Attachment B

State of California

California Air Resources Board

California Standards for Heavy-Duty Remote On-Board

Diagnostic Devices

Adopted: August 22, 2022

NOTE: This document is incorporated by reference in sections 2195 through 2199,

Title 13, California Code of Regulations and is being adopted with this rulemaking, the

proposed text is shown without underline for ease of readability. It contains the device

specifications and certification requirements necessary for the implementation of

vehicle compliance testing for OBD-equipped heavy-duty vehicles as part of the

California’s Heavy-duty Inspection and Maintenance Program. On page 19, Table 4,

item 16 references 13 CCR 1971.1 (h)(4.12), which is from the proposed revisions to

the On-board Diagnostic system requirements and associated enforcement provisions

for passenger cars, light-duty trucks, medium-duty vehicles and engines, and heavy-

duty engines, that was approved by the Board on July 22, 2021, as part of the heavy-

duty OBD and OBD II rulemaking, but which has not yet been approved by the Office

of Administrative Law.

PART I: Definitions.

For the purposes of this document, the following definitions shall apply:

“Authorized representative” means a person who takes responsibility for all the

information submitted for remote on-board diagnostic (ROBD) device certification and

who signs the device certification application.

“Baud rate” means the rate at which data is transmitted on a vehicle internal

communications network.

“Certification” means the process of obtaining an Executive Order with respect to an

ROBD device, complying with the device certification requirements specified in Part III

of this document.

“Controller Area Network (CAN bus)” is an International Organization for

Standardization (ISO) standard (ISO 11898) for vehicle internal communications system

(i.e., bus), designed to allow onboard controllers and external devices to communicate

with one another.

“Device model” means a grouping of similar ROBD devices made by one

manufacturer, vendor, or service provider (e.g., CC-ROBD), that are applicable to the

same vehicle makes and models, and OBD protocol(s).

“Device serial number” means a device unique serial number that the vendor

permanently assigned to a ROBD device.

“DM5” is a standardized diagnostic message in the SAE J1939 onboard diagnostics

communication protocol that reports information related to the diagnostics readiness

of vehicle’s onboard diagnostics system, as defined by parameter definition 5.7.5 of

SAE J1939-73 “Application Layer – Diagnostics”, June 2020.

“DM24” is a standardized diagnostic message in the SAE J1939 onboard diagnostics

communication protocol that reports detailed information about the data supported

by vehicle’s OBD system, as defined by parameter definition 5.7.24 of SAE J1939-73

“Application Layer – Diagnostics”, June 2020.

“Electronic Control Unit (ECU),” also known as electronic control module, is

responsible for controlling one or multiple electrical system(s) in a vehicle.

“InfoType” means the vehicle-specific vehicle information available via Mode $09, as

defined by parameter definition 8.9 of SAE J1979 “E/E Diagnostic Test Modes”,

February 2017.

“Mode $06” also known as “Service $06” is the SAE J1979 service that allows access

to the results of the on-board diagnostic monitoring tests for specific components and

B-1

systems, as defined by parameter definition 8.6 of SAE J1979 “E/E Diagnostic Test

Modes”, February 2017.

“Mode $09” also known as “Service $09” is the SAE J1979 service that provides

vehicle-specific information (e.g., Vehicle Identification Number, Engine Serial

Number), as defined by parameter definition 8.9 of SAE J1979 “E/E Diagnostic Test

Modes”, February 2017.

“Monitor ID” identifies an individual diagnostic test for a Mode $06

component/system, as defined by parameter definition 8.6 of SAE J1979 “E/E

Diagnostic Test Modes”, February 2017.

“OBD data test vehicle” means a vehicle that is used for purposes of testing a

potential ROBD device during the certification process.

“OBD protocol group” means the vehicle’s OBD communication protocol such as SAE

J1939, SAE J1979, or SAE J1979-2.

“Original purchaser” means the first person who purchases and uses a new ROBD

device.

“Owner’s manual” means a document or collection of documents prepared by the

manufacturer of a product for the owners or operators to describe appropriate

maintenance, applicable warranties, and similar information related to operating or

keeping the product. The owner’s manual is typically provided to the original

purchaser at the time of sale. The owner’s manual may be in paper or electronic

format.

“Standardized data link connector” means an OBD device connector incorporated in

each heavy-duty vehicle according to the specifications in section h(2) of the CARB

heavy-duty OBD regulation (section 1971.1, title 13, CCR).

PART II: Device Requirements.

A. Purpose

1. The purpose of Part II is to establish CARB’s requirements for remote OBD

devices in order to be used by OBD-equipped heavy-duty vehicles as a

means of demonstrating compliance with the HD I/M Regulation.

B. Reference Documents: The following sections of the California Code of

Regulations (CCR) are incorporated into this regulation:

1. Section 1968.2, title 13, CCR, “Malfunction and Diagnostic System

Requirements--2004 and Subsequent Model-Year Passenger Cars, Light-

Duty Trucks, and Medium-Duty Vehicles and Engines”, as last amended

October 3, 2019; and

B-2

2. Section 1971.1, title 13, CCR, “On-Board Diagnostic System Requirements -

2010 and Subsequent Model-Year Heavy-Duty Engines”, as last amended

October 3, 2019.

C. Documents Incorporated by Reference: The following documents are

incorporated by reference into this regulation:

1. Section 86.010-18, title 40, Code of Federal Regulations, “On-board

Diagnostics for engines used in applications greater than 14,000 pounds

GVWR”, 2009;

2. ISO 11898-1 “Road vehicles – Controller area network (CAN) – Part 1: Data

link layer and physical signaling”, 2015;

3. ISO 11898-2 “Road vehicles – Controller area network (CAN) – Part 2: High-

speed medium access unit”, 2016;

4. ISO 15031-4 “Road vehicles — Communication between vehicle and

external equipment for emissions-related diagnostics — Part 4: External test

equipment”, 2014;

5. SAE J1699-2 “Test Cases for OBD-II Scan Tools and I/M Test Equipment”,

2017;

6. SAE J1962 "Diagnostic Connector”, July 2016;

7. SAE J1978 "OBD II Scan Tool – Equivalent to ISO/DIS 15031-4", April 2002;

8. SAE J1979 "E/E Diagnostic Test Modes", February 2017;

9. SAE J1979-DA “Digital Annex of E/E Diagnostic Test Modes”, May 2019;

10. ISO 15765-4 "Road Vehicles-Diagnostics Communication over Controller

Area Network (DoCAN) - Part 4: Requirements for emission-related

systems", April 2021;

