THE ULTIMATE GUIDE

TO WORKING WITH

KING STARBOARD

TABLE OF

CONTENTS

04

What is King StarBoard

11 Cutting King StarBoard

17 Sanding & Routing

22 King StarBoard Assembly

26 Tech Specs of King StarBoard

26 Contact Us

3

WHAT IS

KING STARBOARD?

4

WHAT IS

KING STARBOARD?

King StarBoard, developed specically for the marine

environment, is a high-density polyethylene (plastic)

material, perfect for fabricating boat parts and

accessories.

It has been environmentally stabilized to withstand

the harshest marine conditions. This means that

StarBoard does not rot, swell, splinter or split when

exposed to humidity or water. It is resistant to

saltwater, UV rays, chemicals, and corrosion.

Works like wood, lasts a lifetime! StarBoard is easy to

cut and assemble with standard woodworking tools,

and requires little or no nishing.

StarBoard is easy to clean and never needs renishing.

Since its introduction, it has been the preferred boat

building material for marine parts previously made

from teak wood.

4

5

PHYSICAL

CHARACTERISTICS

StarBoard Sheet Sizes

StarBoard is fabricated by being extruded and cut into sheets

measuring 54” x 96” with the exception of sheets 1 ½” thick

measuring 48” x 96”. The edges of the material are smooth

and both the top and bottom surfaces have a durable-matte

texture.

StarBoard Sheet Thickness & Weight Chart

*Custom thickness available upon request (minimum purchase required)

Thickness (in inches)

¼” ⅜” ½” ¾” 1” 1 ½”

Weight (per sq foot) 1.25 lbs 1.875 lbs 2.5 lbs 3.75 lbs 5 lbs 7.5 lbs

6

PHYSICAL

CHARACTERISTICS

Expansion & Contraction

King StarBoard expands when it gets hot and contracts when it gets cold.

z The rate at which it expands and contracts is 1/32” per linear foot -→ for a 40º temperature change

Example: A piece of StarBoard measuring 48” long cut in a 60º→ warehouse will expand to

48.125” in 100→º weather.

While it is important to know that StarBoard does react to temperature changes, for the majority of

applications this is not a major concern.

Additional consideration should be given when:

Example: If you were installing a large door inside of a metal frame, it would be important to

allow that door enough space to expand and contract inside the frame in accordance with

temperature change.

z Working on a large product

z Installing a project that ts tightly in a conned space (i.e. a countertop between two walls)

z Cutting/installing a project in a temperature considerably lower than where it will typically

