EWGAE 2010

Vienna, 8th to 10th September

ACOUSTIC EMISSION ON-LINE INSPECTION OF RAIL WHEELS

Athanasios ANASTASOPOULOS, Konstantinos BOLLAS, Dimitrios

PAPASALOUROS, Dimitrios KOUROUSIS

Envirocoustics SA, El. Venizelou 7 & Delfon, 14452 Metamorphosis, Athens, GREECE,

Tel: +30 210 2846 801-4, fax: +30 210 2846 805, nassos@envirocoustics.gr

Keywords: Acoustic Emission, Train Wheels Inspection, Rail Axes Monitoring, Long Waveforms

Abstract

The ever-increasing demand for safer, faster and cleaner surface transportation such as

railway, imposes heavy usage and loads on train axes and wheels. Such components, during

usage, are subjected to complex, fatigue loading, shock loads, impacts, bending, etc. and/or

combinations of the above. Train wheel and axle failures while train is in operation occasionally

lead to catastrophic failures, possibly with human victims.

Within the scopes of an R&D project, aiming to develop novel methodologies and techniques

for the inspection of wheel sets, extensive Acoustic Emission measurements have been performed

on various trains and trams. In this set up, AE sensors were mounted on the rail aiming to

diagnose wheel problems by monitoring the AE transferred through the rail in real-time and while

the vehicles were moving. The purpose of the trials was to investigate the usage of AE for on-line

detection of defects on wheels such as flats, bearing failures and possibly significant cracks, and

to establish optimum setup parameters in this respect.

The present paper presents the raw data and evaluation results from AE experiments on train

and tram wheels, (both healthy ones and wheels containing known defects). During

measurements different AE sensors were placed on the side of the rails while the railcars or trams

were passing at different speeds. The effect of sensors frequencies and placement were

investigated All different AE monitoring techniques i.e. Time Driven Data, Hit Driven Data as

well as long (>10 sec.) waveforms were acquired simultaneously. Data analysis involved both

traditional AE features, source location and digital signal processing of acquired waveforms. The

Initial results presented herein highlight the different AE behaviour for defected and non-defected

wheels, and indicate clearly the potential of AE as diagnostic tool. Furthermore results shows that

the availability of acquired long, continuous waveforms significantly enhanced analysis

capabilities, when combined with advanced AE DSP software and pattern recognition analysis.

The research leading to these results has received funding from the European Community's

Seventh Framework Programme (FP7/2007-2013) under grant agreement no 218674.

Introduction

Inspection of rail wheels poses inherent difficulties due to accessibility issues, when the

wheels are mounted on the train, but also due to the complex geometry of the wheels, their

shaping and their attachments. As a result, current inspection methodologies are mainly based on

dismounting the wheels and inspecting them off-vehicle, or, in the best case, on an immobile

train, either on a periodic or on a need basis (e.g. see [1]), by means of localized NDT (MT, PT,

UT, EC, VT etc.). Still, however, failures occur, which occasionally lead to catastrophic

accidents. The need to identify wheel flaws at early stages and in a more economic way, reducing

maintenance costs, has steered research efforts towards on-line wheel inspection techniques, such

as vibration and Acoustic Emission. The aim of such techniques is to be able to identify flawed

train wheels, while the train is in-service (moving) and the “screen out” bad wheels for further

inspection and maintenance, in a fast, effective way.

More info about this article: https://www.ndt.net/?id=9758

In this respect, the Acoustic Emission [2] method has been identified as a very promising tool.

Acoustic Emission uses high-frequency, passive piezoelectric transducers, which are mounted on

the side of the rails, in order to detect the stress waves generated by the various possible flaws of

the wheel, for instance, flats, or other circularity defects, which are impacting on the rail while

the wheel is turning, or cracks opening, or even faulty bearings from the axes. Since other

Acoustic Emission sources are present, even in a healthy train (engine noise, frictional noise,

banging noise etc.) the technique, as a first stage stage, usually involves acquiring the AE

“signature” of a vehicle with healthy, “reference” wheels, and comparing this to the one of a

vehicle with defected wheels. The method offers significant advantages compared to other

passive methods, mainly due to the high sensitivity it offers, as well as the fact that the AE

transducers operate within high-frequency range (30-1000kHz), eliminating to a big extend

mechanical noise. Once calibrated and standardized, the method may be employed very

effectively, for instance by mounting sensors on all rails of a depot and “listening” to the trains or

trams as they exit for their shift. Each wheel is “inspected” as it passes from the point of the rail

where the AE sensor is located, thus, within a single day, all wheels in usage may be inspected.

