• Modern design

• Engineer Hold-o

• Selectable sound output 105dB(A) or 85dB(A)

• Optional trigger wire monitoring

• Selectable timers

• Selectable Negative or Positive triggers

• Conrmation Input

• Fault Output

• Test Input

• Backlight option

• Available in Grade 2, Grade 3 or Wire-free (G2 only)

Senza

InStallatIon and operatIng

InStructIonS

CQR Fire & Security. 125, Pasture Road, Moreton, Merseyside. CH46 4TH, United Kingdom

Tel: +44 (0)151 606 1000 | email: info@cqr.co.uk | Web http://www.cqr.co.uk

external WarnIng devIce

Page 2 of 16

v3.1

Index

3 deScrIptIon

3 FeatureS & optIonS

4 locatIon oF partS

5 WIred pcB layoutS

6 WIre-Free pcB layoutS

7 termInal deScrIptIon

7 dIp SWItch SettIngS

8 mountIng InStructIonS

10 WIrIng connectIon guIde Standard Version

11 WIrIng connectIon guIde PLUS Version

12 WIrIng connectIon guIde Wirefree Version

13 FIttIng coverS

14 operatIng InStructIonS

15 SpecIFIcatIon

16 SaFety precautIonS

16 product order codeS

Page 3 of 16

v3.1

This range of external warning devices includes 3 models: 2 wired at Grade 2 & 3 and 1 wire-free at Grade 2 all are

Environmental class IV and can be installed in security systems in accordance with EN50131-1: 2006 + A1: 2009.

The wired models comply to EN50131-4: 2009, WD type Z; the wire-free model complies to EN50131-4:2009, WD type W.

These warning devices feature one piezo and one LED strobe for audible and visual indication of an alarm activation.

Each model includes the latest innovation in electronics and incorporates a lithium Ion battery for better reliability, each

of the wired versions incorporates a smart charging circuit to optimise the battery capability and battery life.

A number of other unique features are listed below.

deScrIptIon

FeatureS & optIonS

Back-light

Only available on the PLUS version.

It is possible to select either ON or ECO (default). In the ON position the back-light is permanently ON. In the ECO

position the inbuilt light sensor will automatically switch the back-light o during the day, thereby reducing power

consumption.

Test

Conrmation

Only available on the PLUS and WIRE-FREE versions.

This feature allows the user to be notied before entering the premises that the intruder alarm system has generated

a conrmed alarm due to 2 or more detectors being activated.

During an alarm activation if a negative (0v) signal is applied to the conrmed input at the same time as a signal is

applied to the siren input the siren tone will change to a rapid tone every few seconds. If a signal is applied to the

strobe input, the strobe ash rate will also change. If the signal is removed from the conrmed input, the tone/ash

rate will revert back to the standard tone/ash rate.

If the signal is removed from the siren/strobe inputs the sounder will stop sounding/ashing regardless of a signal

being applied to the conrmed input.

Only available on the PLUS and WIRE-FREE versions.

If a positive signal is applied to this input it will start the test routine. At the start of the test the fault output terminals

will go open circuit. During the test the siren will sound for 3 seconds, strobe will ash for 3 seconds and battery will

be tested to ensure that all are functioning correctly. At the end of a successful test the Senza will make a low level

sound and the fault output terminals will change to a closed circuit.

If a fault is detected, the fault output terminals will stay open circuit until the fault has been rectied.

Trigger Monitoring

Only available on the PLUS version and is mandatory for all grade 3 installations.

When selected, the device monitors the siren and strobe trigger wire’s integrity by means of monitoring resistors.

These resistors are connected to the opposite signal that is required to activate the siren or strobe i.e. negative siren

trigger signal (default), the monitoring resistor is connected between a positive and the trigger wire in the control

panel. In the event of the siren trigger wire being cut or removed, the fault output circuit will open. In the event of the

strobe trigger wire being cut or removed the strobe will start to ash. The fault output circuit will NOT be activated.

Note:- Fitting the resistor in the warning device does not comply with grade 3 requirements.

Engineer Hold-o

During the rst installation of the Senza this feature allows you to connect the on-board battery without the sounder

sounding, after hold-o voltage is applied the Senza will enter its normal mode. If Hold-o voltage is removed the

sounder will sound.

Fault

Only available on the PLUS and WIRE-FREE versions.

The 2 fault outputs are normally closed and will switch to an open circuit if a fault occurs with the sounder, strobe, and

battery. If trigger wire monitoring has been selected the fault output will also open circuit if a fault is detected. It also

acts as conrmation that the test procedure has been started by going open circuit and on a successful completion of

the test procedure the outputs will go closed circuit.

Volume

Each model will allow you to select the dB(A) level required to comply with the country/regional requirements it is

possible to reduce the sound output from 105dB(A) (default) to maximum sound output of 85dB(A)

Page 4 of 16

v3.1

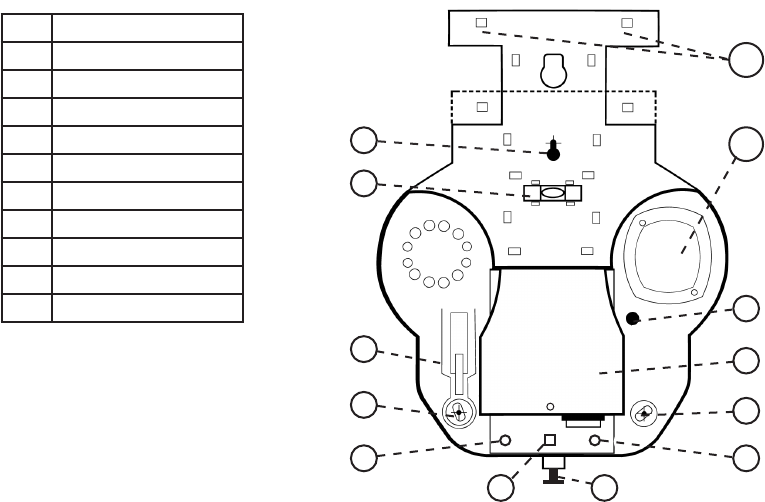

locatIon oF partS

Tamper Return

SAB/SCB

Trigger Signal

Siren Cut-o timer

Only available on the PLUS versions.