be used

z In an environment with drastic temperature changes

7

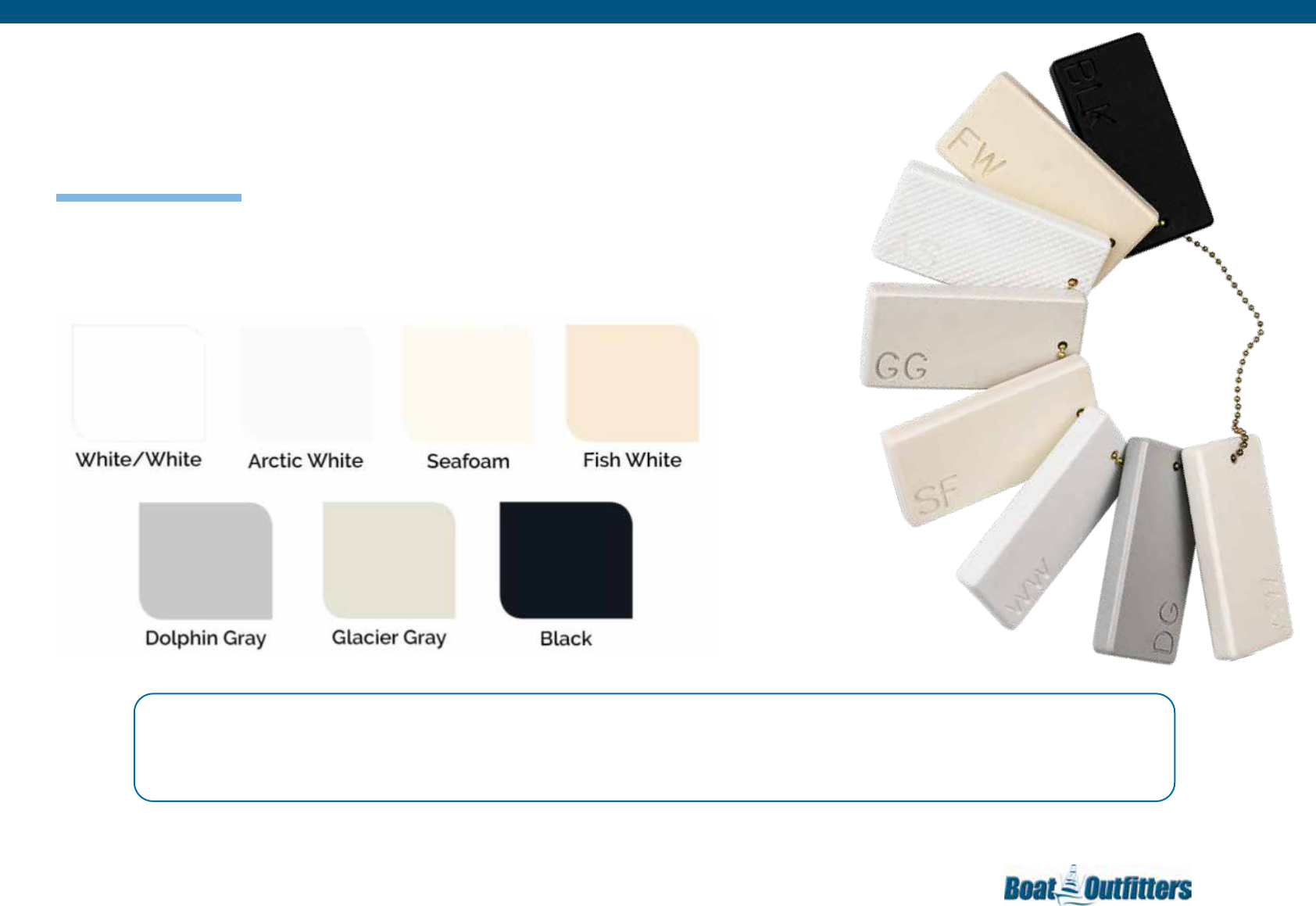

COMMON

COLORS

Available in seven standard colors to match or accent the most common

gelcoat colors. (shown below)

Important Note: Color accuracy can vary considerably on computer monitors and printers. Use the above

images as a general guide of relative color dierences. When color match is absolutely critical, please consider

purchasing a sample chain.

Note: Other colors may be available upon request

8

z Cup Holders

z Steps and Dock Boxes

z Tool holders

z Frames and Trim

z Swim Platforms

z Repurposing old plastic or teak parts

COMMON MARINE

APPLICATIONS

StarBoard is excellent for almost any application where it can be properly

supported. It is not load-bearing and may bend under its own weight

without a stiener.

Applications:

z Countertops

z Cutting Boards

z Tables

z Storage Units/Cabinets

z Grab Rails and Handles

z Hatches and Doors

9

OTHER COMMON

APPLICATIONS

z Bathroom Stalls/ Partitions

z Signage

z Lockers

z Shelving

z Wall Panels

z Decorative Ceiling Panels

z Outdoor Furniture

z Concession Stands

z Healthcare Case Goods

z Indoor and Outdoor Cabinets

z Kick Plates

z Outdoor Kitchens

z Playgrounds

z Tabletops and Counters

The applications with King StarBoard are ENDLESS!

10

CUTTING

KING STARBOARD

11

CUTTING

KING STARBOARD

Use standard woodworking tools to cut! StarBoard cuts faster and more easily than plywood or teak because

it shears instead of tearing and shredding.

