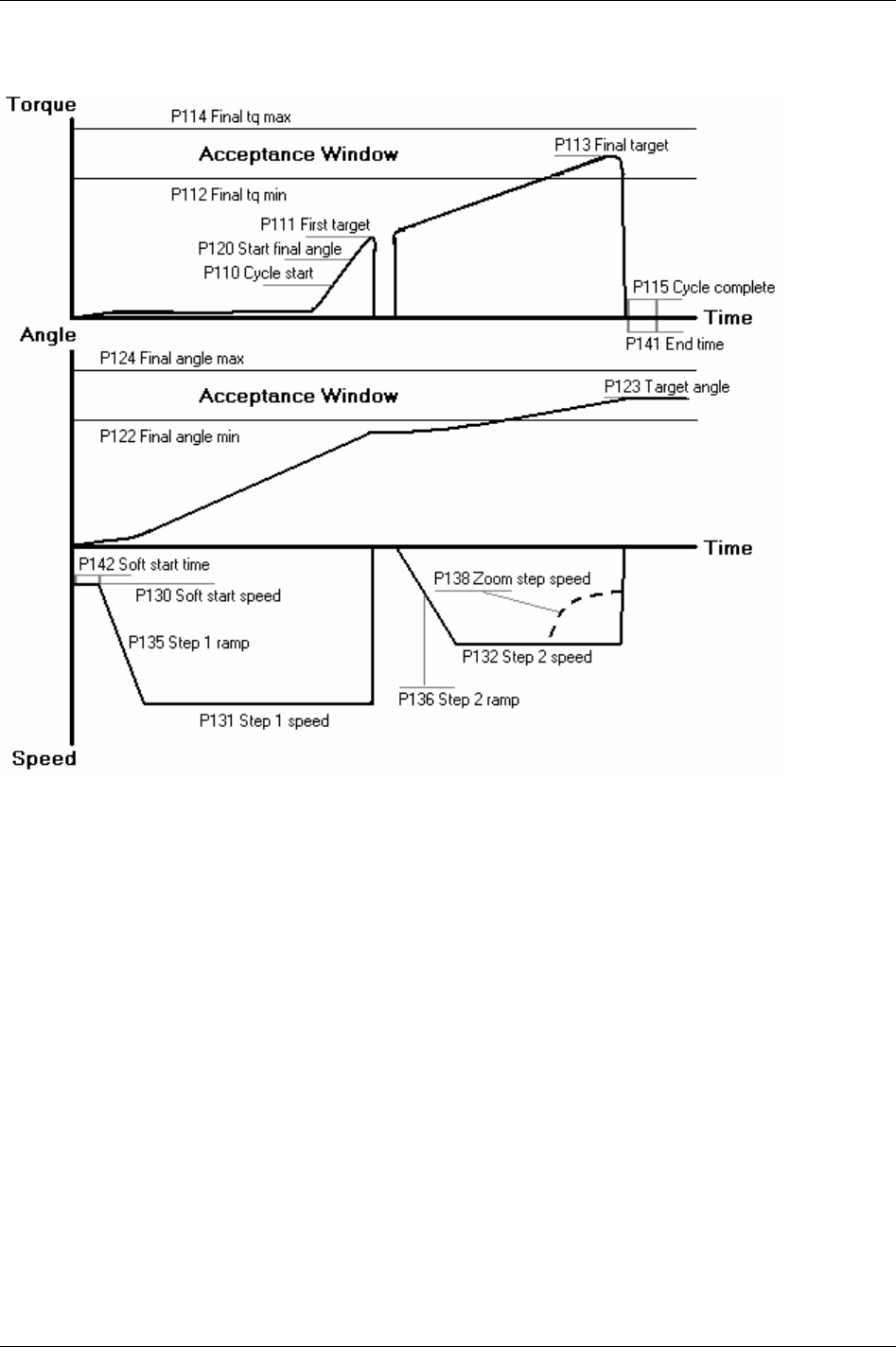

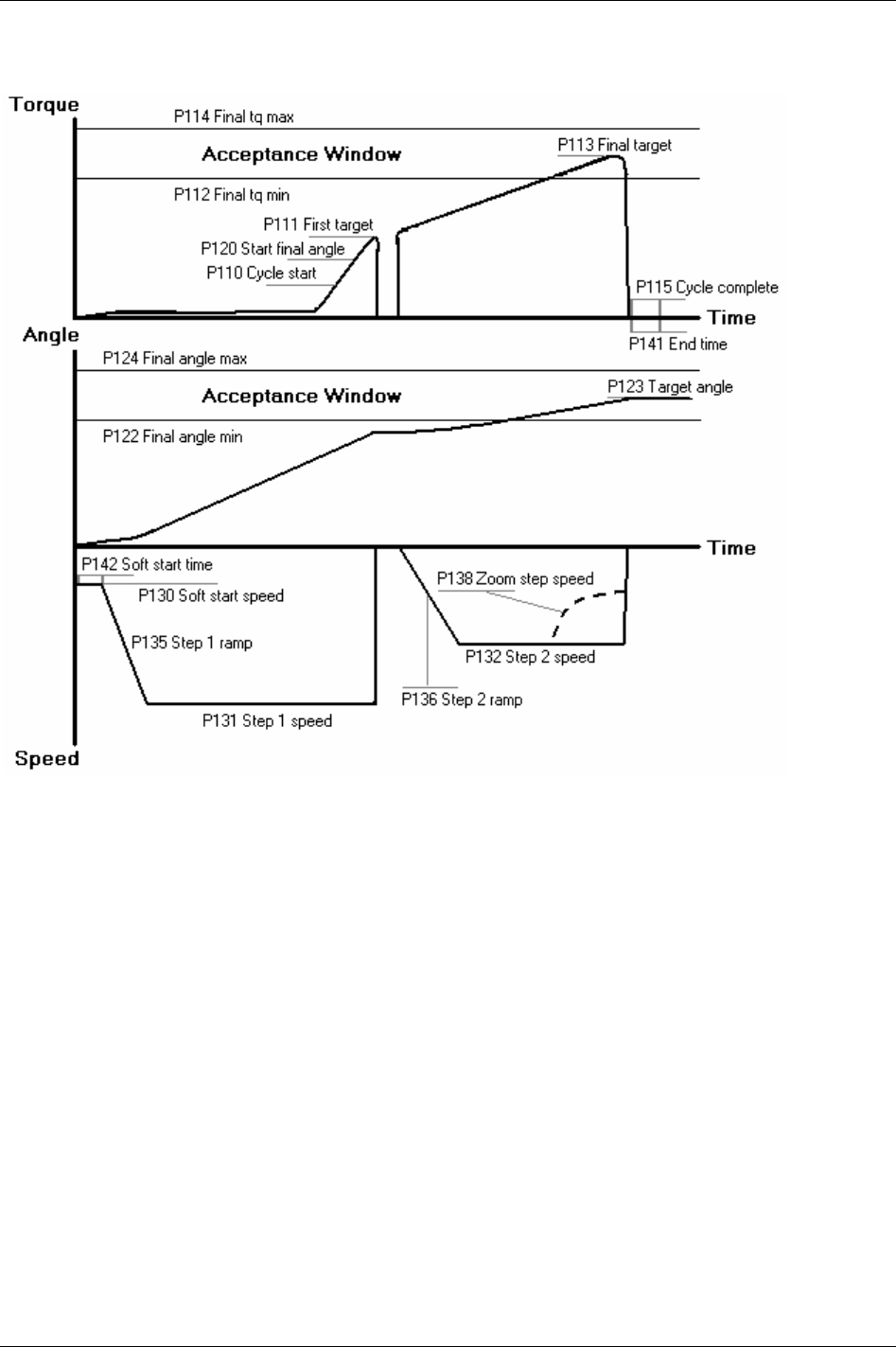

22.1.2 Two stage..............................................................................................................245

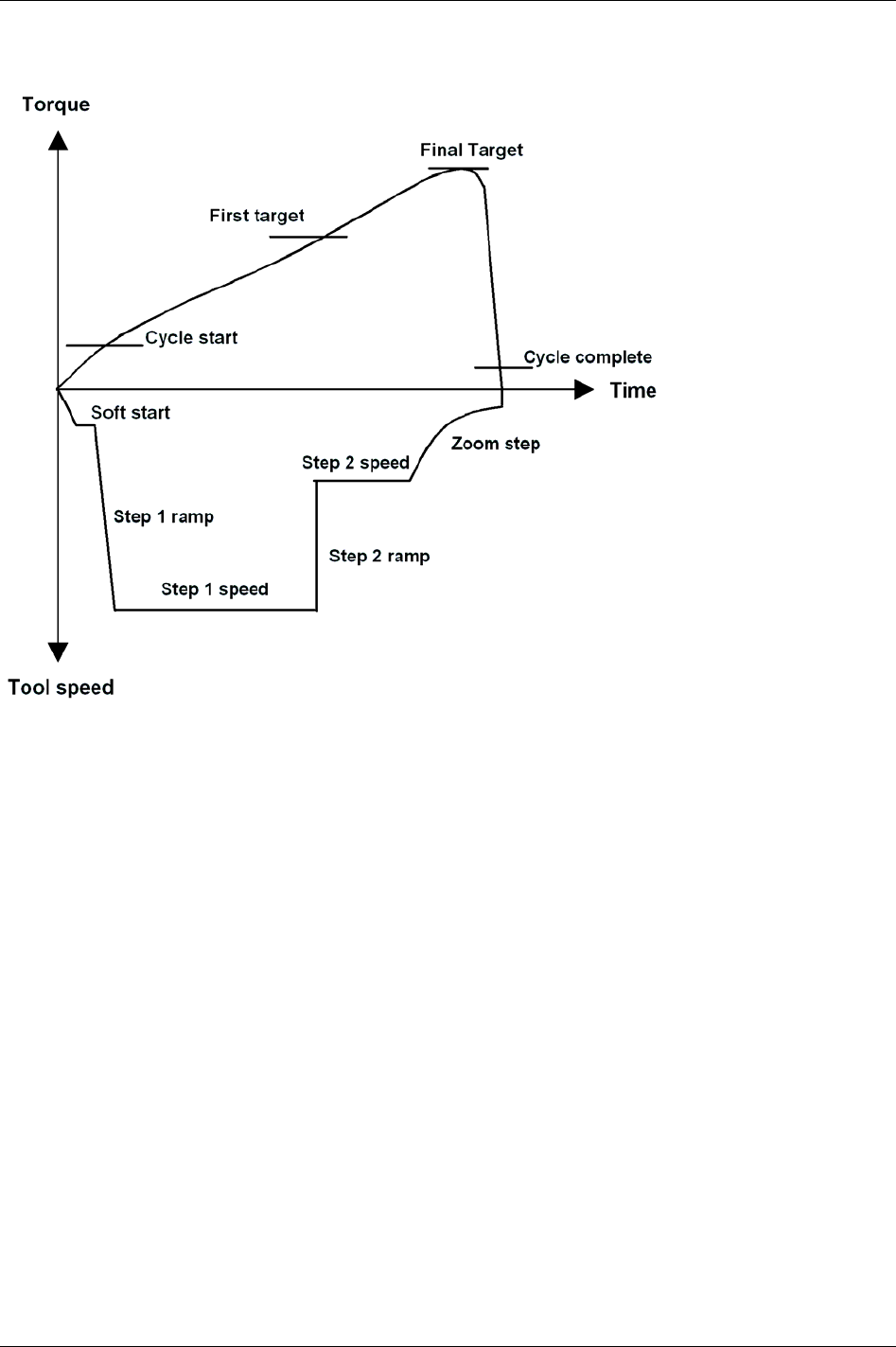

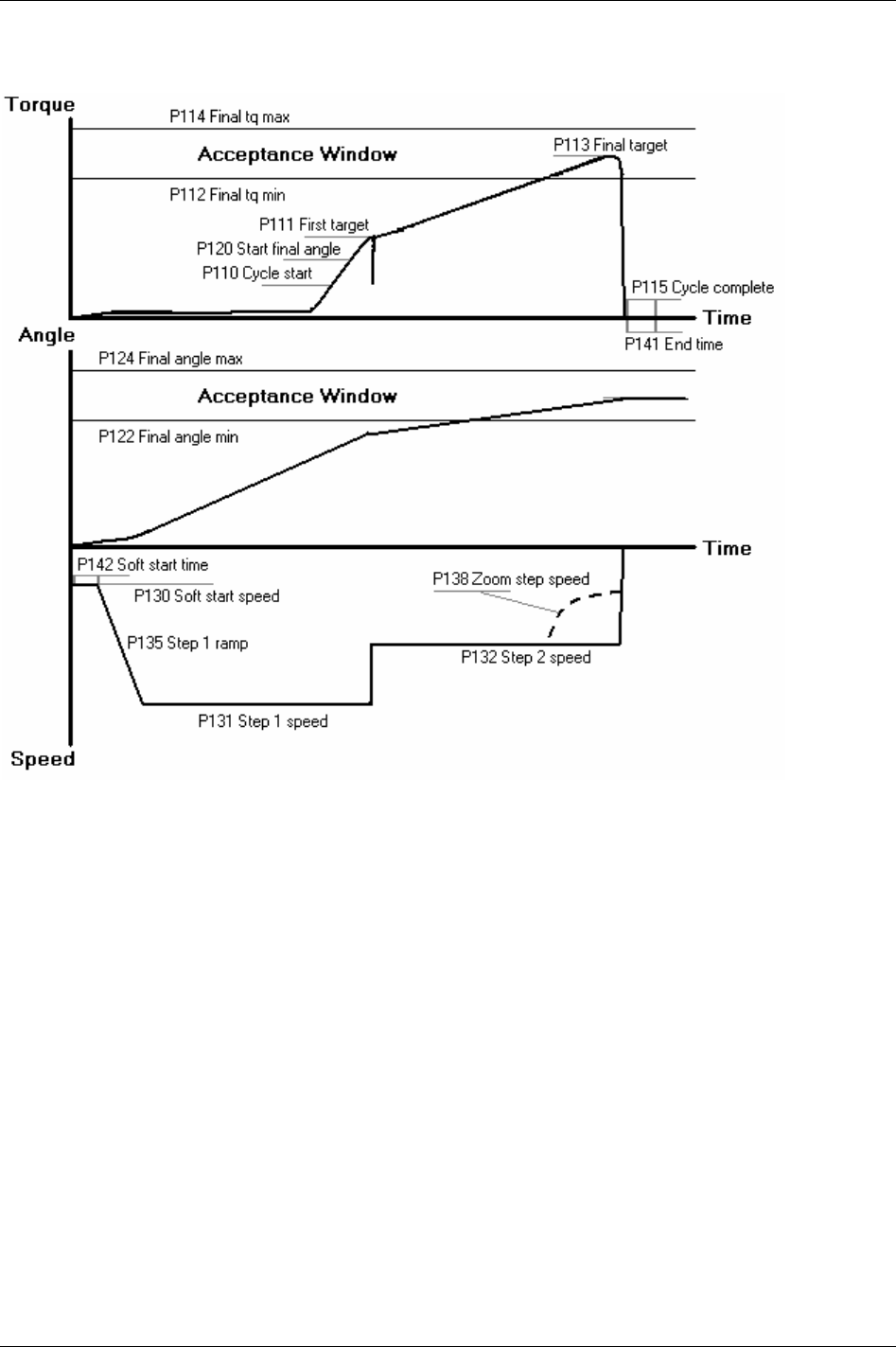

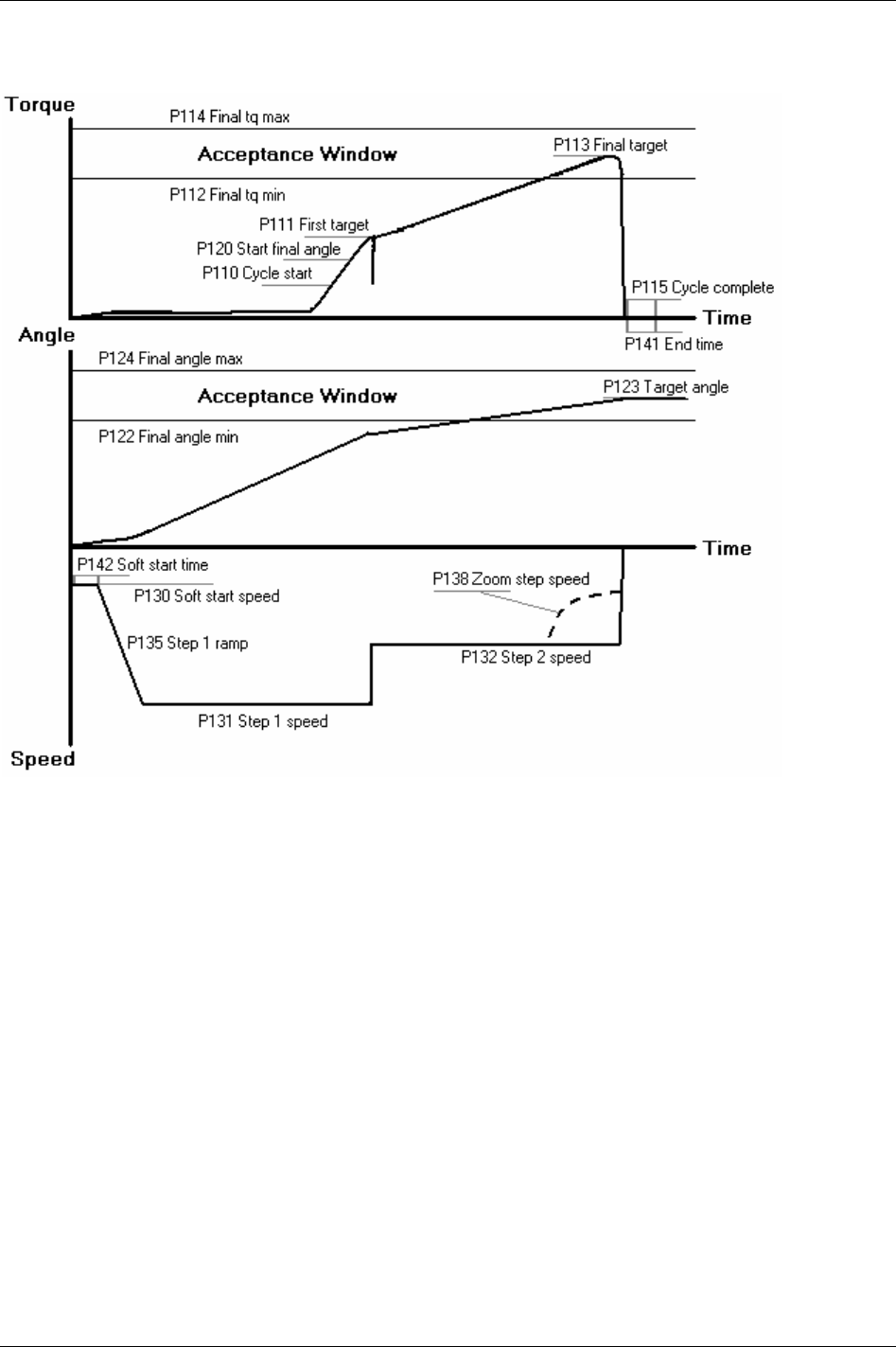

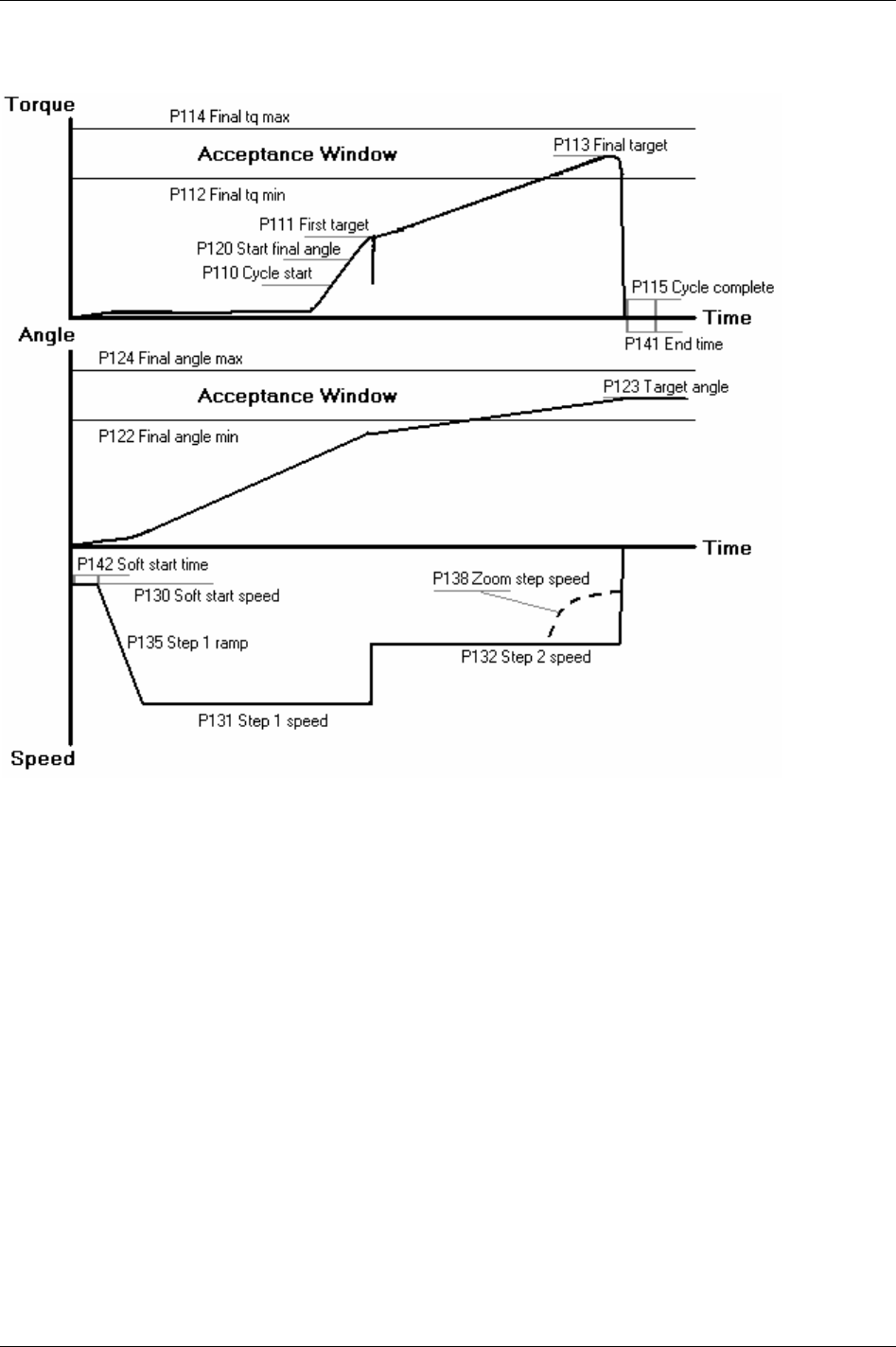

22.1.3 Quick step..............................................................................................................246

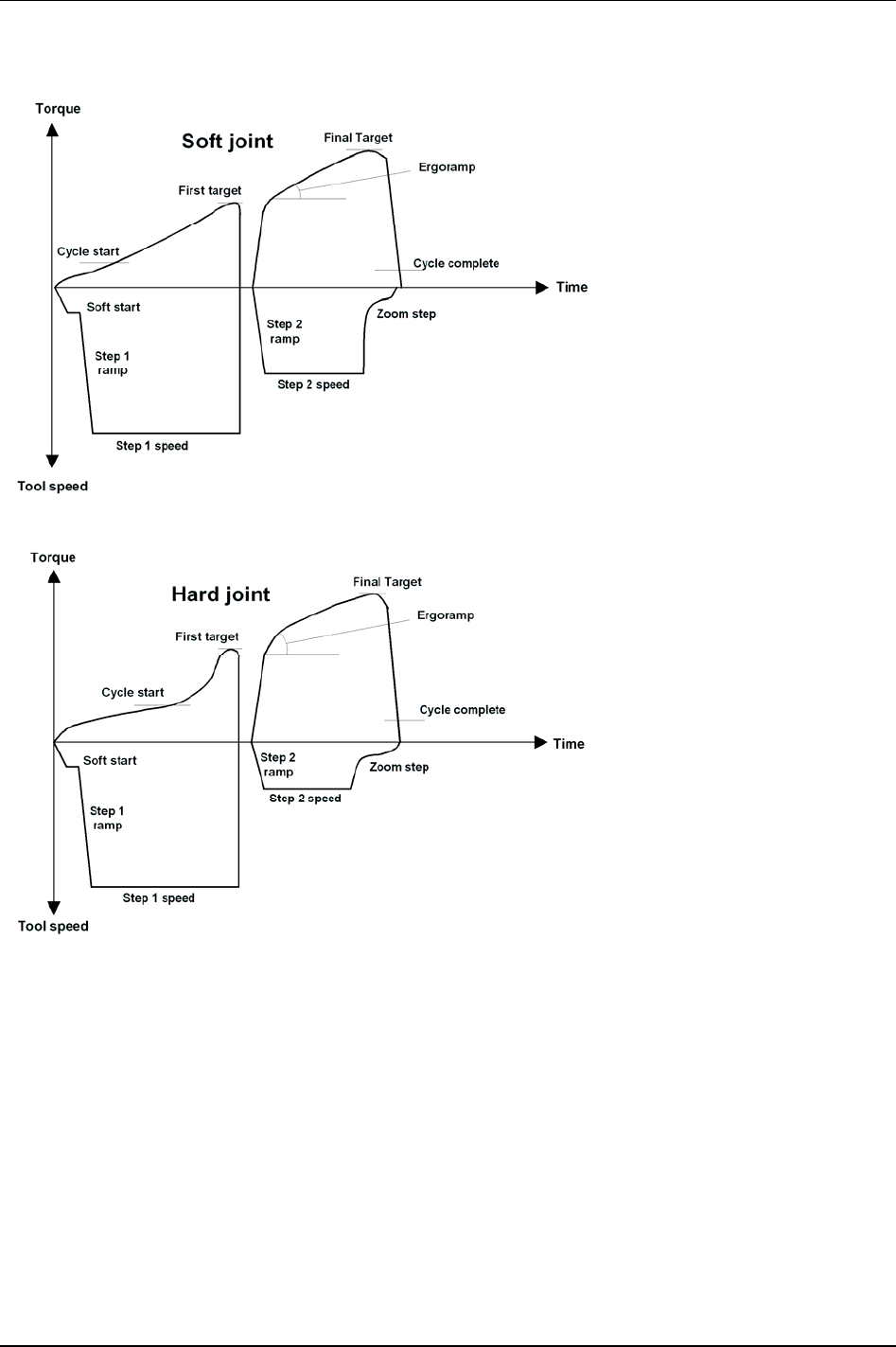

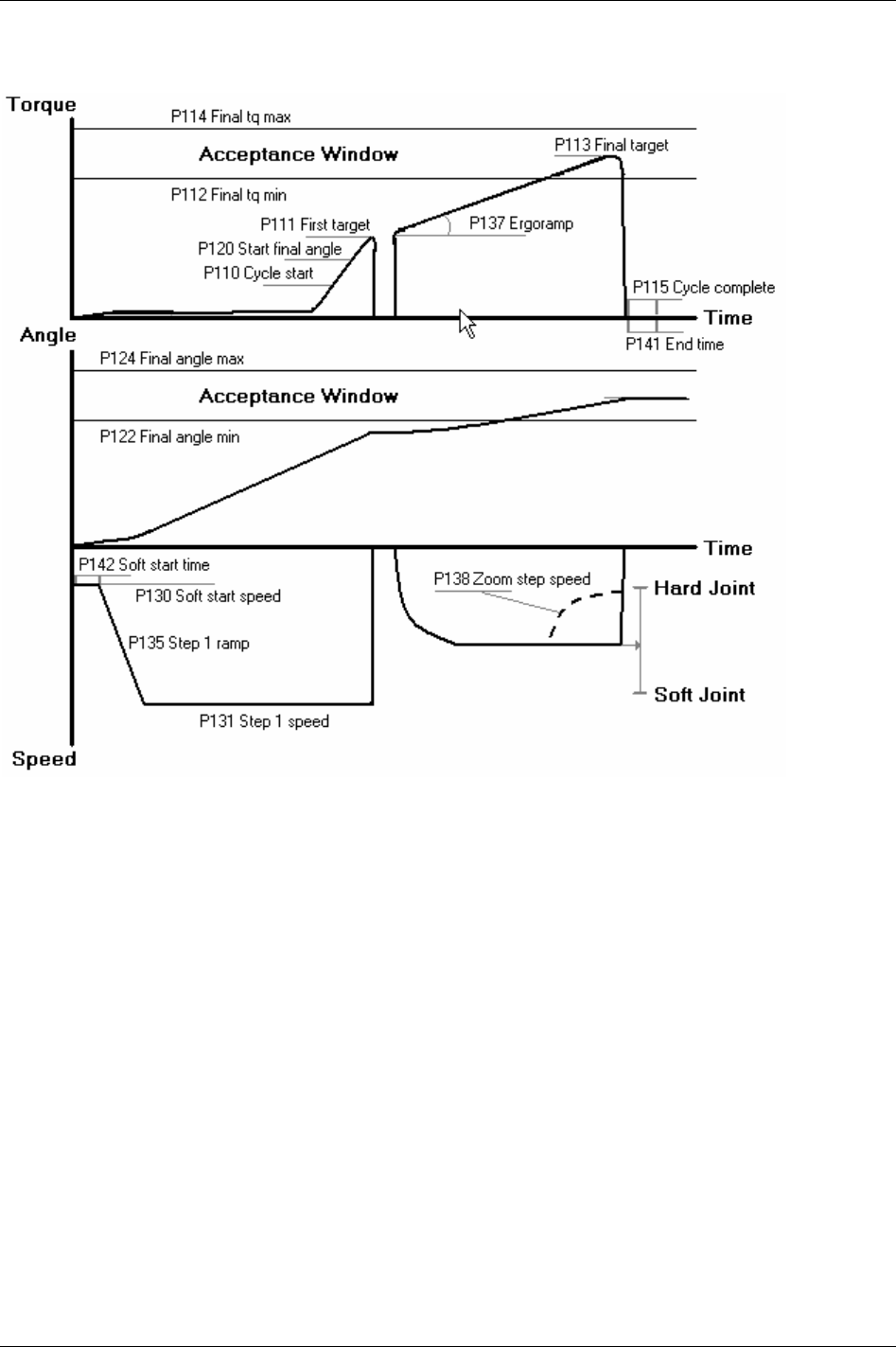

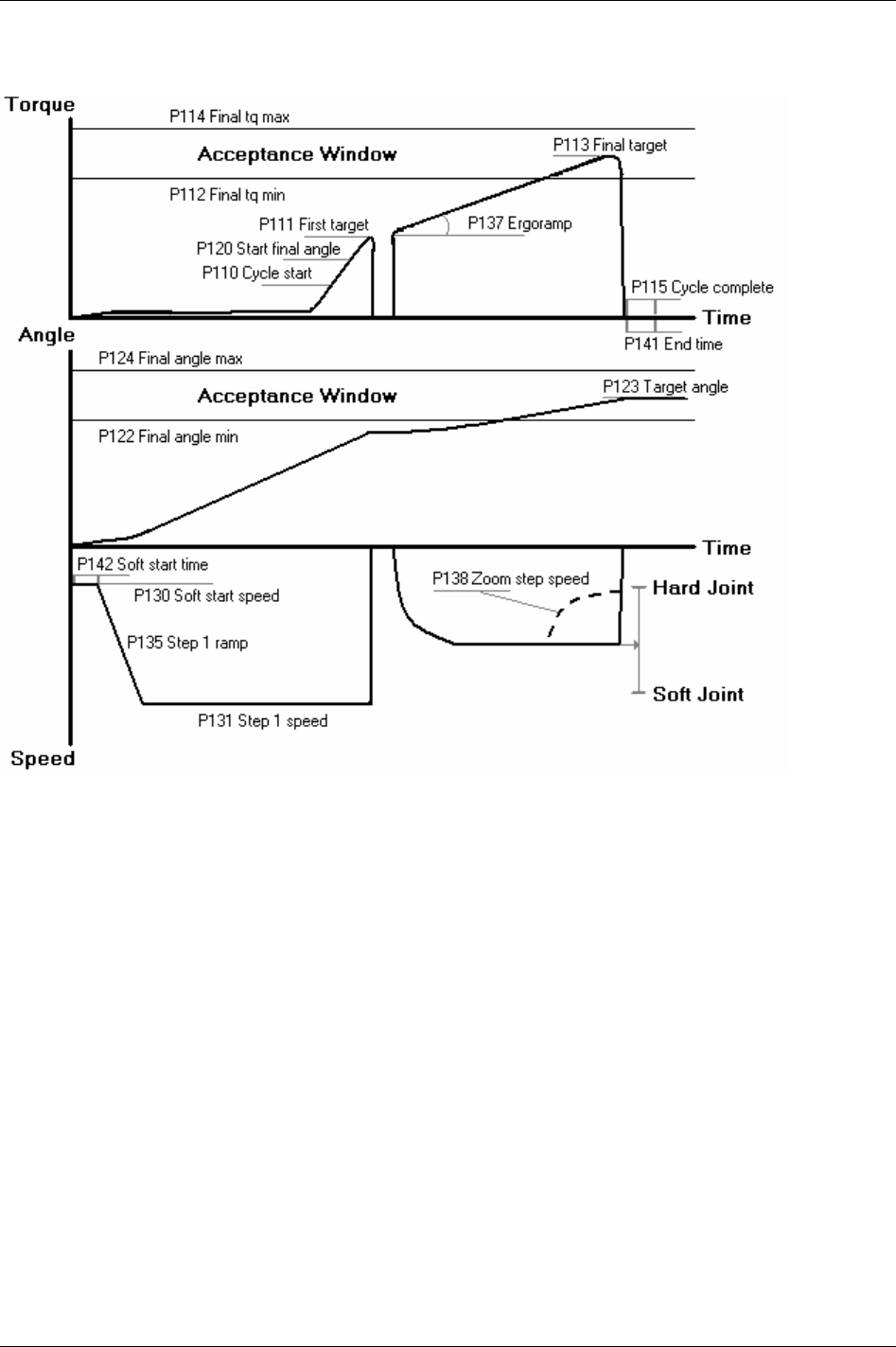

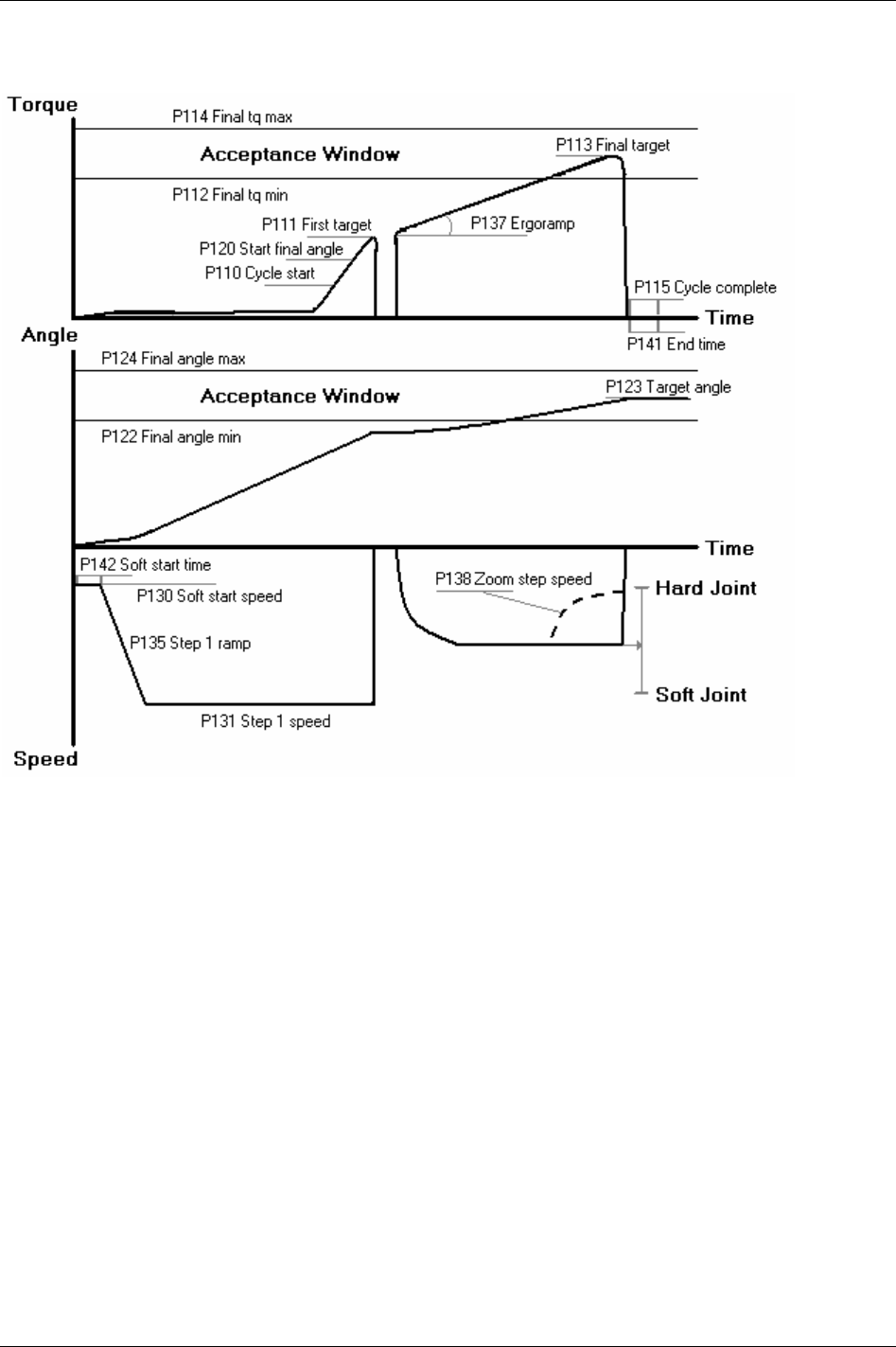

22.1.4 Ergo ramp..............................................................................................................247

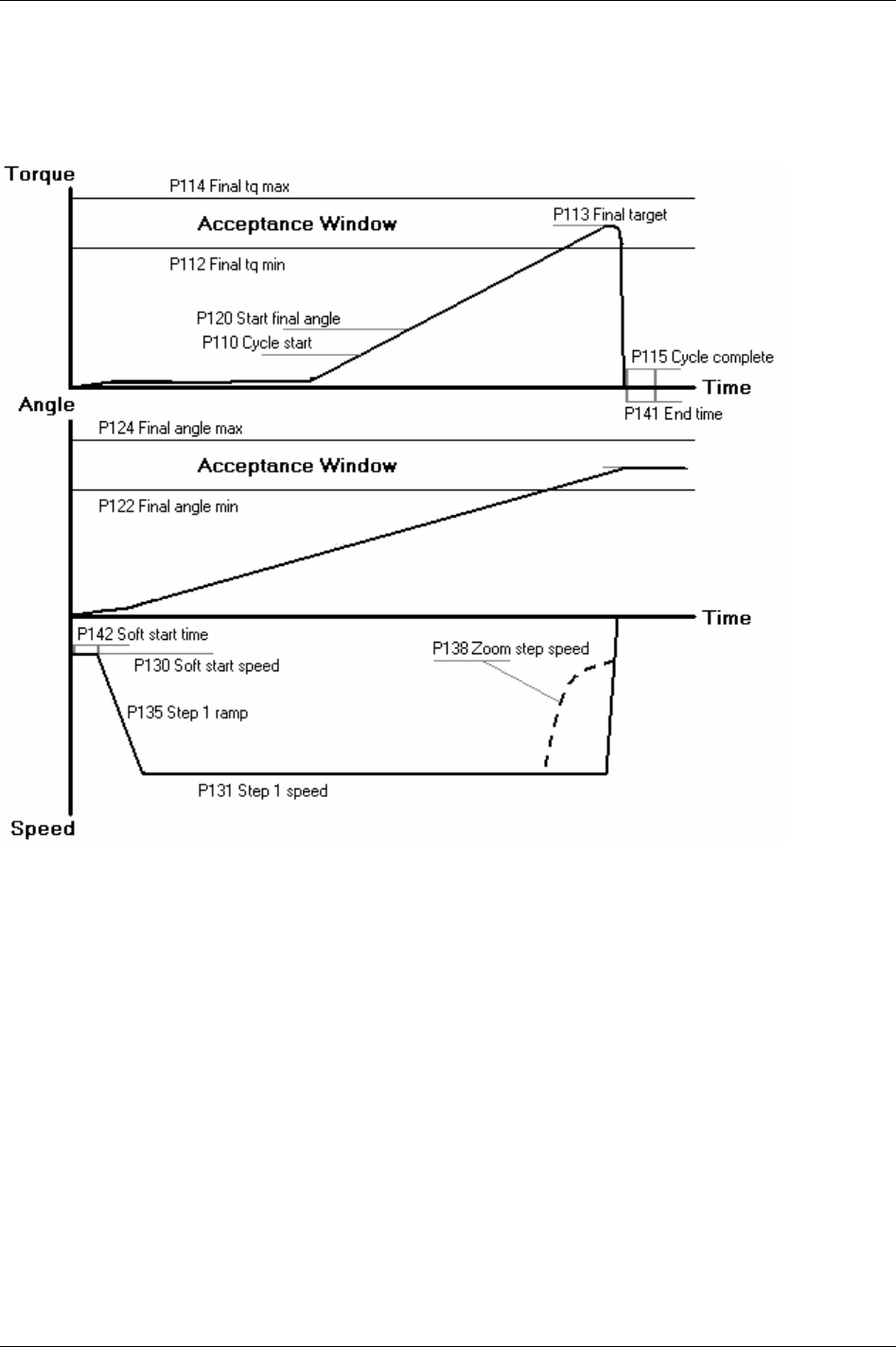

22.2 Tq con/ang mon......................................................................................................248

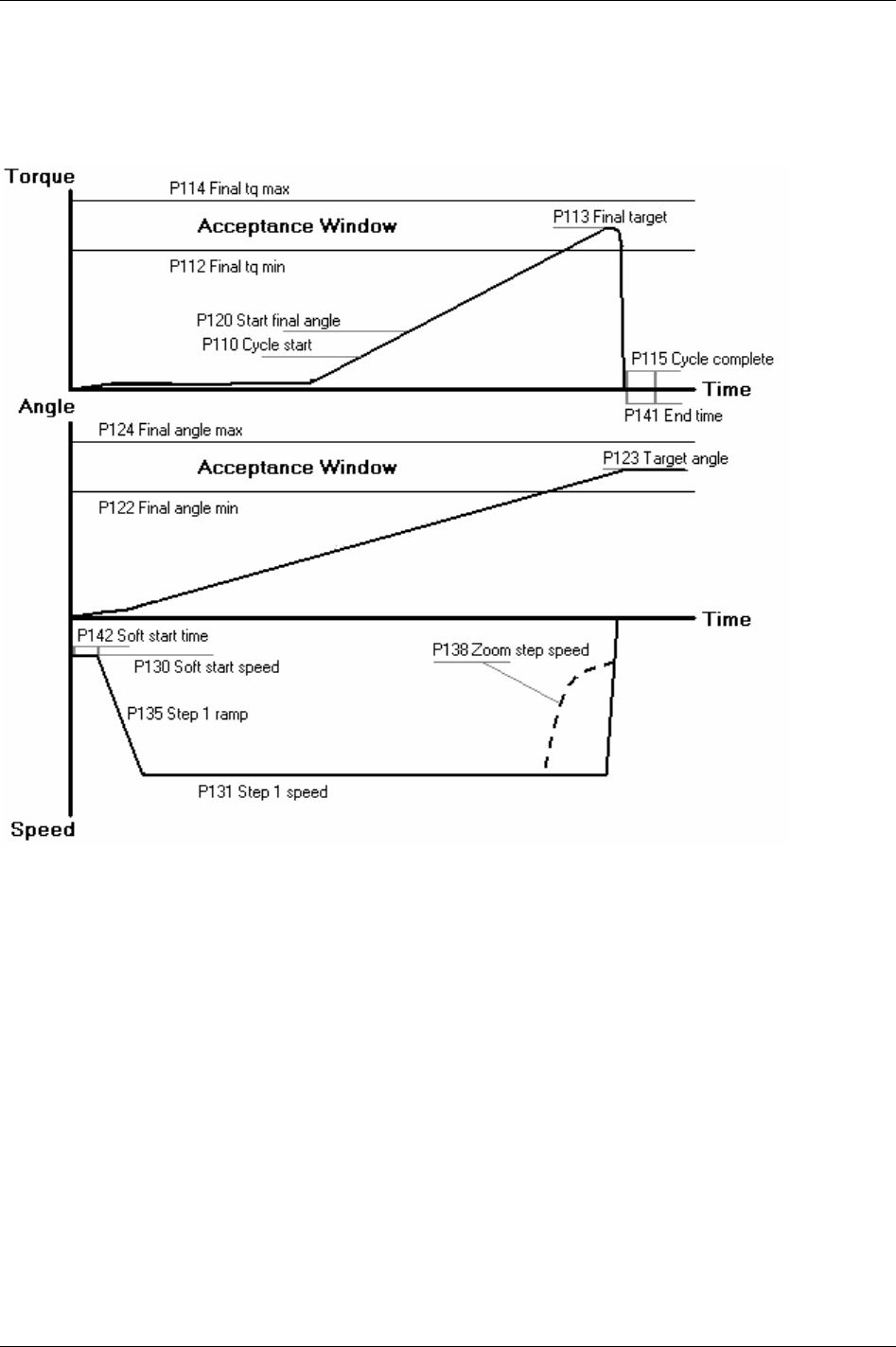

22.2.1 One stage ..............................................................................................................248

22.2.2 Two stage..............................................................................................................249

22.2.3 Quick step..............................................................................................................250

22.2.4 Ergo ramp..............................................................................................................251

22.3 Tq con/ang con (AND)............................................................................................252

22.3.1 One stage ..............................................................................................................252

22.3.2 Two stage..............................................................................................................253

22.3.3 Quick step..............................................................................................................254

22.3.4 Ergo ramp..............................................................................................................255

22.4 Tq con/ang con (OR) ..............................................................................................256

22.4.1 One stage ..............................................................................................................256

22.4.2 Two stage..............................................................................................................257

22.4.3 Quick step..............................................................................................................258

22.4.4 Ergo ramp..............................................................................................................259

22.5 Ang con/tq mon.......................................................................................................260

22.5.1 One stage ..............................................................................................................260

22.5.2 Two stage..............................................................................................................261

22.5.3 Quick step..............................................................................................................262

22.5.4 Ergo ramp..............................................................................................................263

22.6 Reverse ang ...........................................................................................................264

22.7 Rotate spindle forward............................................................................................265

22.8 Rotate spindle reverse............................................................................................266

22.9 DS con....................................................................................................................267

22.9.1 One stage ..............................................................................................................267

22.9.2 Two stage..............................................................................................................267

22.9.3 Quick step..............................................................................................................268

22.9.4 Ergo ramp..............................................................................................................269

23 Digital inputs and outputs................................................................................271

23.1 Digital inputs ...........................................................................................................271

23.2 Digital outputs (relays)............................................................................................274

24 Parameter list ....................................................................................................279

24.1 Pset.........................................................................................................................279

24.1.1 Programming.........................................................................................................279

24.1.2 Programming +......................................................................................................282

Contents

8 (330) 9836 3123 01

24.1.3 Pset setup............................................................................................................. 285

24.1.4 Statistic programming........................................................................................... 285

24.2 Multistage...............................................................................................................288

24.2.1 Setup..................................................................................................................... 288

24.2.2 Multistage programming ....................................................................................... 288

24.3 Job..........................................................................................................................290

24.3.1 Setup..................................................................................................................... 290

24.3.2 Programming ........................................................................................................ 291

24.4 Controller................................................................................................................294

24.4.1 Information............................................................................................................ 294

24.4.2 Configuration ........................................................................................................ 294

24.4.3 Network................................................................................................................. 295

24.4.4 COM ports............................................................................................................. 297

24.4.5 Display .................................................................................................................. 297

24.4.6 Memory................................................................................................................. 298

24.4.7 Accessibility .......................................................................................................... 298

24.5 Tool ........................................................................................................................299

24.5.1 Information............................................................................................................ 299

24.5.2 Configuration ........................................................................................................ 300

24.5.3 Diagnostic ............................................................................................................. 302

24.5.4 Maintenance ......................................................................................................... 303

24.5.5 Buzzer configuration............................................................................................. 305

24.5.6 Sound configuration.............................................................................................. 305

24.6 Accessories............................................................................................................305

24.6.1 Digital I/O.............................................................................................................. 305

24.6.2 I/O bus .................................................................................................................. 306

24.6.3 Printer ................................................................................................................... 306

24.7 Sync .......................................................................................................................307

24.7.1 Programming ........................................................................................................ 307

24.8 Identifier..................................................................................................................307

24.8.1 Identifier setup ...................................................................................................... 307

24.8.2 Card reader........................................................................................................... 308

24.9 Field bus.................................................................................................................308

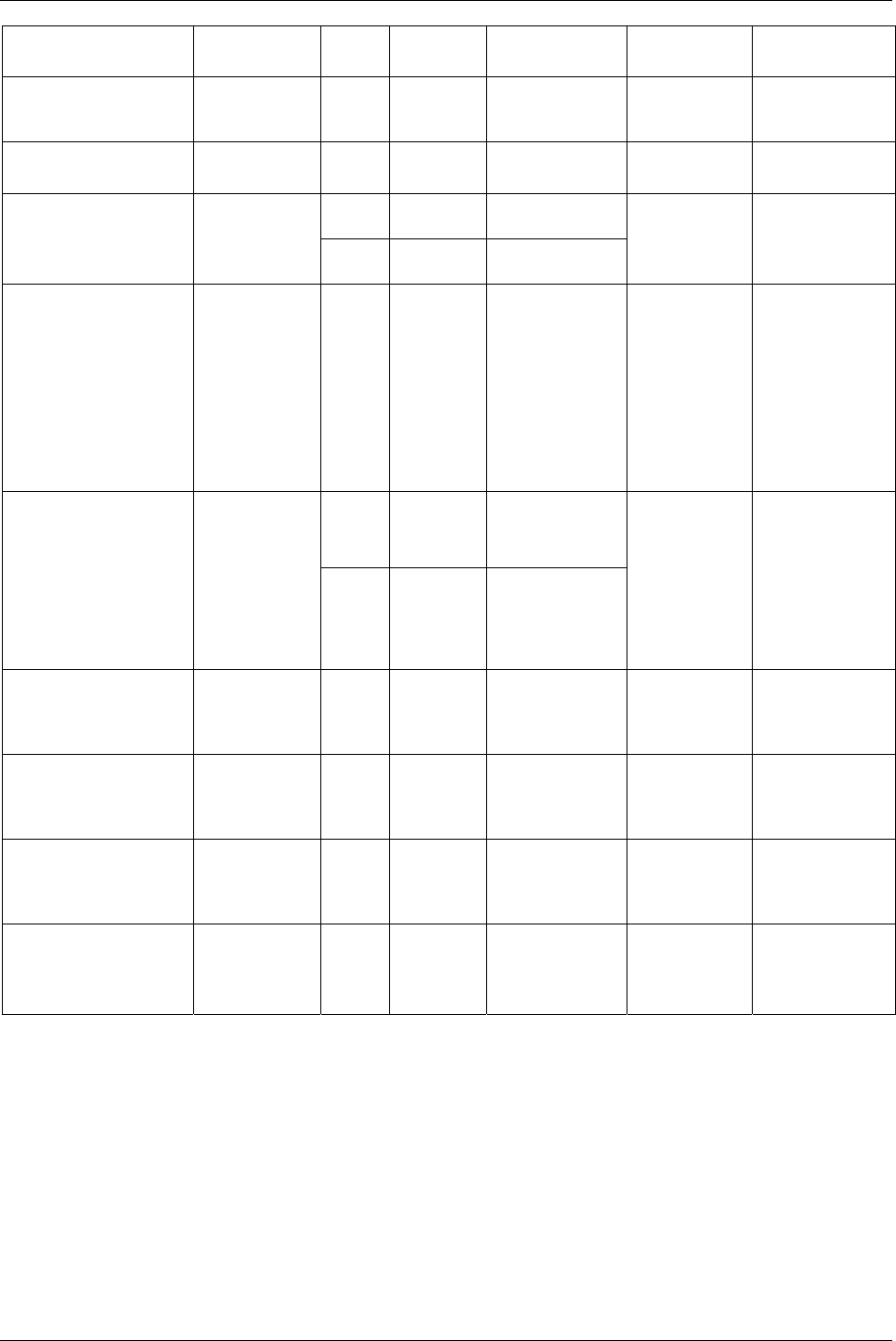

25 Event codes.......................................................................................................311

25.1 Event groups ..........................................................................................................312

25.2 Abbreviations..........................................................................................................313

25.3 Event code list........................................................................................................313

25.3.1 Rundown failures.................................................................................................. 313

25.3.2 Event related errors .............................................................................................. 313

25.3.3 User input events.................................................................................................. 316

25.3.4 Statistical events................................................................................................... 317

25.3.5 Communication events ......................................................................................... 319

25.3.6 Hardware events (tools)........................................................................................ 321

25.3.7 Hardware events (DC3000/MC3000) ................................................................... 322

25.3.8 Hardware events................................................................................................... 323

25.3.9 Software events.................................................................................................... 323

25.3.10 Events MMI3000................................................................................................... 324

25.4 Sub information for event codes.............................................................................324

Contents

9836 3123 01 9 (330)

25.4.1 E102, E103, E107, E117, E131, E133, E137, E139, E140, E146, E147, E149,

E152, E206, E501, E511 and E514......................................................................................325

25.4.2 E112 ......................................................................................................................325

25.4.3 E126 ......................................................................................................................326

25.4.4 E150 ......................................................................................................................327

25.4.5 E156 ......................................................................................................................327

25.4.6 E166 ......................................................................................................................327

25.4.7 E233, E234 and E237 ...........................................................................................328

25.4.8 E236 ......................................................................................................................328

25.4.9 E403, E404, E405 and E406.................................................................................328

25.4.10 E710 ......................................................................................................................329

General safety instructions

1 General safety instructions

Ensure that you read and understand all instructions. Failure to follow all the instructions listed below may

result in electric shock, fire and/or serious personal injury.

