CHAPTER 12

DAMAGE CONTROL

Damage control is the responsibility of ALL

HANDS, from the commanding officer to the newest

recruit.Without proper damage control training, your

shipmatesmaybeinjuredorkilled,orperhapsyourship

may sink. DuringWorldWarII, many ships were saved

because of the positive damage control practices.

For instance, the German battleship Bismarck was

kept afloat and remained inafighting status for an

extended period in spite of the British pounding it with

heavy gunfire.Youcan see that survivability through

positive damage control is not only important for the

United States, but on an international level.

Effective damage control (DC) requires the correct

useofequipmentand techniques to prevent or minimize

the damage effects caused by battle,fire, collision,

grounding,explosion, and so forth. DC also includes

defensive measures used to reduce the effects of

weapons of mass destruction, such as chemical,

biological,andradiological(CBR)warfare.Remember,

our Navy gives you the best damage control training in

the world. As a ship’s crew member, it’s your

responsibility to properly safeguard yourself and your

ship. You learn how to do this through training.

Youmayfeel the information inthischapterdoesn’t

apply to you because of your chosen occupationalfield.

Remember that asaSailor, no matter what your rating,

you may serve aboard ship at any point in your career.

Therefore, asacrew member, you must know your

damage control responsibility. For more in-depth

information about the administration and organization

of damage control, you should refer to the following

manuals:

•

Surface Ship Survivability, Naval Warfare

Publication (NWP) 3-20.31

•

Naval Ship’s Technical Manual (NSTM), chapter

079, vol. 2, “Practical Damage Control”

•

Naval Ship’s Technical Manual (NSTM), chapter

555, vol. 1, “Surface Ship Firefighter”

Our Navy hasacomplete organization in place

relating to damage control. This organization consists

of the following two main parts:

1. The administrative organization, and

2. The battle organization.

ADMINISTRATIVE ORGANIZATION

Learning Objectives: When youfinish this chapter,

you will be able to—

• Identify the chain of command within the

damage control administrative organization.

•

Recognize the functional purpose of each part of

the organization and the interrelationships

between the parts.

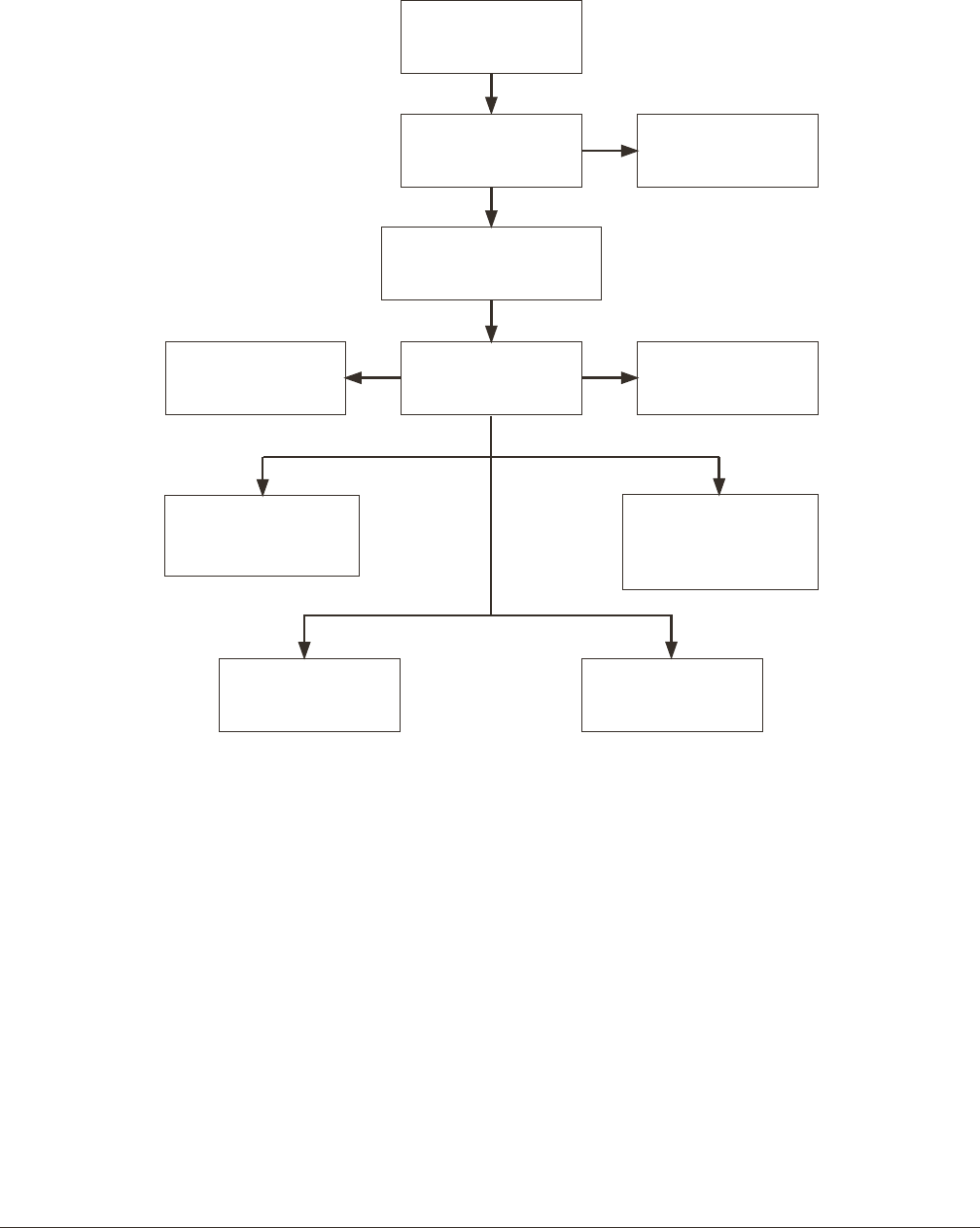

The damage control administrative organizational

chain of command is shown infigure 12-1. As you can

see, the responsibility for damage control begins with

thecommanding officer (CO) ofanaval ship andruns to

the most junior Sailor in the DC division and damage

control petty officer community.

Look atfigure 12-1. As you can see at the level of

the ship’s damage control assistant (DCA), other

personnel report to the DCA. Each person has a

different administrative responsibility and tasking.

Each person reports back up the chain via the DCA.

PURPOSE OF ADMINISTRATIVE

ORGANIZATION

The administrative organization requires the

efforts of all hands to establish and maintain material

readiness conditions. Material readiness is

12-1

…theevents of 14-15 April 1988 have proven that solid damage

control, good training, andsoundleadership basedonexperiencecan

save a ship that is on fire and sinking, to fight another day.

—Paul X. Rinn, CAPT

CO, USS Samuel B. Roberts (FFG-58)

accomplished when DC fittings and equipment

aboard ship are available and in properworking order

to combat any emergency. Aboard ship, there is a

damage control petty officer (DCPO) for each

department or division. The DCPO makes sure that all

emergency equipment andfittings are maintained and

work properly. The DCPO also maintains the

compartment checkoff list.

Eachshiphasaspecifiednumberof damage control

lockers witharepair party assigned. Repair parties and

repair locker personnel, along with the DCPOs, receive

periodic training so they can perform their assigned

duties. The engineer officer is responsible for

maintaining properly trained DCPOs, repair parties,

and repair locker personnel. Under the engineer officer,

the DCA coordinates the efforts of the repair parties to

control damage. Also, the DCA oversees all DC

training. When properly maintained, the administrative

organization reduces and confines any initial damage.

The survivability ofaship depends on the level of

preparedness of its personnel. The condition of the

equipment, shipboard systems, and the amount of

training arefactors that affect the ship’s survivability.

Ship’s bills, records and schedules for maintenance,

written doctrine, and procedures relating to damage

control are all part of the administrative organization of

damage control.

For the list of responsibilities forvarious ship’s

personnel, refer to OPNAVINST 3120.32, or ask your

LPO or LCPO.

12-2

Student Notes:

DAMAGE CONTROLMAN

CHIEF/SENIOR/MASTER

DC DIVISION PERSONNEL

DAMAGE CONTROL

CENTRAL

CONTROL STATION

SPACE SUPERVISOR

COMMANDING

OFFICER

ENGINEER OFFICER

and

DAMAGE CONTROL OFFICER

DAMAGE CONTROL

ASSISTANT

GAS FREE

ENGINEER

SHIP’S

FIRE MARSHAL

EXECUTIVE

OFFICER

DAMAGE CONTROL

TRAIN TEAM

DAMAGE CONTROL

PETTY OFFICERS

FIRE PREVENTION

BMRf1201

Figure 12-1.—Administration organization chain of command.

COMMANDING OFFICER

United States Navy Regulations states thevarious

broad responsibilities of the commanding officer (CO).

These regulations require the commanding officer to

maintain his/her command in a state of maximum

effectiveness forwar. They also require that he/she

repair as much damage as possible immediately after a

battle or action.

To carryoutthis charge,the COmustensure thatthe

ship’s officers and crew are trained and continually

exercised in all aspects of survivability. The CO should

be fullyaware of the adequacy and operability of all

survivability systems and equipment. Shortages and

deficiencies must not be tolerated, and they should be

immediatelyrectified(fixed)or reportedascasualtiesin

the ready reporting system.

EXECUTIVE OFFICER

Theexecutive officer (XO)keeps the command

informed of the ship’s survivability readiness. The XO

carries out the requirements regarding the ship’s

survivability training, the readiness to manage

casualties,andthereadiness to control and recoverfrom

damage. As the team leader, the XOis the senior person

assigned to the damage control training team (DCTT).

The DCTT is responsible for all shipboard drills and

exercises in the area of damage control.

DAMAGE CONTROL TRAINING TEAM

Each ship hasaDCTT. The DCTT trains the ship’s

DC organization in ship equipment, ship systems, and

procedures and techniques relating to the ship’s

survivability. The DCTT is organized to train all types

of DC-related exercises.

The DCTTevaluates and critiques the DC team’s

abilities as well as theirown. The team is made up of a

variety of ratings, which provides the ship withawide

range ofexperience.All team members are qualified, as

a minimum, to at least the level of personnel they are

training and/or evaluating.

ENGINEER OFFICER

The engineer officer is designated as the ship’s

damage control officer. The ship’s engineer officerfills

the billet as the department head of the engineering

department, and the DC division is one of the divisions

in that department. The engineer officer has the

following responsibilities:

•

The operation, care, and maintenance of the

main propulsion plant, auxiliary machinery, and

piping systems

•

The control of damage

•

Theoperationandmaintenanceofelectric power

and distribution systems

•

Repairs to the hull

•

Repairs to material and equipment in other

departments that require the attention of

engineering department

Also the damage control officer (DCO), the

engineerofficer reviews all administrative items drafted

by the DCA and DCA personnel. This isaprimary

administrative duty that occurs before items are routed

to the CO for approval.

DAMAGE CONTROL ASSISTANT (DCA)

The DCA is the primary assistant to the damage

control officer in the areas of damage control;

firefighting; and chemical, biological, and radiological

defense.Forthepurpose of administrative organization,

the DCA is in charge of many programs relating to

damage control on the ship and monitors the

effectiveness of other programs.

The DCA is responsible for the overall

administration and training of the ship’s DC

organization. Under the guidance of the DCA,

individualdepartmentsanddivisionsareresponsiblefor

administrationand training as related to damage control

for their personnel. All ships afloat must meet the

minimum prescribed formal training requirements to

include training for the following personnel:

12-3

Student Notes:

•

All DCTT members

•

In-port emergency teams (IETs)

•

Rescue and assistance (R&A) detail

•

Repair party personnel

•

Damage control petty officer (DCPO)

organization

•

All hands

Shipboard training by the DCTT is scheduled,

executed, and documented to meet the type

commander’s (TYCOM’s) requirements. The DCA

maintains records of all DC personnel qualification

standards (PQS) accomplishment for all hands.

All ship’s instructions relating to casualty

prevention and response are either drafted by or drafted

for and reviewed by the DCA. This review is made

before seeking the approval and signature of the ship’s

CO. The DCA is the residentexpert for the engineer

officer and the command on instructions relating to

casualty prevention and response. The DCA

administers the following billets and programs: DCPO,

gas free engineer (GFE), fire marshal and fire

prevention, and the operation of damage control central

(DCC) and supporting watches.

