Inquest into the deaths of Kate Goodchild,

Luke Dorsett, Cindy Low & Roozbeh

Araghi at Dreamworld, October 2016

Findings and Recommendations

February 2020

CORONERS COURT OF

QUEENSLAND

CORONERS COURT OF QUEENSLAND

INQUEST INTO THE DEATHS OF KATE LOUISE GOODCHILD, LUKE

JONATHAN DORSETT, CINDY TONI LOW, & ROOZBEH ARAGHI

Coroner, Southern Region

Credit for the above photograph is given to Mr. Richard Gosling, Newspix

CORONERS COURT OF QUEENSLAND

FINDINGS OF INQUEST

CITATION: Inquest into the deaths of Kate Louise GOODCHILD,

Luke Jonathan DORSETT, Cindy Toni LOW, &

Roozbeh ARAGHI

TITLE OF COURT: Coroners Court

JURISDICTION: SOUTHPORT

FILE NO(s): 2016/4486, 2016/4485, 2016/4480, 2016/4482

DELIVERED ON: 24 February 2020

DELIVERED AT: BRISBANE

HEARING DATE(s): 18 June 2018 to 29 June 2018

8 October to 19 October 2018

12 November to 22 November 2018

6 & 7 December 2018

FINDINGS OF: James McDougall, Coroner

CATCHWORDS: Coroners: inquest, Dreamworld, amusement device,

Theme Park, safety management systems, ride

maintenance, training, amusement device

regulation, amusement device designer, amusement

device modification, external safety audits.

REPRESENTATION:

Counsel Assisting

Mr Ken Fleming, QC

Ms Rhiannon Helsen, CCoQ

Family of Cindy Low

Mr Matthew Hickey, Counsel instructed by Clayton Utz

Findings of the inquest into the death of Kate Louise Goodchild

Luke Jonathan Dorsett, Cindy Toni Low & Roozbeh Araghi

i

Families of Kate Goodchild & Luke Dorsett

Mr Steven Wybrow, Counsel instructed by Aulich Civil

Law

Family of Roozbeh Araghi

Mr Toby Nielsen, Counsel instructed by Gordon & Barry

Law

Mrs Kim Dorsett (mother, Kate & Luke)

Mr Robert Davis, Counsel instructed by Sneddon, Hall &

Gallop Lawyers

Office of Industrial Relations (Workplace Health & Safety Queensland)