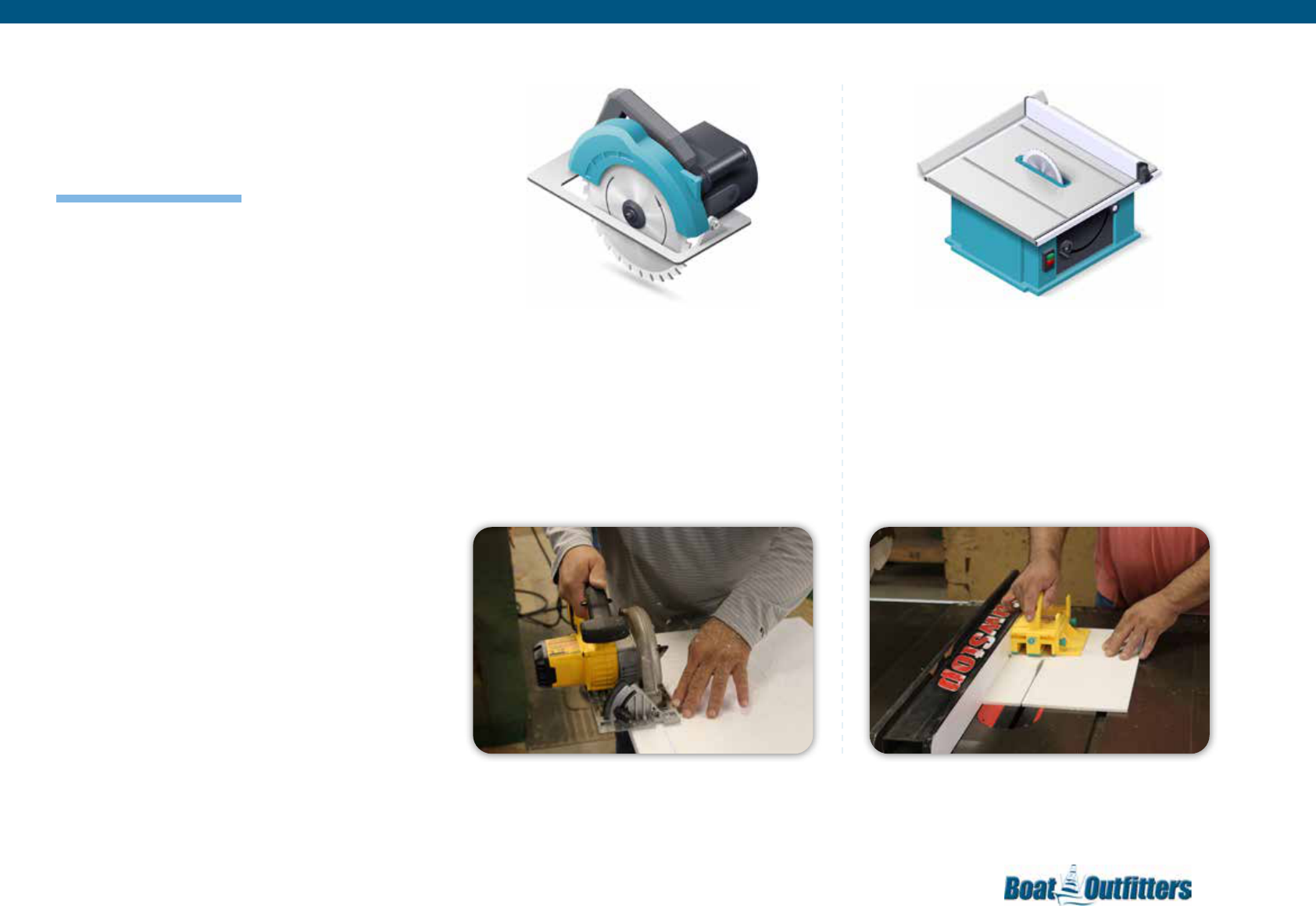

Long Straight Cuts

Circular Saw

Use a sharp carbide blade with a

high tooth count (min: 60-teeth for

10”, 40-teeth for 7.5”)

Less work up front, more nishing/sanding work to clean up the edge

Use a multi-purpose blade

with a high tooth count

(min: 24 TPI)

Table Saw Jig Saw Band Saw

Small Detail Cuts

More work up front creating template,

less work on backend as the router will

provide the cleanest cut

Template Cutting

Use a carbide ush

trimming router bit with a

top bearing

Hand Router

12

CUTTING STARBOARD

BEST PRACTICES

Properly Support The Material

King StarBoard will bend if not properly supported, especially in a hot

environment. We recommend a support at least every 12” for ½” material.

Never store the material leaning against a wall as it could bend/bow.

Use Water Based Markers or Pens (Never Pencils)

Pencil marks can permanently stain the StarBoard while marker/pen

marks can typically be removed with simple household cleaners.

Don’t Go Too Slow

Aim for a feed rate of 12-16 feet per minute for ½” material (slightly slower

for thicker material). If you go too slow you risk the blade overheating

causing the material to melt back on itself.

Consider Having it Custom Cut

If you are at all concerned about your ability to manufacture, please

keep in mind that at Boat Outtters we custom cut to any size and shape

required. Give us a call at 866.633.7961 for a quote!

