Collection and Use of Total Petroleum

Hydrocarbon Data for the Risk-Based

Evaluation of Petroleum Releases

Example Case Studies

Last Updated: October 2018

Published by

Hawai´i Department of Health

Hazard Evaluation and Emergency Response Office

Honolulu, Hawai´i

TPH Risk - Case Studies (HIDOH, October 2018)

ii

Forward

The case studies presented herein highlight the risk-based use of Total Petroleum Hydrocarbon

(TPH) data for soil, soil vapor, groundwater, surface water and ambient air for investigation,

remediation and long-term management of petroleum releases. The case studies were published

by the Hawai´i Department of Health (HIDOH) in association with input from multiple, outside

state and federal regulators as well as private consultants and experts associated with the

petroleum industry. Matthew Small, Science Liaison and senior geologist with Region 9 of the

U.S. Environmental Protection Agency, is in particular acknowledged for his review and

contribution to the information presented. The primary authors, Roger Brewer with the HIDOH

and Manivannan (Mani) Nagaiah with Langan Engineering & Environmental Services, Inc.,

were also active members of the Interstate Technology & Regulatory Council (ITRC) TPH Risk

Evaluation work group at the time that the case studies were prepared and acknowledge

important contributions to this document from many team members. It is anticipated that the

Case Studies will be referenced in the final, ITRC guidance document (publication early 2019)

for examples of the site-specific use of TPH data. Refer to information in the ITRC document for

additional details on specific topics presented in the case studies, as well as the references

provided herein.

The case studies presented within this document will be periodically updated as additional

insight and experience in the risk-based use of TPH and other petroleum-related data is

gained. Comments, edits and suggestions for future updates are welcome. Contact information

for the authors is provided below. Updates to the document are summarized in Attachment 6.

Reference:

HIDOH. 2018. Collection and Use of Total Petroleum Hydrocarbon Data for the Risk-Based

Evaluation of Petroleum Releases, Example Case Studies (March 2018; updated October 2018):

R. Brewer, M. Nagaiah and R. Keller, authors. Hawai´i Department of Health, Hazard Evaluation

and Emergency Response Office. Honolulu, Hawai´i.

Contacts:

Roger Brewer, PhD

Hawai´i Department of Health

Hazard Evaluation and Emergency Response Office

Honolulu, Hawai´i

Email: [email protected]

Manivannan (Mani) Nagaiah, PE

Langan Engineering & Environmental Services, Inc.

110 East Broward Boulevard, Suite 1500

Fort Lauderdale, FL 33301

Tel: 1-610-554-808

Email: mnagaiah@langan.com

TPH Risk - Case Studies (HIDOH, October 2018)

iii

Contents

1 INTRODUCTION .................................................................................................................... 1

1.1 Tiered Risk Assessment .................................................................................................... 2

1.2 Risk-Based Screening Levels (Backward Risk Assessment) ............................................ 3

1.3 Forward Calculation of Risk (Forward Risk Assessment) ................................................ 4

2 USE OF TPH DATA BY LIFE CYCLE STAGES .................................................................. 8

2.1 Release Detection ............................................................................................................ 10

2.2 Site Characterization ....................................................................................................... 10

2.3 Risk Assessment .............................................................................................................. 11

2.4 Remediation and Monitoring ........................................................................................... 11

2.5 Closure ............................................................................................................................. 11

3 EVALUATION OF EXISTING TPH DATA ........................................................................ 12

4 COMMON RISK ASSESSMENT PROBLEMS AND DATA LAPSES .............................. 13

5 CASE STUDIES OVERVIEW ............................................................................................... 14

Attachments

Attachment 1: Case Studies

Attachment 2: Categories of Petroleum Release Sites

Attachment 3: Potential Environmental Concerns

Attachment 4: Example Carbon Range and TPH Screening Levels

Attachment 5: Metabolite Screening Levels

Attachment 6: Updates

TPH Risk - Case Studies (HIDOH, October 2018)

1

1 INTRODUCTION

This document presents a series of case studies and supporting information that highlight the use Total

Petroleum Hydrocarbon (TPH), carbon range and related data for the investigation, risk assessment and

remediation of petroleum releases. Five release scenarios are presented (Attachment 1): 1) Former Fuel

Tank Farm, 2) Active Gas Station, 3) Tanker Truck Accident, 4) Crude Oil Pipeline Rupture and 5) Oil

and Gas Field. Themes considered in development of the case studies are summarized in Attachment 2.

The case studies reflect examples of investigation and risk assessment activities carried out during

different lifecycle stages of site investigation and remedial actions. The types of releases and conditions

illustrated by the case studies are intended to be generic in nature. The data and release scenarios presented

in large part, however, reflect the collective experience of the authors and the numerous consultants,

regulators and industry experts who provided input during preparation of the document. Refer to the

references provided in individual sections for additional information on specific topics. Refer also to the

document “TPH Risk Evaluation at Petroleum Contaminated Sites”, to be published by the Interstate

Technology and Regulatory Council (ITRC) in 2019 (ITRC 2018).

The case studies highlight environmental concerns commonly encountered at petroleum release sites.

Emphasis is placed on the upfront collection of data that is adequate for decision making in order to

minimize the need for remobilization and collection of additional data. The design of sample collection

work plans should reflect the risk question(s) being asked or the specific needs of corrective actions under

consideration. For example, this might include the collection of data needed to determine mean TPH or

carbon range concentrations in targeted, exposure areas and volumes of soil or air in order to assess

potential health risks and/or the collection of data needed define the extent of TPH contamination above

levels of potential concern in order to optimize remedial actions. This necessitates upfront coordination

of the field team with risk assessors and remediation experts likely to be involved in the project at a later

date as well as the overseeing, regulator agency.

The case studies follow a traditional, sequential approach to site investigation and risk assessment (ITRC

2015) with respect to typical lifecycle stages of petroleum release sites. An advancement on traditional

methods is the use of Decision Unit and Multi Increment Sample investigation methods to more efficiently

and reliably bound and characterize contamination (HIDOH 2016; “Multi Increment” is trademarked by

Envirostat, Inc.). This is referred to as “Incremental Sampling Methodology (ISM)” in ITRC guidance

(ITRC 2012), although some discussions in that document are now out-of-date (e.g., erroneous discussion

of statistical evaluation and representativeness of “ISM” samples). Release sites are classified based on

current/former operations, source basis, investigation/risk/remediation status and the impacted

media/receptor and pathway.

Common environmental concerns associated with petroleum releases include:

Direct exposure;

Vapor intrusion;

Leaching and contamination of groundwater;

Drinking water toxicity;

Aquatic toxicity; and

Gross contamination (“ceiling levels”).

TPH Risk - Case Studies (HIDOH, October 2018)

2

A description of these terms is provided in Table 1 and Attachment 3. Refer also to HIDOH (2017)

additional discussion. Example TPH soil, water, air and soil vapor screening levels for each of these

potential concerns are presented in Attachment 4. Published screening levels for sediment are also

presented, although he risk posed to ecological receptors by a petroleum release must normally be assessed

on a site-specific basis due to the variability and complexity of the habitats and receptors impacted. Section

5 presents an overview of the chemistry and toxicity of degraded, petroleum hydrocarbon-related

compounds in water.

1.1 Tiered Risk Assessment

Tiered approaches for the assessment of petroleum contamination in terms of TPH have been adopted by

many state agencies (e.g., MADEP 1994, 2014; CAEPA 2016, HIDOH 2017). In a general sense, the tiers

can be summarized as follows:

Comparison of site data to published screening levels (“Tier 1”);

Limited, site-specific modification of published screening levels (“Tier 2”); and,

Full, site-specific risk assessment including independent, “forward” quantification of risk and/or

“backward” development of site-specific cleanup levels (“Tier3”).

In practice the distinction between different tiers is often blurred, and steps to assess risk beyond simple

comparison of site data to published screening levels are often simply referred to as an “advanced

assessment.” Examples of progressively more detailed approaches to assessment of risk are presented in

Table 1. Tiered approaches provide for a systematic determination of the level of investigation required,

risk evaluation and remediation appropriate for each individual site. This helps to guide investigations and

facilitate the most efficient use of resources for a subject site.

Pre-approved, generic screening levels published by regulatory agencies expedite site characterization and

risk assessment actions and, although not required, can in some instances serve as final cleanup levels.

Proceeding from generic screening levels to a progressively more site-specific risk assessment, as deemed

appropriate or otherwise required by the overseeing regulatory agency, typically decreases the degree of

conservative assumptions used in decision making and improves the efficiency and effectiveness of

decision making.

The degree of detail and emphasis at each level of risk assessment is left to the individual practitioner,

based on site characteristics and the time- and cost-benefit of proceeding to more a detailed assessment.

Properly developed, comprehensive, screening levels minimize the need to advance to successive levels

of risk assessment for relatively simple release sites. Screening levels can instead be directly used to guide

remedial or risk management actions. A more thorough assessment of risk and development of site-

specific screening and cleanup levels might be desirable for large, complex releases that are likely to

require costly investigation and remediation actions.

A “screening level” risk assessment involves comparison of site data to published, generic screening

levels. These are referred to as “Method 1” or “Tier 1” screening levels in some guidance documents (e.g.,

MADEP 2014; CAEPA 2016, HIDOH 2017). This can achieve the following objectives:

Estimate whether the reported TPH levels exceed benchmark or guideline values for relevant

receptors and media;

Identify specific environmental concerns and allow for the completeness of exposure pathways

between TPH contamination and potential receptors to be evaluated; and/or

Develop an initial remediation action plan.

TPH Risk - Case Studies (HIDOH, October 2018)

3

If contamination above screening levels is identified and remedial actions can be carried out relatively

easily and cost-effectively or if the contamination does not pose a potential risk under current conditions,

then proceeding to a more detailed, site-specific risk assessment is generally not necessary. Direct

calculation of risk or with respect to TPH, “noncancer hazard,” as might be done in a traditional, detailed

risk assessment can be accomplished by simple comparison of site data to risk-based screening levels.

The method to do this is discussed under “Forward Calculation of Risk” below.

When necessary, progression to a more site-specific but still limited risk assessment allows targeted

adjustment of individual parameters used to generate generic screening levels without the need for a

lengthy and time consuming, traditional risk assessment. Justification for changes of select parameter

values should be included in the risk assessment report. This might include consideration of alternative

toxicity factors, alternative fate and transport parameter values (e.g., solubility, sorption coefficient, etc.),

alternative target risk, exclusion of incomplete exposure pathways, consideration of site-specific thickness

of contaminated soil, depth to groundwater and indoor air exchange rates among other factors. Limited

modification of generic screening levels, with most default assumptions and approaches still employed,

allows for expedited review of the risk assessment by the overseeing, regulatory agency. If the modified

screening levels are acceptable to all parties for final decision making, then the risk assessment process is

considered complete and a more rigorous, advanced evaluation is not necessary.

An advanced, traditional risk assessment involves the development of more rigorous models supported by

a much more thorough investigation of TPH sources, pathways and receptor characteristics. This process

is discussed in HIDOH (2017). The intention at this stage is to further customize the site-specific criteria

developed under screening level approaches and achieve a more accurate representation of the risk posed

by exposure of receptors to TPH in the affected media. Such methods typically start with an independent

assessment of each potential, environmental concern identified during the screening level assessment and

can include the use of alternative models and approaches, depending on the specific concern of interest.

A hybrid mix of tiered approaches to risk assessment is common, with generic screening levels used to

address relatively simple concerns and more detailed assessments prepared for complex releases or

assessment of risks less amenable to generic screening levels. This include direct testing of soil vapor or

indoor air for TPH or TPH carbon ranges in order to assess vapor intrusion risk, rather than initial

comparison of soil or groundwater data to screening level for this exposure pathway.

1.2 Risk-Based Screening Levels (Backward Risk Assessment)

Generic carbon range or carbon range-weighted, TPH screening levels for the environmental concerns

noted above have been published by several regulatory agencies, as referenced throughout this section.

Example TPH and carbon range screening levels used in the case studies are summarized in Attachment

4. The screening levels presented are for example only and should not be used without consultation with

the overseeing, environmental agency.

As described in Attachment 4, the screening levels presented incorporate commonly used assumptions

regarding the mobility and toxicity of TPH compounds in the environment and potential exposure of

human and ecological receptors. These criteria can be either very specific (e.g. daily residential exposure

to TPH in soil or air through ingestion, dermal absorption and/or inhalation) or more generic (e.g., water

quality guidelines for the protection of specific aquatic species, regardless of whether these receptors are

in fact present in the receiving waters).

Examples and utilization of generic screening levels for TPH and site-specific screening levels for carbon

ranges are included in the case studies presented in Attachment 1. Although the TPH screening levels

TPH Risk - Case Studies (HIDOH, October 2018)

4

presented are based on guidance published by the state of Hawaii (HIDOH 2017), they reflect a

compilation of guidance published by California (CAEPA 2016), Massachusetts (MADEP 2014) and a

host of other states, as well as USEPA’s Regional Screening Level guidance (USEPA 2017).

Several states rely on the use of pre-approved, agency-published, generic screening levels for site

characterization and remediation, with minimal need for development of site-specific screening levels or

quantitative calculation of risk (e.g., MADEP 2014, CAEPA 2016, HIDOH 2017). Screening levels

published by the noted agencies are intended to comprehensively address the most common types of

potential, environmental concerns associated with petroleum-contaminated soil and groundwater. More

detailed assessments are generally reserved for a relatively small number of large, complex sites. Some

states focus on the use of default models for development of site-specific screening levels or calculation

of risk (e.g., Montana, Utah etc.). The models typically focus on direct exposure, however, and the

resulting screening levels might not be adequately protective of leaching, vapor intrusion and/or gross

contamination concerns. Other entities use a hybrid approach, with screening levels that focus on a small

subset of environmental concerns anticipated to drive the need for cleanup or long-term management

specific to their location, such as leaching and potential impacts to groundwater in areas that overlie a

highly vulnerable and irreplaceable drinking water aquifer. Evaluation of other potential concerns, such

as direct exposure or vapor intrusion, is carried out on a site-specific basis as warranted.

An advanced, detailed site-specific evaluation may not necessarily involve the use of quantitative models.

Assessment of potential leaching concerns can, for example, sometimes be more directly evaluated by the

collection of groundwater samples at sites where the soil in question is already in contact with groundwater

or otherwise exposed and reflective of long-term, leaching conditions. The direct collection of soil vapor

data is recommended for assessment of potential vapor intrusion risks when contaminated soil or

groundwater is present within 15-30 feet of the base of an overlying building, rather than reliance on soil

or groundwater vapor intrusion models (ITRC 2014; HIDOH 2017). Published, “gross contamination”

screening levels for short-term vapor emission and other risks posed by the disturbance of heavily-

contaminated soil or groundwater are very useful during the initial stages of an investigation, but actual

risks are best assessed based on observations in the field.

1.3 Forward Calculation of Risk (Forward Risk Assessment)

Models for calculation of generic soil, drinking water and air screening levels that pertain to direct-

exposure risk include the incorporation of a target, noncancer “Hazard Quotient” (USEPA 2017; see

Attachment 4). A Hazard Quotient or “HQ” of “1” reflects an exposure where no adverse health effects

are anticipated. An HQ of greater than “1” does not necessarily indicate that adverse impacts to exposed

receptors is occurring, only that additional evaluation is warranted. Note that cancer risk is typically

assessed in terms of individual, well-studied, known or suspected carcinogenic constituents of petroleum

such as benzene, ethylbenzene, naphthalene and other polyaromatic hydrocarbon (PAH) compounds,

rather than TPH mixtures as whole.

The direct-exposure models for soil, water and air and exposure assumptions used to calculate risk-based

screening levels can be modified to directly calculate risk. In this case the representative exposure

concentration of individual carbon ranges (or total TPH, iif a carbon range-weighted approach is used) is

input into the model and a noncancer HQ that reflects the input concentration and exposure assumptions

is calculated. This approach is often used for complex sites where exposure concerns and remediation

costs warrant the additional time and resources required to prepare a detailed, quantitative assessment of

TPH Risk - Case Studies (HIDOH, October 2018)

5

health risk. Refer to the USEPA RSL guidance for additional information on the quantitative calculation

of risk from input, site-specific sample data (USEPA 2017).

A quick, “forward” calculation of risk can also be carried out by simply dividing site data representative

of “reasonable maximum” exposure conditions by the target carbon range screening level (or carbon

range-weighted TPH screening level) and adjusting with respect to the target risk, in this case the target

HQ, used to develop the screening level:

Where “EAC” is the exposure area concentration, “RBSL” is the risk-based screening level, and “THQ”

is the target HQ used to develop the RBSL.

If a target HQ of “1” was used to calculate the screening level, then the ratio of the site-specific

concentration to the screening level directly reflects the site-specific risk or HQ. The screening level will

otherwise need to be adjusted to reflect a target HQ of “1” for comparison. For example, an exposure area

concentration 500 mg/kg for a contaminant in soil with a risk-based screening level based on an HQ of

“1” of 1,000 mg/kg would yield a site-specific, noncancer Hazard Quotient of 0.5. This suggests an

absence of significant, health risk under the assumed exposure conditions. Similarly, a concentration of a

contaminant in air of 500 µg/m

3

compared to a risk-based screening level of 100 µg/m

3

yields an HQ of

5.0 and suggests that additional evaluation of potential adverse health risks is warranted. This might

include a closer review of actual exposure conditions with respect to assumptions used in the generic

screening level models or even a more detailed review of the toxicity factors incorporated into the models.

Risk assessors use such forward calculations of risk in conjunction with actual site conditions to better

understand health concerns posed to exposed workers or residents. Examples of this approach are included

in Case Study #1. In practice, the results often do not differ significantly from conclusions drawn from

detailed, quantitative risk assessments based on a “reasonable worst-case exposure” scenario, since the

same set of default, exposure assumptions used to develop the screening levels are likely to be considered.

Direct comparison of representative site data to well-thought-out, risk-based screening levels allows for a

more rapid identification of high-risk conditions and expedited actions to reduce or remove exposure, if

warranted.

Cumulative risk or in the case of noncancer concerns a “Hazard Index (HI)” must be calculated and

considered if multiple chemicals with the same target health effect are being evaluated (refer to HIDOH

2017). This will be the case for evaluation of individual carbon ranges. An HI is calculated by simply

adding Hazard Quotients calculated for individual carbon ranges:

…

Where HQ

1

, HQ

2

, HQ

3

, etc., represent the Hazard Quotient calculated for individual carbon ranges. The

calculated HI is evaluated in the same manner as an individual HQ, with a value equal to or less than “1”

indicating that no further assessment is required and a value greater than “1” indicating that further

evaluation of potentially adverse health risks is warranted. Note that it is entirely possible for

concentrations of individual carbon ranges to fall below respective risk-based screening levels and/or meet

a target Hazard Quotient of “1” (i.e., not pose an adverse risk on an individual basis) but the cumulative

Hazard Index to exceed “1” and indicate that further actions are needed.

