Theoretical Minimum Energies

To Produce Steel

for Selected Conditions

March 2000

R.J. Fruehan

O. Fortini

H.W. Paxton

R. Brindle

Prepared under contract to

Energetics, Inc.

Columbia, MD

For the

U.S. Department of Energy

Office of Industrial Technologies

Washington., DC

Carnegie Mellon University

Pittsburgh, PA

THEORETICAL MINIMUM ENERGIES TO PRODUCE STEEL

FOR SELECTED CONDITIONS

R. J. Fruehan

O. Fortini

H.W. Paxton

R. Brindle

Carnegie Mellon University

Pittsburgh, PA

May 2000

Prepared under contract to

Energetics, Inc.

Columbia, MD

for the

U.S. Department of Energy

Office of Industrial Technologies

Washington, DC

DISCLAIMER

This report was prepared as an account of work sponsored by an agency of the United States

Government. Neither the United States Government nor any agency thereof, nor any of their

employees, makes any warranty, expressed or implied, or assumes any legal liability or responsibility

for the accuracy, completeness, or usefulness of any information, apparatus, product, or process

disclosed, or represents that its use would not infringe privately owned rights. Reference herein to any

specific commercial product, process, or service by trade name, trademark, manufacturer, or otherwise

does not necessarily constitute or imply its endorsement, recommendation, or favoring by the United

States Government or any agency thereof. The views and opinions of authors expressed herein do not

necessarily state or reflect those of the United States Government or any agency thereof.

TABLE OF CONTENTS

EXECUTIVE SUMMARY ..................................................... iii

1. INTRODUCTION ..........................................................1

2. BASIC ASSUMPTIONS AND CASES CONSIDERED ...........................1

3. METHODOLOGY ..........................................................2

4. ABSOLUTE THEORETICAL MINIMUM ENERGY VALUES ....................3

5. CASES APPROACHING ACTUAL CONDITIONS ..............................4

6. PRODUCTION OF STAINLESS STEEL .......................................9

7. ROLLING ...............................................................11

8. EFFECT OF YIELD LOSSES ON ENERGY ...................................13

9. OTHER MAJOR ENERGY-CONSUMING ACTIVITIES ........................15

10. TOTAL THEORETICAL MINIMUM ENERGY TO PRODUCE STEEL ........... 16

11. SPECIAL CONSIDERATIONS .............................................16

12. COMPARISON OF TYPICAL ACTUAL AND

THEORETICAL MINIMUM ENERGY ...................................19

13. SUMMARY AND CONCLUSIONS .........................................20

REFERENCES ..............................................................23

APPENDIX A: THEORETICAL CO

2

EMISSIONS FROM

STEELMAKING PROCESSES ..........................................25

Theoretical Minimum Energies to Produce Steel for Selected Conditions i

ii Theoretical Minimum Energies to Produce Steel for Selected Conditions

-- -- --

EXECUTIVE SUMMARY

The energy used to produce liquid steel in today’s integrated and electric arc furnace (EAF)

facilities is significantly higher than the theoretical minimum energy requirements. This study presents the

absolute minimum energy required to produce steel from ore and mixtures of scrap and scrap

alternatives. Additional cases in which the assumptions are changed to more closely approximate actual

operating conditions are also analyzed. The results, summarized in Table E-1, should give insight into

the theoretical and practical potentials for reducing steelmaking energy requirements. The energy values

have also been converted to carbon dioxide (CO

2

) emissions in order to indicate the potential for

reduction in emissions of this greenhouse gas (Table E-2).

The study showed that increasing scrap melting has the largest impact on energy consumption.

However, scrap should be viewed as having "invested" energy since at one time it was produced by

reducing ore. Increasing scrap melting in the BOF may or may not decrease energy if the "invested"

energy in scrap is considered.