All locally legislated safety regulations with regard to installation, operation and maintenance must be

adhered to at all times. Refer installation and servicing to qualified personnel only.

1.1 Work area

Keep the work area clear and well illuminated. Cluttered benches and unlit areas invite accidents.

Do not operate power tools in explosive atmospheres, such as in the presence of flammable liquids, gases, or

dust. Power tools create sparks, which may ignite dust or fumes.

Keep bystanders, children, and visitors at a safe distance while operating a power tool. Distractions may

cause you to lose control.

1.2 Electrical safety

Earthed tools must be plugged into a socket that has been properly installed and earthed according to

appropriate regulations. Never remove the earth pin or modify the plug in any way. Do not use any adapter

plugs. Check with a qualified electrician if you are in any doubt as to whether the outlet is properly earthed.

Should the tools suffer electronic malfunction or breakdown, the earth provides a low resistance path to

carry electricity away from the user. Applicable only to Class I (earthed) tools.

This apparatus must be earthed.

A Power Focus (PF) cannot be fitted with a galvanic isolated voltage as this would inhibit the function of

the Ground Fault Interrupter (GFI). The test button on the GFI also activates the GFI in instances where a

PF is equipped with an isolated transformer. Test the earth fault protector by pressing the test button located

on the rear panel of the PF.

Test the earth protector every month by pressing the test button. Should the earth fault protector disconnect

the system, be sure to find the primary reason before you resume operation.

Avoid physical contact with grounded surfaces such as pipes, radiators, ovens and refrigerators. There is an

increased risk of electric shock if your body is grounded.

Do not expose power tools to rain or wet conditions. Water entering a power tool will increase the risk of

electric shock. This instruction does not apply to tools classified as watertight or splash proof.

For minimum electrical interference, locate the controller as far as possible from sources of electrical noise,

e.g. arc welding equipment etc.

Do not abuse the power lead. Never use the power lead to carry the tool or to pull the plug from a socket.

Keep the power lead away from heat, oil, sharp edges or moving parts. Replace damaged leads immediately.

Damaged leads increase the risk of electric shock.

9836 3123 01 11 (330)

General safety instructions

1.3 Personal safety

Stay alert, watch what you are doing and use common sense when operating a power tool. Do not use a tool

while tired or under the influence of drugs, alcohol, or medication. A momentary lapse in concentration

whilst operating power tools may result in serious personal injury.

Dress properly. Do not wear loose clothing or jewellery. Tie long hair back. Keep your hair, clothing, and

gloves away from moving parts. Loose clothes, jewellery, or long hair can become caught in moving parts.

Avoid accidental starting. Ensure switches are in the off position before plugging in. Carrying a tool with

your finger on the switch or plugging in a tool that has the switch set to “on” is inviting an accident.

Remove adjusting keys or switches before turning the tool on. A wrench or a key that is left attached to a

rotating part of the tool could lead to personal injury.

Do not overreach. Keep proper footing and balance at all times. Proper footing and balance enables better

control of the tool in unexpected situations.

Use clamps or other practical means to secure and support the work piece to a stable platform. Holding the

work by hand or against your body is unstable and may lead to loss of control.

Do not force the tool. Use the correct Atlas Copco Tensor tool for your application. The correct tool will do

the Job better and more safely in a manner for which it was designed.

Do not use a tool if the switch does not work. Any tool that cannot be controlled by the switch is dangerous

and must be repaired.

Disconnect the plug from the power source before making any adjustments, changing accessories, or storing

the tool. Such preventive safety measures reduce the risk of the tool starting accidentally. The mains plug is

considered to be a disconnecting device. Disconnect the tool from the mains by removing the plug from the

socket in order to cut the power.

Store tools out of the reach of children and other untrained persons when not in use. Tools are dangerous in

the hands of untrained users.

Check for misalignment, obstruction of moving parts, damage, and any other condition that may affect tool

operation. If damaged, have the tool serviced before using. Poorly maintained tools cause many accidents.

Only use accessories that are recommended by the manufacturer for your model. Accessories that may be

suitable for one tool may become hazardous when used on another tool.

1.4 Service

Tools should only be serviced by qualified repair personnel. Service or maintenance performed by

unqualified personnel could expose users to serious personal injury.

When servicing a tool, only use original replacement parts. Use of unauthorised parts or failure to follow

maintenance instructions may lead to electric shock or personal injury.

There is a risk of explosion if batteries are incorrectly replaced. Replace only with the same

or equivalent type recommended by the equipment manufacturer. Discard used batteries in

accordance with the manufacturer's instructions.

12 (330) 9836 3123 01

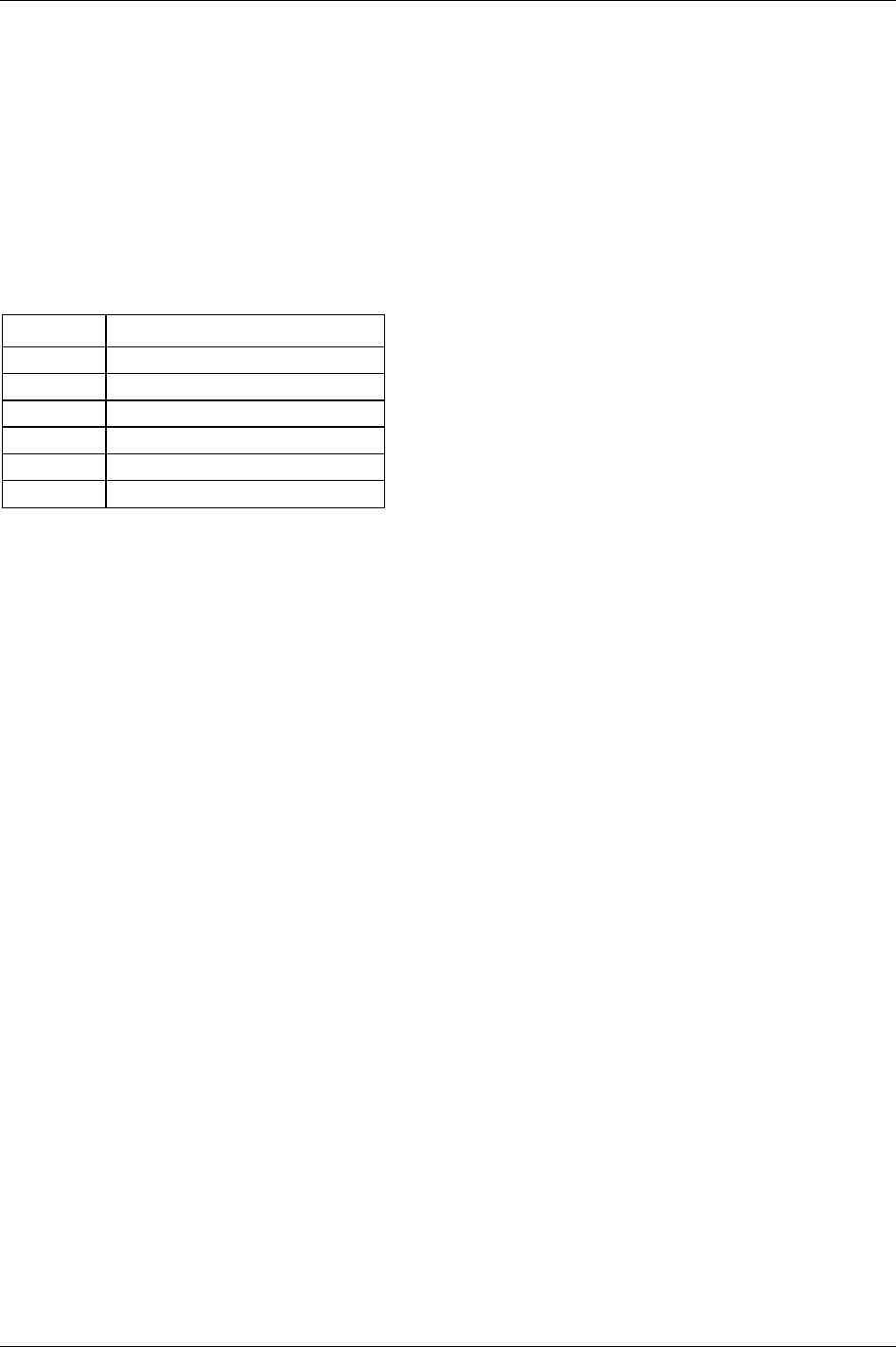

Abbreviations

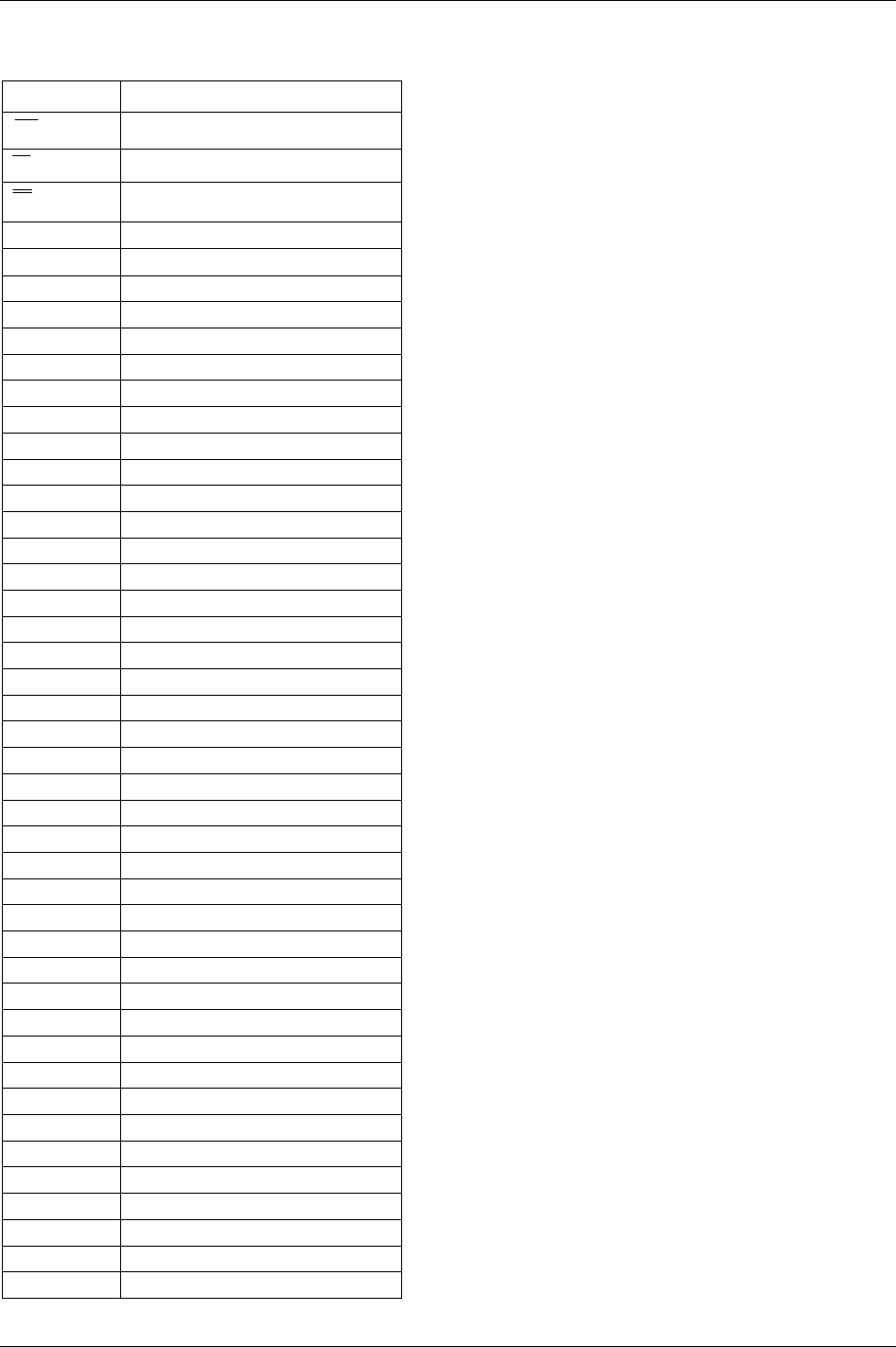

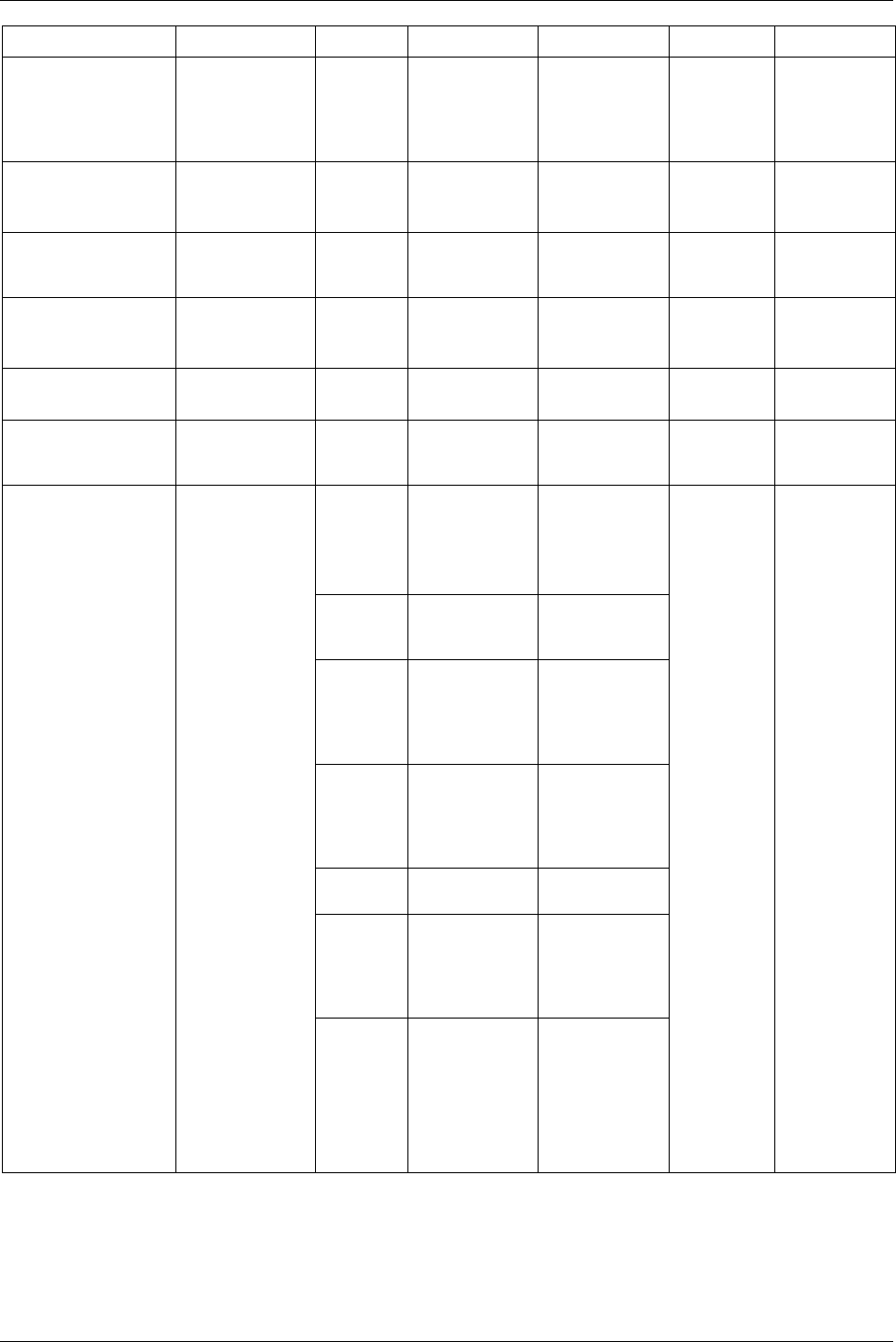

2 Abbreviations

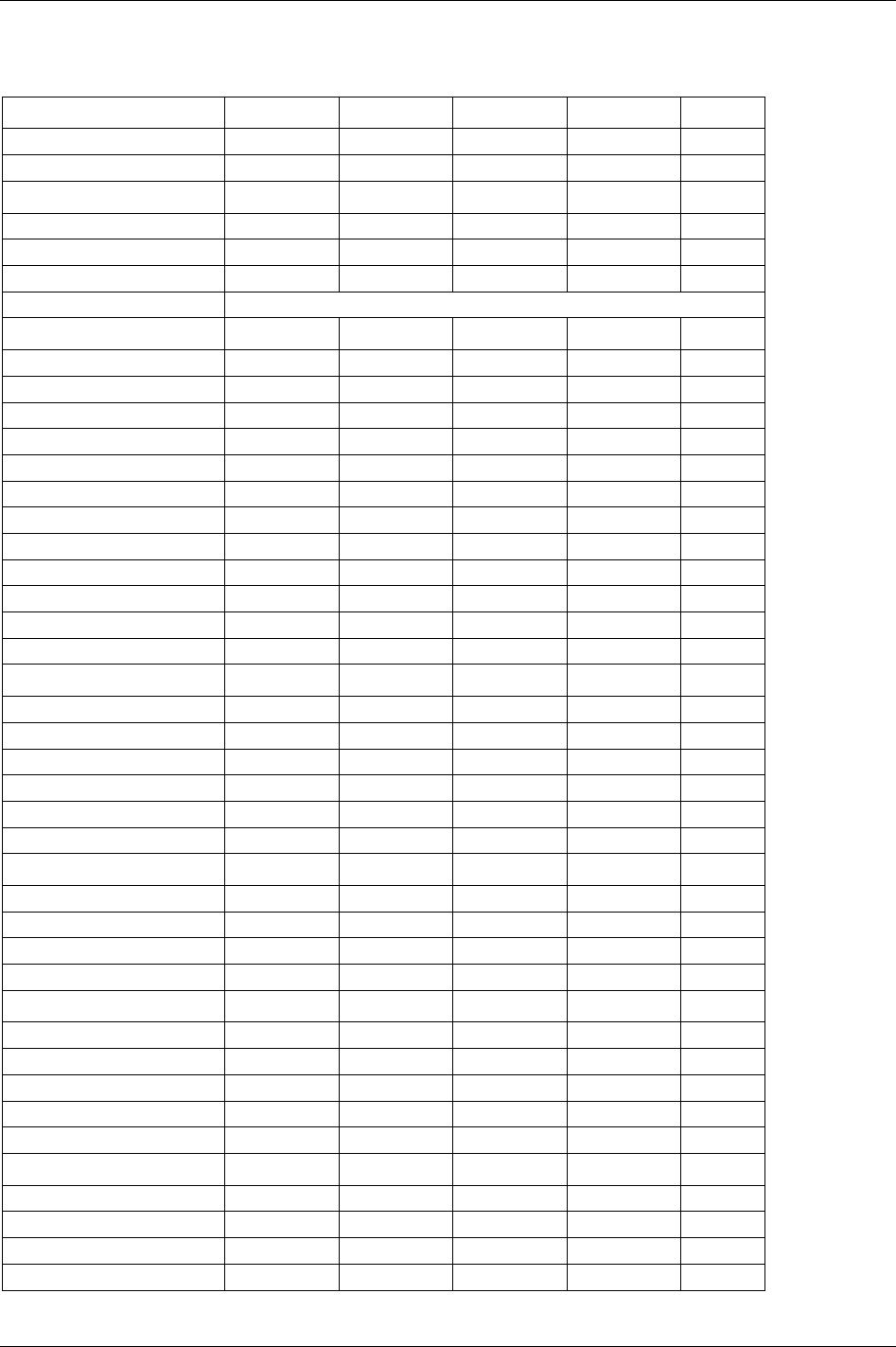

Abbreviation Description

R

The centre line

X

The mean

X

The mean of the average

<= => Arrow (button)

σ

Sigma (standard deviation)

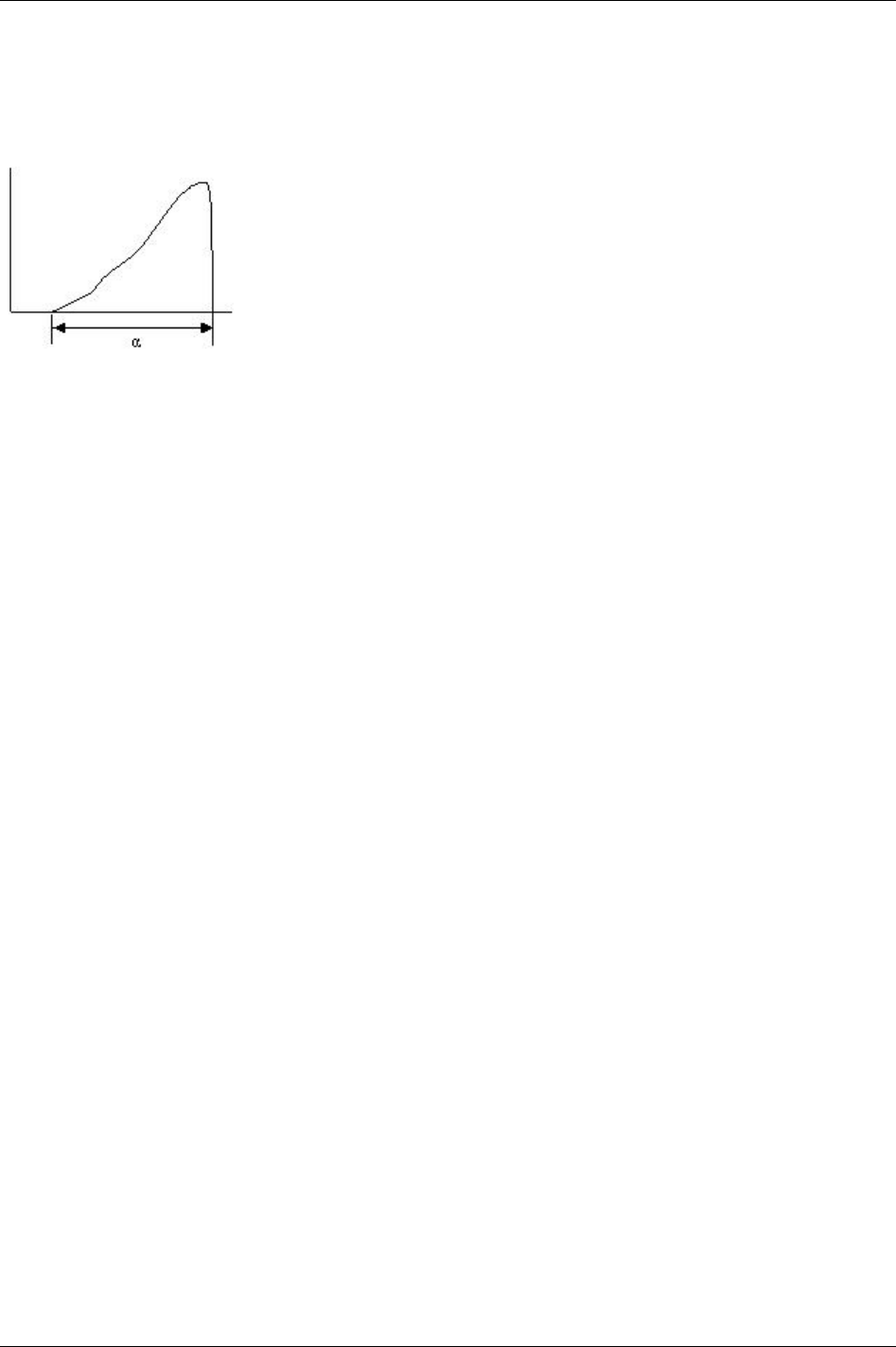

α Alpha (often a symbol for angle)

µ Mu (the values of the mean)

A Ampere

AC Alternating current

ACK Acknowledged

Admin Administration

Ang con Angle control

Ang mon Angle monitoring

ASL Atlas Service Literature

CAN Controller area network

CC Control card

CCW Counter-clockwise

CD Compact disc

Ch Channel

CL Clear (button)

Config Configuration

CW Clockwise

DC Direct Current

Deg Degrees

DigIn Digital input

DigOut Digital output (relay)

DSP Digital signal processor

ft.lb Foot pound

GFI Ground Fault Interrupter

HW Hardware

Hz Hertz (unit of frequency)

I/O Input/output

ID Identification

in.lb Inches pound

IR Infra red

kpm Kilo Pound meter

LCD Liquid Crystal Display

LED Light Emitting Diode

LCK Tool Locked

LCL Lower control Limit

MC Motor card

n Number (of values)

Nm Newton meter

No. Number

9836 3123 01 13 (330)

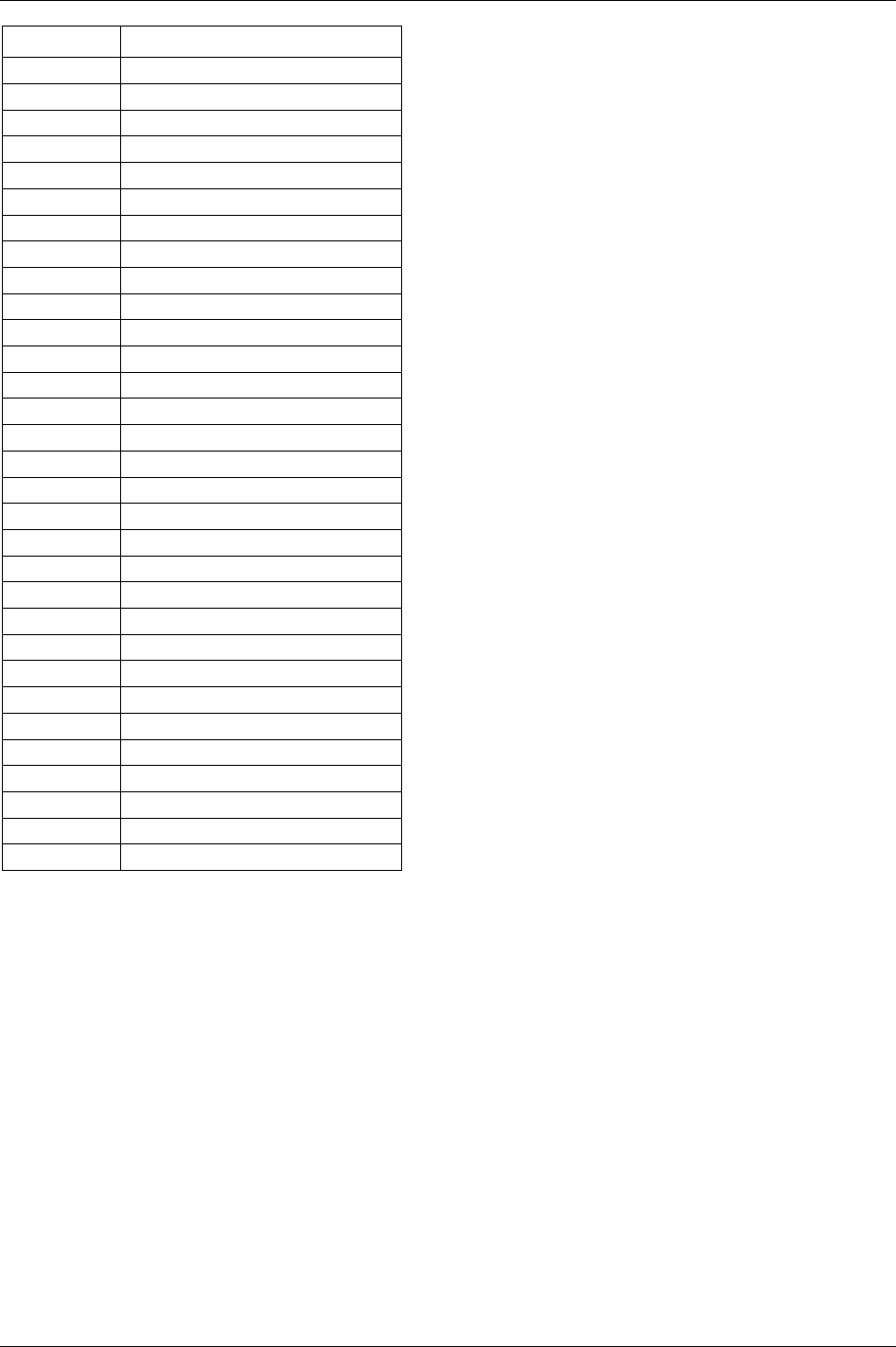

Abbreviations

14 (330) 9836 3123 01

Abbreviation Description

NOK Not approved (tightenings)

nxOK Number of approved (tightenings)

OK Approved (tightenings)

PF Power Focus

PFNR Power Focus not ready (PF not ready)

PLC Programmable logic controller

PROG Program (button)

Pset Parameter set

PVT Prevailing torque

R chart Range chart

RAM Random access memory

RAS Remote access server

RBU Rapid backup memory

rpm Revolutions per minute

RS232 Field bus, serial communication link

S4/S7/S9 Motor sizes in Tensor S tools

SPC Statistic parameter control

STAT Statistic (button)

SW Software

TNR Tool not ready

Tq Torque

Tq con Torque control

Tq mon Torque monitoring

TTPF Tools Talk Power Focus (SW)

UCL Upper control limit

UTL Upper tolerance limit

V Volt

VIN Vehicle Identification Number

X-bar The mean

X-bar-bar The average of means

z subgroup size, group size

Introduction to Power Focus

3 Introduction to Power Focus

Power Focus is the latest generation of control and monitoring systems for advanced tightening

technology. The system is designed for the modern assembly industry with high demands and stringent

quality and efficiency requirements, and offers full modularity through the combination of hardware and

software.

This manual handles the ToolsTalk PF but is also applicable for Power Focus Graph. When

programming on a Power Focus Graph display, we refer to corresponding section in

ToolsTalk PF.

3.1 PF 4000

The PF 4000 is a new generation of control systems suitable for Tensor S, ST, DS and ETX models.

Unlike its predecessor, the PF 3100, the PF 4000 is available in one model with two versions (Compact

and Graph) that can handle all torque levels. This favours your maintenance budget, since fewer backup

units are required.

Advanced control functions built into the Power Focus 4000 prevent the operator deviating from the

required process. When it receives assembly information, the programmed Job function automatically

selects the correct tightening sequence and parameters. When combined with barcode scanning for

component identification, the Job function offers traceable, zero-fault process control.

The controller is equipped with a USB connector for laptop access. It is located on the front of the unit for

maximum accessibility. Communication is also possible over serial RS232, Ethernet TCP/IP and various

field bus types.

The

PF 4000 Graph has an easy-to-read LCD colour

display. Statistical data is collected, analysed and

presented on the screen. Changes and trends in the

assembly process are indicated by diagnostics and

statistical alarms, such as SPC monitor charts and

capability (Cpk) alarms. Alpha-numeric keys allow on-

unit setup and easy checking of traces and statistics. PF

4000 Graph model has a very compact design, and a

standardized mounting plate ensures easy installation

at every workstation.

Completing the range, the

PF 4000 Compact has a basic

operator interface with six-button keyboard and LED

display. Pre-programmed using ToolsTalk PF and with

a PC as the interface, it offers the same functionality as

the Graph model.

See the

PF 4000 ASL (9836 3113 00) for

technical data, dimensions drawings,

connections and spare part list.

PF 4000 Compact

PF 4000 Graph

9836 3123 01 15 (330)

Introduction to Power Focus

16 (330) 9836 3123 01

3.1.1 Logic Configurator

Power Focus 4000 has an integrated Logic Configurator. This provides limited PLC functionality as an

integrated part of the controller, without additional hardware components. It is possible to configure

specific “PLC style” signal flow between the line or the fixture and the PF 4000. For more information see

chapter

Logic Configurator.

3.1.2 SynchroTork

Available in the Power Focus 4000, SynchroTork allows continuous synchronisation of up to six spindles

during final tightening. This will improve assembly quality in the joints where an even clamp force build-

up is critical, such as in U-bolt applications. The torque difference between the spindles is minimised

during the tightening stage by adjusting the individual speeds.

Synchronisation of the tools is assured through high-speed communication via the proprietary Power

Focus accessory bus. It should be noted that this function does not eliminate the need for a reaction bar, or

similar, in higher-torque applications.

3.1.3 Yield control

With the Power Focus 4000 is it possible to apply a Yield control strategy for the cases where to get the

most out of the fastener. While maintaining productivity, the operator can make the fixtured tool shut off

where each individual bolt yields, and not based on a firm torque or angle value.

See function description for Yield control in section

Control strategies.

Introduction to Power Focus

3.2 PF 3000/3100/3102

The PF 3000 is a control system for Atlas Copco Tensor S and DS tools. PF 3100 is a control system for

Atlas Copco Tensor ST tools (including functionality for S and DS tools).

PF 3102 is the control system

for Atlas Copco Tensor SL tools.

Tensor STB tools require a communication kit to work with Power Focus 3100. The kit

consists of a serial port adapter (access point), cable connector (supplies the serial port

adapter with power). For more information see chapter

Tensor tools .

Two different hardware units are available, Graph and Compact.

PF 3000 Compact offers minimum hardware expenditure and is easily stackable for multiple tool

configurations.

PF 3000 Graph models offer full stand-alone programming via an integrated keyboard and

large display located on the front panel of the unit. PF Graph can also be used as a terminal for one or

more PF Compact controllers.

PF 3000 Compact PF 3000 Graph

See the

PF 3000 ASL (9836 2156 01) for technical data, dimensions drawings, connections and

spare part list.

For PF 3102 controllers (SL tool drivers) only the Compact model is available.

3.3 ToolsTalk PF

ToolsTalk PF, a PC software package developed by Atlas Copco, offers easy and user-

friendly programming and real time monitoring of Power Focus units. ToolsTalk PF is

based on extensive experience and thorough analysis of existing manufacturing

industry needs.

ToolsTalk PF can be installed on standard PCs running Windows 2000 or XP and communicates with PF

via the serial port or via Ethernet TCP/IP. The real time monitoring functions include access to Cpk,

Traces, Operator monitor, etc.

9836 3123 01 17 (330)

Introduction to Power Focus

18 (330) 9836 3123 01

3.4 ToolsNet

ToolsNet is a part of the ATS (Assembly Tools Software) that works together with PF to complete the

tightening process.

ToolsNet works together with the controllers and the selected database, MS SQL Server or Oracle to

collect, store and visualise all historic tightening-related data. ToolsNet allows the user to get reports on

shifts, lines, individual vehicles or controllers for process improvement purposes. All the reports can

easily be exported to Excel.

ToolsNet can be used as a standalone product or together with the other modules from the ATS. ToolsNet

as a standalone product:

Tightening data collection and storage in a standard database management system (ORACLE or MS

SQL Server).

Web based reporting interface with standard reports, statistical information and graphs.

Process improvement through extensive statistical process control functionality.

Full traceability of every tightening done with a connected controller.

ToolsNet with Factory Overview:

All functionality as a standalone product.

Factory Overview integrated with ToolsNet - Right-click in Factory Overview to get web reports from

ToolsNet.

ToolsNet with Event Monitor:

All functionality as a standalone product.

Event history in ToolsNet reports.

3.5 Factory Overview

Factory Overview is a part of the ATS (Assembly Tools Software) that works together with PF to complete

the tightening process. Factory Overview is the portal to the tightening process. It visualises the whole

process and makes it possible to monitor all tightening applications from one central place.

Factory Overview can be used both as a standalone product and together with the other modules from the

ATS.

Factory Overview as standalone product:

Graphic overview of tightening status for each controller.

Displays inactive and disconnected controllers.

Direct program control from controller icons together with ToolsTalk PF.

Factory Overview with Event Monitor:

All functionality as a standalone product.

Graphical overview of event status for each controller.

Direct access to event list from controller icons.

Factory Overview with ToolsNet:

Full functionality as a standalone product.

Introduction to Power Focus

Right-click controller icons to view controller’s spindle reports with tightening results.

3.6 Event Monitor

Event Monitor is a part of the ATS (Assembly Tools Software) that work together with PF, ToolsNet,

Factory Overview and the API to complete the tightening process. Event Monitor offers real-time event

reporting from the controllers in a centralised and filtered format.

Event Monitor can be used both as a standalone product and together with the other modules from the ATS.

Event Monitor as a standalone product:

Centralised real-time notification of events, plus a list of the 1000 latest events from all connected units.

Ability to filter the information to suit the user.

Ticketing functionality with comments that can eliminate double work and allows the storing of

comments for future reference.

Web based Java application, easy access from any PC without installation overhead.

Event Monitor with Factory Overview:

Full functionality as a standalone product.

Event status shown for each controller icon as it is reported from the Event Monitor server to the Factory

Overview.

Right-click controller to get a snapshot of the recent events for that controller.

Event Monitor with ToolsNet:

Full functionality as a standalone product.

One database for tightening results and event history offers powerful reporting possibilities.

3.7 API

The API (Application Programmers Interface) is an interface to the Power Focus system that enables users

to access data in PF from custom-made applications.

The Power Focus API is a software library that serves as the interface between the custom application and

the PF. This means that it exports a number of objects and methods that the custom application can access

in order to manipulate the PF without needing to know the details on how the actual communication is

done. The Power Focus API handles all necessary communication between the PC on which the custom

application is installed, and the specific PF involved. The developer of the custom application needs only

to know which objects and function(s) to access, and in some cases how the returned data is formatted.

3.8 RBU

RBU (Rapid Backup Unit) unlocks a specified level of functionality and acts as a back-

up unit for the configuration of PF. There are different types of RBU; gold, silver,

bronze, X (for ETX tool functionality and DS (for Tensor DS tool functionality). The

RBU gold unlocks the full capacity and functionality of the Power Focus. Combine the

RBU giving the required functionality with the chosen hardware.

When a RBU is plugged in to an empty PF, the RBU configuration is transferred to the controller. This

allows the quick installation and replacement of controllers on the assembly line.

9836 3123 01 19 (330)

Introduction to Power Focus

3.9 Cell

A key word in the Power Focus concept is Cell. This means that one PF Graph can monitor and control up

to 19 PF Compact controllers (for a total of 20 units), which saves space and hardware cost. Each Cell can

be connected to the plant’s network via the built-in Ethernet port, and results from the units can be

monitored via the Atlas Copco ToolsNet server.

3.10 Job

By scanning the bar code on an object on the assembly line, Power Focus automatically selects the correct

parameters. This is one example of the

Job function. When all fastenings at one station have been

performed, the operator on the line is given an overall JOB OK (“Station OK”) signal. Several PF units

can be linked together via the network to create a Cell Job, issuing an OK signal when all units in one

Cell have completed their tightenings.

3.11 Sync

Up to 10 synchronised spindles can be setup within one Cell. This function is called Sync. A single start

signal starts all tools and a “Sync OK/NOK” is reported, as well as individual tool results. Step-by-step

configuration and setup makes it easy to modify and to re-use installed equipment.

3.12 Communication

Built-in communication provides efficient use of modern communication technologies with Atlas Copco

products. The Power Focus system can be built to suit the user’s needs, from a simple system offering

many functions, to a complete factory system. Using open standards like TCP/IP, it is possible to connect

and communicate with external systems and allows global communication.

Communicate with one PF at a time via the serial connection or with a complete network of PF units via

the built-in TCP/IP connection.

Power Focus communicates with a range of accessories via the internal I/O bus. PF units and accessories

20 (330) 9836 3123 01

Introduction to Power Focus

can be combined according to the customer’s requirements.

The Power Focus can be configured to communicate via the most common buses on the market; ProfiBus,

DeviceNet, InterBus, etc. Real time communication is done over a proprietary I/O bus for tool

synchronisation. Several outputs can be activated for communication with PLC’s and other external

equipment. Each PF has four relay contacts, four optic isolated inputs and a 24 V DC / 1 A internal power

supply for external control circuits. All inputs and outputs can be configured using the ToolsTalk PF

software. The number of digital inputs and outputs can be increased using an I/O Expander on the I/O

bus.

With Power Focus, full networking capability is available in the controller as an integrated function, in

relation to both hardware and software. ToolsNet is Windows NT compatible, which offers easy to use,

effective database and data collection functions, using standard databases like SQL, Oracle and Microsoft

Access. PF can be connected to a network for central programming and data collection using ToolsNet.

With the modular concept, the Power Focus is the building block used to create complete and cost

efficient solutions that satisfy the various needs of modern industrial assembly operations.

3.13 Accessories

The Power Focus concept features a number of accessories that simplify the guidance and follow-up of

performed tightenings. The accessory functions can be set up using ToolsTalk PF or a PF Graph unit.

The benefit of using serial bus-based accessories (

I/O bus) is that they can be connected in series, from

accessory to accessory rather than hard wiring each accessory to the Power Focus. This arrangement increases

flexibility and affords quick installation.

Power Focus uses 24 V DC, 1 A to power the bus, which is also used to power external I/Os. If more current

is needed, the bus must be powered externally. Every device has a 24 V DC input for this purpose.

The

I/O Expander enables the connection of several inputs and relays when more

than those built-in are required. There are 8 inputs and 8 relays with the same

functionality as the four built-in I/Os. Each input and relay can be configured

individually.

The

Socket Selector is a socket tray with LED’s that can be used to guide the user

through a Job sequence. When using more than one Pset it is very convenient to

use a selector. When a socket is lifted, the corresponding Pset will be selected.

There are two different types of Socket Selectors, selector 4 and selector 8, the

only difference being that selector 4 has four sockets and selector 8 has eight

sockets. The Socket Selector is also communicating on the I/O bus.

The

RE-Alarm gives status information to users using lights and/or audible signals.

The RE-Alarm is connected to the Power Focus on the I/O bus. The RE- alarm is

configured in the Power Focus and it is possible to configure the information.

9836 3123 01 21 (330)

Introduction to Power Focus

The Operator Panel is an external device for the PF. It is a general purpose lamp- and

switchbox, replacing the customer specials that are made today. The Operator Panel

communicates directly with Power Focus and the device configuration is made in ToolsTalk

PF.

See the

Operator Panel user guide (9836 2456 01) for more information.

The StackLight is a flexible light and switch device for Power Focus, PulsorFocus,

PowerMacs and Tensor DS/DL Advanced tightening controllers.

See the

StackLight user guide (9836 2642 01) for more information.

The

Tensor Tracker Arm SL is the latest generation of intelligent torque

reaction arms that add new features to screwdriver technology. In

conjunction with

PF 3102 controller and monitoring system for advanced

tightening technology it represents a new step in productivity and quality

assurance.

See the Tensor Tracker SL user guide (9836 2466 01) for more information.

22 (330) 9836 3123 01

Introduction to Power Focus

3.14 Nutrunners

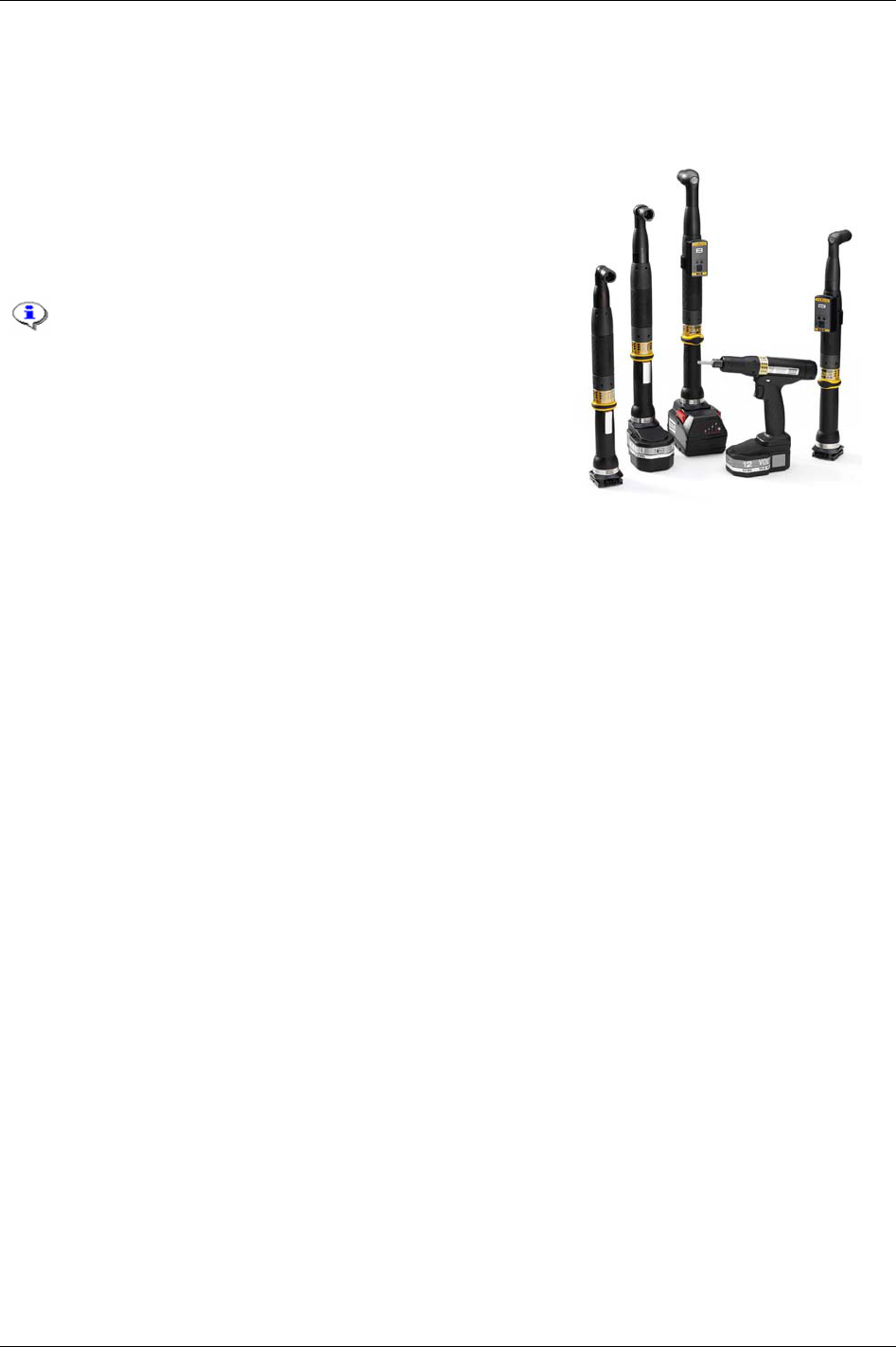

Atlas Copco’s Tensor STB heralds a new generation of transducerised nutrunners in the Tensor family.

STB tools communicate with the

PF 4000 and PF 3100 tightening controller systems through wireless

digital communication, built on IRC (Industrial Radio Communication) technique.

Tensor ST nutrunners communicate with PF 3100 controllers through digital communication, allowing

new tool features and greater flexibility due to not so many wires and leads. Compared with a Tensor S

tool, it is also lighter with improved accessibility.

Atlas Copco’s

Tensor SL is a range of low torque transducerised tools based on Tensor ST technology. SL

tools communicate with the SL driver,

PF 3102, digitally. The controller is used with low voltage SL

tools.

Atlas Copco’s

Tensor S, running on PF 3000/3100 controllers, are available in four different

configurations; fixture, pistol grip, straight and angle application. The three motor types are designated

S4, S7 and S9, indicating different motor outputs and speeds. The tools can be combined in various

models to meet a variety of requirements within the industry. Fixtured applications can easily be installed

and integrated with standard Atlas Copco components.

The ultra-compact

ETX tool is designed for fixtured applications, optimised for extreme functionality,

durability and flexibility. Controlled by

PF 3100 and featuring a “smart” memory chip calibration and

service data. The ETX combines the same advanced control, monitoring options and high productivity as

the Tensor S/ST range, with the bonus of a reduced space requirement and extended spindle durability.

Atlas Copco’s

Tensor DS tools, running on PF 3000/3100 controllers, have no transducer. Instead of

receiving an electrical signal from a strain gauge, the tool derives the torque from several relevant

parameters, such as voltage, speed, temperature and current. The DS tool is proven to achieve excellent

repeatability. However, the operating range is smaller than for a Tensor S tool, and the user might need to

adjust the torque measurement for each Pset and joint for greater accuracy.

An

Open end tool (or tube nut tool) is a Tensor S or ST tool equipped with an Open ended head. It is used

to tighten nuts on tubes and similar applications.

For more tool related information, see chapter

Tensor tools.

3.15 ACTA 3000

An ACTA 3000 performs a full range of functions, from simple torque checks

to advanced graphic tightening analysis. It comes in different models and it is

easy to upgrade.

ACTA 3000 measures torque, angle and pulses and facilitates the conduction

of statistical analyses of the tightening process. An ACTA 3000, together

with the ToolsTalk ACTA PC utility, is a complete SPC tool. Furthermore, it

has a reminder function to notify the user when calibration and maintenance

are due.

9836 3123 01 23 (330)

Getting started with ToolsTalk PF

4 Getting started with ToolsTalk PF

ToolsTalk PF is an application that acts as an interface between the user and the Power Focus. It is used

for programming and monitoring Power Focus from a PC.

With ToolsTalk PF installed, users can communicate with the Power Focus via the serial port (RS232) as

well as over the Ethernet.

Ethernet communication makes the management of Power Focus easy and efficient, since ToolsTalk PF

can be installed on a PC anywhere on the network.

ToolsTalk PF serves as an interface between the user and PF. With ToolsTalk PF, users can create and

edit instructions and settings for the controller. The settings needed to control the tightening process

performed by the Power Focus include; tightening strategies, control parameters, torque parameters,

angle parameters, speed and ramp parameters and time parameters.

The settings are transferred to Power Focus via an Ethernet connection or via the serial port. Process data

can be collected from the Power Focus and monitored in real-time. ToolsTalk PF makes management of

Power Focus easy and efficient, since the software can be installed on any PC on the network.

ToolsTalk PF is fully compatible with Microsoft Windows and supports widely accepted communication

protocols such as; Ethernet, TCP/IP and RS232 (serial communication).

ToolsTalk PF is easy to install:

Insert the installation CD.

Run

Setup.exe and follow the on-screen instructions.

Open ToolsTalk by selecting

Start -> Program -> Atlas Copco Tools AB ->

ToolsTalk Power Focus.

Select between a free trial version for 60 days (demo) or register by enter

installation and license number. Contact your locally Atlas Copco representative

for information how to get the license number.

The software can be registered on the Atlas Copco Tools web site at

http://www.atlascopco.com/tools/software.

9836 3123 01 25 (330)

Getting started with ToolsTalk PF

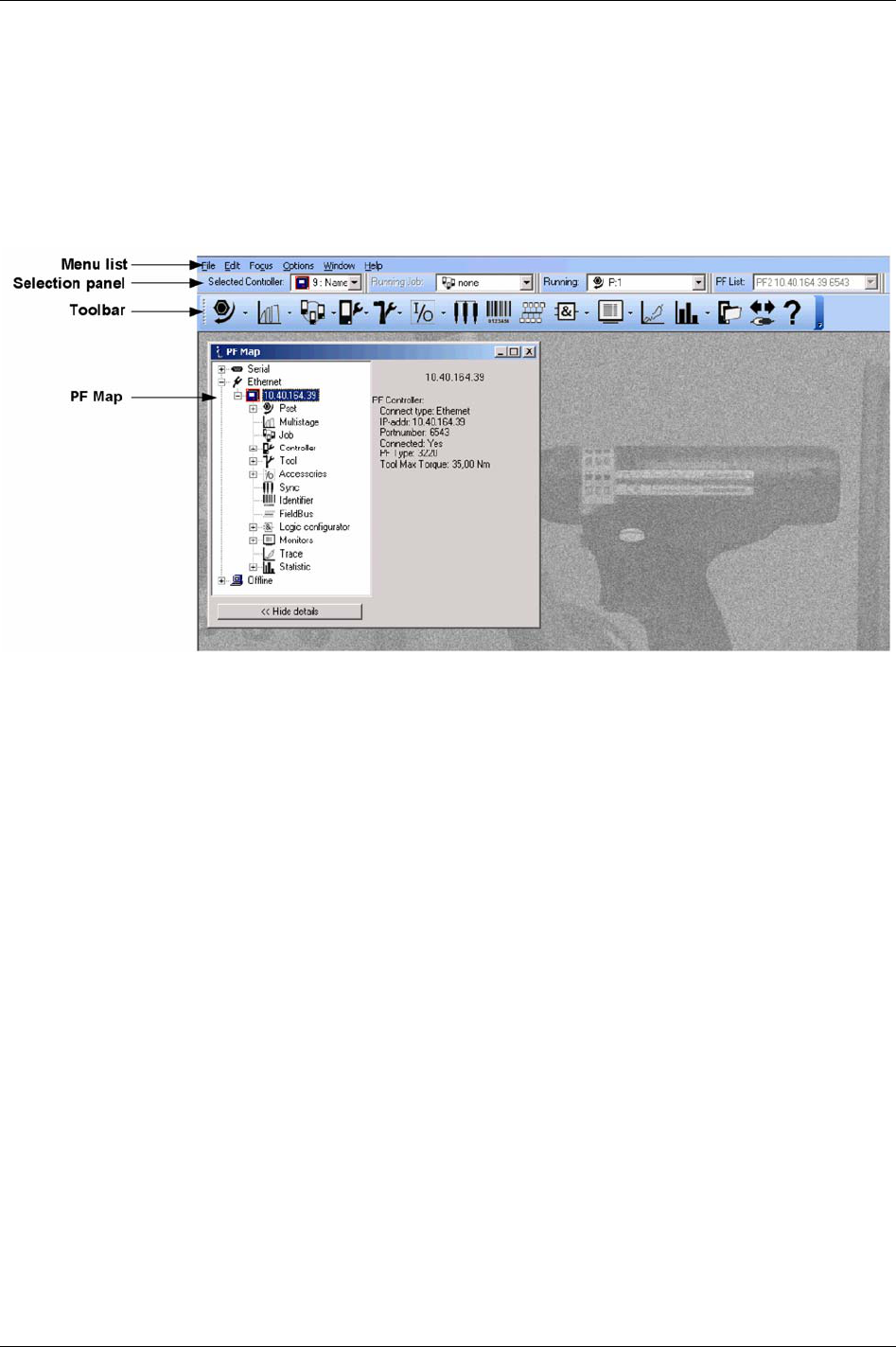

4.1 Overview

Almost every function in ToolsTalk PF has its own window. The figure below shows the ToolsTalk PF

interface with menu list, selection panel, toolbar and PF Map.

