Diagnostics via CANoe Gateways

Version 1.6

2022-08-02

Application Note AN-IND-1-004

Author

Vector Informatik GmbH

Restrictions

Public Document

Abstract

Explains the concept of a diagnostics gateway between CAN and any other bus

system or transport protocol to make CANoe's diagnostics features available when

direct access is not yet possible

Table of Contents

1.0 Overview ........................................................................................................................................ 2

2.0 Diagnostics scenarios .................................................................................................................. 2

2.1 Isolated ECU ........................................................................................................................ 2

2.2 ECU as part of a cluster ....................................................................................................... 2

2.3 ECU integrated into vehicle ................................................................................................. 2

3.0 Diagnostics features in CANoe .................................................................................................... 3

4.0 Diagnostics Gateway .................................................................................................................... 4

4.1 Basic concept ....................................................................................................................... 4

4.2 Gateway level ....................................................................................................................... 5

4.2.1 Network layer, identical transport protocols on both buses ................................................. 5

4.2.2 Transport layer ..................................................................................................................... 6

4.2.3 Diagnostics layer .................................................................................................................. 7

4.3 Important notes .................................................................................................................... 8

5.0 Example: Multi-connection TP-level CAN-FlexRay gateway .................................................... 9

5.1 Overview .............................................................................................................................. 9

5.2 Setup .................................................................................................................................... 9

5.3 Basic idea ............................................................................................................................. 9

5.4 CAPL code .........................................................................................................................10

5.4.1 Variable declaration and initalization .................................................................................10

5.4.2 Configuration of TP-connections........................................................................................10

5.4.3 Find corresponding connection ..........................................................................................11

5.4.4 CAN-side callback implementation ....................................................................................11

5.4.5 FlexRay-side callback implementation...............................................................................12

5.5 Sample data transfers ........................................................................................................13

6.0 Additional Resources .................................................................................................................14

7.0 Contacts .......................................................................................................................................14

Diagnostics via CANoe Gateways

Copyright © 2022 - Vector Informatik GmbH 2

Contact Information: www.vector.com or +49-711-80 670-0

1.0 Overview

CANoe supports a multitude of features for the development of diagnostics in ECUs and vehicles as a

whole. While all features are available on the CAN bus system with ISO transport protocol, not all

features are available on non-CAN bus systems, and not every proprietary transport protocol is

supported.

For most scenarios, a “diagnostics gateway” can make the CAN diagnostics features available to any

bus system. This application note explains the basic scenarios, the currently available features, the

concept of a diagnostics gateway, and finally some CAPL example implementations.

In the final section, a multi-connection CAN-FlexRay TP-level gateway is described in detail.

Please note, that since the time this application note was written, features may have been made

available for additional bus systems. For the latest information and sample implementations, please

have a look at the Vector homepage www.vector.com or call the support hotline.

2.0 Diagnostics scenarios

2.1 Isolated ECU

In this scenario only the ECU is real, all other components of the vehicle are simulated by CANoe. For

example, on a LIN bus CANoe.LIN acts as the master node, while the ECU is directly attached to the

computer’s network interface as a slave.

2.2 ECU as part of a cluster

The ECU as device under test (DUT) is part of a larger component, e.g. a complete sub-bus. There

are other ECUs existing that may interact with the DUT and CANoe, though parts of the remaining bus

may be simulated in CANoe.

In the LIN example, it may be possible that CANoe is not the master here, i.e. the master node can be

a real ECU.

2.3 ECU integrated into vehicle

In this scenario, the ECU is not accessible physically. Instead it is part of the vehicle, and CANoe

cannot be attached to the same bus directly, e.g. the LIN sub-bus in the door of the vehicle.

Diagnostics via CANoe Gateways

Copyright © 2022 - Vector Informatik GmbH 3

Contact Information: www.vector.com or +49-711-80 670-0

3.0 Diagnostics features in CANoe

This is an overview of the diagnostics features available in CANoe 9.0, unless stated otherwise. For

more details please refer to the application note AN-IND-1-001, “CANoe and CANalyzer as Diagnostic

Tools” (available as help document from the start menu, and as “AN-IND-1-

001_CANoe_CANalyzer_as_Diagnostic_Tools.pdf” in the “Doc” folder of your CANoe installation

directory).