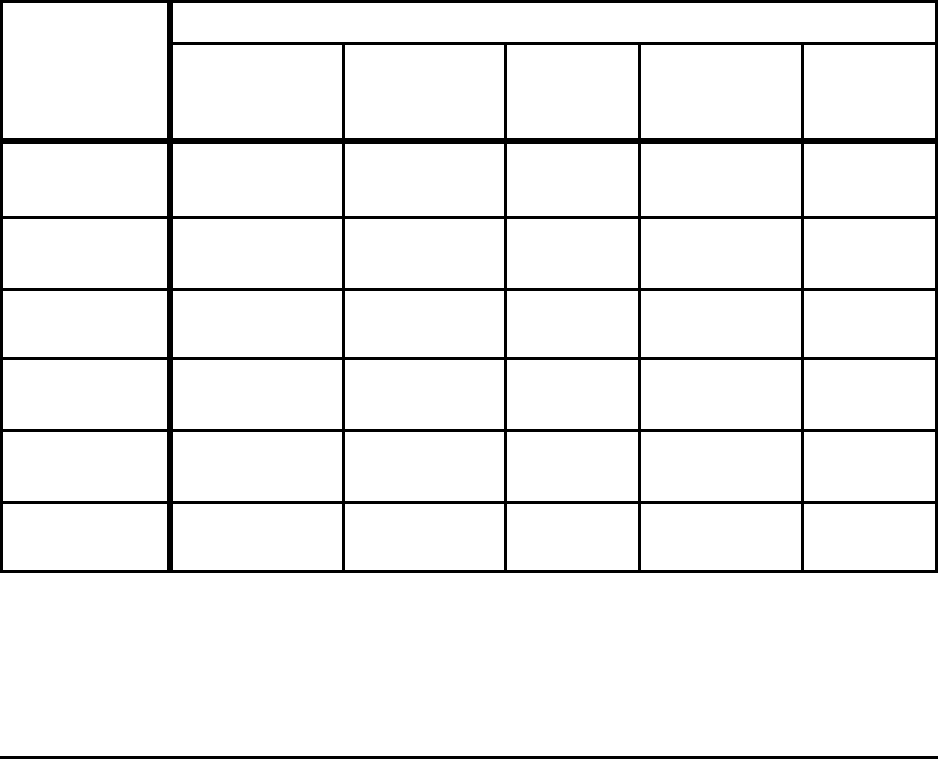

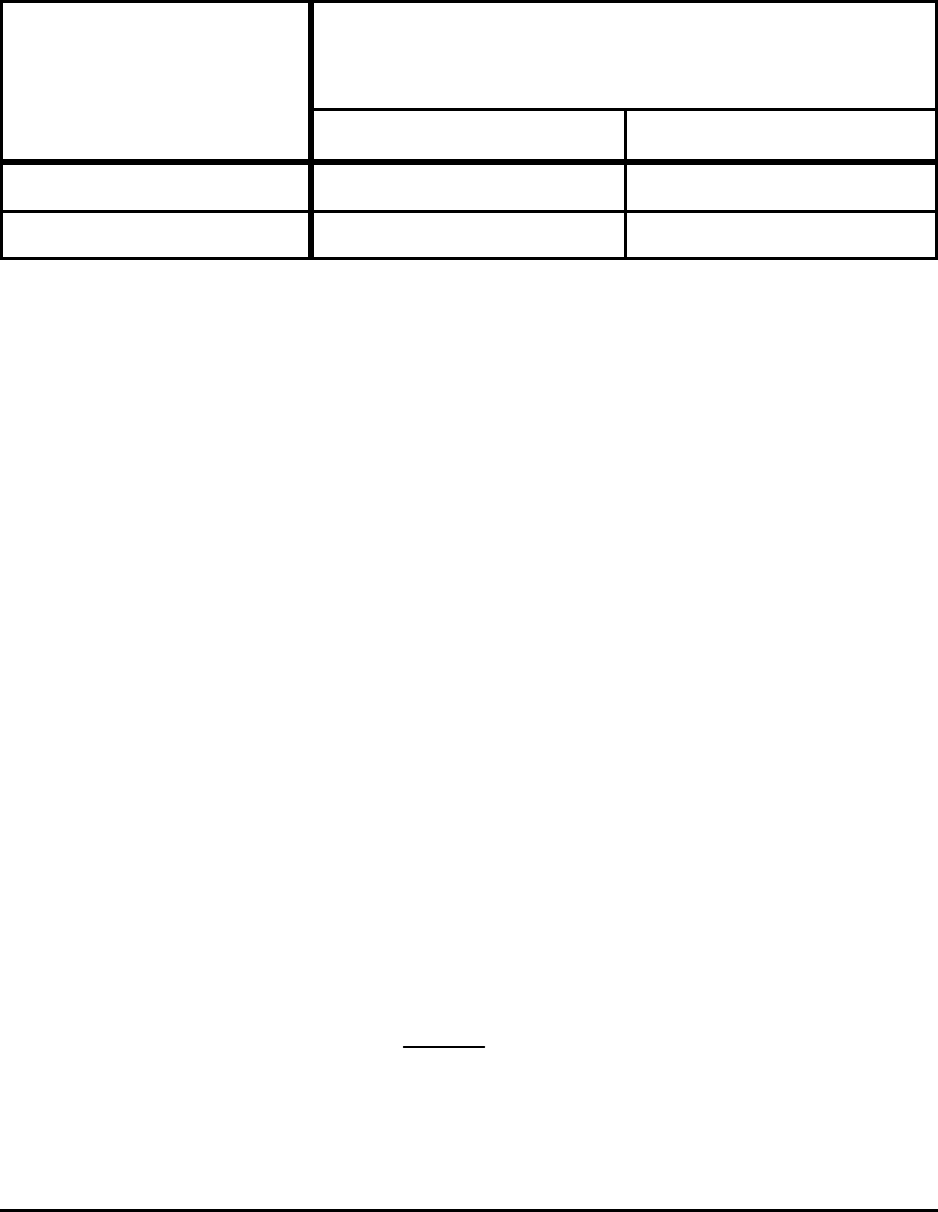

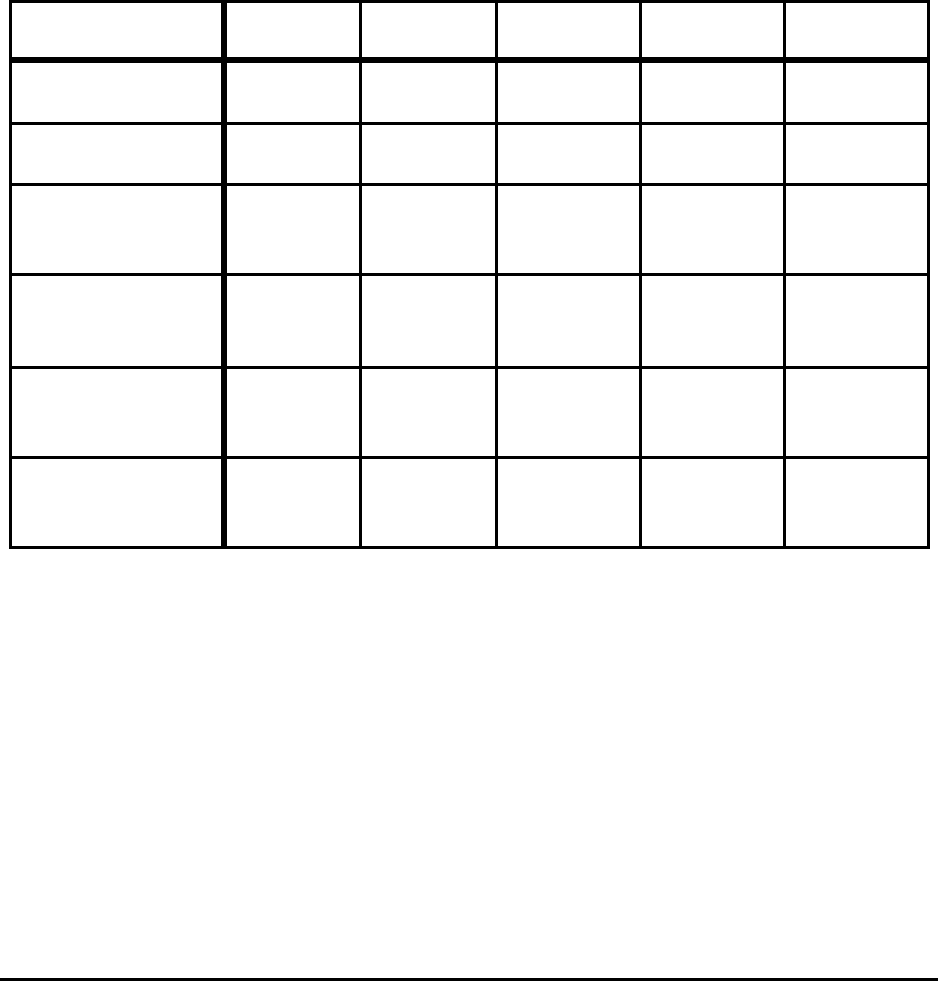

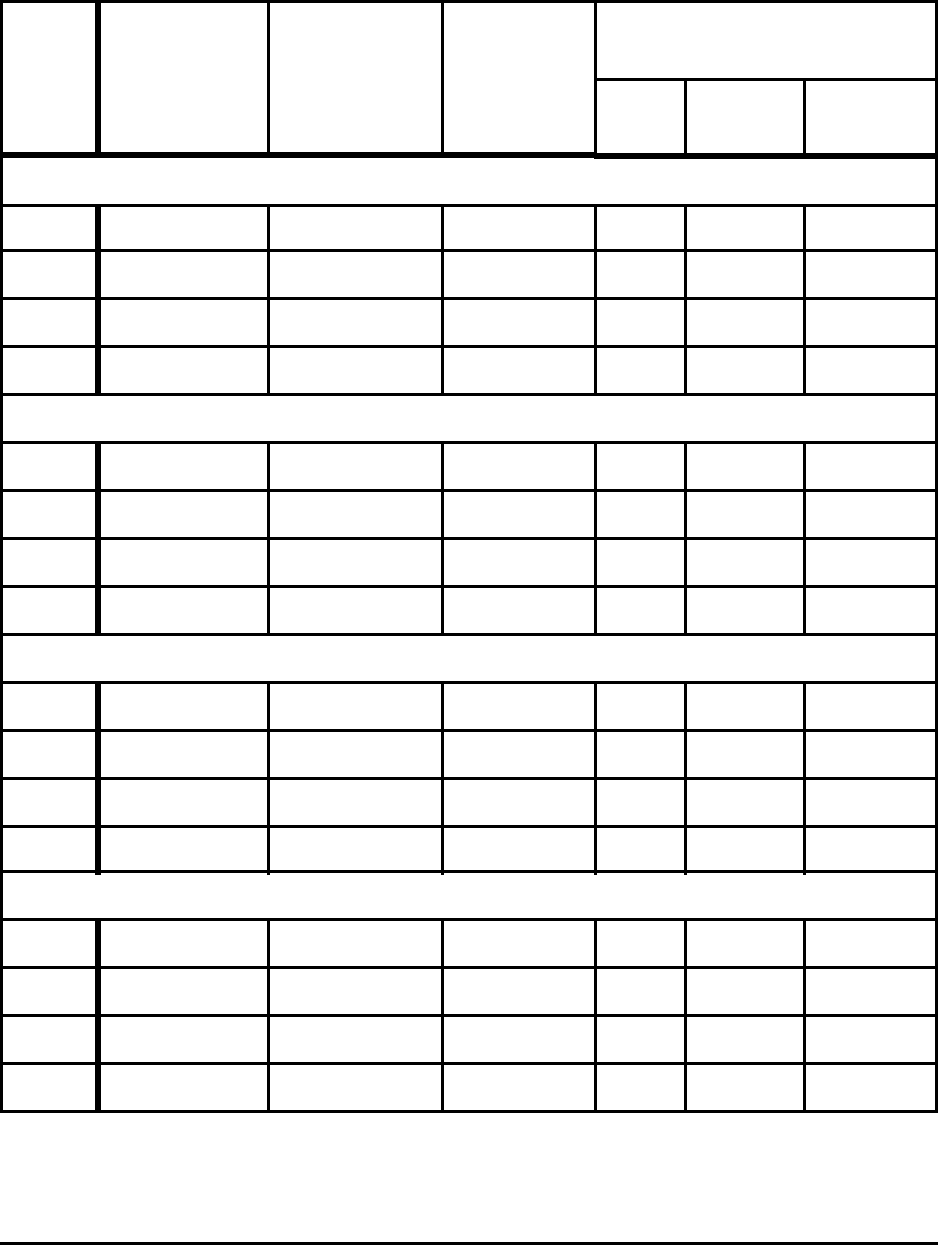

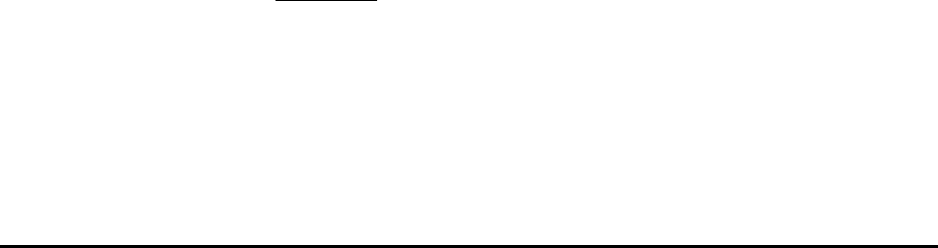

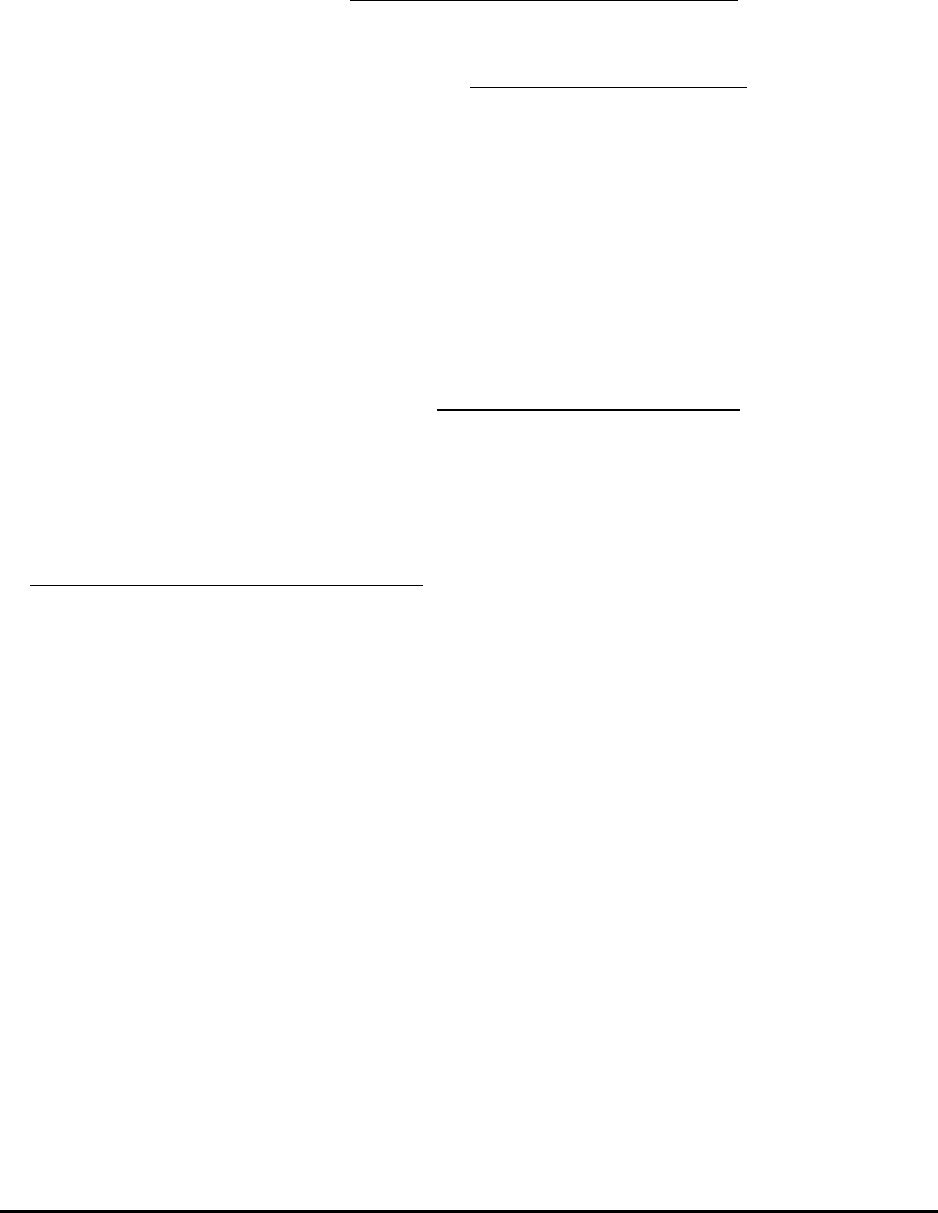

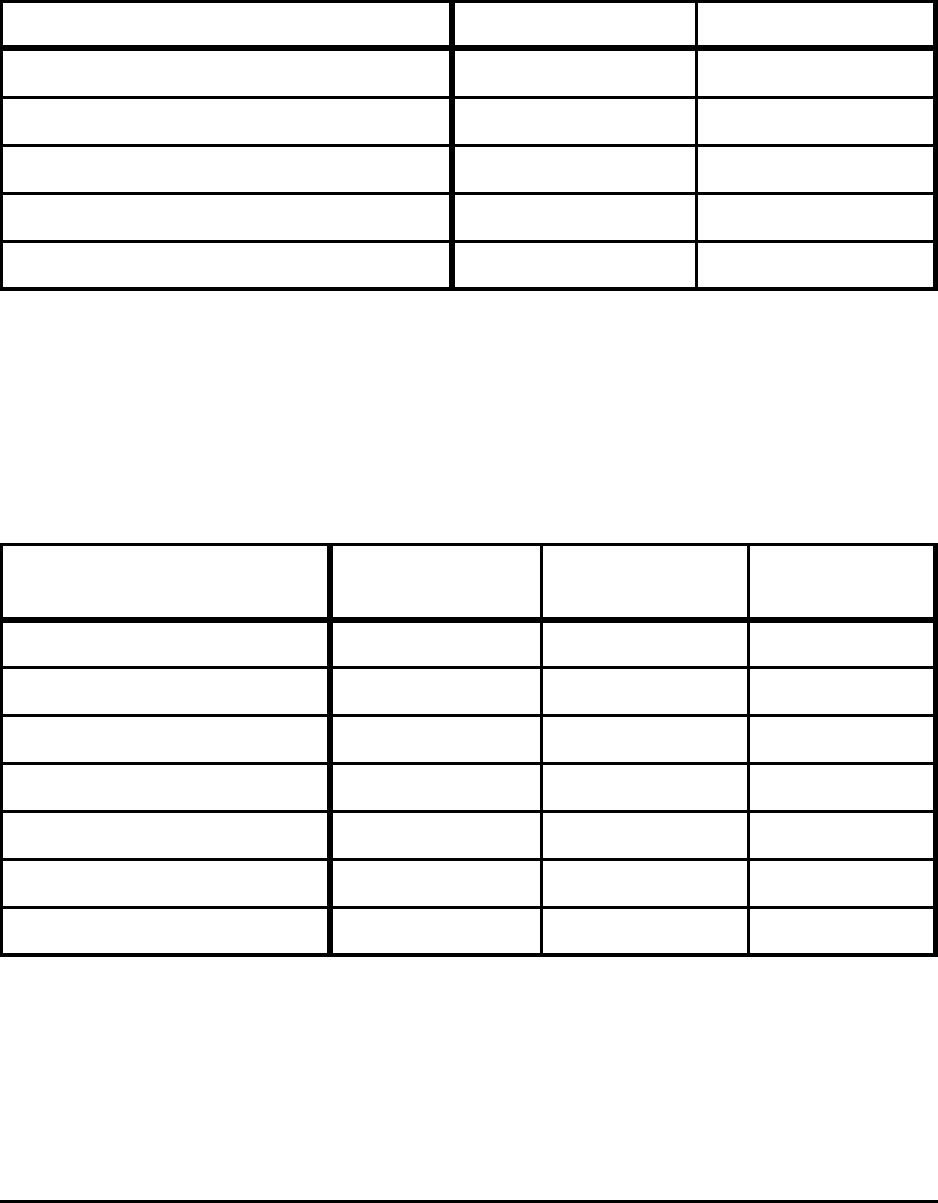

Table E-1. Comparison of Theoretical Minimum Energy

and Actual Energy Requirements for Selected Processes

Process

Energy (GJ/metric ton product)

Actual

Requirements

[10

6

Btu/ton]

Absolute

Minimum

[10

6

Btu/ton]

%

Difference

Practical

Minimum

[10

6

Btu/ton]

%

Difference

Liquid Hot

Metal (5%C)

13 - 14

[11.2 - 12.1]

9.8

[8.5]

25 - 30 10.4

[9.0]

20 - 26

Liquid Steel

(BOF)

10.5 - 11.5

[9.1 - 9.9]

7.9

[6.8]

25 - 31 8.2

[7.1]

22 - 29

Liquid Steel

(EAF)

2.1 - 2.4

[1.8 - 2.1]

1.3

[1.1]

38 - 46 1.6

[1.4]

24 - 33

Hot Rolling Flat 2.0 - 2.4

[1.7 - 2.1]

0.03

[0.03]

99 0.9

[0.8]

55 - 63

Cold Rolling

Flat

1.0 - 1.4

[0.9 - 1.2]

0.02

[0.02]

98 - 99 0.02

[0.02]

98 - 99

18-8 Stainless

Melting

1.2

[1.0]

1.5

[1.3]

Notes:

Actual includes yield losses and is the average of state-of-art and less-efficient operations for the United

States, Japan, and Europe. All of the values exclude electrical generation and transmission losses.

BOF energy is primarily from hot metal; actual process consumes 0.2 to 0.4 GJ/t and, if CO is oxidized to

CO

2

, could theoretically produce 0.5 GJ.

For 18-8 stainless no estimates are available, in particular for HCFeCr.

In all cases, full credit is taken for the energy in off gas.