Acoustic Emission has already been applied for the detection of rail track faults at laboratory

level [3, 4], while, to the authors’ knowledge, a limited number of field experiments has been

carried out [5,6].

The research leading to these results has received funding from the European Community's

Seventh Framework Programme (FP7/2007-2013) under grant agreement no 218674 of

SAFERAIL project [7]. The SAFERAIL consortium seeks to minimise wheel set failures by

developing and successfully implementing a novel on-line system for the inspection of wheels

and axles of moving trains, and a combined ultrasonic-electromagnetic system for faster and

more reliable inspection of the quality of new and old wheel sets during their production and

maintenance. The present work is a study of the application of AE for the on-line inspection of

rail wheels, investigating various hardware parameters such as sensor frequency, test parameters

such as type and velocity of vehicles, as well as data acquisition and analysis strategies. Results

show the ability of the technique to detect wheel flaws, while the methodology is still under

optimization in terms of resources used, and analysis time.

Instrumentation

All presented data has been acquired using systems based on the Physical Acoustics Corp.

PCI-2 AE boards [8], which are unique in offering the capability of acquiring Time and Hit

Driven AE Data at the same time with long waveform streaming directly to hard drive. Four

different types of AE sensors have been investigated: Physical Acoustics’ R3i (30kHz resonant),

R15 (150kHz resonant), R30 (300kHz resonant) and R50 (500kHz resonant). Data was acquired

by AE-Win real-time data acquisition software [9], while advanced data analysis has been

performed using specialized AE data analysis and Pattern Recognition NOESIS software [10].

For the scopes of this work three different data sets of field trials are presented, which were

acquired at three different sites, two involving trains and one involving trams. State-of-the-art AE

equipment has been used, allowing simultaneous acquisition of three different AE data types,

such as Time Driven Data (TDD), Hit Driven Data (HDD) as well as long (>10 sec.) waveform

streams (WFS). The importance of the availability of each individual data type as well as its

significance in data interpretation is clearly demonstrated. Additionally, advanced and versatile

software tools were utilized in order to fully analyse multiple aspects of the acquired data.

