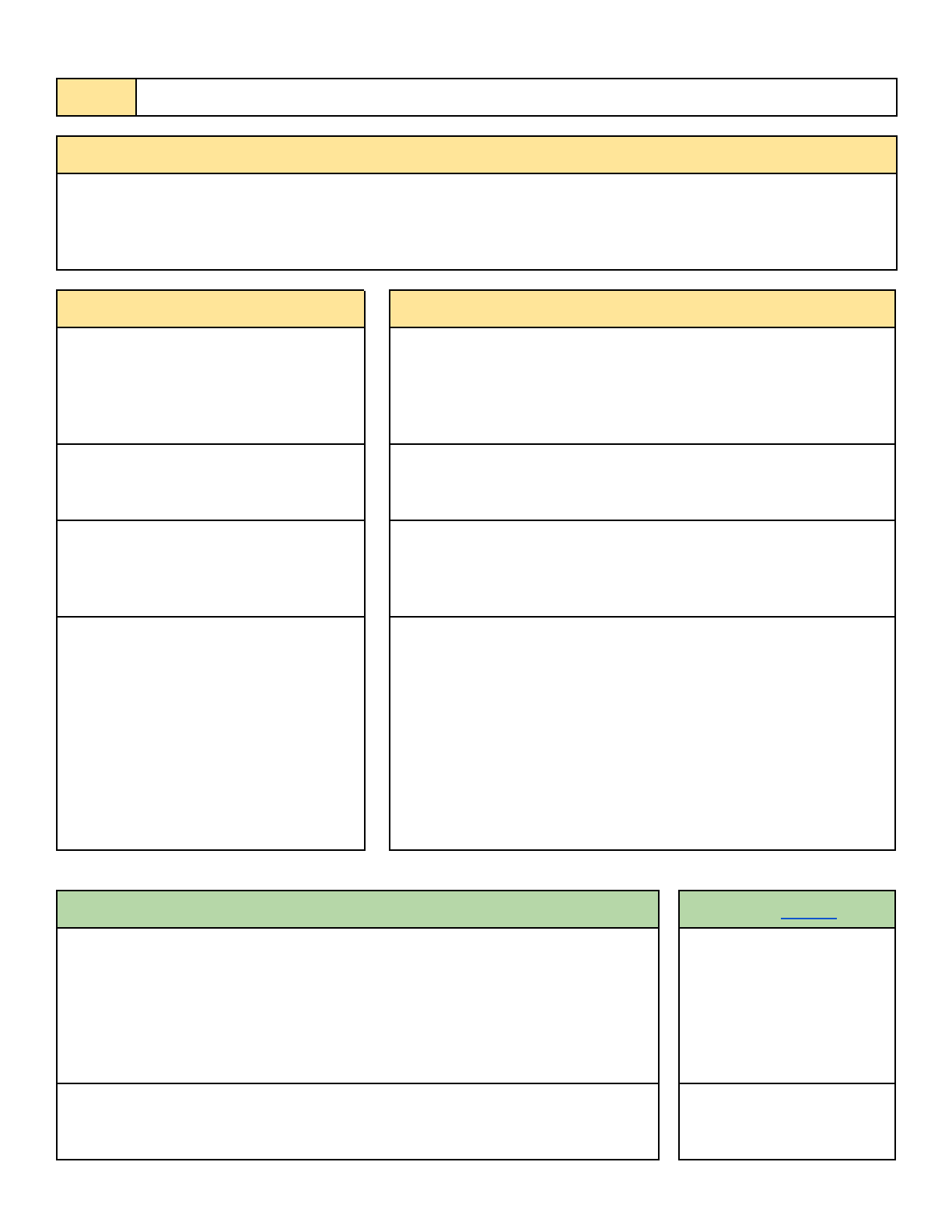

Black Horse Pike Regional School District

580 Erial Road, Blackwood, NJ 08012

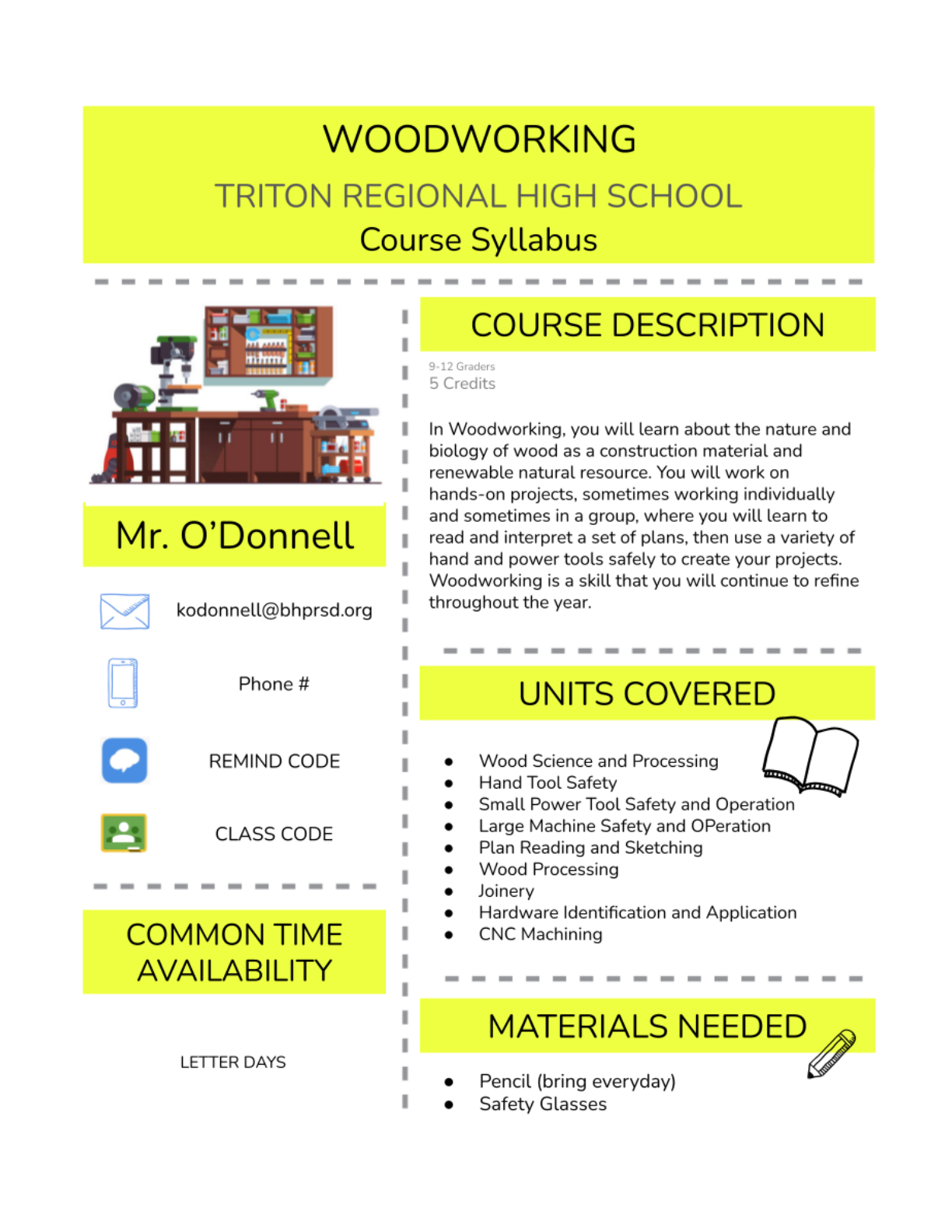

Woodworking

COURSE OF STUDY

Technology Education Department

Written By:

Dustin Keyser

Kyle O'Donnell

Date:

Fall 2023

Supervisor:

Steve Arena

Approved by:

Marcie Geyer, Director of Curriculum & Instruction

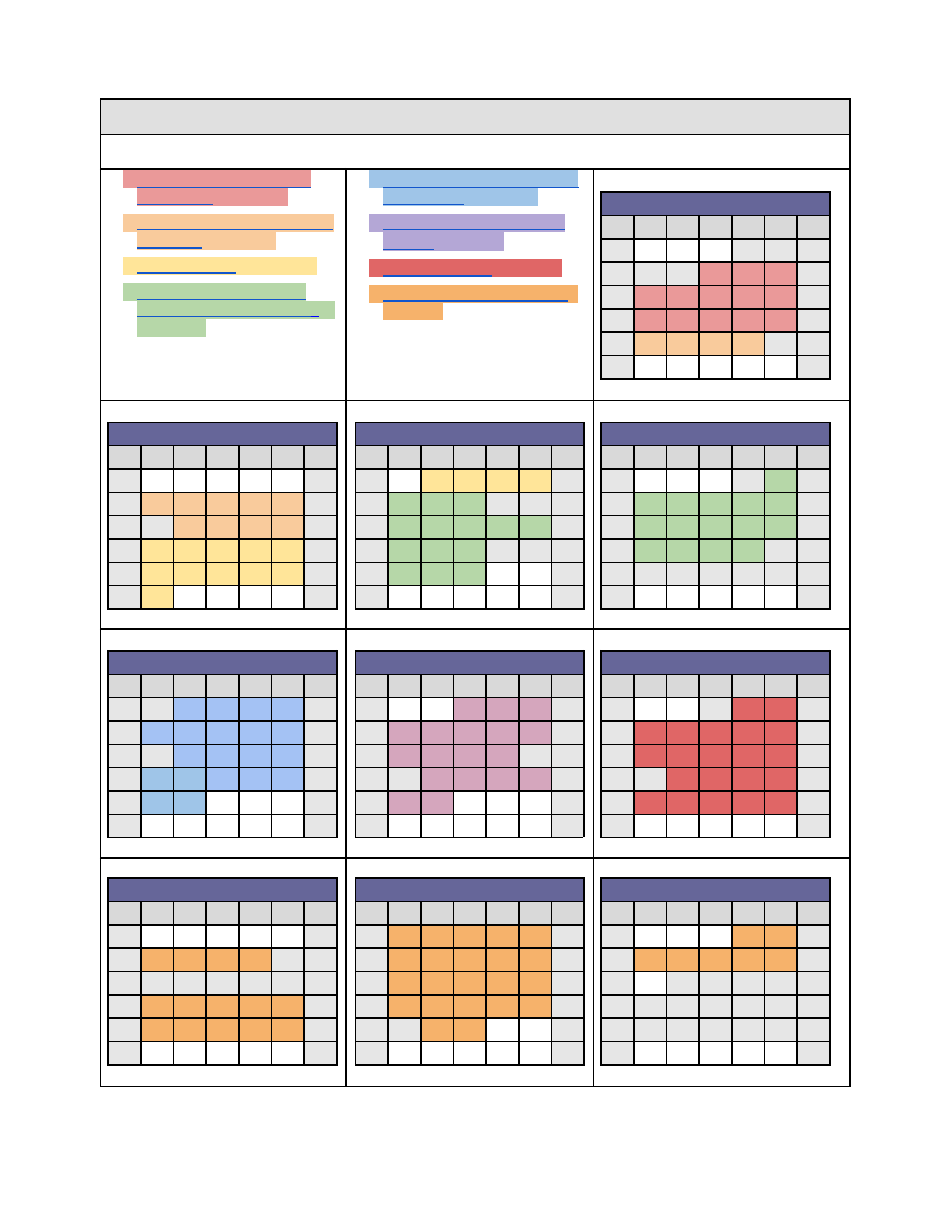

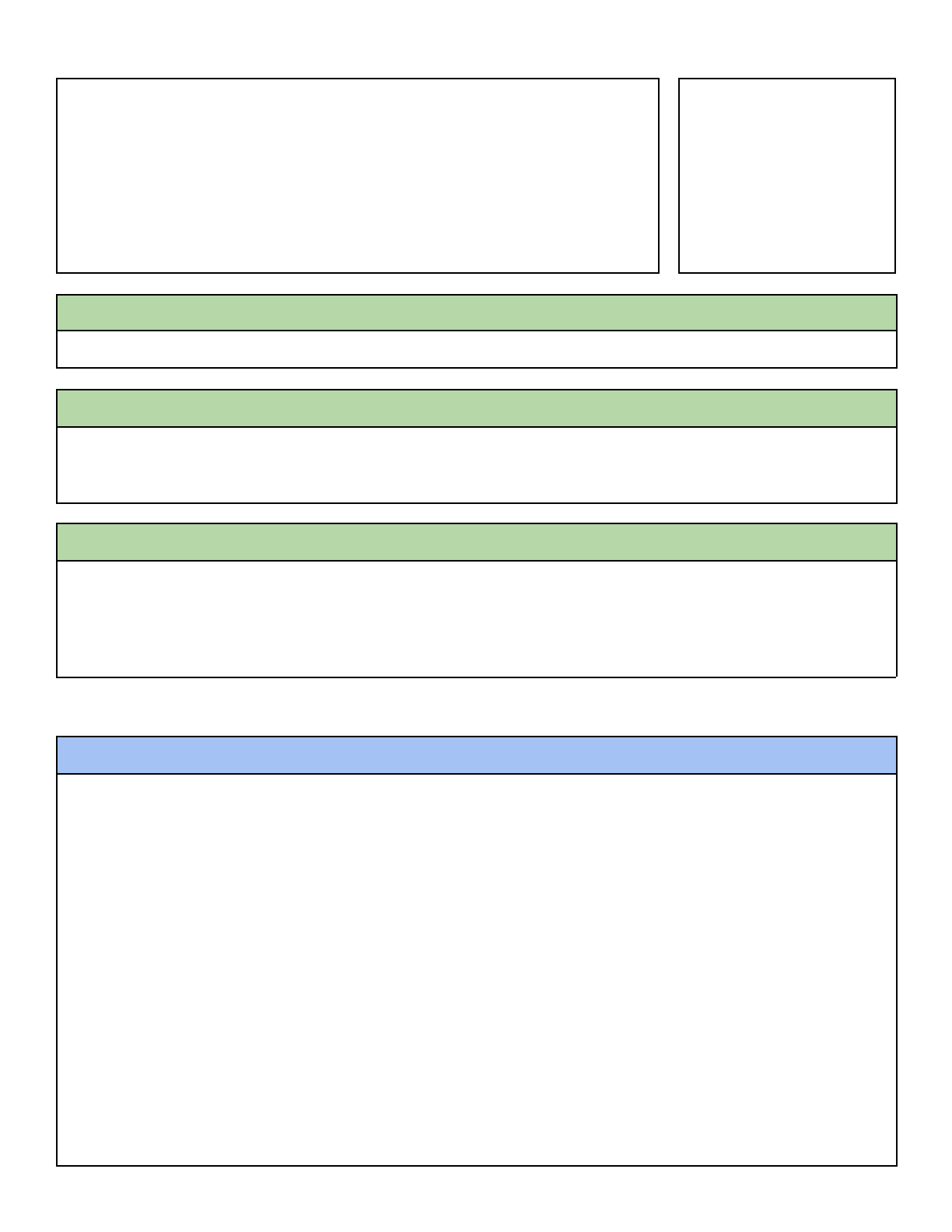

Woodworking

School Calendar

1.Wood Science and Wood

Processing - 3 Weeks

2.Hand and Power Tool Safety

and Uses - 3 Weeks

3.Machine Safety - 3 Weeks

4.Reading and Fabricating

Wood to Woodworking Plans

- 4 Weeks

5.Basic Joinery with a Multiple

Part Project - 7 Weeks

6.Hardwoods and Advanced

Joinery- 4 Weeks

7.CNC Machining - 3 weeks

8.The Woodworking Process -

5 Weeks

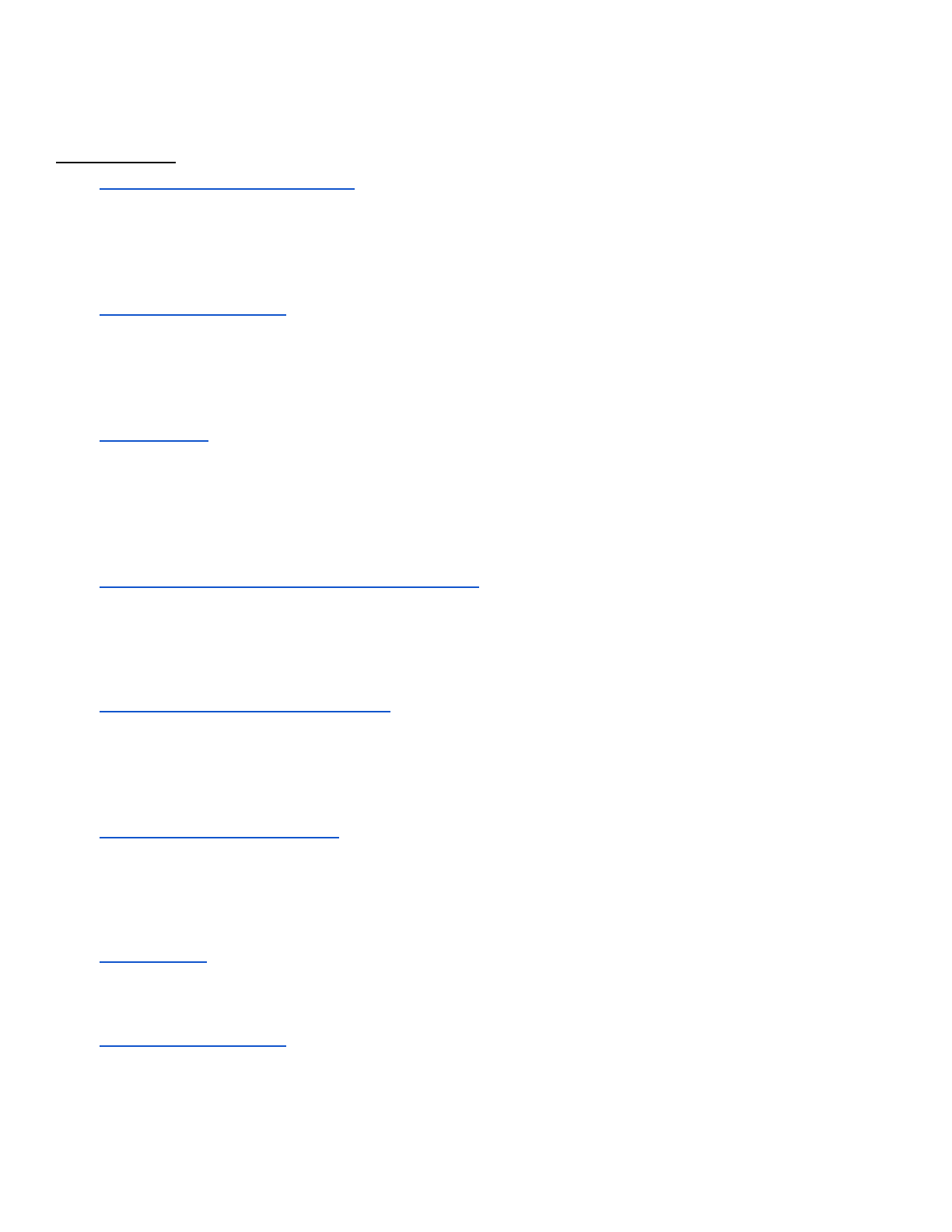

September ‘22

Su

M

Tu

W

Th

F

S

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

25

26

27

28

29

30

October ‘22

Su

M

Tu

W

Th

F

S

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

25

26

27

28

29

30

31

November ‘22

Su

M

Tu

W

Th

F

S

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

25

26

27

28

29

30

December ‘22

Su

M

Tu

W

Th

F

S

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

25

26

27

28

29

30

31

January ‘23

Su

M

Tu

W

Th

F

S

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

25

26

27

28

29

30

31

February ‘23

Su

M

Tu

W

Th

F

S