11. SAE J1939 “Recommended Practice for a Serial Control and

Communications Heavy Duty Vehicle Network – Top Level Document”,

August 2018;

12. SAE J1939-DA “Digital Annex of Serial Control and Communication Heavy

Duty Vehicle Network Data,” March 2020;

13. SAE J1939-3 “On Board Diagnostics Implementation Guide”, 2015;

14. SAE J1939-13 “Off-Board Diagnostic Connector”, October 2016;

15. SAE J1939-21 “Data Link Layer”, October 2018;

B-3

16. SAE J1939-73 “Application Layer – Diagnostics”, June 2019;

17. SAE J1939-81 “Network Management”, March 2017;

18. SAE J3005-1 “Permanently or Semi-Permanently Installed Diagnostic

Communication Devices”, February 2019;

19. SAE J3005-2 “Permanently or Semi-Permanently Installed Diagnostic

Communication Devices, Security Guidelines”, March 2020;

20. SAE J1979-2 “E/E Diagnostic Test Modes: OBDonUDS”, April 2021.

D. General Device Requirements.

1. The ROBD device shall not interfere with the normal operation of the vehicle

or any manufacturer- or third party-installed device in communication with

the vehicle’s OBD system.

2. Any ROBD device used for compliance purposes shall be capable of

performing the following tasks as further specified in the requirements

provided in section E of this Part.

2.1. Establishing connection with the vehicle and verifying vehicle’s

support of OBD at the individual ECU level;

2.2. Collecting the OBD data required to be submitted as part of the HD

I/M Regulation specified in this Part; and

2.3. Submitting data securely via the standardized data submission format

to the electronic reporting system.

3. The ROBD device shall request data from the onboard ECUs indicating OBD

support, as specified in subsection E.2 of this Part.

4. The ROBD device shall timestamp each sent request and received response

from the CAN bus in the submitted data file, as specified in subsection E.4

of this Part.

5. The ROBD device shall be capable of receiving multiple responses when

requesting information (either multiple controllers responding to a request

or a controller responding multiple times to a request).

6. The ROBD device shall support at least one OBD protocol, however it may

support multiple OBD protocols.

7. The ROBD device shall support at least one heavy-duty engine model,

however it may support multiple heavy-duty engine or vehicle models.

B-4

8. The ROBD device shall be functional in standard working and vehicle

environments and thus be resistant to shock, vibration, and environmental

exposure.

9. The ROBD device shall be tamper-resistant to make sure no alteration or

erasure can be made on the data collected.

10. The ROBD device shall have a device unique serial number that is affixed,

engraved, or stamped in a legible manner. This unique serial number shall

be displayed externally and shall match the device’s electronic unique serial

number.

11. The vendor shall warrant to the purchaser and each subsequent purchaser

that the device is designed and built free from defects in materials and

workmanship. Further, the vendor shall ensure that the devices sold for this

program shall be identical in all material respects to the part as described in

the application for device certification for a minimum of one (1) year from

the date of delivery. If a subsequent purchaser obtains the device prior to

the end of the warranty period, the warranty shall extend to the new

purchaser through the required one-year period.

12. The vendor shall ensure proper and functioning communication between the

ROBD device and the electronic reporting system.

13. Broken ROBD devices no longer meeting the requirements of this Appendix

shall not be allowed to submit vehicle compliance data to the electronic

reporting system.

E. Specific Device Requirements.

This section provides detailed specifications for ROBD devices that meet CARB HD

I/M Regulation requirements. The specifications apply to both CC-ROBD and NCC-

ROBD devices, unless indicated otherwise.

1. Diagnostics Connector.

1.1. The ROBD device shall be compliant with SAE J3005-1, J3005-2, and

ISO 15765-4.

1.2. Plug-in ROBD devices (i.e., NCC-ROBD and semi-permanently CC-

ROBD device) developed to meet both SAE J1939, SAE J1979, or

SAE J1979-2 OBD protocols, whichever applicable, shall be capable

of mating to both the connectors defined in SAE J1962/ISO 15031-3

and SAE J1939-13.

1.3. All plug-in ROBD devices shall be capable of connecting to

the standardized data link connector, as specified in subsection E.1.2

B-5

of this Part, as an alternative to any other type of connection that may

be used as the primary connection option.

1.4. The SAE J1979, or SAE J1979-2 ROBD device, whichever applicable,

shall meet the specified requirements in ISO 15765-4 for CAN on

heavy-duty vehicles using these protocols.

1.5. The ROBD device shall meet the same requirements for baud rate, as

specified for the standard OBD connector, in section (h)(2) of CARB

HD OBD regulation (Section 1971.1, Title 13, CCR).

1.6. The J1939 ROBD device shall meet the requirements and guidelines

in SAE J1939-3 for the implementation of OBD on heavy-duty

vehicles using this protocol.

2. Communication with the Vehicle.

2.1. SAE J1939 device.

2.1.1. The ROBD device shall comply with SAE J1939-21 and SAE

J1939-71 when connected to a SAE J1939 vehicle.

2.1.2. The ROBD device shall meet all the requirements in section 4,

SAE J1939-3.

2.1.3. The ROBD device shall act as a client for diagnostics services

provided by the vehicle network, including those specified in

Table 1, SAE J1939-73.

2.1.4. The ROBD device initialization shall be performed prior to

requesting diagnostic services from any ECU. Failure to

complete any of the steps in 2.1.4.1 to 2.1.4.3 shall be defined

as an initialization failure.

2.1.4.1. Address claim: The ROBD device shall meet address

claim and dynamic addressing requirements in SAE

J1939-81. The ROBD device shall only claim address

249 or address 250.

2.1.4.2. Verifying OBD compliance: The ROBD device shall

send a global DM5 request as outlined in SAE J1939-

3.

2.1.4.3. The ROBD device shall confirm OBD compliance (i.e.,

at least one of the vehicle’s onboard ECUs supports

CARB's, U.S. EPA’s (title 40, CFR, section 86.010-18),

or equivalent OBD requirements) after successful

B-6

completion of the address claim process and

receiving DM5 support response(s) from one or more

onboard ECUs.

2.1.5. Identifying the available data: The ROBD device shall send

destination-specific requests for DM24 to all OBD compliant

ECUs identified, as described in subsection E.2.1.4.3 of this

Part and record all the received responses.

