Absorbed Dose Determination in

External Beam Radiotherapy

An International Code of Practice for Dosimetry

Based on Standards of Absorbed Dose to Water

Sponsored by the IAEA, WHO, PAHO and ESTRO

INTERNATIONAL ATOMIC ENERGY AGENCY, VIENNA, 2000

TTEECCHHNNIICCAALL RREEPPOORRTTSS SSEERRIIEESS NNoo..

398

ABSORBED DOSE DETERMINATION

IN EXTERNAL

BEAM RADIOTHERAPY

An International Code of Practice for Dosimetry

Based on Standards of Absorbed Dose to Water

© IAEA, 2000

Permission to reproduce or translate the information contained in this publica-

tion may be obtained by writing to the International Atomic Energy Agency,

Wagramer Strasse 5, P.O. Box 100, A-1400 Vienna, Austria.

Printed by the IAEA in Austria

December 2000

STI/DOC/010/398

ABSORBED DOSE DETERMINATION

IN EXTERNAL

BEAM RADIOTHERAPY

An International Code of Practice for Dosimetry

Based on Standards of Absorbed Dose to Water

TECHNICAL REPORTS SERIES No. 398

INTERNATIONAL ATOMIC ENERGY AGENCY

VIENNA, 2000

FOREWORD

The International Atomic Energy Agency published in 1987 an International

Code of Practice entitled Absorbed Dose Determination in Photon and Electron

Beams (IAEA Technical Reports Series No. 277 (TRS-277)), recommending proce-

dures to obtain the absorbed dose in water from measurements made with an ioniza-

tion chamber in external beam radiotherapy. A second edition of TRS-277 was

published in 1997 updating the dosimetry of photon beams, mainly kilovoltage

X rays. Another International Code of Practice for radiotherapy dosimetry entitled

‘The Use of Plane-Parallel Ionization Chambers in High Energy Electron and Photon

Beams’ (IAEA Technical Reports Series No. 381 (TRS-381)) was published in 1997

to further update TRS-277 and complement it with respect to the area of parallel-plate

ionization chambers. Both codes have proven extremely valuable for users involved

in the dosimetry of the radiation beams used in radiotherapy. In TRS-277 the calibra-

tion of the ionization chambers was based on primary standards of air kerma; this

procedure was also used in TRS-381, but the new trend of calibrating ionization

chambers directly in a water phantom in terms of absorbed dose to water was

introduced.

The development of primary standards of absorbed dose to water for high

energy photon and electron beams, and improvements in radiation dosimetry

concepts, offer the possibility of reducing the uncertainty in the dosimetry of radio-

therapy beams. The dosimetry of kilovoltage X rays, as well as that of proton and

heavy ion beams, interest in which has grown considerably in recent years, can also

be based on these standards. Thus a coherent dosimetry system based on standards of

absorbed dose to water is possible for practically all radiotherapy beams. Many

Primary Standard Dosimetry Laboratories (PSDLs) already provide calibrations in

terms of absorbed dose to water at the radiation quality of

60

Co gamma rays. Some

laboratories have extended calibrations to high energy photon and electron beams or

are in the stage of developing the necessary techniques for these modalities.

Following the recommendations in 1996 of the IAEA Standing Advisory Group

Scientific Committee of the IAEA (WHO) SSDL Network, a Co-ordinated Research

Project was undertaken during 1997–1999 with the task of producing a new interna-

tional Code of Practice based on standards of absorbed dose to water. The Code is

also endorsed by the World Health Organization, the Pan American Health

Organization and the European Society of Therapeutic Radiology and Oncology

(ESTRO). The final draft was reviewed by representatives of the organizations

endorsing the Code and by a large number of scientists.

This Code of Practice fulfils the need for a systematic and internationally

unified approach to the calibration of ionization chambers in terms of absorbed dose

to water and to the use of these detectors in determining the absorbed dose to water

for the radiation beams used in radiotherapy. It provides a methodology for the deter-

mination of absorbed dose to water in the low, medium and high energy photon

beams, electron beams, proton beams and heavy ion beams used for external radia-

tion therapy. The officer at the IAEA responsible for this Code of Practice was

P. Andreo of the Division of Human Health.

EDITORIAL NOTE

Although great care has been taken to maintain the accuracy of information contained

in this publication, neither the IAEA nor its Member States assume any responsibility for

consequences which may arise from its use.

The use of particular designations of countries or territories does not imply any

judgement by the publisher, the IAEA, as to the legal status of such countries or territories, of

their authorities and institutions or of the delimitation of their boundaries.

The mention of names of specific companies or products (whether or not indicated as

registered) does not imply any intention to infringe proprietary rights, nor should it be

construed as an endorsement or recommendation on the part of the IAEA.

Reference to standards of other organizations is not to be construed as an endorsement

on the part of the IAEA.

ABOUT THIS BOOK

The structure of this Code of Practice differs from that of TRS-277 and more

closely resembles that of TRS-381 in that the practical recommendations and data for

each radiation type have been placed in an individual section devoted to that radiation

type. Each essentially forms a different Code of Practice and includes detailed proce-

dures and worksheets.

The Code is addressed to users provided with calibrations in terms of absorbed

dose to water traceable to a Primary Standard Dosimetry Laboratory. This category of

users is likely to become the large majority since most standard laboratories are

prepared to, or are planning to, supply calibrations in terms of absorbed dose to water

at the reference radiation qualities recommended in this Code of Practice. Users who

are not yet provided with calibrations in terms of absorbed dose to water may still

refer to the current air kerma based codes of practice, such as TRS-277 and TRS-381,

or adopt the present document using a calibration factor in terms of absorbed dose to

water derived from an air kerma calibration as described in the text. Whatever proce-

dure is employed, the user is strongly advised to verify exactly what physical quantity

has been selected for the calibration of the reference dosimeter in order to apply the

correct formalism.

A list of abbreviations of organizations mentioned in this Code is given in

Section 1.7.

Every user is invited to critically test this Code of Practice and submit

comments to:

Head, Dosimetry and Medical Radiation Physics Section,

Division of Human Health,

International Atomic Energy Agency,

Wagramer Strasse 5,

P.O. Box 100,

A-1400 Vienna, Austria

E-mail: [email protected]g

Fax: +43–1–26007

CONTENTS

1. INTRODUCTION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

1.1. Background . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

1.2. Advantages of a Code of Practice based on standards

of absorbed dose to water . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

1.2.1. Reduced uncertainty . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

1.2.2. A more robust system of primary standards . . . . . . . . . . . . 6

1.2.3. Use of a simple formalism . . . . . . . . . . . . . . . . . . . . . . . . 7

1.3. Types of radiation and range of beam qualities . . . . . . . . . . . . . . . 7

1.4. Practical use of this Code of Practice . . . . . . . . . . . . . . . . . . . . . . 8

1.5. Expression of uncertainties . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

1.6. Quantities and symbols . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

1.7. Abbreviations of organizations . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

2. FRAMEWORK . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

2.1. The International Measurement System . . . . . . . . . . . . . . . . . . . . . 15

2.1.1. The IAEA/WHO network of SSDLs . . . . . . . . . . . . . . . . . 16

2.2. Standards of absorbed dose to water . . . . . . . . . . . . . . . . . . . . . . . 17

3.N

D,w

BASED FORMALISM . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

3.1. Formalism . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

3.1.1. Reference conditions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

3.1.2. Influence quantities . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

3.2. Correction for the radiation quality of the beam, k

Q,Q

o

. . . . . . . . . 22

3.2.1. A modified k

Q,Q

o

for electron beam cross-calibrations . . . . 24

3.3. Relation to N

K

based codes of practice . . . . . . . . . . . . . . . . . . . . . 26

4. IMPLEMENTATION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

4.1. General . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

4.2. Equipment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

4.2.1. Ionization chambers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

4.2.2. Measuring assembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 38

4.2.3. Phantoms . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 39

4.2.4. Waterproof sleeve for the chamber . . . . . . . . . . . . . . . . . . 41

4.2.5. Positioning of ionization chambers at the

reference depth . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 41

4.3. Calibration of ionization chambers . . . . . . . . . . . . . . . . . . . . . . . . 44

4.3.1. Calibration in a

60

Co beam . . . . . . . . . . . . . . . . . . . . . . . . 44

4.3.2. Calibration in kilovoltage X rays . . . . . . . . . . . . . . . . . . . . 46

4.3.3. Calibration at other qualities . . . . . . . . . . . . . . . . . . . . . . . 46

4.4. Reference dosimetry in the user beam . . . . . . . . . . . . . . . . . . . . . . 48

4.4.1. Determination of the absorbed dose to water . . . . . . . . . . . 48

4.4.2. Practical considerations for measurements in

the user beam . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 48

4.4.3. Correction for influence quantities . . . . . . . . . . . . . . . . . . 49

5. CODE OF PRACTICE FOR

60

Co GAMMA

RAY BEAMS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 57

5.1. General . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 57

5.2. Dosimetry equipment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 57

5.2.1. Ionization chambers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 57

5.2.2. Phantoms and chamber sleeves . . . . . . . . . . . . . . . . . . . . . 57

5.3. Beam quality specification . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 58

5.4. Determination of absorbed dose to water . . . . . . . . . . . . . . . . . . . . 58

5.4.1. Reference conditions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 58

5.4.2. Determination of absorbed dose under

reference conditions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 59

5.4.3. Absorbed dose at z

max

. . . . . . . . . . . . . . . . . . . . . . . . . . . . 60

5.5. Cross-calibration of field ionization chambers . . . . . . . . . . . . . . . . 60

5.6. Measurements under non-reference conditions . . . . . . . . . . . . . . . 60

5.6.1. Central axis depth dose distributions . . . . . . . . . . . . . . . . . 61

5.6.2. Output factors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 61

5.7. Estimated uncertainty in the determination of

absorbed dose to water under reference conditions . . . . . . . . . . . . 62

5.8. Worksheet . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 64

6. CODE OF PRACTICE FOR HIGH ENERGY PHOTON BEAMS . . . . . 66

6.1. General . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 66

6.2. Dosimetry equipment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 66

6.2.1. Ionization chambers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 66

6.2.2. Phantoms and chamber sleeves . . . . . . . . . . . . . . . . . . . . . 67

6.3. Beam quality specification . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 68

6.3.1. Choice of beam quality index . . . . . . . . . . . . . . . . . . . . . . 68

6.3.2. Measurement of beam quality . . . . . . . . . . . . . . . . . . . . . . 69

6.4. Determination of absorbed dose to water . . . . . . . . . . . . . . . . . . . . 70

6.4.1. Reference conditions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 70

6.4.2. Determination of absorbed dose under

reference conditions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 70

6.4.3. Absorbed dose at z

max

. . . . . . . . . . . . . . . . . . . . . . . . . . . . 71

6.5. Values for k

Q,Q

o

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 75

6.5.1. Chamber calibrated in

60

Co . . . . . . . . . . . . . . . . . . . . . . . . 75

6.5.2. Chamber calibrated in a series of photon

beam qualities . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 75

6.5.3. Chamber calibrated at Q

o

with generic

experimental k

Q,Q

o

values . . . . . . . . . . . . . . . . . . . . . . . . . 77

6.6. Cross-calibration of field ionization chambers . . . . . . . . . . . . . . . . 77

6.7. Measurements under non-reference conditions . . . . . . . . . . . . . . . 78

6.7.1. Central axis depth dose distributions . . . . . . . . . . . . . . . . . 78

6.7.2. Output factors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 79

6.8. Estimated uncertainty in the determination of absorbed

dose to water under reference conditions . . . . . . . . . . . . . . . . . . . . 79

6.9. Worksheet . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 81

7. CODE OF PRACTICE FOR HIGH-ENERGY ELECTRON BEAMS . . 84

7.1. General . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 84

7.2. Dosimetry equipment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 84

7.2.1. Ionization chambers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 84

7.2.2. Phantoms and chamber sleeves . . . . . . . . . . . . . . . . . . . . . 85

7.3. Beam quality specification . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 86

7.3.1. Choice of beam quality index . . . . . . . . . . . . . . . . . . . . . . 86

7.3.2. Measurement of beam quality . . . . . . . . . . . . . . . . . . . . . . 86

7.4. Determination of absorbed dose to water . . . . . . . . . . . . . . . . . . . . 88

7.4.1. Reference conditions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 88

7.4.2. Determination of absorbed dose under

reference conditions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 89

7.4.3. Absorbed dose at z

max

. . . . . . . . . . . . . . . . . . . . . . . . . . . . 90

7.5. Values for k

Q,Q

o

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 90

7.5.1. Chamber calibrated in

60

Co . . . . . . . . . . . . . . . . . . . . . . . . 90

7.5.2. Chamber calibrated at a series of

electron beam qualities . . . . . . . . . . . . . . . . . . . . . . . . . . . 90

7.6. Cross-calibration of ionization chambers . . . . . . . . . . . . . . . . . . . . 94

7.6.1. Cross-calibration procedure . . . . . . . . . . . . . . . . . . . . . . . . 94

7.6.2. Subsequent use of a cross-calibrated chamber . . . . . . . . . . 95

7.7. Measurements under non-reference conditions . . . . . . . . . . . . . . . 98

7.7.1. Central axis depth dose distributions . . . . . . . . . . . . . . . . . 98

7.7.2. Output factors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 101

7.8. Use of plastic phantoms . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 101

7.8.1. Scaling of depths . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 102

7.8.2. Plastic phantoms for beam quality specification . . . . . . . . 102

7.8.3. Plastic phantoms for absorbed dose determination at z

ref

. . 103

7.8.4. Plastic phantoms for depth dose distributions . . . . . . . . . . 103

7.9. Estimated uncertainty in the determination of absorbed

dose to water under reference conditions . . . . . . . . . . . . . . . . . . . . 104

7.10. Worksheet . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 107

8. CODE OF PRACTICE FOR LOW ENERGY

KILOVOLTAGE X RAY BEAMS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 110

8.1. General . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 110

8.2. Dosimetry equipment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 111

8.2.1. Ionization chambers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 111

8.2.2. Phantoms . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 112

8.3. Beam quality specification . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 112

8.3.1. Choice of beam quality index . . . . . . . . . . . . . . . . . . . . . . 112

8.3.2. Measurement of beam quality . . . . . . . . . . . . . . . . . . . . . . 114

8.4. Determination of absorbed dose to water . . . . . . . . . . . . . . . . . . . . 115

8.4.1. Reference conditions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 115

8.4.2. Determination of absorbed dose under

reference conditions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 115

8.5. Values for k

Q,Q

o

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 116

8.6. Measurements under non-reference conditions . . . . . . . . . . . . . . . 117

8.6.1. Central axis depth dose distributions . . . . . . . . . . . . . . . . . 117

8.6.2. Output factors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 117

8.7. Estimated uncertainty in the determination of

absorbed dose to water under reference conditions . . . . . . . . . . . . 118

8.8. Worksheet . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 120

9. CODE OF PRACTICE FOR MEDIUM ENERGY

KILOVOLTAGE X RAY BEAMS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 122

9.1. General . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 122

9.2. Dosimetry equipment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 123

9.2.1. Ionization chambers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 123

9.2.2. Phantoms and chamber sleeves . . . . . . . . . . . . . . . . . . . . . 124

9.3. Beam quality specification . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 125

9.3.1. Choice of beam quality index . . . . . . . . . . . . . . . . . . . . . . 125

9.3.2. Measurement of beam quality . . . . . . . . . . . . . . . . . . . . . . 126

9.4. Determination of absorbed dose to water . . . . . . . . . . . . . . . . . . . . 127

9.4.1. Reference conditions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 127

9.4.2. Determination of absorbed dose under

reference conditions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 127

9.5. Values for k

Q,Q

o

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 127

9.6. Measurements under non-reference conditions . . . . . . . . . . . . . . . 129

9.6.1. Central axis depth dose distributions . . . . . . . . . . . . . . . . . 129

9.6.2. Output factors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 131

9.7. Estimated uncertainty in the determination of

absorbed dose to water under reference conditions . . . . . . . . . . . . 131

9.8. Worksheet . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 133

10. CODE OF PRACTICE FOR PROTON BEAMS . . . . . . . . . . . . . . . . . . 135

10.1. General . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 135

10.2. Dosimetry equipment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 137

10.2.1. Ionization chambers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 137

10.2.2. Phantoms and chamber sleeves . . . . . . . . . . . . . . . . . . . . . 137

10.3. Beam quality specification . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 138

10.3.1. Choice of beam quality index . . . . . . . . . . . . . . . . . . . . . . 138

10.3.2. Measurement of beam quality . . . . . . . . . . . . . . . . . . . . . . 139

10.4. Determination of absorbed dose to water . . . . . . . . . . . . . . . . . . . . 140

10.4.1. Reference conditions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 140

10.4.2. Determination of absorbed dose under

reference conditions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 141

10.5. Values for k

Q,Q

o

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 141

10.6. Measurements under non-reference conditions . . . . . . . . . . . . . . . 141

10.6.1. Central axis depth dose distributions . . . . . . . . . . . . . . . . . 145

10.6.2. Output factors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 146

10.6.3. Use of plastic phantoms for relative dosimetry . . . . . . . . . 146

10.7. Estimated uncertainty in the determination of

absorbed dose to water under reference conditions . . . . . . . . . . . . 148

10.8. Worksheet . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 149

11. CODE OF PRACTICE FOR HEAVY ION BEAMS . . . . . . . . . . . . . . . 151

11.1. General . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 151

11.2. Dosimetry equipment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 154

11.2.1. Ionization chambers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 154

11.2.2. Phantoms and chamber sleeves . . . . . . . . . . . . . . . . . . . . . 155

11.3. Beam quality specification . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 156

11.4. Determination of absorbed dose to water . . . . . . . . . . . . . . . . . . . . 156

11.4.1. Reference conditions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 156

11.4.2. Determination of absorbed dose under

reference conditions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 157

11.5. Values for k

Q,Q

o

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 157

11.6. Measurements under non-reference conditions . . . . . . . . . . . . . . . 158

11.7. Estimated uncertainty in the determination of

absorbed dose to water under reference conditions . . . . . . . . . . . . 160

11.8. Worksheet . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 162

APPENDIX I. RELATION BETWEEN N

K

AND N

D,w

BASED

CODES OF PRACTICE . . . . . . . . . . . . . . . . . . . . . . . . . . . 165

I.1.