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

25

26

27

28

March ‘23

Su

M

Tu

W

Th

F

S

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

25

26

27

28

29

30

31

April ‘23

Su

M

Tu

W

Th

F

S

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

25

26

27

28

29

30

May ‘23

Su

M

Tu

W

Th

F

S

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

25

26

27

28

29

30

31

June ‘23

Su

M

Tu

W

Th

F

S

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

25

26

27

28

29

30

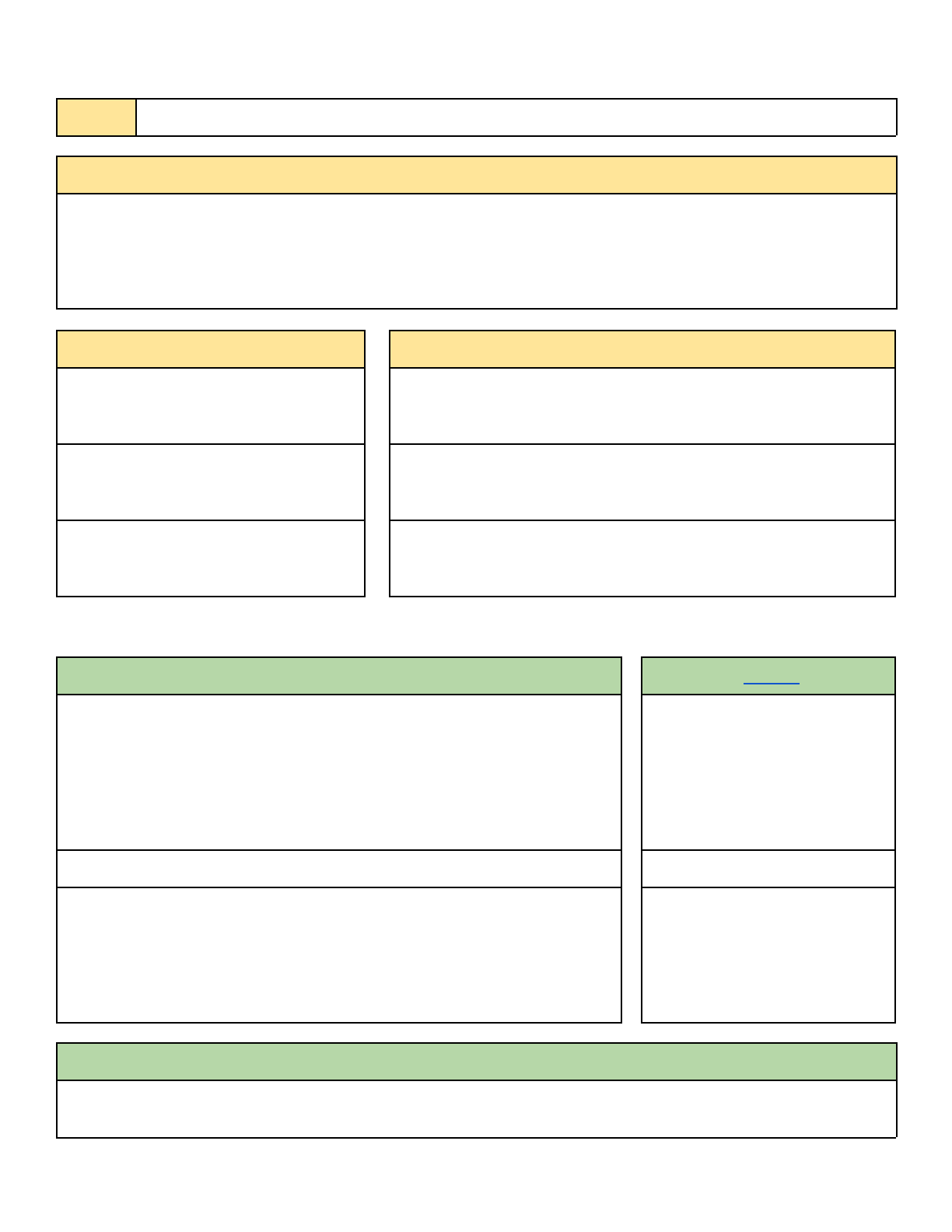

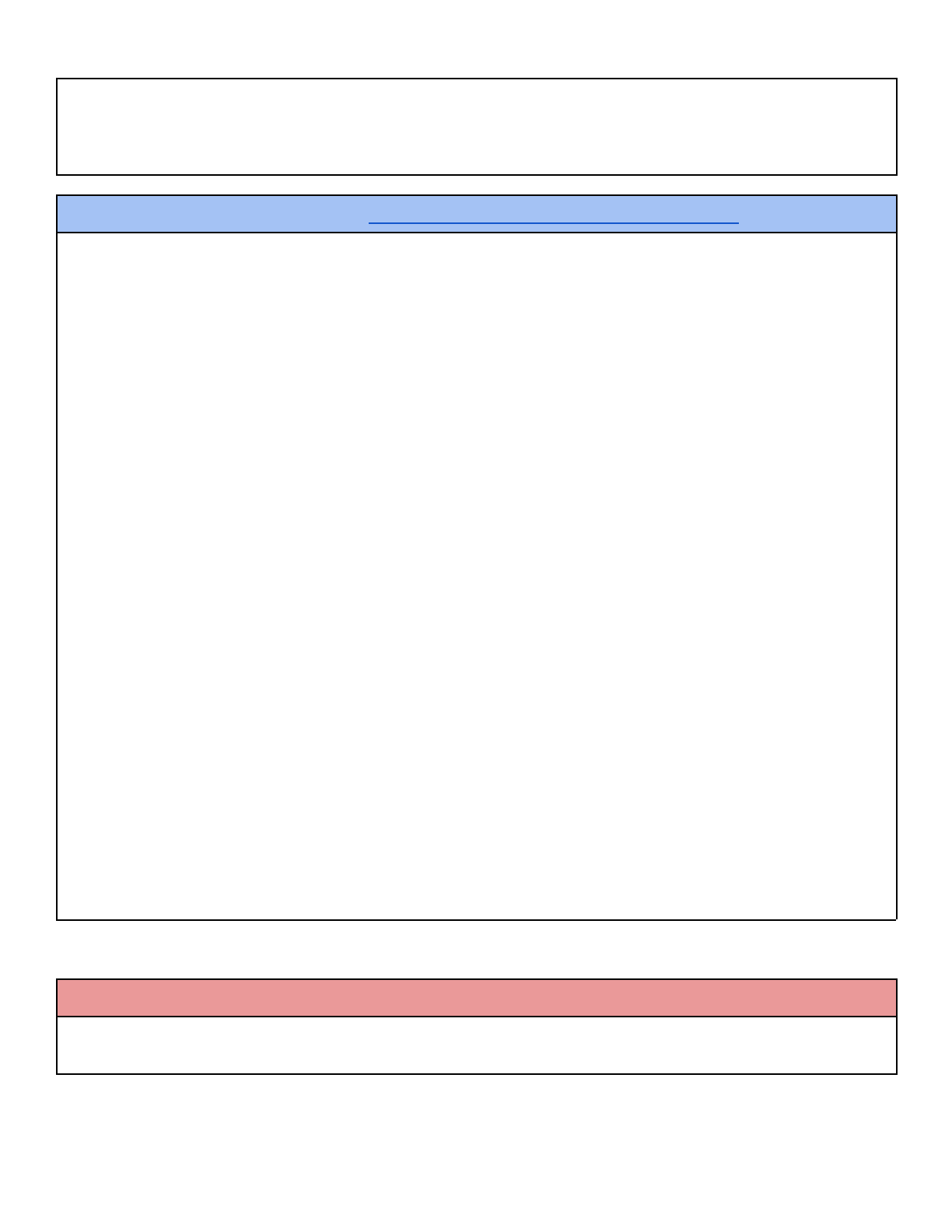

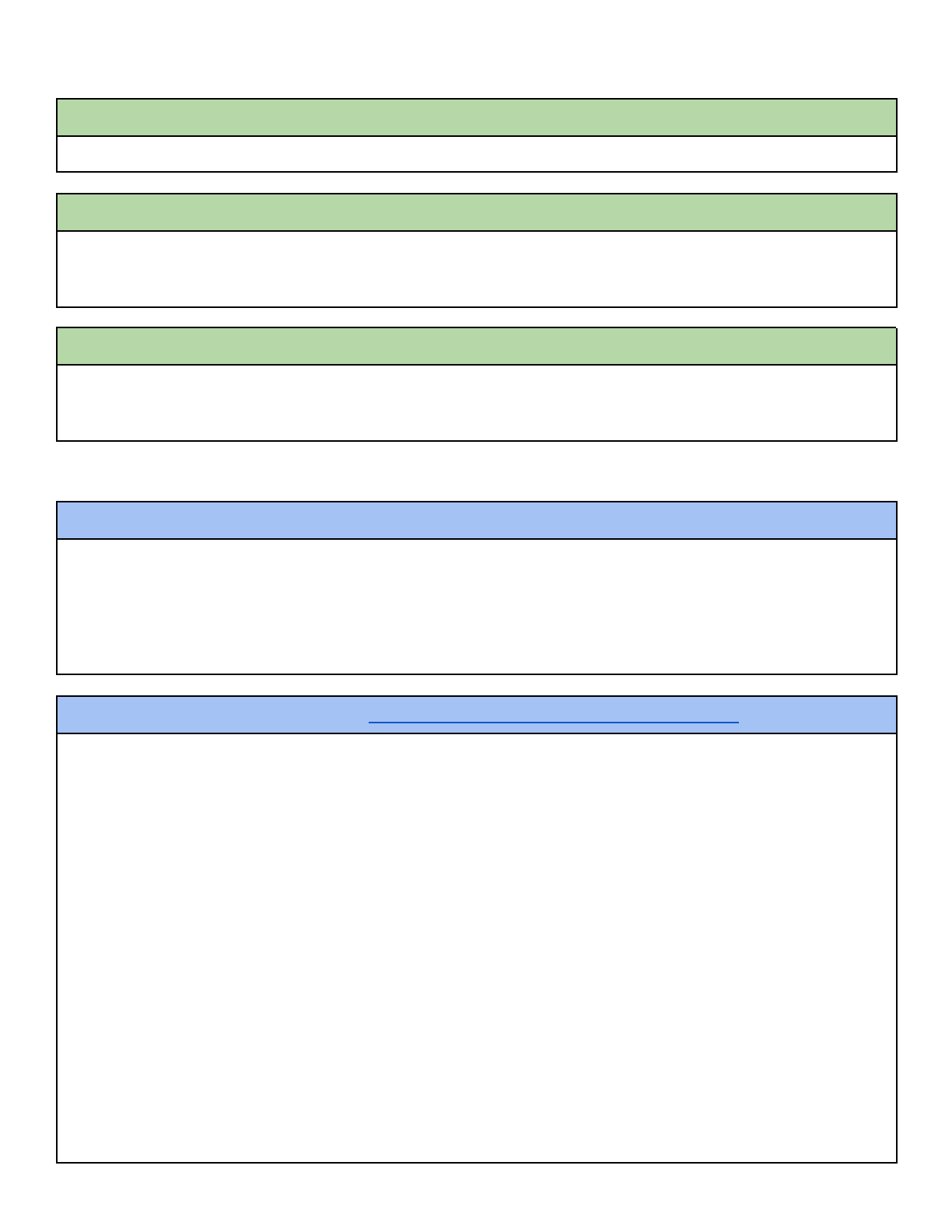

Unit Summaries

Woodworking

Course Content

1. Wood Science and Wood Processing - Students will start the year learning about the origin, types, characteristics,

and internal structure of wood. Students will be introduced to concepts of conservation, dendrochronology, and

the skills and opportunities related to the forestry field. Students will learn to identify multiple types of wood and

manufactured wood products. Students will learn the steps of material processing from tree to finished project

with hand tools. (Activity: Wooden Cookie Lanyard Project)