Theoretical Minimum Energies to Produce Steel for Selected Conditions iii

-- --

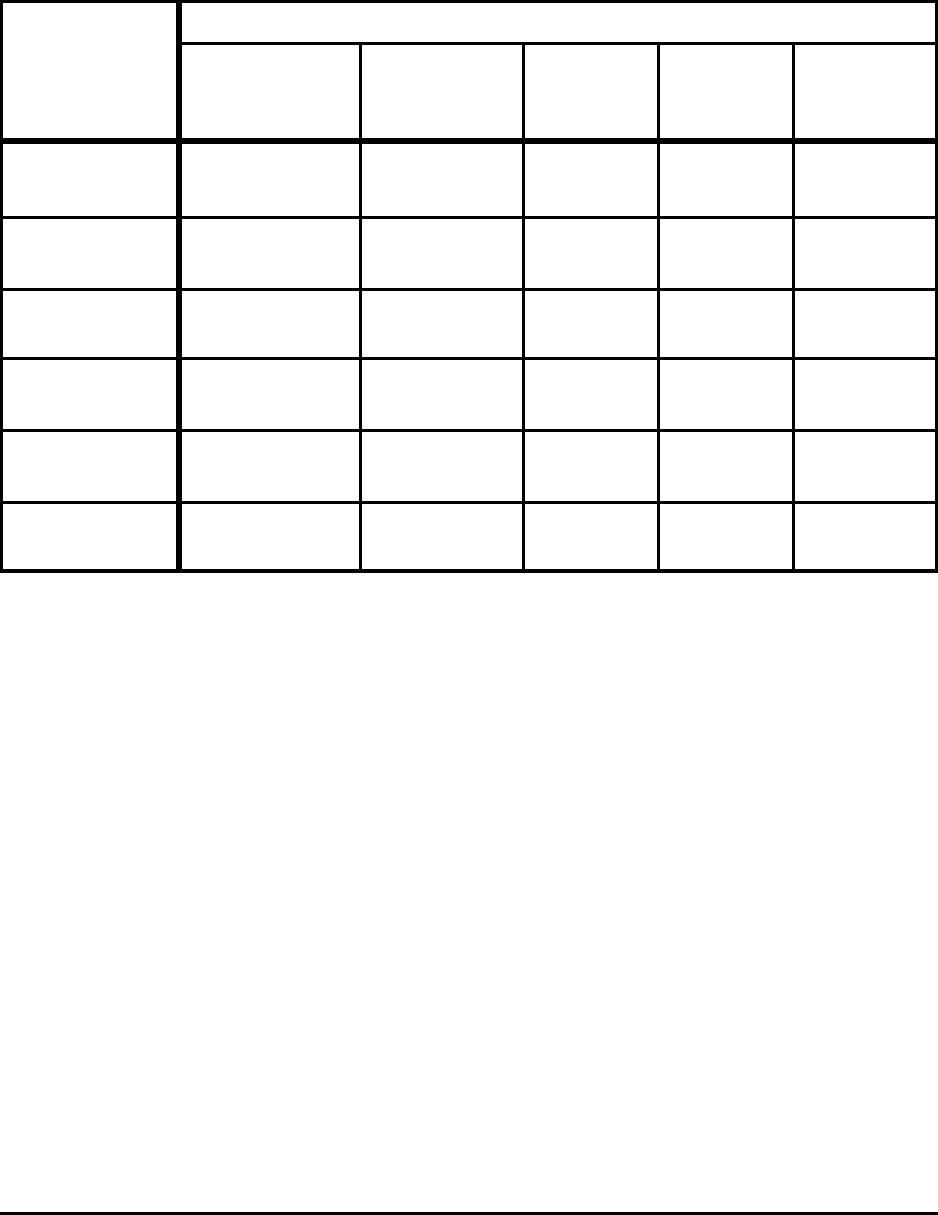

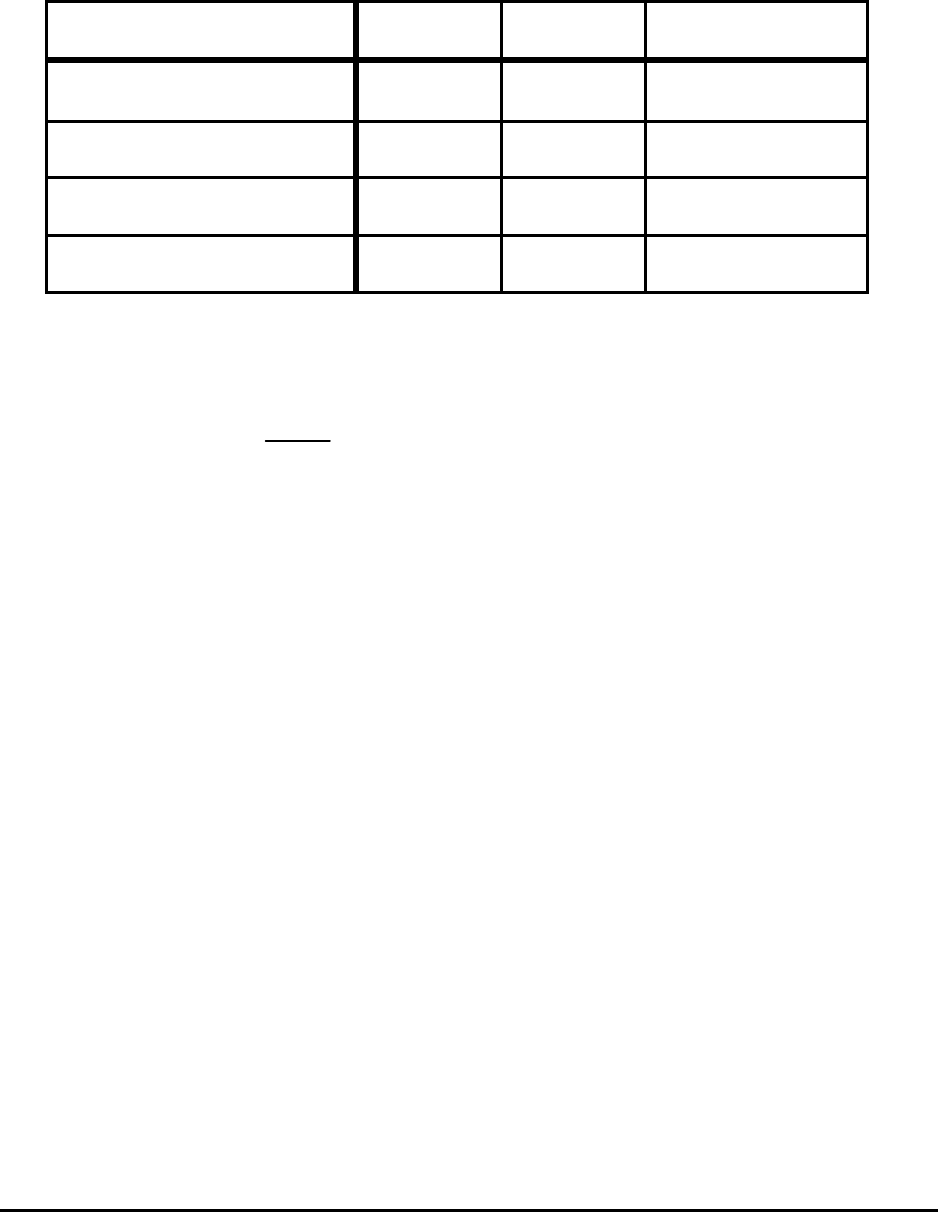

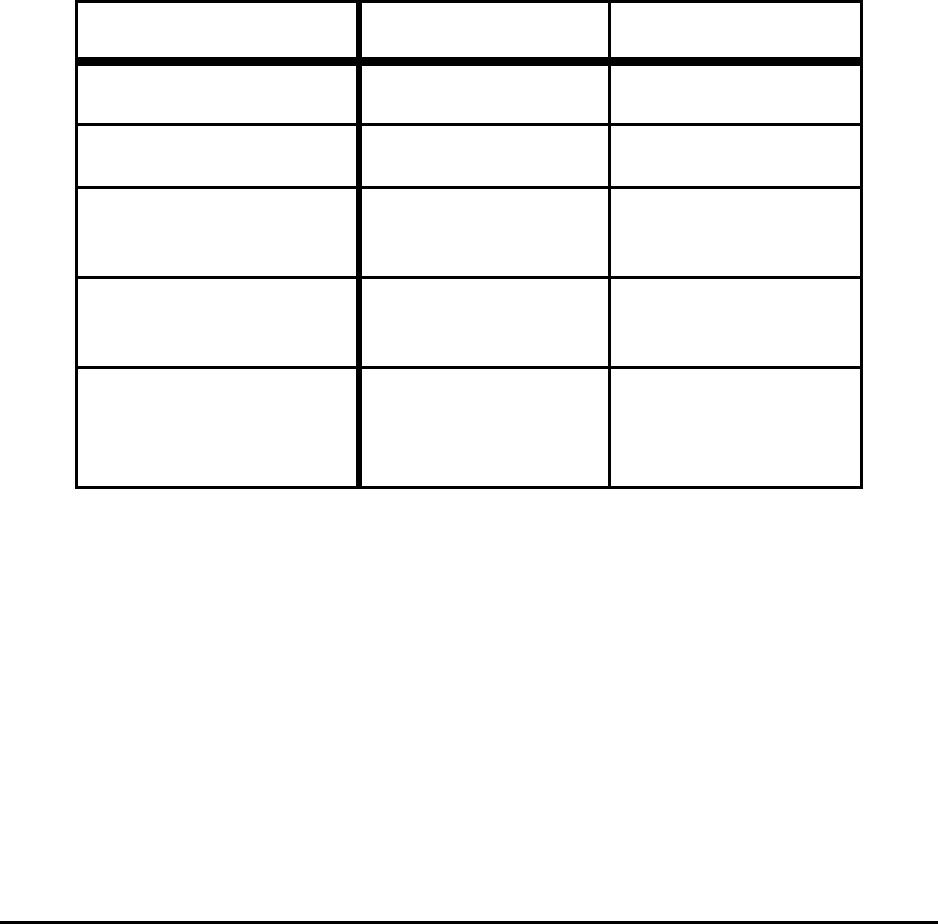

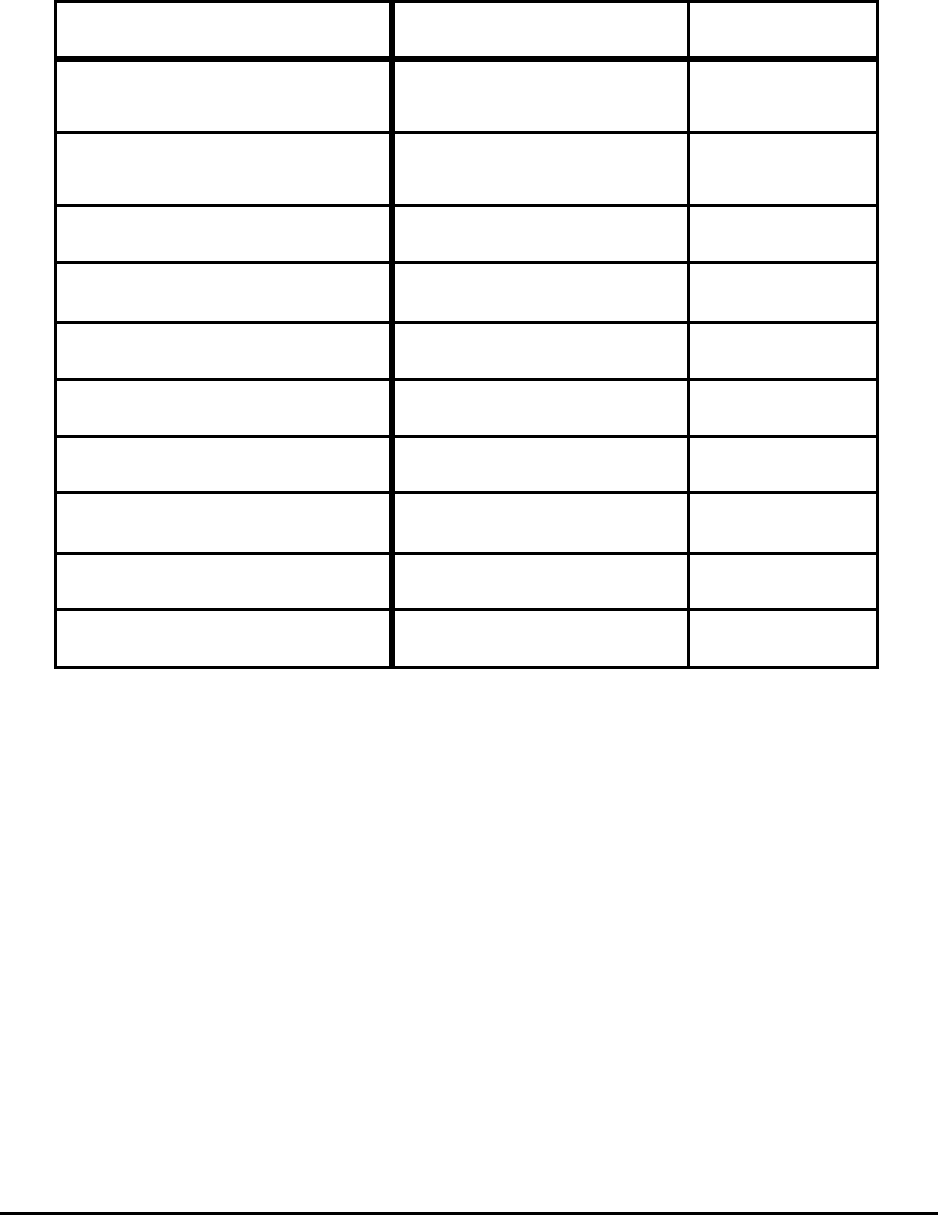

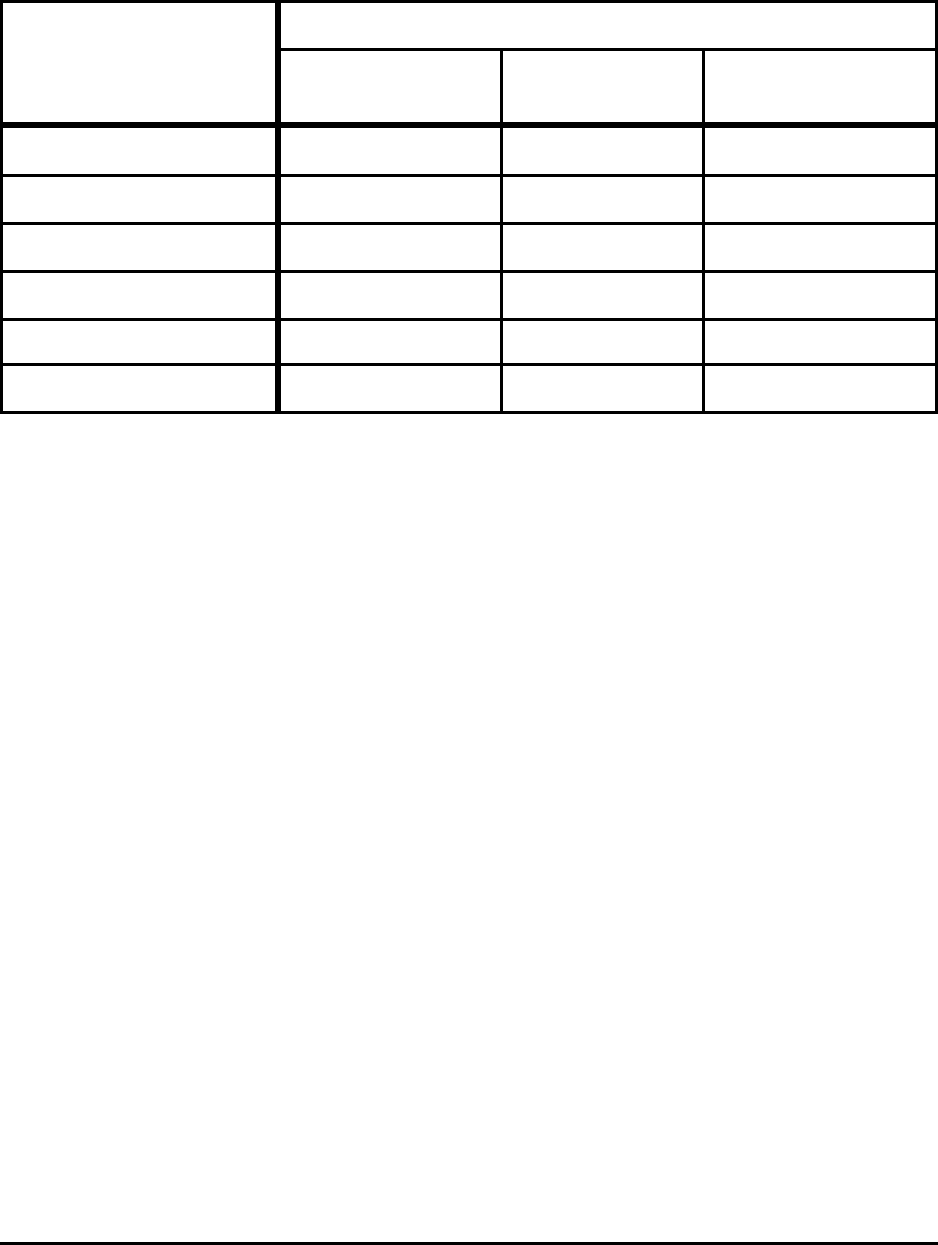

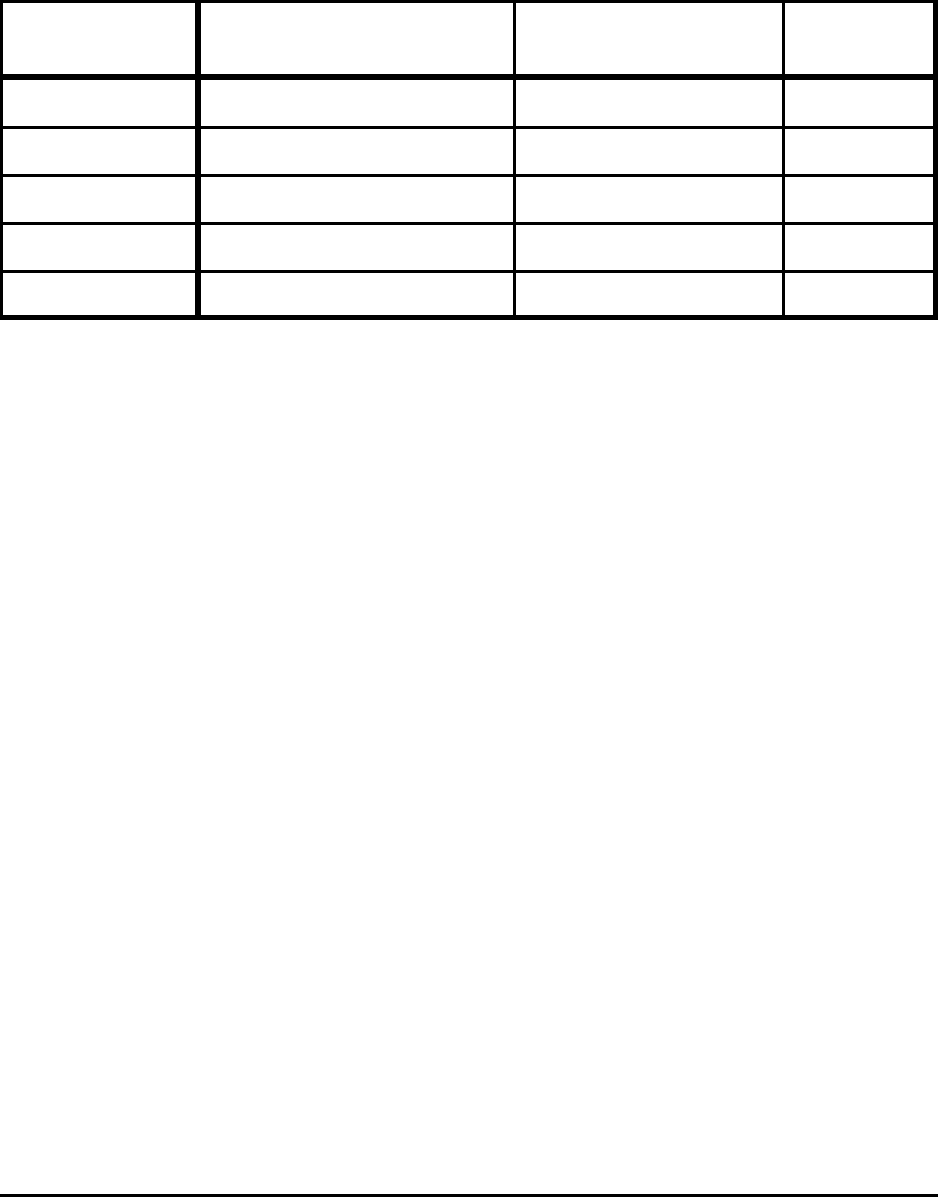

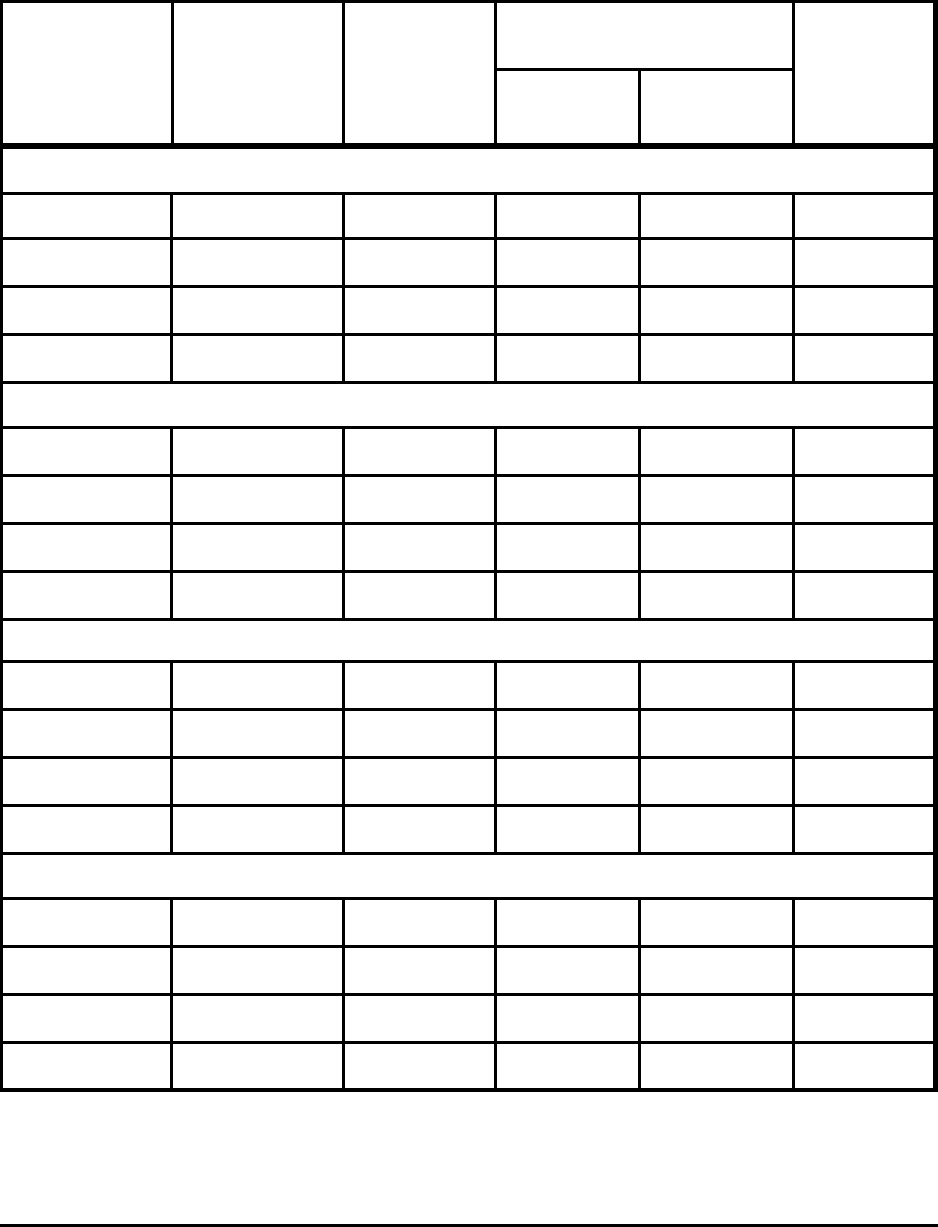

Table E-2. Comparison of Theoretical Minimum

and Actual CO

2

Emissions for Selected Processes

Process

CO

2

Emissions (kg/metric ton product)

Actual

Emissions

[lbs/ton]

Absolute

Minimum

[lbs/ton]

%

Difference

Practical

Minimum

[lbs/ton]

%

Difference

Liquid Hot

Metal

1,447 - 1,559

[2,894 - 3,118]

1,091

[2,182]

25 - 30 1,158

[2,316]

20 - 26

Liquid Steel

(BOF)

189 - 207

[378 - 414]

144

[288]

24 - 30 144

[288]

24 - 30

Liquid Steel

(EAF)

364 - 416

[728 - 832]

225

[450]

38 - 46

[76 - 92]

277

[554]

24 - 33

Hot Rolling

110 - 132

[220 - 264]

2

[4]

98

[196]

50

[100] 55 - 62

Cold Rolling

173 - 243

[346 - 486]

4

[8]

98

[196]

4

[8] 98

18-8 Stainless

Melting

– 208

[416]

260

[520]

Note:

Based on theoretical minimum energy consumption shown in Table E-1.

Other conclusions that can be drawn from the findings are as follows:

• Elimination of ore agglomeration and cokemaking, which are not theoretically necessary to

produce steel, would yield significant energy savings.

• Effective utilization of the energy contained in the off gases from the blast furnace, coke plant,

and direction reduction process is essential.

• The best scrap substitute with respect to energy usage is liquid pig iron or hot metal.

• Gangue and ash in ore and coal increase minimum ironmaking energy by about 6%.

• In BOF steelmaking, the energy to produce steel is less than the energy to produce iron

because scrap is melted in the process.

• Dirt in scrap and air entrainment in an EAF increase the energy required by about 25%.

• When carbon is used in the EAF, about 38% of the CO must be post combusted to CO

2

to

equal electrical energy, even taking into account the production and transmission losses

associated with electrical energy.

• The melting energy for stainless steel is similar to the melting energy for carbon steel, but is

much greater if the energy associated with ferrochrome is included.

• Direct charging of slabs or billets reduces total rolling energy by about 80%.

iv Theoretical Minimum Energies to Produce Steel for Selected Conditions

1. INTRODUCTION

The absolute theoretical minimum energies to produce liquid steel from idealized scrap (100%

Fe) and ore (100% Fe

2

O

3

) are much lower than consumed in practice, as are the theoretical minimum

energies to roll the steel into its final shape. This study presents the absolute minimum energy

required to produce steel from ore and mixtures of scrap and scrap alternatives, clearly

defining the necessary assumptions involved. The energy calculations are then repeated for a

series of cases in which the assumptions are changed one by one to more closely approximate

the actual conditions.

The results should give insight as to what is theoretically and practically possible in terms of

reducing the energy required to produce steel and will also indicate what factors cause significant

increases in energy consumption. The theoretical minimum energies will be compared to typical actual

energy consumptions to determine the potential energy savings for each process. In addition, the

theoretical minimum energies will be converted to CO

2

emissions (detailed in Appendix A), using

assumptions as to the type of energy used and national averages for CO

2

for the type of energy used.

It is not the objective of this study to

examine actual energy consumptions or CO

2

emissions. However, it is useful to compare

approximate industry averages to the minimums

to see what the potential energy savings are for

each process. These comparisons also indicate

the relative energy intensities of the different

steelmaking processes. Particular attention is

given to ironmaking, which consumes 70-80% of

the energy in integrated steel production, and the

electric furnace, which consumes the largest

portion of the overall energy in scrap-based

production.

