Appendix for PowerFocus 6000

Open Protocol

Atlas Copco Tools and Assembly Systems

Appendix Specification release 2.8

Rev. 2 – Valid from 2.8.14

Copyright Atlas Copco Tools and Assembly Systems

Note! This manual can be altered without further notice.

For further information log in to Atlas Copco www.atlascopco.com

Contents

1 Introduction ..................................................................................................................... 3

2 Power Focus 6000 specifics .......................................................................................... 4

2.1 MID support................................................................................................................ 4

2.2 Supported MID Relay and Digital Input Signal ........................................................... 7

2.3 Revision Support ...................................................................................................... 19

2.4 MID 64/65 – Old result data, special support ........................................................... 21

2.5 Usage of Tightening program (Pset) selection ......................................................... 23

2.6 Usage of Tightening program (Pset) batch size ....................................................... 23

2.7 Usage of Sequence (Job) selection ......................................................................... 24

All messages

1 Introduction

Open Protocol is an interface for building applications for remote control or data subscription of

controllers. It is platform independent and can be implemented on Linux, PLC, printers, and all Windows

platforms for example.

The Open Protocol supports Ethernet connection towards Power Focus 6000.

This document specifies all the product Power Focus 6000 specific considerations when using the

Open Protocol.

All messages

2 Power Focus 6000 specifics

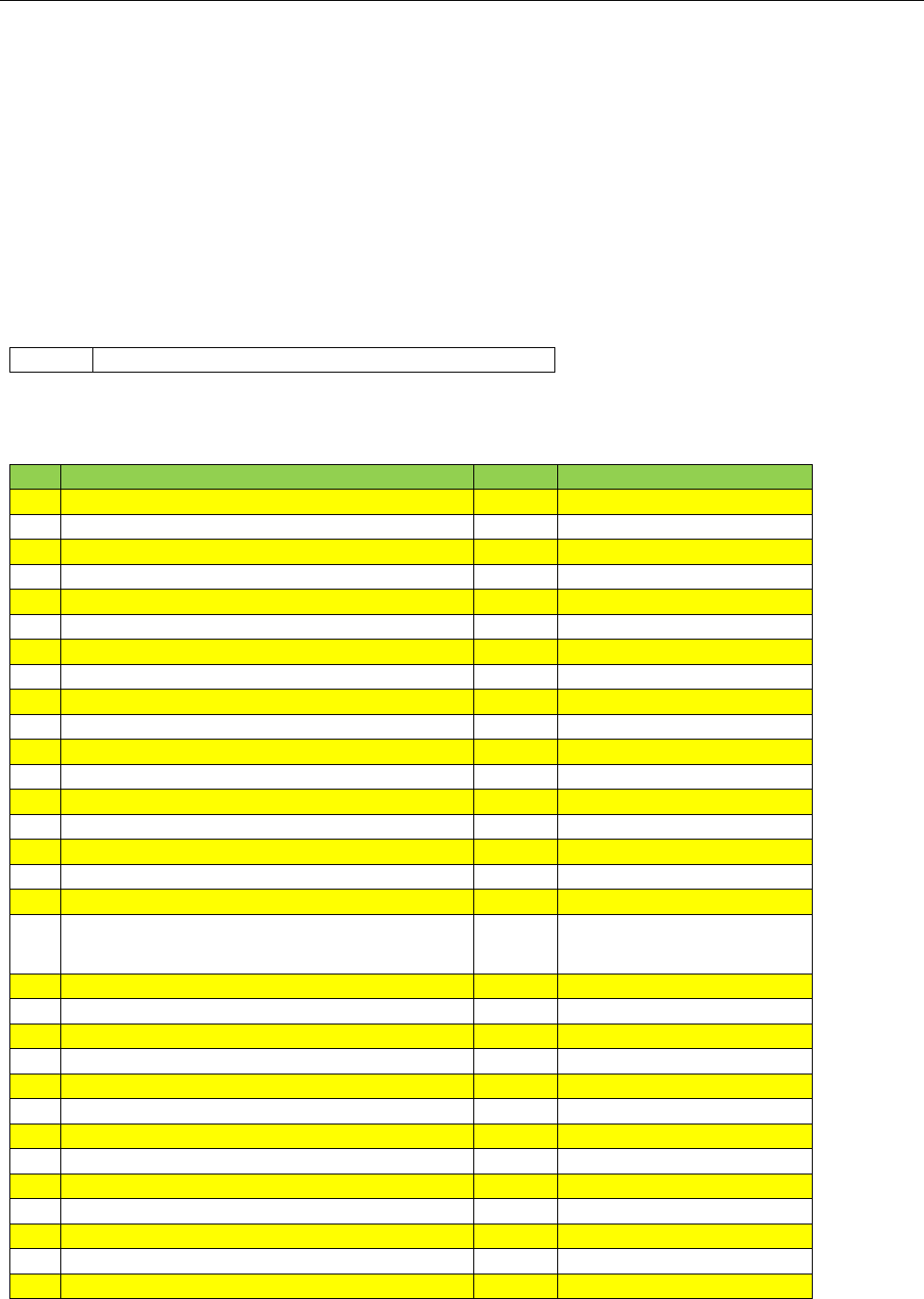

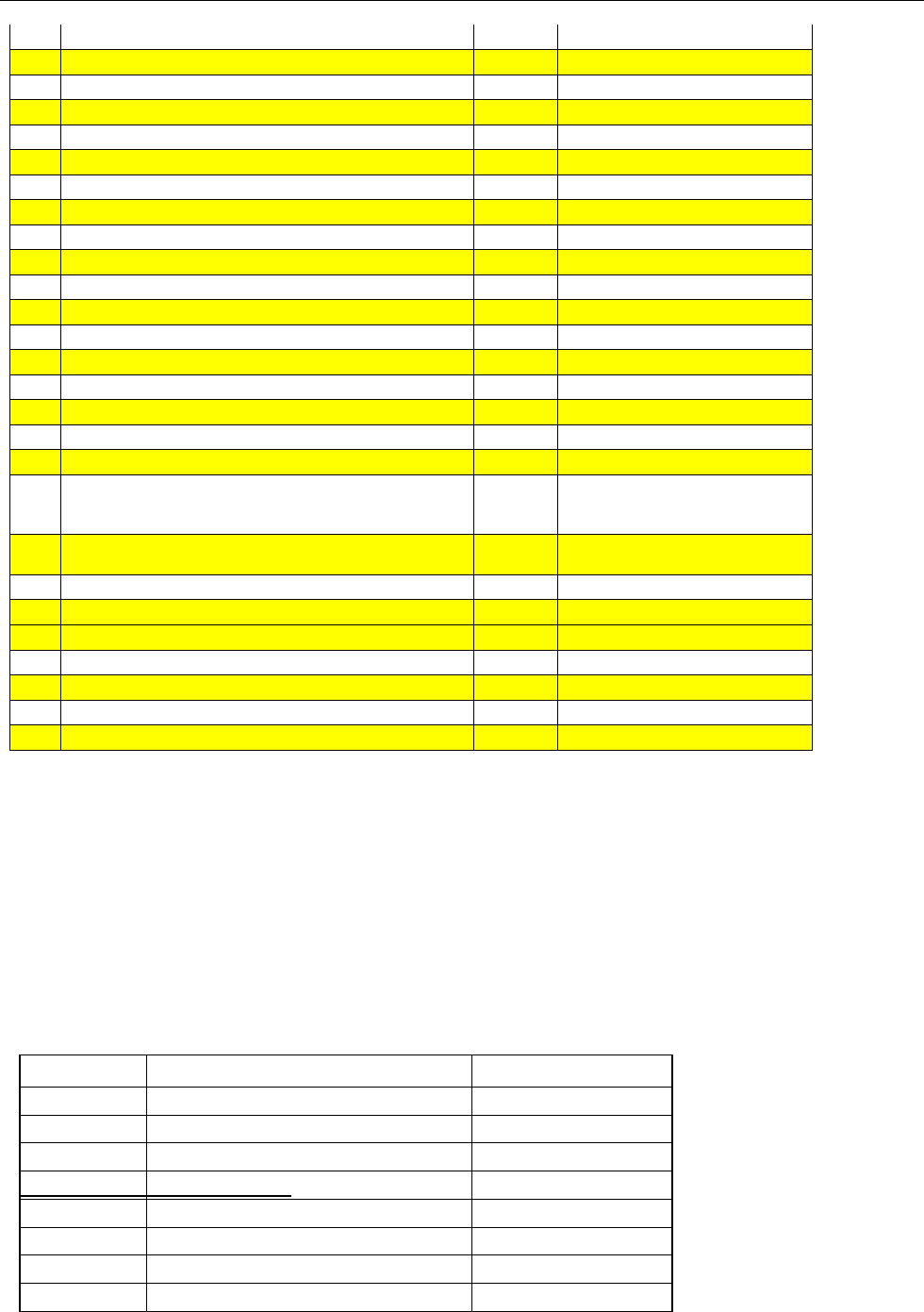

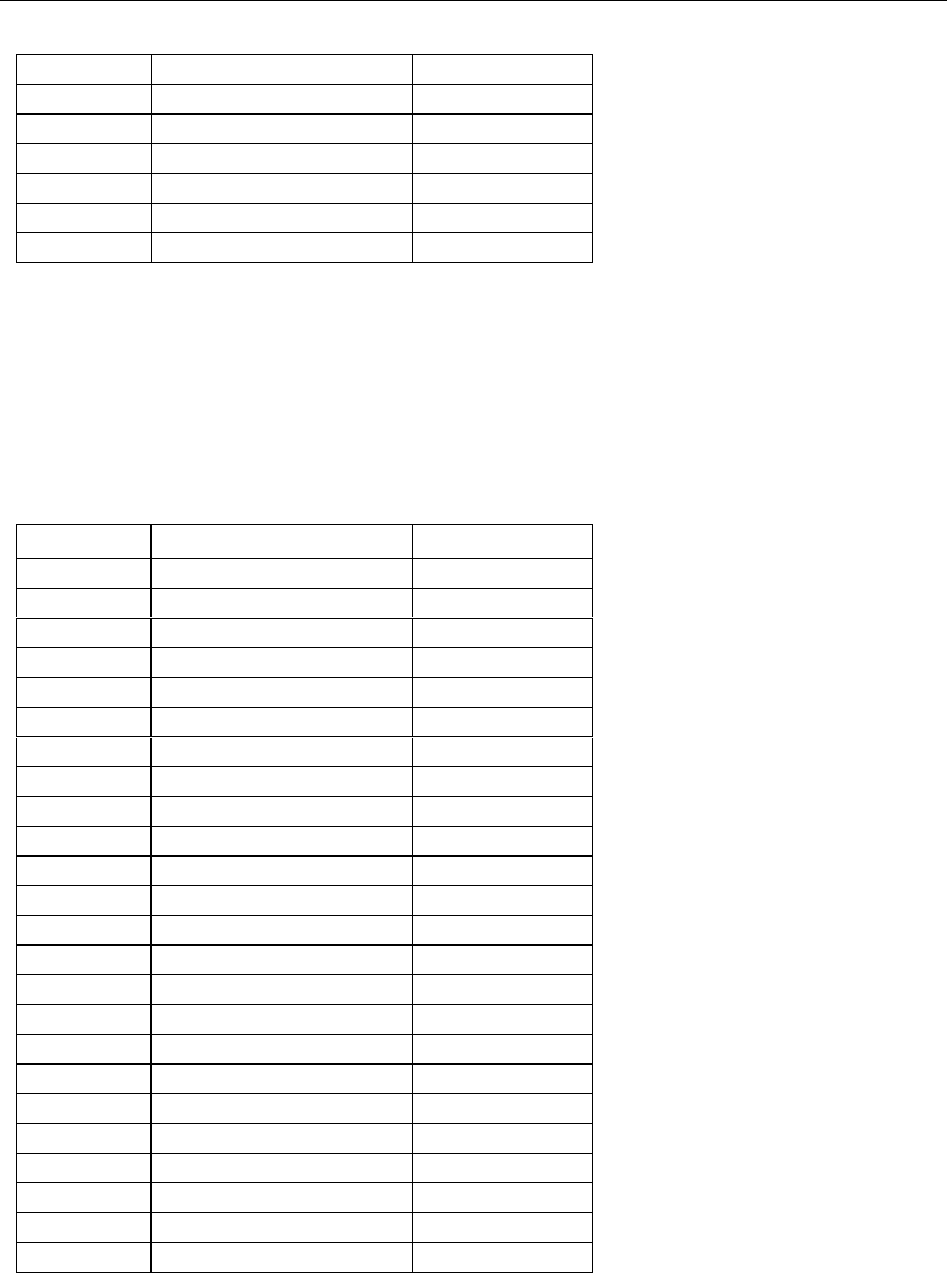

2.1 MID support

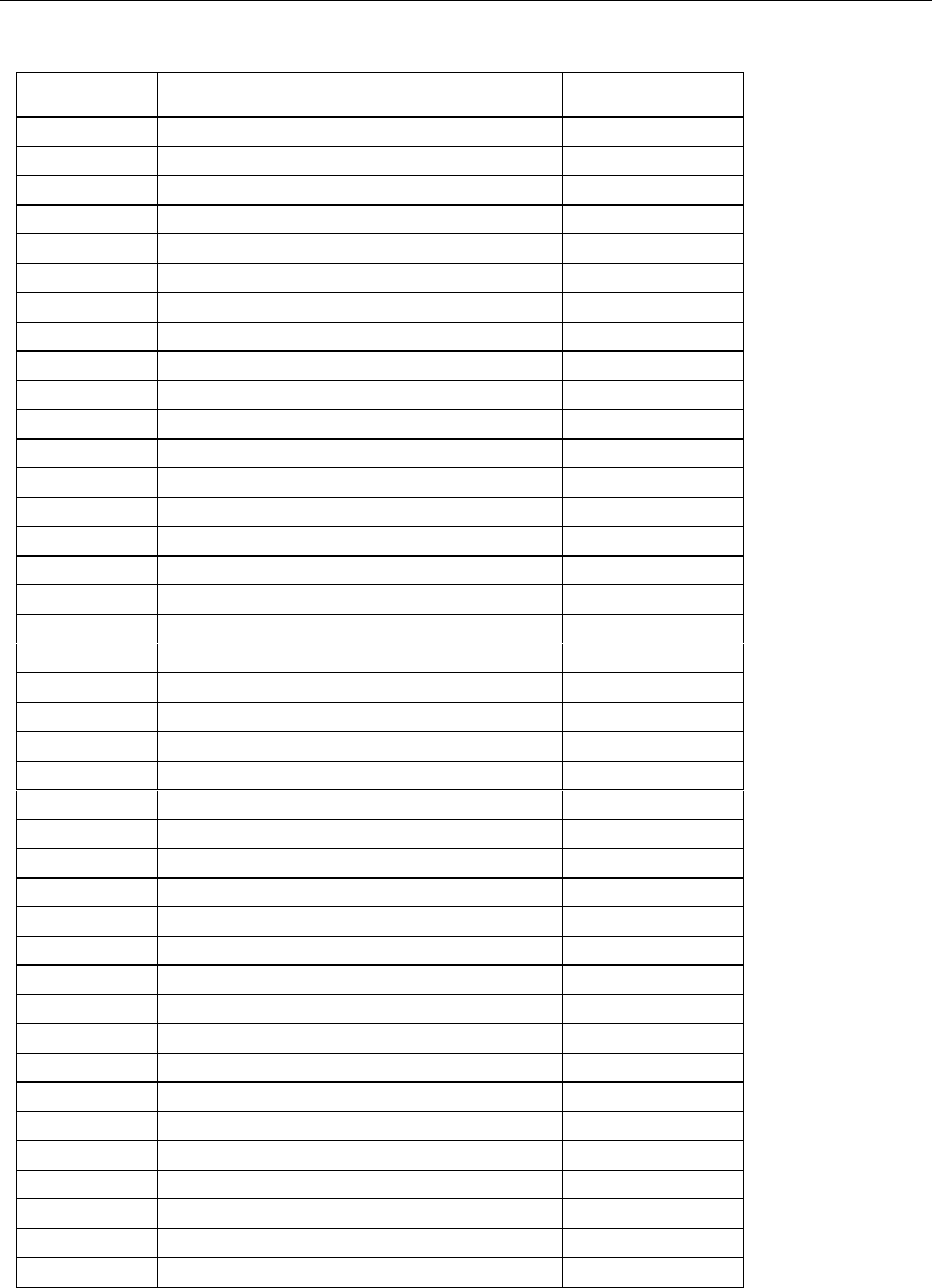

This section lists MID and MIDs revision supported by PF 6000. The Revision figures in the columns set

means that the product has support for all revisions from 0 up to and inclusive the revision figure.

Sign “-“ means that the product hasn’t support for the MID and Revision.

Sign “p” means that at least one revision of the MID is partly supported.

This table is valid for the following releases.