2. Hand Tool Safety and Uses - Students will learn to safely identify, handle, sharpen and use basic hand

woodworking tools to process a board. Students will practice with the tools to master the handsaws, planes,

rasps/files, chisels, mallets, and try squares while they make multiple types of wood shavings. Students will learn

the steps to properly square up a board and attempt to square up a board using their hand tool skills. (Activity:

Square Up a Board with Hand Tools)

3. Machine Safety - Students will learn the universal machine safety rules. Students will learn the specific safety rules

and operating procedures of the bandsaws and power sanders. Students will be introduced to the drill press,

planer, jointer, table saw, belt/disc sanders, and other machines, but the focus will primarily be on the bandsaw.

Students will be responsible for setting up the bandsaw for a safe cut bandsaw and making multiple practice cuts

on the saw. Students will then make two shapes on the bandsaw and sanders and may utilize the hand tools when

applicable. (Activity : Bandsaw Bat, Bandsaw Shape)

4. Reading and Fabricating Wood to Woodworking Plans - Students will learn to read and interpret measurements

from a set of detailed woodworking plans. Students will use these plans, along with layout tools, to accurately

layout their parts on a piece of wood, which they will mill, square up, map and cut out themselves on the

machines. Students will continue learning about machine safety and focus on milling machines in this unit,

including the jointer, planer, table saw, and power miter saw. (Activity: Skills Block)

5. Basic Joinery with a Multiple Part Project - Students will learn to build a project with multiple parts. Students will

be introduced to the full woodworking process, from rough wood to finished product. Students will begin by

reading the set of plans, make a Bill of Materials and Order of Operations, then map out their parts on paper before

milling and processing their pieces. Students will fabricate, assemble with hardware, sand and finish their project,

taking it from rough stock to a fine, finished product. (Activity: Toolbox Project, Rabbet Joint Pencil Box)

6. Hardwoods and Advanced Joinery - Students will continue to expand their knowledge, operation and safety of the

various machines, ultimately taking a project from an idea to a final, finished project. Students will be introduced to

hardwoods, even more complex joinery techniques, and will refine their skills with all of the milling and joinery

machines, including some new ones, like the handheld power router. (Hardwood Joiners Mallet or Handmade

Woodworking Tool)

7. CNC Machining - Students will be introduced to the CNC machines and by the end of this unit, students will create

a VCarve file, safely set up their stock on the CNC Machine, successfully process their design, and clean up and shut

down the machine for future use. (Wooden Spoon, Laser Plaque)

8. The Woodworking Process - Students will work in groups to choose a woodworking project where they will have to

work together to plan, mill, fabricate, assemble, finish multiple projects. This unit caps off the entire year and it is a

chance for students to show their knowledge of project planning, time management, hand tool and machine safety

and operation, and a way for them to showcase their skills with processing and finishing. (Yard/Table top Game

Project)

Programs: Autodesk AutoCAD, Onshape, V-Carve, Shaper

Course Expectations and Skills

1. Come to class each day willing to participate, prepared to learn, and ready to succeed.

2. Phones and other electronic devices should be kept away the entire time.

3. Use your resources when you are stuck (class notes or handouts, posts on Google Classroom, ask a classmate,

search for the solution online, etc.)

4. When prompted to get to work, do not wait. Get to work right away!

5. Engineering is a process. Project will often take weeks or months to complete. Understand that you might not

have the answers today, but if you keep at it and persist through, you will succeed.

6. Strive for accuracy and focus on craftsmanship.

7. See each project through to the end. Incomplete work will not be accepted.

8. Share ideas, help build, and equally contribute to group-based projects.

9. Practice proper attitude and safe discipline at all times.

10. Ask questions and have fun!

Resources:

Wagner, W. H., & Kicklighter, C. E. (2006). “Modern Woodworking (11th Ed.). Goodheart-Willcox Co.

Unit 1:

Wood Science and Hand Tool Woodworking

Unit Summary

Students will start the year learning about the origin, types, characteristics, and internal structure of wood.

Students will be introduced to concepts of conservation, dendrochronology, and the skills and opportunities

related to the forestry field. Students will learn to identify multiple types of wood and manufactured wood

products. Students will apply grain orientation in wood. Students will learn the steps of material processing

from tree to finished project with hand tools.

Essential Questions

Enduring Understandings

● Where does wood come from

and how is it harvested and

processed?

● Wood comes from coniferous and deciduous trees that

are in forests that are logged, harvested, dried,and milled

into boards for use.

● How does the tree’s growth

structure affect its

woodworking properties?

● Woods grain direction flows up and down the tree. Wood

reacts very differently when cut along verses across this

grain pattern.

● What wood working operations

are you currently performing to

the tree/wood?

● We process the wood using tools in a particular order of

operations to make a desired product.

Behavioral Objectives/Learning Outcomes

Standards (NJSLS)

● Identify and compare softwoods and hardwoods and their

sources in nature.

● Identify defects in wood

○ Warps, knots, checks, metal

● Recognize the interconnectivity and relationship between oneself

to nature.

● Identify and explore career paths in forestry related fields.

9.3.12.AG‐NR.2

9.3.12.AG‐PL.2

● Explain and Demonstrate grain orientation comprehension

9.3.MN.6

● Use tools to safely process a tree into a finished project

○ Japanese saw to crosscut

○ Sand through the grits 80-320

○ Layout, center punch, bore holes for cordage

○ Layout and wood burn name into cookie

○ Measure, cut, and assemble cordage

9.3.12.AC‐CST.9

Interdisciplinary Connections

Science - Dendrochronology, environmental studies and sustainability, physics in cutting edge geometry

English - Identify, compare and contrast, explain

21st Century Skills

Communication skills, problem solving, perseverance, collaboration, information literacy, global awareness,

self-direction, social skills, literacy skills, social responsibility, thinking skills

Writing Assignments

Order of Operations

“Tree to Shop” Worksheet

Wooden Cookie Reflection Slide

Activities, Instructional Strategies, and Assignments

Batoning Boards and Branches Activity

Wooden Cookie Project

Accommodations and Modifications (BHPRSD Accommodations and Modifications)

● Provide a variety of concrete examples from familiar contexts

● Build background knowledge of content and vocabulary from familiar contexts prior to readings

● Provide oral & written instructions

● Incorporate multimedia/audio visual representation (YouTube, Discovery Education, TV Show

parodies, etc.) to build understanding

● Use graphic organizers to guide notes, brainstorming, pre-writing, project planning, and test

preparation

● Model through processes during assignments and elicit student-generated thoughts to determine

gaps in understanding

● Highlight, bold, or underline main ideas in readings and in directions for writing assignments in the

curricular areas

● Provide guiding questions to complete during the activity

● Provide chunking of instructional notes and activities to allow for formative assessment (checks for

understanding) before moving on to the next stage

● Choose cooperative learning groups to ensure effective work, maximize productivity and support

socialization

● Use multiple intelligences or the student's learning style to facilitate effective learning when a student

is having difficulty grasping concepts

● Provide demonstrations, utilize pictures, or graphic to assist visual learners to support written text

information

● Include oral discussions, oral presentations, group collaboration, or other oral delivery methods to

support auditory learners

● Utilize hands-on activities, movement or rhythmic experiences to engage tactile/kinesthetic learners

● Provide chunking of assignments into manageable steps, including checklists that clarify directions

for assignments

● Provide a clear, concise version of a scoring rubric prior to the assignment or assessment

● Highlight distinctive features/key concepts

● Provide choice of projects depending on the student’s interests or strengths

● Provide peer assistance/study groups

● Review, repeat, and clarify directions

● Chunk sections of assessment

● Allow for partial credit, when appropriate

● Allow use of familiar contexts to demonstrate understanding of key concepts when use of text

evidence is not necessary

● Provide general assistance with organizational skills

● Utilize homework assignment notebook/planner/agenda

● Provide written intermediate timelines for long assignments

● Have student monitor grade average

● Keep rules simple and clear

● Implement a behavior management system

Formative Assessments

● Checkpoints on student Order of Operations

● “Tree to Shop” Worksheet

Summative Assessments

● Wooden Cookie Name Tag Project

Performance Assessments

● Preparing for Class

● Batoning wood safely

● Cross cutting Wood safely

RETURN TO CALENDAR

RETURN TO UNIT SUMMARIES

Unit 2:

Hand Tool Safety and Uses

Unit Summary

Students will learn to safely identify, handle, sharpen and use basic hand woodworking tools to process a

board. Students will practice with the tools to master the handsaws, planes, rasps/files, chisels, mallets, and

try squares while they make multiple types of wood shavings. Students will learn the steps to properly square

up a board and attempt to square up a board using their hand tool skills.

Essential Questions

Enduring Understandings

● What are the 4 Primary

woodworking tools and what

are they used for?