2.1.5.1. As described in SAE J1939-71, the ROBD device

shall refrain from requesting data that is routinely

broadcast on the network.

2.2. SAE J1979 device.

2.2.1. The ROBD device shall be compliant with SAE J1979.

2.2.2. The ROBD device shall communicate with the vehicle OBD

system using the signaling standard, and meeting the timing

requirements, of ISO 15765-4.

2.2.3. The ROBD device shall meet the standardized communication

requirements for scan devices as illustrated in SAE J1699-2.

2.2.4. The ROBD device shall meet the requirements in SAE

J1978/ISO 15031-4 and SAE 1699/2 to avoid disturbing the

in-vehicle communication.

2.2.5. The ROBD device shall meet the requirements in SAE J3005-1

and J3005-2.

2.2.6. The ROBD device shall utilize the initialization sequence of

ISO 15765-4 in order to establish communication before

sending diagnostic requests.

2.2.7. Identifying the available data: The ROBD device shall record

all responses, including CAN source (i.e., specific ECU), to

Parameter ID (PID) availability requests in Mode $01 sent

during initialization

2.2.8. The ROBD device shall conduct an analogous scan for

available Monitor IDs (MIDs) in Mode $06.

2.2.9. The ROBD device shall conduct an analogous scan for

available InfoTypes in Mode $09.

2.3. SAE J1979-2 device.

B-7

2.3.1. The ROBD device shall be compliant with SAE J1979-2.

2.3.2. The ROBD device shall communicate with the vehicle OBD

system using the signaling standard, and meeting the timing

requirements, of ISO 15765-4.

2.3.3. The ROBD device shall meet the standardized communication

requirements for scan devices as illustrated in SAE J1699-2 or

later version, whichever is applicable for vehicles using SAE

J1979-2.

2.3.4. The ROBD device shall meet the requirements in SAE

J1978/ISO 15031-4 and SAE 1699-2 for vehicles using SAE

J1979-2, to avoid disturbing the in-vehicle communication.

2.3.5. The ROBD device shall meet the requirements in SAE J3005-1

and J3005-2.

2.3.6. The ROBD device shall utilize the initialization sequence of

ISO 15765-4 in order to establish communication before

sending diagnostic requests.

2.3.7. Identifying the available data: The ROBD device shall record

all responses, including CAN source (i.e., specific ECU), to

Service $22 Parameter ID (PID) availability requests sent

during initialization.

2.3.8. The ROBD device shall conduct an analogous scan for

supported monitor test results using Service $19, subfunction

1A.

2.4. The ROBD device shall not communicate with the CAN Bus while the

device is loading, initializing the operating system, or undergoing

firmware or software updates.

2.5. In the case of failed initialization (i.e., vehicle not responding to the

ROBD device within the required duration), the ROBD device shall

repeat the initialization sequence, up to three times.

2.5.1. The ROBD device shall meet the response time requirements

as outlined in SAE J1939-21 and SAE J1979 or SAE J1979-2,

as applicable.

2.5.2. After the third failed initialization attempt, the vendor shall

notify the vehicle owner of the failed communication between

the ROBD device and the vehicle.

B-8

2.5.3. The ROBD device shall submit a “Failed Communication”

message to the electronic reporting system.

2.6. In the case of a vehicle not supporting the relevant OBD requirement

following an initialization sequence, the ROBD device shall repeat the

initialization sequence, up to three times.

2.6.1. If all initialization attempts confirm the initial results, the

vendor shall notify the vehicle owner, as specified in

subsection E.2.5.2 of this Part.

2.6.2. The ROBD device shall submit a “Vehicle not OBD compliant”

message to the electronic reporting system.

3. Collecting the Required OBD Data from the Vehicle.

3.1. The ROBD device shall be capable of collecting all the data, as

specified in sections (h)(4) and (h)(5) of the CARB heavy-duty OBD

regulation (section 1971.1, title 13, CCR) (see Table 4 in subsection

E.6 of this Part for more detail).

3.2. The CC-ROBD device shall collect data, as specified in subsection

E.3.1 of this Part, once every 7 days or at the first engine key ON past

the 7th day, as separate data logs.

3.3. The CC-ROBD device shall collect data only when the vehicle is

stationary and in key ON, engine running status.

4. Formatting the Collected OBD Data. The ROBD device shall meet the

following data format specification for submitting the collected data.

4.1. File Structure. The file shall consist of two sections: the data header,

and the CAN Bus data in hexadecimal format.

4.1.1. Data Header. The data header shall be in ASCII text format

and contain the fields listed in Table 1.

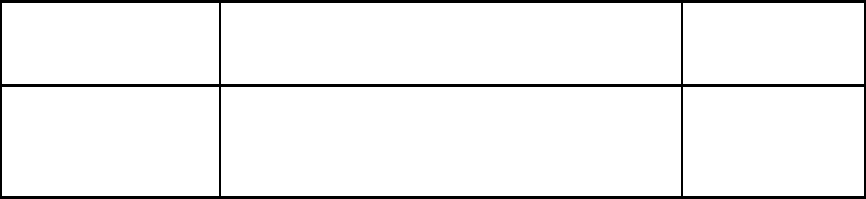

Table 1: Contents of the header section of the submission file

Data Field Name Description of Data

Data Type

(length)

VIN

Vehicle identification number located on

the tested vehicle in CARB-specified

format

String (17)

B-9

SAE Protocol

Vehicle’s OBD communication protocol

(SAE J1939/J1979/J1979-2)

String (10)

Odometer*

Odometer reading of the vehicle at the

time the OBD data is downloaded from

the vehicle OBD system (required if

supported)

Integer (7)

Engine Total

Runtime

Accumulated engine runtime over the

lifetime of the vehicle, as specified in

subsection h(5.2.1.A) of the CARB HD

OBD regulation (section 1971.1, title 13,

CCR)

Integer (10)

Device Name

The model of the ROBD device

String (50)

Device

Manufacturer

Name of the ROBD device manufacturer

String (50)

Device Serial

Number

The serial number of the ROBD device

assigned by the vendor

String (50)

Device Firmware

Number

The firmware/version number of the

software in the ROBD device

String (20)

Firmware

Verification

Number

A number derived from

the ROBD device firmware that verifies

the firmware has not been altered

String (20)

Record ID

A unique value from an ascending

numerical sequence assigned by the

ROBD device to each submission

Integer (7)

Data Collection

Date and Time

The timestamp at the

time the ROBD device starts

downloading

OBD data from the vehicle OBD

system. The timestamp is in coordinated

universal time (UTC) and in the format

of YYYY-MM-DD hh:mm:ss.mmm.