DAMAGE CONTROL DIVISION

The damage control division is responsible for the

damage control systems and equipment on board ship.

The DCA is the senior member (division officer) of the

DC division. As such, the DCAoversees all the paper

work and the scheduling for maintenance of these

systems and equipment.

Damage Control Petty Officer (DCPO)

A petty officer, who has completed the PQS, is

designated as the damage control petty officer (DCPO)

based on TYCOM instructions. Eachwork center has a

DCPO. Division officers nominate DCPOs for

endorsement by the chain of command. The XO gives

thefinal approval for the nomination, replacement, and

rotation of all DCPOs. DCPOs normally serve for a

periodof6months; they checkwith thefiremarshaland

DCA whenfirst assigned to or relieved from this duty.

The DCPO is responsible for—

•

Acquainting themselves with all phases of the

ship’s damage control,firefighting, and defense

procedures

•

Assisting with the instruction of division

personnel in damage control

•

Firefighting, egress, and CBR procedures

•

Ensuring the preparation and maintenance of

damage control checkoff lists for all spaces

under their cognizance

•

Supervising the setting of specified damage

control material conditions within division

spaces and making all required reports

•

Weighing portable CO

2

bottles, inspecting and

testing damage control and firefighting

equipment, and preparing all requiredreports for

approval of the division officer based on current

ship’s instructions and planned maintenance

system (PMS) requirements

• Ensuring all battle lanterns, dog wrenches,

spanners, and other damage control equipment

are in place and inausable condition in all

division spaces

•

Ensuring all compartments, piping, cables, and

damage control equipment are properly

stenciled or identified by color codes based on

NSTM, chapter 079, volume 2, and General

Specifications for Ships of the United States

Navy, NAVSEA S9QQO-AA-SPN-010/

Gen-Spec, chapters 505, 507, and 602

•

Ensuring the posting of safety precautions and

operating instructions in required division

spaces

•

Assisting the division officer in inspection of

division spaces for cleanliness and preservation

and assisting in the preparation of required

reports

12-4

Student Notes:

•

Conducting daily inspections of division spaces

for the elimination of fire hazards

•

Performing any other actions in regard to

damage control and maintenance of spaces that

are directed by the division leading petty officer,

division officer, fire marshall, DCA, and

executive officer

Gas Free Engineer (GFE)

Thegasfree engineer (chief petty officer or above)

decides when it’s safe for personnel to enter closed or

poorlyventilated spaces. The GFE makes sure that all

necessary measures have been taken to eliminate the

risk offire,explosion,exposure to toxic substances,

suffocation, or asphyxiation. The GFE hasaworking

knowledge of all definitions, instruments, and

equipment listed in the GFE program. The shipboard

GFE meets the qualifications and is capable of

performing the duties and responsibilities specified in

NSTM, chapter 074,volume 3, “Gas Free Engineering.”

All Navy ships must be adequately staffed with

personnel qualified to performgasfree engineering

services for normal and emergency situations.

Fire Marshal

All ships designateafire marshal to assist the

engineer officer. Thefire marshal helps the DCA train

personnel to prevent andfightfires. The ship’s fire

marshal and dutyfire marshals are qualified to ensure

continuity of inspections for improperly stored or

inoperative DC equipment. Fire marshals are free of

duties thatwould not let them instantly respond to

emergencies. The fire marshal conducts daily

inspections throughout the ship, paying particular

attention to the following areas:

•

Housekeeping

•

Firefighting equipment, both portable and fixed

•

Safety precautions

•

Flammable liquids

•

Smoking

•

Welding and burning

•

Stowage of compressed gas

•

Fume/spraytight light covers

•

Grease filters/traps, Gaylord hoods

•

Ventilation/air conditioning ducts/flammable

stowage ventilation

•

Material condition

Thefiremarshalhasthefollowingresponsibilities:

•

Submitting reports citing fire hazards and

making recommendations for correction

NOTE

Immediate steps should be taken to

eliminate hazards resulting from poor

housekeeping, welding or burning,

smoking, and equipment deficiencies.

Thefire marshal submits discrepancy

reports to the DCA with copies to the

XO and the appropriate department

head(s) and conducts follow-up

inspections to ensure compliance.

• Conducting training forfire teams, rescue and

assistance teams, and departmental/divisional

DCPOs stressing fire hazard consciousness

•

Setting up a fire watch team before

regular/interim overhauls or availabilities

•

Training and assigning fire watches

•

Beingoverall in charge at thefire scene until

relieved byageneral quarters (GQ) scene leader

andkeeping DCC and/or the OOD informed

with an accurate status of the situation

12-5

Student Notes:

REVIEW 1 QUESTIONS

Q1. The damage control organization is divided into

what two main parts?

a.

b.

Q2. What is the purpose of the administrative phase

of DC?

Q3. Who is responsible to maintain properly trained

DCPOs, repair parties, and repair locker

personnel?

Q4. Who is the senior person assigned asteam leader

on DCTT?

Q5. What person is responsible for making sure that

all battle lanterns, dog wrenches, spanners, and

other damage control equipment are inplace and

in a usable condition within their division?

Q6. Before anyone can enter a poorly ventilated

spaceorvoid,whomustcertifythespaceassafe?

BATTLE ORGANIZATION

Learning Objectives: When youfinish this chapter,

you will be able to—

•

Recognize the battle organization of damage

control parties.

•

Recall the location and contents of shipboard

damage control lockers.

The battle phase starts when the ship has received

actual damage. The DCA coordinates the efforts of the

repair parties from damage control central (DCC).

These efforts may include fighting fires, flooding,

controlling the ship’s stability, and repairing battle

damage. Repair party personnel also use CBR defense

measures (CBR is covered in chapter 13).

PURPOSE OF THE BATTLE

ORGANIZATION

Once the shiphas been damaged, theship’s damage

control battle organization is responsible for restoring

the ship to as near normal operation as possible. The

organizationvaries somewhat from one ship to another,

depending on the size, type, and mission of the ship.

However, the same basic principles apply to all battle

organizations.

The DCA isresponsible, under theengineer officer,

for the ship’s survivability systems. The DCA’s

responsibilities include control of damage; control of

stability, list, and trim;fightingfires; restoration from

damage; medical casualty response; and CBR

countermeasures. The battle station for the DCA is

DCC. The primary damage control battle organization

units are repair parties or teams. Battle dressingstations

(satellite medical stations) should be located near the

repair parties.

DAMAGE CONTROL CENTRAL/CENTRAL

CONTROL STATION

The primary purpose of damage control central

(DCC) is to collect and compare reports fromvarious

repair stations to determine the ship’s condition and the

corrective action to be taken. DCC is the nerve center

and directing force of the entire damage control

organization. Personnel from various shipboard

divisions man DCC. On newer class ships, the central

point for reporting is the central control station (CCS).

The CCS has the added capability of being able to

control the closing offire zone (FZ) doors and certain

valves electronically. Also, CCS can remotely activate

fire-fighting systems.

12-6

Student Notes:

Reports from the repair parties are carefully

checked in DCC/CCS. This is done so that immediate

action can be taken to isolate damaged systems and to

make effective emergency repairs. As reports are

received, graphic records of the damage are made on

damage control diagrams and status boards under the

direction of the DCA.Forexample, reports on flooding

are used to update the status boards showing the liquid

distribution (fuel and water) before the damage

occurred. With this information, the stability and

buoyancy of the ship can be estimated and necessary

corrective measures taken.

In the unlikelyevent DCC/CCS is destroyed or is

unable to retain control,aplan is in place to designate

repair stations to take over the responsibilities of

damage control central.

REPAIR PARTIES

The following chart shows a variety of repair

lockersthat are found on an aircraft carrier. All ships

have a minimum of repair lockers 2, 3, and 5. Each

lockerhas anofficeror senior petty officerincharge.

The makeup of each repair party in these lockers

dependsonthetypeofshipandtheareatheyserve.

Repair Party Personnel

For a repair party to control battle damage

effectively, PQS-qualified personnel are assigned to

specificfunctions and duties. Some personnel may have

more than one assignment, depending on the number

and qualifications of personnelavailable. Repair party

personnel must know theirownarea of responsibility

along with the areas of other repair parties. The

following functions are common to all repair parties:

•

Make repairs to electrical and communication

circuits and rig casualty power.

•

Give first aid and transport injured personnel to

battle dressing stations without seriously

reducingtheparty’s damagecontrolcapabilities.

•

Detect, identify, and measure radiation dose and

dose rate intensities.

•

Decontaminate the affected areas of nuclear,

biological, and chemical attacks.

•

Identify, control,andextinguishalltypesoffires.

•

Control and remove flooding water.

•

Evaluate and correctly report the extent of

damage in the repair parties’ area of

responsibility, to include maintaining—

— Deck plans showing location of CBR

contamination, location of battle dressing

stations, casualty collection and

decontamination stations, and safe routes to

them.

— Graphic display boards showing damage

and action taken to correct disrupted or

damaged systems, using standard DC

symbology and plotting techniques.

•

Make emergency repairs to various piping

systems.

•

Be familiar with all damage control fittings in

the assigned area, such as watertight doors,

hatches, scuttles, ventilation systems, and

various valves.

•

Control and clean up hazardous material spills.

12-7

Student Notes:

Repair Locker Location or Function

Repair 1 Main deck repair

Repair 2 Forward repair

Repair 3 After repair

Repair 4 Amidships repair

Repair 5 Propulsion repair

Repair 6 Ordnance

Repair 7 Gallery deck and island structure

Repair 8 Electronic casualty control

In-Port Emergency Team (IET)

In-port emergency teams are made up of duty

section personnel. IET members are emergency team

member qualified and stand ready to respond to any

type of casualty.

At times, it may be necessary to provide additional

personnel and material support to the IET. These

additional personnel come fromapool ofexcess duty

personnel and assemble atadesignated location. They

can assist in settingfire or flooding boundaries and are

available to back up the primary IET, if needed.

Rescue and Assistance (In Port/At Sea)

All ships are required to have a rescue and

assistance detail in port and at sea. The primary

missions of this detail are to rescue personnel at sea,

assist another unit in distress, and assist persons or

activities in distress ashore. All personnel assigned to

the rescue and assistance detail must, asaminimum, be

qualifiedasanemergencyteammemberandinfirstaid.

Rapid Response Team

When in port or under way, each ship has a

designated rapid response team. This team proceeds

directly to the scene whenafire or flooding is called

away. The team attempts to quickly extinguish or

contain thefire or minimize or stopaflooding. At a

minimum, this team is made up of four personnel

qualified as fire team members and the ship’s fire

marshal. Because immediate response is required,

protective clothing or OBAs aren’t donned. If they are

unable togain control of the casualty withinapreset

time frame,afull IET or GQ team relieves them and

takes over.

General Quarters (GQ)

General quarters is an all handsevolution. It is the

highest state of readiness of the ship, and all repair

lockers are manned and fully equipped to combat

casualties. When responding to GQ, all hands adjust

their clothing to battle dress and proceed to their GQ

stations.

Battle dress—Bottom of pants tucked into boots or

socks, long sleeves pulled down and buttoned, top

button on shirtbuttoned, and flash hood and gloves

donned. All exposed skin covered.

GQ route—Move forward in passageways and up

ladders on starboard side, move aft in passageways and

down ladders on port side. Since all hands will be

moving at the same time, you have to move with the

flow of traffic.

DAMAGE CONTROL LOCKERS

The equipment and materials required for making

battledamage repairsvary according to the natureof the

damage. Since many different kinds of damage can

occur aboard ship, you must know how to useavariety

of equipment and materials.

Checks should be made to see that all damage

control equipment tools and materials on the allowance

list are actually on board and in working order.

Comparing the ship’s allowance list with an accurate

and up-to-date inventory of onboard damage control

equipment does that.

Damage control equipment should be stowed or

installed in its designated location and be readily

accessible. Emergencies can be handled much more

effectively if equipment isavailable than if you have to

waste time looking for it.