TPH Risk - Case Studies (HIDOH, October 2018)

6

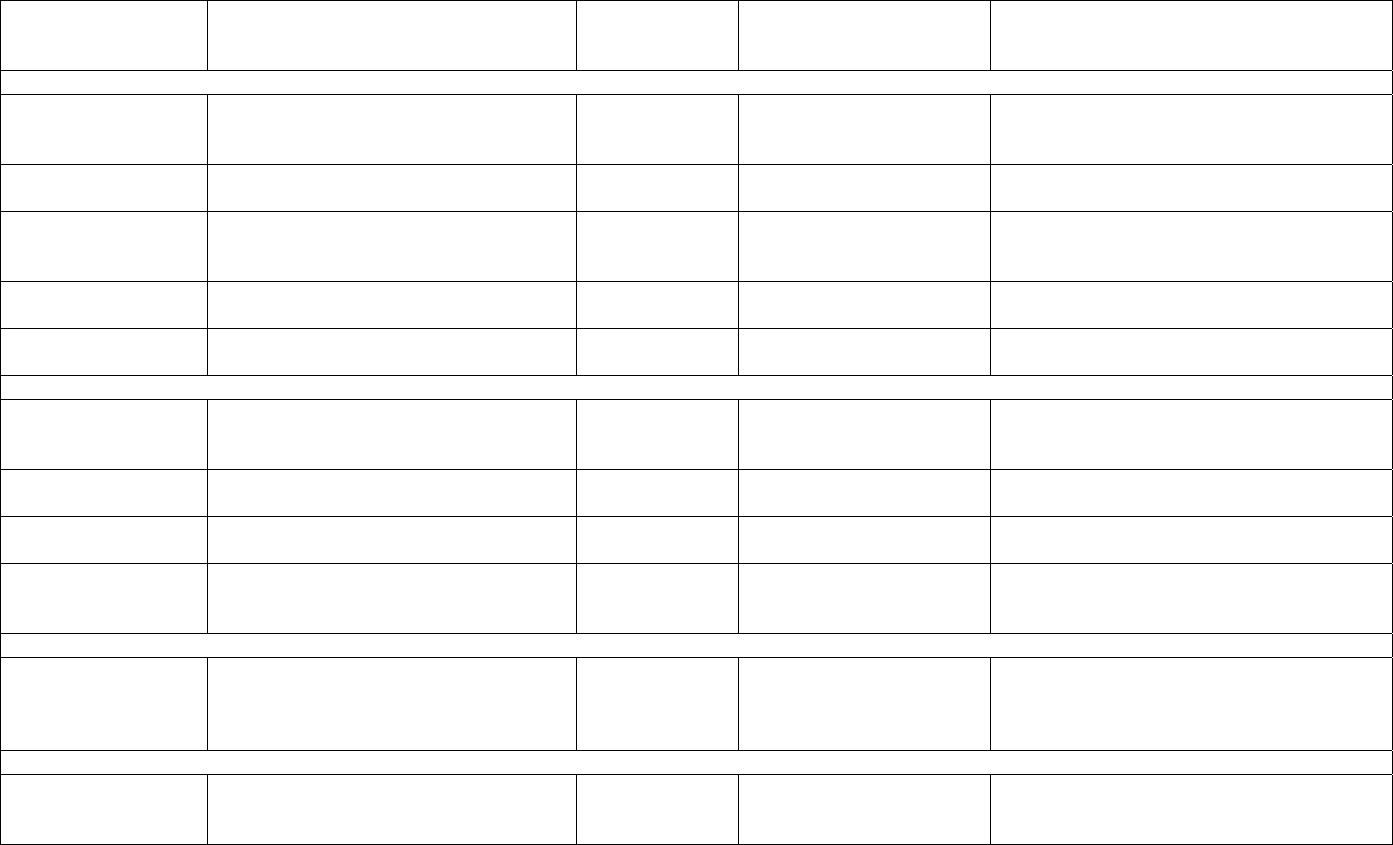

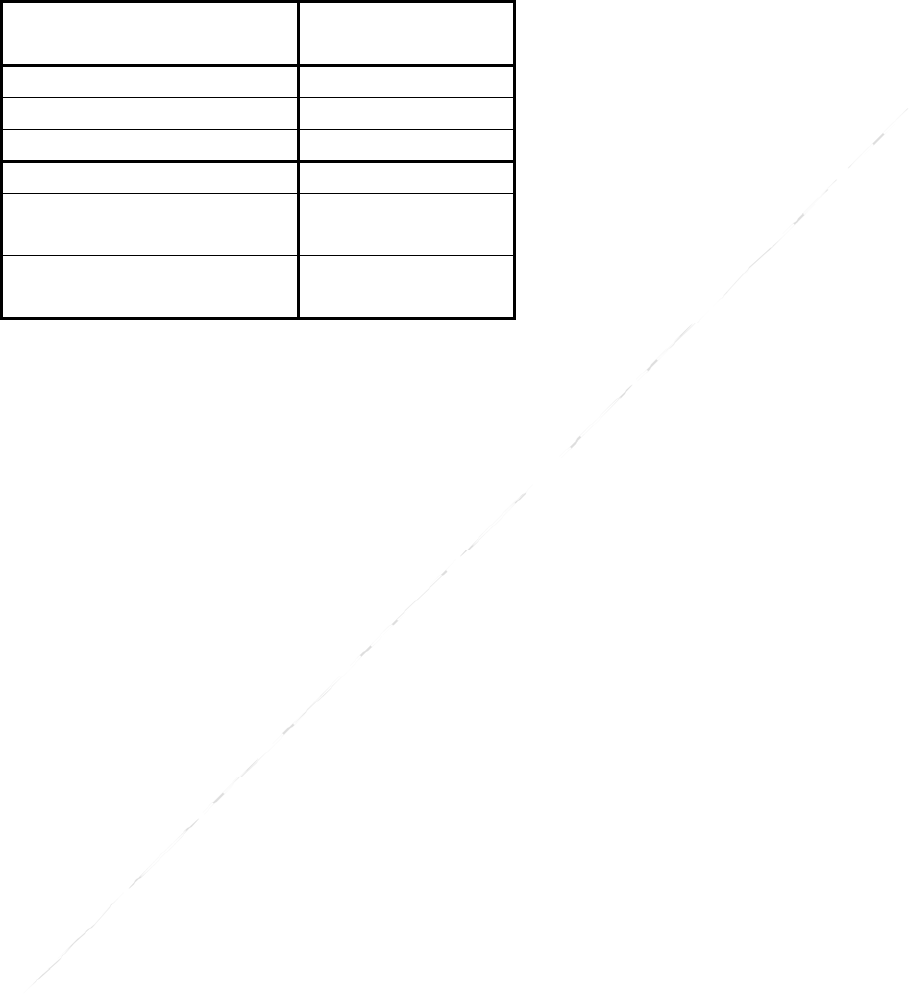

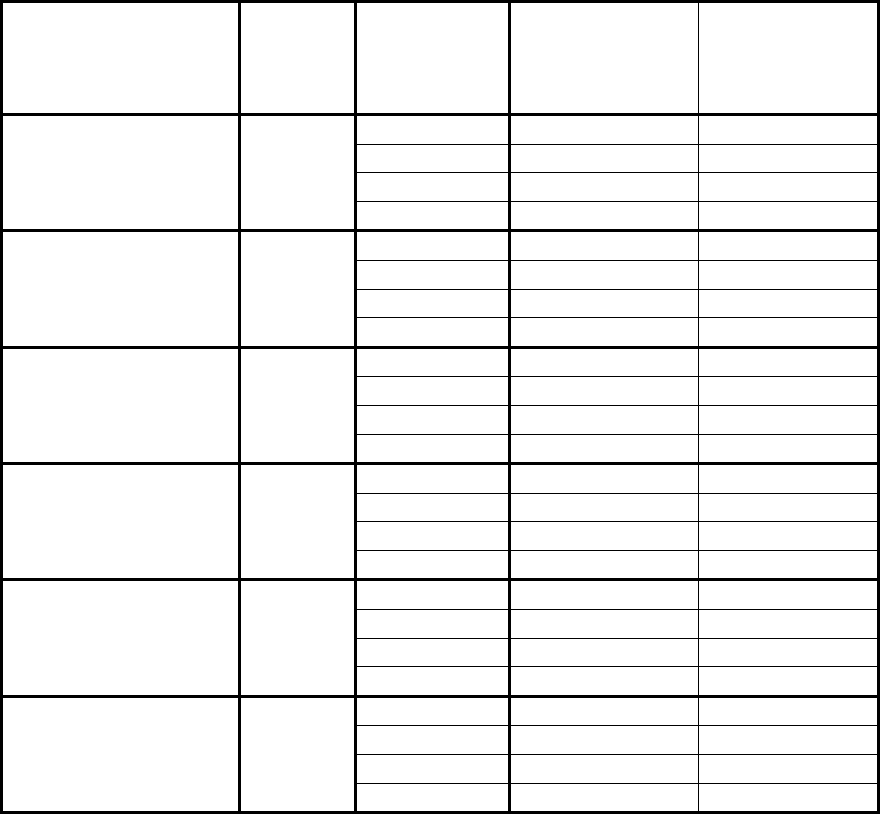

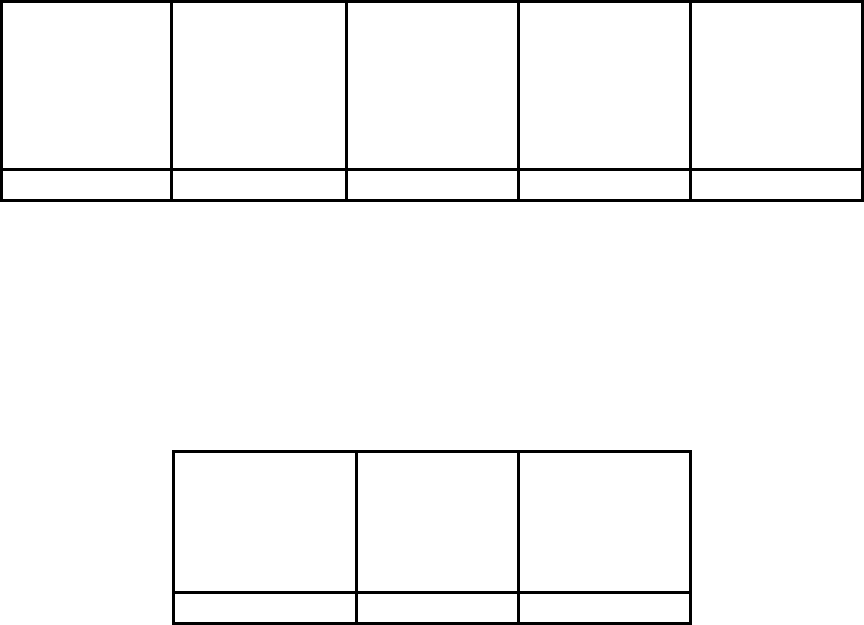

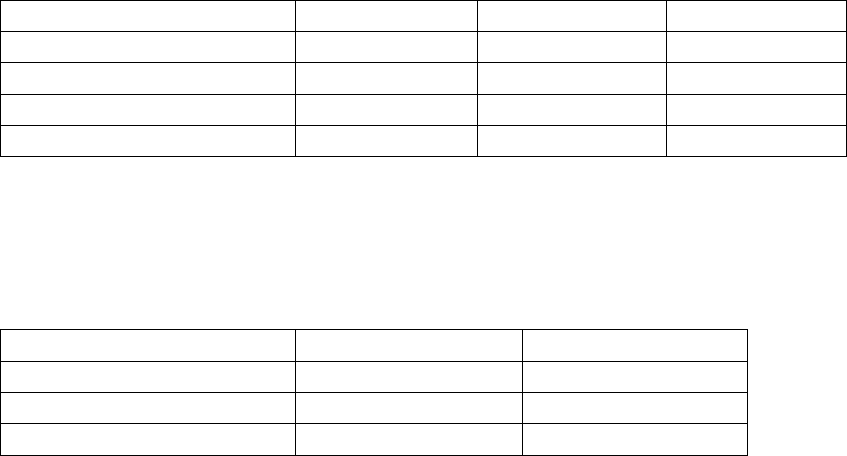

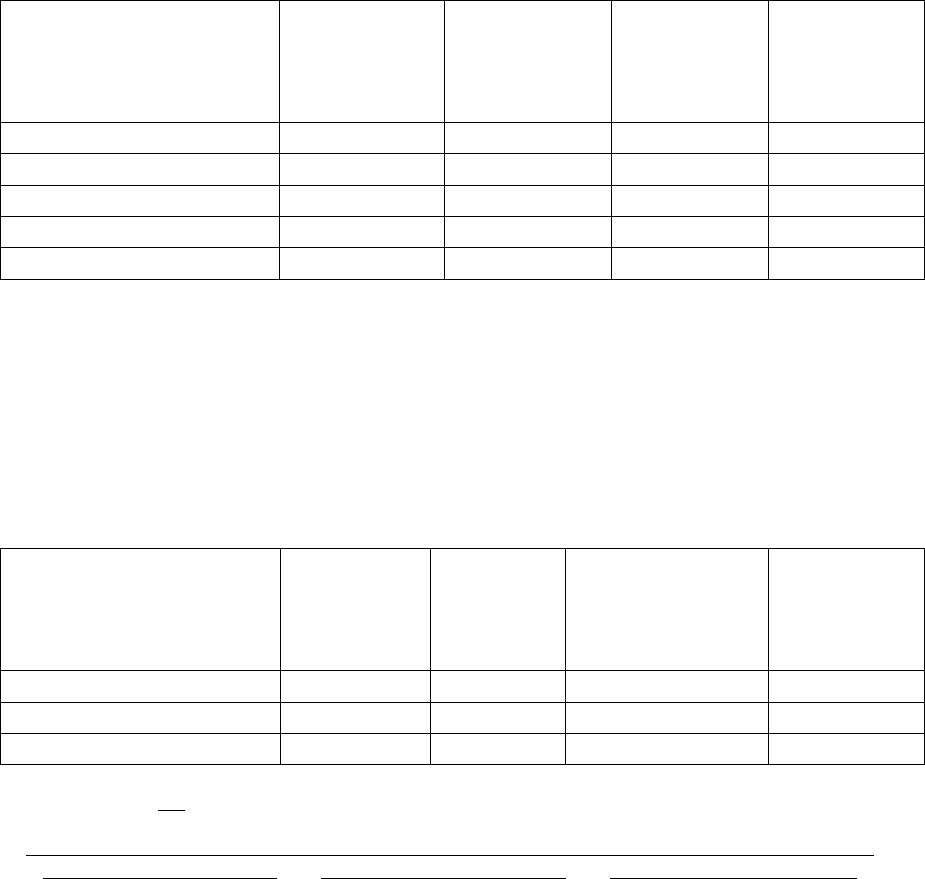

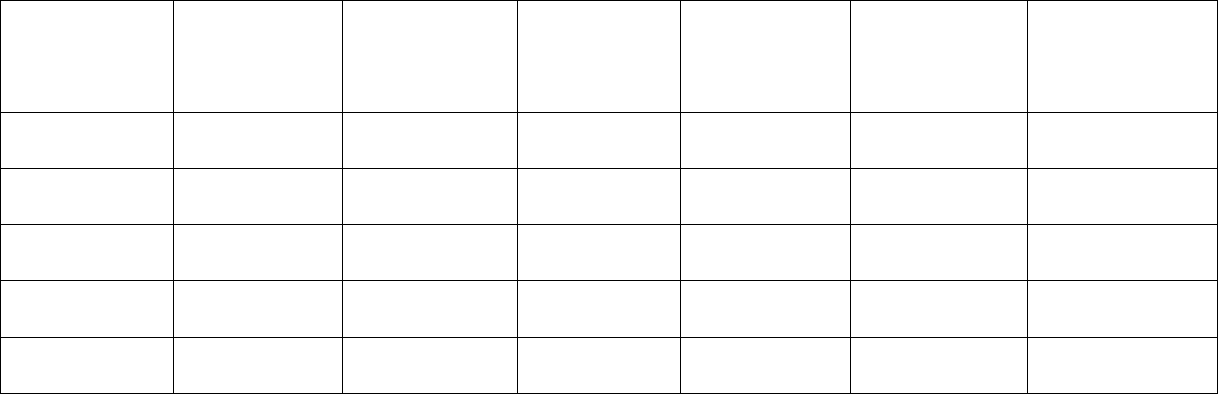

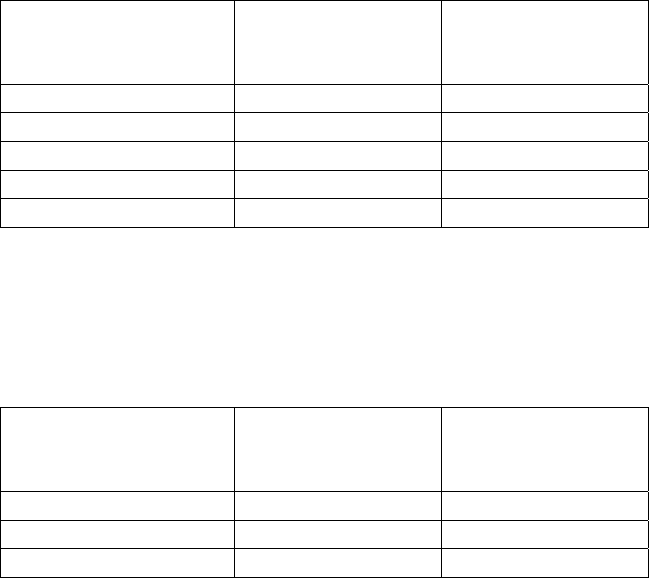

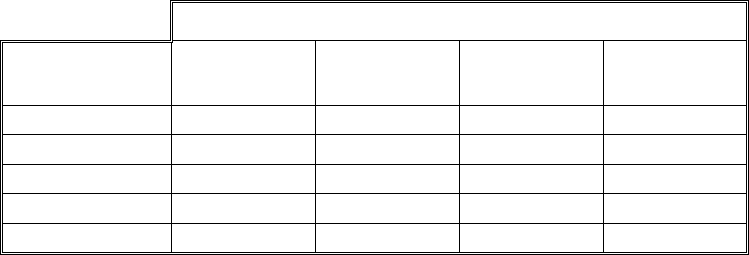

Table 1. Example tiered approaches for assessment of potential environmental concerns associated with TPH and TPH-related contaminants (refer to

HIDOH 2017).

1

Example

Environmental

Concern

2

Description

3

Tier 1: Generic

Screening

Levels?

4

Tier 2: Example Limited

Modifications to Tier 1

Screening Levels

5

Tier 3: Example Advanced Risk

Assessment Approaches

Soil (including exposed sediment)

Direct Exposure

Incidental ingestion, dermal absorption,

inhalation

Yes

Modification of target risk,

toxicity factors and/or

exposure assumptions

Site-specific use of risk calculators, with option

for alternative exposure models (e.g.,

alternative vapor flux model)

Vapor Intrusion Intrusion of vapors into overlying buildings

6

Not

Recommende

d

-

6

Collection of soil vapor data (including subslab

vapor) and/or indoor air data

Leaching

Leaching of TPH or related degradation

products from soil and subsequent impacts

to

g

roundwate

r

7

Yes

7

Limited

Direct assessment of groundwater conditions

(uncapped site or contamination in contact with

g

roundwater),

7

site-specific models

8

Gross Contamination

Presence of free product (NAPL), short-

term vapor emissions, sheens in runoff, etc.

Yes Use of site-specific data

Field evaluation of potential vapor emission and

free product concerns

9

Terrestrial

Ecotoxicit

y

Impacts to terrestrial flora and fauna Limited -

Site-specific ecological risk assessment if

sensitive habitat impacted

Groundwater/Surface Water

10

Direct Exposure

(drinking water

toxicit

y

)

Ingestion of impacted groundwater (+/-

inhalation of vapors and dermal

absorption).

Yes

Modification of target risk,

toxicity factors and/or

exposure assumptions

Site-specific use of risk calculators, with option

for alternative exposure models

Vapor Intrusion Intrusion of vapors into overlying buildings

6

Not

Recommende

d

-

6

Collection of soil vapor data (including subslab

vapor) and/or indoor air data

Aquatic Ecotoxicity

Discharges of impacted groundwater to

aquatic habitats

Yes Limited

Monitoring of plume stability, bioassay tests

usin

g

site-specific samples of

g

roundwate

r

10

Gross Contamination

Presence of free product (NAPL), sheens,

short-term vapor emissions, taste and odors,

etc.

Yes Limited

Field evaluation of free product, sheens, odor

concerns

Soil Vapor

11

Vapor Intrusion Intrusion of vapors into overlying buildings Yes

Modification of target risk,

toxicity factors, exposure

assumptions, vapor entry

rate, air exchan

g

e rate, etc.

Direct testing of indoor air, with concurrent soil

vapor data to verify source, site-specific models

Indoor/Ambient Air

Direct Exposure

Inhalation exposure to indoor air impacted

by intrusion of subsurface vapors.

Yes

Modification of target risk,

toxicity factors and/or

exposure assumptions

Forensics analysis of data to assess source of

indoor air impacts

TPH Risk - Case Studies (HIDOH, October 2018)

7

Table 1 (cont.). Example tiered approaches for assessment of potential environmental concerns associated with TPH and TPH-

related contaminants.

Notes:

1. Availability of screening levels for specific, environmental concerns varies between agencies. Screening levels published by a local agency might

not be applicable in other areas due to assumed target risks, toxicity factors employed, default exposure assumptions, etc. This includes screening

levels for vapor intrusion, since risk is closely linked to local climate conditions and building designs.