Datetime

* PID $7F for SAE J1979, PID $F47F for J1979-2. See SAE

J1939DA for PGNs and SPNs.

B-10

4.1.2. CAN Bus Data.

4.1.2.1. The J1979 or J1979-2, as applicable, ROBD device

shall follow the formatting specification in Table 2 for

the CAN Bus data section of the submission file.

4.1.2.2. The J1939 ROBD device shall follow the formatting

specification in Table 3 for the CAN Bus data section

of the submission file.

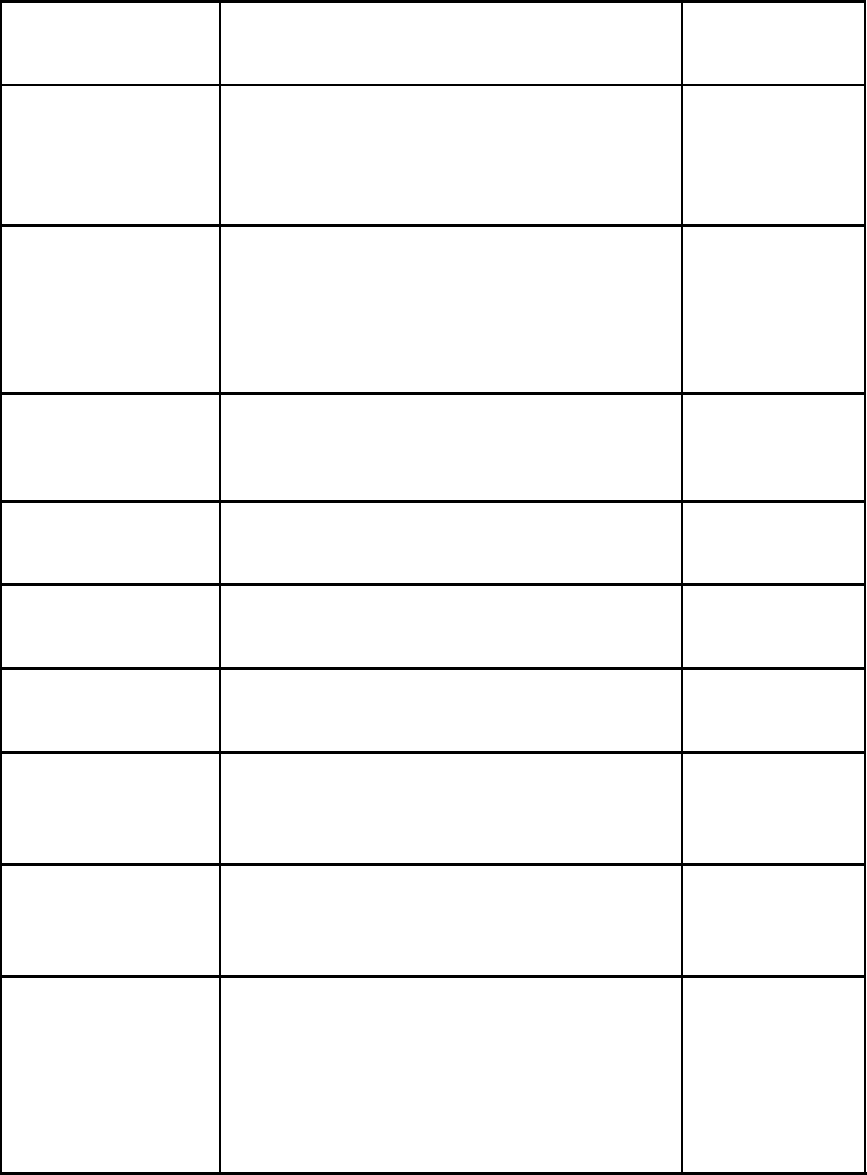

Table 2: CAN Bus data formatting requirements for the J1979 or J1979-2, as

applicable, ROBD device

Data Field

Name

Description of Data

Data Type

(length)

Timestamp

The time that a message is sent from

the ROBD device to the vehicle or received from

the vehicle. The timestamp is in UTC and has

millisecond precision. The timestamp is in the

format of YYYY-MM-DD hh:mm:ss.mmm.

Datetime

Message Type The message type of the data line indicates if the

message was sent from the OBD device to the

vehicle or received from the vehicle.

"REQ" is the request messages sending to the

vehicle, and "RSP" is the response messages

received from the vehicle.

String (3)

ECU Address

The hexadecimal address of the

ECUs that respond to the request. The REQ

messages will not have an ECU

address. The RSP messages will have the

hexadecimal address of the responding ECUs.

String (15)

Message

Data

The data portion of the CAN message sent to or

received from the vehicle's OBD system. The

data shall be ASCII text that represents the

hexadecimal values.

String

B-11

Table 3: CAN Bus data formatting requirements for the J1939 ROBD tool

Data Field

Name

Description of Data

Data Type

(length)

Timestamp

The time that a message is sent from the

ROBD device to the vehicle or received from the

vehicle. The timestamp is in UTC and has

millisecond precision. The timestamp is in the

format of YYYY-MM-DD hh:mm:ss.mmm.

Datetime

Message Type

The message type of the data line indicates if the

message was sent from the ROBD device to the

vehicle or received from the vehicle. "REQ" is the

request messages sending to the vehicle, and

"RSP" is the response messages received from the

vehicle.

String (3)

CAN ID

CAN ID

String (15)

Message Data

The data portion of the CAN message sent to or

received from the vehicle's OBD system. The data

shall be ASCII text that represents the

hexadecimal values.

String

5. Transmitting the Collected Data to the CARB Electronic Reporting System.

5.1. Connection and Authentication: The vendor shall register the ROBD

device in the electronic reporting system as a valid testing device in

order to receive authentication to submit data as part of the HD I/M

Regulation.

5.2. All OBD data submissions to CARB must emanate from a centralized

database maintained by the vendor.

5.3. Data Integrity and Transmission.

5.3.1. Subsequent to formatting the collected data, as specified in

subsection E.4 of this Part, the ROBD device shall encrypt the

data file.

5.3.2. The data shall not be altered or tampered with during or prior

to electronically submitting to the electronic reporting system.

B-12

5.3.3. The data file shall be transmitted securely from the ROBD

device to the electronic reporting system once available.