Damage control equipment must not be used for

any purpose other than damage control. Because

damage control equipment is located throughout the

ship, some people are tempted to use it merely because

it is handy. That must not be allowed. It is important to

make all hands realize their lives may literally depend

onthereadyavailability of damage control equipmentif

an emergency should arise.

REVIEW 2 QUESTIONS

Q1. When does the battle phase of damage control

start?

12-8

Student Notes:

Q2. Where is the battle station for the DCA?

Q3. During GQ, DCC receives reports and casualty

status from—

Q4. What is the minimum requirement to be a

member of the in-port emergency team?

Q5. What are the primary missions of the rescue and

assistance team?

Q6. What is the ship’s highest state of readiness?

COMMUNICATIONS

Learning Objectives: When youfinish this chapter,

you will be able to—

•

Identify the communications devices used

during damage control evolutions.

•

Recognize the purpose of communications

devices used during damage control evolutions.

Communications are vital to the damage control

organization.Without good communications, the entire

organization could break down andfail in its primary

mission. The size and complexity of the surface ships

govern the design of DC communications systems

found aboard ship. Major shipboard DC

communications systems are as follows:

NOTE

All the systems listed below areexplained in

detail in chapter 4 of this TRAMAN.

•

Sound-powered telephones

•

IVCS

•

Ship’s service telephones

•

Announcing systems

•

Intercommunications systems

•

DC WIFCOM

EMERGENCY COMMUNICATIONS

The X40J is an emergency damage control

communication system. It’s employed in theevent of

primary, auxiliary, and supplementary communications

circuitfailure. The X40J is composed of both portable

(“salt and pepper” line) and permanently installed

(risers) components.

ALARMS

The general announcing system (1MC) is

integrated withasystem of alarm signals. The signals

override the microphone control stations and are

intended to notify the ship’s crew of imminent danger.

These alarms, in order of priority, are as follows:

1. Collision

2. Chemical attack

3. General

4. Flight crash

Collision Alarm

The OOD/conning station sounds this alarm signal

when there isapossibility that the ship will run into a

pier, run aground, or anotherwaterborne unit will strike

the ship. All hands should move away from the area of

impact and brace for shock. Afteracollision, all hands

set material condition ZEBRA and are prepared to

control fires and flooding.

Chemical Attack Alarm

The chemical attack alarm signal is sounded by the

OOD/conning station, DCC, and automatically by the

chemical agent point detection system (CAPDS) on

12-9

Student Notes:

shipsso equipped.Thisalarmissounded whentherehas

beenaCBR attack on or in the vicinity of the ship. All

hands must exercise protective measures and

procedures to reduce exposure and personnel injuries.

General Alarm

The general alarm signal is sounded by the OOD to

notify the crew ofabattle condition (GQ). Immediately

after the alarm is sounded, some ships pass theword,

“General quarters, general quarters, all hands man their

battle stations.” All hands report to preassigned stations

following the correct GQ traffic routes and set material

condition ZEBRA.

Flight Crash Alarm

The flight crash alarm is sounded by the OOD or

PreFly to notify ship’s company ofapending or actual

flight deck emergency.

MESSENGERS

Messengers are used to deliver written messages

betweenrepairlockers andDCCasamatterofrecord. If

allmethodsofcommunicationshave failed,messengers

are used to relay orders and information. Messengers

deliver messages between repair lockers and DCC,

between DCC and the bridge, or between other

locations. Messengers should befamiliar with the ship

to get from one place to the other without delay.

Messengers must be able to deliver oral messages

without error.

REVIEW 3 QUESTIONS

Q1. The X40J circuit is commonly referred to as

what kind of line?

Q2. List the namesof the alarmsthat canoverride the

microphone control of the 1MC.

a.

b.

c.

d.

Q3. When all communications systemsfail, how are

messages and orders relayed between repair

lockers and DCC?

SHIP’S INTEGRITY THROUGH

SUBDIVISION

LearningObjective: When youfinish this chapter, you

will be able to—

•

Identify material conditions of readiness and

recognize their purpose.

Naval ships are subdivided into many small

watertight roomsor aswesaywatertightcompartments.

This breaking up process ofavery large area is called

the “compartmentation process.” It limits the spread of

toxic or noxiousgases,fire and flooding, and other

battle damage when it occurs. This system when

combined with material conditions of readiness

(discussed below) increases a ship’s ability to survive.

Each space or compartment onaship is accessed

throughadoortoanew spaceorpassageway connecting

other spaces on the same deck or to the weather deck

area (outside). The space may have a hatch or scuttle

that allowstransit from one deck to another viaaladder.

In some spaces you may have many doors, hatches, and

scuttles. These accesses are eitherwatertight, airtight,

fumetight, oiltight, or nontight by design.

Piping andventilation systemswork on the same

concept as compartment access fittings. They have

valves at strategic points that will isolate sections of a

system, limiting the spread of damage to smaller areas.

Becauseofallthefittingsandclosuresthatare onaship,

you might be asking yourself the question, “How will I

know which ones to close or leave open and when to do

it?” Those answers are covered in the paragraphs to

follow.

12-10

Student Notes:

MATERIAL CONDITIONS OF READINESS

There are three material conditions of readiness.

Those conditions are named XRAY, YOKE, and

ZEBRA. When set, each condition affords the ship with

a level of protection, with XRAY being the least and

ZEBRA the most. Somefittings or closures onaship

may not be classified although the majority of them are

classified. They are identified byaclassification plate

affixed to the closure or fitting, or sometimes the

classification is painted on thebulkhead next to the

item. Ship’s instructions (and Navy instructions)

specify what type of classification an item should hold,

how it will be marked, and when that condition should

beset.Thecommandingofficeroftheshipisauthorized

by instruction to alter this toasmallextent if he/she

desiresbutbasicallythissystemisstandardNavywide.

XRAY. Provides the leastwatertight integrity and

the greatest ease of access throughout the ship. It is set

whenthethreattotheshipisminimal.Condition XRAY

is set duringworking hours when the ship is in port,

when there is no danger of attack, and when there is no

threat from bad weather. Allfittings marked with a

blackXand circleXare closed when condition XRAY

is set.

YOKE. Providesagreater degree ofwatertight

integrity than condition XRAY but t oalesser degree

than the maximum condition.YOKE is normally set at

sea and in port duringwartime. Allfittings marked with

Xs and Ys, Circle X, and CircleYare closed when

condition YOKE is set.

ZEBRA. Provides the greatest degree of

subdivision andwatertight integrity to the ship. It is the

maximum state of readiness for the ship’s survivability

system. Condition ZEBRA is set when the following

situations occur:

1. Immediately when GQ is sounded

2. When entering or leaving port in wartime

3.Tolocalize damageandcontrolfireandflooding

when the crew is not at GQ

4. At any time the CO deems the maximum

condition of survivability should be set

Allfittings marked withXorY,Circle X, CircleY,

Z,Circle Z, and DOG Zs are closed when condition

ZEBRA is set.

The setting of material conditions is normally

carriedoutby thedivisionor department responsiblefor

the compartment and is accomplished by using the

compartment checkoff lists (CCOLs). In an emergency

the repair party personnel responding to the casualty

assisted by those Sailors in the area will set the required

condition to restrict the spread of damage. CCOLs are a

tool used by repair party personnel tofind the damage

controlfittings and closures in each compartment. The

fittings and closures are identified by name (type) and a

number that represent the location of thefittingby deck,

theframe itis locatedat,andthesideofthe spacesimilar

to the compartment identification process. The CCOL

list is posted in each space near the entrance and should

bekept up to date by the division whoowns the space.

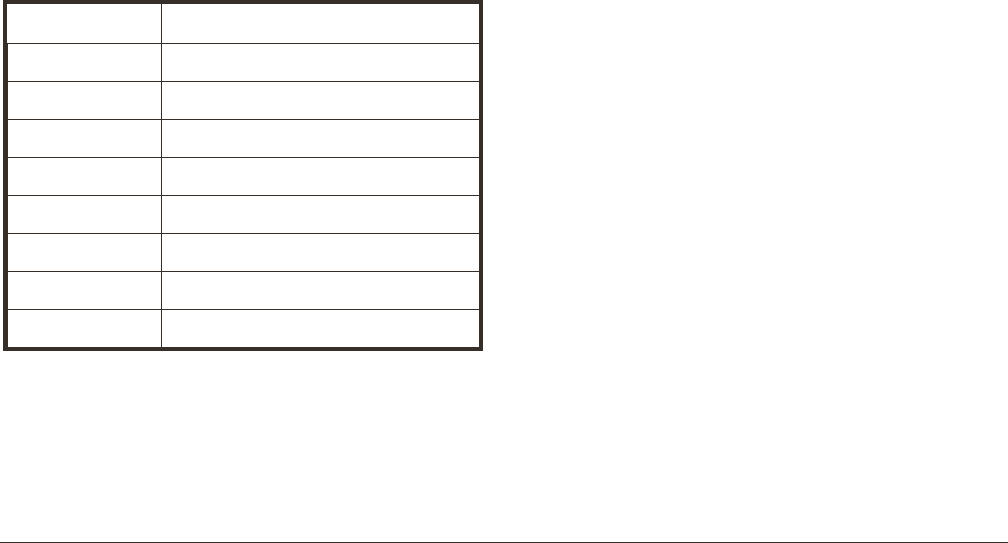

An example of a CCOL is shown in (fig. 12-2).

The normal setting ofamaterial condition should

be logged in the Damage Control Closure Log by each

division or repair party completing the setting. Any

exceptions to the setting should also be noted in the log

so DCC/OOD areaware of the reduction in the ship’s

ability to restrict the spread of potential damage. This

log and the Inoperative Fitting Log are maintained in

either DCC or on the quarterdeck by the OOD. If you

have a need to break (open)afitting that should be

normally set inaspecific condition, you mustfirst

request it open and then log it in before opening the

fitting. If you don’t do this, you are in violation of the

setting and have jeopardized your shipmate’s survival.

When you have completedwork inaspace that you

neededafitting/closure open, close itfirst, then log it

closed. Now those who maintain the log will have a

clear picture of what is open and closed inagiven area

of the ship. In addition to the closure log,alog for

inoperative fittings and closuresexists. As its name

implies,thislog lists all DC-relatedfittingsand closures

on the ship that don’t work properly. It becomes a

tracking tool for future maintenance.

A modified conditionYOKE or modified condition

ZEBRA is sometimes set, rather than the normalsetting

of XRAY, YOKE, or ZEBRA. These are settings of

convenience at the discretion of the CO.

12-11

Student Notes:

12-12

COMP’T NO. 2-108-1-L NAME Crews Berthing (LSD Wing Wall)

ITEM FITTING NUMBER LOCATION AND PURPOSE CLASSIFICATION

DIVISION

RESPONSIBLE

1

2

3

ACCESS

WT DOOR

WT DOOR

WT HATCH

2-108-1

2-129-3

2-108-1

Access to: 2-96-1-L

Access to: 2-120-1-L

Access to: 3-108-1-L

Z

X

X

REPIII

REPIII

S

MISCELLANEOUS CLOSURES

4

5

ATC

ATC

2-108-1

2-108-1

In WITH 2-108-1 used to test:

3-108-1-L

3-103-3-A

3-115-1-A

In WTD 2-108-1 used to test:

2-95-1-L

X

X

E

E

6

7

8

DRAINAGE

DECK SOCKET

(remote)

STC

GAGGED SCUPPER

2-112-1

2-118-1

2-109-1

Bilge eductor overboard

discharge valve 5-112-1

Sound Ball 6-108-1-W

Plumbing drain from

1-110-1-L

X

X

Z

M

R

REPIII

FIRE MAIN & SPRINKLING

SYSTEM AND WASH DOWN

9

10

FMCOV

FMCOV

2-109-1

2-110-1

Cut out to FP 1-109-1

Cut out to Group IV magazine

sprinkler

W

W

REPIII

REPIII

FUEL OIL

11 STC 2-116-1 Sound F.O. & Ball. 6-108-3-FX B

REMOTE OPERATION

12 Remote start/stop switch 2-119-1 For exhaust blower 2-108-1Z REPIII

MISCELLANEOUS UNCLASSIFIED

13

14

15

16

Loud speaker

C.P. Riser Terminal

15 lb CO

2

One OBA

2-114-1

2-119-1

General announcing 1 MC

Casualty Power Outlet

Portable fire extinguisher

In box at Fr. 110 stbd.

