New Jersey

Department of Environmental Protection

Site Remediation and

Waste Management Program

Evaluation of Extractable Petroleum Hydrocarbons

in Soil Technical Guidance

June 2019

Version 1.0

2

TABLE OF CONTENTS

1.0 INTENDED USE OF GUIDANCE ..................................................................................... 4

2.0 PURPOSE ............................................................................................................................ 5

3.0 INTRODUCTION ............................................................................................................... 6

4.0 OVERVIEW OF PROCEDURE: ........................................................................................ 8

4.1 Determine Correct EPH Category .................................................................................... 8

4.1.1 Category 1 Defined: .................................................................................................. 8

4.1.2 Category 2 Defined: .................................................................................................. 8

4.1.3 Mixtures: ................................................................................................................... 8

4.2 Determine Human Health-Based Remediation Goal ....................................................... 8

4.2.1 Exceedance of the EPH Default Product Limits ....................................................... 9

4.2.2 Technical Impracticability – large or complex non-residential sites ...................... 10

4.3 Address Additional Analytical Requirements ................................................................ 11

4.4 Assess Ecological Risk................................................................................................... 11

5.0 EPH EVALUATION STEPS ............................................................................................ 12

5.1 CATEGORY 1 - Discharges of only Number 2 (No. 2) heating oil or diesel fuel:

Residential Land Use ..................................................................................................... 12

5.2 CATEGORY 1 - Discharges of only Number 2 (No. 2) heating oil or diesel fuel:

Non-Residential Land Use ............................................................................................. 16

5.3 CATEGORY 2 – Discharges of petroleum products other than No. 2 heating oil or

diesel fuel: Both Residential and Non-Residential Land Uses ...................................... 19

6.0 GLOSSARY ...................................................................................................................... 24

7.0 ACRONYMS ..................................................................................................................... 26

8.0 REFERENCES .................................................................................................................. 27

APPENDICES

APPENDIX 1 Summary Table of EPH Soil Remediation Criteria,

Thresholds for Additional Analyses and Evaluations,

and EPH Product Limits .................................................................................... 29

APPENDIX 2 EPH Alternative Product Limit Calculation Procedures ................................... 30

2.1 Obtaining Appropriate Grain Size Distribution Data ................................................. 34

2.2 Documentation and Information to be Submitted for Calculation

of an AOC-specific EPH Alternative Product Limit in Soil ....................................... 37

3

2.3 Derivation of Equation for Calculating an EPH Alternative

Product Limit in Soil ................................................................................................... 38

2.4 Variables Table and Table of Petroleum Product Viscosity and Density ................... 46

APPENDIX 3 Established EPH Product Limits, Standards,

Screening Levels, Basis and Policy ................................................................... 53

3.1 EPH Default Product Limits, Basis ............................................................................ 54

3.2 EPH Product Ceiling Limit, Basis .............................................................................. 57

3.3 EPH Category 1: Health Based Soil Remediation Criteria, Derivation...................... 58

3.4 EPH Screening Level, Ecological ............................................................................... 60

3.5 Application of pre-September 2010 Petroleum Hydrocarbon Data ............................ 61

4

EVALUATION OF EXTRACTABLE PETROLEUM HYDROCARBONS IN SOIL

TECHNICAL GUIDANCE

INTENDED USE OF GUIDANCE

This technical guidance is designed to help the person(s) responsible for conducting the

remediation to comply with the New Jersey Department of Environmental Protection

requirements, the Technical Requirements for Site Remediation (Technical Rules), N.J.A.C.

7:26E. This guidance will be used by many different people involved in the remediation of a

contaminated site; such as Licensed Site Remediation Professionals, Non-LSRP environmental

consultants and other environmental professionals. Therefore, the generic term “investigator”

will be used to refer to any person that uses this guidance to remediate a contaminated site on

behalf of a remediating party, including the remediating party itself.

The procedures for a person to vary from the technical requirements in regulation are outlined in

the Technical Rules at N.J.A.C. 7:26E-1.7. Likewise, the procedures for a person to vary from

technical guidance are outlined in the Site Remediation Reform Act, N.J.S.A. 58:10C-14c(4).

In both instances, the investigator must appropriately document and adequately support with data

or other information.

This guidance supersedes previous DEP guidance issued on this topic. Technical guidance may

be used immediately upon issuance. However, the Department recognizes the challenge of using

newly issued technical guidance when a remediation affected by the guidance may have already

been conducted or is currently in progress. To provide for the reasonable implementation of new

technical guidance, the Department will allow a 6-month “phase-in” period between the date the

technical guidance is issued (or the revision date) and the time it is effective for all sites.

This guidance was prepared with stakeholder input. The following people were on the

committee that prepared this document:

David Barskey, Co-Chair, Department (retired)

John Ruhl, Co-Chair, Department

Kathleen Kunze, Department guidance coordinator (retired)

Ronald Baker, USGS New Jersey Water Science Center (retired)

Michel Boufadel, New Jersey Institute of Technology (NJIT)

Geoffrey Clark, LSRP, GHD Services, Inc. (8/25/2015 – 1/10/2017)

John Donohue, Fuel Merchants Association of New Jersey

David Puchalski, LSRP, NewFields Princeton, LLC (1/25/2017 - present)

5

PURPOSE

This technical guidance replaces the previous Protocol For Addressing Extractable Petroleum

Hydrocarbons (EPH Protocol, Version 3.0, 9 August 2010). The main differences between

the August 2010 EPH Protocol and this technical guidance are:

• the addition of six EPH-applicable petroleum products to Table 2-1 of N.J.A.C. 7:26E-

2.1(d);

• the addition of an equation to calculate AOC-specific EPH alternative product limit

concentrations;

• the 8,000 mg/kg EPH default product limit typically associated with Category 1 EPH is

now designated to some Category 2 petroleum products;

• the establishment of an EPH ceiling limit concentration; and

• inclusion of compliance averaging options for the ingestion-dermal exposure pathway per

the Technical Guidance for the Attainment of Remediation Standards and Site-Specific

Criteria (https://www.nj.gov/dep/srp/guidance/#attainment_comp) for EPH Category 1

residential and non-residential soil remediation criteria.

This technical guidance provides direction on how to evaluate the EPH soil sample data from the

site investigation, remedial investigation, and remedial action phases at sites with petroleum

storage and discharge areas of concern (AOCs) pursuant to the Department’s Technical

Requirements for Site Remediation (Technical Rules, N.J.A.C. 7:26E) and the Department’s

guidance library. It is most useful when the horizontal and vertical delineation of the discharge

is complete in both the saturated and unsaturated soil pursuant to N.J.A.C. 7:26E-4.2(a) so that

the distribution of EPH in soil is well understood. This may include the remedial action

verification sampling.

As listed in Table 2-1 at N.J.A.C. 7:26E-2.1(d), this technical guidance addresses petroleum

products that include No. 2 heating oil, diesel fuel, No. 4 heating oil, No. 6 heating oil, hydraulic

oil, cutting oil, crude oil, lubricating oil, waste oil, unknown petroleum hydrocarbons, waste

vehicular crankcase oil, mineral oil, dielectric fluid, dielectric mineral oil, transformer oil, or

manufactured gas plant (MGP) sites. For petroleum products and mixtures not listed in Table 2-

1 at N.J.A.C. 7:26E-2.1(d), consult with the Department contact(s) for EPH listed at

http://www.nj.gov/dep/srp/srra/srra_contacts.htm.

This technical guidance does not apply to discharges from the more volatile petroleum products

(e.g., gasolines, kerosene, jet fuels, or light petroleum distillates), which must be investigated

pursuant to the Technical Rules. Also note that for those situations where multiple petroleum

hydrocarbon mixtures are involved, the evaluation must address all the types known to be

present. Where the petroleum product type is unknown, sampling and analytical parameters for

waste oil must be applied.

In accordance with N.J.A.C. 7:26E-2.1(a)6, the analytical method "Analysis of Extractable

Petroleum Hydrocarbon Compounds (EPH) in Aqueous and Soil/Sediment/Sludge Matrices"

(NJDEP EPH Method 10/08, Revision 3 August 2010) shall be used when investigating

petroleum storage and discharge areas. https://nj.gov/dep/srp/guidance/srra/eph_method.pdf

The results of this analytical method are reported as extractable petroleum hydrocarbons (EPH).

6

INTRODUCTION

This technical guidance applies to all petroleum storage facilities and petroleum discharge AOCs

for EPH analysis of soil required pursuant to N.J.A.C. 7:26E-2.1(d). The focus of this guidance

is on the evaluation of EPH data for its compliance with the EPH soil remediation criteria which

are not included in the Department’s Remediation Standards (N.J.A.C. 7:26D), and on EPH

product limits which are not included in other technical guidance. The EPH soil remediation

criteria and EPH default product limits are summarized in APPENDIX 1.

The Department is mandated by the Brownfield and Contaminated Site Remediation Act

(N.J.S.A. 58:10B-12) to employ a health-based approach when developing remediation

standards. The EPH residential and non-residential soil remediation criteria are based on an

exposure scenario for protection from noncarcinogenic health effects at a hazard index of 1 and

are based solely on effects via the ingestion-dermal exposure pathway. This technical guidance

provides a health-based approach to accomplish the remediation of EPH for the petroleum

products identified in Table 2-1 of N.J.A.C. 7:26E-2.1(d) that require analysis for EPH.

Likewise, remediation shall also comply with Technical Requirements for Site Remediation

(N.J.A.C. 7:26E), including, but not limited to, the requirements to treat or remove free product

and residual product to the extent practicable (N.J.A.C. 7:26E-5.1(e)).

This technical guidance provides direction for:

• Evaluating the EPH soil sample data from the investigation of petroleum storage and

discharge areas (Category 1, Category 2, or mixture).

• Applying the EPH soil remediation criteria (SRC)

A discussion of the derivation of the human health-based residential and non-residential

SRC which are based on the ingestion-dermal exposure pathway is found in Appendix

3.3. Some components of this guidance can be used to address EPH contamination at

sites regulated under the Heating Oil Tank System Remediation (HOTSR) Rule

(N.J.A.C. 7:26F). However, compliance with the HOTSR Rule is not included in this

EPH technical guidance. Refer to the HOTSR Rule and its associated technical

guidance.

• Evaluating the soil sample data for the additional analyses required pursuant to

Table 2-1 at N.J.A.C. 7:26E-2.1(d).

• Evaluating potential ecological concerns pursuant to N.J.A.C. 7:26E-1.16 when the

ecological screening criterion of 1,700 mg/kg EPH is exceeded.

• Applying the EPH default product limits (or an AOC-specific EPH alternative

product limit or the ceiling limit).