PF6000

2.8

Table 1 MID/Revision support

MID

Name

Revision

Ref Chap/Note

0001

Communication start

6

0002

Communication start acknowledge

6 p

0003

Communication stop

1

0004

Command error

1

0005

Command accepted

1

0010

Parameter set ID upload request

1

See chap 2.5

0011

Parameter set ID upload reply

1

See chap 2.5

0012

Parameter set data upload request

4 p

See chap 2.5

0013

Parameter set data upload reply

4 p

See chap 2.5

0014

Parameter set selected subscribe

1

See chap 2.5

0015

Parameter set selected

1 P

See chap 2.5

0016

Parameter set selected acknowledge

1

See chap 2.5

0017

Parameter set selected unsubscribe

1

See chap 2.5

0018

Select Parameter set

1

See chap 2.5

0019

Set Parameter set batch size

1

See chap 2.6

0020

Reset Parameter set batch counter

1

See chap 2.6

0021

Lock at batch done subscribe

1

0022

Lock at batch done upload

1

Note! In PF6000 this signal

indicates when locked by

batch sequence completed

0023

Lock at batch done upload acknowledge

1

0024

Lock at batch done unsubscribe

1

0025

Download Pset. Toyota Appendix

-

0030

Job ID upload request

2

0031

Job ID upload reply

2

0032

Job data upload request

2

0033

Job data upload reply

2 p

0034

Job info subscribe

4

0035

Job info

4 p

0036

Job info acknowledge

4

0037

Job info unsubscribe

4

0038

Select Job

2

See chap 2.7

0039

Job restart

1

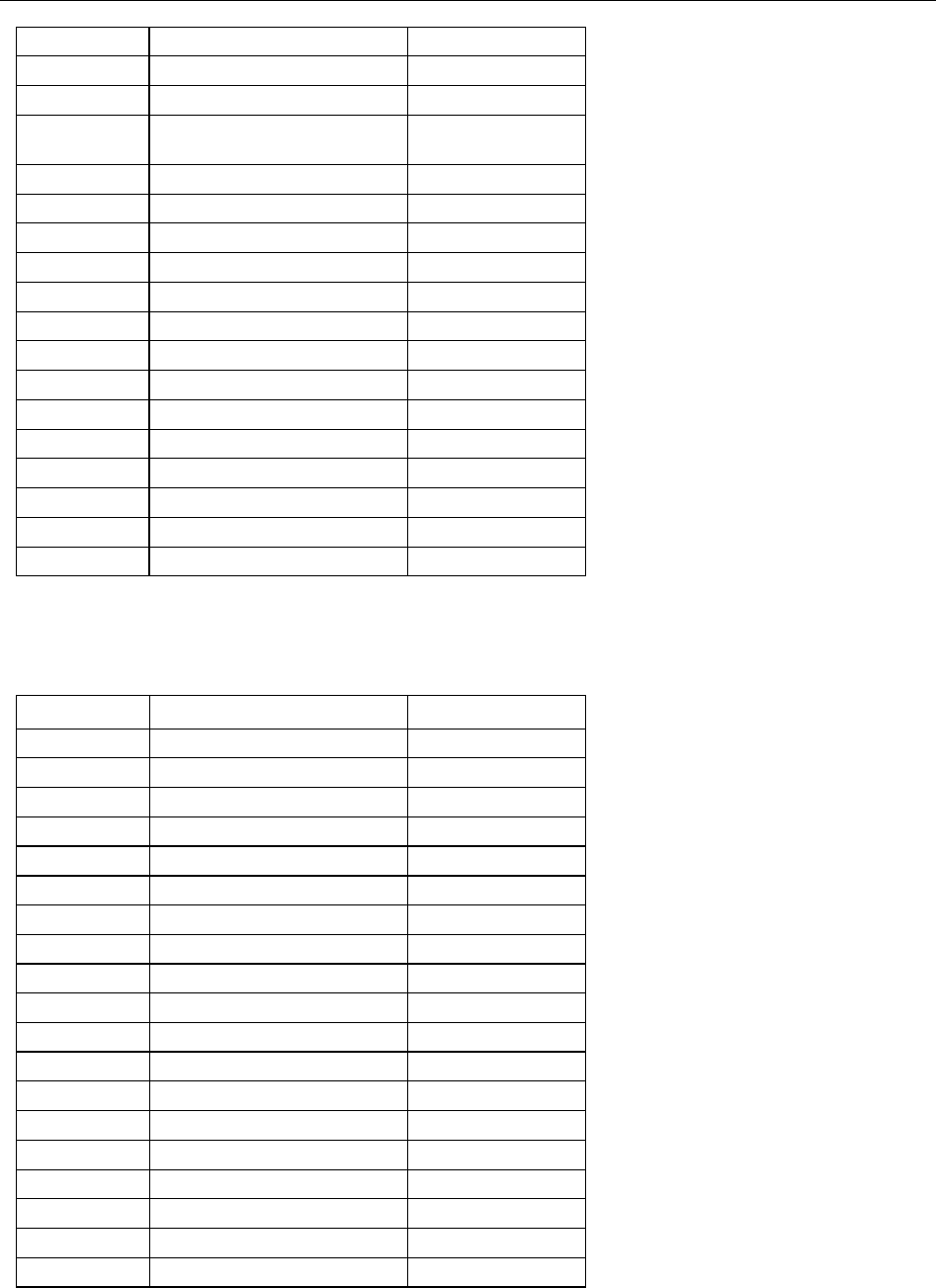

All messages

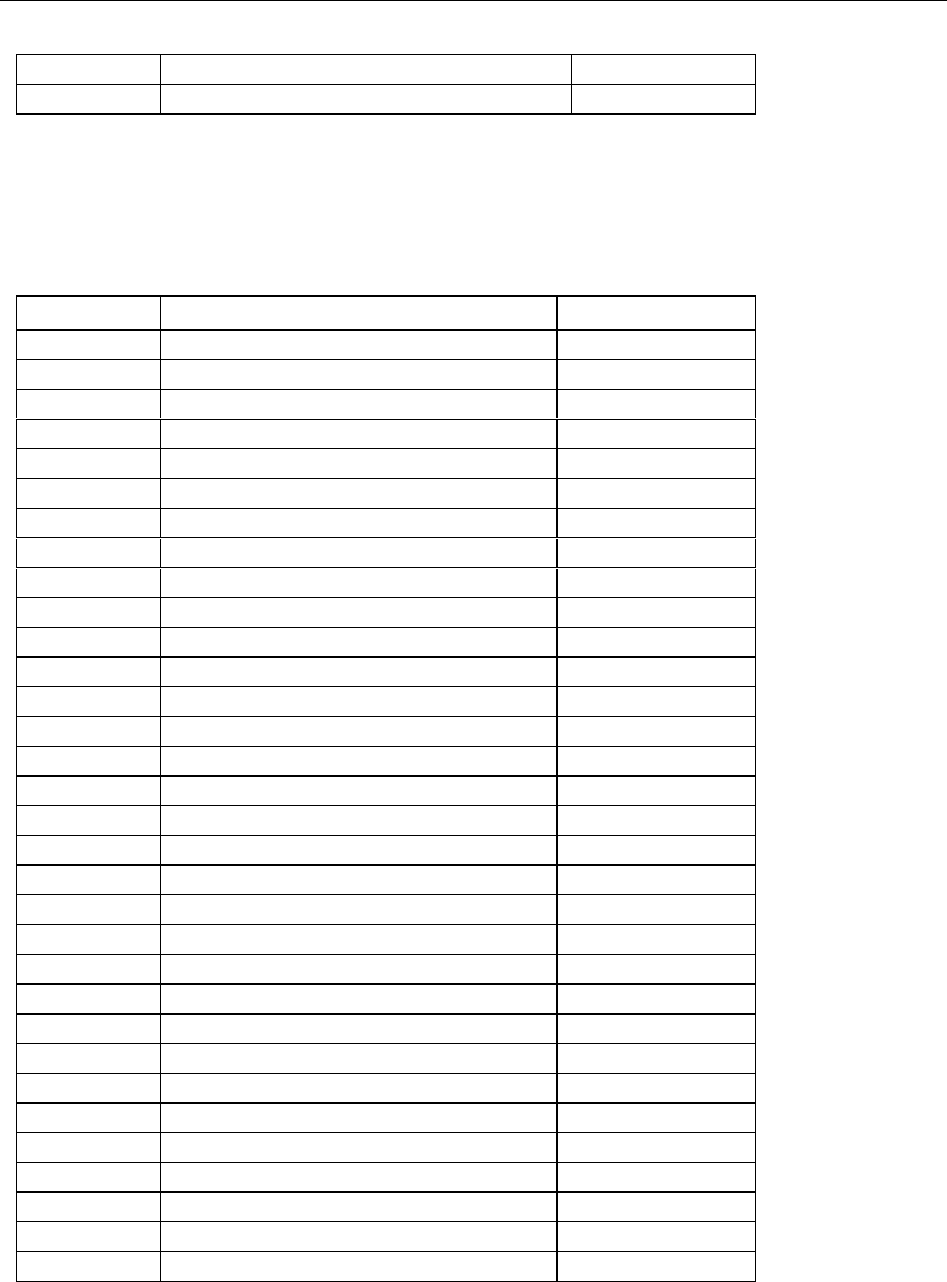

0040

Tool data upload request

5

0041

Tool data upload reply

5 p

0042

Disable tool

1

0043

Enable tool

1

0044

Disconnect tool request

-

0045

Set calibration value request

1

0046

Set primary tool request

-

0047

Pairing handling

-

0048

Pairing status

-

0049

Paring status acknowledge

-

0050

Vehicle ID number download request

1

0051

Vehicle ID number subscribe

2

0052

Vehicle ID number

2

0053

Vehicle ID number acknowledge

2

0054

Vehicle ID number unsubscribe

2

0060

Last tightening result data subscribe

8

0061

Last tightening result data

8 p

0062

Last tightening result data acknowledge

8

0063

Last tightening result data unsubscribe

8

0064

Old tightening result upload request

8

See chapter 2.4 for the

special handling of MID 64

0065

Old tightening result upload reply

8p

See chapter 2.3 for

parameters not supported

0070

Alarm subscribe

3

0071

Alarm

3

0072

Alarm acknowledge

3

0073

Alarm unsubscribe

3

0074

Alarm acknowledged on controller

3

0075

Alarm acknowledged on controller acknowledge

3

0076

Alarm status

3

Only active events that need

acknowledgement are sent.