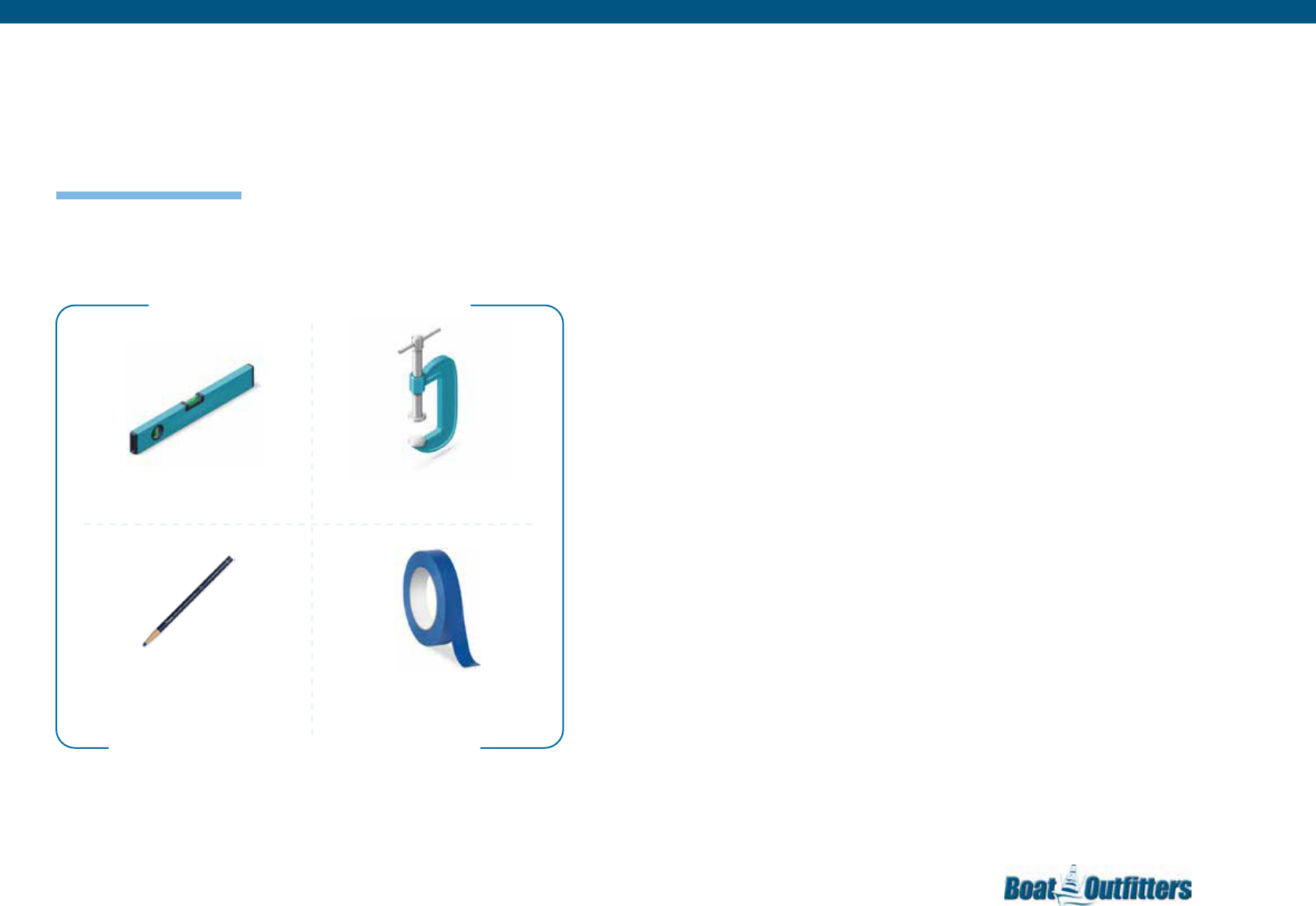

Supplementary Tools

Straightedge

Clamps

China or Water Based

Marker

Painters Tape

13

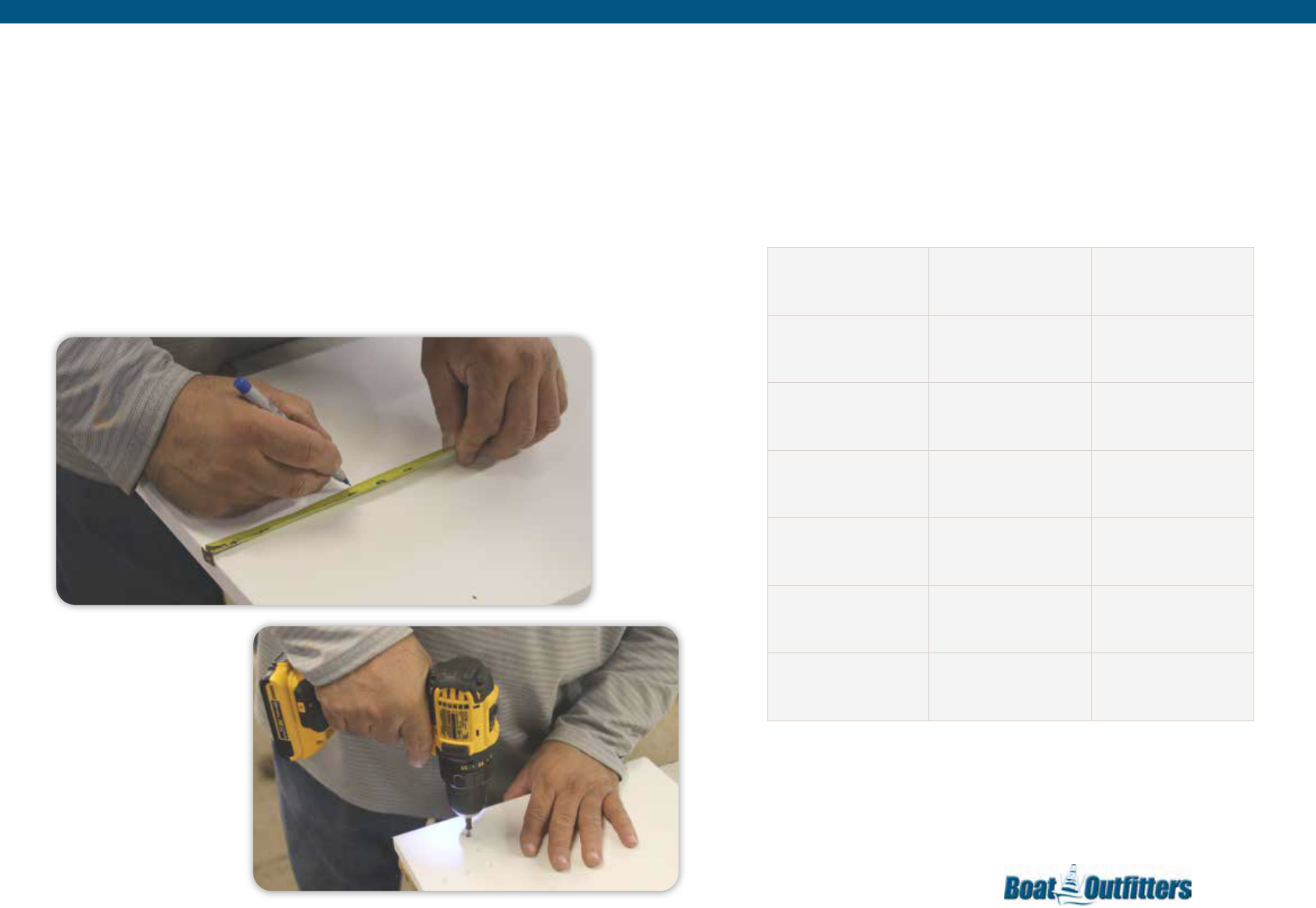

LONG

STRAIGHT CUTS

HOW TO:

z Measure your area accurately prior

to cutting “measure twice, cut once”

z Use a straightedge to draw your

cut line across the material to help

maintain a straight, square cut

z Support the material so it does not

ex when cutting to achieve an

accurate cut

z Blade depth adjustments can be

made to achieve a through cut or

for simply adding a groove in the

material

z Leave extra material when cutting if

a nished edge is required to allow

for routing or sanding

Circular Saw

Table Saw

PROS: Added portability due to

not being permanently axed

CONS: More dicult to achieve

consistent cuts

PROS: Added stability allows for

more consistent cuts, faster

CONS: Less portability

14

SMALL

DETAILED CUTS

HOW TO:

z Ensure all blades are sharp to avoid

a reduced feed rate which can

cause melting of the material

z To avoid veering of your line or

breaking your saw blade, add relief

cuts to allow for easier transitions

z Protect the surface of the material

from the table base and guides

to avoid marring of the material

(masking tape can be used)