Objectives

• Compute the theoretical energy required in

the major steelmaking processes for a

number of conditions

• Compare the theoretical minimum energies to

typical actual energy consumptions to

determine the energy saving potential for

each process considered

• Convert the theoretical minimum energies to

CO

2

emissions using the national averages

for the type of energy used in the process

2. BASIC ASSUMPTIONS AND CASES CONSIDERED

The calculations performed are theoretical; the basic assumptions are given on the next page.

The baseline calculations are the absolute minimum energy to produce liquid iron from pure ore and

scrap. The theoretical minimum energy is then computed for a series of cases, including

•

blast furnace ironmaking,

•

direct reduction,

• oxygen steelmaking, and

• electric arc furnace (EAF) steelmaking.

Also calculated is the energy required for production of hot and cold rolled sheet from conventional

slab casters (254 mm or 10 inch) and thin slabs (50 mm or 1.97 inch) and for the production of bars

Theoretical Minimum Energies to Produce Steel for Selected Conditions 1

(25.4 mm, or 1 inch) from a billet (10.16 mm sq, or 4 inch sq). A number of specific issues are also

addressed, including the energy and CO

2

emissions for calcining limestone, using carbon in EAF, the

effect of yield losses, and the effect of air entrainment in the EAF.

Assumptions Used in the Calculations

• Only energy directly used in the process is considered.

• Energy to produce materials such as alloys, oxygen, refractories, and electrodes is excluded.

• Energy loss in producing and transmitting electrical energy is excluded in initial energy calculations. It

is considered for CO

2

emissions.

• Energy and heat losses are excluded. For example, heat losses from furnaces and energy losses from

mechanical and electrical equipment are not considered.

• Energy credits are allowed but noted. For example, the chemical and thermal energy in the off gas from

the blast furnace is credited to the process.

• Energy used in ore agglomeration and cokemaking are excluded; these are treated separately.

• Energy loss due to yield loss is not considered in the theoretical minimum calculations. However, the

minimum energy loss resulting from yield losses is discussed in Section 8.

3. METHODOLOGY

Several different types of energy were considered in the calculations of theoretical minimum

energy requirements, including

• sensible or heating energy,

• melting and phase transformation energy,

• heats of reactions, and

• heats of solution.

The required thermodynamic data was taken from several sources.

(1-6)

Computer programs

were developed that incorporated the energy and materials balance for the process being considered.

The accuracy of the calculation depends on the accuracy of the data used. In general, the uncertainties

of the calculated energies is 1 to 3%.

Sensible or Heating Energy

In all cases considered, input materials such as ore, carbon, oxygen, and scrap must be heated.

The heat ∆H is given by:

T

2

C

p

dT∆Η =

∫

T

1

C

p

= Heat capacity which is a function of temperature

T

1

, T

2

= the initial and final temperatures

2 Theoretical Minimum Energies to Produce Steel for Selected Conditions

Melting and Phase Transformation

The energies associated with materials melted in the process or going through phase transformations are

included.

Heats of Reactions

Chemical reactions either require energy (endothermic) or give off energy (exothermic). An

example of an endothermic reaction is the dissociation or reduction by carbon of FeO:

FeO = Fe + 1/2 O

2

FeO + C = Fe + CO

Examples of exothermic reactions are the oxidation of carbon to CO or CO

2

and of iron:

C + 1/2 O

2

= CO

C + O

2

= CO

2

Fe + 1/2 O

2

= FeO

Heats of Solution

When two or more components go into solution, heat can be given off or absorbed. These

heats compared to the other types considered are usually small. Examples include the heat of mixing of

CaO and SiO

2

and of Fe and carbon.

4. ABSOLUTE THEORETICAL MINIMUM ENERGY VALUES

The absolute theoretical minimum energy values for ore reduction and scrap melting are shown

in Table 1 and discussed below.

Ore Reduction

The theoretical minimum energy to produce steel from ore was computed by assuming ore is

pure Fe

2

O

3

and is reduced at 298 K, with the resulting iron heated to its melting point and melted. Iron

goes through a number of phase changes whose energies are included. For the theoretical minimum, no

super heat is required and the product is cast into its final shape without finishing. For this case the

energy is 8620 MJ/tonne. For moderate super heat to 1873 K the energy is 8673 MJ/tonne.

Scrap Melting

The theoretical minimum in this case is simply heated and melted. The energy is 1,274

MJ/tonne. For super heating to 1873 K the energy increases to 1327 MJ/tonne. As in the previous

case, it is assumed the product is cast into its final shape.

Theoretical Minimum Energies to Produce Steel for Selected Conditions 3

Table 1. Absolute Theoretical Minimum Energy to Produce Steel

from Pure Ore (Fe

2

O

3

) and Pure Scrap (Fe)

Raw Material

Absolute Theoretical Minimum Energy

as a Function of Tap Temperature

(MJ/t)

1813 K 1873 K

Ore (Fe

2

O

3

) 8,620 8,673

Scrap (Fe) 1,274 1,327

5. CASES APPROACHING ACTUAL CONDITIONS

Blast Furnace Ironmaking

Blast furnace ironmaking or any ironmaking process requires more energy and releases more

CO

2

than any other process to produce steel. The reduction of Fe

2

O

3

to Fe is by far the most energy-

intensive step. The theoretical energy requirements to produce liquid hot metal for selected conditions

along are presented below, with the specific assumptions. Liquid hot metal or pig iron is defined as iron

containing 4% to 5% carbon. Full credit is given for the energy in the off gas. The ironmaking results

are summarized in Table 2.

Ironmaking Case I - Absolute minimum. The iron blast furnace does not produce pure iron

but rather iron nearly saturated with carbon (typically about 5% C). The tap temperature is usually

about 1723 K (1450°C). In this case the energy associated with the carbon is significant and there is a

small positive heat of solution. The energy required to produce hot metal for this case is 9,805 MJ.

For a tap temperature of 1773 K the energy increases to 9,918 MJ. The energy of carbon associated

with the product (50 kg/t) at this point does not release any CO

2

; the CO

2

is released during

steelmaking. Also, the small heat of solution is given back during steelmaking as the carbon is burned.

Ironmaking Case II - Effect of slag resulting from gangue in ore. Ore is not pure Fe

2

O

3

but contains gangue or impurities, primarily SiO

2

and Al

2

O

3

. An ore with 6% gangue and an assumed

consumption of 4% SiO

2

, 1% MnO, and 1% Al

2

O

3

was considered. To form a blast furnace slag, lime

(CaO) is added. A typical slag will have a basicity (B) of 1.2, where B is defined as

B

=

(%CaO)

(%SiO

2

)

4 Theoretical Minimum Energies to Produce Steel for Selected Conditions

--

--

--

--

Table 2. Minimum Energies to Produce Liquid Hot Metal at 1723 K

(1450°C or 2642°F) for Selected Conditions

Metal Composition Gangue Ash

Energy

(MJ/t HM)

Fe - 5%C No No 9,805

Fe - 5%C Yes No 10,216

Fe - 5%C - 0.5%Si - 0.5%Mn Yes No 10,268

Fe - 5%C - 0.5%Si - 0.5%Mn Yes Yes 10,421

Notes: Gangue - 4% SiO

2

- 1% Al

2

O

3

- 1% MnO of ore

Ash - 5% of 500 kg of coal and coke or 25 kg/t HM

Slag Basicity

%CaO

=

1.2

%SiO

2

Energy credit for off gas approximately 5,400 - 5,600 MJ/t HM in each case

In this case all the gangue is assumed to enter the slag. In the calculation, the energy to heat and

melt the gangue and CaO are included. There is a significant negative heat of solution or heat release of

the slag components. Because of the presence of gangue, the energy increases to 10,216 MJ per

tonne of hot metal.

Ironmaking Case III - Effect of slag and reduction of SiO

2

and MnO in slag. During

ironmaking some of the SiO

2

and MnO is reduced. A typical metal composition is as follows:

Fe 94%

C 5%

Si 0.5%

Mn 0.5%

When the energy for slag formation and reduction of SiO

2

and MnO is included, the energy is 10,268

MJ per tonne of hot metal for a tap temperature of 1773 K.

Ironmaking Case IV - Effect of coke ash. Coke and injected coal contain ash. For this case

500 kg of coke plus coal per tonne of hot metal is assumed, with an average ash content of 5% (the ash

is assumed to contain 4% SiO

2

, 1% Al

2

O

3

, and 1% MnO). The assumed 500 kg of coke plus

coal/tonne hot metal is not the theoretical minimum but reflects typical actual values. The other

conditions for slag and reduction are similar to Case III, and the energy increases to 10,421 MJ per

tonne of hot metal.

Theoretical Minimum Energies to Produce Steel for Selected Conditions 5

Direct Reduction

The production of direct reduced iron by a number of processes has increased dramatically in the

past five years. For the purposes of this report direct reduction is defined as any process that converts

ore into a solid product containing primarily metallic iron. The product will also contain gangue from the

ore, along with reductant, carbon, and unreduced iron oxide (FeO). In most cases, natural gas (CH

4

)

supplies the energy. Examples of such processes are Midrex, HyL, FINMET, CIRCORED, and Iron

Carbide.

The general assumptions for direct reduction are the same as for ironmaking in a blast furnace. The

gangue is assumed to be entirely SiO

2

. It is also assumed that the ore is heated to 900°C and reduced.

Full credit for the energy in the off gas is taken. In these processes the off gas is usually recycled back

into the process, and the chemical energy is used but some thermal energy is lost.

As in the reduction of liquid hot metal, the simplest case is considered first and then realistic

computations such as gangue in the ore and carbon in the product are added. All energy values given

are per tonne of product. Some products require more energy when used to produce liquid steel in an

EAF, which is discussed in a later section of this report. The results of the five cases considered are

given in Table 3.

Table 3. Minimum Energies to Produce Direct Reduced Iron at 1173 K

(900°C or 1620°F) Reduction Temperature for Selected Conditions

Ore Product

Energy

(MJ/tonne)

Pure Fe

2

O

3

Fe 8,360

Fe

2

O

3

- 1.4% SiO

2

Fe - 2% SiO

2

8,380

Fe

2

O

3

- 1.4% SiO

2

Fe - 2% SiO

2

- 8% FeO 7,900

Fe

2

O

3

- 1.5% SiO

2

Fe - 2% SiO

2

- 8% FeO - 2% C 8,427

Fe

2

O

3

- 1.5% SiO

2

Fe - 2% SiO

2

- 7.7% FeO - 6% C 9,432

Note: Full credit is assumed for off gas

It is important to note that the energy per tonne of iron is different in each case and the energy to

melt the materials varies. Later in this section, the total energy to produce steel is given for a 50%

scrap - 50% DRI charge.

Oxygen Steelmaking

Oxygen steelmaking (OSM) does not in itself consume energy but instead generates it. In the

process, the carbon, silicon, and other elements in the hot metal are oxidized, producing energy

6 Theoretical Minimum Energies to Produce Steel for Selected Conditions

--

--

primarily used to melt scrap. The energy can also be used to melt and smelt (reduce) waste oxide

briquettes or smelt ore. The amounts of these oxide-containing materials that can be used are

significantly less than scrap because of the energy required to reduce the iron oxides. In the United

States scrap is almost exclusively used as a coolant and is included in this analysis.

Table 4 lists the amounts of scrap that can be melted per tonne of hot metal of selected

compositions. Also given is the amount of liquid steel produced and the energy per tonne of liquid

steel, computed by dividing the energy required to produce the hot metal by the amount of steel

produced.

Table 4. Energy to Produce Steel from Hot Metal and Scrap for Selected Conditions

Hot Metal Slag

Tap T

p

(K)

Scrap

(kg/t HM)

Steel

(kg/t HM)

Energy

(MJ/t steel)

Fe - 5% C 1873 290 1,240 7,907

Fe - 5% C 1923 244 1,194 8,212

Fe - 5%C - 0.5% Si

(coke ash)

B=3

30% FeO

1873 401 1,328 7,853

Fe - 5%C - 0.5%Si

(coke ash)

B=3

30% FeO

1923 353 1,278 8,154

Fe - 5%C - 0.5% Si

(coke ash)

B=3

20% FeO

1873 389 1,320 7,894

Fe - 5%C - 0.5%Si

(coke ash)

B=3

20% FeO

1923 341 1,270 8,205

Note: The decrease in energy per tonne of steel for oxidizing Si and Fe is due to increased scrap melting.

The calculations assume CO to be the off gas no post combustion. For 5% C in the hot metal the

potential energy in the off gas ranges from 950 MJ/t (steel) to1,000 MJ/t if the CO is oxidized to CO

2

.

The results in Table 4 indicate that less energy per tonne of steel is obtained when silicon is present

in the hot metal and iron is oxidized. This is somewhat misleading because the reduced energy per

tonne of steel is from melting scrap using the additional energy from the oxidation of Si and Fe. Since it

takes considerably more energy to produce hot metal from ore than to melt scrap, the energy per tonne

of steel produced is reduced when melting more scrap in OSM. This important fact can be illustrated

by considering a case in which the additional scrap melted by oxidizing Si and Fe was simply melted in

another process. For the case when there is no silicon of iron oxidized to the slag, 290 kg of scrap is

melted and the energy per tonne of steel is 7,907 MJ while for 30% FeO and 0.5% Si, 401 kg of scrap

is melted and the energy is 7,853 MJ per tonne of steel. If the additional 111 kg of scrap was simply

Theoretical Minimum Energies to Produce Steel for Selected Conditions 7

--

melted separately, it would require 146 MJ. This reduces the average energy per tonne of steel to

7,200 MJ for no FeO or SiO

2

in the slag if the additional 111 kg of scrap was simply melted.

Electric Furnace Steelmaking with Scrap

A number of cases were considered for scrap and scrap alternative melting in an EAF. The results

for 100% scrap melting are summarized in Table 5. The energy loss in producing electricity or the

energy required to process the scrap is not considered. Only the energy consumed in the process is

included, not the energy to produce other materials, such as electrodes and refractories.

Table 5. Theoretical Minimum Energies to Produce Steel from Scrap for

Selected Conditions, Tap Temperature 1873 K (1600°C or 2912°F)

Scrap Slag

Energy

(MJ/t)

Fe 1,327

Fe - 0.1%C - 0.2%Si

B = 2.5

%FeO = 25% 1,289

Fe - 0.1%C - 0.2%Si

1% dirt

B = 2.5

%FeO = 25%

1,352

Fe - 0.1%C - 0.2% Si

1% dirt

B = 2.5

%FeO = 35%

1,325

Fe - 0.1%C - 0.2%Si

1% dirt

100 Nm

3

air entrainment

B = 2.5

%FeO = 25%

1,577

Note: The decrease in melting energy with FeO in slag is due to oxidation of Fe

EAF Case I - Absolute Minimum to Melt Iron. The absolute minimum energy is 1,327 MJ/t,

the amount of energy required to heat and melt scrap and super heat the metal to 1873 K.

EAF Case II - Scrap Containing 0.1%C - 0.2%Si. In this case, it is assumed that the carbon

remains in the steel and the silicon is oxidized to SiO

2

. Flux (CaO) is also heated and melted, yielding a

slag with a basicity of 2.5 and 25% FeO. The energy requirement is 1,289 MJ/t. The reduction in

energy from Case I is due to the oxidation of Si and Fe to the slag, which results in a yield loss of 0.6%.

EAF Case III - Scrap Containing 0.1%C - 0.2%Si + 1.0% (10 kg) "Dirt." Scrap also has

other materials with it such as water, soil or dirt, and oil. Based on the final slag formed, considerable

amounts of materials containing SiO

2

and Al

2

O

3

(e.g., dirt) enter the furnace.

8 Theoretical Minimum Energies to Produce Steel for Selected Conditions

--

For 10 kg per tonne of scrap of SiO

2

plus Al

2

O

3

and maintaining a slag basicity of 2.5, the energy

required is increased to 1,352 MJ/t, with a yield loss to the slag of 2.5%

EAF Case IV - Air Entrainment. During EAF steelmaking large quantities of air can be

entrained into the furnace through the furnace door and other openings. It is estimated that 100

nm

3

/tonne of air can be entrained. If the N

2

leaves at 1473 K or 1873 K, the heat associated is 165

MJ and 225 MJ, respectively, increasing the energy from Case III to 1,517 MJ and 1,577 MJ/t,

respectively.

Electric Furnace Steelmaking with DRI and Scrap

The energy required to produce steel with 50% scrap and 50% scrap substitute was calculated.

The scrap was assumed to contain 0.2% Si and 10 kg dirt per tonne. There is no post combustion or

air entrainment in the process. The slag is assumed to have basicity of 2.5 and 25% FeO. The energy

required to produce steel (0.05%C) for several cases is given in Table 6. This table also shows the

energy required to produce steel with solid and liquid pig iron as 50% of the charge. The total energy

given in Table 6 includes the energy to produce the DRI (shown in Table 3).

There are numerous other combinations of scrap and DRI and other assumptions with regards

to slag and post combustion, which were covered in the AD Little report to AISI

(7)

.

6. PRODUCTION OF STAINLESS STEEL

There are numerous grades of stainless steel produced in the United States. The most common is

18-8 type stainless, which contains 18% Cr and 8% Ni. This analysis assumes the production of a

generic 18-8 type stainless steel in an EAF-AOD (Argon Oxygen Decarburization) sequence, which

accounts for over 90% of U.S. stainless steel production.

In the EAF, a mixture of stainless steel scrap, steel scrap, high carbon ferrochrome (HCFeCr), and

nickel are melted and the carbon content is reduced to about 1%. The metal is then transferred to an

AOD vessel where a mixture of O

2

- Ar or O

2

- N

2

gases oxidizes the carbon to its desired level. The

AOD itself does not theoretically require energy and is therefore not considered. After the AOD, a

reductant containing either silicon or aluminum is added to the slag to recover chromium, which is

oxidized to slag. For the assumptions of the present study, this stage also need not be considered.

A typical charge to the EAF per tonne of steel is as follows:

Steel Scrap 350 kg

Stainless Scrap -- 400 kg

The carbon is combusted with oxygen down to 1.0%. The absolute minimum energy for melting

the above charge is 1,213 MJ, which is less than melting Fe because of carbon oxidation. If the scrap

contains 1% dirt and there is no air entrainment, the melting energy is 1,275 MJ/t.

