Improving the casting performance on old Ambassadeurs…for free!

Whenever I acquire a fishing reel I will always strip it down and give it a service-it doesn’t matter if the reel is

new or old. Sometimes new reels come with grease everywhere-ABU must believe that many reels will not

receive any maintenance for a long time so they err on the side of caution. Judging by the condition of some

reels I have seen they have got it right! However, if you do maintain your gear properly then all of this excess

grease and oil can be a hindrance.

Probably the biggest thing you can do to improve the casting (and general) performance of your Ambassadeur is

to give it a service removing all of the excess oil and grease and thoroughly cleaning the spool bearings (or

bushings) before reassembling with the correct amount of oil and grease….in the correct places!

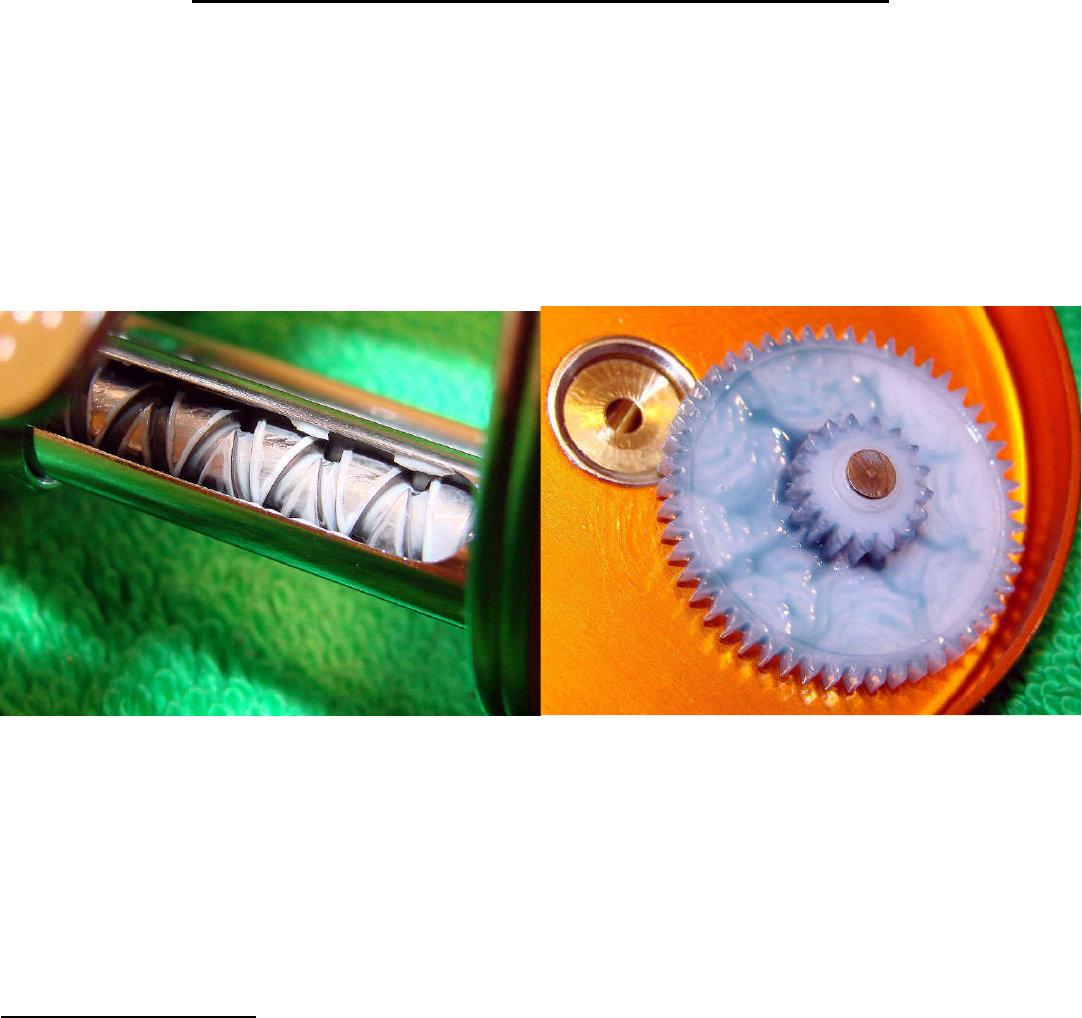

A brand new 5500C (new design) with grease from the factory-all of this grease on the level wind and idler cog

must surely affect casting distances.