Feature

Availability

Transport

protocols

Implementations:

> ISO TP on CAN, LIN and FlexRay

> AMS and MOST High Protocol on MOST

> AUTOSAR TP 2.0 and 3.0 on FlexRay

> AUDI AUTOSAR TP 3.2.1.4 on FlexRay (in a separate package)

> BMW TP on FlexRay (in a separate package)

> K-Line

> DoIP/HSFZ

Transport protocol

observers

Data transfers can be recognized for:

> ISO TP on CAN, LIN and FlexRay

> AMS and MOST High Protocol on MOST

> AUTOSAR TP2.0 and 3.0 on FlexRay

> AUDI AUTOSAR TP 3.2.1.4 on FlexRay (in a separate package)

> BMW TP on FlexRay (in a separate package)

> DoIP/HSFZ

Interpretation of

diagnostics data

Interpretation is available for:

> ISO TP on CAN, LIN and FlexRay

> AMS and MOST High Protocol on MOST

> AUTOSAR TP2.0 and 3.0 on FlexRay

> AUDI AUTOSAR TP 3.2.1.4 on FlexRay (in a separate package)

> BMW TP on FlexRay (in a separate package)

> K-Line

> DoIP/HSFZ

Diagnostic

Console, Fault

Memory and

Session Control

Window

Available for:

> ISO TP on CAN, LIN and FlexRay

> AUTOSAR TP 2.0 and 3.0 on FlexRay

> AUDI AUTOSAR TP 3.2.1.4 on FlexRay (in a separate package)

> BMW TP on FlexRay (in a separate package)

> K-Line

> DoIP/HSFZ

CAPL program

access

Possible from nodes on:

> CAN

> LIN

> FlexRay

> K-Line

> DoIP/HSFZ

CAPL Callback

Interface

Reference implementations available as CAPL include files (*.cin) for:

> CAN

> LIN

> FlexRay (for AUTOSAR and ISO TP)

> K-Line

> DoIP/HSFZ

Test module

access

Diagnostics targets may be located on:

> CAN

> LIN

Diagnostics via CANoe Gateways

Copyright © 2022 - Vector Informatik GmbH 4

Contact Information: www.vector.com or +49-711-80 670-0

Feature

Availability

> FlexRay

> K-Line

> DoIP/HSFZ

Table 1: Availability of CANoe diagnostics features on bus systems and for transport protocols