The basis for the Department’s two default product limits for EPH in soil is detailed in Sanders

(2009) in Appendix 3.1. An EPH product limit of 8,000 mg/kg has been established for

Category 1 EPH. Additionally, the EPH product limit of 8,000 mg/kg is also applied to the

Category 2 EPH products: crude oil (source of No. 2 heating oil); LNAPL at MGP sites, which

7

contain compounds comparable to Category 1 fuels; cutting oils, which are diverse in

compositions; and unknown petroleum hydrocarbons. An EPH product limit of 17,000 mg/kg

has been established for all other Category 2 EPH petroleum products. The EPH default

product limits are based on an assessment of the residual saturation concentrations for various

petroleum products and in various soil types included in a paper by Brost and DeVaull (2000).

The residual saturation data for medium sand (a representative soil texture for most soil in New

Jersey) was selected for establishing default limits for EPH product based on residual

saturation. If the applicable default product limit is exceeded, the investigator can use the

EPH Alternative Product Limit Calculator to calculate an AOC-specific EPH alternative

product limit. In part, the calculator is based on the relationships between soil texture, product

viscosity, and product density. EPH product determined to be immobile by this method can

have an alternative product limit greater than the EPH default product limit concentration, but

may not exceed the 30,000 mg/kg product “ceiling limit”. The Department established the

ceiling limit with the consensus of the stakeholder EPH Technical Guidance Committee

(Appendix 3.2).

Exceedances of the EPH product limits, whether they are the default limits or AOC-specific

EPH alternative product limits, require treatment or removal pursuant to N.J.A.C. 7:26E-5.1(e).

Containment (i.e., engineering control) of EPH product can only be considered where

treatment or removal of EPH product is not practicable pursuant to N.J.A.C. 7:26E-5.1(e).

This technical guidance presumes compliance with all other Departmental rules and guidance

that apply to the remediation of contaminated sites in general and to remediation of petroleum

hydrocarbons contamination in all media. This includes, but is not limited to the following:

• Technical Guidance for Investigation of Underground Storage Tank Systems

• Ecological Evaluation Technical Guidance

• Light Non-aqueous Phase Liquid (LNAPL) Initial Recovery and Interim Remedial

Measures Technical Guidance

• Technical Guidance for the Attainment of Remediation Standards and Site-Specific

Criteria

• Ground Water Technical Guidance: Site Investigation Remedial Investigation Remedial

Action Performance Monitoring

• Technical Guidance for Site Investigation of Soil, Remedial Investigation of Soil, and

Remedial Action Verification Sampling for Soil

• In Situ Remediation: Design Considerations and Performance Monitoring Technical

Guidance Document

The technical guidances listed above can be found at: https://www.nj.gov/dep/srp/guidance/.

8

OVERVIEW OF PROCEDURE:

4.1 Determine Correct EPH Category

In order to apply this guidance, the investigator must determine the appropriate EPH

category or categories requiring evaluation at each petroleum storage and discharge area

pursuant to N.J.A.C. 7:26E-2.1(d), based on the current and historical petroleum products

stored or used at each AOC being investigated.

Category 1 Defined:

Category 1 consists of only No. 2 heating oil and diesel fuel.

Category 2 Defined:

Category 2 consists of No. 4 heating oil, No. 6 heating oil, hydraulic oil, cutting oil,

lubricating oil, crude oil, waste oil, unknown petroleum hydrocarbons, waste vehicular

crankcase oil, mineral oil, dielectric fluid, dielectric mineral oil, transformer oil, or EPH-

type discharges associated with manufactured gas plant (MGP) sites.

Mixtures:

Where both Category 1 and Category 2 petroleum products may have been discharged at

an AOC, unknown petroleum products may have been discharged, waste oil comprised of

Category 1 and Category 2 petroleum products, or complex mixtures such as crude oil or

manufactured gas plant (MGP) materials are of concern, evaluate EPH using both the

Category 1 and the Category 2 sections of this technical guidance. Complex EPH

product mixtures such as crude oil or MGP materials often contain compounds that

display characteristics common to both Category 1 and Category 2 products; and

therefore, need to be evaluated using the guidance for both. For these situations, the

investigator should use the on-line EPH Soil Remediation Criteria (SRC) Calculator and

Category 1 EPH product limit, as summarized below.

4.2 Determine Human Health-Based Remediation Goal

Evaluate the EPH sample concentrations against the applicable EPH Soil Remediation

Criteria (SRC) and the applicable EPH product limit. If the Department has established

an EPH soil remediation standard in N.J.A.C. 7:26D, then the soil remediation

standard (SRS) supersedes the SRC in this technical guidance.

For Category 1, if all EPH soil concentrations are ≤1,000 mg/kg, then remediation is

complete and an unrestricted use Remedial Action Outcome (RAO) can be issued for EPH

in soil. For EPH soil concentrations >1,000 mg/kg for Category 1 EPH at sites with

residential land use, the EPH SRC of 5,100 mg/kg applies. For Category 1 EPH at sites

with non-residential land use, the EPH SRC of 54,000 mg/kg is superseded by the EPH

default product limit of 8,000 mg/kg, or if calculated the lower of an AOC-specific

alternative product limit or 30,000 mg/kg EPH ceiling limit.

9

Because the composition of Category 2 EPH varies by petroleum product, the Department

applies the approach used for Category 1, but the health-based criterion is determined on a

sample-specific basis. For Category 2 EPH, calculate sample-specific EPH SRC using the

Department provided on-line EPH SRC Calculator found at:

https://www.nj.gov/dep/srp/guidance/srra/evaluation_eph_soil_cat2_health_based_calculat

or.xlsm. For residential use, calculate the applicable residential SRC for each sample from

the AOC. For non-residential use, calculate both the residential and non-residential EPH

SRC for each sample from the AOC to determine the sample concentrations to be included

in the institutional control and to establish those areas requiring an engineering control for

the EPH remedial action.

The Technical Rules require the horizontal and vertical delineation of free product and

residual product pursuant to N.J.A.C. 7:26E-4.2(a)4, and the treatment or removal of free

product and residual product to the extent practicable pursuant to N.J.A.C. 7:26E-5.1(e).

The Department previously selected EPH default product limits of 8,000 mg/kg for Category

1 EPH and 17,000 mg/kg for Category 2 EPH (see Appendix 3.1). With this technical

guidance, the default product limit of 17,000 mg/kg for Category 2 EPH is no longer

universally assigned. Instead, either 8,000 mg/kg or 17,000 mg/kg EPH is the applicable

EPH default product limit based on the specific petroleum product (see Appendix 1). If the

default product limit is exceeded, this guidance provides an option for determining an AOC-

specific EPH alternative product limit as described in Appendix 2. Collection of soil

samples for grain size distribution analysis is required if the investigator seeks to develop an

AOC-specific alternative product limit.

Exceedance of the EPH Default Product Limits

Pursuant to N.J.A.C. 7:26E-5.1(e) the person responsible for conducting the remediation

shall treat or remove free product and residual product to the extent practicable.

Consequently, when the concentration of EPH exceeds the default product limits, an

AOC specific alternative product limit, or the EPH ceiling limit, compliance averaging is

not an acceptable alternative for remediation of EPH product. Where EPH product

exceeds the applicable EPH default product limit and an EPH alternative product limit is

calculated, EPH product shall be remediated to the lower of the EPH alternative product

limit or the ceiling limit.

A Remedial Action Permit for soil that includes both institutional controls and

engineering controls is required for a site where the EPH concentration exceeds the

default product limits, an AOC specific alternative product limit or the EPH ceiling limit,

as applicable, and it is impracticable to remove or treat the EPH product.

For situations where there is evidence of EPH free product (e.g., LNAPL on ground

water) and EPH soil concentrations are less than the EPH product limits, additional

investigation or remedial action of soil may be needed to address a source of EPH

product that may not have been previously identified.

10

Technical Impracticability – large or complex non-residential sites

The Department recognizes that compliance with the EPH product limit may be

impracticable for meeting the requirement at N.J.A.C. 7:26E-5.1(e) to treat or remove

free product and residual product at large or complex non-residential sites. For

purposes of this technical guidance, large sites would consist of refineries and

petroleum storage facilities that extend over multiple acres with multiple AOCs. An

example of a complex site is a MGP site. Typically, these large and complex sites also

involve:

• Impacts to ground water or surface water;

• a potential for vapor intrusion or ecological risk;

• off-site migration of EPH product; or

• an active facility with continuing operations.

For these types of sites, the investigator is advised to seek consultation with the

Department before proceeding with a determination of impracticability or making a

final decision on a remedial action. The typical variation for these types of sites may

involve long-term remedial actions that may delay full compliance with the requirement

to treat or remove free product and residual product, or it may involve remedial actions

that include some form of containment and active remedial actions for soil and other

media. All variances from the Technical Rules shall be documented in the applicable

remedial phase report pursuant to N.J.A.C. 7:26E-1.7. All deviations from this

technical guidance shall be documented in the applicable remedial phase report

pursuant to N.J.A.C. 7:26E-1.5(b) and Administrative Requirements for the

Remediation of Contaminated Sites (ARRCS) Rules pursuant to N.J.A.C 7:26C-

1.2(a)3.

There are circumstances where it may be technically impracticable to completely

remediate free product and residual product to the applicable EPH product limit in soil.

Common impediments are physical obstacles that inhibit or preclude accessibility to the

product. It is contingent upon the investigator to evaluate both removal and treatment

options before acceding it is technically impracticable to remediate free product and

residual product, and to include a description of the evaluations used to conclude

technical impracticability in the applicable remedial phase report. Consider using the

Department’s In Situ Remediation: Design Considerations and Performance

Monitoring Technical Guidance Document

(https://www.nj.gov/dep/srp/guidance/#in_situ) for evaluating possible removal and

treatment options. The report must also include a detailed description of the means

used to contain the free product and residual product.

Pursuant to N.J.A.C. 7:26E-5.3, any remediation initiated on or after May 7, 2010,

where either new construction or a change in use creates a residence, a school, or a

child care center, the person responsible for conducting the remediation shall submit a

remedial action workplan pursuant to N.J.A.C. 7:26E-5.5 and obtain the Department's

written approval before implementing a remedial action at any area of concern when

treatment or removal of free product or residual product is not practicable.

11

4.3 Address Additional Analytical Requirements

Address all additional analysis requirements listed in Table 2-1 ("Analytical Requirements

for Petroleum Storage and Discharge Areas") at N.J.A.C. 7:26E-2.1(d). For Category 1

petroleum products, samples are required to be analyzed for 2-methylnaphthalene and

naphthalene when the EPH soil concentrations at the AOC exceed 1,000 mg/kg, and

additional remediation is not to be conducted. For Category 2 petroleum products,

analytical requirements listed in Table 2-1 at N.J.A.C. 7:26E-2.1(d) apply for the selection

of the additional analyses.