During servicing I will take the time to polish up the friction surfaces and do anything I can to make the reel a

little bit smoother. I’ll then change the bearing oil and centrifugal brakes to suit me so that with a free floating

spool I don’t need to thumb the spool until the end of the cast (except in emergencies of course!). The most

important factor for me is ‘user friendliness’. The last thing I want to do when I’m fishing is pick out bird’s

nests!

Bushing 5000 vs. 4600C4

I bought an old 5000 a while back and serviced and tuned it as a matter of course. I didn’t give it much thought

until I was practicing my casting. This is the first bushing reel I have owned so I wanted to familiarize myself

with how it cast and also to work out what size centrifugal brakes to use. As a benchmark I took along a

4600C4 (older version with two centrifugal brake pins).

I put the reels on a 6 ½ ft rod and cast with a ½ oz weight. I was astounded-the 5000 out cast the 4600C4.

Thinking it was a fluke I kept on casting. Every time it was the same-the 5000 cast further. If someone told me

this I wouldn’t believe them-a 5000 with two bushings and a fixed spindle design out casting a 4600C4 with

two spool bearings, a level wind bearing and an ultra-cast spool. It made no sense.

Both reels were completely stock and the 4600C4 had two black plastic brake blocks and Rocket Fuel Red

Label in the bearings whereas the 5000 had two medium fibre brake blocks and 3 in 1 oil in the bushings.

Obviously this is just my experience but it certainly opened my eyes as to how a bit of polishing here and there

can make a huge difference in casting performance and controllability-no more birds’ nests! There are plenty

of optional parts you can fit to your Ambassadeur to improve casting performance-dual bearing level wind,

ceramic bearings, ceramic pawl, ball bearing idler gear, lightweight spool-there is no limit to the options…..and

the cost! However you can make a huge difference as to how your reel casts with a little bit of polishing-and

the best bit is it will cost you next to nothing (assuming you already have the necessary equipment). Old style

Ambassadeurs benefit the most from a polish simply because there are more distance robbing friction surfaces

that can be cleaned up.

What you need

Ideally you will have a Dremel or similar tool and some jeweler’s rouge/ metal polishing paste. I find cotton

buds with a wooden shaft excellent for polishing inside the bushings and pinion gear, whilst felt wheels are

always useful. The idea is to smooth out the surfaces to give them a mirror finish whilst removing as little

metal as possible. You don’t want to change the actual dimensions of the parts-you just want to smooth out

their surfaces.

For polishing I use Dremel jeweler’s rouge and MAAS polishing cream. I personally prefer to use an old

rechargeable Dremel as it has a slower speed setting than a mains powered one.

Dremel tools with various polishing accessories.

Polishing the friction surfaces

When you cast with an old Ambassadeur the main friction surfaces would be:-

• ends of the spool shaft on the copper shims in the side plate caps

• spool shaft on the bushings

• spool shaft on the inside of the pinion gear

• idler gear on the idler gear post

• worm gear

• centrifugal brakes on the brake drum

Polishing these surfaces will make the reel cast more smoothly with less effort. Take your time as it is not

possible to ‘undo’ anything that you have done. When you are happy with the final finish give the part a

