Blasting and Explosives

Quick Reference Guide

2010

Rapid Hazard Assessment

Take 5!

• Isthetasknew?

• Isanythingdifferent?

• Hasanythingchangedsinceyoulast

performedthistask?

• Ifso,STOP,THINKandapplythe

Take5steps!

1 Describe the task.

Whatisthetaskyouareabouttodo?

2 List the Hazards.

Whatarethemainhazardsinvolvedin

carryingoutthetask?

3 List the controls.

Whatcontrolswillyouusetoreduce

therisk?

4 Assess the risk.

UsetheHazardAssessmentTool(HAT)to

determinetheriskaftercontrolsareapplied.

5 Decide what is next.

Applythecontrols.

Isitsafetoproceedwiththetask?

Areadditionalcontrolsrequired?

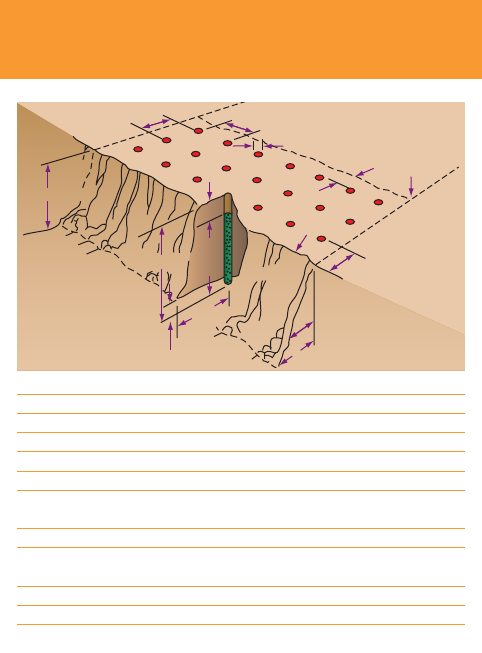

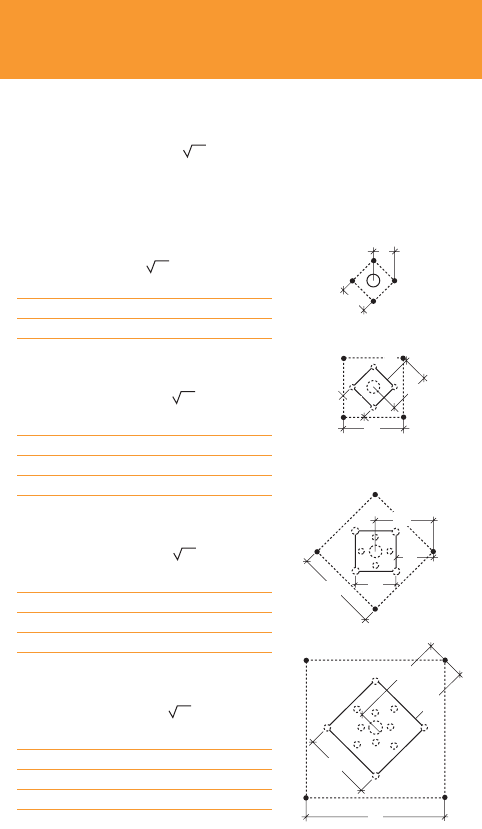

Blast design terminology and formulas

Holelength(L)= BH+SD

Chargelength(C)= L-SL

Blastvolume(V)= BxSxBHxN

Blastedtonnes(T)= VxDensityofrockint/m

3

Volumeofblasthole(Vb)= πxD

2

/4000xL

Massofexplosiveperhole(kg)= VolumeofholelengthchargedxExplosivedensity

PF(kg/m

3

)= Totalexplosivesintheblast/volumeofrock

blasted(forkg/Tonne,dividedbyblastedtonnesT)

RWS= AWSofexplosive/AWSofANFOx100

RBS= (RWSexplosivexexplosivedensity)/

(ANFOdensity)

Energyfactor= PFxRWS

Verticallengthofangledholes= Measuredholelengthxcos

∝

BenchHeight

(BH)

Floor

HoleLength

(L)

Subdrill(SD)

ToeBurden

Toe

FaceAngle(FA)

FreeFace

(C)

Explosive

Column

Height

StemHeight(SL)

DrilledBurden(B)

DrilledSpacing(S)

HoleDiameter(D)

Backbreak

NewCrest

(AfterMucking)

CrestBurden

Crest

∝ = Anglesubtendedfromthe

verticalbytheinclinedhole

π = 3.1416(theratioofthe

circumferenceofacircle

toitsdiameter)

AWS = Absoluteweightstrength

B = Drilledburden(m)

BH = Benchheight(m)

C = Explosivecolumnheightor

chargelength(m)

D = Holediameterinmillimetres

L = Holelength(m)

N = Numberofholesinablast

PF = Powderfactor

RBS = Relativebulkstrength

RWS = Relativeweightstrength

S = Drilledspacing(m)

SD = Subdrill(m)

SL = Stemminglength(m)

T = Blastedtonnes

V = Blastvolume(m

3

)

Theserulesprovideafirstestimateintheabsenceofanybetterdata.

Blast hole diameterinmm≤ 15xBenchheight(BH)inmetres

Bench height(BH)inmetres≥ (Blastholediameter(D)inmm)/15

Burden(B)= (25to40)x(D)

Spacing(S)= 1.15xB(Thisgivesanequilateralpattern)

Subdrill= (3to15)xD

Charge length(C)≥ 20D

Stemming≥ 20xDor(0.7-1.2)xB

Burden stiffness ratio= BH/B :2to3.5goodfragmentation

:>3.5verygoodfragmentation

Stemmingmaterial size = D/10toD/20(Angularmaterialwithminimumfines)

Presplit blasting

Spacing= Holediameterx12

Burden= 0.5xproductionblastburden(B)

Uncharged length at top= 10xD

Powder factor = 0.5kgpersquaremetreofface

Donotstemholes.

Fireallholesonthesamedelay,oringroupsof≥5holes

Smooth Blasting

Spacing= 15xHolediameter(hardrock)

20xHolediameter(softrock)

Burden= 1.25xSpacing

Fireasmanyholesaspossibleononedelay.

Stemholes.

Powder factors

Rules of thumb

Typical powder factors

used in mass blasts

Rock type PF (kg/m

3

)

Hard 0.7-0.8

Medium 0.4-0.5

Soft 0.25-0.35

VerySoft 0.15-0.25

Typical powder factors

used in presplit and smooth blasting

Hole diameter PF (kg/m

3

)

Hard 0.6-0.9

Medium 0.4-0.5

Soft 0.2-0.3

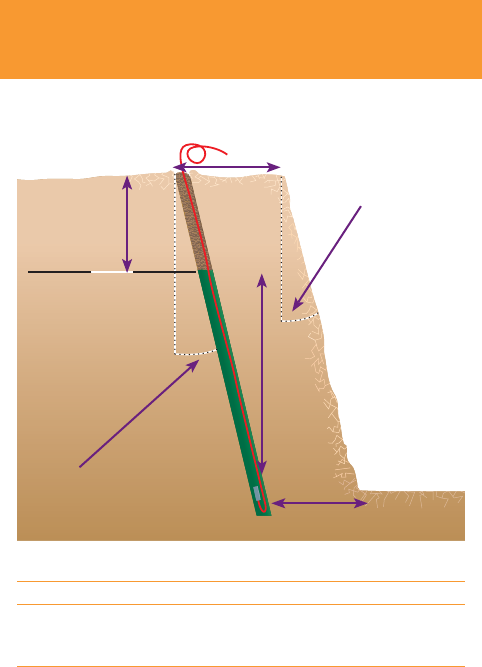

Calculating burdens

Crest Burden (CB) = Distanceblastholecollarisfromcrest

Vertical Stemming Length (VSL) = (measuredstemminglengthxcos[HA])