z Use clamps to avoid shifting of the

material while cutting

z Drill or cut access holes as a starting

point to enter the material when

necessary

z Usage of a jig or fence is

recommended for consistency of

cuts where possible

Jig Saw Band Saw

PROS: Added portability due to

not being permanently axed,

and able to make internal cuts to

surface

CONS: More dicult to achieve

consistent cuts

PROS: Added stability allows for

more consistent cuts

CONS: Less portability, not able to

make internal cuts

A jigsaw or bandsaw work best when cutting irregular shapes

15

HOW TO:

z Create an exact replica template of the part (cut, trim, sand to t)

z Once conrmed, clamp the template to oversized StarBoard and trim

around template using a ½” shank double uted ush trim router bit

z Top or bottom bearing bits acceptable

z Ensure your cut depth extends ¼” below the StarBoard for a clean

consistent cut

Hand Router

Flush Trim Router Bit

PROS: Cleanest Finished Edge

CONS: More upfront work due to

building a template

TEMPLATE

CUTTING

16

SANDING

& ROUTING

17

SANDING & EDGE FINISHING FOR

KING STARBOARD

Sanding or routing the edges of StarBoard is not always needed as a clean cut will produce a clean edge.

However, if you need to smooth out a jagged cut or desire a certain edge, these standard woodworking tools

can help you achieve that.

SANDING

ROUTING

Orbital Sander/Sandpaper Wheel

Hand Router

Use 100-150 grit sandpaper wheel or orbital sander

Hand-sanding the edge is also an option

Use a carbide roundover router bit with bottom bearing

Regardless on style of sanding, be sure to use very ne

sandpaper to avoid creating small, hard-to-clean scratches

Bit size will be determined on thickness of material and

desired edge nish

18

SANDING

STARBOARD

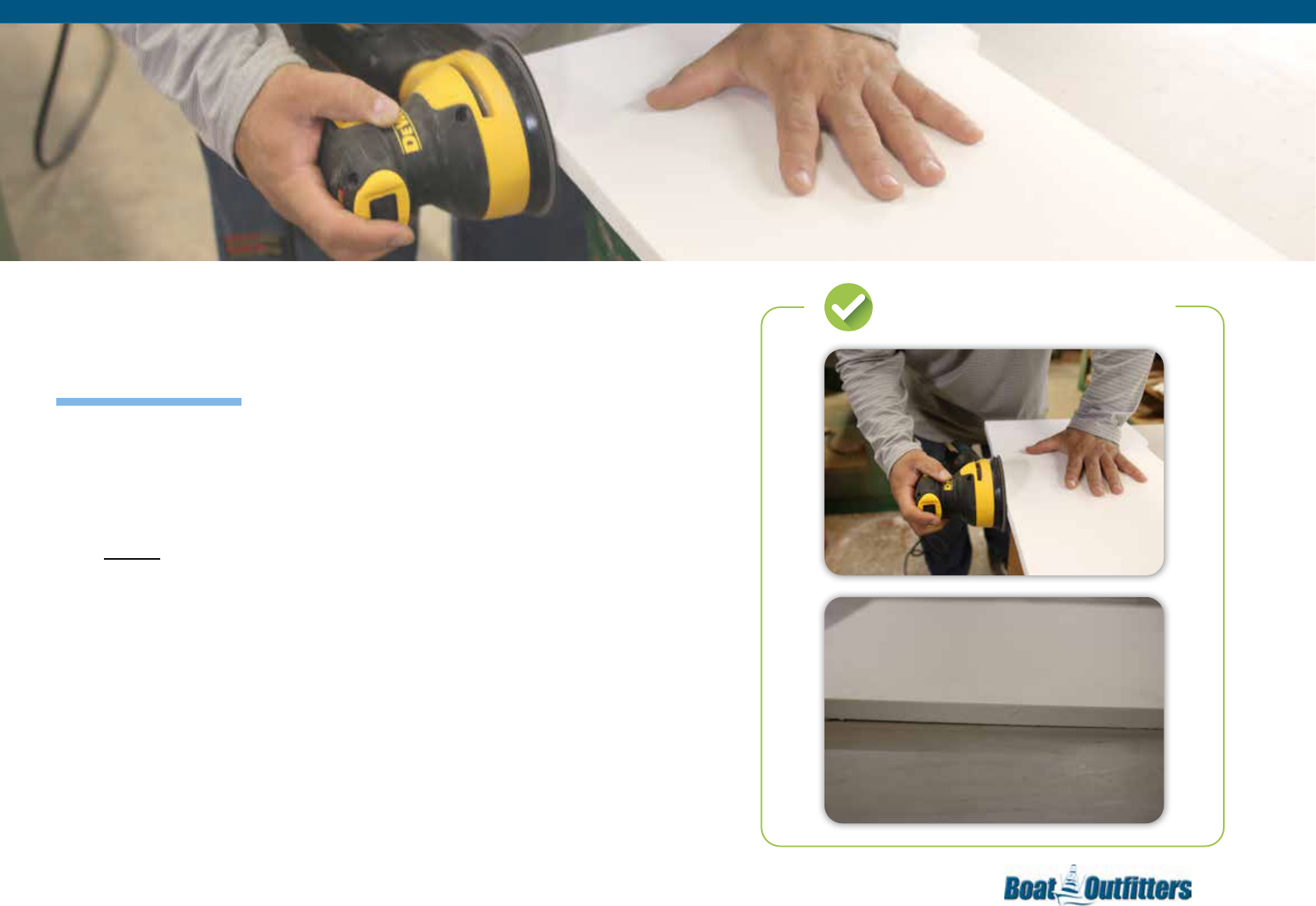

Sanding the Edges

(Cleaning Up a Rough Cut)

The edge of StarBoard can be sanded with an orbital sander

or hand sander to help smooth out a jagged edge.