In SAB mode (default) the power required to produce the sound is drawn from the security systems control panel. In

SCB mode the power required to produce the sound is drawn from the on-board lithium Ion battery.

It is possible to select 1 of 3 optional times depending on the model being used

The PLUS version and the WIRE-FREE version have either 15minutes (default) 3 minutes or intermittent (50sec ON,

50sec OFF, 50sec ON, 50sec OFF, 50sec ON then stops (times are approximate).

The STANDARD model only has 15minutes (default) or intermittent.

Each model allows you to select the triggering method used to activate the siren and strobe, either Negative 0v

applied (default) or positive +ve applied, depending on the output of the control panel you are using.

Only available on the PLUS and WIRE-FREE versions.

Allows you to select either a Negative signal (default) or a positive signal for the Tamper Return signal to match the

requirements of the control panel being used.

Strobe Saver

After 1 hour of continuous activation the strobe ash rate will be reduced from 1Hz to 0.25Hz

WIRE-FREE version Only

During the installation of the Wire-free version it is possible to check that the best location is selected for the warning

device. Whilst in engineer mode the Green LED will ash to indicate that the warning device is communicating

with the control panel module, if the Green LED stops ashing this indicates that it has lost communication with

the control panel module. Relocate the warning device until the Green LED starts to ash, this indicates that

communication have been re-established.

Communication conrmation

4

7

1

3

2

10

8

9

11

1 Key slot mounting hole

2 Spirit level

3 Tamper protection

4 Swivel Mounting hole

5 Comfort LED

6 Strobe LED

7 Cover xing screw

8 Cover to electronics

9 Cable entry

10 Piezo

11 Hinge bracket for cover

4

5 5

6

X

Page 5 of 16

v3.1

WIred pcB layoutS

+BATT -

Connector

Tamper

Return

Pos +ve

Neg -0v

Con-

Strobe

Siren

Test

Fault

+BATT -

Connector

Charge

LED

Tamper

Return

Pos +ve

Neg -0v

Con-

Strobe

Siren

Test

Fault

pluS

Grade 2 & 3

Standard

Grade 2 only

Tamper

LED

Hold-o

LED

Strobe

LED

Connector

for back-light

PCBA

Connector

for Battery

Sounder

Transformer

Option switches

Connection

Terminals

Battery

Battery

charging

LED

}

Tamper

LED

Hold-o

LED

Strobe

LED

Connector

for Battery

Sounder

Transformer

Option switches

Connection

Terminals

Battery

charging

LED

}

Battery

ON

12345678

ON

1234

Page 6 of 16

v3.1

+BATT -

Connector

Tamper

LED

Coms

LED

Strobe

LED

Sounder

Transformer

Battery

Connector

for Battery

Antenna

Enrolment button

Con-

rmed

Tamper

return

Strobe

Hold O

Pos+

Hold O

Neg-

Test

Siren

Fault

Int

3m

15M

<>>

<<>

N<>P Trig

H<>L Vol

N<>P Tamp

Siren

Antenna

Diagnostic

LEDs

Tamper switch/

Enrolment button

Option switches

Connection

Terminals

}

WIre-Free pcB layoutS

control panel module (cpm)

Grade 2 only

WarnIng devIce (Wd)

Grade 2 only

Green

Red

ON

123456

Page 7 of 16

v3.1

Model

Terminal

Number

Terminal

Name

Description

Plus & CPM 9 Fault

These 2 terminals are normally closed, going open when a fault is

detected.

They also act as a conrmation that the test routine has started by

opening and closing after a successful completion of the test routine.

Plus & CPM 8 Fault

Plus & CPM 7 Test A Positive signal from the control panel to start the test routine LED