Figure 12-2.—Compartment checkoff list.

Student Notes:

A modifiedYOKE is sometimes used at sea when

cruising independently in good weather and calm seas

and in port in peacetime. In the modified condition,

YOKEfi+ttings above thewaterline are left open to

improve ventilation and habitability. All other XRAY

and YOKE fittings shipwide will be closed unless

logged on a case-by-case basis as discussed earlier.

An alternative to the setting of ZEBRA shipwide is

the setting of modified ZEBRA. Anexample of the

setting of modified ZEBRAwould be setting Zebra on

the DC deck and below only if the area the shipwas

transiting was a known or suspected hazardous

navigational area. This would provide a higher

survivability stance than conditionYOKE. At the same

timemodifiedZEBRAisless restrictive in therestofthe

ship and will more readily allow theaccomplishment of

other operational requirements. Modified ZEBRA may

result as an upgrade from conditionYOKE or as a

downgrade from condition ZEBRA.

SPECIAL CLASSIFICATIONS

Circle XRAY and YOKE. These fittings are

access fittings to battle stations and compartments

containing equipment that require periodic checks or

fittings that must be opened for ammunition transfer, as

well as some systems.

Circle XRAY and YOKE fittings are normally

closed when condition XRAY o rYOKE are set. They

may be opened without special authority when going to

or securing from general quarters, transferring

ammunition, during periodic space or equipment

checks, or during operation of damage control

equipment. Circle XRAY and YOKE fittings are

marked withablackXorYinablack circle. They

should be secured once passage is complete.

Circle ZEBRA. Thesefittings are closed when

condition ZEBRA is set. They may be opened with the

permission of the CO only. This would be during

extendedperiods of general quarters for the preparation

and distribution of battle messing, to provide access to

sanitaryfacilities, toventilate battle stations, to transit

from squadron ready rooms to the flight deck, and to

allow limited access throughout the ship as the CO

prescribes.

Open Circle ZEBRAfittings must be guarded so

they can be closed immediately because the ship is still

inabattle station position when ZEBRA is set. Circle

ZEBRAfittings are marked witharedZsurrounded by

a red circle.

DOG ZEBRA. Thesefittings are secured when

condition ZEBRA is set and whenever the shipis set for

“darkenship,” whichisanight steamingcondition, nota

material condition. During darken ship thesefittings

and closures are closed to prevent light inside showing

to the outside. DOG ZEBRAfittings are marked with a

red Z surrounded by a black letter D.

NOTE

Darkenship isanight steaming condition,not a

material condition.

WILLIAM. Thesefittings are vital sea suctions,

ventilationfittingsvalves serving vital equipment, and

valves that must be open to maintain mobility andfire

protection. WILLIAM fittings are open during all

material conditions. They are secured only to control

damage, contamination, or to repair equipment served.

WILLIAMfittings are marked withablack colored

letter W.

Circle WILLIAM. Thesefittings, like WILLIAM

fittings,arenormallyopenbutaresecured forprotection

in CBR attack. Fittings that are marked with this

classification are those that provideventilation opening

to the outside of the ship. Circle WILLIAMfittings are

marked with a black W surrounded by a black circle.

REVIEW 4 QUESTIONS

Q1. What is the most important feature ofaship to

ensure its survivability?

12-13

Student Notes:

Q2. List the three basic material conditions of

readiness.

a.

b.

c.

Q3. What material condition provides the least

amount ofwatertightness?

Q4. When is YOKE normally set?

Q5. What material condition is set when GQ is

sounded?

Q6. What fittings are closed to set darken ship?

Q7. To find a list of all DC fittings within a

compartment, you should refer to—

LIFE SUPPORT EQUIPMENT

LearningObjective: When youfinish this chapter, you

will be able to—

•

Identify life support equipment used aboard

ship.

All life support devicesdiscussedinthis chapter are

designed to allow the wearers to breath (and thereby to

escape),continuework,and assistin savingtheshipand

their fellow crew members. Remember that the crew

must save the ship or no one will be saved. Therefore,

the purpose of this section of the chapter is to provide

you with information on the emergency escape

breathing device (EEBD), supplemental emergency

egress device (SEED), oxygen breathing apparatus

(OBA), and self-contained breathing apparatus

(SCBA).

EMERGENCY ESCAPE BREATHING

DEVICE (EEBD)

Studies offire casualties have proven that most

casualties are the result of smoke and toxic fumes and

not from thefire itself.Forthis reason, the EEBD (fig.

12-3)wasdeveloped for emergency escape. It provides

the wearer with 15 minutes of breathable air. It is to be

worn until you can get topside duringevacuation from

below deck spaces. The EEBD is designed to provide

respiratoryandeyeprotectioninanatmospherethatwill

not support life.With the proper training you should be

able to activate and don an EEBD in less than 30

seconds.

12-14

Student Notes:

Figure 12-3. —emergency escape breathing device (EEBD)

WARNING

EEBDs must not be used for firefighting

purposes.

WARNING

Remember, when donning the EEBD, if you

don’t hear the hissing sound of oxygen being

generated, discard the unit and get another.

DANGER

Don’t smoke immediately after using the

EEBD because your hair is saturated with

oxygen and could catch on fire.

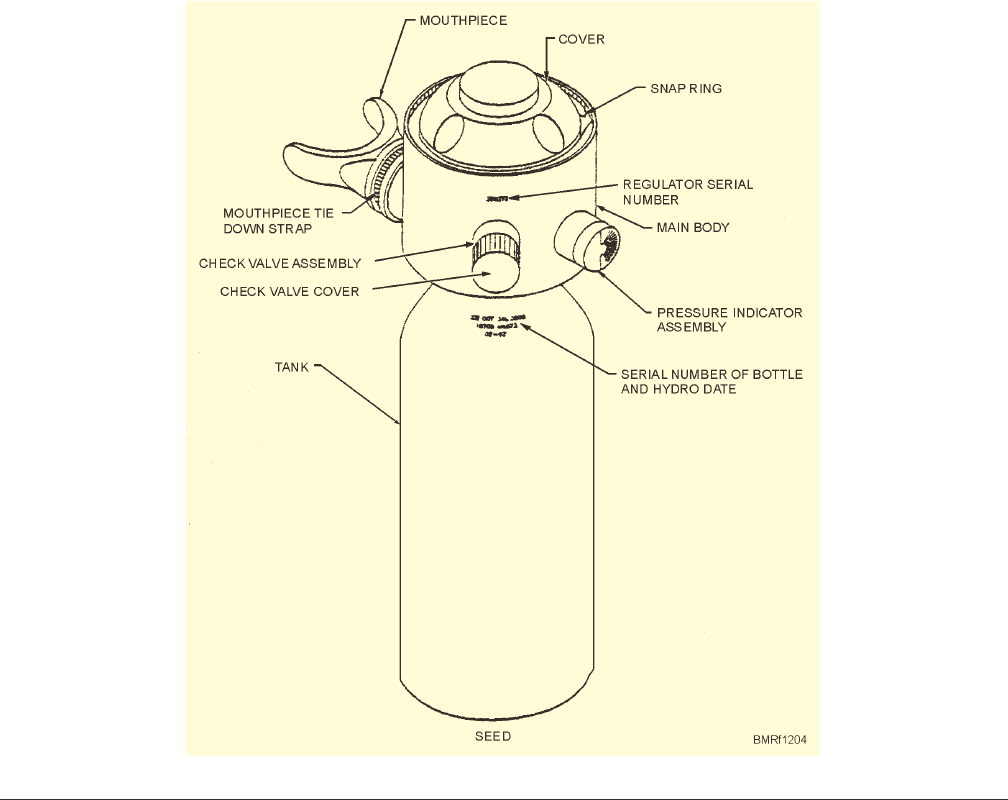

SUPPLEMENTAL EMERGENCY EGRESS

DEVICE (SEED)

Personnel working in engineering spaces wear

supplemental emergency egress devices (SEEDs) on

their belts for easy access. Whenamain spacefire is

calledaway, thewatch stander should use the SEED

(fig. 12-4) to proceed to an EEBD. Thewatch stander

should obtain an EEBD and don it when not in danger

of immediate harm from heat or flames. Because the

SEED lacks protection for the eyes and nose and has a

short operational time, it is a supplemental device.

However, it is immediately available for the

engineering watch standers and is easily operated on

the run. Factors to consider when using these devices

include the following:

12-15

Student Notes:

Figure 12-4.—Supplemental emergency egress device (SEED).

•

How quickly conditions are deteriorating

•

Ease of egress, including travel time to a

breathable atmosphere

•

Operating times for each device

•

Capabilities and limitations of each device

WARNING

Don’t breath through the nose—breath only

through the mouth when using the SEED.

WARNING

SEEDs must not be used for firefighting

purposes.

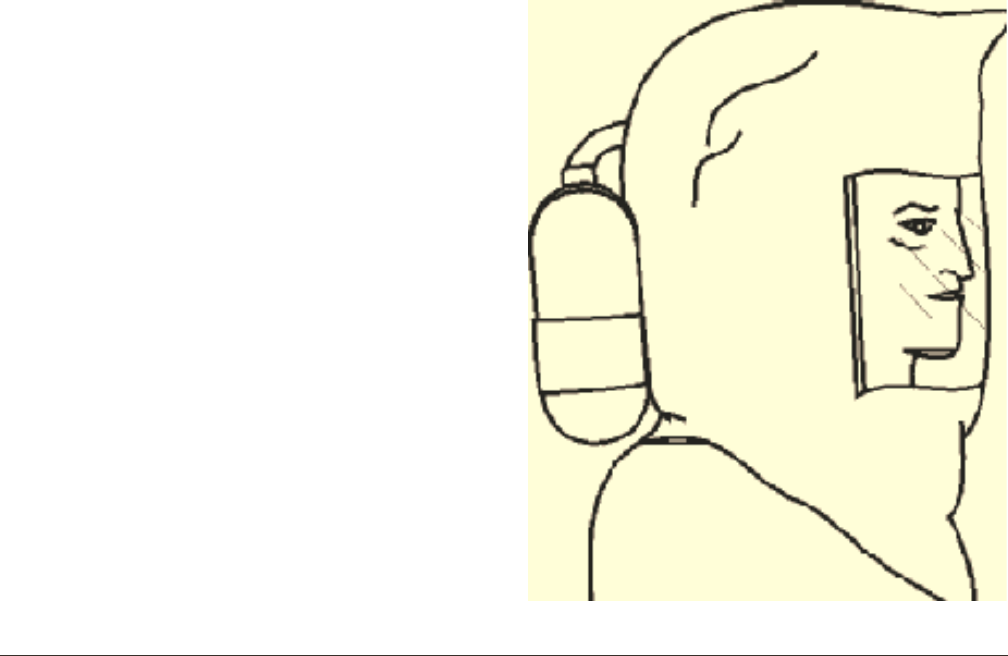

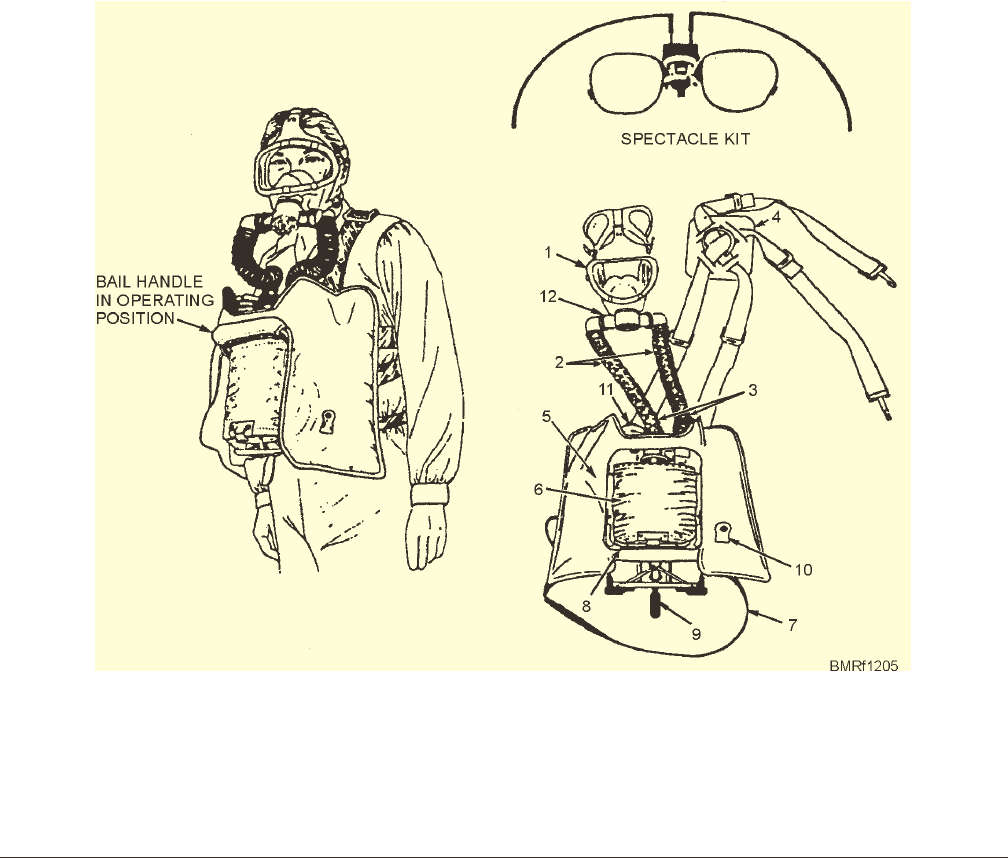

OXYGEN BREATHING APPARATUS (OBA)

The oxygen breathing apparatus (OBA) (fig. 12-5)

isaself-containeddevicethat generatesoxygenthrough

a chemical process and lets the wearer breathe

independently of the surrounding atmosphere.