Toe Burden (TB) = Burdenatfloorlevel

= ([tan(FA)xbenchheight]+CB)-

(tan[HA]xbenchheight)

Angle faced holes

Vertical

Stemming

Length(VSL)

CrestBurden(CB)

HoleAngle(HA)

FaceAngle(FA)

ToeBurden(TB)

Loading density

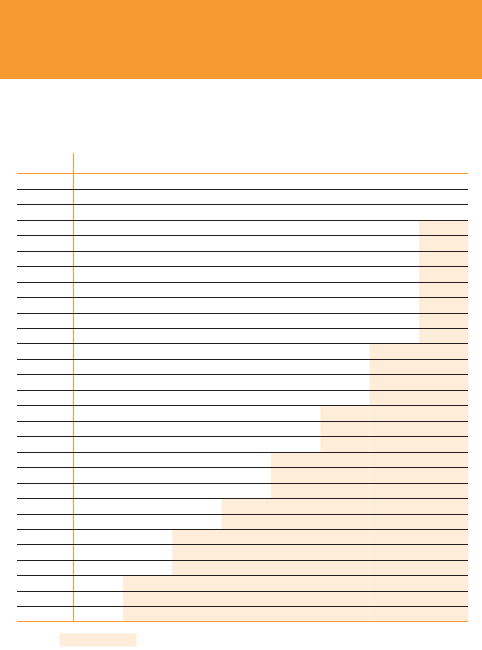

Hole Diameter Kg of explosive per meter of column for given density (g/cm

3

)* Hole Diameter

mm in mm in

0.60 0.80 0.82 0.85 0.90 0.95 1.00 1.05 1.10 1.15 1.20 1.30 1.35 1.40

25 1 0.29 0.39 0.40 0.42 0.44 0.47 0.49 0.52 0.54 0.56 0.59 0.64 0.66 0.69 25 1

32 11/4 0.48 0.64 0.66 0.68 0.72 0.76 0.80 0.84 0.88 0.92 0.97 1.05 1.09 1.13 32 11/4

38 11/2 0.68 0.91 0.93 0.96 1.02 1.08 1.13 1.19 1.25 1.30 1.36 1.47 1.53 1.59 38 11/2

45 13/4 0.95 1.27 1.30 1.35 1.43 1.51 1.59 1.67 1.75 1.83 1.91 2.07 2.15 2.23 45 13/4

51 2 1.23 1.63 1.68 1.74 1.84 1.94 2.04 2.14 2.25 2.35 2.45 2.66 2.76 2.86 51 2

57 21/4 1.53 2.04 2.09 2.17 2.30 2.42 2.55 2.68 2.81 2.93 3.06 3.32 3.44 3.57 57 21/4

64 21/2 1.93 2.57 2.64 2.73 2.90 3.06 3.22 3.38 3.54 3.70 3.86 4.18 4.34 4.50 64 21/2

70 23/4 2.31 3.08 3.16 3.27 3.46 3.66 3.85 4.04 4.23 4.43 4.62 5.00 5.20 5.39 70 23/4

76 3 2.72 3.63 3.72 3.86 4.08 4.31 4.54 4.76 4.99 5.22 5.44 5.90 6.12 6.35 76 3

83 31/4 3.25 4.33 4.44 4.60 4.87 5.14 5.41 5.68 5.95 6.22 6.49 7.03 7.30 7.57 83 31/4

89 31/2 3.73 4.98 5.10 5.29 5.60 5.91 6.22 6.53 6.84 7.15 7.47 8.09 8.40 8.71 89 31/2

95 33/4 4.25 5.67 5.81 6.02 6.38 6.73 7.09 7.44 7.80 8.15 8.51 9.21 9.57 9.92 95 33/4

102 4 4.90 6.54 6.70 6.95 7.35 7.76 8.17 8.58 8.99 9.40 9.81 10.62 11.03 11.44 102 4

108 41/4 5.50 7.33 7.51 7.79 8.24 8.70 9.16 9.62 10.08 10.54 10.99 11.91 12.37 12.83 108 41/4

114 41/2 6.12 8.17 8.37 8.68 9.19 9.70 10.21 10.72 11.23 11.74 12.25 13.27 13.78 14.29 114 41/2

121 43/4 6.90 9.20 9.43 9.77 10.35 10.92 11.50 12.07 12.65 13.22 13.80 14.95 15.52 16.10 121 43/4

127 5 7.60 10.13 10.39 10.77 11.40 12.03 12.67 13.30 13.93 14.57 15.20 16.47 17.10 17.73 127 5

133 51/4 8.34 11.11 11.39 11.81 12.50 13.20 13.89 14.59 15.28 15.98 16.67 18.06 18.76 19.45 133 51/4

140 51/2 9.24 12.32 12.62 13.08 13.85 14.62 15.39 16.16 16.93 17.70 18.47 20.01 20.78 21.55 140 51/2

146 53/4 10.04 13.39 13.73 14.23 15.07 15.90 16.74 17.58 18.42 19.25 20.09 21.76 22.60 23.44 146 53/4

152 6 10.89 14.52 14.88 15.42 16.33 17.24 18.15 19.05 19.96 20.87 21.78 23.59 24.50 25.40 152 6

159 61/4 11.91 15.88 16.28 16.88 17.87 18.86 19.86 20.85 21.84 22.83 23.83 25.81 26.81 27.80 159 61/4

165 61/2 12.83 17.11 17.53 18.18 19.24 20.31 21.38 22.45 23.52 24.59 25.66 27.80 28.87 29.94 165 61/2

172 63/4 13.94 18.59 19.05 19.75 20.91 22.07 23.24 24.40 25.56 26.72 27.88 30.21 31.37 32.53 172 63/4

178 7 14.93 19.91 20.41 21.15 22.40 23.64 24.88 26.13 27.37 28.62 29.86 32.35 33.59 34.84 178 7

187 71/4 16.48 21.97 22.52 23.34 24.72 26.09 27.46 28.84 30.21 31.58 32.96 35.70 37.08 38.45 187 73/8

200 71/2 18.85 25.13 25.76 26.70 28.27 29.85 31.42 32.99 34.56 36.13 37.70 40.84 42.41 43.98 200 77/8

203 8 19.42 25.89 26.54 27.51 29.13 30.75 32.37 33.98 35.60 37.22 38.84 42.08 43.69 45.31 203 8

216 81/2 21.99 29.31 30.05 31.15 32.98 34.81 36.64 38.48 40.31 42.14 43.97 47.64 49.47 51.30 216 81/2

229 9 24.71 32.95 33.77 35.01 37.07 39.13 41.19 43.25 45.31 47.37 49.42 53.54 55.60 57.66 229 9

251 91/2 29.69 39.58 40.57 42.06 44.53 47.01 49.48 51.95 54.43 56.90 59.38 64.33 66.80 69.27 251 91/2

254 10 30.40 40.54 41.55 43.07 45.60 48.14 50.67 53.20 55.74 58.27 60.80 65.87 68.41 70.94 254 10

270 101/2 34.35 45.80 46.95 48.67 51.53 54.39 57.26 60.12 62.98 65.84 68.71 74.43 77.29 80.16 270 105/8

279 11 36.68 48.91 50.13 51.97 55.02 58.08 61.14 64.19 67.25 70.31 73.36 79.48 82.53 85.59 279 11

311 121/4 45.58 60.77 62.29 64.57 68.37 72.17 75.96 79.76 83.56 87.36 91.16 98.75 102.55 106.35 311 121/4

381 15 68.41 91.21 93.49 96.91 102.61 108.31 114.01 119.71 125.41 131.11 136.81 148.21 153.91 159.61 381 15

445 171/2 93.32 124.42 127.53 132.20 139.98 147.75 155.53 163.30 171.08 178.86 186.63 202.19 209.96 217.74 445 171/2

Calculation Kg/m=3.14159xD

2

xP/4,000 Where DistheholediameterinmmPistheexplosivedensitying/cm

3

Todeterminetheloadingfactorforexplosivedensitiesnotlisted,selecttheloadingfactorforthesizeholeinthe1.00g/cm

3

columnthenmultiplyitbytherequireddensitying/cm

3

.