2. Refer to HIDOH 2017 for a more detailed description of the noted environmental concern. Other environmental concerns not listed might also be

applicable on a site-specific basis (e.g., uptake of petroleum into food crops).

3. “Yes” indicates that generic screening levels have been published for the noted environmental concern by some agencies. Presentation of screening

levels for TPH fuel fractions (e.g., TPH as gasoline, diesel or heavy oil) versus screening levels for individual, carbon range fractions varies between

states, as do the specific carbon ranges and toxicity factors considered.

4. Example modifications to risk calculators used to develop published, generic screening levels (not intended to be complete). Note that published

screening levels for some environmental concerns are not based on models amenable to site-specific modification and directly proceeding to

advanced approaches for more site-specific evaluation is required.

5. Example considerations for use of site-specific, risk calculators or other approaches for assessment of risk posed by a specific, environmental

concern (not intended to be complete).

6. Use of models to develop TPH vapor intrusion screening levels for soil and groundwater is not recommended due to poor reliability of models to

predict concentrations of contaminants in vapors away from the source area. Collection of soil vapor (including subslab or near-slab vapor) data is

recommended when contamination is present within 15-30 feet of a building (ITRC 2014; USEPA 2015).

7. Refer to expanded discussion of leaching models in this section. Models most commonly used to develop soil screening levels for leaching

concerns are not directly amenable to site-specific modification.

8. Referred to as “Gross Contamination” in some guidance (e.g., CAEPA 2016; HIDOH 2017) and “Ceiling Levels” in other guidance (e.g., MADEP

2014). These screening levels are intended to identify contaminated soil and groundwater that could result in short-term emission of very high

concentrations of TPH and other volatile chemicals that pose acute, transient health effects if the contamination is disturbed or otherwise exposed in

the future, as well as potential sheens in runoff from excavated soil or sheens in groundwater to be discharged to storm drains during construction-

or subsurface utility-related, dewatering actions.

9. Screening levels for TPH in soil that could pose risks to terrestrial flora and fauna are limited and can vary widely for different species. A site-

specific, ecological risk assessment is recommended in cases where significant risk might be posed to a sensitive, ecological habitat.

10. Applicability of screening levels for TPH-related metabolites in drinking water in terms of toxicity and taste and odor concerns is currently under

review.

11. Refer to HIDOH (2017) and ITRC Petroleum Vapor Intrusion document (ITRC 2015) for additional guidance on this subject.

TPH Risk - Case Studies (HIDOH, October 2018)

8

2 USE OF TPH DATA BY LIFE CYCLE STAGES

This section provides an overview of project life cycle stages for a risk evaluation associated with

a petroleum release under the following five, broad categories:

● Release Detection;

● Site Characterization;

● Risk Assessment;

● Remediation and Monitoring;

● Closure.

Petroleum-release sites can vary in size (refineries, terminals, oil fields) and type (clean-up, re-

development or spill response; see Attachment 2). Other special considerations could include

petroleum or petroleum-based product spills from trains or trucks in urban settings or from

pipelines carrying crude oil or refined products in remote areas. Individual components are

discussed in the following subsections and summarized in Table 2.

TPH Risk - Case Studies (HIDOH, October 2018)

9

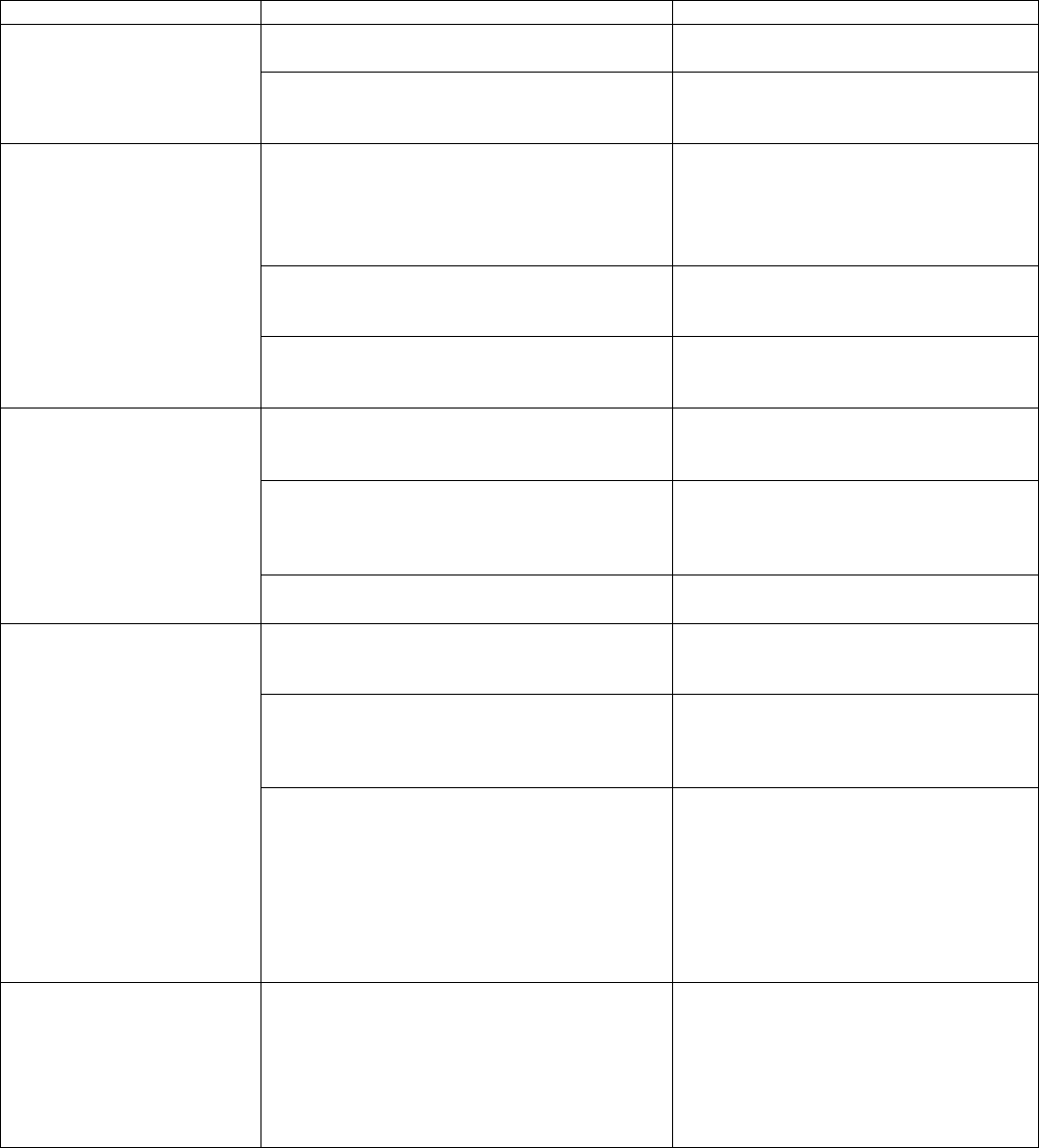

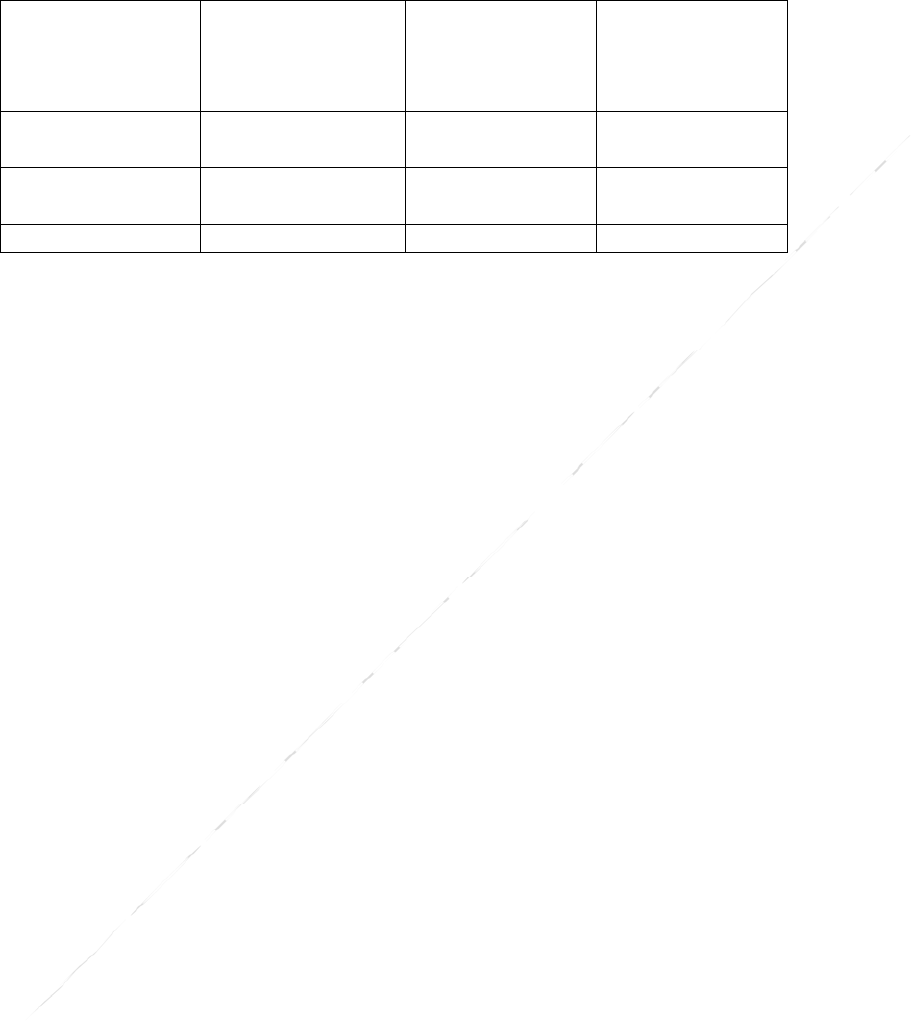

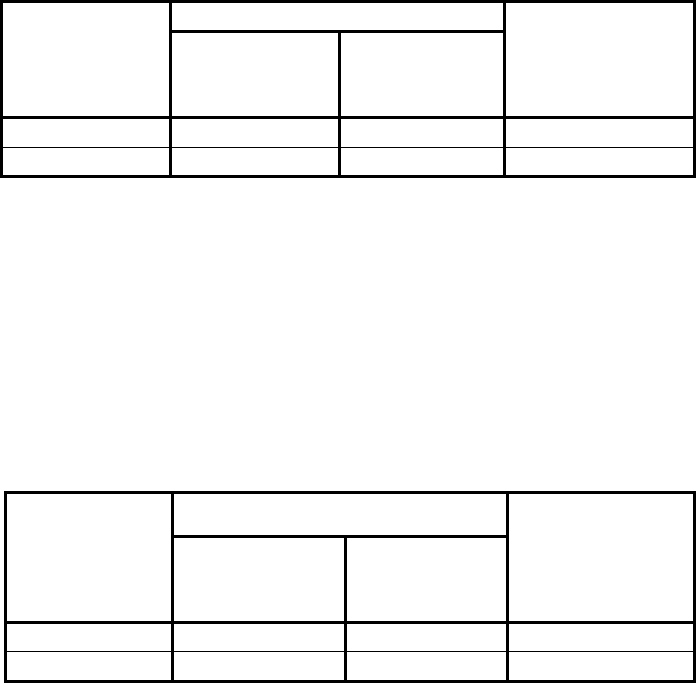

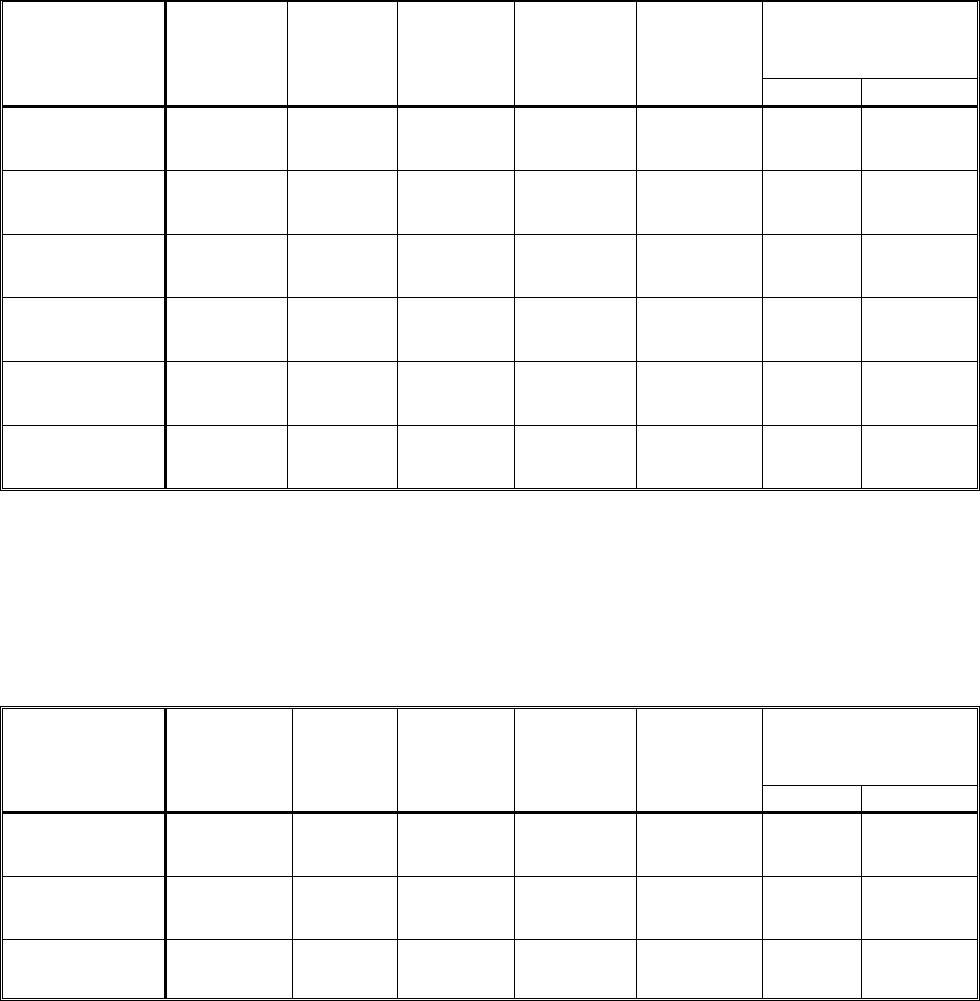

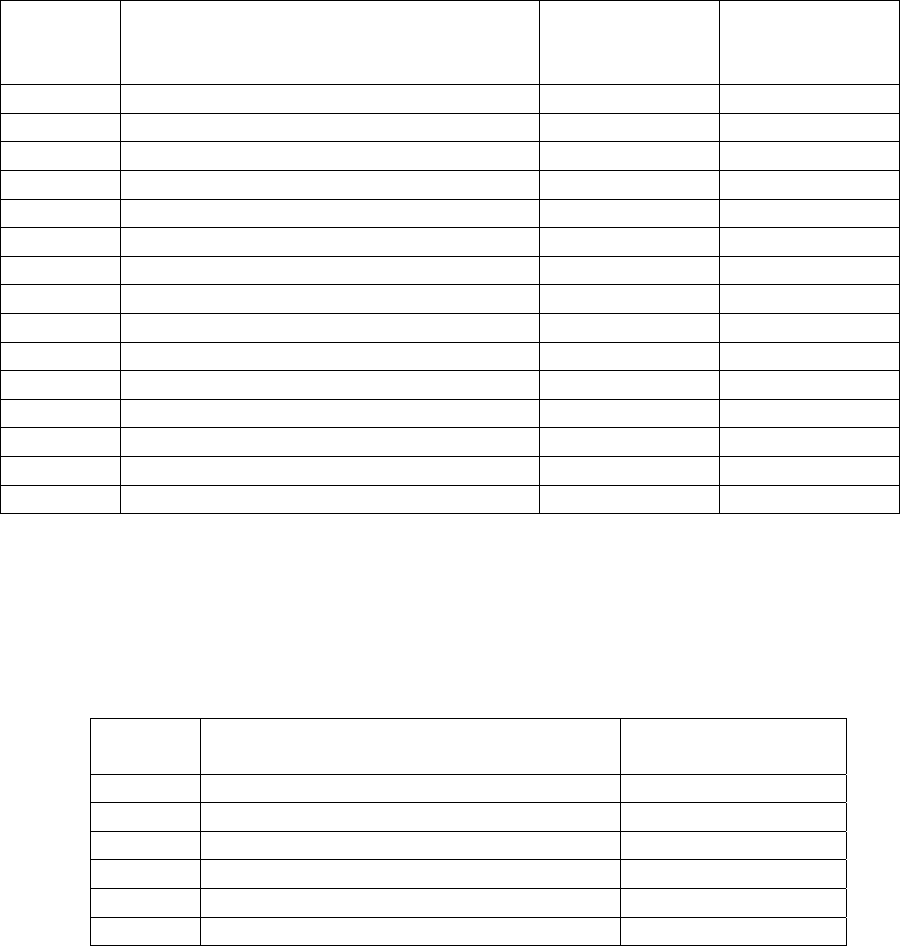

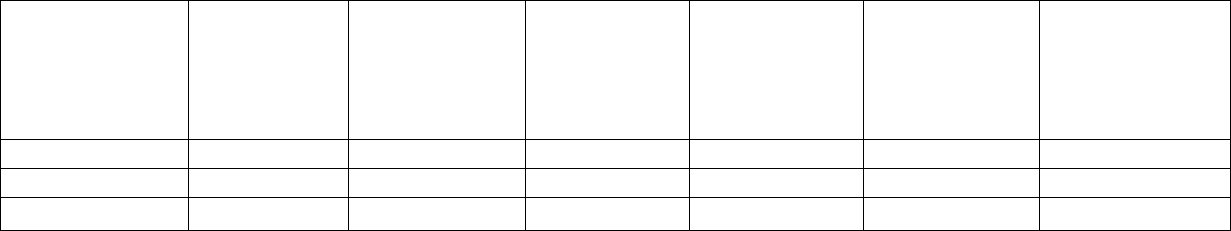

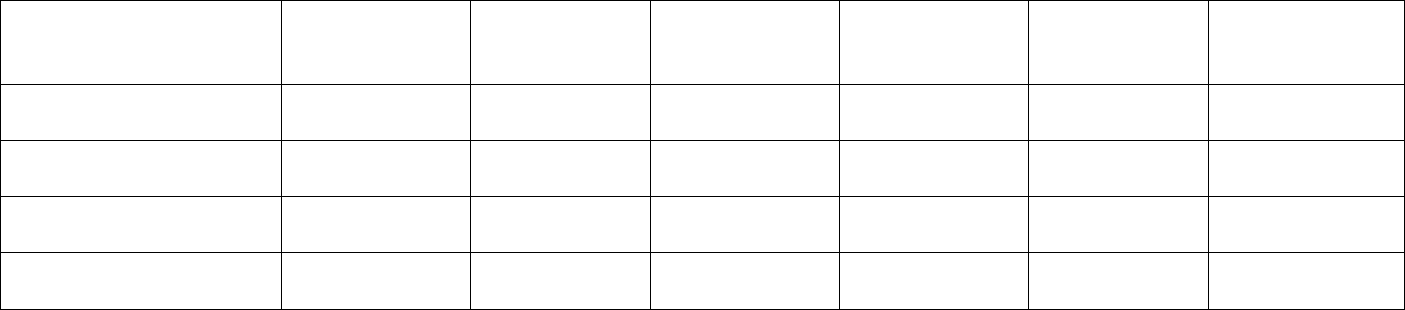

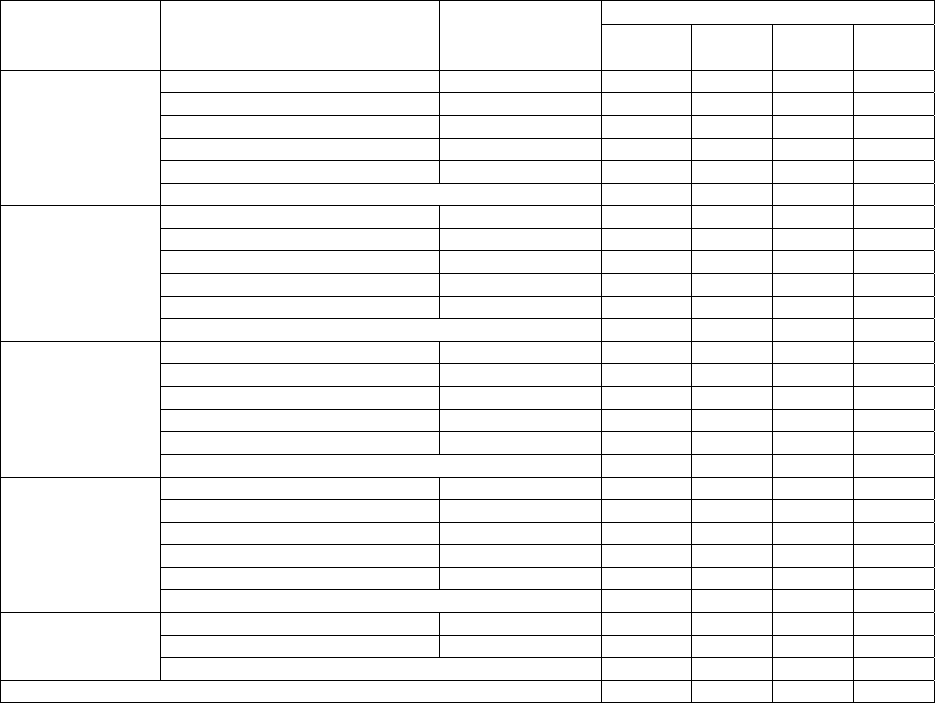

Table 2. Project life cycle stages of typical TPH sites.