Theoretical Minimum Energies to Produce Steel for Selected Conditions 9

--

--

--

Table 6. Theoretical Minimum Energies to Produce Liquid Steel at 1873 K (1600°C or

2912°F) from 50% Scrap and 50% Scrap Substitute

Scrap Substitute

Melting Energy

(MJ/t)

Charge Energy

(MJ/t)

Total Energy

(MJ/t)

None (!00% Scrap Case) 1,289 1,289

Fe - 2% SiO

2

1,403 4,296 5,698

Fe - 2%SiO

2

- 8%FeO 1,559 4,233 5,792

Fe - 2%SiO

2

- 8%FeO -2%C 1,483 4,565 6,048

Fe - 2%SiO

2

- 7.7%FeO - 6%C 1,328 5,223 6,551

Liquid Pig Iron 487 5,388 5,875

Solid Pig Iron 1,145 5,388 6,533

Notes: Liquid Pig (Hot Metal) charged at 1723 K, all others 298 K

If air entrainment is included, it will add 238 MJ/t in each

Slag has B = 2.5 and 25% FeO

HCFeCr 250 kg

Nickel 48 kg

According to the initial assumptions and boundaries of the present calculations the energy to

produce the high carbon ferrochrome is not included. The amount of alloys for carbon steel production

is much smaller than it is for stainless steel. Since the energy in ferrochrome is so high, it is useful to

estimate the theoretical minimum for its production. Only the very simplest case of the absolute

minimum for the production of HCFeCr is considered.

HCFeCr is produced from chromite ore whose composition depends on the specific mine

location. The major component is FeCr

2

O

4

. For the absolute minimum, the ore is considered to be

pure FeCr

2

O

4

and the product 61% Cr - 33% Fe - 6% C. The absolute minimum energy is 11.7

GJ/tonne of product. For the 250 kg used in the present example, the absolute minimum is 2,925 MJ

per tonne of steel; the actual energy will be over 4,000 MJ. It should be noted that HCFeCr is not

produced domestically and therefore no energy is used in the United States. If the minimum energy to

produce ferrochrome is included, the total energy is increased to 3,200 MJ/tonne of 18-8 stainless

steel.

10 Theoretical Minimum Energies to Produce Steel for Selected Conditions

7. ROLLING

There are two general types of rolling -- hot and cold. With hot rolling, the steel either is

reheated or directly charged after casting. Reheating is the major energy consumer in the rolling

process. For both hot and cold rolling, energy is also consumed in deformation, where the deformation

energy (E) is given by

E=sec

where

σ = the yield stress

ε = strain or deformation

c = a constant describing the shape of the stress strain curve, assumed to be an average of 0.7

The strain is defined in terms of the initial and final dimensions, t

o

and t

f

, respectively.

e

= ln

t

o

t

f

The yield strengths used in the following calculations were taken from the Making, Shaping

and Treating of Steel.

(8)

Cases included were hot and cold rolling for flat rolled carbon steel and 18-8 type stainless

(starting from both normal slabs and thin slabs), as well as hot rolling of bars from billet. The effects of

direct charging and billet splitting are also included in the analysis.

For hot rolling, the deformation energy is low because the yield stress is low at high

temperatures. For stainless steel, the yield stress is about three times higher than for carbon steel, while

for bars it is slightly higher than for flat steel because the carbon content is generally higher. The energy

used for heating is fossil fuel and for rolling electrical. Table 7 lists the minimum energies for rolling,

assuming no energy or yield losses.

The results in Table 7 indicate that reheating the slab or billet accounts for the vast majority of

the rolling energy. If slabs of normal thickness are directly charged, as is the case for most thin slabs,

the energy for rolling these slabs is similar to that for thin slabs. Strip casting a 2-mm strip does not

significantly reduce the total energy if the normal slab is directly charged. The total energy for a thin

slab with hot and cold rolling with direct charging is 33 MJ, compared to cold rolling a 2-mm strip to 1

mm, which requires 17 MJ.

During hot rolling the metal being processed cools and must be reheated or deformed at a

lower temperature. These effects require more energy but are not considered.

Theoretical Minimum Energies to Produce Steel for Selected Conditions 11

--

--

--

--

--

--

--

--

Table 7. Theoretical Minimum Energies to Roll Steel for Selected Products and Conditions

Bar Carbon (10 cm billet to 2 cm bar)

a

Slab temperature prior to rolling

b Billet split into 4 pieces prior to rolling

Rolling

Type

Rolling

Temperature

(K)

Slab

Temperature

a

(K)

Reduction

(mm)

Energy

(MJ/t)

Heat

Deform-

ation Total

Flat Carbon Slab (25.4 cm or 10 inch)

Hot 1473 298 254 to 2 825 25 850

Hot 1473 1173 254 to 2 270 25 295

Hot 1473 1473 254 to 2 25 25

Cold 298 298 2 to 1 17 17

Flat Carbon Slab (5.0 cm or 1.97 inch)

Hot 1473 298 50 to 2 825 16 841

Hot 1473 1173 50 to 2 270 16 286

Hot 1473 1473 50 to 2 15 16

Cold 298 298 2 to 1 17 17

Flat 18-8 Stainless Steel Slab (25.4 cm or 10 inch)

Hot 1473 298 254 to 2 825 72 897

Hot 1473 1173 254 to 2 271 72 342

Hot 1473 1473 254 to 2 72 72

Cold 298 298 2 to 1 51 51

Hot 1473 298 10 sq to 2 sq 825 20 845

Hot 1473 1473 10 sq to 2 sq 20 20

Hot 1473 1173 10 sq to 2 sq 270 20 290

Hot

b

1473 1473 10 sq to 2 sq 11 11

12 Theoretical Minimum Energies to Produce Steel for Selected Conditions

8. EFFECT OF YIELD LOSSES ON ENERGY

The calculation of minimum energies assumed no process yield losses. However, yield losses

occur in all processes, and their effect on energy depends on where the yield loss occurs and how much

energy is "invested" in the iron or steel to that point. Some forms of yield loss have been taken into

account and the energy reclaimed in the calculation. For example, in steelmaking Fe is oxidized to the

slag, releasing energy that is used in the process. This energy release has been included in the

steelmaking energy calculation. For oxygen steelmaking, this added energy increased the hot metal

requirement and, therefore, the energy per tonne of steel. For scrap-based EAF, the "invested energy"

in the scrap was not included.

The following section addresses the impact of yield losses related to the various processes. In

all cases, the energy invested in the product is assumed to be that for the most likely case for

production. For example, for oxygen steelmaking the most likely case for production is the case for hot

metal containing silicon. The most likely case for production in the EAF is assumed to include slag and

air entrainment. A summary of the effect of yield loss on the minimum theoretical energy requirements

to produce steel is summarized in Table 8.

Ironmaking and Hot Metal Treatment

Significant yield losses can occur during tapping, handling, and treatment of hot metal. In

particular, iron is extracted with the slag during slag removal after hot metal desulfurization. Yield losses

of 1% to 3% are typical; for a 1% yield loss of liquid pig iron the energy loss would be 104 MJ. If the

iron is recovered from the slag and reused, only the sensible and melting energy (about 14 MJ) is lost.

Steelmaking

Yield losses in both oxygen steelmaking and EAF steelmaking can be significant. The highest

yield loss is FeO to the slag, which can be 5% to 10%. This yield loss releases energy, which was

considered, but more iron must be charged. Both of these effects were taken into account in the results

given for OSM and the EAF. However, there is no energy charge for the increased scrap usage.

Other yield losses can be vaporization of iron (which is oxidized to the dust), other iron losses to the

dust, and losses during tapping and handling.

Vaporization of iron consumes a considerable amount of energy in steelmaking. The energy is

not recovered when the vaporized iron is oxidized in the off gas. For 1.0% iron vaporizing in the BOF

and no energy recovery from iron oxidation, the energy loss is the energy invested in the steel (80 MJ)

and the heat of vaporization (64 MJ), or a total of 144 MJ/t of steel. Typical losses by vaporization

are about 0.5% to 1.0%. In the case of 1.0% iron vaporizing in the EAF, the invested energy in the

steel is less (13 MJ) and the total energy loss is 77 MJ.

The direct energy lost by vaporization, 64 MJ, can actually cause a larger decrease in energy

for oxygen steelmaking. The energy loss will result in less scrap melting, which will cause a shift from

scrap to hot metal. Since hot metal requires considerably more energy than melting scrap, the resulting

increase in energy could be as high as 500 MJ.

Iron is also lost to the dust by simple metal ejection. In this case, only the energy invested is

lost. Again, the iron is oxidized in the off gas and little is recovered. For a 1.0% yield

Theoretical Minimum Energies to Produce Steel for Selected Conditions 13

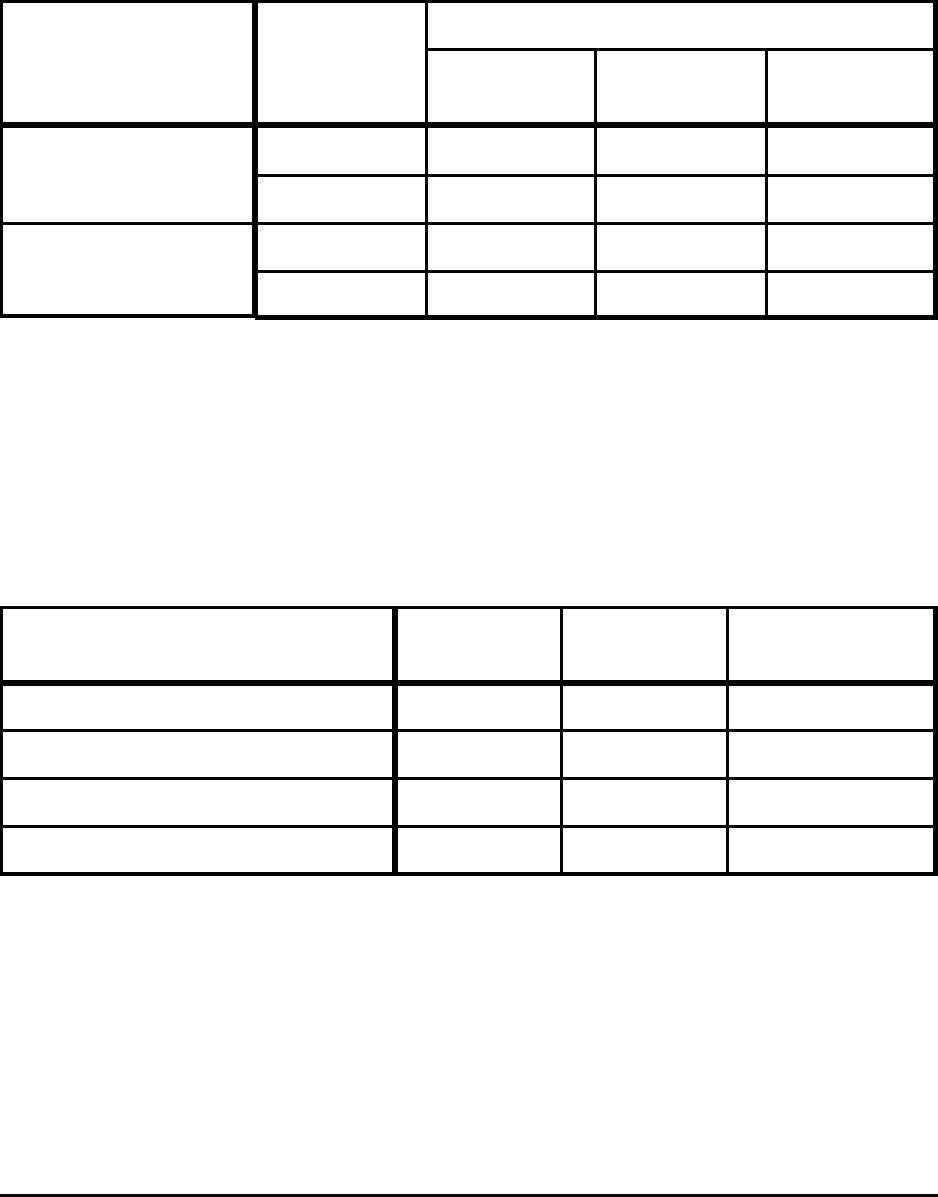

Table 8. Effect of Yield Loss on Minimum Theoretical Energies

to Produce Steel for 1% Yield Loss

Process Type of Loss Energy (MJ/t)

Hot metal loss in pretreatment

Hot metal loss to slag

but recovered 14

Hot metal loss in pretreatment

Hot metal loss to slag

not recovered 104

Direct Reduction Fines lost 60

Direct Reduction Fines recycled 6

BOF Fe vaporized to dust 144

EAF Fe vaporized to dust 102

BOF Fe ejected to dust 80

EAF Fe ejected to dust 16

Hot rolling Fe lost but recovered 13

Cold rolling Fe lost after reheating for 34

Notes: Losses to slag in BOF and EAF were accounted for in the process.

For rolling, if the metal is not recovered or oxidized, the energy invested in the steel is lost (about

80 MJ for BOF and 16 MJ for EAF).

The energy consumed by Fe vaporization reduces scrap melting, thus requiring more hot metal per

tonne of steel. This could represent 500 MJ due to the higher energy associated with hot metal.

loss by metal ejected, the energy loss is 80 MJ for OSM and 16 MJ for EAF steelmaking. The

vaporization or loss of other metals, such as zinc, are possible but not considered.

Direct Reduction

Some material is lost as fines during the production of DRI/HBI. This material is often

recovered and used to form briquettes or injected into an EAF, in which case there is no energy loss.

However, if the material is lost or more likely recycled back into the direct reduction furnace, some

energy is lost. Assuming the material does not reoxidize and is recycled into the process, the energy

loss is 6.2 MJ/t for 1% material recycle. If the material is reoxidized, the energy loss per 1% is 84

MJ/t.

14 Theoretical Minimum Energies to Produce Steel for Selected Conditions

Rolling

One of the largest cost and energy consumers in rolling is yield loss. The yield loss is usually

remelted, requiring about 13 MJ/t for a 1% loss of Fe. However, the yield loss often occurs later in the

process when additional energy has been invested into the steel. For example, if the slab is reheated

and hot rolled, the yield loss after cold rolling results in a 34 MJ/t loss. If the iron is oxidized or not

recovered, the invested energy in the steel is lost. A 1% yield loss applied to the most likely production

cases represents an additional loss of 80 MJ/t for BOF steel and 16 MJ/t for EAF steel.

9. OTHER MAJOR ENERGY-CONSUMING ACTIVITIES

Several significant sources of energy consumption were neglected in computing the theoretical

minimum energies to produce steel for selected conditions. In some cases, estimates of the energy for

these sources can be made while for others the conditions vary greatly and reasonable estimates are

difficult.

In theory, ore agglomeration and cokemaking are not necessary for integrated steel production

and were not considered. However, these processes are virtually always part of actual integrated

steelmaking. Ore agglomeration consists of taking ore fines or concentrate and sintering them into sinter

or pellets. Cokemaking is achieved by heating coal under pressure, driving off volatiles and increasing

the strength of the material. The theoretical minimum energies for these processes were determined by

calculating the energy to heat idealized coal and ore to 1100°C and 1350°C, respectively. In

cokemaking the heat of devolatilization is also required but is usually accounted for in computing the

energy value of coal. The coke output was taken as 0.768 per tonne of the coal input. The volatiles

represent the remainder, which is used as a fuel or for chemicals. The approximate minimum energies

for these processes, along with typical actual consumptions, are given in Table 9. The actual energies

are given as a range because the values vary according to the actual process and its efficiency.

During cokemaking the volatiles are either used for producing chemicals with energy values and

credits or as a fuel in the process itself. The process also produces a relatively rich off gas for which an

energy credit is taken. The total credits are about 4.0 to 5.0 GJ/t steel or 11.8 to 14.5 GJ/t coke. The

values given in Table 9 have taken into account all the energy credits.

The actual and theoretical minimum energy requirements for ore agglomeration are reasonably

close because of the simplicity of the process. For cokemaking the differences are greater because of

process complications and yield losses.

There are other energy-consuming process steps or materials used in steelmaking that were

beyond the scope of this study. Often the energy consumption is very site-specific; the energy is

consumed in another area or even country and depends on process details. These other steps include

• mining of ore, coal, and limestone (integrated production),

• scrap preparation (in scrap-based production),

• transportation of materials to and within the plant, and

• production of alloys, refractories, electrodes, special fluxes, and other materials

consumed in steelmaking.

Theoretical Minimum Energies to Produce Steel for Selected Conditions 15

Table 9. Theoretical Minimum and Typical Energy Consumption

in Cokemaking and Ore Agglomeration

Process

Theoretical Energy Actual Energy

GJ/t (output) GJ/t (steel) GJ/t(output) GJ/t (steel)

Cokemaking 2.0 0.8 5.4 - 6.2 2.2 - 2.6

Ore Agglomeration 1.2 1.6 1.5 - 1.7 2.1 - 2.4

Note: For cokemaking, full credit is taken for off gas and by-product energy, approximately 4-6 GJ.

10. TOTAL THEORETICAL MINIMUM ENERGY TO PRODUCE STEEL

It is difficult to adequately describe the total energy to produce final steel products because it

depends on the process used (EAF or integrated), the raw or charge materials, and the conditions of

rolling. Furthermore, the total does not give any insight as to where and how energy can be conserved.

However, it is somewhat useful to compare process routes and theoretical to actual energy

consumption requirements.

