2023

LED LIGHTING AND

CONTROLS GUIDANCE

Green Proving Ground

FOR FEDERAL BUILDINGS

LED Lighting and Controls Guidance for Federal Buildings

2

Disclaimer

This document was prepared as an account of work

sponsored by the United States Government. While this

document is believed to contain correct information,

neither the United States Government nor any agency

thereof, Pacific Northwest National Laboratory (PNNL),

nor any of their employees, makes any warranty,

express or implied, or assumes any legal responsibility

for the accuracy, completeness, or usefulness of any

information, apparatus, product, or process disclosed,

or represents that its use would not infringe privately

owned rights. Reference herein to any specific

commercial product, process, or service by its trade

name, trademark, manufacturer, or otherwise, does not

constitute or imply its endorsement, recommendation,

or favoring by the United States Government or any

agency thereof, or PNNL. The views and opinions of the

authors expressed herein do not necessarily state or

reflect those of the United States Government or any

agency thereof or PNNL.

Acknowledgments

Pacific Northwest National Laboratory: Michael Myer,

Linda Sandahl, Jessica Collier, Isaiah Steinke

GSA Green Proving Ground: Kevin Powell, Tyler Harris

GSA: Corey Blatt, Michael Bloom, Je Domber,

Susan Minson, Mark Nyquist, Je Schetrompf,

Bryan Steverson, Martin Weiland

DOE: Wyatt Merrill, Bryan Howard, Dylan Jones,

Creshona Armwood, Allison Ackerman, Nael Nmair,

Sarah Butler, Laura Zuber

Tenfold Information Design Services: Andrea Silvestri,

Donna Creason, Carolyn St. Jean, Bill Freais

This work was authored by the Pacific Northwest

National Laboratory, operated by Alliance for Sustainable

Energy, LLC, for the U.S. Department of Energy (DOE)

under Contract No. DE-AC05-76RL01830. Funding was

provided by GSA under Agreement 47PA0119A0008.

The U.S. Government retains, and the publisher, by

accepting the work for publication, acknowledges that

the U.S. Government retains, a nonexclusive, paid-up,

irrevocable, worldwide license to publish or reproduce

the published form of this work, or allow others to do so,

for U.S. Government purposes.