*Fornon-gassedproductsonly.Thedensityofgassedproductsvariesaccordingtodepthinanexplosivecolumn

andtheopencupdensity.Pleaseconsultthe"GassingdensityforTitanblends"tableforfurtherinformation.

Gassing density for Titan blends

Density of Titan 2000 emulsion blends in an explosive column at

different depths for different open cup densities

Depth (m) Open Cup Density (g/cm

3

)

0 0.90 0.95 1.00 1.05 1.10 1.15 1.20 1.25

1

0.92 0.97 1.02 1.07 1.12 1.17 1.21 1.26

2

0.95 0.99 1.04 1.09 1.13 1.18 1.22 1.26

3

0.97 1.01 1.06 1.10 1.15 1.19 1.23

1.27

4

0.98 1.03 1.08 1.12 1.16 1.20 1.24

1.27

5

1.00 1.05 1.09 1.13 1.17 1.21 1.24

1.28

6

1.02 1.06 1.10 1.14 1.18 1.21 1.25

1.28

7

1.03 1.07 1.11 1.15 1.19 1.22 1.25

1.28

8

1.04 1.08 1.12 1.16 1.19 1.23 1.26

1.28

9

1.06 1.10 1.13 1.17 1.20 1.23 1.26

1.29

10

1.07 1.11 1.14 1.18 1.21 1.24 1.26

1.29

12

1.09 1.12 1.16 1.19 1.22 1.24

1.27 1.29

14

1.10 1.14 1.17 1.20 1.23 1.25

1.27 1.29

16

1.12 1.15 1.18 1.21 1.23 1.26

1.28 1.30

18

1.13 1.16 1.19 1.22 1.24 1.26

1.28 1.30

20

1.14 1.17 1.20 1.22 1.25

1.27 1.28 1.30

24

1.16 1.19 1.21 1.24 1.25

1.27 1.29 1.30

28

1.18 1.20 1.23 1.24 1.26

1.28 1.29 1.30

32

1.19 1.22 1.23 1.25

1.27 1.28 1.29 1.31

36

1.20 1.22 1.24 1.26

1.27 1.29 1.30 1.31

40

1.21 1.23 1.25 1.26

1.28 1.29 1.30 1.31

45

1.22 1.24 1.26

1.27 1.28 1.29 1.30 1.31

50

1.23 1.25 1.26

1.27 1.28 1.29 1.30 1.31

55

1.24 1.25

1.27 1.28 1.29 1.30 1.30 1.31

60

1.25 1.26

1.27 1.28 1.29 1.30 1.31 1.31

65

1.25 1.26

1.27 1.28 1.29 1.30 1.31 1.31

70

1.26

1.27 1.28 1.29 1.29 1.30 1.31 1.31

75

1.26

1.27 1.28 1.29 1.30 1.30 1.31 1.31

80

1.26

1.27 1.28 1.29 1.30 1.30 1.31 1.31

Densitiesinbold and highlightedareatorabovethecriticaldensityoftheexplosiveandtheseopencupdensitiesshould not

beusedforthatdepthofexplosivecolumn.

Comments

1. ThistableappliesforTitan2000emulsionblendswithanemulsioncontentof60wt%orgreater.Forhigherdensity

Titan3000andTitan5000emulsionblends,itmaybeusedasaconservativeguide.

2. For50:50wt%gassedblends,duetotherelativelylowemulsioncontenttheminimumopencupdensityshouldbeno

lowerthan1.20g/cm

3

.

3. Todeterminetherequiredopencupdensityforanexplosivecolumnof50m(say),nd50mintheDepthcolumn.Moving

totheright,readoffthedensityimmediatelybeforetheboldeddensitydatabegins(here,1.26g/cm

3

inthe1.00g/cm

3

open

cupdensitycolumn).Thisindicatesthatsufcientgassingchemicalsshouldbeaddedtothegassedexplosiveblendduring

deliverysothatanopencupdensityof1.00g/cm

3

isachieved.Thislevelofgassingchemicalswillensurethatthedensity

atthebottomofthecolumnwillbebelowthecriticaldensity,andthecolumnwilldetonateuponinitiation.

4. Thegassingreactiontakes30-40minutestoachievethedesiredopencupdensityat20°C.Itisnecessarytoallowatleast

thistimetoelapsebetweencompletionofloadingandstemmingthechargedblasthole.Alongerperiodshouldbeallowed

atlowertemperatures.

Volume table

CUBIC METRES OF ROCK PER METRE BLASTHOLE

HOLE BURDEN SPACING

(Metres) (Metres)

1.00 1.25 1.50 1.75 2.00 2.25 2.50 2.75 3.00 3.50 4.00 4.50 5.00 6.00 6.50 7.00 7.50 8.00 8.50 9.00 9.50 10.00 11.00 12.00

1.00 1.25 1.50 1.75 2.00 2.25 2.50 2.75 3.00 3.50 4.00 4.50 1.00

1.25 1.56 1.88 2.19 2.50 2.81 3.13 3.44 3.75 4.38 5.00 5.63 6.25 1.25

1.50 1.88 2.25 2.63 3.00 3.38 3.75 4.13 4.50 5.25 6.00 6.75 7.50 9.00 1.50

2.00 2.50 3.00 3.50 4.00 4.50 5.00 5.50 6.00 7.00 8.00 9.00 10.00 12.00 13.00 2.00

2.25 2.81 3.38 3.94 4.50 5.06 5.63 6.19 6.75 7.88 9.00 10.13 11.25 13.50 14.63 15.75 2.25

2.50 3.13 3.75 4.38 5.00 5.63 6.25 6.88 7.50 8.75 10.00 11.25 12.50 15.00 16.25 17.50 18.75 2.50

2.75 3.44 4.13 4.81 5.50 6.19 6.88 7.56 8.25 9.63 11.00 12.38 13.75 16.50 17.88 19.25 20.63 22.00 2.75

3.00 3.75 4.50 5.25 6.00 6.75 7.50 8.25 9.00 10.50 12.00 13.50 15.00 18.00 19.50 21.00 22.50 24.00 5.50 3.00

4.38 5.25 6.13 7.00 7.88 8.75 9.63 10.50 12.25 14.00 15.75 17.50 21.00 22.75 24.50 26.25 28.00 29.75 31.50 3.50

5.00 6.00 7.00 8.00 9.00 10.00 11.00 12.00 14.00 16.00 18.00 20.00 24.00 26.00 28.00 30.00 32.00 34.00 36.00 38.00 4.00

5.63 6.75 7.88 9.00 10.13 11.25 12.38 13.50 15.75 18.00 20.25 22.50 27.00 29.25 31.50 33.75 36.00 38.25 40.50 42.75 45.00 4.50

7.50 8.75 10.00 11.25 12.50 13.75 15.00 17.50 20.00 22.50 25.00 30.00 32.50 35.00 37.50 40.00 42.50 45.00 47.50 50.00 55.00 5.00

9.00 10.50 12.00 13.50 15.00 16.50 18.00 21.00 24.00 27.00 30.00 36.00 39.00 42.00 45.00 48.00 51.00 54.00 57.00 60.00 66.00 72.00 6.00

11.38 13.00 14.63 16.25 17.88 19.50 22.75 26.00 29.25 32.50 39.00 42.25 45.50 48.75 52.00 55.25 58.50 61.75 65.00 71.50 78.00 6.50