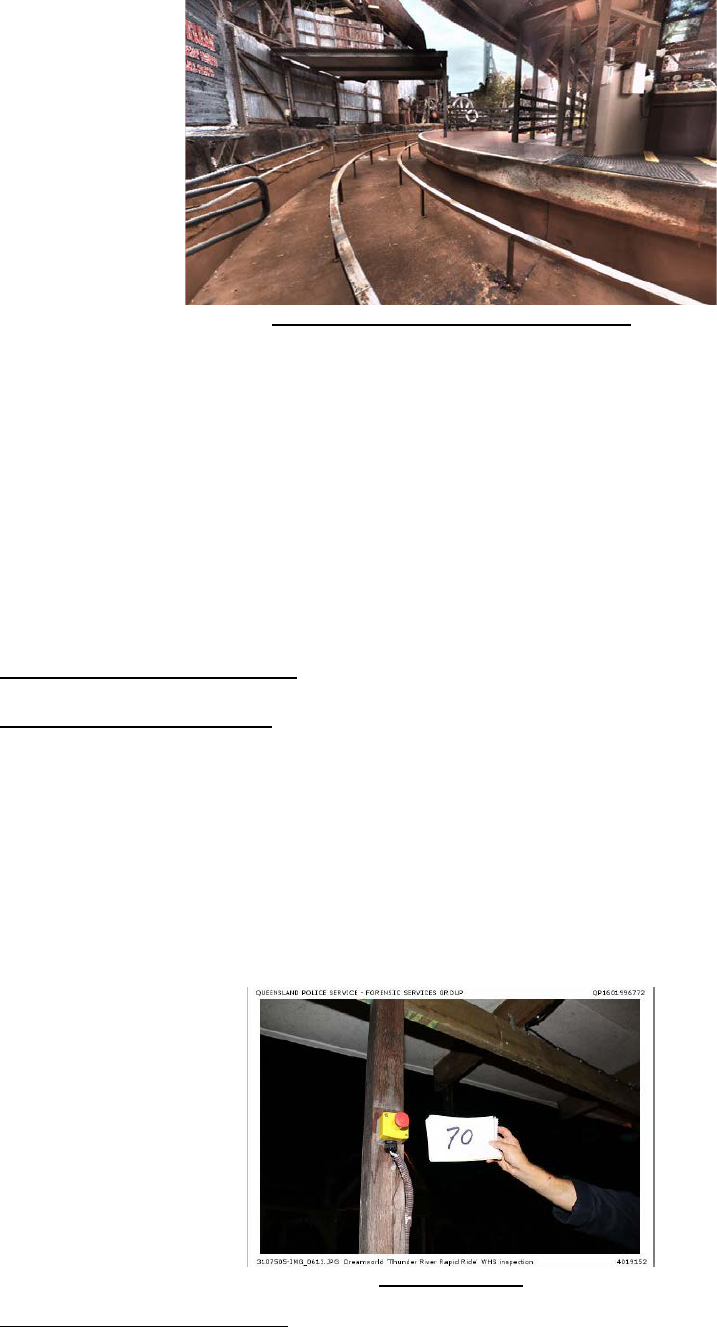

Mr Stephen Gray, Counsel instructed by Crown Law

Ms Courtney Williams

Mr Peter Callaghan SC, instructed by Gilshennan &

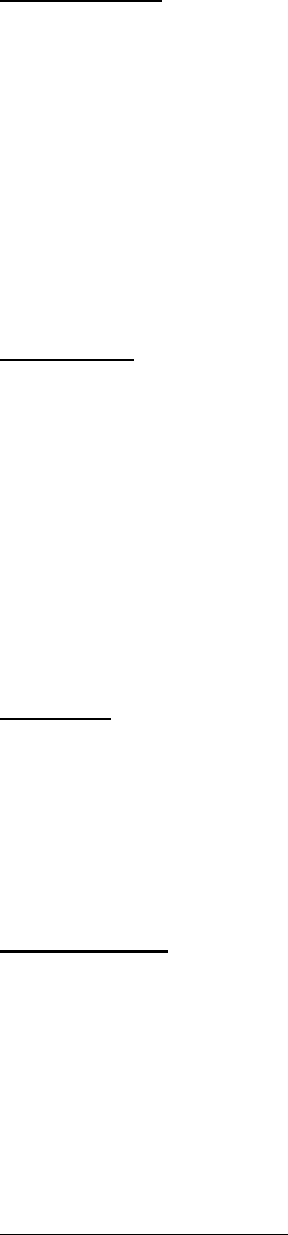

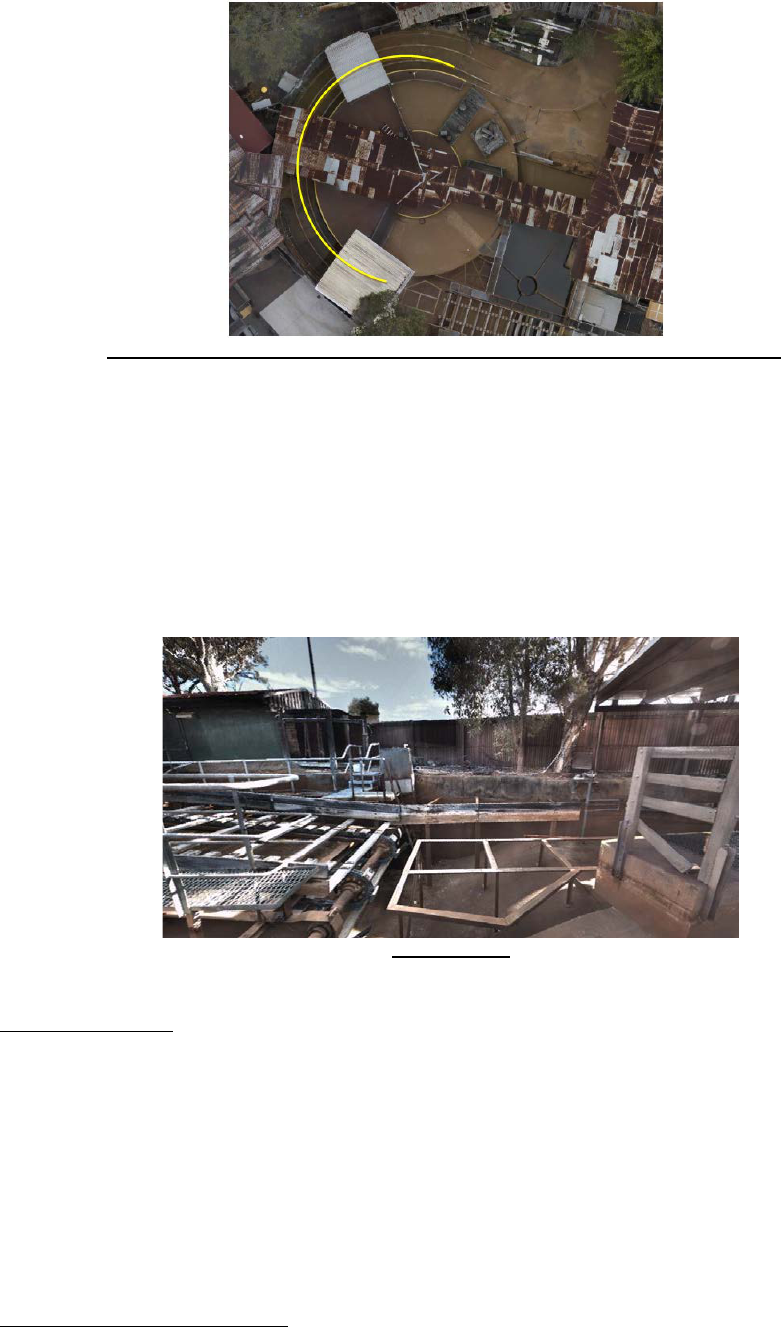

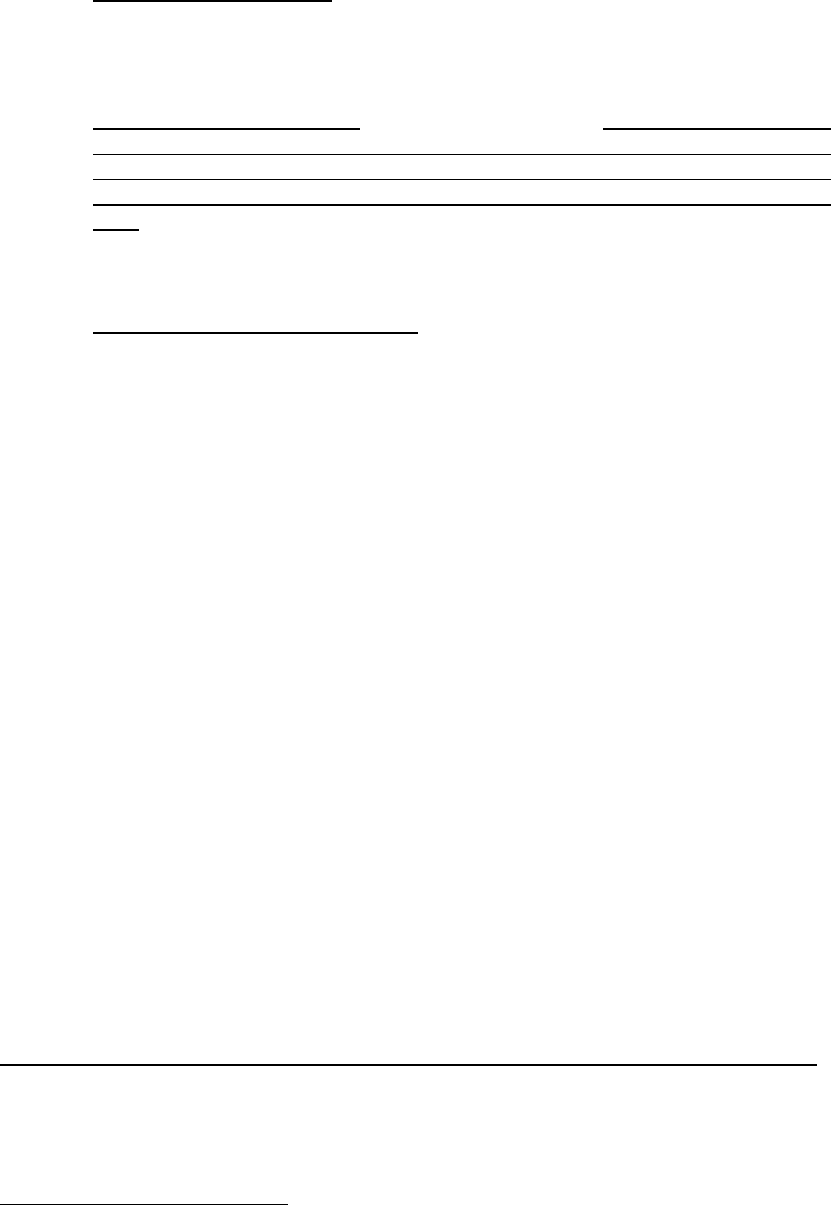

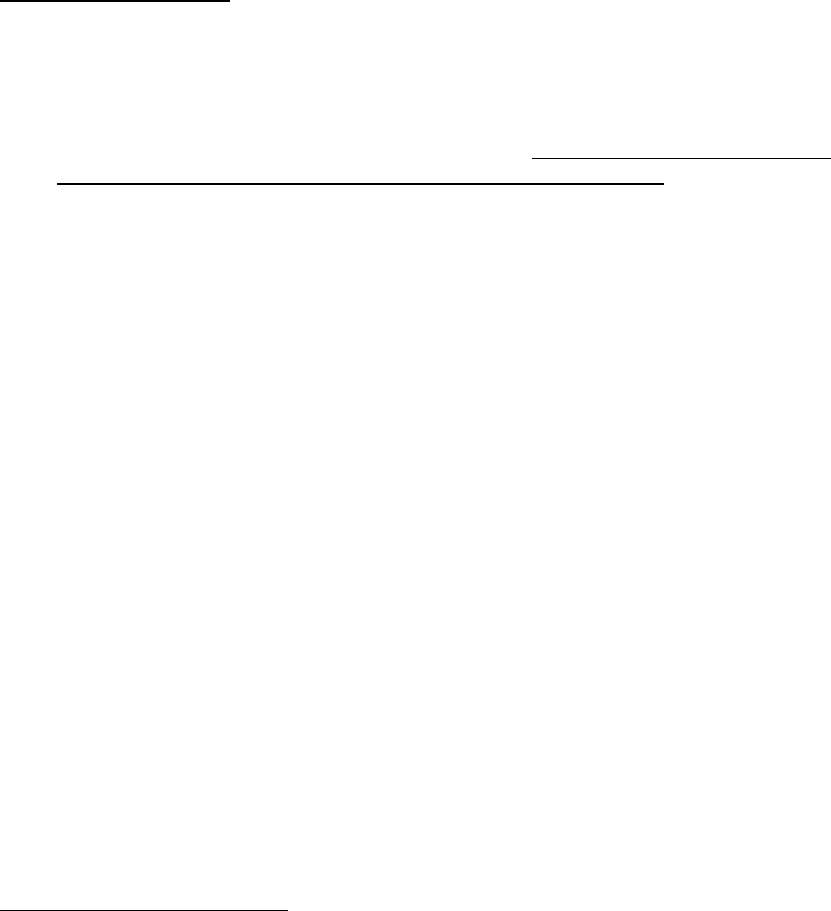

Luton

Ms Chloe Brix, Ms Sarah Cotter, Mr Wayne Cox,

Ms Amy Crisp, Mr Generic Cruz, Mr Francoire De Villiers,

Mr Christopher Deaves, Mr Quentin Dennis, Mr Andrew Fyfe,

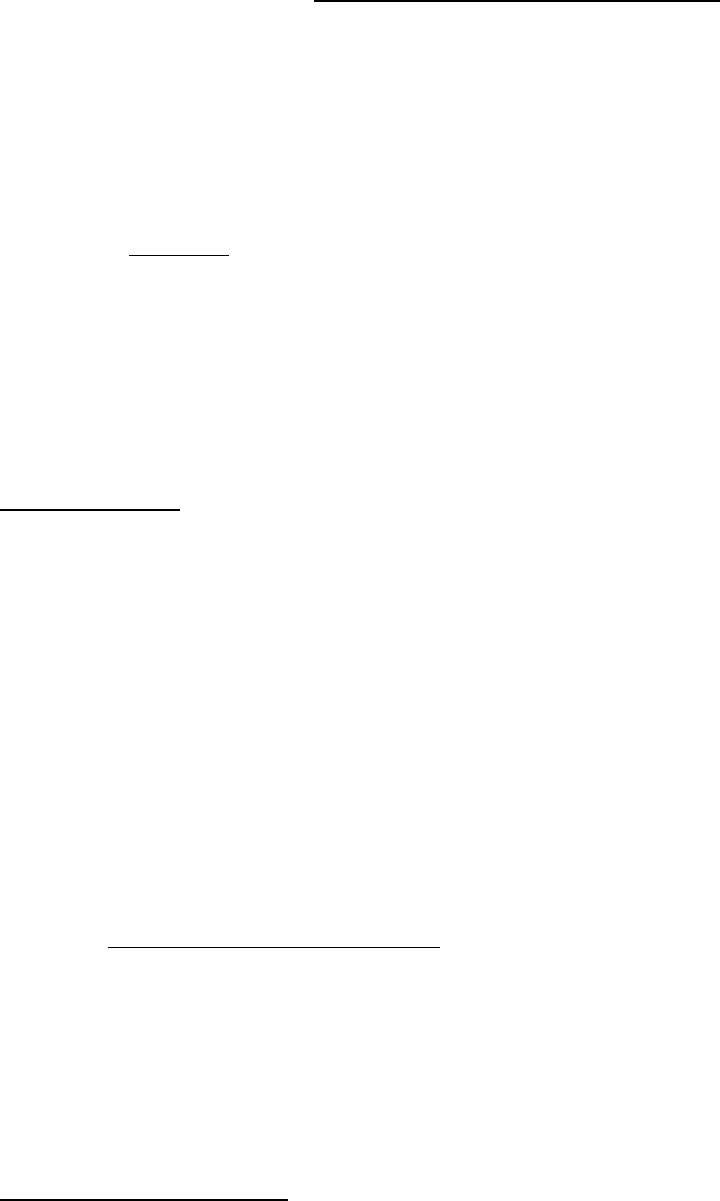

Mr Peter Gardner, Mr Mark Gordon, Ms Nichola Horton,

Mr Jason Johns, Ms Jennie Knight, Mr John Lossie,

Mr Troy Margetts, Mr Steven Murphy, Mr Grant Naumann,

Mr Peter Nemeth, Mr Kamlesh Prasad, Mr Scott Ritchie,

Mr Matthew Robertson, Mr Michael Stead,

Mr Mark Watkins, Mr Timothy Williams, Mr Jacob Wilson

Mr Ralph Devlin QC & Mr Liam Dollar, Counsel

instructed by K & L Gates LLP

Ardent Leisure Ltd trading as Dreamworld

Mr Bruce Hodkinson QC & Mr James Bell QC, instructed

by Baker McKenzie Lawyers & DWF (Australia)

CEO, Dreamworld, Craig Davidson

Mr Gavin Handran, Counsel instructed by Quinn,

Emanuel, Urquhardt & Sullivan LLP

Findings of the inquest into the death of Kate Louise Goodchild

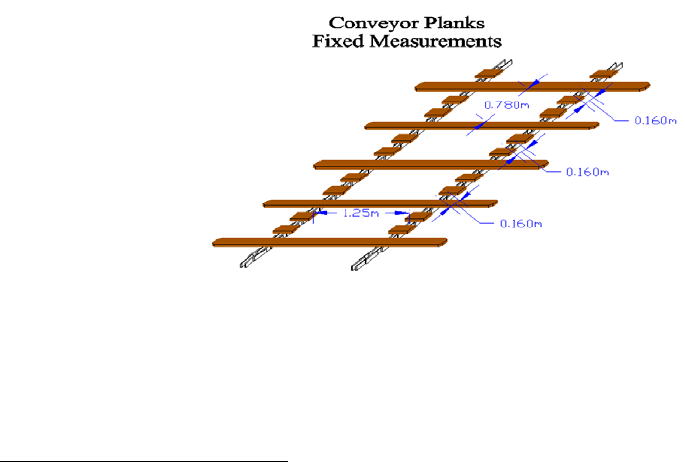

Luke Jonathan Dorsett, Cindy Toni Low & Roozbeh Araghi

ii

Queensland Police Service

Mr Adrian Braithwaite, Counsel instructed by QPU Legal

Group

DANFOSS Australia (Mr Eduardo Gie)

Mr Sean Farrell, Counsel instructed by Mills Oakley

Mr John Clark, Mr Shane Green, Mr Benjamin Hicks,

Mr Nigel Irwin, Ms Rebecca Ramsay, Mr Mark Thompson

Mr Anthony Harding, Counsel instructed by Rankin & Co

Lawyers

Mr Angus Hutchings

Mr Craig Eberhardt, Counsel instructed by Robertson

O’Gorman Solicitors

Mr Tom Polley (Danski Pty Ltd)

Ms Polina Kinchina, Counsel instructed by Colin,

Biggers, Paisley Lawyers

Mr Bob Tan

Mr John Bremhorst, Counsel instructed by Australian

Business Lawyers & Advisors

Findings of the inquest into the death of Kate Louise Goodchild

Luke Jonathan Dorsett, Cindy Toni Low & Roozbeh Araghi

iii

CONTENTS

INTRODUCTION ....................................................................................................................... 6

ISSUES FOR INQUEST ............................................................................................................ 7

ABOUT THE DECEASED PERSONS ...................................................................................... 7

BRIEF SUMMARY OF THE INCIDENT .................................................................................... 8

POST MORTEM FINDINGS .................................................................................................... 10

Kate Goodchild .................................................................................................................... 10

Luke Dorsett ........................................................................................................................ 10

Cindy Low ............................................................................................................................ 10

Roozbeh Araghi ................................................................................................................... 10

DREAMWORLD STRUCTURE & OVERVIEW ...................................................................... 11

THUNDER RIVER RAPIDS RIDE (TRRR) ............................................................................. 15

Configuration of the TRRR .................................................................................................. 16

Forensic Crash Unit Investigation .................................................................................................. 16

Configuration of the TRRR at the Time of the Incident .................................................................. 17

Operating Control System ............................................................................................................. 17

Trough ........................................................................................................................................... 18

Raft Supporting Rails ..................................................................................................................... 18

Conveyor System .......................................................................................................................... 19

Water Pumps ................................................................................................................................. 21

Rafts .............................................................................................................................................. 22

Pneumatic Gates ........................................................................................................................... 23