Where both Category 1 and Category 2 petroleum products are being investigated at an

area of concern (AOC), conduct the applicable additional analyses pursuant to Table 2-1

at N.J.A.C. 7:26E-2.1(d) for each petroleum product. For those situations where the

petroleum product type is unknown, or for Category 2 petroleum products that have been

used and are not virgin products, sampling and analytical parameters for waste

oil/unknown petroleum hydrocarbons apply as listed in Table 2-1 at N.J.A.C. 7:26E-

2.1(d).

A sufficient sample volume should be collected from each sample location for both initial

EPH analysis and the additional analyses specified in Table 2-1 at N.J.A.C. 7:26E-2.1(d).

The investigator should also collect sufficient soil volume for performance of Synthetic

Precipitation Leaching Procedure (SPLP) analysis to evaluate the potential of an impact to

groundwater (IGW) if the results of the additional parameters are detected above the

default IGW soil screening levels. The investigator shall comply with the soil sample

handling and holding time restrictions for EPH analysis stipulated by the analytical method,

the additional analyses specified in Table 2-1 at N.J.A.C. 7:26E-2.1(d), and SPLP available

at: (https://www.nj.gov/dep/srp/guidance/rs/).

4.4 Assess Ecological Risk

For all EPH concentrations exceeding 1,700 mg/kg, the investigator also needs to determine

whether a remedial action is necessary for EPH to address ecological risk pursuant to

N.J.A.C. 7:26E-1.16 and -4.8 and the Department’s Ecological Evaluation Technical

Guidance (https://www.nj.gov/dep/srp/guidance/#eco_eval). Note that an ecological

evaluation is not required at areas of concern that consist of an underground storage tank

storing heating oil for on-site consumption in a one to four family residential building

(Brownfield and Contaminated Site Remediation Act at N.J.S.A. 58:10B-12a).

12

EPH EVALUATION STEPS

Step by step guidance for the completion of the tasks just described is provided below. A

tabular summary of the technical guidance is provided as Appendix 1. All steps in the EPH

evaluation must be followed and all site conditions documented in the applicable remedial phase

report. The licensed site remediation professional is reminded that pursuant to the requirements

of the Administrative Requirements for the Remediation of Contaminated Sites (N.J.A.C. 7:26C-

1.2), departures from this technical guidance require written rationale to be provided if the LSRP

determines the guidance is inappropriate or unnecessary to meet the remediation requirements of

all applicable New Jersey statutes and New Jersey rules.

5.1 CATEGORY 1 - Discharges of only No. 2 heating oil or diesel fuel:

Residential Land Use

The steps below presume a residential land use is the endpoint of the remedial action at the

area of concern (AOC). Complete all steps below with appropriate documentation in the

applicable remedial phase report. Reference to sample contaminant concentrations includes

site investigation, remedial investigation, and remedial action confirmation samples.

When all EPH sample concentrations are ≤1,000 mg/kg at the AOC, then remediation is

complete and an unrestricted use RAO for EPH can be issued.

For all EPH sample concentrations >1,000 mg/kg, complete each of the Steps below to

determine whether remediation of EPH or other contaminants is necessary.

Step 1. Evaluate EPH against RSRC and product limits/ceiling limit

Evaluate all EPH sample concentrations against the 5,100 mg/kg residential soil

remediation criterion (RSRC) and the EPH default product limit of 8,000 mg/kg (or

the lower of the AOC-specific EPH alternative product limit or ceiling limit as

described in Appendix 2), then go to Step 2.

A. For all EPH sample concentrations ≤5,100 mg/kg, remediation is complete for

the EPH RSRC and the EPH default product limit of 8,000 mg/kg. Go to Step

2.

B. For all EPH sample concentrations greater than the EPH default product limit

of 8,000 mg/kg (or the lower of the AOC-specific EPH alternative product

limit or ceiling limit as described in Appendix 2), either:

i. Excavate or treat EPH product-contaminated soil and collect remedial

action confirmation samples, then return to Step 1; or

ii. Contain all soil with EPH concentrations greater than the EPH default

product limit of 8,000 mg/kg (or the lower of the AOC-specific EPH

alternative product limit or ceiling limit) may be considered when

treatment or removal is not practicable pursuant to N.J.A.C. 7:26E-5.1(e).

13

This will require implementation of institutional and engineering

controls. Include appropriate documentation in the remedial action

workplan (RAW) and remedial action report (RAR) to support why

treatment or removal is not practicable and how containment will be

implemented and monitored. This may result in Department review of

the RAW or RAR, so possible containment of EPH product should be

discussed with the Department prior to implementation. A RAW shall

be submitted for Department written approval pursuant to N.J.A.C.

7:26E-5.3(d) for any AOC when new construction of, or a change in use

to, a residence, a school, or child care center will occur. If contaminants

other than EPH will be subject to an institutional and engineering control,

determine whether that engineering control is also feasible as the

engineering control to contain EPH product. Go to Step 1.C.

C. For all EPH sample concentrations >5,100 mg/kg and <8,000 mg/kg (or the

lower of the AOC-specific EPH alternative product limit or ceiling limit as

described in Appendix 2), either:

i. Excavate or treat contaminated soil and collect remedial action

confirmation samples, then return to Step 1, or

ii. Perform compliance averaging using the Department’s Technical

Guidance for the Attainment of Remediation Standards and Site-Specific

Criteria

(http://www.nj.gov/dep/srp/guidance/srra/attainment_compliance.pdf)

a. If compliance requirements are satisfied, then remediation is

complete for the EPH soil remediation criterion and the EPH

product limit. Go to Step 2.

b. If compliance requirements are not satisfied, then repeat Step

1.C.i, or

iii. Consider implementation of institutional and engineering controls, if

feasible after completion of the remaining steps in this technical

guidance. Establishing an institutional and engineering control will

restrict the future use of the property. Go to Step 2.

Step 2. Analyze samples > 1,000 mg/kg EPH for contingency analyses

For all EPH sample concentrations >1,000 mg/kg, collect samples, if not already

collected, for additional analyses of both 2-methylnaphthalene and naphthalene

pursuant to Table 2-1 at N.J.A.C. 7:26E-2.1(d). Determine the number of samples

requiring additional analysis using the table below, then go to Step 3.