There are several ways to start a function in ToolsTalk PF. With almost all functions it is possible to use a

menu item in the menu list. Click on a symbol in the toolbar or double-click on the text in the PF Map.

26 (330) 9836 3123 01

Getting started with ToolsTalk PF

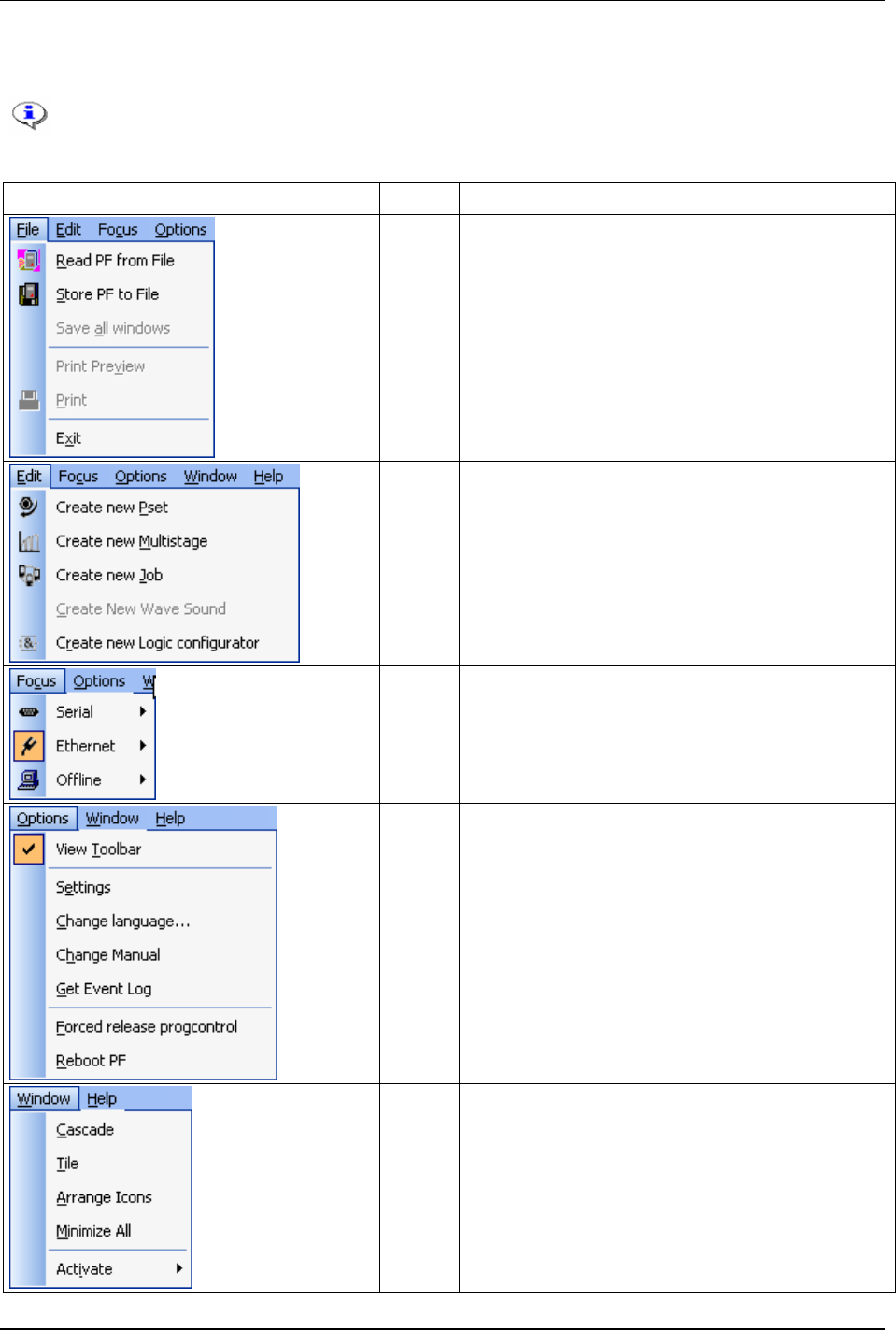

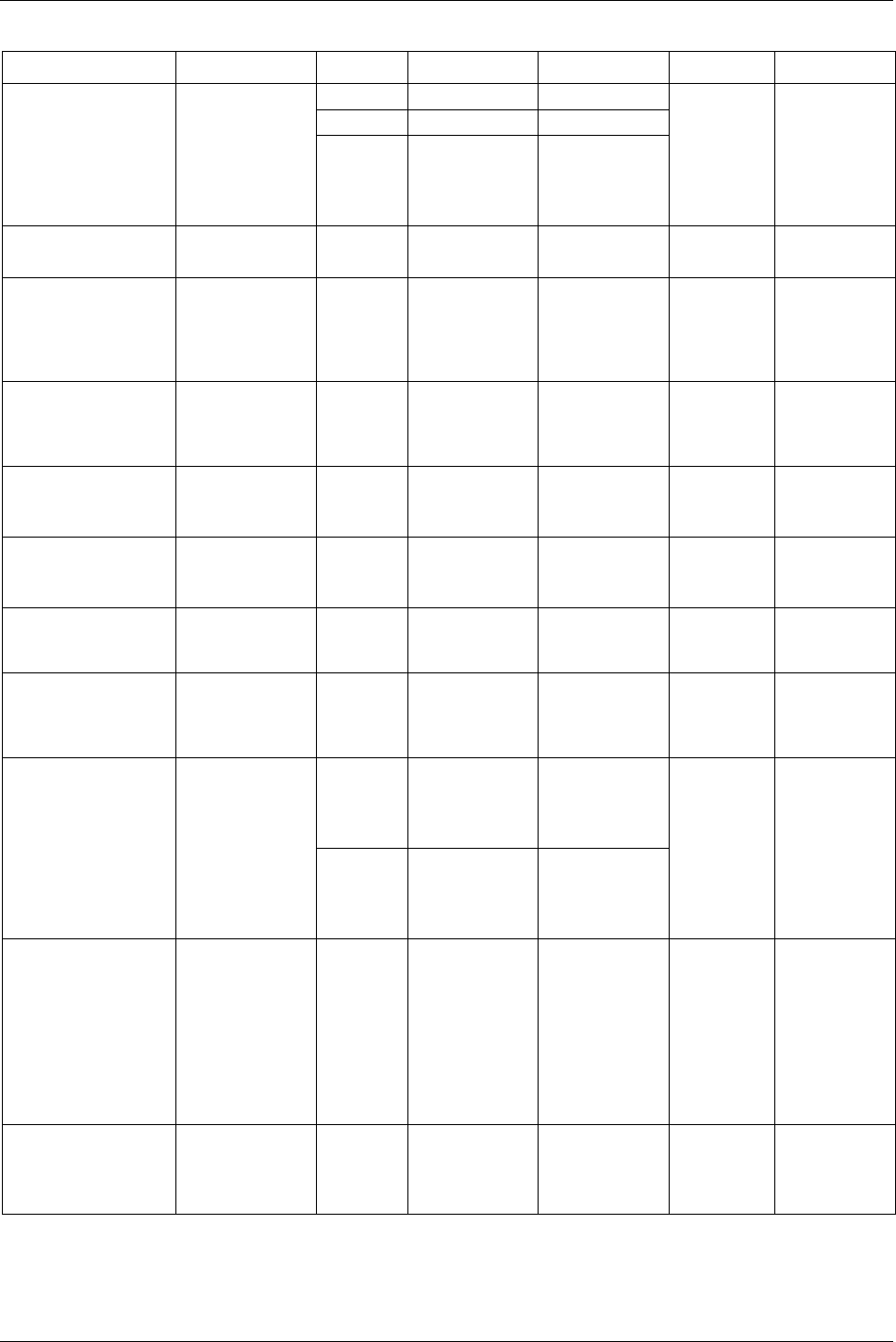

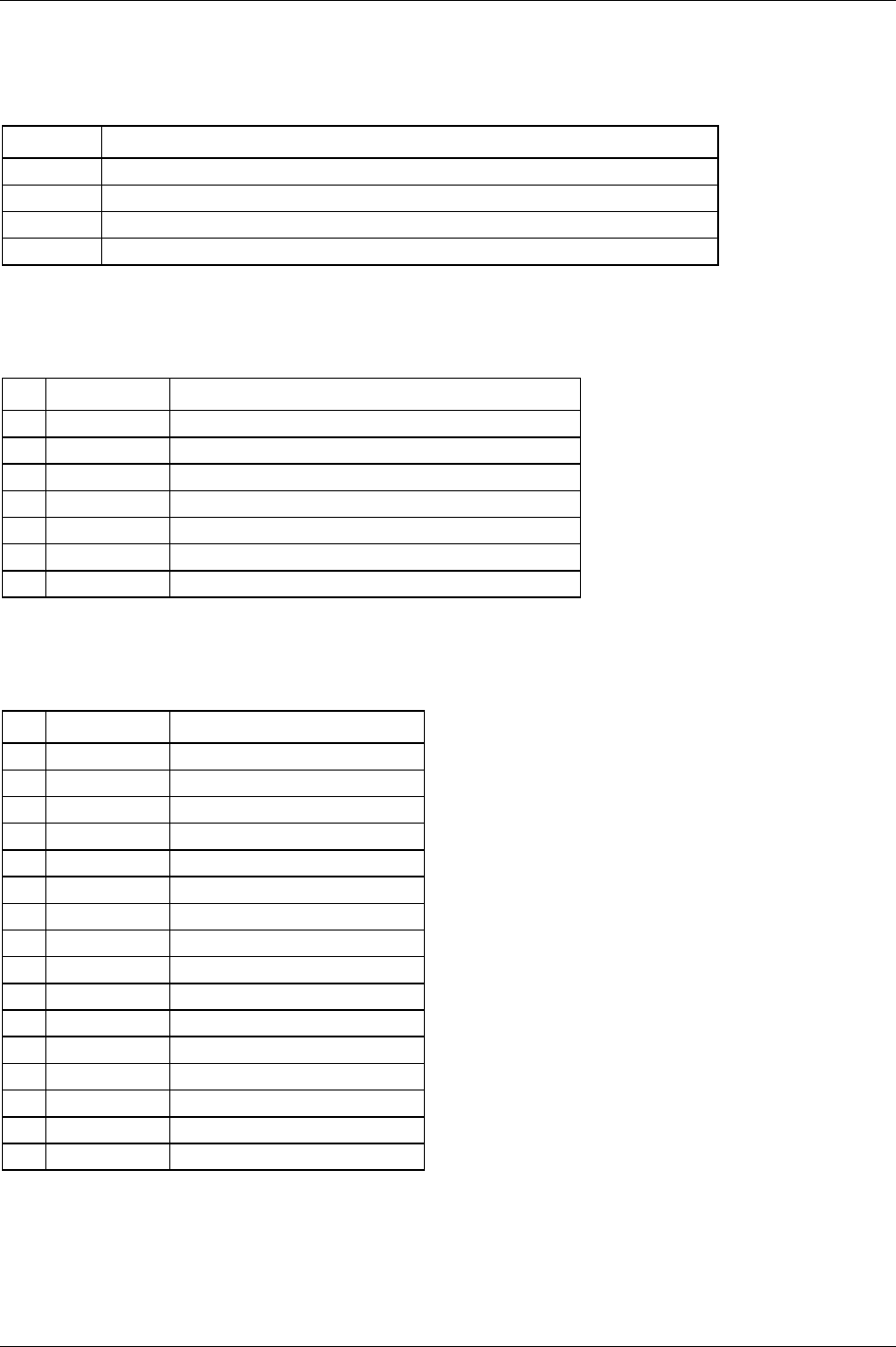

4.1.1 Menu list

An additional menu appears in the Menu list when opening a function window. For example,

when opening a Pset window, a new menu named “Pset” will appear in the menu list.

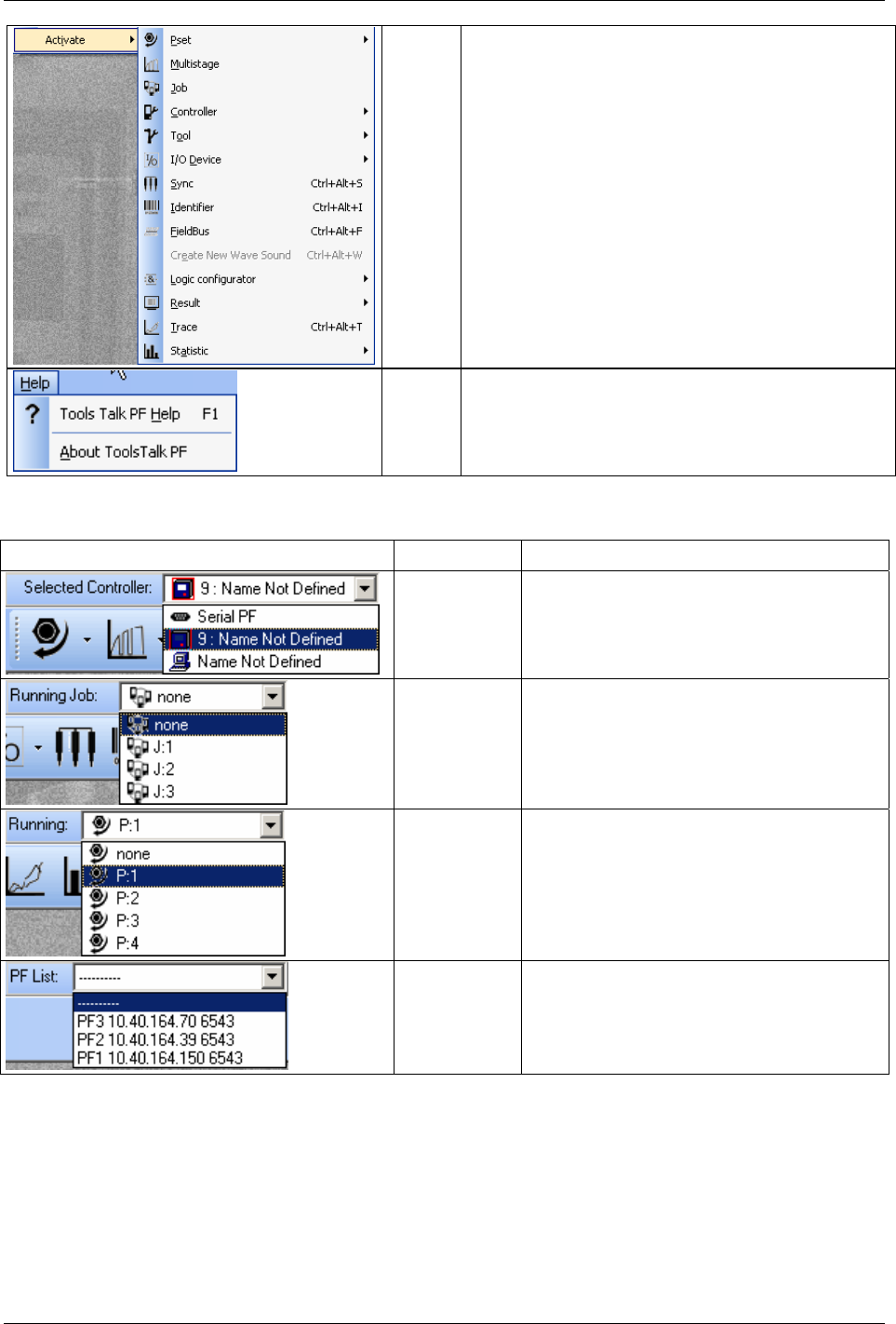

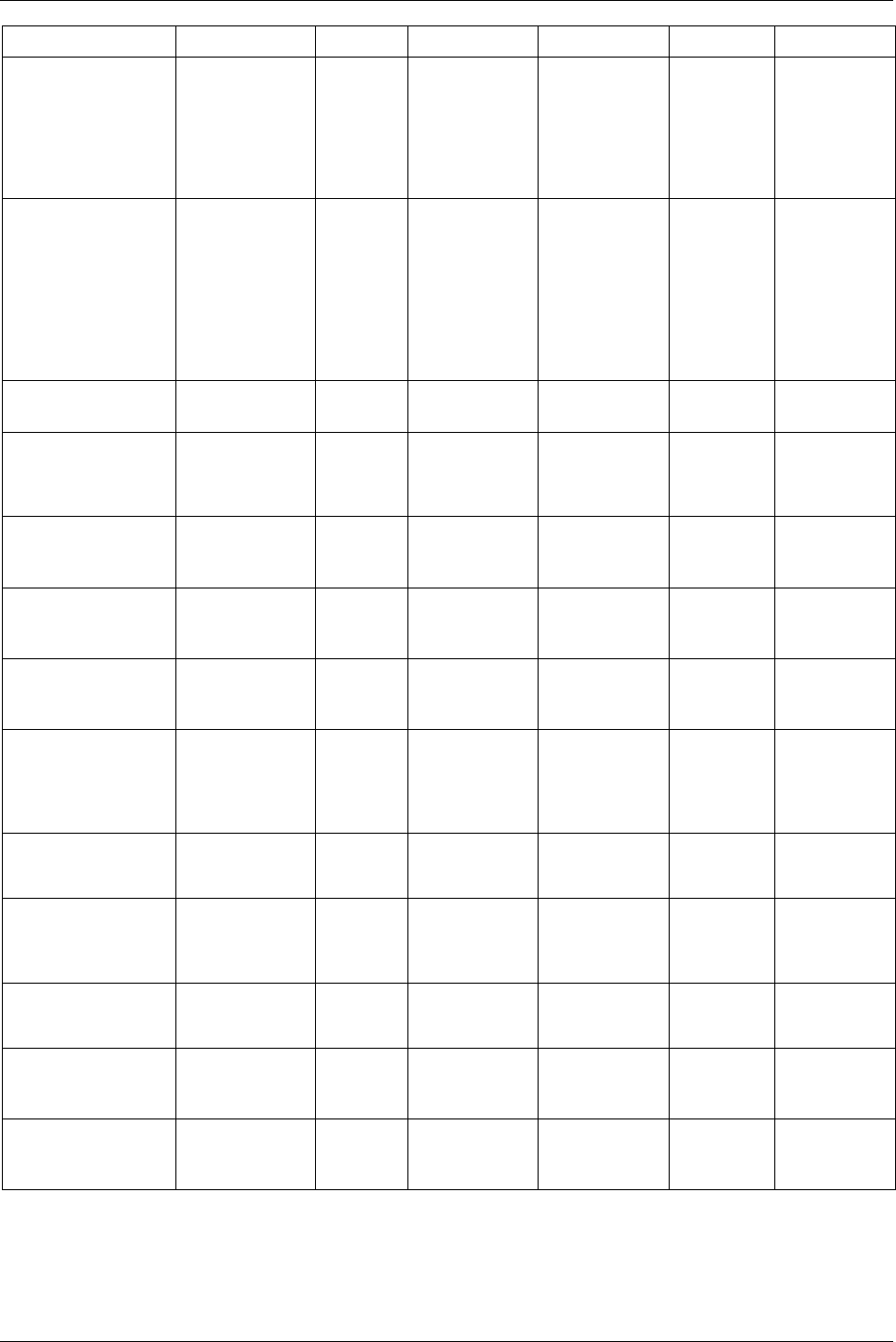

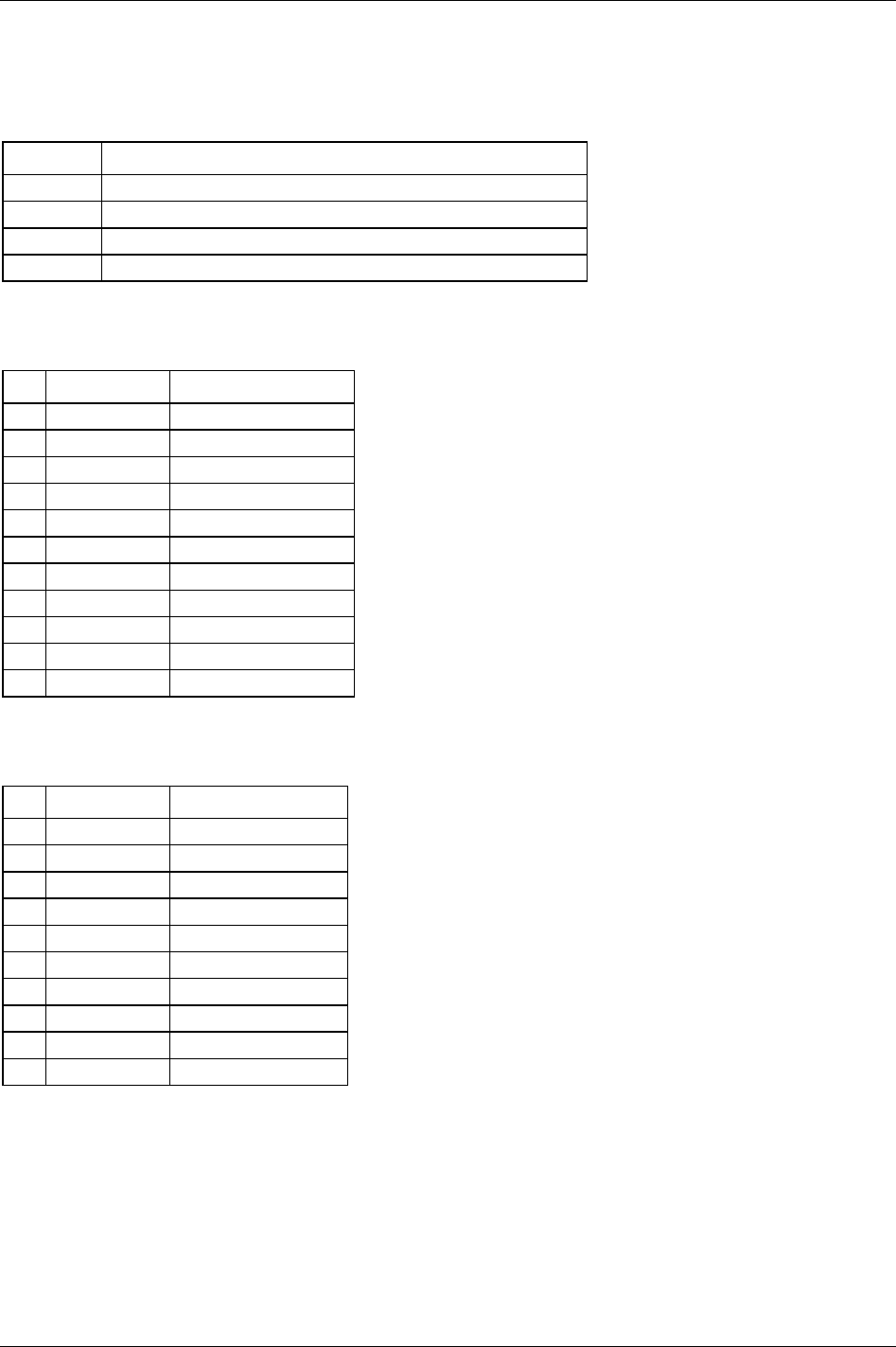

Illustration Name Description

File Read and store files, print and exit ToolsTalk PF from the File

menu.

Edit Create a new Pset, Multistage, Job Wave sound and Logic

Configurator from the Edit menu.

Focus The Focus menu specifies the type of connection to use when

connecting to the Power Focus. Choose between an Ethernet

connection and a Serial connection.

The Offline mode allows access to ToolsTalk PF without the

need for a connection to a Power Focus.

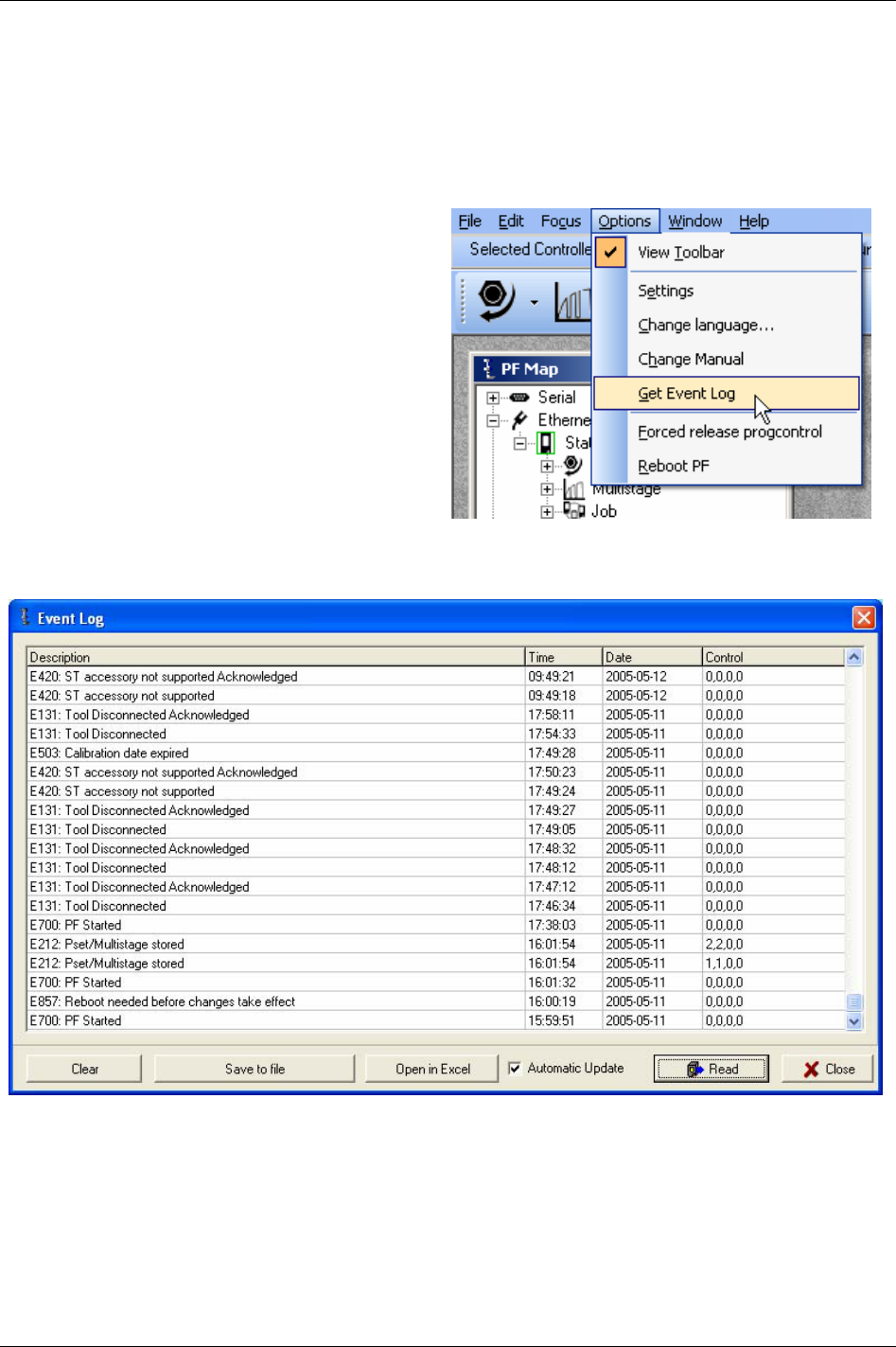

Options From the Options menu it is possible to select whether the

toolbar will be shown or not. The following functions are also

available; Settings, Change language, Change manual, Get

event log, Forced release progcontrol and Reboot PF.

Window Set properties for windows and icons from the Window menu

as well as enable and open the Activate menu.

9836 3123 01 27 (330)

Getting started with ToolsTalk PF

Activate The Activate menu contains a list of all available functions

(Pset, Job, Multistage, etc).

Help The Help menu allows access to the Power Focus help file.

About ToolsTalk PF brings up details about the version of the

ToolsTalk PF program in use.

4.1.2 Selection panel

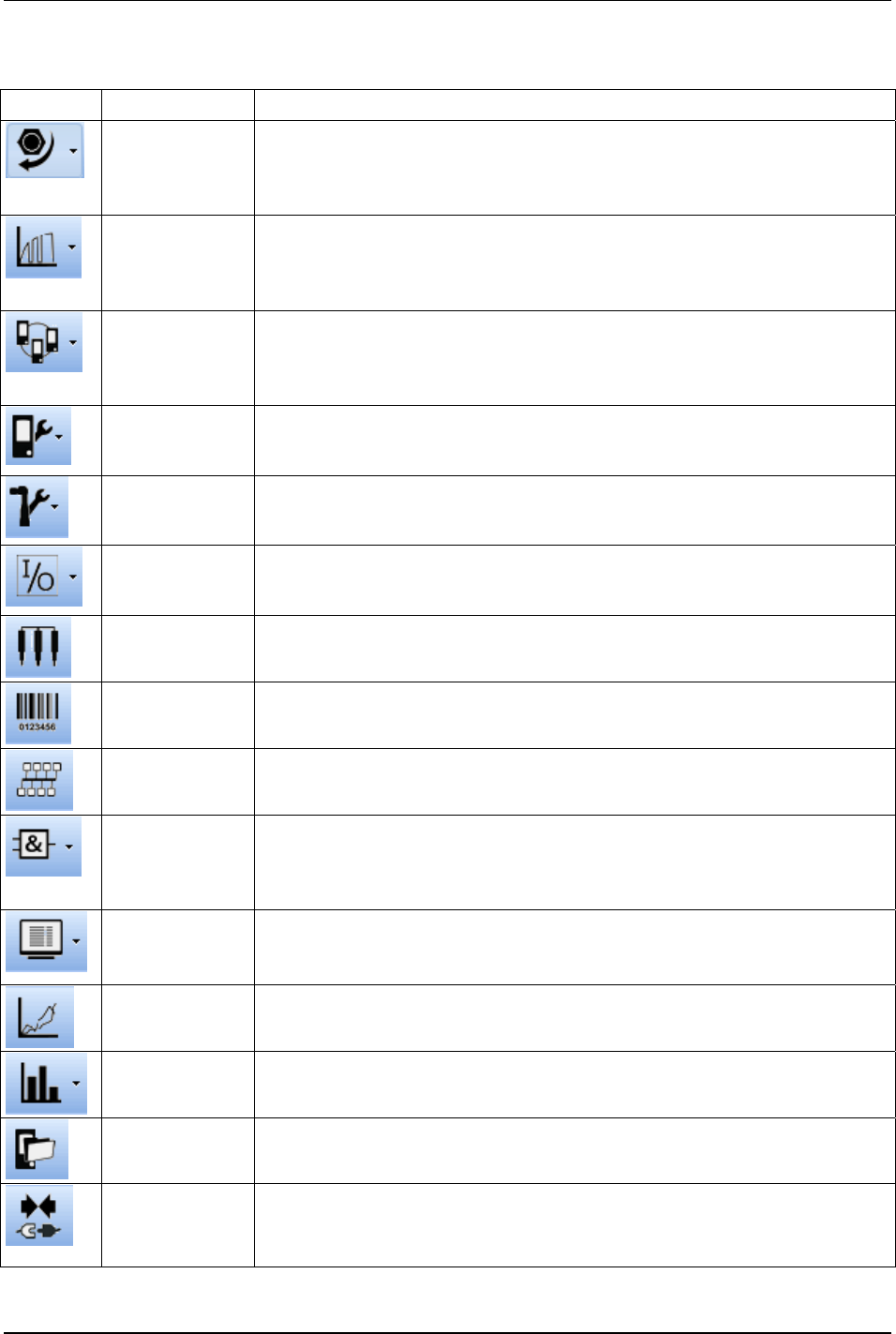

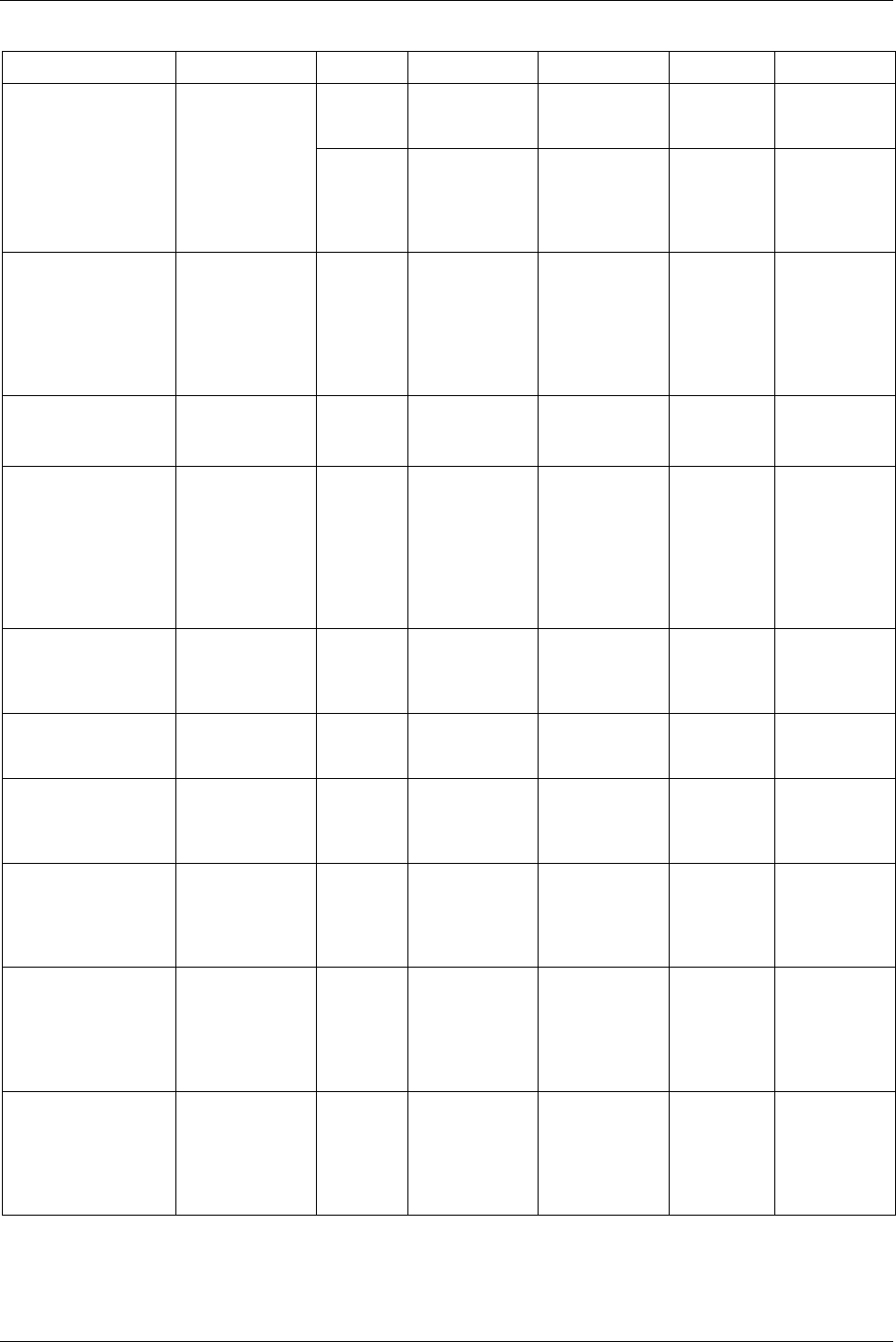

Illustration Name Description

Selected

Controller

The available options are; Serial connection,

Ethernet connection and Offline mode.

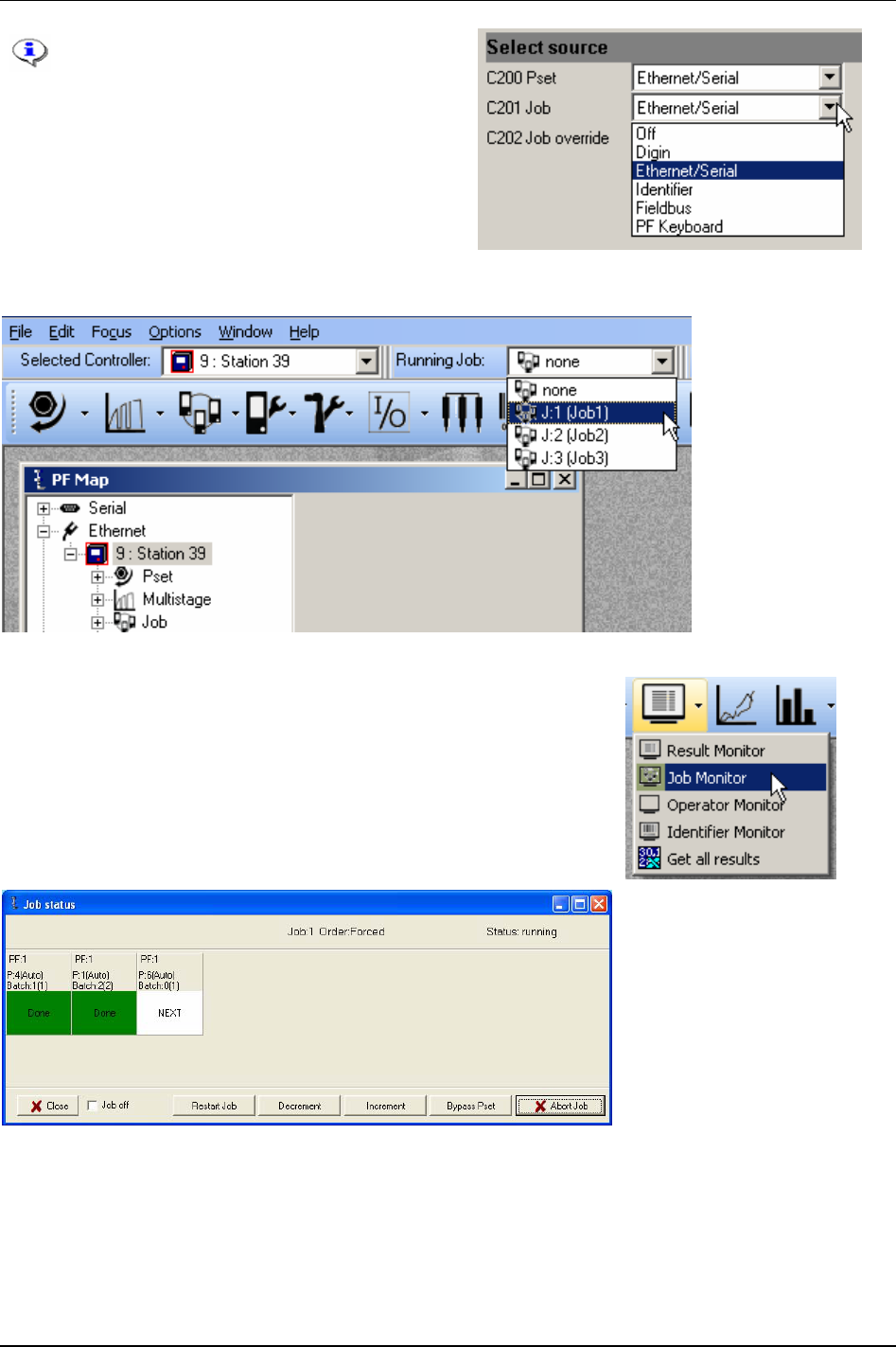

Running Job If parameter

Job select source [C201] is set to

“Ethernet/serial”, it is possible to select a Job to run.

Running

Pset/Multistage

If parameter Pset select source [C200] is set to

“Ethernet/serial”, it is possible to select a Pset or

Multistage to run.

PF List To simplify the Ethernet connection to a Power

Focus use the combo box PF List. Select an item in

the combo box and ToolsTalk PF will connect to the

corresponding Power Focus. The information in the

list contains; name, IP address and port number.

28 (330) 9836 3123 01

Getting started with ToolsTalk PF

4.1.3 Toolbar

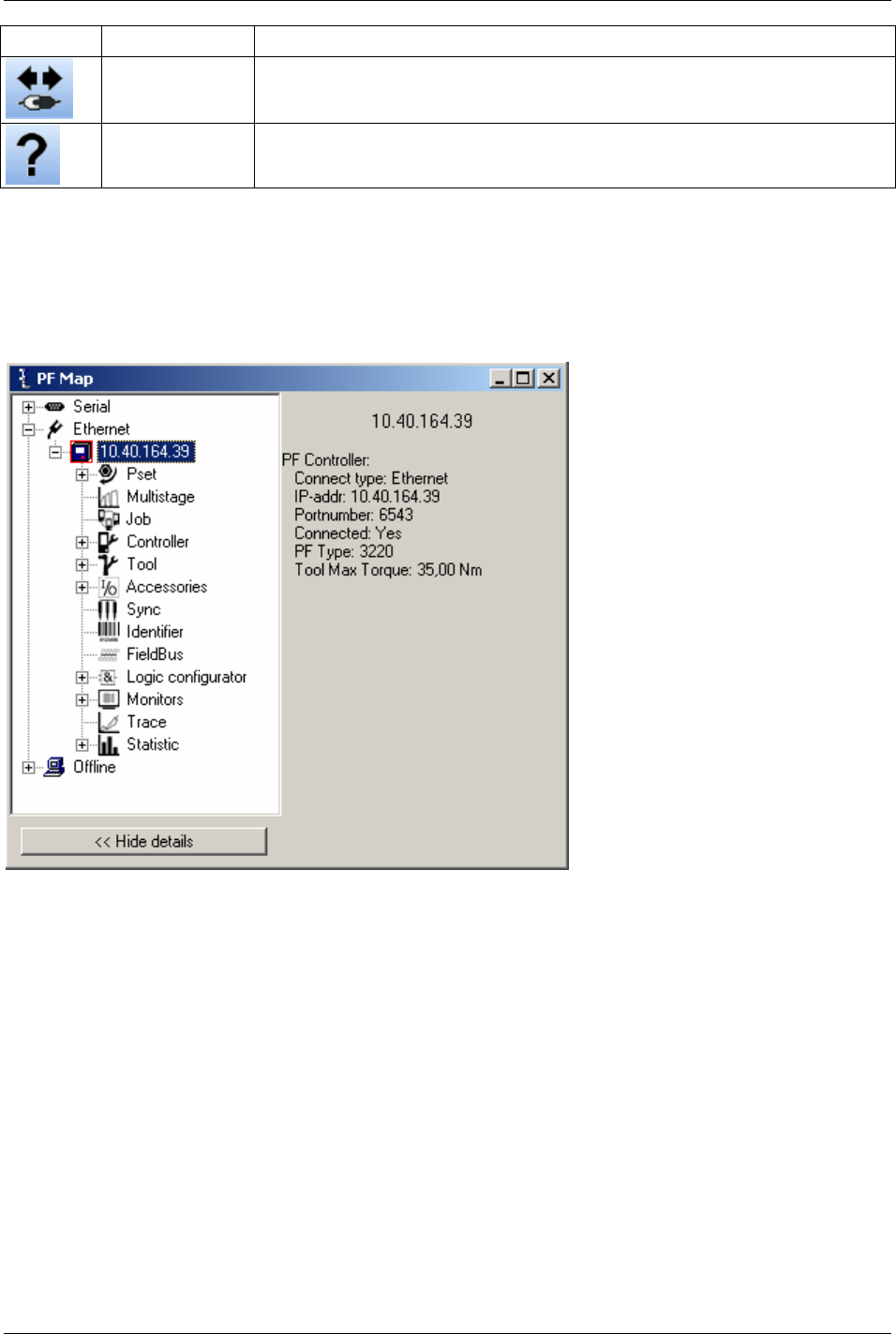

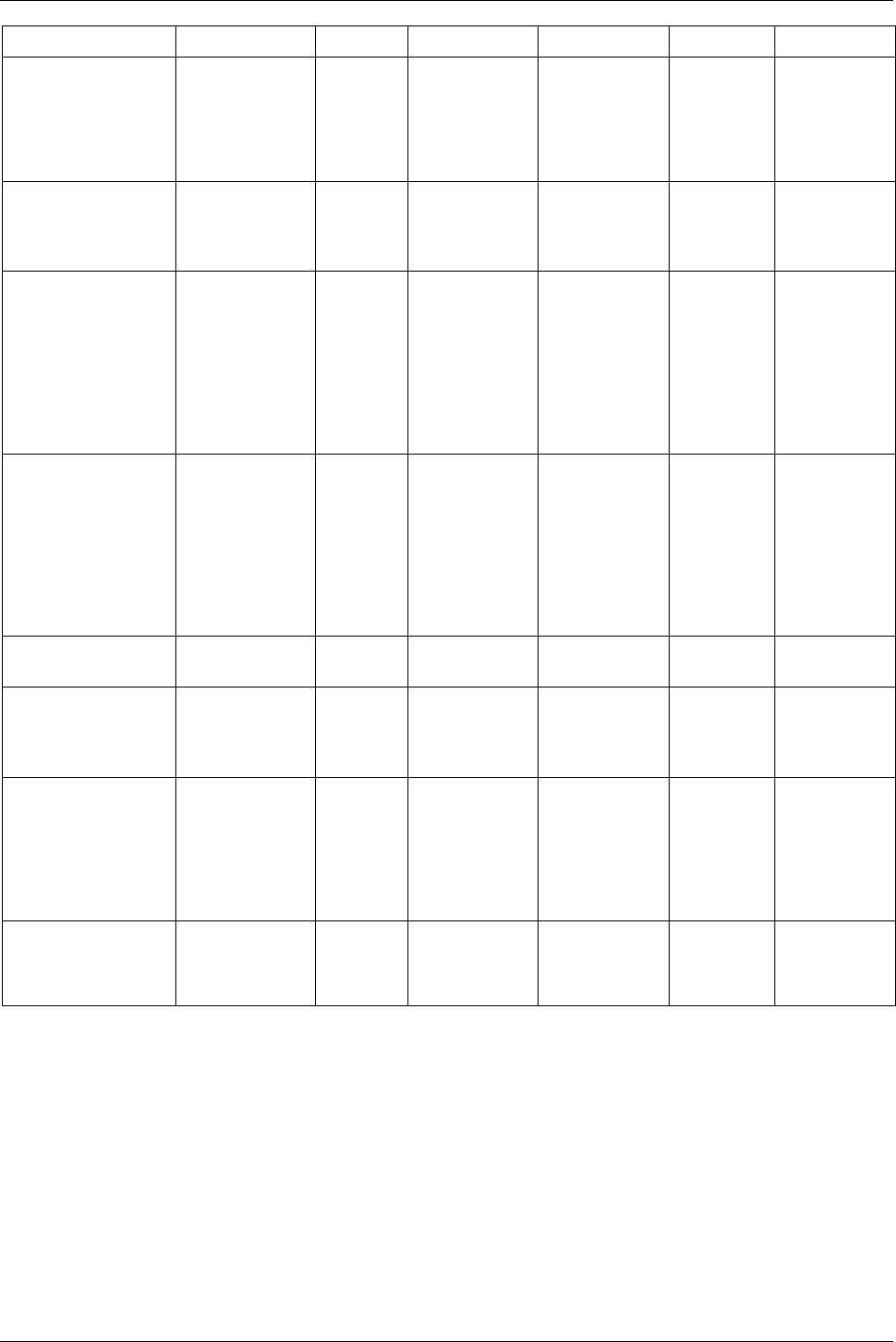

Icon Icon name Description

Pset This icon opens the programming window for the first Pset.

Click on the arrow to the right to select between existing Psets (shown along with number

and name). The list can contain a maximum of 250 Psets.

Use the function in the PF Map to create a new Pset.

Multistage This icon opens the programming window for the first Multistage (if any).

Click on the arrow to the right to select between existing Multistages (shown along with

number and name).

Use the function in the PF Map to create a new Multistage.

Job This icon opens the programming window for the first Job (if any).

Click on the arrow to the right to select between existing Jobs (shown along with number

and name).

Use the function in the PF Map to create a new Job.

Controller This icon opens the first part in the Controller programming section.

Use the arrow to the right to select between all section (Information, Configuration,

Network, COM ports, Display, Memory and Accessibility).

Tool This icon opens the first part in the Tool programming section.

Use the arrow to the right to select between all section (Information, Configuration,

Diagnostic and Maintenance).

Accessories This icon opens the first part in the Accessories programming section.

Use the arrow to the right to select between all section (Digital I/O, I/O bus, Tool bus and

Printer).

Sync This icon opens the Sync programming section.

Identifier This icon opens the Identifier programming section.

Field bus This icon opens the Field bus programming section.

Logic Configurator This icon opens the programming window for the first Logical configurator (if any).

Click on the arrow to the right to select between existing Logical Configurators (shown

along with number and name).

Use the function in the PF Map to create a new Logical configurator.

Monitors Click on the arrow to the right of this icon to select an appropriate monitor; Result monitor,

Job monitor, Operator monitor, Identifier monitor and Get all results.

Result monitor is a convenient way to monitor the tightening status.

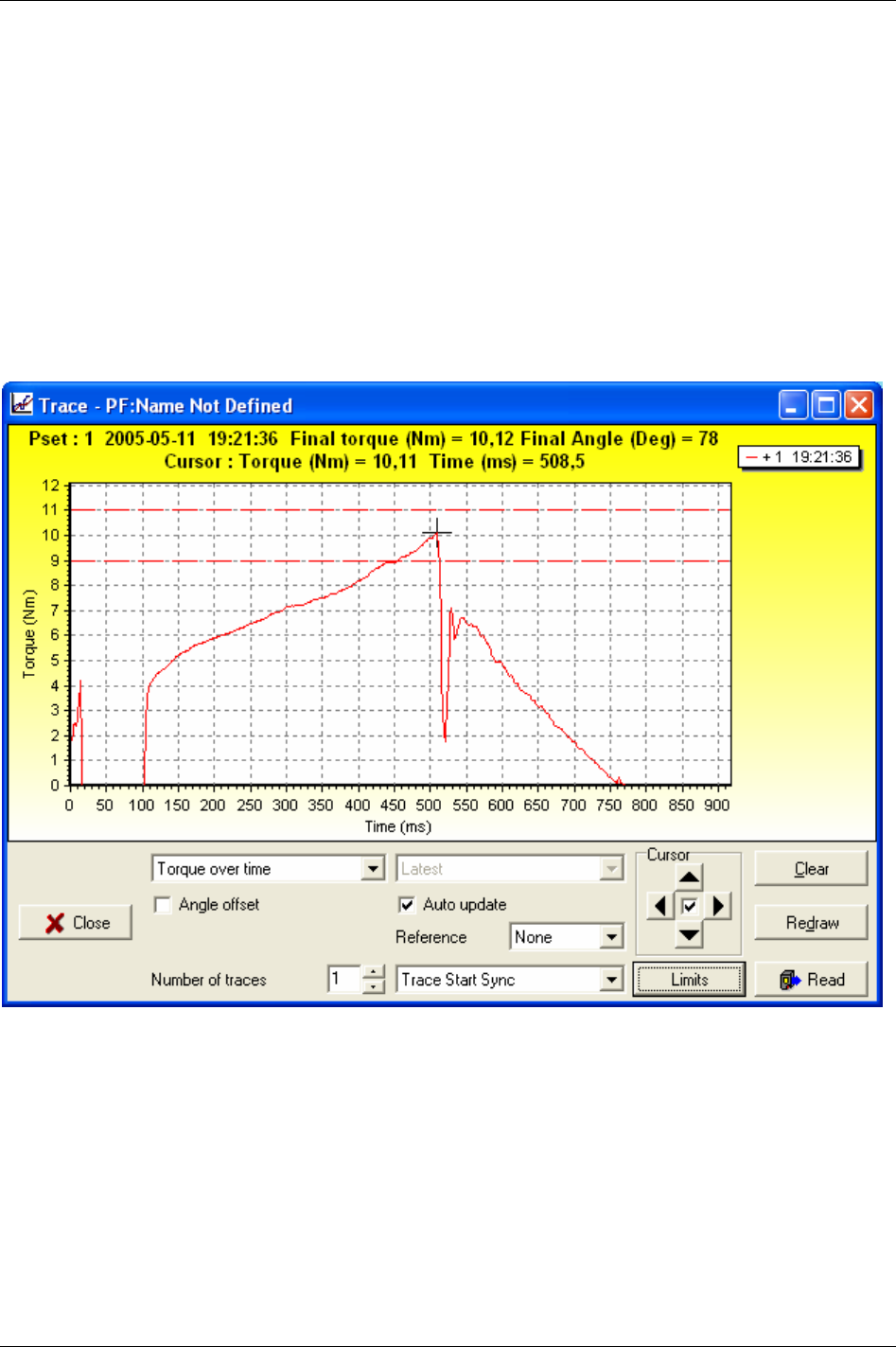

Trace Click the Trace icon to bring up a graphical display of the tightening results.