Project Life Cycle Stage Data Type Use

Release Detection

Conduct preliminary assessment/site

inspection

Overview of site characteristics and

settin

g

s and surroundin

g

areas.

Conduct emergency response/triage As needed and on a case-by-case basis

prior to characterization. Stakeholder and

communit

y

en

g

a

g

ement, as appropriate.

Site Characterization

Soil sample data (consider

1

DU-MIS)

Soil vapor data

Groundwater and surface water data

Sediment data

Ambient indoor or outdoor data

More risk-based representation of

concentrations for targeted, risk-based

area and volume of contaminated soil and

other media

Large Purge Volume (“high purge volume”)

subslab or near-slab vapor data

More risk-based representation of

subslab vapor plume and potential vapor

intrusion concerns

Include gas chromatograms in site

investigation report

Useful for source identification and

applicability of screening levels based on

assumed carbon ran

g

e composition

Risk Assessment

Collect TPH carbon range data for all samples

or a representative subset of samples (soil, soil

vapor, and/or indoor air)

Source identification

Calculation of site-specific, risk-based

TPH screenin

g

levels

Collect groundwater data to assess leaching

concerns if contaminated area uncovered

and/or main mass of contamination in contract

with groundwater

More representative assessment of

leaching concerns

Silica gel cleanup (SGC) data for TPH Separate assessment of risk posed by

p

olar TPH metabolites in

g

roundwate

r

Remediation and Monitoring

LNAPL mobility study Targeted removal of most mobile areas

with LNAPL (for example, high

transmissivit

y

plume).

SGC data for TPH Use SGC data to assess status of

petroleum degradation and identify less-

degraded areas of groundwater for

tar

g

eted treatmen

t

Prepare to-scale maps that identify remaining

contaminated soil, groundwater, soil vapor and

other pertinent media

Include estimate of volume of contaminated

soil and potentially recoverable LNAPL on

groundwater

Ensures visualization of residual

contamination

Assures inclusion of potential

management and disposal costs in future

redevelopment (Brownfield sites)

Incorporate into future site

redevelopment plans (logistics, budget,

design, etc.)

Closure

Prepare a brief “Environmental Hazard

Management Plan” or similar plan that

summarizes specific, potential concerns

associated with residual contamination and

general long-term management requirements

Institutional Controls

Remedial Action Outcome

Regulatory consideration of de minis

contamination for case closure

Site restrictions (environmental

covenants) Closure/post closure long-

term management of residual

contamination.

1. Decision Unit and Multi Increment Sample investigation methods (HIDOH 2016; see also ITRC 2012).

TPH Risk - Case Studies (HIDOH, October 2018)

10

2.1 Release Detection

Background concentrations are typically used to determine whether a petroleum release has

occurred. Depending on the media impacted (soil, groundwater, surface water, soil vapor), several

common screening tools including, but not limited to, flame ionization detector, photoionization

detector or a field gas chromatograph can be used. Special consideration for release discoveries

can include spill responses, during which community air monitoring and public safety measures

are developed and implemented. An important aspect of release detection monitoring is

determining the background concentrations (either natural or anthropogenic) for the appropriate

chemical constituents. Natural background is representative of pristine or pre-industrial conditions.

Anthropogenic background refers to concentrations that may be impacted by human activity, and

unrelated to the release. The initial release discovery data and the understanding of impacts (i.e.,

preliminary Conceptual Site Model (CSM) provide the basis for characterization, screening and

remediation.

2.2 Site Characterization

Site characterization typically occurs in the early stages of petroleum release and builds on the

data obtained during release discovery and emergency response actions, as appropriate. In general,

site characterization describes the physical conditions of the site such as soils, geology, hydrology,

presence of existing contamination, potential for contamination to be released, and the actual and

potential pathways and mechanisms for contamination transport. This stage of the project life cycle

considers the chemical characteristics of the contaminants and their potential to be mobile in the

environment. All of these aspects of site characterization need to be understood to develop a robust

CSM.

Information collected during the characterization phase may support, refute, or provide additional

details for the initial assumptions regarding the petroleum release site. While some information

may not be initially known, information must be collected to support the CSM. Development of

the CSM starts at the beginning of any site remediation/risk evaluation project and continues as

additional information becomes available through site closure.

For example, analytical methods can yield false, elevated levels of dissolved-phase TPH in water

samples due to non-dissolved petroleum (LNAPL) entrained within a sample or polar, non-

hydrocarbon-related compounds associated with organic matter. The toxicity of polar,

hydrocarbon-related, degradation compounds or “metabolites” is considered to be similar to that

of the parent compounds for initial screening purposes (see Attachment 5). As a best practice for

analysis of TPH and TPH-related degradation compounds, first filter sample to remove entrained

soil particles and note the presence or absence of LNAPL droplets. Next, test the water for TPH in

the absence of SGC cleanup to estimate the total, combined concentration of nonpolar, parent

hydrocarbons and potential hydrocarbon-related, polar degradation compounds (“metabolites”).

Apply silica gel cleanup to the sample to remove polar compounds and then retest for TPH and/or

specific carbon range fractions. The resulting non-SGC and SGC data can then be compared to

applicable screening levels (see Attachment 4 and Attachment 5). Samples collected from non-

impacted areas can be used to estimate the background concentration of polar, non-hydrocarbon-

related compounds. This can besubtracted from non-SCG sample data collected in impacted areas

in order to better estimate the concentration of hydrocarbon-related, degradation compounds in the

water and ensure that these compounds are considered in the risk assessment.

TPH Risk - Case Studies (HIDOH, October 2018)

11

2.3 Risk Assessment

Over the past few decades, risk-based decision making has emerged as a powerful basis for

deriving remediation objectives for petroleum release sites. The backbone of a risk-based approach

relies on the essential source–pathway–receptor components of the CSM and the understanding of

the known and plausible mechanisms that govern such interactions.

A TPH ‘mixture’ risk-based evaluation approach, backed by toxicity assessment, ecological risk

assessment, and fate and transport modeling, subject to the significance of exposure pathways, can

be used in the derivation of remedial objectives. When it can be adequately demonstrated that the

potential risk of exposure to human or ecological receptors is acceptable, within agency-specified

limits, then a firm basis for developing risk-based management measures, rather than a prescriptive

approach to remediation, is most appropriate.

2.4 Remediation and Monitoring

Remediation of petroleum release sites is challenging, complex and often accompanied by

indeterminate timelines. The remediation approaches for TPH release sites are further complicated

due to the presence of impacts in multiple media at most sites. A thorough understanding of the

CSM and the results of a robust risk evaluation can assist with arriving at appropriate remedial

management decisions. The development of remediation technologies is beyond the scope of this

document. The case studies used for initial reference in development of when response actions.

Monitoring may be conducted to describe characteristics at a specific location or point in time or

to show how these characteristics change over time or space. This approach is typically used to

evaluate remedial and response actions at petroleum release sites. Monitoring is conducted on a

short-term and long-term basis, and in some instances, even after closure of a site during post-

closure monitoring.

2.5 Closure

Closure is the final stage of the project life cycle and represents the endpoint for response action

at petroleum release sites. At this stage in the process, data planning and collection should have

been managed through a systematic planning process, and remediation is assumed to be complete

for the purposes of making a final determination on whether monitoring may be permanently

discontinued and the site closed. This decision point may be reached at any time during the life

cycle process (for example, during site characterization, remediation, or monitoring). Significant

variation occurs across regulatory programs, but in general, when contaminants are no longer

detected in all media over several monitoring events or over a specified period of time, the remedial

goals are deemed complete.

Due to the significance of achieving closure (no further action), site managers must have a high

degree of confidence that the data fully support closure. Closure should verify that site

contaminants are no longer present in the relevant media or are not present at concentrations that

pose an unacceptable risk to human or ecological receptors. In cases where concentrations of

contaminants are allowed to remain (such as under institutional or engineering control scenarios),

a management plan for residual contamination associated with TPH is key and should be part of

the final remediation documents.

TPH Risk - Case Studies (HIDOH, October 2018)

12

3 EVALUATION OF EXISTING TPH DATA

The case studies include consideration of both historic, bulk TPH data for soil, water and soil vapor

as well as newer, carbon range data. Carbon range data were not routinely collected at petroleum

release sites prior to the mid-2000s in most states and is still uncommon in many areas of the

country. Bulk TPH data based on gas chromatography (e.g., Method 8015; USEPA 2007) have

been collected at petroleum releases since the 1990s. Caution is warranted in the use of older TPH

data, due to lab methods that might have led to the loss of low-range hydrocarbons or might

otherwise bias the data.

Three approaches are available for consideration of existing, bulk TPH data in an environmental

risk assessment: 1) Direct comparison to carbon range-weighed screening levels for TPH based on

the assumed, carbon range composition of the specific type of petroleum present (for example,

gasoline or diesel), 2) Direct comparison to screening levels for the most toxic carbon range

presumed to be present, or 3) Use of site-specific, carbon range data to develop carbon range-

weighted TPH screening levels and/or convert existing TPH data into carbon range fractions. The

first option is typically the most expedient and cost-beneficial for small- to medium-size releases,

especially if published, carbon range-weighted screening levels for TPH are already available. The

second option is possible if only screening levels for individual carbon ranges are available but is

likely to be excessively conservative since the most toxic fractions of petroleum typically only

make up a small proportion of the overall mixture (HIDOH 2017; see also Brewer et al. 2013).

The third option will provide the most accurate picture of potential risks but requires the added

time and expense of additional sample collection for site-specific, carbon range data. Cumulative

risk posed by combined effects of individual carbon ranges that otherwise meet screening levels

must also be considered (see Section 2 above).

Risk-based screening levels based on the assumed carbon range makeup of the specific type of

petroleum released can be used to develop soil, soil vapor, and/or groundwater screening levels

for comparison to existing TPH data (e.g., MADEP 1994, 1996, 2014; CAEPA 2016; HIDOH

2017). Example, carbon range-weighted screening levels included in Attachment 4 and are used

for comparison to hypothetical site data in the case studies. The approximate carbon range makeup

of both fresh petroleum can be estimated within a relatively narrow range of possibilities. The

precise, carbon range composition of weathered TPH can vary both between sites and even within

sites for similar types of fuel. Variability in terms of total TPH toxicity is likely to be minimal in

soil where LNAPL is present, however, given the relatively large groupings of carbon ranges used

to assess risk. The same is true for vapors associated with gasoline, which are predictably

dominated by light-range aliphatics. The carbon range composition of dissolved-phase TPH in

groundwater could vary significantly, however, due differences in the makeup of the original fuel

as well as variability in biological, degradation processes. The composition of vapors associated

with diesel and other middle distillate releases can likewise vary significantly, due to both

biological activity (e.g., anaerobic generation of light-range aliphatics) and due to the original

formulation of the fuel.

Site-specific carbon range data rather than reliance on bulk TPH data and default TPH

compositions are especially useful in these situations. These issues are incorporated into Case

Studies 1 & 2. Consideration should be given to characteristics of the petroleum release, including

differing stages of aging and weathering, and understanding of the CSM. Direct comparison of

TPH Risk - Case Studies (HIDOH, October 2018)

13

TPH data to carbon range-weighted screening levels requires a high level of certainty regarding

the nature of petroleum product(s) released at the site and the reliability of the TPH data. A review

of gas chromatograms for sample data, if available, can greatly assist in this evaluation.

Published data on the carbon range makeup and toxicity of vapors associated with petroleum fuels,

including both gasoline and diesel, are limited (Brewer et al. 2013). Vapors tend to be dominated

by lighter-end aliphatic compounds in comparison to the parent fuel type. Concentrations of TPH

in vapors from gasoline releases tend to be much higher than for diesel release, due to a higher

proportion of light-end compounds in the fuel. Vapors from diesel can, however, include a high

proportion of more toxic, longer-chain aliphatic compounds in comparison to vapors from

gasoline, which are dominated by short-chain aliphatic compounds. In both cases, a significant

vapor intrusion risk is only likely to be present if the source is close enough to an overlying

building (refer to HIDOH 2017; ITRC 2014).

Although not included in the case studies, existing TPH data for soil and groundwater can be

compared to published screening levels for the most toxic hydrocarbon fraction likely to be present

(e.g., MADEP 2014). Example screening levels for individual carbon ranges are included in

Attachment 4. A limited amount of site-specific, carbon range data can be collected from key areas

of a historic release site and used to develop site-specific, carbon range-weighted screening levels.

As an alternative, the data could be used to convert existing, bulk TPH data into carbon range data

for consideration in a more detailed risk assessment. The former is likely to be most cost effective

for small- to medium-size sites, while the latter might be beneficial for a more precise assessment

of contamination associated with large releases and a complex CSM.

The use of default, carbon range-weighted screening levels for bulk TPH in soil, water, air and soil

vapor allows for rapid screening of existing site data. Care should be taken, however, to ensure

that the nature of petroleum-related contamination at the site corresponds reasonably well with

assumptions used to develop the screening levels. This can be carried out in part by review of gas

chromatograms for site-specific sample data and the use of silica gel cleanup or similar methods

to assess the degradation state and makeup of petroleum-related contaminants. Detailed carbon

range analysis of the aliphatic and aromatic makeup of the TPH component of the petroleum and

development of site-specific, TPH screening levels can be carried out as needed. This is not

anticipated to be necessary or cost-beneficial at relatively small sites. Site-specific carbon range

data and bulk TPH toxicity data might, however, be desirable for large releases with potentially

significant, ongoing or near-term risks to human health and the environment.

4 COMMON RISK ASSESSMENT PROBLEMS AND DATA LAPSES

As noted in the case studies, existing TPH data might or might not be adequate for risk-based

assessment of potential environmental concerns at a petroleum-release site. Common types of data

lapses and data usability issues include:

● Reliance on BTEXN and PAH data (i.e., indicator compounds) alone for decision making

in the absence of TPH characterization data for all media (i.e., soil, sediment, water, soil

vapor and/or indoor air);

● Failure to document nature, location and potential environmental concerns posed by

residual contamination;

TPH Risk - Case Studies (HIDOH, October 2018)

14

● Absence of a detailed CSM and consideration of all current or potential sources, pathways

and receptors;

● Focus of initial risk assessment on human direct exposure and lack of data collection and

assessment of other potential concerns, including leaching, vapor intrusion, impacts to

aquatic habitats, gross contamination, and related environmental concerns;

● Inability to assess degradation state of petroleum in groundwater due to lack of silica gel

cleanup data;

● Inability to assess potential environmental concerns posed by polar, TPH-related

metabolites due to lack of groundwater data that excludes silica gel cleanup;

● Bias of existing TPH soil data due to presence of tree sap, pine needles and other non-

petroleum, organic material in samples and inadequate processing and analysis at the

laboratory;

● Bias of existing TPH groundwater or surface water data due to presence of algae, dissolved

organic carbon, fish oils and other non-petroleum, organic material in samples and

inadequate processing and analysis at laboratory;

● Misinterpretation of baseline noise in gas chromatograph signals below 100 µg/L as TPH

in groundwater or surface water samples;

● Use and interpretation of data from different analytical methods (for example, method 8015

vs. state-specific methods); and

● Limitations of data use due to elevated detection limits and laboratory reporting errors.

Additional problems associated with the use of historic data at petroleum release sites are discussed

in individual case studies.

5 CASE STUDIES OVERVIEW

Attachment 1 presents five case studies that highlight the use of TPH and carbon range data for

the investigation, assessment and remediation under different, petroleum-release scenarios. The

case studies are generic in nature but reflect the collective experience of the preparers of the

guidance document and data for sites similar to those discussed. A summary of themes

incorporated into each of the case studies is provided in Table 3.

Case Study #1 involves redevelopment of a former fuel storage terminal impacted with diesel and

gasoline. Shallow groundwater allowed releases to migrate across broad areas. Extensive LNAPL

on the water table poses vapor intrusion risks for new buildings as well as logistical challenges for

management of impacted soil and groundwater during redevelopment. Widespread contamination

of groundwater poses concerns for intentional or inadvertent discharges into a nearby harbor.

Carbon range-weighted screening levels for TPH published by the overseeing regulatory agency

are primarily used to carry out the site investigation and design remedial actions, although site-

specific carbon range data are obtained for vapors in diesel-impacted areas in order to better assess

vapor intrusion risk.

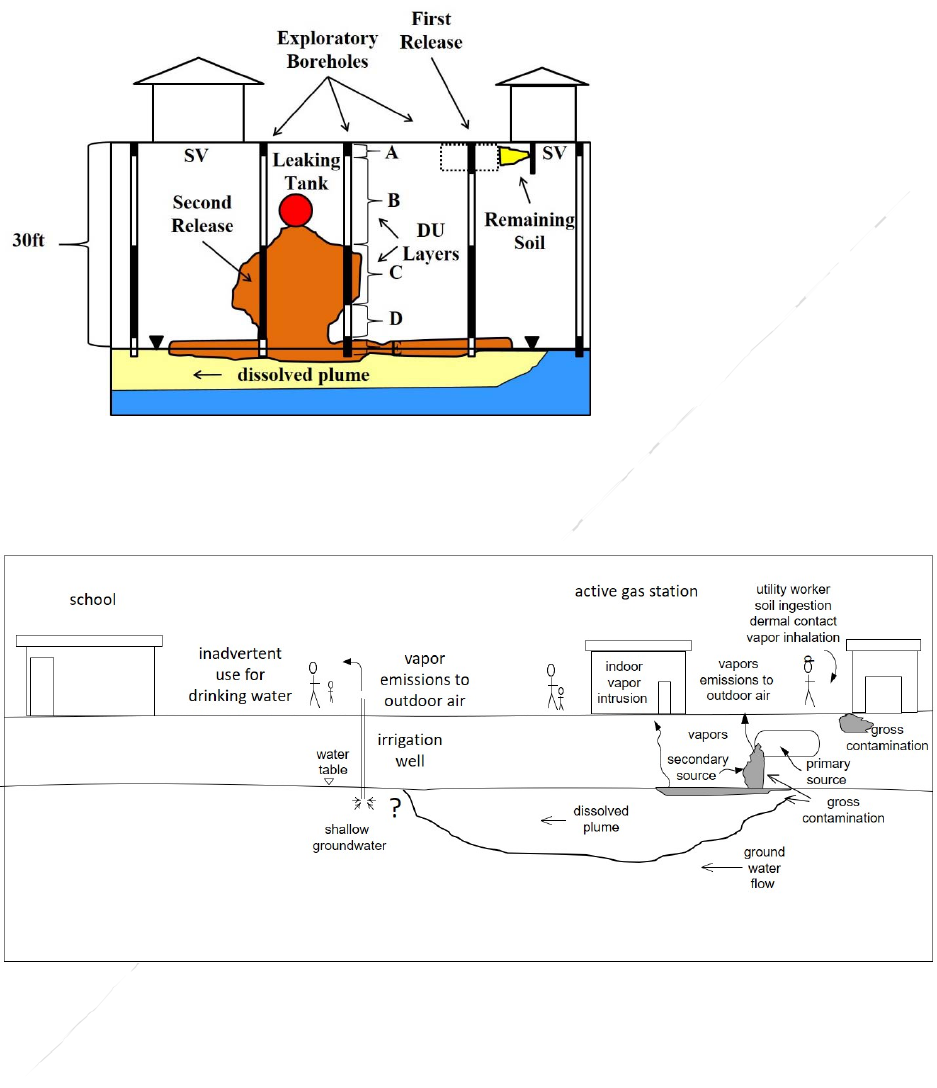

Case Study #2 focuses on the use of TPH data to assess potential risks predicated by past and

recent releases of gasoline at an operating gasoline station. The first release was identified during

removal of a former underground storage tank and was largely remediated, although a small

TPH Risk - Case Studies (HIDOH, October 2018)

15

volume of contaminated soil (<10 cubic yards) had to be left in place due to structural concerns

for an adjacent, maintenance building. Although concentrations of TPH in soil and soil vapor are

relatively high, the amount of LNAPL remaining was considered to be de minimis and no further

action was required, other than proper management and disposal of the soil if disturbed during

future subsurface work at the site. The second release is more extensive and reached groundwater,

at a depth of 25 feet below grade. Soil vapor data suggest potential vapor intrusion concerns for

the overlying store. A shallow water well used by an adjacent school for irrigation is threatened

by a dissolved-phase plume of heavily degraded petroleum emanating from the site. Data for

perimeter monitoring wells are compared to risk-based screening levels for metabolite mixtures in

groundwater to assess risks to workers and students who might inadvertently use the well for

drinking water. The development of example screening levels for metabolites is presented in

Attachment 5.