12.25 14.00 15.75 17.50 19.25 21.00 24.50 28.00 31.50 35.00 42.00 45.50 49.00 52.50 56.00 59.50 63.00 66.50 70.00 77.00 84.00 7.00

13.13 15.00 16.88 18.75 20.63 22.50 26.25 30.00 33.75 37.50 45.00 48.75 52.50 56.25 60.00 63.75 67.50 71.25 75.00 82.50 90.00 7.50

16.00 18.00 20.00 22.00 24.00 28.00 32.00 36.00 40.00 48.00 52.00 56.00 60.00 64.00 68.00 72.00 76.00 80.00 88.00 96.00 8.00

17.00 19.13 21.25 23.38 25.50 29.75 34.00 38.25 42.50 51.00 55.25 59.50 63.75 68.00 72.25 76.50 80.75 85.00 93.50102.00 8.50

18.00 20.25 22.50 24.75 27.00 31.50 36.00 40.50 45.00 54.00 58.50 63.00 67.50 72.00 76.50 81.00 85.50 90.00 99.00108.00 9.00

21.38 23.75 26.13 28.50 33.25 38.00 42.75 47.50 57.00 61.75 66.50 71.25 76.00 80.75 85.50 90.25 95.00 104.50114.00 9.50

22.50 25.00 27.50 30.00 35.00 40.00 45.00 50.00 60.00 65.00 70.00 75.00 80.00 85.00 90.00 95.00 100.00110.00120.00 10.00

24.75 27.50 30.25 33.00 38.50 44.00 49.50 55.00 66.00 71.50 77.00 82.50 88.00 93.50 99.00 104.50110.00121.00132.00 11.00

30.00 33.00 36.00 42.00 48.00 54.00 60.00 72.00 78.00 84.00 90.00 96.00102.00108.00114.00120.00132.00144.00 12.00

Note:Tonnesofrockblastedcanbecalculatedbymultiplyingthevolumeofrockbythedensityoftherock.

CalculationCubicmetresofrock/metresblasthole(V)=burden(B)xspacing(S)

Thisunit Multipliedby Convertsto

Length

metres(m) 3.280 feet(ft)

39.370 inches(in)

inches(in) 25.400 millimetres(mm)

kilometres(km) 0.621 miles

Mass

kilogram(kg) 2.20 lb

metrictonne(t) 1.10 shorttons

ounce

Avoirdupois(oz)28.35 grams(g)

ounceTroy(oz) 31.10 grams(g)

grains 0.06 grams(g)

Energy

joule 0.24 calorie

0.74 ft-lb

calorie 3.09 ft-lb

kilowatt 1.34 horsepower

Volume

cubiccentimetres0.06 in

3

(cm

3

orcc)

cubicmetres(m

3

)1.31 yd

3

cubicfeet(ft

3

) 0.03 m

3

USgallon 3.79 litres(l)

ounces(USfluid)29.57 cm

3

Convertsto Dividedby Thisunit

Thisunit Multipliedby Convertsto

Density

lbs/ft

3

16.02 kg/m

3

gm/cm

3

62.43 lbs/ft

3

Powder Factor

kg/m

3

1.69 lb/yd

3

Speed

m/sec 3.28 ft/sec

in/sec 25.4 mm/sec

km/hour 0.62 miles/hour

Pressure

psi 6.89 kPa

atmosphere(Atm)14.70 psi

bar 14.50 psi

bar 100 kPa

Temperature

fahrenheit-32 0.56 centigrade

centigrade+17.78 1.8 fahrenheit

Area

cm

2

0.16 in

2

m

2

1550.00 in

2

ft

2

0.09 m

2

Convertsto Dividedby Thisunit

Conversion table

Material

Solid Unconfined Young’s Poisson’s

Density Compressive Modulus Ratio

(t/m

3

) Strength (MPa) (GPa)

Basalt 3.00 78–412 20–100 0.14–0.25

Bauxite 2.05

Clay–dense,wet 1.70

Coal,Anthracite 1.60 8–50

Coal,Bituminous 1.36

Dolerite 2.80 290–500

Dolomite 2.96 15–118 20–84 0.1–0.2

Earth,moist 1.80

Gneiss 2.88 78–240 25–60 0.1–0.19

Granite 2.72 100–275 25–70 0.15–0.34

Gypsum 2.80

Ironore 4.89

Limestone 2.64 10–245 10–80 0.1–0.23

Limonite 3.76

Magnetite 5.05

Marble 2.48 50–200 60–90 0.2–0.35

Mica-Schist 2.70

Porphory 2.56

Quartzite 2.50 85–350 26–100 0.15–0.2

Sandstone 2.40 50–160 5–86 0.1–0.3

Shale 2.58 20–150 8–30 0.1–0.3

SilicaSand 2.56

Siltstone 2.25

Slate 2.72 98–196 30–90 0.1–0.44

Talc 2.64

Properties of typical rock types

Perimeterblastingisatechniquetoreducetheoverbreak/backbreakonablast.

Itusuallyutilisesdecoupledchargesincloselyspacedblastholes.

The following formula can be used to estimate the centre to centre distances of

cartridged product for pre-splitting.

PF = Requiredpowderfactor(usually0.3to0.6kg/m

2

)

L = Lengthofchargedhole

S = Spacingbetweenholes

D = Centre–centredistancebetweencartridges(mm)

Q

L = Chargedensityoftheexplosive,inkg/m

B = Burden

Perimeter control

PF =

L x S

0.5

D =

L x Q

L

B x S x PF

Anairblastisanairborneshockwavethatresultsfromthedetonationofexplosives.The

severityofanairblastisdependantonexplosivecharge,distance,andespeciallythe

explosivesconfinement.

Where

P = pressure(kPa)

K = stateofconfinement

Q = maximuminstantaneouscharge(kg)

R = distancefromcharge(m)

Typical K factors

Unconfined 185

Fullyconfined 3.3

Expected damage

kPa

0.3 Windowsrattle

0.7 1%ofwindowsbreak

7 Mostwindowsbreak,plastercracks

30 Riskofdamagetoeardrums

Minimum levels quoted AS 2187.2 – 1993

Humandiscomfort 120db(in)

Onsetofstructuredamage 130db(in)

orhistoricbuildingswherenospecificlimitexists

Airblast

P = K

-1.2

R

Q

0.33

[ ]

Whenanexplosiveisdetonatedinablasthole,apressurewaveisgeneratedinthe

surroundingrock.Asthispressurewavemovesfromtheboreholeitformsseismic

wavesbydisplacingparticles.Theparticlemovementismeasuredtodeterminethe

magnitudeoftheblastvibration.

Maximumparticlevibrationcanbeestimatedusingthefollowingformula.

Where

V = peakparticlevelocity(mm/s)

K= siteandrockfactorconstant

Q= maximuminstantaneouscharge(kg)

B= constantrelatedtotherockandsite(usually-1.6)

R= distancefromcharge(m)

Typical K factors

Freeface–hardorhighlystructuredrock 500

Freefaceaveragerock 1140

Heavilyconfined 5000

Recommended maximum Peak Particle Velocities (AS 2187.2 – 1993)

Housingandlowriseresidentialbuildings, 10mm/s

Commercialbuildingsnotincludedbelow

Commercialandindustrialbuildingsorstructures 25mm/s

ofreinforcedconcreteorsteelconstructions

Forhighrise,hospitals,longfloorspans,dams 5mm/s

orhistoricbuildingswherenospecifiedlimitexists

Expected damage

PPV (mm/s)

13 Lowerlimitfordamagetoplasterwalls

19 Lowerlimitfordrywallstructures

70 Minordamage

140 >50%chanceofminordamagetostructures

190 50%chanceofmajordamage

Ground vibration

V = K

B

R

Q

0.5

[ ]

Shoulder hole Theserefertothoseholesimmediatelybelowtheback

perimeterholes.