Plus & CPM 6 Conrmed

A Negative signal from the control panel to change the Sounder and

Strobe pattern

Plus, standard

& CPM

5

Tamper

Return

A signal from the senza to the control panel to indicate the condition

of the tamper circuit

Plus, standard

& CPM

4 Strobe A signal from the control panel to activate the strobe LED

Plus, standard

& CPM

3 Siren A signal from the control panel to activate the siren LED

Plus, standard

& CPM

2

Hold-o

Positive +ve

A permanent positive DC supply from the control panel

Plus, standard

& CPM

1

Hold-o

Negative 0v

A permanent negative DC supply from the control panel

termInal deScrIptIon

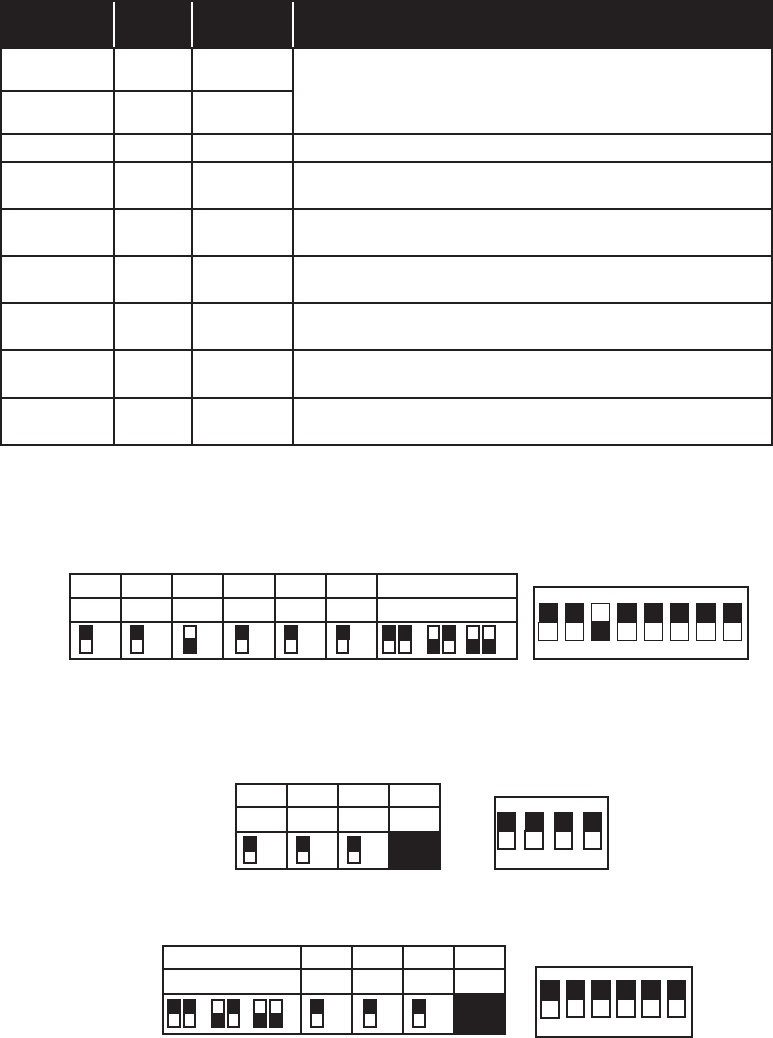

dIp SWItch SettIngS

pluS modelS

Standard modelS

WIre-Free model

1 2 3 4 5 6 7 & 8

Back-light

Tamp

Rtn

SAB/SCB Volume

Trigger

signal

Trigger

Mon

Siren Cut-o timings

ON

ECO

Pos

Neg

SAB

SCB

Lo

Hi

Pos

Neg

ON

OFF

15 3 Int

ON

12345678

Default setting

1 2 3 4

Trigger

signal

Volume

Siren

Timing

Not Used

Pos

Neg

Lo

Hi

Int

15

ON

1234

Default setting

1 & 2 3 4 5 6

Siren Cut-o timings

Trigger

signal

Volume

Tamper

Rtn

Not Used

15 3 Int

Pos

Neg

Lo

Hi

Pos

Neg

Default setting

ON

123456

Page 8 of 16

v3.1

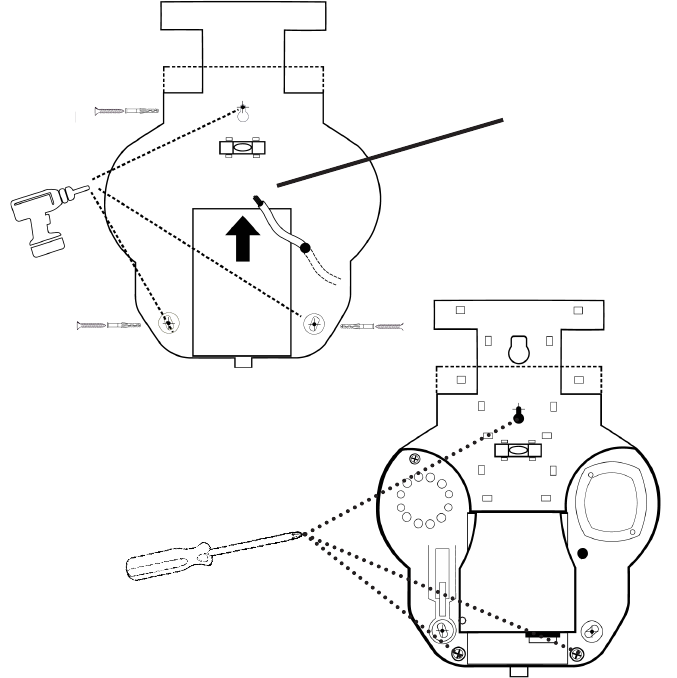

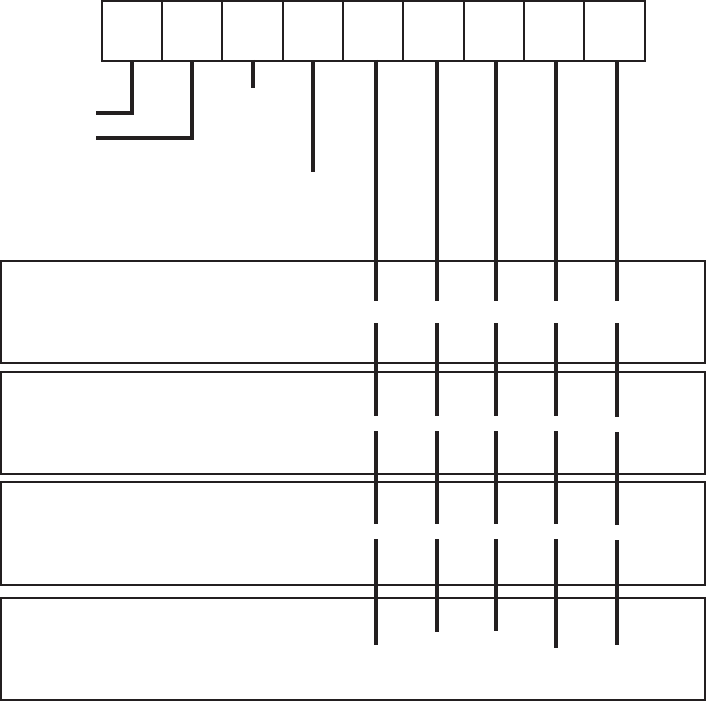

mountIng InStructIonS

Identify a suitable mounting location for the warning device on a at wall. If you are installing the

Wirefree version, you can use the built-in coms feature to locate the best location and ensure the there is

communication between the warning device and the control panel module.