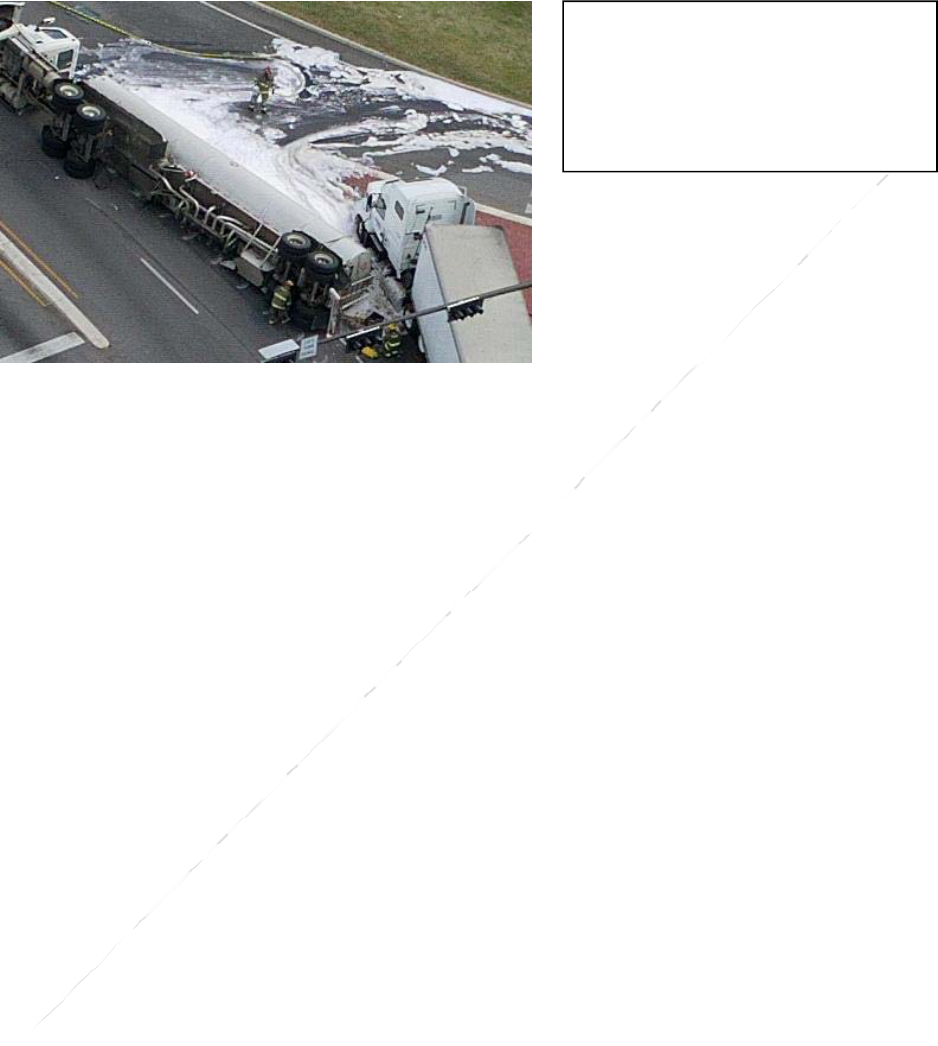

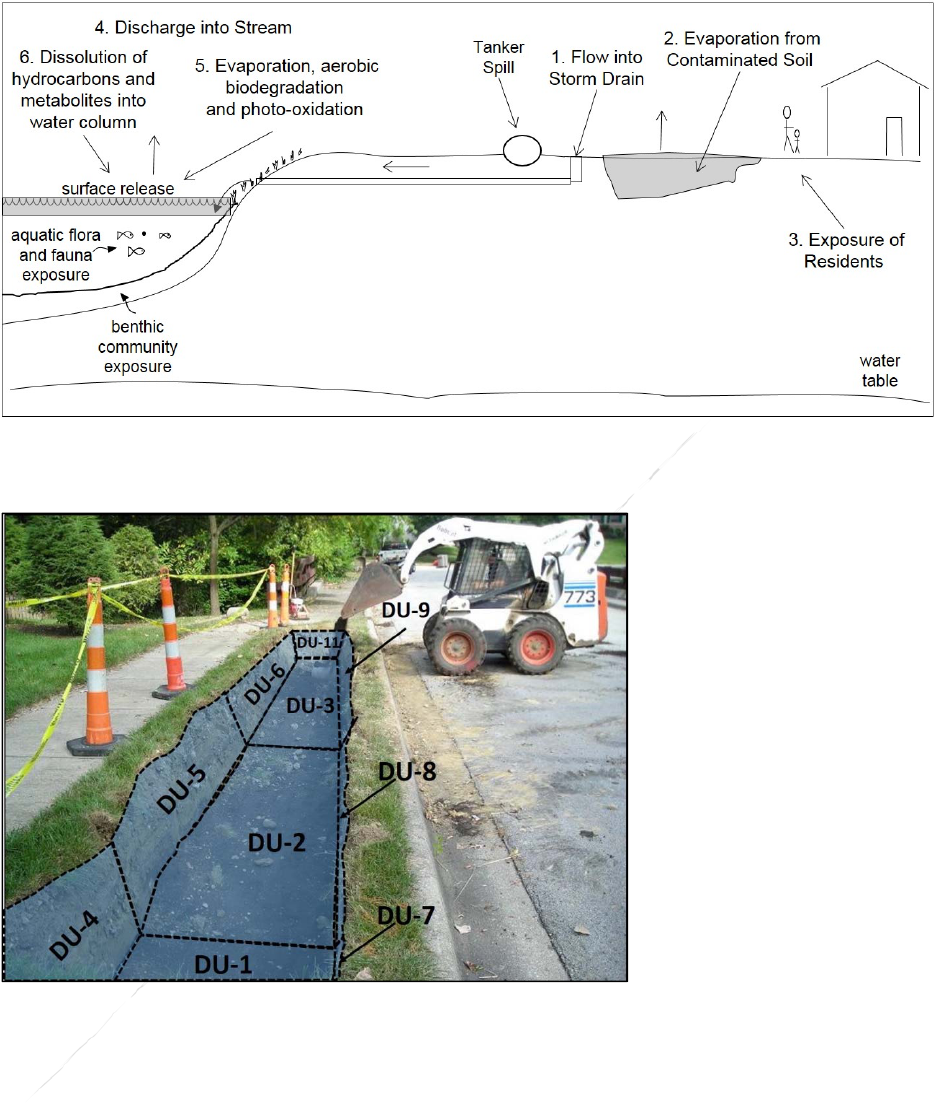

Case Study #3 considers the release of 3,000 gallons of diesel fuel following a tanker truck

accident in a dense, urban area. Much of the fuel remained ponded in the street, but some fuel

spilled over the curb into a resident’s front yard. Some of the fuel also flowed into a storm drain

and entered a nearby stream. Data for vapor samples collected in front of the home exceeded

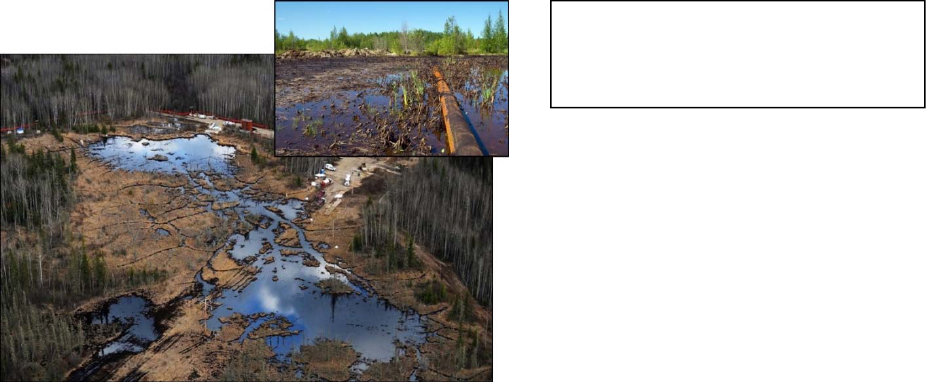

screening levels for both TPH and benzene. Impacted soil was excavated from the yard the

following day. Confirmation soil samples collected based on DU-MIS investigation methods

(HIDOH 2016; see also ITRC 2012) identified the need for additional excavation in one area.

Booms were placed in the stream to minimize the spread of fuel. Free phase LNAPL and gross

contamination was removed as practical as part of the emergency response. The acceptability of

allowing the remaining contamination to naturally attenuate over time is under review by the

overseeing, regulatory agency based on the observed magnitude of near-term impairment to the

stream ecology.

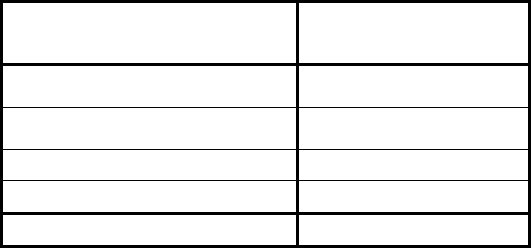

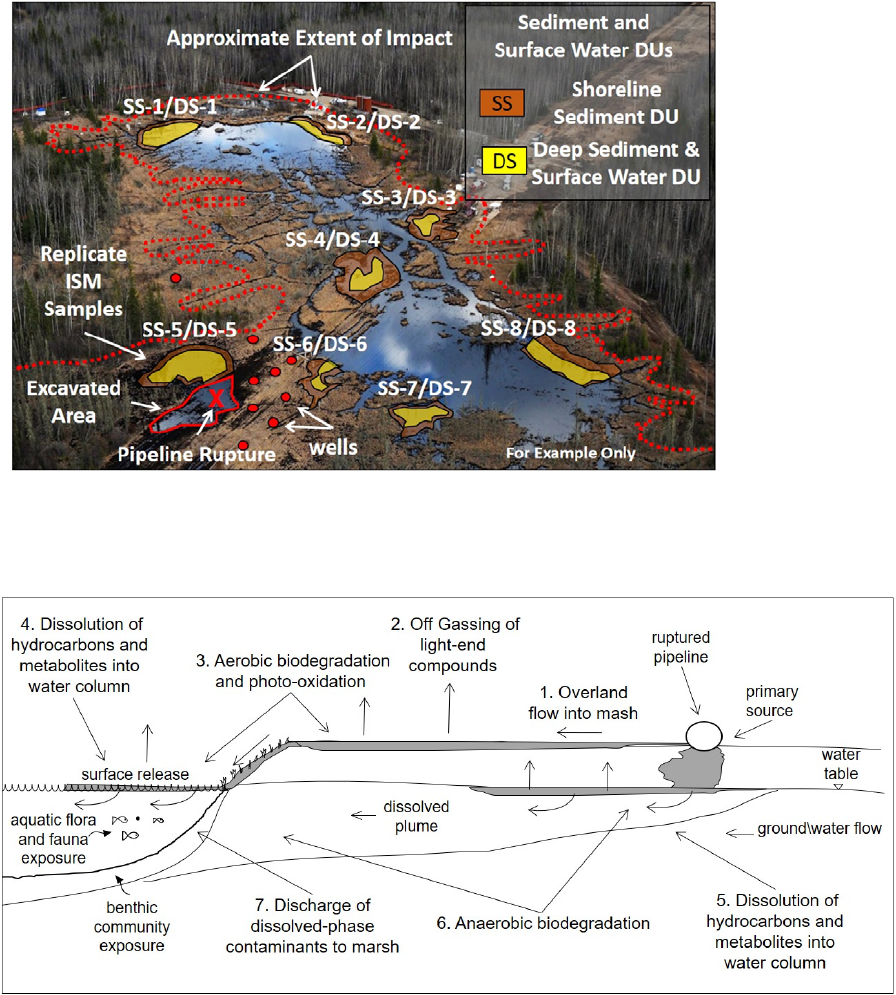

Case Study #4 involves the release of a large amount of light-weight oil from a ruptured pipeline

in a remote area. The oil quickly spread into an adjacent marsh area, with significant impacts to

aquatic flora and fauna. Heavy contamination in the area of the rupture was quickly removed and

the pipeline repaired. Soil, sediment and water samples were collected using DU-MIS methods

and used to monitor the subsequent fate and transport of the petroleum over time and assess the

benefit of additional remedial action, versus allowance for the contamination to naturally degrade

over time.

Case Study #5 presents approaches for the assessment and remediation of petroleum-release

impacts, specifically TPH at an upstream oil and gas exploration and production (E&P) Site, within

a 3,000 acre, remote active cattle ranch. Petroleum-releases from buried drilling waste adjacent to

the active crude oil production well location were noted by the site owner. Topics addressed

include site characterization using TPH and carbon range data in conjunction with indicator

compounds to assess and manage risk for source material, comparison to default and development

of site-specific screening levels, remediation of LNAPL impacted soils, and groundwater impacts,

and residual management.

TPH Risk - Case Studies (HIDOH, October 2018)