PNNL document # PNNL-SA_181443

LED Lighting and Controls Guidance for Federal Buildings

3

Executive Summary

Overview ...................................4

Decision Flowcharts for Linear Lighting & Controls ...5

Financial Inputs for Lighting Decisions ............6

Life-Cycle Cost Eectiveness ...................8

LED Lighting

LED System Features ........................12

Interior LED Retrofit Options ...................14

Type A TLED ...............................15

Type B TLED ...............................16

Type C TLED ...............................17

Troer Retrofit Kits ........................... 18

New Troer and Linear Luminaires ..............19

PoE Lighting ................................20

Other Interior Lighting ........................21

Emergency and Egress Lighting ................22

Exterior Lighting ............................24

Lighting Controls

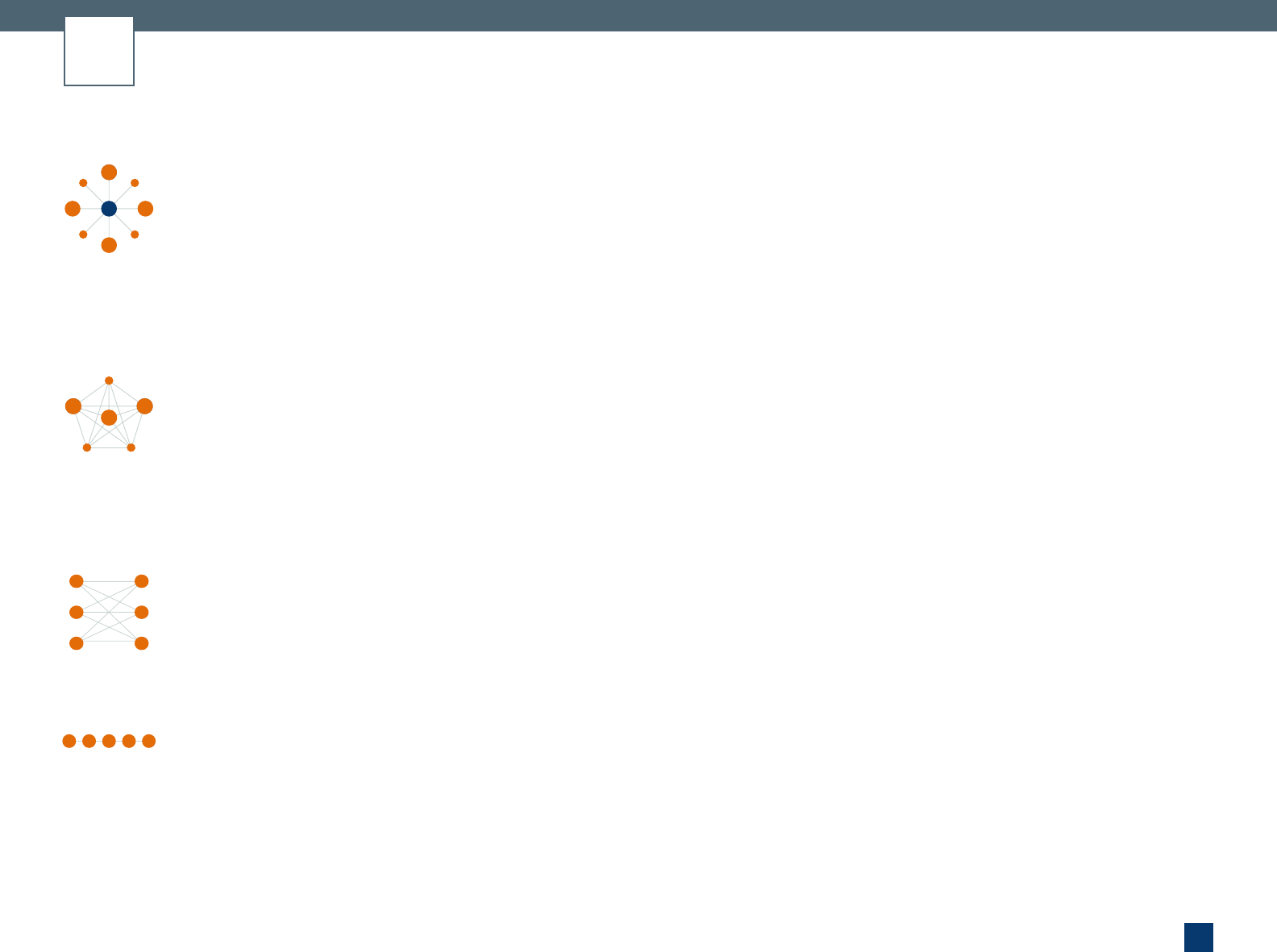

Steps for Designing a Lighting Control System ..27

1

Review Energy Code Requirements .........28

2

Assess Need for Enhanced Capabilities .......29

3

Design Lighting Zone .....................30

4

Select a System Architecture ...............31

5

Determine Sensor and Controller Locations ....36

6

Configure Control Wiring ..................39

7

Identify Communication Protocols ...........41

8

Plan for Retro- and Re-Commissioning ........43

Energy-Saving Capabilities ...................44

Combining Lighting Savings ...................45

Scheduling .................................46

Occupancy Sensing ..........................47

Dimming ..................................49

Daylight-Responsive Control ...................50

Task Tuning. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 51

HVAC Integration ............................52

Demand Response ..........................53

Enhanced Performance Capabilities ...........54

Appendix

List of Figures and Tables .....................56

References ................................57

Contents

In support of the Bulb Replacement Improving Government with High-Eciency Technology

Act, Pub. L. No. 117-202 (October 17, 2022) (BRIGHT Act), this document provides general

guidance to federal agencies on procuring and using the most life-cycle cost-eective and

energy-ecient lighting systems/technology currently available. Many factors, such as site

conditions, design, maintenance, and lighting usage, influence a project’s overall life-cycle

cost eectiveness. As a result, each project will yield a dierent return on investment (ROI).

The guide oers best practices and outlines dierent types of light-emitting diode (LED)

fixtures and control options, how they can benefit buildings and occupants, and where

they are best suited. If designed correctly, new lighting installations, replacements, and

retrofits can provide intrinsic benefits to occupants' health, sense of place, and comfort.

During system selection, begin with code requirements. For example, GSA’s Facility

Standards for the Public Buildings Service (PBS-P100) requires all U.S. General Services

Administration (GSA) projects to meet ASHRAE/IES Standard 90.1.