0077

Alarm status acknowledge

3

0078

Acknowledge alarm remotely on controller

1

0080

Read time upload request

1

0081

Read time upload reply

1

0082

Set time

1

0090

Multi-spindle status subscribe

-

0091

Multi-spindle status

-

0092

Multi-spindle status acknowledge

-

0093

Multi-spindle status unsubscribe

-

0100

Multi-spindle result subscribe

-

0101

Multi-spindle result

-

0102

Multi-spindle result acknowledge

0103

Multi-spindle result unsubscribe

-

0105

Last PowerMACS tightening result data subscribe

-

0106

Last PowerMACS tightening result Station data

-

0107

Last PowerMACS tightening result Bolt data

-

0108

Last PowerMACS tightening result data acknowledge

-

0109

Last PowerMACS tightening result data unsubscribe

-

0110

Display user text on compact

-

0111

Display user text on graph

-

0113

Flash green light on tool

1

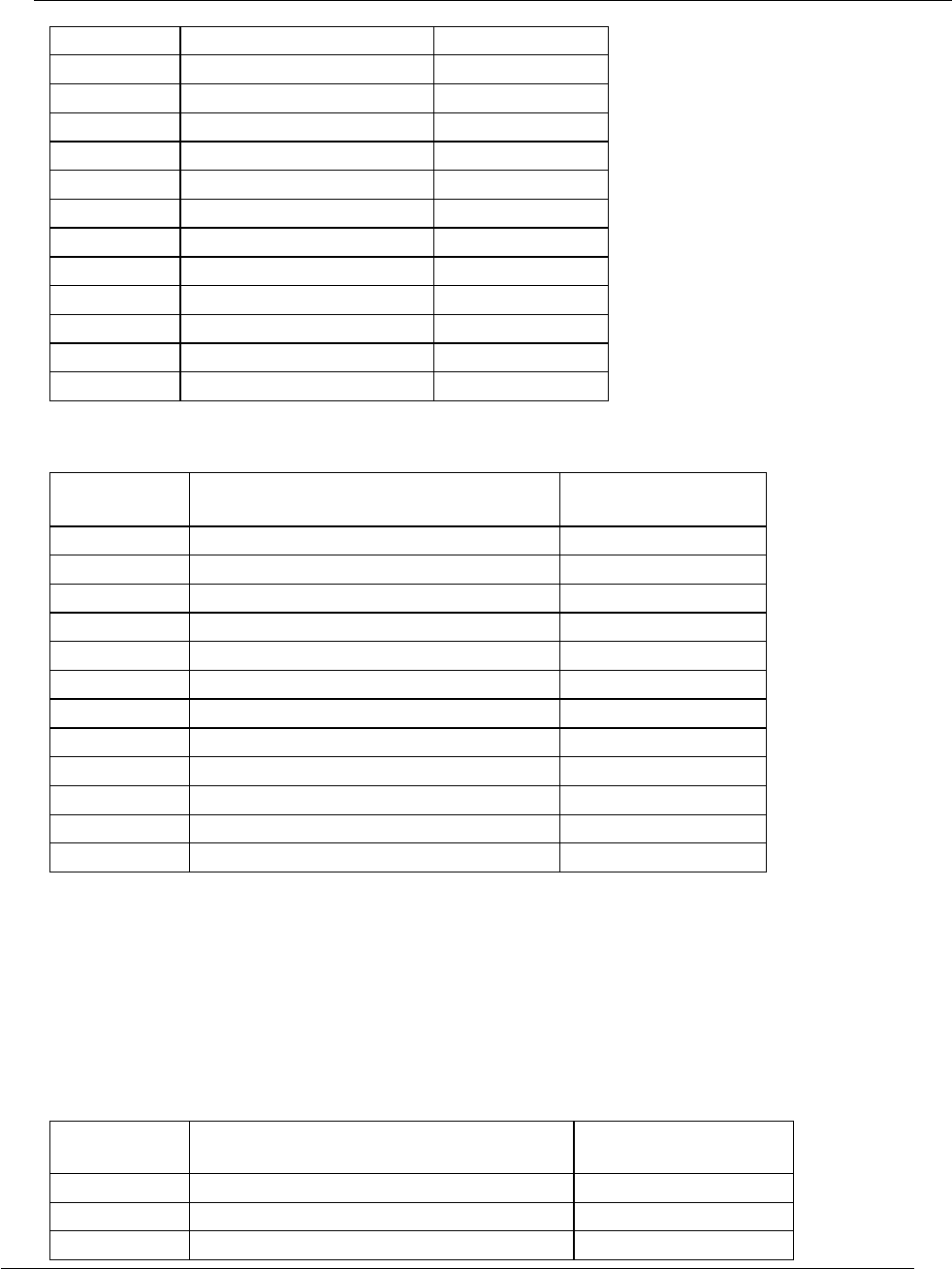

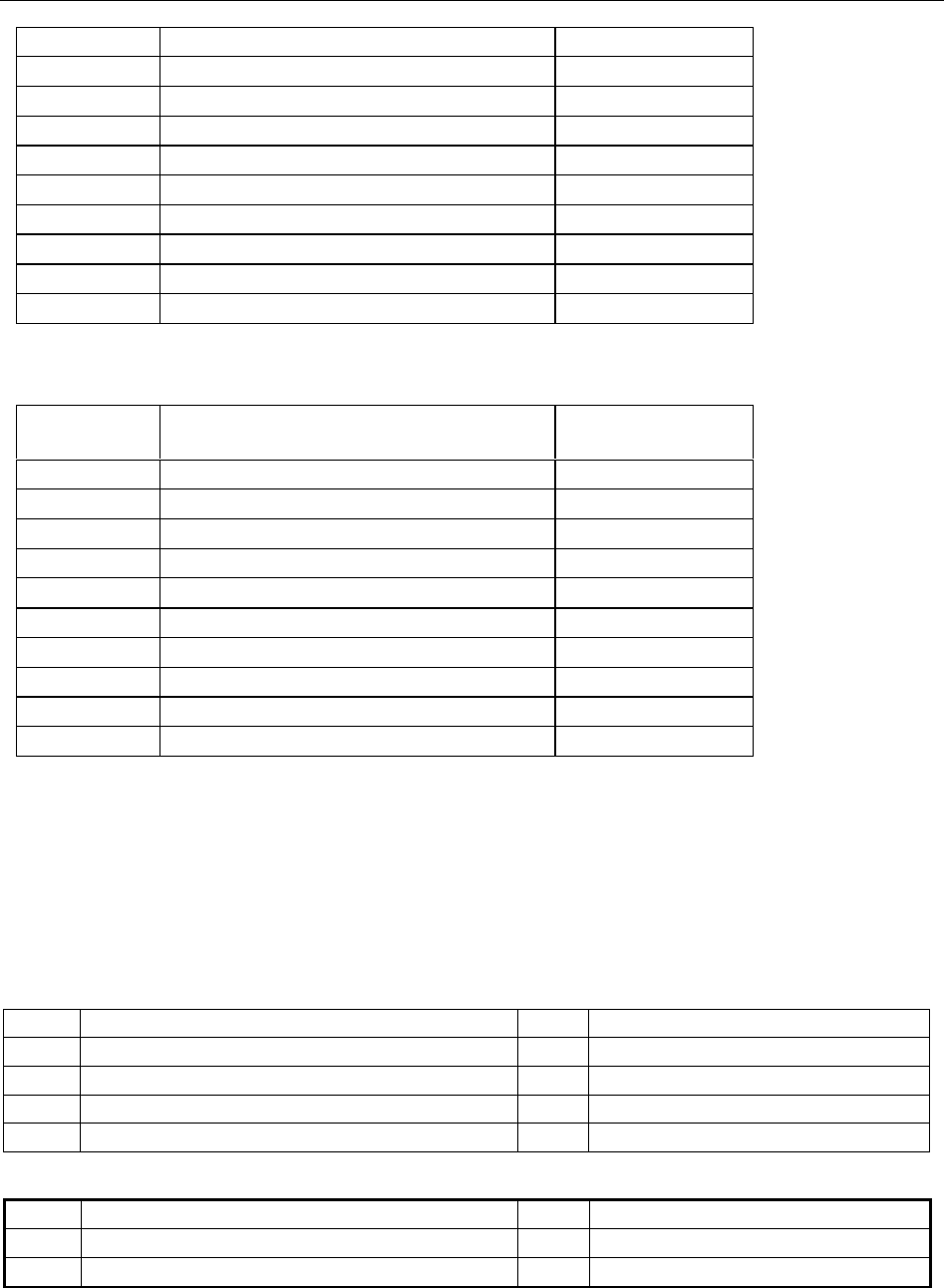

All messages

0120

Job line control info subscribe

1

0121

Job line control started

1

0122

Job line control alert 1

1

0123

Job line control alert 2

1

0124

Job line control done

1

0125

Job line control info acknowledge

1

0126

Job line control info unsubscribe

1

0127

Abort Job

1

0128

Job batch increment

1

0129

Job batch decrement

1

0130

Job off

-

0131

Set Job line control start

1

0132

Set Job line control alert 1

1

0133

Set Job line control alert 2

1

0140

Execute dynamic Job request

1 p

0150

Identifier download request

1

0151

Multiple identifiers work order subscribe

-

0152

Multiple identifiers work order

-

0153

Multiple identifiers work order acknowledge

-

0154

Multiple Identifiers work order unsubscribe

-

0155

Bypass identifier

-

0156

Reset latest identifier

-

0157

Reset all identifiers

-

0200

Set external controlled relays

1 p

0210

Status external monitored inputs subscribe

1

For initial 211, a device with

configured External

monitored signals is needed!