KEEP IN MIND:

z Sanding can produce small grooves and stroke marks (smaller grit helps

limit these)

z It is recommended that if you choose to sand the edge that you then sand

all the edges to give your project a uniform look

SANDING THE EDGE:

19

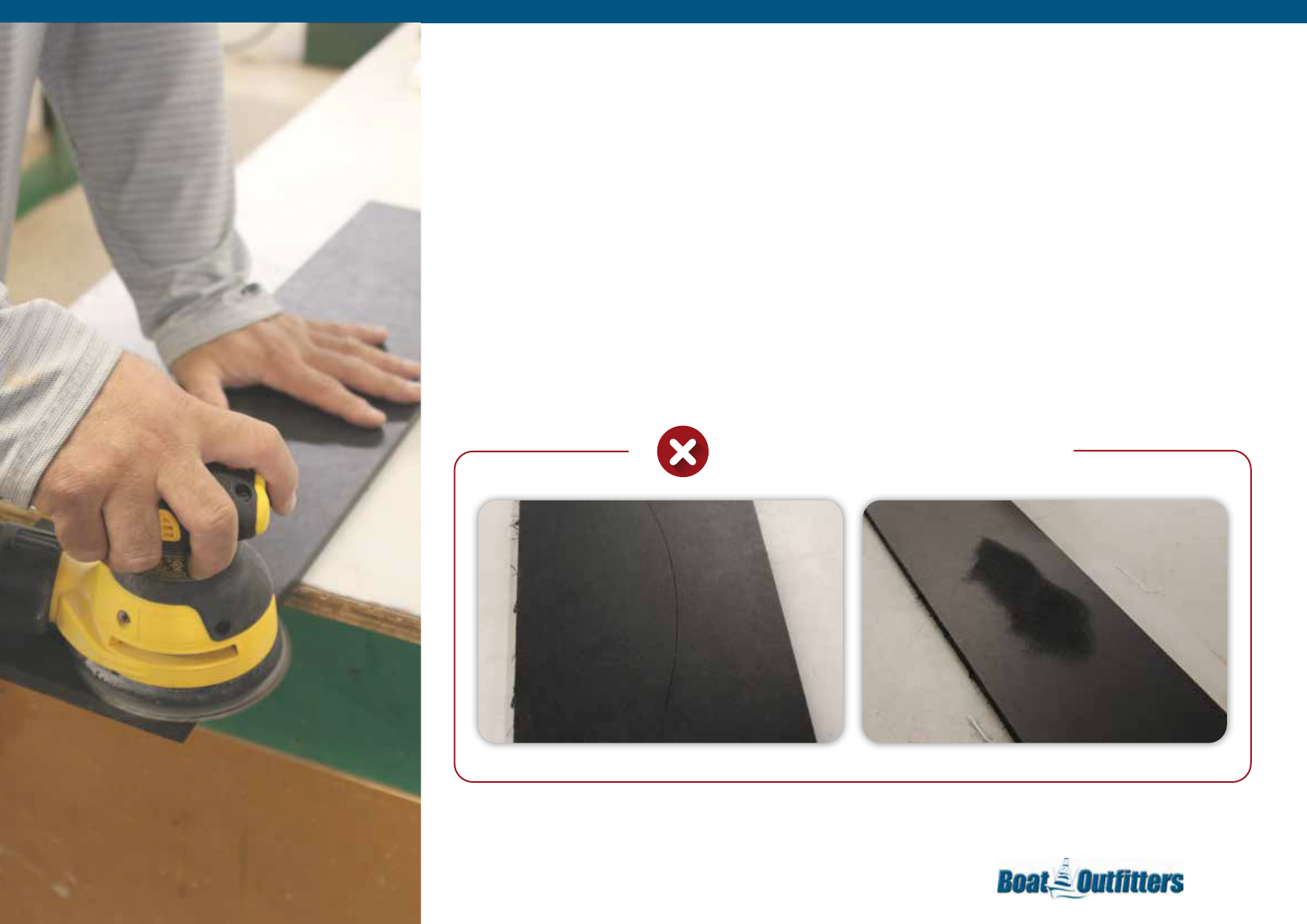

Sanding the Surface

(Removing a Scratch)

We DO NOT recommend sanding the surface of StarBoard!

KEEP IN MIND:

z Surface of StarBoard comes with a uniform matte nish on both sides

z Sanding anywhere on the surface of StarBoard will cause it to lose its uniform matte nish

z Result: Sanding the surface will result in a non-uniform textured surface and marring of

the nish

SANDING THE SURFACE:

20

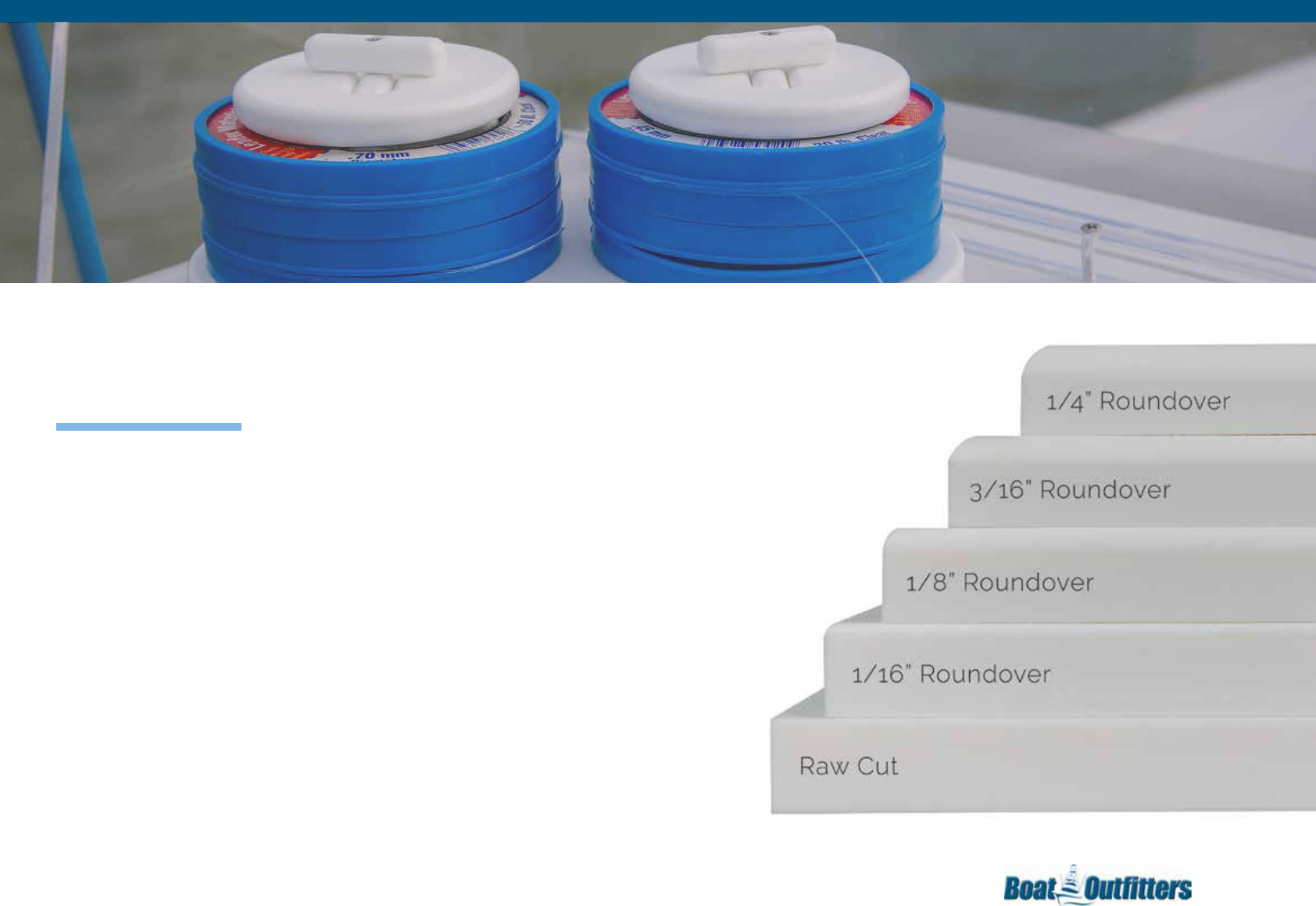

EDGE ROUNDOVERS ON

STARBOARD

Finishing the edges of StarBoard with a router is easy

and can be achieved by using a standard roundover bit.

KEEP IN MIND:

z To leave a nice clean edge, StarBoard material needs to be thicker

than your router bit. This allows the bearing to have good contact

with the StarBoard when routing.