4.0 Diagnostics Gateway

4.1 Basic concept

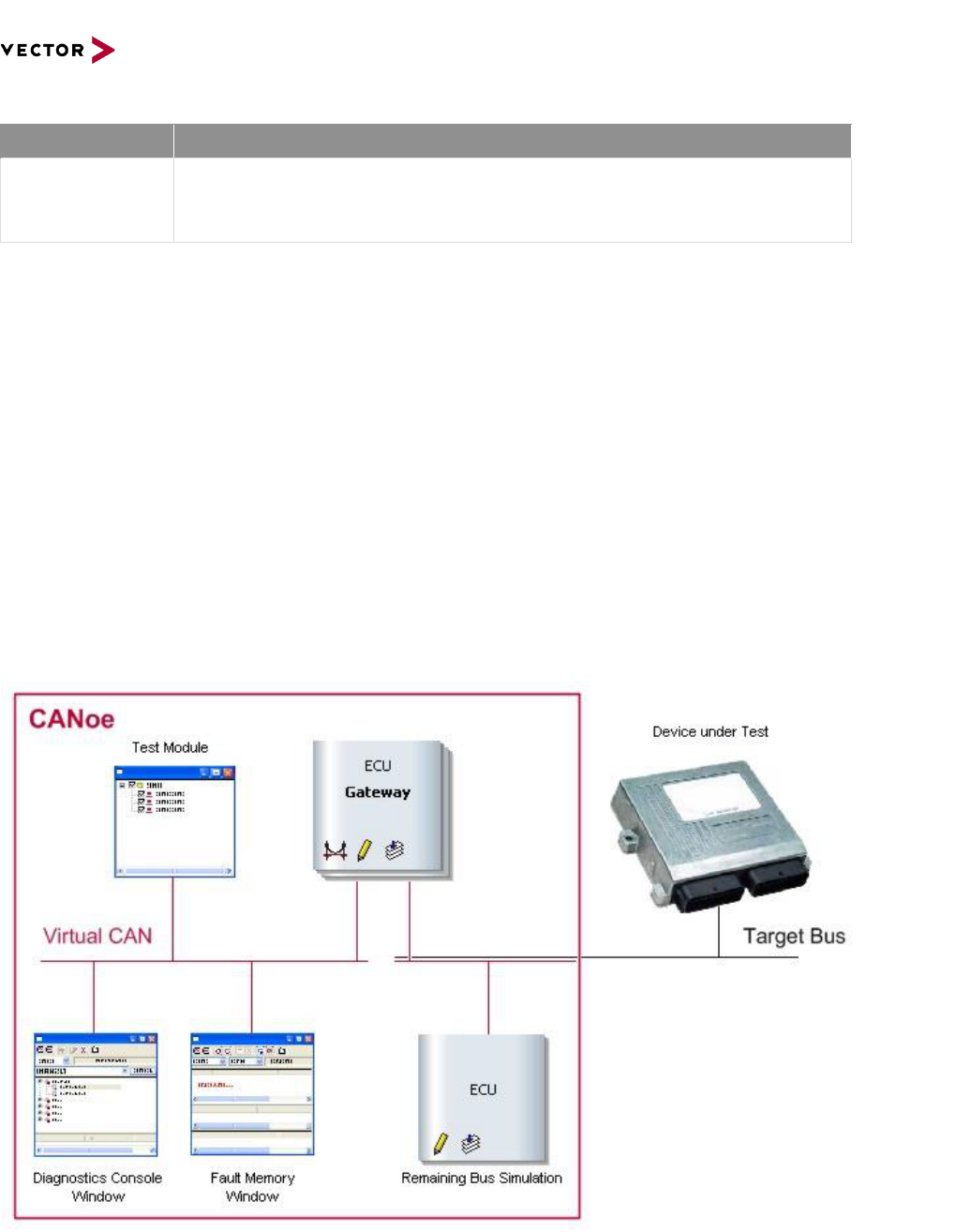

In order to make all of CANoe’s diagnostics features available to the development of ECUs connected

to any target bus system or transport protocol, a diagnostics gateway can be used:

> The diagnostic description is configured for a CAN bus, which may be “virtual”, i.e. does not

require any additional hardware.

> The ECU is connected to a remaining bus simulation as needed for the target bus’ technology,

e.g. a “master” node may be necessary.

> The diagnostics gateway is assigned to both buses. It receives requests on the CAN bus

context and forwards them to the target bus context. Responses from the ECU travel the

reverse way.

> The interpretation of the transferred data is available on the CAN bus, while the low level data

transfers are available on the target bus.

> The Diagnostic Console window and the fault memory window operate normally.

> Diagnostics test modules also work as if the ECU was connected to the CAN bus.

Figure 1: Gateway routing diagnostic information between a bus system which supports diagnostic access natively (e.g. CAN)

and the target bus system.

Diagnostics via CANoe Gateways

Copyright © 2022 - Vector Informatik GmbH 5

Contact Information: www.vector.com or +49-711-80 670-0

4.2 Gateway level

A diagnostics gateway can operate on different levels which affect the transfer delays and possibilities

to filter requests and responses.

Note

The samples only sketch one of several possible implementations!

Please refer to the CANoe help and manual for details on functions and CAPL keywords.

4.2.1 Network layer, identical transport protocols on both buses

For every CAN frame received by the gateway, a target bus frame is sent. For every target bus frame

containing an ISO transport protocol PDU the gateway receives, it sends a frame on CAN. Note that

there may be some frame modification taking place in the gateway, e.g. the ids may be changed or the

length of the frame by adding or stripping padding bytes.

Example: ISO TP level

Source Bus

CAN

ID

DLC

Data

Dir

Target

Bus ID

DLC

Data

Request:

Single

Frame

200

8

02 1A 81 00 00 00 00 00

Rx

Tx

150

24

02 1A 81 00 …

Response:

First Frame

Rx

151

24

10 09 5A 81 12 34 56 78 …

400

8

10 09 5A 81 12 34 56 78

Tx

Flow

Control

200

8

30 00 14 00 00 00 00 00

Rx

Tx

150

24

30 00 14 00 …

Consecutive

Frame

Rx

151

24

21 9A BC DE 00 00 00 00 …

400

8

21 9A BC DE 00 00 00 00

Tx

Discussion:

> No transport protocol implementations have to be present in the gateway.

> Since the data is not stored, gateways of this type provide the smallest transmission delay.

> The transport protocols used on the buses must be identical to the largest extend. Especially

the size and layout of the transferred protocol data must be the same, though additional

padding may be used (as indicated in the example).

Sample Implementation:

On message 0x200

{

<target>message 0x150 tgtMsg = { dlc = 24 };

long i;

for( i = 0; i < this.dlc; ++i)

tgtMsg.byte( i) = this.byte( i);

Diagnostics via CANoe Gateways

Copyright © 2022 - Vector Informatik GmbH 6

Contact Information: www.vector.com or +49-711-80 670-0

SetBusContext( targetBus);

output( tgtMsg);

}

On <target>message 0x150

{

message 0x400 canMsg = { dlc = 8 };

long i;

for( i = 0; i < 8; ++i)

canMsg.byte( i) = this.byte( i);

SetBusContext( canBus);

output( canMsg);

}

4.2.2 Transport layer

The gateway waits for the complete reception of a transport protocol data packet from either direction,

and forwards the data as a whole to the other bus. For a more elaborate example, see the CAN-LIN

gateway implementation in KWPSim on LIN.