It should not be possible to reach the device without the aid of access equipment, where practical it

should be sited under the eaves to give additional protection.

Mark the xing points on the surface of the selected location using the drill template on the back of the

box. Drill 3 holes using a 5.5mm masonry drill 41mm deep for the enclosed wall plugs, insert the wall

plugs into the holes, t the top centre screw, enclosed, leaving it protruding by 25mm.

Feed the cable through the cable entry point on the

senza

and carefully slot the top xing point of the

senza

over the previously installed screw, rotate the 2 x bottom xing points, if necessary, to allow the

holes to line up and x in-place using the enclosed screws.

Please note in order for the tamper protection to function correctly one of the mounting screws is

required to be tted in the removal from wall mechanism as shown below. Do not over-tighten this

screw. If forced removal is attempted this will cause irreversible damage and may need replacing.

X

Use the

template on

back of the Box

Page 9 of 16

v3.1

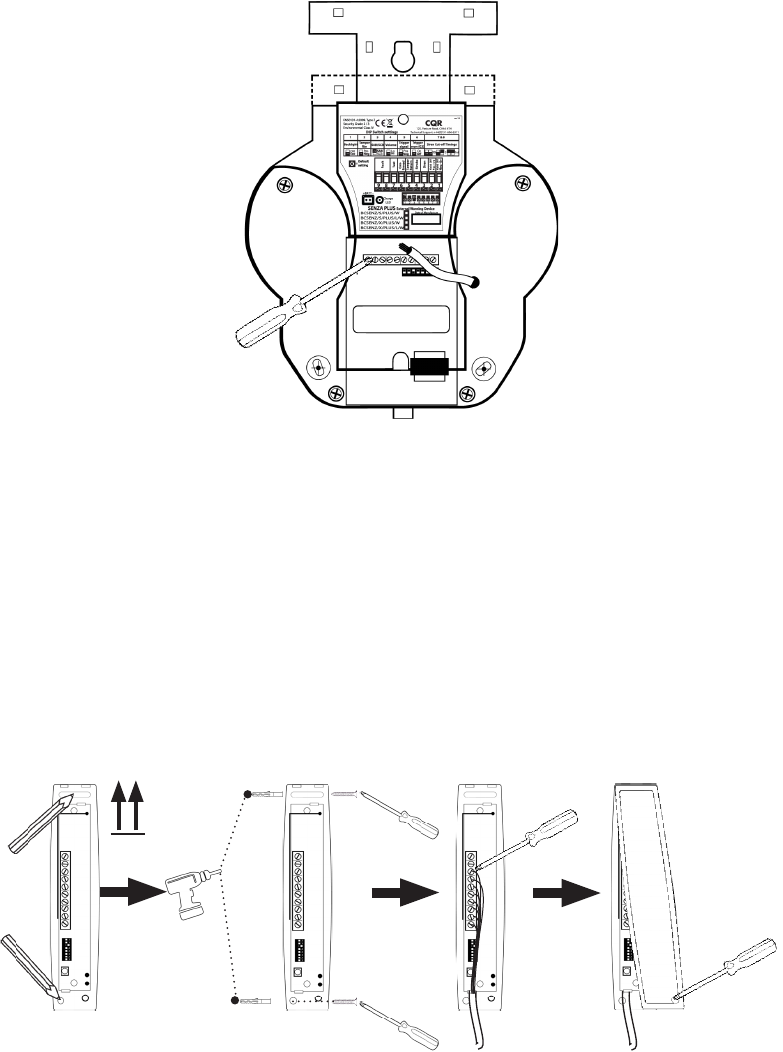

mountIng InStructIonS

control panel model (cpm)

When identifying a suitable mounting location for the CPM, the following points should be noted:

• Do not mount next to an AC source

• Mount away from wireless interference sources (computers, cordless phones, wireless routers, etc.)

• Large metal objects (a distance of 1m is recommended)

Temporarily place the unit in the selected location (do not hold) ensuring that the CPM is vertical,

using the built-in coms feature in the warning device, ensure that there is communication between the

warning device and the CPM see page 12, if not move the location of the CPM and repeat the process.

Mount the CPM in the selected location, connect the CPM to the control panel as shown on page 12.