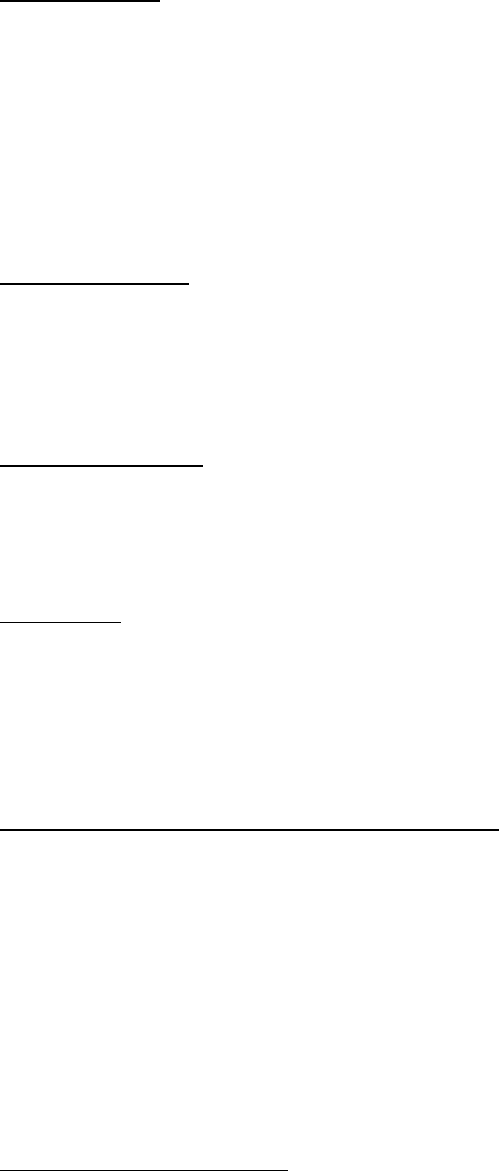

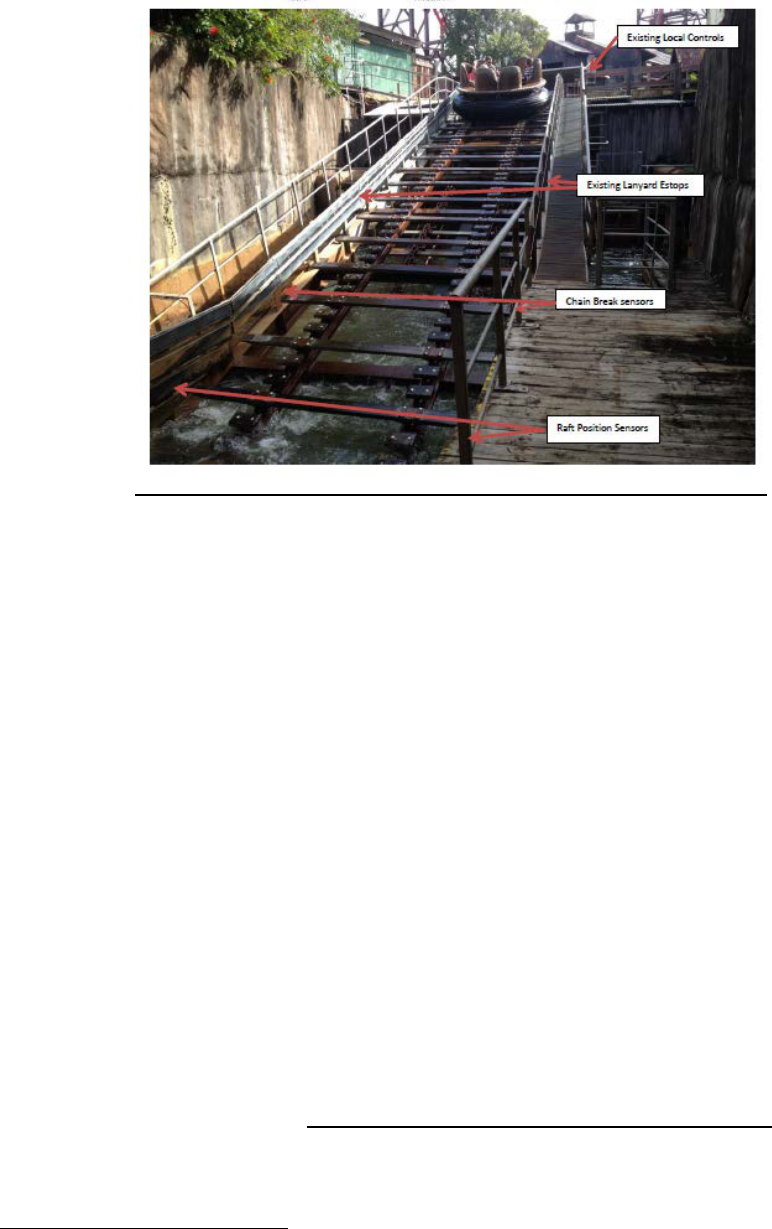

Safety Features of the TRRR .............................................................................................. 24

Emergency Stops (E-Stops) .......................................................................................................... 24

Raft Safety Stop ............................................................................................................................ 25

Chain Break Safety........................................................................................................................ 25

Anti-Roll Back Gates ..................................................................................................................... 25

Water levels ................................................................................................................................... 25

History & Modifications to the TRRR Since 1986................................................................ 25

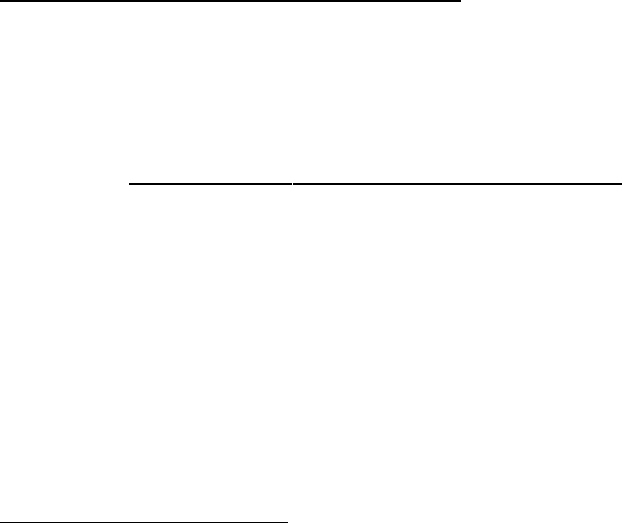

Issues with the Conveyor and Removal of Slats ........................................................................... 26

Turntable Removal ........................................................................................................................ 28

Pumps ........................................................................................................................................... 29

Raft Collar Quote ........................................................................................................................... 30

General Feasible Improvements ................................................................................................... 31

Changes to the Unload Area ......................................................................................................... 31

Raft Track ...................................................................................................................................... 31

Conveyor Chain Break and Raft Slip Monitoring ........................................................................... 32

PFI Modifications to the Log Ride in 2013 ..................................................................................... 36

Other Suggested Modifications to the TRRR ...................................................................... 37

Automated Raft Rotation System .................................................................................................. 37

Single Button Shutdown ................................................................................................................ 38

Sourcing Further Wood for Conveyor in 2016 ............................................................................... 38

TRAINING & OPERATOR PROCEDURES ............................................................................ 39

TRRR Position Responsibilities and Training ..................................................................... 41

Ride Operator Level 1 (No. 3) Deckhand ...................................................................................... 43

Ride Operator Level 2 (No. 2) Load Operation .............................................................................. 45

Ride Operator Level 3 (No. 1) ....................................................................................................... 51

Memorandums for the TRRR .............................................................................................. 55

12 February 2016 .......................................................................................................................... 56

Findings of the inquest into the death of Kate Louise Goodchild

Luke Jonathan Dorsett, Cindy Toni Low & Roozbeh Araghi

Page 1 of 274

29 May 2016 .................................................................................................................................. 57

18

October 2016 ............................................................................................................................ 57

Pre-ride Checks on the TRRR............................................................................................. 58

Emergency Scenario Training ............................................................................................. 59

PAST INCIDENTS ON THE TRRR ......................................................................................... 60

18 January 2001 – H101/0019 – Property Damage ........................................................... 60

Incident Report .............................................................................................................................. 61

Recommendations ........................................................................................................................ 63

Comments About the Incident ....................................................................................................... 63

7 October 2004 .................................................................................................................... 63

Further Consideration and Implementation of the Recommendations by Dreamworld .................. 65

Comments about the Incident ........................................................................................................ 67

28 August 2005 ................................................................................................................... 67

26 February 2008 ................................................................................................................ 68

6 November 2014 – ‘The BUSS Incident’ ........................................................................... 69

13 November 2014 - Bob Tan Email to Leadership Team .................................................. 71

Further Incidents Recorded in Log Reports ........................................................................ 72

DREAMWORLD SAFETY DEPARTMENT ............................................................................. 73

Figtree Reporting System .................................................................................................... 75

TRRR Risk Assessments .................................................................................................... 75

ENGINEERING & TECHNICAL (E&T) DEPARTMENT ......................................................... 78

Safety Issues Identified by E&T Staff .................................................................................. 80

Training for E&T Department Staff ...................................................................................... 81

Role of Junior Engineer ....................................................................................................... 81

Mr. Bob Tan’s Role .............................................................................................................. 82

E&T Department Knowledge of the Design, Modifications and Incidents on the TRRR..... 84

RIDE MAINTENANCE AT DREAMWORLD ........................................................................... 86

Daily Inspection ................................................................................................................... 88

Daily Operator Pre Start Up and Post Operation Shutdown Sheets .............................................. 89

Breakdown Procedure ......................................................................................................... 89

Park Technician Procedure ................................................................................................. 91

TRRR YEARLY PREVENTATIVE MAINTENANCE INSPECTION ....................................... 93

Shutdown June 2016 ........................................................................................................... 93

RECENT BREAKDOWNS OF THE TRRR ............................................................................. 94

19

October 2016 .................................................................................................................. 94

22 October 2016 .................................................................................................................. 95

23 October 2016 .................................................................................................................. 96

Day of the Incident – 25 October 2016 ............................................................................... 97

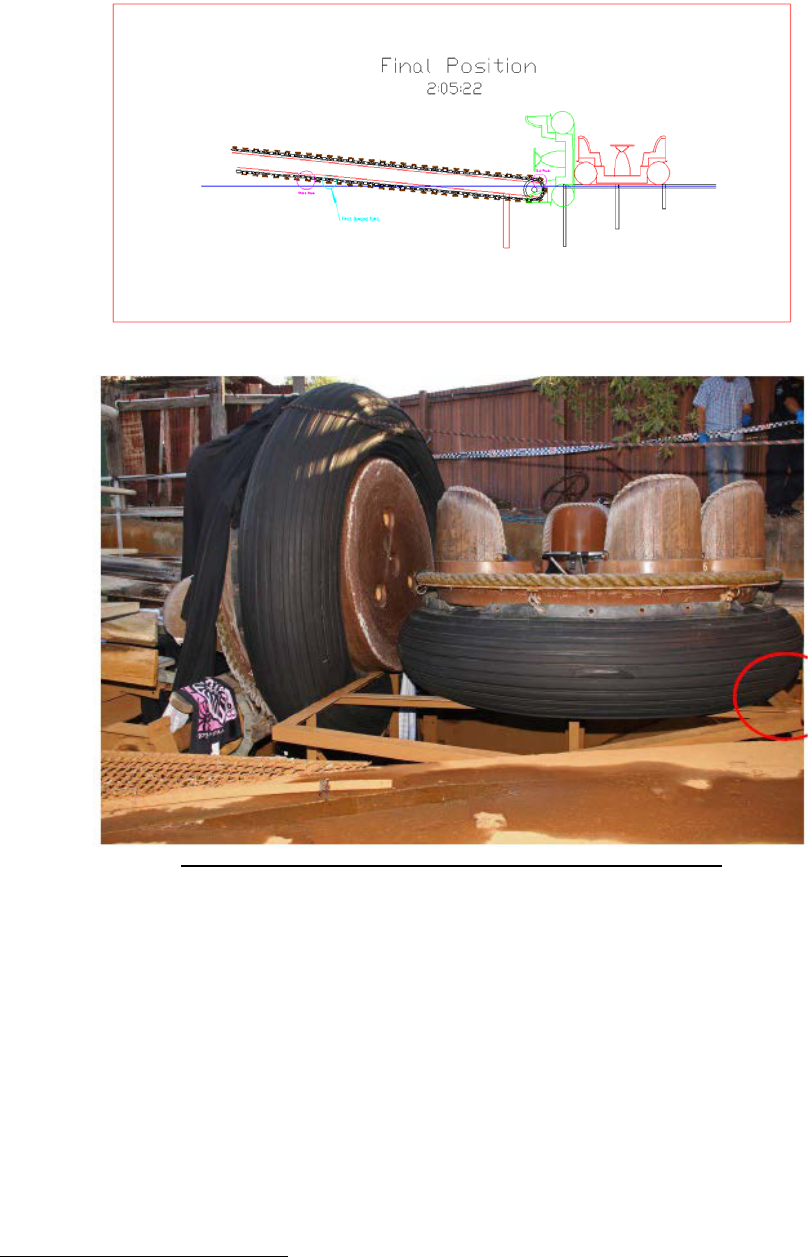

TIMELINE OF EVENTS ON 25 OCTOBER 2016 ................................................................... 97

Immediate Response to the Tragic Incident ...................................................................... 109