Statistic Click on Statistic icon to display statistical results and graphs. Via the arrow to the right it is

possible to select a statistic to run.

PF Map This icon opens the PF Map if it is closed.

Connect The Connect icon changes appearance depending on the connection status. When the PC is

not in contact with the Power Focus, this icon is visible. Clicking on it will establish a

connection between the PC and the PF. Choose connection in “selected controller” list

(ToolsTalk PF menu list).

9836 3123 01 29 (330)

Getting started with ToolsTalk PF

Icon Icon name Description

Disconnect Once a connection is established this icon will appear. Clicking on it will Disconnect the PC

from the PF.

Help This icon opens the Help section.

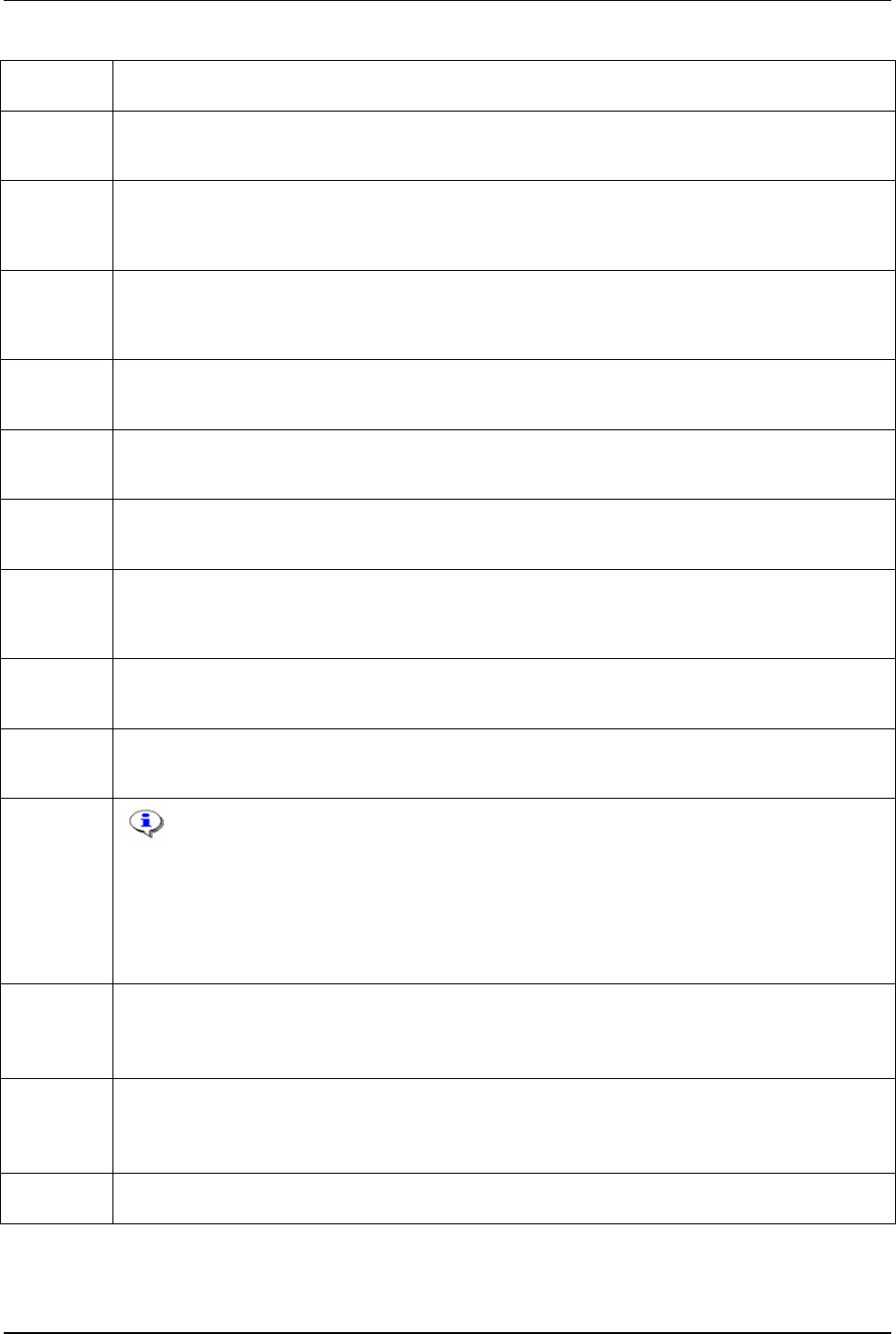

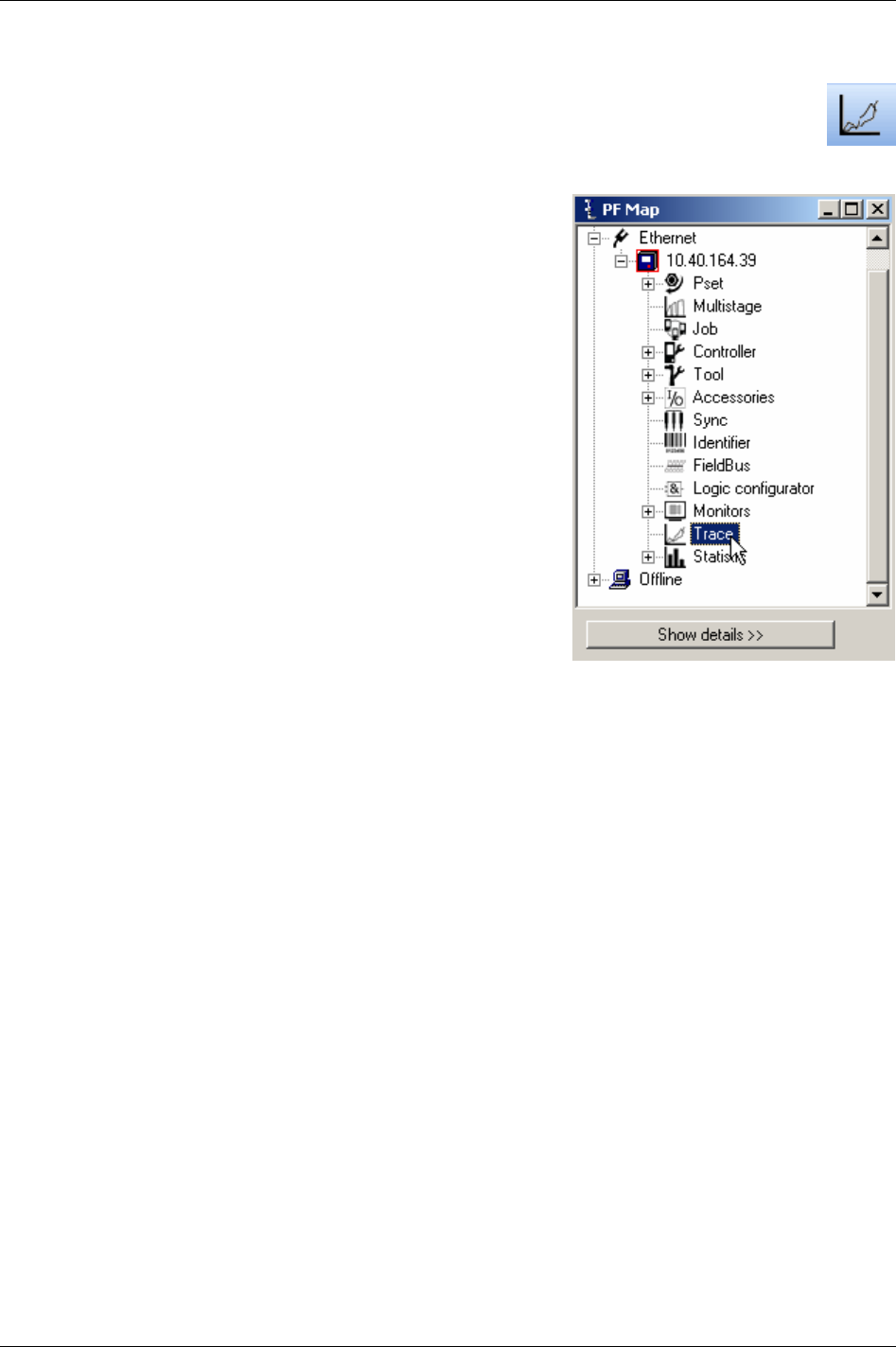

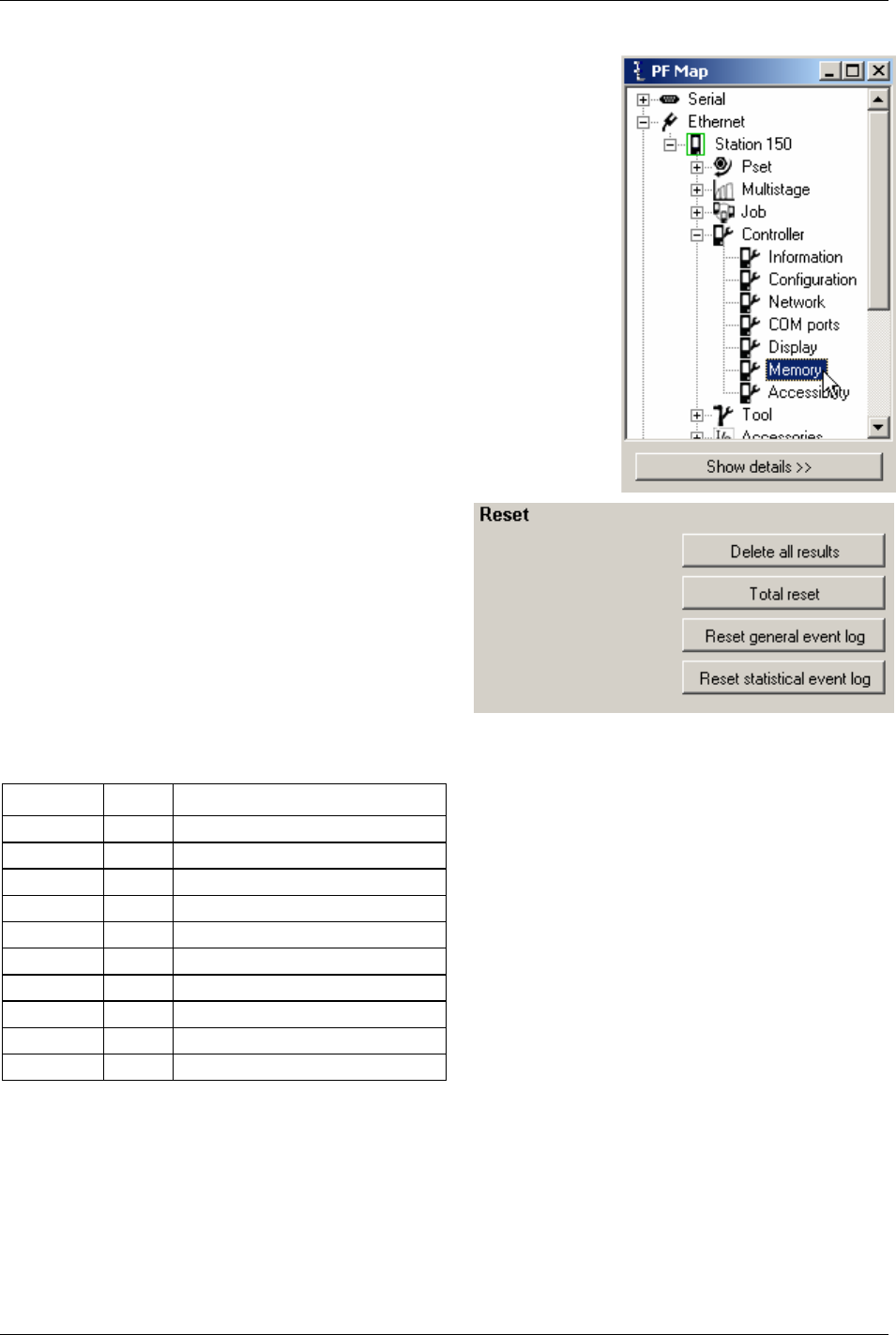

4.1.4 PF Map

The PF Map gives an overview of and shortcuts to all settings in ToolsTalk PF. Click on the minus or plus

symbols to open and close menus and double click on function names (Pset, Multistage, Job, etc) to open

the corresponding function. Brief information about the selected setting is displayed in the right panel of

the PF Map.

Right-click the function names to create a new instance of the function.

30 (330) 9836 3123 01

Getting started with ToolsTalk PF

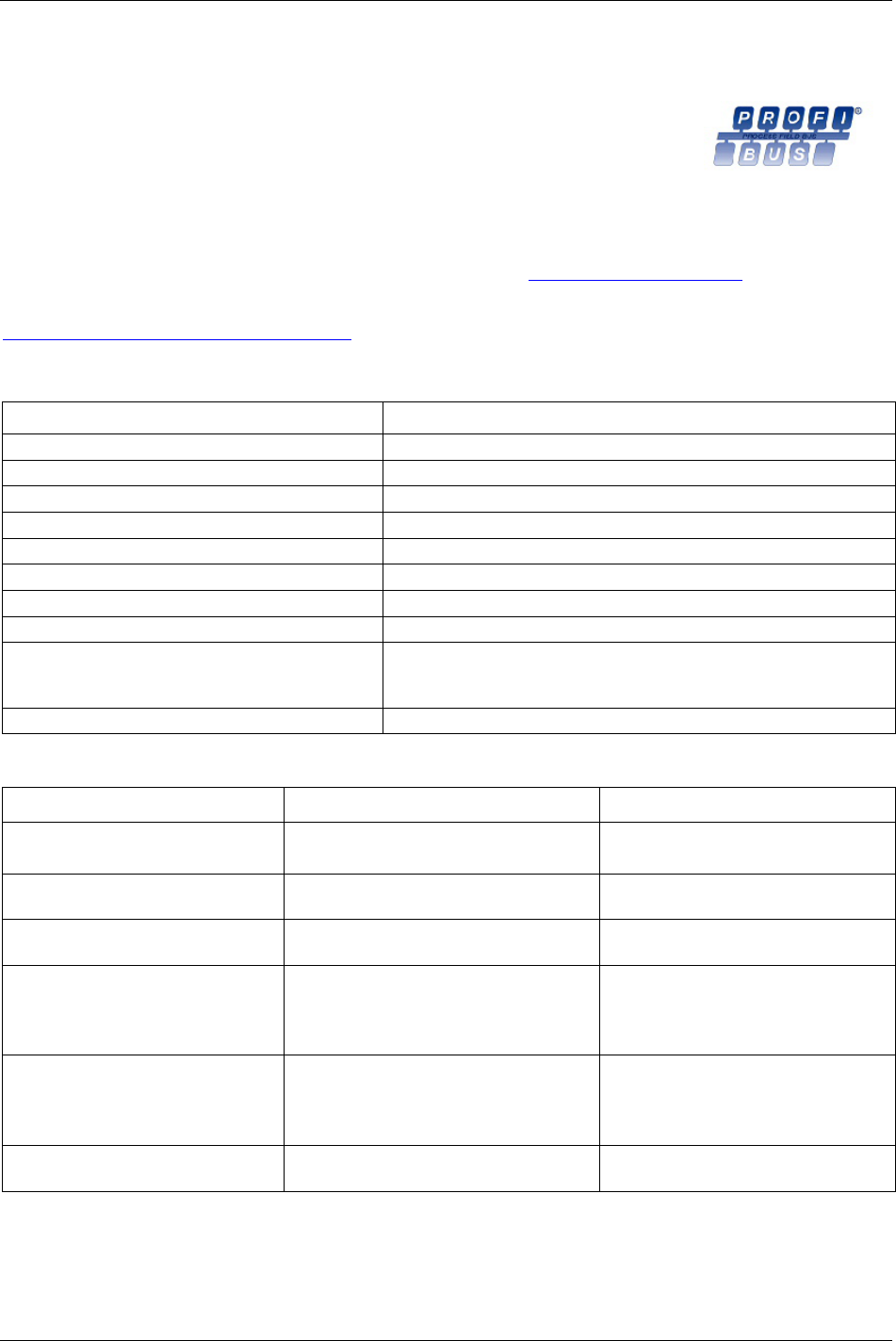

PF Map

function

Description

Pset A Pset contains all the necessary information Power Focus needs to perform a tightening. There are a number of

parameters included in a Pset, among them; control parameters, torque parameters, angle parameters etc.

See chapter

Pset for more information.

Multistage In some instances it is necessary to perform a tightening in several stages. These circumstances require specific

tightening strategies. Multistage allows the user to create linear sequences of up to eight Psets to perform a

tightening divided into stages.

See chapter

Multistage for more information.

Job A Job is a collection of Psets or Multistages, which are useful when performing several multiple tightening

operations, each with different requirements. This is convenient since the operator does not have to select a new

Pset or Multistage for every tightening.

See chapter

Job for more information.

Controller Controller contains information and settings for the PF. This includes network, COM ports, display, memory and

accessibility.

See chapter

Controller for more information.

Tool The Tool branch includes information, configuration, diagnostic and maintenance for the Tensor tool connected

to the PF.

See chapter

Tool for more information.

Accessories In the Accessories branch are the digital inputs and outputs of the PF configured and diagnosed. It also includes

information about the devices connected to the I/O bus and tool bus, and how to configure these devices.

See chapter

Accessories for more information.

Sync Up to ten PF units in the same logical Cell can be synchronised to perform the same task simultaneously, a

function known as Sync. This type of operation requires the Synchronisation of the Power Focuses involved.

With this tool Sync parameters can be created.

See chapter

Sync for more information.

Identifier It is possible to send an Identifier string to a PF. This string is normally generated by a barcode reader connected

to one of the serial ports on the PF (this barcode is in car plants usually known as a VIN or ESN).

See chapter

Identifier for more information.

Field bus Field bus communication is useful for data communication between the PF and PLC’s. It is an effective and fast

way for the data transfer of short data packages.

See chapter

Field bus for more information.