60

Co and high energy photon and electron beams . . . . . . . . . . . . . 165

I.1.1. A summary of notations used for calibration factors . . . . . 169

I.1.2. Comparison of D

w

determinations . . . . . . . . . . . . . . . . . . . 169

I.2. Kilovoltage X ray beams . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 172

APPENDIX II. CALCULATION OF k

Q,Q

o

AND ITS UNCERTAINTY . . . . 174

II.1. General . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 174

II.2.

60

Co gamma radiation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 175

II.2.1. Value for s

w,air

in

60

Co . . . . . . . . . . . . . . . . . . . . . . . . . . . . 175

II.2.2. Value for W

air

in

60

Co . . . . . . . . . . . . . . . . . . . . . . . . . . . . 175

II.2.3. Values for p

Q

in

60

Co . . . . . . . . . . . . . . . . . . . . . . . . . . . . 175

II.2.4. Summary of values and uncertainties in

60

Co . . . . . . . . . . 178

II.3. High energy photon beams . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 178

II.3.1. Values for s

w,air

in high energy photon beams . . . . . . . . . . 178

II.3.2. Value for W

air

in high energy photon beams . . . . . . . . . . . 178

II.3.3. Values for p

Q

in high energy photon beams . . . . . . . . . . . . 181

II.3.4. Summary of uncertainties in high energy photon beams . . 183

II.4. Electron beams . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 185

II.4.1. Values for s

w,air

in electron beams . . . . . . . . . . . . . . . . . . . 185

II.4.2. Value for W

air

in electron beams . . . . . . . . . . . . . . . . . . . . 186

II.4.3. Values for p

Q

in electron beams . . . . . . . . . . . . . . . . . . . . 186

II.4.4. Summary of uncertainties in electron beams . . . . . . . . . . . 189

II.5. Proton beams . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 190

II.5.1. Values for s

w,air

in proton beams . . . . . . . . . . . . . . . . . . . . 190

II.5.2. Value for W

air

in proton beams . . . . . . . . . . . . . . . . . . . . . 192

II.5.3. Values for p

Q

in proton beams . . . . . . . . . . . . . . . . . . . . . . 192

II.5.4. Summary of uncertainties in proton beams . . . . . . . . . . . . 193

II.6. Heavy ion beams . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 194

II.6.1. Value for s

w,air

in heavy ion beams . . . . . . . . . . . . . . . . . . 194

II.6.2. Value for W

air

in heavy ion beams . . . . . . . . . . . . . . . . . . . 196

II.6.3. Value for p

Q

in heavy ion beams . . . . . . . . . . . . . . . . . . . . 196

II.6.4. Summary of uncertainties in heavy ion beams . . . . . . . . . . 196

APPENDIX III. PHOTON BEAM QUALITY SPECIFICATION . . . . . . . . . 198

III.1. Overview of common photon beam quality specifiers . . . . . . . . . . 198

III.2. Advantages and disadvantages of TPR

20,10

. . . . . . . . . . . . . . . . . . 200

III.3. Advantages and disadvantages of PDD(10)

x

. . . . . . . . . . . . . . . . . 203

III.4. Concluding remarks . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 208

APPENDIX IV. EXPRESSION OF UNCERTAINTIES . . . . . . . . . . . . . . . . . 210

IV.1. General considerations on errors and uncertainties . . . . . . . . . . . . 210

IV.2. Type A standard uncertainties . . . . . . . . . . . . . . . . . . . . . . . . . . . . 211

IV.3. Type B standard uncertainties . . . . . . . . . . . . . . . . . . . . . . . . . . . . 212

IV.4. Combined and expanded uncertainties . . . . . . . . . . . . . . . . . . . . . . 213

REFERENCES . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 215

CONTRIBUTORS TO DRAFTING AND REVIEW . . . . . . . . . . . . . . . . . . . . 226

RELATED IAEA PUBLICATIONS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 229

1

1. INTRODUCTION

1.1. BACKGROUND

In its Report 24 on ‘Determination of Absorbed Dose in a Patient Irradiated by

Beams of X or Gamma Rays in Radiotherapy Procedures’, the International

Commission on Radiation Units and Measurements (ICRU) [1] concluded that

“although it is too early to generalize, the available evidence for certain types of

tumour points to the need for an accuracy of ±5% in the delivery of an absorbed dose

to a target volume if the eradication of the primary tumour is sought”. The ICRU

continues, “Some clinicians have requested even closer limits such as ±2%, but at

the present time (in 1976) it is virtually impossible to achieve such a standard”.

These statements were made in a context where uncertainties were estimated at the

95% confidence level, and have been interpreted as if they correspond to approxi-

mately two standard deviations. Thus the requirement for an accuracy of 5% in the

delivery of absorbed dose would correspond to a combined uncertainty of 2.5% at

the level of one standard deviation. Today it is considered that a goal in dose delivery

to the patient based on such an accuracy requirement is too strict and the figure

should be increased to about one standard deviation of 5%, but there are no definite

recommendations in this respect.

1

The requirement for an accuracy of ±5% could,

on the other hand, also be interpreted as a tolerance of the deviation between the pre-

scribed dose and the dose delivered to the target volume. Modern radiotherapy has

confirmed, in any case, the need for high accuracy in dose delivery if new tech-

niques, including dose escalation in 3-D conformal radiotherapy, are to be applied.

Emerging technologies in radiotherapy, for example modern diagnostic tools for the

determination of the target volume, 3-D commercial treatment planning systems and

advanced accelerators for irradiation, can only be fully utilized if there is high

accuracy in dose determination and delivery.

The various steps between the calibration of ionization chambers in terms of

the quantity air kerma, K

air

, at the standardizing dosimetry laboratories and the

1

Several studies have concluded that for certain types of tumors the combined standard

uncertainty in dose delivery should be smaller than 3.3% or 3.5% [2–4], “even if in many cases

larger values are acceptable and in some special cases even smaller values should be aimed

at” [3]. It has also been stated that taking into account the uncertainties in dose calculation

algorithms, a more appropriate limit for the combined standard uncertainty of the dose

delivered to the target volume would be around 5% [4, 5].

2

determination of absorbed dose to water, D

w

, at hospitals using dosimetry protocols

based on the factor

2

N

D,air

(or N

gas

) introduce undesirable uncertainties into the

realization of D

w

. Many factors are involved in the dosimetric chain that starts with a

calibration factor in terms of air kerma, N

K

, measured in air using a

60

Co beam and

ends with the absorbed dose to water, D

w

, measured in water in clinical beams.

Uncertainties in the chain arise mainly from conversions performed by the user at the

hospital, for instance the well known k

m

and k

att

factors used in most codes of practice

and dosimetry protocols [8–19]. Uncertainties associated with the conversion of N

K

to N

D,air

(or N

gas

) mean that in practice the starting point of the calibration of clinical

beams already involves a considerable uncertainty [20]. The estimation of uncertain-

ties given in previous IAEA Codes of Practice [17, 21] showed that the largest

contribution to the uncertainty during beam calibration arises from the different phys-

ical quantities involved and the large number of steps performed, yielding standard

uncertainties of up to 3% or 4%. Even if more recent uncertainty estimates [22, 23]

have lowered these figures, the contribution from the first steps in the radiotherapy

dosimetry chain still do not comply with the demand for low uncertainty to minimize

the final uncertainty in patient dose delivery.

Reich [24] proposed the calibration of therapy level dosimeters in terms of

absorbed dose to water, stressing the advantages of using the same quantity and

experimental conditions as the user. The current status of the development of pri-

mary standards of absorbed dose to water for high energy photons and electrons, and

the improvement in radiation dosimetry concepts and data available, have made it

possible to reduce the uncertainty in the calibration of radiation beams. The devel-

opment of standards of absorbed dose to water at Primary Standard Dosimetry

Laboratories (PSDLs) has been a major goal pursued by the Comité Consultatif pour

les Etalons de Mesure des Rayonnements Ionisants (Section I) [25]. Measurements

of absorbed dose to graphite using graphite calorimeters were developed first and

2

The standard ISO 31-0 [6], ‘Quantities and Units’, has provided guidelines with regard

to the use of the term ‘coefficient’, which should be used for a multiplier possessing dimen-

sions, and ‘factor’, which should be reserved for a dimensionless multiplier. The more recent

standard IEC-60731 [7] is not consistent, however, with the International Organization for

Standardization (ISO) vocabulary and still provides a definition of the term ‘calibration factor’.

Although this Code of Practice continues using the term calibration factor, users should be

aware of the possibility of a change in terminology by standards laboratories in favour of cali-

bration coefficient.

continue to be used in many laboratories. This procedure was considered as an inter-

mediate step between air kerma and direct determination of the absorbed dose to

water, since absolute calorimetric measurements in water are more problematic.

Comparisons of determinations of absorbed dose to graphite were satisfactory and,

consequently, the development of standards of absorbed dose to water was under-

taken in some laboratories. Procedures to determine absorbed dose to water using

methods to measure appropriate base or derived quantities have considerably

improved at the PSDLs in the last decade. The well established procedures are the

ionization method, chemical dosimetry, and water and graphite calorimetry.

Although only the water calorimeter allows the direct determination of the absorbed

dose to water in a water phantom, the required conversion and perturbation factors

for the other procedures are now well known at many laboratories. These develop-

ments lend support to a change in the quantity used at present to calibrate ionization

chambers and provide calibration factors in terms of absorbed dose to water, N

D,w

,

for use in radiotherapy beams. Many PSDLs already provide N

D,w

calibrations at

60

Co gamma ray beams and some laboratories have extended these calibration pro-

cedures to high energy photon and electron beams; others are developing the neces-

sary techniques for such modalities.

At Secondary Standard Dosimetry Laboratories (SSDLs), calibration factors

from a PSDL or from the Bureau International des Poids et Mesures (BIPM) are

transferred to hospital users. For

60

Co gamma ray beams, most SSDLs can provide

users with a calibration factor in terms of absorbed dose to water without much exper-

imental effort, as all SSDLs have such beams. However, it is not possible for them, in

general, to supply experimentally determined calibration factors at high energy

photon and electron beams. Numerical calculations of a beam quality correction

factor, related to

60

Co, can, however, be performed which should be equivalent to

those obtained experimentally but with a larger uncertainty.

A major advance in radiotherapy over the last few years has been the increasing

use of proton and heavy ion irradiation facilities for radiation therapy. Practical

dosimetry in these fields is also based on the use of ionization chambers that may be

provided with calibrations both in terms of air kerma and in terms of absorbed dose

to water, therefore the dosimetry procedures developed for high energy photons and

electrons can also be applicable to protons and heavy ions. At the other extreme of the

range of available teletherapy beams lie kilovoltage X ray beams, and for these the

use of standards of absorbed dose to water was introduced in IAEA Technical Reports

Series No. 277 (TRS-277) [17]. However, for kilovoltage X rays there are, at present,

very few laboratories providing N

D,w

calibrations because most PSDLs have not yet

established primary standards of absorbed dose to water for such radiation qualities.

Nevertheless, N

D,w

calibrations in kilovoltage X ray beams may be provided by

PSDLs and SSDLs based on their standards of air kerma and one of the current

dosimetry protocols for X ray beams. Thus a coherent dosimetry system based on

3

standards of absorbed dose to water is now possible for practically all radiotherapy

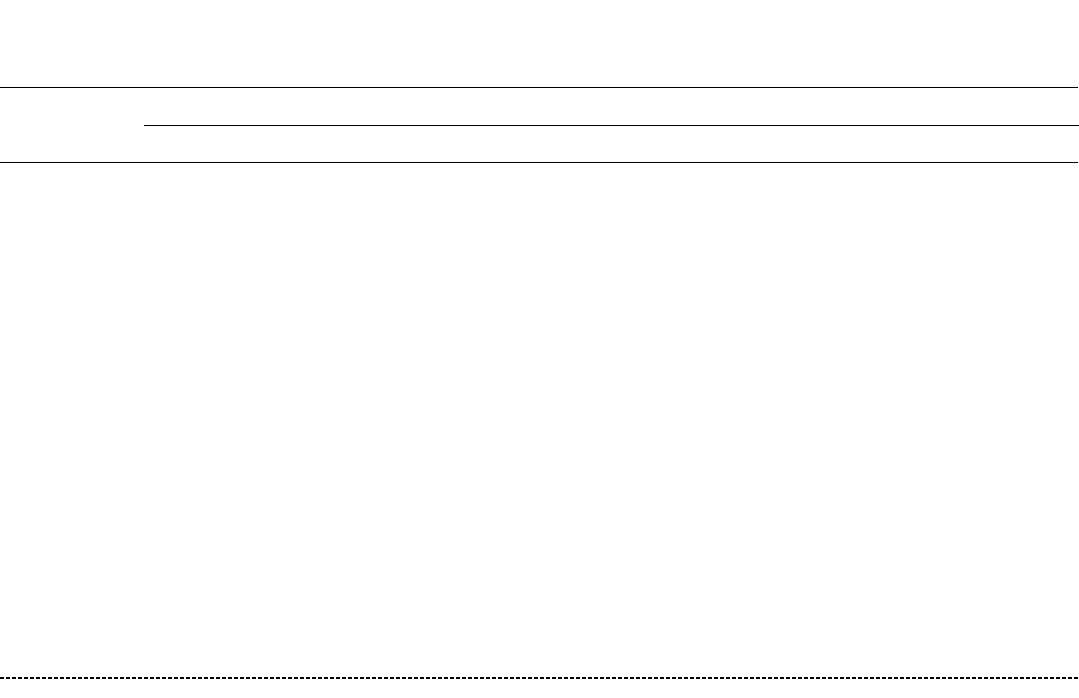

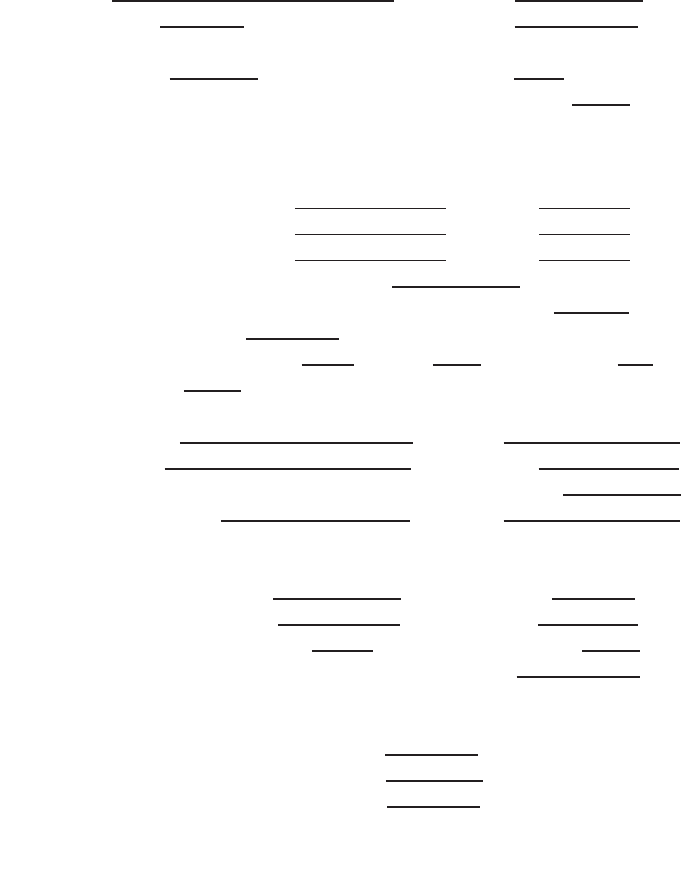

beams [26] (see Fig. 1).

3

This new international Code of Practice for the determination of absorbed dose

to water in external beam radiotherapy, using an ionization chamber or a dosimeter

having an N

D,w

calibration factor, will be applicable in all hospitals and facilities pro-

viding radiation treatment of cancer patients. Even though the nature of these

4

3

For neutron therapy beams, the reference material to which the absorbed dose relates

is ICRU soft tissue [26]. This Code of Practice is based on the quantity absorbed dose to water.

Owing to the strong dependence of neutron interaction coefficients on neutron energy and

material composition, there is no straightforward procedure to derive absorbed dose to soft

tissue from absorbed dose to water. Moreover, neutron dosimetry is traditionally performed

with tissue equivalent ionization chambers, flushed with a tissue equivalent gas in order to

determine the absorbed dose in an homogeneous medium. Although it is possible to express the

resulting formalism [26] in terms of k

Q,Q

o

, for most ionization chamber types there is a lack of

data on the physical parameters which apply to the measurement of absorbed dose to water in

a neutron beam. Therefore, the dosimetry of the radiotherapy neutron beams is not dealt with

in this Code of Practice.