Further Evidence from Ms. Williams ................................................................................. 110

Further Evidence of Mr. Nemeth ....................................................................................... 112

Findings of the inquest into the death of Kate Louise Goodchild

Luke Jonathan Dorsett, Cindy Toni Low & Roozbeh Araghi

Page 2 of 274

Discussion with QPS, OIR & Dreamworld Management on 25 October 2016 ................. 113

TECHNICAL CAUSE & CIRCUMSTANCES OF THE INCIDENT ....................................... 114

Plank Damage and Observations ..................................................................................... 118

Reconstruction of the Incident ........................................................................................... 118

FCU Investigation Findings as to Causation ..................................................................... 119

EARTH FAULT AND PUMP DRIVES EXAMINATION ........................................................ 122

History of VSDs at Dreamworld ......................................................................................... 122

Testing on drives post incident .......................................................................................... 123

Recommended Course of Action in Response to an Earth Fault ..................................... 125

Mr. Ritchie’s Assessment of the Fault Prior to the Tragic Incident ................................... 126

HISTORY OF EXTERNAL SAFETY AUDITS AT DREAMWORLD ..................................... 127

JAK Leisure Company Audits ............................................................................................ 127

May 2003 – Inspection ................................................................................................................ 130

November 2004 – Inspection ....................................................................................................... 132

July 2006 – Inspections ............................................................................................................... 135

September 2009 – Inspections .................................................................................................... 139

March 2013 – Inspections ........................................................................................................... 142

Comments about JAK / Ocean Embassy Safety Audits .............................................................. 144

DRA Safety Management Audits ...................................................................................... 147

February 2013 Audit .................................................................................................................... 148

2014 Audit ................................................................................................................................... 151

Consultancy Visits 2014 .............................................................................................................. 153

2015 Audit ................................................................................................................................... 153

Consultancy Visit - April 2015 ...................................................................................................... 154

Consultancy Visit - December 2015 ............................................................................................ 155

Consultancy Visit - April 2016 ...................................................................................................... 155

Dreamworld’s Response to DRA Audits ...................................................................................... 157

Dreamworld Safety Auditing Strategy FY15 ...................................................................... 157

CHANGES AT DREAMWORLD FOLLOWING THE INCIDENT .......................................... 159

AMUSEMENT PARK REGULATION IN QUEENSLAND .................................................... 161

Brief History of WHS Legislation - Past Decade ............................................................... 162

2011 WHS Act – Regulator Responsibilities ..................................................................... 162

Administrative Functions as of October 2016 ................................................................... 162

Plant Design Registration ............................................................................................................ 163

Plant Registration Renewal ......................................................................................................... 163

Safety Regulations for Plant ........................................................................................................ 164

Compliance Monitoring and Engagement ......................................................................... 168

Industry Guidance & Engagement Activity ........................................................................ 169

AALARA Forum ........................................................................................................................... 170

Annual Amusement Device Stakeholders Forum ........................................................................ 170

Functional Safety Forum ............................................................................................................. 170

Published Guidance Material ....................................................................................................... 170

Enforcement & Sanctions .................................................................................................. 171

Compliance Notices..................................................................................................................... 171

Investigations .............................................................................................................................. 172

Prosecutions ................................................................................................................................ 172

Regulatory Focus on Mobile Amusement Rides .......................................................................... 172

Previous Notifications Made to OIR in Relation to the TRRR by Dreamworld .................. 173

Findings of the inquest into the death of Kate Louise Goodchild

Luke Jonathan Dorsett, Cindy Toni Low & Roozbeh Araghi

Page 3 of 274

CLASS 2 RIDES INSPECTION & REGISTRATION ............................................................ 173

Dreamworld’s Compliance with the Requirement for Renewal of Plant Registration ....... 173

2016 Dreamworld Plant Registration ........................................................................................... 175

Certificate Issued for TRRR ......................................................................................................... 178

Draft Report for all Class 2 Rides ................................................................................................ 179

OIR INSPECTOR AUDITS OF DREAMWORLD PRIOR TO THE INCIDENT ..................... 181

OIR TECHNICAL ADVICE ABOUT THE INCIDENT ............................................................ 184

Technical Advice - Principal OIR Adviser (Mechanical), Mr. David Flatman .................... 184

Inspections and Testing ............................................................................................................... 184

Control Measures ........................................................................................................................ 187

Ride Modifications ....................................................................................................................... 188

Previous Incidents on TRRR ....................................................................................................... 189

Maintenance and Inspections ...................................................................................................... 189

Conclusions ................................................................................................................................. 190

Technical Advice - OIR Principal Inspector, Mr. Ian Stewart ............................................ 190

Issue 1 - Reliance on Administrative Control in Emergency Situations ....................................... 191

Issue 2: Limitations of the Ride Emergency Controls, Systems and Procedures Provided for the

Operator to Respond to Emergencies ......................................................................................... 193

Issue 3 - Monitoring and Prevent of Rafts Colliding in the Unloading Area ................................. 194

Issue 4 – Water Level Monitoring ................................................................................................ 194

Issue 5 – Gap at the End of the Conveyor at the Unloading Area ............................................... 195

PROHIBITION NOTICE – ARDENT LEISURE ..................................................................... 197

REGULATORY RESPONSE FOLLOWING THE INCIDENT ............................................... 198

2016 Audit Campaign ........................................................................................................ 198

2017 Audit Campaign ........................................................................................................ 199

Best Practice Review of OIR ............................................................................................. 200

OIR Plant Inspectors (Amusement Devices) Subgroup ............................................................... 202

Plant Item Registration Working Group ....................................................................................... 203

Amusement Devices Stakeholders and Regulators Forum ......................................................... 204

PROPOSED REGULATORY AMENDMENTS ..................................................................... 204

Draft Further Amendments to the Regulations .................................................................. 204

Major Amusement Parks and the Proposed Safety Case Licensing System ............................... 205

Mandatory Major Inspections of Amusement Devices ................................................................. 206

Operators of Amusement Devices ............................................................................................... 207

Amusement Device Log Books ................................................................................................... 207

Purpose of the New Proposed Safety Case Regime ........................................................ 208

INDUSTRY RESPONSE & INFORMATION ......................................................................... 209

Submission by the Safety Institute of Australia ................................................................. 209

OIR Response to SIA Submission .................................................................................... 211

VILLAGE ROAD SHOW SAFETY SYSTEMS ...................................................................... 214

EXPERT EVIDENCE ............................................................................................................. 217

Engineering Expert Advice ................................................................................................ 217

Report on the Design of the Conveyor System by Dr Frank W. Grigg, Forensic Engineering

Consulting Pty Ltd ....................................................................................................................... 217

Safety Related Control Systems, Summary Report 170326GRa, Expert Report by George

Rutherford, 26 March 2017 .......................................................................................................... 220

Report by Dr Duncan Gilmore, Managing Director and President of Gilmore Engineers Pty Ltd 222

ENGINEERING EXPERT CONCLAVE ................................................................................. 230

Joint Engineering Expert Advice ....................................................................................... 230

Findings of the inquest into the death of Kate Louise Goodchild

Luke Jonathan Dorsett, Cindy Toni Low & Roozbeh Araghi

Page 4 of 274

Expert’s Response to the Proposed Draft Regulations ..................................................... 247

Mr. Chan’s Response to the Expert Evidence .................................................................. 247

FURTHER EXPERT ADVICE ............................................................................................... 248

Human Factors Report on Fatal Incident, Professor Penelope Sanderson ...................... 248

Expert Report by Principal Naval Architect, Mr. Mark Devereaux .................................... 254

Dreamworld Ride Velcro Seatbelt Test, APV Engineering & Testing Service, Mr. Jose de

Freitas ................................................................................................................................ 255

ANALYSIS OF THE CORONIAL ISSUES ............................................................................ 256

The Findings required by s.45 of the Coroners Act 2003 ................................................. 256

Examination of the Thunder River Rapids Ride at the Dreamworld Theme Park, including

but not limited to, the construction, maintenance, safety measures, staffing, history and

modifications. .................................................................................................................... 256

Records ....................................................................................................................................... 261

Technical Circumstances ............................................................................................................ 262

Lack of Automation ...................................................................................................................... 263

Operators Account of the Incident ............................................................................................... 263

Operator Responsibilities ............................................................................................................ 264

Response to the South Pump ‘Earth Fault’ .................................................................................. 265

Examination of the sufficiency of the training provided to staff in operating the Thunder

River Rapids Ride. ............................................................................................................ 266

Consideration of the regulatory environment and applicable standards by which

Amusement Park rides operate in Queensland and Australia, and whether changes need to

be made to ensure a similar incident does not happen in the future. ............................... 267

Mr. Polley’s Conduct.................................................................................................................... 269

Changes Made at Dreamworld Following the Incident ..................................................... 270

What further actions and safety measures could be introduced to prevent a similar future

incident from occurring? .................................................................................................... 270

RECOMMENDATIONS IN ACCORDANCE WITH s.46 ....................................................... 271

DISCRETION TO REFER IN ACCORDANCE WITH s.48 (4) .............................................. 273

Referral of Ardent Leisure Limited to the OIR ................................................................... 274

Mr. Polley ........................................................................................................................... 274

Findings of the inquest into the death of Kate Louise Goodchild

Luke Jonathan Dorsett, Cindy Toni Low & Roozbeh Araghi

Page 5 of 274

INTRODUCTION

1. At around 2:05 pm on 25 October 2016, a tragic incident occurred on the Thunder

River Rapids Ride (TRRR) at Dreamworld Theme Park, Coomera, which claimed

the lives of Ms. Kate Goodchild, Mr. Luke Dorsett, Ms. Cindy Low and Mr.

Roozbeh Araghi. A joint inquest into the circumstances of this tragedy was

convened over a six-week period at various dates in June, October, November

and December 2018, in the Coroners Court of Queensland at Southport.

2. The gravity, complexity and scope of this tragedy at Australia’s largest Theme

Park was reflected in the comprehensive and professional investigations

conducted by the Queensland Police Service (QPS) and the Office of Industrial

Relations, formerly Workplace Health and Safety Queensland (OIR), as well as

the voluminous documentary, photographic and video exhibits obtained during

the course of the inquiry. During the hearing, oral evidence was taken from 59

witnesses, with an expert engineering conclave convened to provide evidence

concurrently.

3. The impact of this tragedy on the community, whilst paling in comparison to that

on the loved ones of those who lost their lives, has been undeniably significant.

Accordingly, the in-depth nature of this inquiry was intended to ensure that such

a tragic event does not happen again.

4. I would like to commend the work of all of those involved in the investigation of

this tragic incident. The investigation was conducted to an exceptionally high

standard, with a great deal of compassion, expertise and dedication by the

Queensland Police Service and Office of Industrial Relation (OIR) officers

involved. The gravity, scope and complexity of this tragedy at Australia’s largest

Theme Park is unparalleled in Queensland’s history, and was carried out to a

remarkable standard under great public scrutiny, with the eyes of the world

watching.

5. Whilst the investigation and ongoing preparation of this inquiry was certainly

collaborative, I would like to make particular commendations to the following

Queensland Police Investigators for their remarkable efforts.

6. I am grateful for the tireless and outstanding work undertaken by Detective

Sergeant Nicola Brown, the lead investigator for this tragic incident. Her standard

of work and dedication has been exceptional, and of great assistance to my

inquiry. The task of investigating such a unique and high-profile incident was

immense, and undertaken by Detective Sergeant Brown in a professional,

diligent, compassionate and comprehensive manner. I am thankful for all her

efforts during the course of these proceedings.

7. The skillful and detailed analysis conducted by Senior Constable Steven

Cornish, the lead Forensic Crash Unit Investigator, with respect to the

mechanical and technical aspects of this tragedy was pivotal to this inquiry. His

dedication and attention to detail ensured that this unique and catastrophic

incident was properly, and with the requisite expertise, investigated and

considered. I am grateful for all his tireless work and commitment.