0211

Status external monitored inputs

1

0212

Status external monitored inputs acknowledge

1

0213

Status external monitored inputs unsubscribe

1

0214

IO device status request

2

0215

IO device status reply

2

0216

Relay function subscribe

1

0217

Relay function

1

0218

Relay function acknowledge

1

0219

Relay function unsubscribe

1

0220

Digital input function subscribe

1

Chapter 2.2

0221

Digital input function

1

0222

Digital input function acknowledge

1

0223

Digin function unsubscribe

1

0224

Set digital input function

1

0225

Reset digital input function

1

0240

User data download

-

0241

User data subscribe

-

0242

User data

-

0243

User data acknowledge

-

0244

User data unsubscribe

-

0250

Selector socket info subscribe

1 P

0251

Selector socket info

1 P

0252

Selector socket info acknowledge

1 P

0253

Selector socket info unsubscribe

1 p

0254

Selector control green lights

2

All messages

0255

Selector control red lights

2

0260

Tool Tag ID request

1

0261

Tool Tag ID subscribe

1

0262

Tool Tag ID

1

0263

Tool Tag ID acknowledge

1

0264

Tool Tag ID unsubscribe

1

0270

Controller reboot request

-

0400

Automatic/Manual mode subscribe

1

0401

Automatic/Manual mode

1

0402

Automatic/Manual mode acknowledge

1

0403

Automatic/Manual mode unsubscribe

1

0410

AutoDisable settings request

-

0411

AutoDisable settings reply

-

0420

Open protocol commands disabled subscribe

1

0421

Open protocol commands disabled

1

0422

Open protocol commands disabled acknowledge

1

0423

Open protocol commands disabled unsubscribe

1

500

Motor tuning result data subscribe

1

501

Motor tuning result data

1

Event 2022 has to be

configured to Display in the

Power Focus

502

Motor tuning result data acknowledge

1

503

Motor tuning result data unsubscribe

1

504

Motor tuning request

1

8000

Audi emergency status subscribe

-

8001

Audi emergency status

-

8002

Audi emergency status acknowledge

-

8003

Audi emergency status unsubscribe

-

9999

Keep alive open protocol communication

0

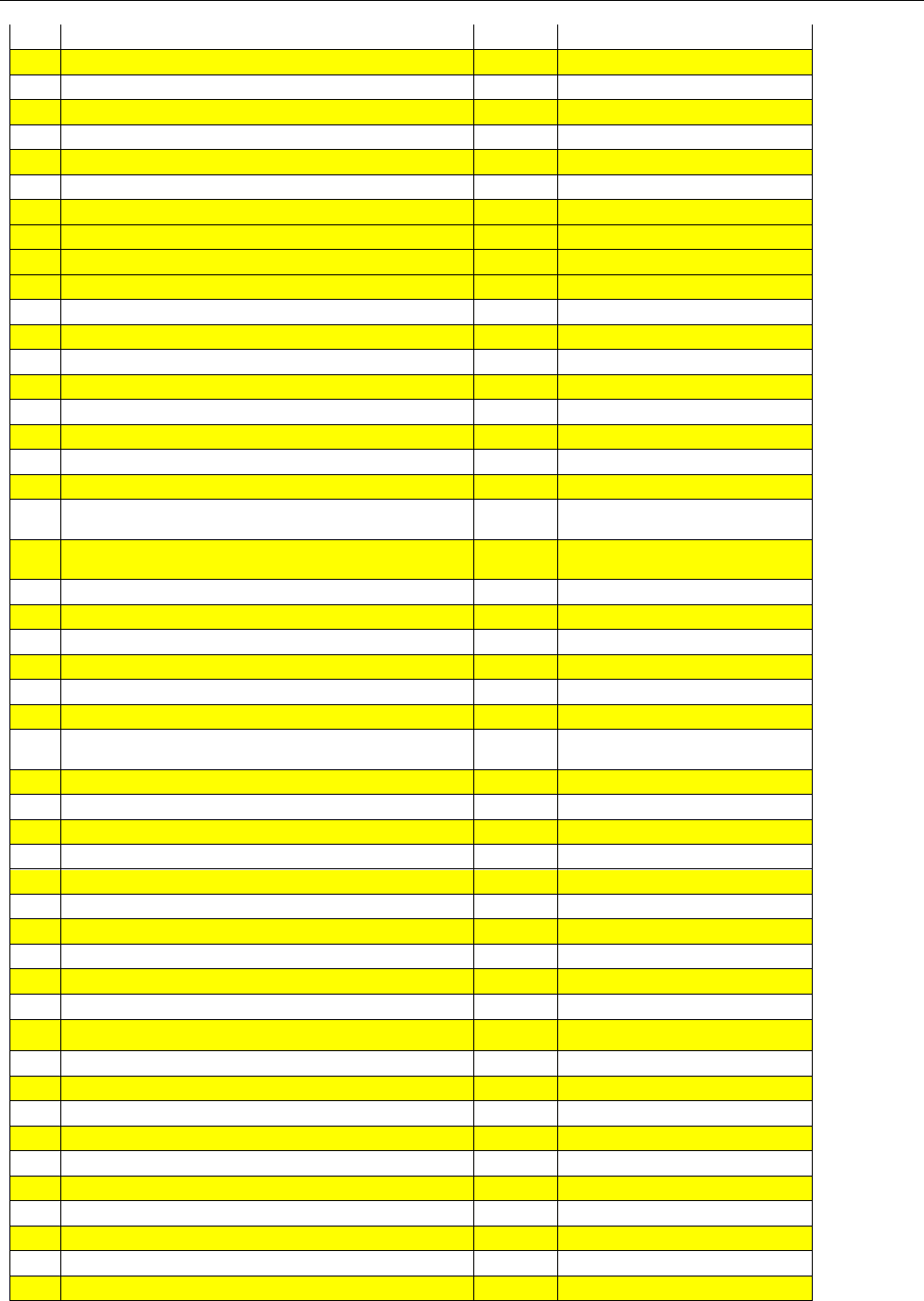

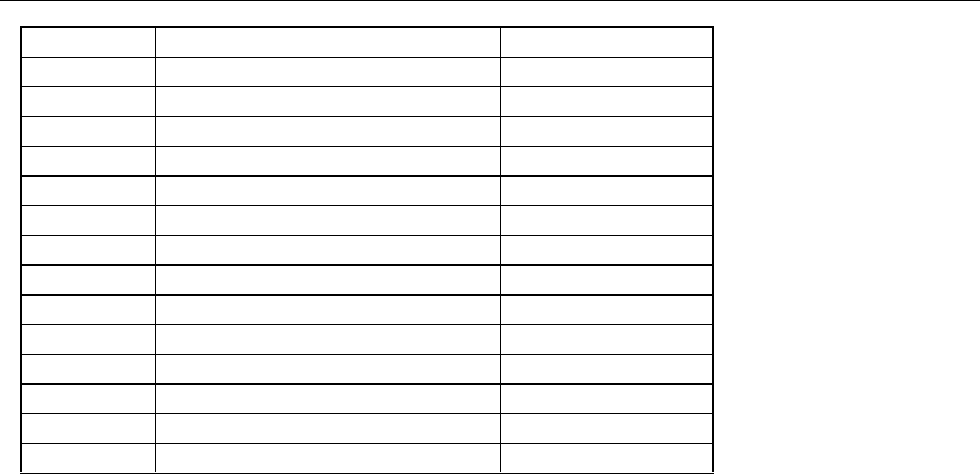

2.2 Supported MID Relay and Digital Input Signal

Table 22 MID 0215 Relay number

Relay number

Relay function

Tracking event

00

Off

01

OK

Yes

02

NOK

Yes

03

Low

No

04

High

No

05

Low Torque

Yes

06

High Torque

Yes

07

Low angle

Yes

All messages

08

High angle

Yes

09

Cycle complete

No

10

Alarm

No

11

Batch NxOK

No

12

Job OK

Yes

13

Job NOK

Yes

14

Job running

Yes

15

Car is done

No

16

Car is done status Ok

No

17

Not used

18

POWER FOCUS ready

Yes

19

Tool ready

Yes

20

Tool start switch

Yes

21

Dir. switch = CW

Yes

22

Dir. switch = CCW

Yes

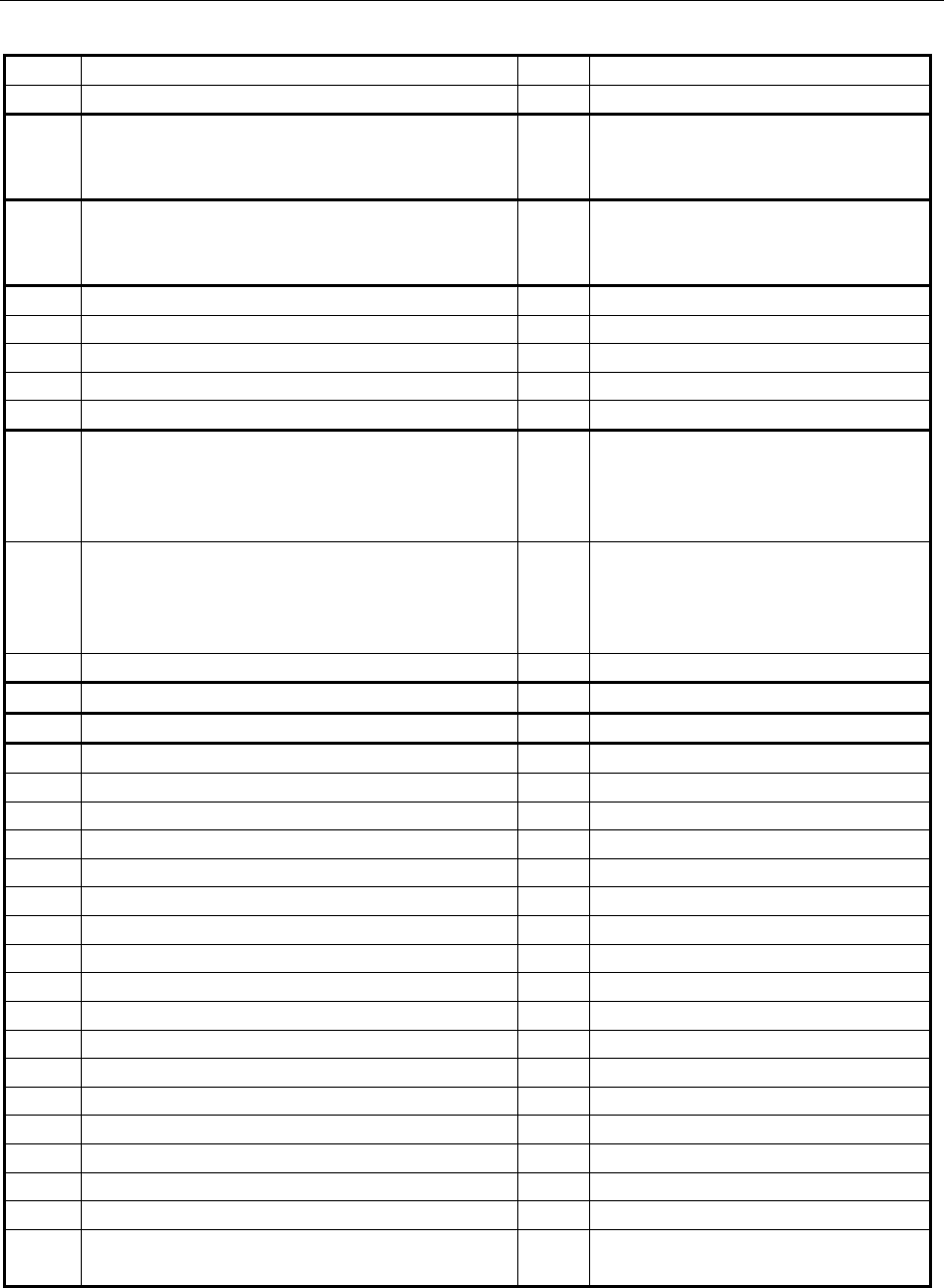

2

X = 31 + 4*Number of relays present

3

Y = X + 8 + 4*Number of digital inputs present

All messages

Relay number

Relay function

Tracking event

23

Tightening direction CCW

No

24

Tool tightening

Yes

25

Tool loosening

Yes

26

Tool running

Yes

27

Tool running CW

Yes

28

Tool running CCW

Yes

29

Statistic alarm

No

30

Tool locked

No

31

Received identifier

No

32

Running Pset bit 0

No

33

Running Pset bit 1

No

34

Running Pset bit 2

No

35

Running Pset bit 3

No

36

Running Job bit 0

No

37

Running Job bit 1

No

38

Running Job bit 2

No

39

Running Job bit 3

No

40

Not used

41

Not used

42

Not used

43

Not used

47

Service indicator

No

48

Fieldbus relay 1

No

49

Fieldbus relay 2

No

50

Fieldbus relay 3

No

51

Fieldbus relay 4

No

52

Tool red light

No

53

Tool green light

No

54

Tool yellow light

No

55

Reserved

No

56

Reserved

No

57

Reserved

No

58

Reserved

No

59

Running Pset bit 4

No

60

Running Pset bit 5

No

61

Running Pset bit 6

No

62

Running Pset bit 7

No

63

Running Job bit 4

No

All messages

64

Running Job bit 5

No

Relay number

Relay function

Tracking event

65

Running Job bit 6

No

66

Running Job bit 7

No

67

Sync OK

No

68

Sync NOK

No

69

Sync spindle 1 OK

No

70

Sync spindle 1 NOK

No

71

Sync spindle 2 OK

No

72

Sync spindle 2 NOK

No

73

Sync spindle 3 OK

No

74

Sync spindle 3 NOK

No

75

Sync spindle 4 OK

No

76

Sync spindle 4 NOK

No

77

Sync spindle 5 OK

No

78

Sync spindle 5 NOK

No

79

Sync spindle 6 OK

No

80

Sync spindle 6 NOK

No

81

Sync spindle 7 OK

No

82

Sync spindle 7 NOK

No

83

Sync spindle 8 OK

No

84

Sync spindle 8 NOK

No

85

Sync spindle 9 OK

No

86

Sync spindle 9 NOK

No

87

Sync spindle 10 OK

No

88

Sync spindle 10 NOK

No

89

Carrier in station

No

90

Enable scanner

Yes

91

Line Control Start

Yes

92

Job Aborted

No

93

External controlled 1

Yes

94

External controlled 2

Yes

95

External controlled 3

Yes

96

External controlled 4

Yes

97

External controlled 5

Yes

98

External controlled 6

Yes

99

External controlled 7

Yes

All messages

100

External controlled 8

Yes

101

External controlled 9

Yes

102

External controlled 10

Yes

103

ToolsNet connection lost

No

104

Open Protocol connection lost

No

105

FieldBus Offline

No

106

Home position

No

Relay number

Relay function

Tracking event

107

Batch NOK

No

108

Selected Channel in Job

No

109

Safe to disconnect tool

No

110

Running Job bit 8

No

111

Running Pset bit 8

No

112

Calibration Alarm

No

113

Cycle start

No

114

Low current

No

115

High current

No

116

Low PVT monitoring

No

117

High PVT monitoring

No

118

Low PVT selftap

No

119

High PVT selftap

No

120

Low tightening angle

No

121

High tightening angle

No

122

Identifier identified

No

123

Identifier type 1 received

No

124

Identifier type 2 received

No

125

Identifier type 3 received

No

126

Identifier type 4 received

No

127

Reserved

128

Reserved

129

Ring button ack.