Ensure CPM

is mounted

Vertical

Page 10 of 16

v3.1

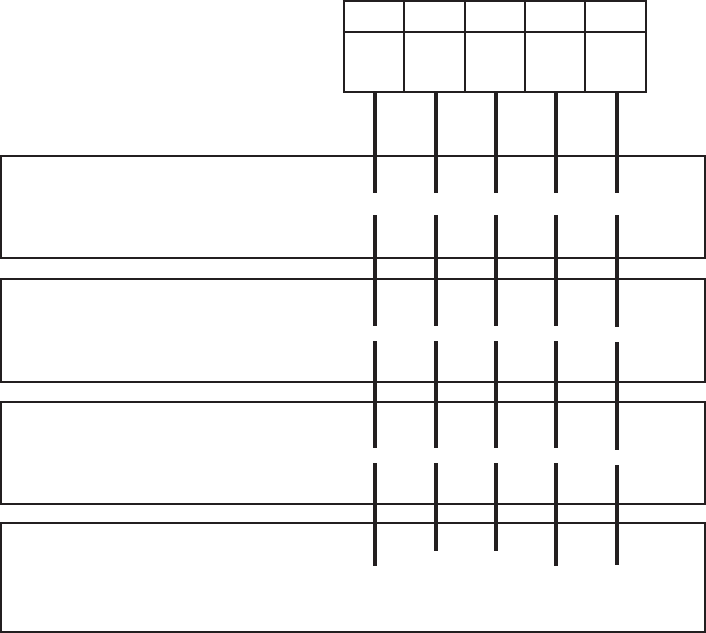

1. Connect Hold-o Neg - 0v to 12v -

2. Connect Hold-o Pos + ve to 12v +

3. Connect Siren to OP BELL

4. Connect Strobe to OP Strobe

5. Connect Tamper Return to an input via a 2K2Ω resistor

1. Connect Hold-o Neg - 0v to D

2. Connect Hold-o Pos + ve to A

3. Connect Siren to B

4. Connect Strobe to S

5. Connect Tamper Return to C

1. Connect Hold-o Neg - 0v to 12v com

2. Connect Hold-o Pos + ve to +12v

3. Connect Siren to BELL

4. Connect Strobe to STRB

5. Connect Tamper Return via a 2K2Ω resistor to D1

1. Connect Hold-o Neg - 0v to 0v

2. Connect Hold-o Pos + ve to 12v

3. Connect Siren to Bell

4. Connect Strobe to STB

5. Connect Tamper Return to TR

Texecom

Pyronix

Honeywell

Scantronic

WIrIng connectIon guIde

1. Ensure that the DIP switches are set to your requirements.

2. Connect the wires to the

senza

as shown below.

3. Plug in the battery and one bleep will be heard.

4. Ensure the tamper switch will close properly and t the lid, two bleeps will be heard.

5. The tamper LED should start to ash twice a second.

6. This will stay like this until hold o voltage is applied or the battery goes at.

7. Connect the control panel as indicated below.

8. Apply power to the

senza.

9. Both the hold-o LED and the tamper LED will now ash. Two bleeps will be heard.

10. After a few seconds the unit will bleep again and the LED’s will ash alternately.

11. After 5 minutes the engineer mode will expire and the LED’s will ash at the normal rate of once per second.

12. The

senza

is now in its normal mode.

Note:- Examples shown below are provided only as a guide, Control panel manufacturers may alter their notation

from time to time and there may be dierences to those shown.

Standard Version

Hold-o

Pos +

SirenStrobe

Tamper

Rtn

Hold-o

Neg -

C AS B D

D1 +12VSTRB BELL

COM

senza ConneCtions

TR +12VSTB BELL

0v

Input 12V

OP

STRB

OP

BELL

12v-

5 4 3 2 1

Page 11 of 16

v3.1

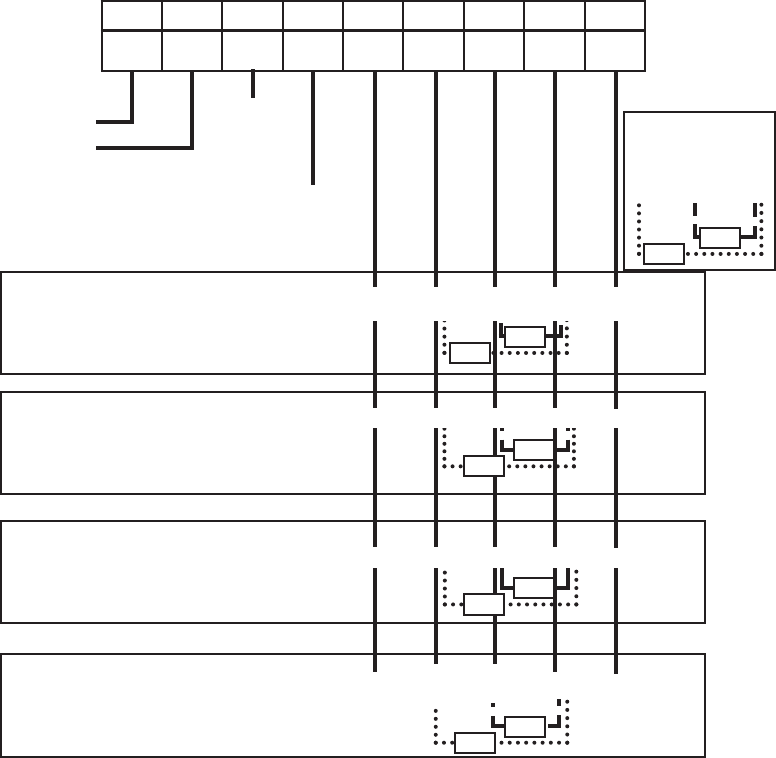

1. Connect Hold-o Neg - 0v to 12v -

2. Connect Hold-o Pos + ve to 12v +

3. Connect Siren to OP BELL

4. Connect Strobe to OP Strobe

5. Connect Tamper Return to an input via a 2K2Ω resistor

1. Connect Hold-o Neg - 0v to D

2. Connect Hold-o Pos + ve to A

3. Connect Siren to B

4. Connect Strobe to S

5. Connect Tamper Return to C

1. Connect Hold-o Neg - 0v to 12v com

2. Connect Hold-o Pos + ve to +12v

3. Connect Siren to BELL

4. Connect Strobe to STRB

5. Connect Tamper Return via a 2K2Ω resistor to D1

1. Connect Hold-o Neg - 0v to 0v

2. Connect Hold-o Pos + ve to 12v

3. Connect Siren to Bell

4. Connect Strobe to STB

5. Connect Tamper Return to TR

WIrIng connectIon guIde

1. Ensure that the DIP switches are set to your requirements.

2. Connect the wires to the

senza

as shown below.