● The saw, plane, file and chisel can be used together to

process wood into simple and complex shapes

● What order of operations must

be followed to attain a square

board?

● A board should be planed, jointed, ripped, then crosscut

on its ends to attain a square board.

● How can safety be maintained

while using sharp tools?

● One must consider many variables to maintain safe work

operation including the person, wood, tool, workshop

setting and careful, mindful focus always be maintained.

Behavioral Objectives/Learning Outcomes

Standards (NJSLS)

● Students will learn skills to utilize hand tools to process a board

square, tools include:

○ Japanese ryoba saw, western crosscut saw,

○ block plane and bench plane

○ Rasp and file

○ Chisel and sharpening stone

○ try square.

9.3.12.AC‐CST.9

9.3.MN‐HSE.2

● Students will learn the order of operations to square a board

○ Try square use, face planing, edge planing, rip cutting, edge

planing to a line, cross cutting, cross filing and draw filing.

9.3.12.AC‐CST.9

● Students will demonstrate safe working practices while working in the

shop and using tools.

9.3.MN‐HSE.2

9.3.MN‐MIR.2

Interdisciplinary Connections

Science - Physics

Math - Geometry

21st Century Skills

Critical thinking, communication skills, creativity, problem solving, perseverance, collaboration, information

literacy, technology skills and digital literacy, media literacy, global awareness, self-direction, social skills,

literacy skills, civic literacy, social responsibility, innovations skills, thinking skills

Writing Assignments

Hand Tools and Uses

Hand Tool Reflection Slide

Activities, Instructional Strategies, and Assignments

Chisels - Safe two handed paring and chopping

Japanese saws - Crosscut and Ripcuts

Coping saw - Cutting simple curves

Planes - Edge planing, face planing, chamfering

Files and Rasps-Shaping and End Grain filing

Use a Try Square with hand tools to “Square a Board”

Accommodations and Modifications (BHPRSD Accommodations and Modifications)

● Provide a variety of concrete examples from familiar contexts

● Provide study guides and support outside of class time to review before assessments (common time

or after school)

● Build background knowledge of content and vocabulary from familiar contexts prior to readings

● Use mental models to building understanding through familiar contexts

● Provide oral & written instructions

● Incorporate multimedia/audio visual representation (YouTube, Discovery Education, TV Show

parodies, etc.) to build understanding

● Use graphic organizers to guide notes, brainstorming, pre-writing, project planning, and test

preparation

● Model through processes during assignments and elicit student-generated thoughts to determine

gaps in understanding

● Highlight, bold, or underline main ideas in readings and in directions for writing assignments in the

curricular areas

● Provide guiding questions to complete during the activity

● Provide chunking of instructional notes and activities to allow for formative assessment (checks for

understanding) before moving on to the next stage

● Choose cooperative learning groups to ensure effective work, maximize productivity and support

socialization

● Use multiple intelligences or the student's learning style to facilitate effective learning when a student

is having difficulty grasping concepts

● Provide demonstrations, utilize pictures, or graphic to assist visual learners to support written text

information

● Include oral discussions, oral presentations, group collaboration, or other oral delivery methods to

support auditory learners

● Utilize hands-on activities, movement or rhythmic experiences to engage tactile/kinesthetic learners

● Provide chunking of assignments into manageable steps, including checklists that clarify directions

for assignments

● Provide a clear, concise version of a scoring rubric prior to the assignment or assessment

● Highlight distinctive features/key concepts

● Provide choice of projects depending on the student’s interests or strengths

● Provide peer assistance/study groups

● Review, repeat, and clarify directions

● Chunk sections of assessment

● Allow for partial credit, when appropriate

● Allow use of familiar contexts to demonstrate understanding of key concepts when use of text

evidence is not necessary

● Provide general assistance with organizational skills

● Utilize homework assignment notebook/planner/agenda

● Provide written intermediate timelines for long assignments

● Have student monitor grade average

● Keep rules simple and clear

● Implement a behavior management system

Formative Assessments

● Notes on Hand Tools

● Hand Tool Reflection Slide

Summative Assessments

● Wood Shavings with Hand Tools

Performance Assessments

● Safety Checkpoints with each tool

RETURN TO CALENDAR

RETURN TO UNIT SUMMARIES

Unit 3:

Machine Safety

Unit Summary

Students will learn the universal machine safety rules. Students will learn the specific safety rules and

operating procedures of the bandsaws and power sanders. Students will be introduced to the drill press,

planer, jointer, table saw, belt/disc sanders, and other machines, but the focus will primarily be on the

bandsaw. Students will be responsible for setting up the bandsaw for a safe cut bandsaw and making

multiple practice cuts on the saw. Students will then make two shapes on the bandsaw and sanders and may

utilize the hand tools when applicable.

Essential Questions

Enduring Understandings

● What are the General Shop

Safety Rules you must always

follow?

● Why do you need to always

wear safety glasses?

● Why is it important to keep the

classroom and the machines

clean?

● What if a machine is not

cutting/drilling or it is making a

strange noise?

● Shop maturity, attitude, and focus.are the foundation of

safety in a shop. A few important rules are to have

proper clothing, proper PPE, instructor is present, only

using tools you have been cleared to use for specific

operations.

● A well organized and clean shop produces a safer

environment.

● Report all incidents and safety relevant information to the

instructor immediately before proceeding to work.

● How do you safely operate the

band saw?

● How do you adjust the guards

on the bandsaw?

● How do you safely operate the

power sander?

● The bandsaw must be set up with guards ¼ inch above

the stock while it is not running.

● Curved and straight cuts are made slowly, keeping

fingers clear of the blade and its path, not forcing the turn

or speed of the saw. Push sticks may be used to keep

fingers clear on small cuts.

● When would you use a band

saw vs. a power sander?

● Bands saw is used first to cut on the waste of the line by

about an ⅛ of an inch, then the power sander can be

used to sand up to the line and smooth out the saw

marks.

● When planning cuts, how do

you accurately measure and

mark for a cut?

● Measure Twice, then mark one clean line with a square.

Place an X on the waste side to ensure the blade cut is

on the waste side.

Behavioral Objectives/Learning Outcomes

Standards (NJSLS)

● Identify Parts of the saw and

● Safely adjust the height of the guard

9.3.MN‐HSE.1

● Layout and cut on the waste side of both a crosscut, rip cut and a

curve adhering the machine safety procedures

9.3.MN.6

● Trace the bat onto ¼ inch Ply

9.3.MN‐HSE.1

● Layout and number the planned cuts

● Cut out the bat profile on the bandsaw and sanders adhering to the

machine safety procedures

● File and sand the bat smooth

● Paint the bat to a finished product

● Trace and plan cuts of another object/shape on the pine/ poplar

● Cut out shape on the bandsaw and sanders

● Sand the object smooth

● Apply a clear coat finish or paint the object.

9.3.MN.6

9.3.MN‐QA.1

Interdisciplinary Connections

STEAM, English, Geometry

21st Century Skills

Critical thinking, communication skills, creativity, problem solving, perseverance, collaboration, information

literacy, technology skills and digital literacy, self-direction, social skills, literacy skills, innovations skills,

thinking skills

Writing Assignments

Students are encouraged to take written notes when taught safety on each machine. Safety Study Guides

will be provided for each machine, but students should be filling out any missing information. Students will be

taking written Safety Quizzes and must pass with a certain grade. Students who do not pass must review the

content with the teacher and retake the safety quizzes before continuing work in the woodworking

classroom.

Activities, Instructional Strategies, and Assignments

This unit is one of the most important because the content students learn here will carry through the rest of

this course and through Advanced Woodworking too. This is where students will learn how to safely operate

some of the machines in the woodworking classroom. In this unit, students will take a deep dive into the

band saw and the power sanders.

1. The teacher will demonstrate how to safely use each machine.

a. Students are required to identify and describe the most important parts of each machine.

b. Students must know how to turn the machine on and off, adjust guards before making a cut,

successfully make a cut, lower guards, and clean the machine for the next student.

2. After each demonstration, students will be given study guides that will have various parts labeled and

a written checklist for how to safely operate each machine. Safety videos of the teacher’s

demonstration and additional support materials will be posted to Google Classroom.

3. Students will take Safety Quizzes on each machine and must pass with a certain grade. Students

who do not pass must review the content with the teacher and retake the safety quizzes before

continuing work in the woodworking classroom.

4. Once students pass the written safety quiz for a machine, they are cleared to use that machine.

Students will be assessed on their ability to safely use these machines.

After learning the safety on these machines, students will make a Plywood Halloween Bat and a Custom

Shape Pine Project. These projects are designed to ease students into Woodworking, get them using the

tools and machines, getting familiar with how they work, feel, and sound. The goal is to build student

confidence and make sure that students are using these machines safely and that they are comfortable. An

emphasis is placed on accuracy of cuts, but as the year progresses, projects get more complex, and

students use these machines more and more, the quality of their work should improve drastically.

Accommodations and Modifications (BHPRSD Accommodations and Modifications)

● Provide study guides and support outside of class time to review before assessments (common time

or after school)

● Build background knowledge of content and vocabulary from familiar contexts prior to readings

● Provide oral & written instructions

● Incorporate multimedia/audio visual representation (YouTube, Discovery Education, TV Show

parodies, etc.) to build understanding

● Use graphic organizers to guide notes, brainstorming, pre-writing, project planning, and test

preparation

● Model through processes during assignments and elicit student-generated thoughts to determine

gaps in understanding

● Highlight, bold, or underline main ideas in readings and in directions for writing assignments in the

curricular areas

● Provide guiding questions to complete during the activity

● Provide chunking of instructional notes and activities to allow for formative assessment (checks for

understanding) before moving on to the next stage

● Choose cooperative learning groups to ensure effective work, maximize productivity and support

socialization

● Provide demonstrations, utilize pictures, or graphic to assist visual learners to support written text

information

● Include oral discussions, oral presentations, group collaboration, or other oral delivery methods to

support auditory learners

● Utilize hands-on activities, movement or rhythmic experiences to engage tactile/kinesthetic learners

● Provide chunking of assignments into manageable steps, including checklists that clarify directions

for assignments

● Provide a clear, concise version of a scoring rubric prior to the assignment or assessment

● Highlight distinctive features/key concepts

● Provide choice of projects depending on the student’s interests or strengths

● Provide peer assistance/study groups

● Review, repeat, and clarify directions

● Chunk sections of assessment

● Provide general assistance with organizational skills

● Provide written intermediate timelines for long assignments

● Have student monitor grade average

● Keep rules simple and clear

Formative Assessments

● Band Saw Written Safety Quiz and Hands-on Quiz

● Power Sander Written Safety Quiz and Hands-on Quiz

Unit 4:

Reading and Fabricating Wood to Woodworking Plans

Unit Summary

Students will learn to read and interpret measurements from a set of detailed woodworking plans. Students

will use these plans, along with layout tools, to accurately layout their parts on a piece of wood, which they

will mill, square up, map and cut out themselves on the machines. Students will continue learning about

machine safety and focus on milling machines in this unit, including the jointer, planer, table saw, and power

miter saw.