thorough clean to remove any trace of polishing compound

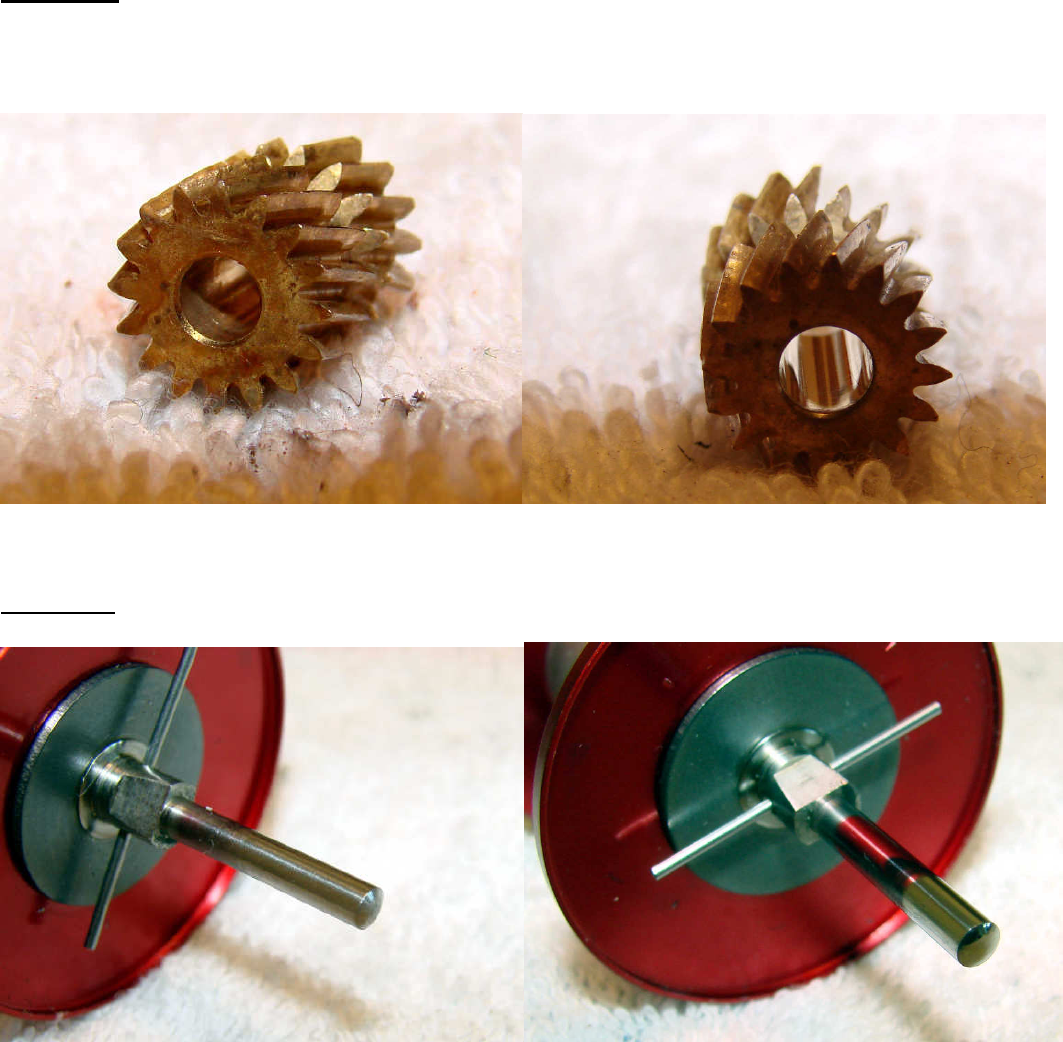

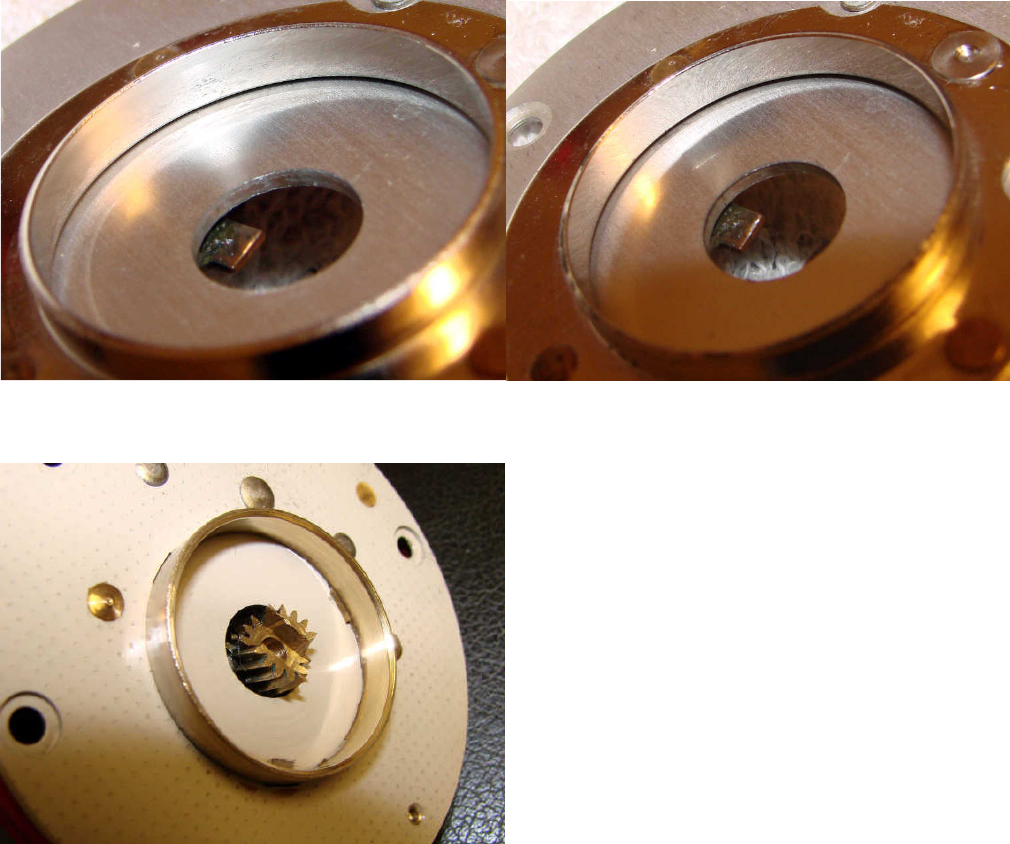

Bushings

Polishing the inside of the bushings gives a smoother contact surface for the spool shaft to ride on.

Before After

Pinion gear

Polishing the inside of the pinion gear reduces friction on the spool shaft.