5.3.4. The CC-ROBD device shall transmit at least one and up to the

15 most recent unsubmitted data logs collected when

submitting to the electronic reporting system.

5.4. Data Storage.

5.4.1. The ROBD device shall have enough internal storage capacity

to store, at minimum, 15 encrypted data files that have not

been submitted.

5.4.2. The collected OBD data shall be retained securely for at least

seven days following a successful submission to the electronic

reporting system.

6. Data Fields.

6.1. Table 4 specifies the OBD data required to be collected by a ROBD

device.

B-13

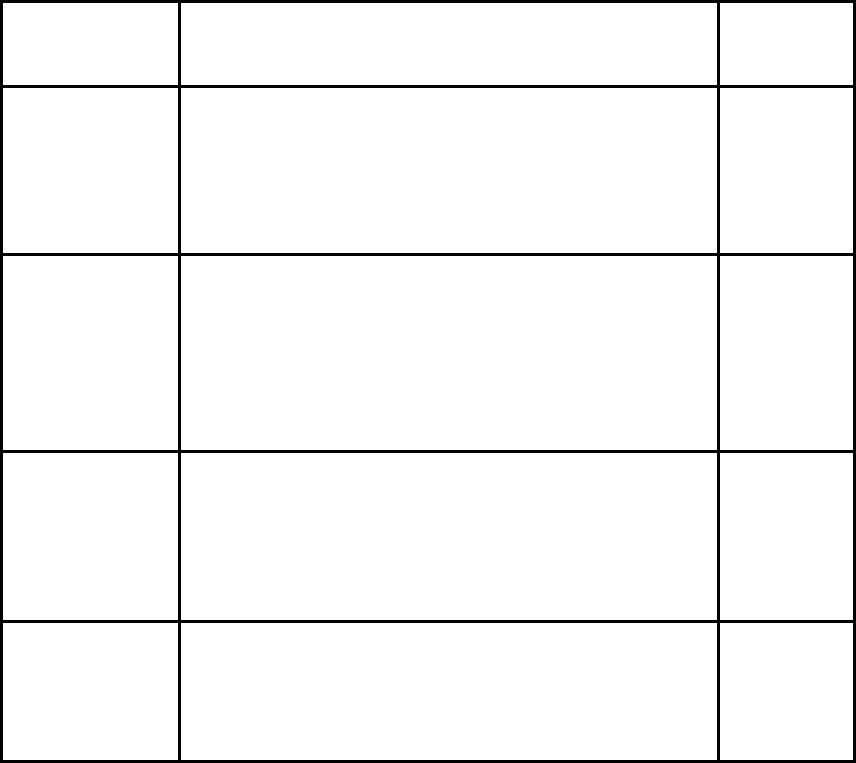

Table 4: Specifications of the OBD data required to be collected by a ROBD device

Item

Data Type

Corresponding

Section in CARB

HD OBD

Diagnostic

Message(s) in

SAE J1939

Diagnostic

Message(s) in

SAE J1979

Diagnostic

Message(s) in

SAE J1979-2

Comments

Regulation (CCR

Title 13, Section

1971.1)

OBD Protocol OBD Protocol OBD Protocol

1

Readiness

status of all

(h)(4.1)

DM5

Mode $01 PID

$01

Service $22 DID

$F501

OBD monitors

listed in

sections (e)

and (g) of the

heavy-duty

OBD

Regulation

2

All data

stream

parameters

(h)(4.2.2)

(h)(4.2.3)

See SAE

J1939DA for

PGNs and

SPNs (include

DM21, DM26,

and DM34)

Mode $01, see

SAE J1979DA

for PIDs

Service $22, see

SAE J1979DA for

$F400 - $F5FF

DIDs

B-14

Item

Data Type

Corresponding

Section in CARB

HD OBD

Regulation (CCR

Title 13, Section

1971.1)

Diagnostic

Message(s) in

SAE J1939

OBD Protocol

Diagnostic

Message(s) in

SAE J1979

OBD Protocol

Diagnostic

Message(s) in

SAE J1979-2

OBD Protocol

Comments

3

Freeze frame

data

(h)(4.3)

DM25

Mode $02

Service $19 $04

DTCMREC

DTC Snapshot

Record Number

= $00 (first

occurrence)

or $F0 (latest

occurrence)

DM24 is

necessary to

interpret

DM25 data.

4

Fault codes

(h)(4.4)

DM1, DM6,

Modes $03,

Service $19 $42

The union of

including DM12, DM23, $07, $0A $33 $08 $02, fault codes

active,

pending, and

permanent

DM28, DM29 Service $19 $42

$33 $04 $02,

Service $19 $55

$33

returned by

DM12 and

DM23 meet

the J1979

definition for

confirmed

fault codes.

B-15

Item

Data Type

Corresponding

Section in CARB

HD OBD

Regulation (CCR

Title 13, Section

1971.1)

Diagnostic

Message(s) in

SAE J1939

OBD Protocol

Diagnostic

Message(s) in

SAE J1979

OBD Protocol

Diagnostic

Message(s) in

SAE J1979-2

OBD Protocol

Comments

5

Test results

(h)(4.5)

DM30

Mode $06

Service $19 $06

DTCMREC $92

Use DM24 to

create ECU-

specific list of

supported

SPNs for test

results. Use

DM7 with a

Test ID value

of 247 and

Failure Mode

Indicator of

31 to obtain

test results

(DM30

responses)

for SPNs

listed in

DM24.