} For example: routing ¼” sheet of StarBoard would

require a 3/16” or smaller router bit

z A carbide roundover bit is recommended

} Bit size is determined upon sheet thickness and desired

edge

21

KING STARBOARD

ASSEMBLY

22

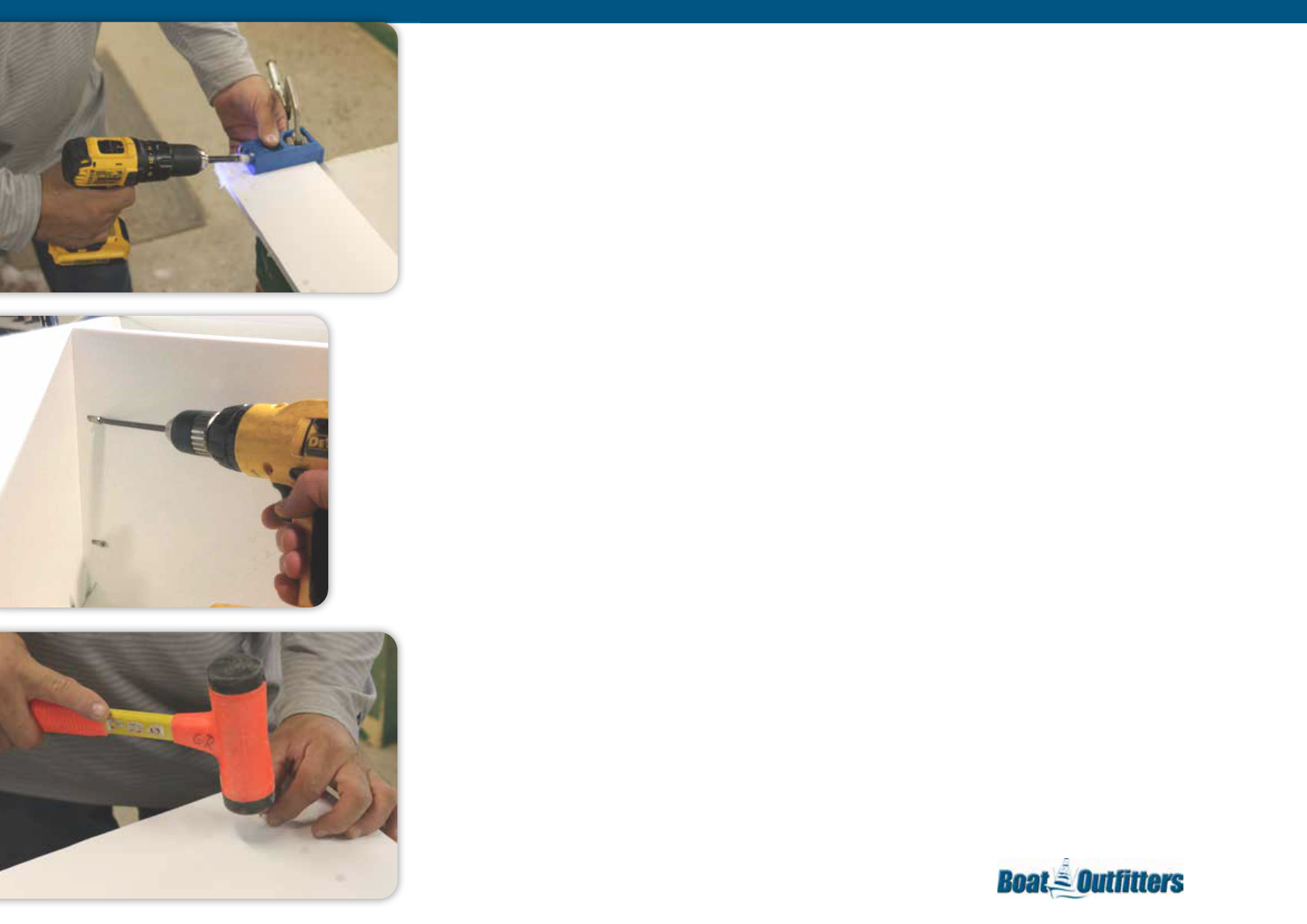

KING STARBOARD

ASSEMBLY

King StarBoard is easy to assemble using standard woodworking tools. You should use mechanical fasteners

(screws, bolts, or threaded inserts) to secure it together.

KEEP IN MIND:

Gluing King StarBoard is NOT recommended!

REQUIRED TOOLS

SUPPLEMENTARY TOOLS

Hand Drill and Bits

Pocket Hole Jig

Threaded Inserts

Rubber Mallet

Starboard Plugs

23

z Use a water based marker/pen to mark StarBoard

} Pencil marks do not wipe o and can gouge material

z Always drill pilot holes for better screw retention

z When screwing into the edge (i.e. “end grain”), your material must be

at least ⅜” thick

Screw Size Pilot Hole Thru Hole

#4 5/64” 1/8”

#6 7/64” 5/32”

#8 1/8” 3/16”

#10 1/8” 7/32”

#12 9/64” 15/64”

#14 5/32” 17/64”

Basic StarBoard Assembly Tips

Pilot Hole to Screw Size Chart

24

Advanced StarBoard Assembly Techniques

HIDING FASTENERS:

z Pocket hole jigs angle screws and help to hide them from view

z You can hide counter-bored screws by hammering StarBoard plugs into the holes

using a rubber mallet

WELDING:

z You can weld King StarBoard using a plastic hot air welder. Welding StarBoard fuses

together two surfaces and creates a waterproof seam

} Welding StarBoard can be challenging insomuch that you are unable to

sand down the welds (like welding metal) to create a smooth nished seam

SCREW RETENTION:

z Threaded inserts can be used to ensure screw retention and avoid stripping material

in locations where a fastener may be frequently added and removed

ADDITIONAL ASSEMBLY:

z Dado or Rabbet cuts can be added at joints for additional strength and ease of

assembly/alignment

z A hand router with a Dado or Rabbet bit can be used to cut a notch before attaching

pieces together

25

SAFETY MEASURES

BEST PRACTICES

Wear Safety Equipment

It is important that the proper safety equipment is worn when using tools

to cut and assemble King StarBoard.

Making sure you wear the proper safety equipment and checking that

your safety equipment is undamaged signicantly lowers your likelihood

of getting injured.

No one wants to get hurt, so by checking that you have the proper

equipment to protect you, you can better keep yourself safe!

Refer To Manufacturer’s Instructions

Please refer to the manufacturer’s instructions/safety manual for each

piece of equipment to review all the safety precautions for each tool.

The manufacturer’s instructions provide you with the knowledge on how

to properly protect yourself from injury with these tools.

Supplementary Tools

Safety Glasses

Ear Protection

Dust Mask

26

Properties Units

ASTM

Nominal Values

Density g/cc D1505 0.955

Tensile Strength @ Yeild psi D638 >4,100

Tensile Modulus psi D638 255,000

Elongation @ Break % D638 >600

Elongation @ Yield % D638 9.8

Flexural Modulus psi D790 185,000

Flexural Stress @ 5% Strain psi D790 3,810

Compressive Properties 10% Strain psi D695 4,950

Durometer Shore D D2240 68

Tensile Impact ft.lbs./in.² D1822 115

Izod Impact Resistance ft.lbs/in.² D256 1.1

Brittleness Temp. ºC (ºF) D746 <-76ºC (<-105ºF)

Vicat Softening Temp ºC (ºF) D1525 123ºC (253ºF)

Heat Deection Temp. 66 psi ºC (ºF) D648 75ºC (167ºF)

Screw and Nail Withdrawal lbs D1761 657 & 63

Flammability Rating UL94 HB

KING STARBOARD

PHYSICAL PROPERTIES SPEC SHEET

FOR MORE INFORMATION OR

ADDITIONAL QUESTION

CONTACT US