14

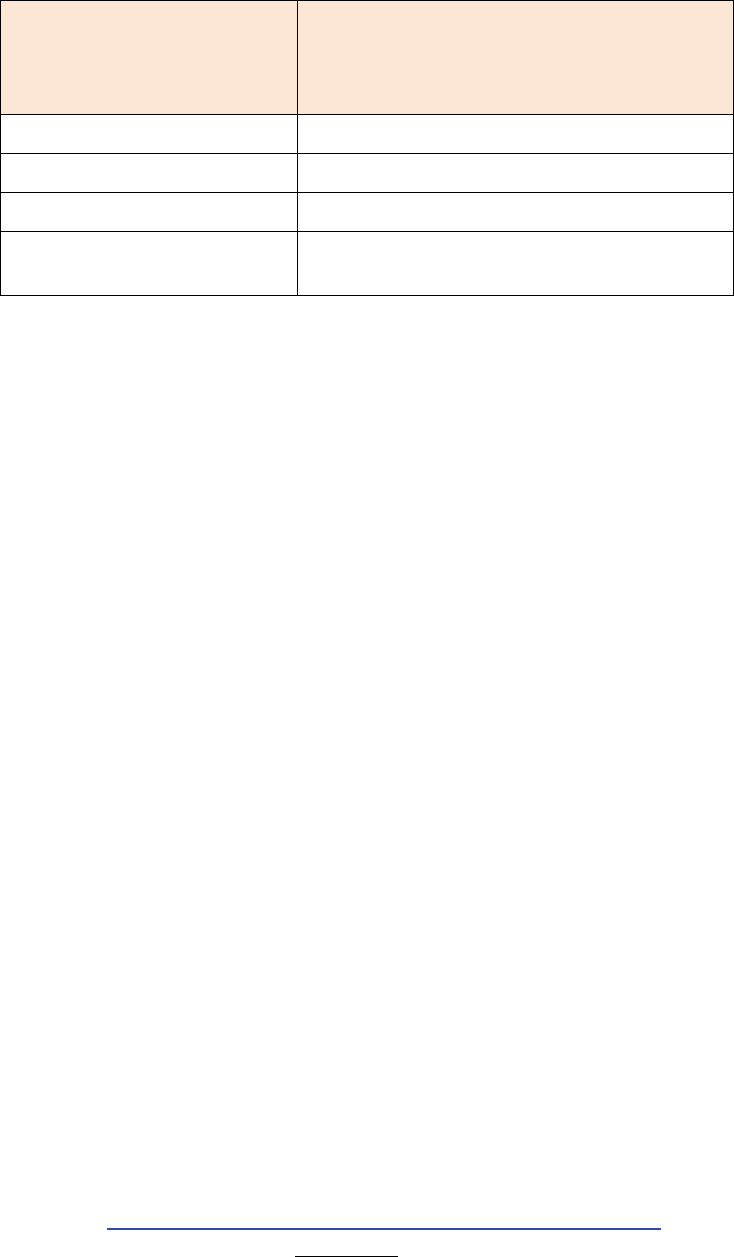

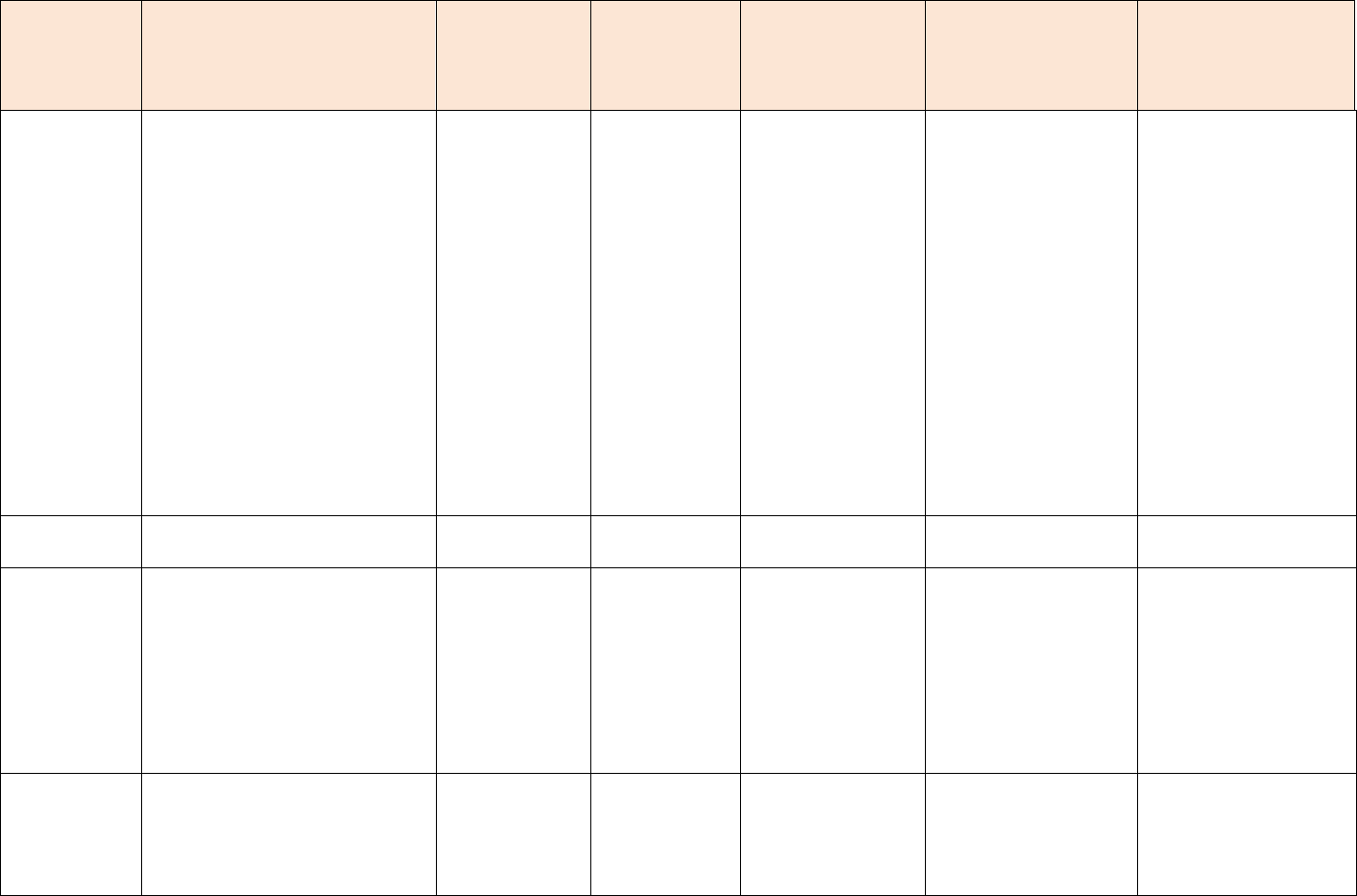

No. of Samples with EPH

>1,000 mg/kg

No. of Samples for Additional

Analyses

1-4 1

5-8 2

9-12 3

13 or more

1 additional sample for each

additional set of 1 to 4 samples

Note: Pursuant to Table 2-1 at N.J.A.C. 7:26E-2.1(d) ("Analytical Requirements

for Petroleum Storage and Discharge Areas"), additional sample analysis shall be

conducted on those samples with the highest EPH concentration(s). The

investigator shall be aware of the soil sample handling and holding time

restrictions for EPH and all additional analyses when evaluating the initial EPH

sample concentrations and should ensure sufficient sample volume is collected

for both EPH and additional analyses.

Step 3. Evaluate the sample concentrations of the contingency analyses

A. If all sample concentrations do not exceed the impact to ground water (IGW)

soil screening level of 8 mg/kg for 2-methylnaphthalene and do not exceed

the residential direct contact soil remediation standard of 6 mg/kg for

naphthalene, then remediation is complete for 2-methylnaphthalene and

naphthalene. Go to Step 4.

B. If any sample concentration is >8 mg/kg for 2-methylnaphthalene or >6 mg/kg

for naphthalene, then

i. Excavate or treat soil and collect remedial action confirmation samples,

then return to Step 3, or

ii. For all samples where the concentration of 2-methylnaphthalene is >8

mg/kg or for all samples where the concentration of naphthalene is >6

mg/kg, using available guidance complete the remedial investigation or

remedial action, as applicable, for these exceedances of the soil

remediation standards (SRS). Go to Step 4.

Note: The following option for 2-methylnaphthalene concentrations

greater than the IGW soil screening level departs from the protocol found

in technical guidance Development Of Site-Specific Impact To Ground

Water Soil Remediation Standards Using The Synthetic Precipitation

Leaching Procedure

(http://www.nj.gov/dep/srp/guidance/rs/splp_guidance.pdf). This option

is applicable only if one or two of the contingency samples analyzed for 2-

15

methylnaphthalene is >8 mg/kg, and is not applicable where three or more

contingency samples analyzed for 2-methylnaphthalene is >8 mg/kg.

Consider conducting SPLP analysis on the one or two samples. Compare

the sample leachate concentrations to the 600 ug/L leachate concentration

for 2-methylnaphthalene.

a. If all sample leachate concentrations are ≤600 ug/L, remediation is

complete for 2-methylnaphthalene. Go to Step 4.

b. If one or both sample leachate concentrations is >600 ug/L,

remediation for 2-methylnaphthalene is not complete. Return to

Step 3.B.

Step 4. Evaluate EPH for ecological concern

Note: An ecological evaluation is not required at areas of concern that consist of

an underground storage tank storing heating oil for on-site consumption in a one to

four family residential building (Brownfield and Contaminated Site Remediation

Act at N.J.S.A. 58:10B-12a). Otherwise, go to Step 4.A.

A. If all EPH sample concentrations are less than or equal to the ecological soil

screening level of 1,700 mg/kg, then the remediation is complete relative to

addressing ecological risk for EPH. For all EPH sample concentrations greater

than the ecological soil screening level of 1,700 mg/kg, go to Step 4.B.

B. For all EPH sample concentrations >1,700 mg/kg, where EPH is present in or

may migrate to an environmentally sensitive natural resource (ESNR), complete

an ecological evaluation pursuant to N.J.A.C. 7:26E-1.16 and 4.8 and the

Department’s Ecological Evaluation Technical Guidance

(http://www.nj.gov/dep/srp/guidance/srra/ecological_evaluation.pdf). In lieu of

an ecological evaluation for a terrestrial soil ESNR, excavate or treat soil until

EPH is less than or equal to 1,700 mg/kg.

i. If a remedial action for EPH to address ecological risk is not necessary

pursuant to N.J.A.C. 7:26E-4.8 and the Department’s Ecological

Evaluation Technical Guidance, then the remediation to address

ecological risk for EPH is complete.

ii. If a remedial action to address ecological risk is required pursuant to

N.J.A.C. 7:26E-4.8 and the Department’s Ecological Evaluation Technical

Guidance, then perform a remedial action for EPH to the site-specific

ecological risk-based remediation goal for the applicable media in an

ESNR. However, EPH cannot exceed 4,000 mg/kg in an ESNR for

terrestrial soil (see Section 6.4.5 in the Ecological Evaluation Technical

Guidance).

16

5.2 CATEGORY 1 - Discharges of only Number 2 (No. 2) heating oil or diesel fuel:

Non-Residential Land Use

The steps below presume a non-residential land use is the endpoint of the remedial action at

the area of concern (AOC). If an unrestricted use is desired, use the Category 1 –

residential land use section of this technical guidance. Complete all steps below with

appropriate documentation in the applicable remedial phase report. Reference to sample

contaminant concentrations includes site investigation, remedial investigation, and remedial

action confirmation samples.

When all EPH sample concentrations are ≤1,000 mg/kg at the AOC, then remediation is

complete and an unrestricted use RAO for EPH can be issued.

For all EPH sample concentrations >1,000 mg/kg, complete each of the Steps below to

determine whether remediation of EPH or other contaminants is necessary.

Step 1. Evaluate EPH against NRSRC and product limits/ceiling limit

Evaluate all EPH sample concentrations against the 54,000 mg/kg non-residential

soil remediation criterion (NRSRC) and the EPH default product limit of 8,000

mg/kg (or the lower of the AOC-specific EPH alternative product limit or ceiling

limit as described in Appendix 2).

A. If all EPH sample concentrations are less than or equal to the EPH default

product limit of 8,000 mg/kg (or the lower of the AOC-specific EPH

alternative product limit or ceiling limit), then remediation is complete for

the EPH NRSRC and the EPH product limit. However, all EPH sample

concentrations greater than the 5,100 mg/kg residential soil remediation

criterion (RSRC) shall be included in an institutional control for the AOC.

In addition, an engineering control may be needed to prevent migration from

the AOC to other media or prevent on-site exposure to surface soil above the

applicable SRC. Go to Step 2.

B. Evaluate all EPH sample concentrations greater than the EPH default product

limit of 8,000 mg/kg (or the lower of the AOC-specific EPH alternative

product limit or ceiling limit), as follows:

i. Excavate or treat EPH product-contaminated soil and collect remedial

action confirmation samples and return to Step 1.A.

ii. Containment of a horizontally and vertically delineated volume of soil

with EPH concentrations greater than the EPH default product limit of

8,000 mg/kg (or the lower of the AOC-specific EPH alternative product

limit or ceiling limit) may be considered when treatment or removal is

not practicable pursuant to N.J.A.C. 7:26E-5.1(e). This will require

implementation of institutional and engineering controls. Include

appropriate documentation in the remedial action workplan (RAW) and

17

remedial action report (RAR) to support why treatment or removal is not

practicable and how containment will be implemented and monitored.

This may result in Department review of the RAW or RAR, so possible

containment of EPH product should be discussed with the Department

prior to implementation. A RAW shall be submitted for Department

written approval pursuant to N.J.A.C. 7:26E-5.3(d) for any AOC when

new construction of, or a change in use to, a residence, a school, or child

care center will occur. If contaminants other than EPH will be subject to

an institutional and engineering control, determine whether that

engineering control is also feasible as the engineering control to contain

EPH product. Finally, all EPH sample concentrations greater than the

5,100 mg/kg residential soil remediation criterion (RSRC) and less than

the EPH product limit shall be included in the institutional control. Go

to Step 2.

Step 2. Analyze samples > 1,000 mg/kg EPH for contingency analyses

For all EPH sample concentrations >1,000 mg/kg, collect samples, if not already

collected, for additional analysis of both 2-methylnaphthalene and naphthalene

pursuant to Table 2-1 at N.J.A.C. 7:26E-2.1(d). Determine the number of samples

requiring additional analysis using the table below, then go to Step 3.

No. of Samples with EPH

>1,000 mg/kg

No. of Samples for Additional

Analyses

1-4 1

5-8 2

9-12 3

13 or more

1 additional sample for each

additional set of 1 to 4 samples

Note: Pursuant to Table 2-1 at N.J.A.C. 7:26E-2.1(d) ("Analytical Requirements for

Petroleum Storage and Discharge Areas"), additional sample analysis shall be

conducted on those samples with the highest EPH concentration(s). The

investigator shall be aware of the soil sample handling and holding time restrictions

for EPH and all additional analyses when evaluating the initial EPH sample

concentrations and should ensure sufficient sample volume is collected for both

EPH and additional analyses.