Experimentation

AE Monitoring of Train Wheelsets in Portugal

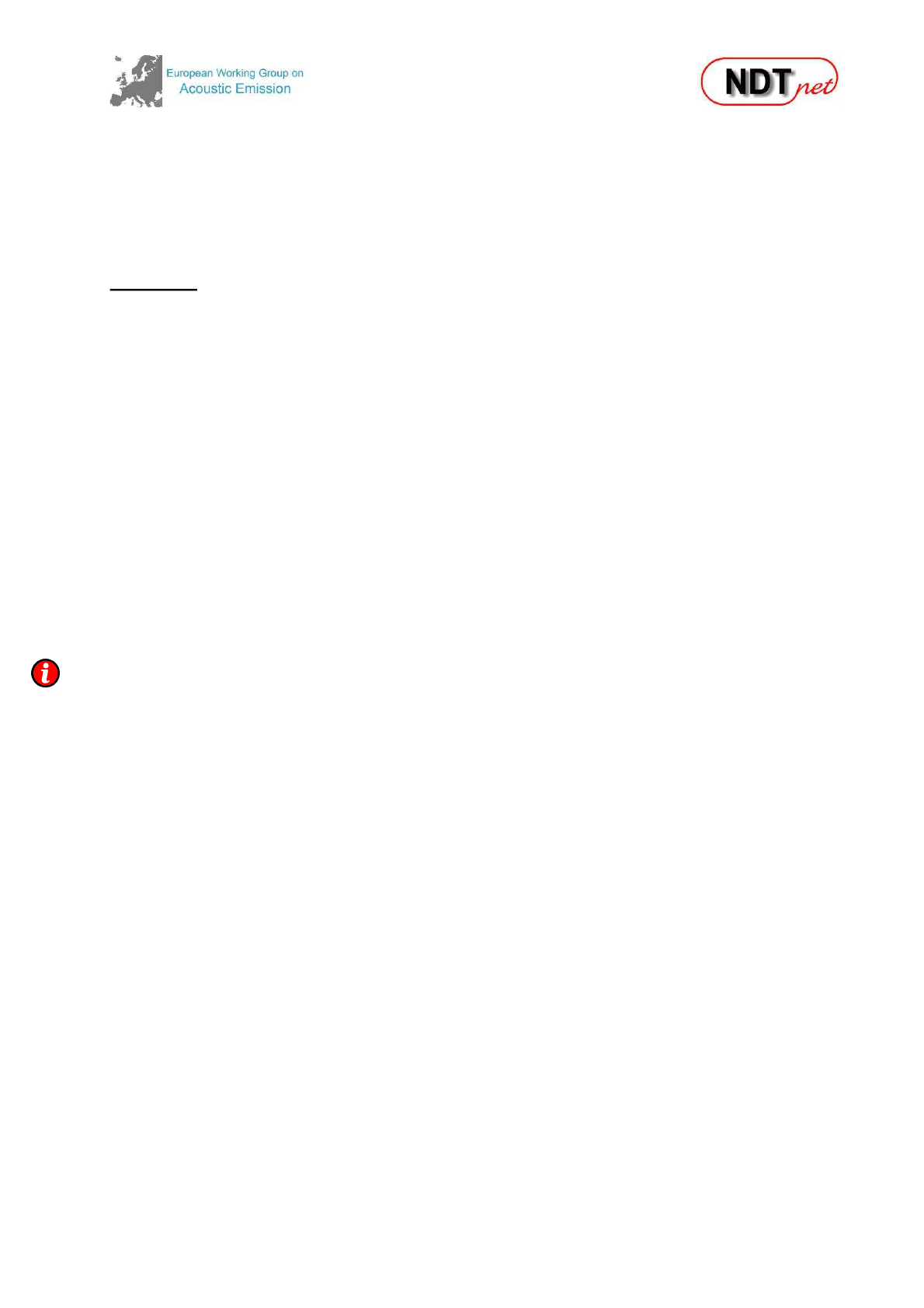

Acoustic Emission trials were performed by placing AE sensors on rails (Fig. 1b) and,

subsequently, monitoring moving railcars. Using a variety of different combinations of AE

sensors, frequency filters, data acquisition software settings, railcar types with known defects on

their wheel sets (Fig. 1a), on different railcar speeds and directions, a large amount of AE data

was acquired, analyzed and investigated, using various techniques, traditional and advanced.

On some of the healthy wheels, flat type defects were produced during the test by executing

emergency brakes on the railcar while it was on the move. Wheels, already reported as containing

flats, were also tested.

During acquisition, all aforementioned AE data types (HDD, TDD, WFS) were acquired for

each channel / sensor used. Signal location was also investigated along the rails in some

occasions.

AE data, location settings and waveforms were analyzed and investigated. Although, initially,

there were no clear conclusions about the capability of the performed experiments to locate the

defects on train wheels, the majority of the data before and after the defects generation showed

evidence of defects existence.

(a) (b)

Fig. 1 - (a) Photo showing a flat defect on a wheel surface created by emergency breaking of the

train. Courtesy of EMEF (b) Train wheel and installed AE sensor.

Data was analyzed using special pattern recognition software (Noesis v.5.5). AE features like

signal amplitude, duration, energy, average signal level etc. of acquired AE signals were

compared using the different resulting data sets from:

• same railcars - different railcar speeds,

• different railcars - similar railcar speeds.

• railcar before defect generation – same railcar after defect generation

All comparisons were performed using data from same train direction.