Currently, the OBA is the primary tool used by

firefighting teams for respiratory protection. The

effective time limit of the oxygen supply is inexcess of

12-16

Student Notes:

1.

2.

3.

4.

Facepiece

Breathing tubes

Breathing tube couplings

Body harness and pad

5.

6.

7.

8.

Breathing bag

Breastplate

Waist strap

Bail assembly handle

(standby position)

9.

10.

11.

12.

Canister release strap

Pressure relief valve and

pull tab timer

Timer

Valve housing

Figure 12-5.—Navy oxygen breathing apparatus (OBA).

45 minutes.Foryour personnel protection you should

set the timer on the OBA for 30 minutes, allowing

15 minutes to leave the area and return to fresh air.

When in operation, the air within the apparatus is

continuously replenished with oxygen while the

chemicals in the canister remove exhaled carbon

dioxide (CO

2

) andwatervapor. Asaresult of this

chemical action, the OBA wearer may survive andwork

in a toxic atmosphere, such as a smoke-filled

compartment.With thefacepiece and canister in place,

using the OBA formsaclosed self-sustaining system.

For personnel having eyeglasses, a spectacle kit is

availableforthe installation of prescription lenses inthe

facepiece.

WARNING

When removing the candle cover, do not

remove the cotter pinwhile pulling the lanyard.

Removal of the cotter pinfires the candle and

starts generating oxygen. If that happens while

the copper foil is intact, internal pressure in the

canister willbuild up,causing thecopper foil or

canister seam to rupture. Do not pull the cotter

pin until the canister is inserted in the OBA and

the bail assembly is up and locked.

CAUTION

Do not pull the breathing bagtab duringnormal

use because the oxygen in the bags will leak

into the atmosphere, causing loss of your

breathing oxygen.

WARNING

Never allow grease, oil, orwater to enter the

neck of the canister. Any of these liquids may

causeaviolent chemical reaction orexplosion.

The chemicals contained in the canister are

injurious to skin and equipment.

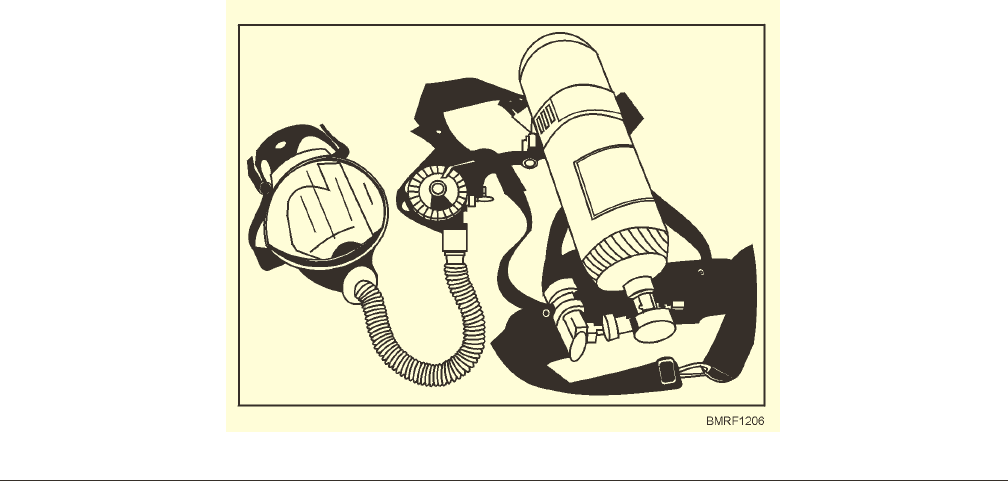

SELF-CONTAINED BREATHING

APPARATUS (SCBA)

The self-contained breathing apparatus (SCBA)

(fig. 12-6) is replacing the OBA throughout the Navy.

The unit’s main components consist of a harness,

high-pressure bottle, pressure regulator, full-face mask,

and the high- and low-pressure hoses as shown below

High-pressure aircylinders arefilled with compressed

gradeDbreathing air and then stored until needed. The

cylinders themselves are rechargeable, replacing the

need for additional canisters in the OBA system.

12-17

Student Notes:

Figure 12-6.—Self-contained breathing apparatus (SCBA).

Once thecylindervalve has been turned on, it

providesacontinuousair supply to the system regulator

via the high-pressure hose. The pressure is reduced by

the regulatorforuse by the wearer, and the low-pressure

hose carries the breathable air into thefacepiece. As a

safety feature, these are positive pressure style

regulators, which means that the air supply to the mask

is just above any demand requirements eliminating any

possibility of toxic fumes from entering the wearer’s

mask.

Thetime eachcylinderlasts willbe determined bya

number offactors. The mainfactors will be the physical

condition and size of the wearer and thework to be

done. Generally, each bottle will last approximately 30

minutes from the time it is activated.

REVIEW 5 QUESTIONS

Q1. How many minutes of air is the EEBD designed

to provide?

Q2. Why should you stayawayfrom open flames

when you first remove an EEBD?

Q3. What should you listen for when donning an

EEBD?

Q4. What device is worn by engineering watch

standers?

Q5. What is the effective time of an OBA?

Q6. When do you pull the cotter pin on an OBA

canister?

FIREFIGHTING

Learning Objectives: When youfinish this chapter,

you will be able to—

•

Recognize the properties ofafire triangle and

fire tetrahedron.

•

Identify the conditions necessary for

spontaneous combustion.

•

Identify the types of heat transfer.

Fire isaconstant threat aboard ship. All possible

measures must be taken to preventafire, or if one is

started, toextinguish it quickly. Fires may start from

several causes—spontaneous combustion,

carelessness, hits by enemy shells, or collision. If the

fireis notcontrolled quickly, it may cause moredamage

than the initial casualty and could cause the loss of the

ship.

FIRE AND FIREFIGHTING

You cannot win againstafire.Youcanfight thefire

and you can hold down its damage;butsome property

will be destroyed and, all too often, people will be

injuredorkilled.Timeisalwayslost,productive workis

stopped,andadditional effortand materials are required

to make repairs and to clean up the mess.

The objective offire prevention, therefore, is to

prevent fires from starting. Fire prevention is an

all-hands, all-day, all-night, heads-up effort.Acigarette

tossedin the wrongdirectioncan causeasmuchdamage

asanenemy bomb. An oilywipingragorasparkingtool

can be as dangerous as an open flame inagasoline

depot.

Each ship is required to institute and maintainafire

prevention program.Your part in thefire prevention

program is as follows:

•

Ensure that all gear is stowed properly.

12-18

Student Notes:

•

Practice good housekeeping procedures, such as

the daily removal of trash from spaces.

•

Practice safety precautions whenworking with

flammable materials.

•

Report all potential fire hazards.

•

Keepfirefighting equipment handy and in good

working order.

•

Ensure closures and fittings are working

properly and report any discrepancies.