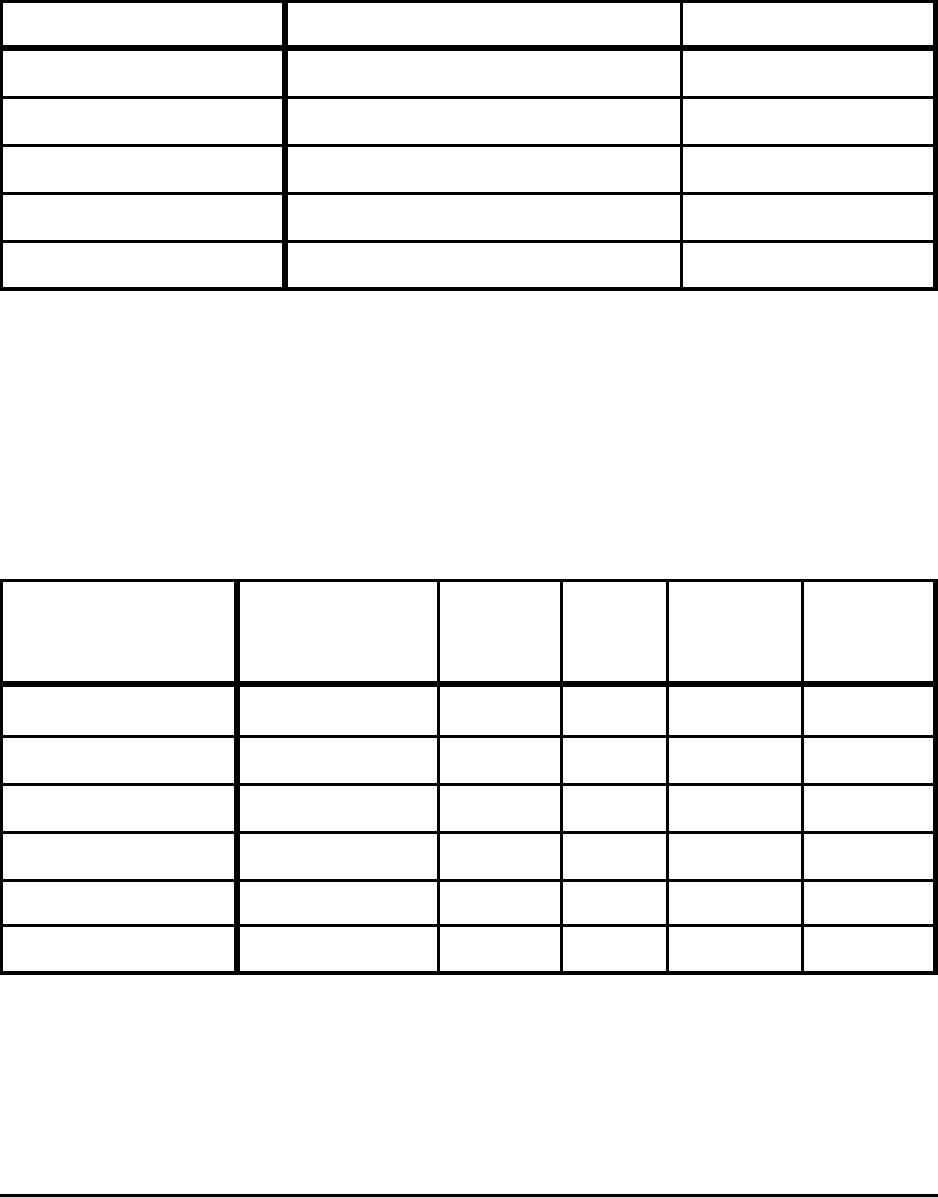

Table 10 summarizes the total energy requirements for producing selected steel products for

selected conditions. The most realistic minimum values are about 8,150 MJ/tonne for integrated

production and 1,600 MJ/tonne for scrap-based production. Yield losses and other additional losses

are not considered.

11. SPECIAL CONSIDERATIONS

This section discusses information regarding theoretical minimum energies that is beyond the

primary scope of this report. Whereas the process primarily uses lime (CaO), the raw material is

limestone (CaCO

3

). The conversion of limestone to lime requires energy and produces CO

2

. The

impact of SiO

2

on gangue materials in the ore and coke on energy is followed through the process.

The impact of post combustion and carbon in the BOF and EAF are also considered.

Energy and CO

2

in Producing CaO

The major flux used in iron and steelmaking is CaO. CaO is obtained from limestone (CaCO

3

)

by heating it and driving off the CO

2

according to the following reaction:

CaCO

3

= CaO + CO

2

The reaction will only occur when the equilibrium pressure reaches one atmosphere. Therefore, the

reactants must be heated to 1155 K and the energy of the reaction supplied.

16 Theoretical Minimum Energies to Produce Steel for Selected Conditions

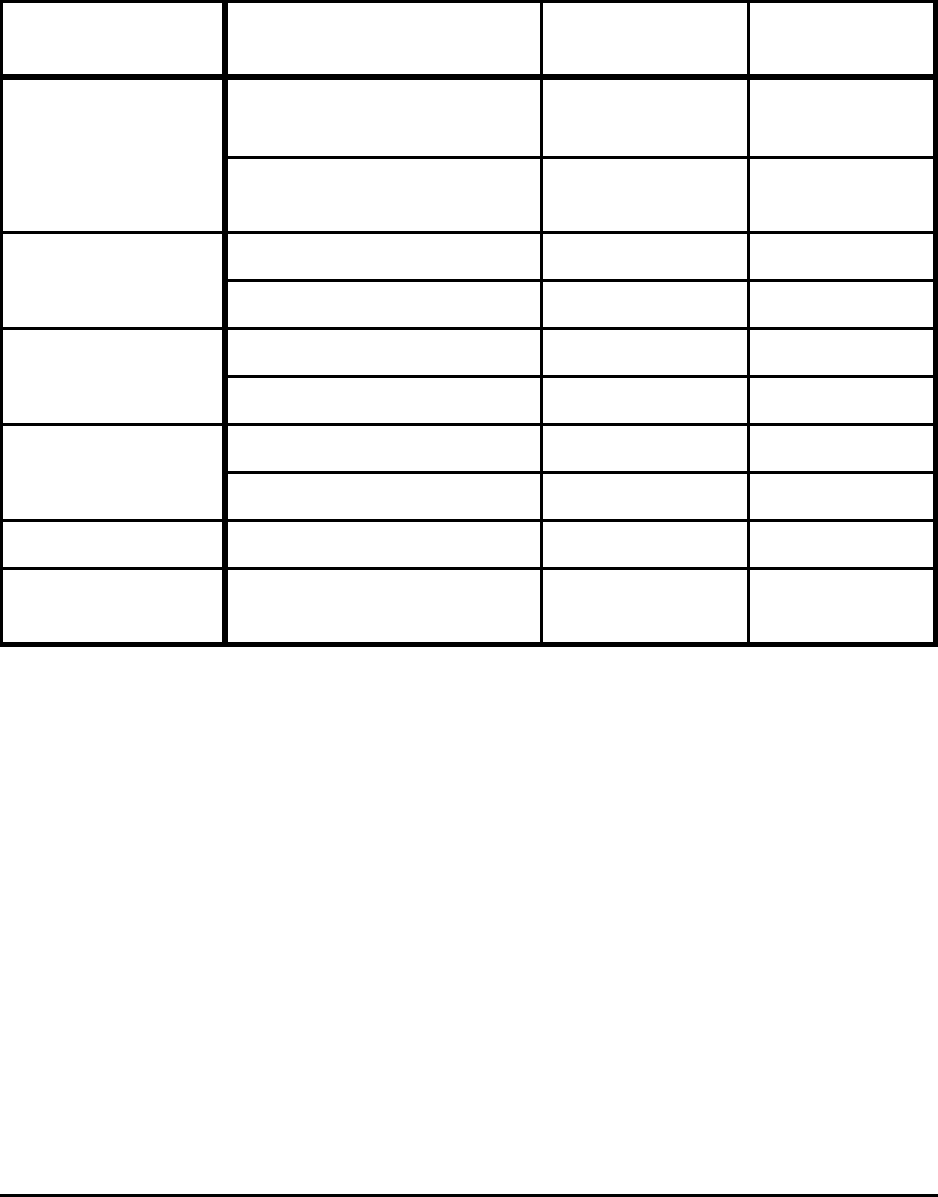

Table 10. Total Theoretical Minimum Energies to Produce

Selected Products for Selected Conditions

Process Product Rolling Energy (MJ/t)

BF-BOF

(Conventional Slab)

Hot Rolled Sheet Direct

Reheat

7,878

8,703

BF-BOF

(Conventional Slab)

Cold Rolled Sheet Direct

Reheat

7,895

8,720

EAF (Scrap)

(Thin Slab)

Hot Rolled Sheet Direct

Reheat

1,341

2,166

EAF Scrap

(Thin Slab)

Cold Rolled Sheet Direct

Reheat

1,358

2,183

EAF (50% DRI)

(Thin Slab)

Cold Rolled Sheet Direct

Reheat

6,081

6,906

EAF (Scrap)

(Billet)

Bar Direct

Reheat

1,345

2,170

EAF (50% DRI)

Billet

Bar Direct

Reheat

6,068

6,893

EAF-AOD

Slab

Cold Rolled

18-8 Stainless

Direct

Reheat

1,397

2,223

EAF-AOD-(HCFeCr)

Slab

Cold Rolled

18-8 Stainless

Direct

Reheat

4,323

5,148

Notes: Does not include ore preparation, cokemaking, or yield losses.

Stainless for melting only and for production of required HCFeCr.

Liquid steel energy:

BF-BOF 7853 MJ/t

EAF-scrap 1355 MJ/t

EAF-DRI 6048 MJ/t

EAF-AOD 1275 MJ/t

EAF-AOD-HCFeCr 4200 MJ/t

Theoretical Minimum Energies to Produce Steel for Selected Conditions 17

To produce one tonne of CaO from CaCO

3

requires a theoretical minimum energy of 4,670

MJ. The product is CaO and CO

2

at 1155 K. It is theoretically possible but highly impractical to

utilize the heat contained in the CaO (1,471 MJ). In addition to the energy required, 0.79 tonnes of

CO

2

is released per tonne of CaO.

Effect of SiO

2

Silica enters the steelmaking process primarily as gangue in the ore or coke ash. Silicon is also

present in scrap. The silica requires energy in ironmaking and steelmaking because it must be heated

and melted along with the appropriate amount of lime. The energy in ironmaking increases by about

110 MJ for 1% extra silica in the gangue or ash. However, this SiO

2

requires CaO. Whereas the

heating and melting is included in the 110 MJ, the production of the CaO is not for a slag basicity of1.2,

which requires 12 kg CaO per 1% SiO

2

. This requires an additional 5.5 MJ, and 0.008 tonnes of CO

2

is released from the limestone.

Energy Credits in Off Gases

Full energy credit was taken for the off gas for the processes of blast furnace ironmaking,

cokemaking, and direct reduction. These credits are a large percentage of the total energy. This

energy must be efficiently utilized for the processes to be energy-efficient. The off gases can be used in

the process itself such as in blast furnace air preheating stoves, in reheating furnaces, or producing

steam for electricity. For integrated steel production, including cokemaking, the total energy in off

gases can be as high as 6-10 GJ per tonne of steel. Therefore, the efficient use of this energy is critical.

Carbon in Steelmaking

Carbon is usually used as a fuel in the EAF and is sometimes used to melt more scrap in a

BOF. The carbon used in an EAF usually contains ash, which reduces its energy value by 5% to15%,

depending on the amount. For these theoretical calculations the material is assumed to be pure carbon.

The reaction product in the presence of carbon or iron is primarily CO. If the carbon is only oxidized

to CO, it is much less efficient than using the same carbon to produce electrical energy. For the carbon

to be as effective as electricity generation and transmission with an efficiency of 36% (which

corresponds to 10 MJ/kWh), it must be post combusted (PC) to 37.6% with 100% of the energy

going to the steel. The equation below represents the post-combustion percentage:

CO

PC

=

2

(100)

CO

+

CO

2

These conditions are difficult to achieve in practice, and in the actual case the required PC

would be higher because of the ash in the carbon. Therefore, using carbon does not reduce energy use

in the EAF, even if the inefficiency of electric power production is considered. However, carbon

oxidation does improve productivity and refining of the steel, which is its primary purpose.

18 Theoretical Minimum Energies to Produce Steel for Selected Conditions

Post Combustion

In steelmaking processes, the equilibrium product for the oxidation of carbon is primarily CO,

with less than 10% CO

2

. It has been recognized for decades that significant quantities of energy are

available if the CO can be combusted to CO

2

in such a way that the CO

2

does not react with iron or

carbon, and the energy can be transferred to the system.

The post combustion reaction is

CO + 1/2 O

2

= CO

2

After accounting for the heating of the oxygen, the heat released at 1873 K is 255 KJ per mole

of CO. For example, if 10% of the CO can be post combusted in OSM with 100% heat- transfer

efficiency, the energy released is 106 MJ per tonne of hot metal. This energy can melt 80 kg of scrap

per tonne of metal, which can significantly reduce the energy to produce steel because of the shift from

ore to scrap. For OSM with a slag basicity of 3 and 30% FeO and a tap temperature of 1873 K, the

energy per tonne of steel is reduced from 7,853 MJ to 7,401 MJ. The major reason for the energy

savings is the use of more scrap.

In the EAF, large amounts of charge carbon are initially oxidized to CO. About 16 MJ/t of

energy is released for 10 kg carbon for each 10% post combustion to CO

2

with 100% heat transfer.

12. COMPARISON OF TYPICAL ACTUAL AND

THEORETICAL MINIMUM ENERGY

Table 11 shows the theoretical minimum energy for the most realistic case and the typical range

of actual energy consumption for selected processes. The low value for the actual consumptions

represents the lowest values for any country as reported by the International Iron and Steel Institute

(IISI), not necessarily best practice.

(9)

For BOF steelmaking, the energies represent the energy of the

hot metal; the steelmaking process itself does not consume significant energy. For hot rolling, the

energy values represent a mixture of direct charging and reheating of conventional slabs. Most likely

the majority of the slabs are reheated and the theoretical values include reheating.

The results indicate that for ironmaking the absolute maximum energy savings available are

about 20% to 25%. Similarly for EAF steelmaking, the absolute maximum savings are about 23% to

33%.

The potential energy savings for rolling are lower simply because the processes use less energy.

Although it is not clear from Table 11, the potential for the greatest energy savings in finishing lies in

direct charging of slabs and billets. This would require major equipment changes and improved clean

steel practices in order to avoid inspection and grinding of slabs and billets.

Table 8 showed the total energy in cokemaking and ore agglomeration to be about 5 GJ/t

(steel). If an ironmaking process can be developed that uses coal and ore fines or concentrates, this

energy could be eliminated.