No

130

DigIn controlled 1

No

All messages

131

DigIn controlled 2

No

132

DigIn controlled 3

No

133

DigIn controlled 4

No

134

Fieldbus carried signals

disabled

No

135

Illuminator

No

136

New parameter set selected

No

137

New Job selected

No

138

Job OFF relay

No

139

Logic relay 1

No

140

Logic relay 2

No

141

Logic relay 3

No

142

Logic relay 4

No

143

Max coherent NOK reached

No

144

Batch done

No

145

Start trigger active

No

146

Final angle start

No

150-250

Reserved

251

Completed Batch bit 0

No

Relay number

Relay function

Tracking event

252

Completed Batch bit 1

No

253

Completed Batch bit 2

No

254

Completed Batch bit 3

No

255

Completed Batch bit 4

No

256

Completed Batch bit 5

No

257

Completed Batch bit 6

No

258

Completed Batch bit 7

No

259

Remaining Batch bit 0

No

260

Remaining Batch bit 1

No

261

Remaining Batch bit 2

No

262

Remaining Batch bit 3

No

263

Remaining Batch bit 4

No

264

Remaining Batch bit 5

No

265

Remaining Batch bit 6

No

266

Remaining Batch bit 7

No

271

Next tight

No

272

Power On

No

273

Toyota fault

No

274

Toyota fault or Ng

No

All messages

275

Open Protocol commands

disabled

No

276

Cycle abort

No

277

Effective loosening

Yes

278

Logic relay 5

No

279

Logic relay 6

No

280

Logic relay 7

No

281

Logic relay 8

No

282

Logic relay 9

No

283

Logic relay 10

No

284

Lock at batch done

No

285

User Id Ok

No

286

Pin Ok

No

287

Battery low

No

288

Battery empty

No

289

Tool connected

No

290

No tool connected

No

291

Toyota fixed stop

No

292

Tyota temp stop

No

293

Function button

Yes

Relay number

Relay function

Tracking event

294

Rehit

No

295

Tightening disabled

Yes

296

Loosening disabled

Yes

297

Positioning disabled

No

298

Motor tuning disabled

No

299

Open End tuning disabled

No

300

Tracking disabled

No

301

Pass authorized

No

302

PLUS Automatic mode

Yes

303

PLUS Emergency mode

No

304

Wear indicator

No

305

Direction alert

No

306

PLUS Bolt reworked

No

307

Line stop

No

All messages

308

Running pset bit 9

No

309

Active XML Result Ack

No

310

Tool in work space

No

311

Tool in product space

No

312

XML protocol active

No

313

Tool enabled by XML

No

314

Necking failure

No

315

PLUS protocol not active

No

316

PLUS No tightening

No

317-350

Reserved

351

Middle course trigger active

No

352

Front trigger active

No

353

Reverse trigger active

No

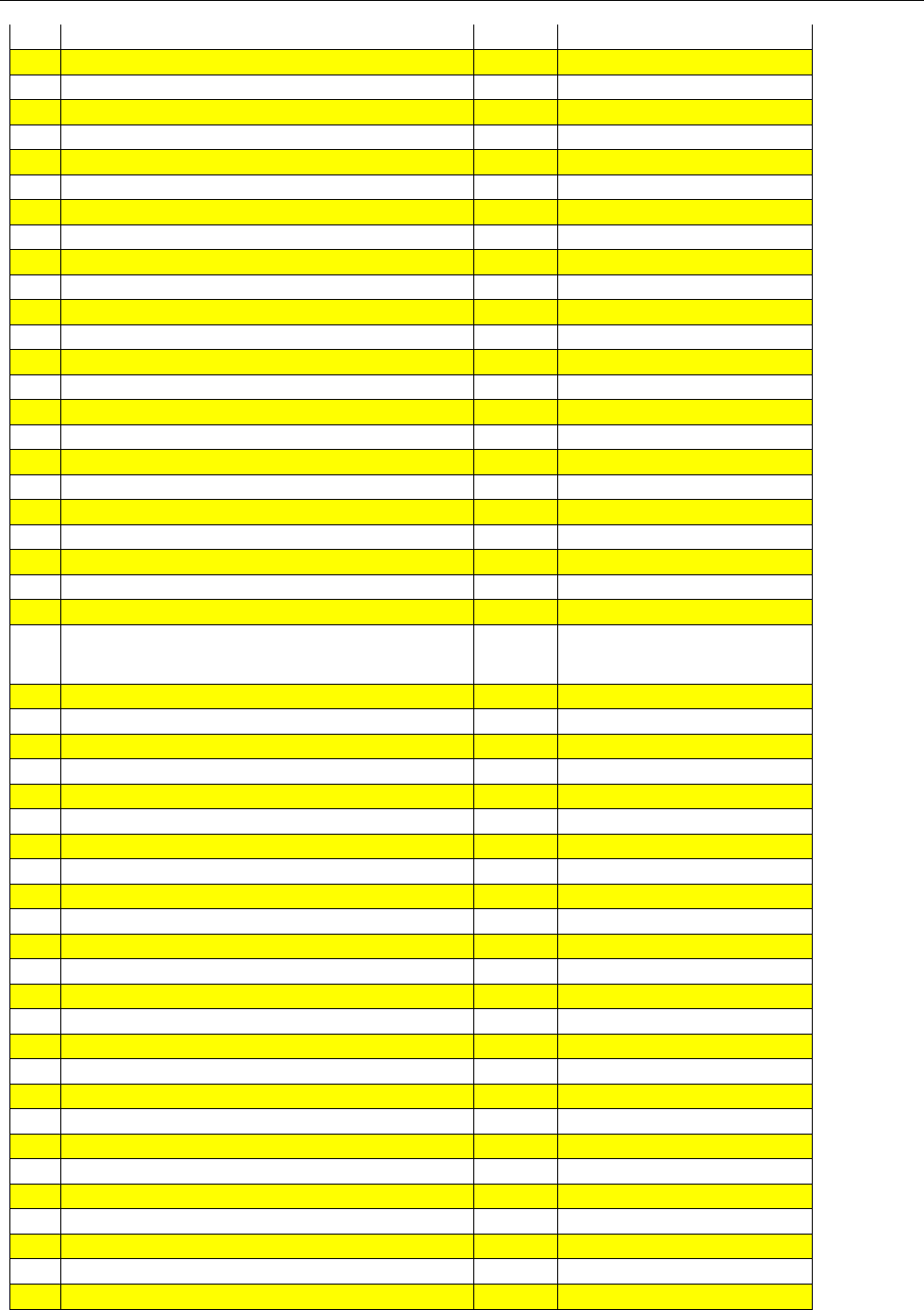

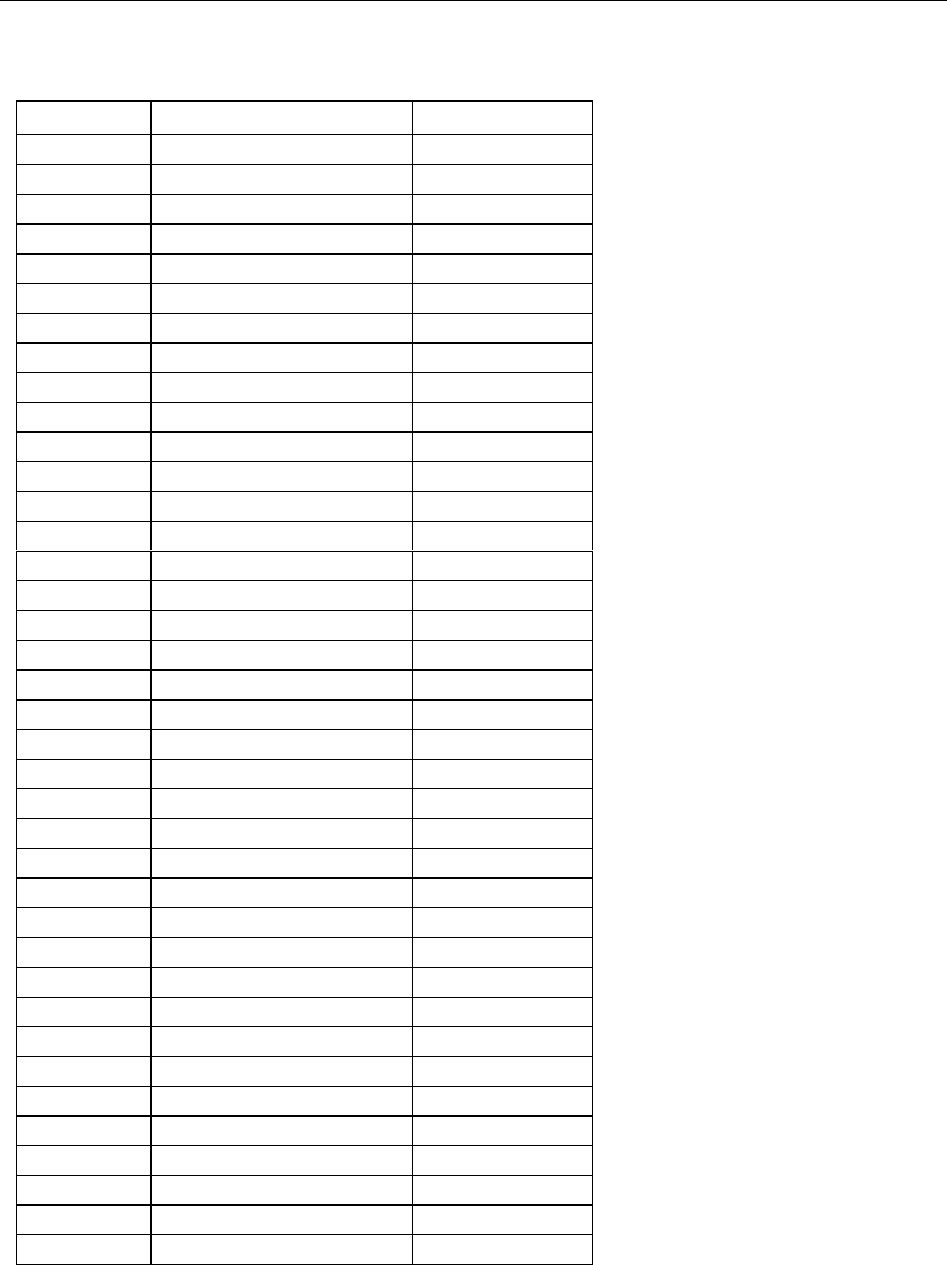

Table 94 MID 0215 DigIn number

DigIN number

DigIN

function

00

Off

01

Reset batch

Yes

02

Unlock tool

Yes

03

Tool disable n.o.

No

04

Tool disable n.c.

No

05

Tool tightening disable

Yes

06

Tool loosening disable

Yes

07

Remote start puls

Yes

08

Remote start cont.