Example: ISO TP with fixed length frames to ISO TP with variable length frames

Source Bus

CAN

ID

DLC

Data

Dir

Target

Bus ID

DLC

Data

Request from Tester to Gateway

200

8

02 1A 81 00 00 00 00 00

Rx

Forward of request from Gateway to ECU

Tx

160

3

02 1A 81

Response from ECU to Gateway

Rx

170

8

10 09 5A 81 12 34 56 78

Tx

160

3

30 00 14

Rx

170

4

21 9A BC DE

Forward of request from Gateway to Tester

400

8

10 09 5A 81 12 34 56 78

Tx

200

8

30 00 14 00 00 00 00 00

Rx

400

8

21 9A BC DE 00 00 00 00

Tx

Discussion:

> This type of gateway provides the most generic form of forwarding while sticking to KWP/UDS,

since it is possible to connect between any type of bus system and transport protocol.

> Note that the buffering of the transported data in the gateway will introduce a significant delay

into the communication. It might be possible to change certain protocol parameters (e.g. the

separation time in ISO TP) to reduce this delay.

> For both sides of the gateway complete implementations of the transport protocols have to be

present, and the protocols have to be configured correctly. But other than that, no in-depth

knowledge of the protocol has to be used.

Diagnostics via CANoe Gateways

Copyright © 2022 - Vector Informatik GmbH 7

Contact Information: www.vector.com or +49-711-80 670-0

Sample Implementation:

CanTp_ReceptionInd( long connHandle, byte rxBuffer[])

{

SetBusContext( targetBus);

TargetBusSend( rxBuffer, elcount( rxBuffer));

}

TargetBus_DataInd( BYTE data[])

{

SetBusContext( canBus);

CanTpSendData( connHandle, data, elcount( data))

}

4.2.3 Diagnostics layer

A gateway operating on this highest level of abstraction can translate from a completely different

communication protocol to the standard KWP/UDS, i.e. especially ECUs using proprietary protocols

for diagnostics can be made accessible to the CANoe diagnostics features.

Example: ISO TP/KWP to a proprietary protocol

Source Bus

CAN

ID

DLC

Data

Dir

Proprietary protocol

1

Request "Read all identified DTCs":

Single

Frame

200

8

04 18 02 FF 00 00 00 00

Rx

Query individual DTCs

Tx

01 01 90 01

Rx

02 01 00

Tx

01 01 90 02

Rx

02 01 13

…

Tx

01 01 90 27

Rx

02 01 15

Response carrying the identified DTCs:

First Frame

400

8

10 11 58 05 90 02 13 90

Tx

Flow

Control

200

8

30 00 14 00 00 00 00 00

Rx

Consecutive

Frames

400

8

21 08 13 90 20 15 90 21

Tx

400

8

22 15 90 27 15 00 00 00

Tx

1

Non-existing example

Diagnostics via CANoe Gateways

Copyright © 2022 - Vector Informatik GmbH 8

Contact Information: www.vector.com or +49-711-80 670-0

Discussion:

> This is the most flexible form of diagnostics gateway, since it can react to the requests on

application level.

> A gateway of this type will be very specific typically, i.e. for every ECU (type) another gateway

implementation might be necessary.

> Automatic configuration of such a gateway will be very hard to realize.

Sample Implementation:

On DiagRequest Door.FaultMemory_ReadAllIdentified

{

ClearCurrentDTCList();

gNextDTCToRead = 0x9001;

ReadNextDTC();

}

ReadNextDTC()

{

<target> message 01 mQueryOneDTC = { dlc = 4, byte(0) = 1, byte(1) = 1 };

mQueryOneDTC.byte(2) = gNextDTCToRead / 256;

mQueryOneDTC.byte(3) = (BYTE) gNextDTCToRead;

SetBusContext( targetBus);

output( mQueryOneDTC);

// There should be timeout handling; omitted here

}

On <target> message 02

{

if( this.byte(2) != 0)

AddDTCtoCurrentDTCList( gNextDTCToRead, this.byte(2));

++gNextDTCToRead;

if( gNextDTCToRead > 0x9027)

{

// Last DTC queried, so send DiagResponse to tester

SendCurrentDTCListToTester();

} else

{

ReadNextDTC();

}

}

4.3 Important notes

There are caveats that must be considered before relying on a diagnostics gateway for critical

projects:

> Depending on the gateway’s implementation, some additional delay time will be introduced

into the communication.

> With connection oriented transport protocols like DoIP or MOST High Protocol, the gateway

has to setup connections to the ECU. This may be done on demand for each diagnostic

transfer individually or once during an initialization phase. In the latter case the gateway may

have to keep this connection alive during phases where no diagnostic transfers are made.