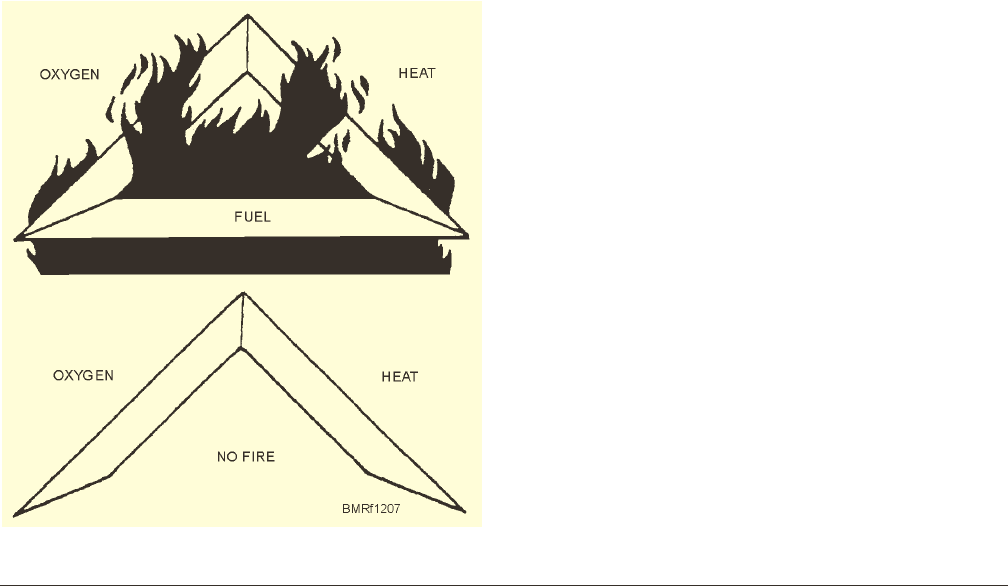

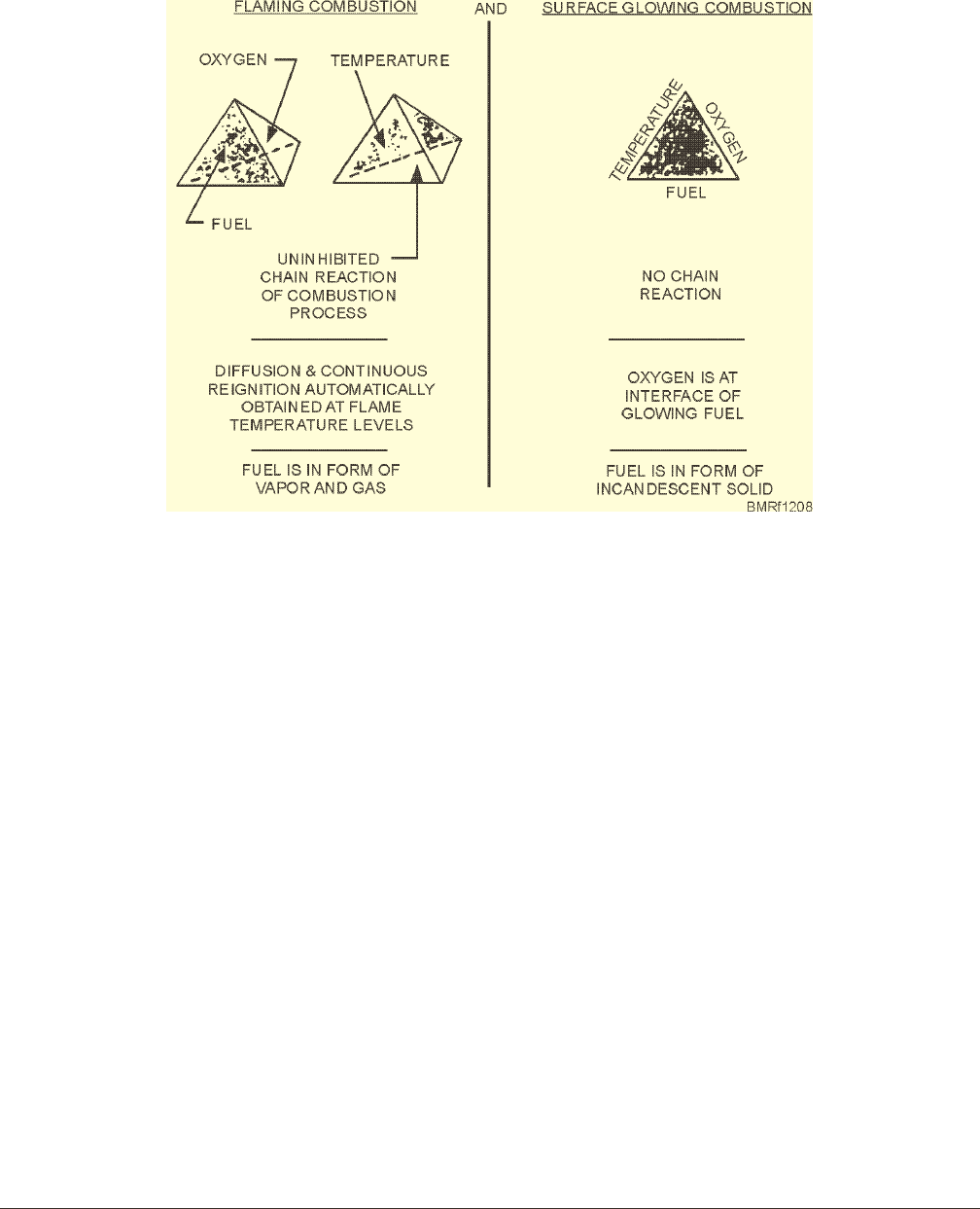

FIRE TRIANGLE

The entire chemistry and physics of fire and

burning, or combustion, can be simplified into a

relationship between three components—fuel, heat

(temperature), and oxygen (air).Tohaveafire in any

combustible substance, each one of these components

must be present to help each other. Picture these

components in the form ofatriangle, as shown infigure

12-7.

Look atfigure 12-7. Here, you can see that if the

oxygenreacts with thefuel,it creates heat,whichcauses

a draft or some other condition that takes in more

oxygen and creates still more heat, and so on. Or the

heat may cause more fuel to becomeavailable (such as

causinggasoline to boil intovapor), which then takes

more oxygen toburn and creates more heat, which then

producesstill morefuel,andsoon. Theburningreaction

can go in many different directions.

The modern science of firefighting and fire

extinguishment is based on the sides of thefire triangle

and an uninhibited chain reaction of burning.

Obviously, thefirefightercanremove one or more of the

components to cause theburning to stop. The type of

firefighting agent thefirefighter has at hand determines

which component or components of the triangle will be

removed.

Anotherwaythefirefightercanstop thefire(andthe

combustion) is to place a screen between any two

components of the triangle. If thefighter uses an agent

asatemporary screen that breaks the triangle, thefire

goesout.Obviously, thefirecan quickly startupagainif

this method is used because each of the three necessary

components is still therewaiting to start thefire again

once the screen is gone.

FIRE TETRAHEDRON

Thefire triangle describes the requirements for

surface glowing or smoldering, but it doesn’t

completely describe flaming combustion requirements.

A fourth requirement, an uninhibited chain reaction, is

needed for flames toexist. This is shown by thefire

tetrahedron (fig. 12-8).Atetrahedron isasolidfigure

with four triangularfaces. It is useful for illustrating the

flaming combustion process because it provides for the

chemical chain reaction requirement and each face

touches the other three sides. As described for thefire

triangle, flaming combustionstops whenone of thefour

sides of the fire tetrahedron is removed.

SPONTANEOUS COMBUSTION

Fire, also called burning or combustion, isarapid

chemical reaction that results in the release of energy in

the form of light and heat. Most spontaneous

combustion involvesvery rapid oxidation; that is, the

12-19

Student Notes:

Figure 12-7.—Requirements for combustion.

chemical reaction by which oxygen combines

chemically with the burning material.

Such things as rags or paper soaked with oil or with

paints or solvents are particularly subject to

spontaneous combustion if they are stowed in confined

spaces where the heat caused by oxidation cannot be

dissipated rapidly enough.

Afire involving combustible fuel or other material

must have an ignition source, and the material must be

hot enough toburn. The lowest temperature at which a

flammable material gives off vaporsthatwillburn when

a flame or spark is applied is called the flash point. The

fire point, whichisusuallyafew degreeshigherthan the

flash point, is the temperature at which the fuel will

continuetoburn after it has been ignited.Theignitionor

self-ignition point is the lowest temperature to which a

material must be heated to give off vapors that willburn

without the aid ofaspark or flame. In otherwords, the

ignition point is the temperature at which spontaneous

combustion occurs. The ignition point is usually at a

much higher temperature than the fire point.

METHODS OF HEAT TRANSFER

Heat fromafire is transferred by one or more of the

following methods:

1. Conduction

2. Convection

3. Radiation

Conduction

Conduction is the transfer of heat throughabody or

from one body to another by directphysical contact.For

example, onahot stove, heat is conducted through the

pot to its contents.Wood is ordinarilyapoor conductor

of heat,butmetals are good conductors. Since most

ships are constructed of metal, heat transfer by

conduction isapotential hazard. Fire can move from

onefire zone to another, one deck to another, and one

compartment to another by heat conduction.

Often, the skillful application ofwater, using fog

patternstorapidlycoatandrecoatsurfaceswithafilmof

water, will slow or halt the transmission of heat by

conduction.Fogpatterns coat surfaces more efficiently

12-20

Student Notes:

Figure 12-8.—Tetrahedron and fire triangle.

than solid streams, reducing run off and the effect on

ship stability.

Convection

Convection is the transfer of heat through the

motion of circulating gases or liquids. Heat is

transferred by convection through the motion of smoke,

hot air, and heated gases produced by a fire.

When heat is confined (as withinaship), convected

heat moves in predictable patterns. Thefire produces

lighter than airgases that rise toward high parts of the

ship. Heated air, which is lighter than cooler air, also

rises. As these heatedcombustion products rise, cool air

takes their place; the cool air is heated, in turn, and then

rises to the highest point it can reach.

Hot smoke originating atafire onalow deck will

travel horizontally alongpassageways, and then upward

by way of ladder and hatch openings, heating

flammable materials in its path.Topreventfire spread,

release the heat, smoke, andgases to the atmosphere.

However, the structural design of a ship makes it

difficult to rapidly cut openings through decks,

bulkheads, or the ship’s hull for ventilation. It is

imperative that thefire be confined to the smallest

possible area. Doors and hatchways should bekept

closed when they are not in use. Ifafire is discovered,

attempts should be made to close off all openings to the

fire area untilfirefighting personnel and equipment can

be brought into position to fight the fire.

Radiation

Heat radiation is the transfer of heat fromasource

across an intervening space; no material substance is

involved. The heat travels outward from thefire in the

same manner as light; that is, in straight lines. When it

contactsabody, it’s absorbed, reflected, or transmitted.

Absorbed heat increases the temperature of the

absorbing body. For example, radiant heat that is

absorbed by anoverhead will increase the temperature

of that overhead, perhaps enough to ignite its paint.

Heat radiates in all directions unless it’s blocked.

Radiant heat extends fire by heating combustible

substances in its path, causing them to producevapors,

then igniting the vapor.

Withinaship, radiant heat raises the temperature of

combustible materials near thefire and, depending on

the ship’s design, at quite some distance from thefire.

Shipfires can spread asaresult of radiatingbulkheads

and decks. Intense radiated heat can make an approach

to thefireextremely difficult.Forthis reason,protective

clothing should be worn by firefighters.

REVIEW 6 QUESTIONS

Q1. Fire prevention is the responsibility of—

Q2. List the three components that make up a fire.

a.

b.

c.

Q3. What process is involved in most cases of

spontaneous combustion?

Q4. List the three methods of heat transfer.

a.

b.

c.

CLASSES OF FIRE

LearningObjective: When youfinish this chapter, you

will be able to—

•

Recognize the four classifications offire and

identify the means used to extinguish them.

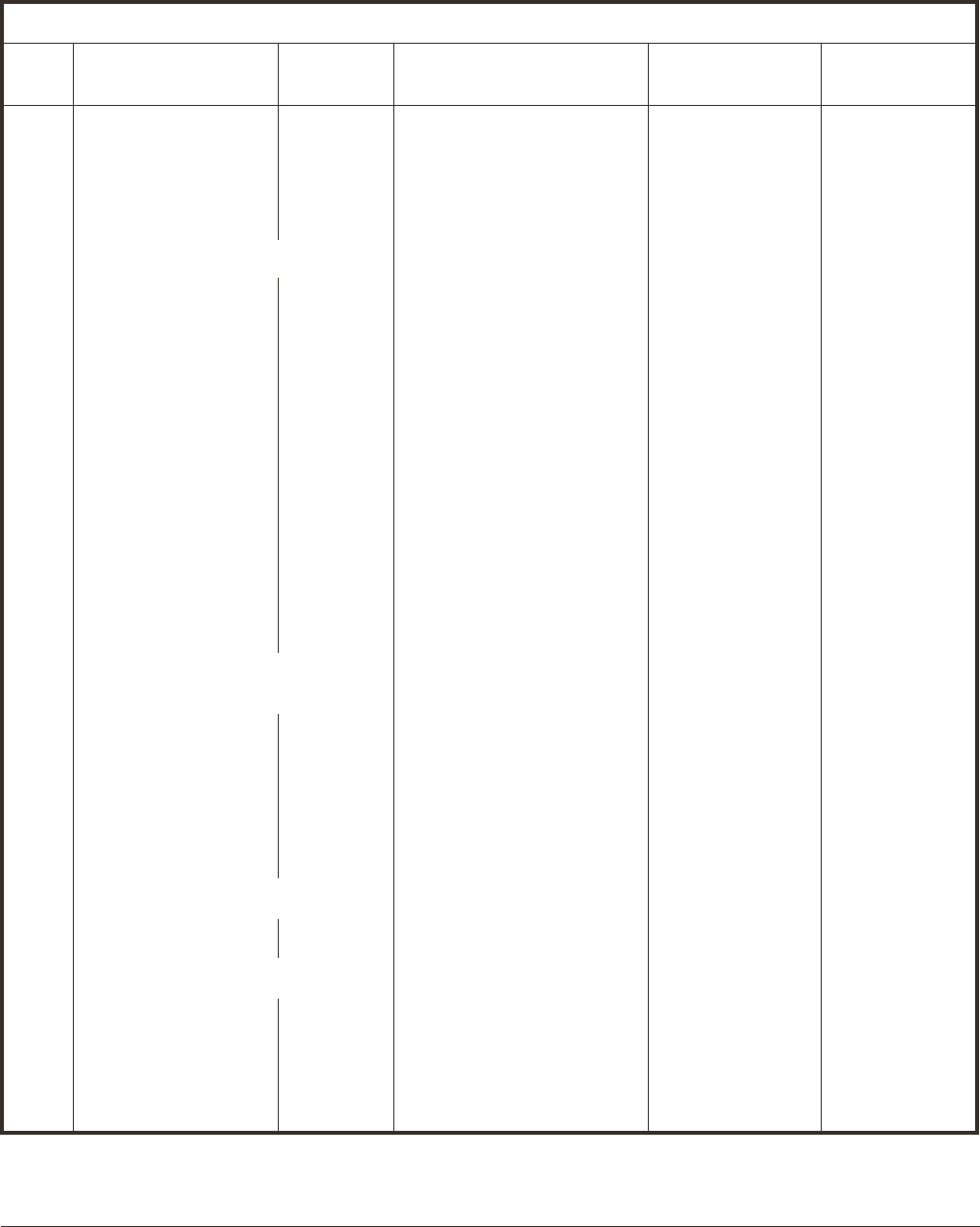

Fires are divided into four classifications, each

indicating the type of materialburning. By knowing the

12-21

Student Notes:

class offire, the primary agent and best method for

extinguishing thefire can be determined as shown in

figure 12-9.