6

Software

calibration ID

(Cal-ID)

(h)(4.6)

(h)(4.7)

DM19

Mode $09

InfoType $04

Service $22

InfoType $F804

B-16

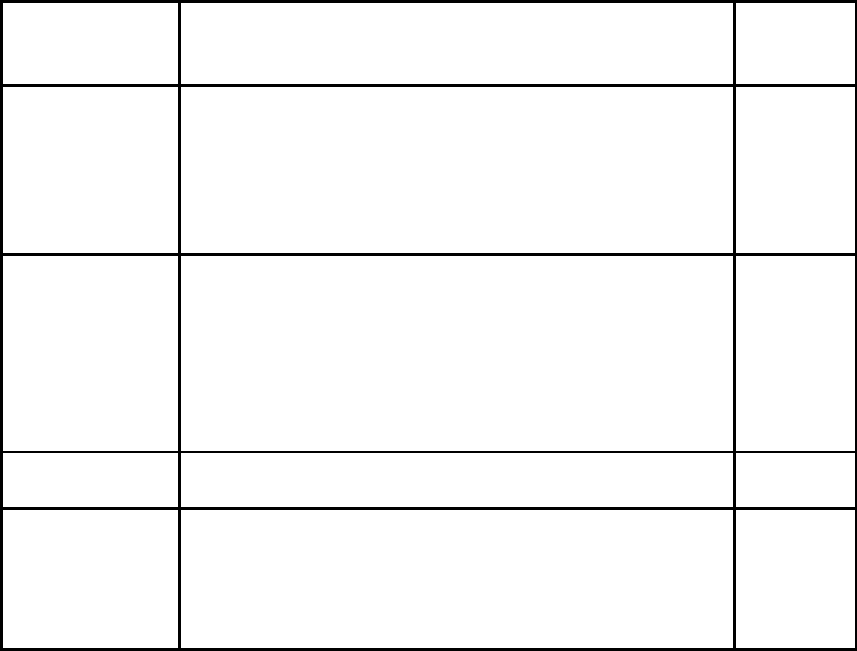

Item

Data Type

Corresponding

Section in CARB

HD OBD

Regulation (CCR

Title 13, Section

1971.1)

Diagnostic

Message(s) in

SAE J1939

OBD Protocol

Diagnostic

Message(s) in

SAE J1979

OBD Protocol

Diagnostic

Message(s) in

SAE J1979-2

OBD Protocol

Comments

7

Calibration

(h)(4.6)

DM19

Mode$09

Service $22

Verification

Number

(CVN)

(h)(4.7) InfoType $06 InfoType $F806

8

VIN

(h)(4.8)

PGN: 65260

SPN: 237

Mode$09

InfoType $02

Service $22

InfoType $F802

9

Engine serial

number

(h)(4.8)

PGN: 65259

SPN: 588

Mode $09

InfoType $0D

Service $22

InfoType $F80D

10

Engine family

(h)(4.2)

DM56

Mode $09

InfoType $13

Mode $09

InfoType $F813

Applies to

2024 and

subsequent

model year

engines

11

ECU name

(h)(4.9)

PGN: 60928

SPN:2848

Mode $09

InfoType $0A

Service $22

InfoType $F80A

12

Monitor in-use

performance

ratio

(h)(5.1)

DM20

Mode $09

InfoType $0B

Service $19 $06

DTCMREC $91

13

Engine run

time tracking

data

(h)(5.2)

See SAE

J1939DA for

PGNs and

SPNs

Mode $01, see

SAE J1979DA

for PIDs

Service $22, see

SAE J1979DA for

DIDs

B-17

Item

Data Type

Corresponding

Section in CARB

HD OBD

Regulation (CCR

Title 13, Section

1971.1)

Diagnostic

Message(s) in

SAE J1939

OBD Protocol

Diagnostic

Message(s) in

SAE J1979

OBD Protocol

Diagnostic

Message(s) in

SAE J1979-2

OBD Protocol

Comments

14

NOx

emissions

tracking data

(h)(5.3)

PGNs: 64258

thru 64279

Mode $09

InfoTypes $61 -

$76

Service $22

InfoTypes $F861 -

$F876

Applies to all

OBD systems

in 2022 and

subsequent

model year

diesel

engines

15

GHG tracking

data

(h)(5.4) thru

(h)(5.6)

PGNs: 64252

thru 64257

Mode $09

InfoTypes $41 -

$49, $50 - $5B

Service $22

InfoTypes $F841 -

$F849, $F850 -

$F85B

Applies to all

OBD systems

in 2022 and

subsequent

model year

diesel

engines

16

PM filter

regeneration

event data

(h)(5.8)

See SAE

J1939DA for

PGNs and

SPNs

Mode $01

PID $8B

Service $22 DID

$F48B

Applies to

2024 and

subsequent

model year

engines

B-18

Item

Data Type

Corresponding

Section in CARB

HD OBD

Regulation (CCR

Title 13, Section

1971.1)

Diagnostic

Message(s) in

SAE J1939

OBD Protocol

Diagnostic

Message(s) in

SAE J1979

OBD Protocol

Diagnostic

Message(s) in

SAE J1979-2

OBD Protocol

Comments

17

Readiness

status of each

monitor within

a readiness

group

N/A

N/A

N/A

Service $19 $56

$33 RGID

Data

available for

every OBD

monitor tied

to a

readiness

group

B-19

Part III: Requirements for Vendors.

A. Overview and Applicability.

The Executive Officer shall certify devices and provide an Executive Order for the

device to the vendor if the vendor meets the requirements specified in this appendix.

A vendor submitting a device for certification shall submit the full, complete, and

current configuration proposed for sale and consumer use and have design control of

the device.

B. Certification Application.

1. Prior to submitting a certification application, a vendor shall submit a test plan

detailing the vendor initial validation testing methodology described in subsection

C.1 of this Part. Prior to conducting testing, the vendor shall ensure the test plan is

approved by the Executive Officer.

2. A vendor shall complete and submit device certification application forms

approved by the Executive Officer and other required information for evaluation of

the application. Applications shall be submitted during a one (1) month open

collection period per year, as designated by Executive Officer.

2.1. All information included as part of an application package shall be

true, accurate, and include complete statements and information. The

application package shall not omit information relevant to the

requirements specified in this appendix.

2.2. An authorized representative of the company shall attest to the

information included in the application and approve and sign the

application.

2.3. The application shall include the following information and shall be

approved by the Executive Officer prior to CARB staff performing any

verification testing specified in subsection C.2 of this Part:

2.3.1. A detailed description of the design of the device and how

the device is consistent with and meets the requirements

specified in Part II of this document.

2.3.2. Device manufacturer, if vendor is not the manufacturer of the

device.

2.3.3. Device Model.

2.3.4. Method used for vendor initial validation testing, e.g. OBD

data test vehicles that include model year, make, model, etc.

B-20

2.3.5. Engine Original Equipment Manufacturer (OEM), engine

family and engine model year(s), vehicle makes and models

that the device can be used on.

2.3.6. Applicable OBD protocol(s) of the device.

2.3.7. Vendor shall identify if they plan to update devices already in

use in existing vehicle(s).

2.3.8. Vendor documentation of initial validation testing meeting the

requirements specified in subsection C.1 of this Part.