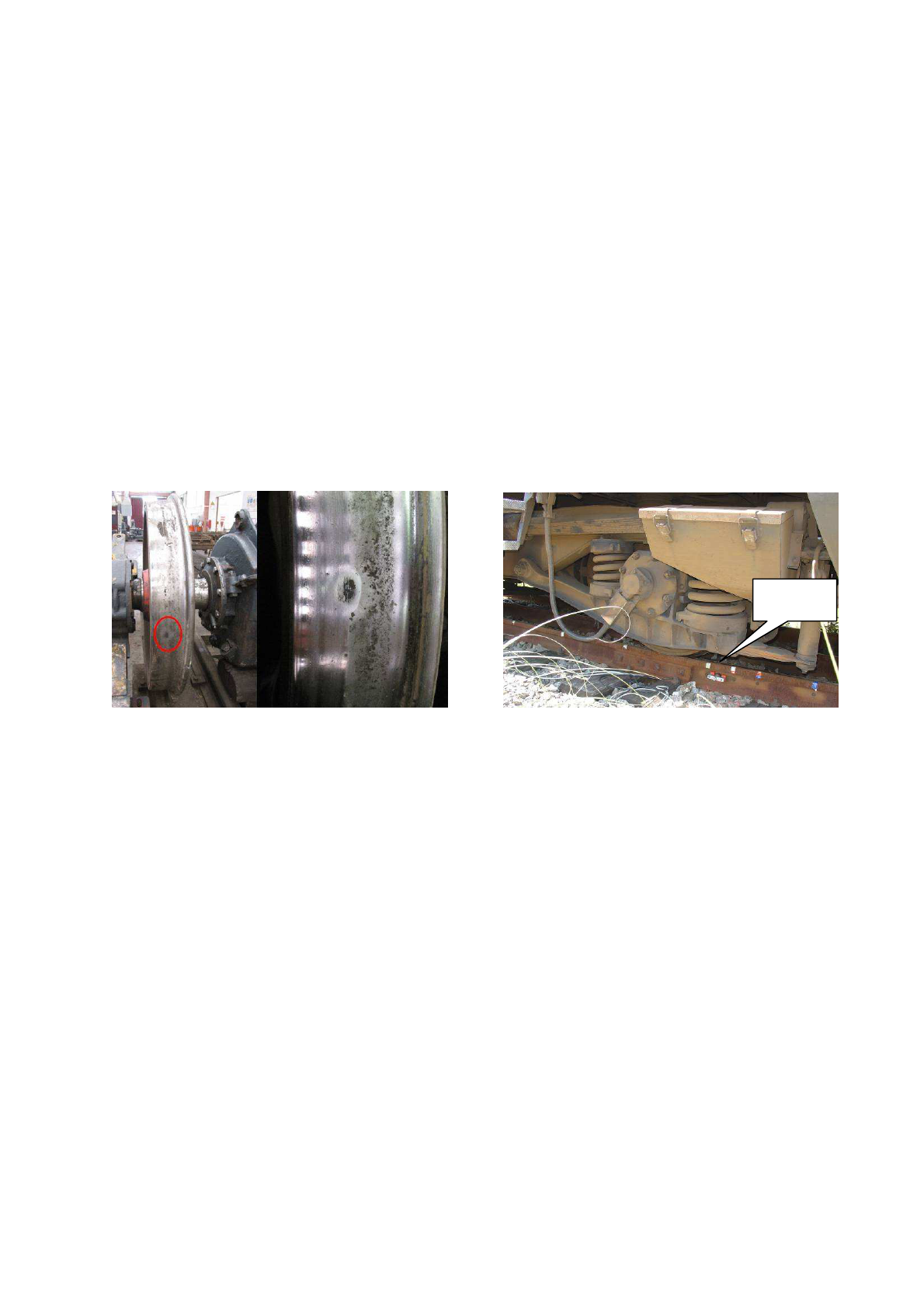

Data analysis focused on location capabilities of hit-driven AE data (HDD). In cases where

location was applied, more events appeared during defected railcar movement. As can be

observed in Fig. 2, on low (5km/h) and medium (20km/h) speed the number of located AE events

is higher for the defected railcar. In opposite, on higher speed (40km/h) less AE events can be

located.

AE

sensor

Fig. 2 - AE events location graphs of AE signals density for different railcar speeds 5, 20 and

40km/h, before any emergency break (clear wheelsets) and after 7 emergency breaks (defected

wheelsets).