3. Plug in the battery and one bleep will be heard.

4. Ensure the tamper switch will close properly and t the lid, two bleeps will be heard.

5. The tamper LED should start to ash twice a second.

6. This will stay like this until hold o voltage is applied or the battery goes at.

7. Connect the control panel as indicated below.

8. If Trigger wire monitoring is selected the 2 x 1kΩ resistors must be tted prior to power up (G3 requirement).

9. Apply power to the

senza.

10. Both the hold-o LED and the tamper LED will now ash. Two bleeps will be heard.

11. After a few seconds the unit will bleep again and the LED’s will ash alternately.

12. After 5 minutes the engineer mode will expire and the LED’s will ash at the normal rate of once per second.

13. The

senza

is now in its normal mode.

Note:- Examples shown below are provided only as a guide, Control panel manufacturers may alter their notation

from time to time and there may be dierences to those shown.

PLUS Version

Fault Fault Test

Con-

rmed

Hold-o

Pos +

SirenStrobe

Tamper

Rtn

Hold-o

Neg -

C D

D1

COM

Texecom

Pyronix

senza ConneCtions

Honeywell

TR

0v

Input

12v-

Connect to a

suitable input

within the

control panel

Connect to a

suitable output

within the

control panel

Connect to a

suitable output

within the

control panel

1kΩ

1kΩ

1kΩ

1kΩ

1kΩ

1kΩ

1kΩ

1kΩ

AB

+12VBELLSTRB

S

+12VSTB BELL

12V

OP

STRB

OP

BELL

Scantronic

1kΩ

1kΩ

Pull-up resistors

required for trigger

wire monitoring

G3 requirement

9 8 7 6 5 4 3 2 1

Page 12 of 16

v3.1

WIrIng connectIon guIde

Wirefree Version

Fault Fault Test

Con-

rmed

Hold-o

Pos +

SirenStrobe

Tamper

Rtn

Hold-o

Neg -

CPM Connections

Connect to a

suitable input

within the

control panel

Connect to a

suitable output

within the

control panel

1. Connect Hold-o Neg - 0v to 12v -

2. Connect Hold-o Pos + ve to 12v +

3. Connect Siren to OP BELL

4. Connect Strobe to OP Strobe

5. Connect Tamper Return to an input via a 2K2Ω resistor

1. Connect Hold-o Neg - 0v to D

2. Connect Hold-o Pos + ve to A

3. Connect Siren to B

4. Connect Strobe to S

5. Connect Tamper Return to C

1. Connect Hold-o Neg - 0v to 12v com

2. Connect Hold-o Pos + ve to +12v

3. Connect Siren to BELL

4. Connect Strobe to STRB

5. Connect Tamper Return via a 2K2Ω resistor to D1

1. Connect Hold-o Neg - 0v to 0v

2. Connect Hold-o Pos + ve to 12v

3. Connect Siren to Bell

4. Connect Strobe to STB

5. Connect Tamper Return to TR

Texecom

Pyronix

Honeywell

Scantronic

C AS B

D

D1 +12VSTRB BELL

COM

TR +12VSTB BELL

0v

Input

12V

OP

STRB

OP

BELL

12v-

Connect to a

suitable output

within the

control panel

1. Connect the CPM to the control panel as shown in the ‘Senza CPM connections’ below, ensuring that the DIP

switches are set to your requirements. The Green and Red LEDs should ash alternately.

2. Connect the battery in the WD. The CPM and WD should automatically pair. This is indicated by the Green LED on

the WD ashing every 2 seconds. If not refer to Installation and operating instructions on ‘How to pair’.

3. During the next 30 minutes the WD will be in engineer mode, after which it will automatically leave this mode.

Note: if the tamper is still open the sounder will sound.

4. Whilst the WD is in engineer mode the Green LED ashes every 2 seconds to indicate that the WD is

communicating with the CPM.

5. Using this feature will allow you to select the best position for the WD to be installed, if the Green LED stops

ashing it has lost communication with the CPM and should be repositioned.

6. The Blue LED on the WD ashing every 2 seconds indicates that the tamper is closed.

7. To exit Engineer mode briey apply a trigger to the Siren input of the CPM the Strobe will ash once and the

sounder will chirp.

8. Normal operating mode is indicated by the Green and Blue LEDs on the WD ashing alternately every 4 seconds.

Note:- Examples shown below are provided only as a guide, Control panel manufacturers may alter their notation

from time to time and there may be dierences to those shown.