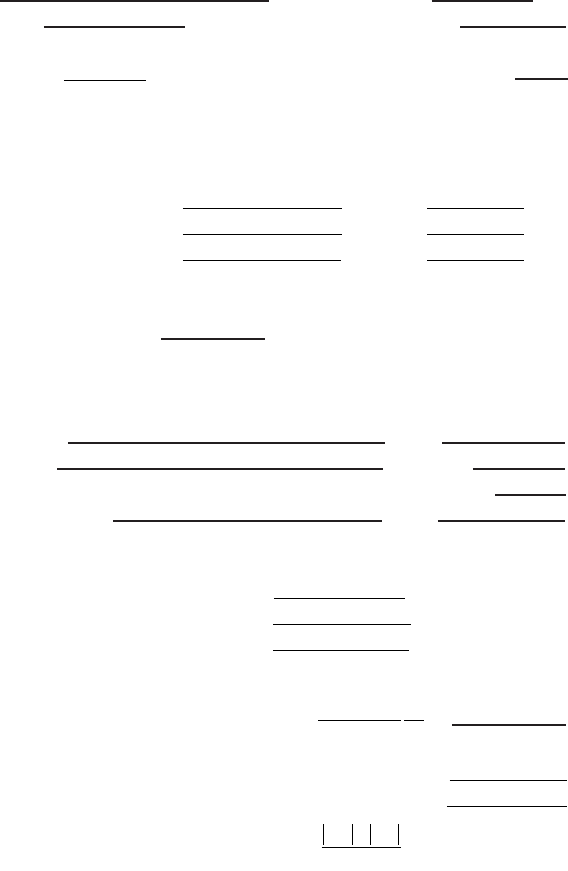

FIG. 1. Coherent dosimetry system based on standards of absorbed dose to water. Primary

standards based on water calorimetry, graphite calorimetry, chemical dosimetry and iono-

metry allow the calibration of ionization chambers in terms of absorbed dose to water, N

D,w

.

A single Code of Practice provides the methodology for the determination of absorbed dose to

water in the low, medium,

60

Co and high energy photon beams, electron beams, proton beams

and heavy ion beams used for external radiation therapy.

institutions may be widely different, this Code of Practice will serve as a useful doc-

ument to the medical physics and radiotherapy community and help achieve unifor-

mity and consistency in radiation dose delivery throughout the world. The Code of

Practice should also be of value to the IAEA/WHO network of SSDLs in improving

the accuracy and consistency of their dose determination, and thereby the standard-

ization of radiation dosimetry in the many countries which they serve.

1.2. ADVANTAGES OF A CODE OF PRACTICE BASED ON STANDARDS OF

ABSORBED DOSE TO WATER

Absorbed dose to water is the quantity of main interest in radiation therapy,

since this quantity relates closely to the biological effects of radiation. The advantages

of calibrations in terms of absorbed dose to water and dosimetry procedures using

these calibration factors have been presented by several authors [20, 27, 28] and are

described in detail in an ICRU report on photon dosimetry [29]. A summary of the

most relevant aspects is given below.

1.2.1. Reduced uncertainty

The drive towards an improved basis for dosimetry in radiotherapy has caused

PSDLs to devote much effort in the last two decades towards developing primary

standards of absorbed dose to water. The rationale for changing the basis of calibra-

tions from air kerma to absorbed dose to water was the expectation that the calibra-

tion of ionization chambers in terms of absorbed dose to water would considerably

reduce the uncertainty in determining the absorbed dose to water in radiotherapy

beams. Measurements based on calibration in air in terms of air kerma require

chamber dependent conversion factors to determine absorbed dose to water. These

conversion factors do not account for differences between individual chambers of a

particular type. In contrast, calibrations in terms of absorbed dose to water can be per-