Yes

09

Tool start loosening

Yes

10

Batch increment

Yes

11

Bypass Pset

Yes

DigIN number

DigIN

function

12

Abort Job

Yes

13

Job off

No

14

parameter set toggle

No

All messages

15

Reset relays

No

16

parameter set select bit 0

Yes

17

parameter set select bit 1

Yes

18

parameter set select bit 2

Yes

19

parameter set select bit 3

Yes

20

Job select bit 0

Yes

21

Job select bit 1

Yes

22

Job select bit 2

Yes

23

Job select bit 3

Yes

24

Reserved

25

Reserved

26

Reserved

27

Reserved

28

Line control start

Yes

29

Line control alert 1

Yes

30

Line control alert 2

Yes

31

Ack error message

Yes

32

Fieldbus digin 1

No

33

Fieldbus digin 2

No

34

Fieldbus digin 3

No

35

Fieldbus digin 4

No

36

Flash tool green light

No

37

Reserved

38

Reserved

39

Set bistable relay 1

Yes

40

Set bistable relay 2

Yes

41

Reserved

42

Reserved

43

Reserved

44

Reserved

45

parameter set select bit 4

No

46

parameter set select bit 5

No

47

parameter set select bit 6

No

48

parameter set select bit 7

No

49

Job select bit 4

No

50

Job select bit 5

No

51

Job select bit 6

No

52

Job select bit 7

No

53

Batch decrement

Yes

All messages

DigIN number

DigIN

function

54

Job restart

No

55

End of cycle

No

56

Tool back in position

No

57

Reset tool locked

No

58

DC switch in AND

No

59

DC switch out AND

No

60

DC switch in OR

No

61

DC switch out OR

No

62

Click wrench 1

No

63

Click wrench 2

No

64

Click wrench 3

No

65

Click wrench 4

No

66

ID Card

No

67

Automatic mode

Yes

68

External monitored 1

Yes

69

External monitored 2

Yes

70

External monitored 3

Yes

71

External monitored 4

Yes

72

External monitored 5

Yes

73

External monitored 6

Yes

74

External monitored 7

Yes

75

External monitored 8

Yes

76

Select next parameter set

No

77

Select previous parameter set

No

78

Disable FB Job status

No

79

Timer enable tool

No

80

Master unlock tool

Yes

81

ST Scan request

No

82

Disconnect tool

No

83

Job select bit 8

No

84

Parameter set select bit 8

No

85

Request ST scan

No

86

Reset NOK counter

Yes

87

Bypass identifier

No

88

Reset latest identifier

No

89

Reset all identifier

No

90

Set home position

No

91

DigOut monitored 1

No

92

DigOut monitored 2

No

93

DigOut monitored 3

No

All messages

94

DigOut monitored 4

No

95

Disable ST Scanner

No

DigIN number

DigIN

function

96

Disable fieldbus carried signals

No

97

Toggle CW/CCW

No

98

Toggle CW/CCW for next run

No

99

Set CCW

No

100

Dig In emergy mode

No

101

Dig in pass

No

102

Dig in interlock off

No

103

Dig in backup tool

No

104

Open Protocol commands disable

No

105

Logic digIn 1

No

106

Logic digIn 2

No

107

Logic digIn 3

No

108

Logic digIn 4

No

109

Logic digIn 5

No

110

Logic digIn 6

No

111

Logic digIn 7

No

112

Logic digIn 8

No

113

Logic digIn 9

No

114

Logic digIn 10

No

115

Dig In start timing

No

116

Dig In request timing

No

117

Dig In judgement timing

No

118

Dig In stop timing

No

119

Dig in request and start timing

No

120

Forced CCW once

No

121

Forced CCW toggle

No

122

Forced CW once

No

123

Forced CW toggle

No

124

Dig In poka yoke pass

No

125

Poka yoke backup tool

No

126

Tool behind

No

127

Tool in front of

No

All messages

128

Toyota test mode

No

129

Pset select bit 9

No

130

Store current tightening program in the tool

No

131

Active XML result send

No

132

Tool in work space

No

133

Tool in product space

No

134

Flash tool yellow light

No

135

XML Emergency mode

No

150-200

Reserved

No

201

Tool blue light IO controlled

No

DigIN number

DigIN

function

202

Tool blue light

No

203

Tool green light IO controlled

No

204

Tool green light

No

205

Tool red light IO controlled

No

206

Tool red light

No

207

Tool yellow light IO controlled

No

208

Tool yellow light

No

209

Tool white light IO controlled

No

210

Tool white light

No

300-349

Reserved

No

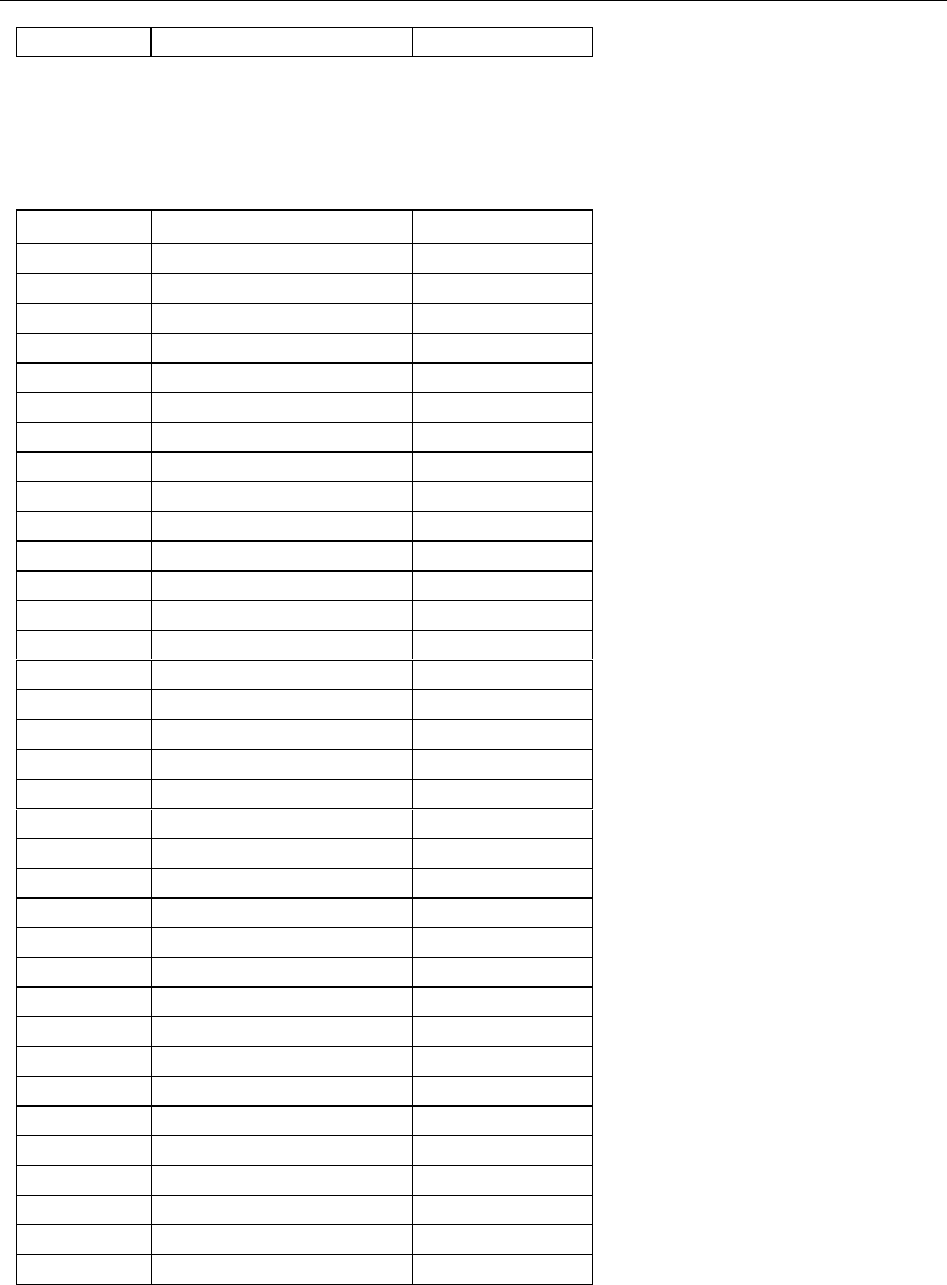

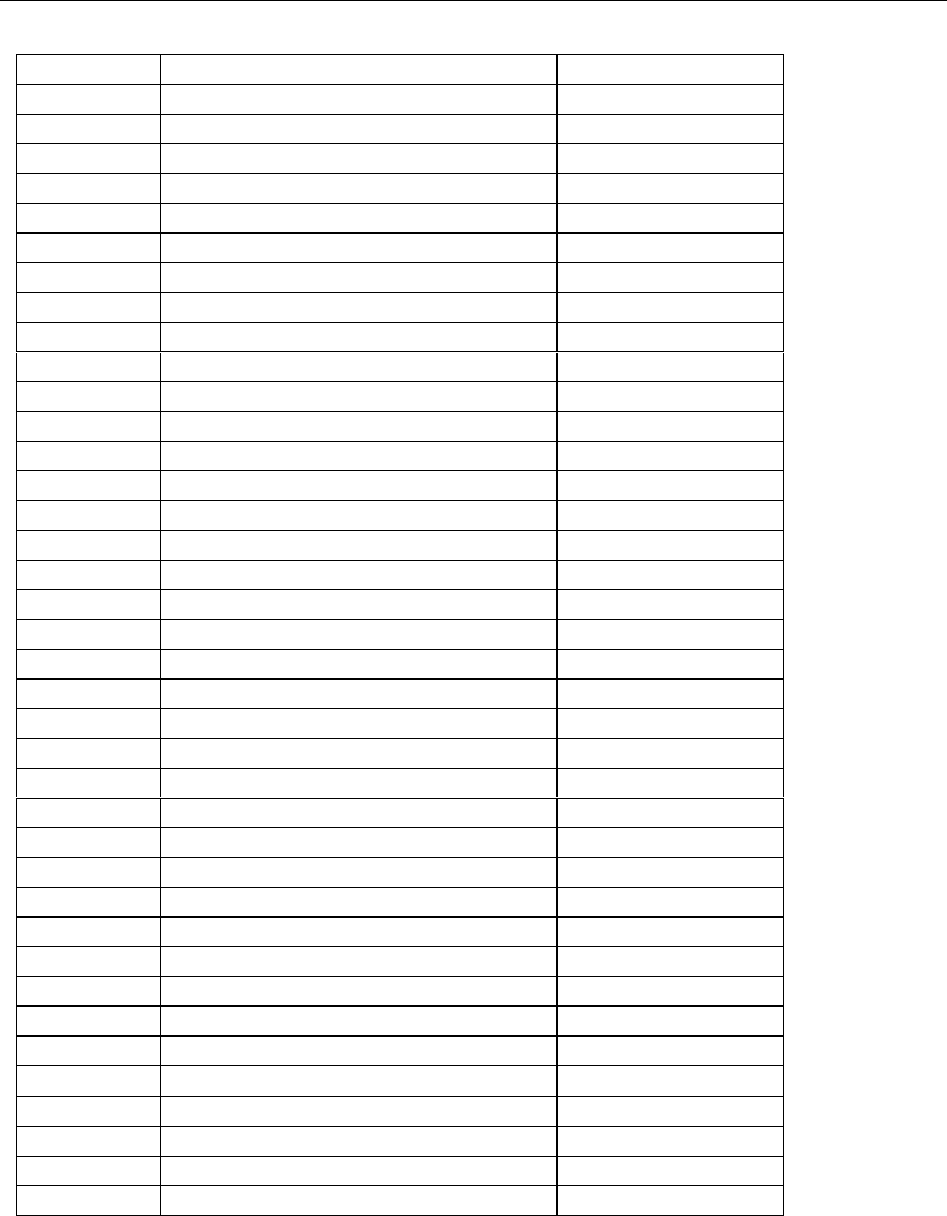

2.3 Revision Support

Table 2 Parameters not supported in PF6000

MID

MID

Rev

Parameter

All

All

Cell Id

13

Parameter set data upload reply

1

Batch size

Table 3 Parameters not supported or managed under special conditions in PF6000

MID

MID

Rev

Parameters/Conditions

2

CommunicationStartAcknowledge

2

Supplier code

2

CommunicationStartAcknowledge

3

Open Protocol version

All messages

2

CommunicationStartAcknowledge

4

RBU Type

2

CommunicationStartAcknowledge

5

System subtype

12

Parameter set data upload request

3,4

Not supporting different Pset file

versions, always interpret as

00000000

13

Parameter set data upload reply

3,4

Parameter 14, 19, 20 not

supported. Parameter 17, angle

used for calculating time

33

Job Data

1

Max time for first tightening

33

Job Data

1

Use line control

33

Job Data

1

Repeat Job

33

Job Data

1

Tool loosening

33

Job Data

3

Job List

35

Job Info, parameter 4

1

Show batch size for current

batch. If legacy counter mode is

used, it will count as specified in

OP Specification

35

Job Info, parameter 5

1

Show batch count for current

batch. If legacy counter mode is

used, it will count as specified in

OP Specification

35

Job Info

3

Job step type

39

Job restart

1

No check if performed

41

Tool data upload reply

2

Motor size

61

LastTighteningResultDataUploadReply

1

Channel ID

61

LastTighteningResultDataUploadReply

2

Strategy Options

61

LastTighteningResultDataUploadReply

2

current monitoring status

61

LastTighteningResultDataUploadReply

2

prevail torque monitoring status

61

LastTighteningResultDataUploadReply

2

prevail torque compensate status

61

LastTighteningResultDataUploadReply

2

tightening error status

61

LastTighteningResultDataUploadReply

2

rundown angle

61

LastTighteningResultDataUploadReply

2

current monitoring min

61

LastTighteningResultDataUploadReply

2

current monitoring max

61

LastTighteningResultDataUploadReply

2

current monitoring value

61

LastTighteningResultDataUploadReply

2

selftap torque

61

LastTighteningResultDataUploadReply

2

prevail torque monitoring min

61

LastTighteningResultDataUploadReply

2

prevail torque monitoring max

61

LastTighteningResultDataUploadReply

2

prevail torque

61

LastTighteningResultDataUploadReply

2

job sequence number

61

LastTighteningResultDataUploadReply

2

sync tightening id

61

LastTighteningResultDataUploadReply

5

Customer tightening error code

61

LastTighteningResultDataUploadReply

6

Prevail Torque compensate

value

All messages

61

LastTighteningResultDataUploadReply

6

Tightening error status 2

61

LastTighteningResultDataUploadReply

8

Start final angle not supported

for multistep

61

LastTighteningResultDataUploadReply

998

Number of stages in multistage

61

LastTighteningResultDataUploadReply

998

Number of stage results

61

LastTighteningResultDataUploadReply

998

Stage result

65

OldTighteningResultUploadReply

2

Strategy options

65

OldTighteningResultUploadReply

2

Current Monitoring Status

65

OldTighteningResultUploadReply

2

Prevail Torque monitoring status

65

OldTighteningResultUploadReply

2

Prevail Torque compensate

status

65

OldTighteningResultUploadReply