Logic

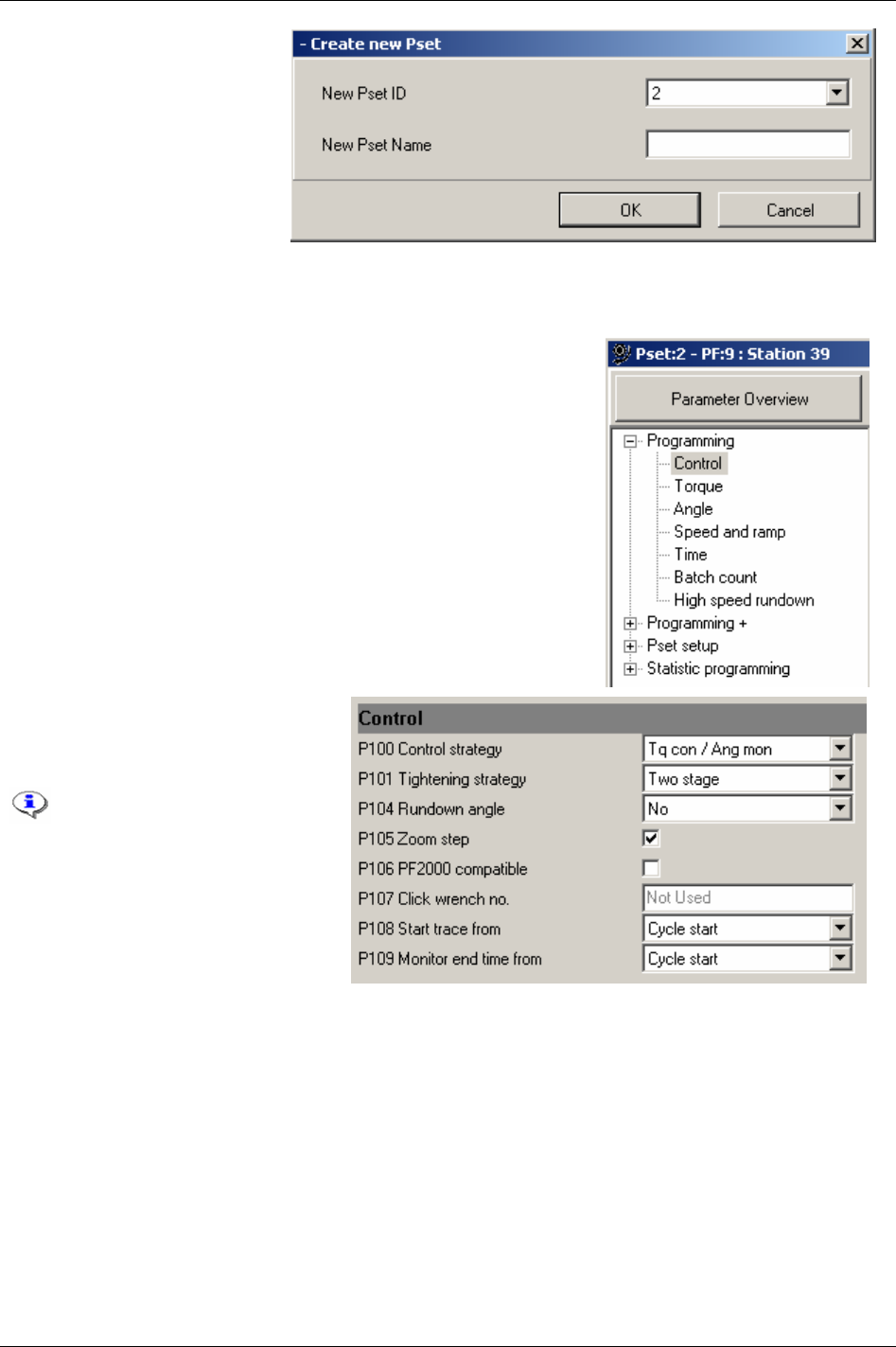

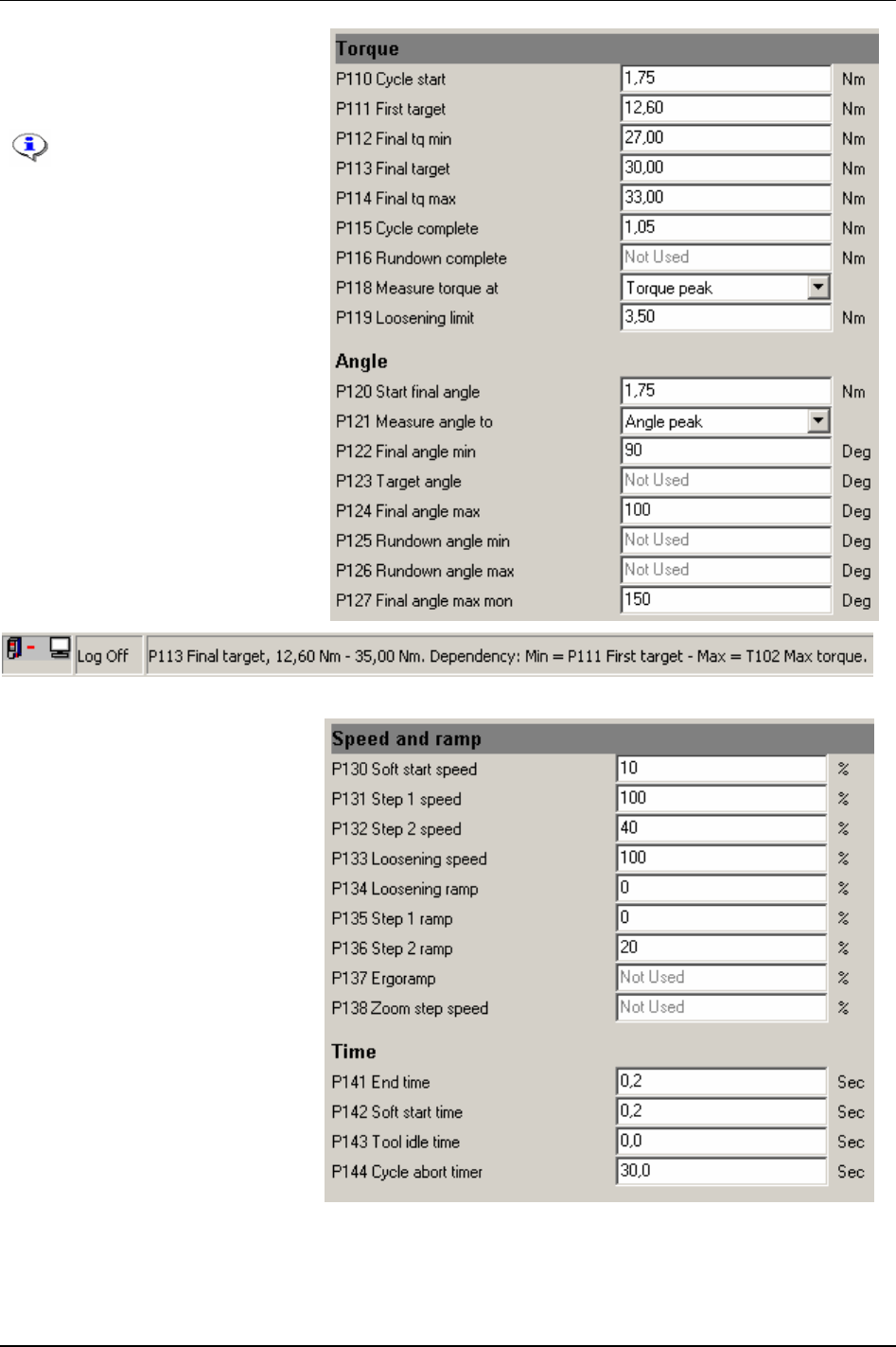

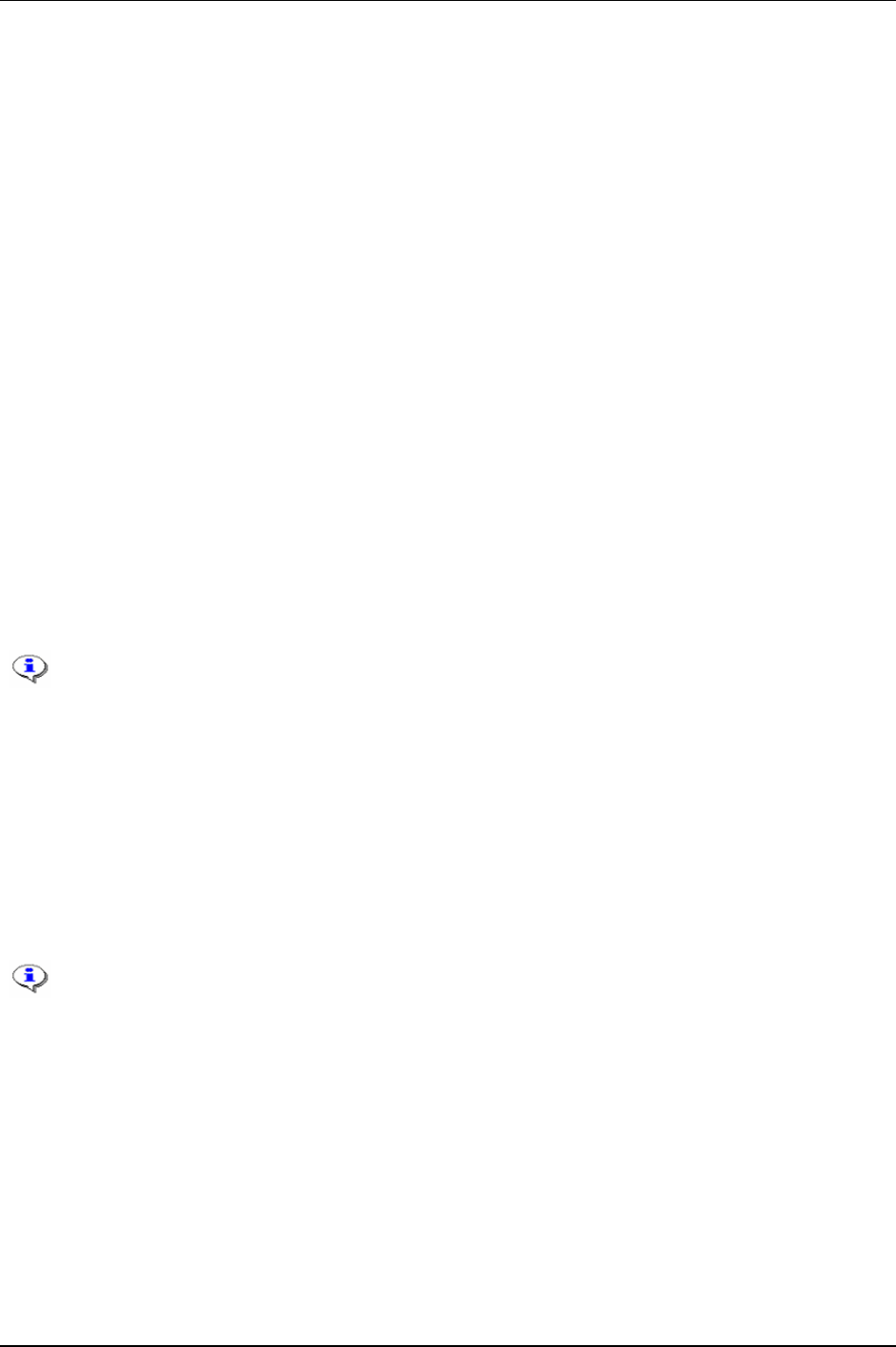

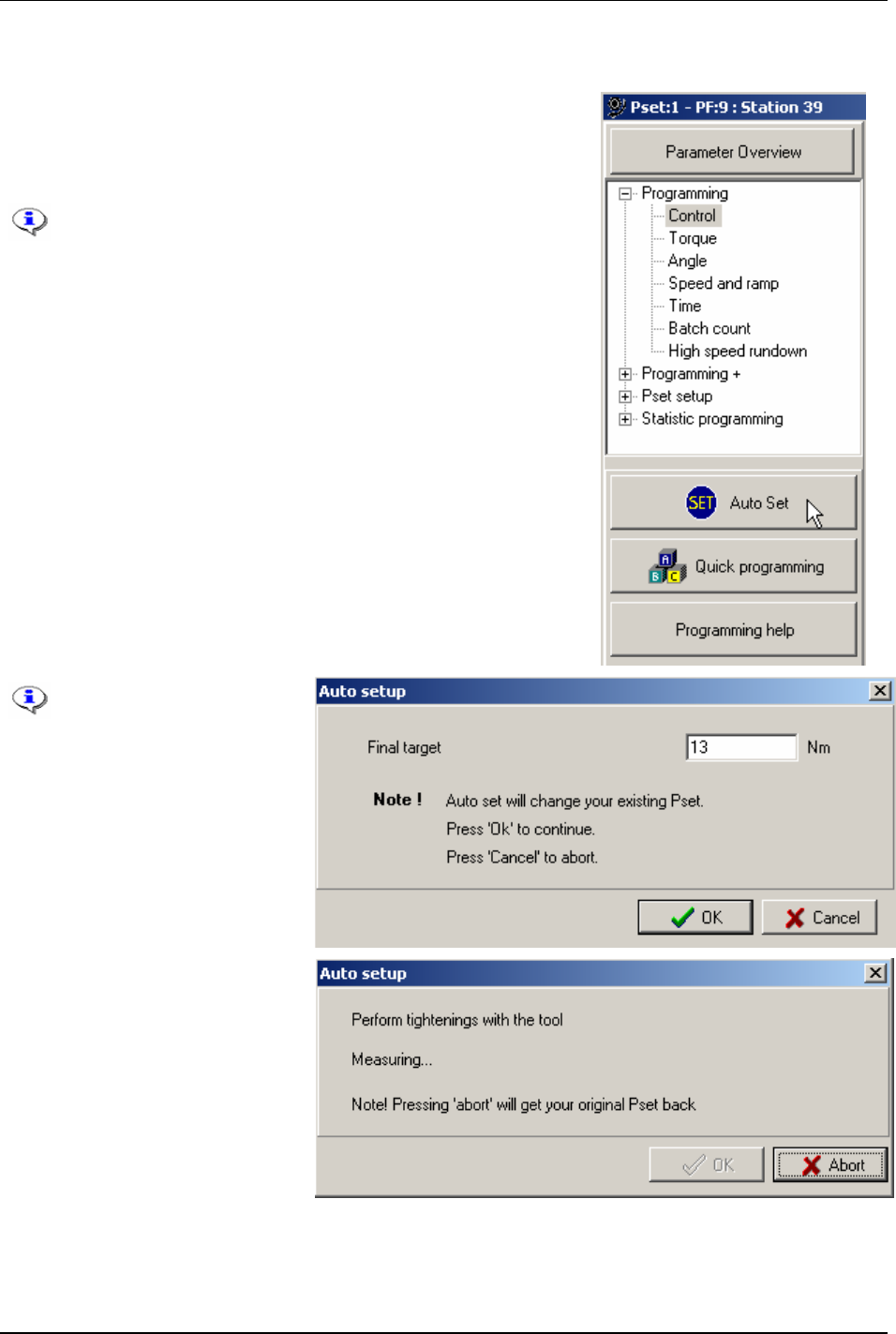

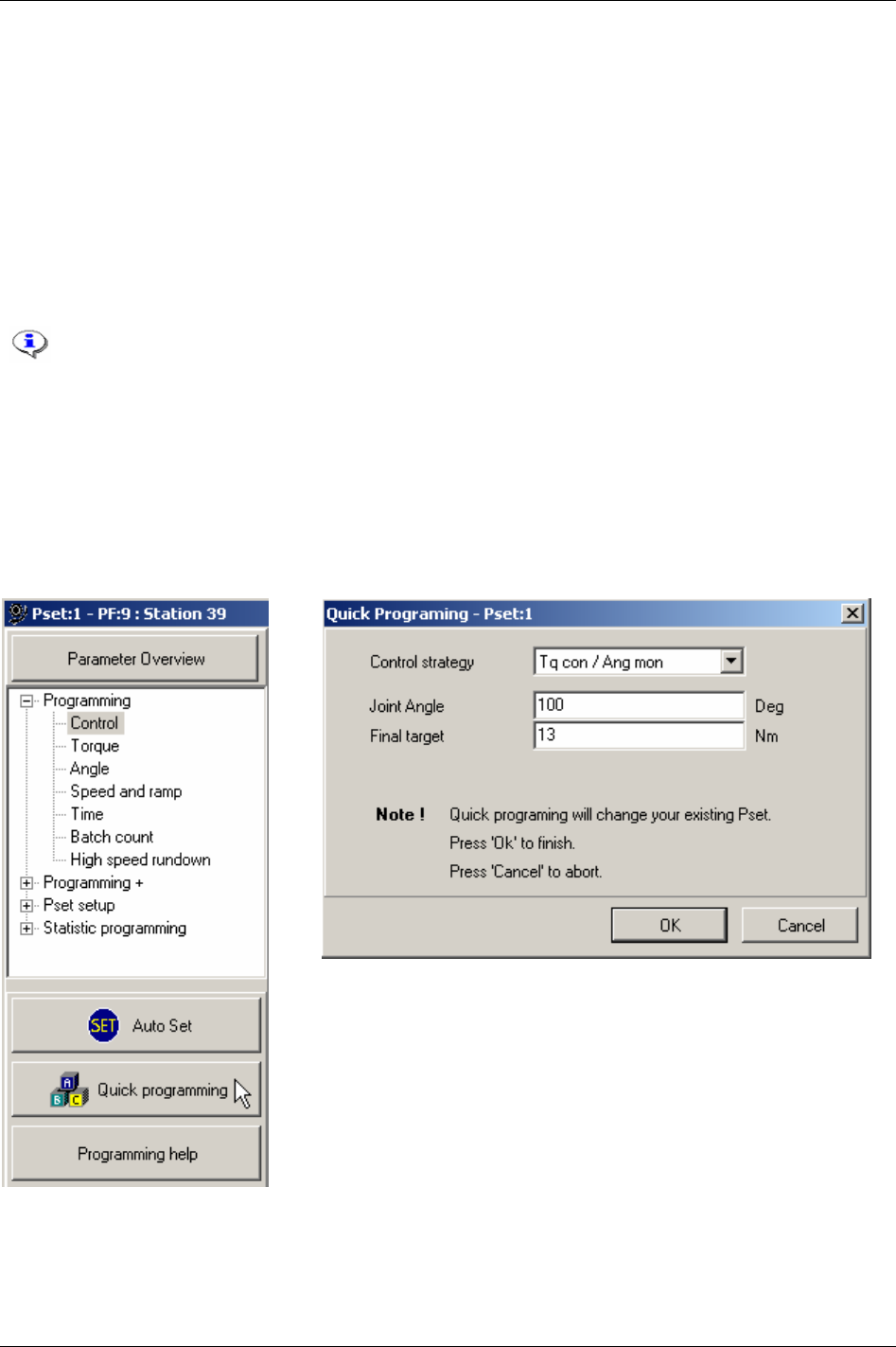

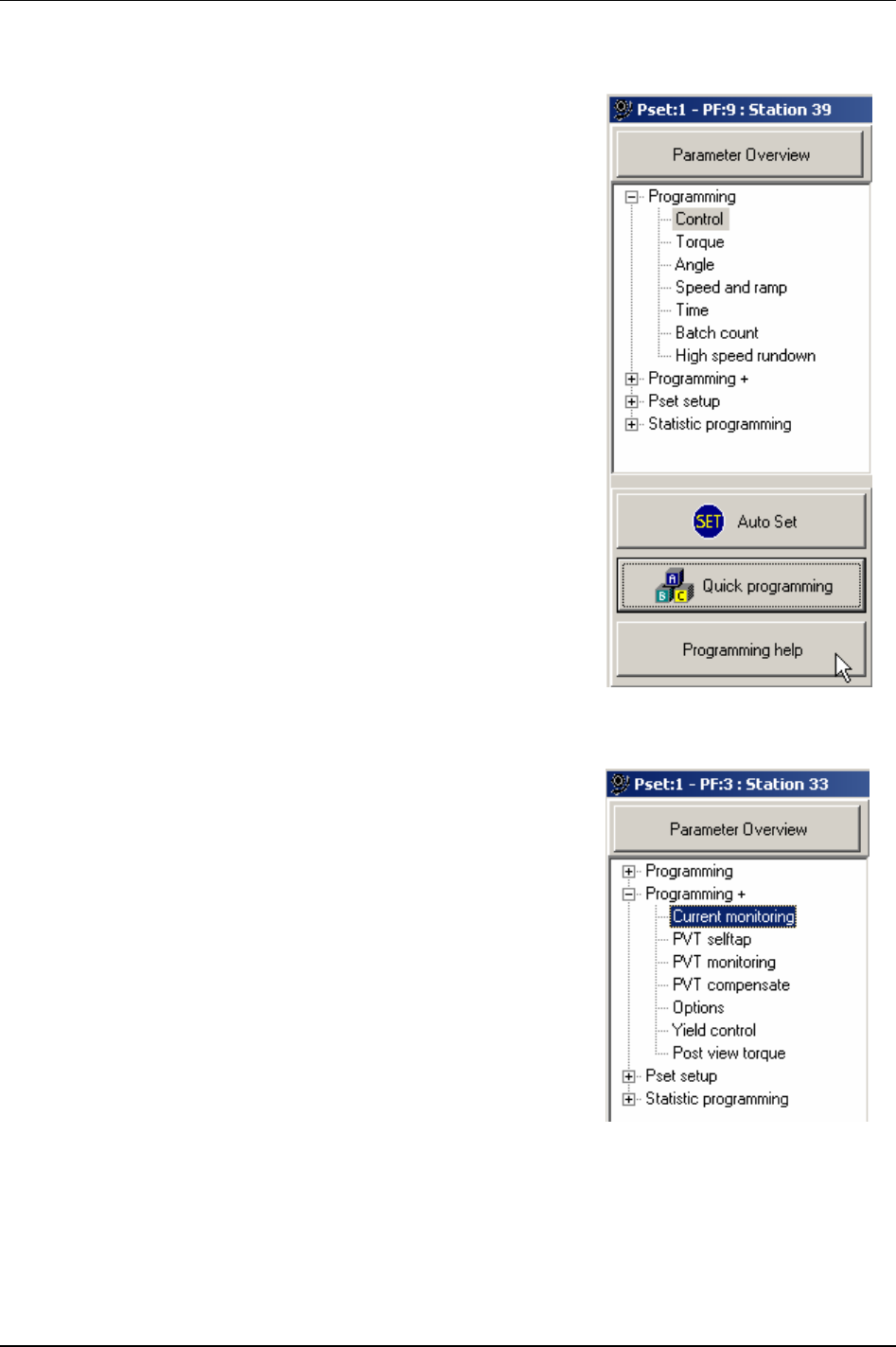

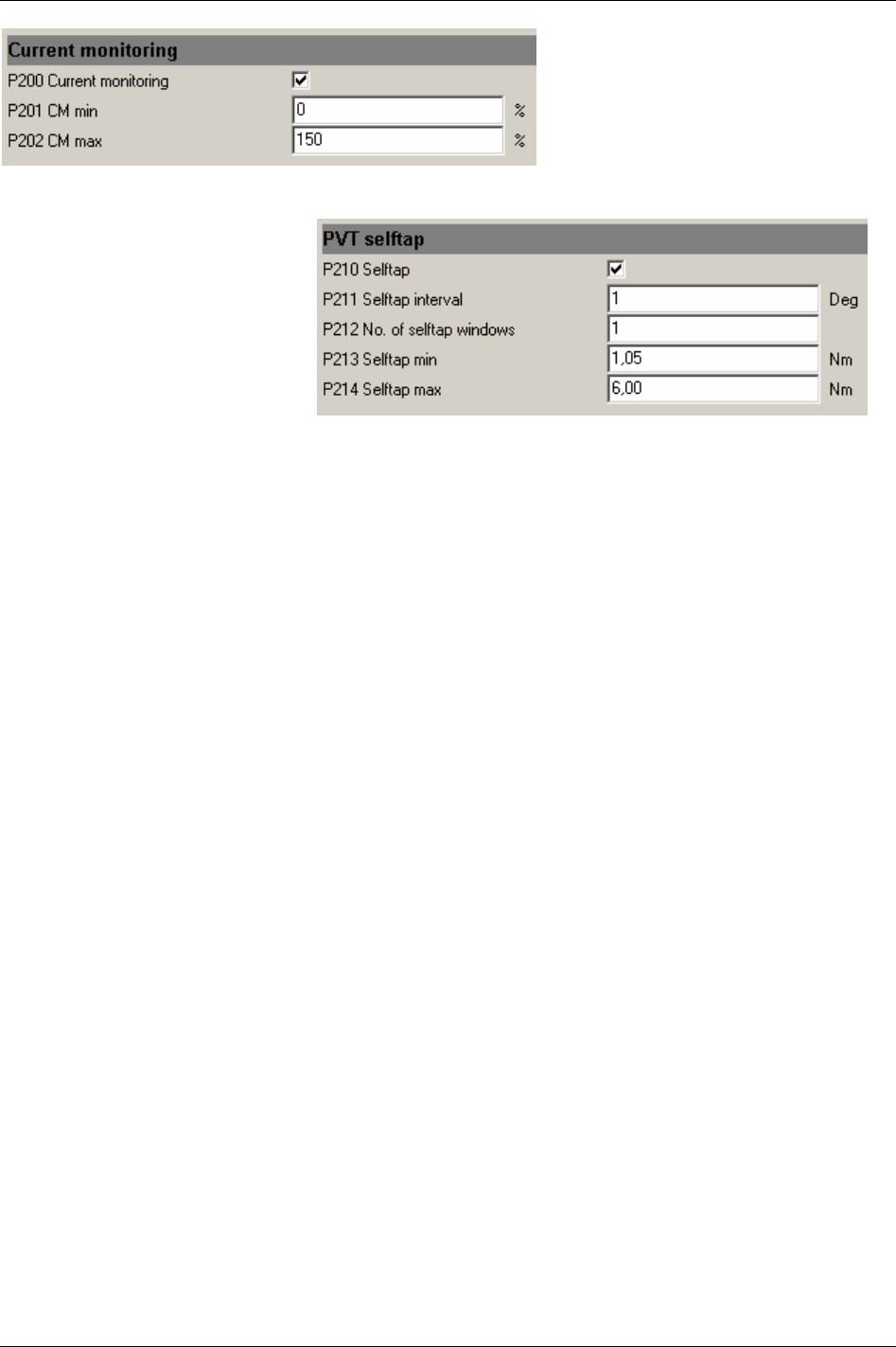

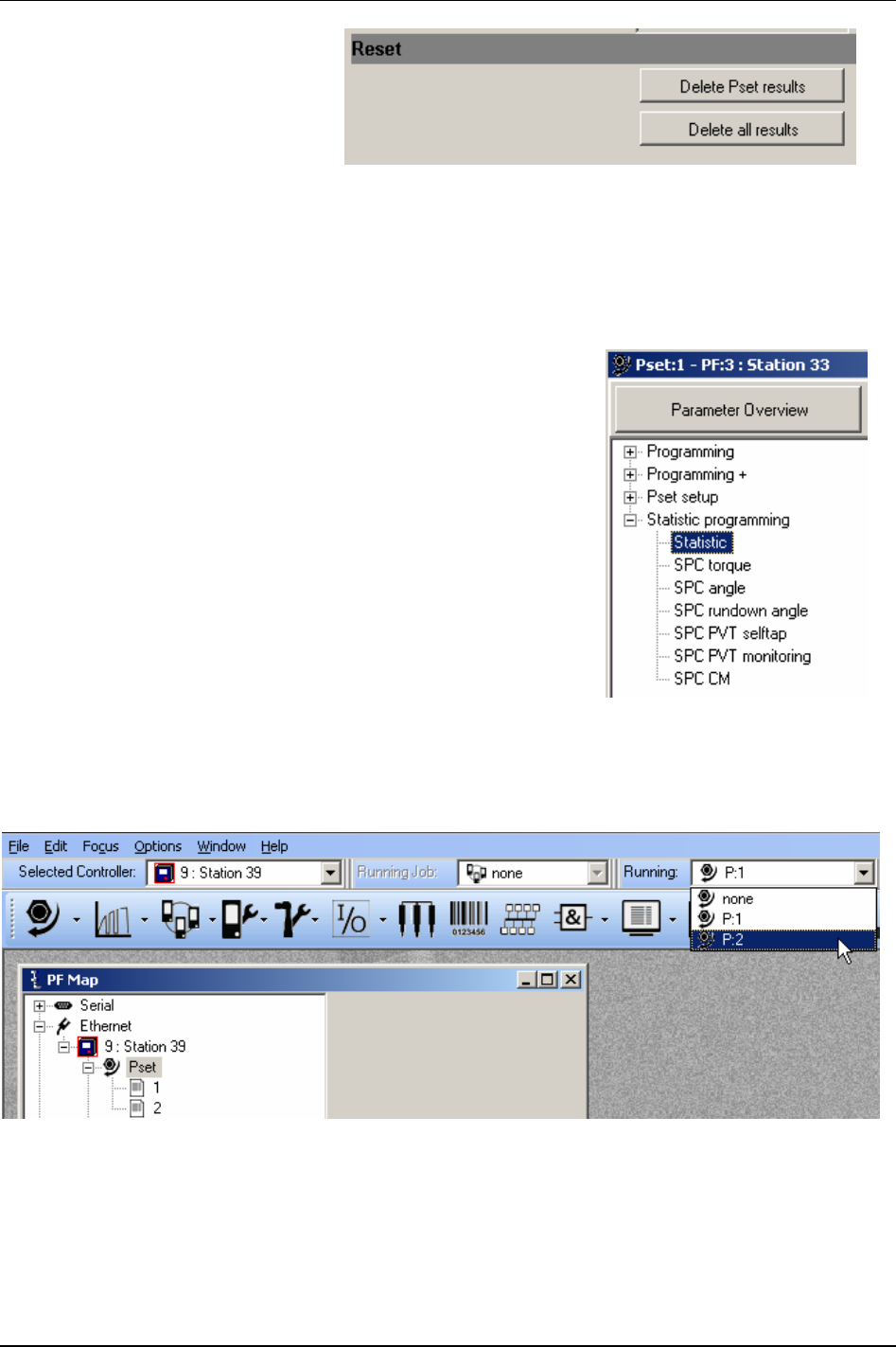

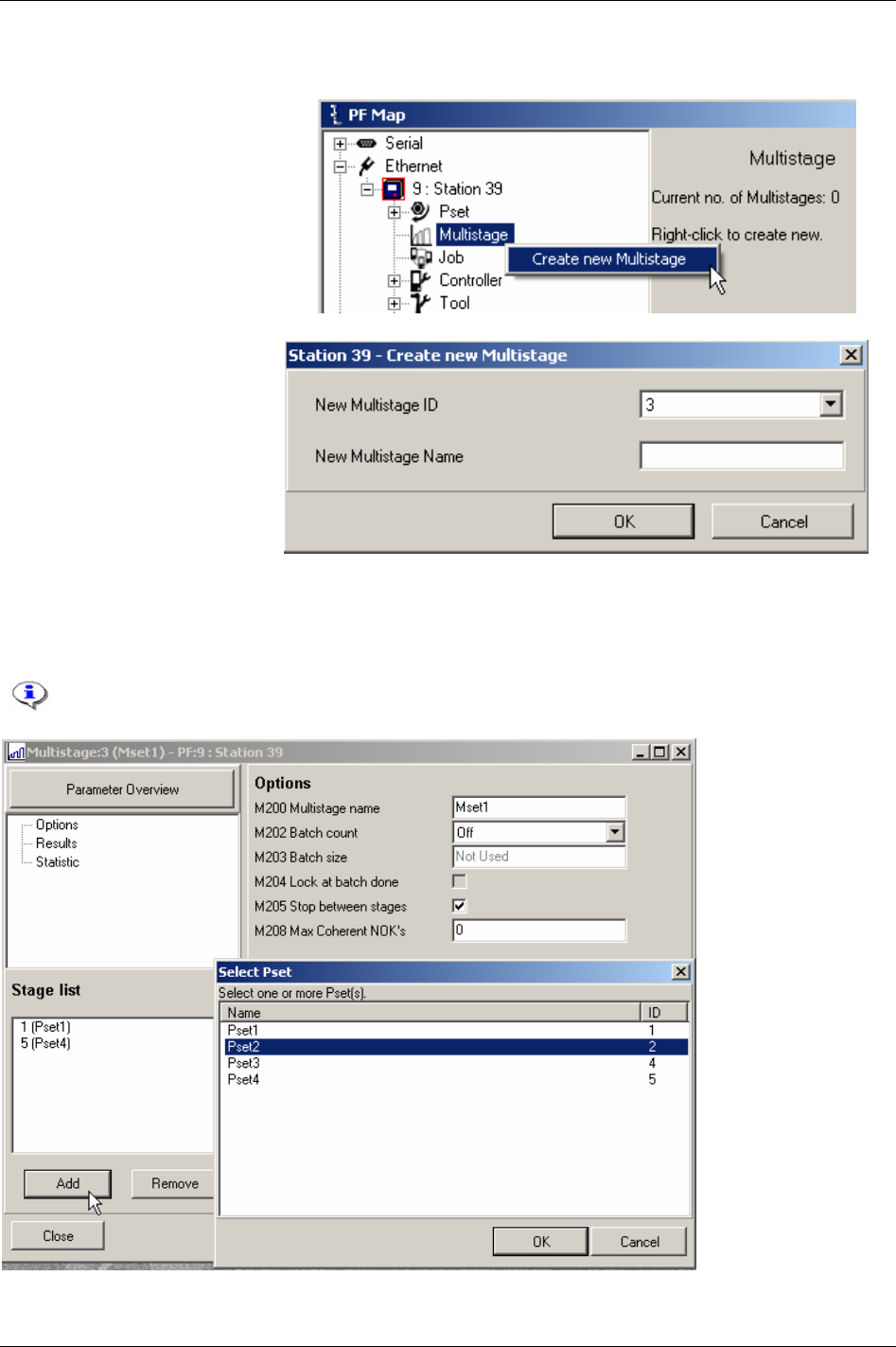

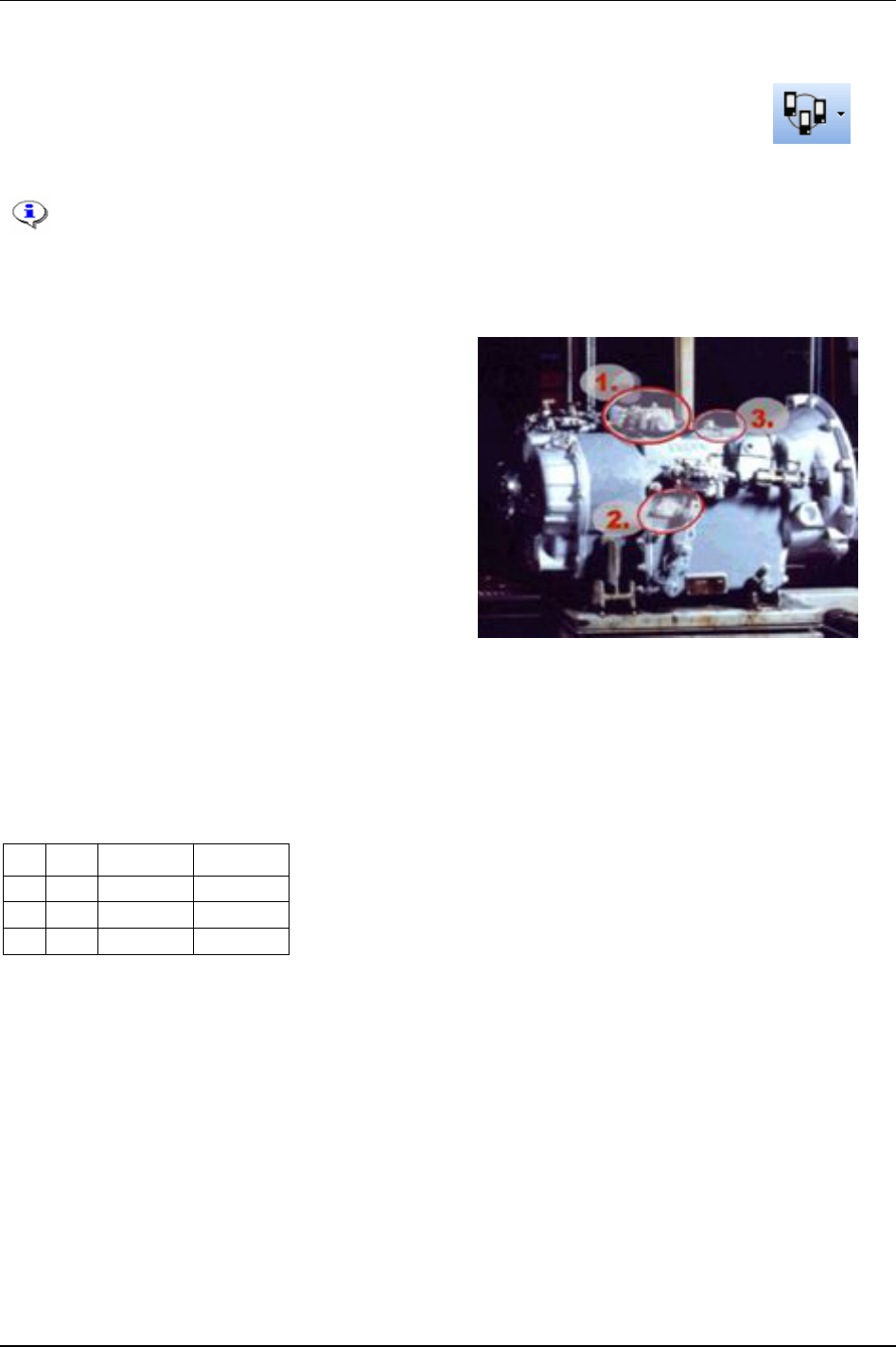

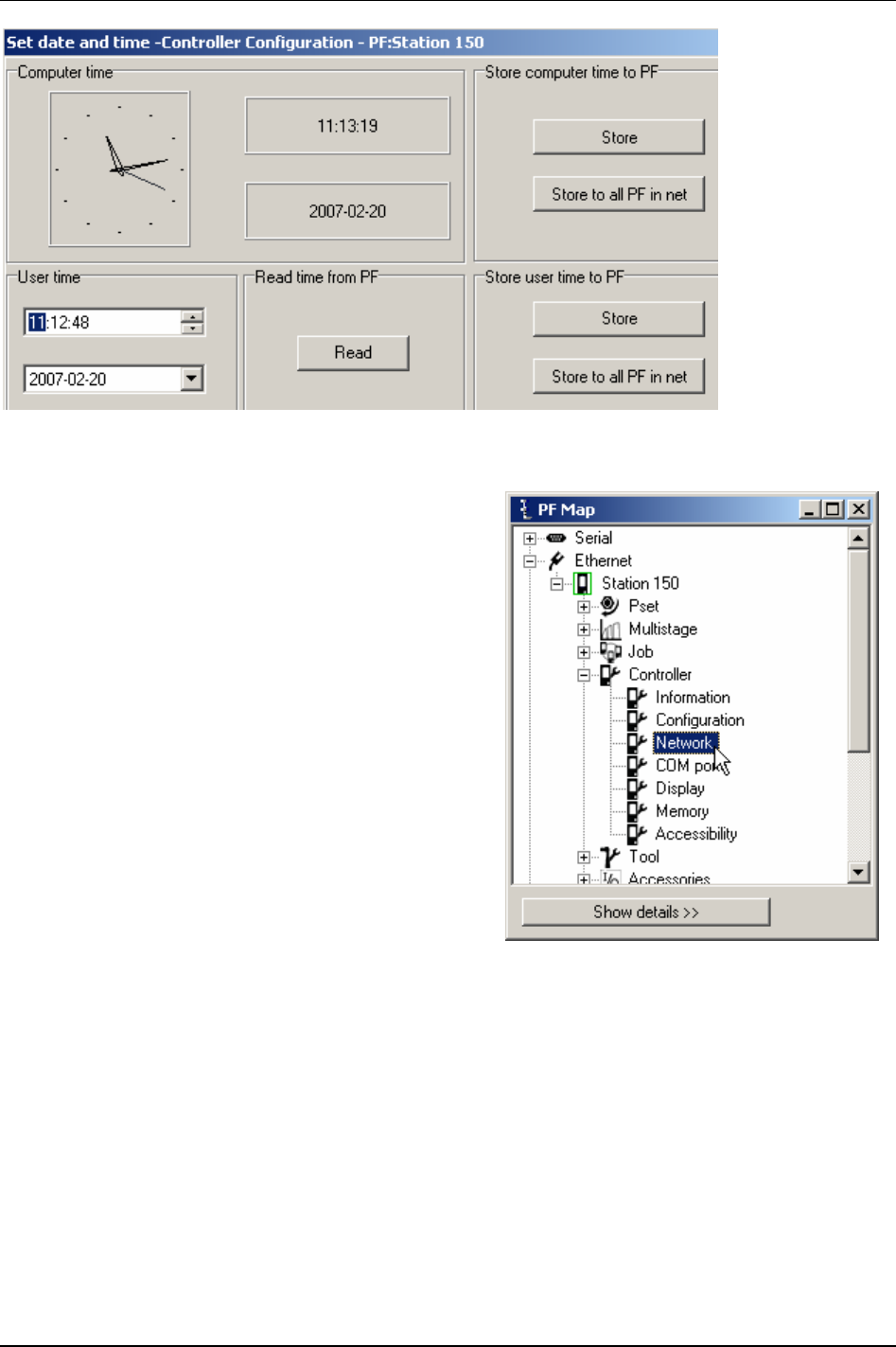

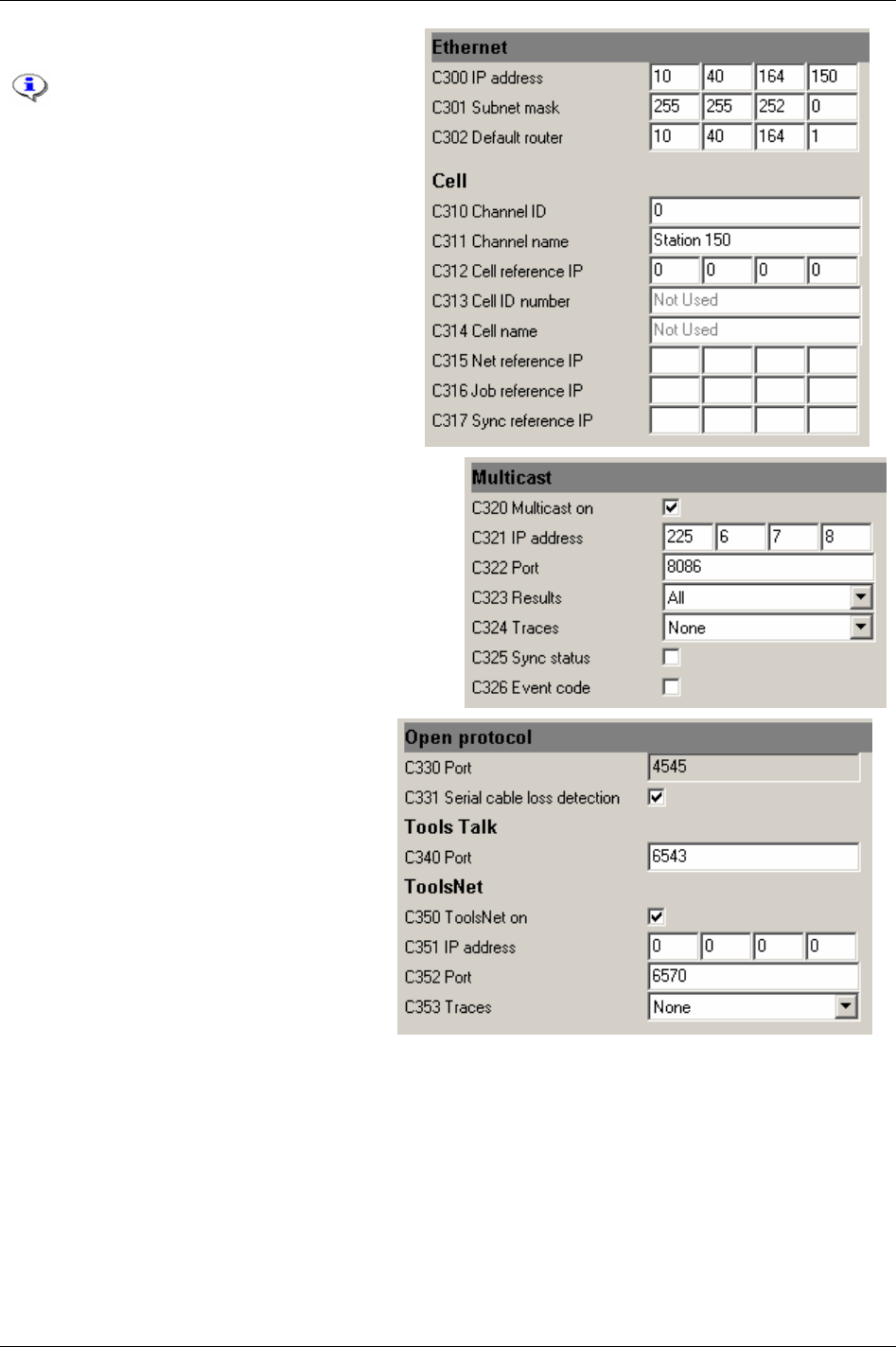

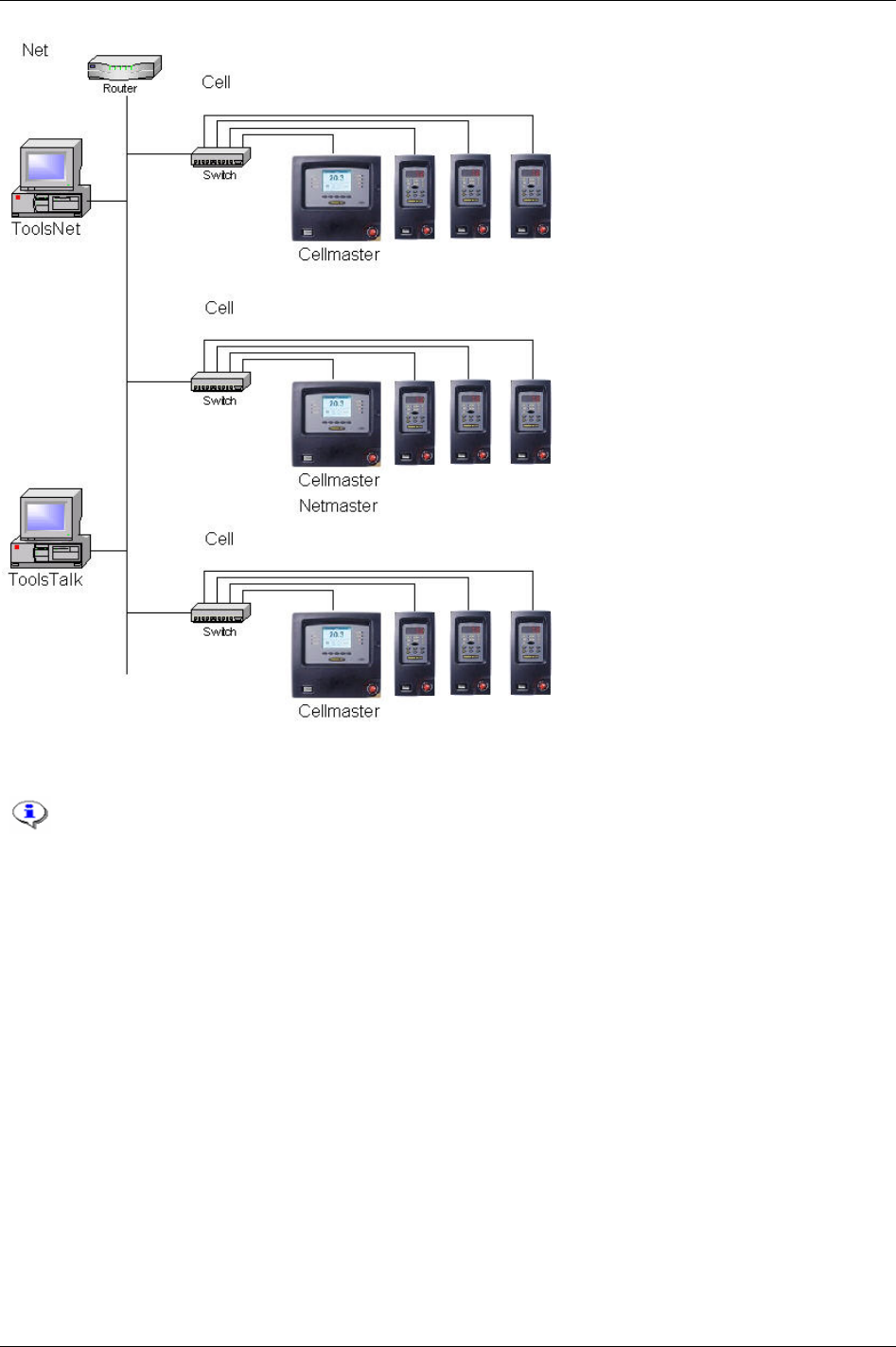

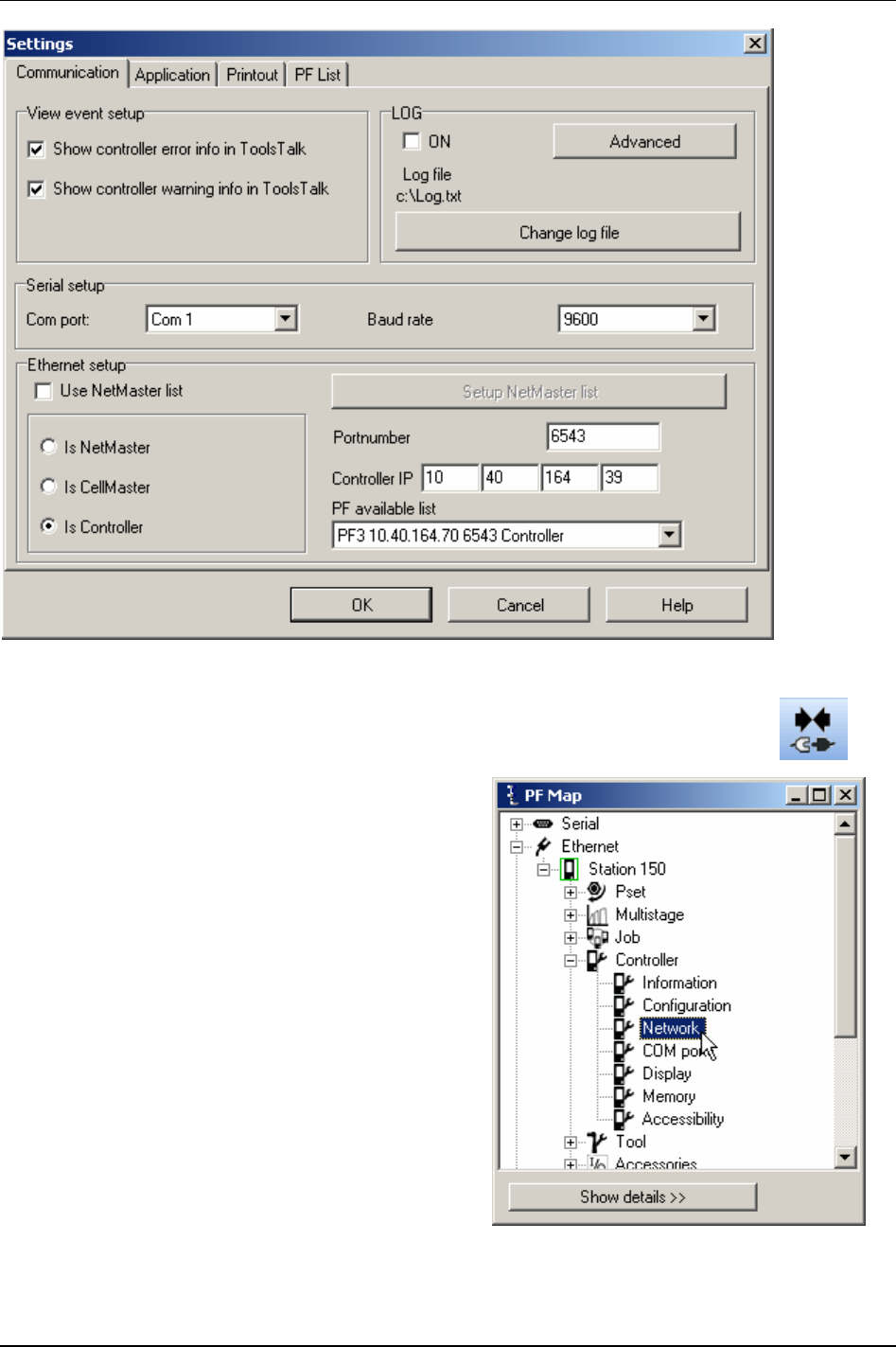

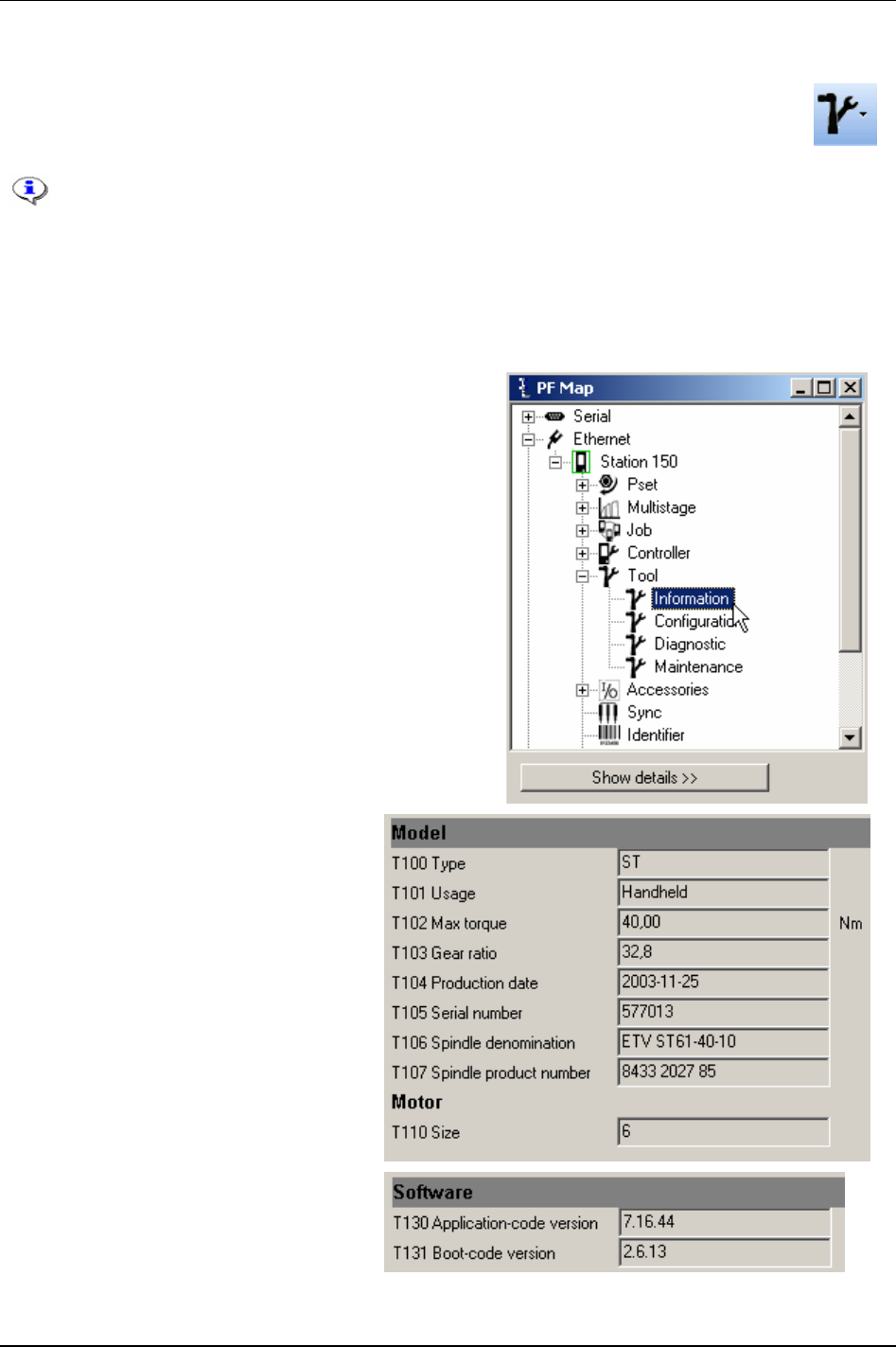

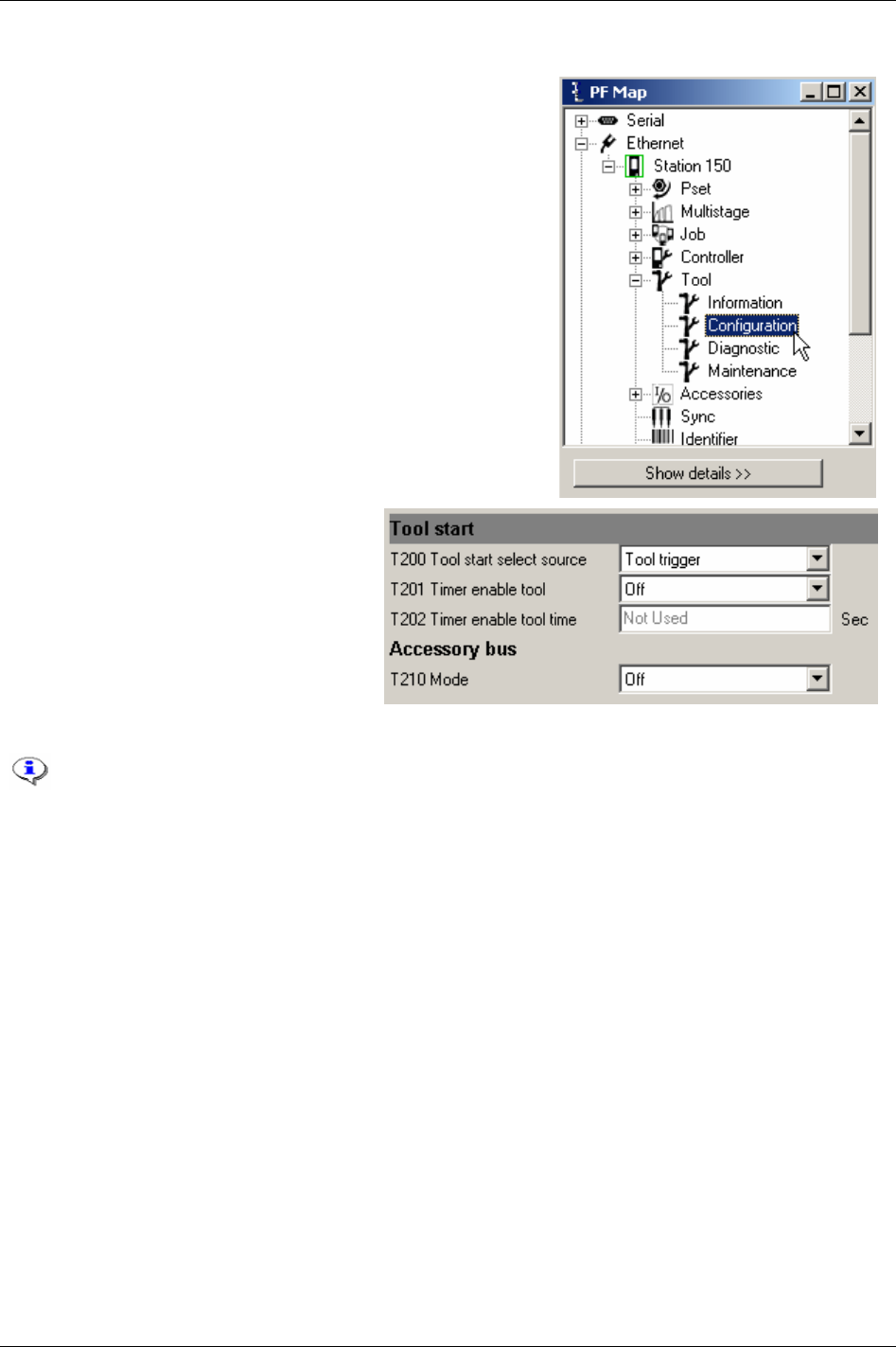