2.3.9. A detailed proposal for finding applicable fleets/vehicles to

test devices in the field to meet the vendor field testing

requirements specified in subsection C.3 of this Part, including

expected testing locations and the estimated number of

vehicles broken down by fleet, engine OEM, engine model

year, vehicle make and model, fuel type, and OBD protocol.

After the Executive Officer approves the detailed proposal,

any changes or deviations from the plan shall be reviewed and

approved by CARB.

2.3.10. A proposed timeline for completing the field testing

requirements specified in subsection C.3 of this Part.

2.3.11. Any additional information that may be necessary to help

verify that the device meets the requirements of this Part.

3. Vendor shall provide a copy of the warranty statement that will be provided to the

original purchaser of the device as specified in Part II subsection D.11.

4. Vendor shall provide a Statement of Compliance to unconditionally certify that all

the devices are designed with tamper-resistant components, built as described in

the certification application, and comply with the requirements of this Part.

5. Vendor shall provide a statement to the original purchaser of a certified device to

provide assurance that the device is valid for use in the HD I/M program from the

date indicated in the Executive Order until the end of the calendar year, that it

must be recertified annually, and may be decertified by CARB at any time if

deviations are identified.

6. Vendor shall provide a written document to describe the process and provide a set

schedule of performing updates to the hardware, firmware, or software.

7. Vendor shall provide a name of an agent for service located in the United States.

Service on this agent constitutes service on the vendor for any action by CARB or

otherwise by the United States related to the requirements of this Part.

B-21

C. Testing Requirements for Certification.

The following certification testing shall be performed to demonstrate that the device

meets the program requirements and shall be completed in the following phases:

1. Vendor Initial Validation Testing. Testing shall be completed by the vendor

following the required specifications and test conditions described below prior to

submitting their application package and shall be consistent with the requirements

in Part II.

1.1. Vendor shall test their device(s) using the specified test conditions

below.

1.1.1. Test at least one vehicle from every OBD protocol group

applicable to the device and provide three consecutive ROBD

submission files from each vehicle that demonstrates that the

engine revolutions per minute (RPM) is greater than zero and

the vehicle speed is equal to zero.

1.1.2. Test at least one vehicle from every OBD protocol group

applicable to the device and provide three consecutive ROBD

submission files from each vehicle where the MIL is

commanded OFF, there are no pending, active, or permanent

trouble codes, and all vehicle supported readiness monitors

are in a ready state.

1.1.3. Test at least one vehicle from every OBD protocol group

applicable to the device and provide three consecutive ROBD

submission files from each vehicle where the MIL is

commanded ON, and there is at least one stored active

diagnostic trouble code and at least one pending diagnostic

trouble code.

1.1.4. Test at least one vehicle from every OBD protocol group

applicable to the device and provide three consecutive ROBD

submission files from each vehicle where the MIL is

commanded ON and there is at least one permanent

diagnostic trouble code.

1.1.5. Test at least one vehicle from every OBD protocol group

applicable to the device and provide three consecutive ROBD

submission files from each vehicle where the MIL is

commanded OFF, there are no diagnostic trouble codes, and

at least one monitor is not ready.

1.1.6. Test at least one vehicle from every OBD protocol group

applicable to the device and provide three consecutive ROBD

B-22

submission files from each vehicle showing that the electronic

VIN is received from the vehicle and is not a user inputted

VIN.

1.1.7. Test at least one hybrid vehicle from every OBD protocol

group applicable to the device and provide three consecutive

ROBD submission files where the MIL is commanded OFF,

there are no pending, current, or permanent diagnostic

trouble codes, and all vehicle supported readiness monitors

are in a ready state.

1.1.8. Test at least one alternative fuel vehicle from every OBD

protocol group applicable to the device and provide three

consecutive ROBD submission files from each vehicle where

the MIL is commanded OFF, there are no pending current, or

permanent diagnostic trouble codes, and all vehicle

supported readiness monitors are in a ready state.

1.1.9. Test at least one vehicle from every OBD protocol group

applicable to the device and provide three consecutive ROBD

submission files from the different communication baud rates

(i.e. 250/500 kilobits per second (kbps)) supported by the

protocols.

1.1.10. Specifically for CC-ROBD devices, test at least one vehicle

from every OBD protocol group applicable to the device and

provide three submission files that contain multiple data logs

that were collected and stored every seven days as specified

in Part II subsection E.3.2.

1.2. In addition to the ROBD submission files that are submitted with the

initial validation testing, the vendor shall include the following

additional information in an organized format:

1.2.1. OBD data test vehicle(s): Year, Make, Model, VIN (or OBD

simulator)

1.2.2. The OBD protocol of the vehicle(s)

1.2.3. Engine and engine family of test vehicles

1.2.4. Additional test data or engineering evaluations if the

Executive Officer or the vendor deems it necessary to validate

the testing accuracy of the device.

2. CARB Device Verification Testing. The Executive Officer shall perform device

verification testing or review testing results to ensure the device meets all

B-23

specifications, to verify if the device successfully communicates with and collects

the requested data, or to validate the device’s ability to meet the required testing

specifications.

2.1. Vendor shall submit at least two (2) production ready devices that

have valid unique device serial numbers, as well as any equipment

that would be packaged with the devices including extension cables,

splitting cables, installation kits, or the owner’s manual, to the

Executive Officer for verification and certification.

2.2. Each device provided shall be in a configuration that is suitable for

testing. It shall have all the necessary equipment, instrumentation,

and set up information that was used for vendor initial validation

testing.

2.3. The Executive Officer shall issue results to the vendor. If the device

passes all of CARB’s verification testing, the device shall be allowed

to advance to the certification requirements specified in subsection

C.3.

2.4. If the device fails any portion of CARB’s verification testing, the

devices may be returned to the vendor. After addressing the device

deficiencies, if the vendor testing results show remediation, the

vendor may resubmit a new certification package to the Executive

Officer.

3. Vendor Field Testing. Testing shall be completed by the vendor using devices in

the exact same configuration as those that completed the CARB device verification

testing.

3.1. Vendor shall perform real-world testing by collecting data from an

applicable heavy-duty vehicle population (non-gasoline with GVWR

greater than 14,000 lbs.) and complete within 90 days from the start

of field testing.

3.1.1. Vendor shall include a representative sample of vehicle makes,

engine families, and fuel types within the tested vehicle

population that the device may be used on once certified.

3.1.2. Vendor shall use a minimum of 10 devices with the

configuration that completed CARB verification testing.