16

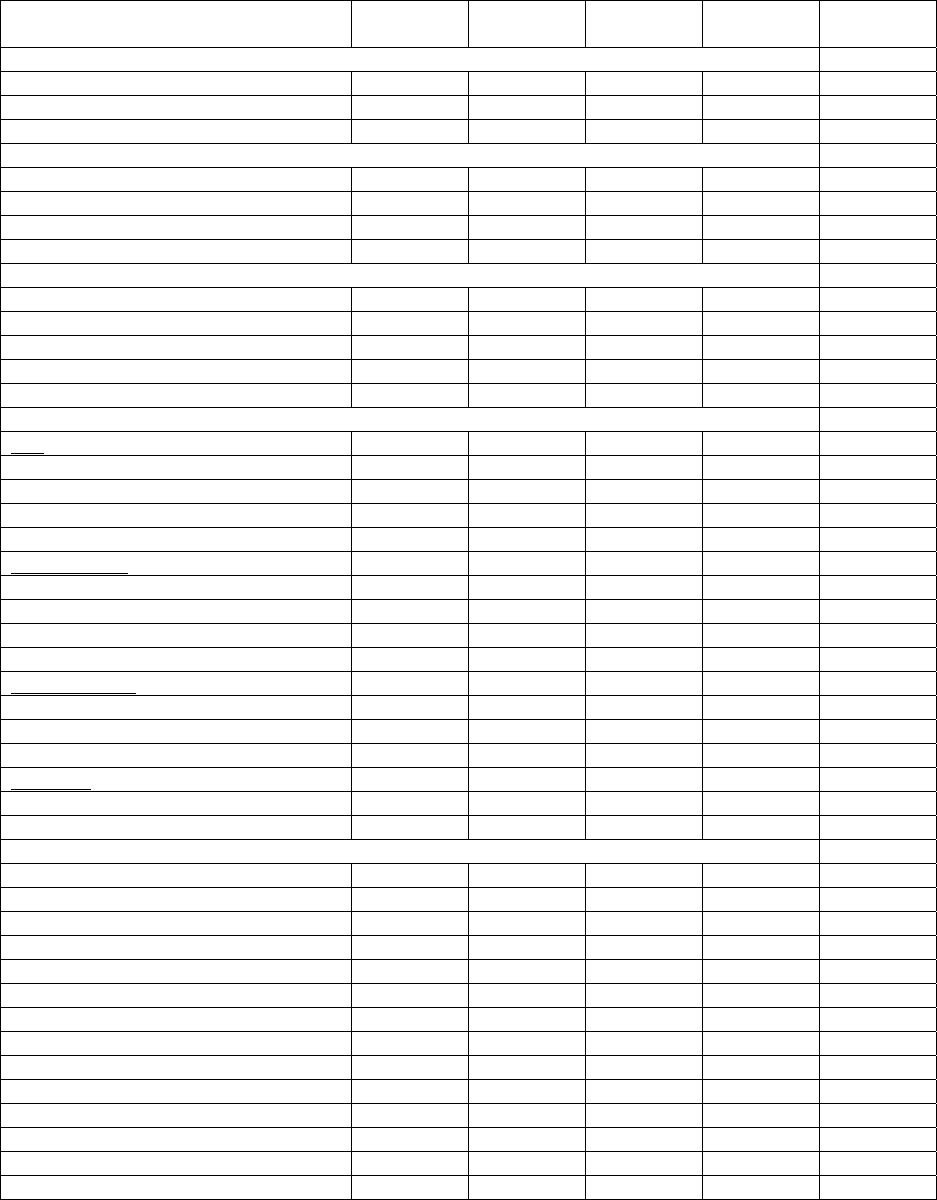

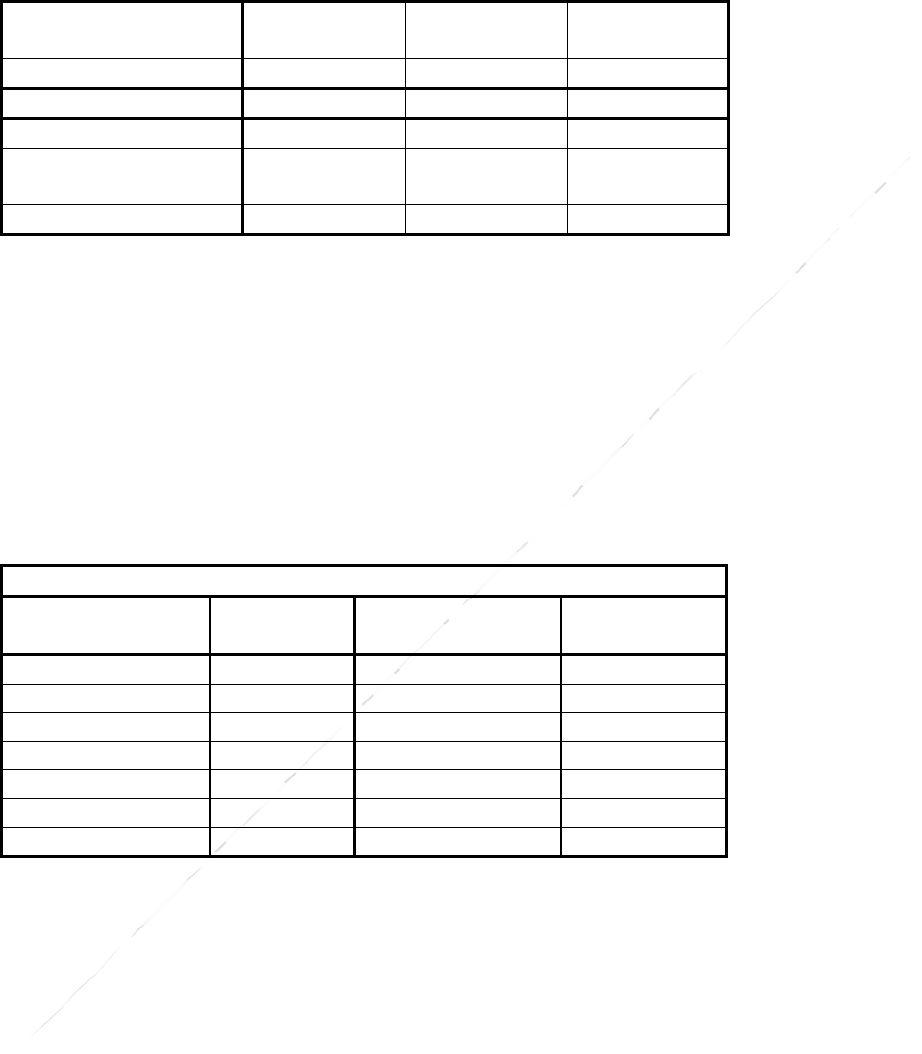

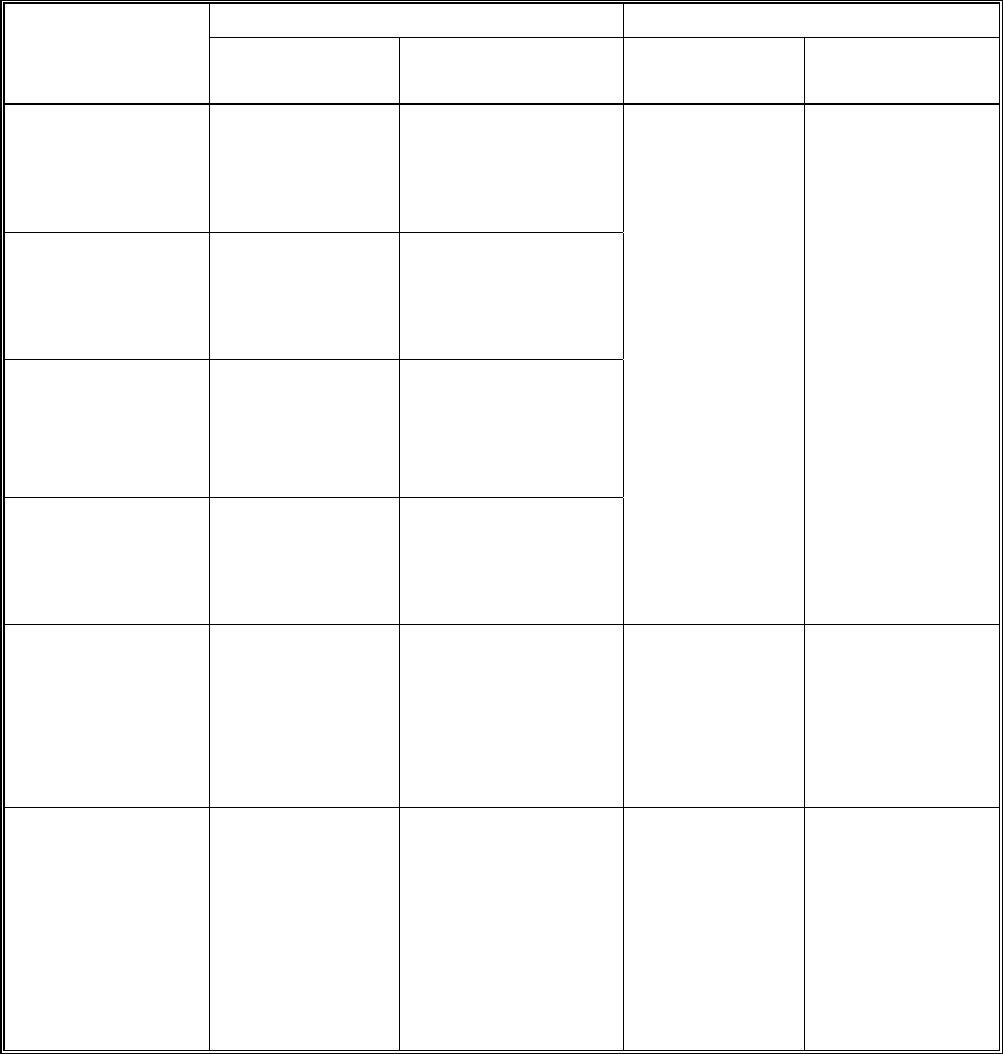

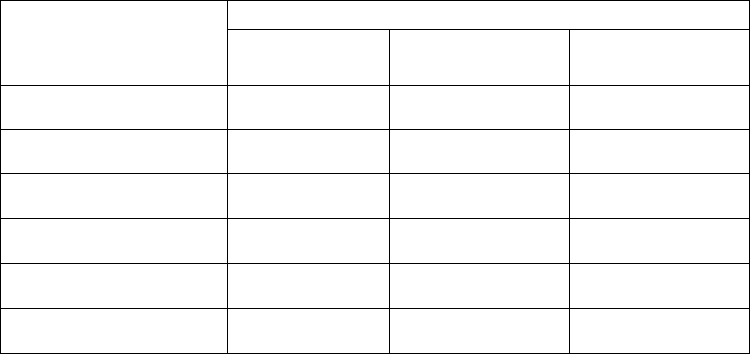

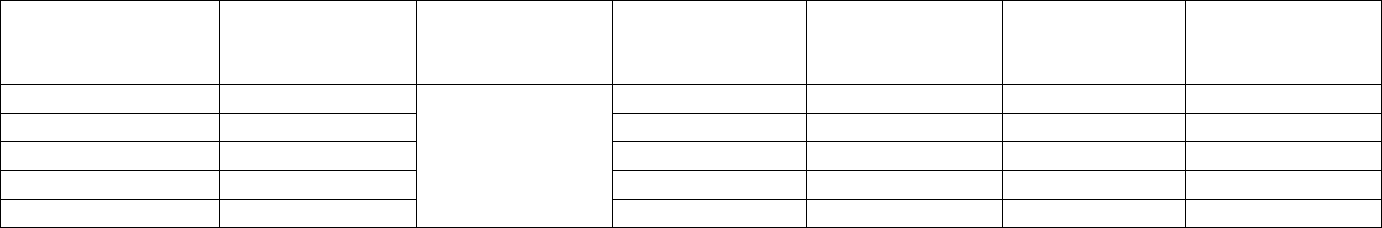

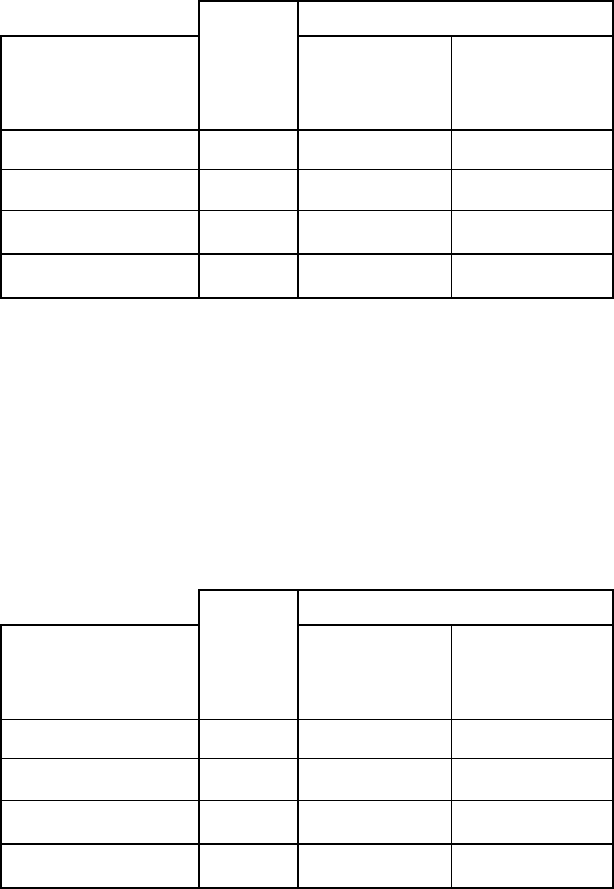

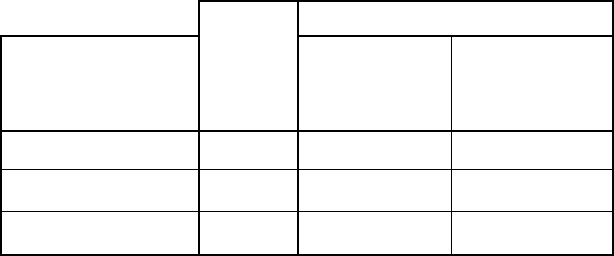

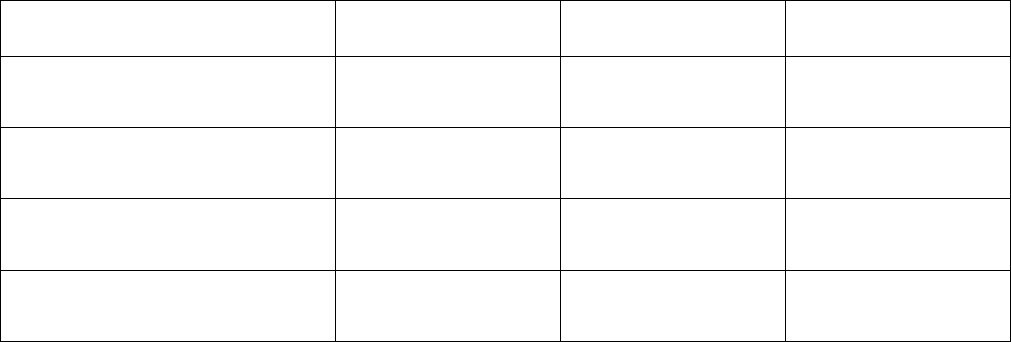

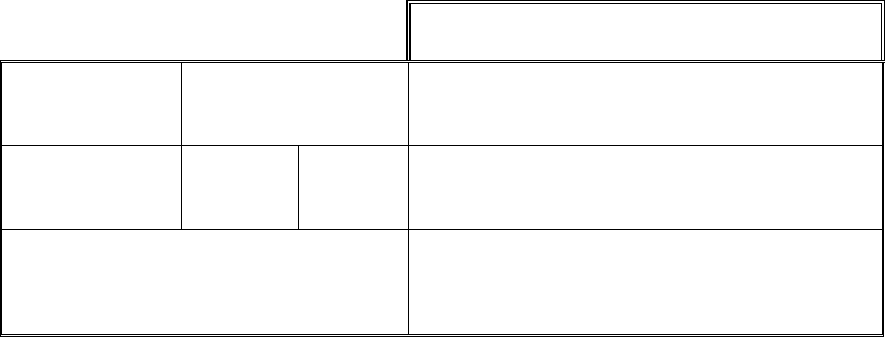

Table 3. Summary of key topics incorporated into case studies.

Topic

#1: Tank

Farm

#2: Gas

Station

#3: Tanker

Truck

#4: Oil

Pipeline

#5: Oil

E&P

Site Status:

Active X X X

Inactive X X

Redevelopmen

t

X

Petroleum Type:

Gasoline (standard) X X

Gasoline (low-

b

enzene) X

Diesel X X X

Crude Oil X X

Impacted Media:

Soil X X X X X

Soil Vapo

r

X X X

Groundwate

r

X X X X

Sediment X X

Surface Wate

r

X X

Environmental Concerns:

Soil

Direct Exposure X X X X

Vapor Intrusion X X

Gross Contamination X X X X X

Leachin

g

X X X X

Groundwater

Drinkin

g

Water (toxicit

y

) X X

Vapor Intrusion X X

Aquatic Toxicit

y

X X X

Gross Contamination X X X X X

Surface Water

Drinkin

g

Water (toxicit

y

)

Aquatic Toxicit

y

(pela

g

ic) X X

Gross Contamination X X X

Sediment

Aquatic Toxicit

y

(benthic) X X

Gross Contamination X X

Screening Levels:

Fractions (

g

eneric) X

Fractions (site-specific) X

Fraction-Wei

g

hted TPH (

g

eneric) X X X X X

Fraction-Wei

g

hted TPH (site-specific) X X X

Drinkin

g

Water Metabolites X X

Other Topics:

Shor

t

-Term Vapor Emissions X X

Silica Gel Cleanup X X X X X

Expanded DU-MIS (ISM) Sample Notes X X

Expanded Fate and Transport Notes X X X

Methane Generation X

Back

g

round Or

g

anic Carbon (water) X

Aquatic Toxicit

y

(site-specific) X

De

M

inimis Ris

k

X X

TPH Risk - Case Studies (HIDOH, October 2018)

17

References

Brewer, R., Nagashima, J., Kelley, M. and M. Rigby. 2013. Risk-Based Evaluation of Total

Petroleum Hydrocarbons in Vapor Intrusion Studies: International Journal of Environmental

Research and Public Health, Volume 10, pp 2441-2467.

CAEPA. 2016. Screening for Environmental Concerns at Sites with Contaminated Soil and

Groundwater: California Environmental Protection Agency, Regional Water Quality Control

Board, San Francisco Bay Area Region.

Gustafson, J.; Tell, J.G. and D. Orem. 1997. Total Petroleum Hydrocarbon Working Group Series,

Volume 3: Selection of Representative TPH Fractions Based on Fate and Transport

Considerations; Association for Environmental Health and Sciences: Amherst, MA, USA.

HIDOH. 2016. Technical Guidance Manual: Hawai′i Department of Health, Hazard Evaluation

and Emergency Response. August 2016.

HIDOH. 2017. Evaluation of Environmental Hazards at Sites with Contaminated Soil and

Groundwater – Tropical Pacific Edition: Hawai‘i Department of Health, Hazard Evaluation

and Emergency Response. Fall 2017.

IDEM. 2010. Risk Integrated System of Closure, Technical Resource Guidance Document:

Indiana Department of Environmental Management, June 2010.

ITRC, 2012, Incremental Sampling Methodology: Interstate Technology Regulatory Council,

February 2012.

ITRC. 2014. Petroleum Vapor Intrusion: Fundamentals of Screening, Investigation, and

Management: Interstate Technology & Regulatory Council. Washington, D.C. October 2014.

ITRC. 2015. Decision Making at Contaminated Sites, Issues and Options in Human Health Risk

Assessment: Interstate Technology & Regulatory Council. January 2015.

ITRC. 2018. TPH Risk Evaluation at Petroleum Contaminated Sites (draft March 2018): Interstate

Technology & Regulatory Council. Anticipated publication 2019.

KDHE. 2016. Total Petroleum Hydrocarbons (TPH) and LNAPL Characterization, Remediation

and Management: Kansas Department of Health and Environment, Bureau of Environmental

Remediation. Policy # BER-041. May 2017.

MADEP. 1994. Background Documentation for the Development of the MCP Numerical

Standards: Massachusetts Department of Environmental Protection, Bureau of Waste Site

Cleanup and Office of Research and Standards. April 1994.

MADEP. 1996. Implementation of the VPH/EPH Approach: Massachusetts Department of

Environmental Protection. May 1996.

MADEP. 2002. Characterizing Risks Posed by Contaminated Sites: Implementation of the

MADEP VPH/EPH Approach: Massachusetts Department of Environmental Protection,

Bureau of Waste Site Cleanup, October 31, 2002.

MADEP. 2014. MCP Numerical Standards Development Spreadsheets: Massachusetts

Department of Environmental Protection, Bureau of Waste Site Cleanup. Updated June 2014.

TPH Risk - Case Studies (HIDOH, October 2018)

18

USEPA 2007. Method 8015C, Nonhalogenated Organics by Gas Chromatography: U.S.

Environmental Protection Agency, Office of Resource Conservation and Recovery, February

2007.

USEPA. 2015. Technical Guide for Addressing Petroleum Vapor Intrusion at Leaking

Underground Storage Tank Sites: U.S. Environmental Protection Agency, Office of

Underground Storage Tanks, June 2015, Washington, D.C., EPA 510-R-15-001.

USEPA. 2017. Screening Levels for Chemical Contaminants: U.S. Environmental Protection

Agency, June 2017 (and updates), prepared by Oak Ridge National Laboratories.

TPH Risk Case Studies (HIDOH, October 2018)

Attachment 1: Example Case Studies

19

Attachment 1

Example Case Studies

Case Study #1: Former Fuel Tank Farm

Case Study #2: Active Gas Station

Case Study #3: Tanker Truck Accident

Case Study #4: Crude Oil Pipeline Rupture

Case Study #5: Exploration and Production

TPH Risk Case Studies (HIDOH, October 2018)

Attachment 1: Example Case Studies

Case Study #1: Former Fuel Tank Farm

20

Case Study #1: Former Fuel Tank Farm

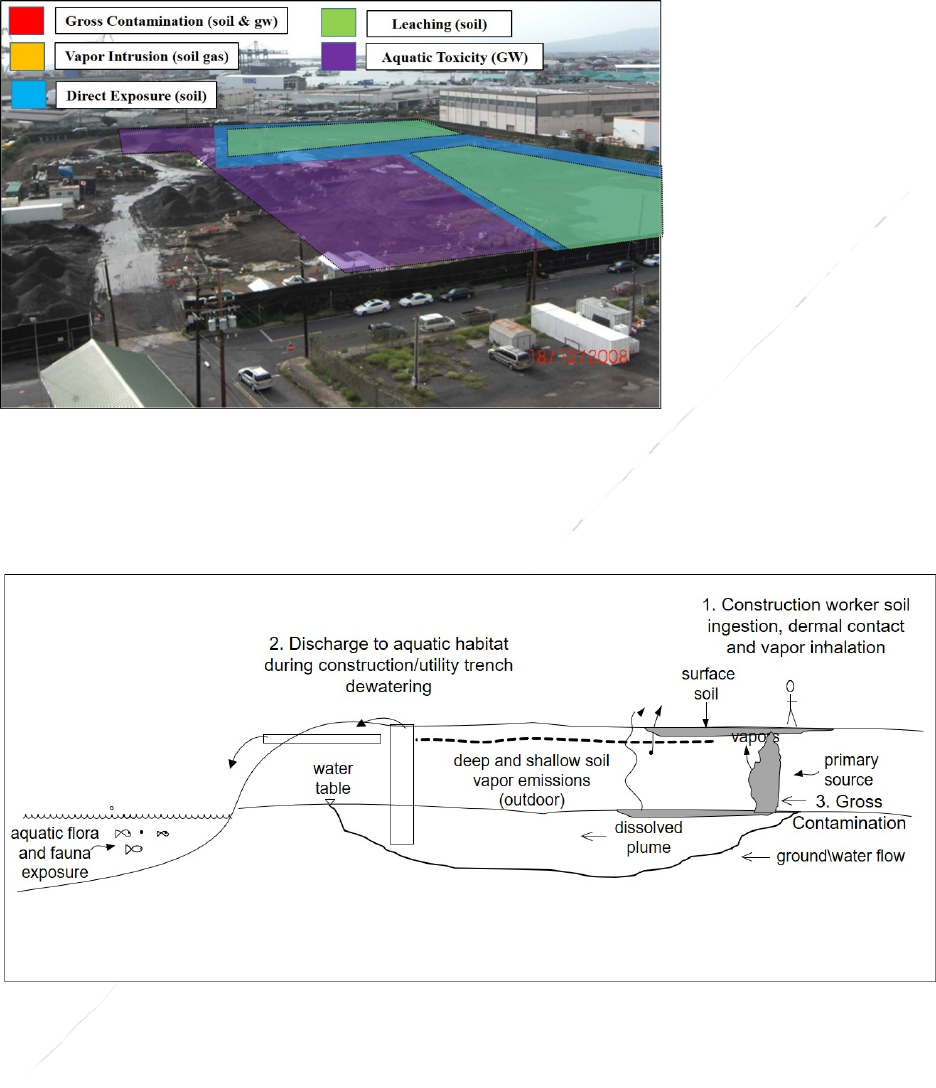

Figure 1-1. Former fuel storage terminal to be

redeveloped as a commercial complex.

Summary

This case study presents approaches for assessment of petroleum-related potential environmental

concerns at a ten-acre, decommissioned fuel-tank farm slated for commercial redevelopment.