Page 13 of 16

v3.1

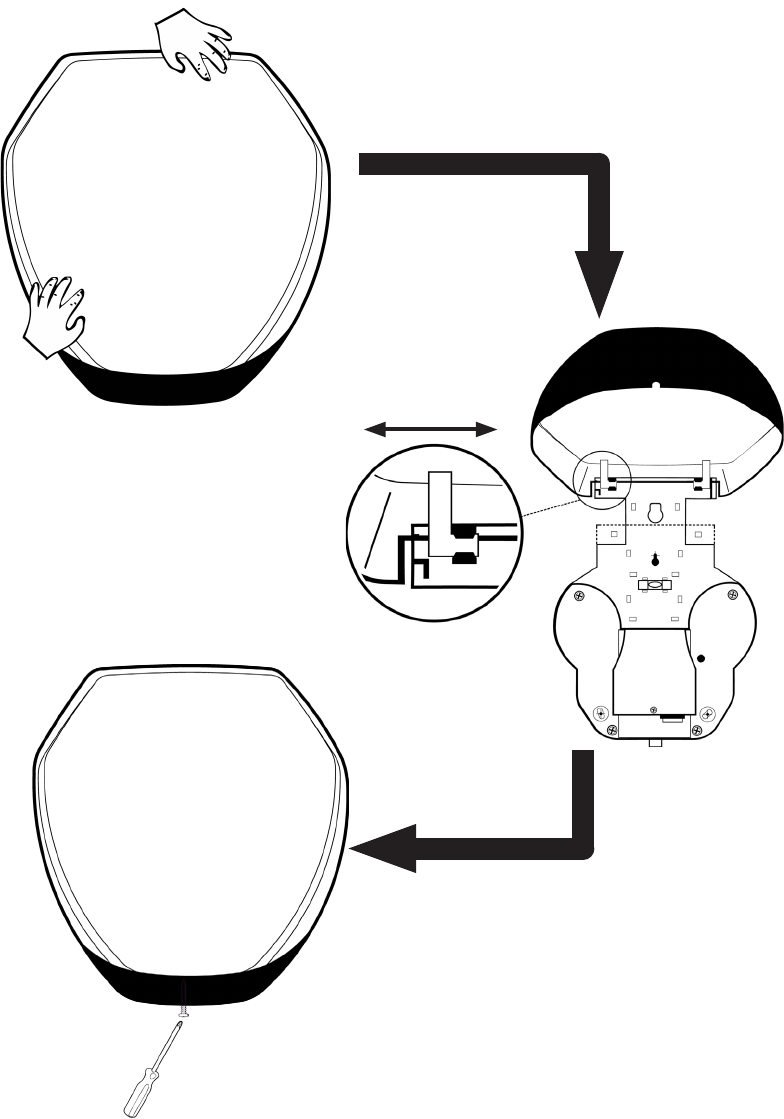

FIttIng coverS

Cover

Lock

UnLock

Page 14 of 16

v3.1

operatIng InStructIonS

Please refer to the DIP switch setting on page 7 to setup the device for the conguration you require.

To activate the siren apply an appropriate signal (depending on selection made via the DIP switch) to the

SIREN terminal (3). To deactivate the siren remove the applied signal.

To activate the strobe apply an appropriate signal (depending on selection made via the DIP switch) to

the STROBE terminal (4). To deactivate the strobe remove the applied signal.

During an activation of the Siren and/or Strobe, if a negative signal is applied to the Conrmed Terminal

(6) it will change the Siren tone and/or the Strobe ash rate. Removal of the signal will result in the Siren

tone and/or the Strobe ash rate returning to it normal tone/rate.

If the device’s tamper protection is activated by opening the cover or by forcibly removing the warning

device from the wall, the signal (depending on the selection made via DIP switch) will be removed from

the Tamper Return terminal (5). Closing the cover will result in the signal being restored.

Note: The Senza is designed not to sound when the tamper switch is opened to allow for the installation/

service engineer to access the unit without genterating a sound, however this will depend on the

condition/settings of the control panel it is connected to e.g if the panel is in a set condition the sounder

may sound.

If a positive signal is applied to the Test input (7) it will start the test routine.

If the rechargeable battery is disconnected from the device or is not capable of supplying

power to the device, then the Fault output circuit will open.

The loss of the remote power source to the device will activate the siren for the pre selected time via DIP

switches 7 & 8 on the

Plus

or DIP switch 3 on the

standard.

the

Green

(tamper) and

red

(hold-o) comfort LEDs ash alternately at 1Hz. If the

Green

LED stops

ashing this indicates that the tamper protection for the cover and/or the removal from wall is open. If

the

red

LED stops ashing this indicates that there is no voltage on the Hold-o terminals.

The Red battery LED is illuminated when the battery is healthy. If the LED is extinguished this indicates

that the battery is disconnected or faulty.

Wired models

Please refer to the DIP switch setting on page 7 to setup the device for the conguration you required.

To activate the siren apply an appropriate signal (depending on selection made via the DIP switch) to the

SIREN terminal. To deactivate the siren remove the applied signal.

To activate the strobe apply an appropriate signal (depending on selection made via the DIP switch) to

the STROBE terminal. To deactivate the strobe remove the applied signal.

During an activation of the siren and/or strobe, if a negative signal is applied to the Conrmed Terminal

it will change the siren tone and or the strobe ash rate. Removal of the signal will result in the siren tone

and/or the strobe ash rate returning to it normal tone/rate.

If the device’s tamper protection is activated by opening the cover or by forcibly removing the warning

device from the wall, the signal (depending on the selection made via DIP switch on the CPM) will be

removed from the Tamper Return terminal and the sounder will sound. Closing the cover will result in the

signal being restored and the sounder stopping.

If a positive signal is applied to the Test input it will start the test routine. Failure of the test routine will

result in the fault output staying open.

The battery is monitored every 24hrs and this test checks the condition of the battery by applying a load

to the battery. If the battery fails this test the fault output will open circuit.

the

Green

(coms) and

Blue

(tamper)

comfort LEDs ash alternately every 5 seconds. If the

Blue

LED stops

ashing this indicates that the tamper protection for the cover and/or the removal from wall is open.

If the

Green

LED stops ashing this indicates that there is no communication with the control panel

module.

Wire-free model

Page 15 of 16

v3.1

Hold o voltage: 10-15 vDC (12 vDC nominal)

Current Consumption @ 12 vDC: SAB Mode SCB mode

Quiescent: ~35mA (battery fully charged) ~35mA (battery fully charged)

Back-light ON ~55mA ~55mA

Alarm (Sounder & Strobe): ~300mA ~120mA

Siren: ~175mA ~110mA

Strobe: ~55mA ~55mA

Sounder: Type: Piezo

Acoustic Output: Tone

Sound duration: ≤ 15 minutes, ≤ 3 minutes or intermittent

Sound Output Levels: ~105db(A) @ 1 metre

Triggering Method: -ve applied, +ve applied

Strobe: Type: LED

Flash Rate: ~ 60 per minute

Strobe saver mode: ~ 7 per minute

Triggering Method: -ve applied, +ve applied

Battery: Type: Lithium Ion (rechargeable)

Nominal Voltage: 3.7 volt

Capacity: 2000mAh

LED Indicators: Tamper (GREEN), Hold-o (RED) and Battery charging (RED)

Tamper Detection: Removal from mounting and cover.