Theoretical Minimum Energies to Produce Steel for Selected Conditions 19

--

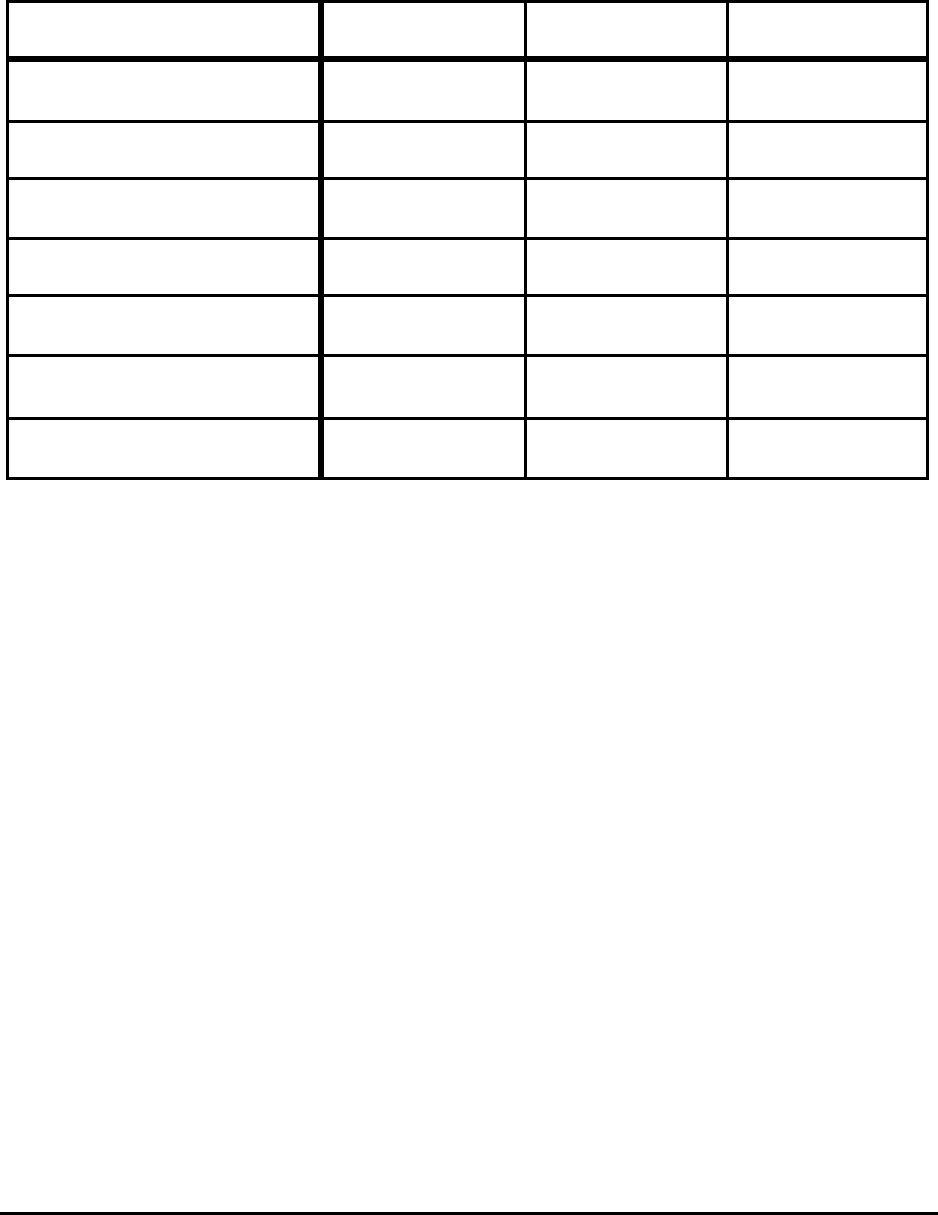

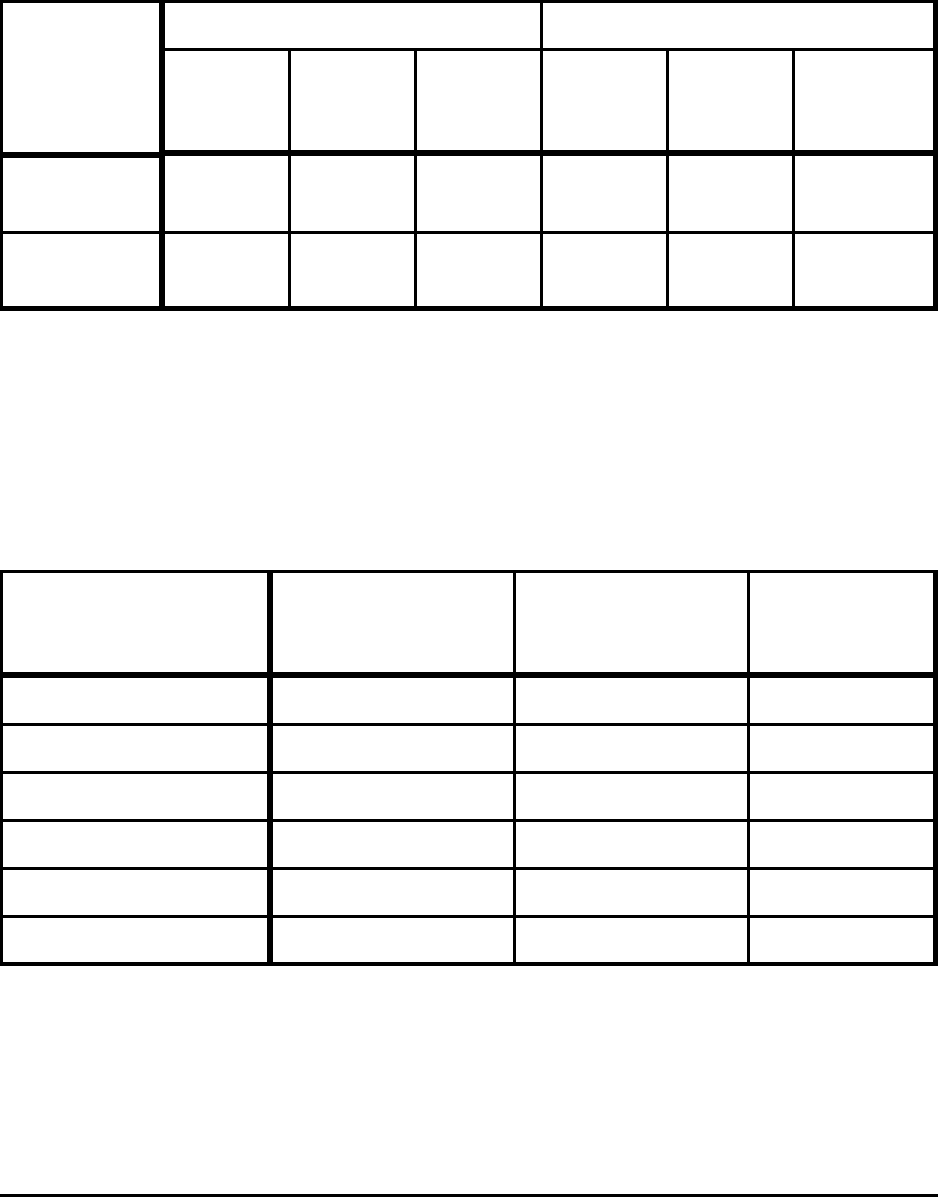

Table 11. Practical Theoretical Minimum and Energy for Selected Processes

Process

Energy (GJ/t product)

Absolute

Minimum

Practical

Minimum

Reported

Consumption

Liquid Hot Metal (5%C) 9.8 10.4 13 - 14

Liquid Steel (BOF) 7.9 8.2 10.5 - 11.5

Liquid Steel (EAF) 1.3 1.6 2.1 - 2.4

Hot Rolling Flat 0.03 0.9 2.0 - 2.4

Cold Rolling Flat 0.02 0.02 1.0 - 1.4

18-8 Stainless Melting 1.2 1.5

Notes:

Actual includes yield losses and is the average of state-of-art and less-efficient operations for the United

States, Japan, and Europe.

BOF energy is primarily from hot metal; actual process consumes 0.2 to 0.4 GJ/t and, if CO is oxidized to

CO

2

, could theoretically produce 0.5 GJ.

For 18-8 stainless no estimates are available, in particular for HCFeCr

In all cases, full credit is taken for the energy in off gas.

13. SUMMARY AND CONCLUSIONS

The theoretical minimum energies to produce several steel products for ore- and scrap-based

processes were computed. In general, only the energy for the process itself was considered and not

the energy used to produce input materials or electricity. The cases included ironmaking, direct

reduction, oxygen steelmaking, scrap and scrap substitute, EAF steelmaking, production of 18-8 type

stainless, and rolling of cast material to final shape. In addition, the effects of yield loss, gangue, and use

of carbon post combustion (as well as other special cases) on energy consumption were estimated.

Table 12 presents a comparison of the theoretical minimums to actual typical energy consumption

values. Some additional findings are shown in the summary box.

Increasing scrap melting has the largest impact on energy consumption. However, scrap should be

viewed as having "invested" energy since at one time it was produced by reducing ore. Therefore, it

should be used wisely. For example, oxidizing it to the slag may reduce energy in the process but the

"invested" energy is lost. Also, increasing scrap melting in the BOF may or may not decrease energy if

the "invested" energy in scrap is considered. Scrap supplies are not unlimited, and new iron from ore

will always be required.

20 Theoretical Minimum Energies to Produce Steel for Selected Conditions

-- -- --

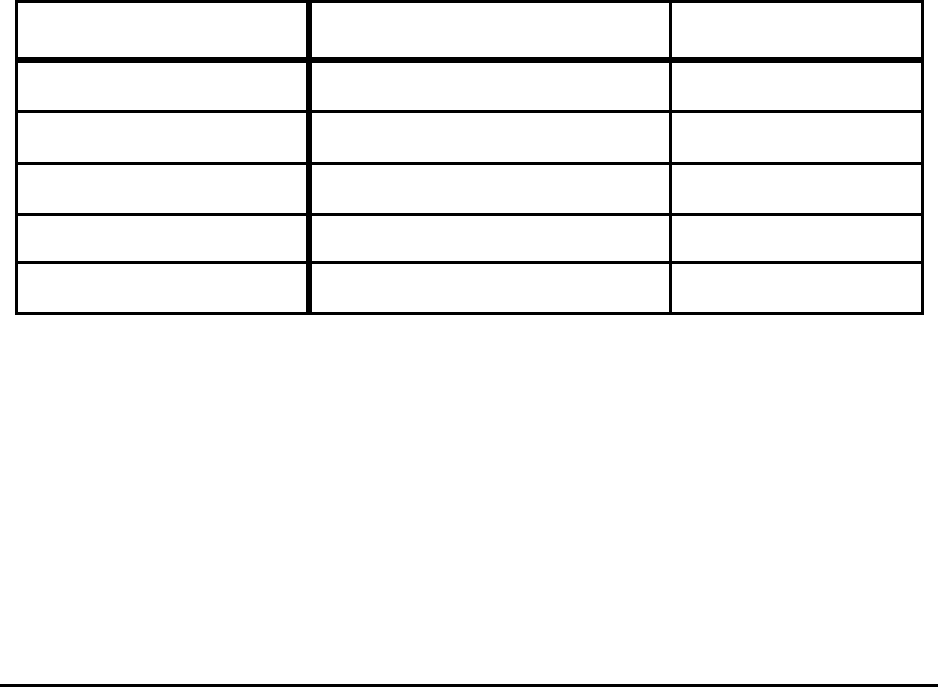

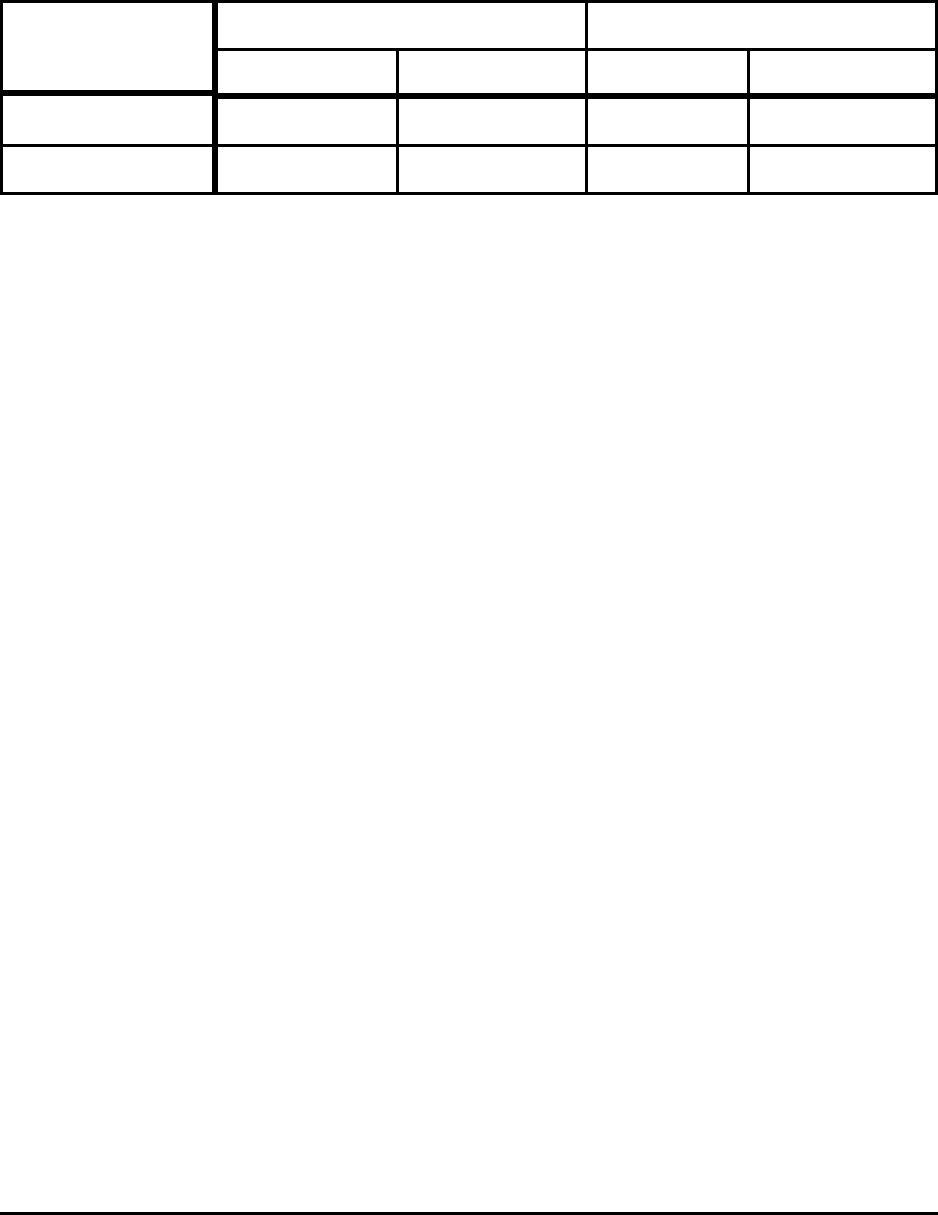

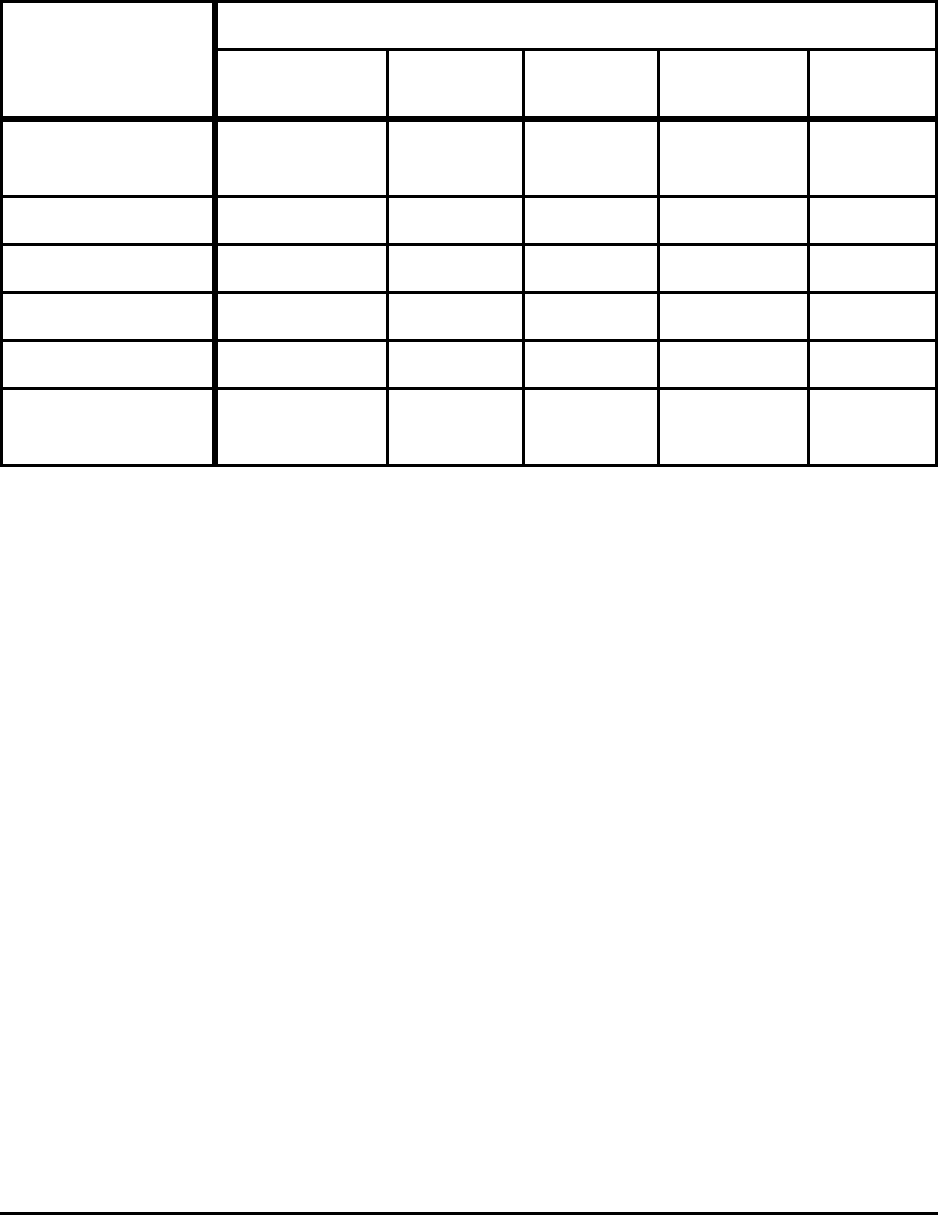

Table 12. Comparison of Theoretical Minimum Energy

and Actual Energy Requirements for Selected Processes

Process

Energy (GJ/t product)

Actual Energy

Requirements

Absolute

Minimum

%

Difference

Practical

Minimum

%

Difference

Liquid Hot Metal

(5%C)

13 - 14 9.8 25 - 30 10.4 20 - 26

Liquid Steel (BOF) 10.5 - 11.5 7.9 25 - 31 8.2 22 - 29

Liquid Steel (EAF) 2.1 - 2.4 1.3 38 - 46 1.6 24 - 33

Hot Rolling Flat 2.0 - 2.4 0.03 99 0.9 55 - 63

Cold Rolling Flat 1.0 - 1.4 0.02 98 - 99 0.02 98 - 99

18-8 Stainless

Melting

1.2 1.5

Notes: Actual includes yield losses and is the average of state-of-art and less-efficient operations for the United

States, Japan, and Europe.

BOF energy is primarily from hot metal; actual process consumes 0.2 to 0.4 GJ/t and, if CO is oxidized to

CO

2

, could theoretically produce 0.5 GJ.

For 18-8 stainless no estimates are available, in particular for HCFeCr.

In all cases, full credit is taken for the energy in off gas.

Other conclusions that can be drawn from the findings are as follows:

• Elimination of ore agglomeration and cokemaking, which are not theoretically necessary to produce

steel, would yield significant energy savings.

•

Effective utilization of the energy contained in the off gases from the blast furnace, coke plant, and

direction reduction process is essential.

• The best scrap substitute with respect to energy usage is liquid pig iron or hot metal.

Theoretical Minimum Energies to Produce Steel for Selected Conditions 21

Additional Findings

Effect of Gangue and Ash

•

Gangue and ash in ore and coal increase minimum energies by 0.6 GJ (about 6%) for ironmaking.

Direct Reduction

•

Energy requirements for direct reduction per tonne of iron are similar to those for the blast furnace.

Scrap in the BOF

•

In BOF (OSM) steelmaking, the energy to produce steel is less than the energy to produce iron

because scrap is melted in the process.

•

Due to the "invested" energy in scrap any process that increases scrap melting lowers the total energy

because of the substitution of scrap for ore.

Variables in the EAF

•

Dirt in scrap and air entrainment in an EAF increase the energy required by 0.3 GJ/t (about 25% of the

total energy).

• Total energy increases dramatically when using scrap substitute such as DRI or pig iron with scrap in

an EAF. The best scrap substitute with respect to energy usage is liquid pig iron or hot metal.

Stainless Steel

• The melting energy for stainless steel is similar to the melting energy for carbon steel. However, the

energy is much greater if the energy associated with ferrochrome is included.

Direct Charging

• Direct charging of slabs or billets reduces total rolling energy by about 80%.

Ore Agglomeration and Cokemaking

• Ore agglomeration and cokemaking, which are not theoretically necessary to produce steel, have

significant theoretical minimum energies (1.6 and 0.8 GJ/t steel, respectively) and actual energies (2.2

and 2.4 GJ/t, respectively).

Limestone Calcination

• Calcination of limestone requires 4.7 GJ/t CaO and releases 0.79 tonnes of CO

2

.

Post Combustion

•

Post combustion can significantly increase scrap melting in the BOF and decrease energy required in

the EAF.

Carbon in the EAF

•

When carbon is used in the EAF, about 38% of the CO must be post combusted to CO

2

to equal

electrical energy, even taking into account the production and transmission losses associated with

electrical energy.

Off-Gas Energies

•

Off-gas energies from the blast furnace, coke plant, and direct reduction were significant and were

credited to the processes. For example, the total energy credit for coke and ironmaking is 6-10 GJ.