formed under similar conditions to subsequent measurements in the user beam, so

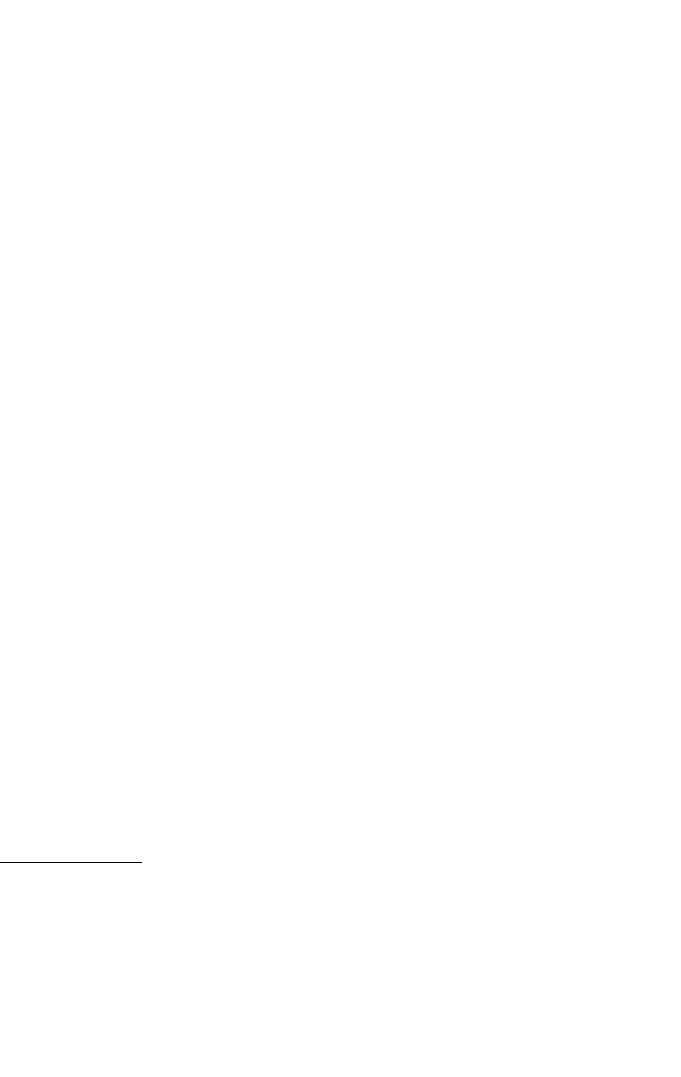

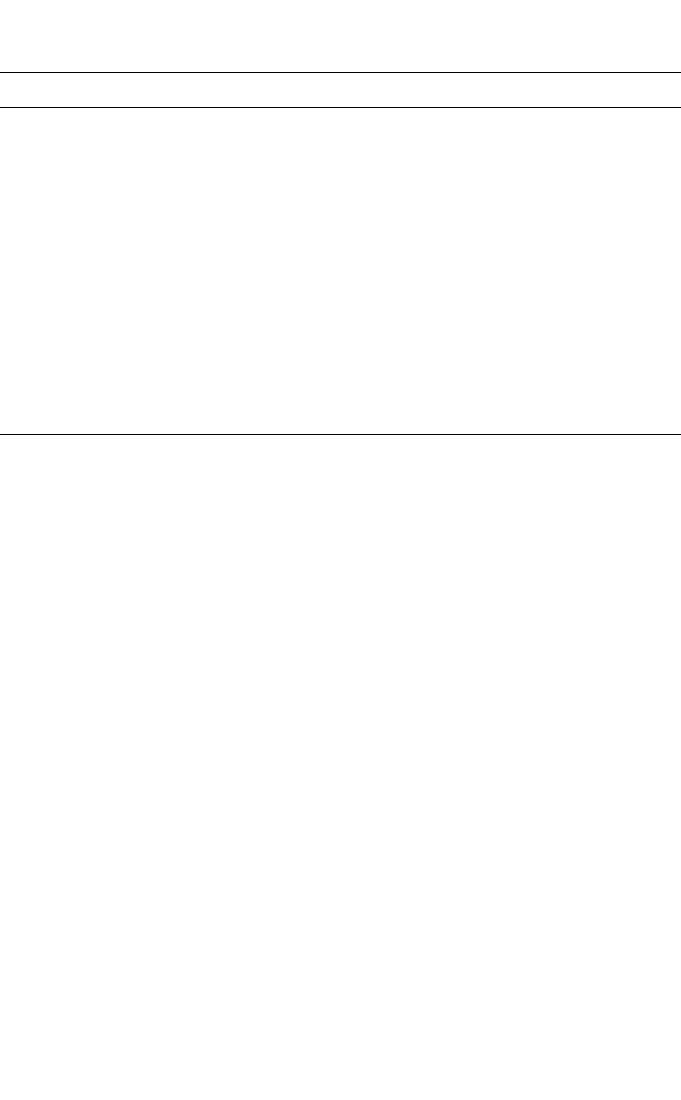

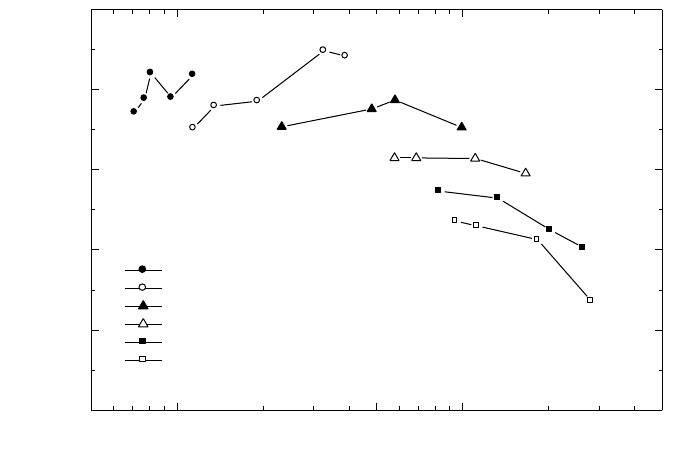

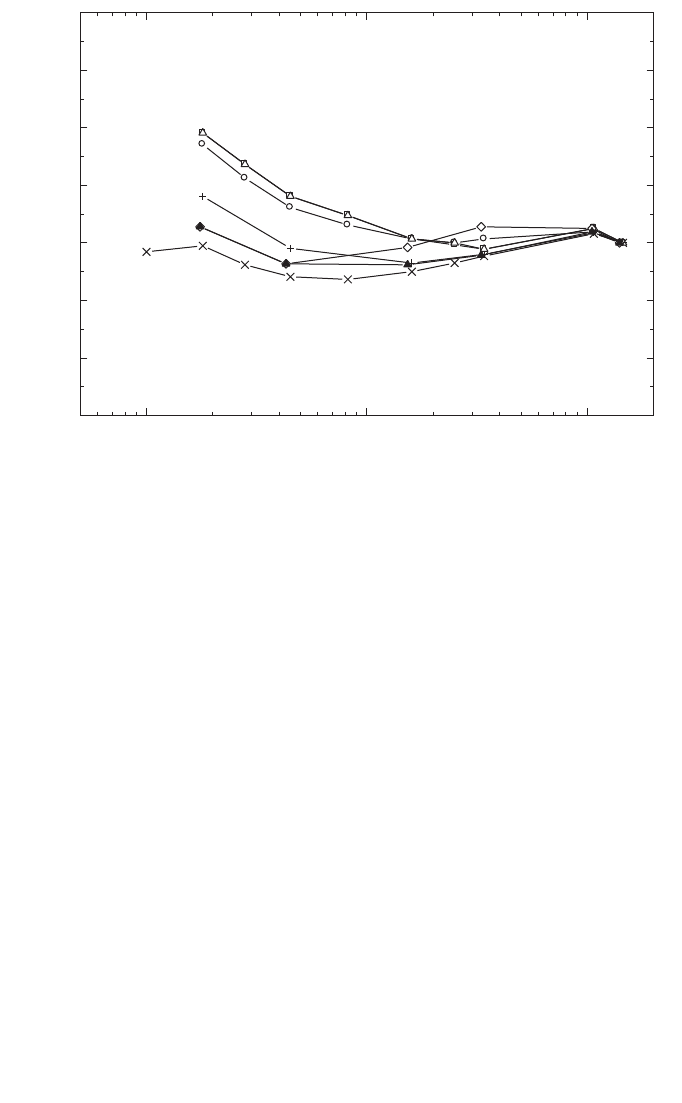

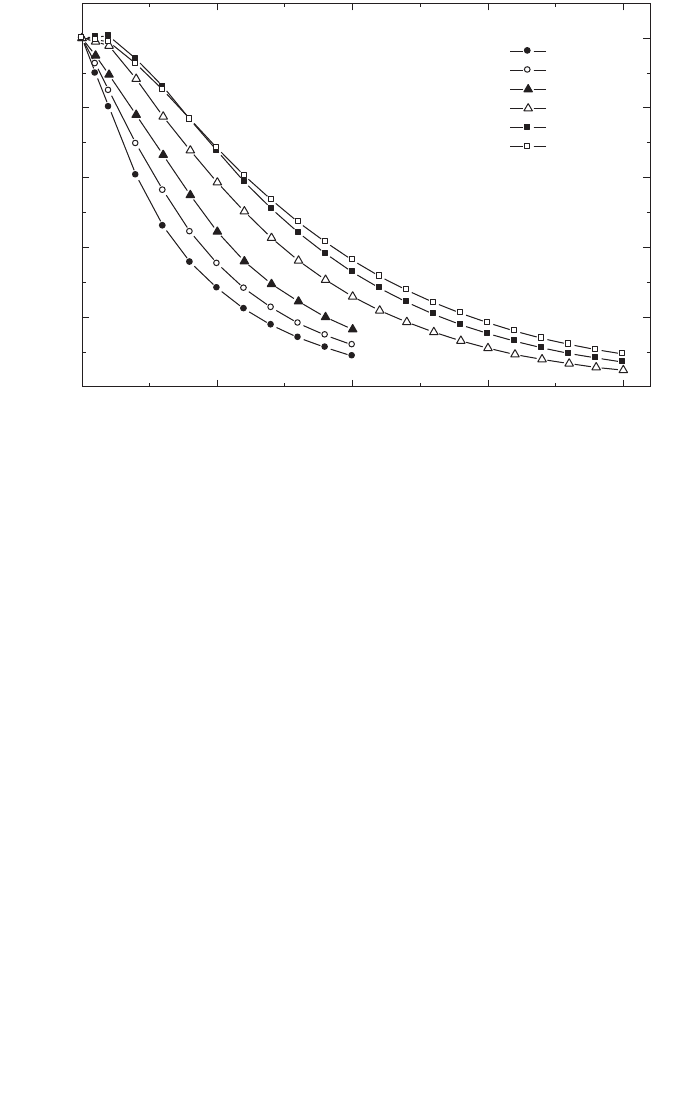

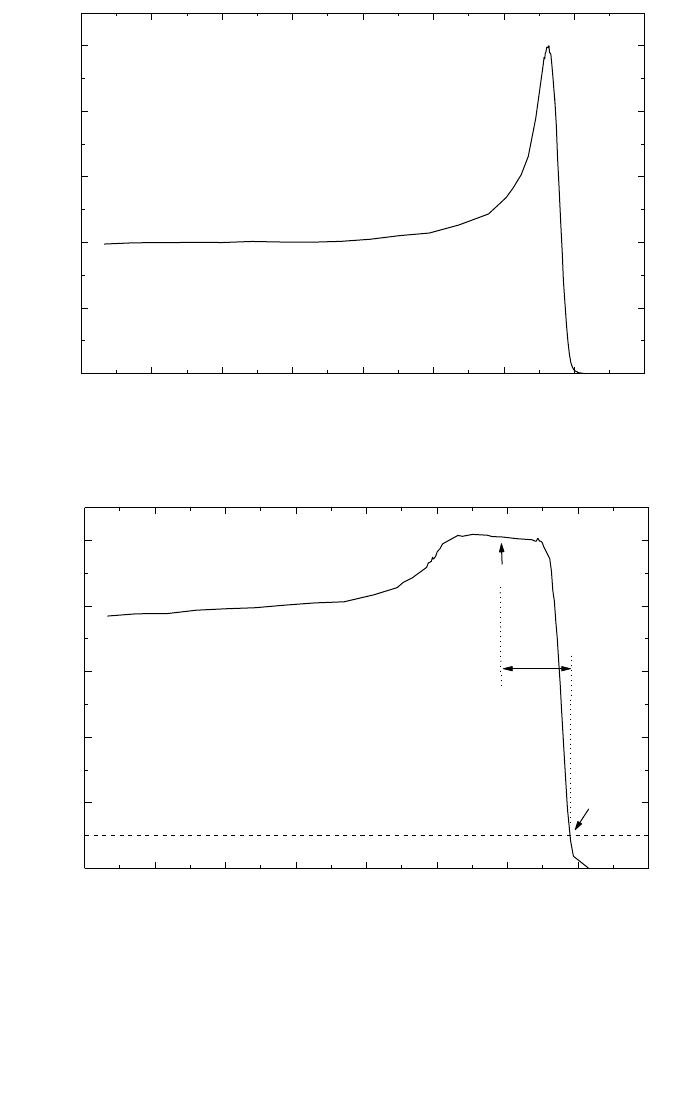

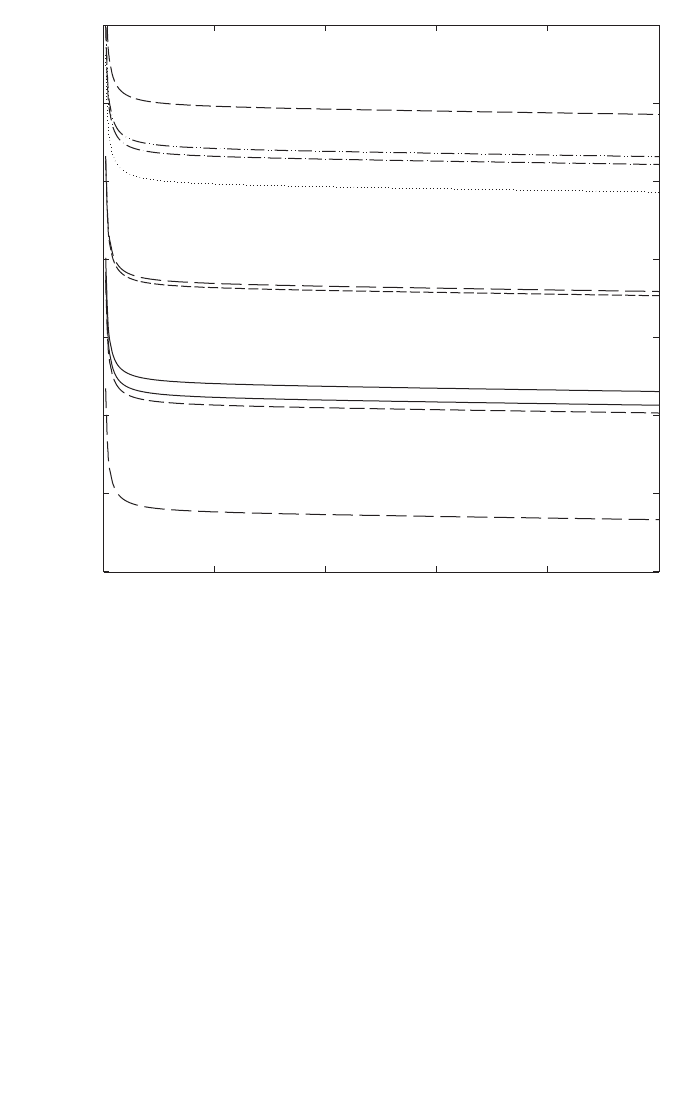

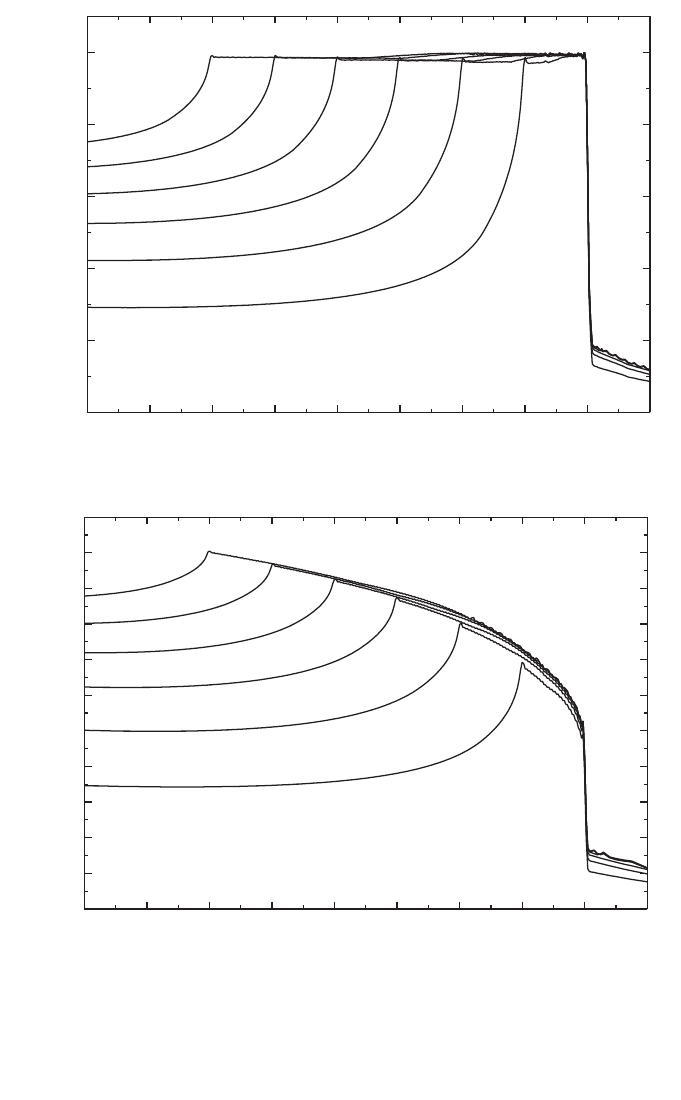

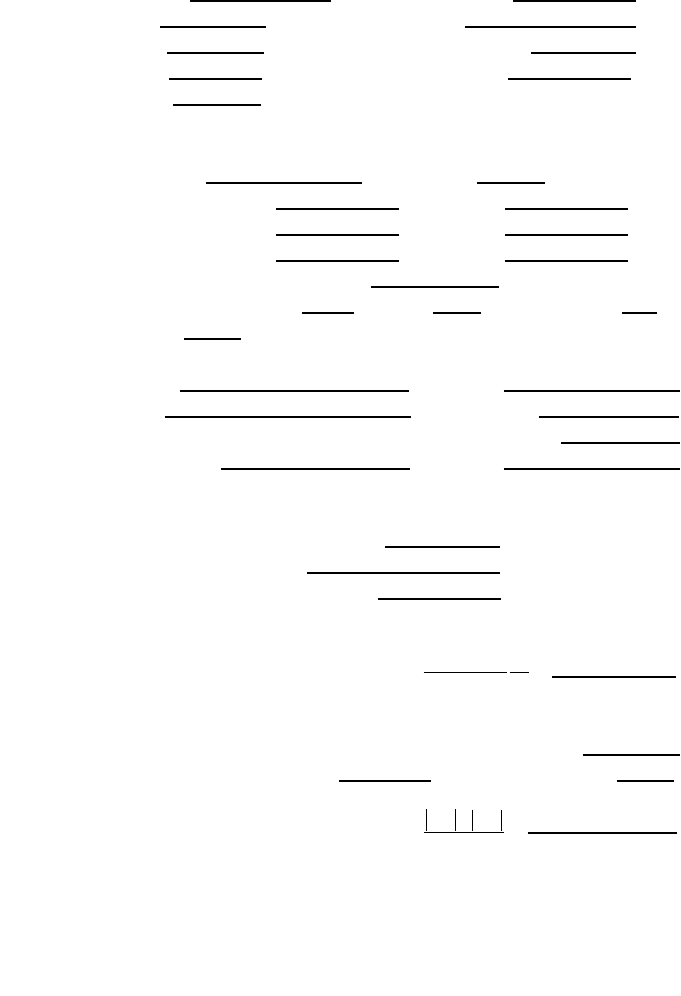

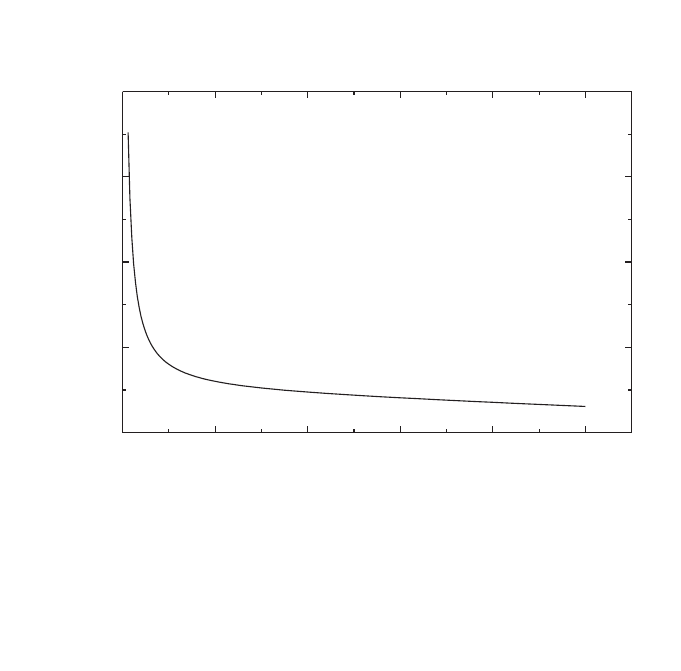

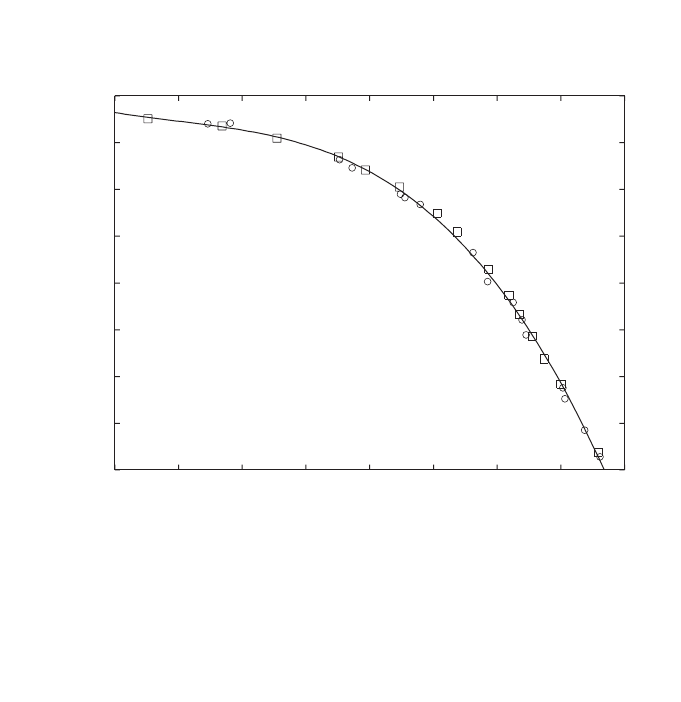

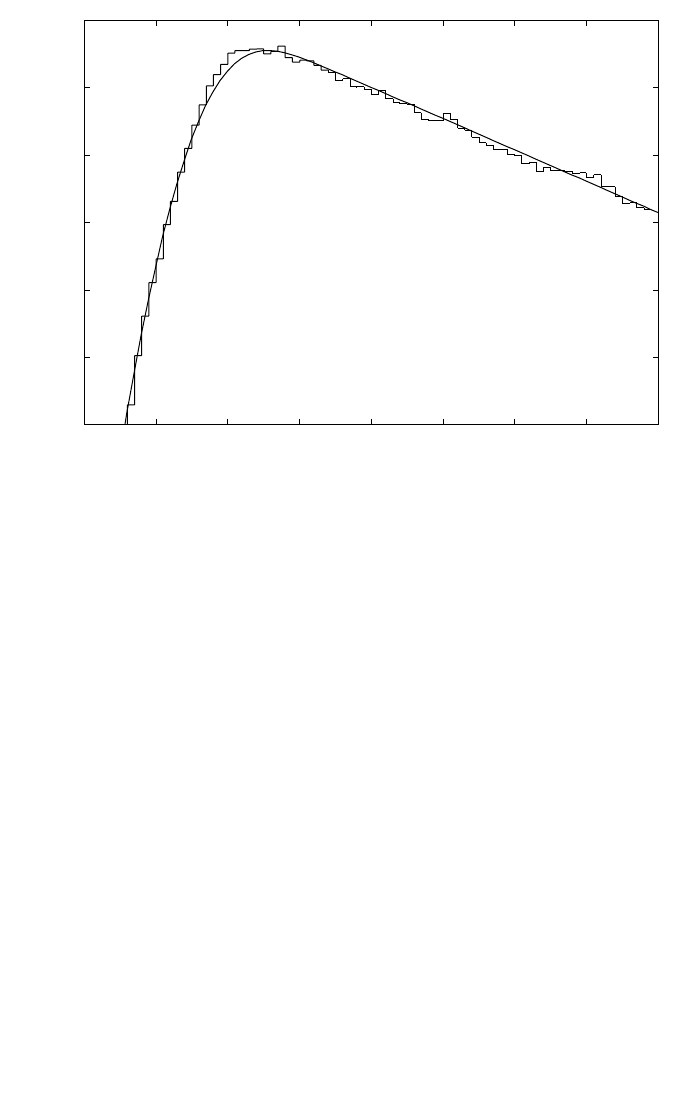

that the response of each individual chamber is taken into account. Figure 2 shows

chamber to chamber variations, demonstrated for a given chamber type by the lack of

constancy in the N

D,w

/N

K

ratio at

60

Co, for a large number of cylindrical ionization

chambers commonly used in radiotherapy dosimetry. For a given chamber type,

chamber to chamber differences of up to 0.8% have also been reported by the

BIPM [30]. The elimination of the uncertainty component caused by the assumption

that all chambers of a given type are identical is a justification for favouring direct

calibration of ionization chambers in terms of absorbed dose to water.

In principle, primary standards of absorbed dose to water can operate in both

60

Co beams and accelerator beams. Thus, for high energy photon and electron

5

radiation, an experimental determination of the energy dependence of ionization

chambers becomes available, resulting in reduced uncertainty owing to the effect of

beam quality. Similar conclusions can be drawn for therapeutic proton and heavy ion

beams, although primary standards of absorbed dose to water are not yet available at

these radiation qualities.

1.2.2. A more robust system of primary standards

Despite the fact that the quantity of interest in radiation dosimetry is absorbed

dose to water, most national, regional and international dosimetry recommendations

are based on the use of an air kerma calibration factor for an ionization chamber,

traceable to a national or international primary standard of air kerma for

60

Co gamma

radiation. Although international comparisons of these standards have exhibited very

good agreement, a substantial weakness prevails in that all such standards are based

on ionization chambers and are therefore subject to common errors. In addition,

depending on the method of evaluation, a factor related to the attenuation in the

6

1.07

1.08

1.09

1.10

1.11

1.12

N

NE 2561

and

NE 2611

NE 2571

NE 2581

PTW 30001

PTW 30002

PTW 30006

PTW 23333

D,w

/ N

K

PTW 30004

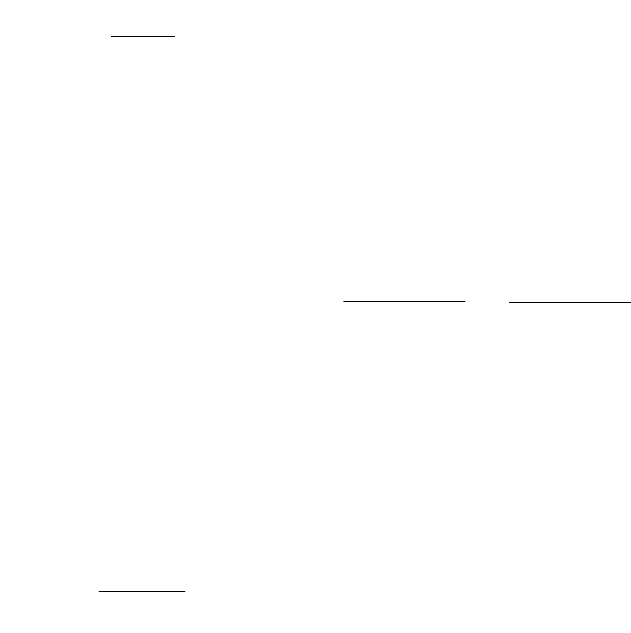

FIG. 2. The ratio of

60

Co calibration factors N

D,w

/N

K

is a useful indicator of the uniformity

within a given type of chamber [30]. Chamber to chamber variations, demonstrated by

differences in the ratio N

D,w

/N

K

for chambers of a given type, are shown for a large number

of cylindrical ionization chambers commonly used in radiotherapy dosimetry (see Table 3 for

a description of each chamber type). The large variation for NE 2581 chambers is considered

to be caused by the hygroscopic properties of the A-150 plastic walls (data measured in the

IAEA Dosimetry Laboratory).

chamber wall entering into the determination of the quantity air kerma has been found

to differ by up to 0.7% for some primary standards [31]. In contrast, primary

standards of absorbed dose to water are based on a number of different physical

principles. There are no assumptions or estimated correction factors common to all of

them. Therefore, good agreement among these standards (see Section 2.2) gives much

greater confidence in their accuracy.

1.2.3. Use of a simple formalism

The formalism given in Ref. [17] and in most national and international

dosimetry protocols for the determination of absorbed dose to water in radiotherapy

beams is based on the application of several coefficients, perturbation and other cor-

rection factors. This is because of the practical difficulty in making the conversion

from the free-air quantity air kerma to the in-phantom quantity absorbed dose to water.

This complexity is best demonstrated by considering the equations needed, and the

procedures for selecting the appropriate data. Reliable information about certain phys-

ical characteristics of the ionization chamber used is also required. Many of these data,

such as displacement correction factors and stopping-power ratios, are derived from

complex measurements or calculations based on theoretical models. A simplified pro-

cedure starting from a calibration factor in terms of absorbed dose to water, and

applying correction factors for all influence quantities, reduces the possibility of errors

in the determination of absorbed dose to water in the radiation beam. The simplicity of

the formalism in terms of absorbed dose to water becomes obvious when the general

equation for the determination of absorbed dose to water is considered (see Section 3).

1.3. TYPES OF RADIATION AND RANGE OF BEAM QUALITIES

This Code of Practice provides a methodology for the determination of

absorbed dose to water in the low, medium and high energy photon beams, electron

beams, proton beams and heavy ion beams used for external radiation therapy. The

ranges of radiation qualities covered in this report are given below (for a description

of the beam quality index see the corresponding sections):

(a) Low energy X rays with generating potentials up to 100 kV and HVL of 3 mm

Al (the lower limit is determined by the availability of standards);

4

7

4

The boundary between the two ranges for kilovoltage X rays is not strict and has an

overlap between 80 kV, 2 mm Al and 100 kV, 3 mm Al. In this overlap region, the methods for

absorbed dose determination given in Sections 8 or 9 are equally satisfactory, and whichever is

more convenient should be used.

(b) Medium energy X rays with generating potentials above 80 kV and HVL of

2 mm Al (see footnote 4);

(c)

60

Co gamma radiation;

(d) High energy photons generated by electrons with energies in the interval

1–50 MeV, with TPR

20,10

values between 0.50 and 0.84;

(e) Electrons in the energy interval 3–50 MeV, with a half-value depth, R

50

,

between 1 and 20 g/cm

2

;

(f) Protons in the energy interval 50–250 MeV, with a practical range, R

p

, between

0.25 and 25 g/cm

2

;

(g) Heavy ions with Z between 2 (He) and 18 (Ar) having a practical range in water,

R

p

, of 2 to 30 g/cm

2

(for carbon ions this corresponds to an energy range of

100 MeV/u to 450 MeV/u, where u is the atomic mass unit).

1.4. PRACTICAL USE OF THIS CODE OF PRACTICE

Emphasis has been given to making the practical use of this report as simple as

possible. The structure of this Code of Practice differs from that of TRS-277 [17] and

more closely resembles Technical Reports Series No. 381 (TRS-381) [21] in that the

practical recommendations and data for each radiation type have been placed in an

individual section devoted to that radiation type. Each essentially forms a different

Code of Practice, including detailed procedures and worksheets. The reader can per-

form a dose determination for a given beam by working through the appropriate sec-

tion; the search for procedures or tables contained in other parts of the document has

been reduced to a minimum. Making the various Codes of Practice independent and

self-contained has required an unavoidable repetition of some portions of text, but this

is expected to result in a publication which is simple and easy to use, especially for

users having access to a limited number of radiation types. The first four sections con-

tain general concepts that apply to all radiation types. Appendices provide a comple-

ment to the information supplied in the various sections.