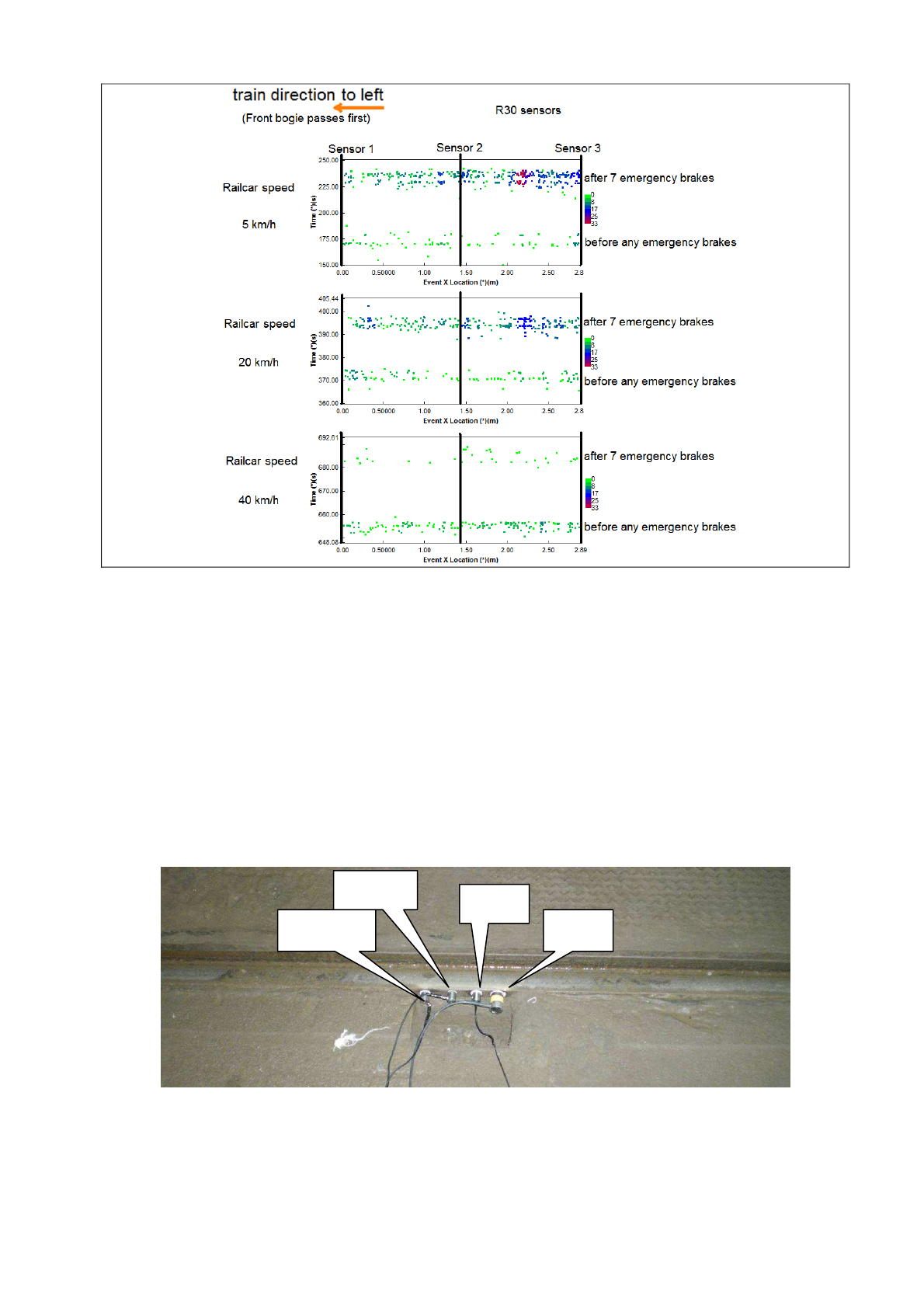

AE Monitoring of Tram Wheelsets in Antwerp Belgium

Acoustic Emission acquisition was performed on four different trams of different types and

defect status (two with defected wheel sets and two with undefected ones). AE was acquired

during 22 tram passes at varying speeds, in both directions. Four different types of AE sensors

were used (PAC R3i, R30, R15, R50). Due to the difficulty of accessing the rear part of the rail,

no location groups could be setup and no magnetic clamps could be used for placing the sensors.

All sensors were attached on the rail using special adhesive grease (see Fig. 3). Depending on the

different resonant frequencies of the sensors, measurements using various low and high pass

frequency filters were performed.

Fig. 3: AE sensors placement on the external rear side of the rail.

Whereas various types of analyses have been performed, such as comparison between data of

defected and non defected railcars, repeatability check of data acquired with same conditions

(same railcar and railcar speed, same railcar direction etc.), attempt to separate signals of

different wheels by long waveform analysis, filtering effectiveness check on acquired data, etc.,

R50

R30

R15

R3i

analysis of this particular set of data (tram measurements) focused mainly on long waveform

processing with advanced DSP.