Many substances,such as liquids,gases, and solids,

are used asfirefighting agents. The selection and use of

theseagentsvarieswiththe classoffire,itslocation,and

theextent of thefire involvement. Although seawater is

the mostvaluablefirefighting agentavailable based on

its endless supply, considerations should always be

takentodetermineifwateristhe bestagent toputoutthe

type of fire being fought.

REVIEW 7 QUESTIONS

Q1. Match the class offirewiththe types of materials

involved.

12-22

Student Notes:

CLASSES OF

FIRE

TYPES OF MATERIALS

INVOLVED

METHOD(S) OF EXTINGUISHING

A

Wood and wood products,

cloth, textiles and fibrous

materials, and paper and

paper products.

Water in straight or fog pattern. If the fire is deep-seated,

aqueous film forming foam (AFFF) is more effective than

seawater and can be used as a wetting agent.

B

Flammable liquids, such as

gasoline, diesel fuel (F-76),

jet fuels, hydraulic fluid, and

lube oil. Also, involves

flammable gases.

Extinguished with AFFF, Halon 1211, Halon 1301, or

potassium bicarbonate (PKP). Never extinguish flammable

gases unless there is a good chance that the flow of gas can

be secured. Securing the flow of gas is the single most

important step in controlling a gas fire.

C Energized electrical fires.

Use nonconductive agents, such as CO

2

, Halon 1211, or

water spray. Most effective tactic is to de-energize and

handle the fire as a class A fire. If fire isn’t deep-seated,

clean agents that don’t a cleanup problem are preferred

(CO

2

or Halon 1211).

D

Combustible metals, such as

magnesium and titanium.

Water in quantity, using fog patterns. When water is

applied to burning class D materials, explosions may occur.

Apply water from a safe distance or from behind shelter.

Figure 12-9.—Classes of fire.

MATERIALS CLASSES OF FIRE

a. Hydraulic fluid A

b. Energized circuit board B

c. Paper C

d. Gasoline D

e. Magnesium

f. Cloth

g. Titanium

Q2. What is the mostavailable heat-removing agent

for shipboard use?

Q3. AFFFwasdeveloped to combat what class of

fire?

Q4.

CO

2

is the primary agent to disrupt the fire

triangle of what class fire?

Q5. Whatisaneffective agentagainstaclassDfire?

DAMAGE CONTROL EQUIPMENT

LearningObjective: Whenyoufinish this chapter, you

will be able to—

•

Identify the portable equipment and fixed

systems that make up the shipboard inventory of

protection equipment.

As you’ve learned in this chapter, damage control is

anallhands job. Thetime ittakesto getafireor flooding

under control is vital.Youshould becomefamiliar with

the portable equipment andfixedsystems that make up

your ship inventory of protection equipment. Because

of the large amount ofexplosives, fuels, and other

flammablematerialsaboard ship, you must know where

equipment is located and how to use it before an

emergency exists.

Knowing where equipment is and how to use it

applies not only tofirefighting equipmentbutalso the

equipment used for flooding or CBR protection. The

equipment and its storage locationvaries from ship to

ship, so you must know your ship.

You mayfind yourself thefirst person on the scene,

so knowing the basic rules of damage control and

equipment usage may make the difference in the loss of

many spaces orashipmate’s life. Perhaps you will be

called to serve onafire party or flooding detail. As a

team member, keep in mind, the lack of equipment and

procedures could result in a disastrous outcome.

Figures 12-10 through 12-15 show someexamples

of the equipment that’s common to all ships. These

figures show onlyasmall amount of what you’llfind in

a ship’s repair locker.

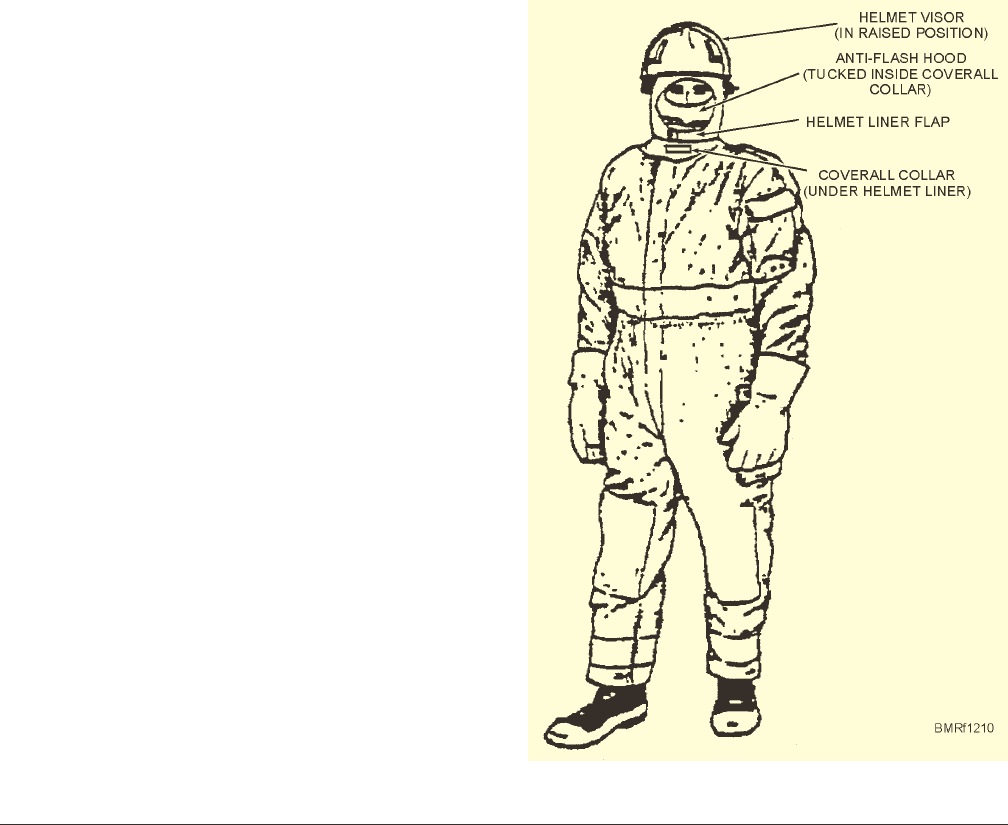

THE FIREFIGHTER ENSEMBLE

Thefirefighter’s ensemble (fig. 12-10) is used to

protect thefirefighter from short duration flame (flash)

exposure, heat, and falling debris.

12-23

Student Notes:

Figure 12-10.—Firefighter’s ensemble.

ANTI-FLASH CLOTHING

Anti-flash clothing (fig. 12-11) is used to protect

personnel from high temperatures resulting from the

useofexplosive weapons andfromburnscaused byfire.

The clothing consists of the following two items:

1. Anti-flash hood

2. Anti-flash gloves

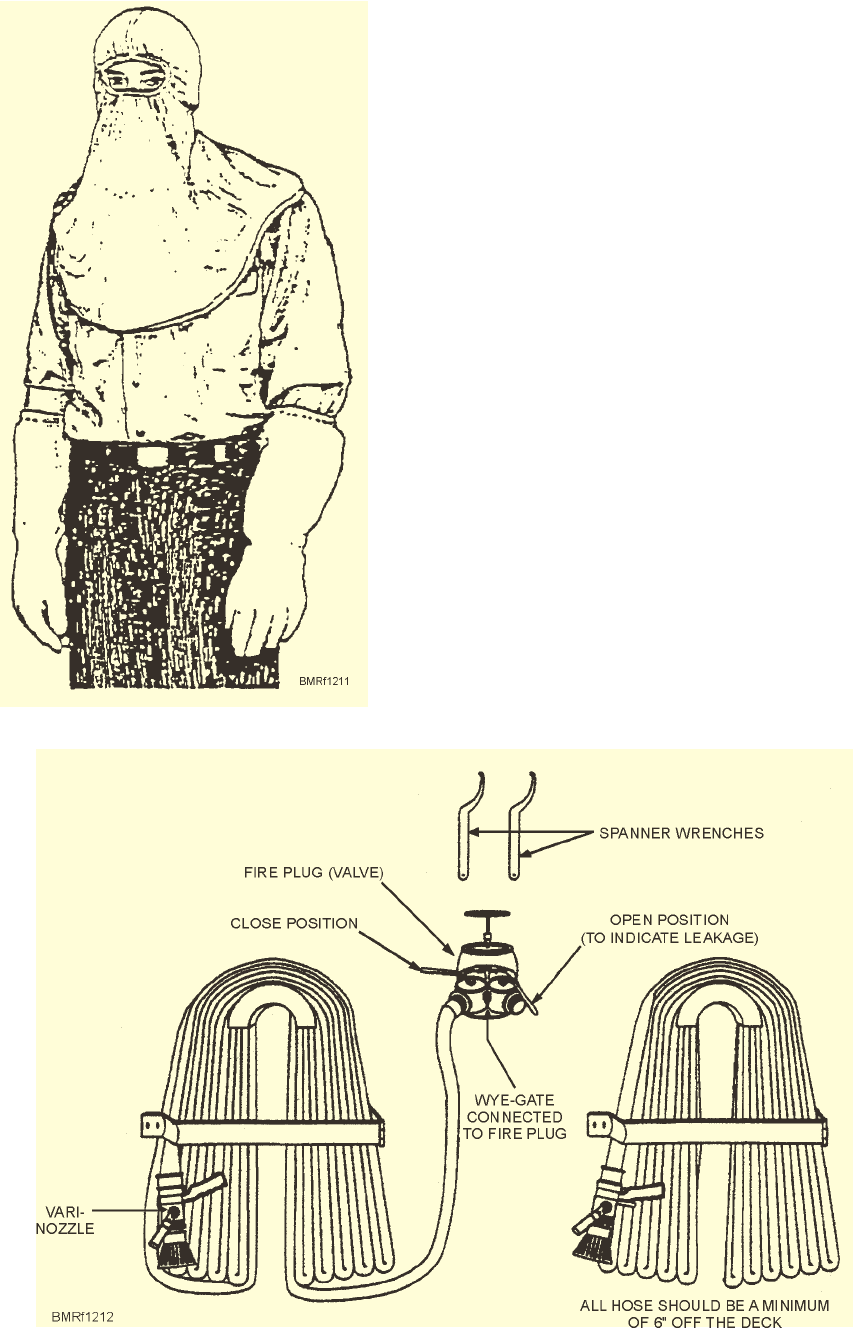

FIRE HOSE STATION

A fire hose station (fig. 12-12) is commonly

referred to as either a fire station or a fireplug. Thefire

hose station is the location ofafireplug and associated

equipment. Branches of thefiremain system supply

water to thefire hose stations throughout the ship.

Generally, fire hose stations aboard frigates and larger

ships have 1 1/2-inchfireplugs andfire hose stations

aboard ships larger than frigates have 2 1/2-inch

fireplugs.