Compared with previous codes of practice or dosimetry protocols based on

standards of air kerma (see Refs [17, 21]), the adoption of this Code of Practice will

introduce small differences in the value of the absorbed dose to water determined in

clinical beams. Detailed comparisons will be published in the open literature, and the

results are expected to depend on the type and quality of the beam and on the type of

ionization chamber. Where differences arise, it is important to notice that they might

be due to: (i) inaccuracies in the numerical factors and expressions (for example k

m

,

p

wall

, etc.) in the N

K

based method and, to a lesser extent, in this Code of Practice, and

(ii) the primary standards to which the calibrations in terms of air kerma and absorbed

dose to water are traceable. Even for

60

Co gamma radiation, which is generally better

8

characterized than other modalities, beam calibrations based on the two different

standards, K

air

and D

w

, differ by typically 1% (see Appendix I); the value derived

using this Code of Practice is considered to be the better estimate. Any conclusions

drawn from comparisons between protocols based on standards of air kerma and

absorbed dose to water must take account of the differences between primary stan-

dards.

1.5. EXPRESSION OF UNCERTAINTIES

The evaluation of uncertainties in this Code of Practice follows the guidance

given by the ISO [32]. Uncertainties of measurements are expressed as relative stan-

dard uncertainties and the evaluation of standard uncertainties is classified into type

A and type B. The method of evaluation of type A standard uncertainty is by statis-

tical analysis of a series of observations, whereas the method of evaluation of type B

standard uncertainty is based on means other than statistical analysis of a series of

observations. A practical implementation of the ISO recommendations, based on the

summaries provided in Refs [33] and [17], is given for completeness in Appendix IV

of this Code of Practice.

Estimates of the uncertainty in dose determination for the different radiation

types are given in the appropriate sections. Compared with estimates in previous

codes of practice, the present values are generally smaller. This arises from the greater

confidence in determinations of absorbed dose to water based on D

w

standards and,

in some cases, from a more rigorous analysis of uncertainties in accordance with the

ISO guidelines.

1.6. QUANTITIES AND SYMBOLS

Most of the symbols used in this Code of Practice are identical to those used in

Refs [17] and [21], and only a few are new in the context of standards of absorbed

dose to water. For completeness, a summary is provided here for all quantities of

relevance to the different methods used in this Code of Practice.

c

pl

Material dependent scaling factor to convert ranges and depths mea-

sured in plastic phantoms into the equivalent values in water. This

applies to electron, proton and heavy ion beams. Note that in this Code

of Practice the depths and ranges are defined in units of g/cm

2

, in con-

trast to their definition in cm in Ref. [21] for electron beams. As a

9

result, the values given for c

pl

in this Code for electrons differ from

those for C

pl

given in Ref. [21]. The use of lowercase for c

pl

denotes

this change.

csda Continuous slowing down approximation.

D

w,Q

Absorbed dose to water at the reference depth, z

ref

, in a water phantom

irradiated by a beam of quality Q. The subscript Q is omitted when the

reference beam quality is

60

Co. Unit: gray (Gy).

E

o

, E

z

Mean energy of an electron beam at the phantom surface and at depth

z, respectively. Unit: MeV.

h

pl

Material dependent fluence scaling factor to correct for the difference

in electron fluence in plastic compared with that in water at an equiva-

lent depth.

HVL Half-value layer, used as a beam quality index for low and medium

energy X ray beams.

k

i

General correction factor used in the formalism to correct for the effect

of the difference in the value of an influence quantity between the

calibration of a dosimeter under reference conditions in the standards

laboratory and the use of the dosimeter in the user facility under

different conditions.

k

elec

Calibration factor of an electrometer.

k

h

Factor to correct the response of an ionization chamber for the effect of

humidity if the chamber calibration factor is referred to dry air.

k

pol

Factor to correct the response of an ionization chamber for the effect of

a change in polarity of the polarizing voltage applied to the chamber.

k

Q,Q

o

Factor to correct for the difference between the response of an ioniza-

tion chamber in the reference beam quality Q

o

used for calibrating the

chamber and in the actual user beam quality Q. The subscript Q

o

is

omitted when the reference quality is

60

Co gamma radiation (i.e. the

reduced notation k

Q

always corresponds to the reference quality

60

Co).

k

s

Factor to correct the response of an ionization chamber for the lack of

complete charge collection (due to ion recombination).

k

TP

Factor to correct the response of an ionization chamber for the effect of

the difference that may exist between the standard reference tempera-

ture and pressure specified by the standards laboratory and the temper-

ature and pressure of the chamber in the user facility under different

environmental conditions.

M

Q

Reading of a dosimeter at quality Q, corrected for influence quantities

other than beam quality. Unit: C or rdg.

M

em

Reading of a dosimeter used as an external monitor. Unit: C or rdg.

(

µ

en

/

ρ

)m

1

,m

2

ratio of the mean mass energy absorption coefficients of materials m

1

and m

2

, averaged over a photon spectrum.

10

N

D,air

Absorbed dose to air chamber factor of an ionization chamber used in

air kerma based dosimetry protocols (cf. Refs [17, 21]). This is the N

gas

of Ref. [9]. The factor N

D,air

was called N

D

in Ref. [11] and in Ref. [17],

but the subscript ‘air’ was included in Ref. [21] to specify without

ambiguity that it refers to the absorbed dose to the air of the chamber

cavity. Care should be taken by the user to avoid confusing N

D,air

, or the

former N

D

, with the calibration factor in terms of absorbed dose to

water N

D,w

described below (see Appendix I). Unit: Gy/C or Gy/rdg.

N

D,w,Q

o

Calibration factor in terms of absorbed dose to water for a dosimeter at

a reference beam quality Q

o

. The product M

Q

o

N

D,w,Q

o

yields the

absorbed dose to water, D

w,Q

o

, at the reference depth z

ref

and in the

absence of the chamber. The subscript Q

o

is omitted when the reference

quality is a beam of

60

Co gamma rays (i.e. N

D,w

always corresponds to

the calibration factor in terms of absorbed dose to water in a

60

Co

beam). The factor N

D,w

was called N

D

in Ref. [9], where a relationship

between N

gas

and N

D

was given similar to that described in Section 3.3

and Appendix I. The symbol N

D

is also used in calibration certificates

issued by some standards laboratories and manufacturers instead of

N

D,w

. Users are strongly recommended to ascertain the physical quan-

tity used for the calibration of their detectors in order to avoid serious

mistakes.

5

Unit: Gy/C or Gy/rdg.

N

K,Q

o

Calibration factor in terms of air kerma for a dosimeter at a reference

beam quality Q

o

. Unit: Gy/C or Gy/rdg.

p

cav

Factor that corrects the response of an ionization chamber for effects

related to the air cavity, predominantly the in-scattering of electrons

that makes the electron fluence inside a cavity different from that in the

medium in the absence of the cavity.

p

cel

Factor that corrects the response of an ionization chamber for the effect

of the central electrode during in-phantom measurements in high

energy photon (including

60

Co), electron and proton beams. Note that

this factor is not the same as in Ref. [17], where the correction took into

account the global effect of the central electrode both during calibration

of the chamber in air in a

60

Co beam, and during subsequent measure-

ments in photon and electron beams in a phantom. To avoid ambigui-

ties, Ref. [21] called the correction factor used in Ref. [17] p

cel-gbl

,

11

5

The difference between N

D,air

and N

D,w

is close to the value of the stopping-power

ratio, water to air, in

60

Co gamma rays. A confusion in the meaning of the factors could

therefore result in an error in the dose delivered to patients of approximately 13% (see

Appendix I).

keeping the symbol p

cel

exclusively for in-phantom measurements (see

Appendix I).

PDD Percentage depth dose.

p

dis

Factor that accounts for the effect of replacing a volume of water with

the detector cavity when the reference point of the chamber

6

is taken to

be at the chamber centre. It is the alternative to the use of an effective

point of measurement of the chamber, P

eff

. For plane-parallel ioniza-

tion chambers, p

dis

is not required.

P

eff

The effective point of measurement of an ionization chamber. For the

standard calibration geometry, i. e. a radiation beam incident from one

direction, P

eff

is shifted from the position of the centre towards the

source by a distance which depends on the type of beam and chamber.

For plane-parallel ionization chambers P

eff

is usually assumed to be sit-

uated in the centre of the front surface of the air cavity.

7

The concept of

the effective point of measurement of a cylindrical ionization chamber

was used for all radiation types in Ref. [17], but in this Code of Practice

it is only used for electron and heavy ion beams. For other beams, ref-

erence dosimetry is based on positioning the reference point of the

chamber at the reference depth, z

ref

, where the dose is determined. The

reference point of an ionization chamber is specified for each radiation

type in the corresponding section.

p

Q

Overall perturbation factor for an ionization chamber for in-phantom

measurements at a beam quality Q. It is equal to the product of various

factors correcting for different effects, each correcting for small pertur-

bations; in practice these are p

cav

, p

cel

, p

dis

and p

wall

.

p

wall

Factor that corrects the response of an ionization chamber for the non-

medium equivalence of the chamber wall and any waterproofing

material.

Q General symbol to indicate the quality of a radiation beam. A subscript

‘o’, i.e. Q

o

, indicates the reference quality used for the calibration of an

ionization chamber or a dosimeter.

rdg Value, in arbitrary units, used for the reading of a dosimeter.

12

6

The reference point of a chamber is specified in this Code of Practice in each section

for each type of chamber. It usually refers to the point of the chamber specified by a calibra-

tion document to be that at which the calibration factor applies [33].

7

This assumption might fail if the chamber design does not follow certain requirements

regarding the ratio of cavity diameter to cavity height as well as that of guard ring width to

cavity height (see Ref. [21]).

R

50

Half-value depth in water (in g/cm

2

), used as the beam quality index for

electron beams.

R

p

Practical range (in g/cm

2

) for electron, proton and heavy ion beams.

R

res

Residual range (in g/cm

2

) for proton beams.

r

cyl

Cavity radius of a cylindrical ionization chamber.

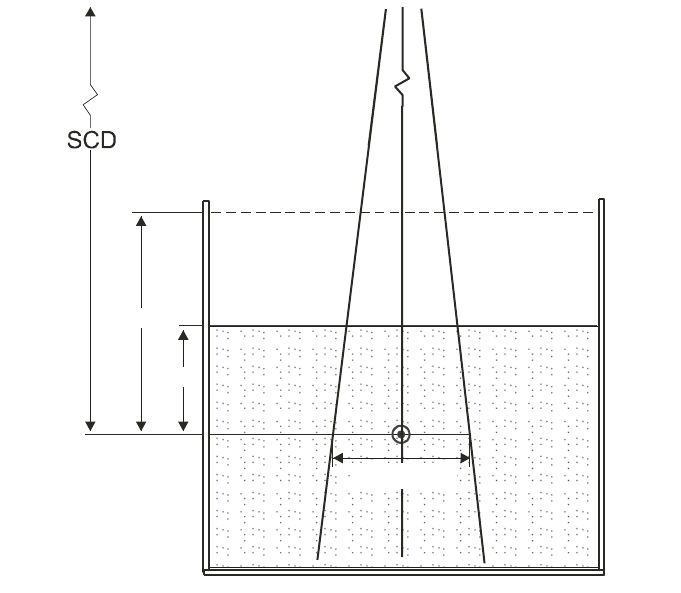

SAD Source–axis distance.

SCD Source–chamber distance.

SOBP Spread-out Bragg peak.

SSD Source–surface distance.

s

m,air

Stopping-power ratio medium to air, defined as the ratio of the mean

restricted mass stopping powers of materials m and air, averaged over

an electron spectrum. For all high energy radiotherapy beams in this

Code of Practice, except for heavy ion beams, stopping-power ratios

are of the Spencer–Attix type with a cut-off energy ∆ = 10 keV (see

Ref. [11]).

TMR Tissue–maximum ratio.

TPR

20,10

Tissue–phantom ratio in water at depths of 20 and 10 g/cm

2

, for a field

size of 10 cm × 10 cm and an SCD of 100 cm, used as the beam quality

index for high energy photon radiation.

u

c

Combined standard uncertainty of a quantity.

W

air

The mean energy expended in air per ion pair formed.

z

max

Depth of maximum dose (in g/cm

2

).

z

ref

Reference depth (in g/cm

2

) for in-phantom measurements. When

specified at z

ref

, the absorbed dose to water refers to D

w,Q

at the inter-

section of the beam central axis with the plane defined by z

ref

.

13

14

1.7. ABBREVIATIONS OF ORGANIZATIONS

The following abbreviations are used in this report to refer to different organi-

zations involved in radiation dosimetry:

ARPANSA Australian Radiation Protection and Nuclear Safety Agency, Australia

BEV Bundesamt für Eich- und Vermessungswesen, Austria

BIPM Bureau International des Poids et Mesures

CCEMRI(I) Comité Consultatif pour les Etalons de Mesure des Rayonnements

Ionisants (Section I) (Consultative Committee for Standards of

Ionizing Radiation). Since September 1997, the CCEMRI and its

sections have been renamed CCRI.

CCRI(I) Comité Consultatif des Rayonnements Ionisants (Section I)

(Consultative Committee for Ionizing Radiation)

CIPM Comité International des Poids et Mesures

ENEA- Ente per le Nuove Tecnologie, l’Energia e l’Ambiente, Instituto

INMRI Nazionale di Metrologia delle Radiazioni Ionizzanti, Italy

ICRU International Commission on Radiation Units and Measurements

IEC International Electrotechnical Commission

IMS International Measurement System

ISO International Organization for Standardization

LPRI Laboratoire Primaire de Métrologie des Rayonnements Ionisants,

France

NIST National Institute of Standards and Technology, USA

NPL National Physical Laboratory, United Kingdom

NRC National Research Council, Canada

NRL National Radiation Laboratory, New Zealand

OIML Organisation Internationale de Métrologie Légale

PTB Physikalisch-Technische Bundesanstalt, Germany

15

2. FRAMEWORK

2.1. THE INTERNATIONAL MEASUREMENT SYSTEM

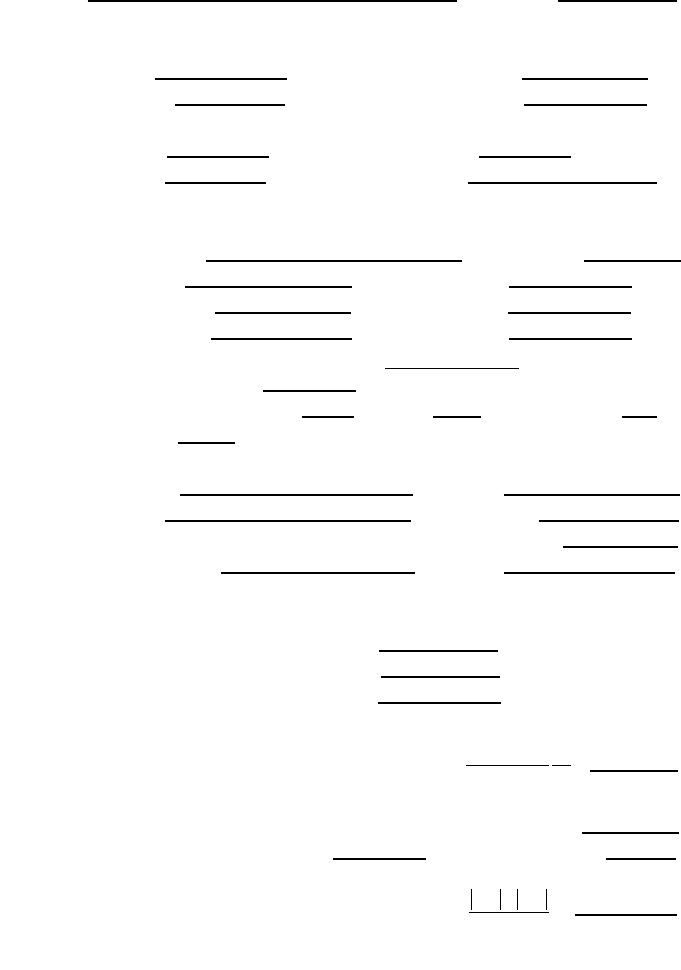

The International Measurement System for radiation metrology provides the

framework for consistency in radiation dosimetry by disseminating to users calibrated

