Torque Tool Ethernet Driver

© 2024 PTC Inc. All Rights Reserved.

Torque Tool Ethernet Driver

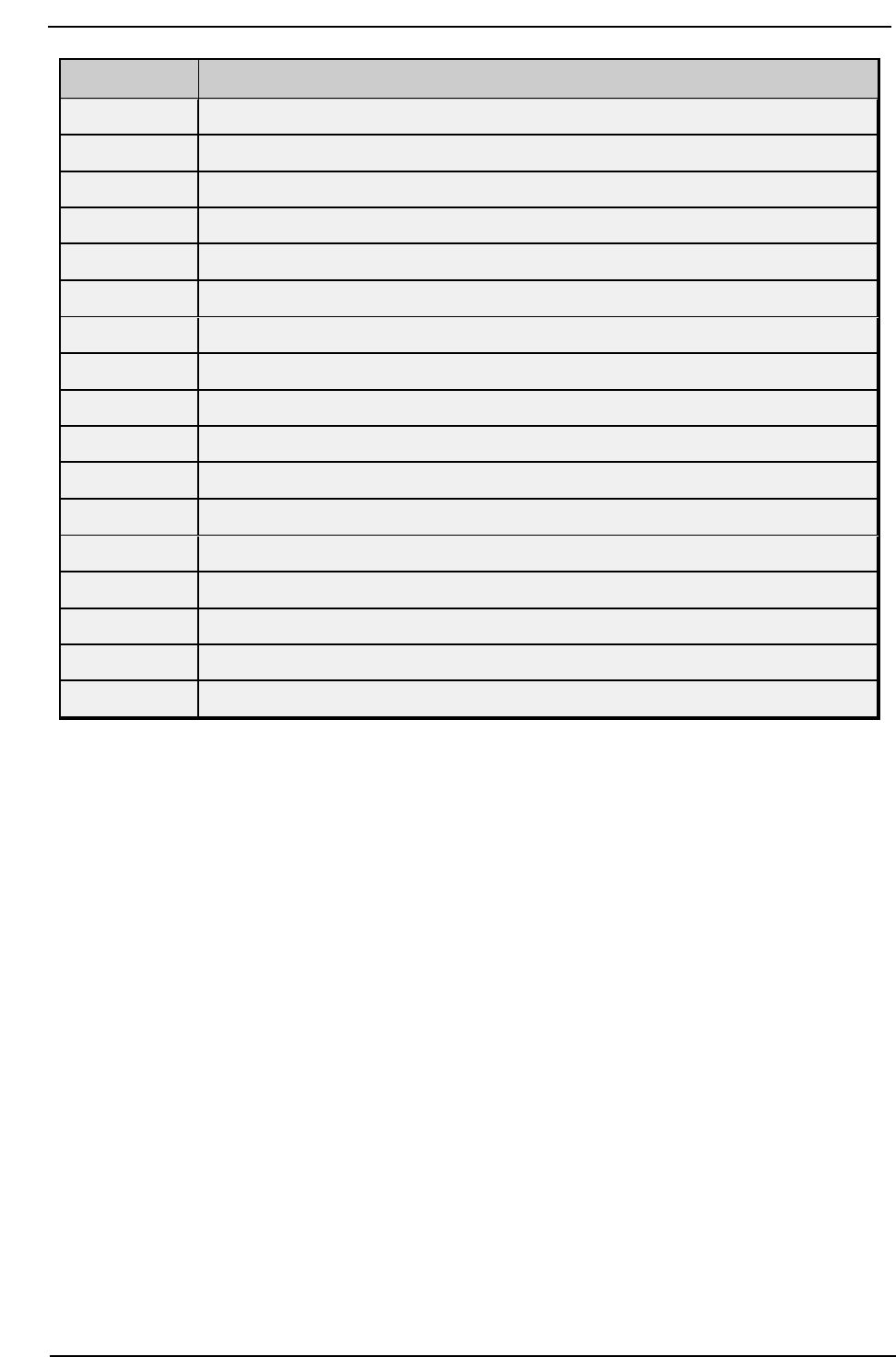

Table of Contents

Torque Tool Ethernet Driver

1

Table of Contents

2

Torque Tool Ethernet Driver

5

Overview

5

Setup

5

Channel Properties — General 6

Tag Counts 6

Channel Properties — Ethernet Communications 7

Channel Properties — Write Optimizations 7

Channel Properties — Advanced 8

Device Properties — General 9

Operating Mode 10

Tag Counts 10

Device Properties — Scan Mode 10

Device Properties — Timing 11

Device Properties — Communications Parameters 12

Device Properties — Settings 13

Device Properties — Redundancy 14

Optimizing Communications

15

Data Types Description

16

Address Descriptions

17

Message IDs

18

Command Set: Alarm

20

Command Set: Auto-Disable Settings

21

Command Set: Communication

22

Command Set: Dynamic Job Request

23

Command Set: Flash

23

Command Set: Identifiers

23

Command Set: IO Interface

24

Command Set: Job Info

26

Command Set: Job Data

27

Command Set: Job Number Data

29

Command Set: Last Tightening Results

29

Command Set: Multi-Spindle Results

34

Command Set: Old Tightening Results

36

www. ptc.com

2

Torque Tool Ethernet Driver

Command Set: Operation Result

40

Command Set: Parameter Set Data

40

Command Set: Parameter Set Numbers

41

Command Set: Parameter Set Selected

42

Command Set: Program Messages

43

Command Set: Selector Messages

43

Command Set: Time

44

Command Set: Tool Data

45

Command Set: Trace Curve Data Messages

47

Command Set: User Data Messages

49

Command Set: VIN

49

Event Log Messages

50

Error Descriptions

50

Address <address> is out of range for the specified device or register. 51

Array size is out of range for address <address>. 51

Array support is not available for the specified address: <address>. 51

Data type <type> is not valid for device address <address>. 51

Device address <address> contains a syntax error. 51

Device address <address> is read only. 52

Subscription failed for device <device>, <type> subscription. 52

Unable to bind to adapter: <adapter name>. Connect failed. 52

Winsock initialization failed (OS error = <error>). 52

Winsock shut down failed (OS error = <error>). 53

Winsock V1.1 or higher must be installed to use the driver. 53

Device <device name> failed to connect. 53

Device <device name> is not responding. 53

Unable to read tag <tag name>: Device <device name> encountered a parsing error. 54

Unable to read tag <tag name>: Device <device name> received an error response (Error <error

code>). 54

Unable to read unsolicited packed data group: Device <device name> received an error response

(Error <error code>). 55

Unable to write tag <tag name>: Device <device name> encountered a parsing error. 55

Unable to write tag <tag name>: Device <device name> received an error response (Error <error

code>). 55

Unable to write tag <tag name>: Device <device name> received invalid data for write. 56

Unable to write to <address> on device <device name>. 56

Error Codes 56

Appendix — Dynamic Job Request

60

www. ptc.com

3

Torque Tool Ethernet Driver

Torque Tool Ethernet Driver

Help version 1.087

CONTENTS

Overview

What is the Torque Tool Ethernet Driver?

Setup

How do I configure a device for use with this driver?

Optimizing Communications

How do I get the best performance from the driver?

Data Types Description

What data types does the Torque Tool Ethernet Driver support?

Address Descriptions

How do I reference a data location in a Torque Tool Ethernet device?

Error Descriptions

What error messages does the Torque Tool Ethernet Driver produce?

Overview

The Torque Tool Ethernet Driver provides a reliable way to connect Torque Tool Ethernet devices to OPC Cli-

ent applications; including HMI, SCADA, Historian, MES, ERP, and countless custom applications. It is inten-

ded to work with all devices supporting the Torque Tool Open Protocol.

Setup

Supported Devices

The Torque Tool Ethernet Driver is designed to work with any device that supports the Torque Tool Open

Protocol. The driver has been tested with the Stanley QA Alpha Controller and the Atlas Copco Power Focus.

Channel and Device Limits

The maximum number of channels supported by this driver is 1024. The maximum number of devices sup-

ported by this driver is 1024 per channel.

www. ptc.com

5

Torque Tool Ethernet Driver

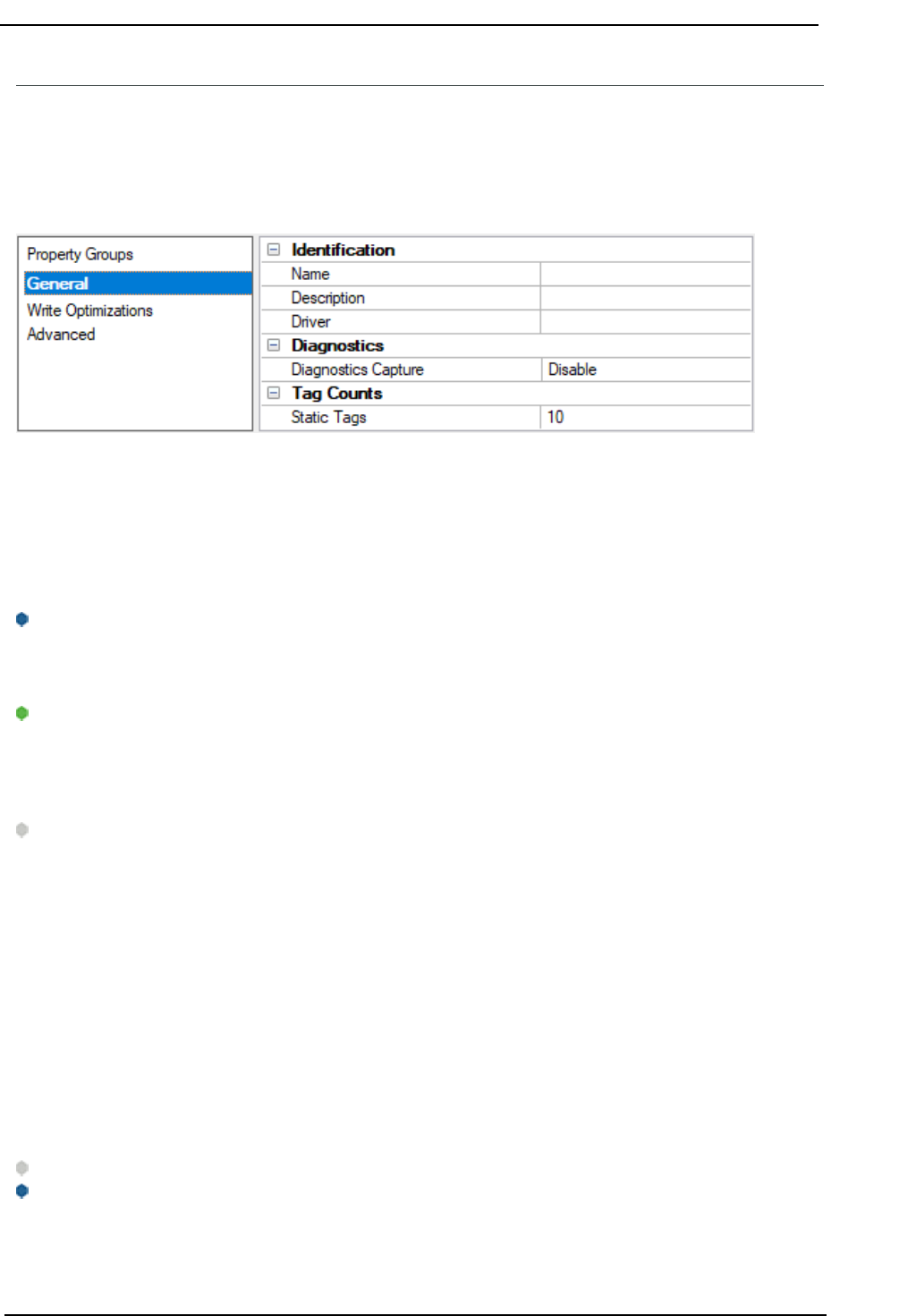

Channel Properties — General

This server supports the use of multiple simultaneous communications drivers. Each protocol or driver used

in a server project is called a channel. A server project may consist of many channels with the same com-

munications driver or with unique communications drivers. A channel acts as the basic building block of an

OPC link. This group is used to specify general channel properties, such as the identification attributes and

operating mode.

Identification

Name:Specify the user-defined identity of this channel. In each server project, each channel name must be

unique. Although names can be up to 256 characters, some client applications have a limited display win-

dow when browsing the OPCserver's tag space. The channel name is part of the OPC browser information.

The property is required for creating a channel.

For information on reserved characters, refer to "How To... Properly Name a Channel, Device, Tag, and Tag

Group" in the server help.

Description: Specify user-defined information about this channel.

Many of these properties, including Description, have an associated system tag.

Driver:Specify the protocol / driver for this channel. Specify the device driver that was selected during chan-

nel creation. It is a disabled setting in the channel properties. The property is required for creating a chan-

nel.

Note: With the server's online full-time operation, these properties can be changed at any time. This

includes changing the channel name to prevent clients from registering data with the server. If a client has

already acquired an item from the server before the channel name is changed, the items are unaffected. If,

after the channel name has been changed, the client application releases the item and attempts to re-

acquire using the old channel name, the item is not accepted. Changes to the properties should not be

made once a large client application has been developed. Utilize proper user role and privilege man-

agement to prevent operators from changing properties or accessing server features.

Diagnostics

Diagnostics Capture: When enabled, this option makes the channel's diagnostic information available to

OPC applications. Because the server's diagnostic features require a minimal amount of overhead pro-

cessing, it is recommended that they be utilized when needed and disabled when not. The default is dis-

abled.

Note:This property is not available if the driver does not support diagnostics.

For more information, refer to "Communication Diagnostics" and "Statistics Tags"in the server help.

Tag Counts

www. ptc.com

6

Torque Tool Ethernet Driver

Static Tags:Provides the total number of defined static tags at this level (device or channel). This inform-

ation can be helpful in troubleshooting and load balancing.

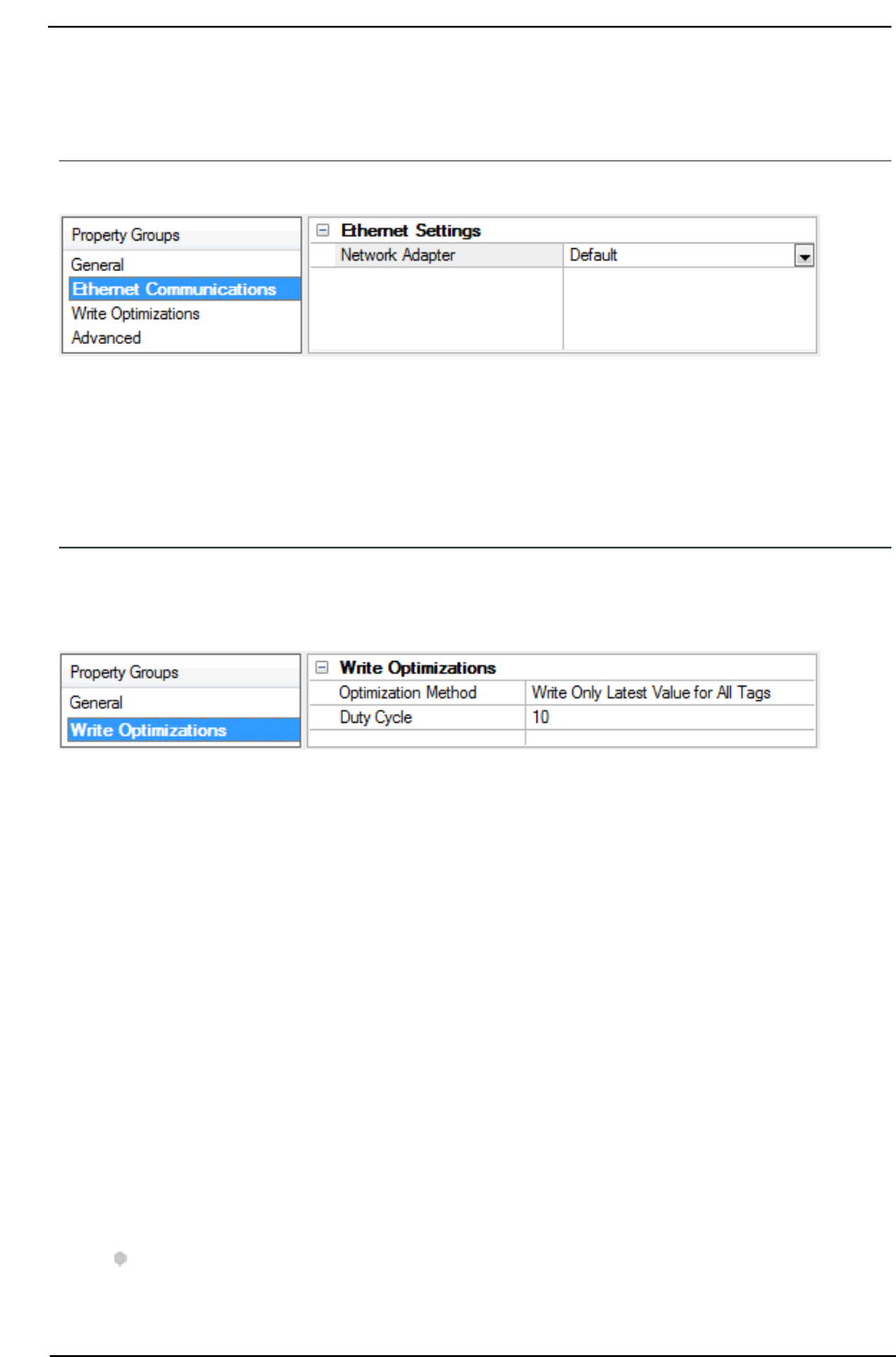

Channel Properties — Ethernet Communications

Ethernet Communication can be used to communicate with devices.

Ethernet Settings

Network Adapter:Specify the network adapter to bind. When left blank or Default is selected, the oper-

ating system selects the default adapter.

Channel Properties — Write Optimizations

The server must ensure that the data written from the client application gets to the device on time. Given

this goal, the server provides optimization properties to meet specific needs or improve application respons-

iveness.

Write Optimizations

OptimizationMethod: Controls how write data is passed to the underlying communications driver. The

options are:

l

Write All Values for All Tags:This option forces the server to attempt to write every value to the

controller. In this mode, the server continues to gather write requests and add them to the server's

internal write queue. The server processes the write queue and attempts to empty it by writing data

to the device as quickly as possible. This mode ensures that everything written from the client applic-

ations is sent to the target device. This mode should be selected if the write operation order or the

write item's content must uniquely be seen at the target device.

l

WriteOnlyLatest Value forNon-BooleanTags: Many consecutive writes to the same value can

accumulate in the write queue due to the time required to actually send the data to the device. If the

server updates a write value that has already been placed in the write queue, far fewer writes are

needed to reach the same final output value. In this way, no extra writes accumulate in the server's

queue. When the user stops moving the slide switch, the value in the device is at the correct value at

virtually the same time. As the mode states, any value that is not a Boolean value is updated in the

server's internal write queue and sent to the device at the next possible opportunity. This can greatly

improve the application performance.

Note: This option does not attempt to optimize writes to Boolean values. It allows users to optim-

www. ptc.com

7

Torque Tool Ethernet Driver

ize the operation of HMI data without causing problems with Boolean operations, such as a moment-

ary push button.

l

WriteOnlyLatestValueforAllTags:This option takes the theory behind the second optimization

mode and applies it to all tags. It is especially useful if the application only needs to send the latest

value to the device. This mode optimizes all writes by updating the tags currently in the write queue

before they are sent. This is the default mode.

Duty Cycle: is used to control the ratio of write to read operations. The ratio is always based on one read

for every one to ten writes. The duty cycle is set to ten by default, meaning that ten writes occur for each

read operation. Although the application is performing a large number of continuous writes, it must be

ensured that read data is still given time to process. A setting of one results in one read operation for every

write operation. If there are no write operations to perform, reads are processed continuously. This allows

optimization for applications with continuous writes versus a more balanced back and forth data flow.

Note: It is recommended that the application be characterized for compatibility with the write optim-

ization enhancements before being used in a production environment.

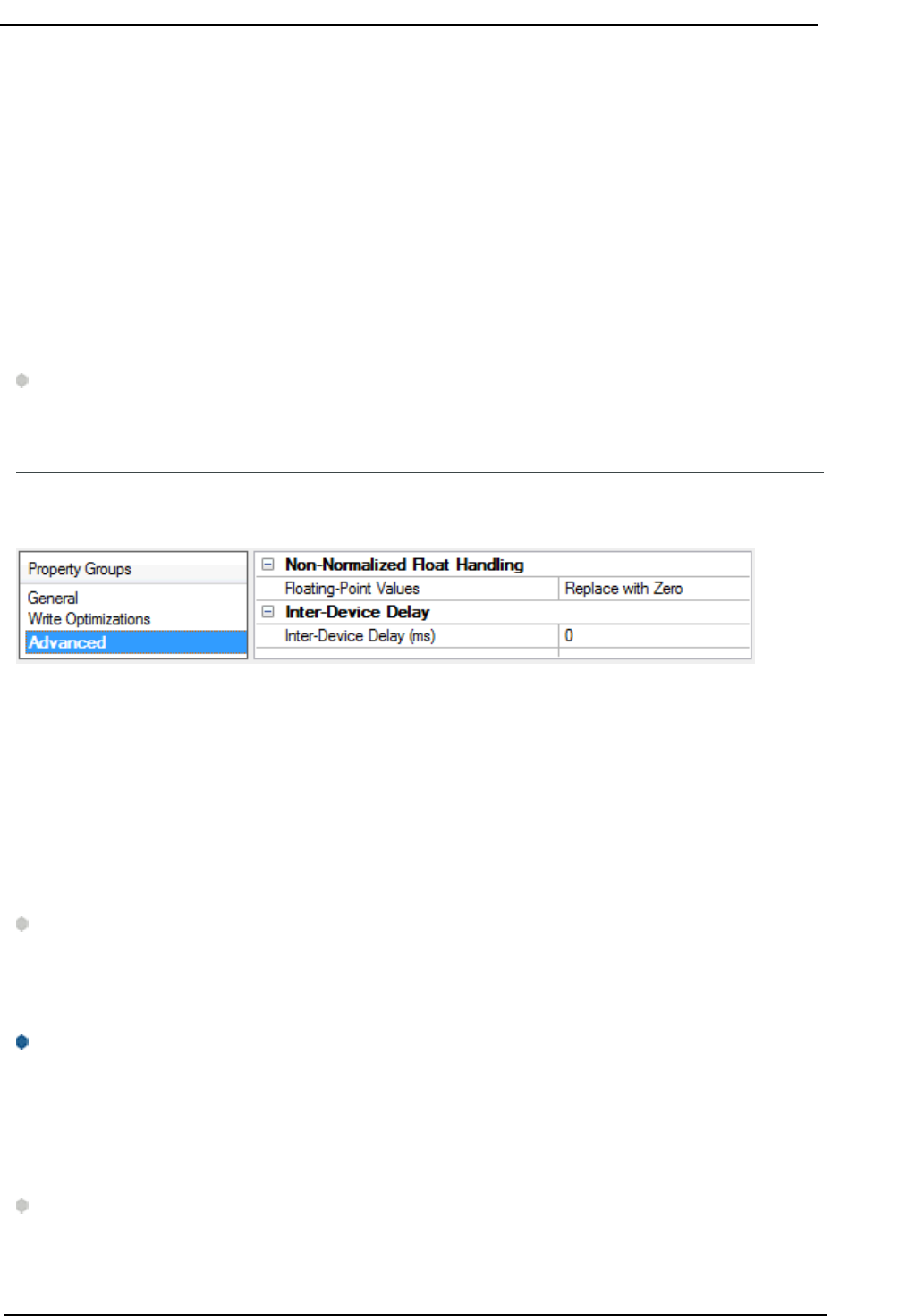

Channel Properties — Advanced

This group is used to specify advanced channel properties. Not all drivers support all properties; so the

Advanced group does not appear for those devices.

Non-NormalizedFloatHandling: A non-normalized value is defined as Infinity, Not-a-Number (NaN), or as

a Denormalized Number. The default is Replace with Zero. Drivers that have native float handling may

default to Unmodified. Non-normalized float handling allows users to specify how a driver handles non-nor-

malized IEEE-754 floating point data. Descriptions of the options are as follows:

l

Replace with Zero:This option allows a driver to replace non-normalized IEEE-754 floating point val-

ues with zero before being transferred to clients.

l

Unmodified:This option allows a driver to transfer IEEE-754 denormalized, normalized, non-num-

ber, and infinity values to clients without any conversion or changes.

Note:This property is disabled if the driver does not support floating-point values or if it only supports

the option that is displayed. According to the channel's float normalization setting, only real-time driver tags

(such as values and arrays) are subject to float normalization. For example, EFM data is not affected by this

setting.

For more information on the floating-point values, refer to "How To ... Work with Non-Normalized Floating-Point

Values" in the server help.

Inter-Device Delay: Specify the amount of time the communications channel waits to send new requests to

the next device after data is received from the current device on the same channel. Zero (0) disables the

delay.

Note:This property is not available for all drivers, models, and dependent settings.

www. ptc.com

8

Torque Tool Ethernet Driver

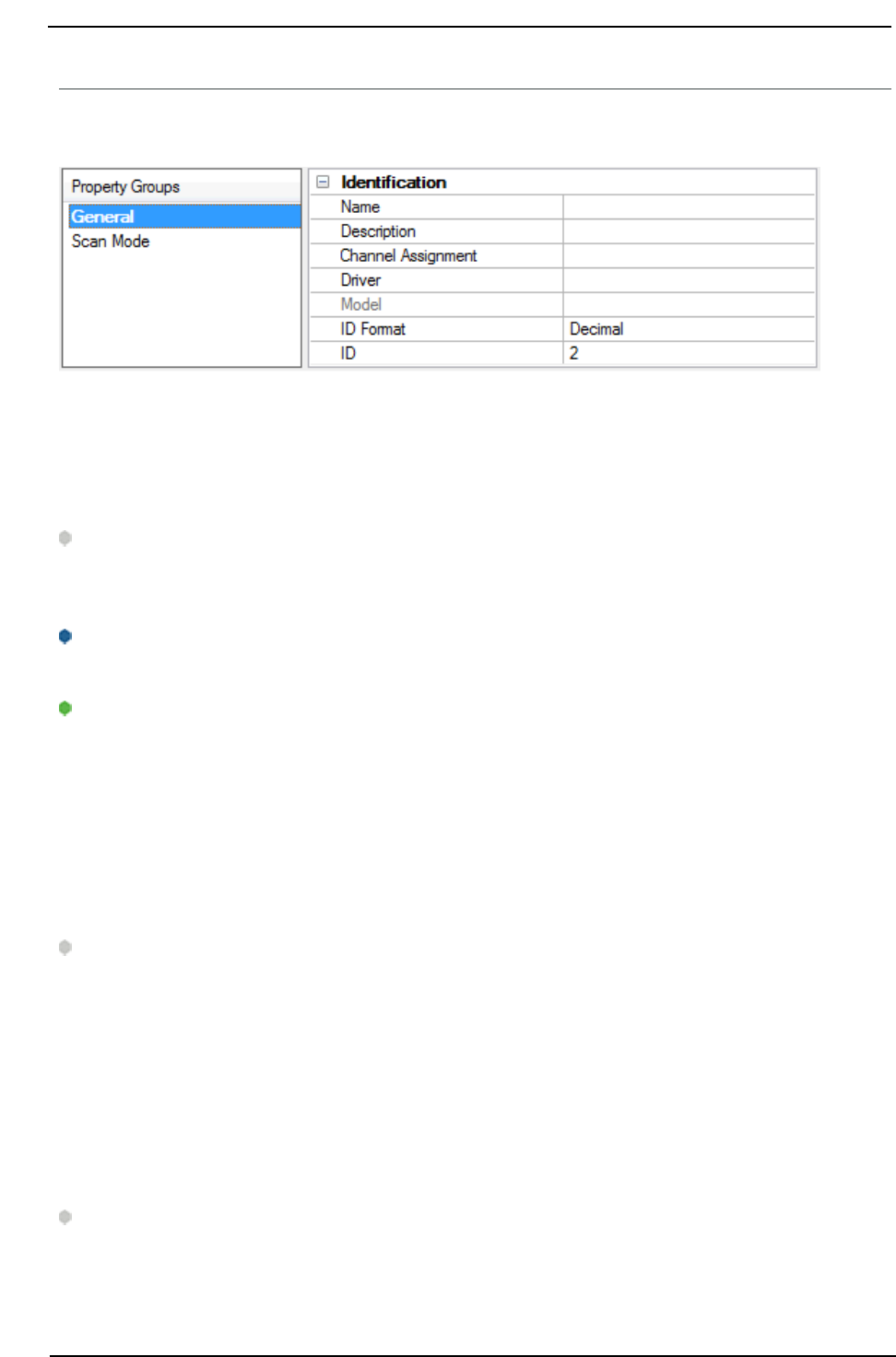

Device Properties — General

A device represents a single target on a communications channel. If the driver supports multiple controllers,

users must enter a device ID for each controller.