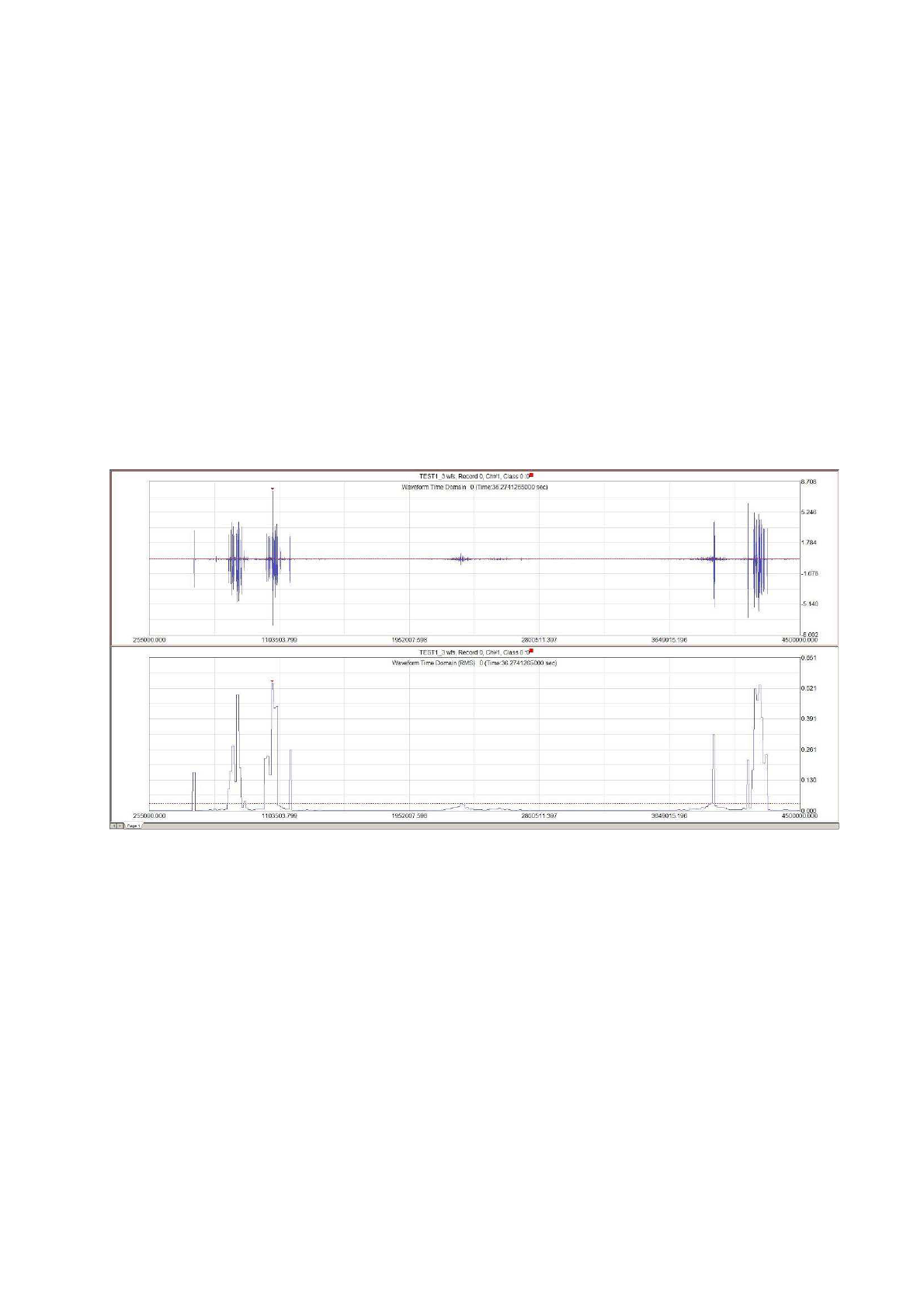

Analysis of long waveforms either by mere observation / focusing or using DSP tools,

revealed the great potential that such type of AE data offers. Observation of the overall signal

acquired during passing of a wheel above the sensor position, allows the determination of the

effective monitoring time, i.e. the period of time during which the train creates detectable AE

signals, thus, allowing data collection period determination for future tests (Fig. 4). Further

focusing in the waveform, allows the user to observe peaks in the voltage signal which are

generated when each axis passes right on top of the sensor. Furthermore, the existence of flats

may also be demonstrated as voltage peaks, thus, zooming on such, and performing frequency

analysis on specific sections, it is possible to observe the frequency contents of specific sources,

enhancing signal interpretation. Finally, RMS or ASL processing which basically offer a

“smoother” or averaged representation of the signal, allows the user to conveniently perform

time-based calculations, such as observe the time difference of the axes and bogies as they pass

from each sensor and allow macroscopic observation of signal level differences which may be

periodic (appearing at a frequency coinciding with the rotation frequency), indicating transient /

banging AE from flats, or continuous, indicating possible bearing problems.

Fig. 4 - AE waveforms (up) and RMS graphs (down) acquired by a PAC R50 sensor during

passes of a railcar (tram) with 3 bogies (6 axes) and a flat on the first axis. Axes passes are

demonstrated by the periodic voltage peaks, while flats, possibly by the extra peaks in the first

bogie pass (left side of graph)

AE Monitoring of Train Wheel sets at UK

Previous tests had revealed the potential of location analysis of feature-based AE data and long

waveform analysis and had shown that wheel geometric anomalies may well be demonstrated in

the time domain as peaks in the signal voltage. Having this in mind, and in order to fine tune the

detection capabilities of AE based for the real time monitoring of rail tracks a different setup

(Fig. 5) was used at VTG Site in Long Marston UK.

Fig. 5 - Sensor setup on rail track.