LED Lighting covers the dierent types of LED installations, including tubular LEDs (TLEDs),

retrofit kits, and new fixtures. This section focuses on interior linear lighting because such

systems represent the majority of lighting within the federal real estate portfolio.

Lighting Controls discusses the decisions that need to be made when selecting a control

system that complies with applicable code, GSA requirements, project objectives, energy

savings, and enhanced performance capabilities.

This guidance also presents lessons learned from evaluations conducted by GSA’s Green

Proving Ground (GPG) and other real-world federal building deployments.

Use this guide as a

roadmap and reference

to select the best lighting

system for your facility.

Overview

LED Lighting and Controls Guidance for Federal Buildings

4

LED Lighting and Controls Guidance for Federal Buildings

5

The BRIGHT Act directs federal agencies to procure the

most life-cycle cost-eective and energy-ecient lighting

systems currently available.

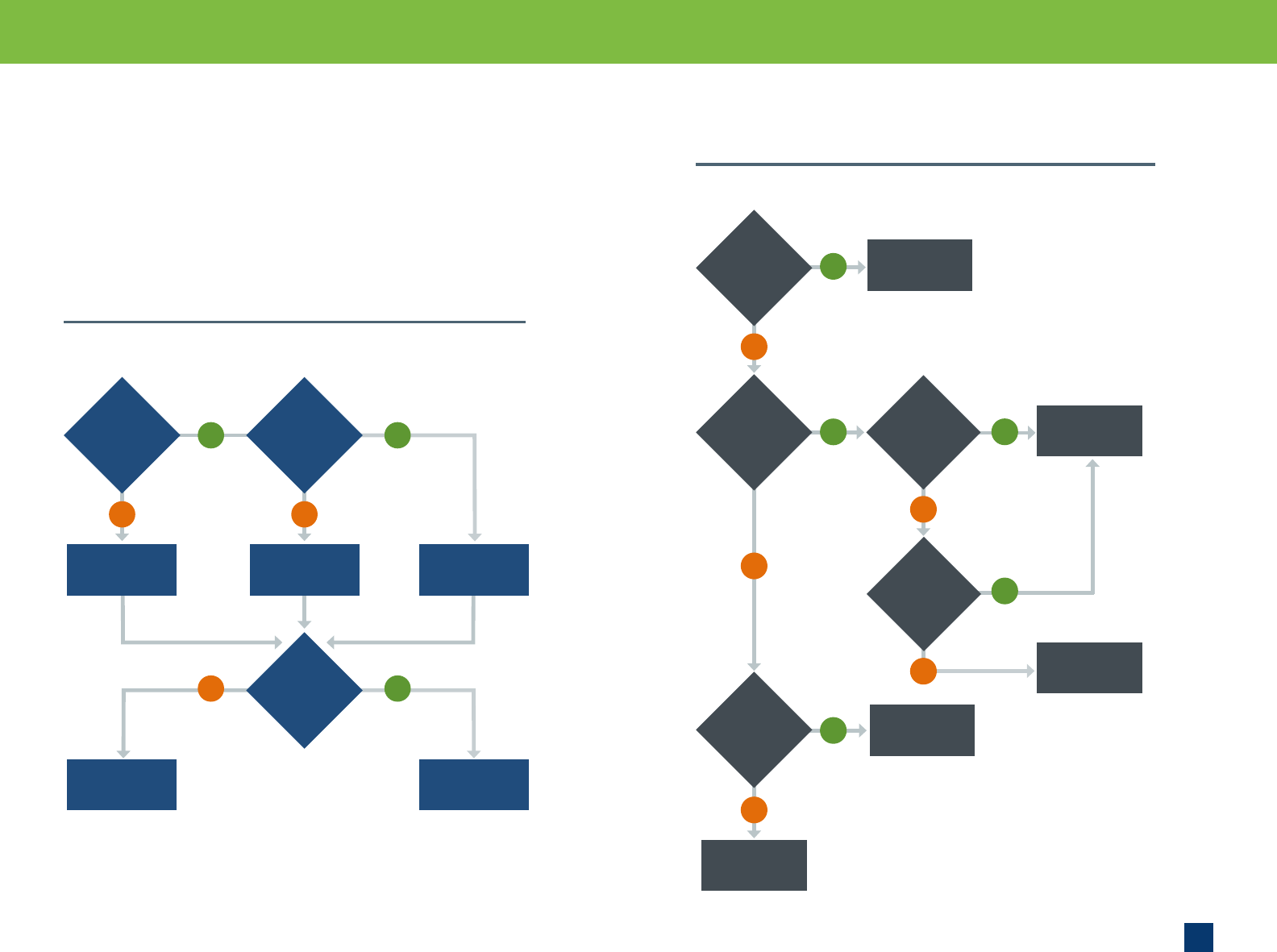

Use these decision flowcharts to help determine which

technologies and systems will be most cost eective

for retrofitting your linear fixture lighting.

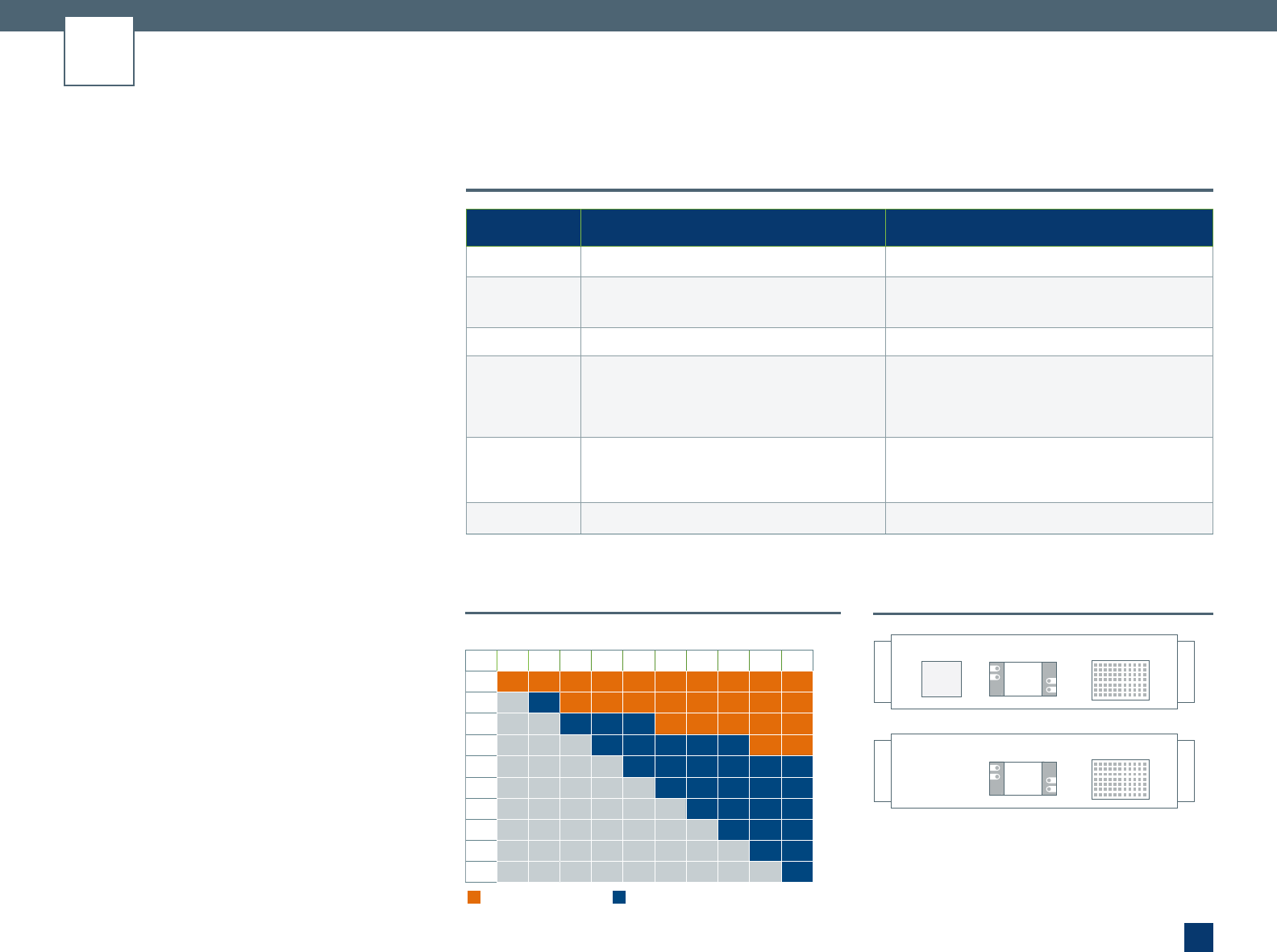

Figure 2

Decision Flowchart for Retrofitting Linear LED Lighting

Type A TLED

Lamp »

Type C TLED

Lamp »

New Fixtures »

Type B TLED

Lamp »

Retrofit Kit »

NO

NO

NO

NO

NO

YES

YES

YES

YES

YES

Asset

held for < 3

years?