Essential Questions

Enduring Understandings

● Why do we measure to 1/16”?

● How do you move back and

forth between fractions and

decimals?

● Measuring to a 16th of an inch is common practice in

woodworking. Tape measures usually are marked in

1/16th of an inch increments.

● What is an orthographic view?

● Why is it important to have the

top, front and side views of

parts?

● What is an isometric view?

● How can detailed views help

with understanding a part?

● How are woodworking

drawings different and how are

they similar to other drawings?

● An orthographic three view drawing which shows front,

top and right side views is usually necessary to show all

of the dimensions and features of a project.

● Isometric drawings give a lifelike three dimensional view

of the object.

● Detail views and sectional views can be used to gain

new vantage points to show details, and also to enlarge

small details.

● What are the steps you take

when squaring up a board?

● How do you use a square?

● There is a specific process used to attain a square

board. We must machine all the surfaces in a specific

order which utilizes reference surfaces. We must plane,

joint, rip and then crosscut the board.

● The try square is used to check surfaces for flatness and

angles for squares.

● How do you safely operate the

jointer?

● How do most injuries occur on

the jointer?

● Jointer takes small shavings with the grain from the

bottom edge of the board that must be 10” in length.

One slides the piece of wood on edge from the infeed to

the outfeed table while keeping fingers 4” clear of the

blade.

● Main Safety Considerations - Clothing, finger placement,

length and grain orientation, take multiple thin passes,

correct feed direction and speed.

● How do you safely operate the

planer?

● When using the planer, how

much material should you take

off with each pass?

● Wood is fed flat, with the grain, into the rollers and

cutterhead on the infeed table. Wood is kept stable while

clothing and hands are kept clear of the planer. Do not

stand in the kickback zone.

● Only take passes up to 1/16 of an inch in depth. Do not

plane smaller than ¼ inch,thick and 1 foot long stock.

● How do you safely operate the

table saw?

● Stock is rip cut, crosscut and joints milled with a table

saw and accessory. Hands kept 4 inches from the blade.

● What is kickback?

● What is the difference between

the fence and the miter

gauge?

● While ripping the wood must stay tight to the fence to

prevent wood kickback,

● Use a fence to rip cut or a miter gauge to crosscut

● How do you safely operate the

power miter saw?

● How do you prevent your

piece of wood from kicking?

● A conventional cut is made front to back of the saw.

Saws are brought to full speed and a slow steady

crosscut is made.The wood must be 12 inches long and

properly fit in the saw being used. Fingers are kept 4-8

inches away from the blade.

● To prevent kickbacks: No rip cuts, and no small pieces.

Securely hold the wood flat and joint edge tight to the

fence with adequate pressure. A clamp may be

occasionally needed to keep a board stable.

Behavioral Objectives/Learning Outcomes

Standards (NJSLS)

● Students will measure accurately to within 1/16 of an inch

9.3.ST.1

● Students will interpret the orthographic drawings.

● Students will use measurements to transfer the drawings information

into a clean accurate layout on the wood.

9.3.12.AC‐DES.6

● Students will recall the safety rules of the milling machinery including

table saw, power miter saw, jointer, and planer.

● Students will properly operate the machinery following all safe

operating procedures.

● Students will fabricate a “skills block” to a specific set of plans to

enhance mastery of the machine procedures.

9.3.12.AC‐CST.5

9.3.MN‐QA.5

Interdisciplinary Connections

STEAM, English, Geometry

21st Century Skills

Critical thinking, communication skills, creativity, problem solving, perseverance, collaboration, information

literacy, technology skills, self-direction, social skills, literacy skills, innovations skills, thinking skills

Writing Assignments

Students will be given notes and worksheets that teach measurement tools and techniques.

Students will be given notes and worksheets that teach students how to read and interpret woodworking

drawings.

Students are encouraged to take written notes when taught safety on each machine. Safety Study Guides

will be provided for each machine, but students should be filling out any missing information. Students will be

taking written Safety Quizzes and must pass with a certain grade. Students who do not pass must review the

content with the teacher and retake the safety quizzes before continuing work in the woodworking

classroom.

Activities, Instructional Strategies, and Assignments

Students will take a deep dive into measurement and woodworking drawings. Students are expected to

follow along with notes and handouts provided. This will serve as the basis for all the projects that are to

follow in Woodworking and Advanced Woodworking.

This unit is one of the most important because the content students learn here will carry through the rest of

this course and through Advanced Woodworking too. This is where students will learn how to safely operate

some of the machines in the woodworking classroom. In this unit, students will take a deep dive into the

jointer, planer, power miter saw, and the table saw.

1. The teacher will demonstrate how to safely use each machine.

a. Students are required to identify and describe the most important parts of each machine.

b. Students must know how to turn the machine on and off, adjust guards before making a cut,

successfully make a cut, lower guards, and clean the machine for the next student.

2. After each demonstration, students will be given study guides that will have various parts labeled and

a written checklist for how to safely operate each machine. Safety videos of the teacher’s

demonstration and additional support materials will be posted to Google Classroom.

3. Students will take Safety Quizzes on each machine and must pass with a certain grade. Students

who do not pass must review the content with the teacher and retake the safety quizzes before

continuing work in the woodworking classroom.

4. Once students pass the written safety quiz for a machine, they are cleared to use that machine.

Students will be assessed on their ability to safely use these machines.

After learning the safety on these machines, students will process rough lumber to a final, milled and

squared block. This project is designed to give students experience on the machines covered in this unit, but

also to show them how to turn rough lumber into a usable piece. The goal is to build student confidence and

make sure that students are using these machines safely and that they are comfortable.

Accommodations and Modifications (BHPRSD Accommodations and Modifications)

● Provide study guides and support outside of class time to review before assessments (common time

or after school)

● Build background knowledge of content and vocabulary from familiar contexts prior to readings

● Provide oral & written instructions

● Incorporate multimedia/audio visual representation (YouTube, Discovery Education, TV Show

parodies, etc.) to build understanding

● Use graphic organizers to guide notes, brainstorming, pre-writing, project planning, and test

preparation

● Model through processes during assignments and elicit student-generated thoughts to determine

gaps in understanding

● Highlight, bold, or underline main ideas in readings and in directions for writing assignments in the

curricular areas

● Provide guiding questions to complete during the activity

● Provide chunking of instructional notes and activities to allow for formative assessment (checks for

understanding) before moving on to the next stage

● Choose cooperative learning groups to ensure effective work, maximize productivity and support

socialization

● Provide demonstrations, utilize pictures, or graphic to assist visual learners to support written text

information

● Include oral discussions, oral presentations, group collaboration, or other oral delivery methods to

support auditory learners

● Utilize hands-on activities, movement or rhythmic experiences to engage tactile/kinesthetic learners

● Provide chunking of assignments into manageable steps, including checklists that clarify directions

for assignments

● Provide a clear, concise version of a scoring rubric prior to the assignment or assessment

● Highlight distinctive features/key concepts

● Provide choice of projects depending on the student’s interests or strengths

● Provide peer assistance/study groups

● Review, repeat, and clarify directions

● Chunk sections of assessment

● Provide general assistance with organizational skills

● Provide written intermediate timelines for long assignments

● Have student monitor grade average

● Keep rules simple and clear

Formative Assessments

● Jointer Written Safety Quiz and Hands-on Quiz

● Planer Written Safety Quiz and Hands-on Quiz

● Table Written Safety Quiz and Hands-on Quiz

● Practice Piece: Square and Mill a piece of wood

Summative Assessments

● Hands-on Safety:

○ Skills Block Project

Performance Assessments

● Safely utilize all tools and machines

RETURN TO CALENDAR

RETURN TO UNIT SUMMARIES

Unit 5:

Basic Joinery and Building a Multiple Part Project

Unit Summary

Students will learn to build a project with multiple parts. Students will be introduced to the full woodworking

process, from rough wood to finished product. Students will begin by reading the set of plans, make a Bill of

Materials and Order of Operations, then map out their parts on paper before milling and processing their

pieces. Students will fabricate, assemble with hardware, sand and finish their project, taking it from rough

stock to a fine, finished product.

Essential Questions

Enduring Understandings

● How does one organize the

steps and plan of the

woodworking process?

● The wood working process consists of:

○ Research and development, reading and making

plans,, milling, fabrication, assembly, finishing.

● What 3 documents make up a

set of plans?

● A sufficient set of mechanical drawings

● A Bill of Materials

● Order of Operations

● Why is a bill of materials

important?

● What is an order of

operations?

● What are the considerations in

creating the order of

operations?

● A bill of materials is the cut list of the final dimensions of

the rectangular stock in the project. This is referred to

while milling the stock square to dimension. It can be

used to calculate wood volume and material cost.

● An order of operations is a detailed list of operations and

cuts to perform.

● We prioritize Safety, then Accuracy, then Efficiency.when

creating an order of operations.

● How can we safely, accurately,

and efficiently mill the wood

into the dimensioned parts?

● How can we accurately create

the layout on the wood?

● What special operations must

be performed to accurately

fabricate the piece?

● With total focus and organization we can efficiently take

turns milling boards to size.

● Precise measurements and layout lines are diligently and

carefully drawn using layout tools.