Identification

Name:Specify the name of the device. It is a logical user-defined name that can be up to 256 characters

long and may be used on multiple channels.

Note: Although descriptive names are generally a good idea, some OPC client applications may have a

limited display window when browsing the OPC server's tag space. The device name and channel name

become part of the browse tree information as well. Within an OPC client, the combination of channel name

and device name would appear as "ChannelName.DeviceName".

For more information, refer to "How To... Properly Name a Channel, Device, Tag, and Tag Group" in server help.

Description: Specify the user-defined information about this device.

Many of these properties, including Description, have an associated system tag.

Channel Assignment:Specify the user-defined name of the channel to which this device currently belongs.

Driver:Selected protocol driver for this device.

Model:Specify the type of device that is associated with this ID. The contents of the drop-down menu

depend on the type of communications driver being used. Models that are not supported by a driver are dis-

abled. If the communications driver supports multiple device models, the model selection can only be

changed when there are no client applications connected to the device.

Note:If the communication driver supports multiple models, users should try to match the model selec-

tion to the physical device. If the device is not represented in the drop-down menu, select a model that con-

forms closest to the target device. Some drivers support a model selection called "Open," which allows

users to communicate without knowing the specific details of the target device. For more information, refer to

the driver documentation.

ID:Specify the device's driver-specific station or node. The type of ID entered depends on the com-

munications driver being used. For many communication drivers, the ID is a numeric value. Drivers that sup-

port a Numeric ID provide users with the option to enter a numeric value whose format can be changed to

suit the needs of the application or the characteristics of the selected communications driver. The format is

set by the driver by default. Options include Decimal, Octal, and Hexadecimal.

Note: If the driver is Ethernet-based or supports an unconventional station or node name, the device's

TCP/IP address may be used as the device ID. TCP/IP addresses consist of four values that are separated by

periods, with each value in the range of 0 to 255. Some device IDs are string based. There may be additional

properties to configure within the ID field, depending on the driver.

www. ptc.com

9

Torque Tool Ethernet Driver

Operating Mode

Data Collection:This property controls the device's active state. Although device communications are

enabled by default, this property can be used to disable a physical device. Communications are not attemp-

ted when a device is disabled. From a client standpoint, the data is marked as invalid and write operations

are not accepted. This property can be changed at any time through this property or the device system tags.

Simulated:Place the device into or out of Simulation Mode. In this mode, the driver does not attempt to

communicate with the physical device, but the server continues to return valid OPC data. Simulated stops

physical communications with the device, but allows OPC data to be returned to the OPC client as valid data.

While in Simulation Mode, the server treats all device data as reflective: whatever is written to the simulated

device is read back and each OPC item is treated individually. The data is not saved if the server removes

the item (such as when the server is reinitialized). The default is No.

Notes:

1. This System tag (_Simulated) is read only and cannot be written to for runtime protection. The Sys-

tem tag allows this property to be monitored from the client.

2. When a device is simulated, updates may not appear faster than one (1) second in the client.

Simulation Mode is for test and simulation purposes only. It should never be used in a production envir-

onment.

Tag Counts

Static Tags:Provides the total number of defined static tags at this level (device or channel). This inform-

ation can be helpful in troubleshooting and load balancing.

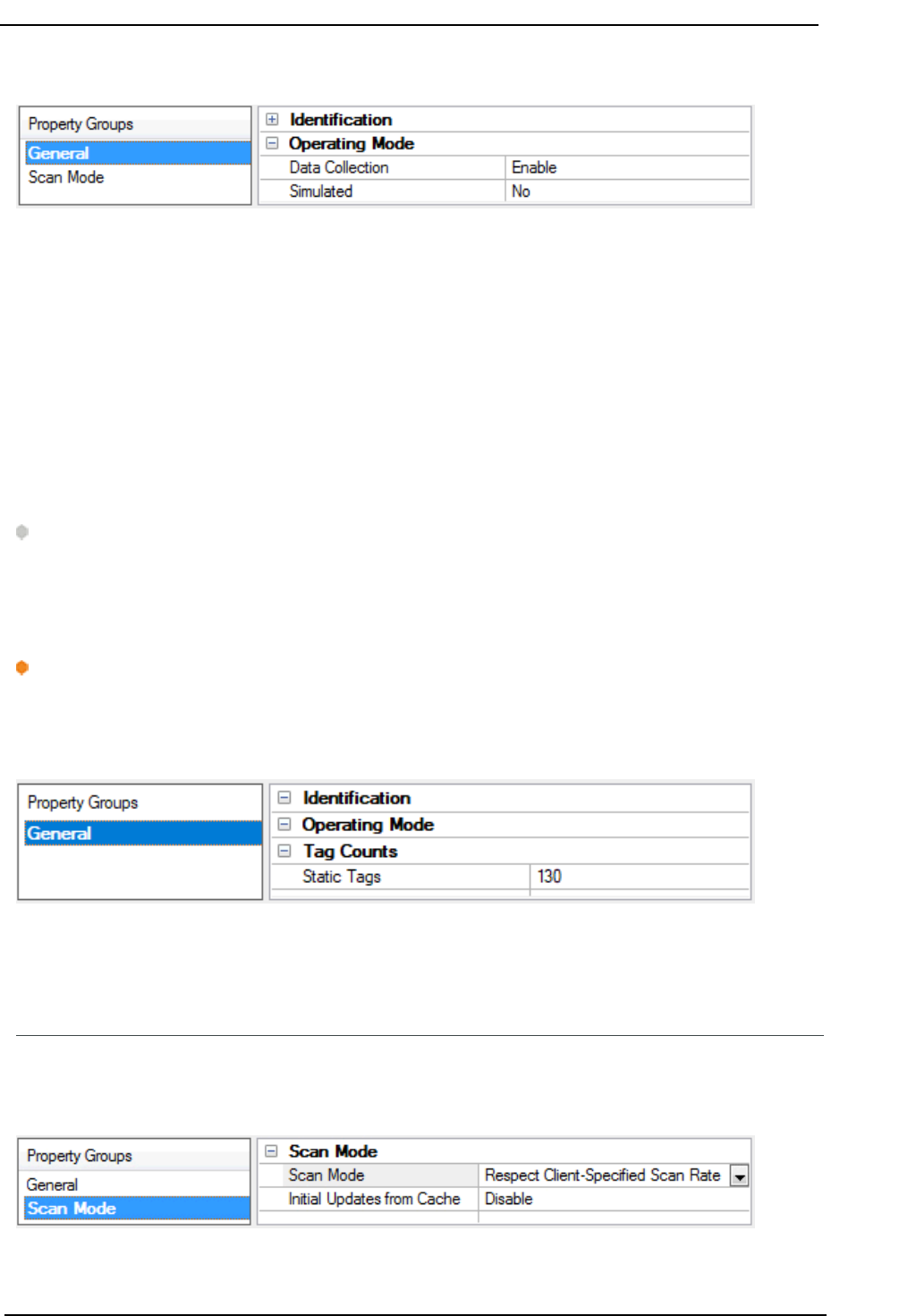

Device Properties — Scan Mode

The Scan Mode specifies the subscribed-client requested scan rate for tags that require device com-

munications. Synchronous and asynchronous device reads and writes are processed as soon as possible;

unaffected by the Scan Mode properties.

www. ptc.com

10

Torque Tool Ethernet Driver

Scan Mode: Specify how tags in the device are scanned for updates sent to subscribing clients. Descriptions

of the options are:

l

Respect Client-Specified Scan Rate:This mode uses the scan rate requested by the client.

l

Request Data No Faster than Scan Rate:This mode specifies the value set as the maximum scan

rate. The valid range is 10 to 99999990 milliseconds. The default is 1000 milliseconds.

Note:When the server has an active client and items for the device and the scan rate value is

increased, the changes take effect immediately. When the scan rate value is decreased, the changes

do not take effect until all client applications have been disconnected.

l

Request All Data at Scan Rate:This mode forces tags to be scanned at the specified rate for sub-

scribed clients. The valid range is 10 to 99999990 milliseconds. The default is 1000 milliseconds.

l

Do Not Scan, Demand Poll Only:This mode does not periodically poll tags that belong to the

device nor perform a read to get an item's initial value once it becomes active. It is the OPC client's

responsibility to poll for updates, either by writing to the _DemandPoll tag or by issuing explicit

device reads for individual items. For more information, refer to "Device Demand Poll" in server help.

l

Respect Tag-Specified Scan Rate:This mode forces static tags to be scanned at the rate specified

in their static configuration tag properties. Dynamic tags are scanned at the client-specified scan

rate.

Initial Updates from Cache: When enabled, this option allows the server to provide the first updates for

newly activated tag references from stored (cached) data. Cache updates can only be provided when the

new item reference shares the same address, scan rate, data type, client access, and scaling properties. A

device read is used for the initial update for the first client reference only. The default is disabled; any time a

client activates a tag reference the server attempts to read the initial value from the device.

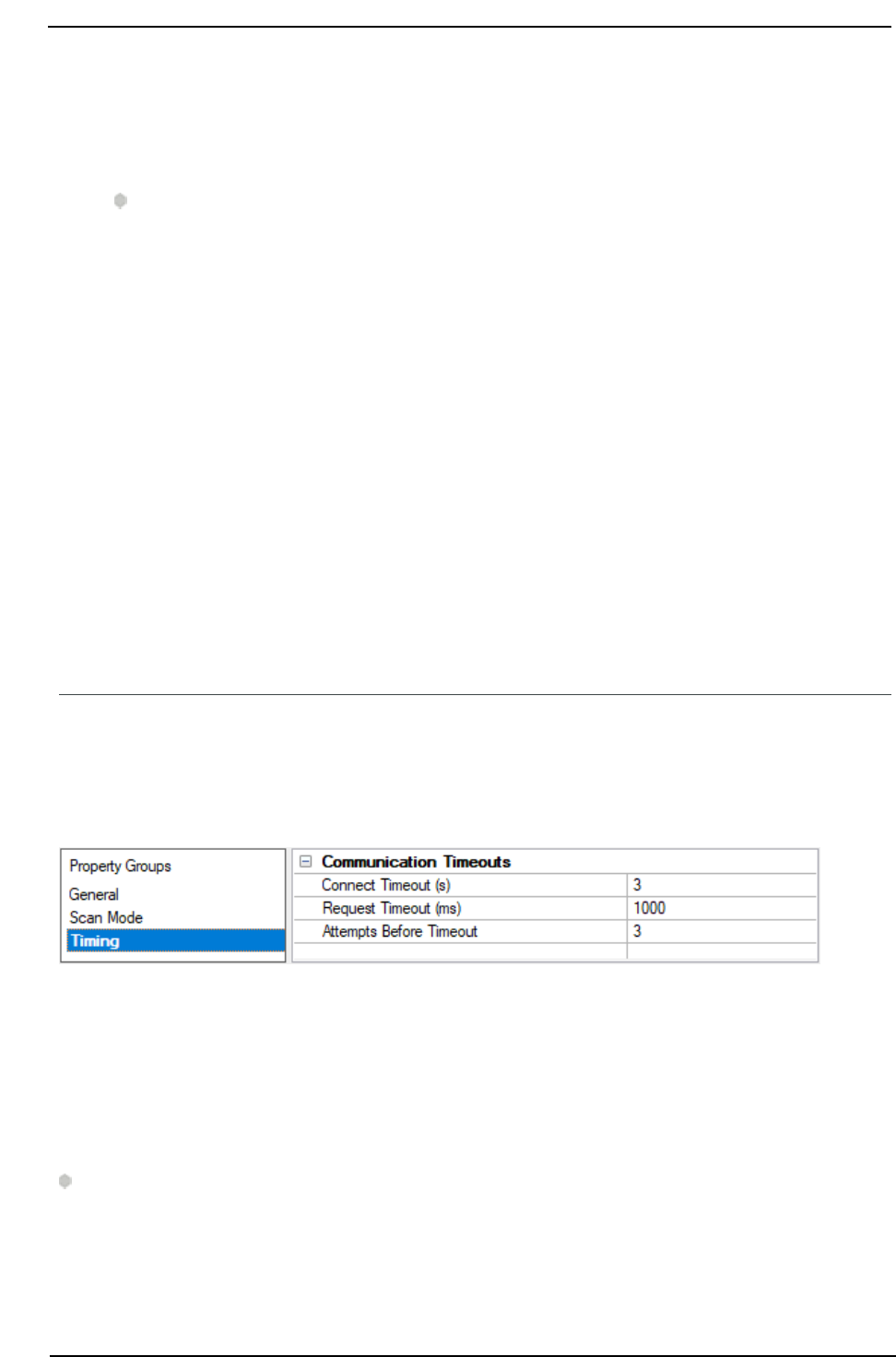

Device Properties — Timing

The device Timing properties allow the driver's response to error conditions to be tailored to fit the applic-

ation's needs. In many cases, the environment requires changes to these properties for optimum per-

formance. Factors such as electrically generated noise, modem delays, and poor physical connections can

influence how many errors or timeouts a communications driver encounters. Timing properties are specific

to each configured device.

Communications Timeouts

Connect Timeout:This property (which is used primarily by Ethernet based drivers) controls the amount

of time required to establish a socket connection to a remote device. The device's connection time often

takes longer than normal communications requests to that same device. The valid range is 1 to 30 seconds.

The default is typically 3 seconds, but can vary depending on the driver's specific nature. If this setting is not

supported by the driver, it is disabled.

Note: Due to the nature of UDP connections, the connection timeout setting is not applicable when com-

municating via UDP.

Request Timeout:Specify an interval used by all drivers to determine how long the driver waits for a

response from the target device to complete. The valid range is 50 to 9999999 milliseconds (167 minutes).

The default is usually 1000 milliseconds, but can vary depending on the driver. The default timeout for most

www. ptc.com

11

Torque Tool Ethernet Driver

serial drivers is based on a baud rate of 9600 baud or better. When using a driver at lower baud rates,

increase the timeout to compensate for the increased time required to acquire data.

Attempts Before Timeout:Specify how many times the driver issues a communications request before

considering the request to have failed and the device to be in error. The valid range is 1 to 10. The default is

typically 3, but can vary depending on the driver's specific nature. The number of attempts configured for

an application depends largely on the communications environment. This property applies to both con-

nection attempts and request attempts.

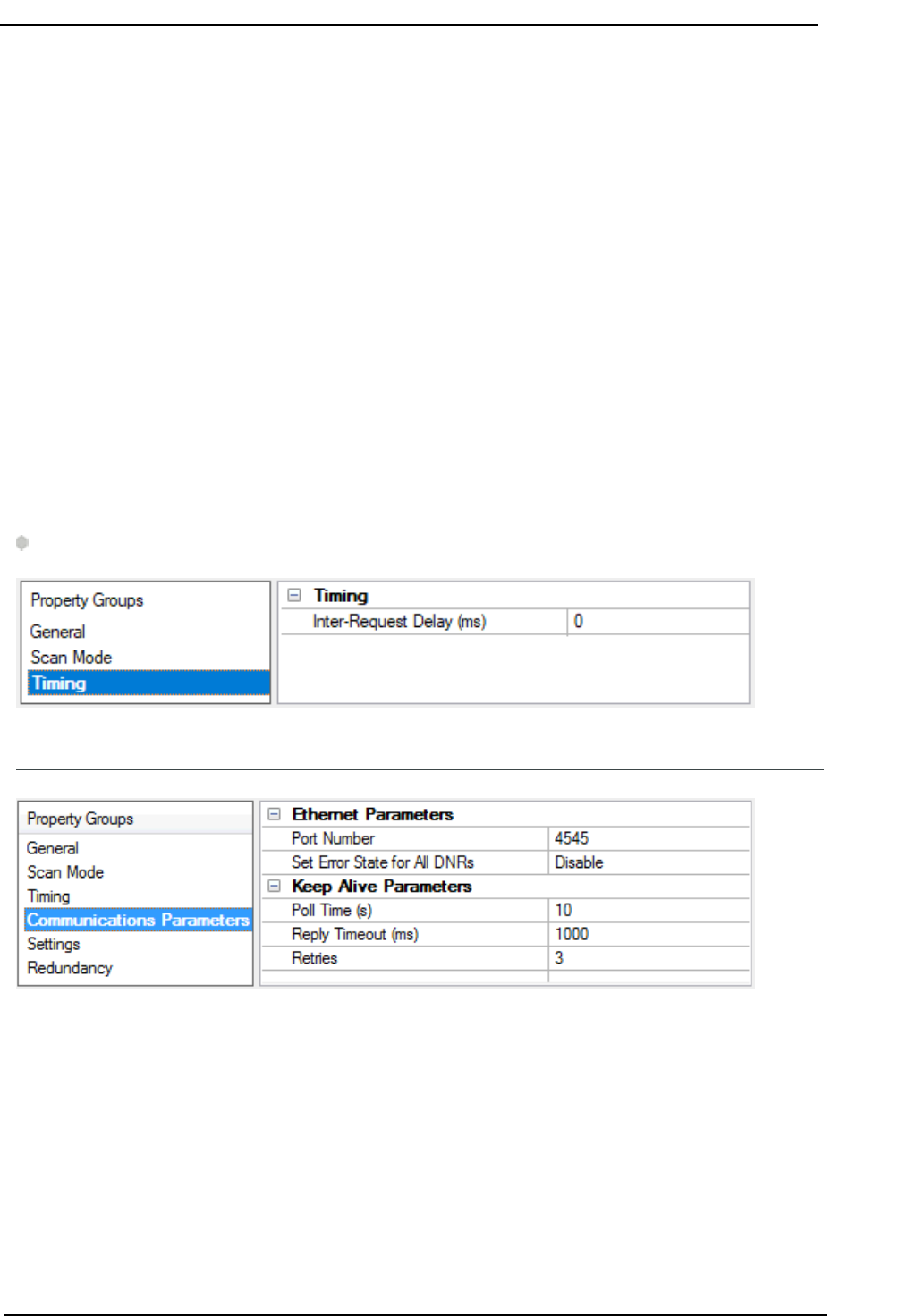

Timing

Inter-Request Delay: Specify how long the driver waits before sending the next request to the target

device. It overrides the normal polling frequency of tags associated with the device, as well as one-time

reads and writes. This delay can be useful when dealing with devices with slow turnaround times and in

cases where network load is a concern. Configuring a delay for a device affects communications with all

other devices on the channel. It is recommended that users separate any device that requires an inter-

request delay to a separate channel if possible. Other communications properties (such as communication

serialization) can extend this delay. The valid range is 0 to 300,000 milliseconds; however, some drivers may

limit the maximum value due to a function of their particular design. The default is 0, which indicates no

delay between requests with the target device.

Note: Not all drivers support Inter-Request Delay. This setting does not appear if it is not available.

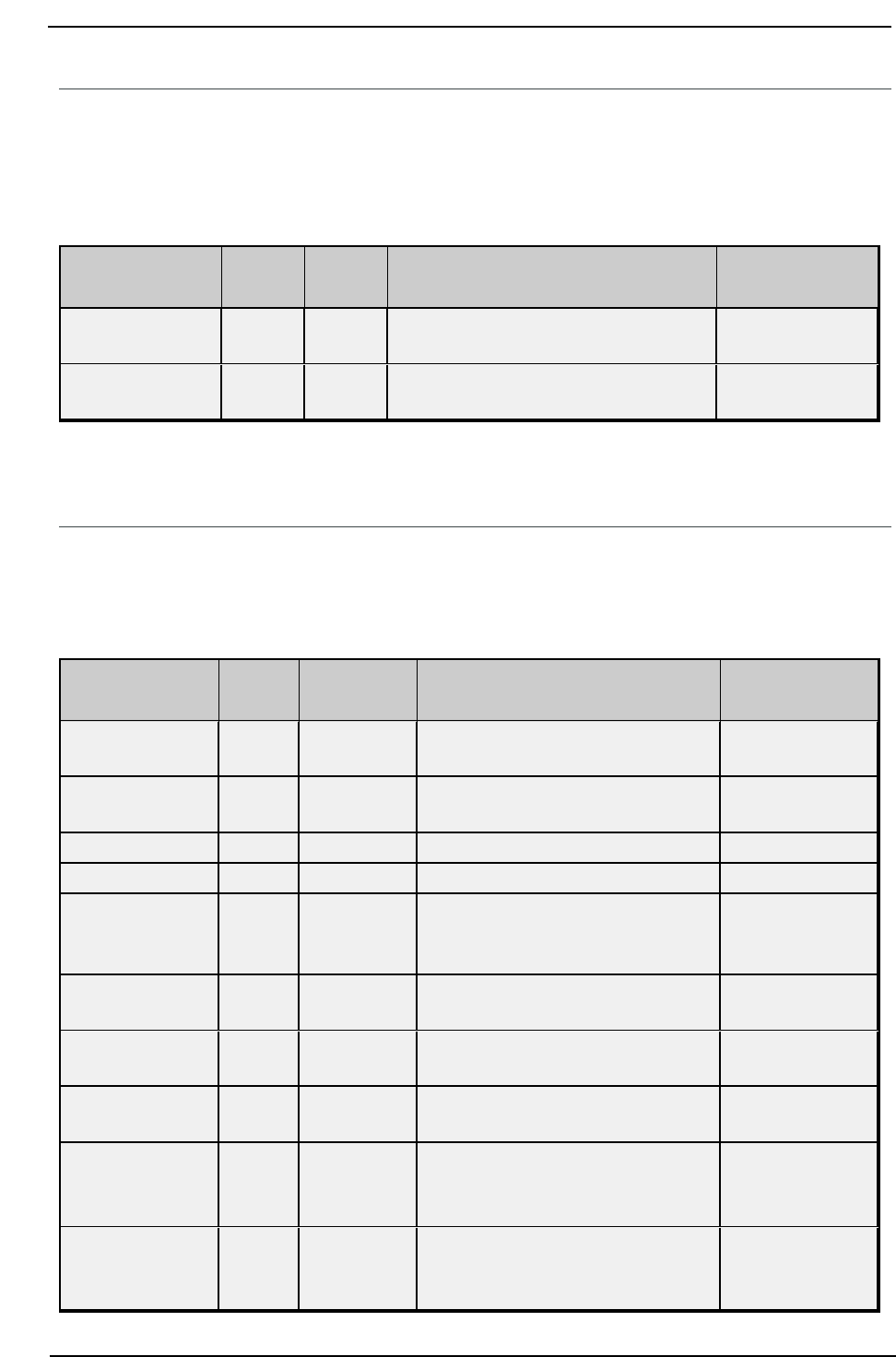

Device Properties — Communications Parameters

Ethernet Parameters

Port Number: Specify the port number that the driver will use when connecting to the device. The valid

range is 0 to 65535. For Open Protocol, the default setting is 4545. For FEP, the default setting is 9001.

Set Error State for All DNRs: When enabled, the driver will set the error state if the device does not

respond (DNR) to writes or subscription requests. The driver will always set the error state if the device does

not respond to reads. The default setting is disabled.

Keep-Alive Parameters

www. ptc.com

12

Torque Tool Ethernet Driver

Poll Time: Specify the amount of time of inactivity before the driver will send a Keep Alive message to the

device. The valid range is 1 to 15 seconds. The default setting is 10 seconds.

Caution: If the Keep Alive interval is set to a value greater than 10 seconds, the driver may post "Device

Not Responding" messages to the Event Log. This is because the device closes the connection.

Reply Timeout: Specify the amount of time that the driver will wait for a response from a Keep Alive mes-

sage. The valid range is 100 to 30000 milliseconds. The default setting is 1000 milliseconds (1 second).

Fail After: Specify the number of times that the driver will attempt to send a Keep Alive message before con-

sidering it to have failed. The valid range is 1 to 10. The default setting is 3.

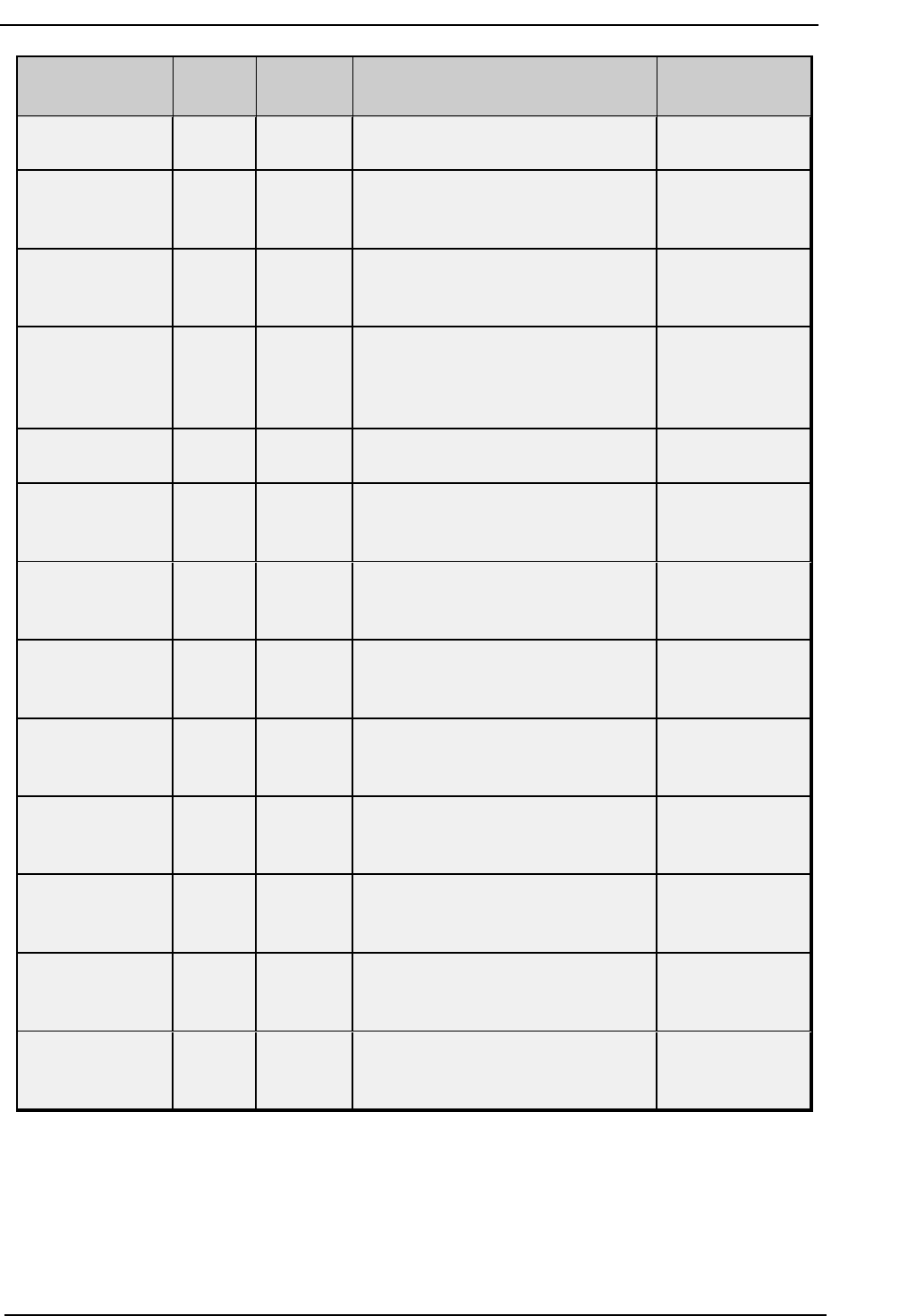

Device Properties — Settings

The Settings properties are used to request different revisions of messages from the device. To request a

specific message revision, enter the message revision number for that message. If the device does not sup-

port revisions, enter 0.