> If a virtual CAN channel is used, hardware synchronization is only possible with CANoe

versions 7.1 and newer and driver versions 6.8 and newer.

Diagnostics via CANoe Gateways

Copyright © 2022 - Vector Informatik GmbH 9

Contact Information: www.vector.com or +49-711-80 670-0

5.0 Example: Multi-connection TP-level CAN-FlexRay gateway

5.1 Overview

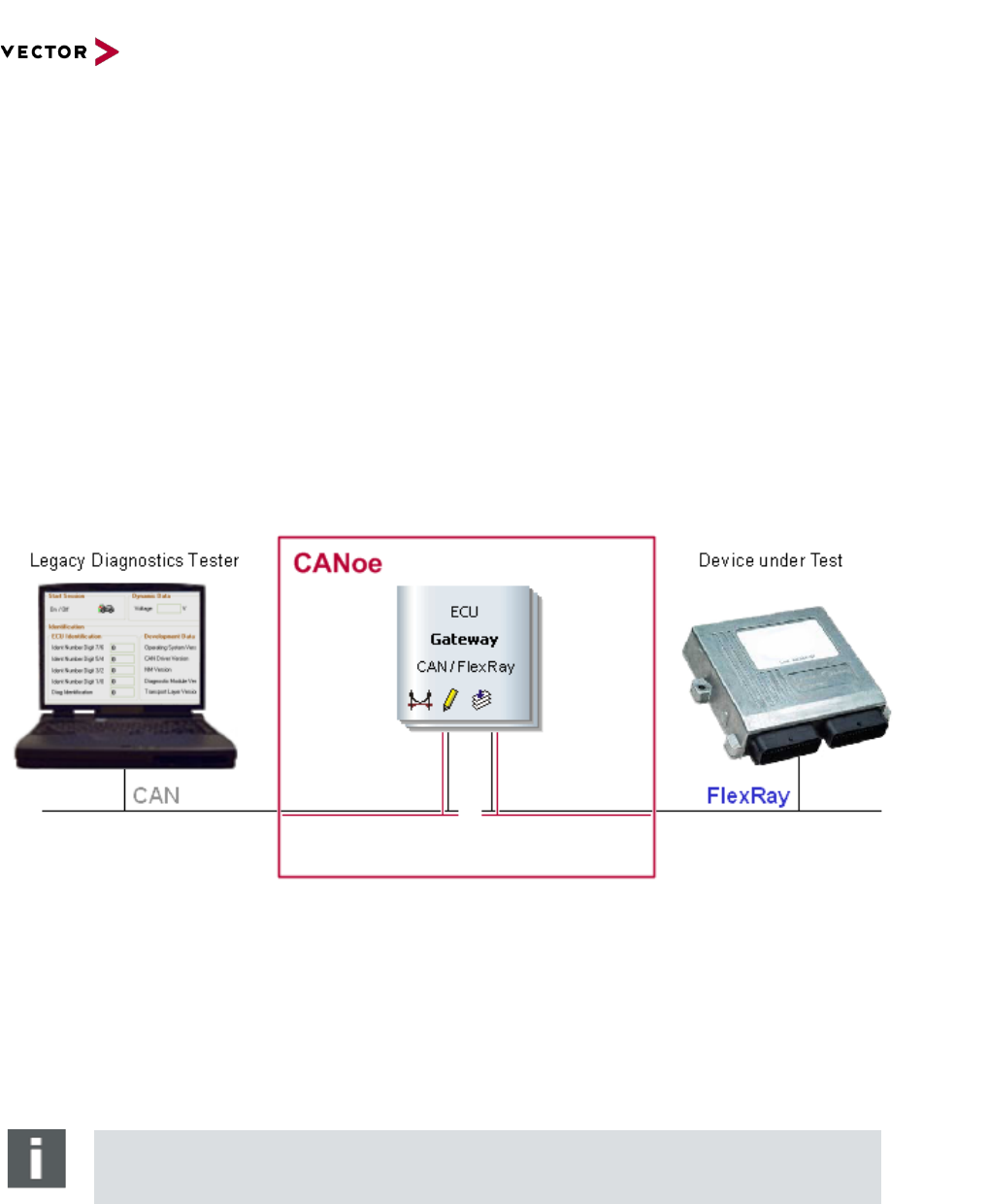

In this example a complete ISO TP on CAN – AUTOSAR TP on FlexRay gateway is documented that

allows a diagnostic tester on a CAN network to simultaneously access several ECUs on a FlexRay

network.

5.2 Setup

The gateway consists of one CANoe simulation node that is attached to a CAN and a FlexRay

network. The node is configured to load the modeling libraries “AutosarFlexRayTP3.vmodule” and

“OSEK_TP.vmodule” as component on all networks.