Burncut Theburncutconsistsofagroupofblastholesarrangedina

regularpatternaroundoneormoreunchargedreliefholes.

Thefirstfiringblastholebreaksbothintothevoidofferedby

theunchargedreliefholesandtowardsthefreefaceprovided

bythetunnelface.

Easer Holeadjacenttocutarea.

Lifters Theblastholesalongthebottomofthedevelopedround.

Properperformanceoftheliftersareessentialinachieving

goodfloorcontrol.

Perimeter blastholes Perimeterblastholesarethosewhichformtheboundaryof

thetunnel.Explosiveloadingdensitiesintheseblastholesare

generallylowerthanthoseintheremainderoftheblast,as

theirprimerequirementistominimiseback-breakageand

provideagoodcontour.

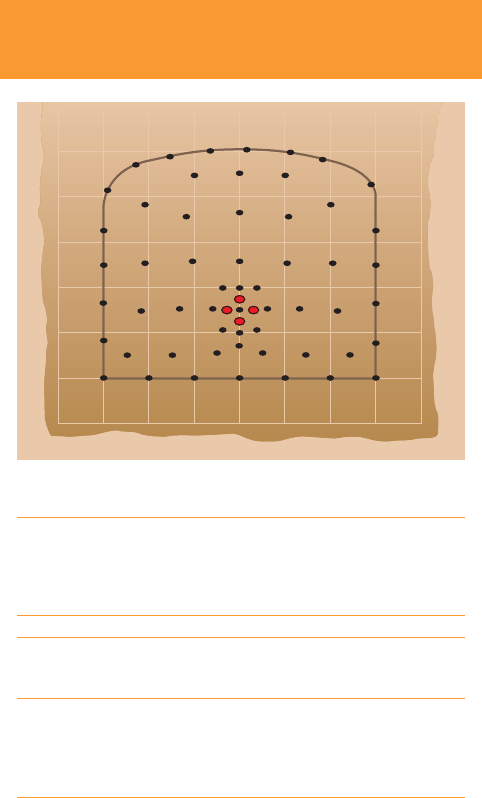

Underground blast design

LifterHoles

ShoulderHoles

PerimeterHoles

KneeHoles

EaserHoles

Burncut

Design of cut

Thefollowingformulaeareusedforthegeometricdesignofthecutarea:

Formultiplereamerholes:ø=dn

Where:d=diameterofemptyreamerholes

n=numberofreamerholes

The cut:

1st square: a=1.5ø

W

1=a2

ø mm = 76 89 102 127 154

amm = 110 130 150 190 230

W

1mm = 150 180 210 270 320

2nd square: B1=W1

C-C=1.5W1

W2=1.5W12

ø mm = 76 89 102 127 154

W

1 = 150 180 210 270 320

C-C = 225 270 310 400 480

W

2mm = 320 380 440 560 670

3rd square: B2=W2

C-C=1.5W2

W3=1.5W22

ø mm = 76 89 102 127 154

W

2mm = 320 380 440 560 670

C-C = 480 570 660 840 1000

W

3mm = 670 800 930 1180 1400

4th square: B3=W3

C-C=1.5W3

W4=1.5W32

ø mm = 76 89 102 127

W

3mm = 670 800 930 1180

C-C =1000 1200 1400 1750

W

3mm = 1400 1700 1980 2400

Underground blast design

W1

a

W4

W3

C-C

B3

W3

W2

C-C

W2

W2

W1

C-C

B1

Design of lifter & easer holes

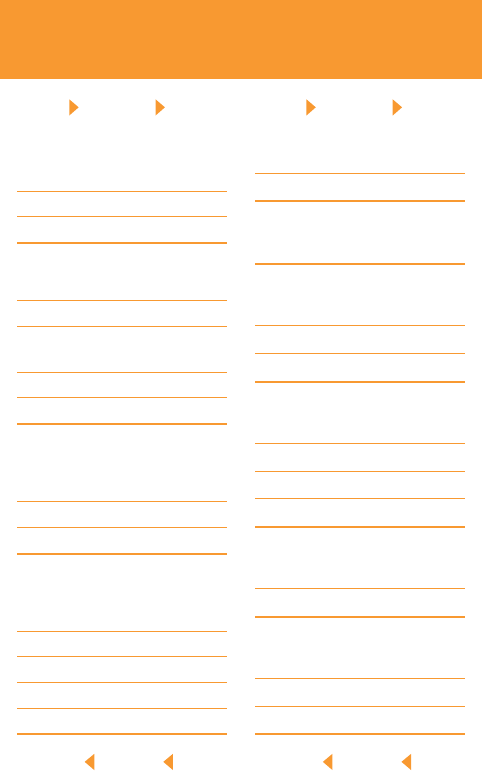

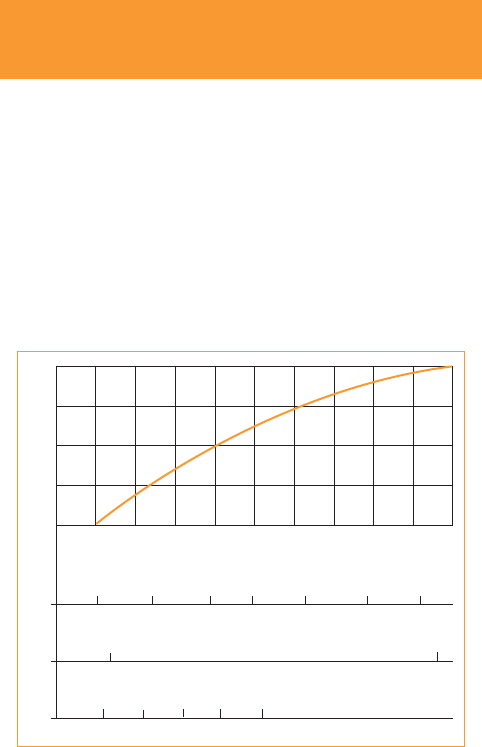

Whenthecutholeshavebeencalculated,therestofthedevelopmentroundmay

becalculated.

Theroundisdividedinto:

• lifterholes

• sideholes

• backholes

• easerholeswithbreakageupwardsandhorizontally

• easerholeswithbreakagedownwards

Tocalculateburdens(B)andchargesforthedifferentpartsoftheroundthefollowing

graphmaybeusedasabasis.

Underground blast design

1.2

1.1

1

0.9

0.8

0.6 0.8 1.0 1.2 1.4 1.6 1.8 2.0 2.2 2.4 2.6

30 35 38 41 45 48 51

Chargeconcentration,kg/m

Powermite

®

Proinfilmcartridges.Typicaldensity=1.20g/cm

3

Continuousliftercharge

ANFO,pneumaticallycharged

Burden,m

Blasthole

diameter,mm

Pipecharge

diameter,mm

Blasthole

diameter,mm

51

38 41 45 48 51

30

TITAN

®

% Density* Energy Recomm Recomm Water

Emulsion ANFO (g/cm

3

) (MJ/kg) sleep time minimum hole Resistance

Product (wt%) (days) diameter (mm)