Asset

held for < 5

years?

Fixture has

> 2 fluorescent

lamps?

Is dimming

required?

Will the

ceiling be

changed?

Figure 1

Decision Flowchart for Lighting Controls

Centrally

Networked »

Room-Based » Stand-Alone »

Zone-Based »

NO NO

NO

YES YES

YES

Space

for 5+

people?

Integrate

with

HVAC?*

More than

5 sensors

needed?

Luminaire-

Level »

* Heating, ventilation, and air conditioning (HVAC) integration is recommended for buildings over 50k

ft

2

; consider for buildings over 25k ft

2

LED Lighting and Controls Guidance for Federal Buildings

6

Buy American Act

The Buy American Act (BAA) requires federal agencies

to procure products that are at least 50% produced in

the U.S. Most LED chips are manufactured overseas, so

BAA-compliant products need to be assembled here. If

the U.S. has a trade agreement with another country, a

product assembled in that country also meets the BAA

requirement. BAA can sometimes limit options, and

lower-cost products are not necessarily the best choice.

Look for good quality products and manufacturer track

records. Many vendors enable internet searching by

BAA status.

Demand Charges

Demand charges and other grid-related operational

costs continue to rise and, in some locations, can

exceed actual energy costs.

Federal Building

Performance Standard

In December 2022, the Biden-Harris Administration

established the first Federal Building Performance

Standard. This standard requires agencies to cut energy

use in 30% of the building space owned by the Federal

Government by 2030. Implementing LED and controls

will assist in meeting this requirement.

First Costs

Some lighting options might have a lower first cost

but a greater life-cycle cost compared to other options.

Most lighting equipment (fixtures, controls, and sensors)

will have at least a 15-year life cycle, and per BRIGHT

Act requirements, this period of performance should

be used.

Heating Interactions

The heat generated by most older lighting technology

aects the ambient temperature and, therefore,

the heating, ventilation, and air conditioning (HVAC)

system. Consider cooling savings, particularly in hot

climates, when converting to LED lighting. In a deep

retrofit, if lighting is part of the process, consider

downsizing the HVAC system.

Maintenance, Controls

Controls, for the most part, should not have ongoing

maintenance costs, but they will need to be

reprogrammed as space changes and may need

periodic system updates.

Financial Inputs for Lighting Decisions

There are many factors that influence the overall cost eectiveness of a project, and each project

will yield a dierent return on investment (ROI). Consider the following when evaluating the financial

returns on a lighting project.

Maintenance, Exterior LED

Exterior lighting operation and maintenance (O&M)

costs are often significantly higher than those associated

with interior lighting because exterior lighting is replaced

more frequently and because replacing it can require

special equipment. In some cases, the cost of servicing

parking lot lighting using bucket trucks can exceed the

cost of the lighting. The maintenance savings from an

exterior LED lighting installation should be factored into

new and existing GSA O&M contracts.

Maintenance, Interior LED

Since LEDs last about twice as long as fluorescent

lamps, a conversion to LEDs will result in less

maintenance. GSA’s GPG technology evaluations

(GPG-024, LED Fixtures with Integrated Advanced

Lighting Controls) at the Ralph H. Metcalfe Federal

Building in Chicago, IL, and the Peachtree Summit

Federal Building in Atlanta, GA, found that 25% of the

cost savings from converting fluorescent to LED lights

was due to reduced maintenance. Over a 15-year period,

the cumulative present value of avoided maintenance

costs was over $1.00/ft

2

. In contrast, during this same

period, the cumulative present value of avoided energy

cost was about $3.50/ft

2

. Renegotiating your O&M

contract may result in significant savings.