Step 3. Evaluate the sample concentrations of the contingency analyses

A. If all sample concentrations do not exceed the impact to ground water (IGW)

soil screening level of 8 mg/kg for 2-methylnaphthalene and do not exceed

the non-residential direct contact soil remediation standard of 17 mg/kg for

18

naphthalene, then remediation is complete for 2-methylnaphthalene and

naphthalene. Go to Step 4.

B. If any sample concentration is >8 mg/kg for 2-methylnaphthalene or >17 mg/kg

for naphthalene, then

i. Excavate or treat soil and collect remedial action confirmation samples,

then return to Step 3, or

ii. For all samples where the concentration of 2-methylnaphthalene is >8

mg/kg or for all samples where the concentration of naphthalene is >17

mg/kg, using available guidance complete the remedial investigation or

remedial action, as applicable, for these exceedances of the soil

remediation standards (SRS). Go to Step 4.

Note: The following option for 2-methylnaphthalene concentrations

greater than the IGW soil screening level departs from the protocol found

in technical guidance Development Of Site-Specific Impact To Ground

Water Soil Remediation Standards Using The Synthetic Precipitation

Leaching Procedure

(http://www.nj.gov/dep/srp/guidance/rs/splp_guidance.pdf). This option

is applicable only if one or two of the contingency samples analyzed for 2-

methylnaphthalene is >8 mg/kg, and is not applicable where three or more

contingency samples analyzed for 2-methylnaphthalene is >8 mg/kg.

Consider conducting SPLP analysis on the one or two samples. Compare

the sample leachate concentrations to the 600 ug/L leachate concentration

for 2-methylnaphthalene.

a. If all sample leachate concentrations are ≤600 ug/L, remediation is

complete for 2-methylnaphthalene. Go to Step 4.

b. If one or both sample leachate concentrations is >600 ug/L,

remediation for 2-methylnaphthalene is not complete. Return to

Step 3.B.

Step 4. Evaluate EPH for ecological concern

Note: An ecological evaluation is not required at areas of concern that

consist of an underground storage tank storing heating oil for on-site

consumption in a one to four family residential building (Brownfield and

Contaminated Site Remediation Act at N.J.S.A. 58:10B-12a). Otherwise,

go to Step 4.A.

A. If all EPH sample concentrations are less than or equal to the ecological soil

screening level of 1,700 mg/kg, then the remediation is complete to address

ecological risk for EPH. For all EPH sample concentrations greater than the

ecological soil screening level of 1,700 mg/kg, go to Step 4.B.

19

B. For all EPH sample concentrations >1,700 mg/kg, where EPH is present in or

may migrate to an environmentally sensitive natural resource (ESNR), complete

an ecological evaluation pursuant to N.J.A.C. 7:26E-1.16 and 4.8 and the

Department’s Ecological Evaluation Technical Guidance

(http://www.nj.gov/dep/srp/guidance/srra/ecological_evaluation.pdf). In lieu of

an ecological evaluation for a terrestrial soil ESNR, excavate or treat soil until

EPH is less than or equal to 1,700 mg/kg.

i. If a remedial action for EPH to address ecological risk is not necessary

pursuant to N.J.A.C. 7:26E-4.8 and the Department’s Ecological

Evaluation Technical Guidance, then the remediation to address

ecological risk for EPH is complete.

ii. If a remedial action to address ecological risk is required pursuant to

N.J.A.C. 7:26E-4.8 and the Department’s Ecological Evaluation Technical

Guidance, then perform a remedial action for EPH to the site-specific

ecological risk-based remediation goal for the applicable media in an

ESNR. However, EPH cannot exceed 4,000 mg/kg in an ESNR for

terrestrial soil (see Section 6.4.5 in the Ecological Evaluation Technical

Guidance).

5.3 CATEGORY 2 – Discharges of petroleum products other than No. 2 heating oil or

diesel fuel: Both Residential and Non-Residential Land Uses

CATEGORY 2 petroleum products include: Numbers 4 and 6 heating oil, hydraulic oil,

cutting oil, lubricating oil, crude oil, waste oil, unknown petroleum hydrocarbons, waste

vehicular crankcase oil, mineral oil, dielectric fluid, dielectric mineral oil, or waste mineral

oil, or EPH-type discharges associated with manufactured gas plant (MGP) sites.

The steps below address unrestricted use, limited restricted use, and restricted use remedial

actions. Limited restricted use will require an institutional control (i.e., deed notice), but

usually not an engineering control. Restricted use will require both an institutional control

and an engineering control. Because a sample-specific soil remediation criterion (SRC) for

EPH is generated for each sample, none of the compliance averaging options described in the

Department’s Technical Guidance for the Attainment of Remediation Standards and Site-

Specific Criteria can be used for Category 2 EPH. Determine the applicable EPH default

product limit of either 8,000 mg/kg or 17,000 mg/kg based on the specific petroleum product

or products stored or discharged. Complete all steps below with appropriate documentation

in the applicable remedial phase report. Reference to sample contaminant concentrations

includes site investigation, remedial investigation, and remedial action confirmation samples.

Step 1. Determine sample-specific EPH soil remediation criterion

For each sample, determine the sample-specific soil remediation criterion (SRC) for

EPH.

20

A. Determine whether each sample is to be analyzed for EPH using the non-

fractionation or fractionation option in the NJDEP EPH Method (N.J.A.C.

7:26E-2.1(a)6).

i. If there is reason to believe that the EPH concentration in a sample is

≤2,300 mg/kg, then the non-fractionation option of the NJDEP EPH

Method may be used. It is important to ensure sufficient sample

volume is collected in case the sample requires fractionation when the

non-fractionated EPH concentration is >2,300 mg/kg.

ii. If there is reason to believe that the EPH concentration in a sample is

>2,300 mg/kg, or if the non-fractionated EPH concentration for a sample

is >2,300 mg/kg, then analyze the sample using the fractionation option

of the NJDEP EPH Method.

B. For each EPH sample concentration, determine whether the sample-specific

health-based soil remediation criterion (SRC) shall be calculated using the

Department’s on-line EPH SRC Calculator.

i. For each non-fractionated or fractionated EPH sample with a

concentration ≤2,300 mg/kg, go to Step 5.

ii. For each fractionated EPH sample with a concentration >2,300 mg/kg, use

the Department’s on-line EPH SRC Calculator to calculate the sample-

specific EPH SRC for both the residential and non-residential exposure

pathways. Go to Step 2.

Step 2. Evaluate fractionated EPH against SRC and product limits/ceiling limit

Evaluate each fractionated EPH sample concentration >2,300 mg/kg against the

sample-specific EPH SRC for the applicable residential or non-residential land use

and the applicable EPH default product limit of 8,000 mg/kg or 17,000 mg/kg (or

the lower of the AOC-specific EPH alternative product limit or ceiling limit as

described in Appendix 2).

A. For all EPH sample concentrations less than or equal to the calculated

residential soil remediation criteria (RSRC) and are less than or equal to the

applicable EPH default product limit of 8,000 mg/kg or 17,000 mg/kg, go to

Step 5.

B. For all samples where the EPH sample concentrations are greater than the

calculated RSRC and are less than or equal to the applicable EPH default

product limit of 8,000 mg/kg or 17,000 mg/kg, complete Steps 4 and 5.

C. For all samples where the EPH sample concentrations are greater than the

calculated RSRC and are also greater than the applicable EPH default product

21

limit of 8,000 mg/kg or 17,000 mg/kg (or AOC-specific EPH alternative

product limit or ceiling limit), complete Steps 3, 4, and 5.

D. For all samples where the EPH sample concentrations are less than or equal to

the calculated RSRC and are greater than the applicable EPH default product

limit of 8,000 mg/kg or 17,000 mg/kg (or AOC-specific EPH alternative

product Limit or ceiling limit), complete Steps 3 and 5.

Step 3. EPH concentration greater than the applicable default product limit

For all samples with EPH concentrations greater than the applicable EPH default

product limit of 8,000 mg/kg or 17,000 mg/kg (or the lower of the AOC-specific

EPH alternative product limit or ceiling limit):

A. Excavate or treat EPH product-contaminated soil and collect remedial action

confirmation samples, then return to Step 2.

B. Containment of a horizontally and vertically delineated volume of soil with

EPH concentrations greater than the applicable EPH default product limit of

8,000 mg/kg or 17,000 mg/kg (or the lower of the AOC-specific EPH

alternative product limit or ceiling limit) may be considered when treatment or

removal is not practicable pursuant to N.J.A.C. 7:26E-5.1(e). This will require

implementation of institutional and engineering controls. Include appropriate

documentation in the remedial action workplan (RAW) and remedial action

report (RAR) to support why treatment or removal is not practicable and how

containment will be implemented and monitored. This may result in

Department review of the RAW or RAR, so possible containment of EPH

product should be discussed with the Department prior to implementation. A

RAW shall be submitted for Department written approval pursuant to N.J.A.C.

7:26E-5.3(d) for any AOC when new construction of, or a change in use to, a

residence, a school, or child care center will occur. If contaminants other than

EPH will be subject to an institutional and engineering control, determine

whether that engineering control is also feasible as the engineering control to

contain EPH product.

Step 4. EPH concentration greater than its calculated SRC

For each sample with an EPH concentration greater than its calculated SRC:

A. Excavate or treat soil and collect remedial action confirmation samples based

on the calculated sample-specific SRC for the applicable residential or non-

residential AOC land use and selected unrestricted, limited restricted, or

restricted use remedial action, then return to Step 2.

B. Implement either institutional or institutional and engineering controls as

follows:

22

i. For residential AOC land use, for all EPH sample concentrations greater

than their calculated RSRC, implement an institutional control and

appropriate engineering control.

ii. For non-residential AOC land use:

a. For all EPH sample concentrations greater than their calculated

RSRC, but less than or equal to their calculated non-residential SRC

(NRSRC), implement an institutional control.

b. For all EPH sample concentrations greater than their calculated

NRSRC, implement institutional and engineering controls.

Step 5. Determine additional analytical requirements

A. Perform all additional analyses that apply based upon the petroleum product(s)

discharged, as listed in Table 2-1 at N.J.A.C. 7:26E-2.1(d).

B. Evaluate the additional analytical sample concentrations as follows:

i. For all sample concentrations that do not exceed the applicable soil

remediation standards (N.J.A.C. 7:26D) and the default IGW soil

screening levels (or AOC-specific IGW soil remediation standards), go to

Step 6.

ii For all sample concentrations that exceed the applicable soil remediation

standards (N.J.A.C. 7:26D) or the default IGW soil screening levels (or

AOC-specific IGW soil remediation standards), complete the remedial

investigation or remedial action, as applicable. Go to Step 6.