The networks have to be configured to allow communication with real hardware on CAN (if a stand-

alone tester should be used) and FlexRay: On CAN, the correct baud rate has to be selected. On

FlexRay, the cluster definitions have to be read from a FIBEX database that includes the cycle layout.

Please refer to the CANoe manual for more details.

Figure 2: Schematics of a CAN/FlexRay gateway for routing diagnostic frames.

5.3 Basic idea

The basic idea for this multi-connection CAN-FlexRay TP-level gateway is a list of pairs of connection

identifiers, pairing one connection on CAN with one on FlexRay. Whenever data arrives on a

connection, the corresponding connection on the other bus is searched, and the data received in the

gateway is sent on this connection.

Note

Please note the changed timing behavior of such a TP-level gateway (cf. 4.2.2)!

Diagnostics via CANoe Gateways

Copyright © 2022 - Vector Informatik GmbH 10

Contact Information: www.vector.com or +49-711-80 670-0

5.4 CAPL code

5.4.1 Variable declaration and initalization

In the section of global variables, the basic configuration information is kept.

variables

{

dword gContextCAN;

dword gContextFR;

// This map is used to find the corresponding connection

// This will be initialized with 0 on start, i.e. invalid

long gConnectionMap[10][2]; // [0] for CAN, [1] for FlexRay

}

During the pre-start phase, the gateway’s bus contexts have to be retrieved in order to access the

correct network later.

Note

If a modeling library like e.g. OSEK_TP.vmodule or DoIP.vmodule is added manually to a

simulation node which is connected to several networks (like in a typical gateway node),

this will create a separate instance of this modeling library for each of these networks.

This is true even if the library might not fit to the network type (e.g., if the DoIP.vmodule

was added to a CAN network). In this case, when initializing the modeling library (e.g.,

creating a connection with CanTpCreateConnection()) or when trying to send data (e.g.,

using CanTPSendData()), it is necessary to select the correct instance of the modeling

library via its “bus context”, i.e. the network to which this instance is connected. You can

select this bus context using the CAPL function setBusContext().

The network names have to be replaced with those used in the actual configuration!

on preStart

{

gContextCAN = GetBusNameContext( "CAN"); // Replace with actual

gContextFR = GetBusNameContext( "FlexRay"); // names!

On FlexRay, it might be necessary to register slots for sending during the pre-start phase. This

depends on the way FlexRay slots are defined; please refer to the respective manuals.

// Register frames used on FlexRay for TP

SetBusContext( gContextFR);

FrTP_ReserveSendSlots(120 , 1); // Replace with actual values!

}

5.4.2 Configuration of TP-connections

The TP connections are created on their respective buses and configured explicitly.

Note: The CanTp CAPL API of the OSEK_TP.vmodule modeling library is used here (available with

CANoe 7.0); please refer to its technical reference in the help (search for “OSEK TP » Functions »

Function Overview”).

on start

{

long conn; // handle for the connections

// First pair

SetBusContext( gContextCAN); // access the CAN network side

conn = CanTpCreateConnection(0); // normal mode

CanTpSetRxIdentifier( conn, 0x200); // replace with tester’s CAN ID

Diagnostics via CANoe Gateways

Copyright © 2022 - Vector Informatik GmbH 11

Contact Information: www.vector.com or +49-711-80 670-0

CanTpSetTxIdentifier( conn, 0x400); // replace with ECU’s CAN ID

CanTpSetBlockSize( conn, 0); // additional configuration

CanTpSetSTmin( conn, 5);

gConnectionMap[0][0] = conn; // Set CAN side connection handle

SetBusContext( gContextFR); // access FlexRay network side

conn = FrTP_CreateConnUnicast(120,121); // replace with ECU’s send/receive slots

FrTP_SetAddresses( conn, 2, 4444,1234); // replace with ECU’s send/receive addr.

// Routing here:

// CAN 0x200 >> FlexRay 4444

// FlexRay 1234 >> CAN 0x400

// Note that the API of this function

// depends on the used TP protocol on

// FlexRay!

FrTP_SetMaxPDULength( conn, 32); // additional configuration

gConnectionMap[0][1] = conn; // Set FlexRay side connection handle

// Second pair ...

}

5.4.3 Find corresponding connection

The following utility functions will retrieve the corresponding connection on the other bus, or return 0 if

no such connection is found.