StandardS:

EN50131-1: 2006 + A2: 2017 Security Grade: 2/3, Environmental Class: IV

EN50131-4: 2009 Warning device Type: Z

WarnIng devIce (Wd)

Battery : Type: Lithium Manganese Dioxide (non-rechargeable)

Nominal Voltage: 3 volt

Capacity: 4700mAh

Approximate life: ~2 years (depending on the number and duration of activations)

Current Consumption:

Quiescent: ~3.5mA

Alarm (Sounder & Strobe): ~245mA

Sounder: Type: Piezo

Acoustic Output: Tone

Sound duration: ≤ 15 minutes, ≤ 3 minutes or intermittent

Sound Output Levels: ~105db(A) @ 1 metre

Strobe: Type: LED

Flash Rate: ~ 60 per minute

Strobe saver mode: ~ 7 per minute

LED Indicators: Tamper (BLUE), Comms (GREEN)

Tamper Detection: Removal from mounting and cover.

Radio Frequency: 868MHz Narrowband

Communication Distance: 100m (Line of Site)

control panel module (cpm)

Power supply: 10-15vDC (12vDC nominal)

Current Consumption @12vDC:

Quiescent: ~20mA

Alarm (Sounder & Strobe): ~30mA

LED indicators: RED & GREEN used for diagnostics

Tamper Detection: Cover and Removal from mounting

StandardS:

EN50131-1:2006 + A2:2017; Security Grade 2, Environmental Class II(CPM) IV(WD)

EN50131-4:2009; Type W

EN50131-5-3:2017; Grade 2

SpecIFIcatIon

Wired

Wire-free

Page 16 of 16

v3.1

Never remove the cover when the strobe is ashing.

The piezo transformer will be hot during and after sounding. Whilst not directly hazardous, touching it

when hot will cause discomfort and should be avoided.

When the Senza is in an alarm condition, high voltages are present. Before removing the cover, stop the

piezo and strobe from operating.

Failure to observe the following precautions regarding the batteries could lead to danger of heating,

ignition, explosion and leaking of hazardous chemicals.

• Do not throw into a re

• Do not heat

• Do not overcharge

• Do not reverse charge

• Do not attempt to charge the battery used in the wire-free version as it is not rechargeable

• Do not short circuit the battery wires

• Do not disassemble

Always observe local regulations when disposing of a battery.

Plastic bags can suocate, always dispose of packaging carefully.

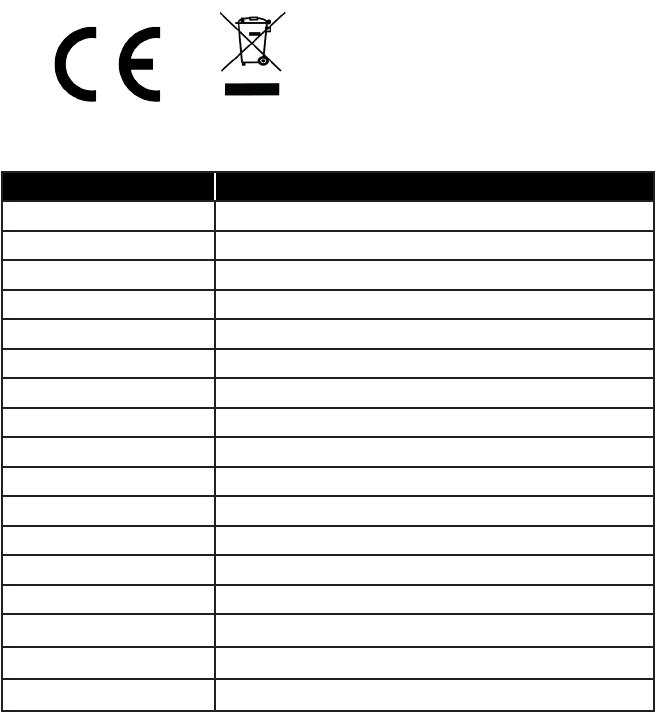

Order code Description

BCSENZ/S/STD/W Senza S Grade 2 Backplate White

BCSENZ/S/PLUS/W Senza S Grade 2/3 Backplate White

BCSENZ/S/PLUS/L/W Senza S Grade 2/3 Backplate White with Backlight

BCSENZ/S/WF/W Senza S Wirefree Kit White (WD & CPM)

BCSENZ/S/COV/W/B Senza S Cover White with Blue Lens

BCSENZ/S/COV/W/B/L Senza S Cover White with Blue Lens with Backlight Panel

BCSENZ/S/DUM/WH Senza S Dummy Backplate White

BCSENZ/X/STD/W Senza X Grade 2 Backplate White

BCSENZ/X/PLUS/W Senza X Grade 2/3 Backplate White

BCSENZ/X/PLUS/L/W Senza X Grade 2/3 backplate White with Backlight

BCSENZ/X/WF/W Senza X Wirefree Kit (WD & CPM)

BCSENZ/X/COV/W Senza X Cover White

BCSENZ/X/COV/W/L Senza X Cover White with Backlight Panel

BCSENZ/X/DUM/W Senza X Dummy Backplate

BCSENZ/S/WF/WD/W Senza S Wirefree Warning device Backplate (WD)

BCSENZ/X/WF/WD/W Senza X Wirefree Warning device Backplate (WD)

BCSENZ/WF/CPM/WH Senza Wirefree Control Panel Module White (CPM)

SaFety precautIonS

product order codeS