Topics addressed include removal of “gross contamination” to reduce the mass of petroleum in the

source area, assessment of remaining vapor intrusion risk using Total Petroleum Hydrocarbon

(TPH) and carbon range data for vapor samples and comparison with default as well as site-specific

screening levels, and management of residual contamination during and after redevelopment of

the site.

Groundwater is situated five to ten feet below the ground surface. Two separate areas of petroleum

releases were identified. The first is associated with the former aboveground storage tank (AST)

area used primarily for gasoline but with some diesel contamination present. The second is

associated with historic leaks from a now abandoned, diesel pipeline that borders the southern

perimeter of the property. Total Petroleum Hydrocarbon (TPH) data using USEPA Method 8015M

for soil and water and Method TO-3 for soil vapor were initially obtained for both areas.

Carbon range data were obtained for subslab vapor samples collected from the gasoline-release

area (see Attachment 4; after HIDOH 2017). The data were used to develop site-specific, carbon

range-weighted soil vapor screening levels for TPH for comparison to subsequent soil vapor data

in order to save money on testing and ensure that cumulative vapor intrusion risk was considered.

This allowed the use of somewhat less conservative, soil vapor screening levels to assess risk and

design remedial actions for this area.

Carbon range data were collected up front for soil vapor samples collected from the diesel-release

area. The carbon range makeup of vapors from diesel-type fuels can vary widely (see Brewer et

al. 2013). Standard total TPH tests using “TO” methods can also vary significantly from more

reliable, carbon range test data. This makes the collection of site-specific carbon range data more

desirable at diesel release sites. This allowed for the development of site-specific, carbon-range

Relative Applicability:

- Brownfield re-development

petroleum sites.

- Small to mid-size tank farms

(i.e., gasoline distribution

centers).

- Small ports that handle

petroleum products.

TPH Risk Case Studies (HIDOH, October 2018)

Attachment 1: Example Case Studies

Case Study #1: Former Fuel Tank Farm

21

weighted screening levels to assess potential vapor intrusion risk. Uncertainty in total TPH data

for diesel vapors limited the reliability of this data, however, and carbon range data were collected

for all subsequent soil vapor samples from the diesel area and used to assess cumulative, vapor

intrusion risk.

The main mass of contaminated soil is in direct contact with groundwater. Direct monitoring of

groundwater is therefore appropriate for assessment of leaching concerns in release areas. A

comparison of groundwater data with and without silica gel cleanup (SGC) indicates that the

dissolved-phase plume outside of areas with light, non-aqueous-phase liquid (LNAPL) is heavily

degraded and likely dominated by TPH-related metabolites.

Remediation of the site to address high-risk areas of shallow free product was carried out, with

vented, passive vapor barriers to be installed under future buildings in order to address any

remaining, vapor intrusion risk. Groundwater was re-infiltrated onsite rather than discharged into

a storm sewer in order to protect nearby, aquatic habitats that the sewers drain to. Barriers will be

placed in new sewer lines in order to minimize offsite migration of contamination.

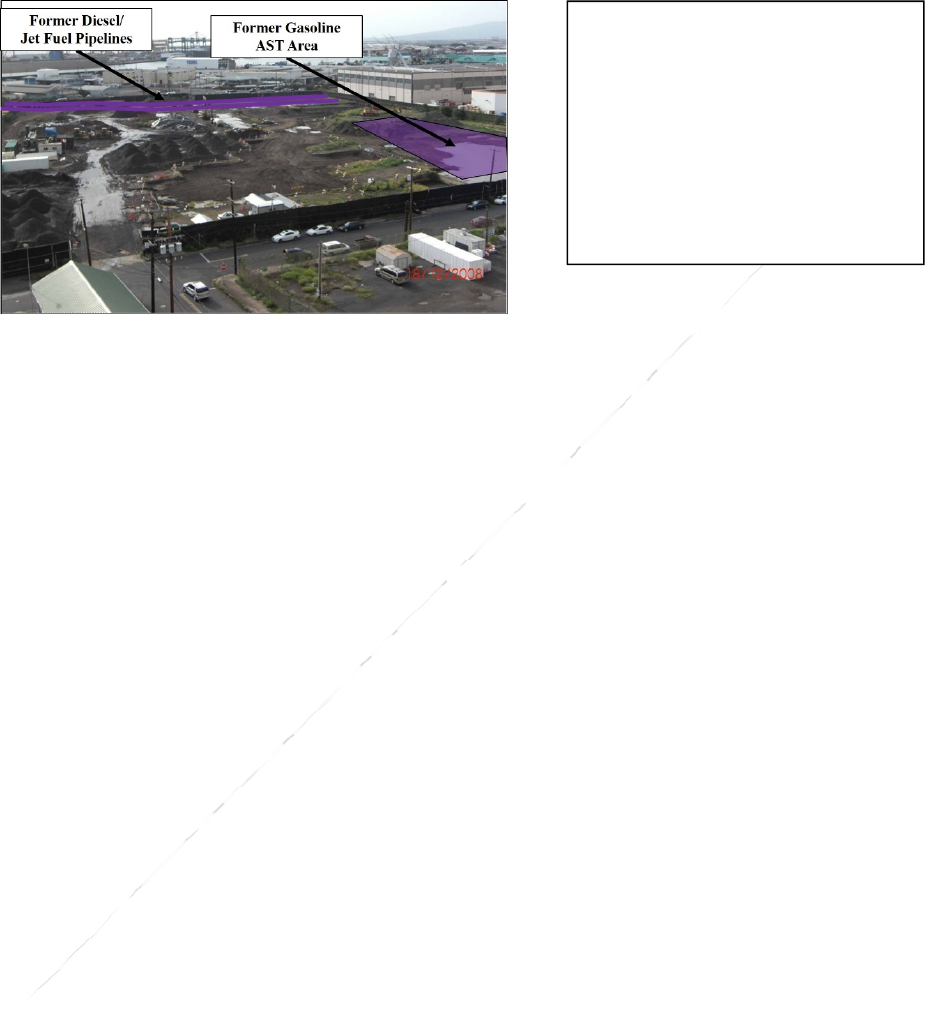

1. Site Setting (Figure 1-1)

Ten-acre, former diesel and gasoline aboveground storage tank (AST) farm that operated

for 50+ years;

Commercial/industrial setting with no residents within ½ mile;

Pipelines for diesel/jet fuel border southern edge of property;

Depth to groundwater = 10 feet (unconfined; not a current or potential source of drinking

water);

No water supply wells within one mile;

Located within ½ mile of a surface water body;

Climate Zone: Cold (mean daily temperature <65°F more than 300 days per year; used for

vapor intrusion assessment);

Geology: Unconsolidated gravel, sand and silt (fill and marine sediments);

Primary Contaminants of Potential Concern (COPCs): TPHgasoline (TPHg), TPHdiesel

(TPHd), benzene, toluene, ethylbenzene, xylenes and naphthalene (BTEXN);

Facility decommissioned, with all aboveground structures removed;

Planned commercial redevelopment;

Status: Investigation and initial remedial actions complete. Site prepped for redevelopment

as a commercial shopping center. “Environmental Hazard Management Plan (EHMP)”

prepared for construction phase of redevelopment, to be updated with “as-built” EHMP

following completion of construction.

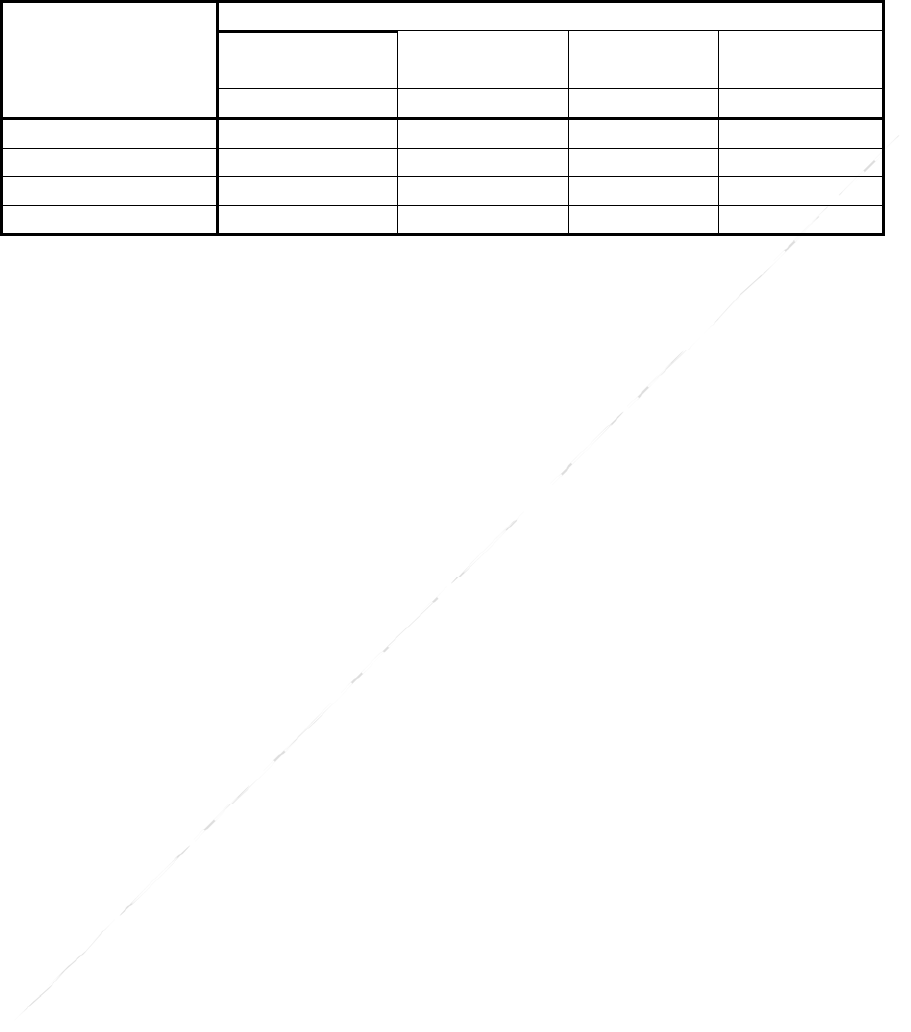

2. Site Characterization (Figure 1-2)

Soil and groundwater investigation revealed significant gasoline contamination in vicinity

of former ASTs and diesel and jet fuel contamination adjacent to former fuel pipelines.

TPH Risk Case Studies (HIDOH, October 2018)

Attachment 1: Example Case Studies

Case Study #1: Former Fuel Tank Farm

22

Discrete soil samples collected from borings and exploratory pits;

Groundwater samples collected from temporary monitoring wells screened across the top

of the water table;

Soil vapor samples collected from temporary points to better assess potential vapor

intrusion concerns (former slabs removed; vapor samples collected 3-5ft below ground

surface to minimize leakage to outdoor air);

Samples tested for TPHg and TPHd using Method 8015M for soil and groundwater and

Methods TO-15 (summa, >C5-C12) and TO-17 (sorbent tube, >C12) for soil vapor;

Extent of contamination reasonably well delineated based on data collected and field

observations;

LNAPL present on groundwater over three-acre area under former fuel tanks and half-acre

under former pipeline area;

LNAPL and dissolved-phase plume stable and not migrating offsite above levels of

potential concern (slow but progressive reduction in dissolved-phase concentrations

outside of LNAPL area);

Sub 100 µg/L concentrations of TPH reported in samples collected from un-impacted,

upgradient wells in the absence of SGC assumed to represent background organic material

in groundwater;

TPH carbon range data obtained for soil vapor samples from the gasoline and diesel-release

areas in order to better assess vapor chemistry and develop site-specific vapor intrusion

screening levels (data reasonably consistent between samples).

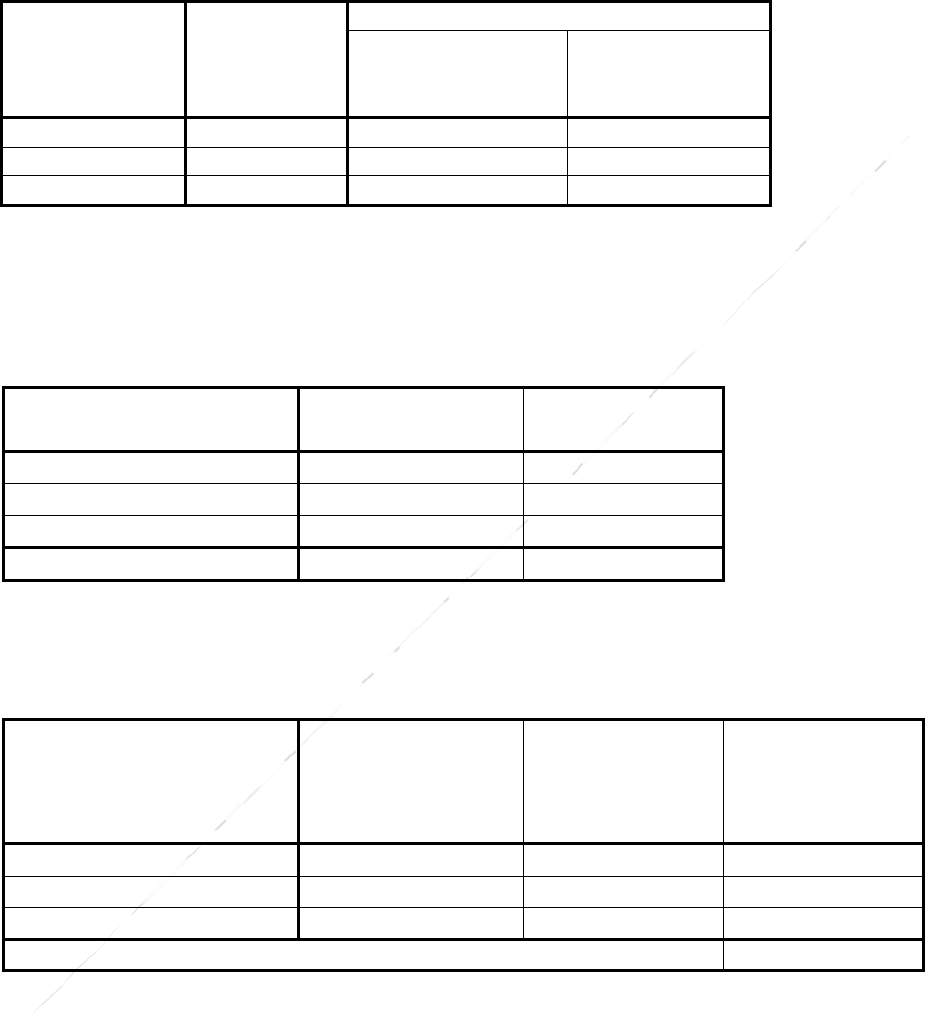

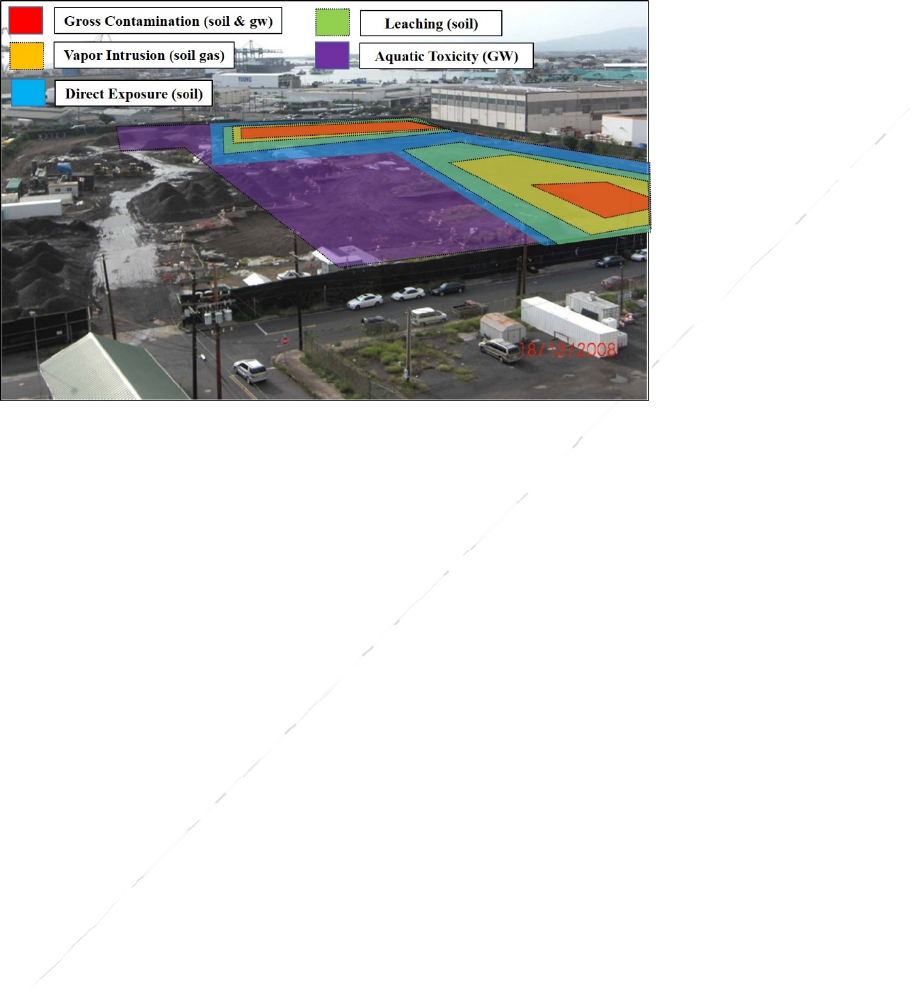

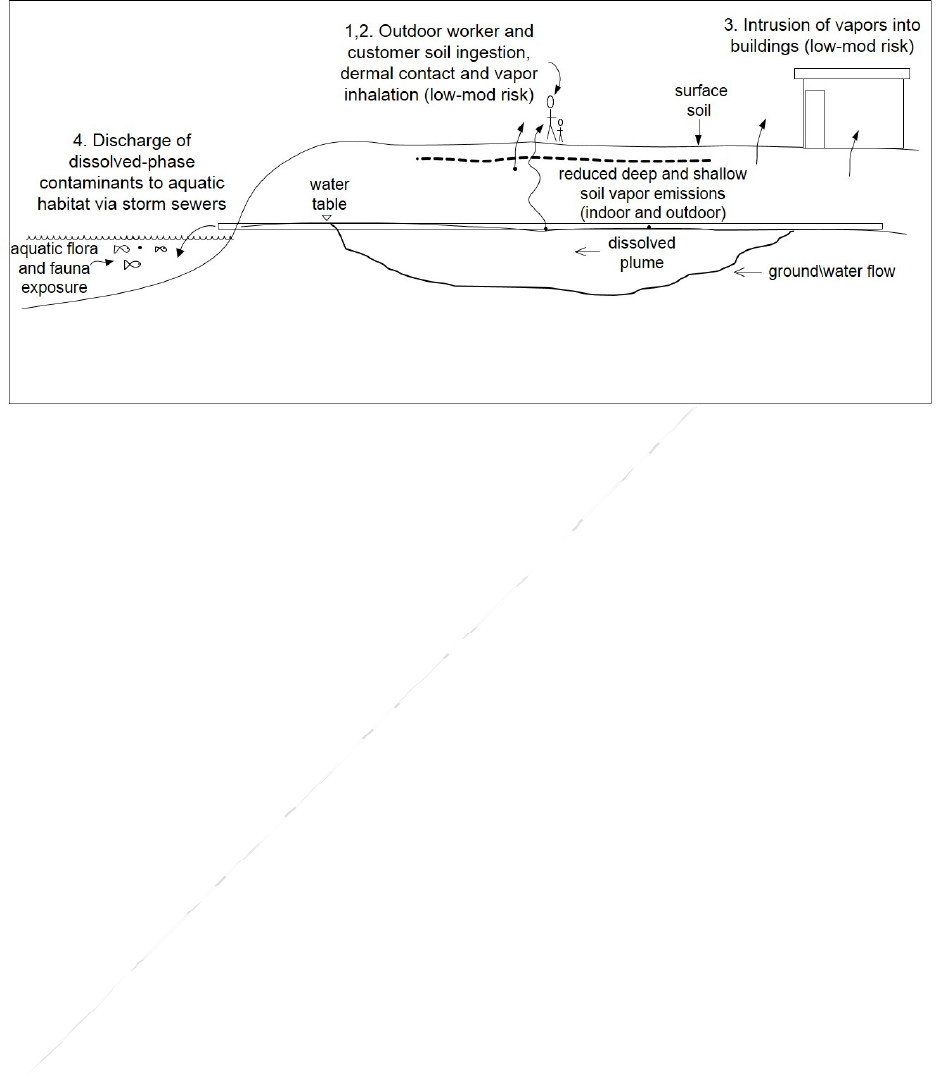

3. Potential Environmental Concerns (Figure 1-4 and Figure 1-5)

Soil, groundwater and soil vapor data compared to environmental screening levels for