Findings of the inquest into the death of Kate Louise Goodchild

Luke Jonathan Dorsett, Cindy Toni Low & Roozbeh Araghi

Page 6 of 274

ISSUES FOR INQUEST

8. On 3 April 2018 and 25

May 2018, at pre-inquest hearings, the following issues

for the inquest were determined:

a. The findings required by s.45 (2) of the Coroners Act 2003; namely the

identity of the deceased person, when, where and how they died and

what caused the death.

b. The circumstances and cause of the fatal incident on the Thunder River

Rapids Ride at the Dreamworld Theme Park, which occurred on 25

October 2016.

c. Examination of the Thunder River Rapids Ride at the Dreamworld Theme

Park, including but not limited to, the construction, maintenance, safety

measures, staffing, history and modifications.

d. Examination of the sufficiency of the training provided to staff in operating

the Thunder River Rapids Ride.

e. Consideration of the regulatory environment and applicable standards by

which Amusement Park rides operate in Queensland and Australia, and

whether changes need to be made to ensure a similar incident does not

happen in the future.

f. What further actions and safety measures could be introduced to prevent

a similar future incident from occurring?

ABOUT THE DECEASED PERSONS

9. Ms. Kate Louise Goodchild was born on 3 August 1984 in Canberra. She resided

with her partner of 15 years, David Turner, and their two children, Ebony and

Evie in Ngunnawal, ACT. She was a dedicated wife and mother, who had a

wonderful sense of humour.

1

She had three siblings, Luke Dorsett, Jeremy

Goodchild and Peta Harrison. At the time of her death, Ms. Goodchild worked for

the Department of Human Services, having previously worked in various public

service and private organisations.

10. Mr. Luke Johnathan Dorsett was born on 28 March 1981 in Canberra, and is Ms.

Kate Goodchild’s older brother. He resided with his adored partner of 10 years,

Mr. Roozbeh Araghi in the ACT. He worked for the Department of Human

Services. Like his sister Kate, Mr. Dorsett was dedicated to his role in the public

service and had an immense work ethic. He was described as an extraordinary

role model to those around him.

2

11. Mrs. Cindy Toni Low was born in Whakatane, New Zealand on 19 May 1974.

She and her husband, Mr. Mathew Low travelled to Sydney and settled there in

2001. They had two children, Keiran Elijah Low and Isla Grace Low. Mrs. Low

was a dedicated wife and mother, who was described by her family as vibrant,

intelligent and social.

3

She lived at East Gosford and worked as a personal

assistant at a property valuation company.

1

Ex B1, pg. 11

2

Ex B1, pg. 12

3

Ex B1, pg. 11

Findings of the inquest into the death of Kate Louise Goodchild

Luke Jonathan Dorsett, Cindy Toni Low & Roozbeh Araghi

Page 7 of 274

12. Mr. Roozbeh Araghi was born on 7 September 1978 in Iran to parents Behrooz

Araghi and Vivien Hadden Araghi. He had two siblings, Simon Sirus Araghi and

Darius Araghi and was the father of Zachary Araghi Dawson and Harrison Araghi

Dawson. He resided in the ACT with his loving partner of 10 years, Mr. Dorsett.

He held a Bachelor of Arts (Honours) from Sydney University and worked for the

Australian Bureau of Statistics. He was known amongst his friends and

colleagues as a ‘tireless defender of the under privileged’.

4

BRIEF SUMMARY OF THE INCIDENT

13. On Tuesday 25 October 2016, Dreamworld opened as usual at 10:00 am. The

Thunder River Rapids Ride (TRRR) commenced operating with nine rafts in

circulation and two Ride Operators. This is the maximum number of rafts allowed

in circulation for a two Operator model.

5

14. At around 2:00 pm on 25 October 2016, Cindy Low and her son Kieran, Kate

Goodchild and her daughter Ebony Turner, along with Kate’s brother, Luke

Dorsett and his partner Roozbeh Araghi, boarded Raft 5 of the TRRR. At the

time, the weather was dry and clear.

15. The TRRR, which is no longer in commission, was an aquatic based family

orientated ‘moderate thrill ride’, which was suitable for patrons over the age of

two. It was designed to simulate white water rafting for six patrons, with the option

of having three children seated on an adult’s lap, within a circular raft.

Statistically, it was the most popular ride in the Theme Park.

6

16. Raft 5 travelled through the water course without incident before being picked up

by the conveyor at the end of the ride and moved towards the elevated unloading

area. At this time, Raft 6, which was dispatched in front of Raft 5, became

stranded on the steel support rails situated at the end of the conveyor near the

unloading area. Raft 5 continued to travel on the conveyor where it collided with

Raft 6 before being lifted and pulled vertically into the conveyor mechanism.

Ebony and Kieran, who were seated at the top of Raft 5, were able to free

themselves and escape to safety. Ms. Goodchild, Ms. Low, Mr. Dorsett and Mr.

Araghi were caught in the mechanism of the ride, and were either trapped in the

raft or ejected into the water beneath the conveyor.

17. The Ride Operators and some patrons immediately responded to the incident,

attempting to assist those trapped in the raft and in the watercourse. Emergency

services were contacted, and various Dreamworld staff responded to the

incident. Unfortunately, all attempts to provide medical assistance to Ms.

Goodchild, Mr. Dorsett, Ms. Low and Mr. Araghi were unsuccessful, and they

were declared deceased at the scene.

18. A major investigation code named ‘Operation Oscar Holocene’ was immediately

commenced by QPS, which included support from various internal specialty

units, including the Forensic Crash Unit, who carried out testing and an expert

analysis of the scene and circumstances of the incident. Given the scale of the

investigation and nature of the incident, support was also provided by the State

Crime and Intelligence, Counter-Terrorism and Major Events Command.

4

Ex B1, pg. 12

5

Ex B1

6

Ex B3C(50), pg. 20

Findings of the inquest into the death of Kate Louise Goodchild

Luke Jonathan Dorsett, Cindy Toni Low & Roozbeh Araghi

Page 8 of 274

19. The scope of the QPS investigation was twofold. Firstly, to determine whether

there was any criminal negligence or criminal responsibility under the Criminal

Code 1899, and also to identify, report and obtain evidence, which could assist

the South Eastern Coroner in his investigation of the incident, establish a cause

of death, make the requisite findings under the Coroners Act 2003 and identify

any possible preventative recommendations. In addition to undertaking an expert

forensic examination and search of the incident scene, a multitude of witnesses

were interviewed, including eye witnesses, Ride Operators, Dreamworld

management staff, maintenance workers, current and former Dreamworld

employees, Queensland Ambulance Service (QAS) officers, and Dreamworld

patrons. Relevant evidence from the scene was seized, extensive photographs

of the incident site taken, and various external and internal subject matter experts

were engaged in order to comprehensively canvas all of the pertinent issues

associated with the tragedy, and to ensure a thorough and expert analysis was

conducted of the incident and scene.

20. Due to the nature of the coronial investigation, its gravity and scope, OIR, whilst

undertaking their own separate statutory investigation, assisted QPS in

examining the incident. Various interviews and evidence was obtained pursuant

to s.171 of the Work Health and Safety Act 2011, for an array of potential

witnesses, who refused to provide voluntary statements to QPS, however, were

highly relevant to provide context, evidence, information regarding training,

maintenance, safety and the history of the TRRR.

21. The OIR investigation into the circumstances of the tragedy was also extensive,

and various professionals and experts were employed to provide comment as to

components of the incident, the ride and regulatory history. OIR officers attended

site immediately following the incident and continued to work concurrently with

QPS investigators throughout the course of the inquiry.

22. Extensive documentary evidence was also sought from Ardent Leisure, as well

as other external parties, by way of numerous coronial directions. As a result,

voluminous records pertaining to a myriad of issues, including the TRRR,

modifications made, training, maintenance, job descriptions, operations at

Dreamworld, certifications, workplace health and safety related issues, meeting

minutes, safety decisions, policies and procedures, directions and complaints,

were obtained.

23. Ultimately, comprehensive coronial reports with extensive annexures, including

statements, interviews and documentary exhibits, were furnished by Detective

Sergeant Nicola Brown, Gold Coast Criminal Investigation Branch and Senior

Constable Steven Cornish, Forensic Crash Unit (FCU), Coomera.

24. As Coroner I attended the scene of the tragedy and was briefed by officers

approximately two hours after the event and before the forensic pathologists

attended. I also attended the day of testing and reconstruction, in company with

my Counsel Assisting, Ms. Rhiannon Helsen and my Investigations Officer, Mr.

Mark Ozolins.

Findings of the inquest into the death of Kate Louise Goodchild

Luke Jonathan Dorsett, Cindy Toni Low & Roozbeh Araghi

Page 9 of 274

POST MORTEM FINDINGS

Kate Goodchild

25. An external and full internal post-mortem examination was carried out on 26

October 2016 by Pathologist, Dr Dianne Little. A CT scan and toxicological

testing was also conducted.

7

26. The post-mortem examination revealed the presence of severe chest and

abdominal injuries. A band of abrasions and bruising were found across the

upper and mid trunk, as well as the corresponding area across the left upper

arm. Internal injuries found included multiple rib fractures, fragmentation of the

liver, transection of the duodenum and torn blood vessels to the right kidney.

These injuries were the direct cause of death and suggestive of a crushing blow

to this area of the body. There was no evidence of drowning.

Luke Dorsett

27. An external and full internal post-mortem examination was carried out on 26

October 2016 by Pathologist, A/Professor Alex Olumbe. A CT scan and

toxicological testing was also conducted.

8

28. The external examination revealed extensive bruising and abrasions over the

entire body. Multiple severe contusions and crushing injuries to the neck, spine

and ribs, as well as the liver, were found following the internal examination.

These injuries were consistent with having been caused by multiple compressive

impacts, particularly to the cervical area, and upper section of the thoracic spinal

column, resulting in severing of the brain stem, as well as other injuries. Death

would have been rapid. There was no evidence of drowning.

Cindy Low

29. An external and full internal post-mortem examination was carried out on 25

October 2016 by Pathologist, Dr Dianne Little. A CT scan and toxicological

testing was also conducted.

9

30. Extensive multiple injuries were observed to the head, chest, abdomen, pelvis

and limbs, the combined effect of which was found to be the cause of death.

Roozbeh Araghi

31. An external and full internal post-mortem examination was carried out on 25

October 2016 by Pathologist, A/Professor Alex Olumbe. A CT scan and

toxicological testing was also conducted.

10

32. The cause of death was extensive disruptive chest injuries evidence of which

was evident internally and externally. The mechanism of death was found to be

a single disruptive compressive impact to the middle section of the chest due to

a rapid movement by an implement. Death would have been rapid. There was

no evidence of drowning.

7

Ex A3 & A4

8

Ex A7 & A8

9

Ex A11 & A12

10

Ex A15 & A16

Findings of the inquest into the death of Kate Louise Goodchild

Luke Jonathan Dorsett, Cindy Toni Low & Roozbeh Araghi

Page 10 of 274

DREAMWORLD STRUCTURE & OVERVIEW

33. The Dreamworld Theme Park is located on the Gold Coast at 1 Dreamworld

Parkway, Coomera. It was developed by John Longhurst and was officially

opened to patrons on 15 December 1981. Over the years, Dreamworld has

expanded, and is now Australia’s largest Theme Park comprised of various

themed rides, wildlife and television branded attractions. Ardent Leisure Group,

an Australian based leisure company, currently owns and operates Dreamworld,

having acquired the park in 1998 from the Macquarie Leisure Trust.

11

Ardent

Leisure operates Dreamworld along with the adjacent Whitewater World,

Skypoint, AMF Bowling, Kingpin Bowling, and Good Life Health Clubs throughout

Australia, New Zealand and the United States of America.

12

Ardent Leisure

Limited was incorporated on 28 April 2003 and took over the ownership,

management and responsibility of the Dreamworld assets from that date. The

TRRR had long been in operation at that time. The documentation Ardent

inherited in 2003 could well be described as “scant”. They commenced their own

record keeping from that date.