Two R30a sensors and two R15i sensors were mounted on the same track at 1/3 distance from

the tracks ends (Fig. 6). Similarly on the opposite track two R15i’s were mounted in order to

acquire any AE transients that may propagate across through various wave paths. The use of

R30a sensors with approximate center frequency at 300kHz or even higher (R50’s) is deemed

necessary where higher signal to noise ratio is needed. With higher SNR the acquired signals are

less prone to active mechanical noise sources (engine etc) that are usually found at lower parts of

the spectrum and contaminate or mask useful AE data with meaningless random noise. The

results presented here are based on raw data acquired with high density TDD while full analysis

is ongoing. Using TDD with a very high sampling rate, a near-continuous acquisition of time-

based AE Features can be achieved (ASL, RMS, Absolute Energy, etc.). Further investigation of

this type of AE data can be performed by superimposing the acquired HDD data with the TDD on

specialized software [10] in order to quantify the AE activity resulting from variations of the

signal. In order to link the AE activity generated from active defects, two different flat surfaces

with spans 2.5cm and 5cm were created on the circumference of a wheel with an angle grinder

(Fig. 7 (a),(b)).

(a) (b)

Fig. 6 - R30a with R15i (a),(b)

(a) (b)

Fig. 7 - (a) 2.5cm flat surface on wheel – (b) 5cm flat surface on wheel

0.22

0.8m

3.57m

3.57m

0.36

0.12m

0.16m

R15i

–

CH2

R30a–CH6

R30a

-

CH5

R15i

–

CH1

10.97m

The train’s configuration was a locomotive and two attached wagons with identical

dimensions. The first wagon after the locomotive was used as a reference wagon, since its wheel

sets had no defects. AE activity was acquired during forward (left-to-right) and backwards (right-

to-left) movement. Different data sets were acquired for different speed levels for these two

directions.

(a)

(b)

(c)