Note: The FEPmodel does not support message revisions, and will disable these options.

Message Revisions

Alarm: Specify the revision number for alarm messages. Supported values are 0 to 3, with 0 as the default.

This affects MIDs 0070 through 0078.

Communication: Specify the revision number for communication messages. Supported values are 0 to 6,

with 0 as the default. This affects MIDs 0001 and 0002.

Job Data: Specify the revision number for job data messages. Supported values are 0 to 3, with 0 as the

default. This affects MIDs 0032 and 0033.

Job Info: Specify the revision number for job info messages. Supported values are 0 to 4, with 0 as the

default. This affects MIDs 0034 through 0037.

Job State: Specify the revision number for job ID upload, job select, and job restart messages. Supported

values are 0 to 2, with 0 as the default. This affects MIDs 0030, 0031, 0038, and 0039.

www. ptc.com

13

Torque Tool Ethernet Driver

Last Tightening: Specify the revision number for the last tightening results messages. Supported values are

0 to 5 and 999 (for low-bandwidth version), with 0 as the default. This affects MIDs 0060 through 0063.

Old Tightening: Specify the revision number for the old tightening results messages. Supported values are

0 to 7, with 0 as the default. This affects MIDs 0064 and 0065.

Selector Lights: Specify the revision number for the selector control light messages. Supported values are 0

to 2, with 0 as the default. This affects MIDs 0254 and 0255.

ToolData: Specify the revision number for the tool data results messages. Supported values are 0 to 5, with

0 as the default. This affects MIDs 0040 and 0041.

VIN: Specify the revision number for the vehicle identification number (VIN) messages. Supported values

are 0 to 2, with 0 as the default. This affects MIDs 0051 through 0054.

Options

Disable Tool On LTR: When enabled, the driver will disable the tool whenever a last tightening results (LTR)

message is received. This ensures that no LTR data is overwritten before the system has had time to process

it. The default setting is disabled.

Revision Format: Specify how the driver should format the revision number for commands that use the

default revision (revision 0). By default, when the driver sends a revision 0 message it leaves the revision

number blank. Some devices do not support this and require the revision number to be explicitly set. Set-

ting this to Zero or One forces the driver to use 0 or 1 for the revision number in the message.

Use Generic Subscribe: Newer devices may only support subscribing using the Generic Subscribe MID 8.

Enabling this property changes the driver to use MID 8 when subscribing data updates.

Use Unsolicited Data Packing: Specify if the driver should update all tags for a given command set at once

or update those tags individually at their specified scan rate.

Device Properties — Redundancy

Redundancy is available with the Media-Level Redundancy Plug-In.

Consult the website, a sales representative, or the user manual for more information.

www. ptc.com

14

Torque Tool Ethernet Driver

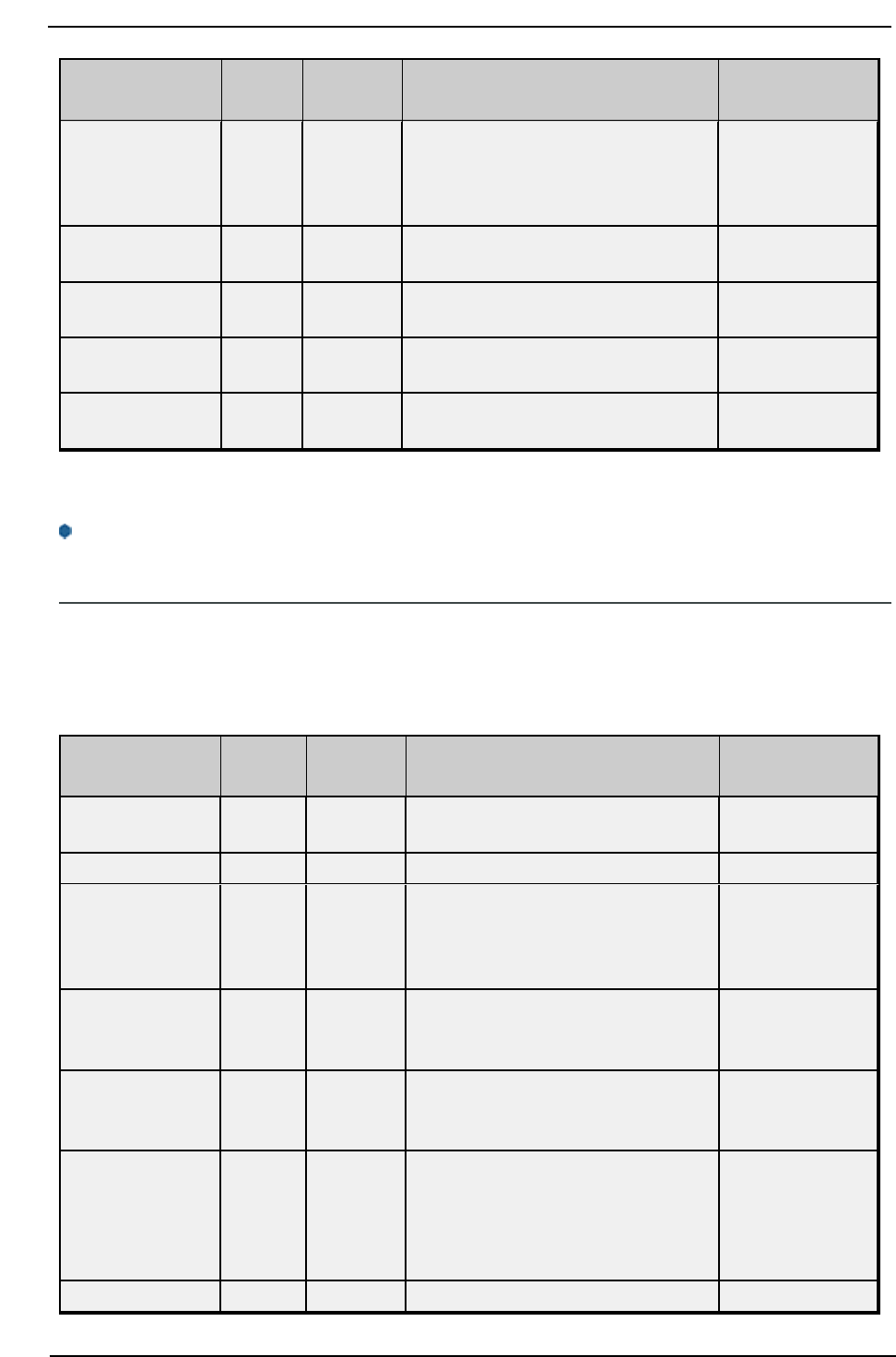

Optimizing Communications

The Torque Tool Ethernet Driver has been designed to provide the best performance with the least amount

of impact on the system's overall performance. While the driver is fast, there are a couple of guidelines that

can be used to control and optimize the application and gain maximum performance.

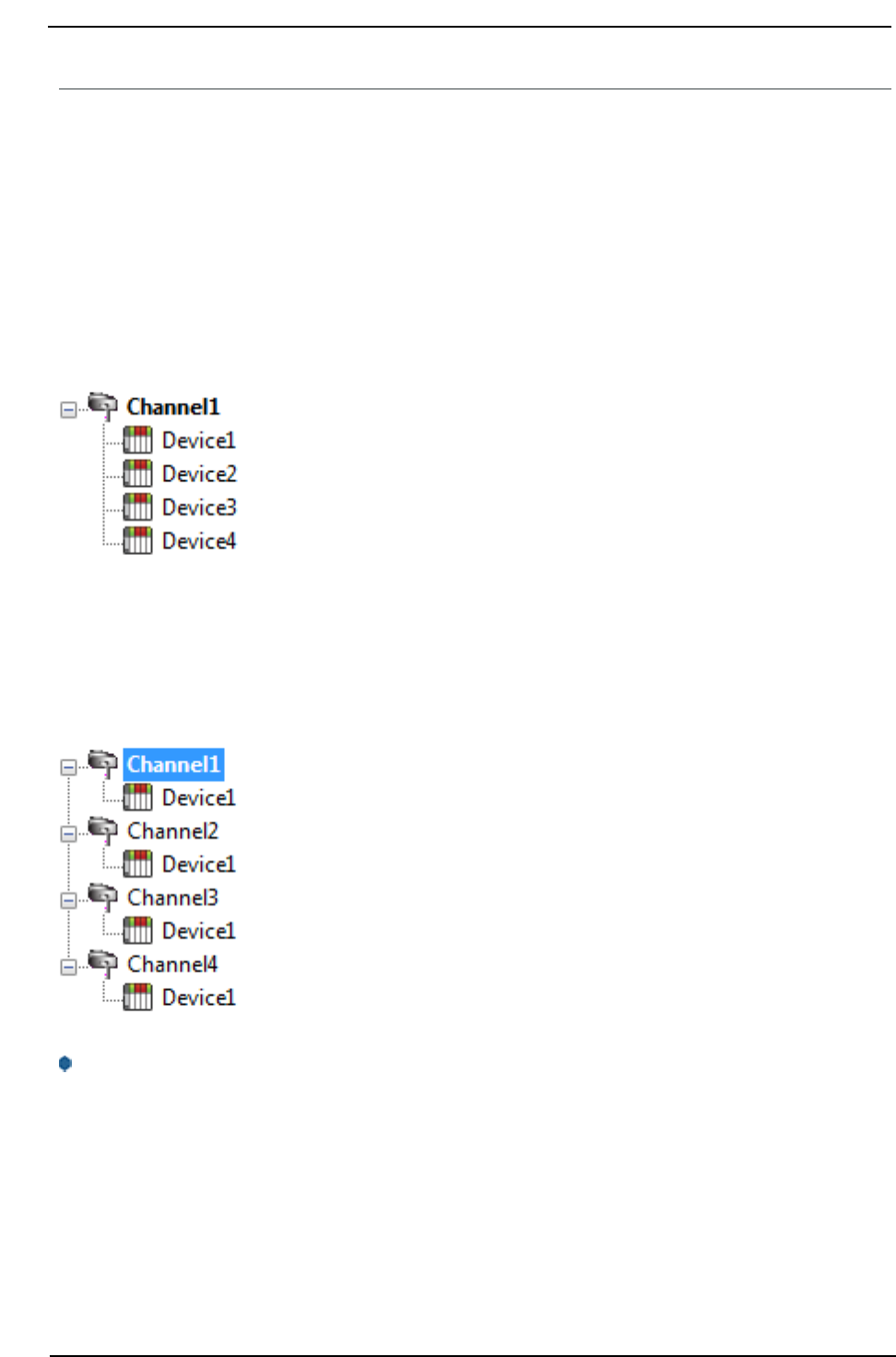

This server refers to communications protocols like Torque Tool Ethernet as a channel. Each channel

defined in the application represents a separate path of execution in the server. Once a channel has been

defined, a series of devices must then be defined under that channel. Each of these devices represents a

single Torque Tool controller from which data will be collected. While this approach to defining the applic-

ation will provide a high level of performance, it won't take full advantage of the Torque Tool Ethernet Driver

or the network. An example of how the application may appear when configured using a single channel is

shown below.

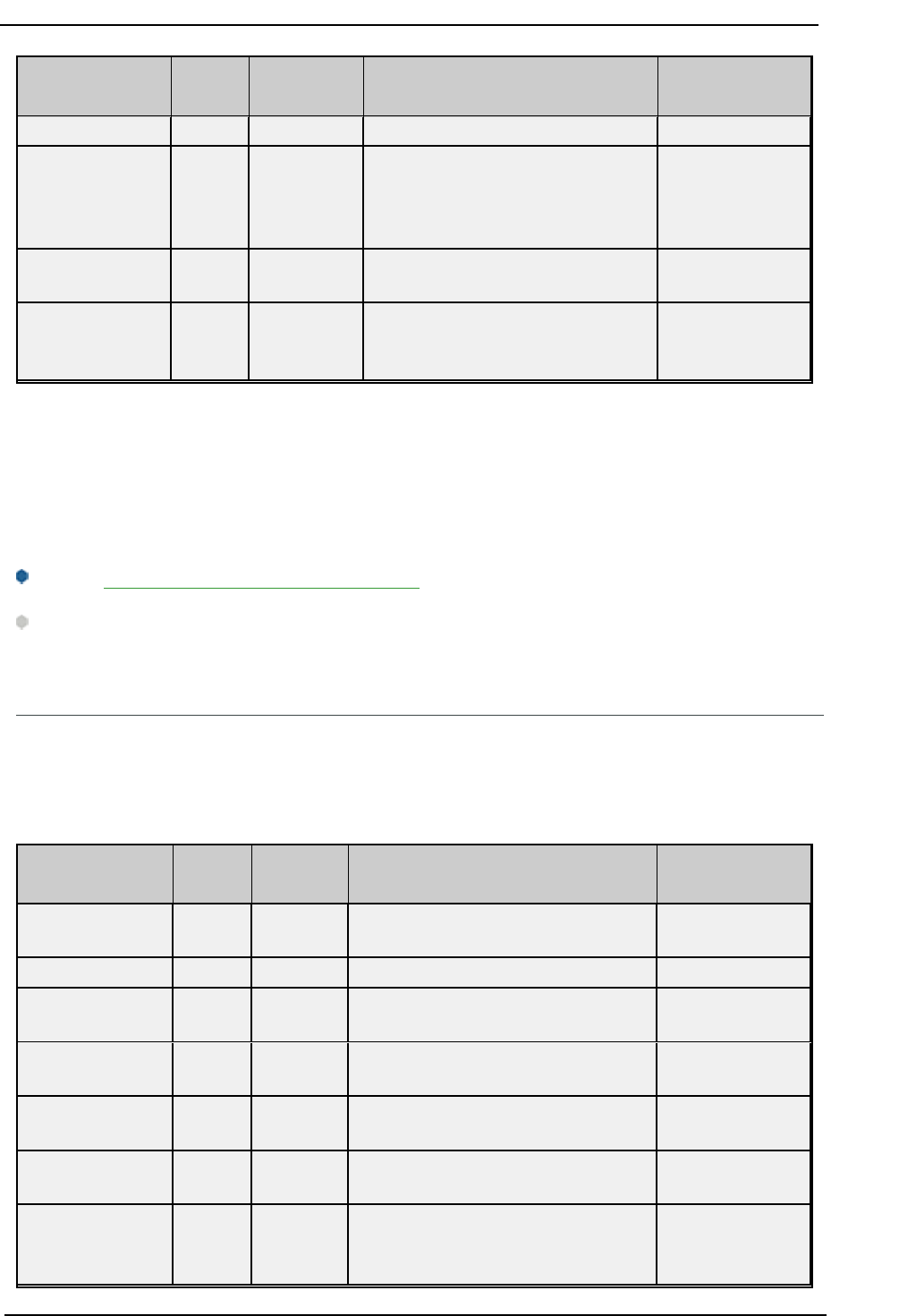

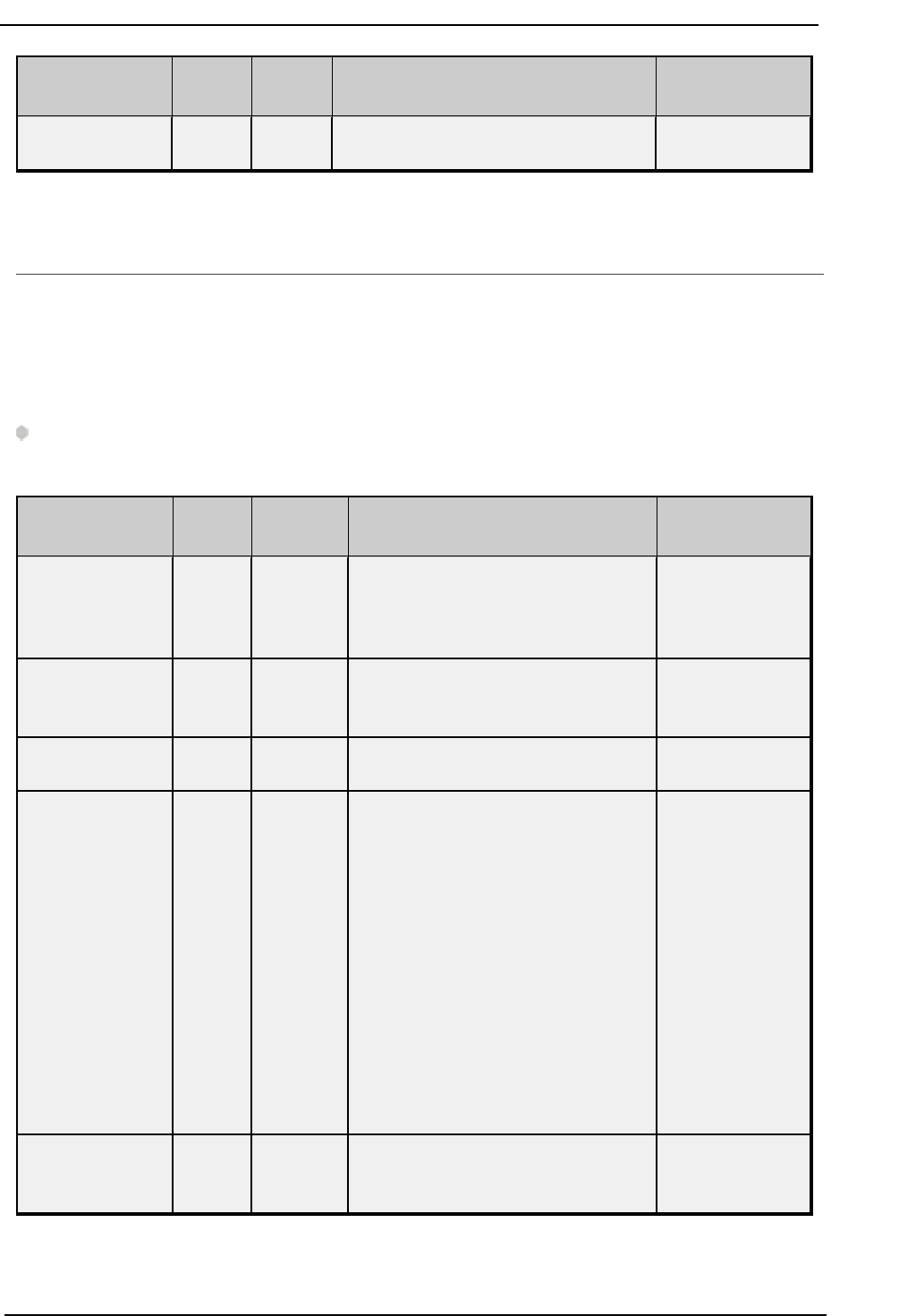

Each device appears under a single channel. In this configuration, the driver must

move from one device to the next as quickly as possible to gather information at

an effective rate. As more devices are added or more information is requested

from a single device, the overall update rate begins to suffer.

If the Torque Tool Ethernet Driver could only define one single channel, the example shown above would be

the only option available; however, the driver can define up to 1024 channels. Using multiple channels dis-

tributes the data collection workload by simultaneously issuing multiple requests to the network. An

example of how the same application may appear when configured using multiple channels to improve per-

formance is shown below.

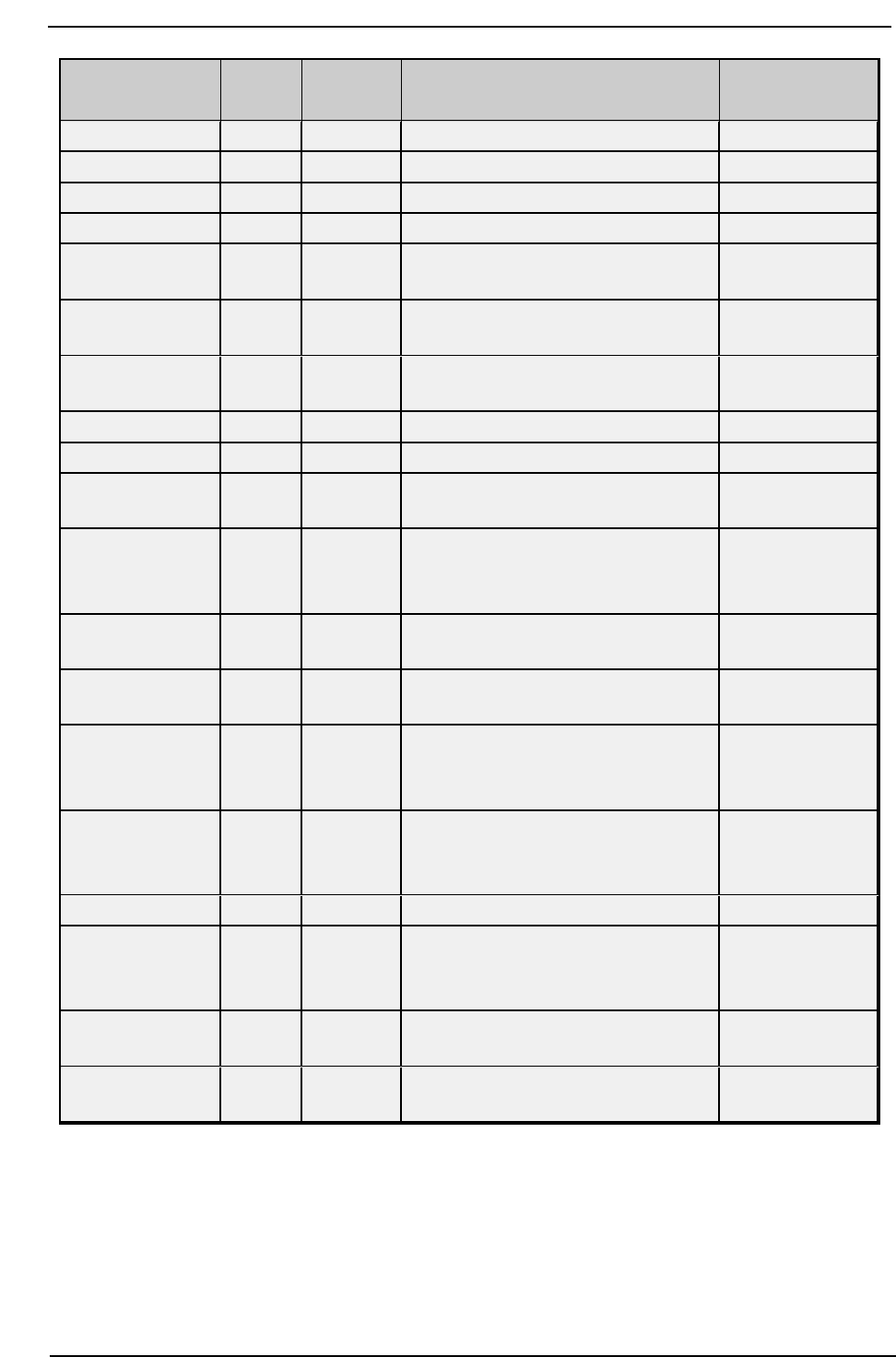

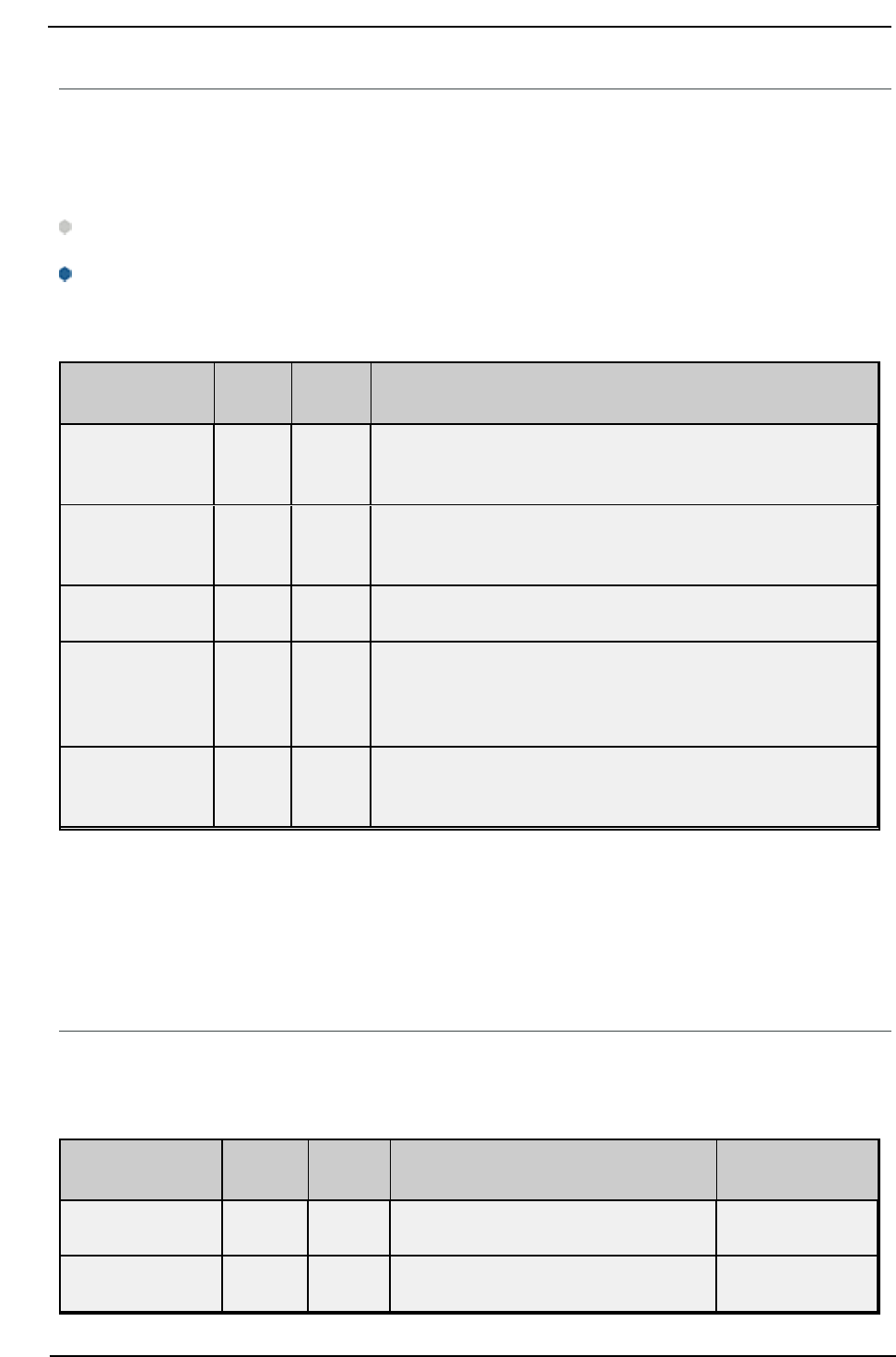

Each device has now been defined under its own channel. In this configuration, a

single path of execution is dedicated to the task of gathering data from each

device. If the application has 1024 or fewer devices, it can be optimized exactly

how it is shown here.

The performance will improve even if the application has more devices. While

fewer devices may be ideal, the application will still benefit from additional chan-

nels. Although by spreading the device load across all channels will cause the

server to move from device to device again, it can now do so with far less devices

to process on a single channel.