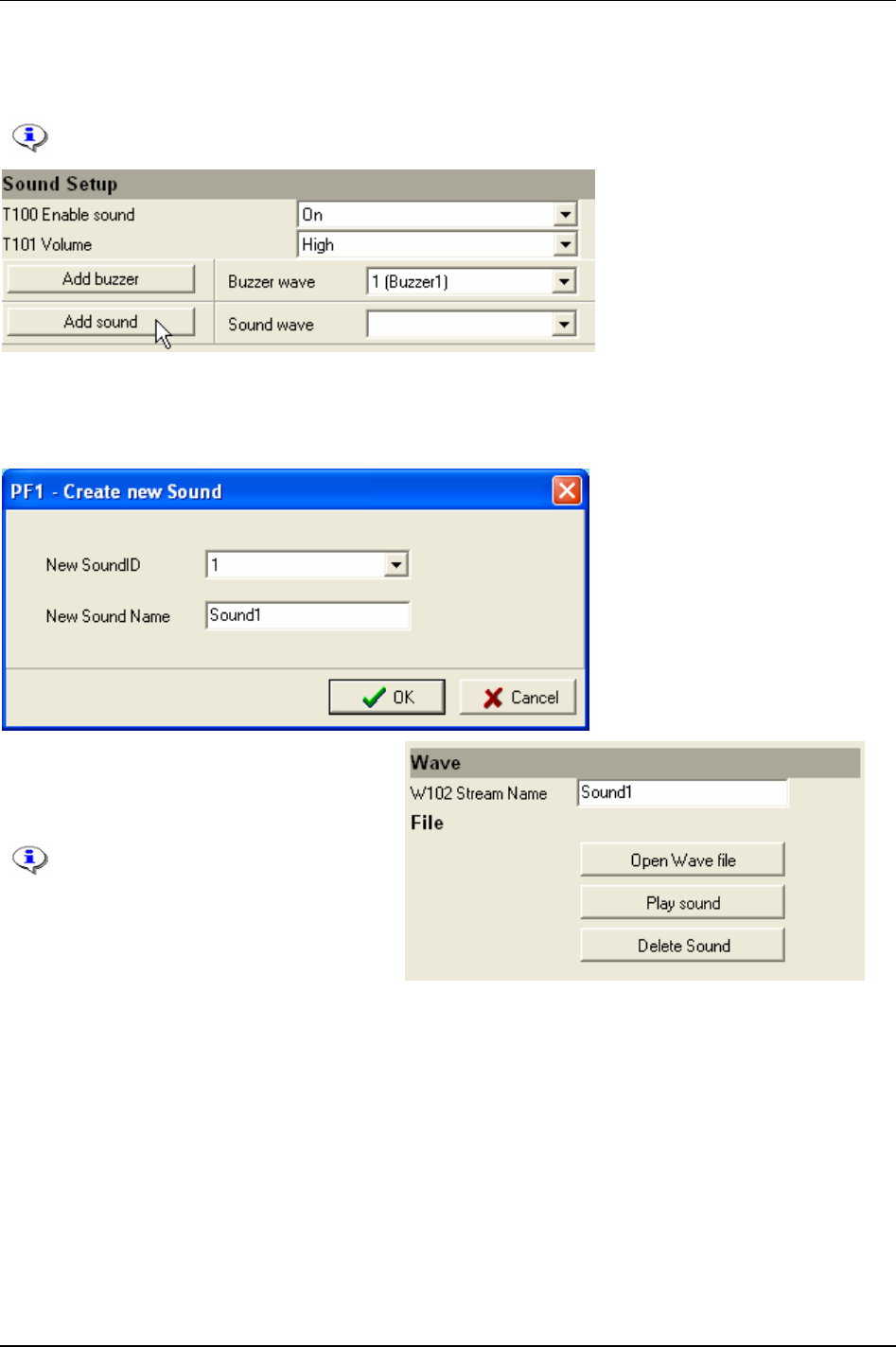

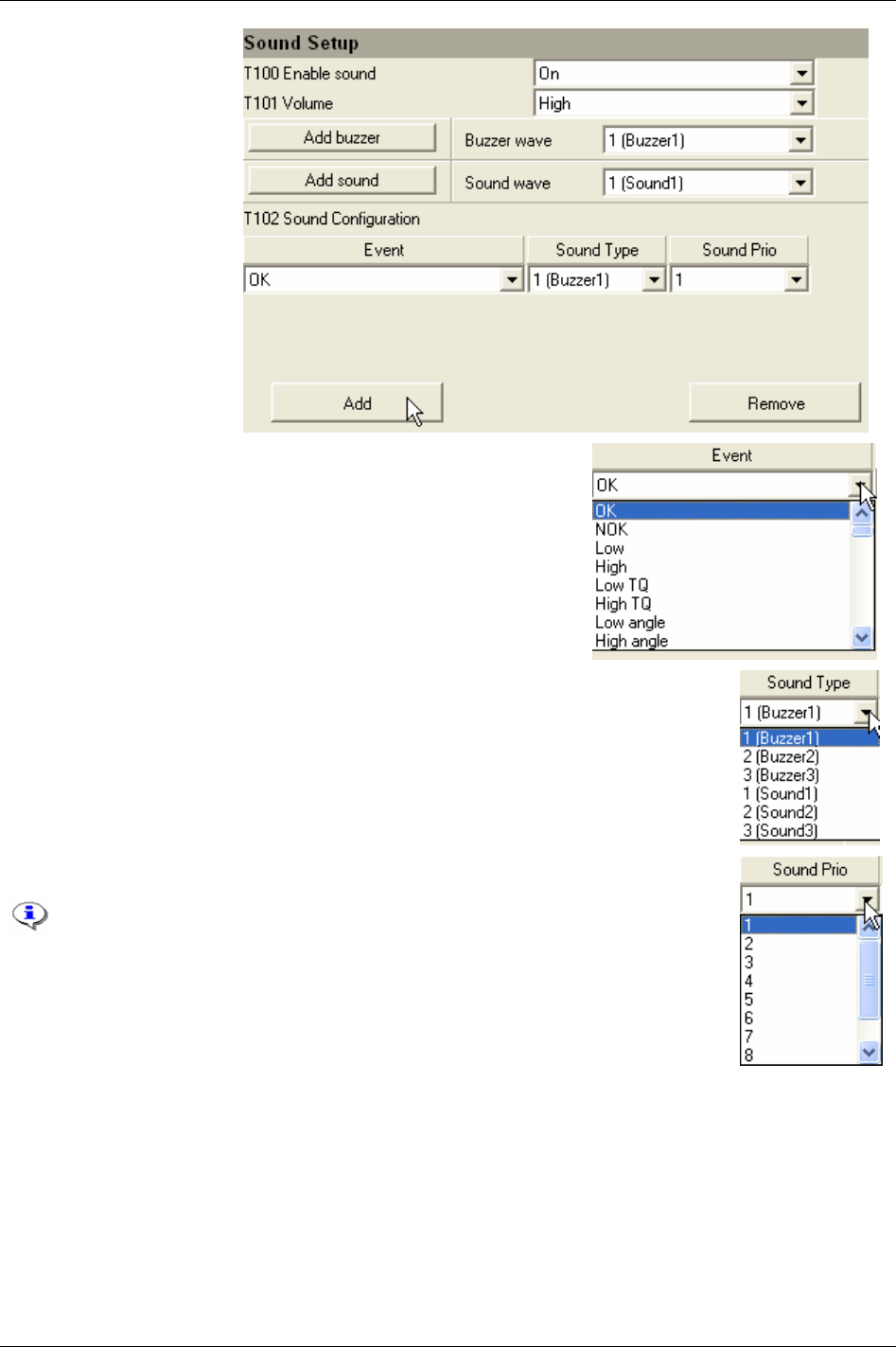

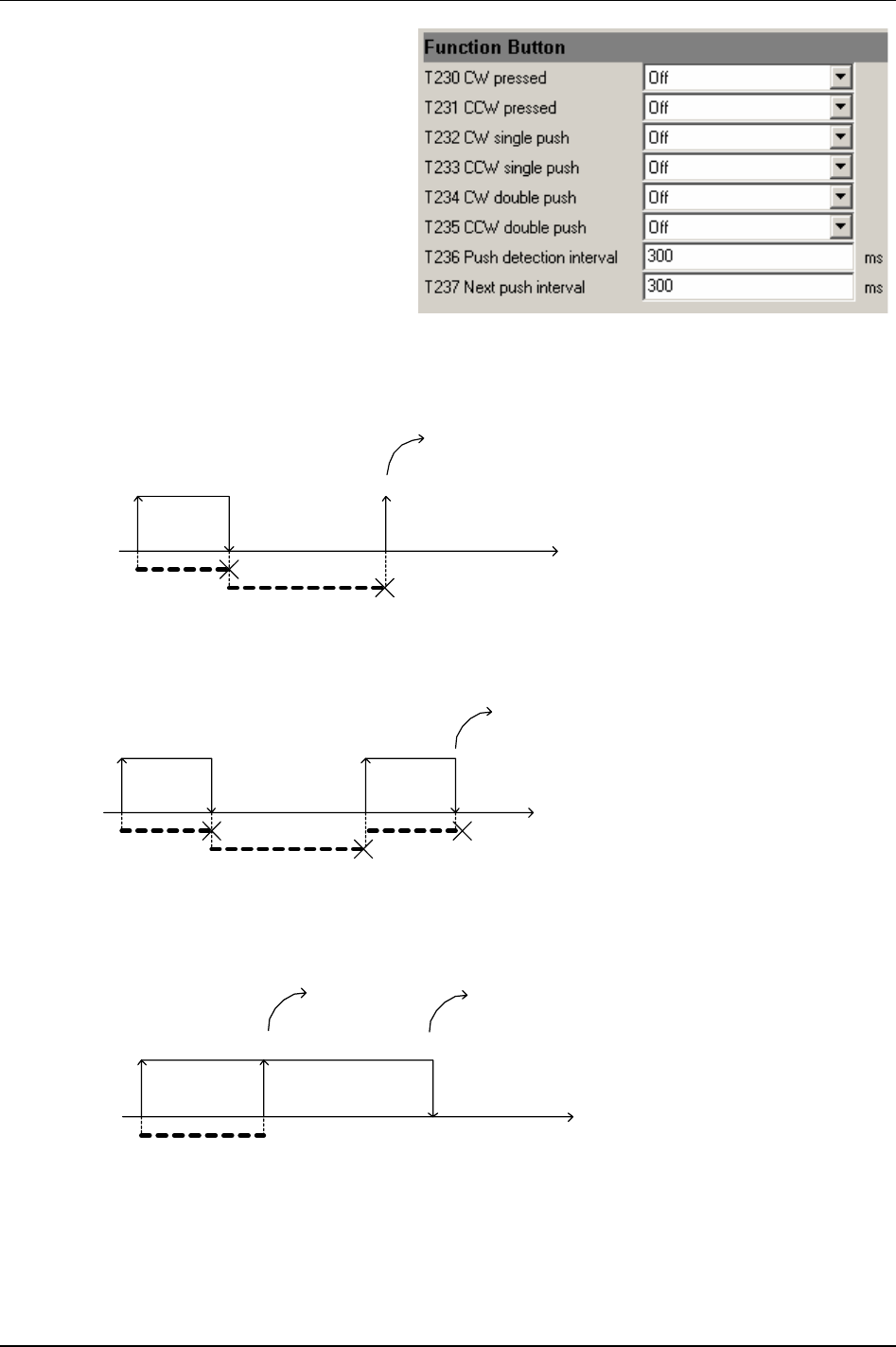

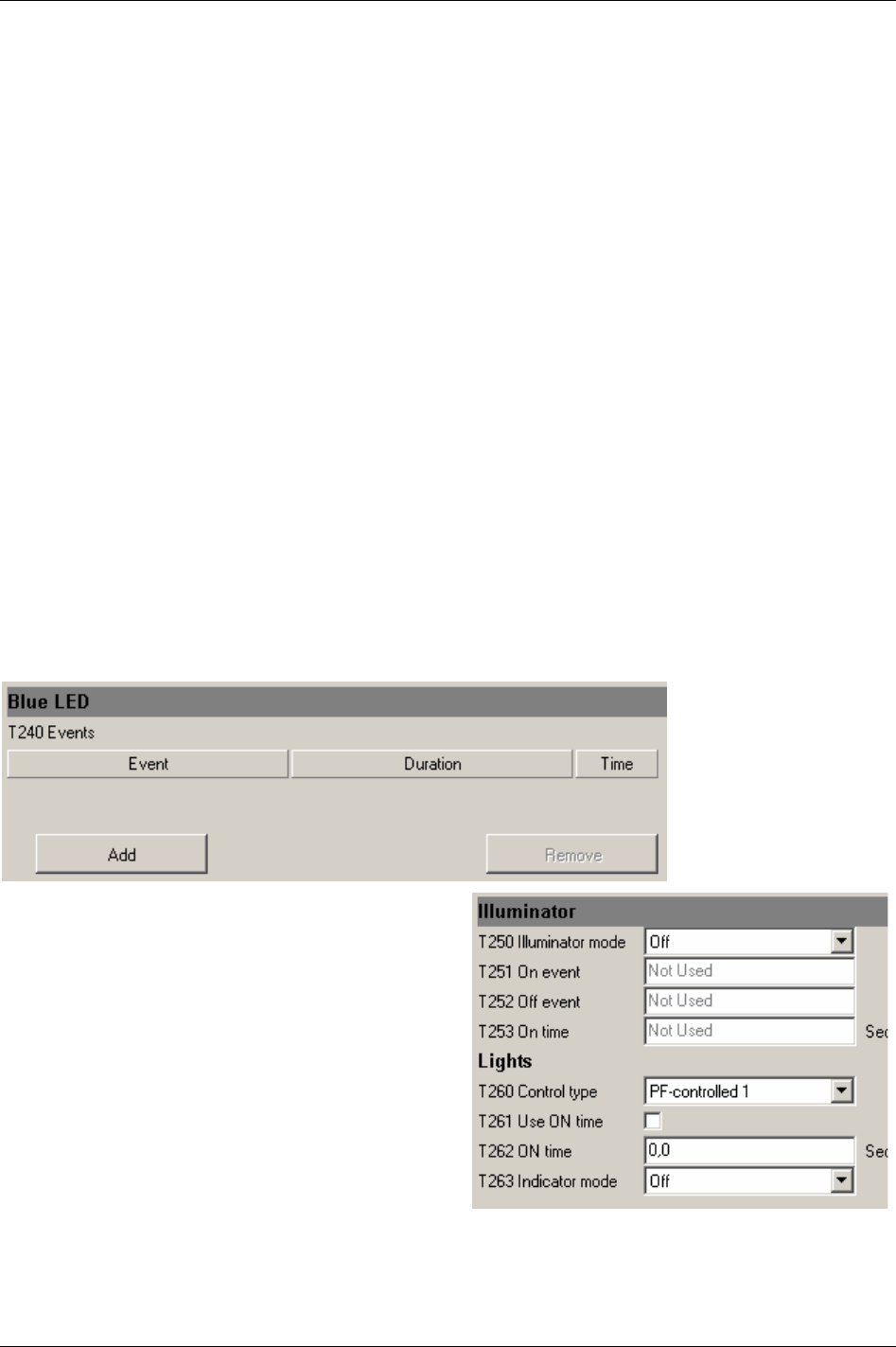

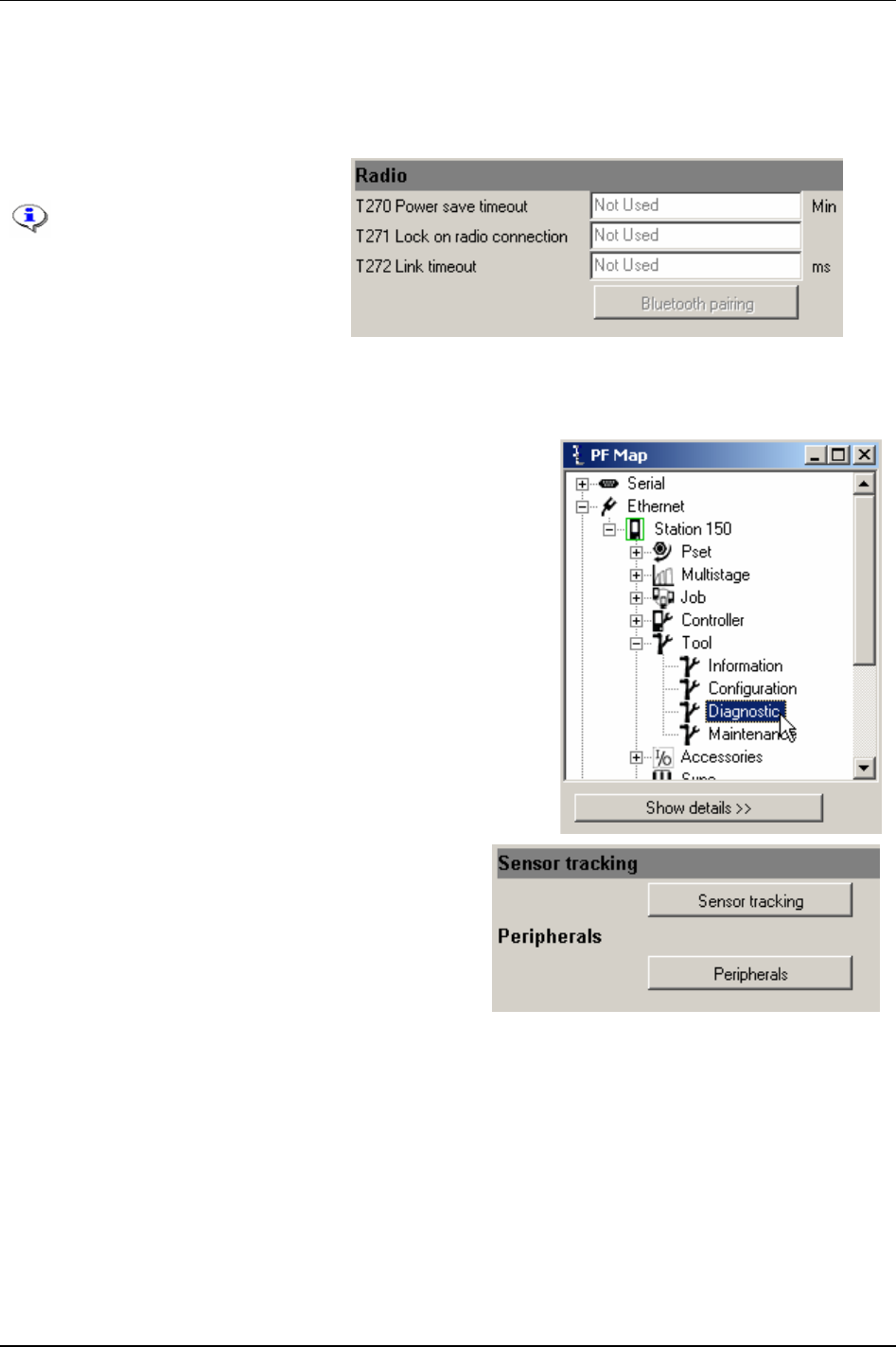

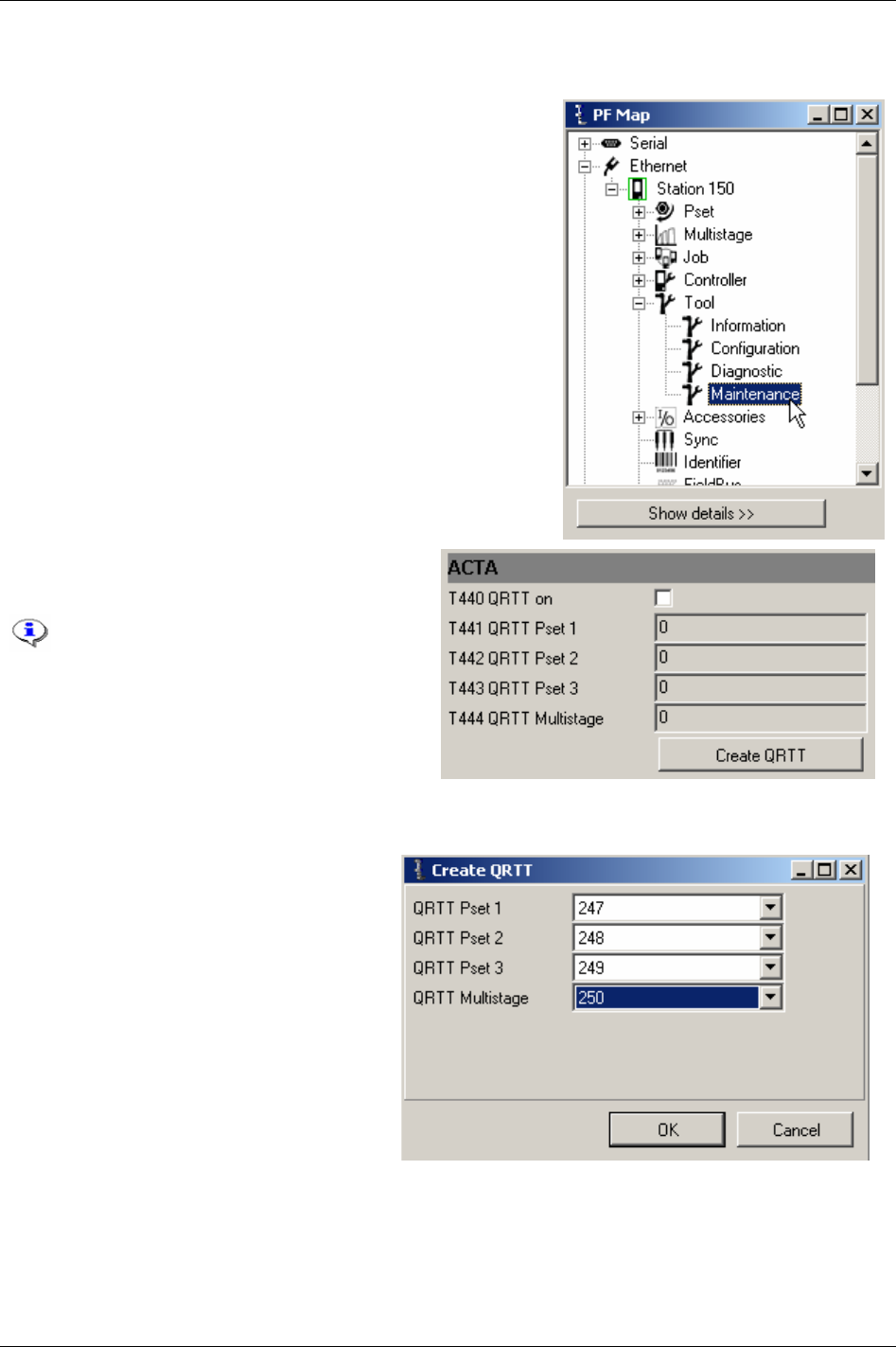

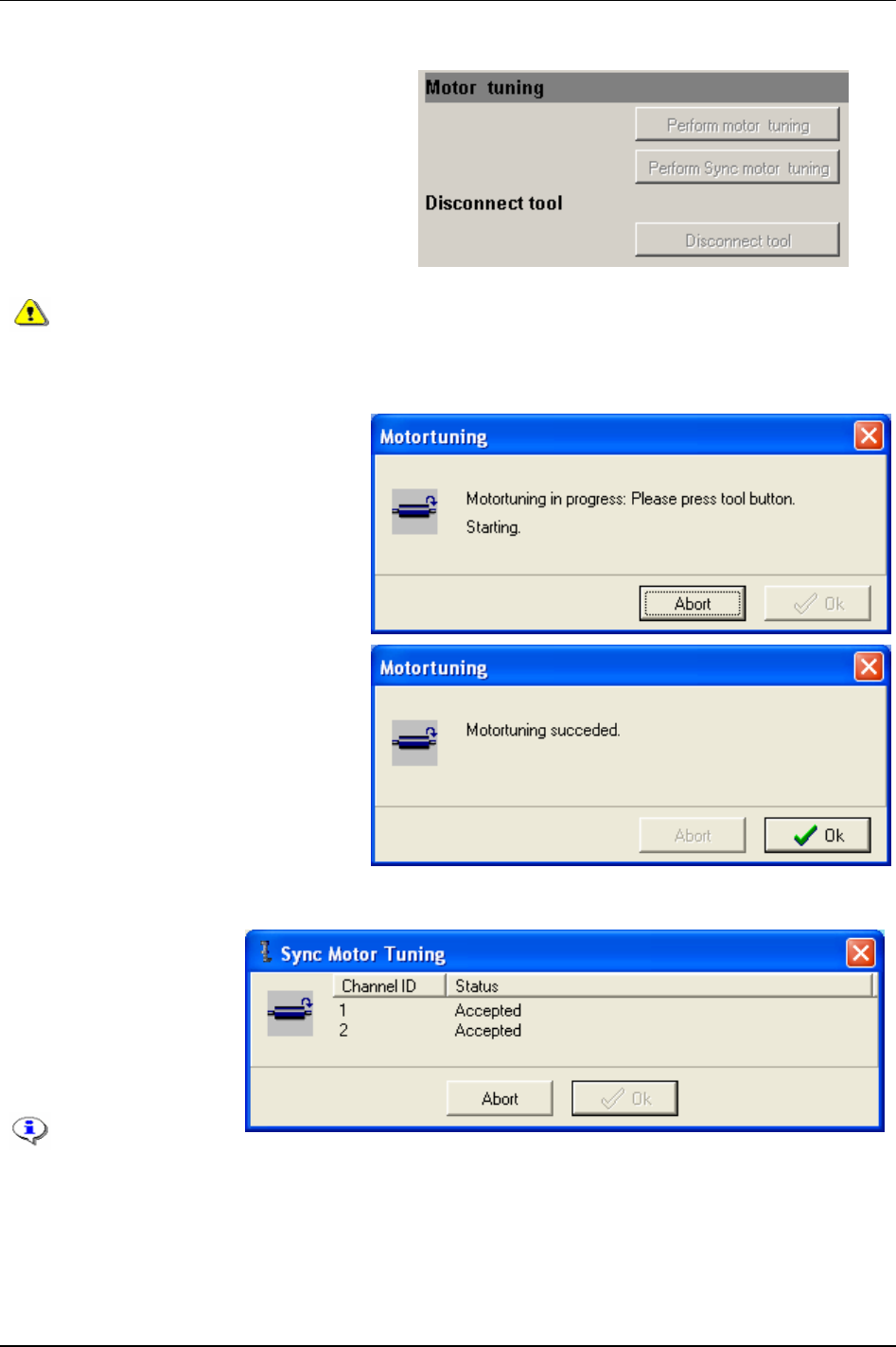

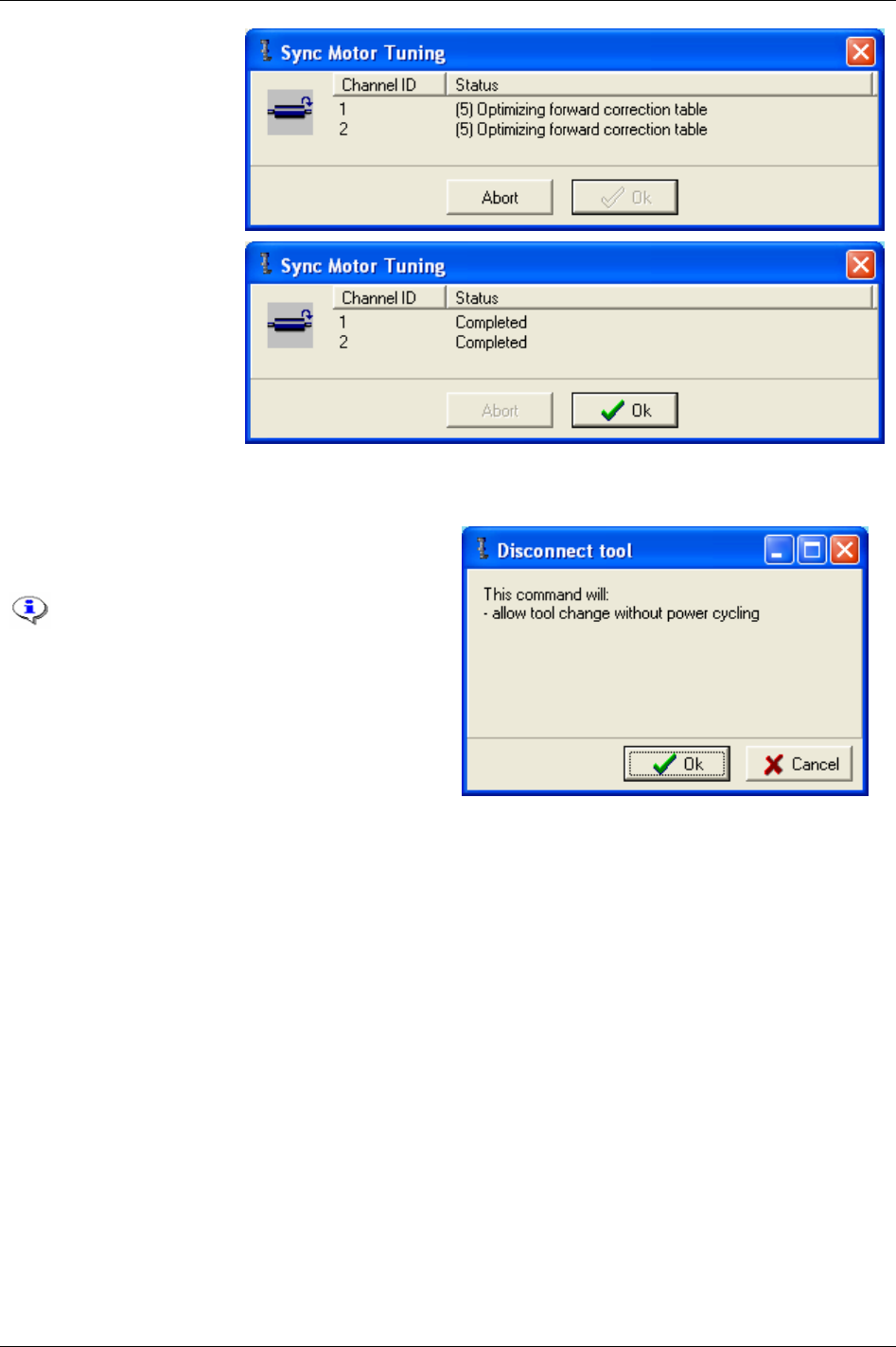

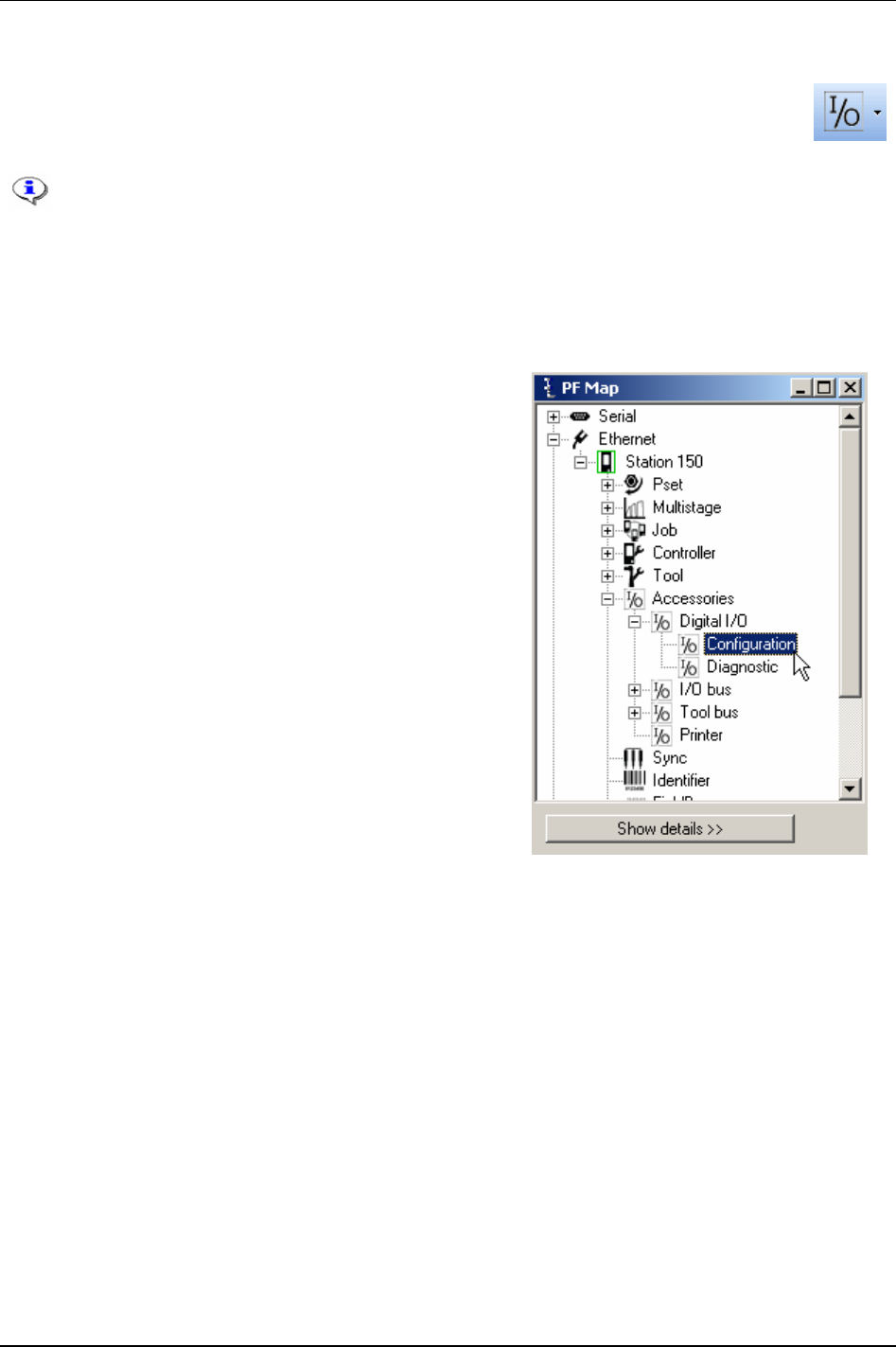

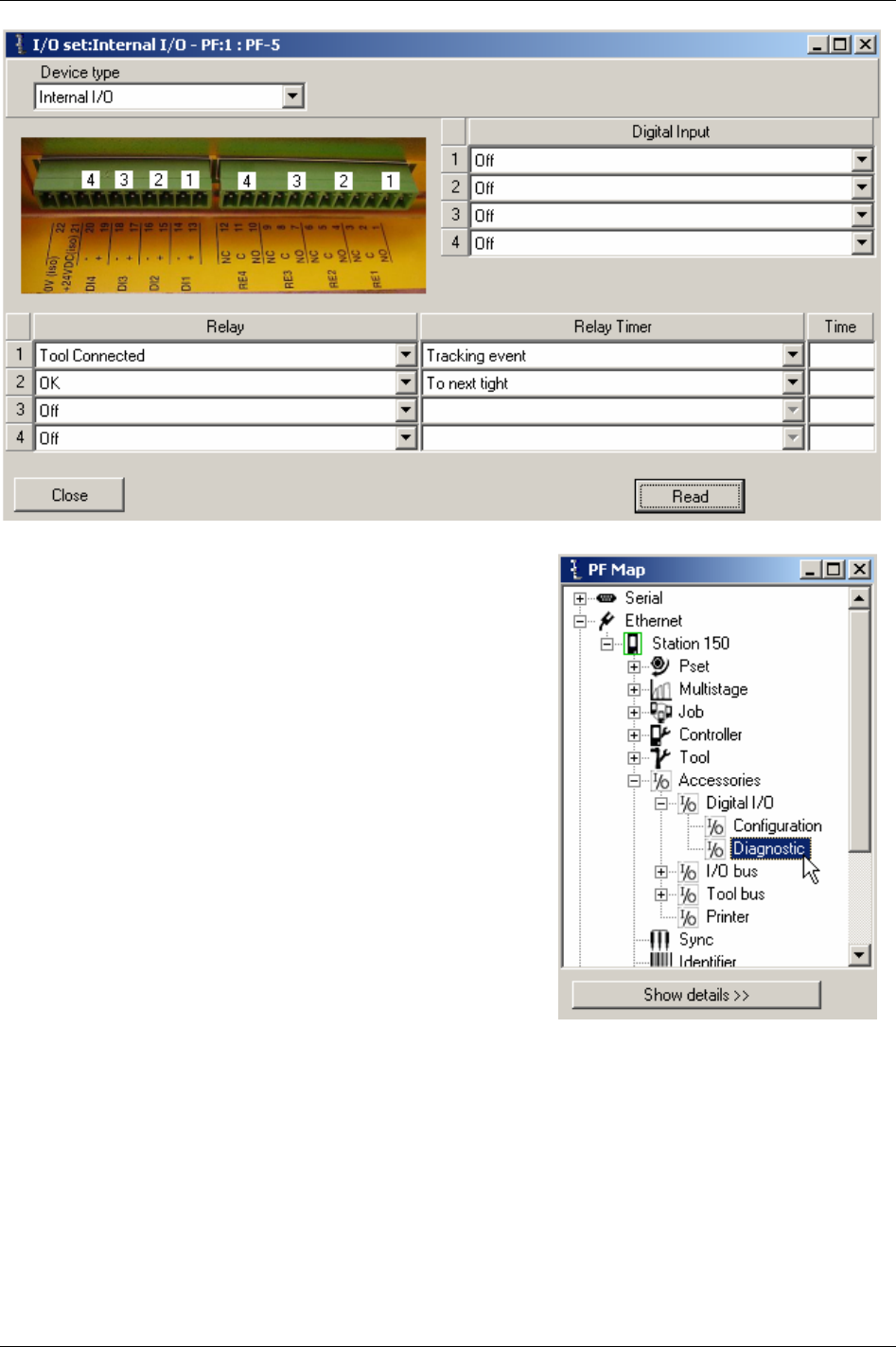

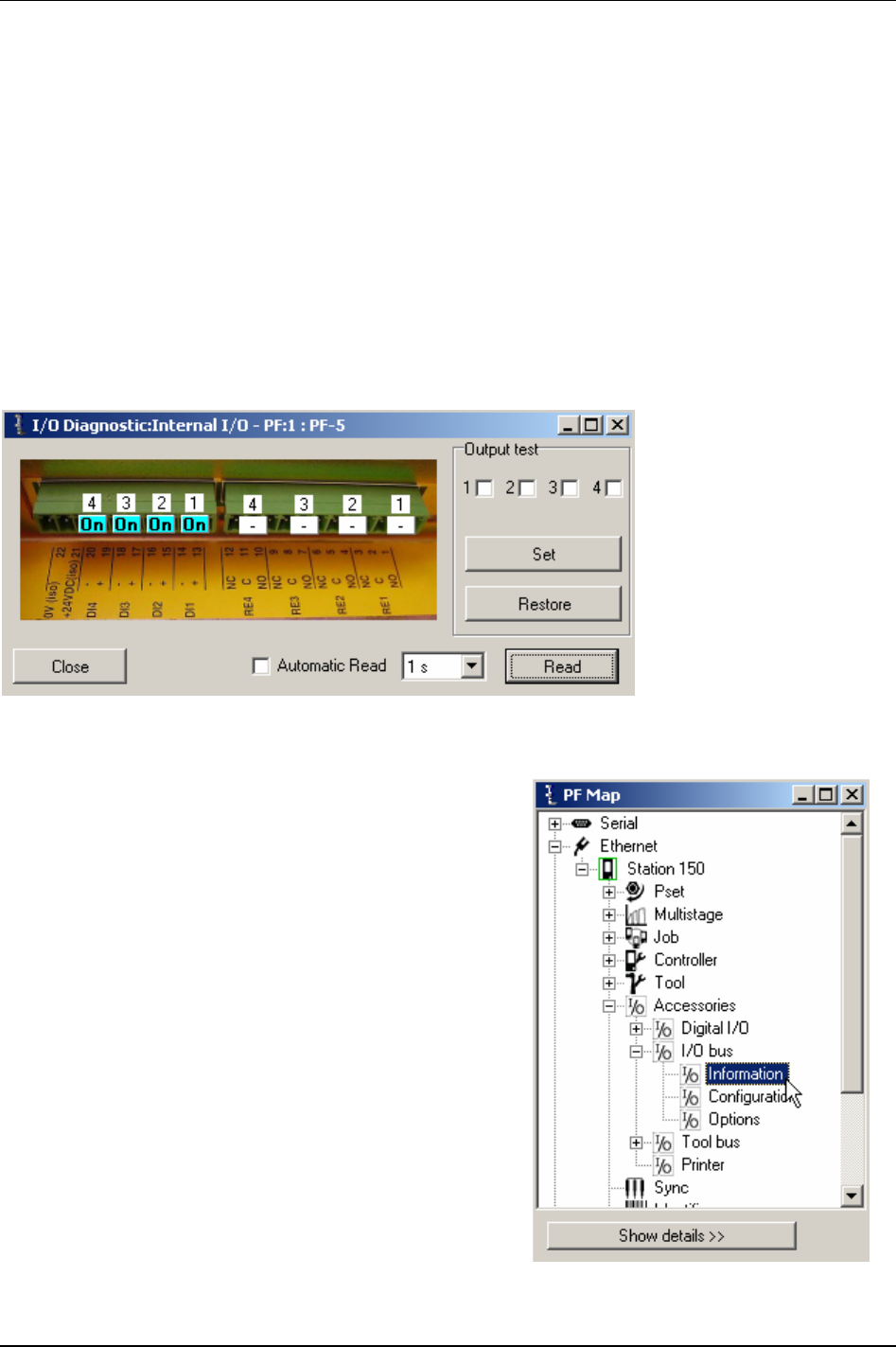

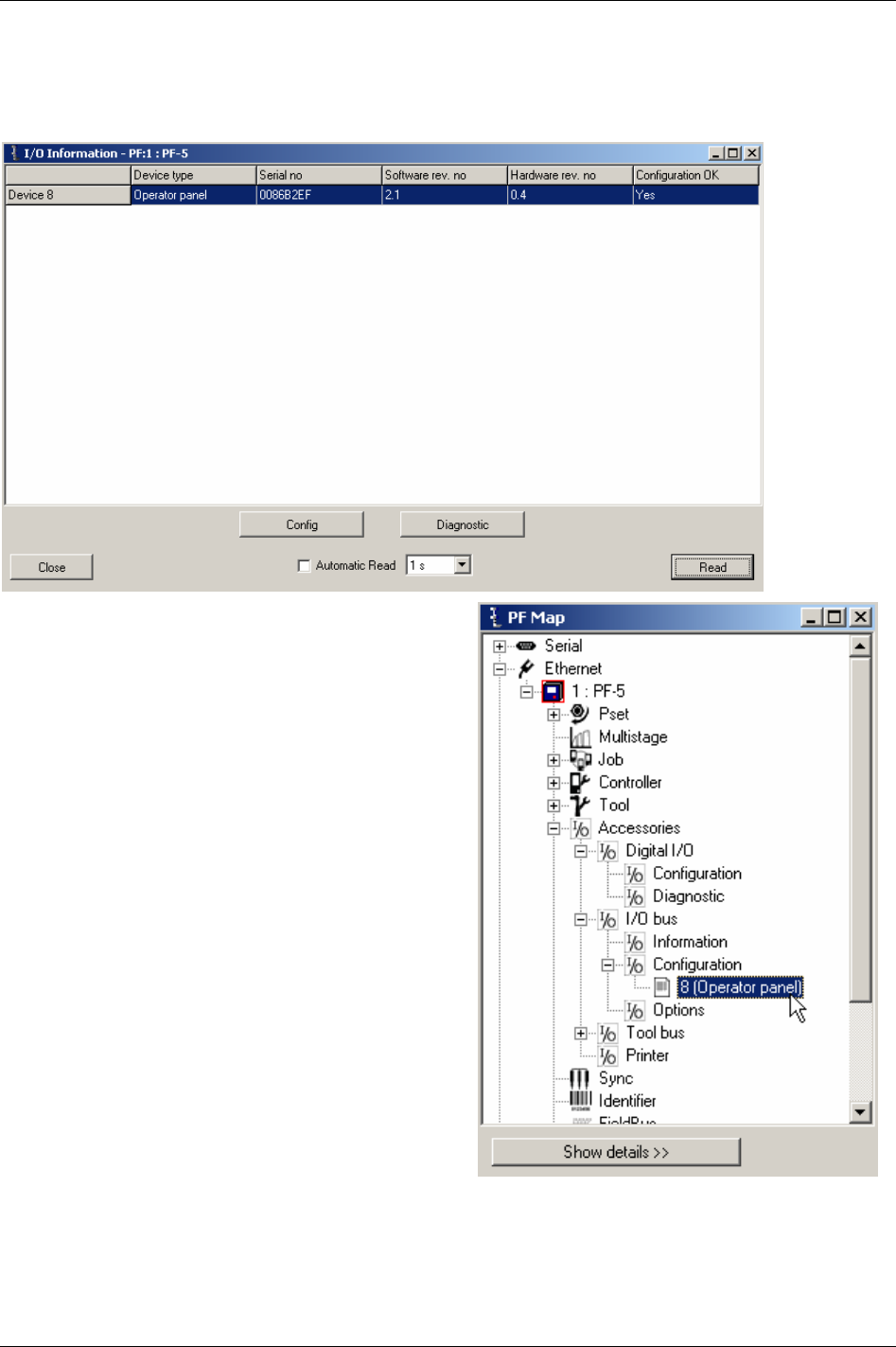

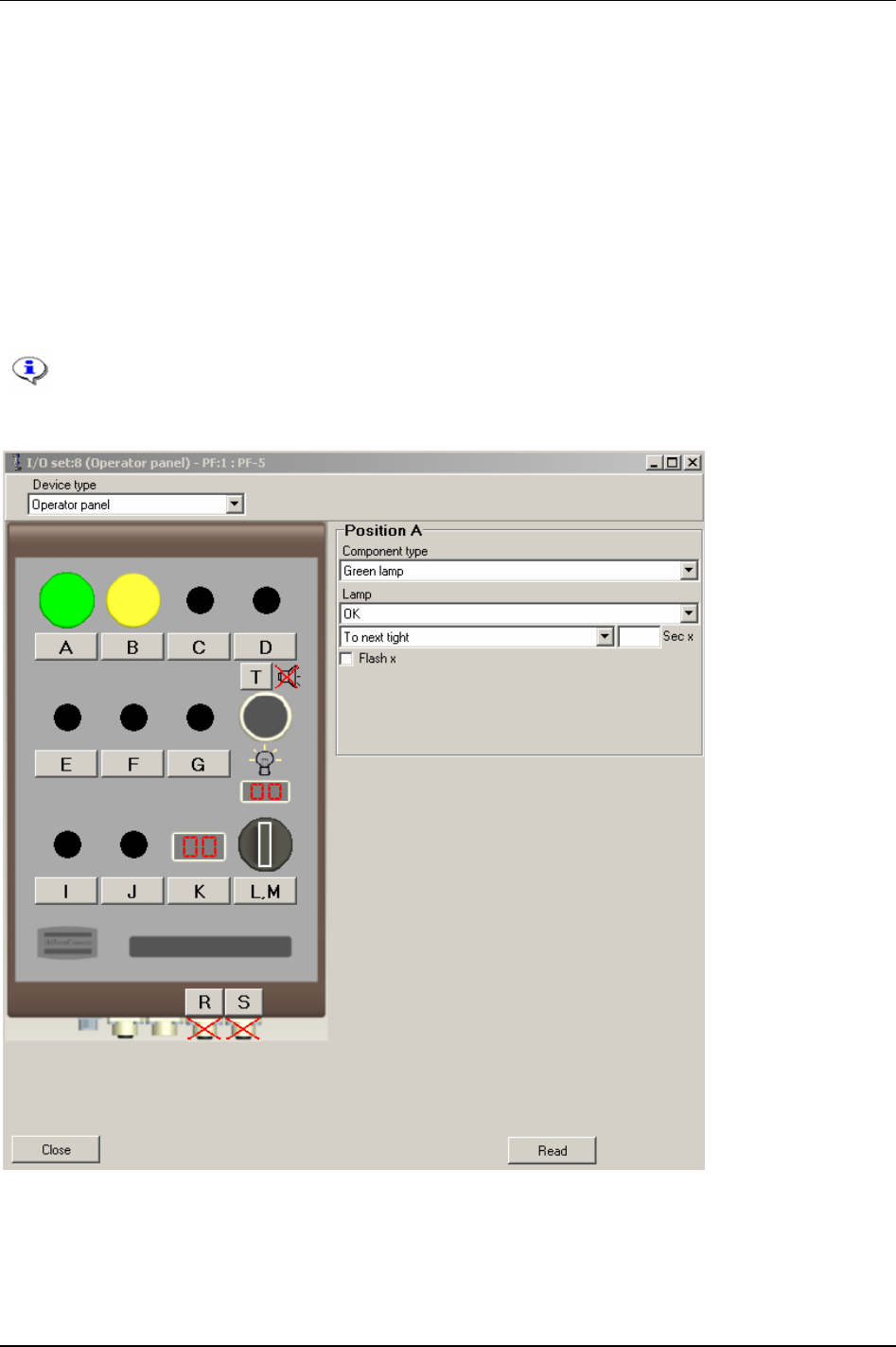

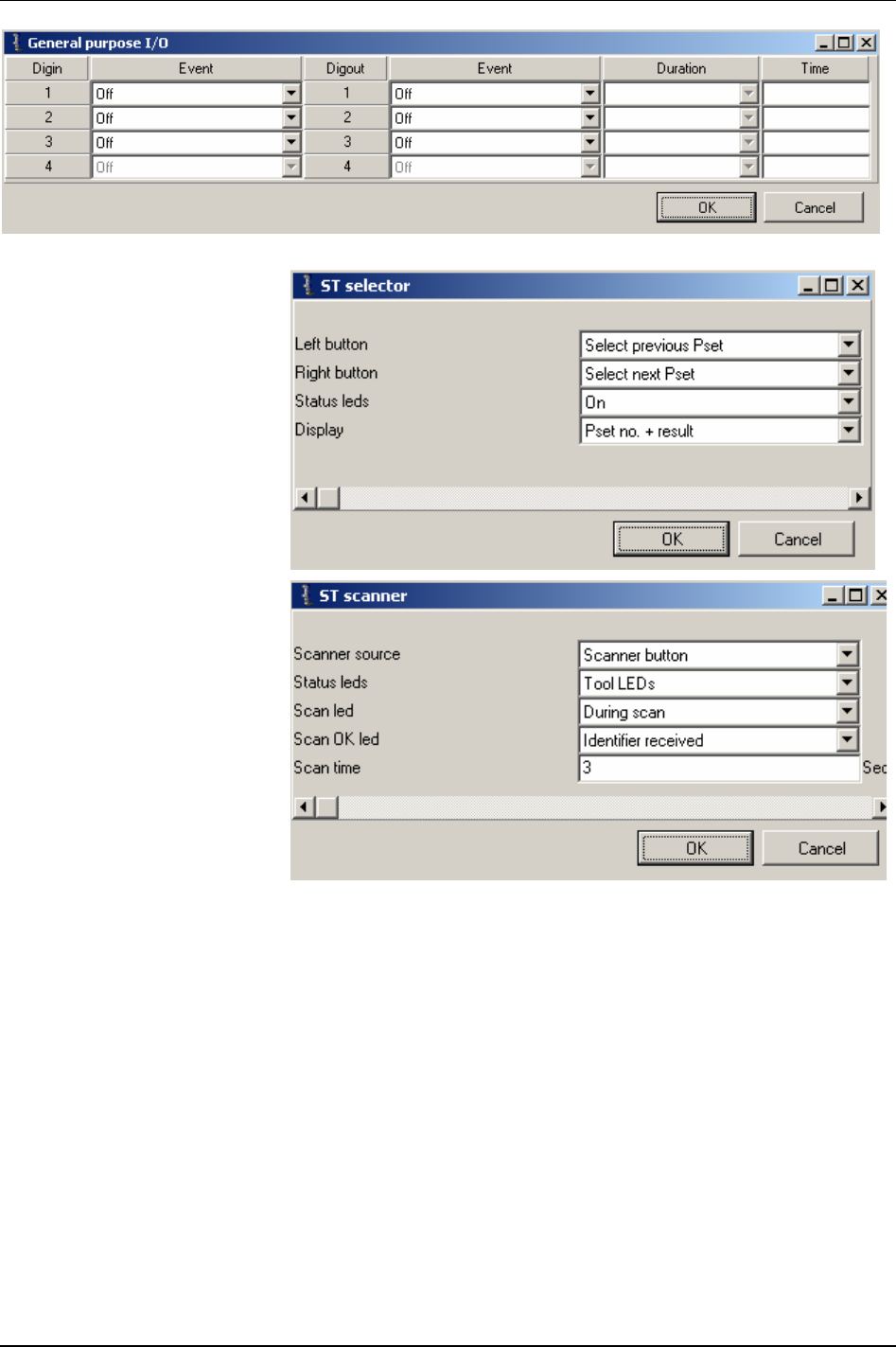

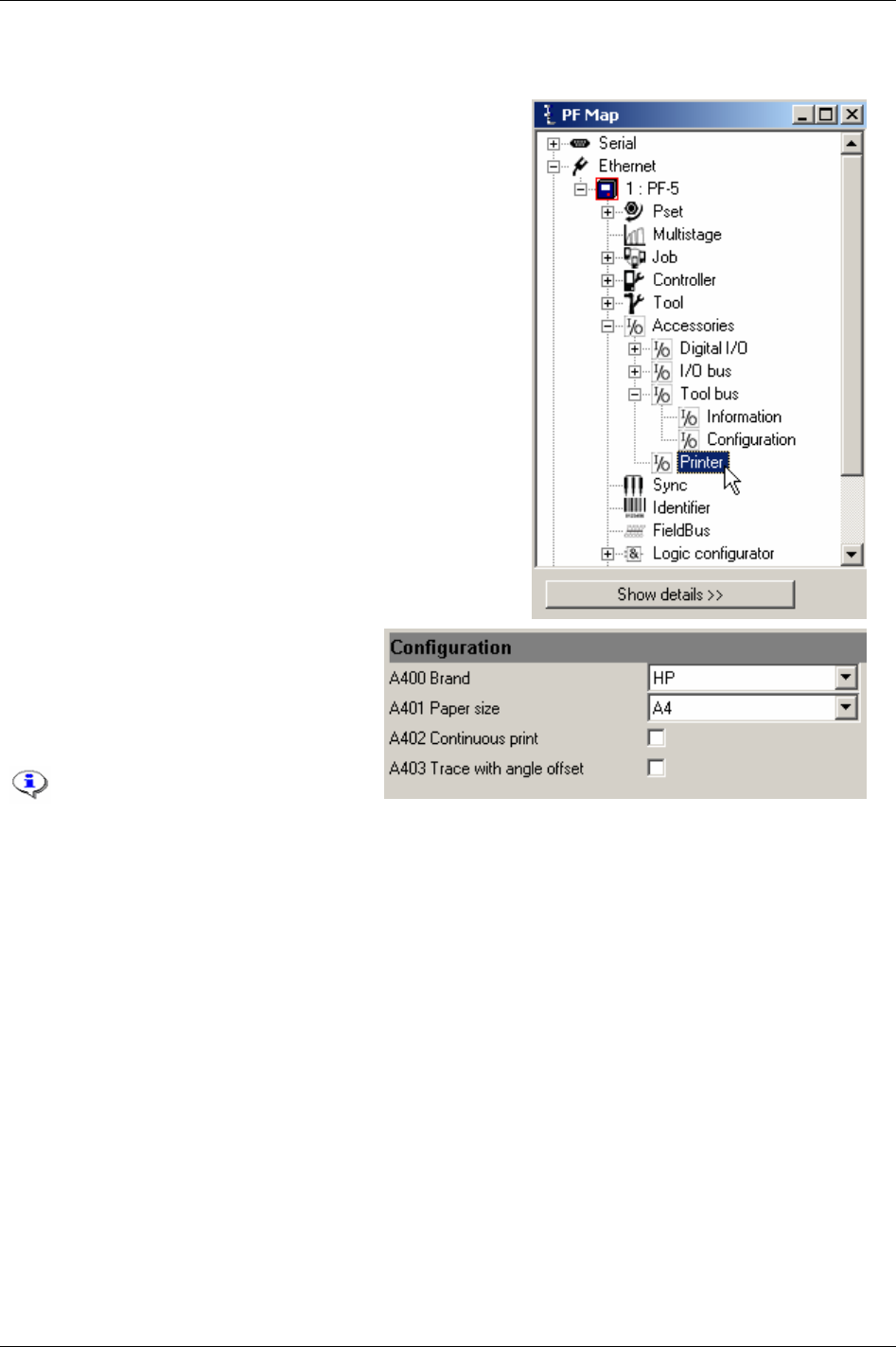

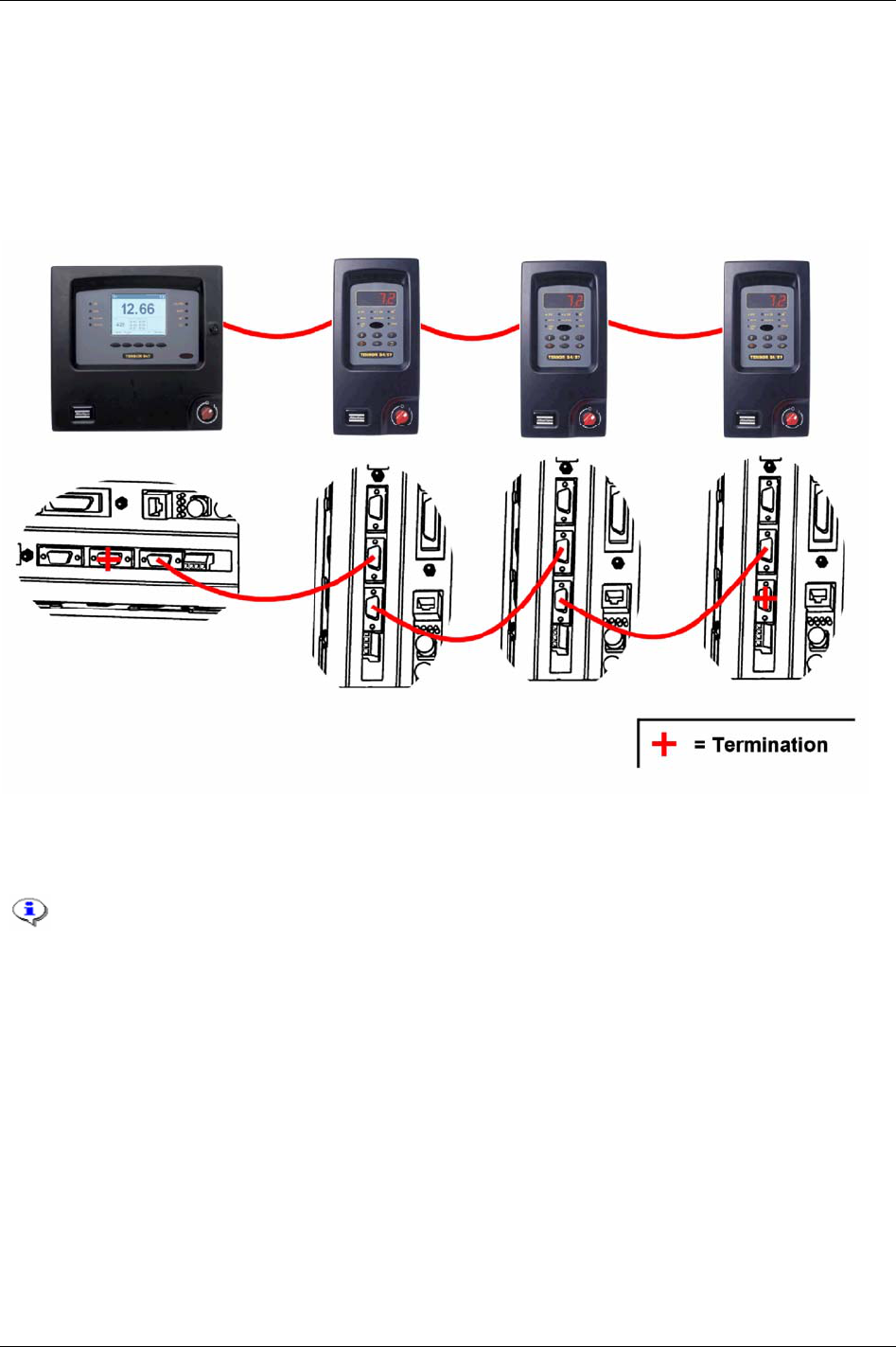

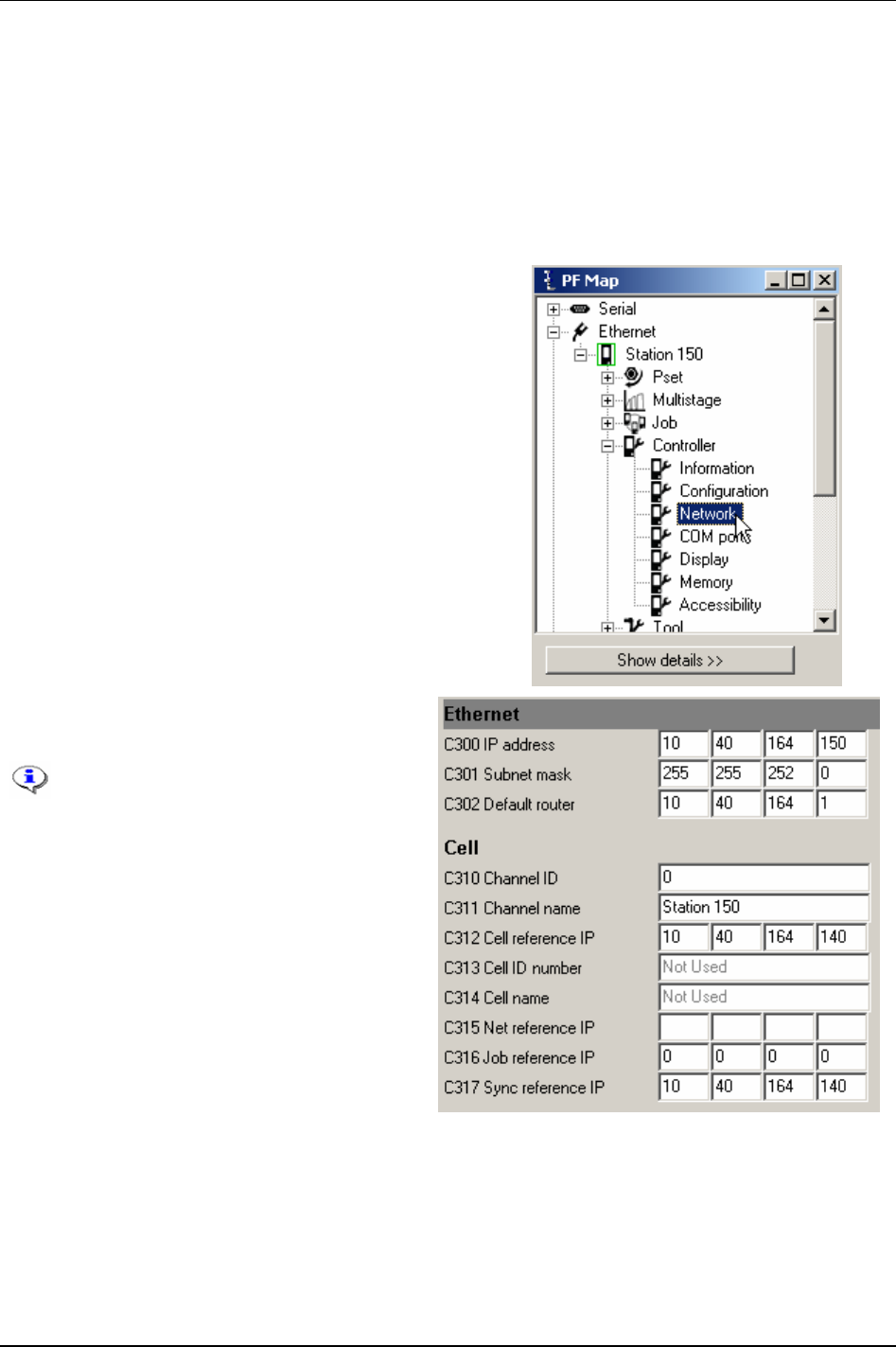