● Machine the joinery, curves and more complicated cuts

within the parts of the project.

● How will we connect the

wooden parts together?

● How do we prepare for

assembly?

● What methods can be used to

assemble furniture and wood?

● The Assembly process is used to connect together

wooden parts into a project.

● We prepare for assembly by doing dry assembly, and

gathering and organizing clamps and gluing materials.

● The three methods of assembling wood include joinery,

glue, and fasteners.

● How do we prepare the wood

for finishing?

● What are pros and cons of

common finishes?

● What are the safety concerns

with different finishes?

● What is a common finishing

process?

● We sand with the grain. Sanding the piece 3 times:rough

100, medium150 and smooth 220 grit. We dampen and

raise the grain between sanding grits.

● There are many finishes and the best finish must be

chosen based on intended use, desired look, and

specific application.

● Different finishes have specific safety protocols. Clean

up, fumes, fire, hazardous waste, solvents, skin irritants,

carcinogenic materials that may need to be considered.

● We commonly apply a thinned sealer coat of finish. Then

brush a few heavier coats. Once dry the finish is lightly

sanded smooth with 320 and steel wool. Thinned down

final coats are wiped on. It is smoothed with fine steel

wool and then waxed with furniture wax.

● How can we reflect and learn

from our experience?

● What does the overall

woodworking process involve?

● We must learn from our experiences

● In woodworking we always follow the woodworking

process: Plan, mill, fabricate, assemble, finish.

Behavioral Objectives/Learning Outcomes

Standards (NJSLS)

● Students will interpret the plans and draw a right view of the box.

● Students will interpret the plans and create a “Bill of Materials”

● Students will interpret the plans and create a “Order of Operations”

9.3.ST‐ET.4

● Students will mill the rough lumber into final dimensioned stock

● Students will draw layout of the joinery and shapes

● Students will fabricate the dimensioned parts into final shape with

special operations.

● Students will assemble the parts into the project.

● Students will finish the box following finishing procedures.

9.3.12.AC‐DES.6

9.3.12.AC‐CST.5

Interdisciplinary Connections

Math, Engineering, science. vocational

21st Century Skills

Critical thinking, communication skills, creativity, problem solving, perseverance, collaboration, information

literacy, technology skills and digital literacy, media literacy, global awareness, self-direction, social skills,

literacy skills, civic literacy, social responsibility, innovations skills, thinking skills

Writing Assignments

Reflection Slide

Activities, Instructional Strategies, and Assignments

Orthographic Drawing of Right View

Bill of Materials

Order of Operations

Building a Tool Box Project

Toolbox Reflection Slide

Making Plans for Rabbet Joint Box

Building a Rabbet Joint Box

Rabbet Joint Box Reflection Slide

Accommodations and Modifications (BHPRSD Accommodations and Modifications)

● Provide a variety of concrete examples from familiar contexts

● Provide study guides and support outside of class time to review before assessments (common time

or after school)

● Build background knowledge of content and vocabulary from familiar contexts prior to readings

● Use mental models to building understanding through familiar contexts

● Provide oral & written instructions

● Incorporate multimedia/audio visual representation (YouTube, Discovery Education, TV Show

parodies, etc.) to build understanding

● Use graphic organizers to guide notes, brainstorming, pre-writing, project planning, and test

preparation

● Model through processes during assignments and elicit student-generated thoughts to determine

gaps in understanding

● Highlight, bold, or underline main ideas in readings and in directions for writing assignments in the

curricular areas

● Provide guiding questions to complete during the activity

● Provide chunking of instructional notes and activities to allow for formative assessment (checks for

understanding) before moving on to the next stage

● Choose cooperative learning groups to ensure effective work, maximize productivity and support

socialization

● Use multiple intelligences or the student's learning style to facilitate effective learning when a student

is having difficulty grasping concepts

● Provide demonstrations, utilize pictures, or graphic to assist visual learners to support written text

information

● Include oral discussions, oral presentations, group collaboration, or other oral delivery methods to

support auditory learners

● Utilize hands-on activities, movement or rhythmic experiences to engage tactile/kinesthetic learners

● Provide chunking of assignments into manageable steps, including checklists that clarify directions

for assignments

● Provide a clear, concise version of a scoring rubric prior to the assignment or assessment

● Highlight distinctive features/key concepts

● Provide choice of projects depending on the student’s interests or strengths

● Provide peer assistance/study groups

● Review, repeat, and clarify directions

● Chunk sections of assessment

● Allow for partial credit, when appropriate

● Allow use of familiar contexts to demonstrate understanding of key concepts when use of text

evidence is not necessary

● Provide general assistance with organizational skills

● Utilize homework assignment notebook/planner/agenda

● Provide written intermediate timelines for long assignments

● Have student monitor grade average

● Keep rules simple and clear

● Implement a behavior management system

Formative Assessments

● Bill of Materials,

● Order of Operations

● Milling Checkpoint

● Layout Checkpoint

● Fabrication Checkpoint

● Assembly Checkpoint

● Finish Checkpoint

Summative Assessments

● Tool Box Project

● Rabbet Joint Box Project

Performance Assessments

● Safely utilize all tools and machines

RETURN TO CALENDAR

RETURN TO UNIT SUMMARIES

Unit 6:

Hardwoods and Advanced Joinery

Unit Summary

Students will continue to expand their knowledge, operation and safety of the various machines, ultimately

taking a project from an idea to a final, finished project. Students will be introduced to hardwoods, even more

complex joinery techniques, and will refine their skills with all of the milling and joinery machines, including

some new ones, like the handheld power router.

Essential Questions

Enduring Understandings

● What are the steps in the

woodworking process?

● How do we add joinery into the

planning process?

● Planning, milling, fabricating, assembly and finishing are

the general steps of the wood working process.

● We study auxiliary drawings of joints and then write the

cuts into the “order of operations” during the fabrication

stage of the project. .

● During the fabrication process,

What machines and tools are

commonly utilized to cut

joinery?

● Routers, tables saws, dado blades, power miter saws,

drill presses, fine backsaws, planes, and chisels are

commonly utilized in cutting joinery.

● How do we accommodate the

woodworking process for

hardwood stock?

● We must slow down the feed rate of hardwood stock into

machines. We must take thinner passes with routers,

planers and jointers.

Behavioral Objectives/Learning Outcomes

Standards (NJSLS)

● Draw an orthographic drawing of the Mallet or advanced joinery

project

9.3.ST‐ET.2

● Create a Bill of Materials from the orthographic drawing,

9.3.ST‐ET.2

● Create an Order of Operations

9.3.ST‐ET.2

● Utilize milling machines to safely the wood into dimensioned stock

9.3.12.AC‐CST.5

● Accurately layout and cut joinery utilizing joinery techniques and

procedures.

9.3.ST.6

● Assemble the wooden mallet or advanced joinery project

9.3.ST.6

● Apply the wood finishing process to the mallet or project

9.3.ST.6

● Reflect upon the experience and woodworking process.

9.3.ST‐SM.3

Interdisciplinary Connections

Math, Science, Manufacturing, Vocational

21st Century Skills

Critical thinking, communication skills, creativity, problem solving, perseverance, collaboration, information

literacy, technology skills and digital literacy, media literacy, global awareness, self-direction, social skills,

literacy skills, civic literacy, social responsibility, innovations skills, thinking skills

Writing Assignments

Project Reflection

Activities, Instructional Strategies, and Assignments

Orthographic Drawing

Bill Of Materials

Order of Operations

Mill dimensioned lumber checkpoint

Layout Checkpoint

Fabrication Checkpoint

Router manipulative and Written Quiz

Assembly Checkpoint

Finishing Checkpoint

Reflection Activity and Slide

Accommodations and Modifications (BHPRSD Accommodations and Modifications)

● Provide a variety of concrete examples from familiar contexts

● Provide study guides and support outside of class time to review before assessments (common time

or after school)

● Build background knowledge of content and vocabulary from familiar contexts prior to readings

● Use mental models to building understanding through familiar contexts

● Provide oral & written instructions

● Incorporate multimedia/audio visual representation (YouTube, Discovery Education, TV Show

parodies, etc.) to build understanding

● Use graphic organizers to guide notes, brainstorming, pre-writing, project planning, and test

preparation

● Model through processes during assignments and elicit student-generated thoughts to determine

gaps in understanding

● Highlight, bold, or underline main ideas in readings and in directions for writing assignments in the

curricular areas

● Provide guiding questions to complete during the activity

● Provide chunking of instructional notes and activities to allow for formative assessment (checks for

understanding) before moving on to the next stage

● Choose cooperative learning groups to ensure effective work, maximize productivity and support

socialization

● Use multiple intelligences or the student's learning style to facilitate effective learning when a student

is having difficulty grasping concepts

● Provide demonstrations, utilize pictures, or graphic to assist visual learners to support written text

information

● Include oral discussions, oral presentations, group collaboration, or other oral delivery methods to

support auditory learners

● Utilize hands-on activities, movement or rhythmic experiences to engage tactile/kinesthetic learners

● Provide chunking of assignments into manageable steps, including checklists that clarify directions

for assignments

● Provide a clear, concise version of a scoring rubric prior to the assignment or assessment

● Highlight distinctive features/key concepts

● Provide choice of projects depending on the student’s interests or strengths

● Provide peer assistance/study groups

● Review, repeat, and clarify directions

● Chunk sections of assessment

● Allow for partial credit, when appropriate

● Allow use of familiar contexts to demonstrate understanding of key concepts when use of text

evidence is not necessary

● Provide general assistance with organizational skills

● Utilize homework assignment notebook/planner/agenda

● Provide written intermediate timelines for long assignments

● Have student monitor grade average

● Keep rules simple and clear

● Implement a behavior management system

Formative Assessments

● Written Router Quiz

● Orthographic drawing

● Bill of Materials

● Order of Operations

Summative Assessments

● Rabbet Joint Sliding Box Project

● Hardwood Mallet

Performance Assessments

● Safe operation of milling and fabrication machines.