Note: Some devices support only one Ethernet connection. For these devices, only one channel and

device should be configured.

www. ptc.com

15

Torque Tool Ethernet Driver

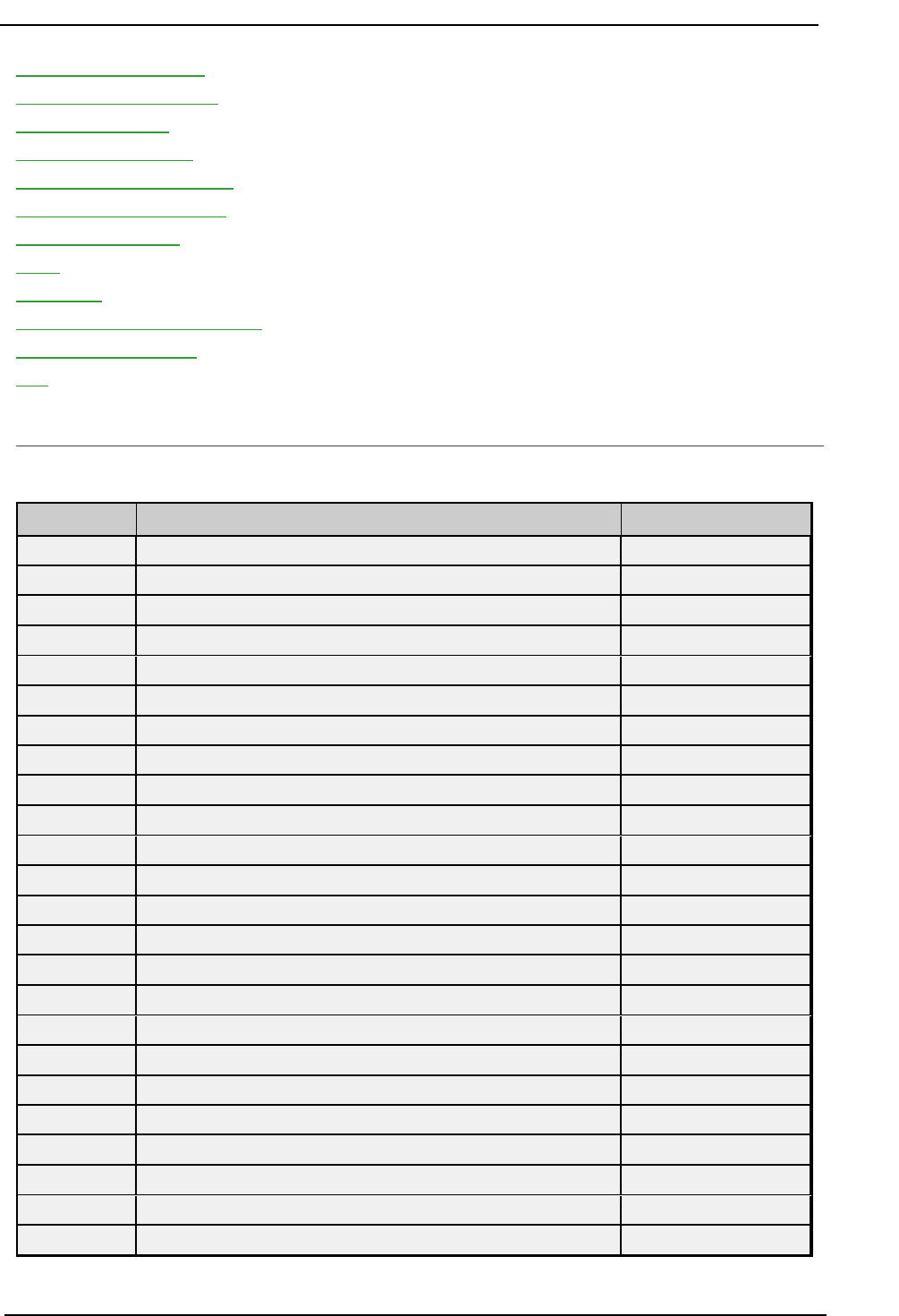

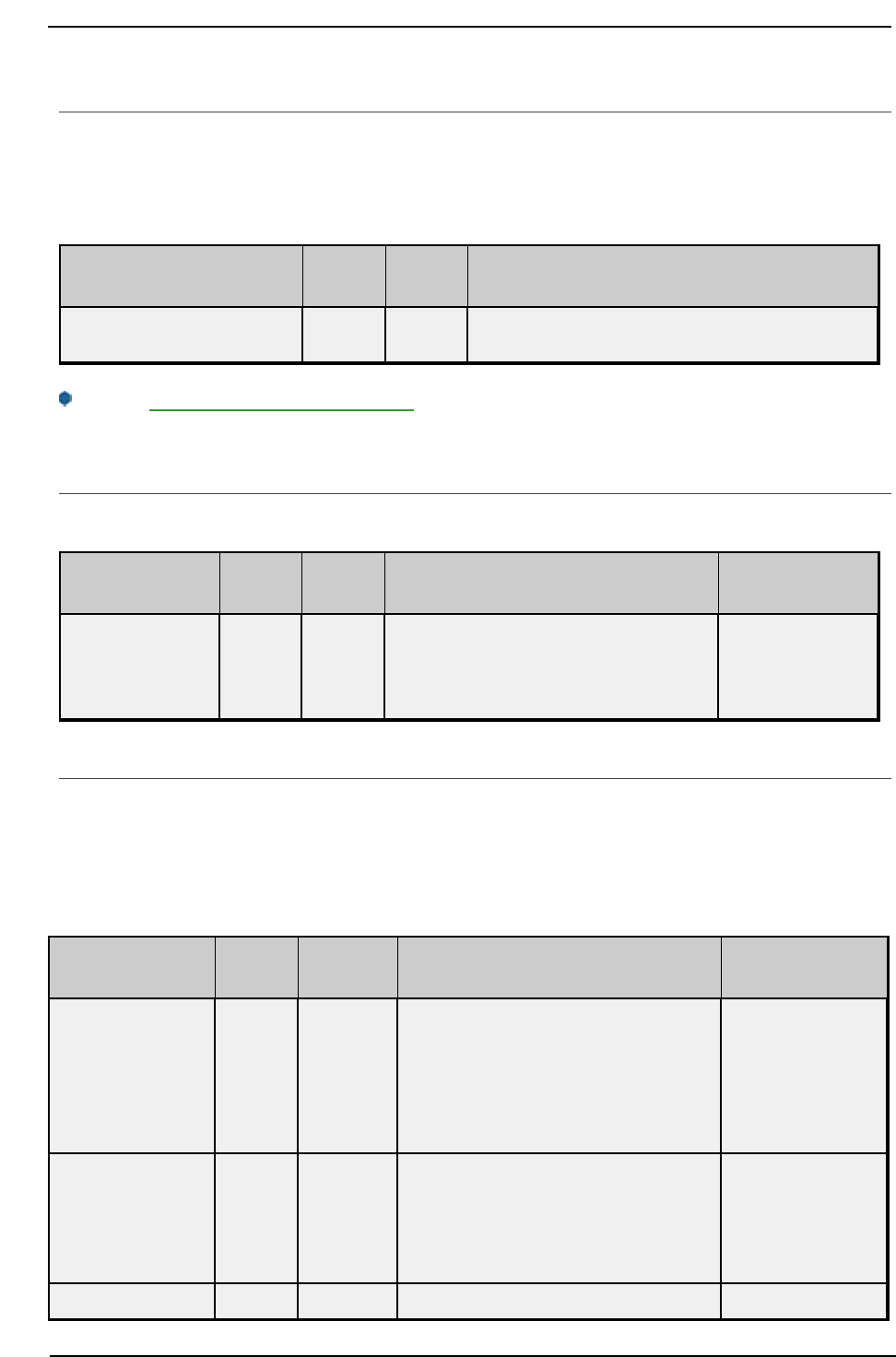

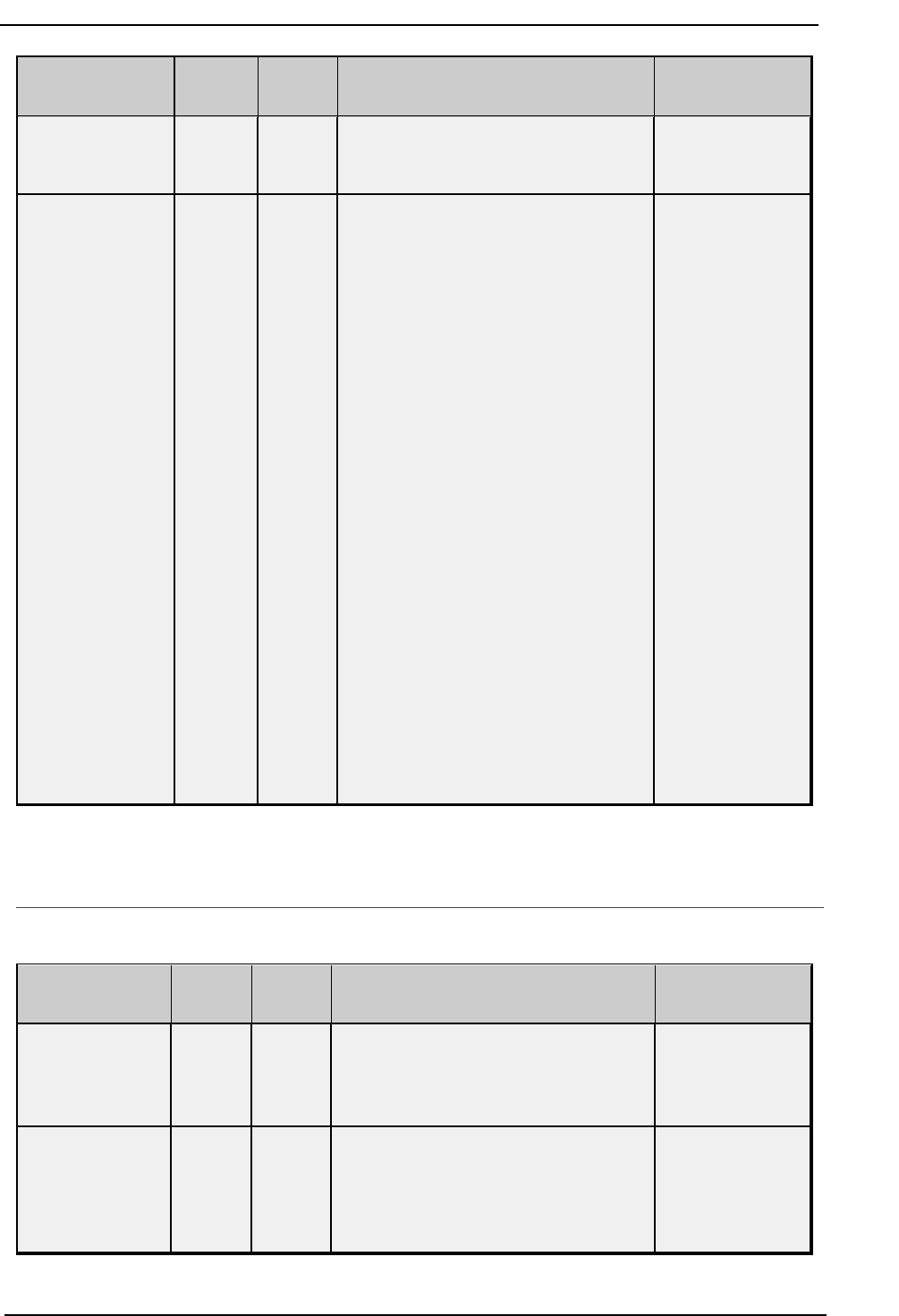

Data Types Description

The Torque Tool Ethernet Driver supports the following data types.

Data Type Description

Boolean Single bit

Word Unsigned 16-bit integer

Short* Signed 16-bit integer

DWord Unsigned 32-bit integer

Long* Signed 32-bit integer

String ASCII text string

Float 32-bit floating point value

Date* 64 bit date and time value

Double* 64-bit floating point value

*These types are not used natively, but are supported through conversion.

Note: All non-variable tags used in the driver have a fixed data type. Therefore, it is recommended that

users allow the driver to use the default data type for the point.

www. ptc.com

16

Torque Tool Ethernet Driver

Address Descriptions

The Torque Tool Ethernet Driver specifies addresses by the name of the item that will be addressed. It may

be optionally followed by a bit or index number. The syntax is ITEMNAME<.BIT/INDEX>, where:

l

ITEMNAME: The name of the item that will be addressed.

l

BIT/INDEX: The bit number for items using bit fields, or index for arrayed items. The bit/index is only

used for certain address items.

Important: Bits are 0-based, with 0 being the LSB. Array indices are 1-based, with 1 being the first item.

Unsolicited Data

Some of the command sets are sent unsolicited by the device. These command sets will not have data avail-

able until the device sends the data to the driver. All unsolicited command sets have a NEWDATA item,

which will be set to 1 when new data arrives. Users may then clear this flag back to 0 by writing any value to

it.

Message Revisions

Some commands have multiple message revisions which hardware may support. Some items are only avail-

able for certain message revisions. These items have been marked as being available in a certain message

revision. For example, an item marked with (Rev 2) is only available in message revision 2 or later. Some

messages also have a low-bandwidth version available and will be marked appropriately.

Variable Data

Instead of adding revisions to allow for more information to be sent, the Open Protocol specification sup-

ports Variable Data fields. These are dynamic results where any number of values are returned. Each Vari-

able Data field contains the information needed to describe that piece of data and can be uniquely

identified by specifying the Message ID (MID), the Parameter ID (PID), and the Step number. To allow access

to these values, the format of the tag addresses needs to be “MID”.”PID”.”Step”.Unit; where Step and Unit

are optional. If Unit is specified, the Unit value is returned as a numeric value that corresponds to different

unit types (as defined in the Open Protocol specification). For example, to get the Final Torque on a MT

Focus 6000, the tag address might be ‘1202.30237’. To get the units of that value, use this tag address:

‘1202.30237.Unit’. MID901 variable data tags (such as 901.30424) contain graph markers and their respect-

ive values for plotting within the curve data returned in MID900 messages. There are common PID values

and there are PID values that are specific to the device. Refer to the Open Protocol specification and the device

specific specification for more information.

Protocols

The Torque Tool Ethernet Driver supports the OpenProtocol model and the Ford Ethernet Protocol(FEP)

model. Each protocol supports a set of commands that have one or more items available for addressing.

Not all command sets are supported for each model. For more information, select a link from the list below.