34. Within Dreamworld, under the command of the Chief Executive Officer (CEO),

are the following Departments:

13

• Operations;

• Engineering and Technical (E&T);

• Life Sciences;

• Retail;

• Sales and Marketing;

• Food and Beverage;

• Safety;

• Finance and Administration; and

• Employee relations.

35. The CEO of Dreamworld, at the time of the tragic incident, was Mr. Craig

Davidson. All General Managers of the above Departments, and the Chief

Financial Officer reported directly to him.

14

He held the ultimate decision making

authority for Dreamworld, and liaised directly with the Ardent Leisure Board as

to all relevant matters, including safety, expenditure and the like.

15

In a

responsibility statement for the CEO, which was signed by Mr. Davidson on 20

March 2015, it notes, inter alia, that the position is responsible for the health and

safety in all areas of their control and is responsible to:

16

11

Ex B1, pg. 9

12

Ex B1

13

Ex B12(26)

14

Ex C8(10), pg. 11

15

Ex C8(10), pg. 11

16

Ex C7(580)

Findings of the inquest into the death of Kate Louise Goodchild

Luke Jonathan Dorsett, Cindy Toni Low & Roozbeh Araghi

Page 11 of 274

• Assist the business to develop and implement the Work Health and

Safety Plan and actively support the Plan to meet the safety objectives;

• Ensure that managers under their delegation are aware of the work health

and safety responsibilities;

• Ensure that relevant personnel perform risk assessments and implement

controls in accordance with an relevant Regulations, Australian

Standards and Codes of Practice;

• Establish an annual review of the Safety Management System to ensure

it reflects the current legislation and supports the needs of the company;

• Regularly assess (at least every year), via internal auditing, how

effectively operations comply with the required health and safety

standards; and

• Participate in and support safety inspections – shall conduct at least one

safety inspection of the Business per year.

36. The Operations Department, which is one of the largest within the Park, has a

number of subsets, including Aquatics, Attractions, Entertainment, Costume,

Security, Guest Services, Reception, Cleaning and Gardening.

17

The Operations

Department is responsible for the ‘smooth running of the park throughout the

day’ and encompasses the Ride Operators, supervisors, relief supervisors and

instructors.

18

At the time of the tragic incident, Mr. Troy Margetts was the

Operations Manager at Dreamworld. He had held this role since 2014, having

commenced employment with Dreamworld in 1990.

19

He was required to report

directly to Mr. Davidson.

37. Mr. Andrew Fyfe was the Attractions and Entertainment Manager at Dreamworld,

which was a subset of the Operations Department. He reported to the Operations

Manager, having held this position for the past 10 years.

20

Mr. Fyfe was

responsible for the daily operations of White Water World slide attendants,

Dreamworld Ride Operators and the Attractions Supervisory team, as well as the

entertainment staff and Laundry and uniform operations.

21

38. Within the Operations Department, Ms. Nichola Horton was the Operations

Systems Administrator, having worked at Dreamworld in various roles since

2002.

22

This role, which commenced in 2016, reported directly to Mr. Margetts,

and was responsible for examining systems in place across operations through

audits to determine what improvements could be made.

23

As part of this role, Ms.

Horton was involved in amending and writing Ride Operator procedures for

various rides within Dreamworld and ensuring these were placed onto Liferay, a

new electronic document library.

24

She also had carriage of accounts for

Operations, which included ordering for the Operations Department.

25

Ms.

17

Ex B12(26), pg. 5

18

Ex B12(26), pg. 5

19

Ex B3C(50), pg. 6 & 7

20

Ex B3A(17), [7]; Ex C8(6), pg. 5

21

Ex B3A(17), [8]; Ex C8(6), pg. 5

22

T25-4, lines 40-47

23

Ex B3C(25), [2]; Ex C7(24)

24

T25-8, lines 17-40

25

Ex B3C(25), [2]

Findings of the inquest into the death of Kate Louise Goodchild

Luke Jonathan Dorsett, Cindy Toni Low & Roozbeh Araghi

Page 12 of 274

Horton also performed the role of Duty Manager at Dreamworld, which involved

responding to guest complaints, any ride related emergencies, or any major

events.

39. At the time of the incident, the Attractions Supervisors, who reported to Mr. Fyfe,

included Ms. Jennie Knight, Mr. Jason Johns, Ms. Tracey McGraw and Ms.

Sarah Cotter.

26

The responsibilities of the Supervisors were to ‘ensure the safe

and efficient daily operations of the Attractions Department through effective

management of people resources and operational efficiencies…’ which included

supervising the activities of attractions staff on a daily basis, attendance at daily

operational calls, Code 6’s and breakdowns on rides.

27

A Code 6 is the code

used when a ride has ceased operation due to a technical fault. Each of the

Supervisors had been Ride Operators previously and progressed to the position

of Supervisor.

40. Relief Supervisors within the Attractions and Entertainment Department are

responsible for supervising park operations, which includes supervising the

Operators out on the rides, being called out to breakdowns, being out in the park

to ensure that the operation runs smoothly and assisting to manage guest

issues.

28

41. According to the Attractions and Aquatics Induction Handbook, Supervisors in

the Operations Department were responsible for the day to day operation of the

park, which included daily supervision of all team members, liaising with other

Departments as necessary, attending emergency situations, hazard and incident

reporting, assessing team member’s performance and assisting with guest

enquiries.

29

They were also expected to work with management and various

team members to execute new ideas and initiatives.

42. Meetings were held weekly with Mr. Margetts, Mr. Fyfe and the Supervisors

within the Operations Department. Financial results were discussed, as were any

relevant findings from recent Executive Meetings, with Managers providing an

update as to any issues associated with their area.

30

Whilst ride down times and

safety were not generally discussed during these meetings, any prolonged delay,

unscheduled maintenance or ride shutdowns were canvassed.

31

43. The Engineering and Technical (E&T) Department within Dreamworld is

‘responsible for the servicing and maintenance of all of our rides and

attractions’

32

and is required to attend a ride in the event of a breakdown during

daily operations. Personnel in this Department include multiple technical

specialties, including electricians and mechanical fitters and turners. At the time

of the incident, Mr. Christopher Deaves was the General Manager of

Engineering. Whilst he had no tertiary engineering qualifications, he held an

Advanced Diploma in Mechanical Engineering, as well as a Diploma of Business,

Health and Safety and trade qualifications.

33

Mr. Scott Ritchie (Electrical), Mr.

Mark Watkins and Mr. Wayne Cox were all Supervisors within the Department.

26

Ex B3A(11), [2]; Ex C8(6), pg. 5

27

Ex C7(19), pg. 1 & 2; Ex C8(6), pg. 6

28

Ex C6(46), [13]

29

Ex B12(26), pg. 7

30

Ex B3C(50), pg. 19

31

Ex B3C(50), pg. 19 & 20

32

Ex B12(26), pg. 5; T5-19

33

Ex B3C(46), pg. 5 & 6

Findings of the inquest into the death of Kate Louise Goodchild

Luke Jonathan Dorsett, Cindy Toni Low & Roozbeh Araghi

Page 13 of 274

44. Long-term former employee, Mr. Bob Tan, who resigned from Dreamworld in

January 2016, commenced working at the Park in 1987 as the Assistant

Maintenance Controller. He subsequently performed a number of roles, including

the Projects Manager (1992), Technical and Services Director (1995),

Maintenance Controller (2003), General Manager of Engineering (2009), before

taking on the role of Director of Special Projects within the Engineering

Department (2014) when Mr. Deaves was promoted to the General Manager of

Engineering.

34

Mr. Tan reported directly to the CEO. During his tenure at

Dreamworld, he became a qualified engineer, however, was not RPEQ certified.

45. At the time of the incident, the Safety Department at Dreamworld was

responsible for assisting with safety compliance at the Park, and to continually

improve culture/business practice in conjunction with other Departments.

35

Mr.

Mark Thompson was the Safety Manager at the time having commenced in the

position in March 2016.

36

He was responsible for delivering training on general

safety matters at induction, park-wide safety matters, responding to issues raised

through the incident system and implementing control measures for these

hazards and investigating suspected safety breaches, as well as oversight of the

First Aid Clinic.

37

Mr. Thompson reported to Mr. Angus Hutchings, who was the

Group Safety Manager for Ardent Leisure.

38

Mr. Hutchings had held this position

since 2010, and was responsible for providing advisory services with respect to

safety and strategic planning to all of the Ardent Leisure business groups,

including Dreamworld.

39

From 2004 until 2010, Mr. Hutchings held the position

of Dreamworld Safety Manager.

40

In both roles, he was required to report to the

CEO. Mr. Hutchings had prior experience working for the Safety Regulator, OIR,

however, had not previously been involved in implementing or devising safety

systems.

41

46. Within Dreamworld there were also a number of subset groups and teams, which

met at various intervals to discuss different matters. From the records provided,

the most pertinent groups relevant to the decision making within the Park seem

to be as follows:

(i) The Leadership Team, which consisted of General Managers of the

various Departments within the Park, including Mr. Margetts, Mr.

Thompson, Mr. Tan and Mr. Deaves.

42

A wide range of issues were

discussed during these meetings, including safety, financials, guest

service issues, rides and upcoming events.

43

The CEO would sometimes

attend these meetings if needed.

(ii) The Executive Safety Committee consisted of the CEO and General

Managers of the Departments, which at the time of the incident relevantly

seems to have included Mr. Craig Davidson, Mr. Deaves, Mr. Hutchings

and Mr. Margetts.

44

Topics discussed at these meetings included ride

34

Ex B3C(54), pg. 20; Ex F12(540)

35

Ex C6(51), [40]

36

Ex C6(51), [3]

37

Ex C6(51), [3]

38

Ex C6(51), [7] & [8]

39

Ex C8(10), pg. 5 & 6

40

Ex C8(10), pg. 8

41

T21-28 & 29

42

Ex C8(6), pg. 19; Ex C8(10), pg. 14-17

43

Ex C8(10), pg. 18

44

Ex C8(6), pg. 19; Ex C6(51), [33]; Ex C8(4), pg. 9

Findings of the inquest into the death of Kate Louise Goodchild

Luke Jonathan Dorsett, Cindy Toni Low & Roozbeh Araghi

Page 14 of 274

modifications.

45

(iii) The Engineering Management Team, which consisted of the General

Manager of Engineering and Supervisors, as well as Mr. Thompson, as

the Safety Manager. Weekly meetings were conducted,

46

with issues

associated with rides, including down-times, being discussed.

47

47. Further specific details as to the Safety and E&T Departments at Dreamworld

and their respective responsibilities and staffing, commence at page 78.

THUNDER RIVER RAPIDS RIDE (TRRR)

48. The TRRR commenced operation in December 1986, as part of the rustically

themed Gold Rush Country section of the Theme Park. It was manufactured in-

house at Dreamworld between 1985 and 1986, and was based upon a 1979

Intamin Amusement Ride called ‘Rapids Ride’.

48

Information as to the original

construction and subsequent modifications to the TRRR, as provided by Ardent

Leisure and OIR, are minimal. A summary of the information provided as to the

various modifications and alterations made to the ride over its 30 year

commission, are outlined further below commencing at page 25.

49. The TRRR was designed by consultant engineers. Mr. Len Shaw, the

Engineering Services Manager for Dreamworld, oversaw the construction. The

engineering drawings were provided at the time to Workplace Health and Safety

(as it then was) and approved by the Chief Inspector of Machinery for the Division

of Occupational Safety.

50. On 14 August 1987, the design of the TRRR was approved by the Chief Inspector

of Machinery in principle, subject to safety devices and guarding being found to

be to the requisite satisfaction of the District Inspector of Machinery.

49

Supporting

documentation to the design approval indicates that the ride was certified at that

time by a Consulting Engineer attesting to the safe structural integrity of the

design, and that it was compliant with the Australian Standards.