TITAN2000G(Gassed) 0 1.05-1.25* 2.5 12 102 Excellent

TITAN2010(HeavyANFO) 90 0.86

#

3.6 14

ø

102 Poor

TITAN2020(HeavyANFO) 80 0.97

#

3.4 14

ø

102 Poor

TITAN2030(HeavyANFO) 70 1.10

#

3.3 14

ø

102 Poor

TITAN2040(HeavyANFO) 60 1.25

#

3.2 14

ø

127 Poor

TITAN2050(Blend) 50 1.32

#

3.1 14 203 Average

TITAN2050G(Gassed) 50 1.20-1.25* 3.1 12 102 Average

TITAN2060G(Gassed) 40 1.05-1.25* 3.0 12 102 Good

TITAN2070G(Gassed) 30 1.05-1.25* 2.9 12 102 Excellent

TITAN2080G(Gassed) 20 1.05-1.25* 2.7 12 102 Excellent

TITAN2090G(Gassed) 10 1.05-1.25* 2.6 12 102 Excellent

TITAN3000G(Gassed) 0 1.05-1.25* 2.7 12 76 Excellent

TITAN3010(HeavyANFO) 90 0.86

#

3.6 14

ø

89 Poor

TITAN3020(HeavyANFO) 80 0.93

#

3.5 14

ø

89 Poor

TITAN3030(HeavyANFO) 70 1.05

#

3.4 14

ø

102 Poor

TITAN3040(HeavyANFO) 60 1.23

#

3.3 14

ø

127 Poor

TITAN3060G(Gassed) 40 1.05-1.25* 3.1 12 89 Good

TITAN3070G(Gassed) 30 1.05-1.25* 3.0 12 76 Excellent

TITAN3080G(Gassed) 20 1.05-1.25* 2.9 12 76 Excellent

TITAN3090G(Gassed) 10 1.05-1.25* 2.8 12 76 Excellent

TITAN4000G(Gassed) 0 1.05-1.25* 2.4 12 102 Excellent

TITAN4010(HeavyANFO) 90 0.85

#

3.6 12

ø

102 Poor

TITAN4020(HeavyANFO) 80 0.96

#

3.4 12

ø

102 Poor

TITAN4030(HeavyANFO) 70 1.10

#

3.3 12

ø

102 Poor

TITAN4040(HeavyANFO) 60 1.26

#

3.2 12

ø

152 Poor

TITAN4050(Blend) 50 1.32

#

3.0 12 152 Average

TITAN4050G(Gassed) 50 1.05-1.25* 3.0 12 102 Average

TITAN4060G(Gassed) 40 1.05-1.25* 2.9 12 102 Good

TITAN4070G(Gassed) 30 1.05-1.25* 2.8 12 102 Excellent

TITAN4080G(Gassed) 20 1.05-1.25* 2.6 12 102 Excellent

TITAN4090G(Gassed) 10 1.05-1.25* 2.5 12 102 Excellent

TITAN5000G(Gassed) 0 1.05-1.25* 2.7

^

102 Excellent

TITAN5010(HeavyANFO) 90 0.88

#

3.6

^

102 Poor

TITAN5020(HeavyANFO) 80 0.94

#

3.5

^

102 Poor

TITAN5030(HeavyANFO) 70 1.05

#

3.4

^

102 Poor

TITAN5040(HeavyANFO) 60 1.21

#

3.3

^

152 Poor

TITAN5050(HeavyANFO) 50 1.31

#

3.2

^

203 Average

TITAN5060(Blend) 40 1.32

#

3.0

^

250 Good

TITAN5060G(Gassed) 40 1.05-1.25* 3.1

^

102 Good

TITAN5065G(Gassed) 35 1.05-1.25* 3.0

^

102 Good

TITAN5070G(Gassed) 30 1.05-1.25* 3.0

^

102 Excellent

TITAN5080G(Gassed) 20 1.05-1.25* 2.9

^

102 Excellent

TITAN5090G(Gassed) 10 1.05-1.25* 2.8

^

102 Excellent

TITAN7000(Gassed) 0 0.80-1.25 2.9 30

†

35 Excellent

TITAN7000i(Gassed) 0 0.80-1.25 2.9

^

35 Excellent

TITAN7000SX(Gassed) 0 0.80-1.25 2.8

^

35 Excellent

* Inholegassedproductdensityisdependentonholedepth.

#

DensitiesmayvaryduetovariationsintheANprilldensity.Forblendswith50%emulsionorgreater,pleaseconsultyour

DynoNobelrepresentativetoensuretheproductissuitableforyourapplication.

ø

Forunreactivegroundindryholeconditionswithnowaterpresent.Dewateredholesmayreducesleeptime.

^

ForapplicationsinreactivegroundconditionspleaseconsultyourDynoNobelrepresentativetoundertaketheappropriate

testworkpriortothedevelopmentofsuitablesitespecificprocedures.

†

Forupholeapplications,sleeptimesaredependentongeology,waterandinholeconditions.

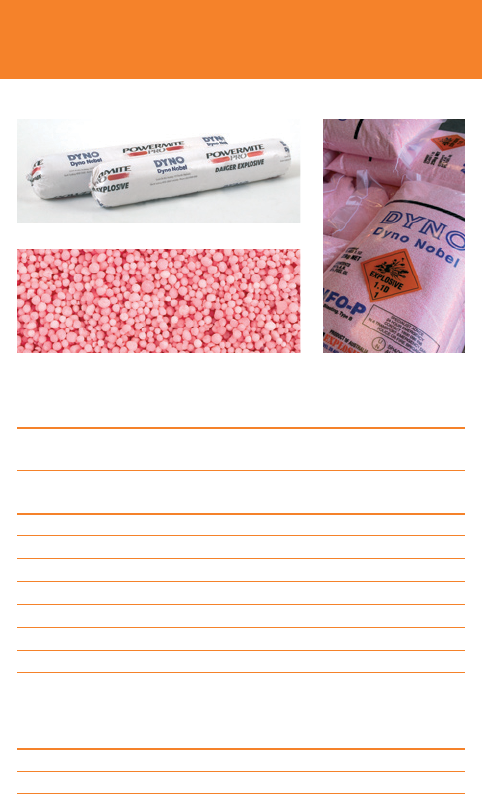

Bulk products

Powermite

®

Pro

Typical density Theoretical energy comparison VoD

(g/cm

3

) Energy (MJ/kg) RWS RBS (m/s)

1.16-1.23 <=32mm2.78 121 183 3400

>=45mm2.72

Packaging Quantity Average cartridge Case

per 25kg case weight (g) weight kg

25mmx200mm 219 114 25

25mmx700mm 60 416 25

32mmx200mm 135 185 25

32mmx700mm 34 736 25

55mmx400mm 33 758 25

65mmx400mm 21 1190 25

80mmx400mm 15 1670 25

ANFO – bagged

Typical density Theoretical energy comparison Recomm

(Poured) g/cm

3

(MJ/kg) RWS RBS min hole (mm)

Poured 0.8-0.85 3.7 100 100 75

Blowloaded 0.85-0.95 3.7 100 116 25

Packaged products

Powermite

®

Pro ANFO – bagged

ANFO – bulk

Packaged products

SANFOLD

®

Z-BAR

®

Edge Z-BAR

®

Lifter

SANFOLD

®

Typical Typical Theoretical Recomm Recomm

density density energy min hole min hole

(Poured) (Blow loaded) comparison (Poured) (Blow loaded)

g/cm

3

g/cm

3

(MJ/kg) (mm) (mm)

SANFOLD

®

70 0.75 0.87 3.63 40 32

SANFOLD

®

50 0.55 0.67 3.51 50 –

SANFOLD

®

30 0.3 0.54 3.28 50 40

Z-BAR

®

Diameter Charge VoD Maximum case

(mm) (kg/m) weight (kg)

Z-BAR

®

Edge Tube-19 Tube-0.30 6500 20

Primer-29 Primer-0.50

Z-BAR

®

Lifter 29 0.50 6500 25

Z-BAR

®

Edge Z-BAR

®

Lifter

Length Quantity per case Length per case Quantity per case Length per case

2.5m 20 50 15 37.5

3.0m 18 54 12 36

3.5m 16 56 10 35

4.0m 13 52 9 36

4.5m 12 54 8 36

Initiation systems – downhole

NONEL

®

MS Series

NONEL

®

MS

Heavy Duty Series

NONEL

®

MS Series

Delay Clip Nominal firing Time between

period (ms) colour time (ms) delays (ms)