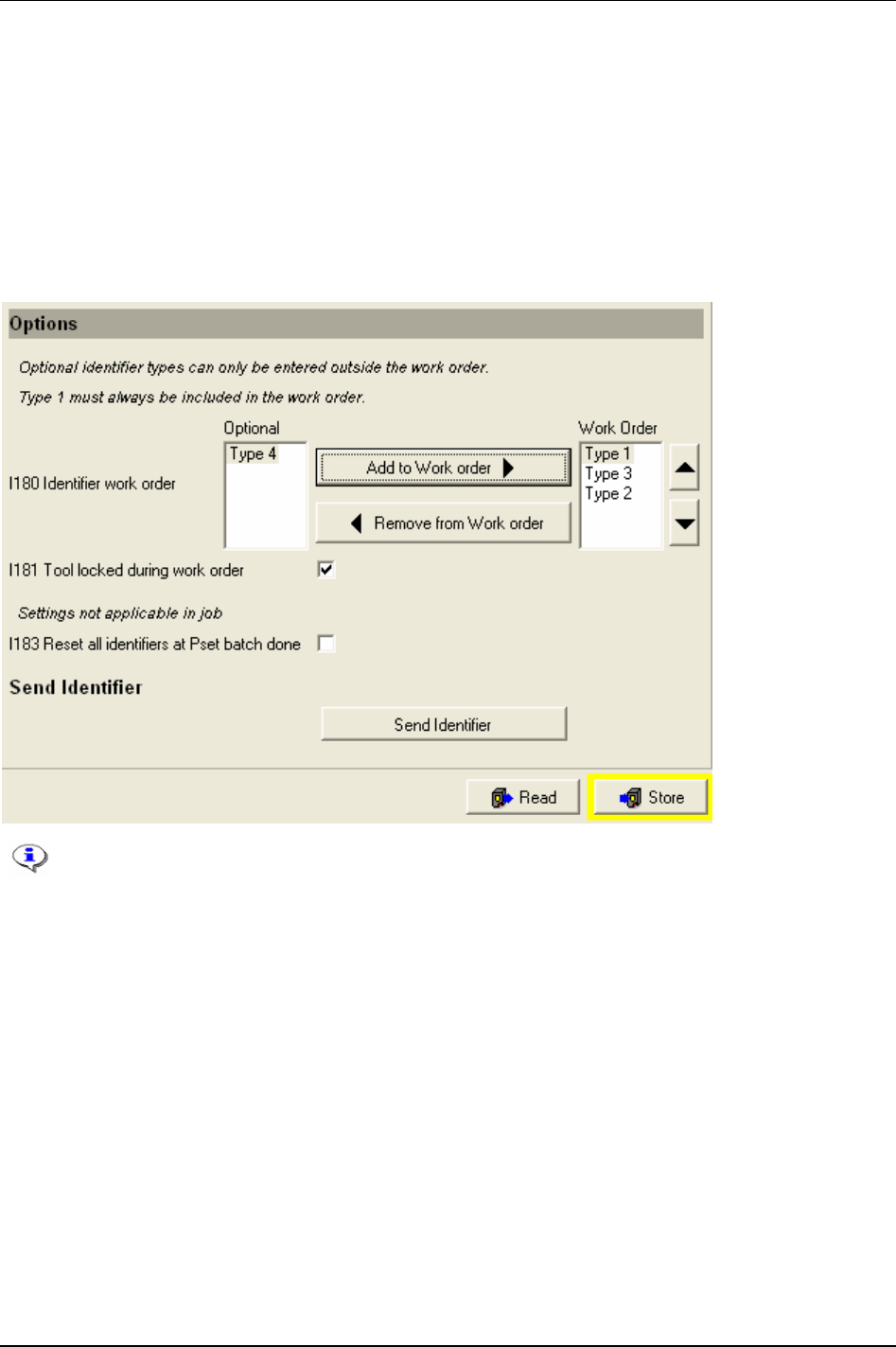

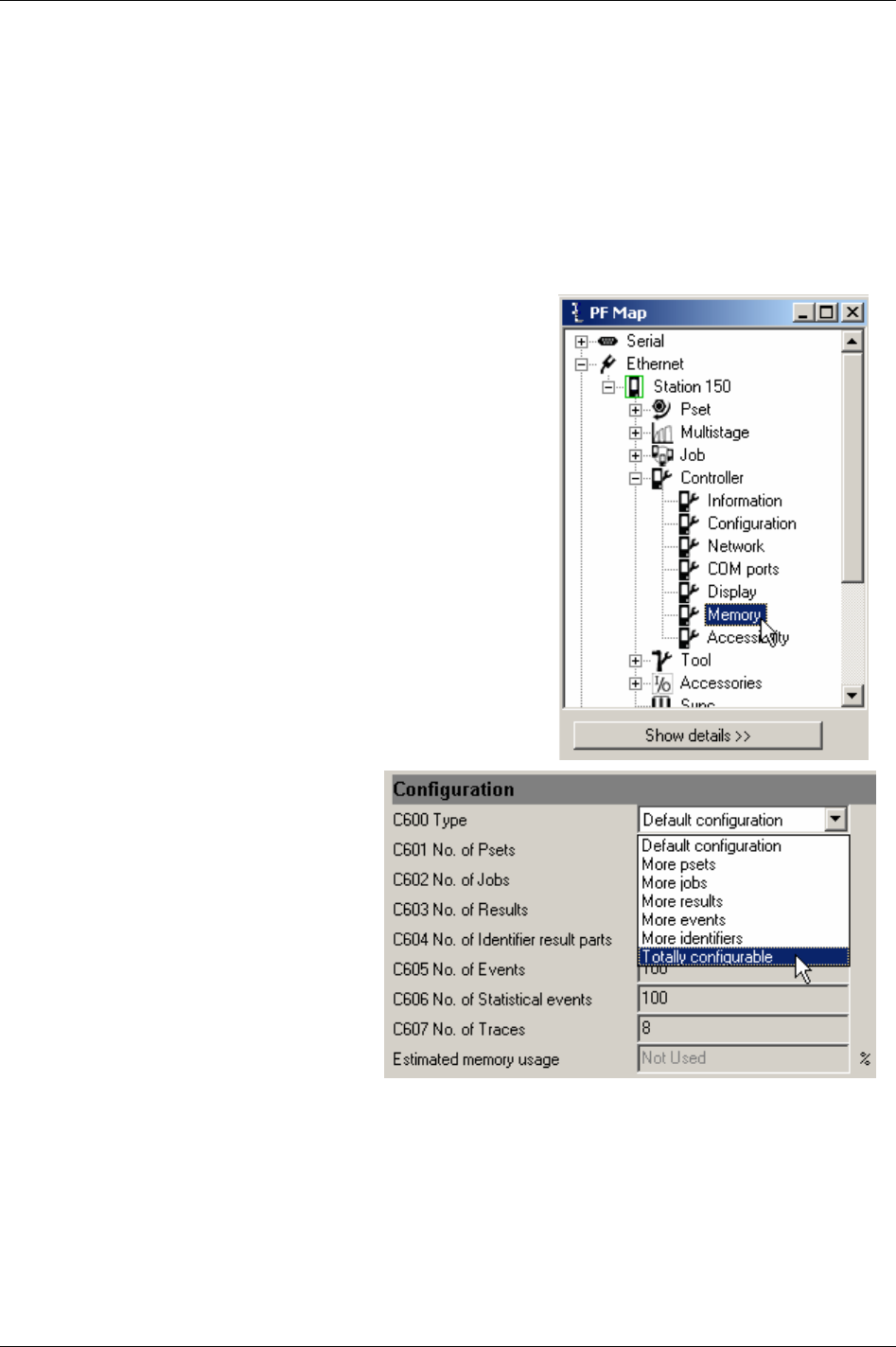

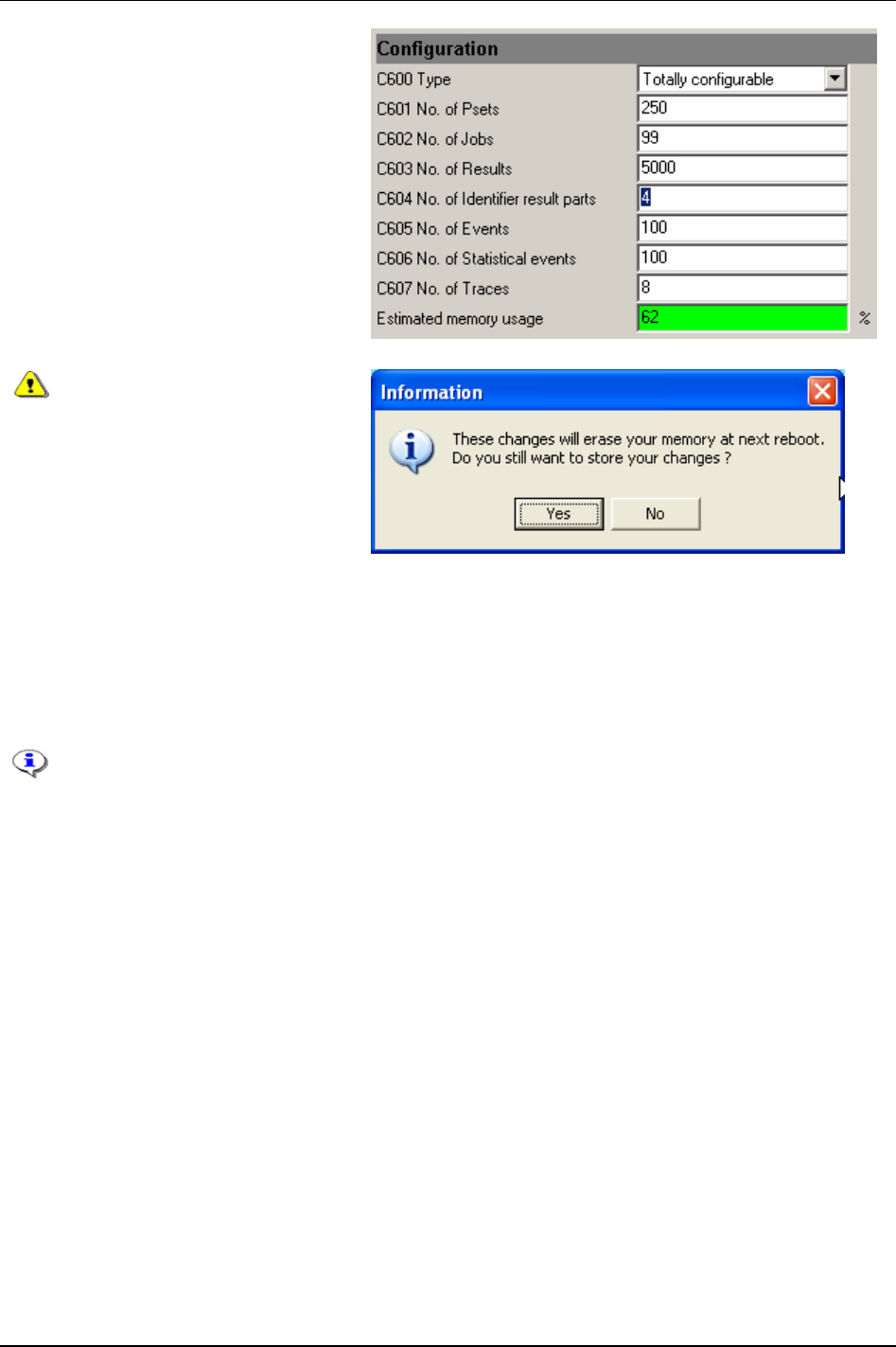

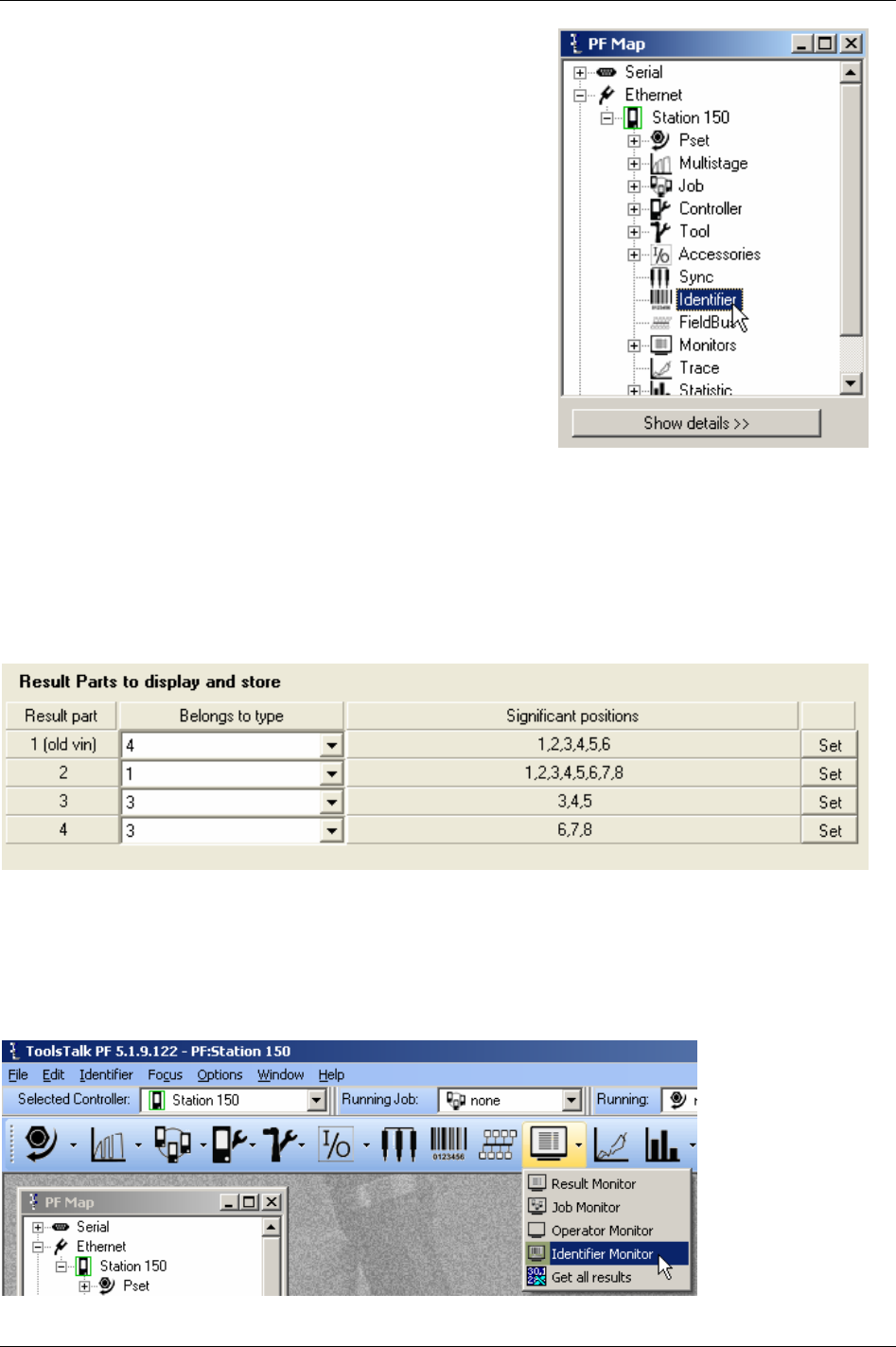

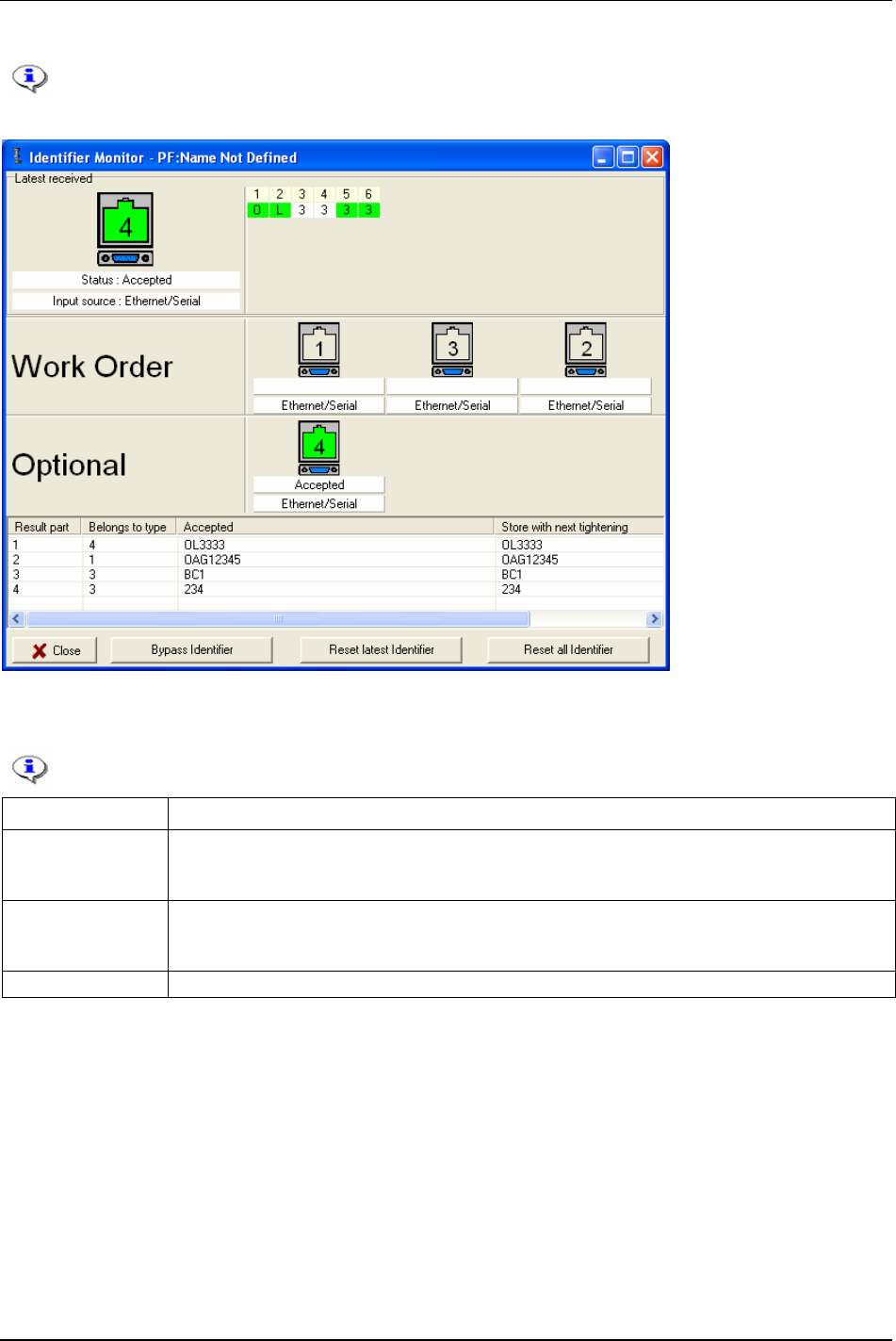

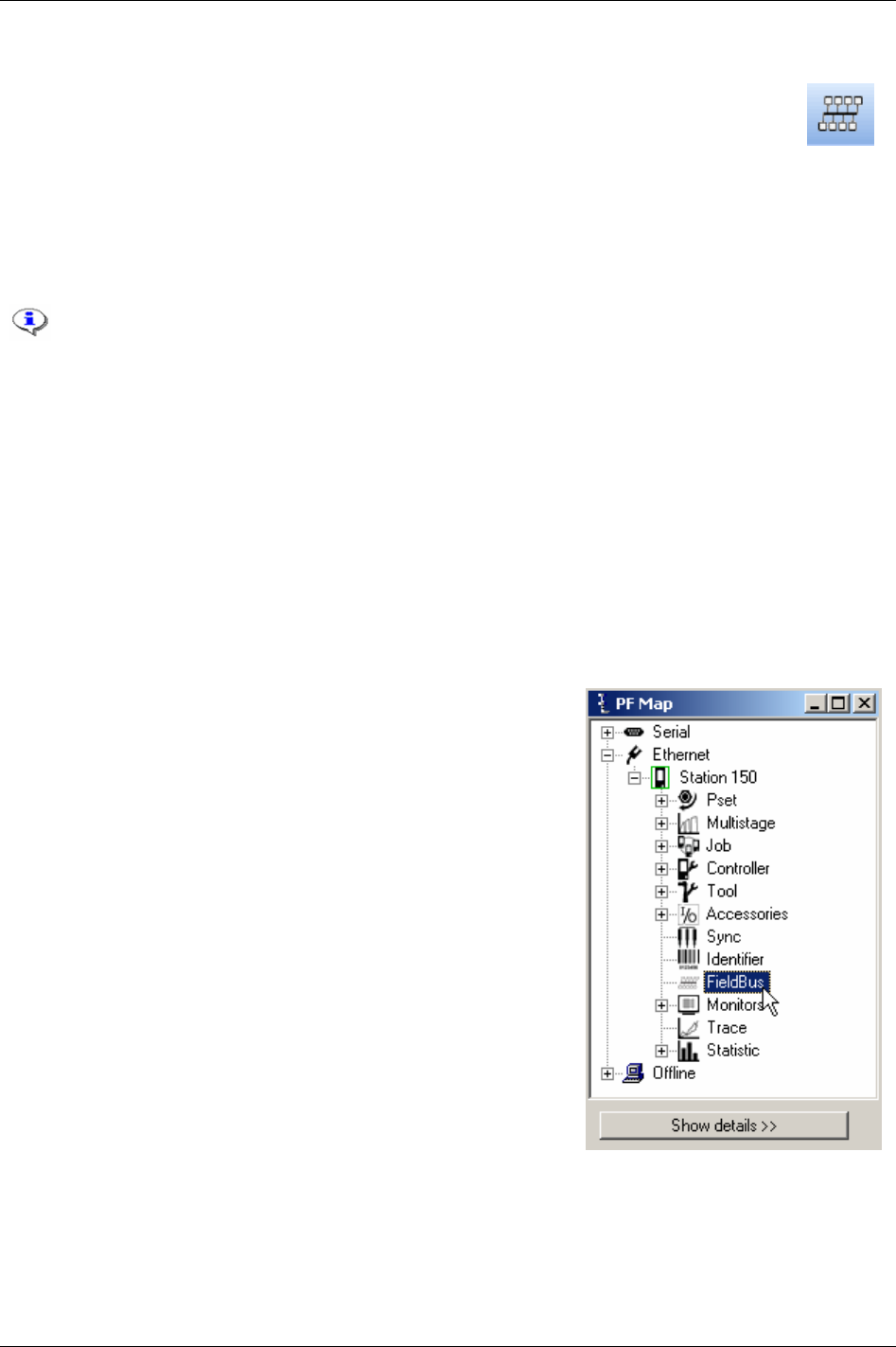

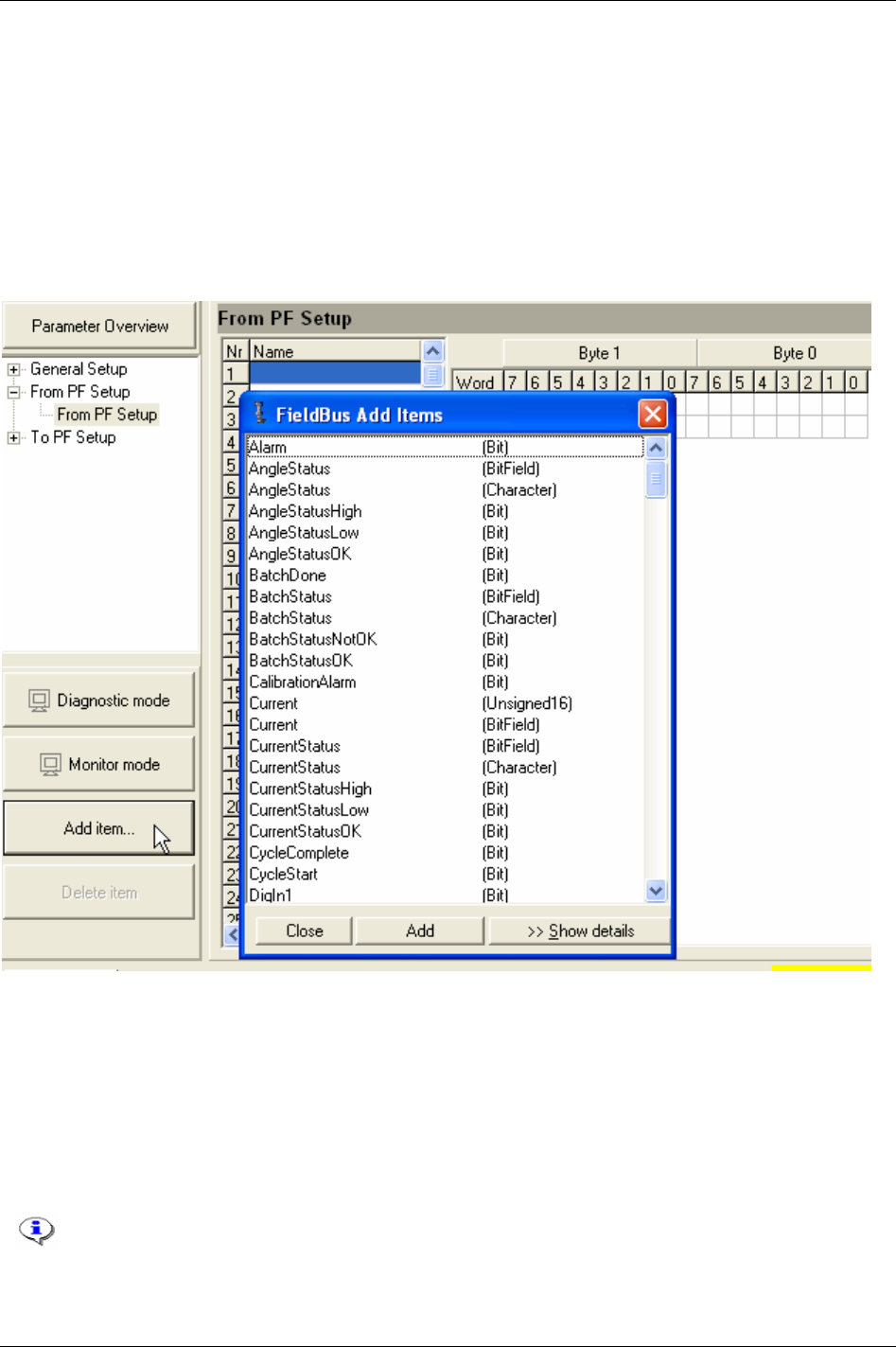

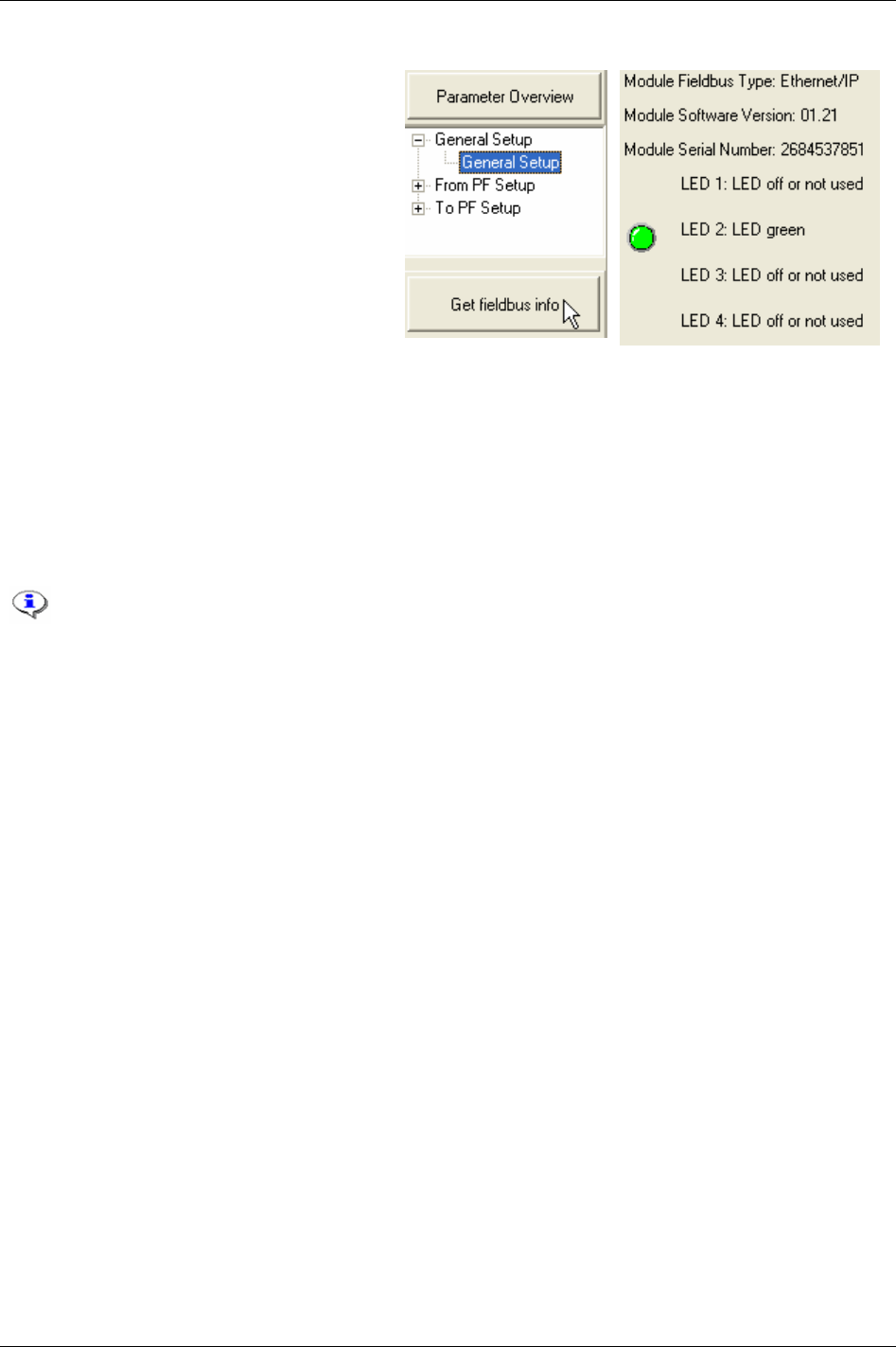

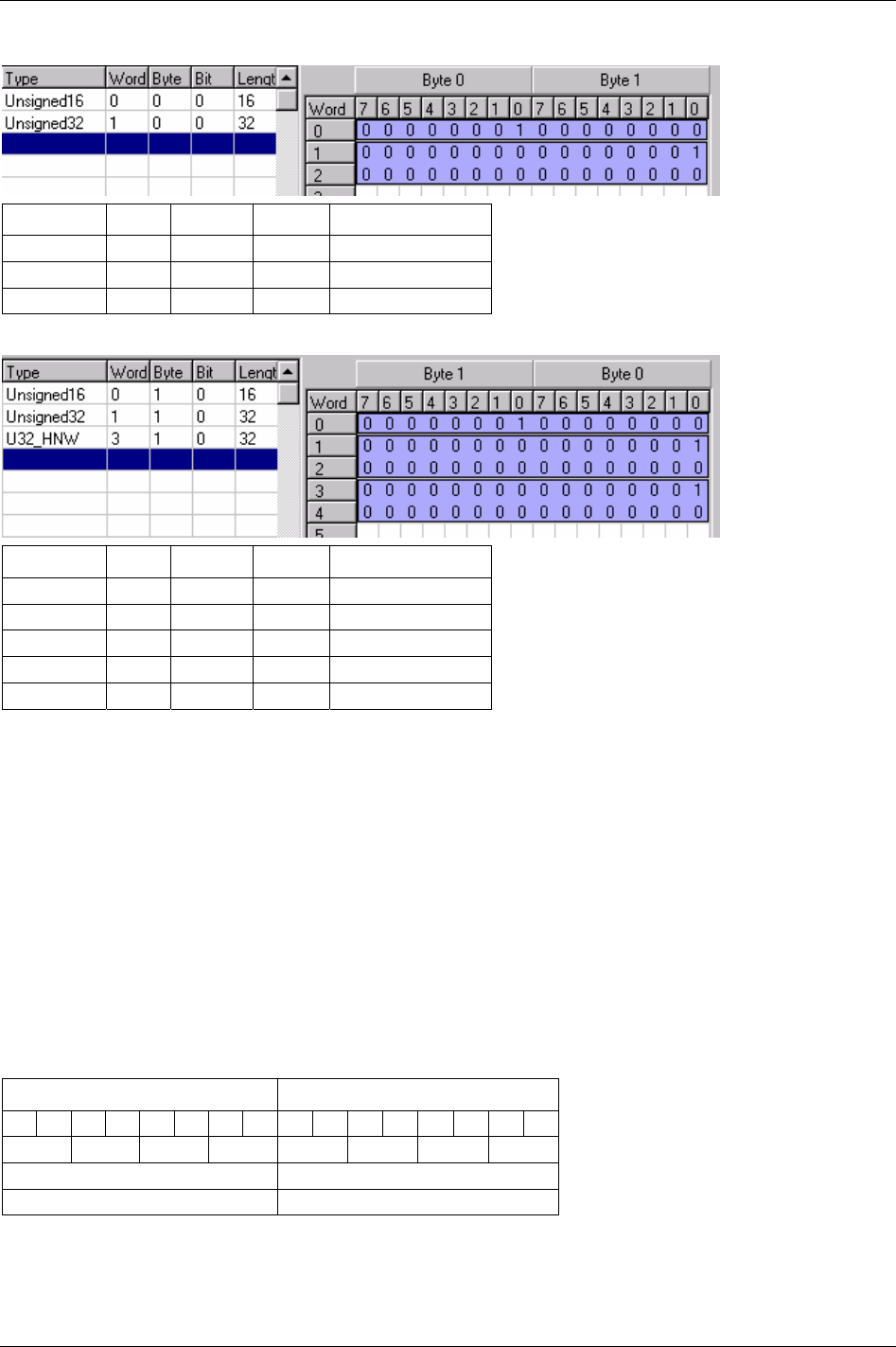

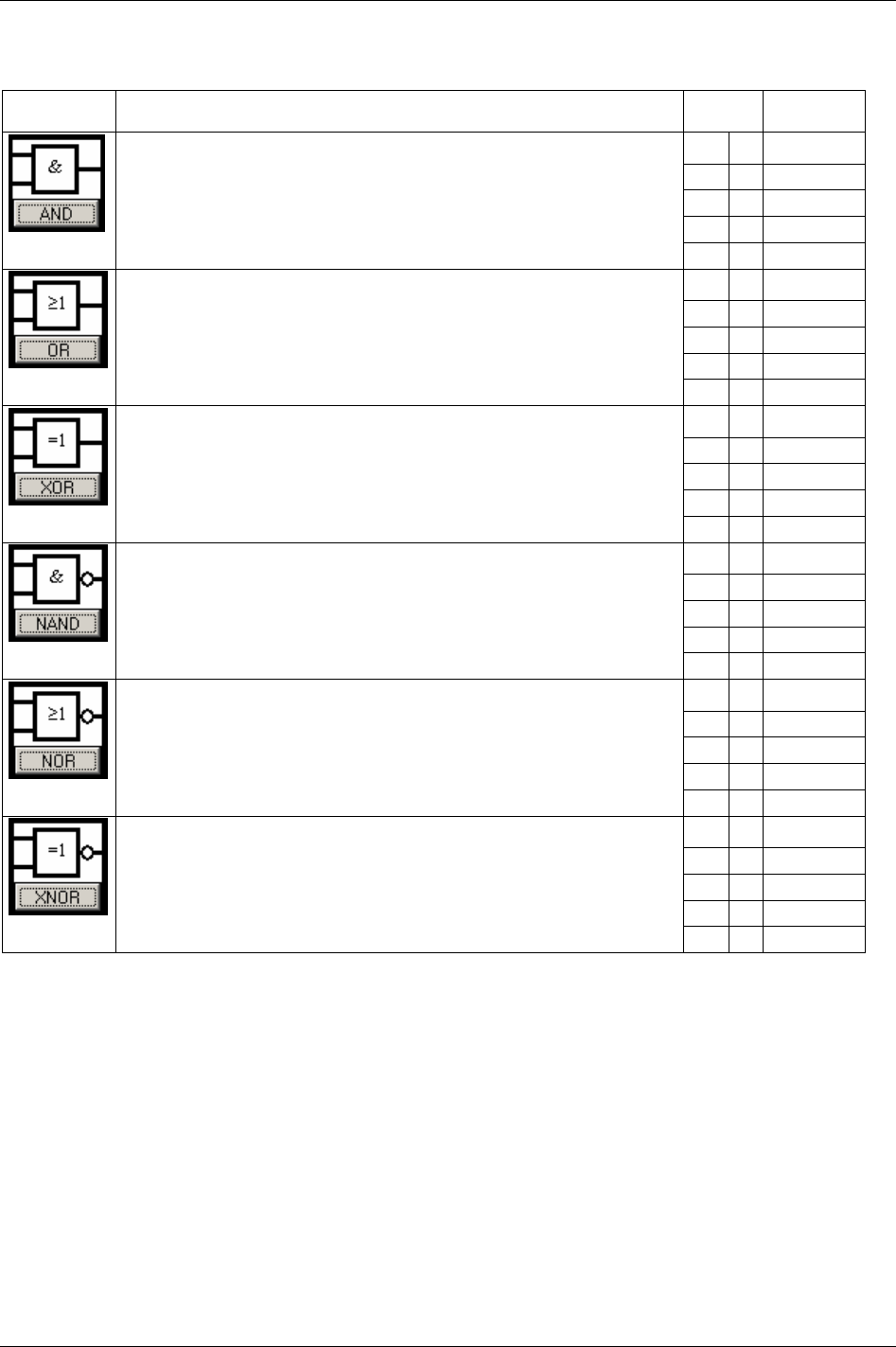

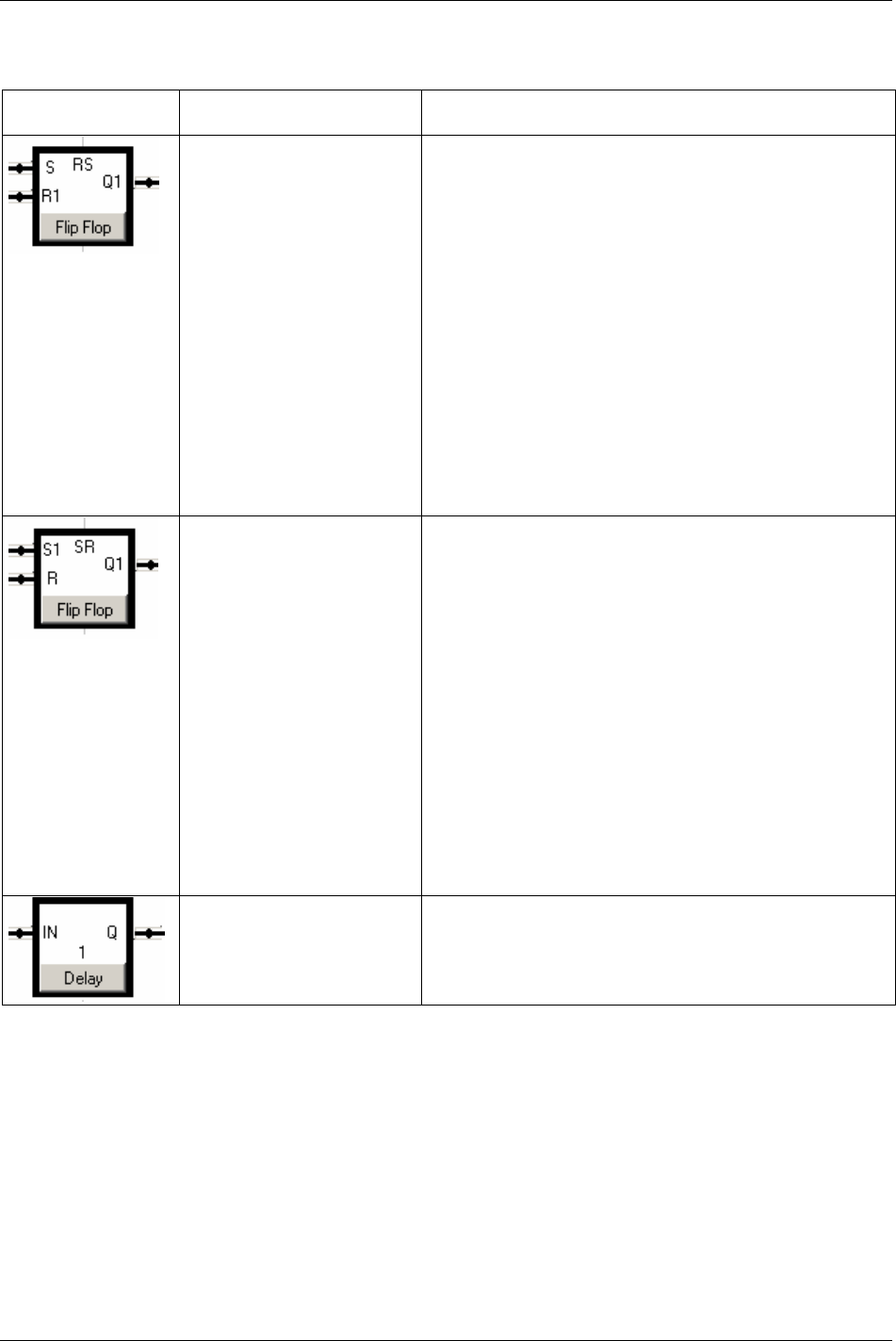

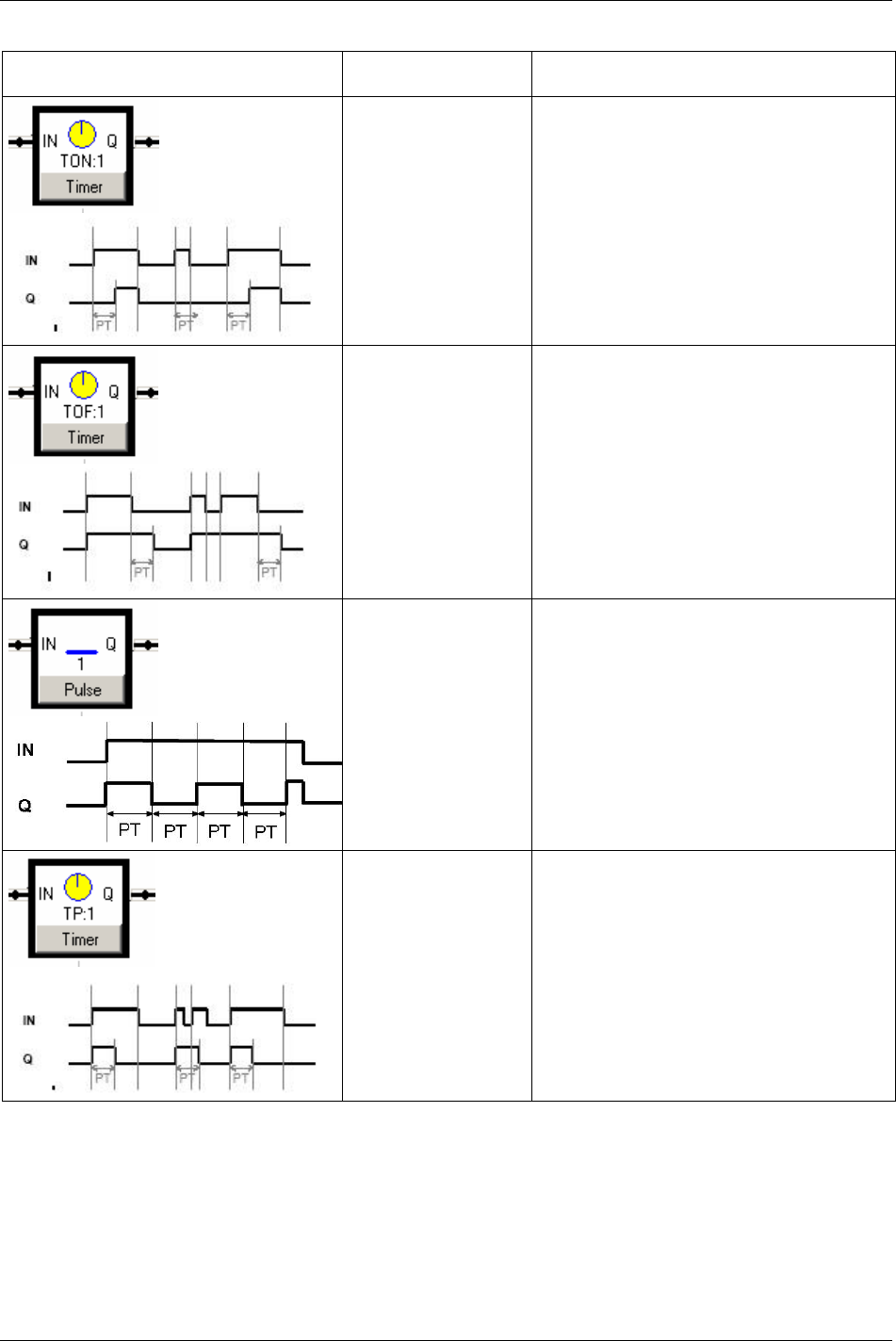

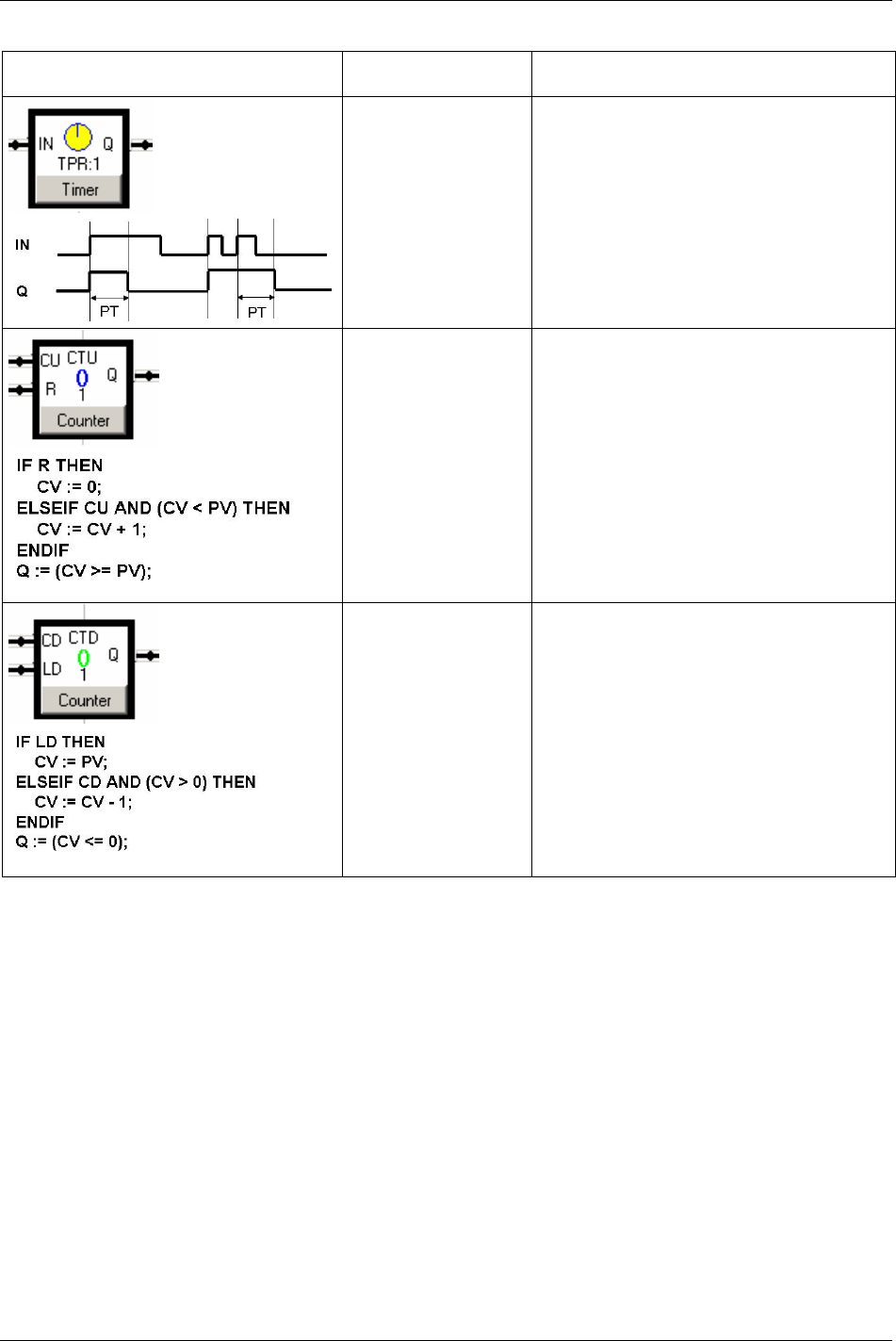

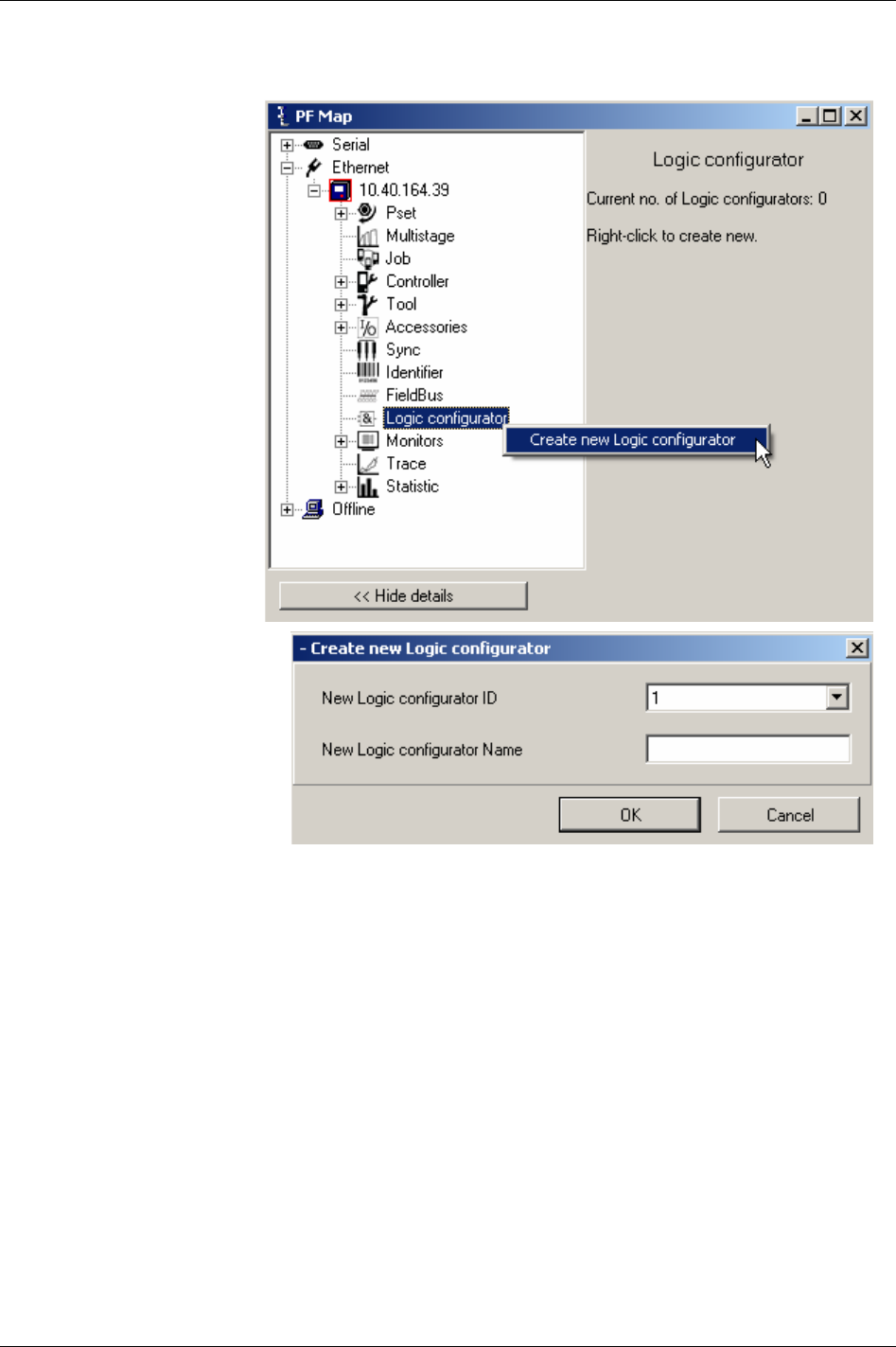

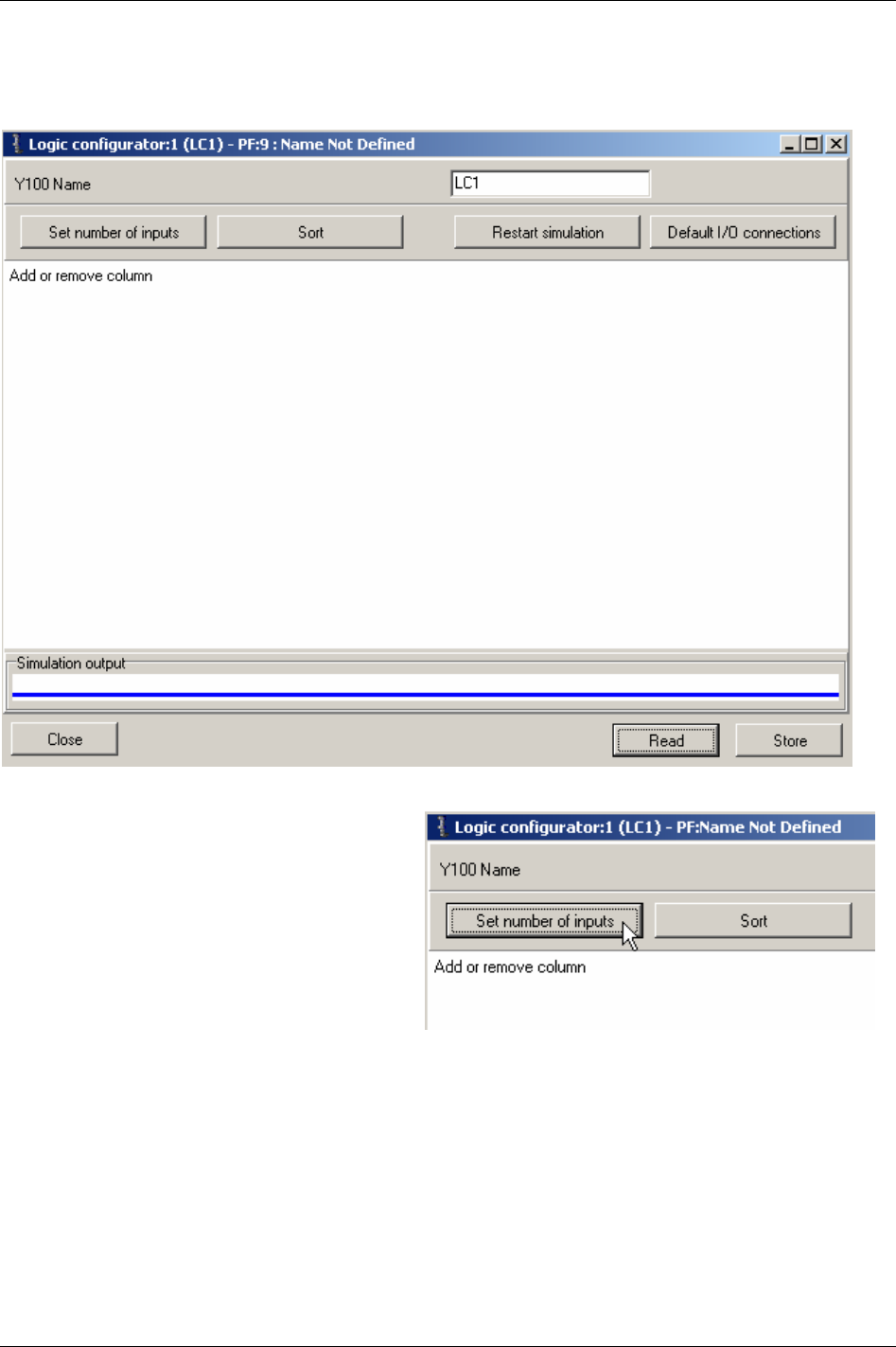

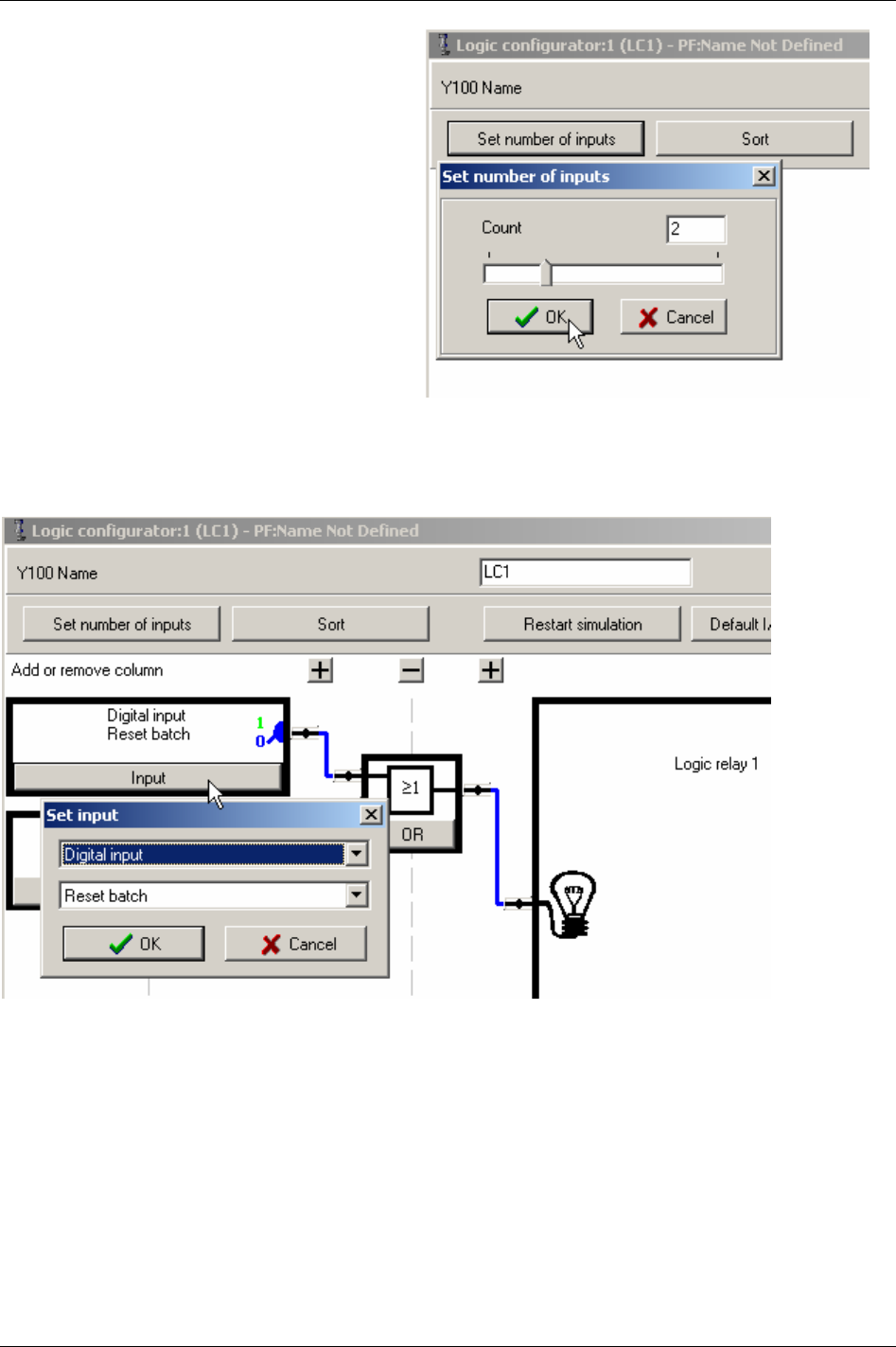

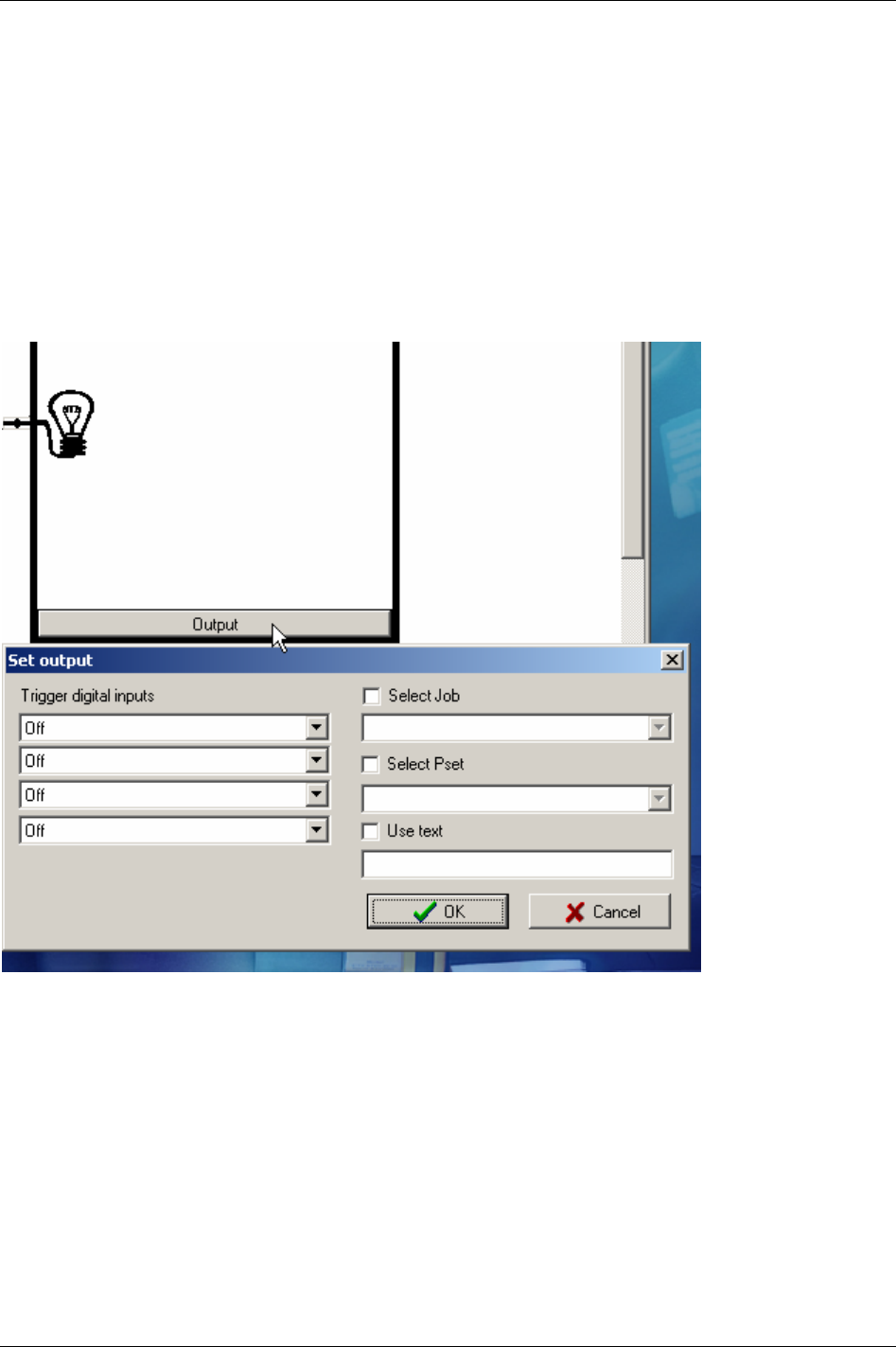