50

51. The TRRR was designed as a family orientated, aquatic based amusement ride,

which consisted of a raft that seated six occupants. Riders entered a long

partially indoor queue with a number of switchbacks, along with an express line

for the Ride Express pass holders. Upon reaching the front of the queue, riders

were guided onto a circular raft by one of two TRRR Ride Operators, before

being dispatched from the loading area. The ride then proceeded to be propelled

by a natural flow of water through the man-made river’s watercourse, which

includes calm and turbulent rapids, with rafts reaching speeds of up to 45 kph.

51

52. The raft travelled a watercourse (rapids) through various troughs and tunnels,

which was approximately 450 m long.

52

A wooden conveyor transported the rafts

at the end of the ride to the unload area. The duration of the ride, until the

commencement of the conveyor, was approximately three minutes and 16

45

Ex C5(51), [36]

46

Ex C6(51), [30]; Ex B3C(53), pg. 11

47

Ex B3C(53), pg. 11 & 12

48

Ex B1, pg. 10

49

Ex F9C(3)(a), [9]; Ex F9C(3)(b), pg. 1

50

Ex F9C(3)(b), pg. 3

51

Ex B1, pg. 10

52

Ex F9A(1), pg. 3

Findings of the inquest into the death of Kate Louise Goodchild

Luke Jonathan Dorsett, Cindy Toni Low & Roozbeh Araghi

Page 15 of 274

seconds

53

with a 35 second delay between each raft. It took approximately 42

seconds for a raft to travel on the conveyor and arrive at the unloading area.

54

The approximate total ride time for the TRRR was 4 minutes and 10 seconds.

55

53. Riders could get wet during the course of the ride, which ended when the raft

was elevated and transported by a conveyor towards the unloading area, which

is adjacent to where patrons are loaded onto the ride.

54. Below is an aerial view of the ride, with the path travelled by each raft through

the watercourse highlighted in yellow.

FIGURE: Ex F9A(1), pg. 4

Configuration of the TRRR

Forensic Crash Unit Investigation

55. As part of the QPS investigation, the mechanical and technical aspects of the

TRRR, its operation and the tragic incident were analysed by Senior Constable

Steven Cornish from the FCU at Coomera. This analysis included detailed

consideration of the technical operation of the ride and its components in their

entirety, relevant supporting documentation as to the ride and its history, as well

as the mechanism and timeline of the incident. Extensive on-site testing of each

component of the ride was carried out, in addition to various attempts to

reconstruct the tragic incident.

56. Senior Constable Cornish’s findings were detailed in a supporting coronial report,

with the various testing and other diagrams and exhibits annexed.

56

57. The findings reached by Senior Constable Cornish were accepted and reinforced

by expert evidence provided by way of a conclave during the inquest hearing,

and have formed the basis for the details as to the configuration of the TRRR,

the timeline of the incident, and the cause.

53

Ex B2, pg. 6

54

Ex B2, pg. 6

55

Ex B1, pg. 10

56

Ex B2

Findings of the inquest into the death of Kate Louise Goodchild

Luke Jonathan Dorsett, Cindy Toni Low & Roozbeh Araghi

Page 16 of 274

Configuration of the TRRR at the Time of the Incident

58. There were a number of major components of the TRRR, which whilst operating

individually, also played an integral and interdependent role within the overall

successful function of the ride.

57

The central components of the ride consisted of

a trough, water pumps, conveyor system, rafts, pneumatic gates, operating

control system and raft support rails.

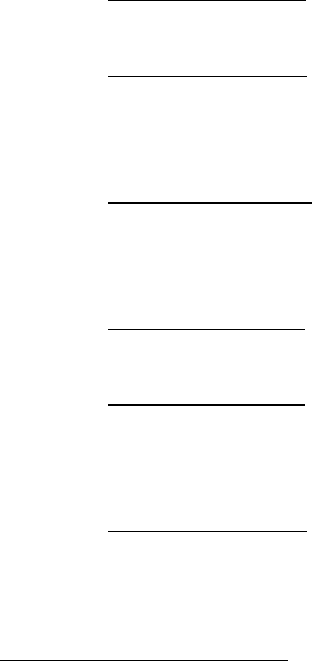

FIGURE EX. F9A(1), PG. 7: OVERVIEW OF TRRR WITH LOCATION OF LOADING &

UNLOADING AREA, PUMPS, CONVEYOR & RAILS

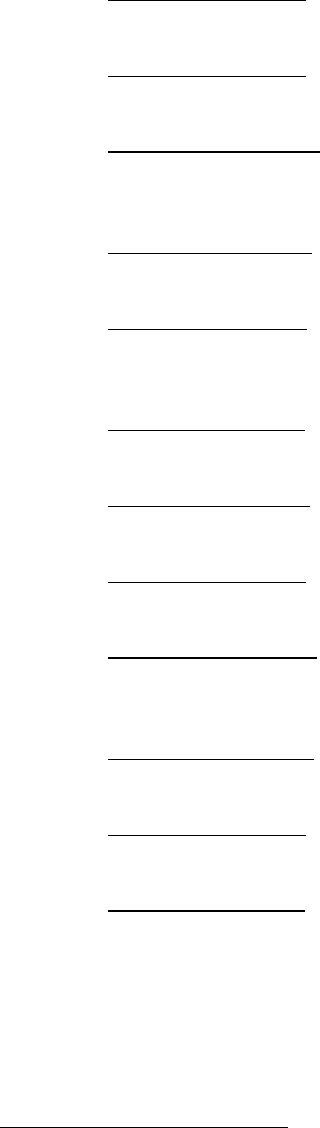

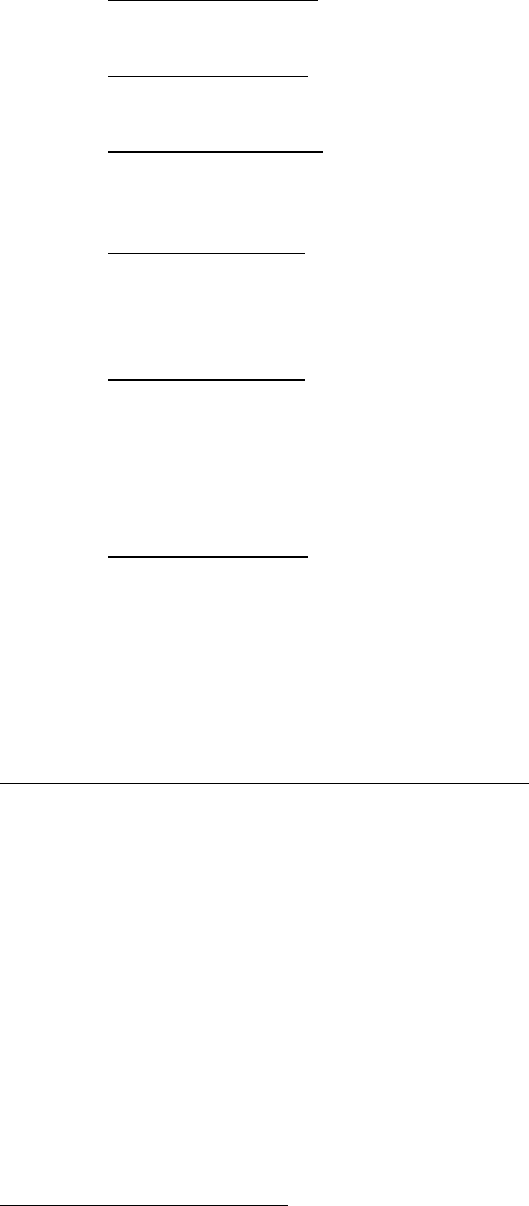

Operating Control System

59. The main operating control panel was located at the designated loading area of

the ride.

58

It had the capability of operating all of the independent components of

the ride, and was the only panel to have this access. The CCTV from five

cameras located around the ride were displayed on a monitor within a partitioned

wooden area. The position of this panel allowed the Ride Operator to oversee

the trough area as the rafts departed, as well as the conveyor system and unload

area.

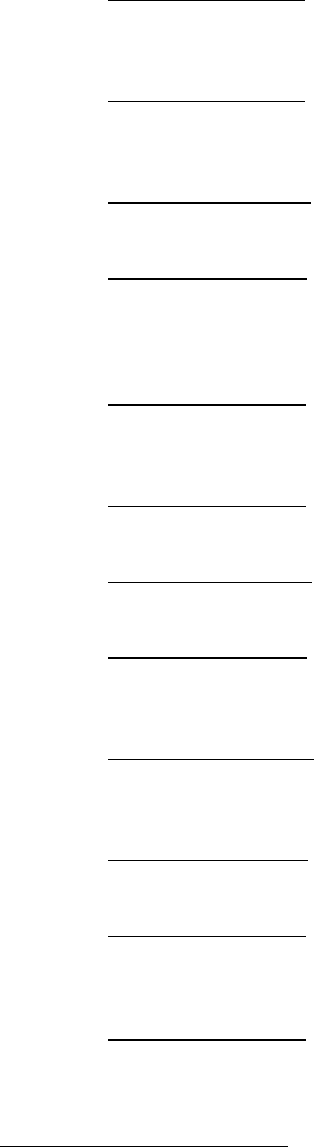

MAIN CONTROL PANEL AS IT APPEARED OCT 2016 - EX B2, PG. 30

57

Ex B2, pg. 6

58

Ex B2, pg. 8

Findings of the inquest into the death of Kate Louise Goodchild

Luke Jonathan Dorsett, Cindy Toni Low & Roozbeh Araghi

Page 17 of 274

60. There is an approximate distance of 12 metres between the Main Ride Operator

and the Unload Operator.

59

Due to the distance from the conveyor and unload

area, as well as the wooden structure of the control unit and exit walkway fencing,

the line of sight of the end of the conveyor by the Ride Operator stationed at this

panel was somewhat obstructed.

60

There was no electronic communication

between the two Operators.

Trough

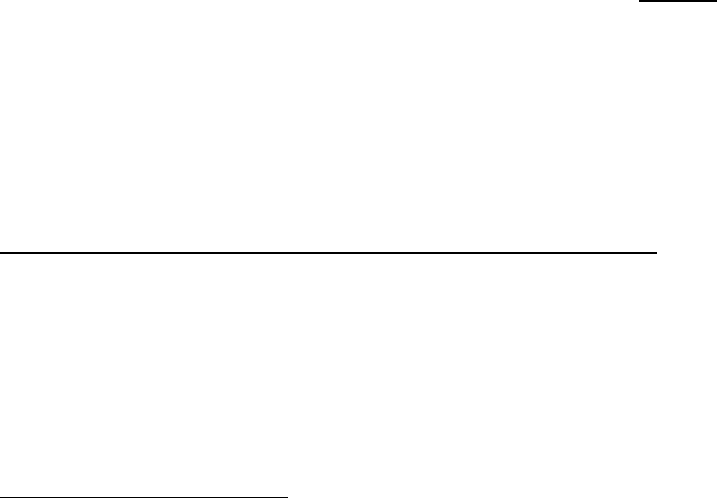

61. The trough was the channeling system, which the water flows through over a

distance of 410 metres, transporting the rafts and occupants.

61

It was generally

constructed of concrete with a depth of 1.3 metres and a width measuring

between three to five metres around the course of the ride.

62

62. Along the length of the trough, there were a series of turns, barriers and floor

mounted wooden logs. These elements were designed to create a turbulent flow

for the water, and to simulate a rafting experience. There were also a number of

tunnels, one of which had animations and attractions related to the ride and

operated by motion sensors.

63

63. Through the load and unload area of the ride there were outer metal guide rails

and wooden barge planks on the trough, which were designed to assist with the

loading and unloading of guests from the rafts.

64

Raft Supporting Rails

64. Mounted throughout the trough system in the load and unload areas of the ride

were steel raft support rails, which were primarily intended to prevent the rafts

from heeling (tipping) or flipping whilst occupants were embarking or

disembarking.

65

The rails also prevented the rafts from dropping to the bottom of

the trough in the event that the water level reduced or completely dissipated.

65. The steel railings were a dual system constructed of 100 mm wide right angle

steel, spaced 1450 mm apart (outer to outer) and bolted to the concrete floor of

the trough.

66

Within the level area of the trough between the load and unload

areas, the railings were positioned a minimum of 700mm above ground level and

remained level for the complete length of the construction.