Step 6. Evaluate EPH for ecological concern

Note: An ecological evaluation is not required at areas of concern that

consist of an underground storage tank storing heating oil for on-site

consumption in a one to four family residential building (Brownfield and

Contaminated Site Remediation Act, N.J.S.A. 58:10B-12a). Otherwise, go

to Step 6.A.

A. If all EPH sample concentrations are less than the ecological soil screening

level of 1,700 mg/kg, then the remediation is complete to address ecological

risk for EPH. For all EPH sample concentrations greater than the ecological

soil screening level of 1,700 mg/kg, go to Step 6.B.

B. For all EPH sample concentrations >1,700 mg/kg, where EPH is present in or

may migrate to an environmentally sensitive natural resource (ESNR),

complete an ecological evaluation pursuant to N.J.A.C. 7:26E-1.16 and 4.8 and

the Department’s Ecological Evaluation Technical Guidance

(http://www.nj.gov/dep/srp/guidance/srra/ecological_evaluation.pdf). In lieu

23

of an ecological evaluation for a terrestrial soil ESNR, excavate or treat soil

until EPH is less than or equal to 1,700 mg/kg.

i. If a remedial action for EPH to address ecological risk is not necessary

pursuant to N.J.A.C. 7:26E-4.8 and the Department’s Ecological

Evaluation Technical Guidance, then the remediation to address

ecological risk for EPH is complete.

ii. If a remedial action to address ecological risk is required pursuant to

N.J.A.C. 7:26E-4.8 and the Department’s Ecological Evaluation Technical

Guidance, then perform a remedial action for EPH to the site-specific

ecological risk-based remediation goal for the applicable media in an

ESNR. However, EPH cannot exceed 4,000 mg/kg in an ESNR for

terrestrial soil (see Section 6.4.5 in the Ecological Evaluation Technical

Guidance).

24

GLOSSARY

Area of concern (AOC) – defined in the Technical Requirements For Site Remediation,

N.J.A.C. 7:26E-1.8.

Category 1 EPH – consists of discharges of only Number 2 (No. 2) fuel oil and/or diesel fuel.

Category 2 EPH – consists of discharges of petroleum hydrocarbon mixtures other than No. 2

fuel oil and/or diesel fuel (i.e., Number 4 fuel oil, Number 6 fuel oil, hydraulic oils, cutting oils,

crude oil, lubricating oil, waste oil, waste vehicular crankcase oil, and waste mineral oil.

Environmentally sensitive natural resource – an area defined at N.J.A.C. 7:1E-1.8(a), or an

area or resource that is protected or managed pursuant to the Pinelands Protection Act, N.J.S.A.

13:18A-1 et seq., and the Pinelands Comprehensive Management Plan, N.J.A.C. 7:50.

EPH alternative product limit concentration in soil – for a specified petroleum product for an

AOC, it is the lower concentration of either the median of the calculated EPH product limit

concentrations for an inputted set of grain size samples or the EPH ceiling limit.

EPH ceiling limit – the maximum concentration of EPH allowed to remain in soil on a sample-

specific basis which is 30,000 mg/kg as established in this guidance.

EPH default product limits – the 8,000 mg EPH/kg soil and 17,000 mg EPH/kg soil generic

concentrations established as upper limits in the NJDEP’s “Default EPH Product Limits for No.

2 Fuel Oil, Diesel, and Heavier TPH Products” (Sanders 2009 in Appendix 3.1) to prevent the

occurrence of mobile free product.

Extractable Petroleum Hydrocarbons (EPH) – For the purposes of this technical guidance, the

results in milligrams of EPH per kilogram of soil or sediment as determined and reported using

the NJDEP analytical method "Analysis of Extractable Petroleum Hydrocarbon Compounds

(EPH) in Aqueous and Soil/Sediment/Sludge Matrices" (NJDEP EPH Method 10/08, Revision 3

August 2010) https://nj.gov/dep/srp/guidance/srra/eph_method.pdf.

Free product – defined in the Technical Requirements For Site Remediation, N.J.A.C. 7:26E-

1.8.

Heating oil tank system – defined in the Heating Oil Tank System Remediation Rules, N.J.A.C.

7:26F-1.5.

Petroleum product – For the purposes of this technical guidance, the petroleum products listed

in TABLE 2-1 Analytical Requirements For Petroleum Storage And Discharge Areas of

N.J.A.C. 7:26E-2.1(d) that require analysis for EPH in Soil/Sediment.

Residual product – defined in the Technical Requirements For Site Remediation, N.J.A.C.

7:26E-1.8.

25

Technical impracticability – a condition where remediation of soil is not feasible from an

engineering perspective because of the extent or type of physical impediment(s) that limit the

ability to complete soil remediation to the applicable standards or criteria. Cost is only

considered as subordinate to that of ensuring protection of public health, safety and the

environment.

26

ACRONYMS

AOC area of concern

CSM conceptual site model

EPH extractable petroleum hydrocarbons

ESNR environmentally sensitive natural resource

HOTS heating oil tank system

IGW impact to ground water

LNAPL light non-aqueous phase liquid

LSRP licensed site remediation professional

mg/kg milligrams per kilogram

MGP manufactured gas plant

MLE multiple lines of evidence

NAPL non-aqueous phase liquid

NJDEP New Jersey Dept. of Environmental Protection

NRSRC non-residential soil remediation criterion

RAO remedial action outcome

RAR remedial action report

RAW remedial action workplan

RSRC residential soil remediation criterion

SPLP synthetic precipitation leaching procedure

SRC soil remediation criteria

SRP Site Remediation Program

SRS soil remediation standards

TPH total petroleum hydrocarbons

USEPA United States Environmental Protection Agency

UST underground storage tank

27

REFERENCES

ASTM. (ASTM International). 2007. Standard Test Method for Particle-Size Analysis of Soils

(Withdrawn 2016). ASTM D422-63(2007)e2. www.astm.org

ASTM. (ASTM International). 2017. Standard Test Methods for Particle-Size Distribution

(Gradation) of Soils Using Sieve Analysis, ASTM D6913 / D6913M-17. www.astm.org

ASTM. (ASTM International). 2017. Standard Test Method for Particle-Size Distribution

(Gradation) of Fine-Grained Soils Using the Sedimentation (Hydrometer) Analysis. ASTM

D7928-17. www.astm.org

Bear, J. 1988. Dynamics of Flow in Porous Media. New York, Dover.

Bobo, A. M., N. Khoury, H. Li, and M. C. Boufadel. 2012. "Groundwater Flow in a Tidally

Influenced Gravel Beach in Prince William Sound, Alaska," Journal of Hydrologic Engineering

17(4): 494-494.

Boufadel, M. C., M.T. Suidan, A. D. Venosa, C.H. Rauch, and P. Biswas. 1998. “2D Variably

Saturated Flows: Physical Scaling and Bayesian Estimation.” Journal of Hydrologic Engineering,

3(4): 223-231, October 1998.

Brost, E. J. and G. E. DeVaull. “NonAqueous Phase Liquid (NAPL) Mobility Limits in Soil.”

Soil & Groundwater Research Bulletin (9): June 2000.

Cedergren, H. R. 1967. Seepage, Drainage, and Flow Nets. New York, John Wiley and Sons.

Clark, M. M. 1996. Transport Modeling for Environmental Engineers and Scientists. New York,

John Wiley and Sons Inc.

de Marsily, G. 1986. Quantitative Hydrogeology, Groundwater Hydrology for Engineers. San

Diego and London, Academic Press, Inc.

Fetter, C.W. 1994. Applied Hydrogeology. Third Edition, Prentice Hall.

Mualem, Y. 1976. "A new model for predicting the hydraulic conductivity of unsaturated porous

media," Water Resources Research 12(3).

NJDEP. 2008. Guidance Document, Inhalation Standards Compliance, Development Of

Alternative Remediation Standards For The Inhalation Pathway, June 2008.

NJDEP. 2014. Frequently Asked Questions for the Impact to Ground Water Pathway in Soil

Remediation Standards, Version 2.0, March 2014.

28

USDA-SCS (United States Department of Agriculture-Soil Conservation Service). 1987. Soil

Mechanics Level 1, Module 1 – Unified Soil Classification System, Study Guide.

https://www.nrcs.usda.gov/Internet/FSE_DOCUMENTS/stelprdb1044811.pdf

van Genuchten, M. T. 1980. "A closed-form equation for predicting the hydraulic conductivity of

unsaturated soils," Soil Science Society of America Journal 44(5): 892-898.

van Genuchten, M.T., F.J. Leij, and S.R. Yates. (1991) The RETC Code for Quantifying the

Hydraulic Functions of Unsaturated Soils. USEPA Report, EPA/600/2-91/065, (NTIS 92-

119668).

Vukovic, M. and A. Soro. 1992. "Determination of hydraulic conductivity of porous media from

grain-size composition," Water Resources Publications. Littleton, Colorado.