1 Red 25 25

2 Blue 50 25

3 Brown 75 25

4 Orange 100 25

5 Aqua 125 25

6 Gold 150 25

7 LimeGreen 175 25

8 Pink 200 25

9 DarkGreen 225 25

10 Purple 250 25

11 LightBlue 275 25

12 LightGreen 300 25

13 Mauve 325 25

14 Mustard 350 25

15 Crimson 375 25

16 Yellow 400 25

17 DarkBlue 425 25

18 Green 450 25

19 Orange 475 25

20 White 500 25

21 RubineRed 550 50

22 Grey 600 50

23 Black 650 50

24 Brown 700 50

25 Red 750 50

26 Blue 800 50

27 Brown 900 100

28 Orange 1000 100

Packaging Winding NONEL

®

Tube

Length (m) Units per case configuration Standard or Heavy Duty

3.6 250 Coiled Standard

4.8 200 Coiled Standard

6.0 150 Coiled Standard

7.2 150 Coiled Standard

9.0 100 Coiled Standard+HD

12.0 75 Sleeved Standard+HD

15.0 75 Sleeved Standard+HD

18.0 50 Sleeved Standard+HD

24.0 30 Spooled Standard+HD

30.0 30 Spooled HD

36.0 30 Spooled HD

45.0 30 Spooled HD

60.0 30 Spooled HD

80.0 30 Spooled HD

NONEL

®

tube: Standard HeavyDuty

Colour Red Orange

Diameter 3.0mm

Detonator #12Strength

Initiation systems – downhole

NONEL

®

LP Series

Delay Clip Nominal firing Time between

period (ms) colour time (ms) delays (ms)

0 White 25 25

1 Red 500 475

2 Blue 800 300

3 Brown 1100 300

4 Orange 1400 300

5 Aqua 1700 300

6 Gold 2000 300

7 LimeGreen 2300 300

8 Pink 2700 400

9 Black 3100 400

10 Purple 3500 400

11 LightBlue 3900 400

12 DarkGreen 4400 500

13 Mauve 4900 500

14 Mustard 5400 500

15 Crimson 5900 500

16 Yellow 6500 600

17 DarkBlue 7200 700

18 Green 8000 800

Packaging

Length (m) Units per case Winding configuration

3.6 250 Sidewinder

4.8 200 Sidewinder

5.4 150 Sidewinder

6.0 150 Sidewinder

15.0 75 Sleeve

24.0 30 Spool

36.0 30 Spool

NONEL

®

tube: Standard

Colour Yellow

Diameter 3.0mm

Detonator #12Strength

NONEL

®

LP Series

Initiation systems – open-cut

NONEL

®

EZTL Series

Delay period (ms) Clip colour

0 Green

9 Violet

17 Yellow

25 Red

42 White

67 Blue

109 Black

150 DarkGreen

176 Orange

200 Gold

Packaging

Length (m) Units per case Winding configuration

3.6 200 coiled

4.8 150 coiled

6.0 150 coiled

7.2 150 coiled

9.0 100 Figure80

12.0 75 Figure80

15.0 75 Figure80

18.0 50 Figure80

Tube colour Yellow

Detonator Lowstrength

Clip capacity6

NONEL

®

EZTLSeries

Initiation systems – open-cut

NONEL

®

MS Connector

Delay period (ms) Clip colour

9 Violet

17 Yellow

25 Red

42 White

67 Blue

109 Black

150 DarkGreen

176 Orange

200 Gold

Packaging

Unitspercase 200

Tube

Standard Orange

NONEL

®

MS Connector

NONEL

®

Starter

NONEL

®

Lead Line

Reel-off initiation system (nodetonator)

Length 1000m(twopercase)

VOD 2100m/sec(+/-300)

Tube StandardYellow

NONEL

®

Starter

Packaging

Length (m) Units per case Winding configuration

100 15 Spooled

300 4 Spooled

500 4 Spooled

Tube

Standard Yellow

NONEL

®

Lead Line

Nominal Diameter Length Units per Priming

weight (mm) (mm) case

(g)

Trojan Spartan 150 150 36 119 95 Capsensitive

Trojan Spartan 400 400 55 119 40 Capsensitive

Trojan NBU 400 400 55 119 40 Primacord4

Trojan Ringprime 250 46 175 42 Capsensitive

NB:SpidersforRingprime

®

have125mmdiameterandcomeinseparate70unitlots.

Initiation systems

Trojan Spartan

Cast Boosters

Trojan NBU Trojan Ringprime

®

Core load Diameter Minimum Packaging

(g/m) (mm) strength (kg)

PrimaCord

®

5 5 4.2 68 2x500mrolls

PrimaLine

®

10 10 5 68 2x350mrolls

PrimaCord

®

5

Detonating Cords

PrimaLine

®

10

Initiation systems

Electric Super

™

Starter

Electric Super

™

Starter

Description

Delaytime(ms) 0

FuseHeadresistance(ohm) 1.92

Firingcurrent,minimum

recommended,(A)

Serieswiring 3ampsACor1.5ampsDC

Parallelwiring 1ampACorDCperdetonator

Series-in-parallelwiring 2ampsACorDCperseries

Legwires(m) 3.5

Strength(#) 10

The maximum recommended continuous firing current

is 10 amps per detonator.

The SmartShot System

SmartShot Electronic Detonator System

Packaging

Length (m) Units per case

10/7 18

20/10 18

20/15 18

35/0.2 18

45/0.2 18

60/0.2 8

Blasting accessories

DynoStart (DS2)

ELECTRONICBLASTINGMACHINE

DynoStartisabatterypoweredelectronicblasting

machineforinitiationofNONEL

®

tube.Electrical

energyisconvertedintoastrongshockwaveofhigh

temperaturethat,whenappliedinsideaNONEL

®

tubebythemeansofanelectrode,initiatesthetube.

DynoStartusesacommon9Vbatteryandadurable

electrode.Bothbatteryandelectrodeareeasyto

change.Theelectrodecanberemovedfromthe

blastingmachineatanytimetopreventunauthorised

usage.DynoStartisdesignedtorequiretheuseof

bothhandswheninitiatingtheblast.Thisistoavoid

unintentionalfiringofablast.

DynoStart (DS2)

NONEL

®

Starter Gun

BLASTINGMACHINE

TheNONEL

®

StarterGunisasimpleandhighly

effectivehandheldblastingmachine,robustly

constructedfrommetalalloysandstainlesssteel.

IthasanintegralsafetydeviceandusesShotShell

PrimersNo.20asprimercaps.Itisacomplete

blastingmachine,nootherequipmentbeingneeded

toinitiateaNONEL

®

tube.

NONEL

®

Starter Gun

Blasting accessories

Stinger Exploder 10 Shot

TheSB10isacompactcapactivedischarge

exploder.Theunitispoweredby1.5VAAbatteries.

Aremovablemagnetickeycontrolssecurityofthe

firingmechanismandapushbuttonoperatesthe

firingcircuit.Areadylightilluminateswhenthe

firingcapacitorisfullycharged.

Stinger Exploder 10 Shot

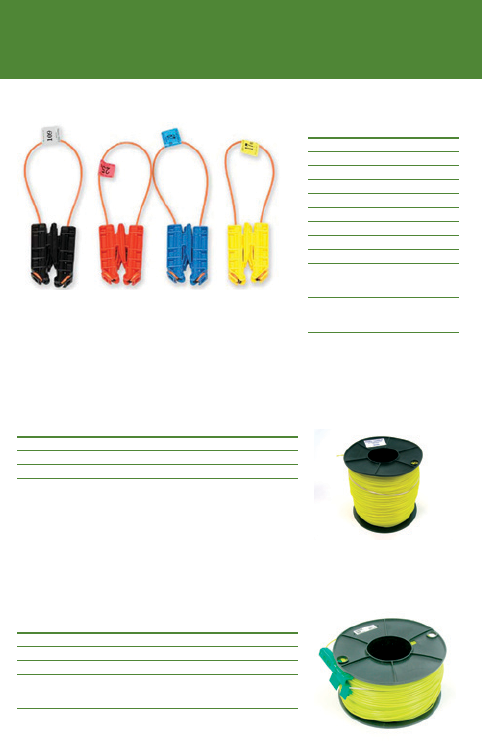

Scorpion

®

TheScorpion

®

isadeviceusedtocentralisedetonators

intheborehole.Constructedfromextrudedplastic,

Scorpion

®

comprisesoffourfinsattachedtoacentral

spineandfacilitatesdirectprimingofANFOandTitan

7000bulkemulsioninsmalldiameter,dryblastholes,

usedintunnellingandundergroundminedevelopment.