TPHg and TPHd (see example data in Tables 1-1a, 1-2, 1-3a and 1-4a);

Comparison of soil data to screening levels indicate gross contamination (e.g., free product,

heavy staining, high vapors if disturbed, etc.), direct exposure and leaching concerns for

TPHg and TPHd in former AST area and the western area of the former fuel pipelines;

Calculation of a noncancer Hazard Quotient (HI) for individual TPH types and assuming

data in Table 1-1a representative of entire site as a single, commercial/industrial exposure

area indicates a cumulative Hazard Index (HI) of 53, with risk posed primarily by exposure

to TPHd in soil (Table 1-1b);

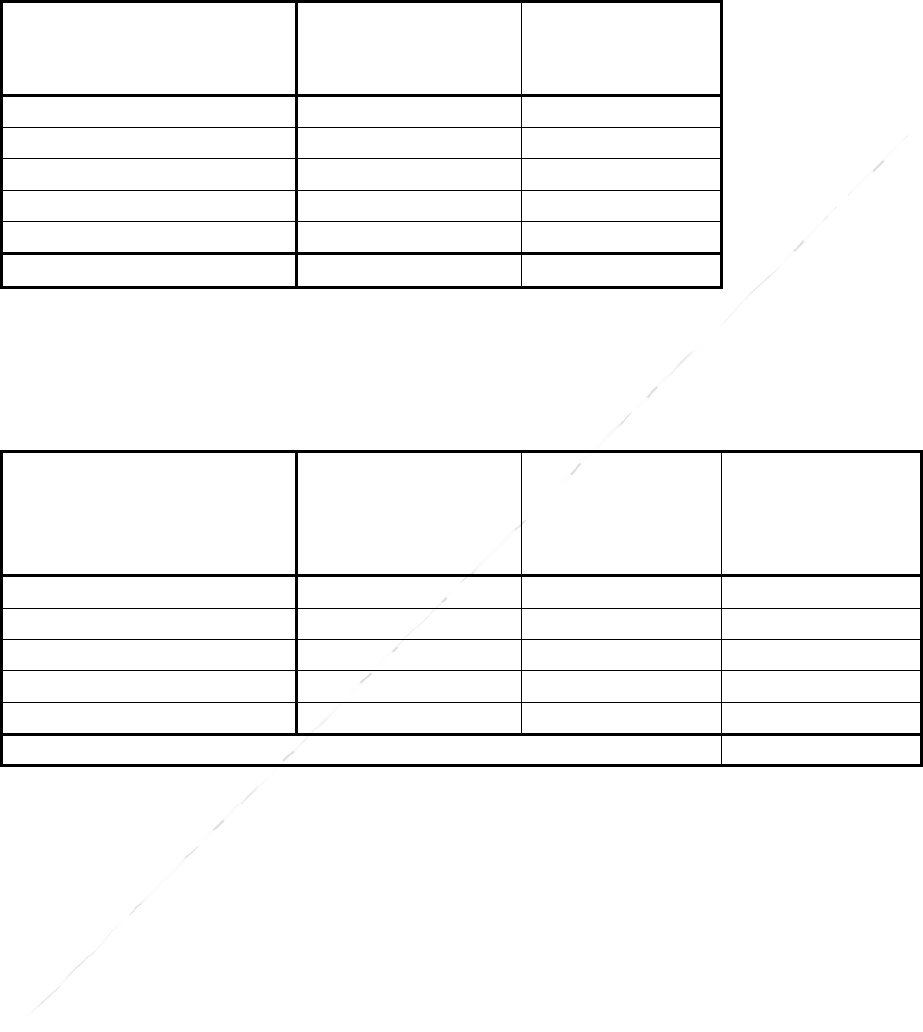

Comparison of groundwater data (non-SGC) to screening levels suggested gross

contamination concerns in same areas (e.g., LNAPL and/or strong odors, confirmed by

product in some wells) and exceedance of aquatic toxicity screening levels for large area

of site;

Comparison of non-SGC and SGC data for groundwater indicate significant degradation

of petroleum-related compounds outside of areas with LNAPL;

TPH Risk Case Studies (HIDOH, October 2018)

Attachment 1: Example Case Studies

Case Study #1: Former Fuel Tank Farm

23

Review of chromatograms indicate contamination is typical of petroleum compounds with

no evidence of unrelated contaminants, natural or anthropogenic, associated with the site

or with interferences related to sampling or analysis methods;

Concentrations of TPH in vapors exceeds lower explosive limit (LEL) in some areas of

gasoline LNAPL, with small pockets of methane approaching LELs in both gasoline and

diesel areas;

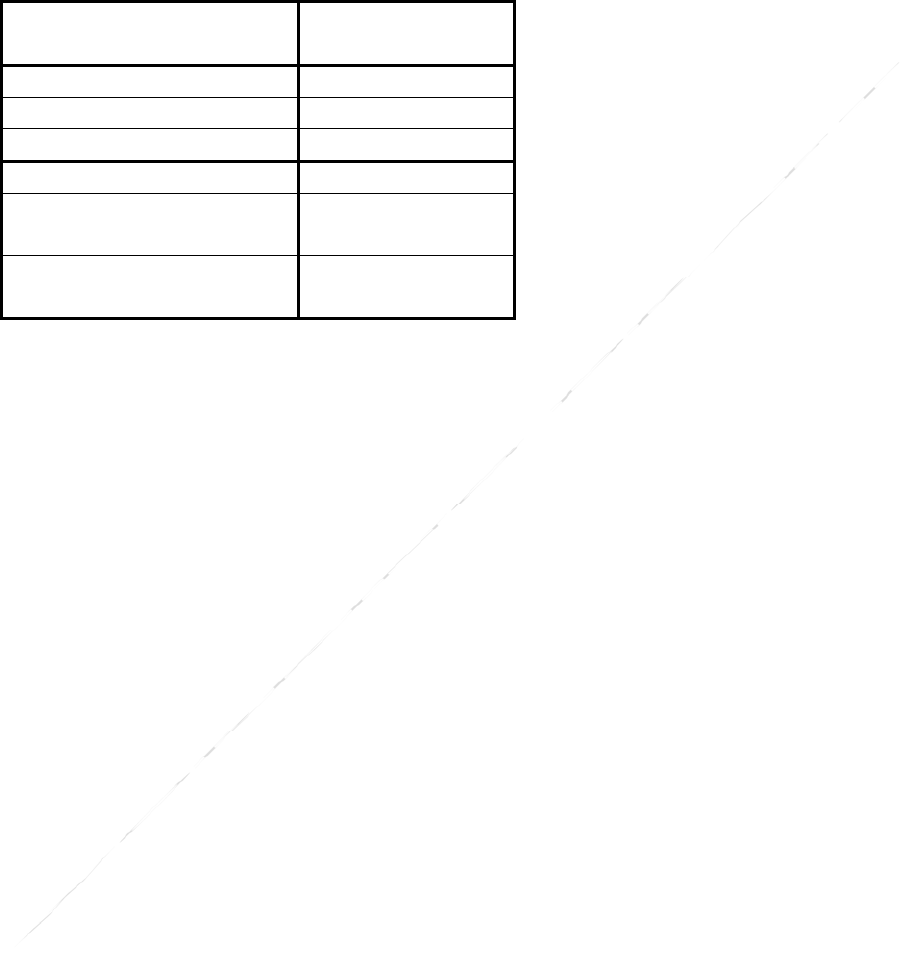

Comparison of soil vapor data to site-specific screening levels for vapor intrusion indicate

significant, potential vapor intrusion concerns for future buildings in areas where LNAPL

is present in soil and/or on shallow groundwater;

Calculation of noncancer HQs for individual carbon ranges assuming data in Table 1-3a

for gasoline vapors and 1-4a for diesel vapors are representative of subslab vapors under

future buildings indicates a high, potential vapor intrusion risk for both areas of the site;

Vapor intrusion risk posed by gasoline vapors is driven by C5-C8 aliphatics (Table 1-3b);

Vapor intrusion risk posed by diesel vapors is driven by C9-C12 aliphatics (Table 1-4b);

Site-specific carbon range vapor data were used to calculate carbon range-weighted

inhalation toxicity factors and corresponding soil vapor screening levels for gasoline and

diesel vapors for use in subsequent investigations (Tables 1-3c and 1-4c));

Soil vapor screening levels for evaluation of total TPH data in the gasoline-release area are

considered reliable for assessment of vapor intrusion risk, but uncertainty in the reliability

total TPH data for diesel vapors limits use of these screening levels;

Comparison of the relative ratios of TPH:Benzene ratios for soil vapor data in gasoline-

contaminated area suggests that vapor intrusion risk posed by TPH will be adequately

addressed by a reduction of benzene to below target screening levels, provided that a target

10

-6

excess cancer risk is adhered to (TPH: Benzene ratio <935:1; Table 1-5);

Additional evaluation of TPH data required if a lower, target excess cancer risk is used to

assess acceptable vapor intrusion risk posed by benzene;

Comparison of TPH: Benzene ratios (TPH measured as sum of carbon ranges) for vapor

data collected from diesel-contaminated area suggests that TPH could still pose a vapor

intrusion risk even in cases where benzene concentrations in vapor meet target screening

levels (TPH: Benzene ratio >452:1; see Table 1-5);

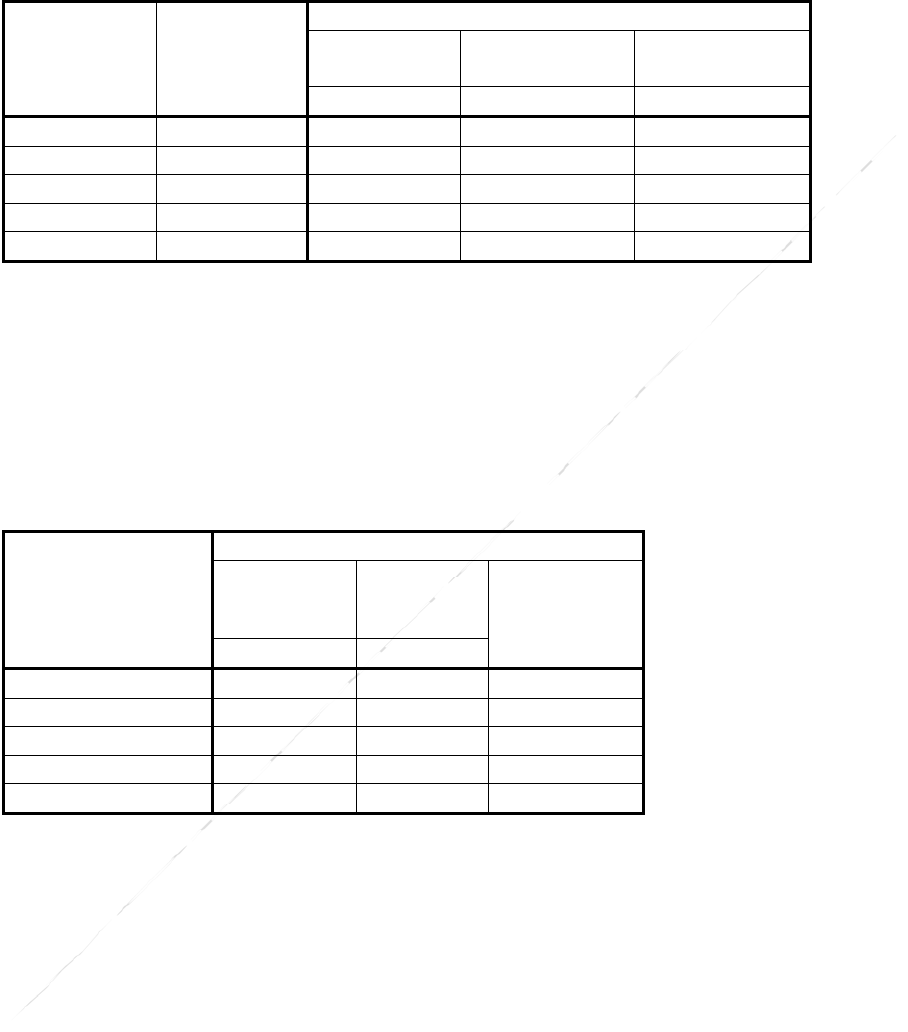

Summary of contaminated media and environmental concerns in the absence of

remediation (Figure 1-2):

o Direct exposure (TPHg & TPHd; subsurface soil));

o Vapor intrusion (TPHg & TPHd; subsurface soil and groundwater);

o Aquatic toxicity (TPHg & TPHd; groundwater);

o Gross contamination (TPHg & TPHd; subsurface soil and groundwater).

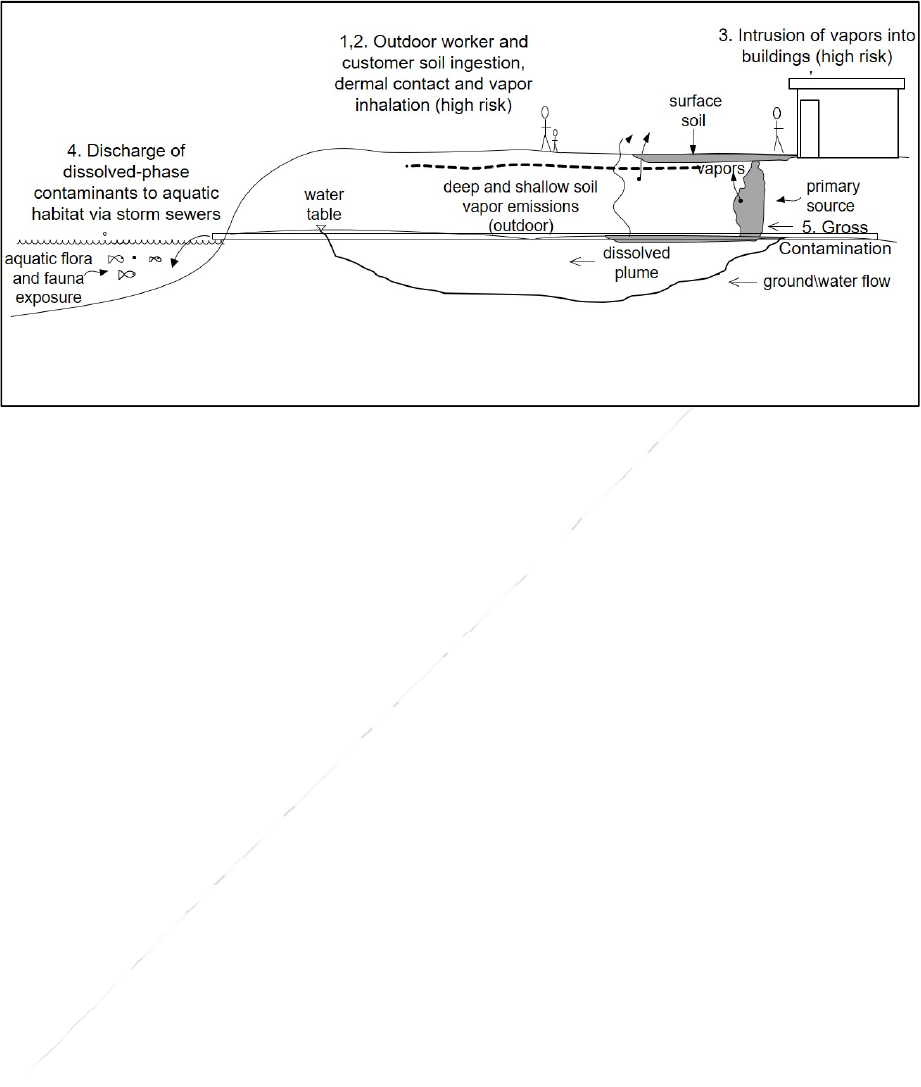

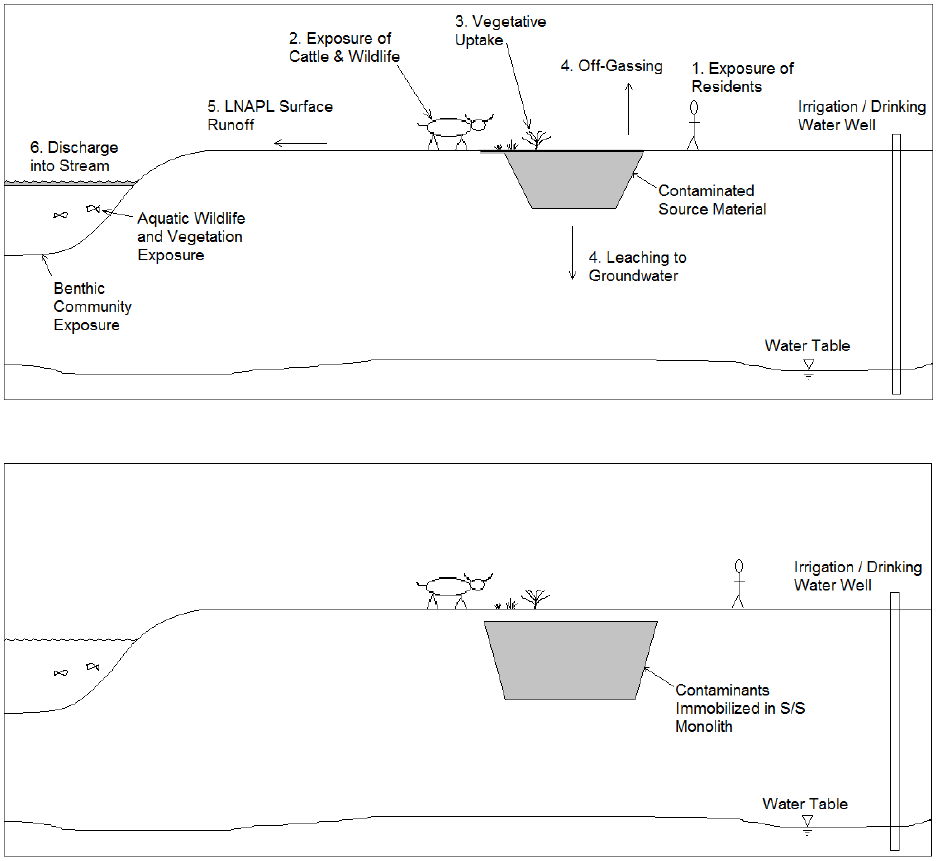

Conceptual Site Model (CSM) of potential environmental concerns assuming no

remediation (Figure 1-3):

TPH Risk Case Studies (HIDOH, October 2018)

Attachment 1: Example Case Studies

Case Study #1: Former Fuel Tank Farm

24

o Soil:

Direct exposure (TPHg & TPHd; short-term, high risk for construction workers);

Direct exposure (TPHg & TPHd; long-term, high risk for future workers and

customers);

Leaching (TPHg & TPHd; ongoing contamination of shallow groundwater)

Gross contamination (TPHg & TPHd; potential short-term generation and offsite

migration of high-concentration vapors when disturbed; short-term management

and disposal issues for utility repair and other subsurface activities, spread of

contamination and equipment fouling during construction, etc.);

o Groundwater:

Aquatic toxicity (TPHg & TPHd; migration of contaminated groundwater into

nearby, surface water bodies via natural flow into storm drains not connected to

retention areas or intentional discharge during dewatering activities; no current

impacts identified);

Gross contamination (TPHg & TPHd; same as soil and including leakage of free

product into storm sewers or utility vaults; TPH and methane <10% of LEL in

sewers and vaults);

o Soil Vapors:

Vapor intrusion (TPHg & TPHd; high risk of long-term exposure for future

workers and customers).

4. Site Remediation and Redevelopment

Remedial actions:

o Gross contamination (including LNAPL on groundwater) and high-risk areas with

contaminant concentrations above screening levels for direct-exposure and vapor