// Return CAN connection handle for a FlexRay connection handle

long GetCanConn( long frConn)

{

dword i;

for( i = 0; i < elcount(gConnectionMap); ++i)

{

if( gConnectionMap[i][1] == frConn)

return gConnectionMap[i][0];

}

return 0;

}

// Return FlexRay connection handle for a CAN connection handle

long GetFrConn( long canConn)

{

dword i;

for( i = 0; i < elcount(gConnectionMap); ++i)

{

if( gConnectionMap[i][0] == canConn)

return gConnectionMap[i][1];

}

return 0;

}

5.4.4 CAN-side callback implementation

The TP implementation in the OSEK_TP.vmodule modeling library will indicate the arrival of data, the

completion of a data transfer, and errors by calling special CAPL callback functions. These functions

have to be implemented in the gateway.

Note that data received on a CAN connection is sent immediately on the corresponding connection on

the FlexRay network.

CanTp_ReceptionInd( long handle, BYTE data[])

{

long frConn, status;

// Find the corresponding FlexRay connection

frConn = GetFrConn( handle);

Diagnostics via CANoe Gateways

Copyright © 2022 - Vector Informatik GmbH 12

Contact Information: www.vector.com or +49-711-80 670-0

if( !frConn)

{

return; // no corresponding FlexRay connection found!

}

// Forward data to other bus

SetBusContext( gContextFR); // access FlexRay network side

status = FrTP_DataRequest( frConn, data, elcount(data));

SetBusContext( gContextCAN); // reset to CAN network side

if( status != 0)

FrTP_ErrorInd( frConn, status); // forward error to our handler

}

CanTp_SendCon( long handle, dword txCount)

{

// Sending of data succeeded

}

CanTp_ErrorInd( long handle, long error)

{

char cErrorText[13][30] = {

"(no error)"

, "Timeout while waiting for CF" // 1

, "Timeout while waiting for FC" // 2

, "Wrong Sequence Number" // 3

, "TP_DLL busy" // 4

, "Unexpected PDU" // 5

, "Timeout waiting for Tx-Ack" // 6

, "WFT Overrun" // 7

, "Buffer overflow" // 8

, "Wrong parameter" // 9

, "Invalid FlowStatus received" // 10

, "Transfer abort requested" // 11

// Sentinel

, "unknown error!"

};

long i;

if( error < 0 || error >= elcount(cErrorText))

i = elcount(cErrorText) - 1;

else

i = error;

write( "CanTp_ErrorInd(%d): %s", error, cErrorText[i]);

}

5.4.5 FlexRay-side callback implementation

The TP implementation in the AutosarFlexRayTP3.vmodule modeling library will indicate the arrival of

data, the completion of a data transfer, and errors by calling special CAPL callback functions. These

functions have to be implemented in the gateway.

Note that data received on a FlexRay connection is sent immediately on the corresponding connection

on the CAN network.

FrTP_ReceptionInd(long handle, BYTE data[])

{

long canConn, status;

// Find the corresponding CAN connection

canConn = GetCanConn( handle);

if( !canConn)

{

return; // No corresponding CAN connection found!

Diagnostics via CANoe Gateways

Copyright © 2022 - Vector Informatik GmbH 13

Contact Information: www.vector.com or +49-711-80 670-0

}

// Forward data to other bus

SetBusContext( gContextCAN); // access CAN network side

status = CanTpSendData( canConn, data, elcount(data));

SetBusContext( gContextFR); // reset to FlexRay network side

if( status != 0)

CanTp_ErrorInd( canConn, status); // forward error to our handler

}

FrTP_TxConfirmationInd( long handle)

{

// Sending of data succeeded!

}

FrTP_ErrorInd(long connectionHdl, dword error)

{

char cErrorText[14][60] = {

"(no error)"

, "Some mandatory settings are missing, e.g. the addresses"

, "The value given contradicts another setting made earlier"

, "The send request was rejected due to another transmission"

, "A reception was active when FF or SF was received"

, "A negative ACK was received for acknowledged connections"

, "The bus did not confirm transmission of a frame in time"

, "The transmitter did not receive a FC (or AF) in time"

, "The receiver did not receive the next CF in time"

, "(unknown)"

, "(unknown)"

, "The peer rejected the data since it is too long"

, "Peer sent an undefined Ack"

// Sentinel

, "unknown error!"