● Efficient operating procedures of assembly process

● Diligent perform Finishing process

RETURN TO CALENDAR

RETURN TO UNIT SUMMARIES

Unit 7:

CNC Machining

Unit Summary

Students will be introduced to the CNC machines and by the end of this unit, students will create a VCarve

file, safely set up their stock on the CNC Machine, successfully process their design, and clean up and shut

down the machine for future use. Students will use the CNC machine for project fabrication.

Essential Questions

Enduring Understandings

● How has the CNC Machine

changed the manufacturing

process?

● Compare and contrast how a

CNC Machine impacts the

design process vs. using hand

tools.

● CNC stands for computer numerical control and these

machines play an important role in the manufacturing

industry. These complex machines are controlled by a

computer and provide a level of efficiency, accuracy and

consistency that would be impossible to achieve through

a manual process.

● As a result, manufacturers can produce parts in less

time, reduce waste and eliminate the risk of human error.

● Only highly skilled and educated people can operate

CNC Machines because of their complexity.

● How do you set up, run, break

down, and maintain the CNC

Machine?

● What is the difference between

an upcut and downcut bit?

● What are some safety rules

and considerations you must

follow when using the CNC

Machine?

● As with other machines in the Woodworking Classroom,

the CNC Machine requires knowledge, skill, and some

common sense to operate. The tools must be set up the

correct way to ensure they run safely and that no

damage or injury comes to the machine or the operator.

● The CNC Machine operator has to be smarter than the

tool. They have to keep an eye out for things that could

potentially go awry, especially when plunging down into a

material to cut.

Behavioral Objectives/Learning Outcomes

Standards (NJSLS)

● Consider how the CNC Machine has changed the manufacturing

process.

● Describe career opportunities and means to achieve those

opportunities related to CNC Machining.

9.3.MN.1

9.3.MN.4

● Identify the parts of the CNC Machine

● Correctly prepare the VCarve file

● Set up the tooling, clamps, and work piece

● Successfully run the VCarve file and produce a final piece

● Clean up the machine, run routine maintenance and follow all safety

rules while using the CNC Machine

9.3.12.AC‐CST.9

9.3.MN‐HSE.1

9.3.MN‐HSE.3

Interdisciplinary Connections

English - Research a CNC Machining-related career and prepare a presentation on that career

21st Century Skills

Critical thinking, communication skills, creativity, problem solving, perseverance, collaboration, information

literacy, technology skills and digital literacy, media literacy, global awareness, self-direction, social skills,

literacy skills, civic literacy, social responsibility, innovations skills, thinking skills

Writing Assignments

CNC Machinist - Career Investigation Activity

Activities, Instructional Strategies, and Assignments

Students will ensure that their VCarve file is set up correctly, with the appropriate tooling settings. The CNC

Machine requires student’s full attention and students will be setting up the CNC Machine, including

clamping down their work piece, running the machine and cleaning-up. Since there is only one machine,

students who are waiting to use the CNC Machine will be researching the history of the CNC Machine, its

impacts on the manufacturing process, and potential careers related to CNC Machining.

Accommodations and Modifications (BHPRSD Accommodations and Modifications)

● Provide a variety of concrete examples from familiar contexts

● Provide study guides and support outside of class time to review before assessments (common time

or after school)

● Build background knowledge of content and vocabulary from familiar contexts prior to readings

● Use mental models to building understanding through familiar contexts

● Provide oral & written instructions

● Incorporate multimedia/audio visual representation (YouTube, Discovery Education, TV Show

parodies, etc.) to build understanding

● Use graphic organizers to guide notes, brainstorming, pre-writing, project planning, and test

preparation

● Model through processes during assignments and elicit student-generated thoughts to determine

gaps in understanding

● Highlight, bold, or underline main ideas in readings and in directions for writing assignments in the

curricular areas

● Provide guiding questions to complete during the activity

● Provide chunking of instructional notes and activities to allow for formative assessment (checks for

understanding) before moving on to the next stage

● Choose cooperative learning groups to ensure effective work, maximize productivity and support

socialization

● Use multiple intelligences or the student's learning style to facilitate effective learning when a student

is having difficulty grasping concepts

● Provide demonstrations, utilize pictures, or graphic to assist visual learners to support written text

information

● Include oral discussions, oral presentations, group collaboration, or other oral delivery methods to

support auditory learners

● Utilize hands-on activities, movement or rhythmic experiences to engage tactile/kinesthetic learners

● Provide chunking of assignments into manageable steps, including checklists that clarify directions

for assignments

● Provide a clear, concise version of a scoring rubric prior to the assignment or assessment

● Highlight distinctive features/key concepts

● Provide choice of projects depending on the student’s interests or strengths

● Provide peer assistance/study groups

● Review, repeat, and clarify directions

● Chunk sections of assessment

● Allow for partial credit, when appropriate

● Allow use of familiar contexts to demonstrate understanding of key concepts when use of text

evidence is not necessary

● Provide general assistance with organizational skills

● Utilize homework assignment notebook/planner/agenda

● Provide written intermediate timelines for long assignments

● Have student monitor grade average

● Keep rules simple and clear

● Implement a behavior management system

Formative Assessments

● Creating the VCarve file with correct settings

● Clamping and Tool Preparation Checklist

Summative Assessments

● CNC Wooden Spoon, Laser Engraved Plaque

Performance Assessments

● Safety checkpoints on the CNC Machine

● Safe operation of the CNC Machine, including set up, running, break down and clean up

RETURN TO CALENDAR

RETURN TO UNIT SUMMARIES

Unit 8:

The Woodworking Process

Unit Summary

Students will work in groups to choose a woodworking project where they will have to work together to plan,

mill, fabricate, assemble, finish multiple projects. This unit caps off the entire year and it is a chance for

students to show their knowledge of project planning, time management, hand tool and machine safety and

operation, and a way for them to showcase their skills with processing and finishing.

Essential Questions

Enduring Understandings

● What type of information can

we reveal about a potential

project through research?

● Many features and options of a project can be revealed

through research. We must research the overall project

idea, materials needed, the joinery possibilities, size and

dimension options, strength requirements, finish

requirements.

● How can we integrate this

research into our planning

process?

● We will utilize the information we have collected to make

the 3 project planning documents, Drawing, BOM, and

Order of Operations.

● What project specific

considerations must be

recognized while making your

plans?

● Each project has a unique and specific set of

considerations including intended use, material, safety,

size, and how many are being produced.

● What is the order of machine

operations in squaring and

dimensioning the stock?

● What special fabrication

operations must be used to

fabricate the complex shapes

and joinery?

● How will project features affect

the assembly and finishing

process?

● Rough crosscut, joint edge, rip cut, cross cut the end to

properly square a board..

● ;Layout and jig and fixture machine set ups are critical to

fabricating complex joinery and shapes.

● Size, shape, type of material, intended use, time

constraints all determine the assembly and finishing

details chosen.

Behavioral Objectives/Learning Outcomes

Standards (NJSLS)

● Utilize the research and design process to select a project

● Research various important elements and options of the project

● Create a overall rough plan for the project

● Create a mechanical drawings

● Create a Bill of Materials

● Create an “Order of Operations”

9.3.ST‐ET.2

● Safely operate machinery to mill square dimensioned parts

● Layout and fabricate the joinery and shapes of the project

● Assemble and Finish the Project

9.3.12.AC‐CST.5

Interdisciplinary Connections

Math, Science, Engineering, Vocational

21st Century Skills

Critical thinking, communication skills, creativity, problem solving, perseverance, collaboration, information

literacy, technology skills and digital literacy, media literacy, global awareness, self-direction, social skills,

literacy skills, civic literacy, social responsibility, innovations skills, thinking skills

Writing Assignments

“Project idea” presentation outline

Order of Operations

Project Reflection

Activities, Instructional Strategies, and Assignments

Research presentation

Rough Plan

Mechanical Drawings

Bill of Materials

Order of Operations

Project Reflection

Accommodations and Modifications (BHPRSD Accommodations and Modifications)

● Provide a variety of concrete examples from familiar contexts

● Provide study guides and support outside of class time to review before assessments (common time

or after school)

● Build background knowledge of content and vocabulary from familiar contexts prior to readings

● Use mental models to building understanding through familiar contexts

● Provide oral & written instructions

● Incorporate multimedia/audio visual representation (YouTube, Discovery Education, TV Show

parodies, etc.) to build understanding

● Use graphic organizers to guide notes, brainstorming, pre-writing, project planning, and test

preparation

● Model through processes during assignments and elicit student-generated thoughts to determine

gaps in understanding

● Highlight, bold, or underline main ideas in readings and in directions for writing assignments in the

curricular areas

● Provide guiding questions to complete during the activity

● Provide chunking of instructional notes and activities to allow for formative assessment (checks for

understanding) before moving on to the next stage

● Choose cooperative learning groups to ensure effective work, maximize productivity and support

socialization

● Use multiple intelligences or the student's learning style to facilitate effective learning when a student

is having difficulty grasping concepts

● Provide demonstrations, utilize pictures, or graphic to assist visual learners to support written text

information

● Include oral discussions, oral presentations, group collaboration, or other oral delivery methods to

support auditory learners

● Utilize hands-on activities, movement or rhythmic experiences to engage tactile/kinesthetic learners

● Provide chunking of assignments into manageable steps, including checklists that clarify directions

for assignments

● Provide a clear, concise version of a scoring rubric prior to the assignment or assessment

● Highlight distinctive features/key concepts

● Provide choice of projects depending on the student’s interests or strengths

● Provide peer assistance/study groups

● Review, repeat, and clarify directions

● Chunk sections of assessment

● Allow for partial credit, when appropriate

● Allow use of familiar contexts to demonstrate understanding of key concepts when use of text

evidence is not necessary

● Provide general assistance with organizational skills

● Utilize homework assignment notebook/planner/agenda

● Provide written intermediate timelines for long assignments

● Have student monitor grade average

● Keep rules simple and clear

Formative Assessments

● Research Project

● Rough Plan

● Mechanical Drawing

● Bill of materials

● Order Of Operations

Summative Assessments

● Choice Project (Yard Games or Tabletop Games)

● Project Reflection Slide

Performance Assessments

● Safe Machining Fabrication Checkpoint

● Assembly Checkpoint

● Finishing Checkpoint

RETURN TO CALENDAR

RETURN TO UNIT SUMMARIES