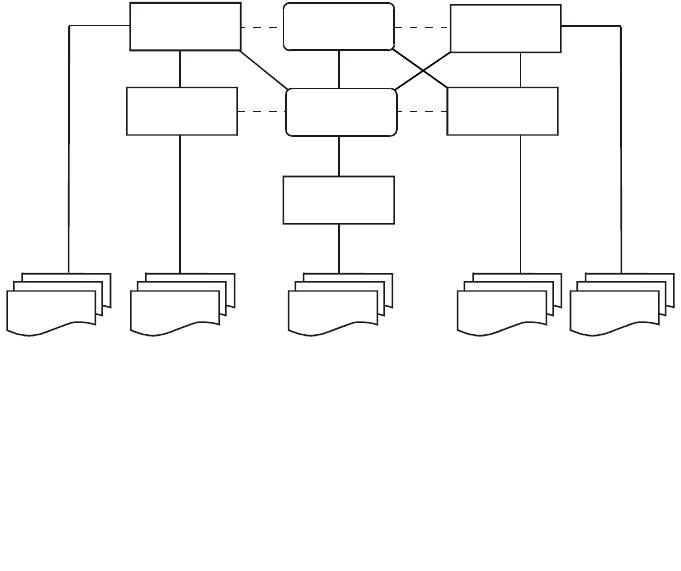

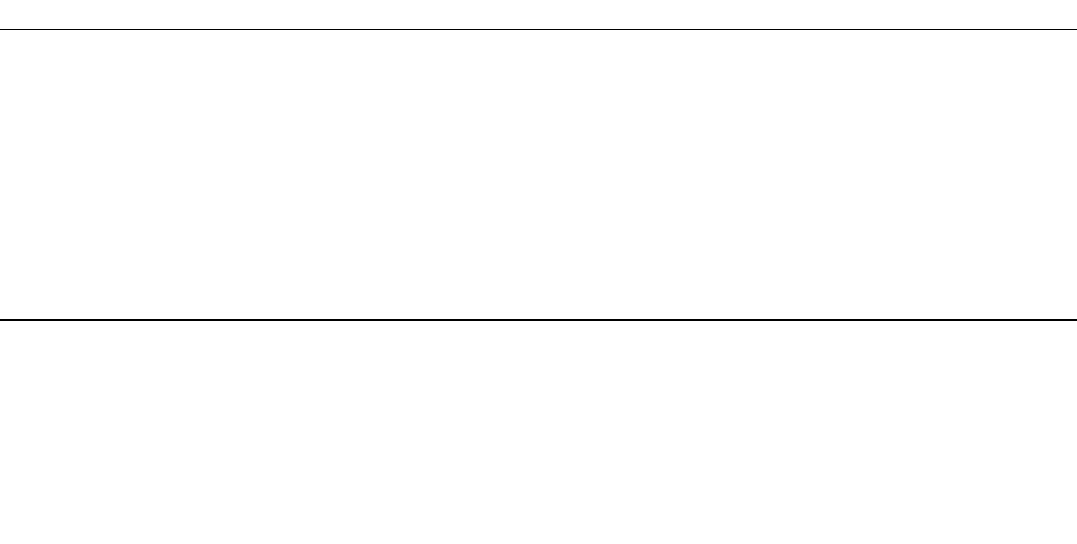

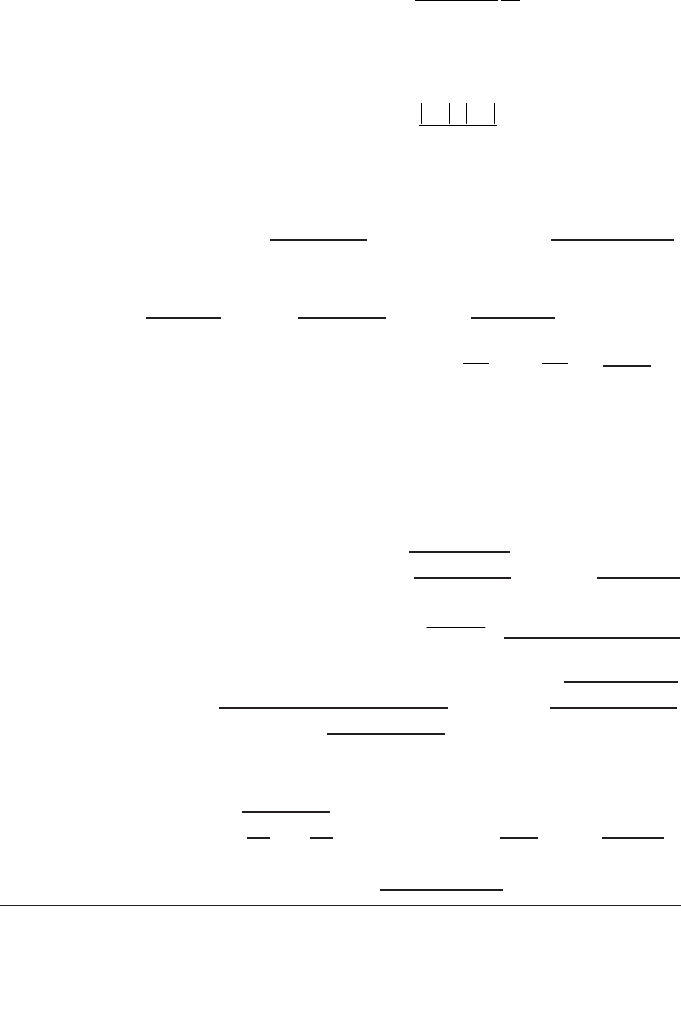

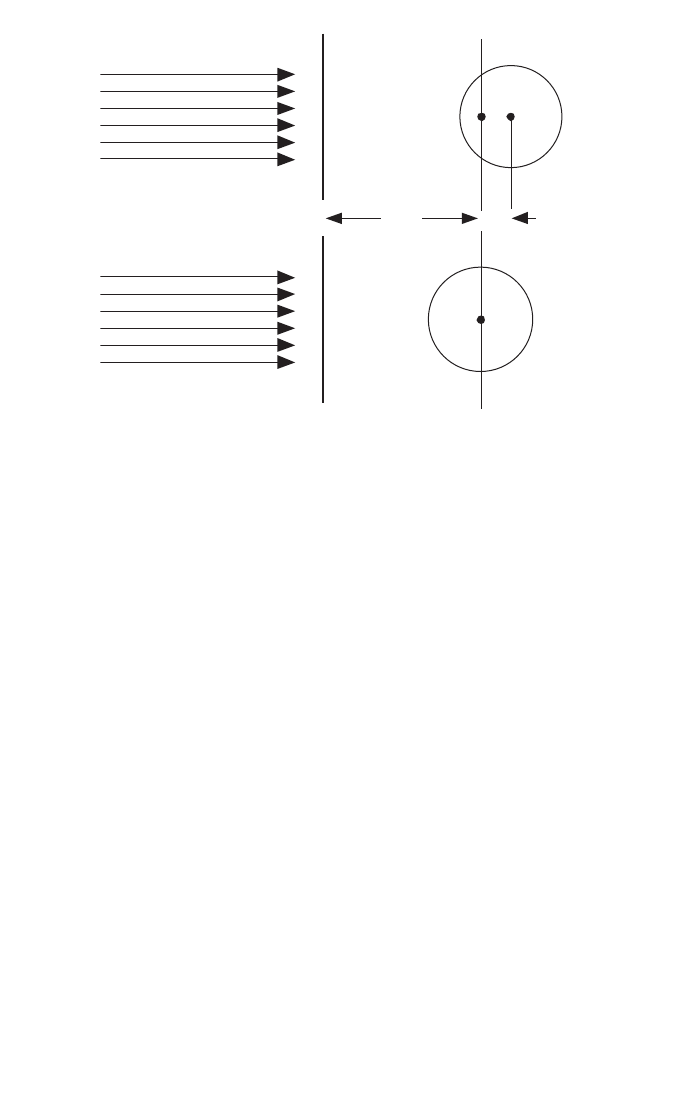

radiation instruments which are traceable to primary standards (see Fig. 3).

The BIPM was set up by the Metre Convention (originally signed in 1875), with

48 States as members as of 31 December 1997 [34]. It serves as the international

centre for metrology, with its laboratory and offices in Sèvres (France), with the aim

of ensuring worldwide uniformity in matters relating to metrology. In radiation

dosimetry, the PSDLs of many States of the Metre Convention have developed pri-

mary standards for radiation measurements (see Table 1) that are compared with those

of the BIPM and other PSDLs. However, worldwide there are only some twenty

countries with PSDLs involved in radiation dosimetry and they cannot calibrate the

very large number of radiation dosimeters that are in use all over the world. Those

national laboratories that maintain primary standards calibrate the secondary

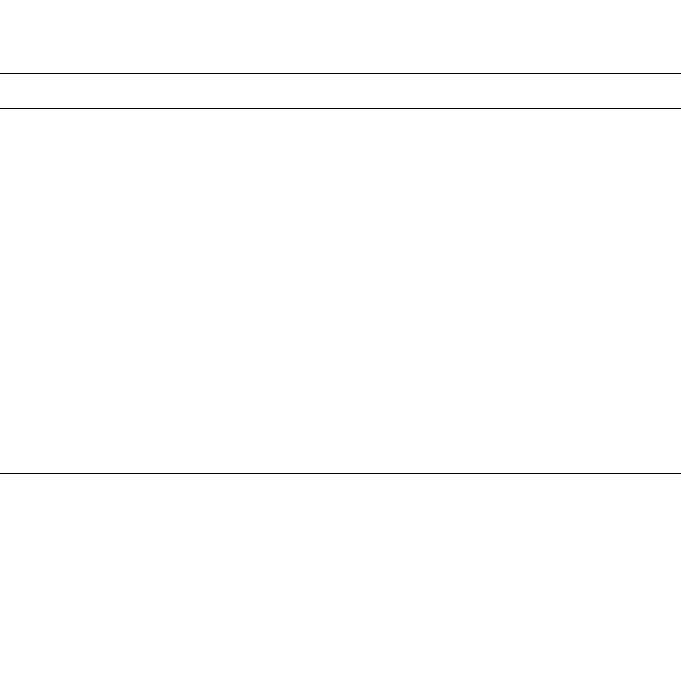

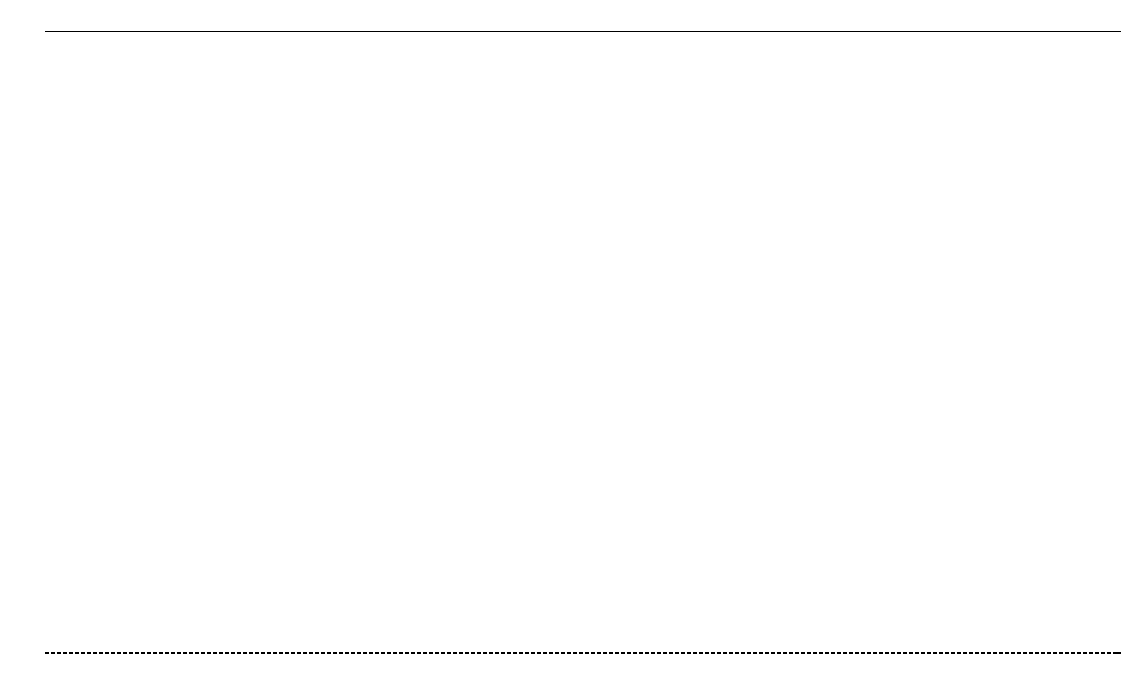

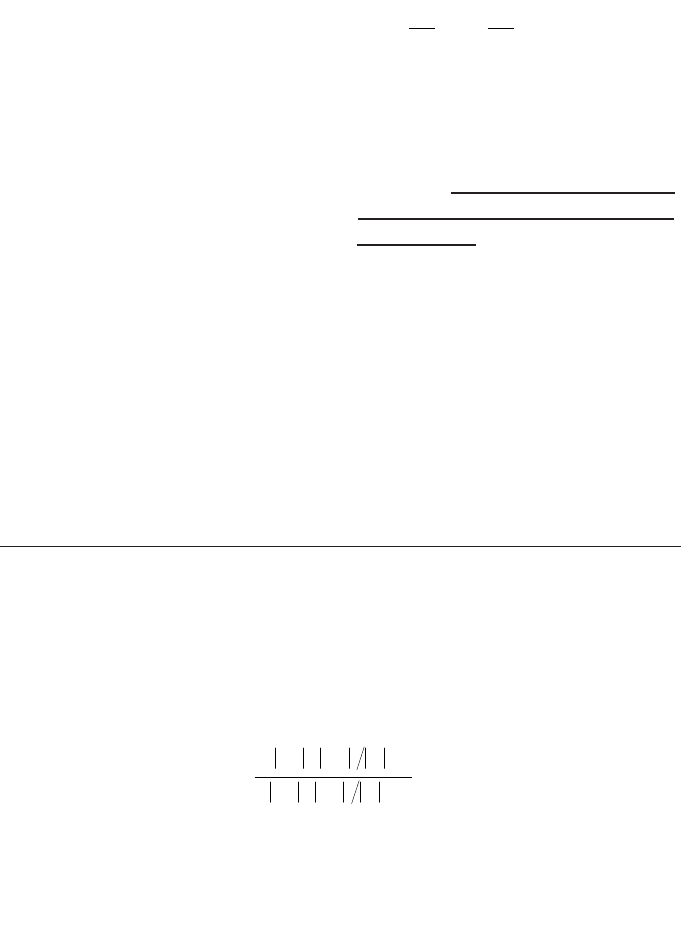

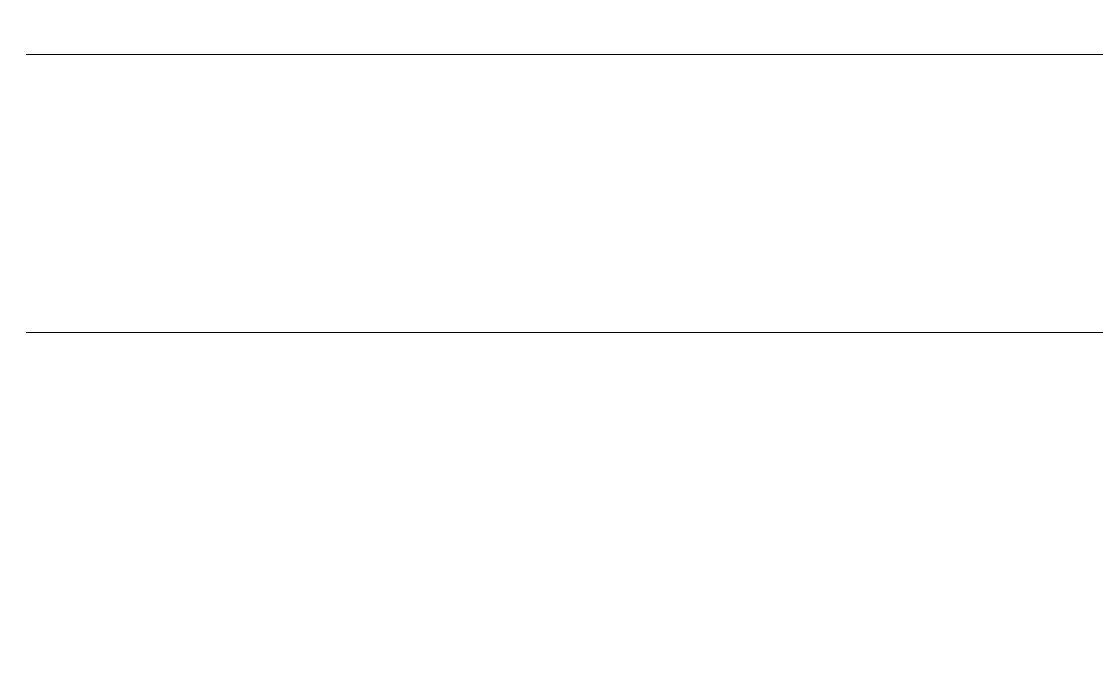

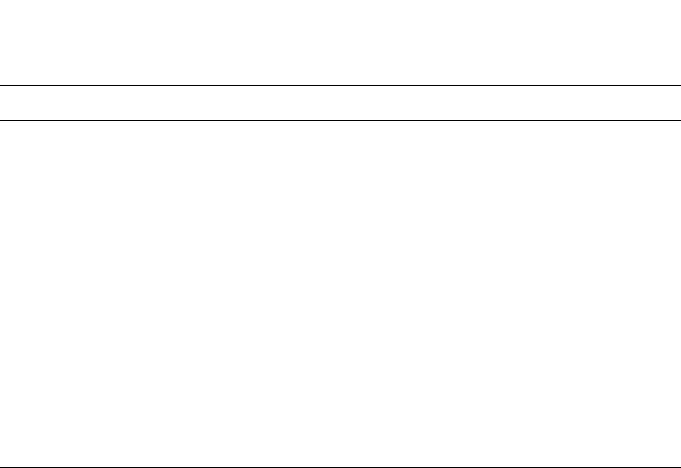

FIG. 3. The International Measurement System (IMS) for radiation metrology, where the

traceability of user reference instruments to primary standards is achieved either by direct

calibration in a Primary Standard Dosimetry Laboratory (PSDL) or, more commonly, in a

Secondary Standard Dosimetry Laboratory (SSDL) with direct link to the BIPM, a PSDL or to

the IAEA/WHO network of SSDLs. Most SSDLs from countries not members of the Metre

Convention achieve the traceability of their standards through the IAEA. The dashed lines

indicate intercomparisons of primary and secondary standards.

PSDLs

SSDLs

SSDLs

PSDLs

SSDLs

BIPM

IAEA

Users Users Users Users Users

16

standards of SSDLs (see Table 1), which in turn calibrate the reference instruments

of users (some PSDLs also calibrate the reference instruments of users).

2.1.1. The IAEA/WHO network of SSDLs

The main role of the SSDLs is to bridge the gap between PSDLs and the users

of ionizing radiation by enabling the transfer of dosimeter calibrations from the

TABLE 1. CLASSIFICATION OF INSTRUMENTS AND STANDARDS

LABORATORIES (adapted from Ref. [33])

Classification of instruments Standards laboratories

Primary standard Primary Standard Dosimetry Laboratory (PSDL)

An instrument of the highest A national standardizing laboratory designated

metrological quality that permits by the government for the purpose of

determination of the unit of a quantity developing, maintaining and improving primary

from its definition, the accuracy of standards in radiation dosimetry.

which has been verified by

comparison with the comparable Secondary Standard Dosimetry Laboratory (SSDL)

standards of other institutions at A dosimetry laboratory designated by the competent

the same level. authorities to provide calibration services, and

which is equipped with at least one secondary

Secondary standard standard that has been calibrated against a primary

An instrument calibrated by standard.

comparison with a primary standard

National standard

A standard recognized by an official

national decision as the basis for

fixing the value in a country of all

other standards of the given quantity.