29

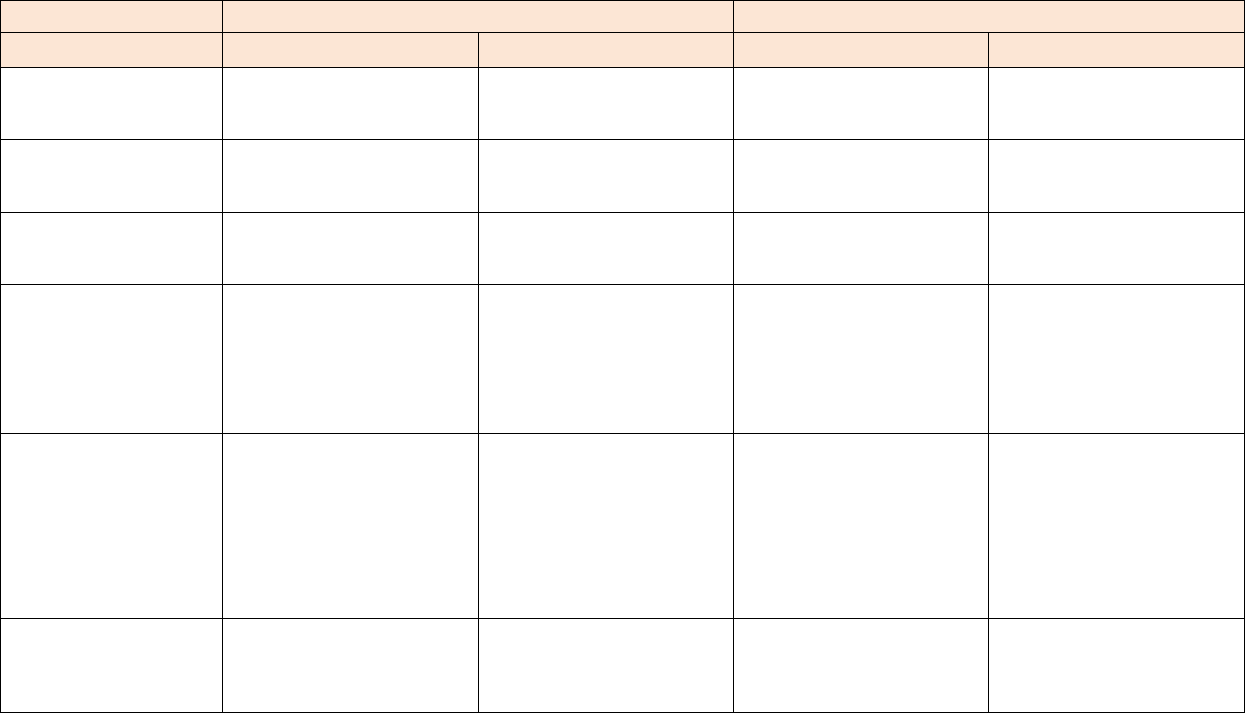

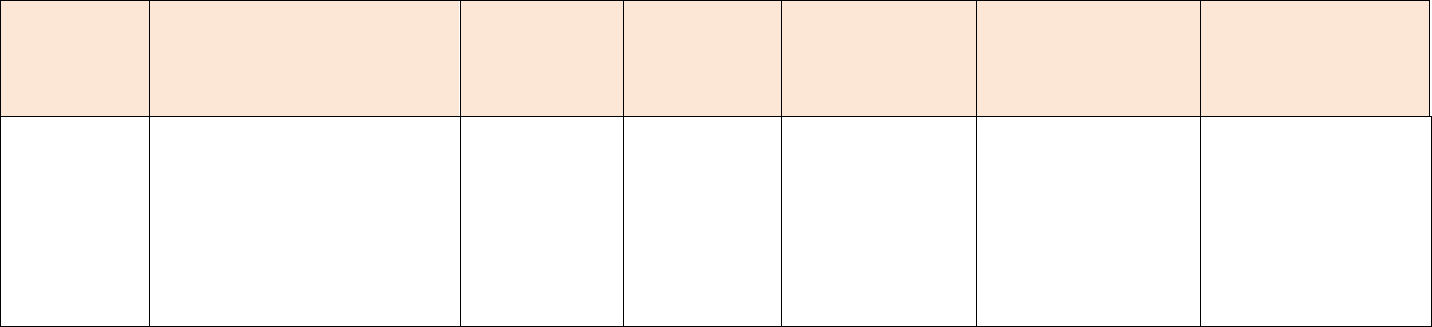

APPENDIX 1

Summary Table of EPH Soil Remediation Criteria, Thresholds for Additional Analyses and Evaluations, and EPH Product Limits

EPH Category Category 1 Category 2

AOC Use Residential *

1

Non-residential *

1

Residential *

1

Non-residential *

1

EPH Soil Remediation

Criteria

5,100 mg/kg 54,000 mg/kg Sample-specific calculation Sample-specific calculation

EPH Threshold

Concentration for

Additional Analyses

>1,000 mg/kg >1,000 mg/kg

Pursuant to N.J.A.C. 7:26E-

2.1, Table 2-1

Pursuant to N.J.A.C. 7:26E-

2.1, Table 2-1

Additional Analyses

(if required)

2-methylnaphthalene and

naphthalene

2-methylnaphthalene and

naphthalene

Pursuant to N.J.A.C. 7:26E-

2.1, Table 2-1

Pursuant to N.J.A.C. 7:26E-

2.1, Table 2-1

EPH Default Product

Limit

8,000 mg/kg 8,000 mg/kg

17,000 mg/kg (except for

MGP, crude oil, cutting oil,

and unknown petroleum

products which are 8,000

mg/kg; waste oil is parent

product dependent)

17,000 mg/kg (except for

MGP, crude oil, cutting oil,

and unknown petroleum

products which are 8,000

mg/kg; waste oil is parent

product dependent)

AOC-specific EPH

Alternative Product

Limit Concentration

for Soil

Lower of:

AOC-specific median of

Calculated EPH Product

Limit Concentration for

grain size samples

-OR-

30,000 mg/kg ceiling limit

Lower of:

AOC-specific median of

Calculated EPH Product

Limit Concentration for

grain size samples

-OR-

30,000 mg/kg ceiling limit

Lower of:

AOC-specific median of

Calculated EPH Product

Limit Concentration for

grain size samples

-OR-

30,000 mg/kg ceiling limit

Lower of:

AOC-specific median of

Calculated EPH Product

Limit Concentration for

grain size samples

-OR-

30,000 mg/kg ceiling limit

EPH Threshold

Concentration for

Ecological

Evaluation*

2

>1,700 mg/kg >1,700 mg/kg >1,700 mg/kg >1,700 mg/kg

*1

: For tank systems subject to the Heating Oil Tank System Remediation (HOTSR) Rule (N.J.A.C. 7:26F), refer to the HOTSR Rule for specific requirements.

*2

: An ecological evaluation is not required at areas of concern that consist of an underground storage tank storing heating oil for on-site consumption in a one

to four family residential building (Brownfield and Contaminated Site Remediation Act, N.J.S.A. 58:10B-12a).

Technical Guidance for Evaluation of Extractable Petroleum Hydrocarbons in Soil

30

APPENDIX 2

EPH Alternative Product Limit Calculation Procedures

2.1 Obtaining Appropriate Grain Size Distribution Data

2.2 Documentation and Information to be Submitted for Calculation of an AOC-

specific EPH Alternative Product Limit in Soil

2.3 Derivation of Equation for Calculating an EPH Alternative Product Limit in

Soil

2.4 Variables Table and Table of Petroleum Product Viscosity and Density

31

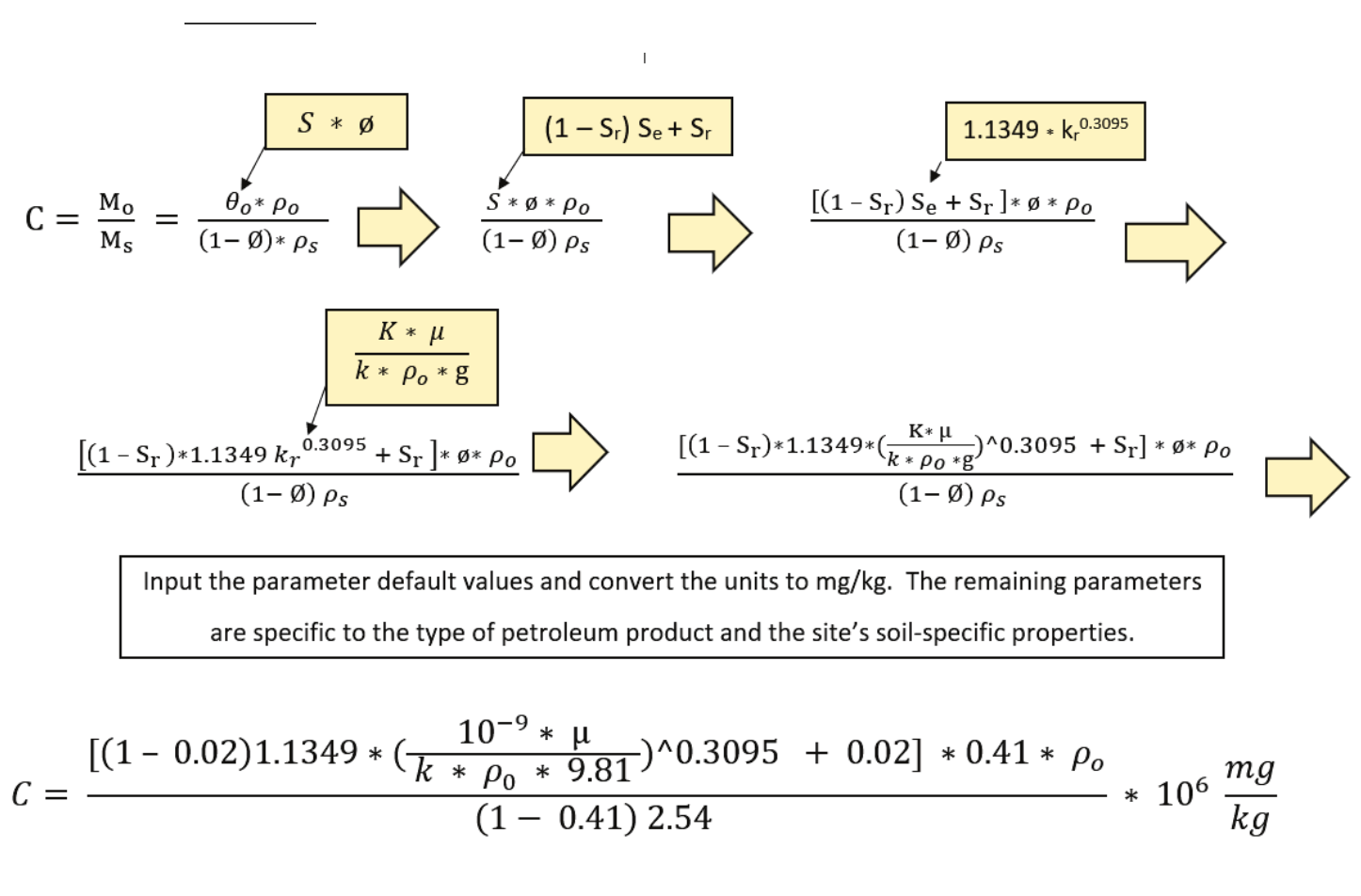

APPENDIX 2

EPH Alternative Product Limit Calculation Procedures

When to use the EPH Alternative Product Limit Calculator

The Department’s selection of and basis for the two EPH default product limits in soil is

provided in Appendix 3.1. To summarize, the Department relied on residual

concentration calculations published by Brost and DeVaull in 2000. For Category 1 EPH,

the Department selected 8,000 mg/kg based on the value listed by Brost and DeVaull for

medium sand. For Category 2 EPH, the Department selected 17,000 mg/kg based on the

“residual saturation for fuel oils heavier than diesel” assuming all soils are composed of

“medium sand”. The Department also judged “that the value of 17,000 mg/kg used for

heavier fuel oil is also adequately protective for lubricating oils” for a generic New Jersey

soil composed of medium sand.

It is recognized that not all soils in New Jersey have textures solely consisting of medium

sand. Consequently, the EPH Technical Guidance Committee developed an equation that

provides the investigator via a spreadsheet calculator, a method to determine an AOC-

specific EPH alternative product limit concentration based on the AOC-specific soil texture

and the stored or discharged petroleum product(s).