Before After

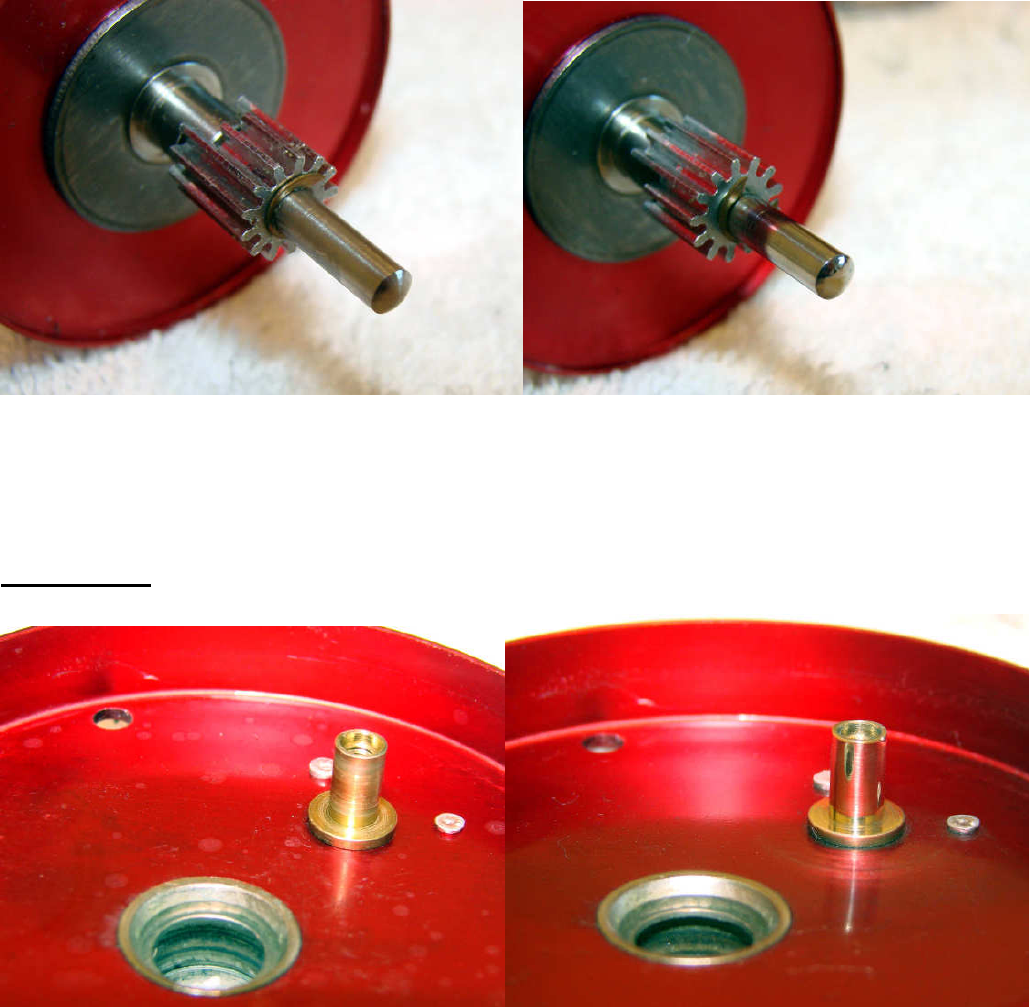

Spool shaft

Before After

If your reel has bearings then only polish the tip of the shaft (where it contacts the copper shims in the spool

cap) and the portion of the shaft where the pinion gear sits. Do not polish the shaft where the bearing sits-if

you do the inner race of the bearing may not ‘grip’ the shaft sufficiently and you will have just turned your

bearing into an expensive bushing! If your reel has bushings then polish the portion of the shaft where the

bushing sits.

If you wrap the spool shaft with electrical tape you can place the spool in an electric drill without marring the

shaft and turn it at a very slow speed. Using a soft cloth with metal polish, apply gentle pressure to the shaft to

polish it. Be very careful as a mistake can damage the spool-if you are not confident of your abilities then do

not try this.

Before After

Again on the other side of the spool shaft only polish the tip if your reel has bearings. If you have bushings (as

in this case), then polish where the bushing sits on the shaft.

Idler gear post

Before After

Polishing the idler gear post gives a smoother surface for the idler gear to ride on.