Alarm

Auto-Disable Settings

Flash

Identifiers

Job Info

Job Number Data

Job Data

Last Tightening Results

www. ptc.com

17

Torque Tool Ethernet Driver

Multi Spindle Results

Old Tightening Results

Operation Result

Parameter Set Data

Parameter Set Numbers

Parameter Set Selected

Selector Messages

Time

Tool Data

Trace Curve Data Messages

User Data Messages

VIN

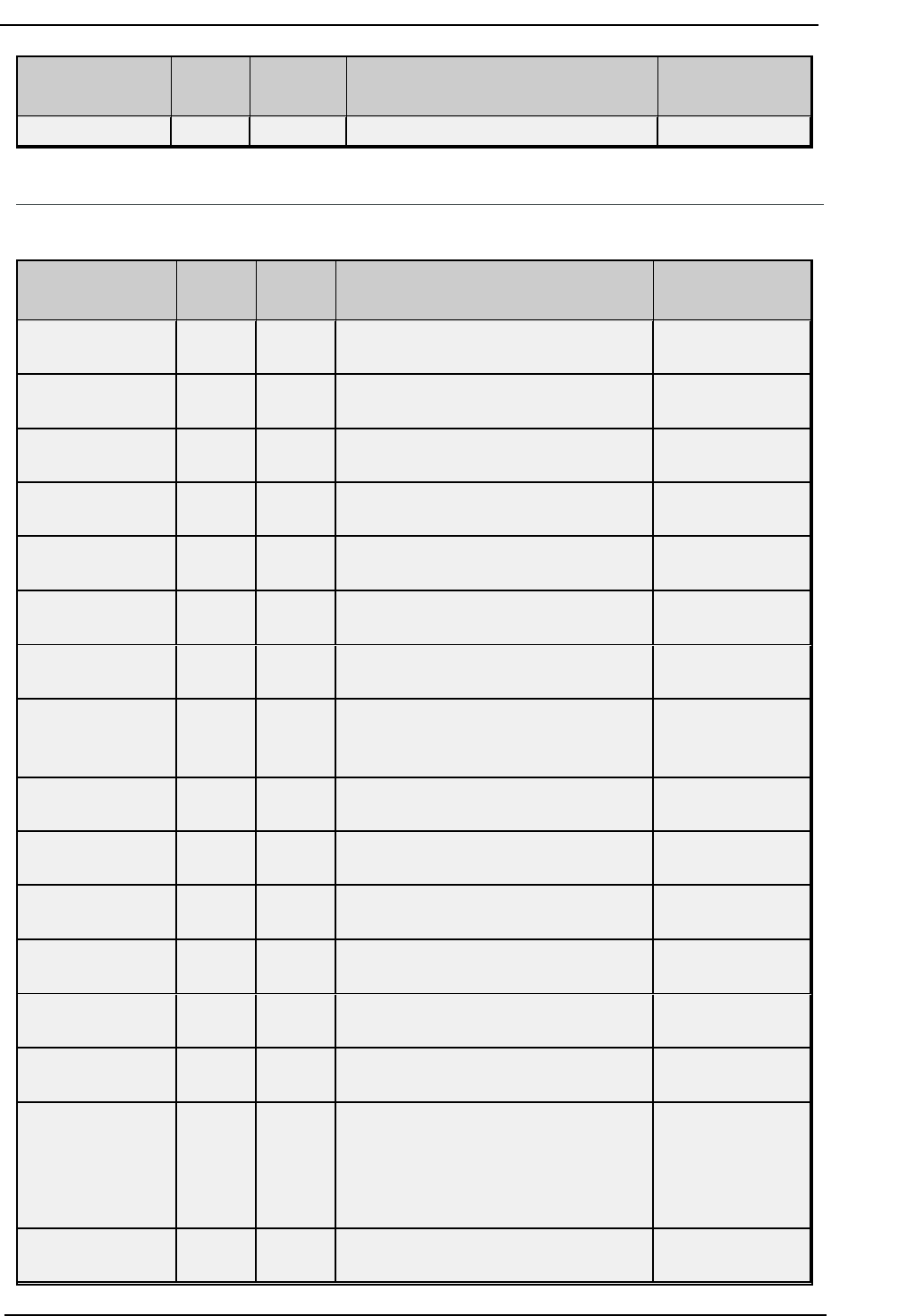

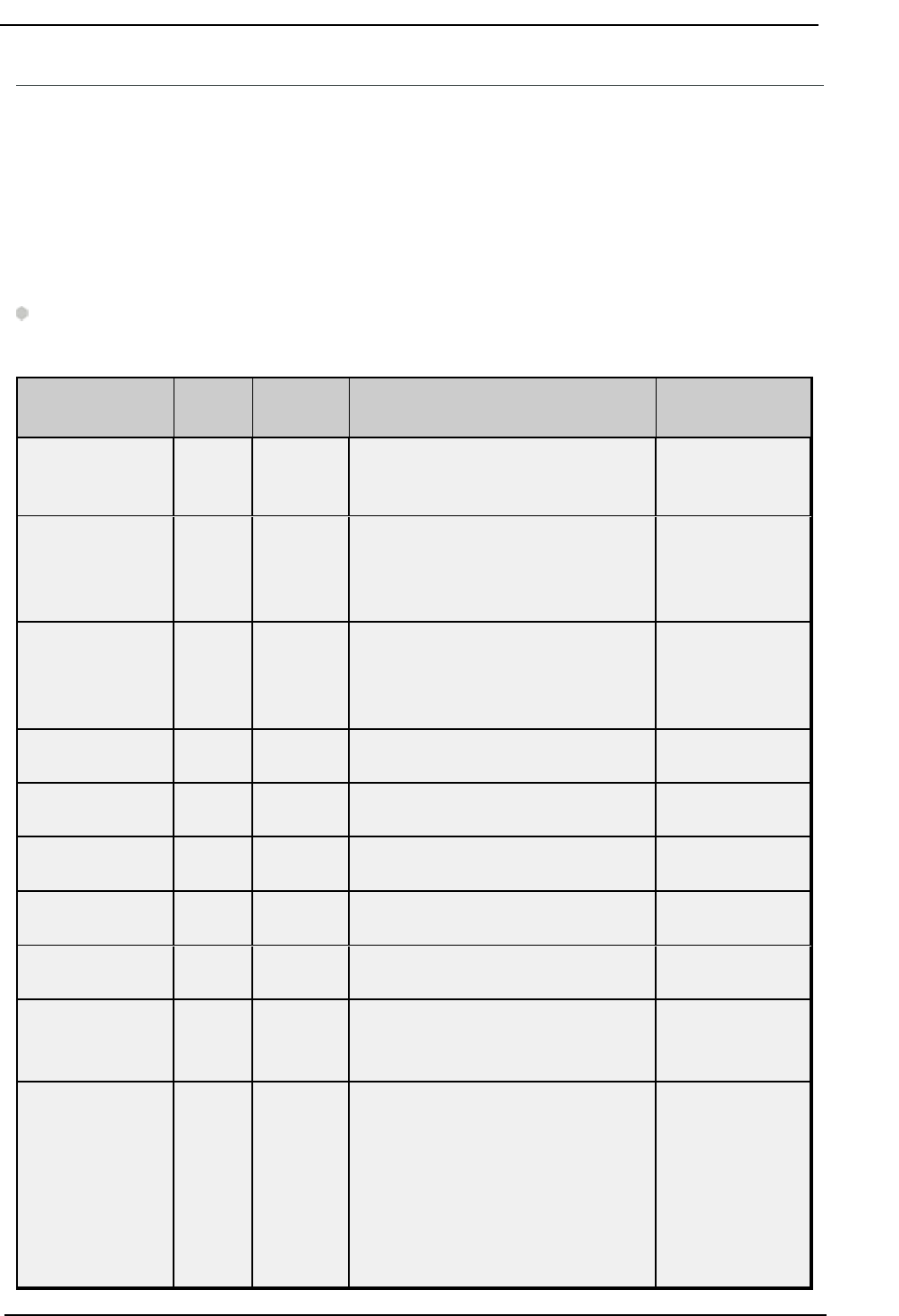

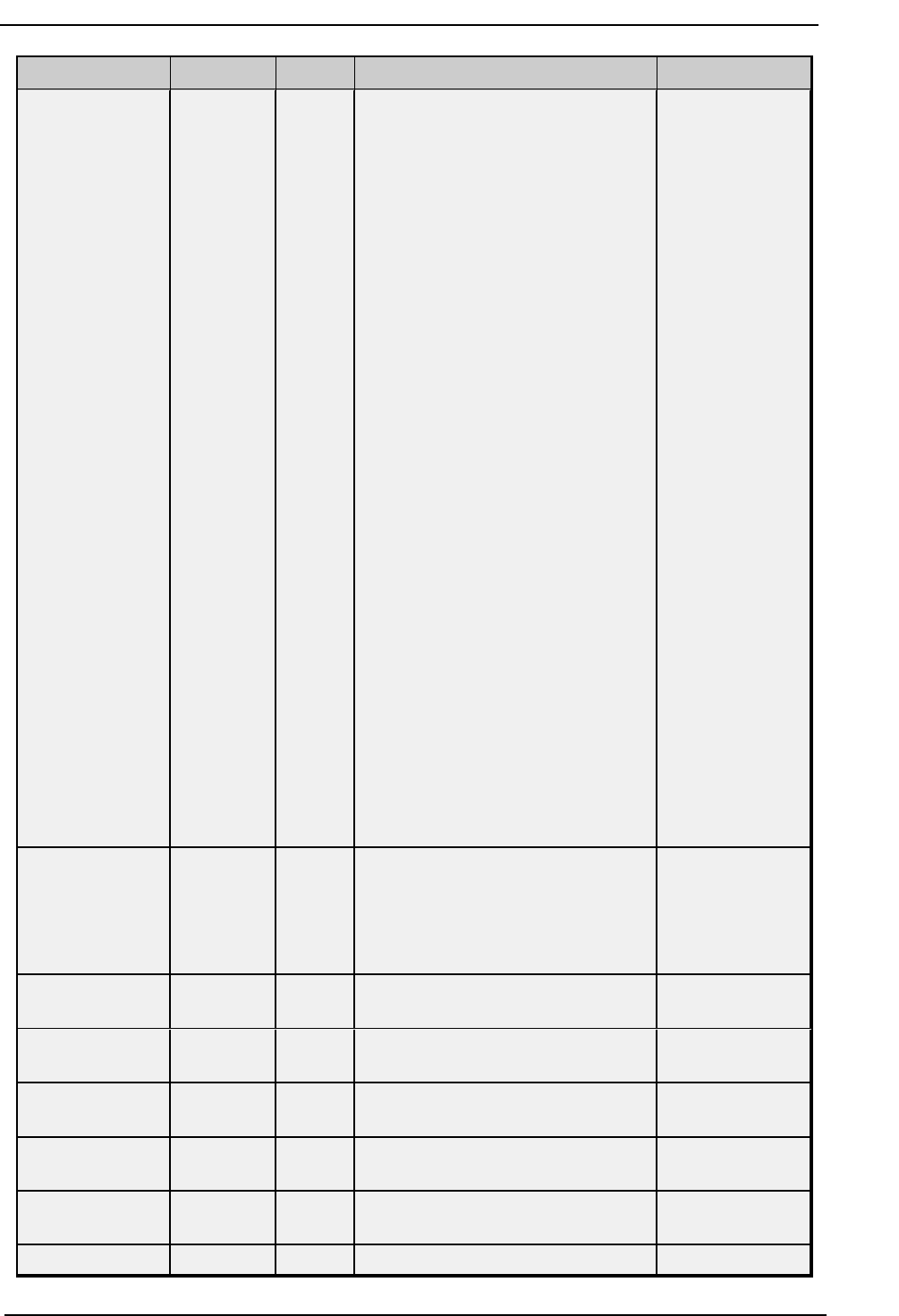

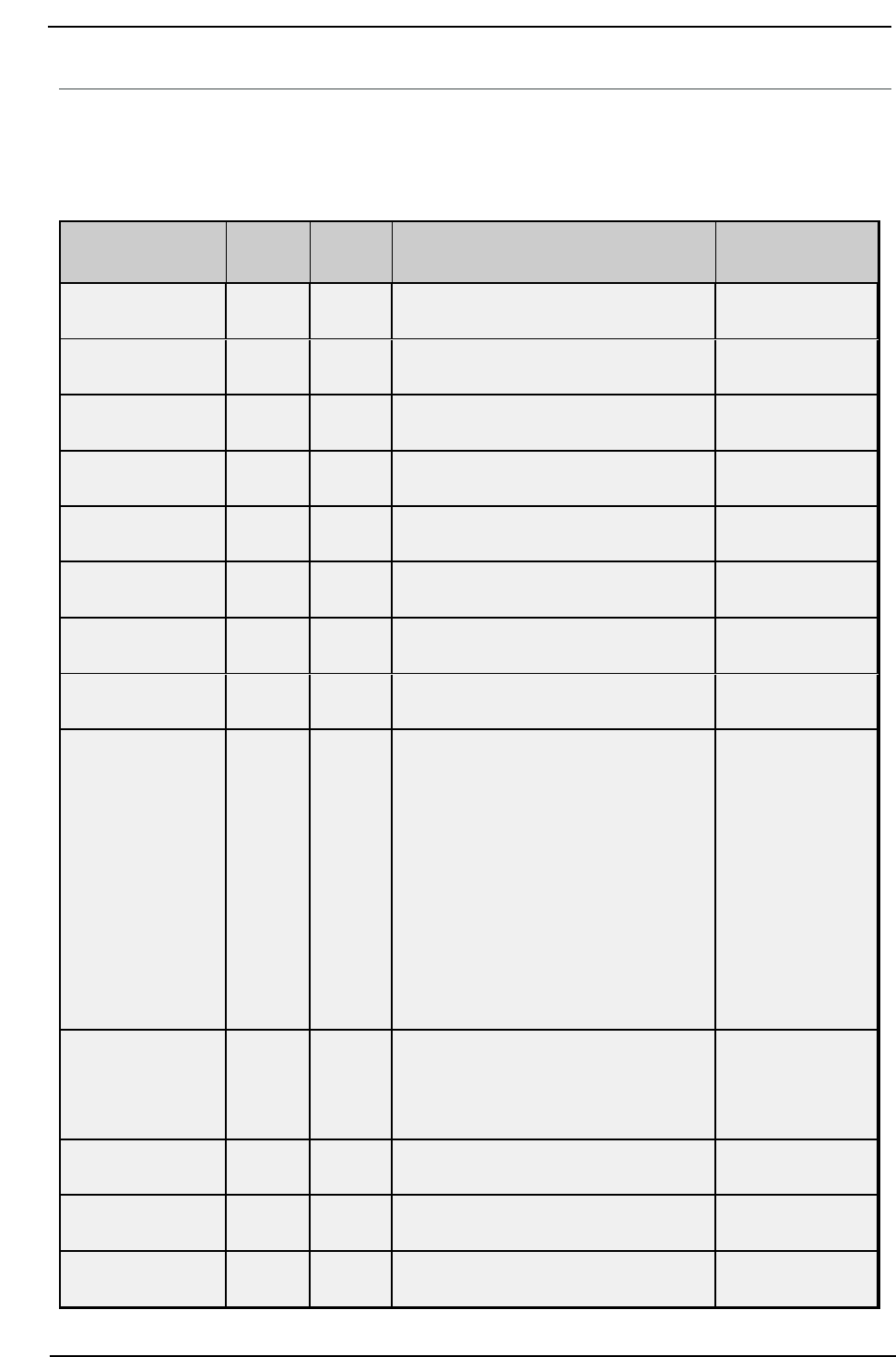

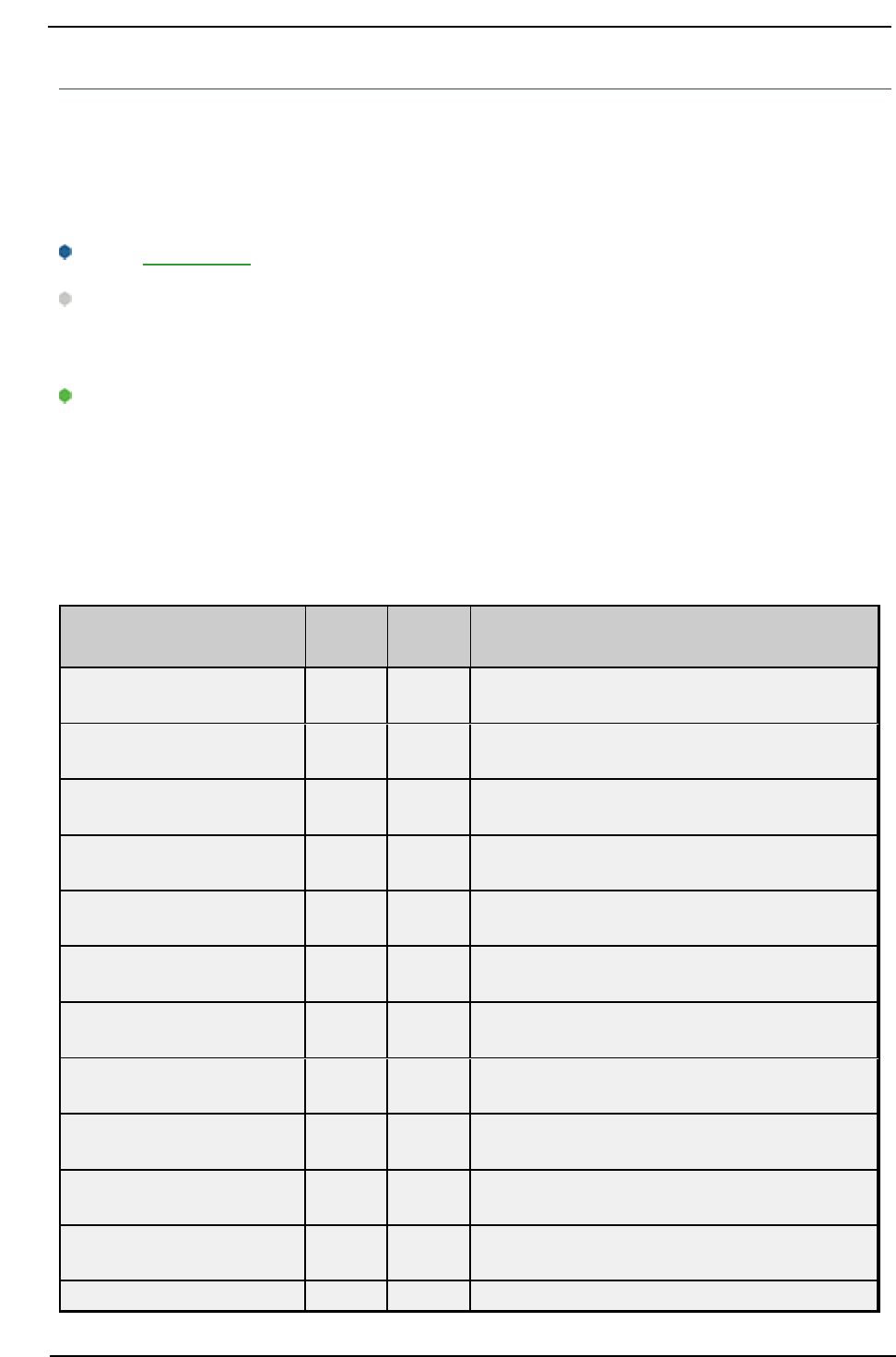

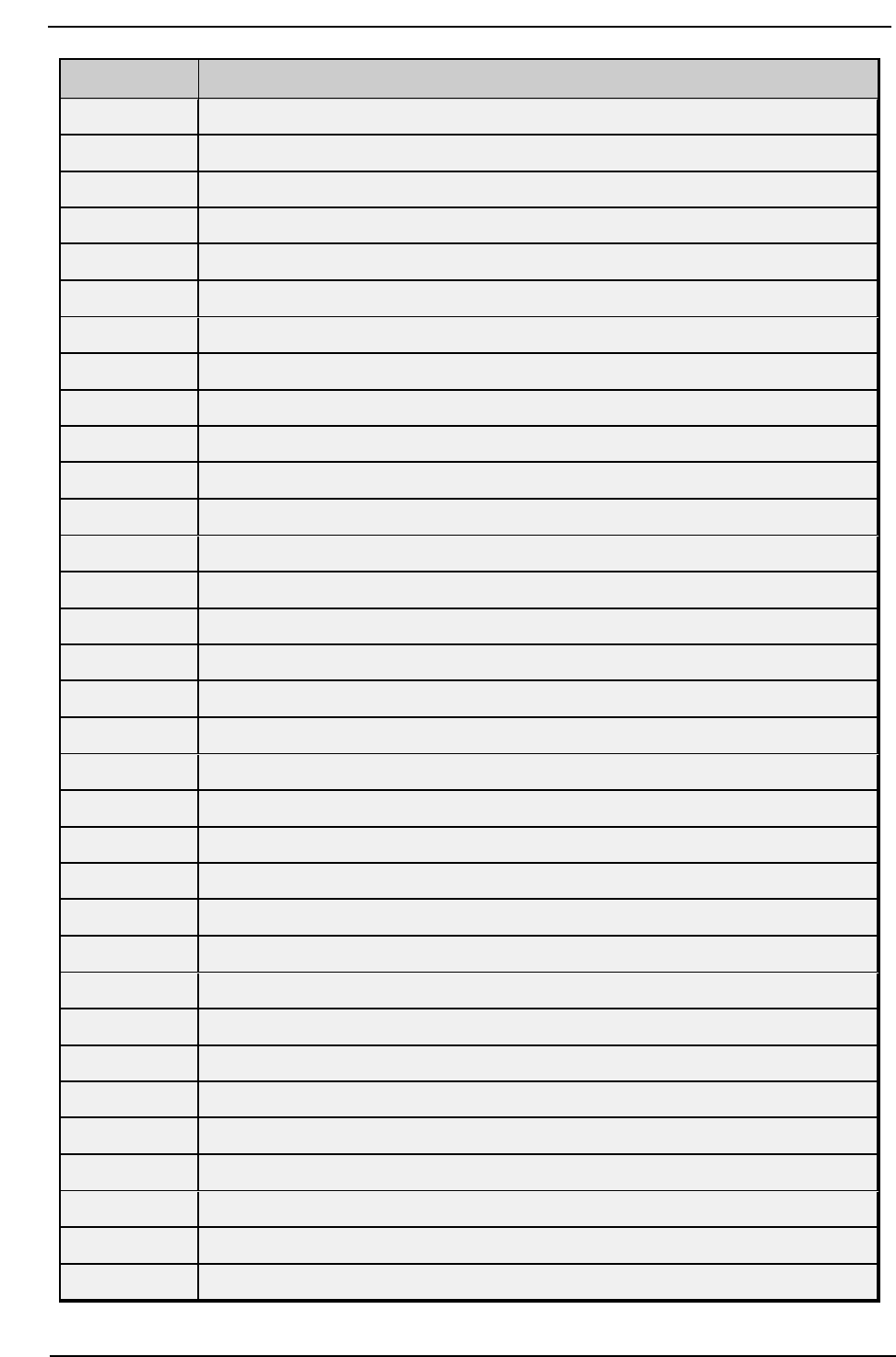

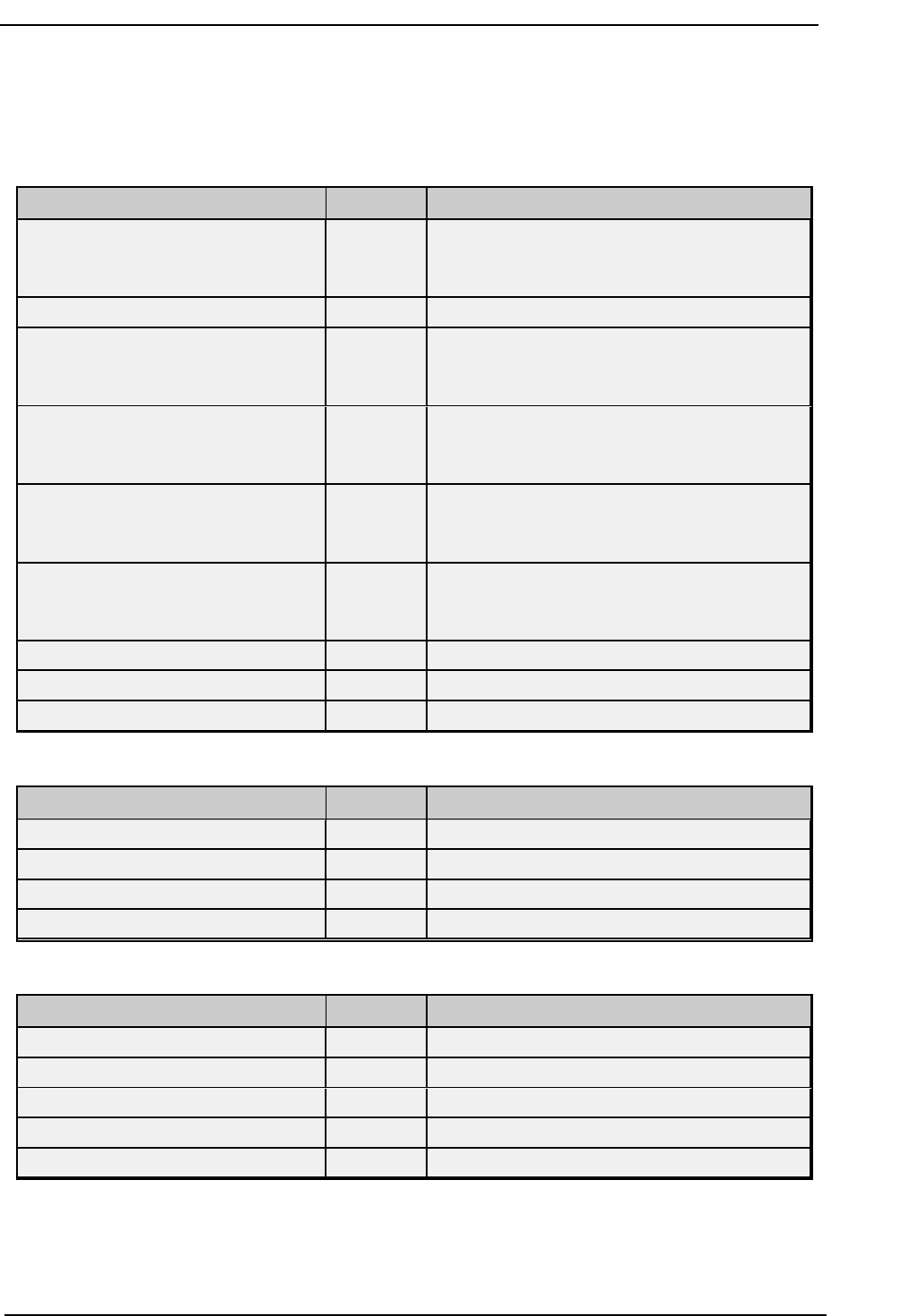

Message IDs

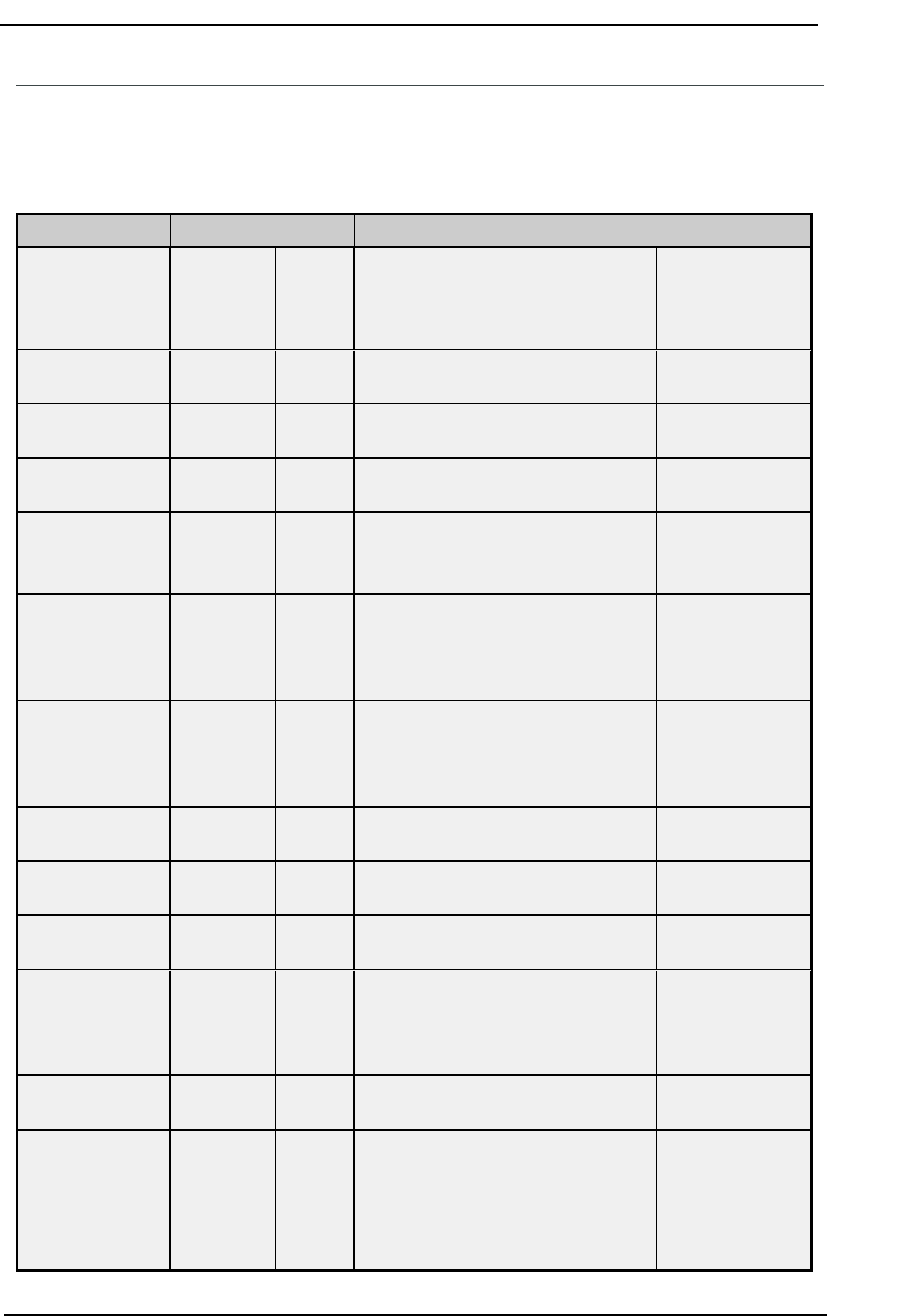

For more information on the Message IDs (MIDs) supported by each device model, refer to the table below.