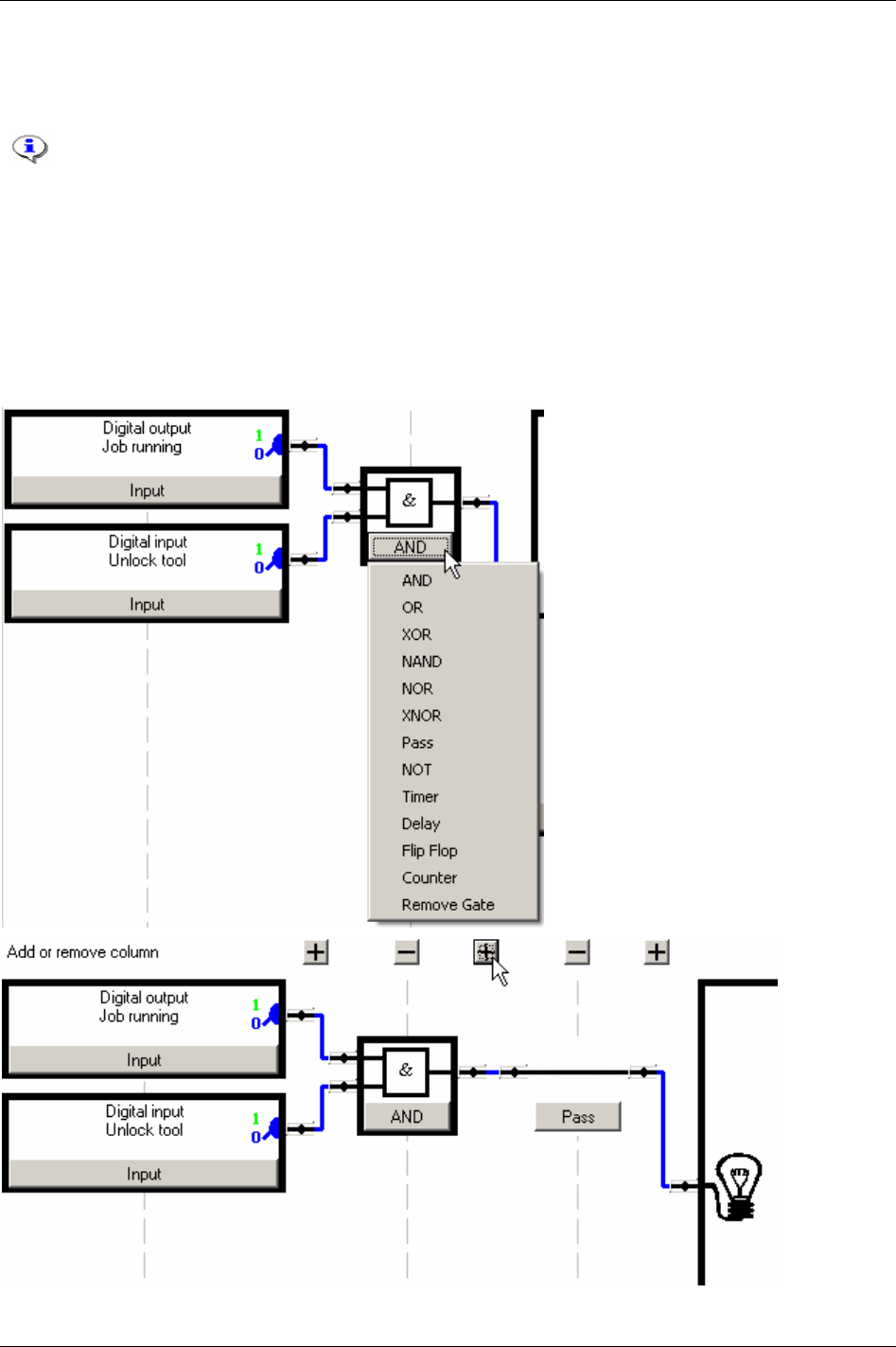

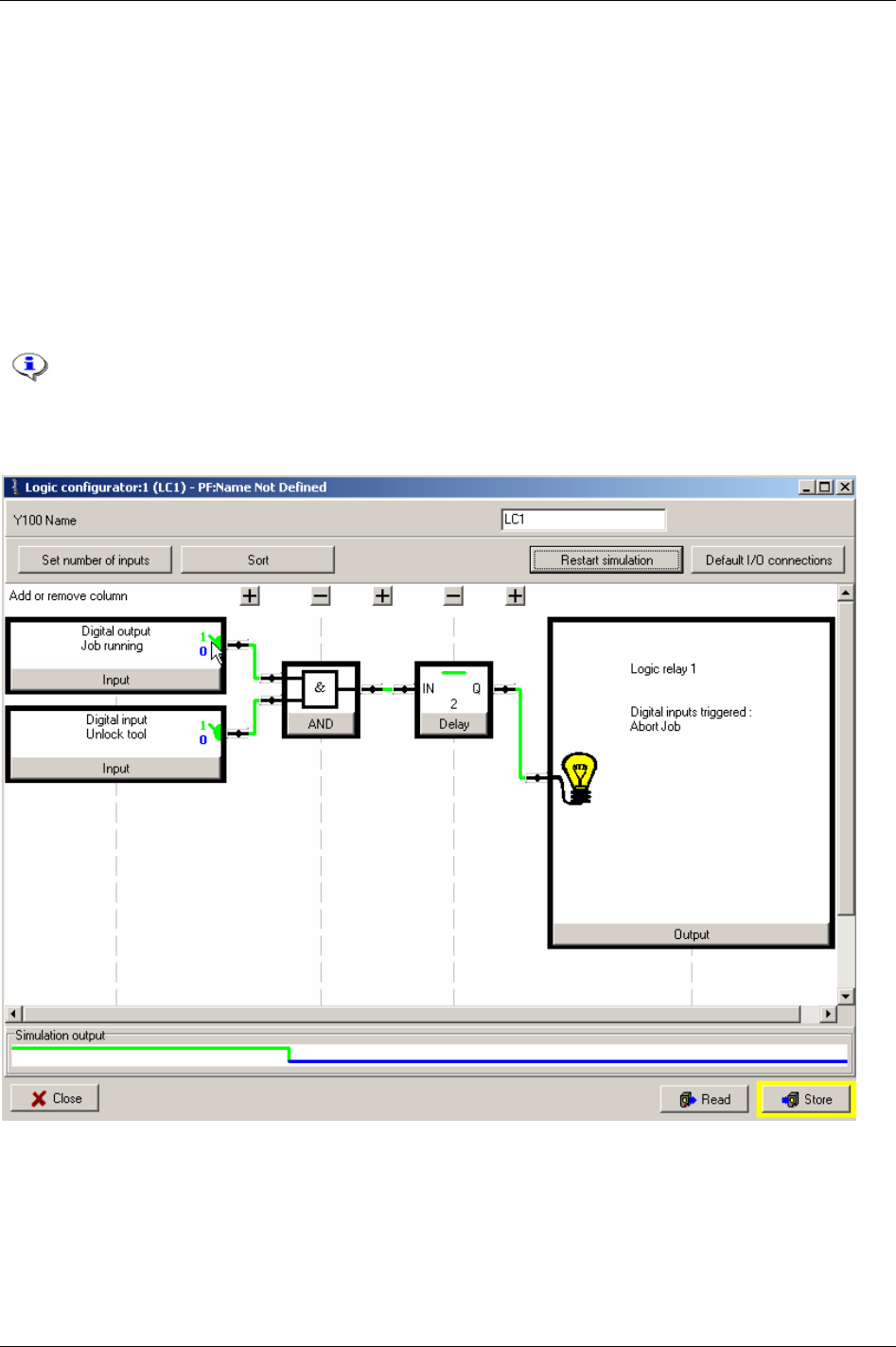

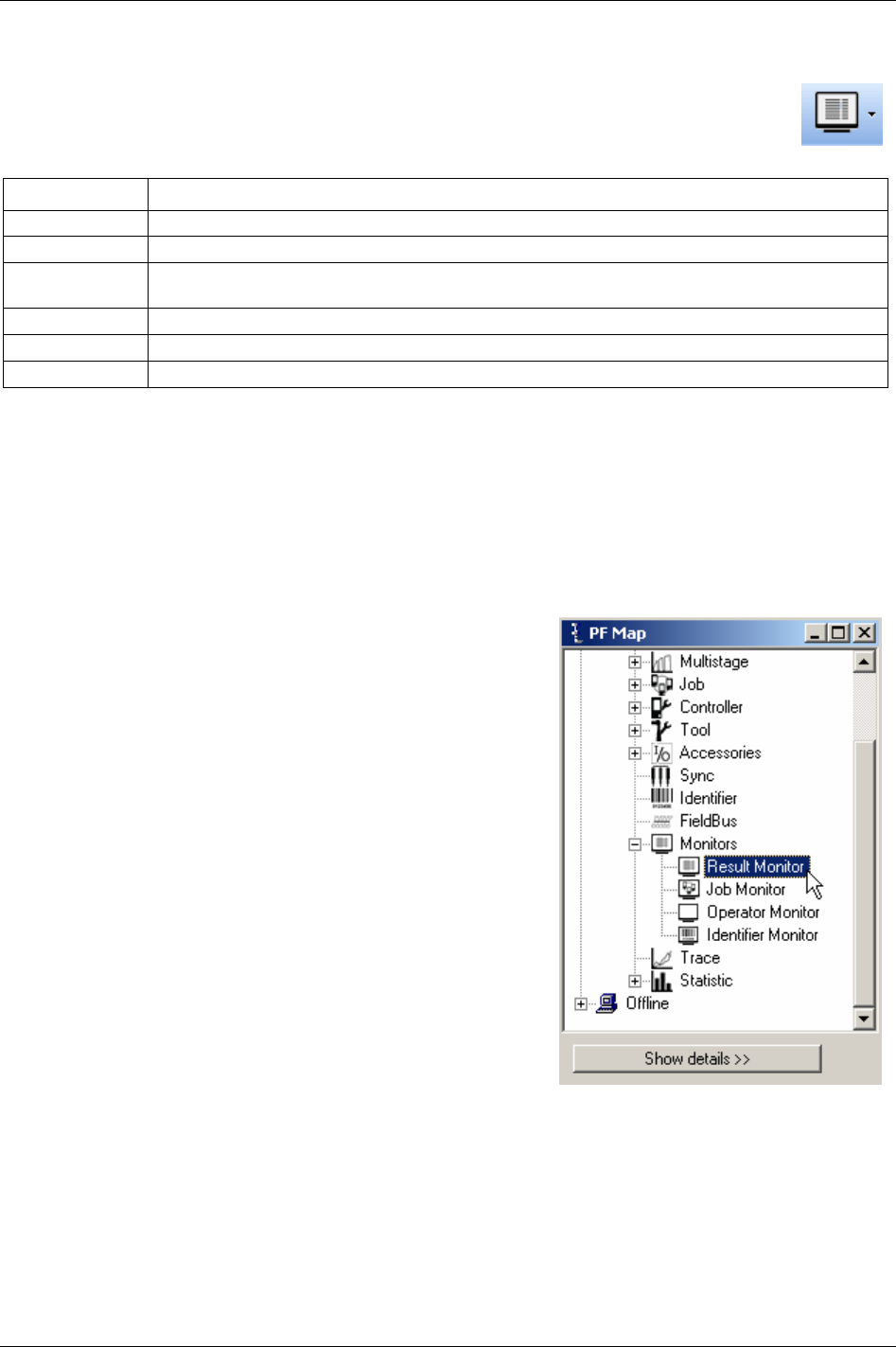

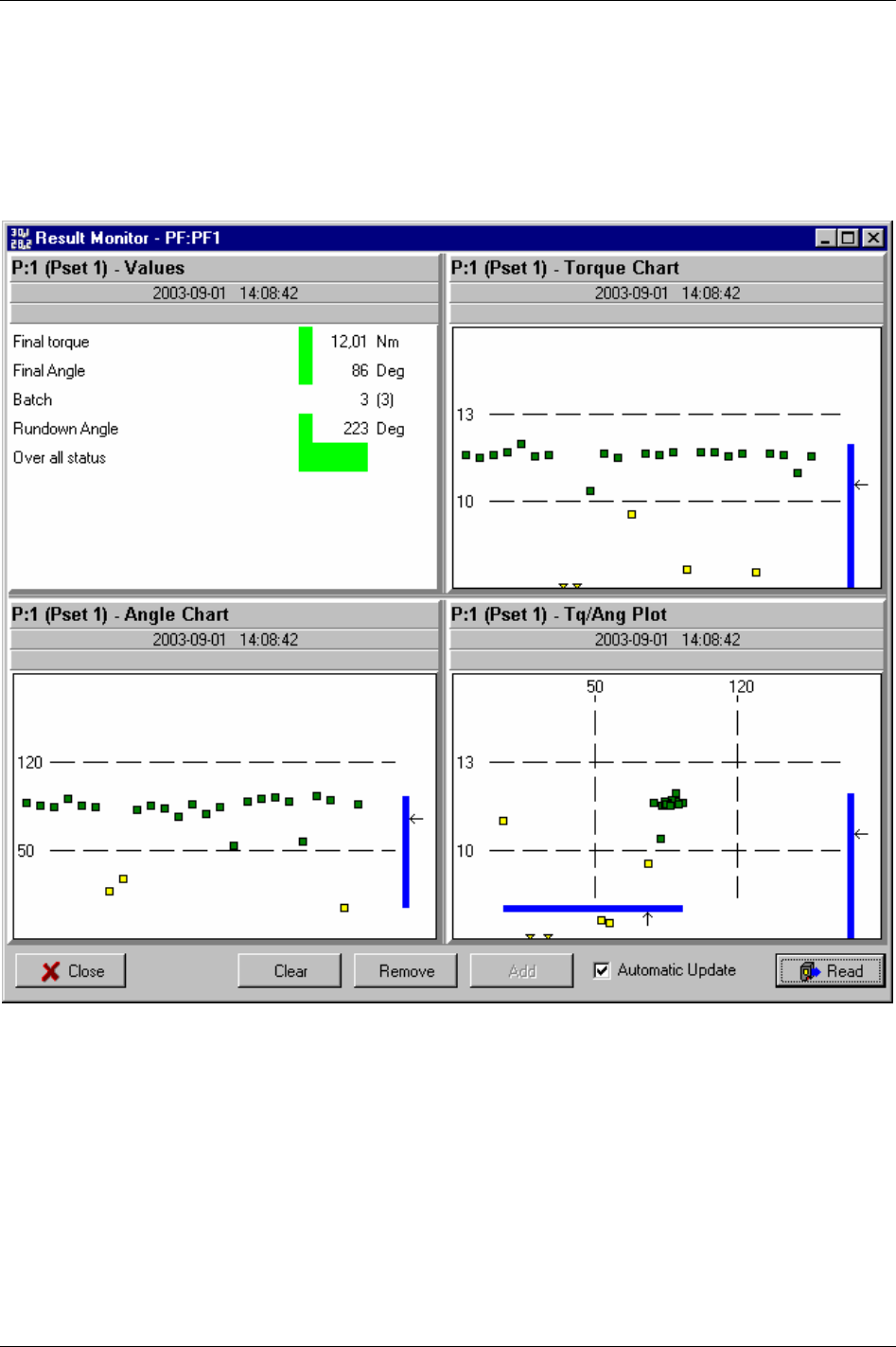

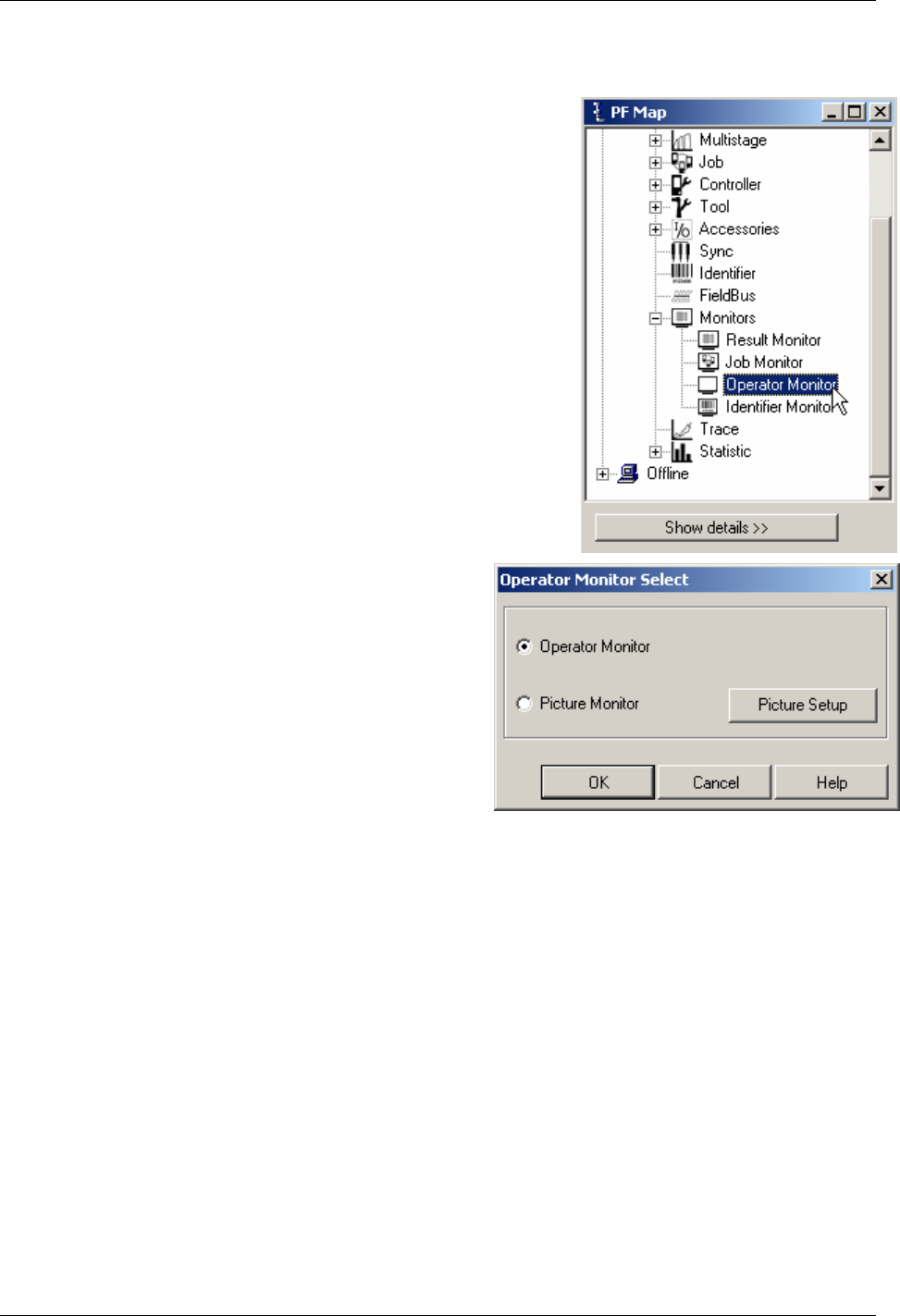

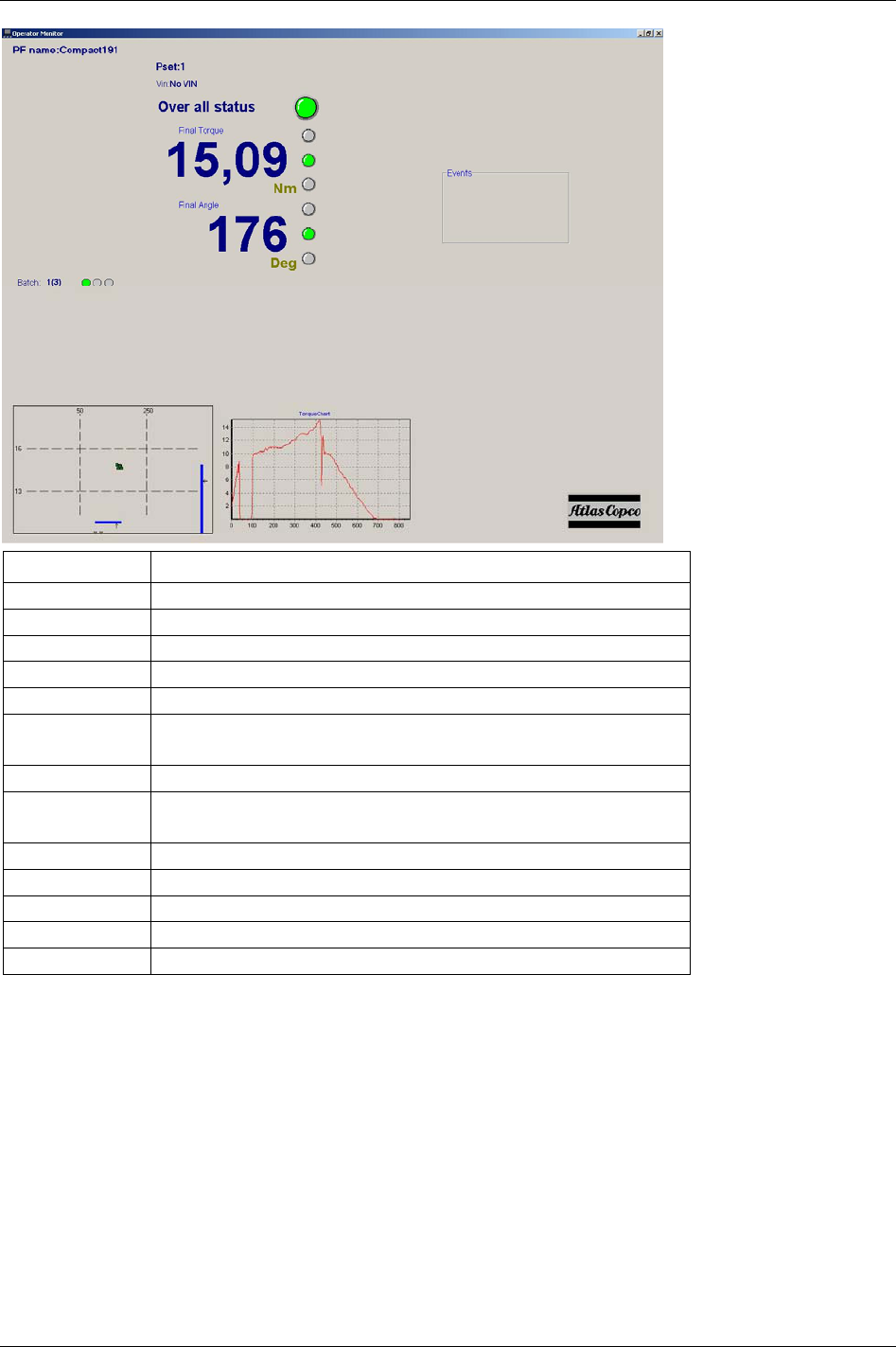

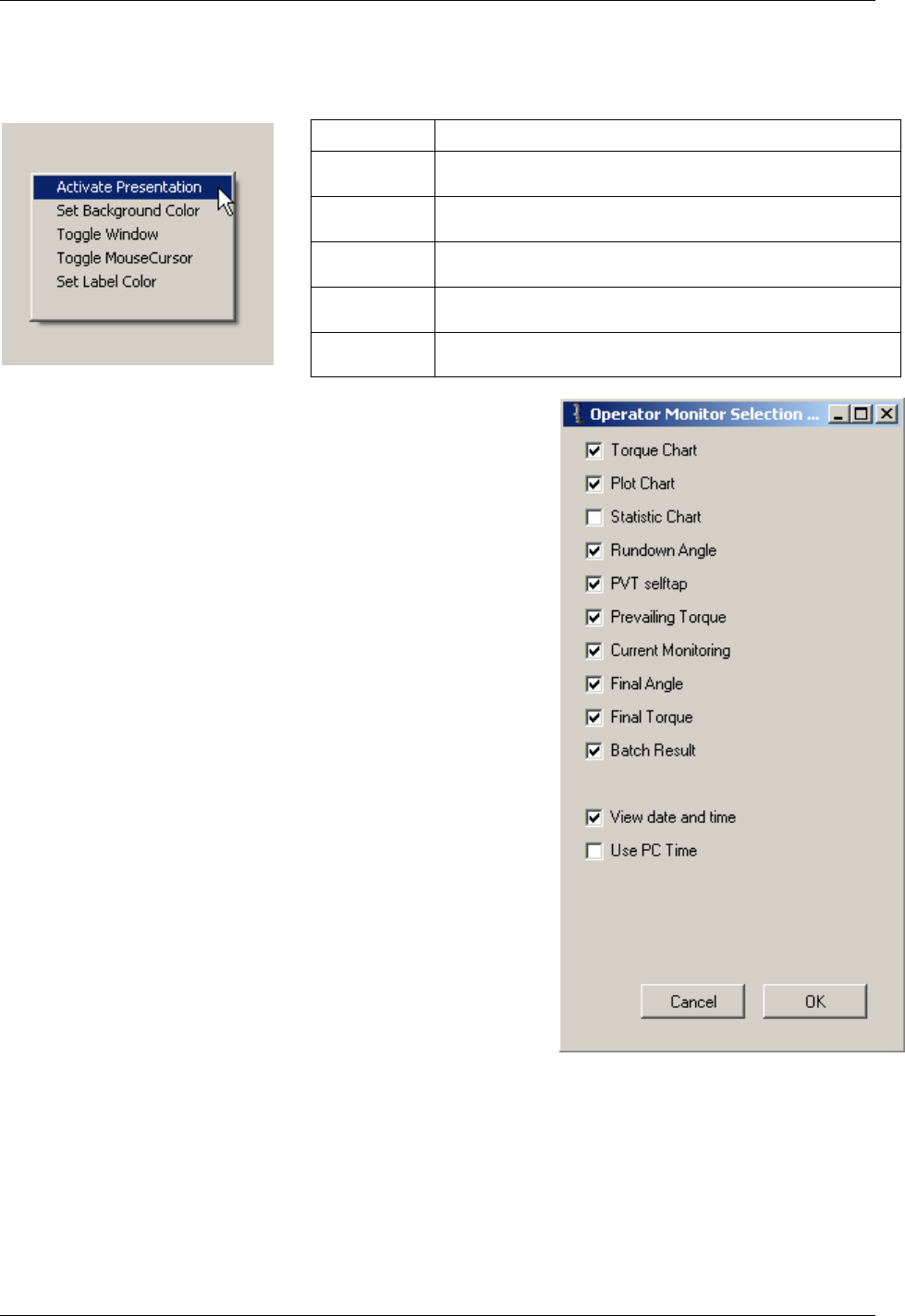

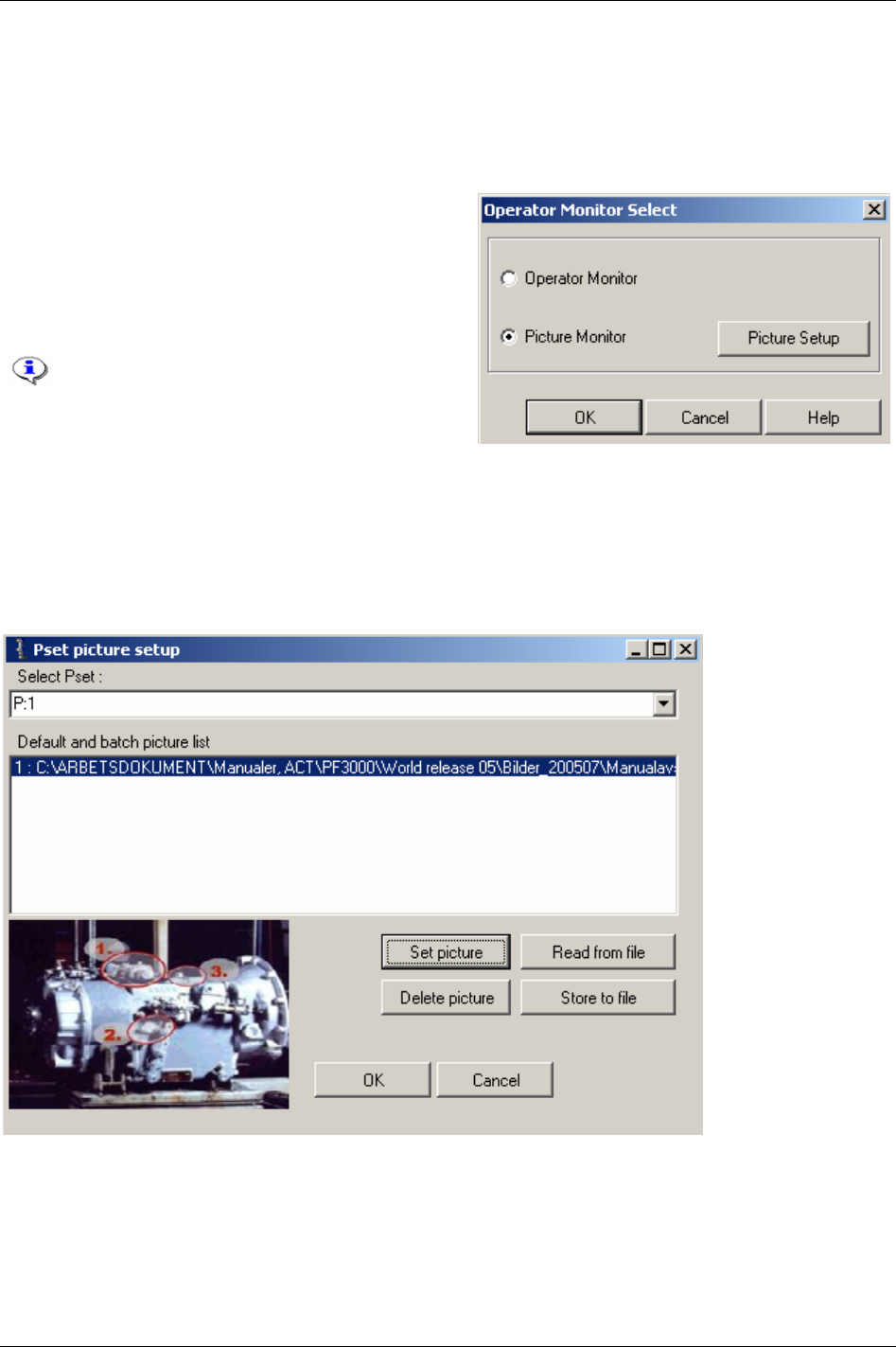

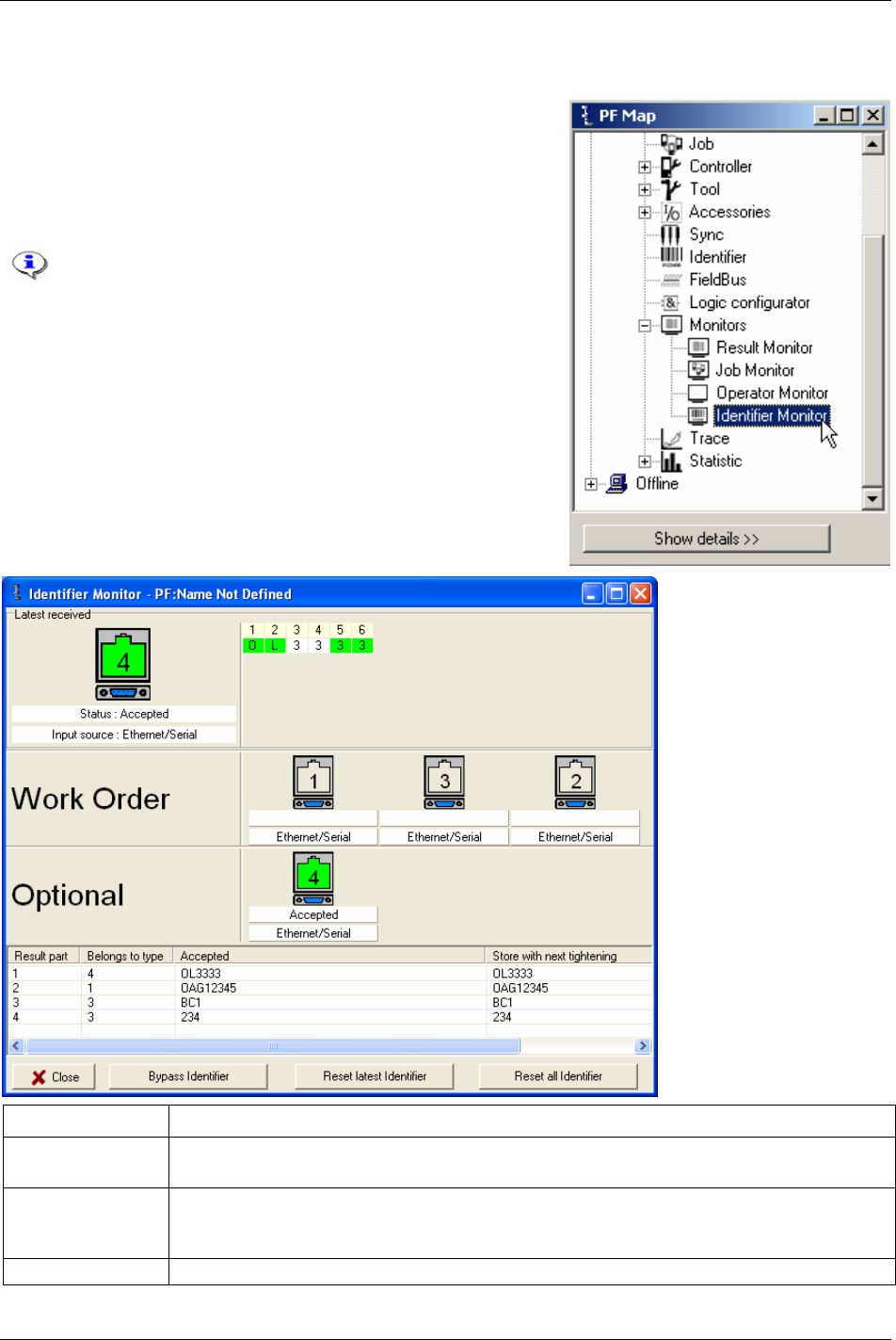

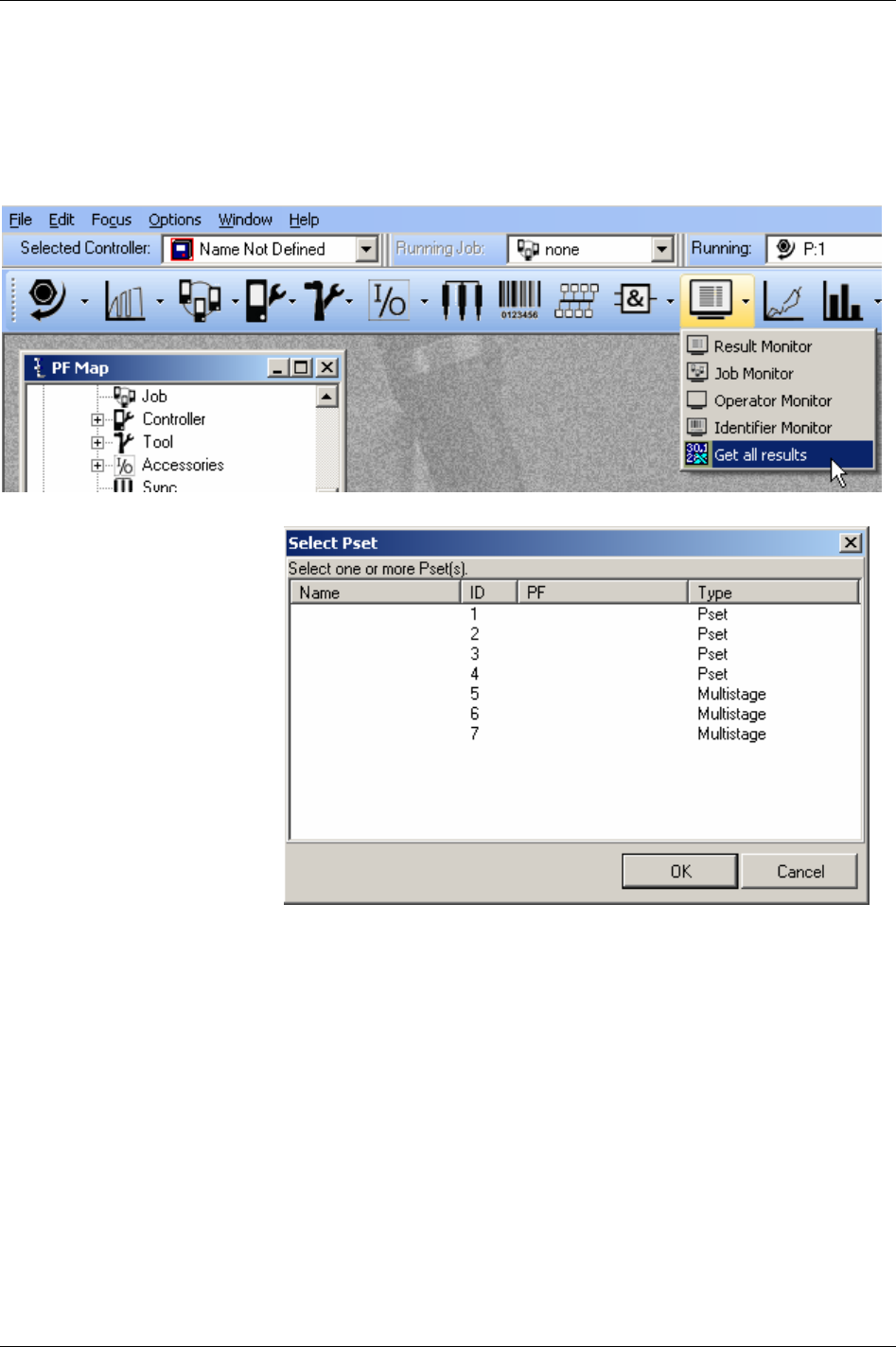

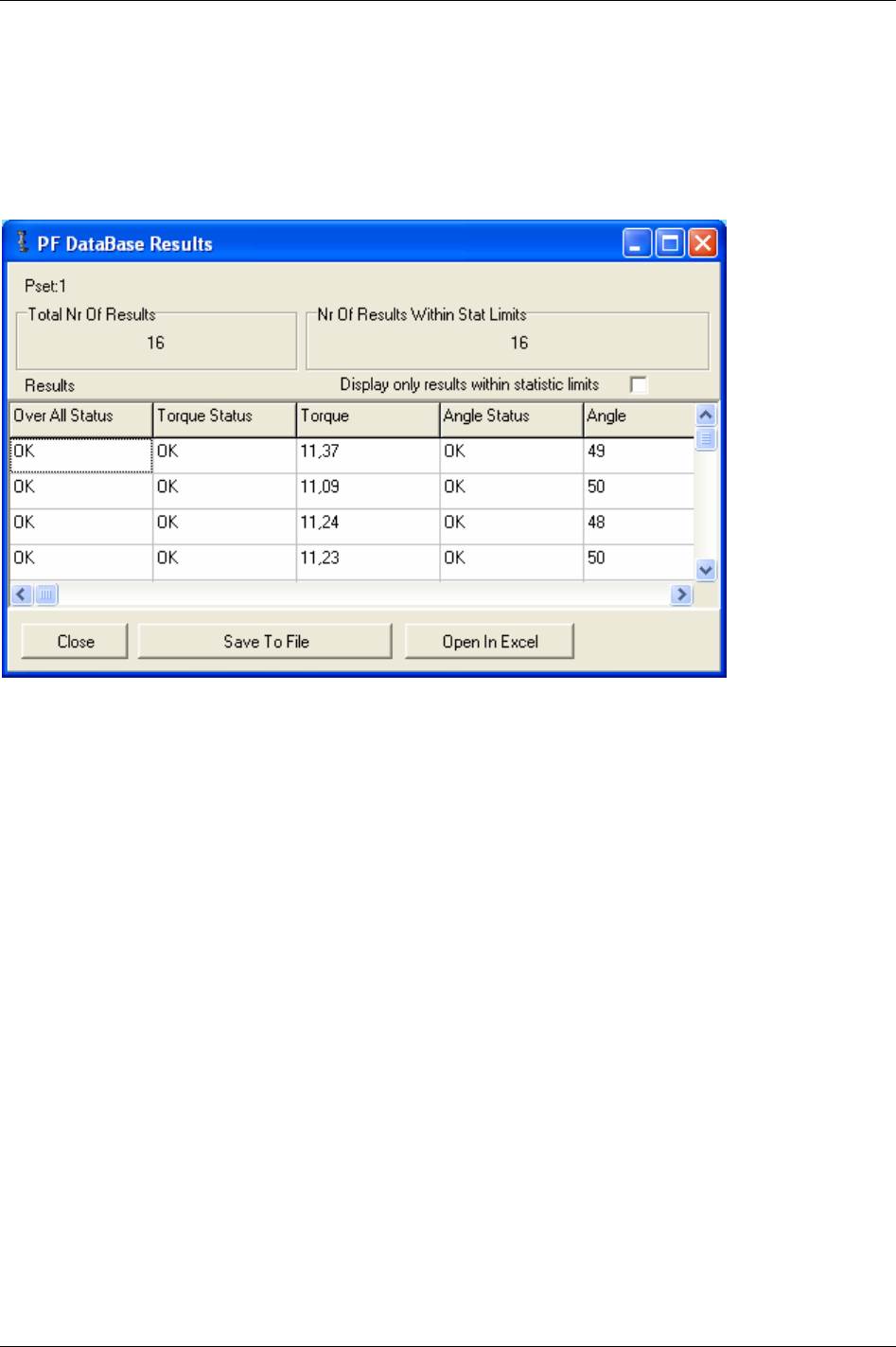

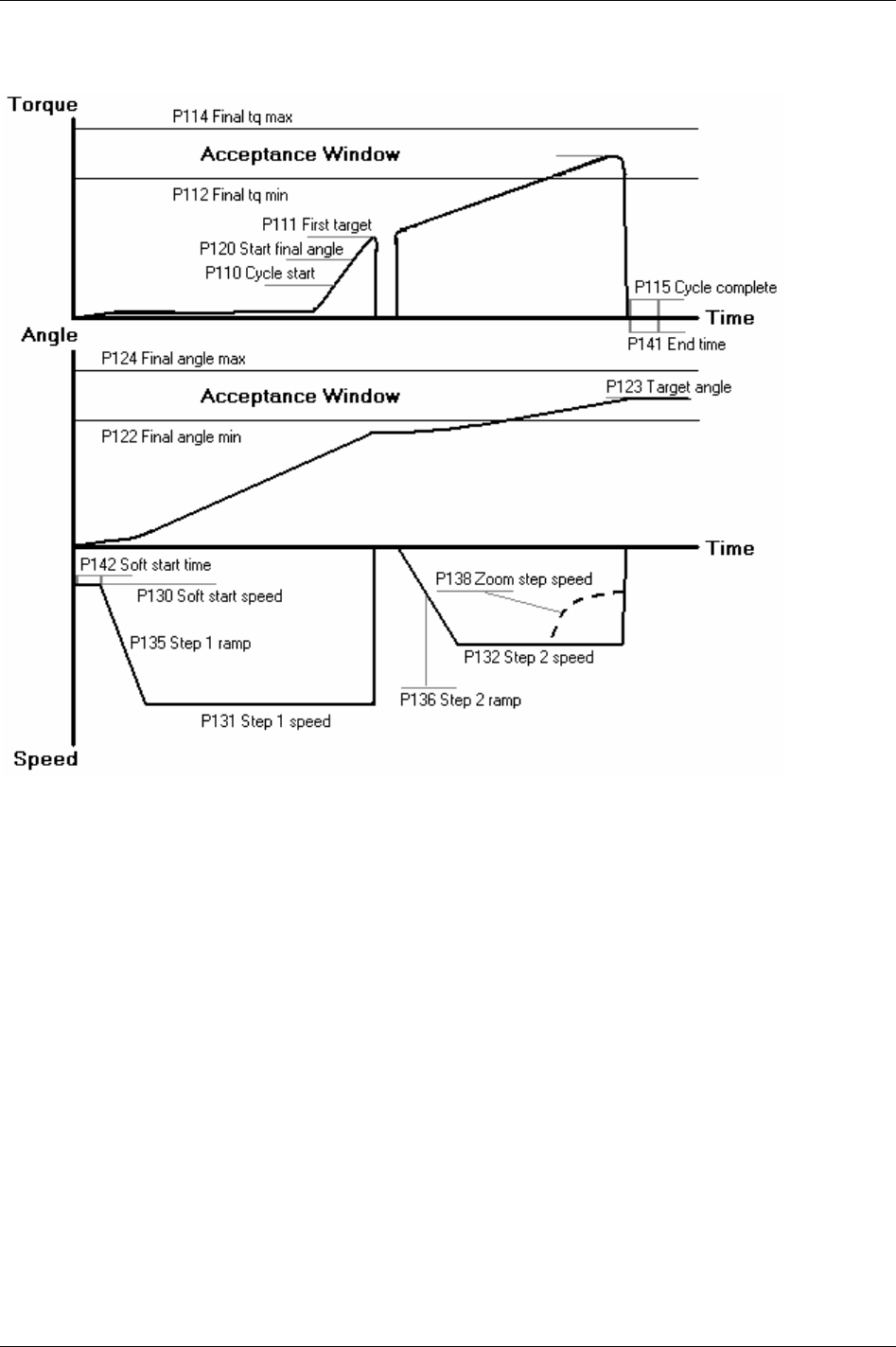

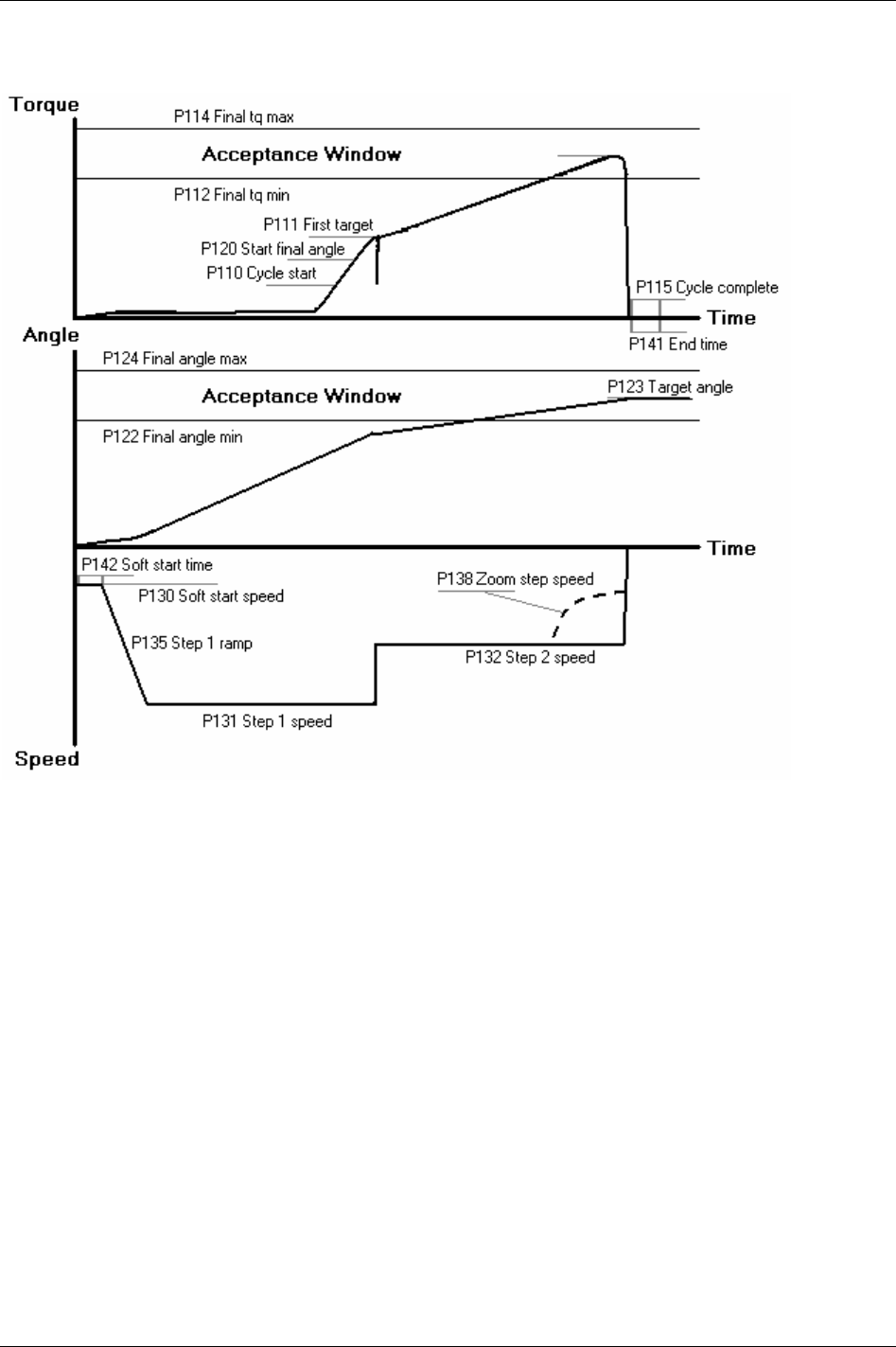

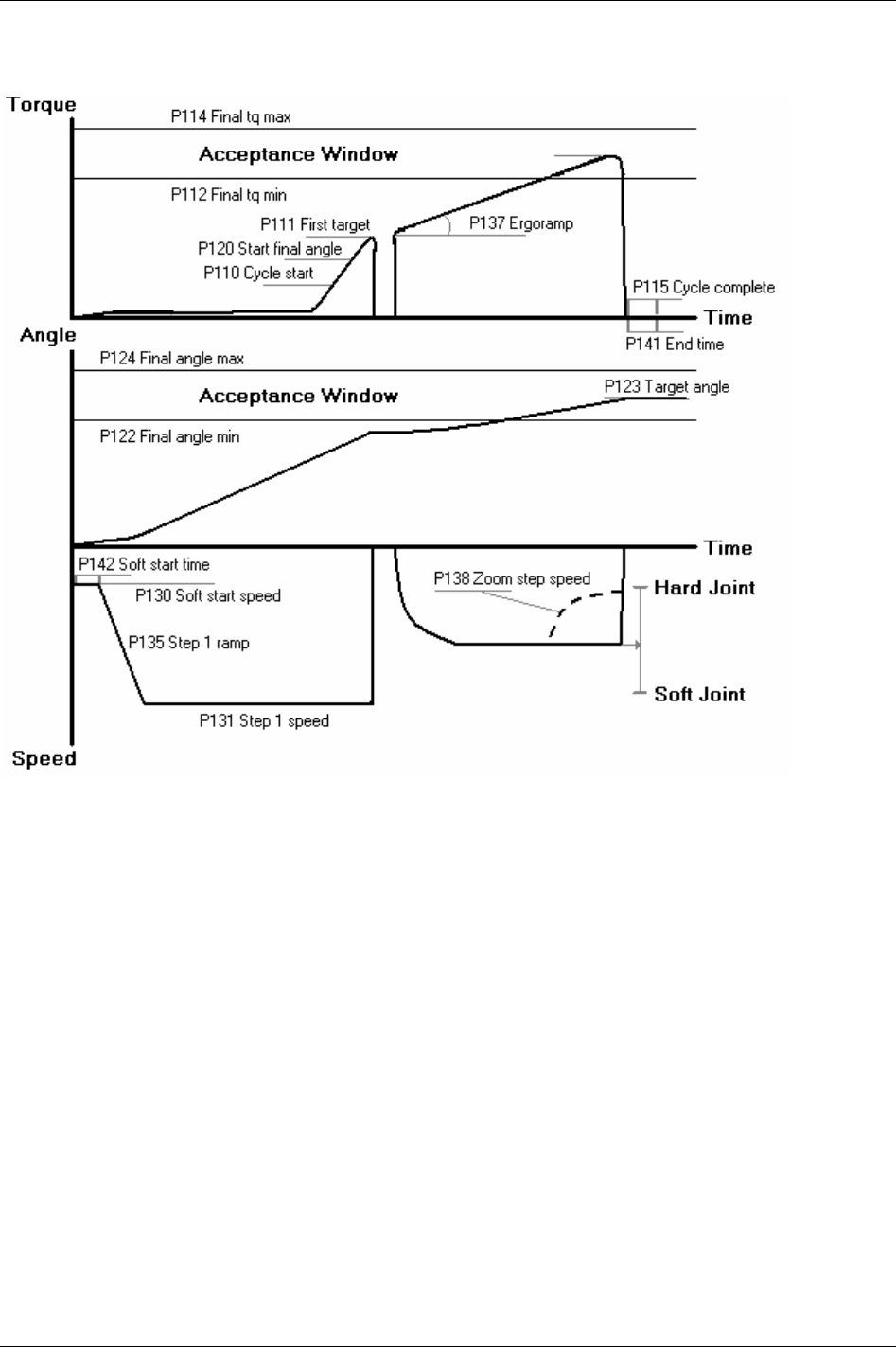

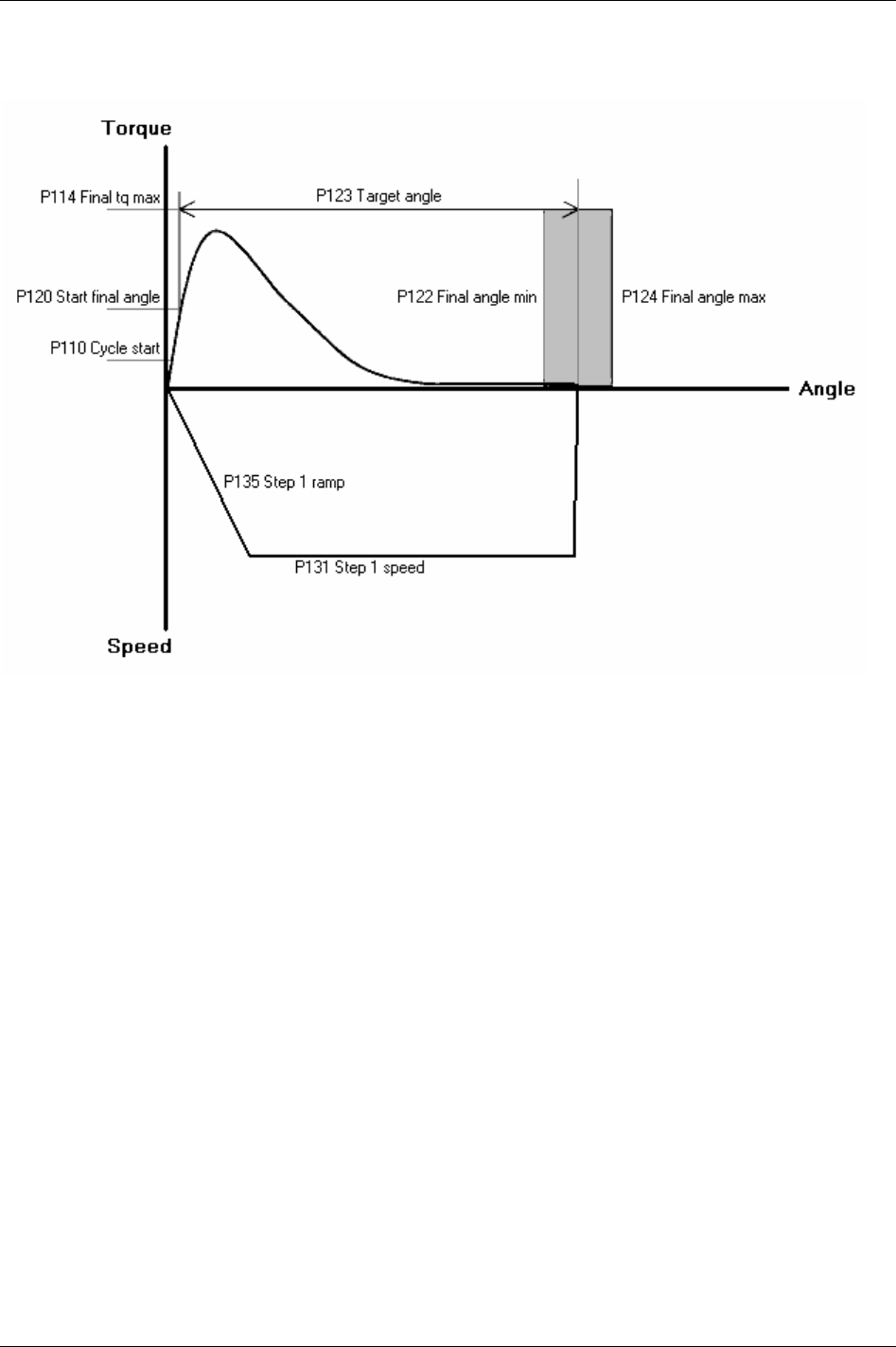

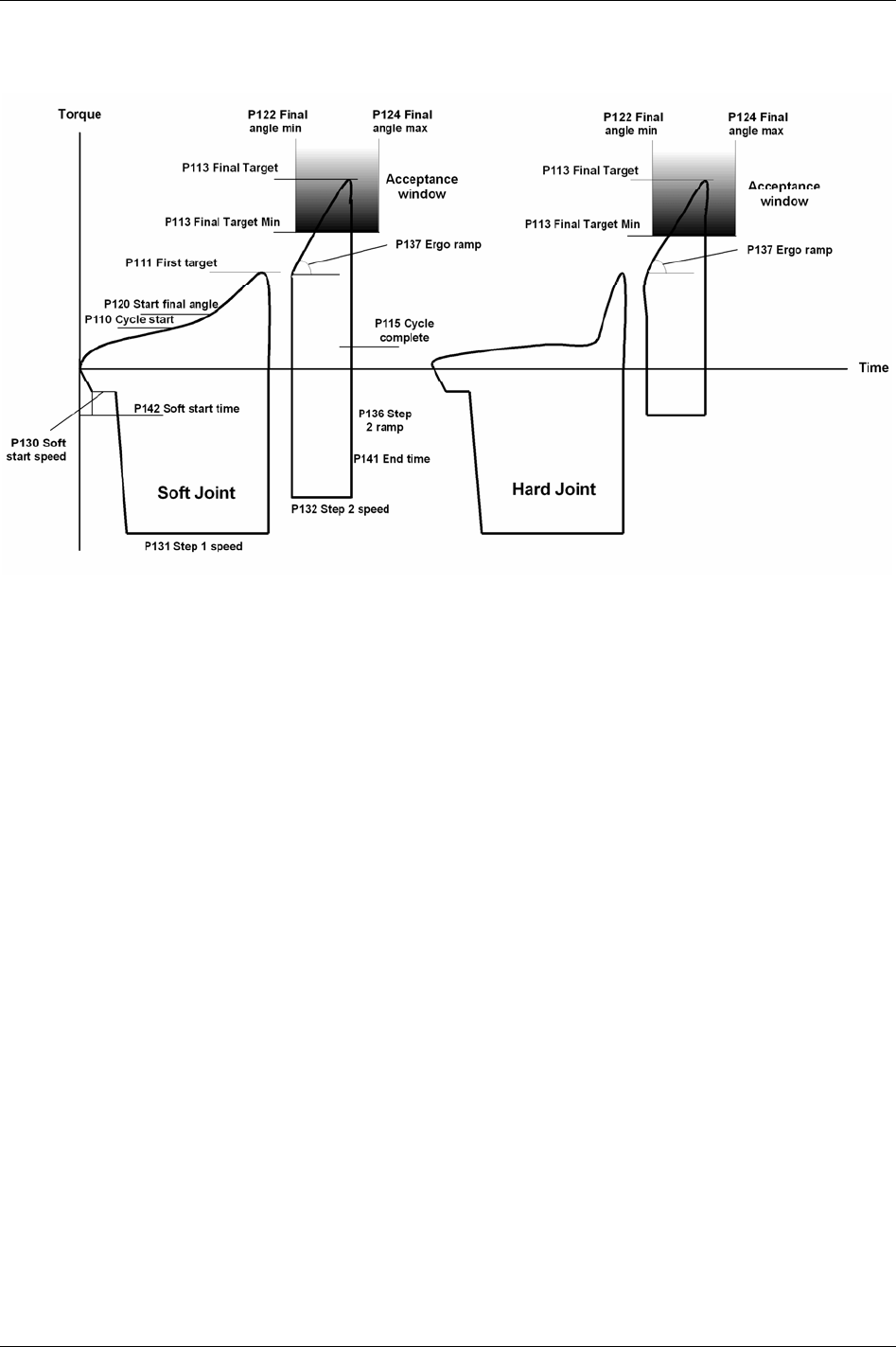

Configurator