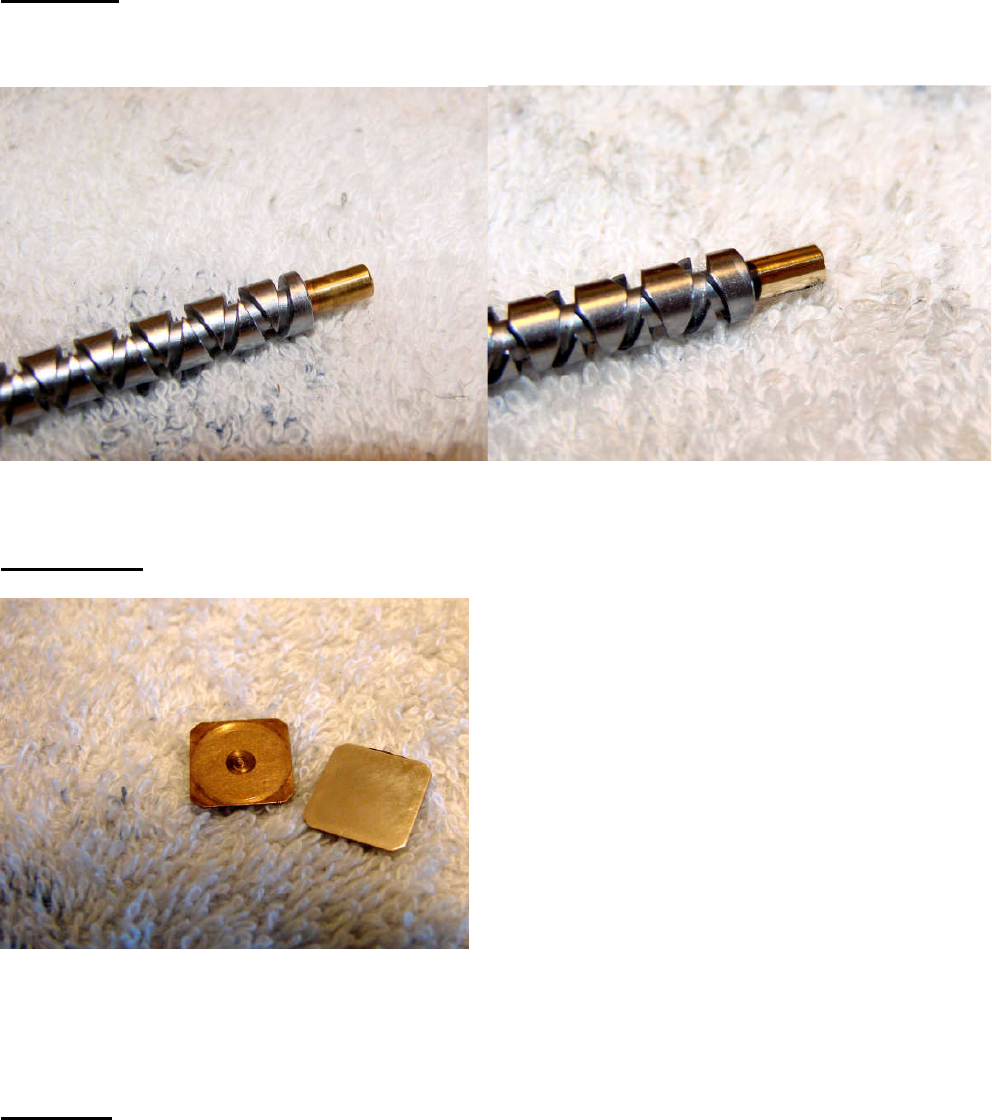

Worm gear

Polish the end of the worm gear where it contacts the plastic bushing in the worm cover.

Before After

Copper shims

Unpolished shim to the left and a polished one to the right.

A polished shim gives a much smoother surface for the end of the spool shaft to sit on. If you use the spool cap

to help with cast control then the control is far more progressive if the shims and spool shaft ends have been

polished.

Brake ring

Centrifugal brakes rely on friction to work so naturally you would not want to reduce the friction on the brake

ring. However, polishing out any minor imperfections on the brake ring actually seems to improve the action of

the centrifugal brakes. With a polished brake ring the brakes make better contact with the ring and the action of

the brakes is more progressive and consistent. This makes for more controllable and consistent casting.

Before After

The improvement is most noticeable on the Ambassadeurs that have the older style brass brake rings but an

improvement can still be seen on reels with chrome brake rings.

All of the polishing work will have reduced the friction on the moving parts during casting. The result is less

effort to cast the same distance- your reel will cast further and in a more controlled manner.

After polishing up the various parts of your reel take the time to work out what combination of centrifugal

brakes and oil works best for your casting style-you will only have to do it once and it will save you a lot of

frustration picking out birds’ nest during fishing time.

© Tim Parratt 2008