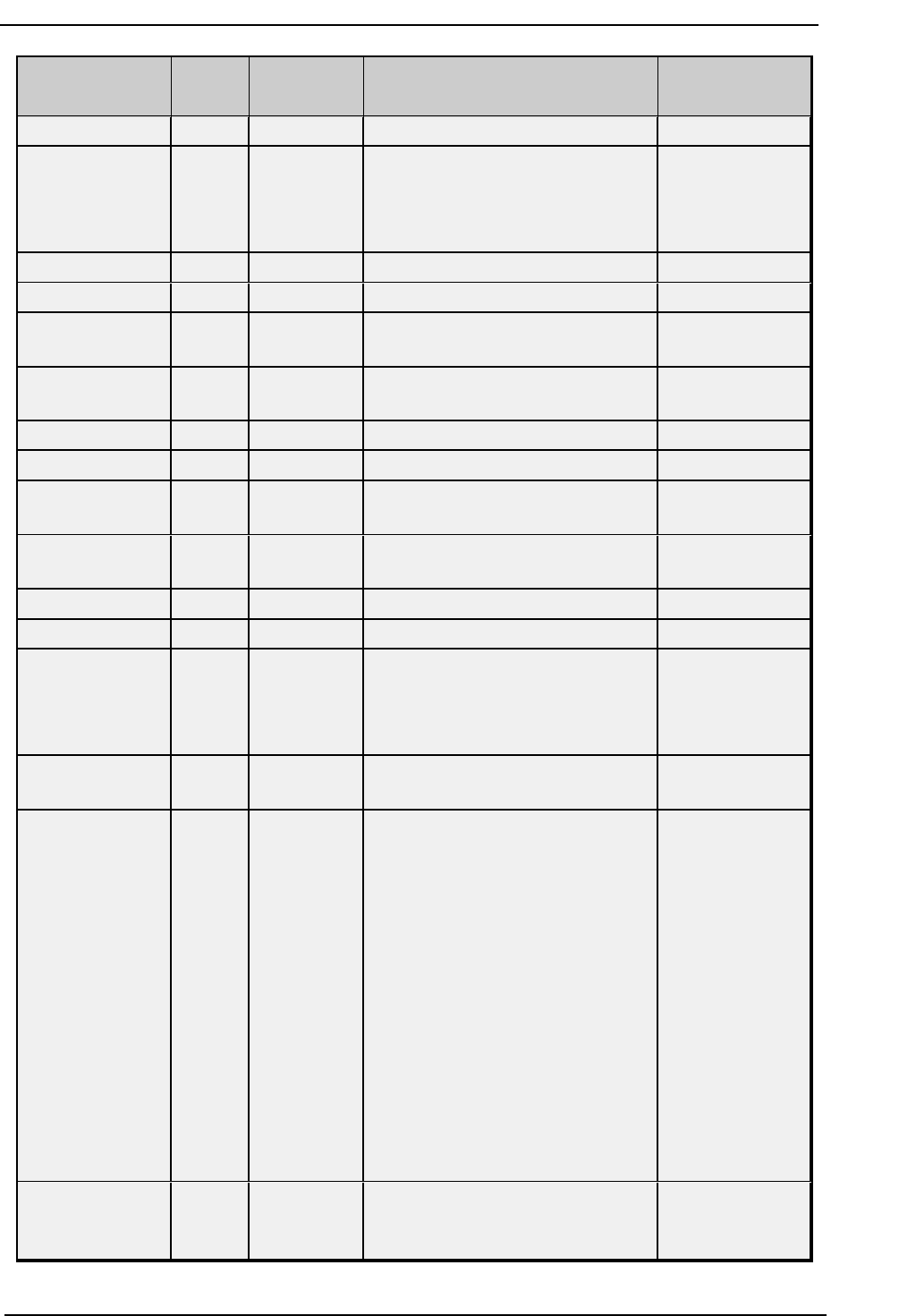

Message ID Description Supported Models

0001 Start communication Open, FEP

0002 Start communication acknowledge Open, FEP

0003 Stop communication Open, FEP

0004 Command error Open, FEP

0005 Command accepted Open, FEP

0008 Generic Subscription Open

0010 Pset number upload request Open, FEP

0011 Pset number upload reply Open, FEP

0012 Pset data upload request Open, FEP

0013 Pset data upload reply Open, FEP

0014 Pset selected subscribe Open, FEP

0015 Pset selected telegram Open, FEP

0016 Pset selected telegram acknowledge Open, FEP

0017 Pset selected unsubscribe Open, FEP

0018 Selected Pset Open, FEP

0019 Set Pset batch size Open, FEP

0020 Reset Pset batch size Open, FEP

0030 Job numbers upload request Open, FEP

0031 Job numbers upload reply Open, FEP

0032 Job data upload request Open

0033 Job data upload response Open

0034 Job selected/info subscribe Open, FEP

0035 Job selected/info Open, FEP

0036 Job selected/info acknowledge Open, FEP

www. ptc.com

18

Torque Tool Ethernet Driver

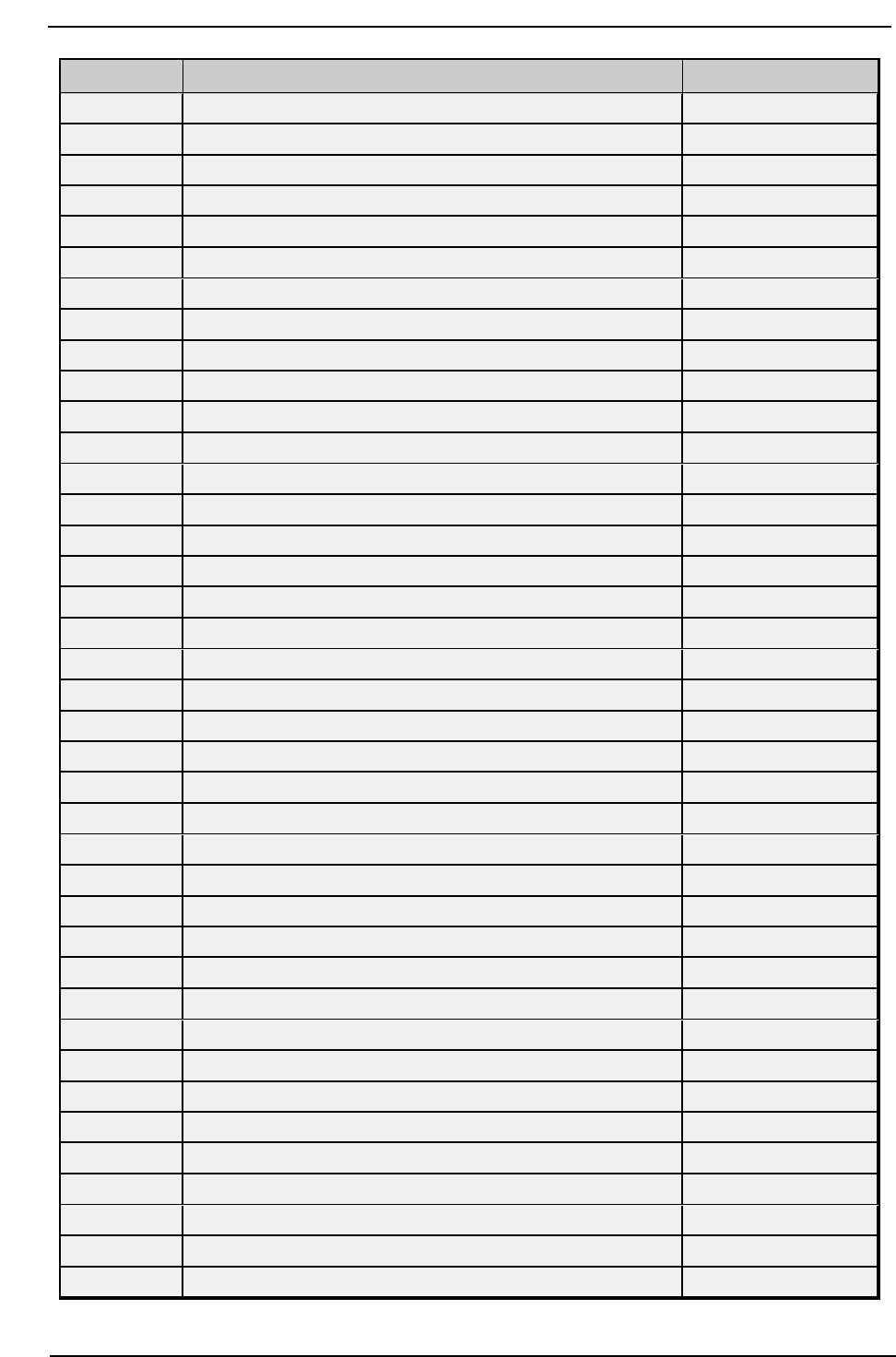

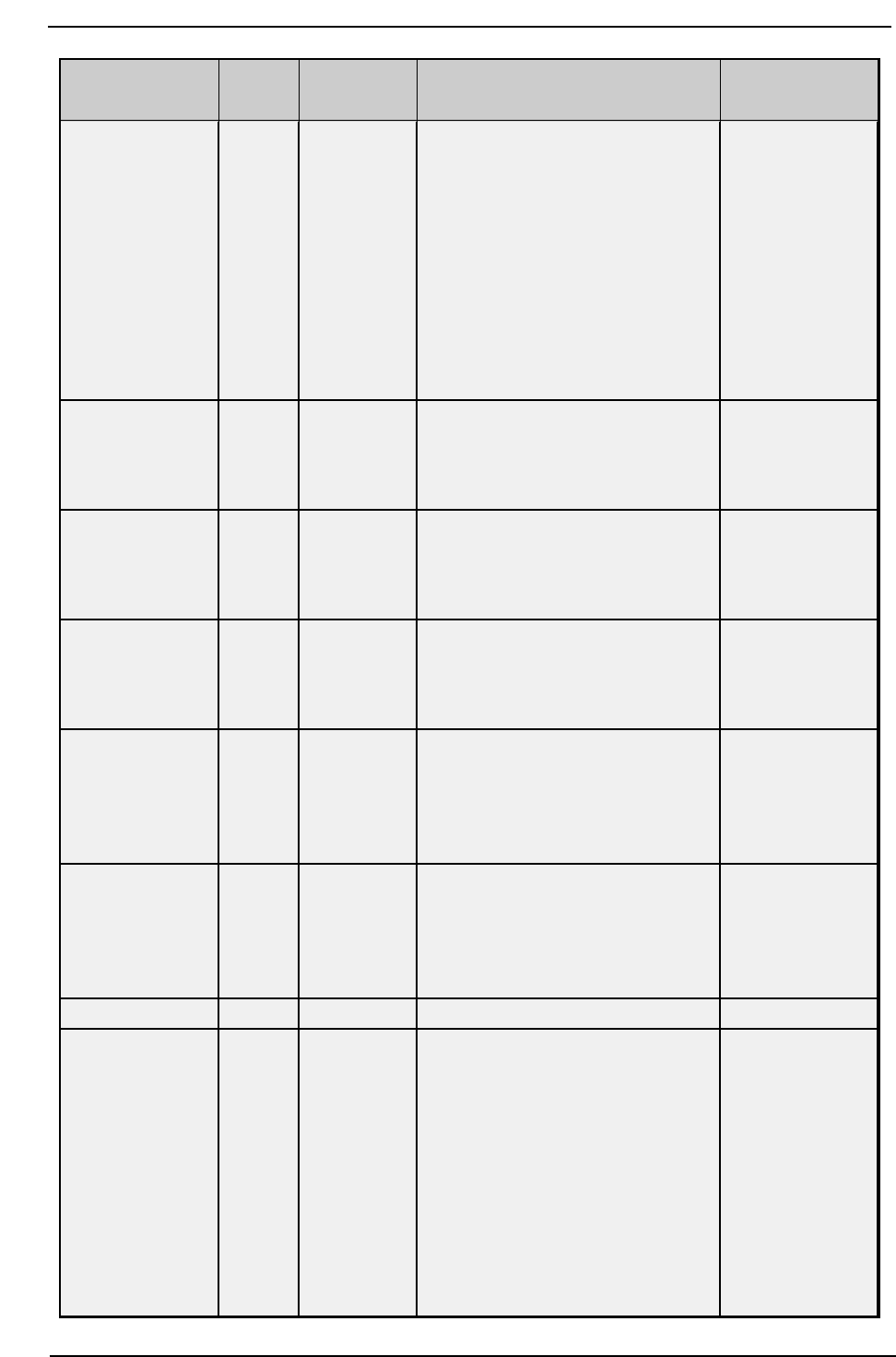

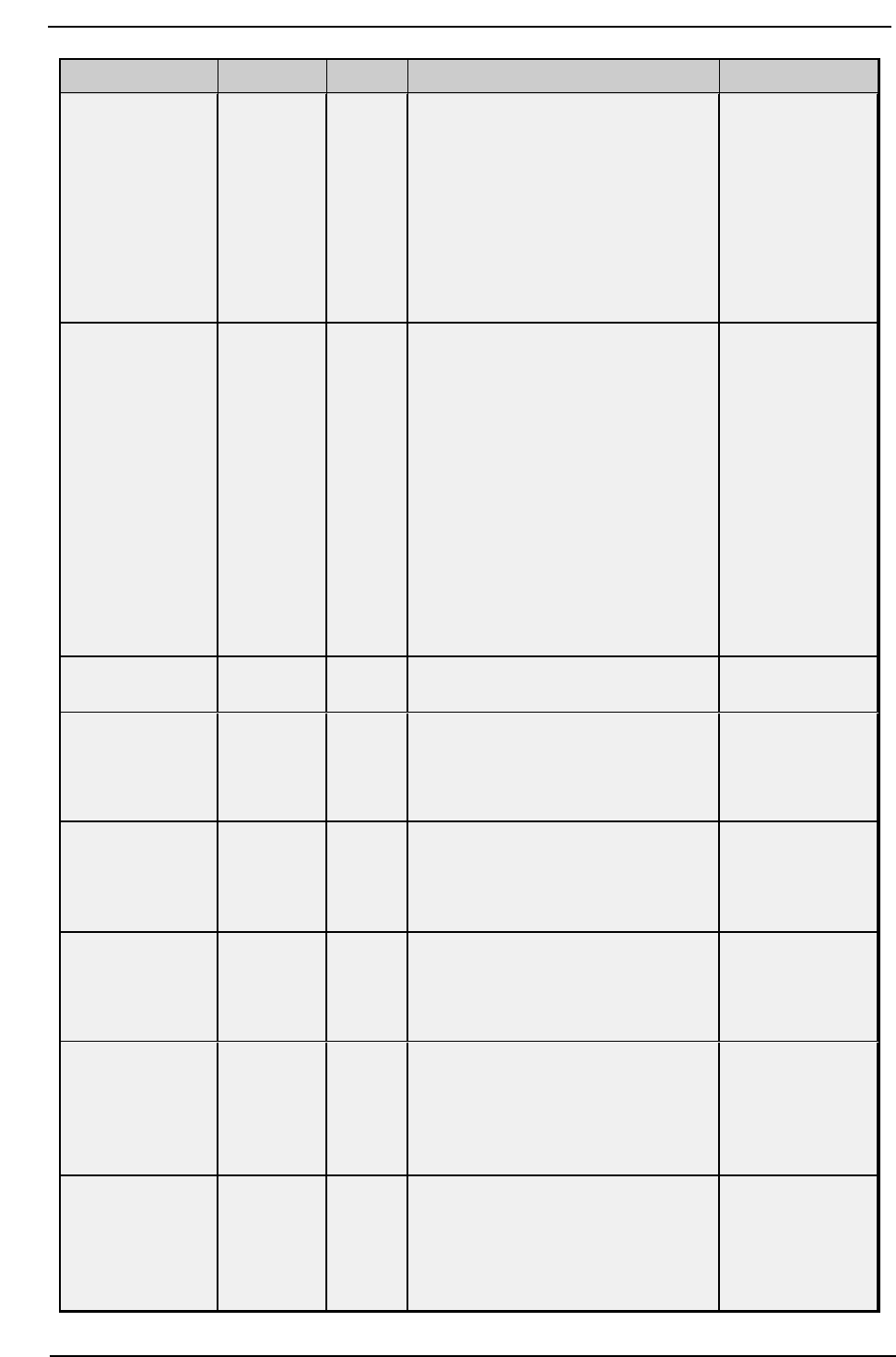

Message ID Description Supported Models

0037 Job selected/info unsubscribe Open, FEP

0038 Job selected in PF3000 Open, FEP

0039 Job restart Open, FEP

0040 Tool data upload request Open, FEP

0041 Tool data upload reply Open, FEP

0042 Disable tool Open, FEP

0043 Enable tool Open, FEP

0050 VIN download request Open, FEP

0051 VINupload subscribe Open, FEP

0052 VIN number upload Open, FEP*

0053 VIN upload acknowledge Open, FEP

0054 VIN upload subscribe Open, FEP

0060 Last Tightening Result (LTR) subscribe Open, FEP

0061 LTRupload Open, FEP*

0062 LTR upload acknowledge Open, FEP

0063 LTR unsubscribe Open, FEP

0064 Old Tightening Results (OTR) upload request Open, FEP

0065 OTR upload reply Open, FEP*

0070 Alarm subscribe Open, FEP

0071 Alarm upload reply Open, FEP

0072 Alarm upload acknowledge Open, FEP

0073 Alarm unsubscribe Open, FEP

0074 Alarm acknowledge on Torque controller Open, FEP

0075 Alarm acknowledge on Torque controller acknowledge Open, FEP

0076 Alarm status Open, FEP

0077 Alarm status acknowledge Open, FEP

0080 Time upload request Open, FEP

0081 Time upload Open, FEP

0082 Set time in torque controller Open, FEP

0100 Multi-spindle result subscribe Open, FEP

0101 Multi-spindle result upload Open, FEP**

0102 Multi-spindle result upload acknowledge Open, FEP

0103 Multi-spindle result unsubscribe Open, FEP

0113 Flash green light tool Open, FEP

0127 Job Cancel Open, FEP

0128 Batch increment Open

0140 Dynamic Job Request Open

0200 Set external controlled relays Open

0210 Status externally monitored inputs subscribe Open

www. ptc.com

19

Torque Tool Ethernet Driver

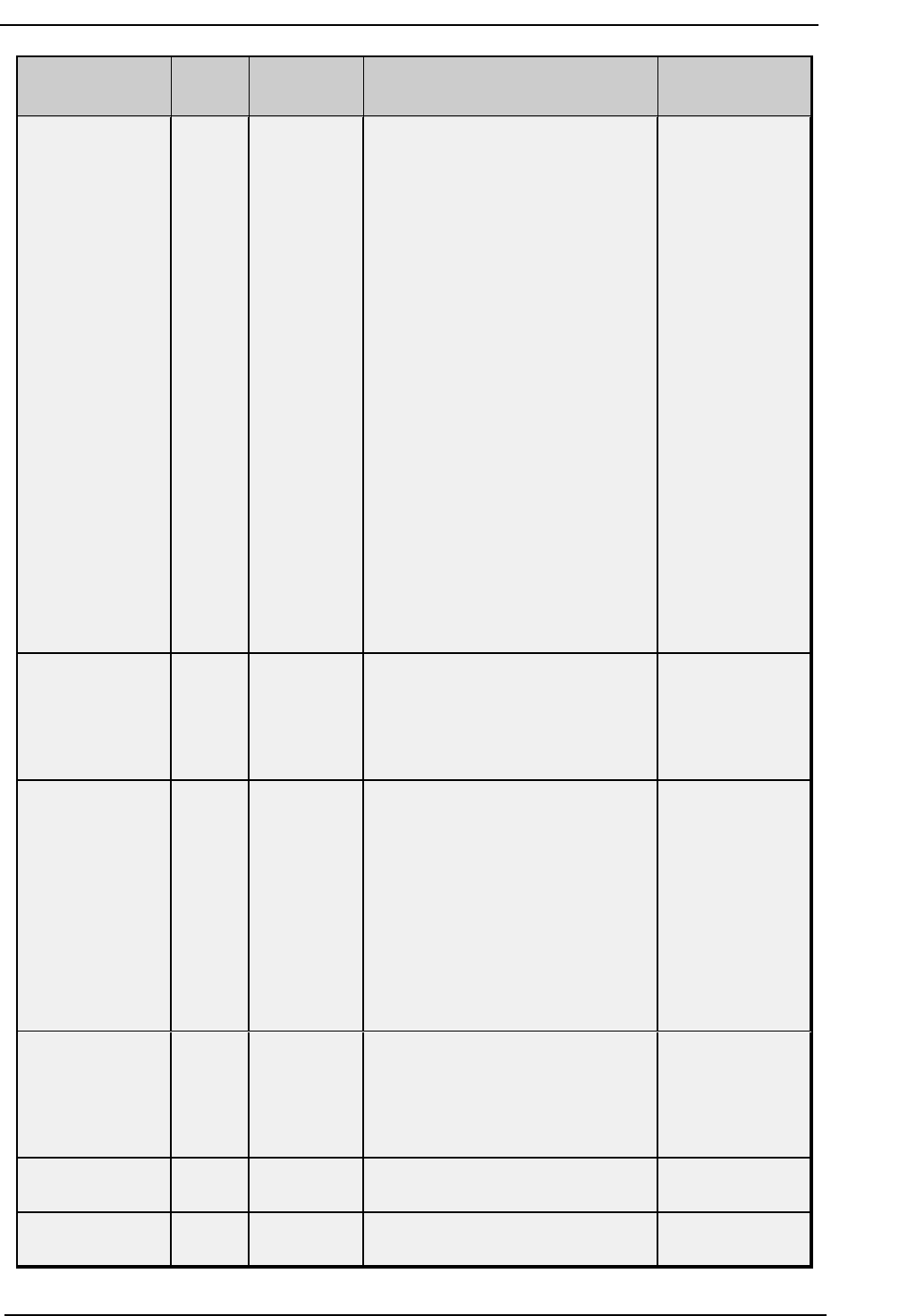

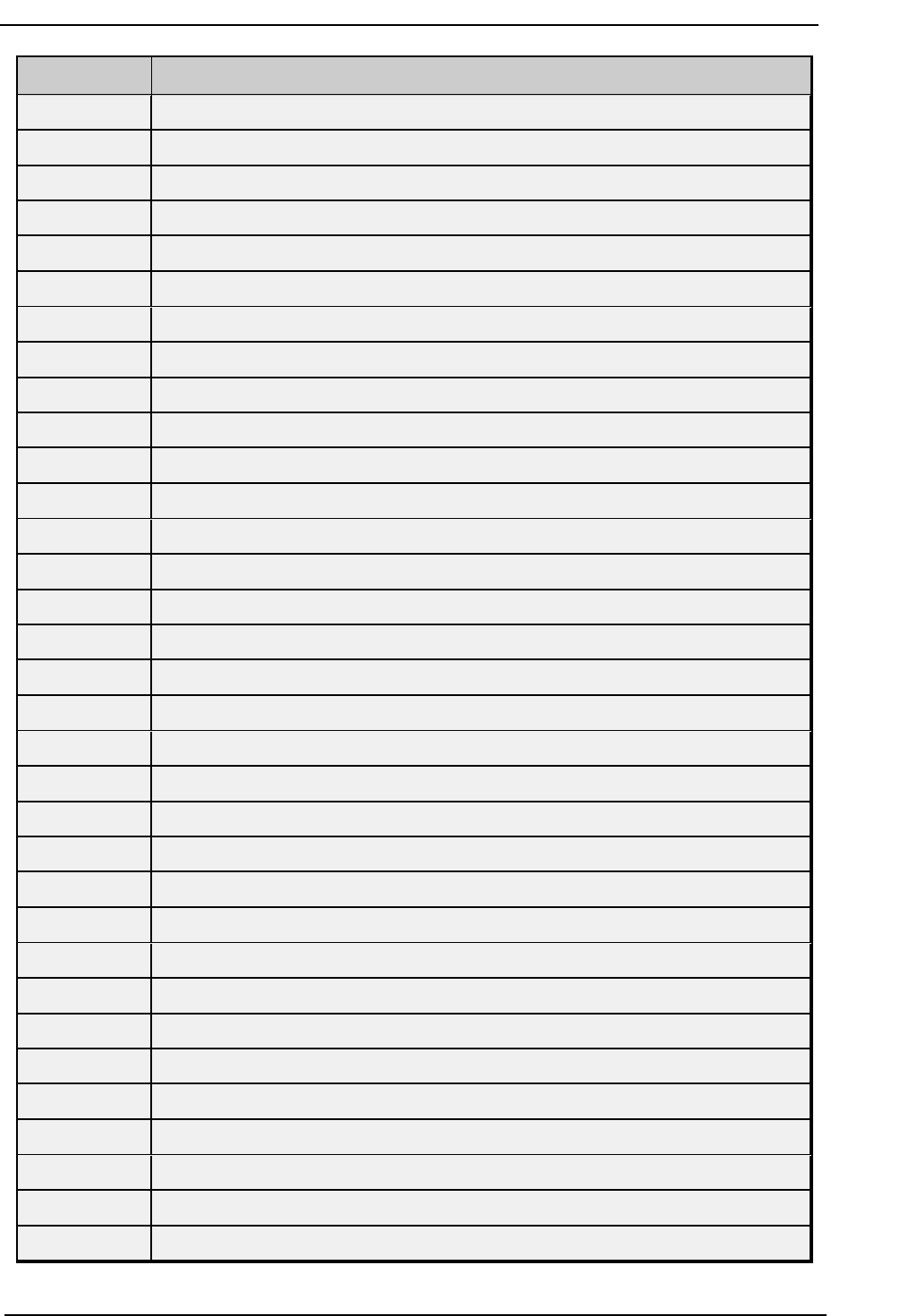

Message ID Description Supported Models

0211 Status externally monitored inputs upload Open

0212 Status externally monitored inputs upload acknowledge. Open

0213 Status externally monitored inputs unsubscribe Open

0216 Relay function subscribe Open

0217 Relay function data Open

0218 Relay function acknowledge Open

0219 Relay function unsubscribe Open

0224 Set digital input function Open

0225 Reset digital input function Open

0240 User Data Download Open

0241 User Data Subscribe Open

0242 User Data Message Open

0254 Selector control green lights Open

0255 Selector control red lights Open

0400 Auto/man mode subscribe FEP

0401 Auto/man mode upload FEP

0402 Auto/man mode acknowledge FEP

0403 Auto/man mode unsubscribe FEP

0410 Auto disable setting request FEP

0411 Auto disable setting reply FEP

0900 Trace Curve Data Message Open

0901 Trace Plot Parameters Open

1201 Operation result overall data Open

1202 Operation result object data Open

2500 Tightening program message download Open

2501 Tightening program message upload Open

9999 Keep alive Open, FEP

*Only supports MID Revision 1 as indicated in Revision 4.62 of the FEP specification.

**Unlike Open protocol, FEP does not use batch size, batch counter, and batch status parameters.

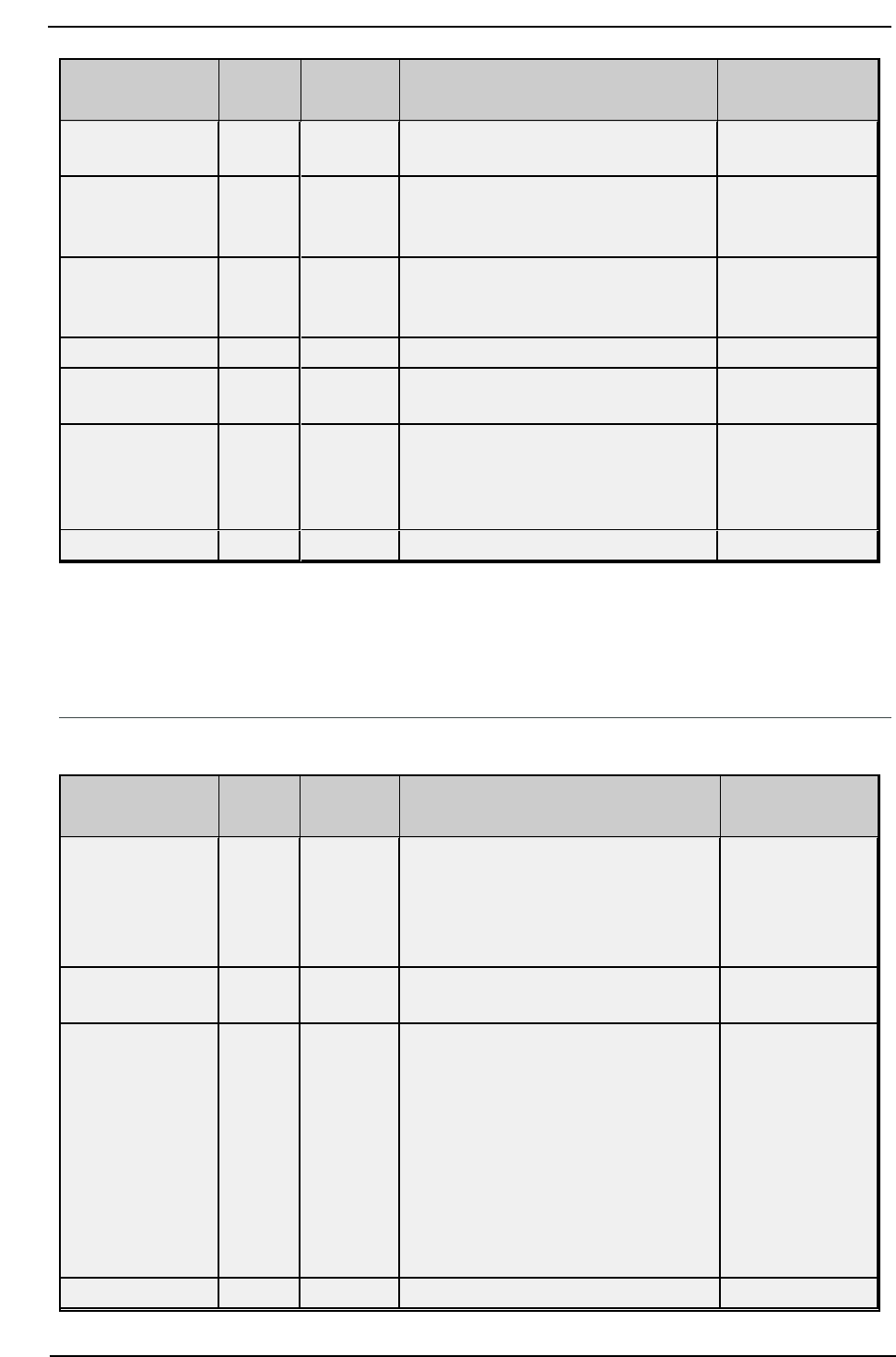

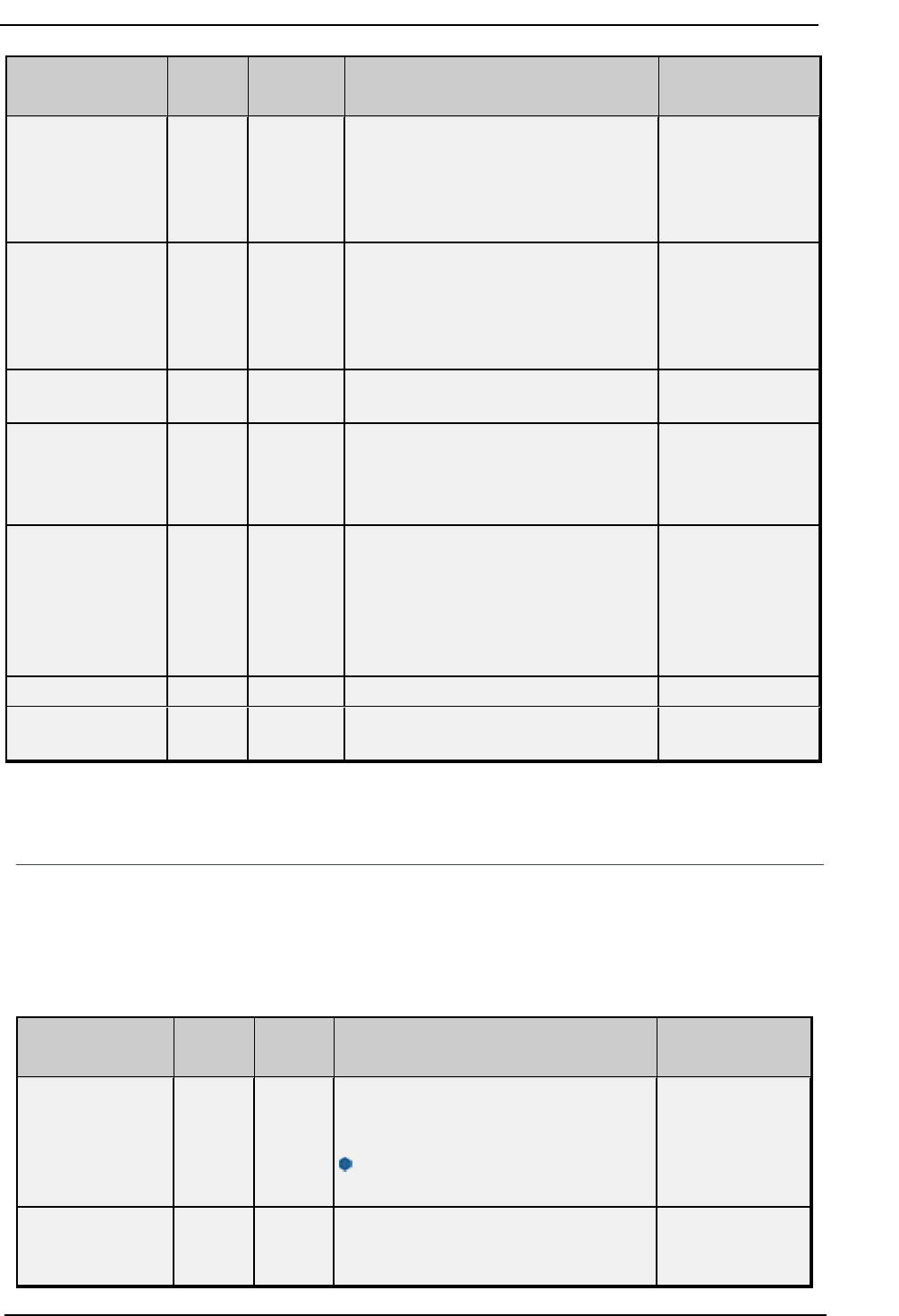

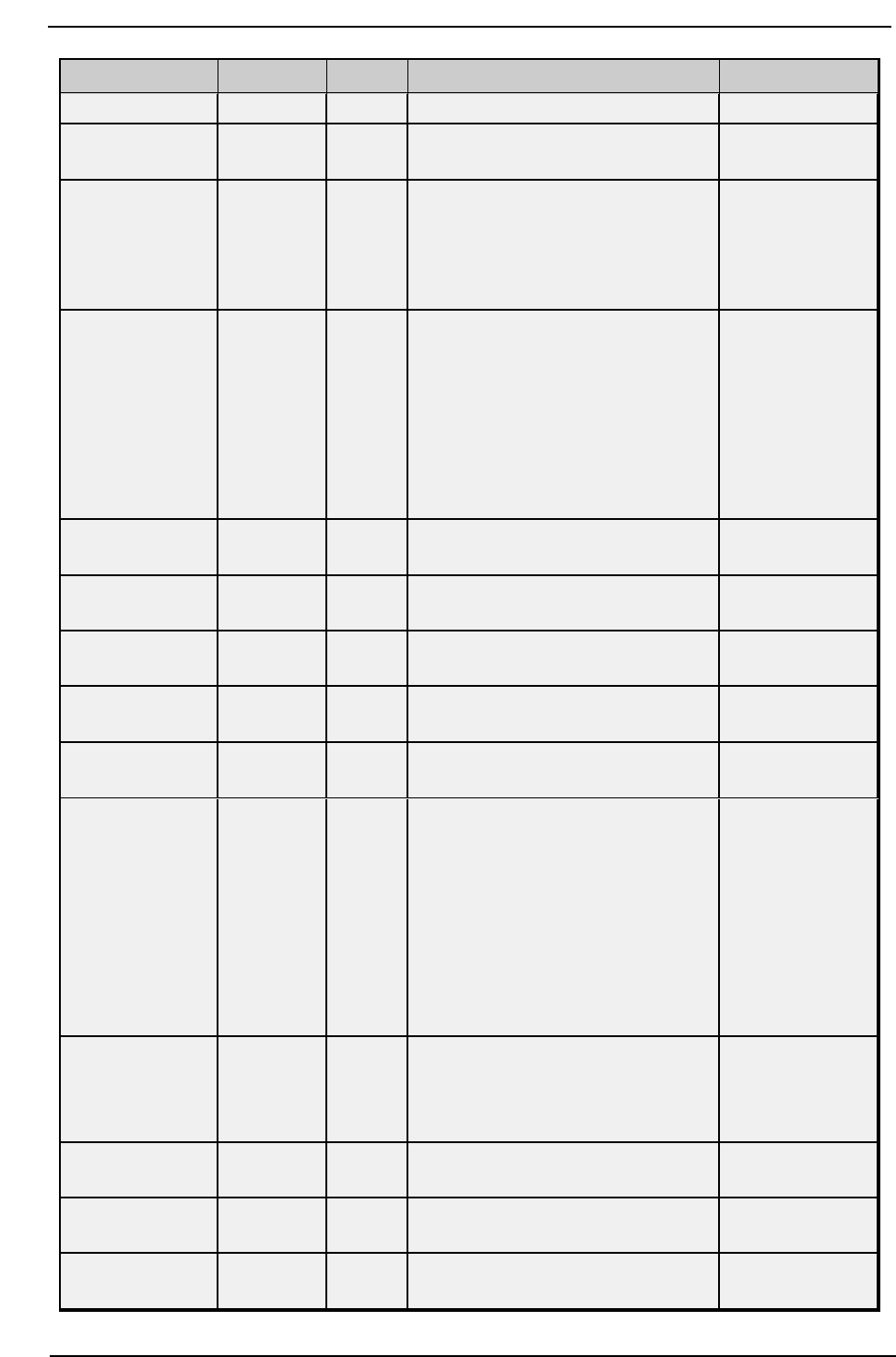

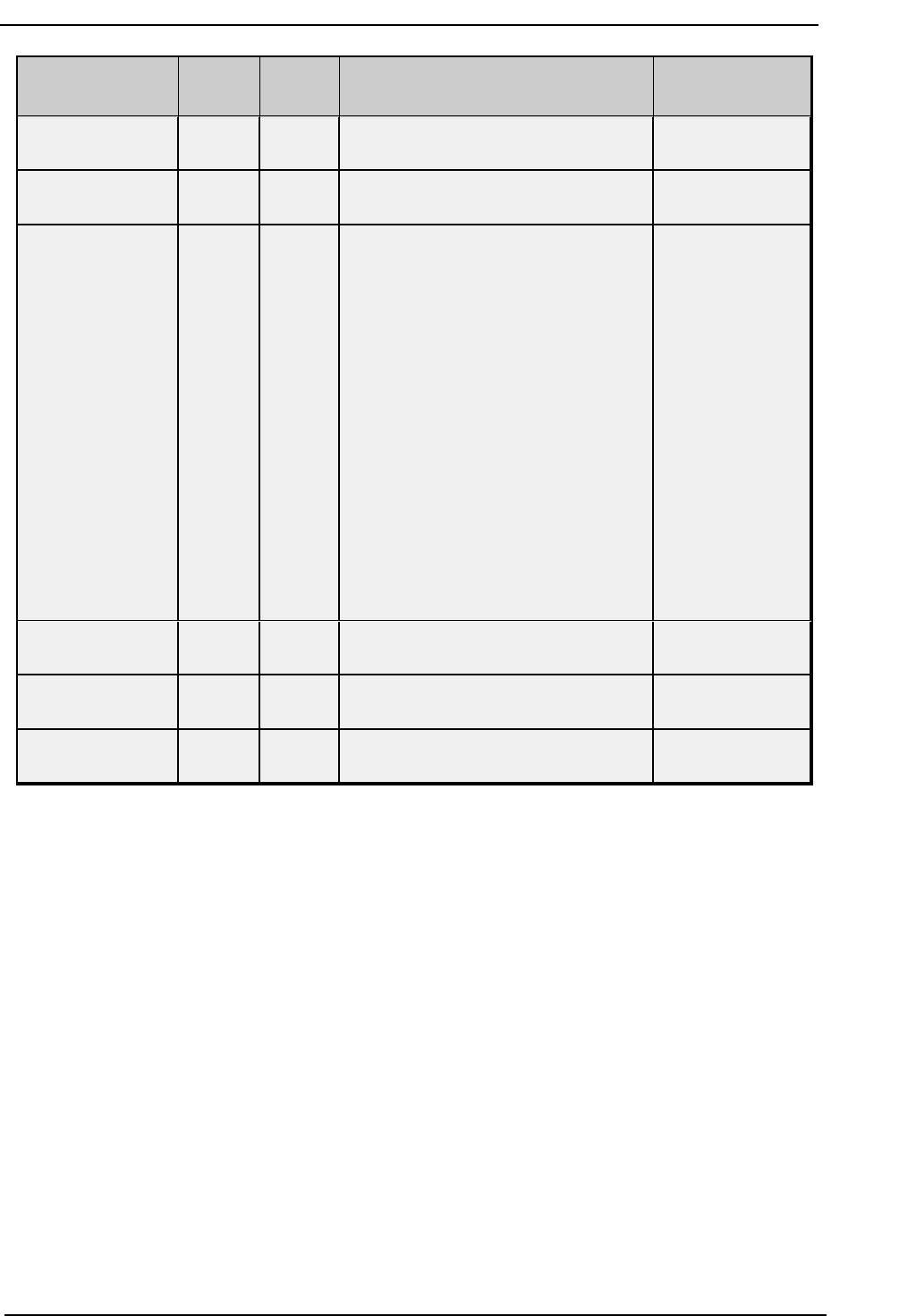

Command Set: Alarm

The Alarm command set is used to receive alarm data. All items belonging to this command set use MID 70

(Alarm subscribe) for the subscription request. The device sends the data through MID 71 and MID 76,

which are acknowledged with MID 72 and MID 77, respectively.