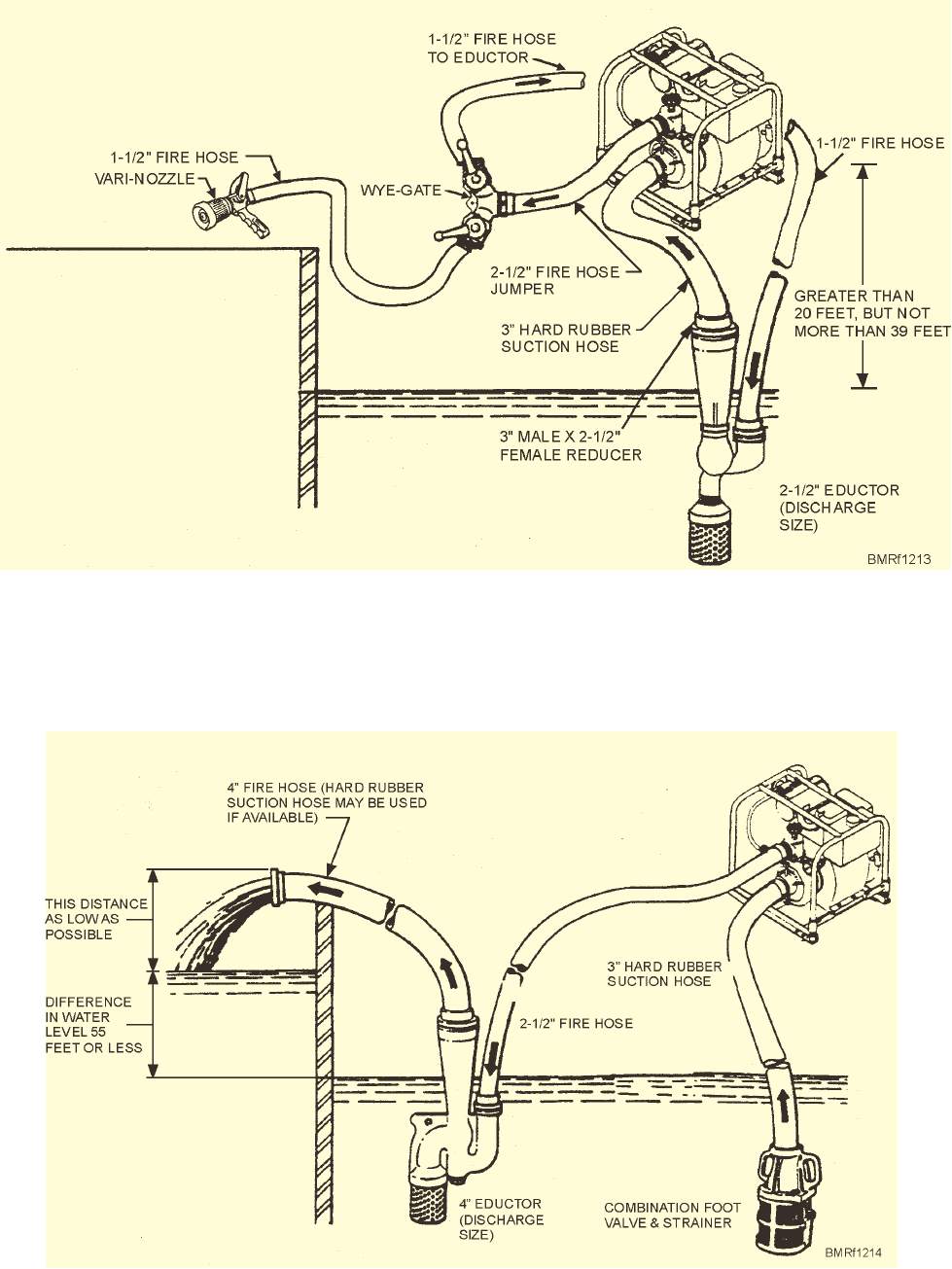

P-100 PUMP

The P-100 pump is a diesel-engine-driven

portable pump unit. It’s designed for firefighting (fig.

12-13) and limited dewatering (fig. 12-14) functions

aboard ships.

12-24

Figure 12-12.—Fire hose station.

Figure 12-11.—Anti-flash clothing.

12-25

Figure 12-14.—Dewatering hookup.

Figure 12-13.—Firefighting hookup.

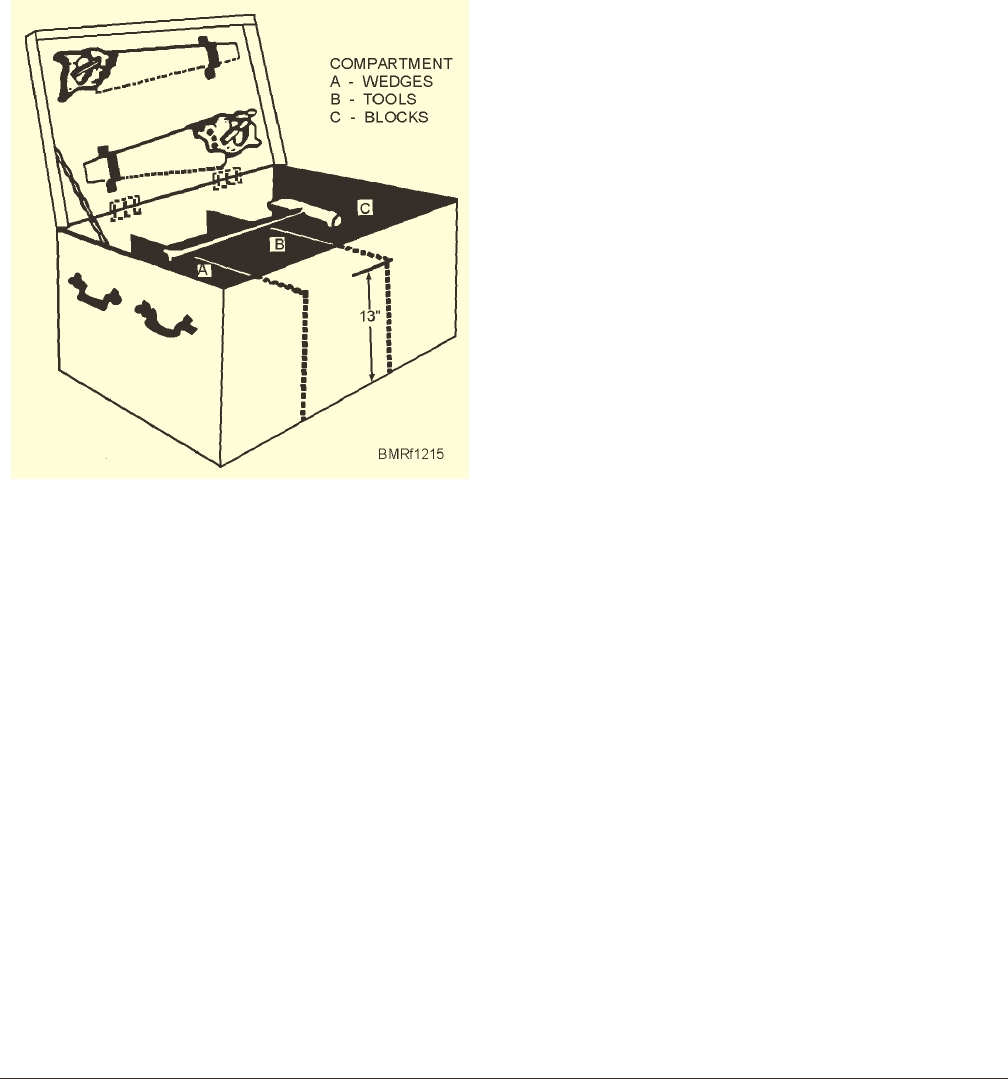

DAMAGE CONTROL SHORING CHEST

Each repair station hasadamage control shoring

chest (fig. 12-15). The chest is divided into three

compartments to separate the different tools and

materials needed for shoring.

REVIEW 8 QUESTION

Q1. Describe the purpose of the following items.

a. Damage control shoring chest

b. P-100 pump

c. Firefighter ensemble

d. Anti-flash clothing

e. Fire hose station

SUMMARY

A ship lives or dies depending on its crew’s ability

to combat a wide range of casualties, and these

casualties are not restricted to times of conflict.

Casualties can occur while moored in your homeport,

at anchorageoverseas, or duringaroutine peacetime

deployment. The requirement for every person on

board, from the commanding officer to thefireroom

messenger, to have a good,basic knowledgeof damage

control procedures and constant training and drills in

combating shipboard casualties is essential to the

ship’s survival. This training and preparation

demonstrated during the Persian Gulf crisis saved

several U.S. Navy ships that sustained considerable

damage. If these crews had not been trained in damage

control, these ships and most likelyalarge portion of

their crews may have been lost.

The proper use of the closure log is just as

important as knowing how to don an OBA or useafire

hose. Thebusiness of damage control is serious. Learn

it well; your life, the lives of your shipmates, and your

ship depend on it.

REVIEW 1 ANSWERS

A1. The damage control organization is divided into

the—

a.

Administrative organization

b.

Battle organization

A2. The purpose of the administrative phase of DC

is to establish and maintain material

readiness conditions.

A3.

The engineer officer is responsible for

maintaining properly trained DCPOs, repair

parties, and repair locker personnel.

A4.

The XO is the senior person assigned as team

leader on DCTT.

12-26

Figure 12-15.—Damage control shoring chest.

Student Notes:

A5.

The DCPO is responsible for making sure that

all battle lanterns, dog wrenches, spanners, and

other damage control equipment are inplace and

in a usable condition within their division.

A6. Beforeanyoneentersapoorlyventilatedspaceor

void, the gas free engineer (GFE) certifies the

space as safe.

REVIEW 2 ANSWERS

A1.

The battle phase of damage control starts when

the ship receives actual damage.

A2.

The battle station for the DCA is DCC/CSS.

A3. DCC receives reports and casualty status from

repair parties.

A4. Theminimumrequirement to beamember of the

in-port emergency team is to be repair party

qualified.

A5. The primary missions of the rescue and

assistance team are to assist persons from the

water, other units in distress, and other

persons or activities in distress ashore.

A6.

General quarters is the highest state of

readiness.

REVIEW 3 ANSWERS

A1. The X40J circuitry is commonly referred to as

the salt and pepper line.

A2. The alarms that canoverride the microphone

control of the IMC are the

a.

Collision

b.

Chemical attack

c.

General

d.

Flight crash

A3. When all communications systems fail,

messengers are used to deliver messages and

orders between repair lockers and DCC.

REVIEW 4 ANSWERS

A1. Survivability of the ship can be ensured by

compartmentation.

A2. The three basic material readiness conditions

are—

a.

XRAY

b.YOKE

c.

ZEBRA

A3.

Material condition XRAY provides the least

amount ofwatertightness.

A4.

Normally, YOKE is set at sea and in port during

wartime.

A5.

Material condition ZEBRA is set when GQ is

sounded.

A6.

DOG ZEBRA fittings are closed to set darken

ship.

A7. To find a list of all DC fittings within a

compartment, you should refer to the

compartment checkoff list.

REVIEW 5 ANSWERS

A1.

The EEBD is designed to provide 15 minutes of

air.

A2.Youshould stayawayfrom open flames when

youfirst remove an EEBD becauseyour hair is

saturated with oxygen and could catch fire.

A3. When donning an EEBD, you should hear a

hissing sound.

A4.

Engineering watch standers wear a SEED.

A5.

The effective time of an OBA is 45 minutes.

A6.

You pull the cotter pin on an OBA after the

canister has been inserted in the OBA and

locked in place.

REVIEW 6 ANSWERS

A1.

Firepreventionisthe responsibilityof allhands.

A2. Thethreecomponentsthatmakeupafireare—

a.

Heat

b.

Fuel

c.

Oxygen.

12-27

A3. Most cases of spontaneous combustion involve

the process of rapid oxidation.

A4. The three methods of heat transfer are—

a.

Conduction

b.

Radiation

c.

Convection

REVIEW 7 ANSWERS

A1.

A2.

Sea water is the mostavailable heat-removing

agent for shipboard use.

A3.

AFFFwas developed to combat class B fires.

A4.

CO

2

is the primary agent to disrupt thefire

triangle of class C fires.

A5.

Waterfog is an effective agent againstaclass D

fire.

REVIEW 8 ANSWERS

A1. The purposes of the following items are as

follows:

a.

Damage control shoring chest. A chest thatis

divided into compartments for storing

materials used for shoring.

b.

P-100 pump. The P-100 pump can be used

to fight fires or to dewater spaces.

c.

Firefighter ensemble. The firefighter

ensemble protects personnel from short

duration flames, heat, and falling debris.

d.

Anti-flash clothing. Anti-flash clothing

protects personnel from heat caused by

high explosive weapons and fromburns

caused byfire.There are two items that

make up anti-flash clothing—anti-flash

gloves and the anti-flash hood.

e.

Fire hose station. Thefire hose station is

where the fireplug and associated

equipment is located.

12-28

MATERIALS CLASSES OF FIRE

a. Hydraulic fluid

B

b. Energized circuit board

C

c.Paper

A

d. Gasoline

B

e. Magnesium

D

f. Cloth

A

g.Titanium

D