67

59

Ex B2, pg. 65

60

Ex B2, pg. 9 & 65

61

Ex B2, pg. 11

62

Ex B2, pg. 11

63

Ex B2, pg. 11

64

Ex B2, pg. 11

65

Ex B2, pg. 12

66

Ex B2, pg. 13

67

Ex B2, pg. 13

Findings of the inquest into the death of Kate Louise Goodchild

Luke Jonathan Dorsett, Cindy Toni Low & Roozbeh Araghi

Page 18 of 274

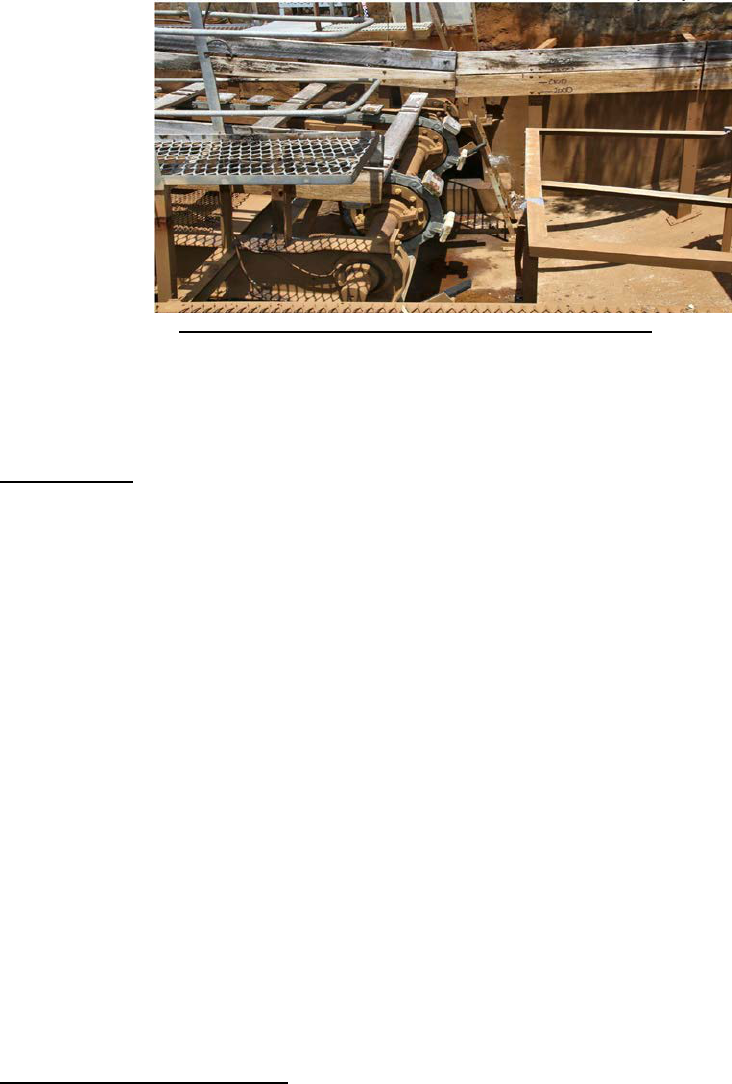

DEPICTS THE RAILING SYSTEM THROUGH ENTRY/EXIT AREA - EX B2, PG. 12

66. Additionally, there were a series of support railings in the trough prior to the

beginning of the conveyor (bottom), which were installed in 2015.

68

67. In the area of the incident at the end of the conveyor (top), there was no variation

in the level, with the support rails having been adapted to suit the sloping nature

of the flooring leading back to the area beneath the conveyor, known as the ‘pit’.

69

This area is where the water for the ride was gravity drained back into the storage

reservoir.

EX B2, PG. 14

Conveyor System

68. The conveyor on the TRRR was a mechanical device, which was chain driven

by an electric motor. The conveyor belt was constructed of a series of wooden

planks of two variations in size and evenly spaced along the belt.

70

The conveyor

was located towards the end of the ride, and was used to carry rafts from the end

of the trough system up to the unloading area.

69. The drive axle and two cogs were fixed to the western end of the conveyor where

the electric motor was attached. There was a dual chain system, which the

68

Ex B2, pg. 13

69

Ex B2, pg. 14

70

Ex B2. Pg. 16

Findings of the inquest into the death of Kate Louise Goodchild

Luke Jonathan Dorsett, Cindy Toni Low & Roozbeh Araghi

Page 19 of 274

planks were attached to, that was pulled along from the drive axle.

71

The

conveyor was driven by its own dedicated, power source and control system,

which was not linked to any other of the ride’s components.

70. The main control system for the conveyor was located at the Main Control Panel,

with a further control box, primarily used for maintenance purposes, located next

to the conveyor away from public access.

72

At the Operator control panel, there

was a start and stop button, as well as a reset button, which could be used to

restart the conveyor in the event that it was stopped under the Emergency Stop

procedures.

73

Upon depressing the start button, it became illuminated to show it

was operating whilst the red button flashed. The red button initiates the slow shut

down of the conveyor. There was no Emergency stop for the conveyor available

at the Main Control Panel.

74

71. During testing of the conveyor and Main Control Panel, Investigators found that

depressing the stop button for the conveyor was sufficient to initiate a slow stop.

75

A slow stop of the conveyor took 8 seconds for the conveyor to come to a

complete stop.

76

Activation of the E-Stops were found to stop the conveyor in

two seconds.

77

72. Given the location of the incident and mechanism involved, extensive

examination of the conveyor was undertaken by Senior Constable Cornish and

other officers, which included intricate manual measurements.

78

Video

recordings of the conveyor’s movements also assisted to calculate speeds, as

well as the interaction with the rafts, supporting railings and water flow.

79

73. The measurements of the conveyor planks, including the spacing and

configuration, are as follows:

80

74. The speed of the conveyor was found to be 2.7 kph.

81

75. An open air gap was found between the end of the conveyor closest to the unload

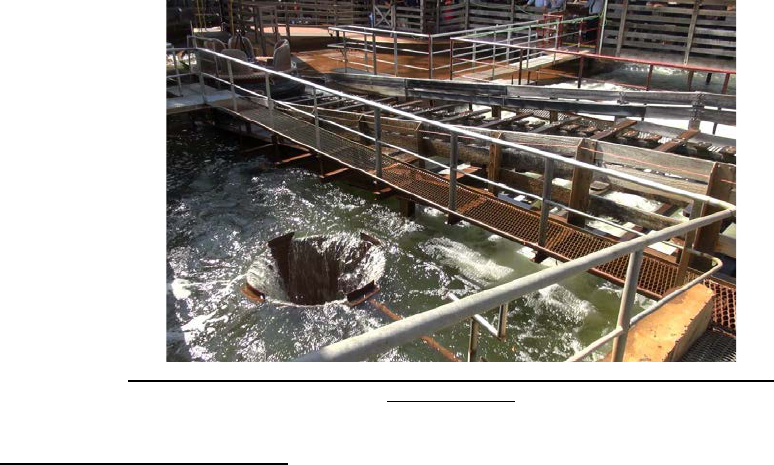

station and the beginning of the raft supporting rails. This interface area, which

was significant during the incident as it was into this gap that Raft 5 was pulled

down once inverted, was extensively examined and measured. The gap of the

71

Ex B2. Pg. 16

72

Ex B2. Pg. 16

73

Ex B2, pg. 37

74

Ex B2, pg. 37

75

Ex B2, pg. 37

76

Ex B2, pg. 54; T2-43 & 44

77

Ex B2, pg. 82

78

Ex B2. Pg. 16

79

Ex B2. Pg. 16

80

Ex B2. Pg. 17

81

Ex B2, pg. 20

Findings of the inquest into the death of Kate Louise Goodchild

Luke Jonathan Dorsett, Cindy Toni Low & Roozbeh Araghi

Page 20 of 274

interface between the conveyor’s long planks at their furthest point, and the

leading edge of the support rail was found to be 430 mm, with a 760 mm gap

between the leading edge of the support rails and the drive axle (when

exposed).

82

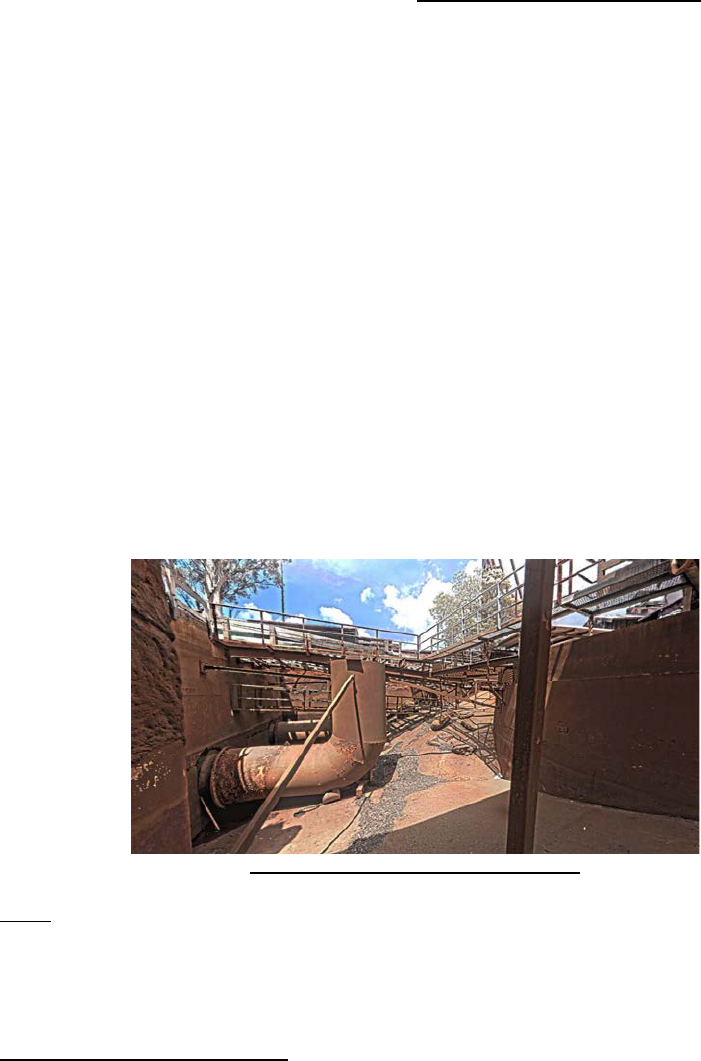

DEPICTS SIDE PROFILE OF INTERFACE, Ex. B2, pg. 21

76. Further details as to the modifications made to the conveyor over the duration of

the ride’s 30 year commission commence at page 25.

Water Pumps

77. There were two Danfoss VLT Aqua VLT 8502 Drives, which operated the two

induction motors (water pumps) utilised by the ride.

83

The drives were installed

in 2006.

84

The pumps were referred to as the North and South pumps due to

their positioning. The pumps were located under the conveyor belt, in a separate

confined enclosure.

78. The controls for both the pumps (stop and start) were located at the Main Control

Panel by way of separate buttons. A display on the panel also showed the amps

for the respective pumps. This was a predetermined figure, which took into

account the condition of the pump and the operating hertz of the motor in the

main electrical room.

85

For the TRRR pumps, the reading was to be below 500

amp, and was generally between 430-460 amps.

86

The control panel had no

mechanism to allow for a variation of the power of the pump, which would

subsequently vary the water flow. The variation in the amp usage was

determined by the water level in the reservoir. The lower the water level, the

higher the amp output to maintain the constant flow through the outlet.

87

79. The amp display, red and green lights, were the only visible aspect on the panel,

which showed that the pump was functioning.

88

Each pump functioned

independently of the other, and could be started and stopped separately.

89

An

emergency stop at the panel also deactivated the North pump only.

90

There was

82

Ex B2, pg. 20

83

Ex B2, pg. 23; Ex G2, [24]

84

Ex G2

85

Ex B2, pg. 35

86

Ex B2, pg. 36

87

Ex B2, pg. 35

88

Ex B2, pg. 35

89

Ex B2, pg. 23

90

Ex B2, pg. 35

Findings of the inquest into the death of Kate Louise Goodchild