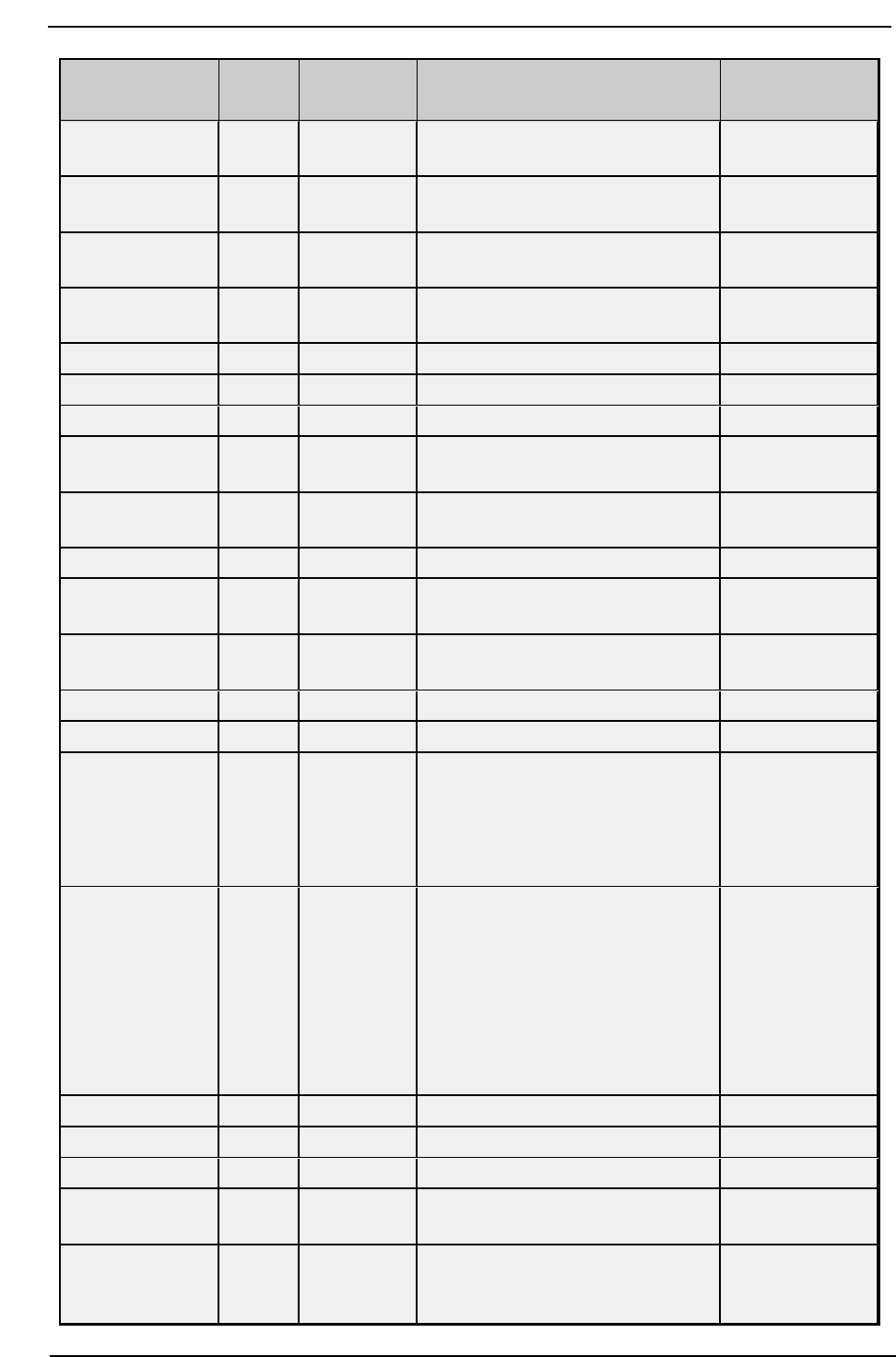

Item Data

Type

Access Description Data Range

ALARM_STATUS Boolean Read Only

0 if no alarm is active, 1 if an alarm is

currently active*

0-1

ALARM_ERROR String Read Only Error code 4 characters,

www. ptc.com

20

Torque Tool Ethernet Driver

Item Data

Type

Access Description Data Range

5 characters (Rev

2)

ALARM_C_READY Boolean Read Only Controller ready status:

1 = OK

0 = NOK

0-1

ALARM_T_READY Boolean Read Only Tool ready status:

1 = OK

0 = NOK

0-1

ALARM_TIME String Read Only Timestamp 19 characters

ALARM_NEWDATA Boolean Read/Write New data flag. Set to 1 when new data

arrives. Write a 0 to this flag to clear it.

0-1

ALARM_T_HEALTH Word,

Short

Read Only (Rev 3) Reports the tool status:

0 = Not Applicable

1 = OK

2 = NOK

0-2

ALARM_TEXT String Read Only (Rev 3) The text assigned to the alarm. 50 characters

*The ALARM_STATUS flag is valid on an initial connection to the device. Any subsequent alarm messages

after the initial update set the quality of the tag to "Bad" because the status is no longer provided by the

device.

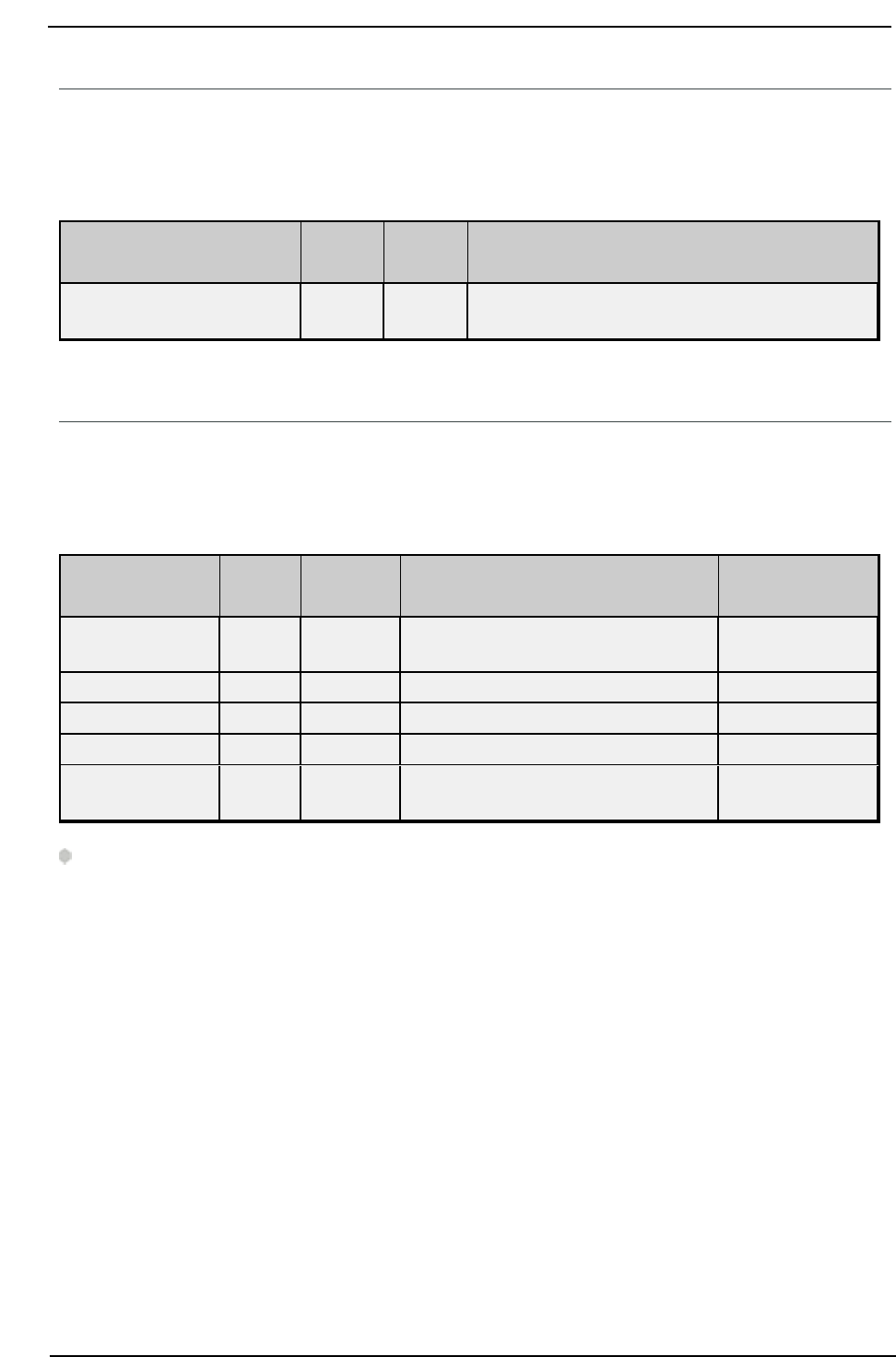

Command Set: Auto-Disable Settings

The Auto-Disable Settings command set is only supported by the FEPmodel.

Item Data

Type

Access Description Data Range

AD_SETTING

Word,

Short

Read Only

Auto-Disable setting. AD_SETTING and

AD_BATCH data is retrieved using MID

410 (AutoDisable settings request) for

the request, which is replied to with

MID 411 (AutoDisable settings reply)

0-99

AD_BATCH Word,

Short

Read Only Current batch 0-99

AM_MODE Boolean Read Only Automatic/Manual mode. AM_MODE

uses MID 400 (Automatic/Manual mode

subscribe) for the subscription request.

The device sends the data through MID

401(Automatic/Manual mode), which is

replied to by MID 402 (Auto-

matic/Manual mode acknowledge).

0 = Automatic Mode

1 = ManualMode

2-10

AM_NEWDATA Boolean Read/Write New data flag. Set to 1 when new data 0-1

www. ptc.com

21

Torque Tool Ethernet Driver

Item Data

Type

Access Description Data Range

arrives. Write a 0 to this flag to clear it.

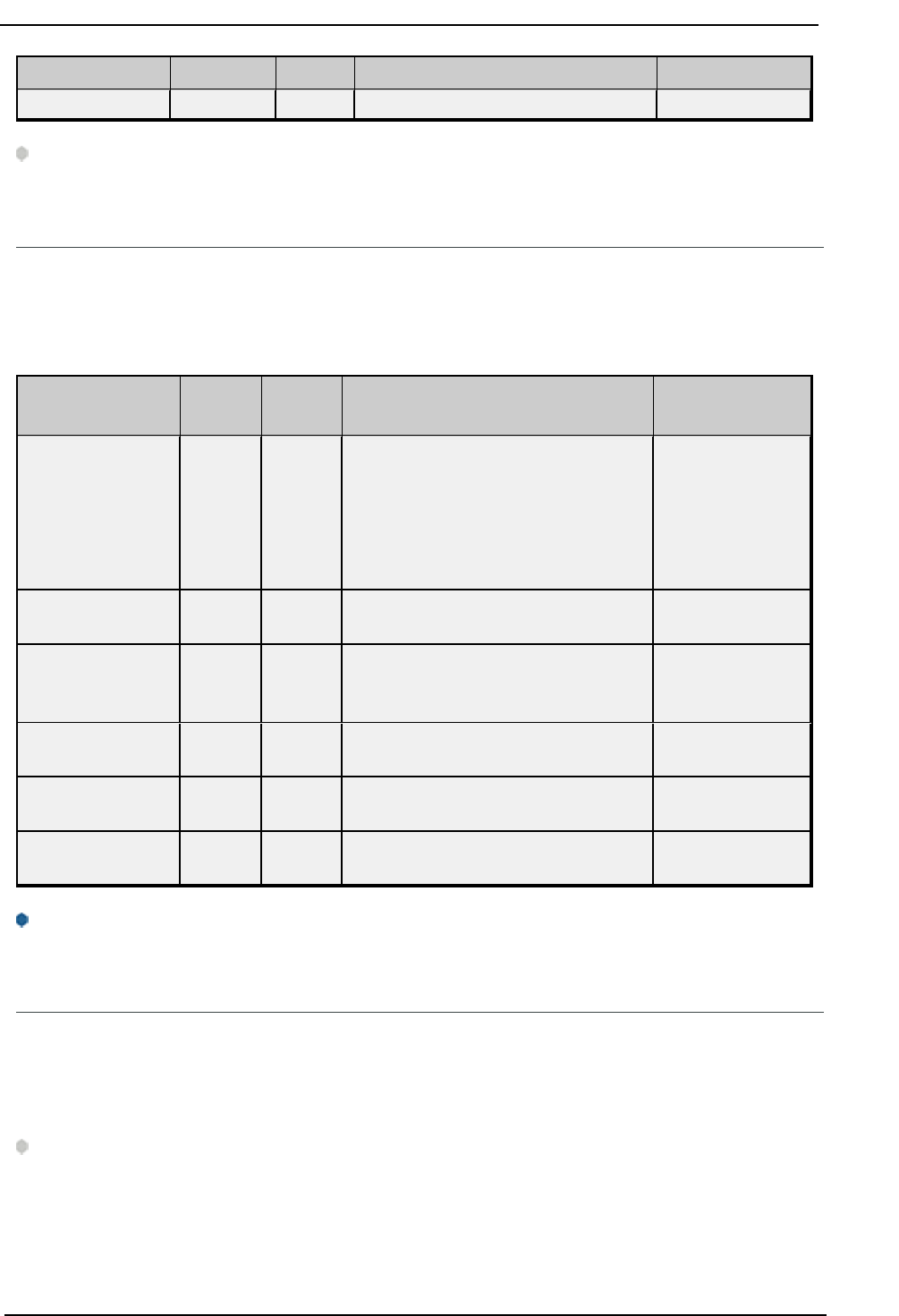

Command Set: Communication

The Communication command set is used to get information about the controller.

Item Data

Type

Access Description Data Range

COMM_CELL_ID Word,

Short

Read

Only

The cell ID of the controller 0-9999

COMM_CHANNEL_

ID

Word,

Short

Read

Only

The channel ID of the controller 0-20

COMM_CLIENT_ID Word,

Short

Read

Only

(Rev 2) The client ID 0-9

COMM_CONTROL_

NAME

String Read

Only

The name of the controller 25 characters

COMM_CONTROL_

SER_NUM

String Read

Only

(Rev 4) The serial number of the con-

troller

10 characters

COMM_CONTROL_

SOFT_VER

String Read

Only

(Rev 3) The controller software version 19 characters

COMM_LINK_

SUPPORT

Word,

Short

Read

Only

(Rev 6) Specifies that linking handling is

supported if 1

1

COMM_

PROTOCOL_

VERSION

String Read

Only

(Rev 3) The Open Protocol version sup-

ported by the controller's current firm-

ware

19 characters

COMM_RBU_TYPE String Read

Only

(Rev 4) The rapid backup unit (RBU) type 24 characters

COMM_SEO_NUM_

SUPPORT

Word,

Short

Read

Only

(Rev 6) Specifies that sequence number

handling is supported if 1

1

COMM_STATION_

ID

DWord,

Long

Read

Only

(Rev 6) The station ID or cell ID of the

controller

0-4294967295

COMM_STATION_

NAME

String Read

Only

(Rev 6) The station name of cell name of

the controller

25 characters

COMM_SUPPLIER_

CODE

String Read

Only

(Rev 2) The 3-character supplier code for

the controller

3 characters

COMM_SYS_

SUBTYPE

Word,

Short

Read

Only

(Rev 5) The system subtype of the con-

troller

0-2

COMM_SYS_TYPE Word,

Short

Read

Only

(Rev 5) The system type of the controller:

0 = System type not set

1 = Power Focus 4000

2 = Power MACS 4000

3 = Power Focus 6000

0-999

COMM_TOOL_

SOFT_VER

String Read

Only

(Rev 3) The tool software version 19 characters

www. ptc.com

22

Torque Tool Ethernet Driver

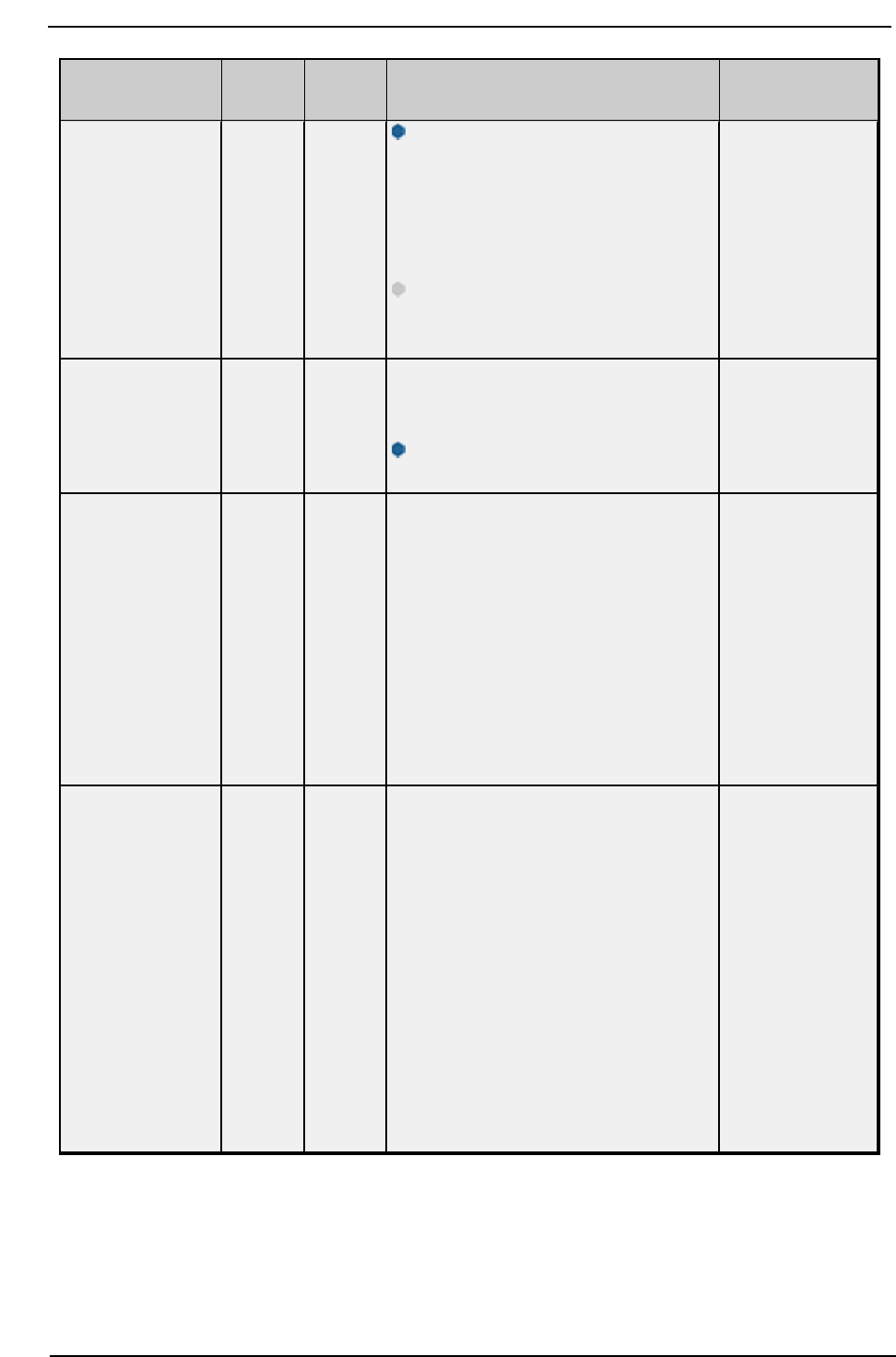

Command Set: Dynamic Job Request

The dynamic job request command set requests a dynamic job to be executed, which is immediately

executed (if possible) by the controller but not saved in the controller memory. A dynamic job lifetime is the

time for the job to be executed. If the controller is powered off before the completion of the job, the

dynamic job is lost. The message is sent using MID 140.

Item Data

Type

Access Description

DYNAMIC_JOB_REQUEST String Write

Only

Passes the message to the device with the string

written as a message payload

See Also: Appendix — Dynamic Job Request, Reference the Torque Tool Open Protocol Specification for fur-

ther information.

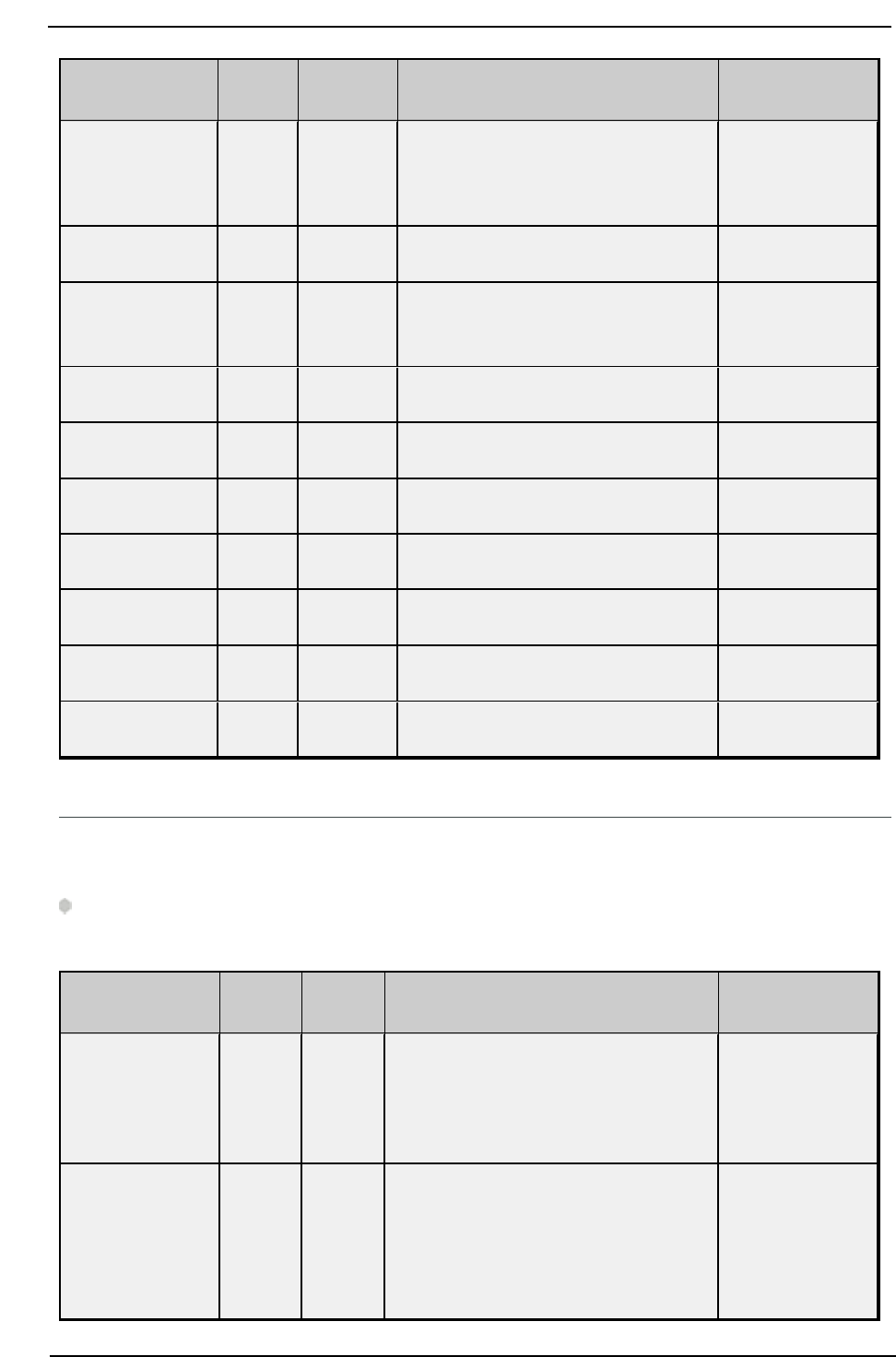

Command Set: Flash

The Flash command set is used to cause the tool's green light to flash.

Item Data

Type

Access Description Data Range

FLASH Boolean Write

Only

Write any value to this item to cause the

green light on the tool to flash until an

operator pushes the tool trigger. FLASH

uses MID 113 (Flash green light on tool).

N/A

Command Set: Identifiers

The Identifiers command set is used to manage the multiple identifiers in the controller. It is only supported

by the Open Protocol model. All tags prefixed by MID_ are subscription based and use MID 151 (Multiple

identifiers work order subscribe) for the subscription request. The device sends the item data to the server

through MID 152 (Multiple Identifiers work order), which the server responds to with MID 153 (Multiple Iden-

tifiers work order acknowledge).

Item Data

Type

Access Description Data Range

ID_DOWNLOAD String Write Only Write the identifiers to this item to send

the identifiers to the controller. ID_

DOWNLOAD uses MID 150 (Identifier

download request) to send the identifier

that was written to the item to the con-

troller.

100 characters

ID_BYPASS Boolean Write Only Write any value to this item to bypass

the next identifier expected in the work

order. ID_BYPASS uses MID 155 (Bypass

Identifier) to bypass the next identifier

expected in the work order.

N/A

ID_RESET Boolean Write Only Write any value to this item to reset the N/A

www. ptc.com

23

Torque Tool Ethernet Driver

Item Data

Type

Access Description Data Range

latest identifier or bypassed identifier in

the work order. ID_RESET uses MID 156

(Reset latest Identifier) to reset the

latest identifier or bypassed identifier in

the work order.