2

Tightening error status

65

OldTighteningResultUploadReply

2

Current Monitoring Value

65

OldTighteningResultUploadReply

2

Self-tap torque

65

OldTighteningResultUploadReply

2

Prevail torque

65

OldTighteningResultUploadReply

2

Job sequence number

65

OldTighteningResultUploadReply

2

Sync tightening ID

65

OldTighteningResultUploadReply

2

Tool serial number

65

OldTighteningResultUploadReply

5

Customer tightening error code

65

OldTighteningResultUploadReply

6

Prevail Torque compensate

value

65

OldTighteningResultUploadReply

6

Tightening error status 2

65

OldTighteningResultUploadReply

8

Start final angle not supported

for multistep

140

Dynamic Job

1

Not supported Parameters:

5,6,7,8,10,11,12,14,15,16,17,18

Not checking if Pset exist.

200

SetExternalControlledRelays

1

Will set signals Generic IO 1-10

251

SelectorSocketInfoUpload

1

Multiple selectors will be sent as

device one. Configuration and

mapping in VS important, socket

08 can be in selector 2 etc.

2.4 MID 64/65 – Old result data, special support

In the PF6000, all results are assigned an ID, as in the PF4000. However, these IDs are global and if

multiple tools are used (and in most other cases) the tightening ID for a result is not incremented by one.

So this imply that an integrator doesn’t know which ID it shall send to get a specific result. The partially

support for the old result MIDs (64 and 65) shall therfore be used as described below.

The integrator shall always use 0 to get the latest result, as in the PF4000. If the integrator knows an ID to

start from it shall send the ID decremented by one. The PF6000 will then answer with the latest result on a

global level. The result received at the integrator will most probably not have the ID it sent, but it is

All messages

guaranted that the result is the previous from the ID sent. The integrator shall then use the received ID

decremented by one to get the next latest result. This shall then be continued until the integrator recives an

ID it knows or until the PF6000 doesn’t find any more results.

Important to know if more than one tool is or have been used at the station: The old result will be fetched

at a global level that will say the received result may belong to another tool/Virtual Station than the

connected one. It is thetrefore important for the integrator to filter the recived old result against the Station

Id that is part of Rev 7 in MID 65 and in Rev 6 of the Communication start Ack, MID 2.

Example of fetching three old results, integrator knows about tightening ID 10204 and the stations uses

two tools.

Integrator sends: MID 1, Communication start

PF6000 answer: MID 2, Station ID in parameter 14 is 6534 and saved by Integrator.

Integrator sends: MID 64, ID = 0

PF6000 answer: MID 65, tightening ID = 10230, Station ID = 6534

Integrator sends: MID 64, ID = 10229

PF6000 answer: MID 65, tightening ID = 10226, Station ID = 6534

Integrator sends: MID 64, ID = 10225

PF6000 answer: MID 65, tightening ID = 10220, Station ID = 6685 (not the connected VS, throw away)

Integrator sends: MID 64, ID = 10219

PF6000 answer: MID 65, tightening ID = 10216, Station ID = 6685 (not the connected VS, throw away)

Integrator sends: MID 64, ID = 10215

PF6000 answer: MID 65, tightening ID = 10209, Station ID = 6534

Integrator sends: MID 64, ID = 10208

PF6000 answer: MID 65, tightening ID = 10204, Station ID = 6534

The received tightening ID was known by the integrator, all missed results fetched from PF6000.

All messages

2.5 Usage of Tightening program (Pset) selection

In order to be able to select tightening programs in Power Focus 6000 the Virtual Station needs to use a

Source Tightening as task. If using MID 0010-0011 with no task or any other task but Source Tightening,

the Power Focus 6000 will send a list back containing indexes of all tightening programs from Tightening

menu. If a Source Tightening is not selected, the Power Focus 6000 will not be able to use MID 0018 and

instead, the Power Focus 6000 will respond with error MID 0004, status 03 – Parameter set cannot be set.

When a Source Tightening is used the Tightening program list that will be sent by MID 0011 will consist

of the list that is configured in the selected Source Tightening task. The ID/index in the message will be

the same as the configured “Identifier number” in the Source Tightening. That will say, it will NOT be the

Tightening program index found in the Tightening menu.

When selecting by MID 0018, the ID/index to send is the one that is received with MID 0011. This is the

configured “Identifier number” in the selected Source Tightening. If trying to select and ID/index that is

not configured as an “Identifier number”, even if there is a Tightening program with this index in the

tightening menu, the error MID 0004, status 03 – Parameter set can not be set, will be sent from the Power

Focus 6000.

When subscribing for selected Tightening program, MID 0014-0017, the sent ID/index from the Power

Focus 6000 will always be the index for the Tightening program found in the tightening menu. This

implies that the configured “Identifier number” in the selected Source Tightening will never be sent with

MID 0015. In all MIDs containing Tightening program info (like MID 0061), the ID/index will always be

the one found in the tightening menu, not the configured “Identifier number” in the selected Source

Tightening.

When using MID 0012 to fetch Tightening program data, the ID/index to use shall always be the one

found in the tightening menu and not the configured “Identifier number” in the selected Source

Tightening.

2.6 Usage of Tightening program (Pset) batch size

In Power Focus 6000 it is possible to run dynamic batch control on Tightening program level. To do so the

Virtual Station need to run a Source Tightening task configured to use External Batch Control. It is then

possible to send MID 0019 to select a batch size for a configured Tightening Program.

If a command request to set batch size for a non-existing Tightening Program, that is a non programmed

identifier in the list in the Source Tightening configuration, a command error MID 0004 with status 79

will be returned.

It is possible to setup batch sizes for non selected Tightening Programs, but that is in the Source

Tightening configuration list. However, if there is a configuration change of the running Source

Tightening, the cached batch sizes will be reset and the client need to set all batch sizes again.

MID 0020 is now also supported to reset current running batch. However, the payload data will not have

any effect. The Power Focus 6000 will not check if the reset command is for the current running

Tightening Program.

All messages

2.7 Usage of Sequence (Job) selection

Since Power Focus 6000 release 2.7 the virtual station is required to run a Source Batch configured with

number as selection input, to select Job, MID 0038 and get Job list, MID 0030-0031. If this requriment is

not fulfilled, MID 0030-0031 and MID 0038 will not work. If using MID 0030-0031 without Source

Batch configured with numbers, the Power Focus 6000 will send an empty list back. If trying to use MID

0038 without a Source Batch configured with numbers, the Power Focus 6000 will respond with error

MID 0004, status 20 – Job can not be set.