3.1.3. For NCC-ROBD devices, a minimum of 100 OBD data

submissions shall be obtained from a minimum of 100 vehicles

per OBD protocol that a device is certifying to.

B-24

3.1.4. For CC-ROBD devices, a minimum of 100 data submissions

shall be obtained from a minimum of 30 vehicles per OBD

protocol that device is certifying to.

3.1.4.1. For CC-ROBD devices specific to vehicles for one

vehicle make, a minimum of 50 data submissions

shall be obtained from a minimum of 10 vehicles.

3.2. Vendor shall electronically submit required testing data through the

electronic reporting system.

3.3. Vendor shall ensure successful communication between the device

and the vehicle.

3.4. Vendor shall obtain a successful connectivity rate of 99.9 percent for

all data supported by a vehicle’s OBD system as listed in Table 4.

3.5. The Executive Officer may adjust the connectivity rate in 0.10 percent

increments for the following reasons:

3.5.1. If it is determined through an engineering evaluation that the

stringency of the required connectivity rates needs to be

loosened or tightened

3.5.2. If it is determined that a technical or engineering issue inhibits

the ability to meet the required connectivity rates

3.6. Vendor shall ensure that the device is continuously in compliance with

the configuration that completed CARB verification testing.

3.7. If the vendor would like to exempt a vehicle(s), a request shall be

made to CARB. The request shall contain the technical reasons and

supporting data that explains why the vehicle should be exempted

from the calculation. The request shall be approved by the Executive

Officer prior to submitting the test results.

3.8. If vendor cannot complete the field testing at the end of 90 days,

vendor shall contact CARB by the 60th day and provide the reason(s)

why the field testing may not be completed on time.

3.8.1. The Executive Officer will evaluate whether the vendor shall

be allowed to continue with the testing or shall be required to

resubmit a new application and restart the certification

process. The criteria used to make this determination shall

include:

B-25

3.8.1.1. Vendor’s reasoning as to why the field testing is not

able to be completed on time;

3.8.1.2. Whether unavoidable and unexpected issues

occurred during the allotted testing period that made

meeting the required deadline infeasible;

3.8.1.3. Whether the current testing completed to this point is

consistent with the requirements that devices must

meet to obtain certification; and

3.8.1.4. Additional test data may be requested by the

Executive Officer to make this determination.

3.9. If the device fails to meet the requirements during field testing, the

vendor shall determine the reason(s) for device failure.

3.9.1. The Executive Officer shall evaluate whether the vendor shall

be allowed to retest their device in this phase after addressing

the deficiencies or shall be required to resubmit a new

application and restart the certification process. The criteria to

be used to make this determination shall include:

3.9.1.1. Vendor’s provided explanation explaining for the

cause(s) of their device failure, with supporting

information, and modifications needed to fix the

issue(s);

3.9.1.2. Whether unavoidable and unexpected issues

occurred during the allotted testing period that made

meeting the required deadline infeasible;

3.9.1.3. Whether the technical reasons the device failed and

the recommended solution require further laboratory

testing to confirm that the issue was remedied;

3.9.1.4. How close the testing device is from being approved

for certification; and

3.9.1.5. Additional test data requested by the Executive

Officer to make this determination.

3.9.2. If the device fails a second attempt of field testing, the vendor

shall be determined to have failed the certification process.

The vendor may resubmit a new certification application after

addressing any deficiencies.

B-26

D. Post-Certification Requirements.

1. Once the device meets the certification testing requirements, the Executive Officer

shall issue the vendor an Executive Order. The vendor may sell the device and use

the device for compliance purposes with this HD I/M Regulation only if the vendor

possesses a valid Executive Order. An Executive Order is valid from the indicated

effective date until the end of the calendar year for which it is issued. The vendor

may renew annually the certification for the device by following the procedure

described in section F of this Part.

2. With CARB approval, the vendor shall provide necessary device updates as

provided in the set schedule that was approved by CARB as specified in subsection

B.6 of this Part. The Executive Officer may waive the set schedule update if a

problem is detected with the device that critically impacts the compliance with the

certified configuration. Upon CARB’s request, the vendor shall provide an

approved emergency update.

3. Vendor shall notify user(s) of any changes in the certified device.

4. Vendor shall resubmit a certification application for any changes that modify the

device’s certified configuration.

E. Reporting and Recordkeeping Requirements.

1. The vendor shall electronically report certified devices via the electronic reporting

system and keep this information up to date.

2. Organize and maintain the following records:

2.1. A copy of all application documents as specified in sections B through

D of this Part, including, the test plan, application forms, test results,

warranty statement, statement of compliance, and any other

information provided to CARB such as device updates.

2.2. A list of device unique serial numbers for all devices produced and

sold including the original purchaser or user company name, original

purchaser or user contact information, and device model under each

Executive Order.

3. Keep required test data and all other information specified in this Part for five years

after CARB issues the Executive Order.

4. Records shall be readily available and stored in the same format as the submitted

certification application and on any media, as long as the vendor can promptly

send organized records in English to the Executive Officer if requested within 72

hours.

B-27

F. Recertifying Annually.

1. Prior to the conclusion of the certification period, the vendor shall submit a

recertification application for a new Executive Order provided the device continues

to meet the required specifications.

1.1. If the Executive Officer determines that the device still meets the

required specifications, the device shall be recertified for another one

(1) year period.

1.2. Devices determined not to continually fulfill the required

specifications shall not be recertified and shall be removed from use

for compliance determination for this Part.

1.2.1. After addressing the device deficiencies, the vendor may

resubmit a new certification application package to the

Executive Officer for approval.

G. Decertifying Devices.

If CARB finds that a certified vendor fails to furnish or install required software updates

to the device or fails to meet the specifications and requirements as stated in this Part,

the Executive Officer shall decertify the device in writing or by electronic mail with a

specified effective date of the decertification. After the device is decertified, the

device is considered noncompliant and shall no longer be used in the program for

compliance determination purposes. The vendor shall notify the user(s) of the change

in the device certification status.

H. Other Provisions.

1. Any person who fails to comply with these requirements or fails to submit

information, reports, or statements required by this Part may be subject to citation

as specified in section 2198.2 and their device or devices may be subject to

decertification under section G of this Part.

2. Any person who knowingly submits any false statement or representation in any

application, report, statement, or other document filed, maintained, or used for the

purposes of compliance with this chapter may be subject to citation as specified in

section 2198.2 and their device or devices may be subject to decertification under

section G of this Part.

B-28