Length 130m

Diameter 38mm

Construction extrudedplastic

Scorpion

®

Blasting accessories

Lo-Stat ANFO Hose

TheLo-StatANFOHoseisaconductivethermoplastic

tubeusedfordeliveryofexplosivesinunderground

applications.

Description Product specification

20mm hose 25mm hose

Internal Diameter 18.4mm-19.6mm 24.6mm-25.4mm

Outside Diameter 26.4mm-27.6mm 29.8mm-30.2mm

Wall Thickness 3.7mm-4.4mm 2.3mm-2.7mm

Resistance/m metre 15-25KΩ 15-25KΩ

Total Resistance (wholecoil) <1.6MΩ <1.6MΩ

Nominal Weight 330-370g/m 210-230g/m

Lo-Stat ANFO Hose

Stempac

ThestempacisastemmingdeviceconstructedusingStemtiteblastcontrolplugsand

crushedaggregateinascaledplasticpackage.Thestempacenablesblastholesthathave

beendrilledhorizontaloratanangleabovehorizontaltobestemmed.Itisdesigned

tobeplacedinablastholeaftertheloadinghasbeencompletedandbelocated80cm

belowtheexplosivecolumn.Disassembledcomponentsshown.Assembledproduct

includesyntheticsleeve.SizeofStempaccanvarydependingonholediameter.

Stempac

Blasting accessories

Twin Twist Bell Wire

Insulation colour RedandWhiteTwist

Roll size 500metres

Number of cores2

Current rating (A) 1.8

Electrical Resistance @ 20

C

(mΩ/m) per core 62

Twin Twist Bell Wire

Firing Cable – Heavy Duty

Insulation colour Red –

Fig 8 outer sheath,

Red and White core

Roll size 100metres

Number of cores 2

Electrical Resistance @ 20

C

(mΩ/m) per core 12.9

Firing Cable – Heavy Duty

AirblastAirborneshockwaveresulting

fromthedetonationofexplosives.

Back breakRockbrokenbeyondthe

limitsofthelastrow.

Borehole pressureThepressurewhich

thegassesofdetonationexertonthe

boreholewall.

Charge weight Theamountofexplosive

chargeinkilograms.

Column chargeAcontinuouschargeof

explosivesinaborehole.

Critical diameterTheminimumdiameter

forpropagationofastabledetonation.

CutoffsAportionofanexplosive

columnthathasfailedtodetonatedueto

rockmovement.

DecouplingTheuseofexplosiveproducts

havingsmallervolumethanthevolumeof

theblastholeitoccupies.

Delay blastingTheuseofdelay

detonatorsorconnectorstoseparate

chargesbyadefinedtime.

Density massperunitvolume.

Detonation pressure Thepressure

createdinthereactionzoneofa

detonatingexplosive.

ExplosiveAnychemicalormixture

ofchemicalsthatcanreacttoproduce

anexplosion.

Free faceArocksurfacethatprovidesthe

rockwithroomtoexpandwhenblasted.

FlyrockRockthatispropelledthrough

airfromablast.

FragmentationMeasuretodescribe

thesizeofdistributionofbrokenrock

afterblasting.

Ground vibrationGroundmovement

causedbythestresswavesemanating

fromablast.

InitiationTheactofdetonatingexplosives

byanymeans.

Line drillingAmethodofoverbreak

controlwhichusesaseriesofclosely

spacedholesthatarenotcharged.

Loading densityTheweightofexplosives

permetreofborehole.

Maximum Instantaneous Charge (MIC)

Massofexplosivedetonatinginsome

definedtimeperiod,usually8milliseconds.

Overbreak Excessivebreakageofrock

beyondthedesiredexcavationlimit.

Particle velocityThespeedofmovement

inagivendirectionofarockorsoilmass.

Pre-split Acontrolledblastinwhich

decoupledchargesarefiredinholeson

theperimeteroftheexcavationpriorto

themainfiring.

Relative Bulk Strength (RBS)Theenergy

yieldperunitvolumeofanexplosive

comparedtoANFO.

Relative Weight Strength (RWS) The

energyyieldperunitmassofanexplosive

comparedtoANFO.

SpacingThedistancebetweenboreholes

inthesamerow.

StemmingInertmaterialusedtoconfine

thegassesgeneratedduringdetonation.

Swell factorTheratioofthevolumeof

brokenrocktothevolumeofin-siturock.

Velocity of detonationThevelocityat

whichadetonationprogressesthrough

anexplosive.

Glossary

DISCLAIMER

Theinformationandsuggestionscontainedinthisdocumentconcernexplosive

productsthatshouldonlybedealtwithbypersonshavingtheappropriate

technicalskills,trainingandlicence.Theresultsobtainedfromtheuseofsuch

productsdependtoalargedegreeontheconditionsunderwhichtheproducts

arestored,transportedandused.

WhileDynoNobelmakeseveryefforttoensurethedetailscontainedinthe

documentareasaccurateaspossible,theconditionsunderwhichtheproducts

areusedarenotwithinitscontrol.Eachuserisresponsibleforbeingawareof

thedetailsinthedocumentandtheproductapplicationsinthespecificcontext

oftheintendeduse.Iftechnicaladviceisrequiredinthespecificapplicationof

theproductsthenyoushouldcontactDynoNobelforassistance.

Tothefullextentpermittedbylaw,DynoNobelmakesnowarrantiesinrelation

totheproductsitsellsandbearsnorisk,responsibilityorliabilityarisingfrom

theuseoftheproductsandtheinformationinthisdocumentbythebuyeror

useroftheproducts.

DynoNobelAsiaPacificPtyLimited(ACN003269010)isasubsidiaryof

IncitecPivotLimited(ACN004080264).

®TITAN,Powermite,DynoSplit,SANFOLD,Z-BAR,NONEL,Cobra,DYNO,

Ringprime,PrimaCord,PrimaLine&Scorpionareregisteredtrademarksof

theDynoNobel/IncitecPivotGroup.

©DynoNobelAsiaPacificPtyLimited2010.Reproductionwithoutpermission

isstrictlyprohibited.

REF0110/0210/AZZAUS/2K

Dyno Nobel Asia Pacific

Queensland

PrincipalPlaceofBusiness

282ParingaRoad

GibsonIsland

MurarrieQld4172

Australia

POBox3559

TingalpaDCQld4173

Australia

Telephone:+61730263900

Fax:+61730263999

New South Wales

MtThorleyTechnicalCentre

5WoodlandRoad

MtThorleyNSW2330

Australia

PMB17

SingletonNSW2330

Australia

Telephone:+61265742500

Fax:+61265746849

Western Australia

PerthOffice

Level6,553HayStreet

PerthWA6000

Australia

Telephone:+61894254500

Fax:+61894254555

KalgoorlieOffice

EminSt

POBox684

KalgoorlieWA6430

Australia

Telephone:+61890808600

Fax:+61890218871

Victoria

RegisteredOffice

70SouthbankBoulevard

SouthbankVic3006

Australia

Telephone:+61386954400

Fax:+61386954419

www.dynonobel.com