Reference instrument

An instrument of the highest

metrological quality available at a given

location, from which measurements

at that location are derived.

Field instrument

A measuring instrument used for

routine measurements whose

calibration is related to the reference

instrument.

17

primary standard to user instruments [35]. In 1976, a network of SSDLs was estab-

lished as a joint effort by the IAEA and WHO in order to disseminate calibrations to

users by providing the link between users and primary standards, mainly for countries

that are not members of the Metre Convention. By 2000, the network included 73 lab-

oratories and 6 SSDL national organizations in 61 IAEA Member States, of which

over half are in developing countries. The SSDL network also includes 20 affiliated

members, among them the BIPM, several national PSDLs, the ICRU and other inter-

national organizations that provide support to the network [36].

As the organizer of the network, the IAEA has the responsibility to verify that

the services provided by the SSDL member laboratories follow internationally

accepted metrological standards (including traceability for radiation protection

instruments). The first step in this process is the dissemination of dosimeter calibra-

tions from the BIPM or PSDLs through the IAEA to the SSDLs. In the next step,

follow-up programmes and dose quality audits are implemented by the IAEA for the

SSDLs to guarantee that the standards disseminated to users are kept within the levels

of accuracy required by the IMS [36].

One of the principal goals of the SSDL network in the field of radiotherapy

dosimetry is to guarantee that the dose delivered to patients undergoing radiotherapy

treatment is within internationally accepted levels of accuracy. This is accomplished

by ensuring that the calibrations of instruments provided by the SSDLs are correct,

emphasizing the participation of the SSDLs in quality assurance programmes for

radiotherapy, promoting the contribution of the SSDLs to support dosimetry quality

audits in therapy centres and assisting if needed in performing the calibration of

radiotherapy equipment in hospitals.

2.2. STANDARDS OF ABSORBED DOSE TO WATER

There are three basic methods currently used for the absolute determination of

absorbed dose to water: calorimetry, chemical dosimetry and ionization dosimetry. At

present, these are the only methods that are sufficiently accurate to form the basis of

primary standards for measurements of absorbed dose to water [29]. The PSDLs have

developed various experimental approaches to establish standards of absorbed dose to

water. These standards are described briefly and the results of international

comparisons of absorbed dose to water are presented below.

In most PSDLs the primary standards of absorbed dose to water operate in a

60

Co gamma ray beam and in some PSDLs the standards of absorbed dose to water

operate also at other radiation qualities such as high energy photons, electrons and

kilovoltage X rays. Primary standards operating in

60

Co gamma ray beams or in

photon and electron beams produced by accelerators are based on one of the

following methods below.

18

— The ionization chamber primary standard consists of a graphite cavity chamber

with accurately known chamber volume, designed to fulfil as far as possible the

requirements of a Bragg–Gray detector. The chamber is placed in a water

phantom and the absorbed dose to water at the reference point derived from the

mean specific energy imparted to the air of the cavity [37].

— The graphite calorimeter developed by Domen and Lamperti [38] is used with

slight modifications by several PSDLs to determine the absorbed dose to

graphite in a graphite phantom. The conversion to absorbed dose to water at the

reference point in a water phantom may be performed in different ways, for

example by application of the photon fluence scaling theorem or by measure-

ments based on the cavity ionization theory [39, 40].

— The water calorimeter offers a more direct determination of the absorbed dose

to water at the reference point in a water phantom. The sealed water system

[41, 42] consists of a small glass vessel containing high purity water and a ther-

mistor detector unit. Water purity is important because the heat defect of water

is strongly influenced by impurities. With the sealed water arrangement high

purity water can be saturated with various gases to create a mixture for which

the heat defect has a well defined and stable value.

— The water calorimeter with Fricke transfer dosimeter [43] is based on the mea-

surement of the average temperature increase induced by the absorption of high

energy photons. The water is stirred continuously and the absorbed dose to

water averaged over the volume of the vessel is determined. The Fricke solu-

tion is calibrated by irradiation under the same conditions and the absorbed

dose to water at the reference point in a water phantom is obtained using the

Fricke dosimeter as the transfer standard.

— The Fricke standard of absorbed dose to water determines the response of the

Fricke solution using the total absorption of an electron beam in the solu-

tion [44]. Knowing the electron energy, the beam current and the absorbing

mass accurately, the total absorbed energy can be determined and related to the

change in absorbance of the Fricke solution as measured spectrophotometri-

cally. The absorbed dose to water at the reference point in a water phantom is

obtained using the Fricke dosimeter as the transfer standard.

The methods outlined above are not applied at PSDLs to primary standards for

use in kilovoltage X ray beams. Absolute measurements for the determination of

absorbed dose to water in kilovoltage X ray beams have been based so far almost

exclusively on the use of extrapolation ionization chambers [45].

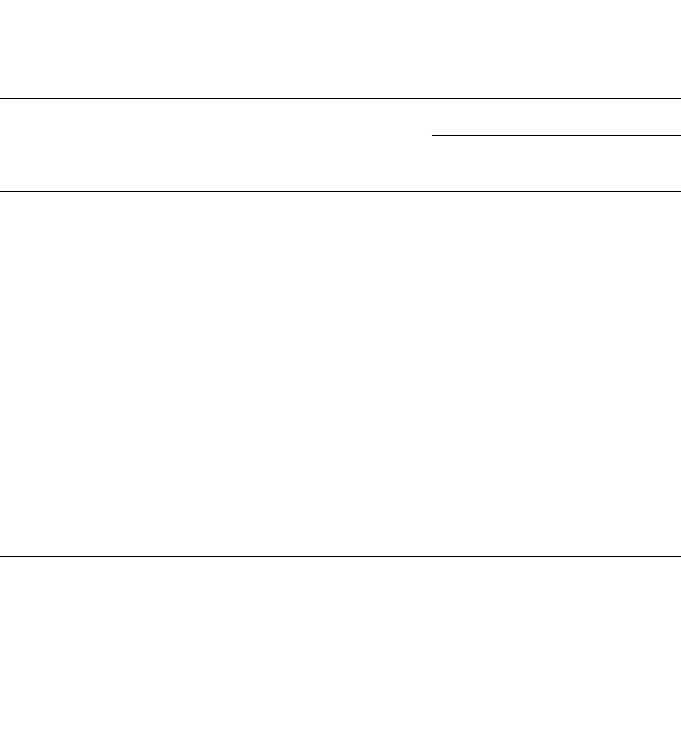

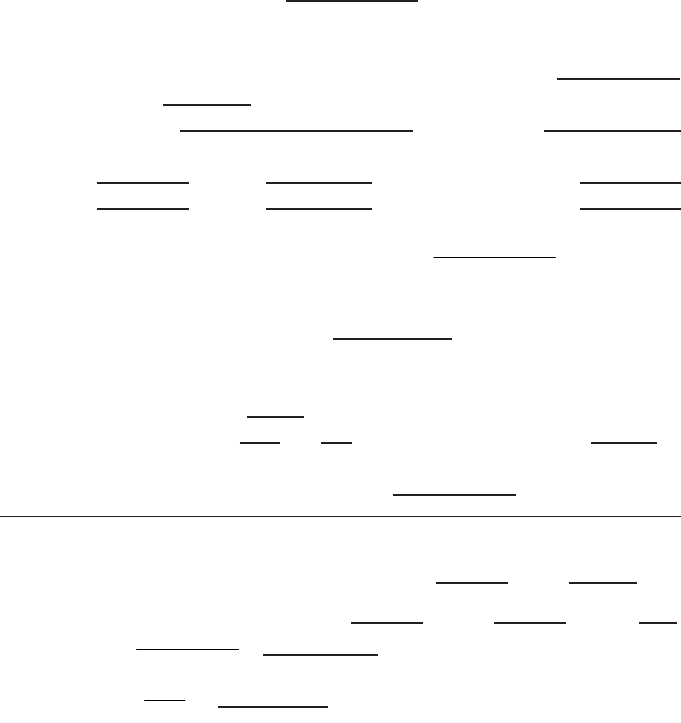

Comparisons of primary standards of absorbed dose to water have been carried

out over the past decade [29, 46, 47], whereas comparisons of air kerma primary stan-

dards have a much longer history. The results of comparisons at the BIPM in terms of