22 Theoretical Minimum Energies to Produce Steel for Selected Conditions

REFERENCES

1. V. F. Campos and R. M. Figueira, Dados Termodinamicos para Metalurgistas, EEUFMG, Belo

Horizonte, Minas Gerais, Brazil, p. 392, 1977.

2. O. Kubaschewski, E. Evans and C. B. Alcock, Metallurgical Thermochemistry, Pergamon Press,

New York, NY 1967.

3. S. Ban-ya, M. Hino, “Chemical Properties of Molten Slags,” ISIJ, p. 278, 1991.

4. E. T. Turkdogan, “Physicochemical Properties of Molten Slags and Glasses,” The Metals Society, 1

Carlton House Terrace, London, p. 516, 1983.

5. M. W. Chase, Jr. et al. Ed: JANAF Thermochemical Tables, 3rd Ed., American Chemical Society,

1985.

6. J. F. Elliott, M. Gleiser and V. Ramakreshna: Thermochemistry for Steelmaking, Addison-Wesley

Publishing, Reading, MA.

7. “New and Emerging Sources of Iron,” R.J. Fruehan, Prepared for the American Iron and Steel

Institute, 19xx?

8. The Making, Shaping and Treating of Steel, 10th Edition, AISE, Pittsburgh, PA, 1985.

9. “Energy Use in the Steel Industry, International Iron and Steel Institute, September 1998.

Theoretical Minimum Energies to Produce Steel for Selected Conditions 23

24 Theoretical Minimum Energies to Produce Steel for Selected Conditions

APPENDIX A

THEORETICAL CO

2

EMISSIONS

FROM STEELMAKING PROCESSES

Theoretical Minimum Energies to Produce Steel for Selected Conditions 25

In this section, the CO

2

emissions associated with the energies required to produce steel are calculated.

The following tables present theoretical CO

2

emissions from various steelmaking processes for a

number of conditions. These conditions are based on those used in the preceding analysis of theoretical

energy consumption for steel production.

Emission factors were calculated by considering the heats of reaction for the following reactions:

C + ½ O

2

� CO

2

- “H

rxn

= 395.3 kJ/mol (1)

H

2

+ ½ O

2

� H

2

O - “H

rxn

= 247.3 kJ/mol

(2)

C + 2H

2

� CH

4

- “H

rxn

= 91.0 kJ/mol (3)

CH

4

+ 2O

2

� CO

2

+ H

2

O - “H

rxn

= 798.9 kJ/mol

(4)

These reactions represent the basic reactions that occur when fuel (carbon or methane) is combusted.

By using these heats of reaction and the energy requirements for each process (shown in the report),

the necessary amount of moles of fuel can be calculated. Once the amount of fuel is known,

stoichiometry dictates the amount of CO

2

generated by the combustion of that fuel. Because the

production of electricity is not a matter of simple chemical reaction, the emission factor for electricity

(U.S. grid) accepted by the American Iron and Steel Institute (AISI) was used in this analysis (AISI

1996). Table A-1 shows the emission factors used in this analysis according to the assumptions noted

and compares them to the AISI emission factors for each fuel source considered. Some assumptions

have been made to simplify calculations and are noted below:

• The energy for ironmaking is assumed to come from 100% carbon and converted entirely to

CO

2

when consumed.

•

Natural gas is assumed to be 100% methane and converted entirely to CO

2

and H

2

O when

consumed.

• Electricity emissions include efficiency and transmission losses.

• Emissions for BOF steelmaking are a result of 50 kg C/tonne HM that remains in the liquid pig

iron and is used as fuel during oxygen steelmaking. This carbon is not combusted to CO

2

during the ironmaking step and thus is not included in the emissions for ironmaking. Since

oxygen steelmaking generates rather than consumes energy, this process has no additional

combustion emissions beyond the 50 kg C/tonne HM remaining in the liquid pig iron.

The minimum theoretical energy consumption data presented in the body of this report are not estimates

but rather actual physical quantities. When those energy data are converted to CO

2

emissions, a

number of assumptions and approximations are necessary. Particularly, while the energy data are

simply energy (no fuel type is specified), fuel types must be specified when calculating carbon

emissions. Additionally, carbon emission factors have been estimated based on the composition of

common fuel sources. The distinction between the theoretical minimum energy consumption as a

physical quantity and the minimum CO

2

as an estimate must be made clear.

26 Theoretical Minimum Energies to Produce Steel for Selected Conditions

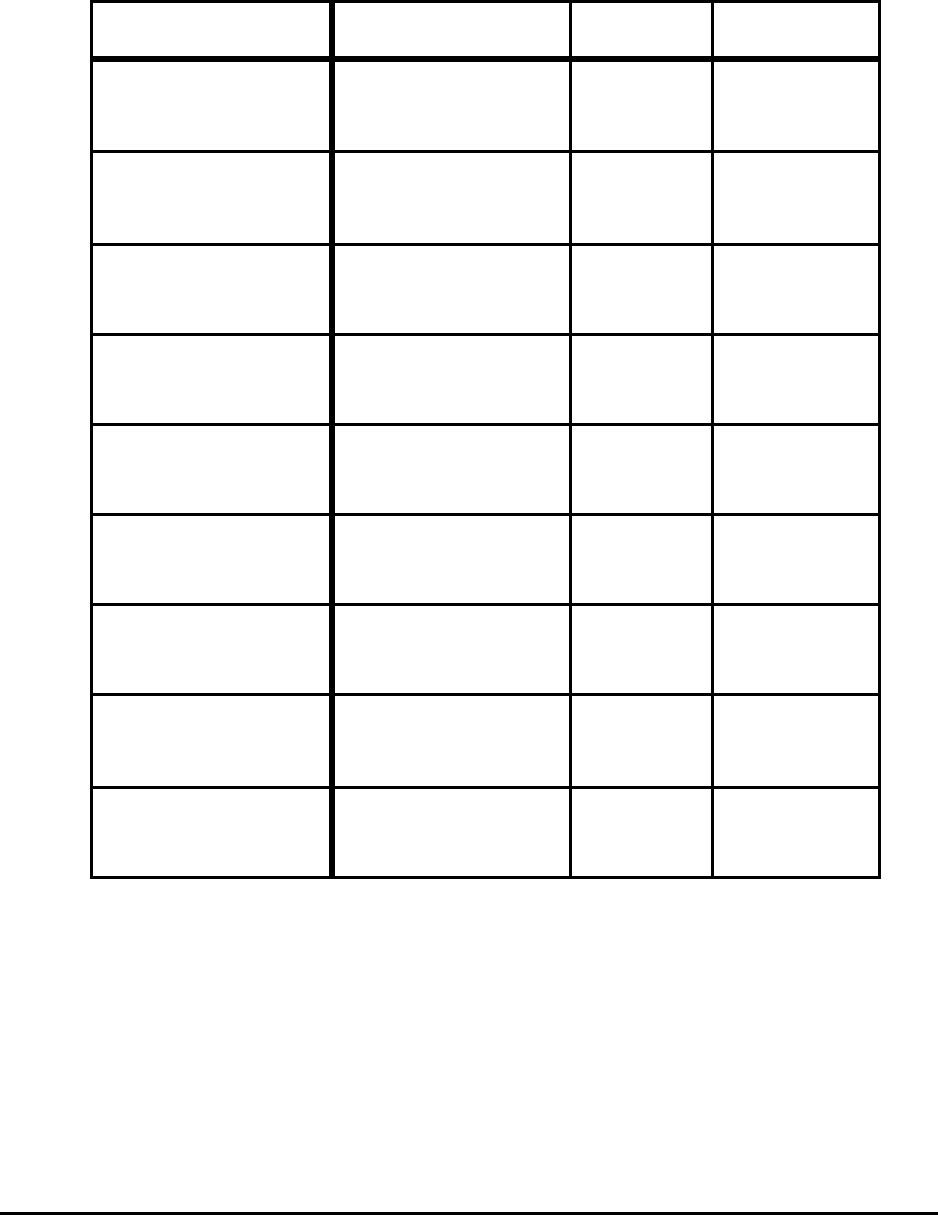

Table A-1. Emission Factors Used to Convert Theoretical Energy Consumption

to CO

2

Emissions

Fuel Source

Theoretical Emission Factor

(kg CO

2

/MJ)

AISI Emission Factor

(kg CO

2

/MJ)

Difference

(percent)

Coke 0.111 0.109 1.8

Natural Gas 0.055 0.050 9.1

Hydrogen 0 0 0.0

Electricity N/A 0.173 N/A

Coke Oven Gas 0.055 0.046 16.4

Source: Survey of Consumption of Energy in the U.S. Iron and Steel Industry, American Iron and Steel Institute,

1996.

Notes:

Coke is assumed to be 100% carbon combusted to 100% CO

2

.

Natural gas is assumed to be 100% methane and combusted to 100% CO

2

and H

2

O.

Electricity emission factor accounts for transmission and efficiency losses at the power plant (based on IISI

value for the U.S. grid).

Hydrogen used as fuel does not result in any CO

2

emissions.

Coke oven gas used as fuel is considered as natural gas when considering CO

2

emissions.

The remainder of this appendix consists of the following tables:

Table A-2. Absolute Theoretical Minimum CO

2

Emissions for Producing Steel from Pure Ore

(Fe

2

O

3

) and Pure Scrap (Fe)

Table A-3.

Minimum CO

2

Emissions to Produce Liquid Hot Metal at 1723 K for Selected

Conditions

Table A-4. Minimum CO

2

Emissions to Produce Direct Reduced Iron at 1173 K Reduction

Temperature for Selected Conditions

Table A-5.

Minimum CO

2

Emissions to Produce Steel from Hot Metal and Scrap for Selected

Conditions

Table A-6. Minimum CO

2

Emissions to Produce Steel from Scrap for Selected Conditions, Tap

Temperature = 1873 K

Table A-7.

Minimum CO

2

Emissions to Produce Liquid Steel at 1873 K from 50% Scrap and

50% Scrap Substitute

Table A-8. Minimum CO

2

Emissions to Roll Steel for Selected Products and Conditions

Table A-9. Effect of Yield Loss on Minimum CO

2

Emissions to Produce Steel for 1% Loss

Table A-10.

Minimum and Typical CO

2

Emissions in Cokemaking and Ore Agglomeration

Table A-11.

Practical Minimum CO

2

Emissions for Selected Processes

Theoretical Minimum Energies to Produce Steel for Selected Conditions 27

Table A-2. Absolute Theoretical Minimum CO

2

Emissions

for Producing Steel from Pure Ore (Fe

2

O

3

) and Pure Scrap (Fe)

Raw Material

Temperature

(degrees K)

Carbon Emissions (kg CO

2

/tonne)

Fuel = Carbon

Fuel = Natural

Gas

Fuel =

Electricity

Ore (Fe

2

O

3

)

1813 960 475 1,494

1873 966 478 1,503

Scrap (Fe)

1813 142 70 221

1873 148 73 230

Notes: Based on theoretical minimum energy consumption shown in Table 1.

Absolute theoretical minimum energy consumption is independent of fuel type and not based on any actual

production process. Therefore, the three main sources of fuel have been used to calculate theoretical

carbon emissions for each.

Table A-3. Minimum CO

2

Emissions to Produce Liquid Hot Metal

at 1723 K for Selected Conditions

Material Consumption Gangue Ash

CO

2

(kg/

tonne HM)

Fe - 5% C No No 908

Fe - 5% C Yes No 954

Fe - 5% C - 0.5% Si - 0.5% Mn Yes No 960

Fe - 5% C - 0.5% Si - 0.5% Mn0 Yes Yes 977

Notes: Based on theoretical minimum energy consumption shown in Table 2.

Gangue contains 4% SiO

2

, 1% Al

2

O

3

, and 1% MnO. Ash content is 25 kg/tonne hm (5% of coal and coke

used).

Fuel used in ironmaking is assumed to be 100% coke.

Carbon that remains in the hot metal (5% C, or 50 kg C/tonne HM) is subtracted from the overall carbon

emissions for liquid hot metal production shown in this table. Those carbon emissions are attributed to the

process in which that carbon is used as fuel (i.e., raw steel production from hot metal, see Table A-5).

28 Theoretical Minimum Energies to Produce Steel for Selected Conditions

Table A-4. Minimum CO

2

Emissions to Produce Direct Reduced Iron

at 1173 K Reduction Temperature for Selected Conditions

Ore Product CO

2

(kg/tonne)

Pure Fe

2

O3 Fe 461

Fe

2

O

3

- 1.4% SiO

2

Fe - 2% SiO

2

462

Fe

2

O

3

- 1.4% SiO

2

Fe - 2% SiO

2

- 8% FeO 435

Fe

2

O

3

- 1.5% SiO

2

Fe - 2% SiO

2

- 8% FeO - 2% C 391

Fe

2

O

3

- 1.5% SiO

2

Fe - 2% SiO

2

- 7.7% FeO - 6% C 300

Notes:

Based on theoretical minimum energy consumption shown in Table 3.

The energy used to produce direct reduced iron is assumed to be 100% natural gas.

When carbon remains in the final product (the final two rows in the table above), that carbon is subtracted

from the overall CO

2

emissions of the process. The subtracted CO

2

is attributed to the process in which the

carbon is used as fuel (i.e., liquid steel production from scrap and scrap substitute, Table A-7).

Table A-5. Minimum CO

2

Emissions to Produce Steel

from Hot Metal and Scrap for Selected Conditions

Hot Metal Slag

Tap

Temp.

(K)

Scrap

(kg)

Steel

(kg/tonne

HM)

CO

2

(kg/tonne)

Fe - 5% C – 1873 290 1,240 148

Fe - 5% C – 1923 244 1,194 135

Fe - 5% C - 0.5% Si B = 3; 30% FeO 1873 401 1,328 138

Fe - 5% C - 0.5% Si B = 3; 30% FeO 1923 353 1,278 143

Fe - 5% C - 0.5% Si B = 3; 20% FeO 1873 389 1,320 139

Fe - 5% C - 0.5% Si B = 3; 20% FeO 1923 341 1,270 144

Notes: Based on theoretical energy consumption shown in Table 4.

Oxygen steelmaking is theoretically an energy-producing process due to the exothermic nature of the

reactions taking place. Therefore, fuel consumption is theoretically not needed, and carbon emissions do

not result from the combustion of fuels.

The CO

2

emissions shown are the result of the 5% carbon (50 kg/tonne HM) in the hot metal feed that is

consumed during steelmaking. The carbon is actually used as a fuel source for melting scrap and is

converted to CO

2

in this process.

Theoretical Minimum Energies to Produce Steel for Selected Conditions 29

Table A-6. Minimum CO

2

Emissions to Produce Steel from

Scrap for Selected Conditions, Tap Temperature = 1873 K

Scrap Slag CO

2

(kg/tonne steel)

Fe – 230

Fe - 0.1%C - 0.2% Si B=2.5; 25% FeO 223

Fe - 0.1%C - 0.2% Si -1% dirt B=2.5; 25% FeO 234

Fe - 0.1%C - 0.2% Si -1% dirt B=2.5; 35% FeO 230

Fe - 0.1%C - 0.2% Si -1% dirt -100 Nm

3

air B=2.5; 25% FeO 275

Notes:

Based on theoretical energy consumption shown in Table 5.

Energy is assumed to be 100% electricity, using a conversion factor of 10,500 Btu/kWh to include

transmission and efficiency losses.

Table A-7. Minimum CO

2

Emissions to Produce Liquid Steel

at 1873 K from 50% Scrap and 50% Scrap Substitute

Input

Melting Energy

(MJ/tonne steel)

Charge Energy

(MJ/tonne steel)

CO

2

(kg/tonne

steel)

None (100% Scrap Case) 1,289 – 234

Fe - 2% SiO

2

1,403 4,296 480

Fe - 2% SiO

2

- 8% FeO 1,559 4,233 503

Fe - 2% SiO

2

- 8% FeO - 2% C 1,483 4,565 548

Fe - 2% SiO

2

- 8% FeO - 6% C 1,328 5,223 640

Liquid Pig Iron 487 5,388 779

Solid Pig Iron 1,145 5,388 893

Notes:

Based on theoretical energy consumption shown in Table 6.

Liquid pig iron is charged at 1723 K, all others at 298 K; melting energy is assumed to be 100% electricity.

Charge energy is assumed to be 100% natural gas for DRI and 100% coke for pig iron.

In addition to the CO

2

emissions generated from fuel consumption, the carbon contained in the input

materials is converted to CO

2

in this process (10.8 kg C/tonne, 2%C DRI; 33.2 kg C/tonne, 6%C DRI; 25.8 kg

C/tonne pig iron).

30 Theoretical Minimum Energies to Produce Steel for Selected Conditions

Table A-8. Minimum CO

2

Emissions to Roll Steel for Selected Products and Conditions

Rolling

Temperature

(K)

Slab

Temperature

(K)

Reduction

(mm)

Energy (MJ/tonne)

CO

2

(kg/tonne)Heat

Deforma-

tion

Flat Carbon (25.4 cm slab)

1473 298 254 - 2 825 25 50

1473 1173 254 - 2 270 25 19

1473 1473 254 - 2 – 25 4

298 298 2 - 1 – 17 3

Flat Carbon (5.0 cm slab)

1473 298 50 - 2 825 16 48

1473 1173 50 - 2 270 16 18

1473 1473 50 - 2 – 16 3

298 298 2 - 1 – 17 3

Flat 18-8 Stainless (25.4 cm slab)

1473 298 254 - 2 825 72 58

1473 1173 254 - 2 270 72 27

1473 1473 254 - 2 – 72 12

298 298 2 - 1 – 51 9

Bar Carbon (10 cm billet to 2 cm bar)

1473 298 10 sq - 2 sq 825 20 49

1473 1473 10 sq - 2 sq – 20 4

1473 1173 10 sq - 2 sq 270 20 18

1473 1473 10 sq - 2 sq – 11 2

Notes: Based on theoretical energy consumption shown in Table 7.

Heating energy is assumed to be 100% natural gas.

Deformation energy is assumed to be 100% electricity.

Theoretical Minimum Energies to Produce Steel for Selected Conditions 31

Table A-9. Effect of Yield Loss on Minimum CO

2