};

long i;

if( error < 0 || error >= elcount(cErrorText))

i = elcount(cErrorText) - 1;

else

i = error;

write( "FrTP_ErrorInd(%d): %s", error, cErrorText[i]);

}

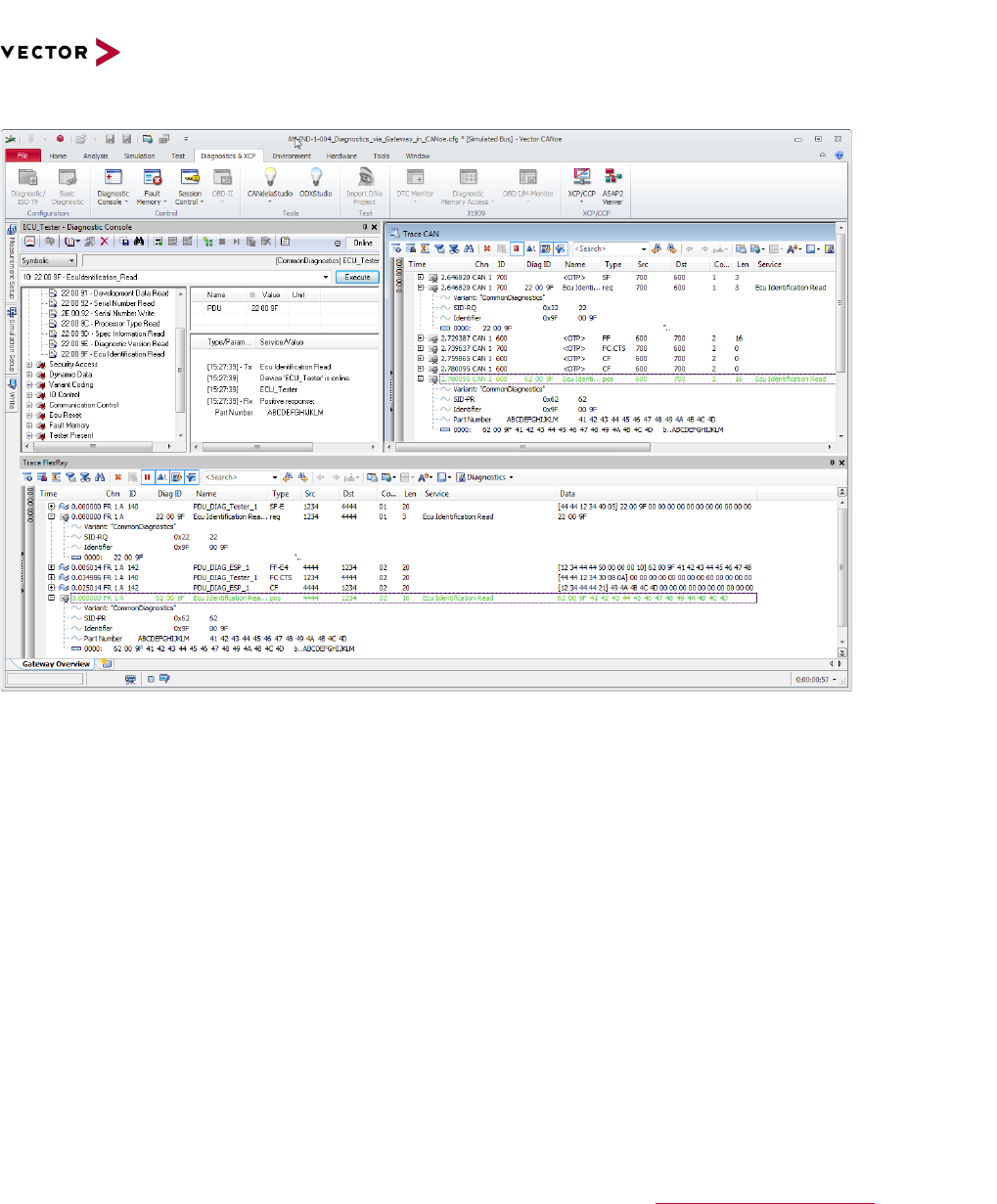

5.5 Sample data transfers

In this example a diagnostics request is sent using the Diagnostic Console on CAN to the gateway,

forwarded on FlexRay, and responded by a simulated ECU. The response is sent back via the

gateway to the Diagnostic Console. The console can display the response as if the ECU was attached

to CAN.

Diagnostics via CANoe Gateways

Copyright © 2022 - Vector Informatik GmbH 14

Contact Information: www.vector.com or +49-711-80 670-0

Figure 3: With the gateway in place, the diagnostic features of CANoe (e.g. Diagnostic Console) can be used to access the

target ECU.

6.0 Additional Resources

VECTOR APPLICATION NOTE

AN-IND-1-001 “CANoe and CANalyzer as Diagnostic Tools”

SAMPLE CONFIGURATIONS

KWPSim on LIN Demo, file location: <CANoe.LIN>\Demo_LIN_CN\KWPSim_Lin

MOST Diagnostic Gateway Demo, file location:

<CANoe.MOST>\Demo_MOST_CN\MOSTDiagnostics

CANOE/DENOE DOCUMENTATION

FlexRay TP AUTOSAR documentation in the CANoe help

7.0 Contacts

For a full list with all Vector locations and addresses worldwide, please visit http://vector.com/contact/.