ID_RESETALL Boolean Write Only Write any value to this item to reset all

identifiers in the work order. ID_

RESETALL uses MID 157 (Reset all Iden-

tifiers) to reset all identifiers in the cur-

rent work order.

N/A

MID_TYPE Word,

Short

Read Only Identifier type number* 1-4

MID_IN_ORDER Boolean Read Only Included in work order*

0 = No

1 = Yes

0-1

MID_STATUS Word,

Short

Read Only Status in work order*

0 = Not accepted

1 = Accepted

2 = Bypassed

3 = Reset

0-3

MID_ID String Read Only Identifier* 25 characters

MID_NEWDATA Boolean Read/Write New data flag. Set to 1 when new data

arrives. Write a 0 to this flag to clear it.

N/A

*These items require an array index (1..4).

Command Set: IO Interface

The IOInterface command set is used to control external IO devices connected to the Torque Tool device.

The driver sends the Relay Function data subscription request through MID 216. After subscription, the

device sends item data to the driver using MID 217 and the driver acknowledges receipt of the item data

using MID 218. MID 219 is used by the driver to unsubscribe to Relay Function data, typically as client ref-

erences to Relay Function tags are removed from the server.

Item Data

Type

Access Description Data Range

RESET_DIGITAL_

INPUT

Word,

Short

Write

Only

Resets the digital input function with the

entered digital input value using MID

225. These values are device specific.

Refer to the device documentation for

more information.

0-999

RELAY_

FUNCTION.#

Word,

Short

Read

Only

Allows the user to get relay information

for the first 500 (0-499) functions defined

on the controller.

0, 1

www. ptc.com

24

Torque Tool Ethernet Driver

Item Data

Type

Access Description Data Range

Refer to the controller documentation to

determine which relay number corresponds

to what relay function.

Values received are:

0 = Not Active

1 = Active

Note: The server only supports relays

that are Tracking Events; events where

the value changes based on a condition.

SET_DIGITAL_

INPUT

Word,

Short

Write

Only

Sets the digital input function with the

entered digital input value using MID

224. These values are device specific.

Refer to the device documentation for

more information.

0-999

STATUS_RELAY_# Word,

Short

Write

Only

Set "external controlled" relays

Write to this item to set the status of the

corresponding external relay number. All

other relays are sent a '3'.

0 = Off

1 = On (fast)

2 = Flashing

3 = Keep the same results

STATUS_RELAY_# tags use MID 200 (Set

externally controlled relays) to set indi-

vidual relay statuses.

0-3

STATUS_DIGIN_# Boolean Read

Only

Get "external controlled" digital input

statuses

This item uses an unsolicited command

set to get the current status of all digital

inputs whenever one of them change.

The valid DigIn range is 1-8.

0 = Off

1 = On

STATUS_DIGIN_# tags use MID 210

(Status externally monitored inputs sub-

scribe) to subscribe to individual digital

input statuses, the data is sent from the

device to the server using MID 211

(Status externally monitored inputs).

0, 1

www. ptc.com

25

Torque Tool Ethernet Driver

Command Set: Job Info

The Job Info command set is used to receive data on the selected job, to allow the user to select a different

job, and to control job execution.

JOB_JOBNUM uses MID 38 (Select Job) to set the current job, JOB_RESTART uses MID 39 (Job restart) to

restart a job, JOB_ABORT uses MID 127 (cancel job) to terminate the current job. All other tags use MID 34

(Job info subscribe) to subscribe to job info. The device sends job info to the server using MID 35 (Job info),

which is responded to with MID 36 (Job info acknowledge). If the device supports 4-digit Job IDs, revision 2

or higher must be used.

Note: Some command set items also have alias names. In the table below, the alias name will be listed

beneath the item where applicable.

Item Data

Type

Access Description Data Range

JOB_JOBNUM

LINK_LINKNUM

Word,

Short

Read/Write The selected job number. To select a

different job, write a job number to this

item.

0-99 (Rev 1)

0-9999 (Rev 2+)

JOB_STATUS*

LINK_STATUS*

Word,

Short

Read Only Job batch status

0 = Job batch not completed

1 = Job batch OK

2 = Job batch NOK

0-2

JOB_BMODE*

LINK_BMODE*

Word,

Short

Read Only Job batch mode

0 = Only the OK bolts are counted

1 = Both the OK and the NOK bolts are

counted

0-1

JOB_BSIZE*

LINK_BSIZE*

Word,

Short

Read Only Job batch size 0-9999

JOB_BCOUNT*

LINK_BCOUNT*

Word,

Short

Read Only Job batch counter 0-9999

JOB_TIME*

LINK_TIME*

String Read Only Timestamp for the job info 19 characters

JOB_STEP* Word,

Short

Read Only The current step the job is on. 0-999 (Rev 3 and

4**)

JOB_SCOUNT* Word,

Short

Read Only The number of steps in the job. 0-999 (Rev 3 and

4**)

JOB_STYPE* Word,

Short

Read Only The step type

1 = Batch Step

2-6 = Reserved

0-99 (Rev 3 and

4**)

JOB_TSTATUS* Word,

Short

Read Only The status of the job tightening:

0 = JobTight OFF

1 = JobTight OK

2 = JobTight NOK

3 = JobTight Terminated

4 = JobTight Incremented

5 = JobTight Decremented

6 = JobTight Bypassed

0-10 (Rev 4)

www. ptc.com

26

Torque Tool Ethernet Driver

Item Data

Type

Access Description Data Range

7 = JobTight Reset Batch

8 = JobTight Loosening

9 = JobTight Free Batch

10 = JobTight Job Terminated

JOB_NEWDATA

LINK_NEWDATA

Boolean Read/Write New data flag. Set to 1 when new data

arrives. Write a 0 to this flag to clear it.

0-1

JOB_RESTART

LINK_RESTART

Word,

Short

Write Only Write a job number to this item to

restart that job

0-99 (Rev 1)

0-9999 (Rev 2)

JOB_ABORT

LINK_ABORT

Boolean Write Only Write any value to this item to ter-

minate the current job

N/A

JOB_BATCH_

INCREMENT*

Boolean Write Only Write any value to this item to incre-

ment the batch number

N/A

*This item is only supported by the Open Protocol model.

** This tag may not be valid for some devices when using revision 4.

Consult device documentation for supported MIDs and data fields.

Command Set: Job Data

The Job Data command set is used to request the configuration of a specific job. To request a job, write the

Job ID to JOBDATA_JOBID. All items belonging to this comment set use MID 32 (Job Data Upload Request) to

request the data, which is replied to with MID 33 (Job Data Upload Reply). If the device supports 4 digits Job

IDs, revision 2 or higher must be used.

Item Data

Type

Access Description Data Range

JOBDATA_JOBID Word,

Short

Read/Write Write a Job ID to this item to request

the job’s configuration

0-9999

JOBDATA_NAME String Read Only The name of job 25 characters

JOBDATA_

FORCED_ORDER

Word,

Short

Read Only Forced Order

0 = Free Order

1 = Forced Order

2 = Free and Forced

0-2

JOBDATA_MAX_

FIRST_

TIGHTENING_TIME

Word,

Short

Read Only Maximum time for first tightening 0-9999

JOBDATA_MAX_

COMPLETION_

TIME

DWord,

Long

Read Only Maximum time to complete the job 0-99999

JOBDATA_BATCH_

MODE

Word,

Short

Read Only Job batch mode/batch count type

0 = Only the OK tightenings are coun-

ted

1 = Both OK and NOK tightenings are

counted

0-1

JOBDATA_LOCK_ Boolean Read Only Lock at Job done True/False

www. ptc.com

27

Torque Tool Ethernet Driver

Item Data

Type

Access Description Data Range

ON_DONE True = Yes

False = No

JOBDATA_LINE_

CONTROL

Boolean Read Only Use line control

True = Yes

False = No

True/False

JOBDATA_REPEAT_

JOB

Boolean Read Only Repeat Job

True = Yes

False = No

True/False

JOBDATA_TOOL_

LOOSENING

Word,

Short

Read Only Tool loosening

0 = Enable

1 = Disable

2 = Enable only on NOK tightening

0-2

JOBDATA_TOOL_

RESERVED

Word,

Short

Read Only Reserved for Job repair 0-1

JOBDATA_

PARAMETER_

CHANNEL_ID

Word,

Short*

Read Only The parameter’s Channel ID 0-99

JOBDATA_

PARAMETER_TYPE_

ID

Word,

Short*

Read Only The parameter’s Type ID 0-999

JOBDATA_

PARAMETER_

AUTO_VALUE

Boolean* Read Only The parameter’s Auto Value True/False

JOBDATA_

PARAMETER_

BATCH_SIZE

Word,

Short*

Read Only The parameter’s batch size 0-99

JOBDATA_

PARAMETER_

COUNT

Word,

Short

Read Only The number of parameters in the job 0-99 (Rev 3)

JOBDATA_

PARAMETER_

SOCKET

Word,

Short*

Read Only The parameter’s socket number 0-99 (Rev 3)

JOBDATA_

PARAMETER_STEP_

NAME

String* Read Only The parameter’s step name 25 characters (Rev

3)

JOBDATA_

PARAMETER_STEP_

TYPE

Word,

Short*

Read Only The parameter’s step type 0-99 (Rev 3)

*This item requires an array index or bit index. The valid array / bit index range is 1 to 99.

www. ptc.com

28

Torque Tool Ethernet Driver

Command Set: Job Number Data

The Job Number Data command set is used to request generic job data on the controller. Some command

set items also have alias names. In the table below, the alias name will be listed beneath the item where

applicable. All items belonging to this command set use MID 30 (Job ID upload request) for requesting the

item data, which is replied to with MID 31 (Job ID upload reply). If the device supports 4-digit Job IDs, revi-

sion 2 or higher must be used.

Item Data

Type

Access Description Data Range

JOBN_COUNT

LINKN_COUNT

Word,

Short

Read

Only

Count of the number of valid jobs 0-99 (Rev 1)

0-9999 (Rev 2)

JOBN_ID

LINKN_ID

Word,

Short*

Read

Only

Valid job numbers (the number available

is specified by JOBN_COUNT)

0-99 (Rev 1)

0-9999 (Rev 2)

*This item requires an array index or bit index. The valid array / bit index range is 1 to 9999.

Command Set: Last Tightening Results

The Last Tightening Results command set is used to receive data for the last tightening. All items belonging

to this command set use MID 60 (Last tightening result data subscribe) for the subscription request. The

device sends the data through MID 61 (Last tightening result data), which is replied to by MID 62 (Last tight-

ening result acknowledge).

Item Data

Type

Access Description Data Range

LTR_CELL_ID Word,

Short

Read Only Cell ID 0-9999

LTR_CHAN_ID Word,

Short

Read Only Channel ID 0-99

LTR_TC_NAME String Read Only Torque controller name 25 characters

LTR_VIN String Read Only Vehicle ID number* 25 characters

LTR_JOB Word,

Short

Read Only Job number* 0-99 (Rev 1)

0-9999

(Rev 2+)

LTR_PSET Word,

Short

Read Only PSet number* 0-999

LTR_BATCH_SIZE Word,

Short

Read Only Batch size* 0-9999

LTR_BATCH_

COUNTER

Word,

Short

Read Only Batch counter* 0-9999

LTR_TIGHT_

STATUS

Word,

Short

Read Only Tightening status*

0 = NOK

1 = OK

0-1

LTR_TORQUE_

STATUS

Word,

Short

Read Only Torque status*

0 = Low

1 = OK

0-2

www. ptc.com

29

Torque Tool Ethernet Driver

Item Data

Type

Access Description Data Range

2 = High

LTR_ANGLE_

STATUS

Word,

Short

Read Only Angle status*

0 = Low

1 = OK

2 = High

0-2

LTR_TORQUE_MIN Float Read Only Torque minimum limit 0-9999.99

LTR_TORQUE_MAX Float Read Only Torque maximum limit 0-9999.99

LTR_TORQUE_

TARGET

Float Read Only Torque final target 0-9999.99

LTR_TORQUE_

VALUE

Float Read Only Torque value* 0-9999.99

LTR_ANGLE_MIN DWord Read Only Angle minimum value, in degrees 0-99999

LTR_ANGLE_MAX DWord Read Only Angle maximum value, in degrees 0-99999

LTR_ANGLE_

TARGET

DWord,

Long

Read Only Target angle value, in degrees 0-99999

LTR_ANGLE_VALUE DWord,

Long

Read Only Turning angle value, in degrees* 0-99999

LTR_TIMESTAMP String Read Only Timestamp* 19 characters

LTR_CHANGETIME String Read Only Last change in PSet settings* 19 characters

LTR_BATCH_

STATUS

Word,

Short

Read Only Batch status*

0 = NOK

1 = OK

2 = Batch not used

0-2

LTR_ID DWord,

Long

Read/Write** Tightening ID* 0-4294967295

LTR_STRATEGY Word,

Short

Read Only (Rev 2) Strategy

1 = Torque control

2 = Torque control / angle monitoring

3 = Torque control / angle control

AND

4 = Angle control / torque monitoring

5 = DS control

6 = DS control torque monitoring

7 = Reverse angle

8 = Reverse torque

9 = Click wrench

10 = Rotate spindle forward

11 = Torque control angle control OR

12 = Rotate spindle reverse

99 = No strategy

0-99

LTR_STRAT_OPT Boolean Read Only (Rev 2) Strategy options

This item requires a bit number (0-15)

0-1

www. ptc.com

30

Torque Tool Ethernet Driver

Item Data

Type

Access Description Data Range

Bit 0 = Torque

Bit 1 = Angle

Bit 2 = Batch

Bit 3 = PVT monitoring

Bit 4 = PVT compensate

Bit 5 = Selftap

Bit 6 = Rundown

Bit 7 = CM

Bit 8 = DS control

Bit 9 = Click wrench

Bit 10 = RBW monitoring

LTR_RDA_STATUS Word,

Short

Read Only (Rev 2) Rundown angle status

0 = NOK

1 = OK

2 = High

0-2

LTR_CMON_

STATUS

Word,

Short

Read Only (Rev 2) Current monitoring status

0 = NOK

1 = OK

2 = High

0-2

LTR_ST_STATUS Word,

Short

Read Only (Rev 2) Selftap status

0 = NOK

1 = OK

2 = High

0-2

LTR_PTM_STATUS Word,

Short

Read Only (Rev 2) Prevail torque monitoring

status

0 = NOK

1 = OK

2 = High

0-2

LTR_PTC_STATUS Word,

Short

Read Only (Rev 2) Prevail torque compensate

status

0 = NOK

1 = OK

2 = High

0-2

LTR_PVT Float Read Only (Rev 6) PVT compensation value 0-99999.99

LTR_TERR_STATUS Boolean Read Only (Rev 2) Tightening error status

This item requires a bit number (0-31)

Bit 0 = Rundown angle max shut off

Bit 1 = Rundown angle min shut off

Bit 2 = Torque max shut off

Bit 3 = Angle max shut off

Bit 4 = Selftap torque max. shut off

Bit 5 = Selftap torque min. shut off

Bit 6 = Prevail torque max. shut off

0-1

www. ptc.com

31

Torque Tool Ethernet Driver

Item Data

Type

Access Description Data Range

Bit 7 = Prevail torque min. shut off

Bit 8 = Prevail torque compensate

overflow

Bit 9 = Current monitoring max shut

off

Bit 10 = Post view torque min. torque

shut off

Bit 11 = Post view torque max. torque

shut off

Bit 12 = Post view torque angle too

small

Bit 13 = Trigger lost

Bit 14 = Torque less than target

Bit 15 = Tool hot

Bit 16 = Multistage cancel

Bit 17 = Rehit

Bit 18 = DS measure failed

Bit 19 = Current limit reached

Bit 20 = End time out shutoff

Bit 21 = Remove fastener limit

exceeded

Bit 22 = Disable drive

LTR_TERR_

STATUS_

COMBINED

DWord,

Long

Read Only (Rev 2) All tightening error status bits

are combined in one value. Refer to

LTR_TERR_STATUS to review the match

of each bit and the value.

0 to 4294967295

(DWord)

-2,147,483,648 to

2,147,483,647

(Long)

LTR_TERR_

STATUS2

Boolean Read Only (Rev 6) Tightening error status 2

This item requires a bit number (0-31)

Bit 0 = Drive deactivated

Bit 1 = Tool stall

Bit 2 = Drive hot

Bit 3 = Gradient monitoring high

Bit 4 = Gradient monitoring low

Bit 5 = Reaction bar failed

Bit 6 - 31 = Reserved

0-1

LTR_TERR_

STATUS2_

COMBINED

DWord,

Long

Read Only (Rev 6) All tightening error status 2

bits are combined in one value. Refer

to LTR_TERR_STATUS2 to review the

match of each bit and the value.

0 to 4294967295

(DWord)

-2,147,483,648 to

2,147,483,647

(Long)

LTR_RDA_MIN DWord,

Long

Read Only (Rev 2) Rundown angle minimum

value, in degrees

0-99999

LTR_RDA_MAX DWord,

Long

Read Only (Rev 2) Rundown angle maximum

value, in degrees

0-99999

www. ptc.com

32

Torque Tool Ethernet Driver

Item Data

Type

Access Description Data Range

LTR_RDA_VALUE DWord,

Long

Read Only (Rev 2) Rundown angle value

reached, in degrees

0-99999

LTR_CM_MIN Word,

Short

Read Only (Rev 2) Current monitoring minimum

limit

0-999

LTR_CM_MAX Word,

Short

Read Only (Rev 2) Current monitoring maximum

limit

0-999

LTR_CM_VALUE Word,

Short

Read Only (Rev 2) Current monitoring value in

percent

0-999

LTR_ST_MIN Float Read Only (Rev 2) Selftap minimum limit 0-9999.99

LTR_ST_MAX Float Read Only (Rev 2) Selftap maximum limit 0-9999.99

LTR_ST_TORQUE Float Read Only (Rev 2) Selftap torque. 0-9999.99

LTR_PTM_MIN Float Read Only (Rev 2) Prevail torque monitoring min-

imum limit

0-9999.99

LTR_PTM_MAX Float Read Only (Rev 2) Prevail torque monitoring

maximum limit

0-9999.99

LTR_PT Float Read Only (Rev 2) Prevail torque value 0-9999.99

LTR_JOB_SEQ_

NUM

Word,

Short

Read Only (Rev 2) Job sequence number 0-65535

LTR_STID Word,

Short

Read Only (Rev 2) Synch tightening ID 0-65535

LTR_SERIAL_NUM String Read Only (Rev 2) Tool serial number 14 characters

LTR_PSET_NAME String Read Only (Rev 3) Parameter set name 25 characters

LTR_UNITS Word,

Short

Read Only (Rev 3) Torque value units

1 = Nm

2 = Lbf.ft

3 = Lbf.In

4 = Kpm

1-4

LTR_RESULT_TYPE Word,

Short

Read Only (Rev 3) Result type

1 = Tightening

2 = Loosening

3 = Batch Increment

4 = Batch decrement

5 = Bypass Pset result

6 = Cancel job result

7 = Sync tightening

1-7

LTR_IDR2 String Read Only (Rev 4) Identifier result part 2 25 characters

LTR_IDR3 String Read Only (Rev 4) Identifier result part 3 25 characters

LTR_IDR4 String Read Only (Rev 4) Identifier result part 4 25 characters

LTR_CUSTOM_ERR String Read Only (Rev 5) Customer tightening error

code

4 characters

LTR_MULTISTAGE_

COUNT

Word Read Only (Rev 998) Number of run stages. For

each completed stage the final

torque and the final angle are repor-

0-99

www. ptc.com

33

Torque Tool Ethernet Driver

Item Data

Type

Access Description Data Range

ted.

LTR_MULTISTAGE_

ANGLE.N

Long*** Read Only (Rev 998) The turning angle stage

value in degrees. Each turn rep-

resents 360 degrees. ‘N’ is the stage

number in the tightening.

0-99999

LTR_MULTISTAGE_

TORQUE.N

Float*** Read Only (Rev 998) The stage torque value. ‘N’

is the stage number in the tightening.

0.0-999999.0

LTR_NEWDATA Boolean Read/Write New data flag. Set to 1 when new

data arrives. Write a 0 to this flag to

clear.

0-1

*These items are available in the low-bandwidth (revision 999) message.

**Writing any value to the Tightening ID will set the value in the driver to 0. This will not have any effect on

the hardware.

***These items require an array index or bit index. The valid array / bit index range is 1 to 99.

See Also: Appendix - LTR Revision 998 Tag Behavior for more information.

Note: Any commands that require special revisions (such as 2, 3, and so forth) are not supported by the

FEP Protocol model.

Command Set: Multi-Spindle Results

The Multiple Spindle Results command set can be used to receive data that includes tightening results for

tools that have multiple spindles. All items belonging to this command set use MID 100 (Multi-spindle result

subscribe) for the subscription request. The device sends the data through MID 101 (Multi-spindle result),

which is replied to by MID 102 (Multi-spindle result data acknowledge).

Item Data

Type

Access Description Data Range

MS_NUMBER

Word,

Short

Read Only Number of running spindles 2-10

MS_VIN String Read Only Vehicle ID number 25 characters

MS_JOBNUM Word,

Short

Read Only Job number (Link Group) 0-99

MS_PSET Word,

Short

Read Only Parameter set (App) 0-999

MS_BSIZE* Word,

Short

Read Only Batch size 0-9999

MS_BCOUNT* Word,

Short

Read Only Batch counter 0-9999

MS_BSTATUS*

Word,

Short

Read Only

Batch status

0 = NOK

1 = OK

www. ptc.com

34

Torque Tool Ethernet Driver

Item Data

Type

Access Description Data Range

2 = Batch not used

MS_TMIN Float Read Only Torque minimum limit 0-9999.99

MS_TMAX Float Read Only Torque maximum limit 0-9999.99

MS_TTARG Float Read Only Torque final target 0-9999.99

MS_AMIN

DWord,

Long

Read Only Angle minimum limit 0-99999

MS_AMAX

DWord,

Long

Read Only Angle maximum limit 0-99999

MS_ATARG

DWord,

Long

Read Only Angle final target 0-99999

MS_CHANGETIME String Read Only Last change in setting 19 characters

MS_TIME String Read Only Time stamp 19 characters

MS_SYNCID

DWord,

Long

Read Only Sync tightening ID 0-99999

MS_SYNCSTAT

Word,

Short

Read Only

Overall tightening status

0 = NOK

1 = OK

0-1

SPD_NUM**

Word,

Short

Read Only Spindle number 1-10

SPD_CHAN**

Word,

Short

Read Only Channel ID 1-20

SPD_STATUS**

Word,

Short

Read Only

Overall spindle status

0 = NOK

1 = OK

0-1

SPD_TSTATUS**

Word,

Short

Read Only

Individual torque status

0 = NOK

1 = OK

0-1

SPD_TORQUE** Float Read Only Individual torque 0-9999.99

SPD_ASTATUS**

Word,

Short

Read Only

Individual angle status

0 = NOK

1 = OK

0-1

SPD_ANGLE**

DWord,

Long

Read Only Individual angle 0-99999

MS_NEWDATA Boolean Read/Write

New data flag. Set to 1 when new data

arrives. Write a 0 to this flag to clear it.

0-1

*Although this was not supported by the Open protocol, the Torque Tool Ethernet Driver supports this fea-

ture. This feature is supported by prefixing the Address Item with the Spindle number delimited by a ':' (e.g.

01:VIN_VIN). For the Open protocol, the spindle data is ignored.

**This item requires an array index. The maximum array index is given by MS_Number.

www. ptc.com

35

Torque Tool Ethernet Driver

Command Set: Old Tightening Results

The Old Tightening Results command set is used to retrieve data for an old tightening result. To retrieve the

data for a tightening result, write the Tightening ID to the OTR_ID field. All items belonging to this command

set use MID 64 (Old tightening result upload request) for requesting the item data, which is replied to with

MID 65 (Old tightening result upload reply).

Item Data Type Access Description Data Range

OTR_ID DWord,

Long

Read /

Write

Tightening ID. Write the Tightening ID

to this item to retrieve data for that

tightening. Writing 0 will retrieve the

last tightening results.

0-4294967295

OTR_VIN String Read

Only

Vehicle ID number 25 characters

OTR_PSET Word, Short Read

Only

PSet number 0-999

OTR_BCOUNT Word, Short Read

Only

Batch counter 0-9999

OTR_TIGHTSTAT Word, Short Read

Only

Tightening status

0 = NOK

1 = OK

0-1

OTR_TORQSTAT Word, Short Read

Only

Torque Status

0 = Low

1 = OK

2 = High

0-2

OTR_ANGSTAT Word, Short Read

Only

Angle Status

0 = Low

1 = OK

2 = High

0-2

OTR_TORQUE Float Read

Only

Torque value 0-9999.99

OTR_ANGLE DWord,

Long

Read

Only

Turning angle value in degrees 0-99999

OTR_TIME String Read

Only

Timestamp 19 characters

OTR_BATSTAT Word, Short Read

Only

Batch status

0 = NOK

1 = OK

2 = Batch not used

0-2

OTR_JOBNUM Word, Short Read

Only

(Rev 2) Job number 0-9999

OTR_STRATEGY Word, Short Read

Only

(Rev 2) Strategy

1 = Torque control

2 = Torque control / angle monitoring

3 = Torque control / angle control AND

4 = Angle control / torque monitoring

-99

www. ptc.com

36

Torque Tool Ethernet Driver

Item Data Type Access Description Data Range

5 = DS control

6 = DS control torque monitoring

7 = Reverse angle

8 = Reverse torque

9 = Click wrench

10 = Rotate spindle forward

11 = Torque control angle control OR

12 = Rotate spindle reverse

99 = No strategy

OTR_STROPT Boolean Read

Only

(Rev 2) Strategy options

This item requires a bit number (0-15)

Bit 0 = Torque

Bit 1 = Angle

Bit 2 = Batch

Bit 3 = PVT Monitoring

Bit 4 = PVT Compensate

Bit 5 = Selftap

Bit 6 = Rundown

Bit 7 = CM

Bit 8 = DS Control

Bit 9 = Click Wrench

Bit 10 = RBW Monitoring

-1

OTR_BSIZE Word, Short Read

Only

(Rev 2) Batch size 0-9999

OTR_RASTAT Word, Short Read

Only

(Rev 2) Rundown angle status

0 = NOK

1 = OK

2 = High

0-2

OTR_CMSTAT Word, Short Read

Only

(Rev 2) Current monitoring status

0 = NOK

1 = OK

2 = High

-2

OTR_STSTAT Word, Short Read

Only

(Rev 2) Selftap status

0 = NOK

1 = OK

2 = High

0-2

OTR_PTMSTAT Word, Short Read

Only

(Rev 2) Prevail torque monitoring

status

0 = NOK

1 = OK

2 = High

0-2

OTR_PTCSTAT Word, Short Read

Only

(Rev 2) Prevail torque compensate

status

0 = NOK

1 = OK

2 = High

0-2

www. ptc.com

37

Torque Tool Ethernet Driver

Item Data Type Access Description Data Range

OTR_TERRSTAT Boolean Read

Only

(Rev 2) Tightening error status

This item requires a bit number (0-31):

Bit 0 = Rundown angle max shut off

Bit 1 = Rundown angle min shut off

Bit 2 = Torque max shut off

Bit 3 = Angle max shut off

Bit 4 = Selftap torque max shut off

Bit 5 = Selftap torque min shut off

Bit 6 = Prevail torque max shut off

Bit 7 = Prevail torque min shut off

Bit 8 = Prevail torque compensate

overflow

Bit 9 = Current monitoring max shut

off

Bit 10 = Post view torque min torque

shut off

Bit 11 = Post view torque max torque

shut off

Bit 12 = Post view torque Angle too

small

Bit 13 = Trigger Lost

Bit 14 = Torque Less Than Target

Bit 15 = Tool Hot

Bit 16 = Multistage Cancel

Bit 17 = Rehit

Bit 18 = DS Measure Failed

Bit 19 = Current Limit Reached

Bit 20 = EndTime out Shutoff

Bit 21 = Remove fastener limit

exceeded

Bit 22 = Disable drive

-1

OTR_TERRSTAT_

COMBINED

DWord,