The derivation of the equation for calculating an EPH alternative product limit in soil is

provided in Appendix 2.3. The equation includes several variables which are defined and

described in Appendix 2.4. For consistency and protectiveness, the Department has fixed

several variables utilizing conservative assumptions for nearly all the variables. The

investigator needs only to identify the discharged petroleum product(s) and obtain the

“effective diameter” (D

10

) value from grain size distribution analyses from soil as the same

lithology (i.e., same depth interval) as the EPH product zone. Calculating an AOC-specific,

EPH alternative product limit concentration is most useful when the soil texture is finer

than medium sand as reflected by the D

10

value. Based on the conceptual site model

(CSM) and multiple lines of evidence (MLE), the investigator determines whether the EPH

default product limit or the EPH alternative product limit concentration becomes the

EPH product limit for the AOC. The decision to calculate an EPH alternative product limit

concentration in lieu of using the EPH default product limit resides with the investigator.

Variables used in the equation are defined in Appendix 2.4 including a table of petroleum

product-specific density and dynamic viscosity values assigned to the petroleum products

for which the EPH Alternative Product Limit Calculator can be used.

The technical guidance addressing the number and locations of soil samples needed to

determine the D

10

value is provided in Appendix 2.1. Refer to Appendix 2.2 for the

documentation and information to be included in the applicable remedial phase document

when an AOC-specific EPH alternative product limit has been calculated and applied to EPH

remediation in soil.

32

The following steps outline the process to complete the calculation of an AOC-specific EPH

alternative product limit:

Step 1. For each AOC, complete horizontal and vertical delineation of EPH in soil to the

applicable EPH default product limit concentration for the petroleum product that

was stored or discharged. Delineation of EPH must be completed in both the

saturated and unsaturated zones without regard to the property boundary pursuant

to N.J.A.C. 7:26E-4.2(a)4.

Step 2. Soil samples for grain size analysis may be collected at any time. If the

investigator suspects that the petroleum product discharge may exceed the EPH

default product limit when conducting remediation, it may be prudent to collect soil

samples for grain size analysis early in the investigation. It should be noted that

soil samples for grain size analysis should be free of EPH so that the laboratory

sieves and hydrometers are not adversely impacted. It is important to discuss this

aspect with the laboratory to avoid sample rejection.

Step 3. The soil samples should be sent under proper chain-of-custody procedures to

the laboratory. If it is not certain whether there is an exceedance of the EPH

default product limit, the grain size samples may be placed on “laboratory hold”

until the EPH analyses are completed. The determination of grain size is a

physical test, without any holding time restrictions on soil samples.

Step 4. The soil samples for grain size analysis can be analyzed using an appropriate

analytical method that accurately characterizes the soil grain sizes including clay,

silt, sands and gravel mass fraction. The laboratory report will provide the weight

fractions for specific sieve and hydrometer particle sizes. The ultimate goal is to

identify the effective diameter D

10

which represents the equivalent particle size in

millimeters where 10% by dry weight passes (i.e., is finer). It is suggested the

investigator request the laboratory calculate the D

10

to decrease the quantity of

manual data entry into the EPH Alternative Product Limit Calculator. Alternately,

because the laboratory reports the mass fraction of the grain sizes, the EPH

Alternative Product Limit Calculator can determine the D

10

value for each soil

sample.

Step 5. After receiving the laboratory report, access the Department’s on-line EPH

Alternative Product Limit Calculator and follow the instructions to calculate an EPH

Alternative Product Limit Concentration for Soil for the AOC.

Step 6. The Calculator automatically determines the “EPH Alternative Product Limit

Concentration for Soil in this AOC” by determining the median of the calculated EPH

product limit concentrations for the grain size samples that were inputted and

comparing the median against the 30,000 mg/kg EPH Ceiling Limit concentration.

The more stringent (lesser concentration) between the median value and the ceiling

limit is the “EPH Alternative Product Limit Concentration for Soil in this AOC”.

33

If the AOC has more than one lithologic zone with EPH concentrations that exceed the EPH

default product limit (i.e., when the petroleum product discharge has migrated to other

distinct soil textures) calculate an AOC-specific alternative product limit for each additional

product zone. An AOC-specific alternative product limit must be calculated for each

distinct soil matrix where an EPH concentration exceeds an EPH default product limit (see

Appendix 2.1). If more than one petroleum product is being investigated or was

discharged at the AOC, calculate an EPH alternative product limit concentration for soil for

each petroleum product.

34

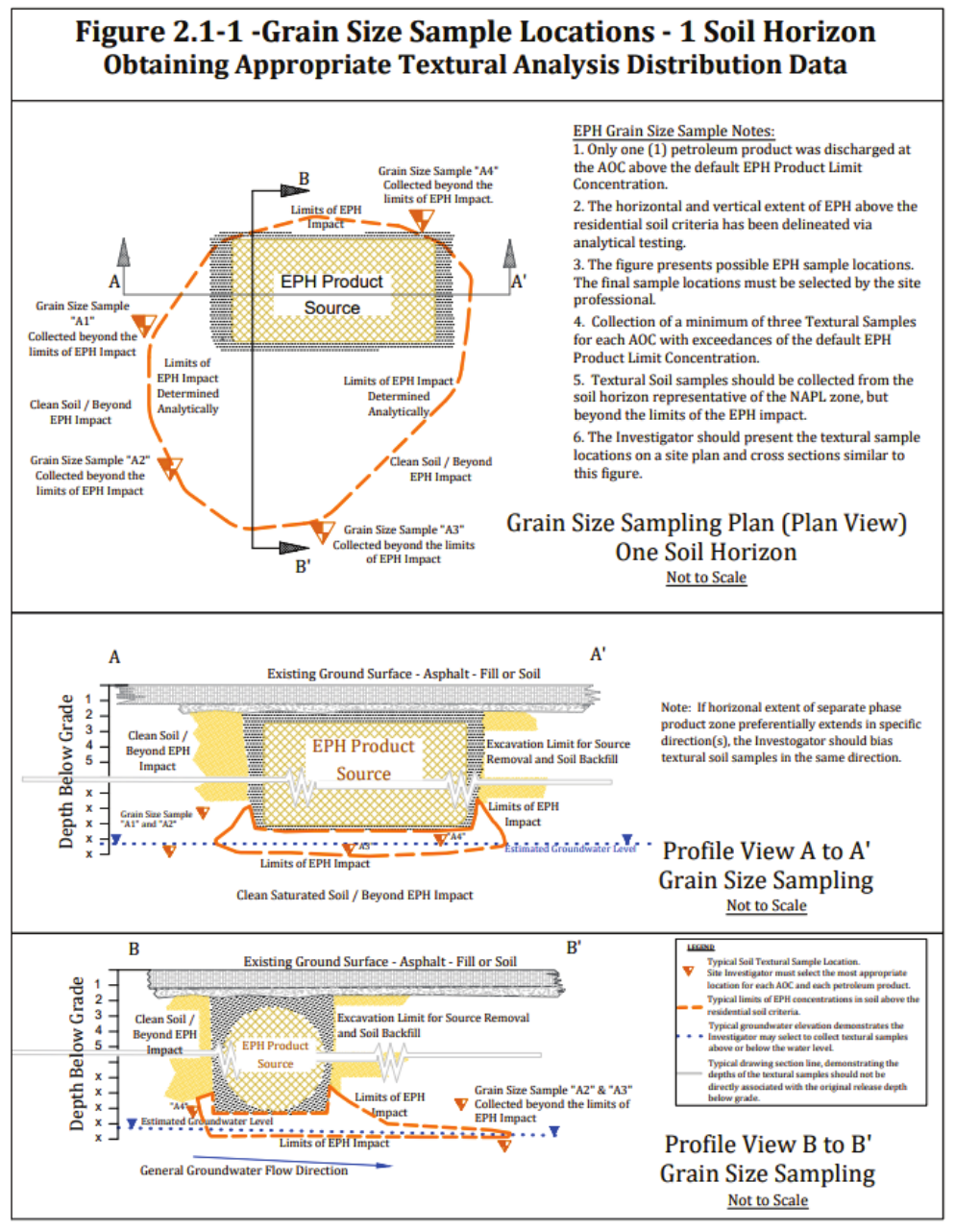

Appendix 2.1

Obtaining Appropriate Grain Size Distribution Data

The following describes the process for collection of an appropriate number and characteristics

of soil samples for grain size distribution analysis for calculation of an AOC-specific EPH

alternative product limit concentration. The grain size distribution data generated via sieve

and hydrometer analyses are used to derive the effective diameter “D

10

” input parameter for use

in the Department’s EPH Alternative Product Limit Concentration Calculator. The calculator

employs grain size distribution analyses. A web-link to several test methods is included in

Section 8.0 REFERENCES.

Selection of appropriate soil samples for grain size distribution analysis should be based on the

conceptual site model, characterization of the limits of EPH concentrations in the soils and

include consideration of soil lithology for each distinct stratigraphic horizon containing

petroleum product in exceedance of the applicable default product limit within the AOC. The

guidance was developed with the perspective that the soil to be evaluated for developing an EPH

alternative product limit was deposited naturally, and that the horizontal variation in texture

across short “AOC-sized” distances is expected to be minimal. Where historic fill material is

documented, the investigator must determine if the historic fill material is suitable for

calculation of an EPH alternative product limit concentration. Soil samples from historic fill

material may not be amenable to the sieve and hydrometer analyses because of inherent

contamination; consultation with the laboratory is recommended. Also, non-uniform historic

fill material (e.g., construction debris, non-hazardous solid waste, etc.) may not be amenable to

developing an EPH alternative product limit. For these situations, use the EPH default product

limits. The procedures for collecting soil samples, whether naturally deposited or from

suitable historic fill material, are described below.

It is recommended that the investigator first delineate the horizontal and vertical extent of the

EPH product mass to the applicable EPH product limit concentration pursuant to N.J.A.C. 7:26E-

4.2(a)4. However, it may be possible to collect soil samples for grain size distribution analysis

concurrent with EPH product delineation. Whichever option is chosen, grain size soil samples

should be collected as close as practicable to the EPH product mass to be most representative of

the soil lithology retaining EPH concentrations in exceedance of the default product limit. The

investigator is cautioned that analytical laboratories may reject samples for grain size analyses

which contain EPH. Therefore, the investigator should contact the prospective laboratory to

determine the constraints under which the laboratory will analyze petroleum-contaminated

samples for grain size distribution.

The Department’s Office of Quality Assurance does not offer certification for grain size/particle

size analyses.

Collect grain-size soil samples free of EPH from locations that are side-gradient to the mass of