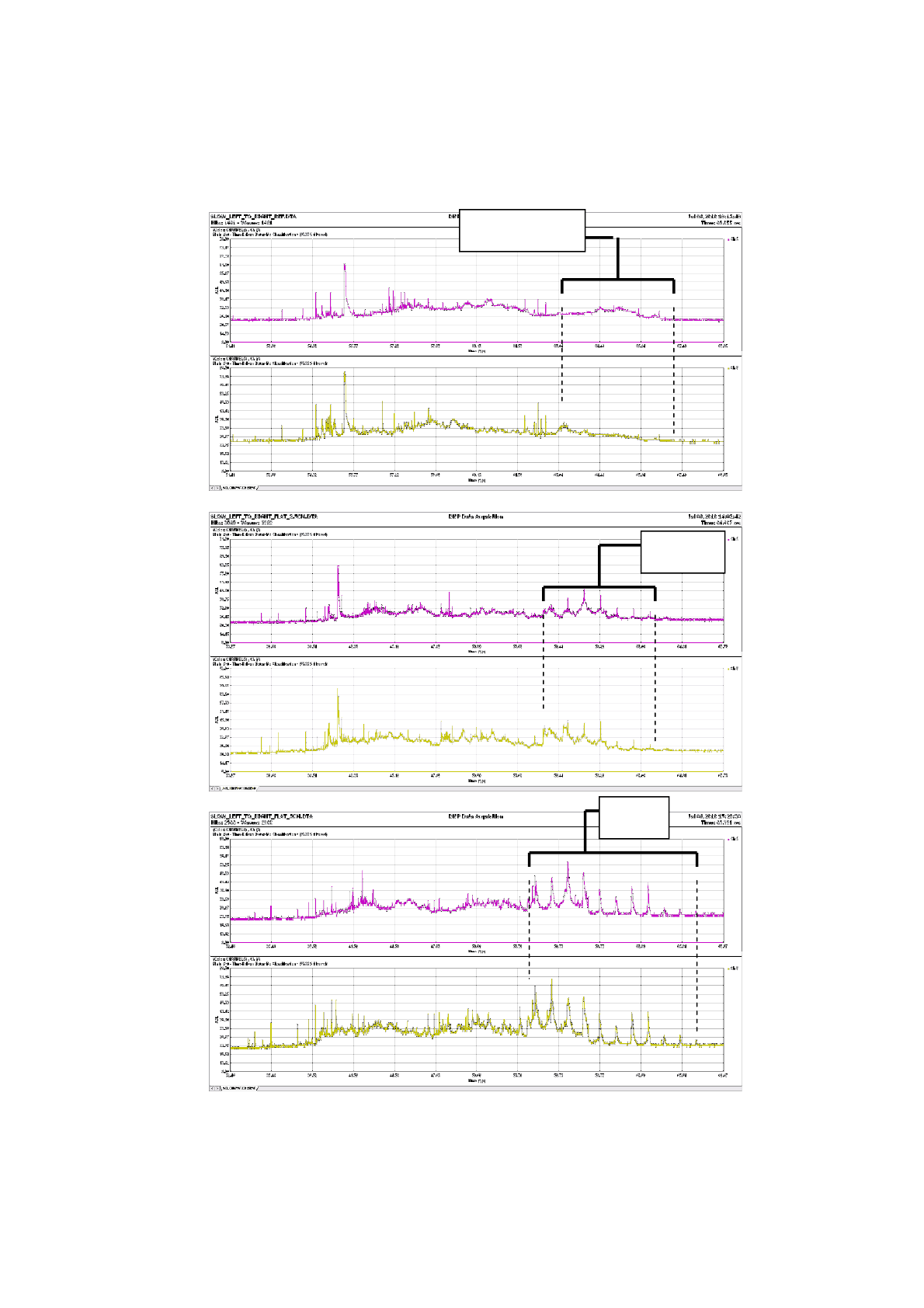

Fig. 8 - (a) Reference Train Movement (b) 2.5cm flat defect surface (c) 5cm flat defect surface –

All Graphs Channel 5 ASL VS Time Top/Channel 6 ASL VS Time Bottom

As becomes clear from Fig. 8, both defects are clearly depicted as periodic spikes in the ASL

vs. Time graphs. Such spikes are completely missing from the reference (healthy) wagon.

2.5cm

5cm

No Defects

Additionally, time measurements between the edges of the spikes have shown that these occur at

a frequency coinciding with the wheel rotation frequency.

Conclusions

Recent work in Acoustic Emission monitoring of train wheelsets on moving trains and trams

using AE sensors mounted on the rails has verified the great potential of the method in detecting

geometric defects such as flat surfaces on wheel circumference. To achieve optimum results,

multi-dimensional analysis has been performed, combining TDD, HDD and long waveforms

streams acquired simultaneously. Combined analysis with specialized software is required to

reveal the full potential of all available data in the time and frequency domain. Placing more than

one AE sensor on the rail track and setting up a location group can show evidence of flats

existence on lower railcar speeds, but for exact location of the defect further work is required.

Acknowledgment

The research leading to these results has received funding from the European Community's

Seventh Framework Programme (FP7/2007-2013) under grant agreement no 218674, SAFERAIL

project (http://www.saferail.net/). The authors would like to thank all Project Partners and

gratefully acknowledge the contribution of Vlaamse Vervoersmaatschappij De Lijn, Belgium,

VTG Rail, UK and EMEF SA, Portugal for providing access and resources for the tests.

References

1. Norme Européenne CEN/TC 256, prEN 15313:2007: Railway applications — In-service

wheelset operation requirements and in-service and off-vehicle wheelset maintenance.

2. ASTM Standard E1316, 2005, “Standard Terminology for Nondestructive Examinations”,

ASTM International

3. Bruzelius K., Mba D., “An initial investigation on the potential applicability of Acoustic

Emission to rail track fault detection”, NDT&E International 37 (2004) 507–516

4. Thakkar N.A., Steel J.A., Reuben R.L., “Rail–wheel interaction monitoring using Acoustic

Emission: A laboratory study of normal rolling signals with natural rail defects”, Mechanical

Systems and Signal Processing 24 (2010) 256–266

5. Thakkar N.A., Steel J.A., Reuben R.L., Knabe G., Dixon D., Shanks R.L., “Monitoring of

Rail-Wheel Interaction Using Acoustic Emission (AE)”, Advanced Materials Research Vols.

13-14 (2006) pp 161-168

6. Private Communication with MISTRAS GROUP SA – EPA, 27 Rue Magellan ZAC des

Portes de Sucy, F 94470 Sucy-en-Brie, France, Tel: +33.1.49.82.60.40

7. “SAFERAIL - Development of Novel Inspection Systems for Railway Wheelsets”, by

Anastassopoulos, A., Barros, P., Bey, F.

,

Blakeley, B.

, Boynard, C.

Braz, R, Courinha, J.,

Davis, C.

, Day, N.

, Dias, D.

, De Donder, E.

, Kerkyras, S.

, Kerkyras, Y.

, Laeremans, M.

,

Liaptsis, D.

, Lugg, M.

, Lugg, P.

, Nicholson, P.I.

, Nobre, T.

, Papaelias, M.

, Pinto, M.

,

Roberts, C.

, Vanhonacker, T.

, Vermeulen, F., Presented at CM 2010 and MFPT 2010, The

Seventh International Conference on Condition Monitoring and Machinery Failure Prevention

Technologies 22-24 June 2010, Ettington Chase, Stratford-upon-Avon, England

8. PAC’s site: http://www.pacndt.com/index.aspx?go=products&focus=/multichannel/pci2.htm

9. Physical Acoustics Corporation, AEwin

TM

Software, Installation, Operation and User’s

Reference Manual, rev. 2. Princeton Junction, New Jersey, USA.

10. NOESIS Ver.5.2, Envirocoustics, User’s Manual.