absorbed dose to water for

60

Co gamma radiation are given in Ref. [48] (see

19

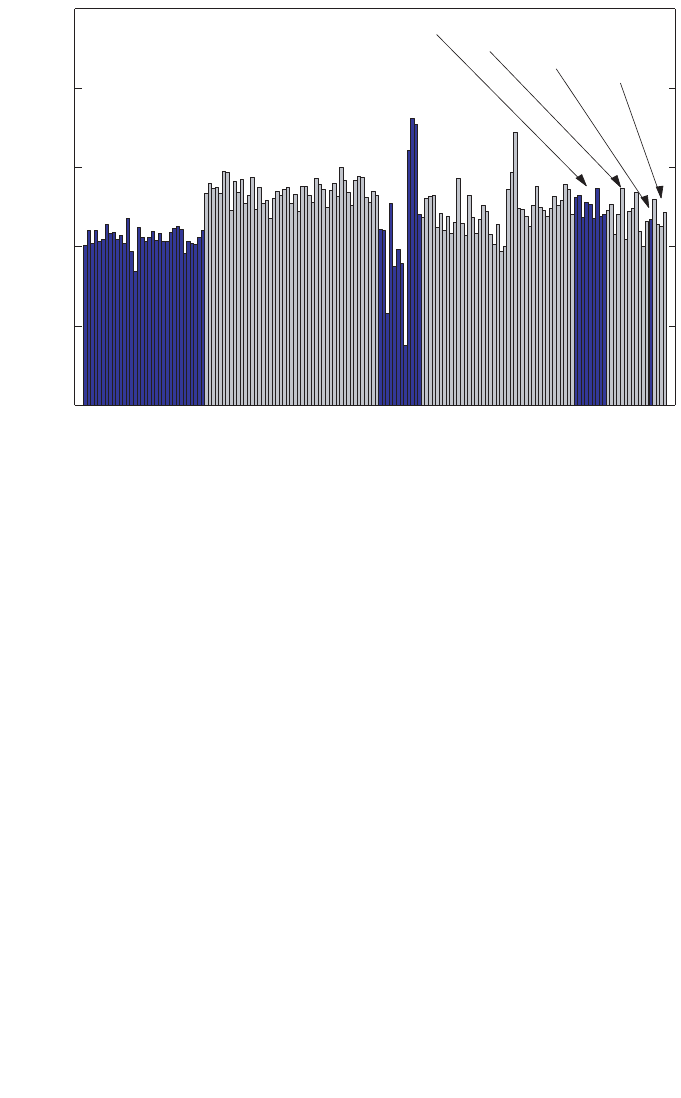

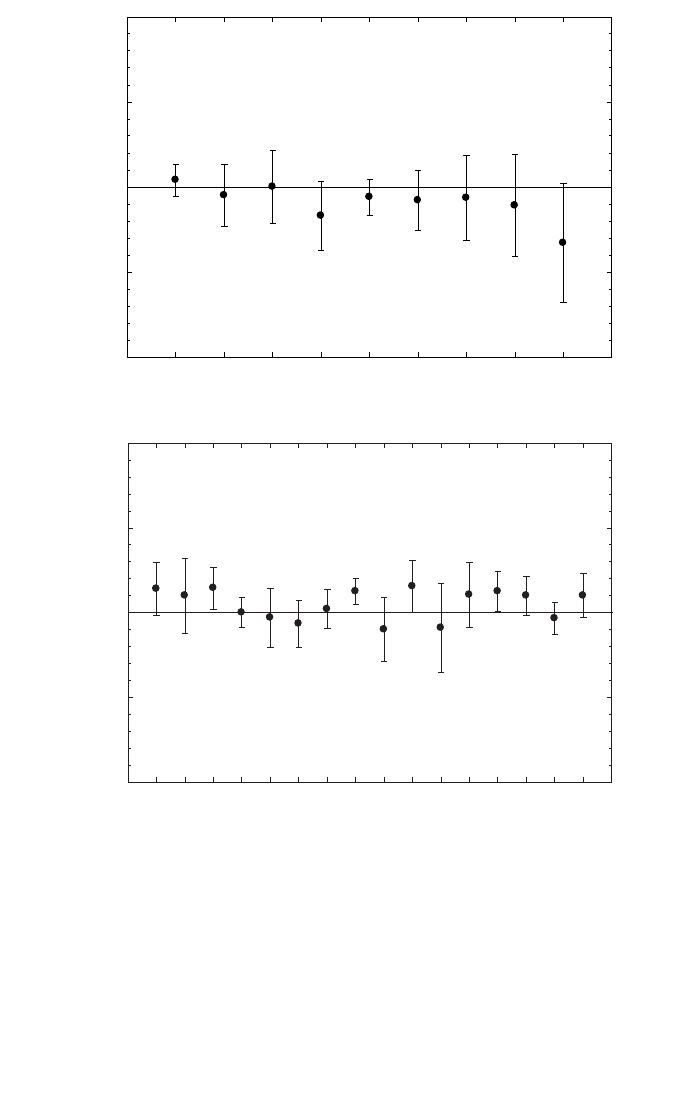

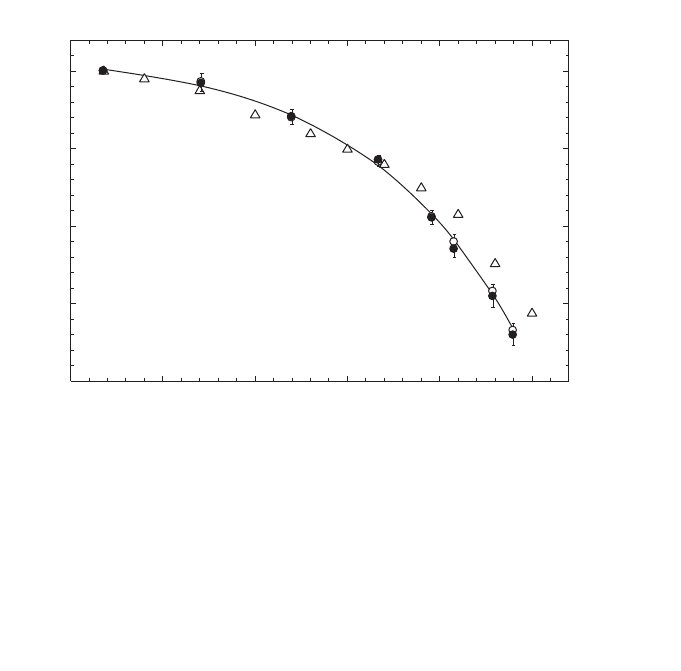

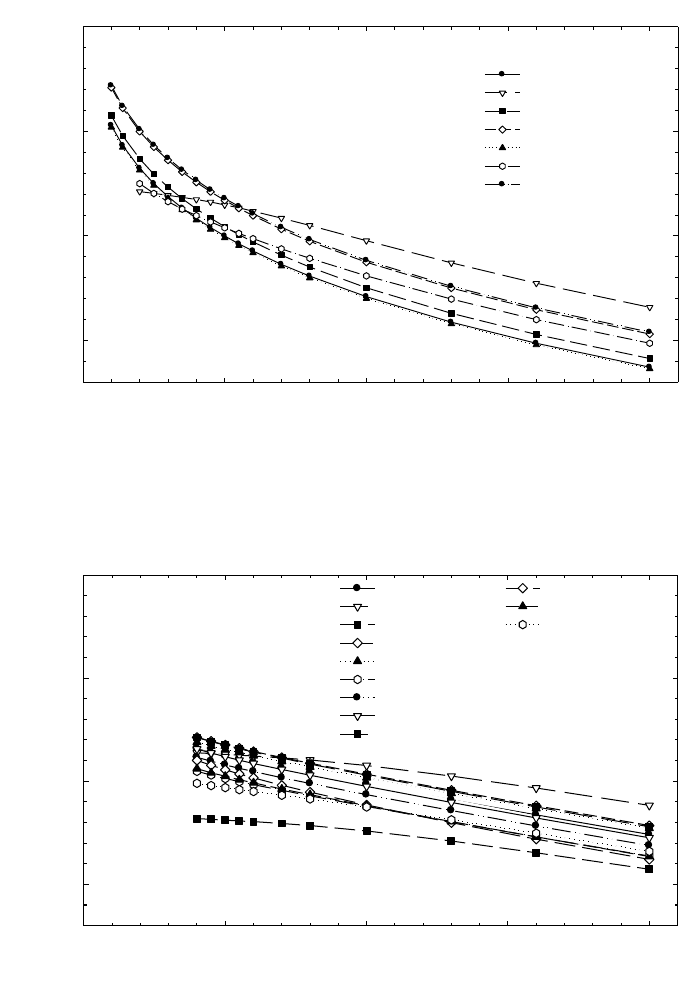

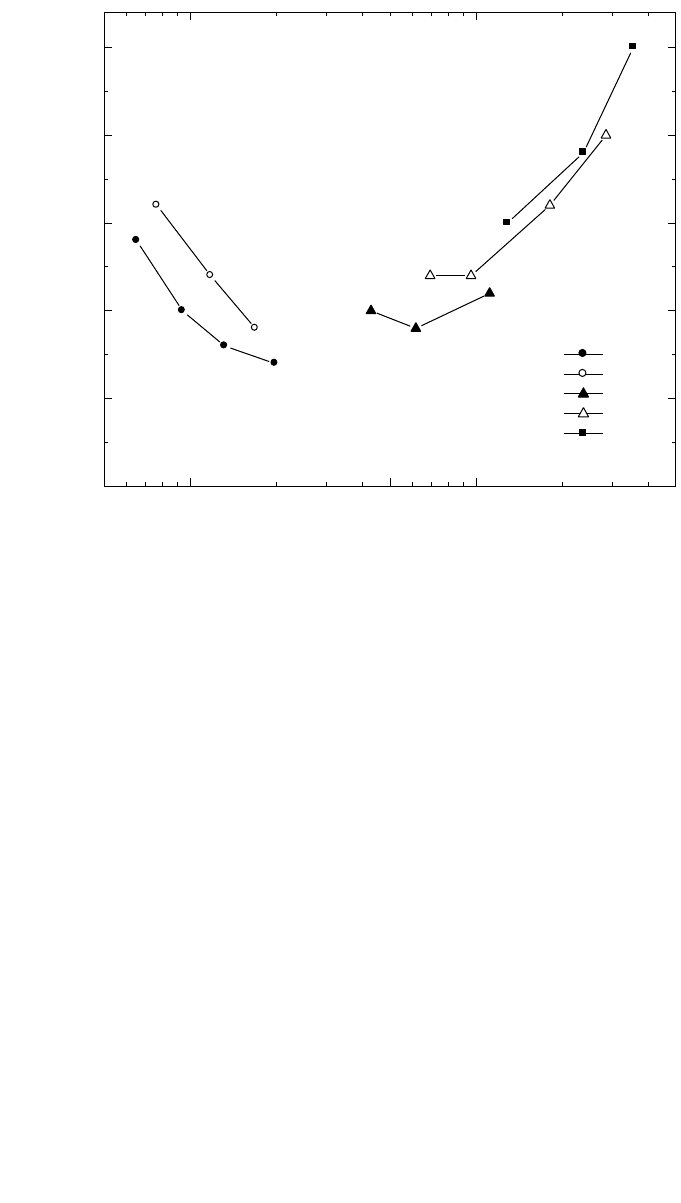

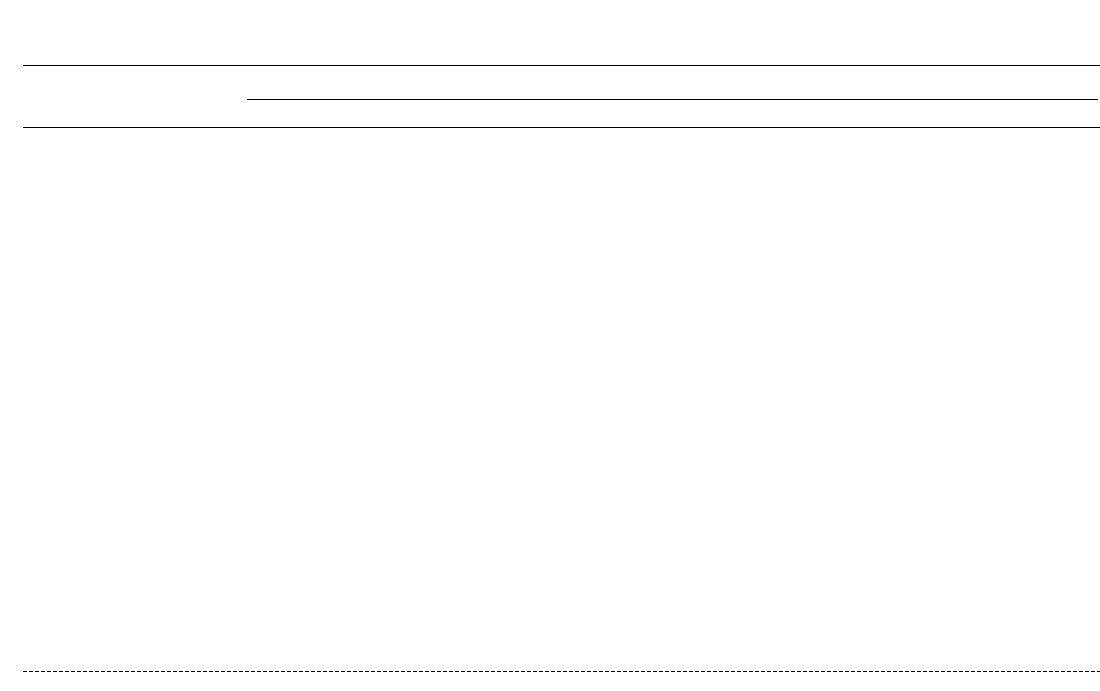

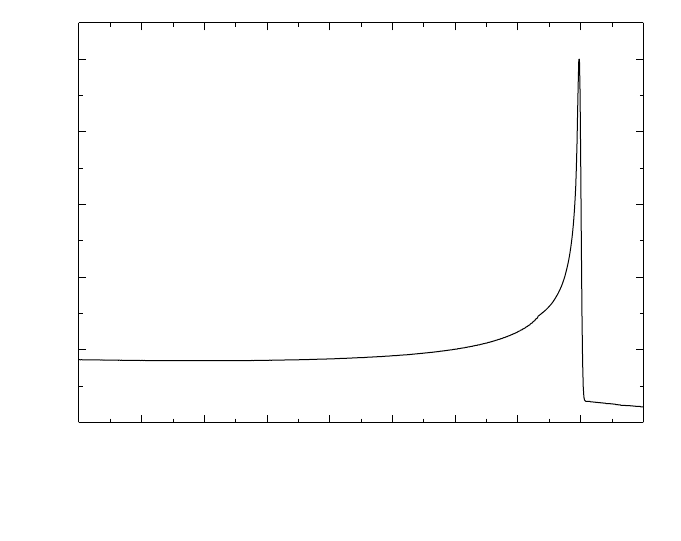

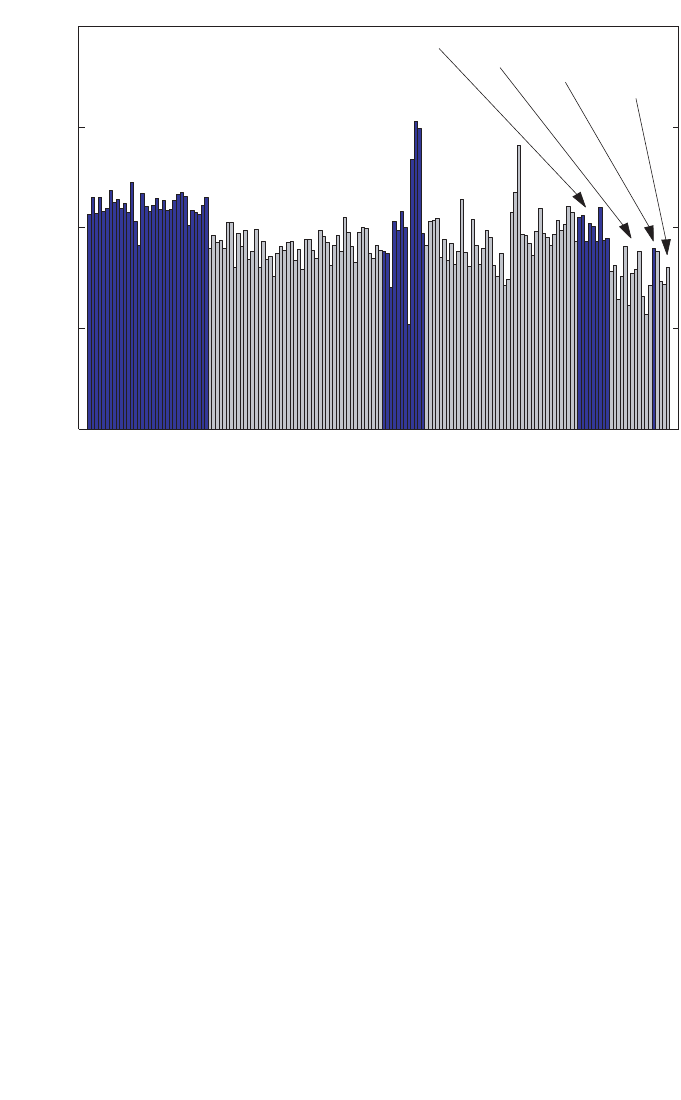

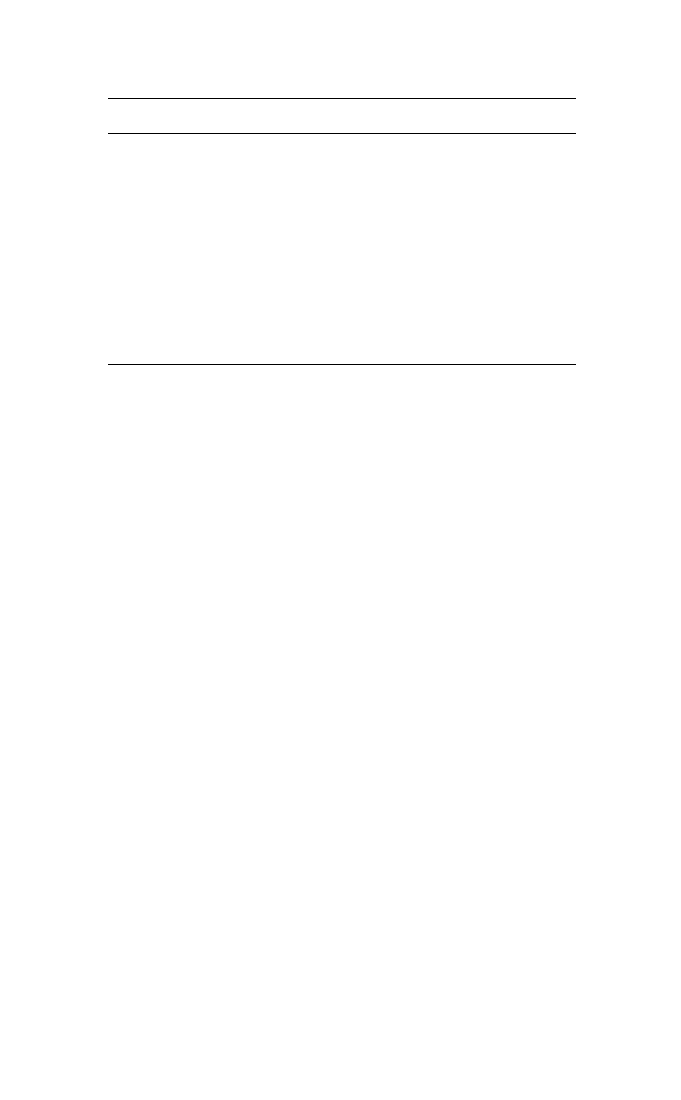

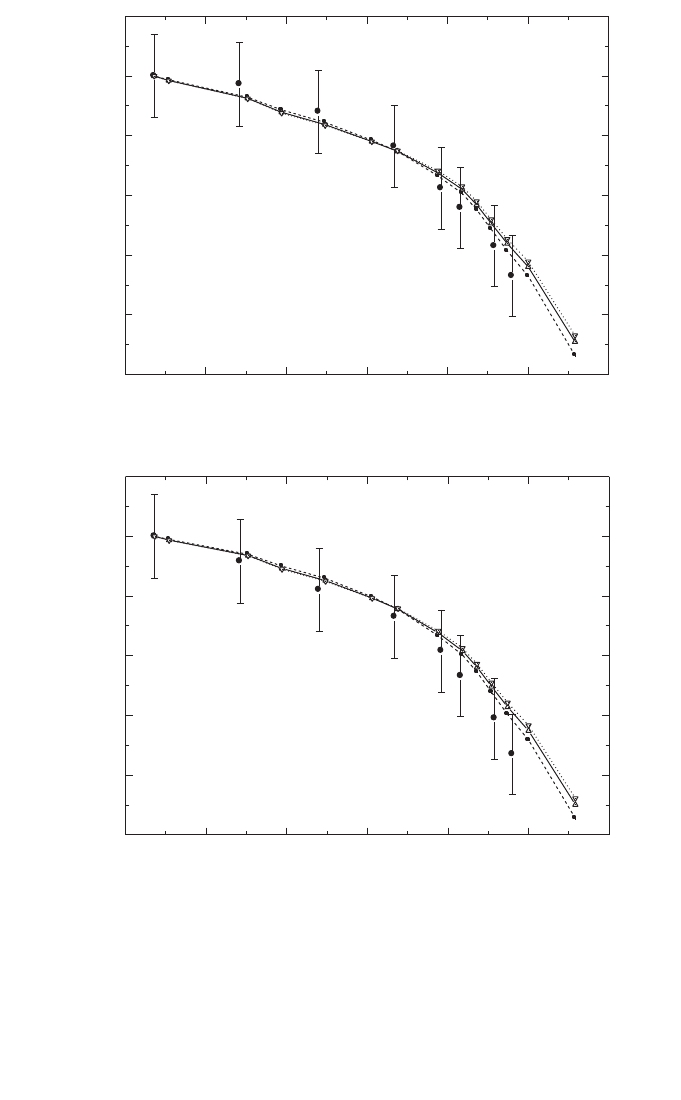

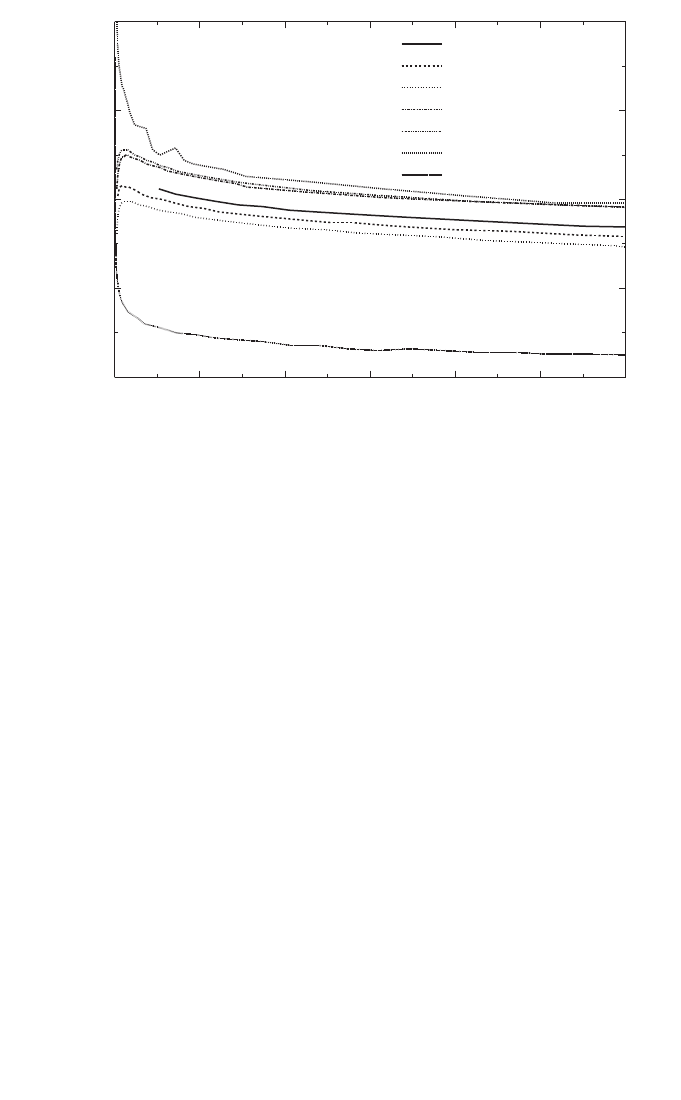

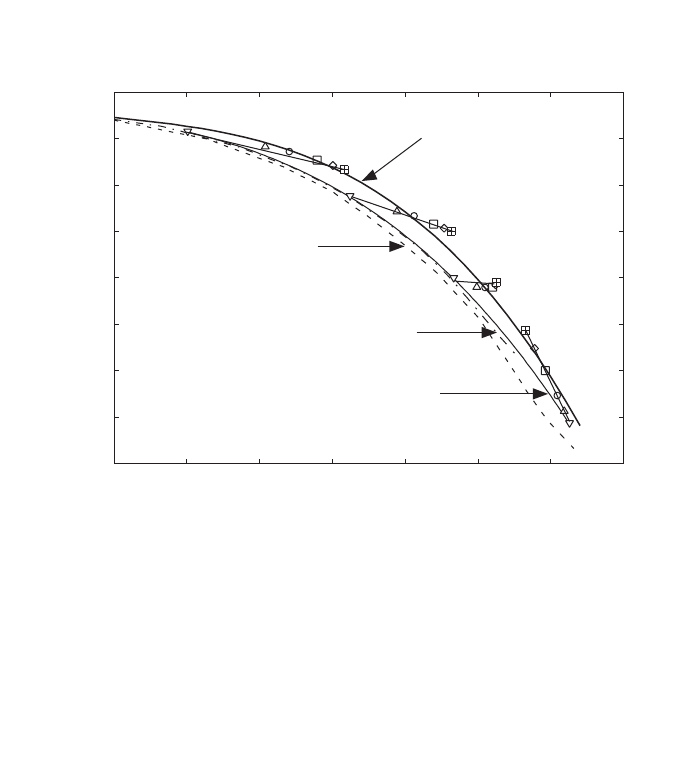

FIG. 4. (a) Results of comparisons of standards of absorbed dose to water at the BIPM in the

60

Co beam [48]. The results are relative to the BIPM determination and are those for the most

recent comparison for each national metrology institute, the oldest dating from 1989. The

uncertainty bars represent the relative standard uncertainty of the determination of absorbed

dose to water at each institute. Information on the primary standards used by the PSDLs is

given in Table 2. (b) Results of comparisons of standards for air kerma at the BIPM in the

60

Co

beam [48]. The results are relative to the BIPM determination and are those for the most

recent comparison for each national metrology institute. The uncertainty bars represent the

relative standard uncertainty of the air kerma determination at each institute.

D

w

(PSDL) / D

w

(BIPM)

0.98

0.99

1.00

1.01

1.02

ARPANSA

Australia

BEV

Austria

BIPM ENEA

Italy

LPRI