LED Lighting and Controls Guidance for Federal Buildings

7

Performance Contracts

Energy savings performance contracts (ESPCs) come

with a price premium and have longer simple paybacks

than directly funded projects. In an ESPC, energy savings

are guaranteed for a number of years into the future.

Roughly one-third of GSA projects use ESPC financing.

Rebates

You can find rebate opportunities at DSIRE, ENERGY

STAR Rebates for Commercial Buildings, or

BriteSwitch. In a 2022 analysis, 77% of U.S. utilities

oered lighting rebates.

Rebates for networked lighting controls increased

by 16% in 2022. Rebates for non-networked lighting

controls have been relatively stable since 2008.

Utility Areawide Contracts

GSA establishes long-term government-wide contracts

with regulated public utility companies. These areawide

contracts (AWCs) can be used to install LED lighting

and controls through an energy management services

agreement task order. The benefits of using an AWC for

energy eciency work include streamlined acquisition

and better access to utility rebates and incentives.

Warranty

Because GSA holds on to its buildings, and most

LED devices have a 15-year or longer lifespan, look

for 10-year warranties on kits, luminaires, and control

systems. Check that the warranty period is not longer

than the age of the company.

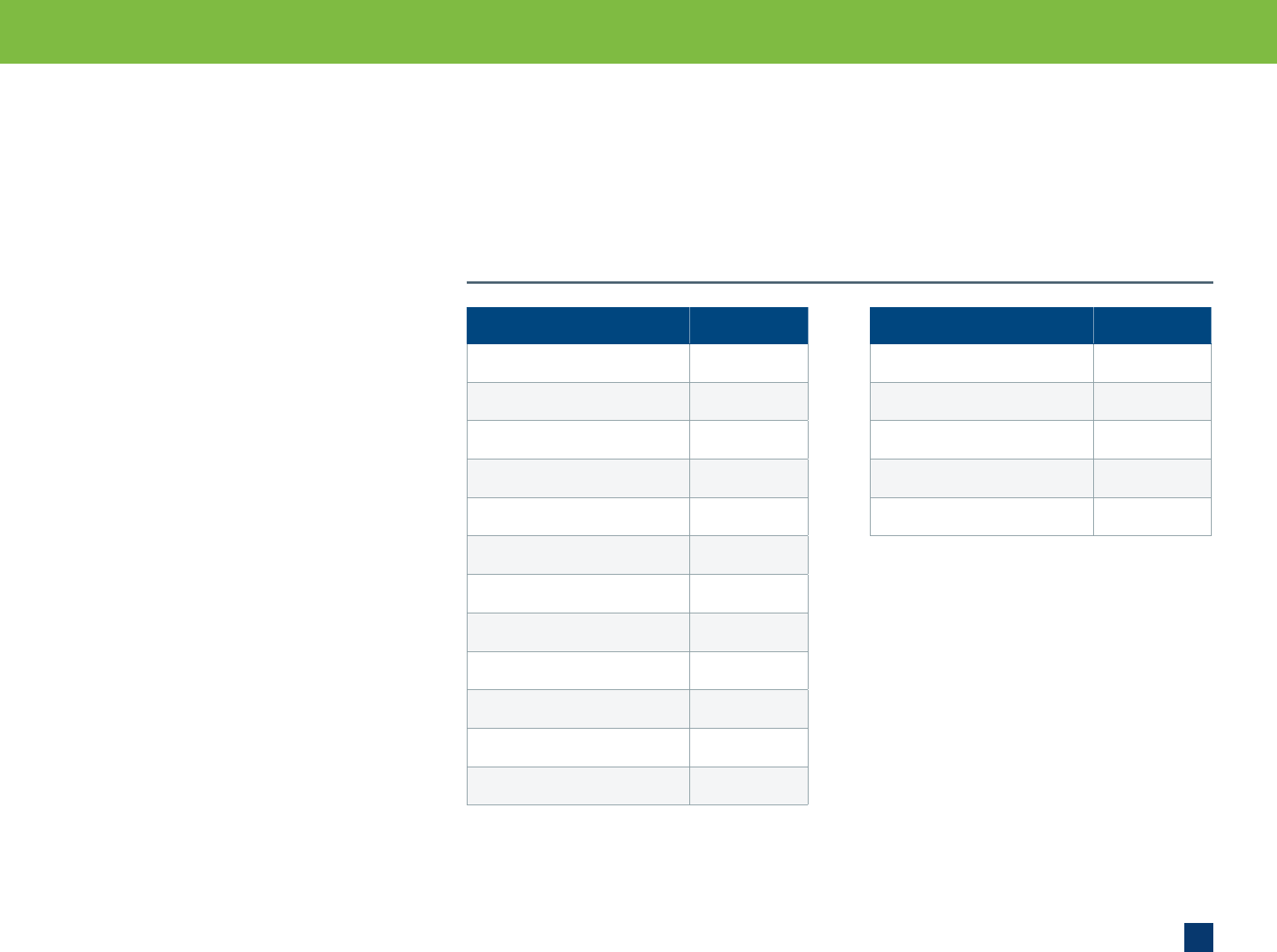

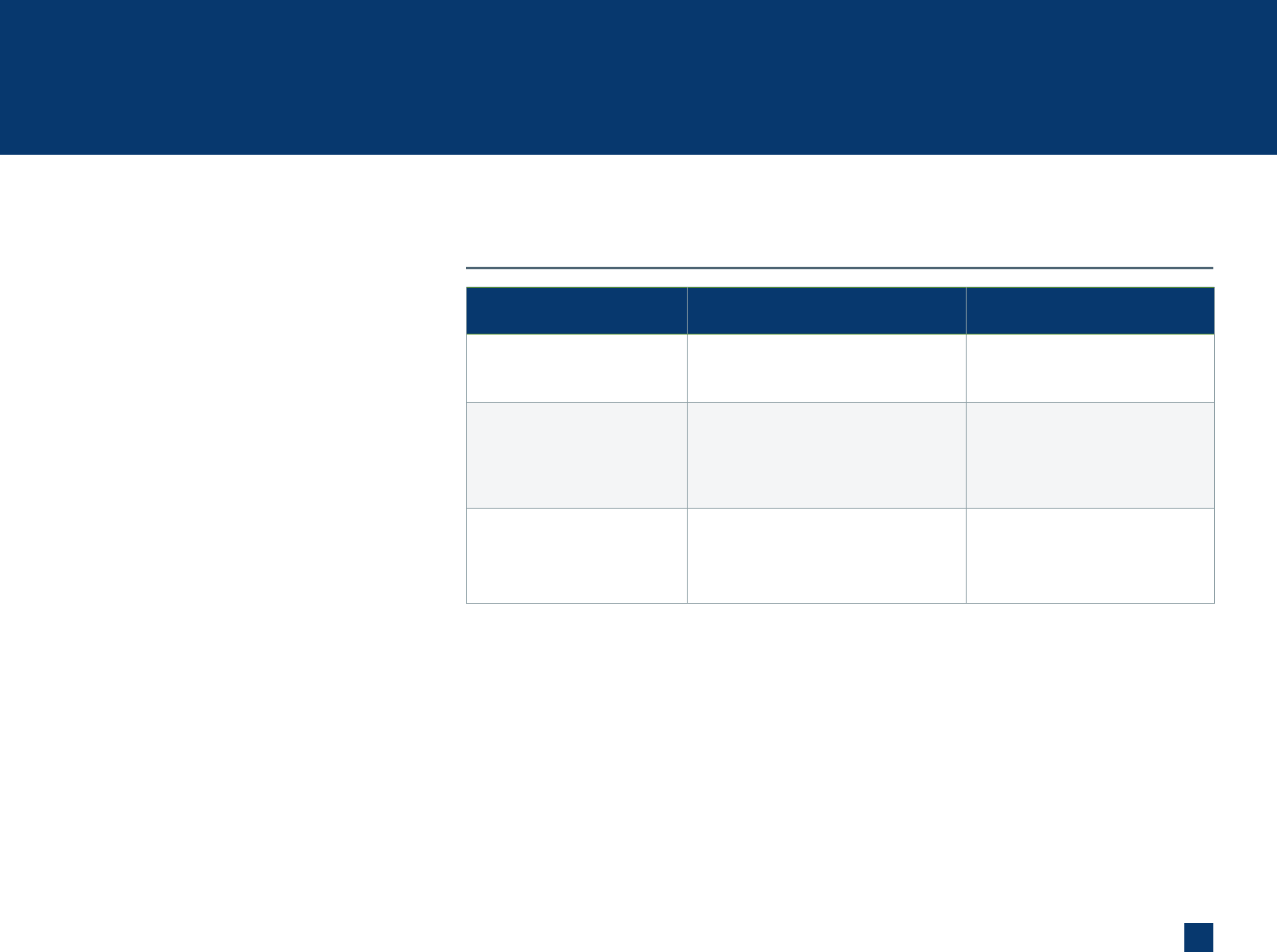

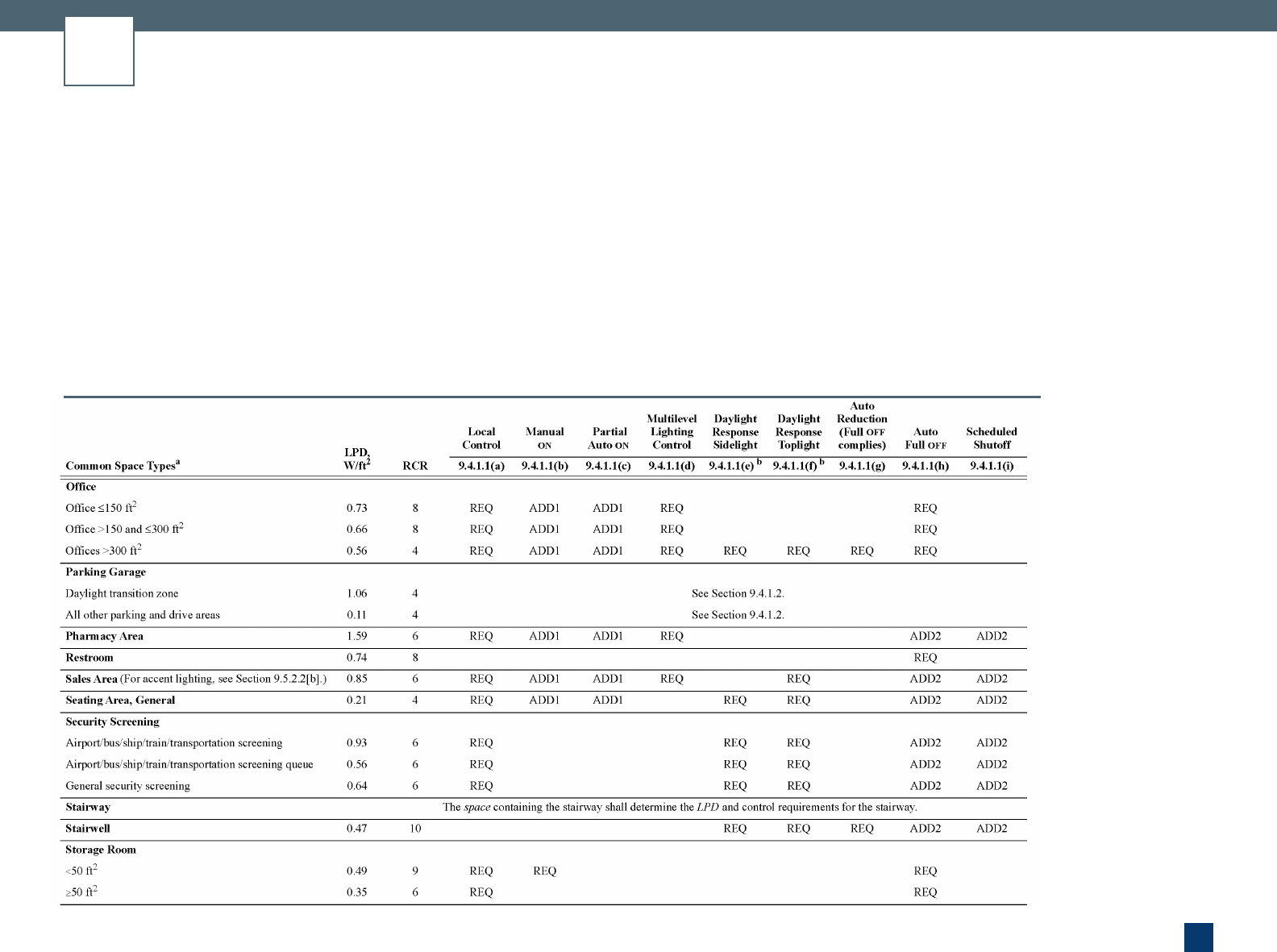

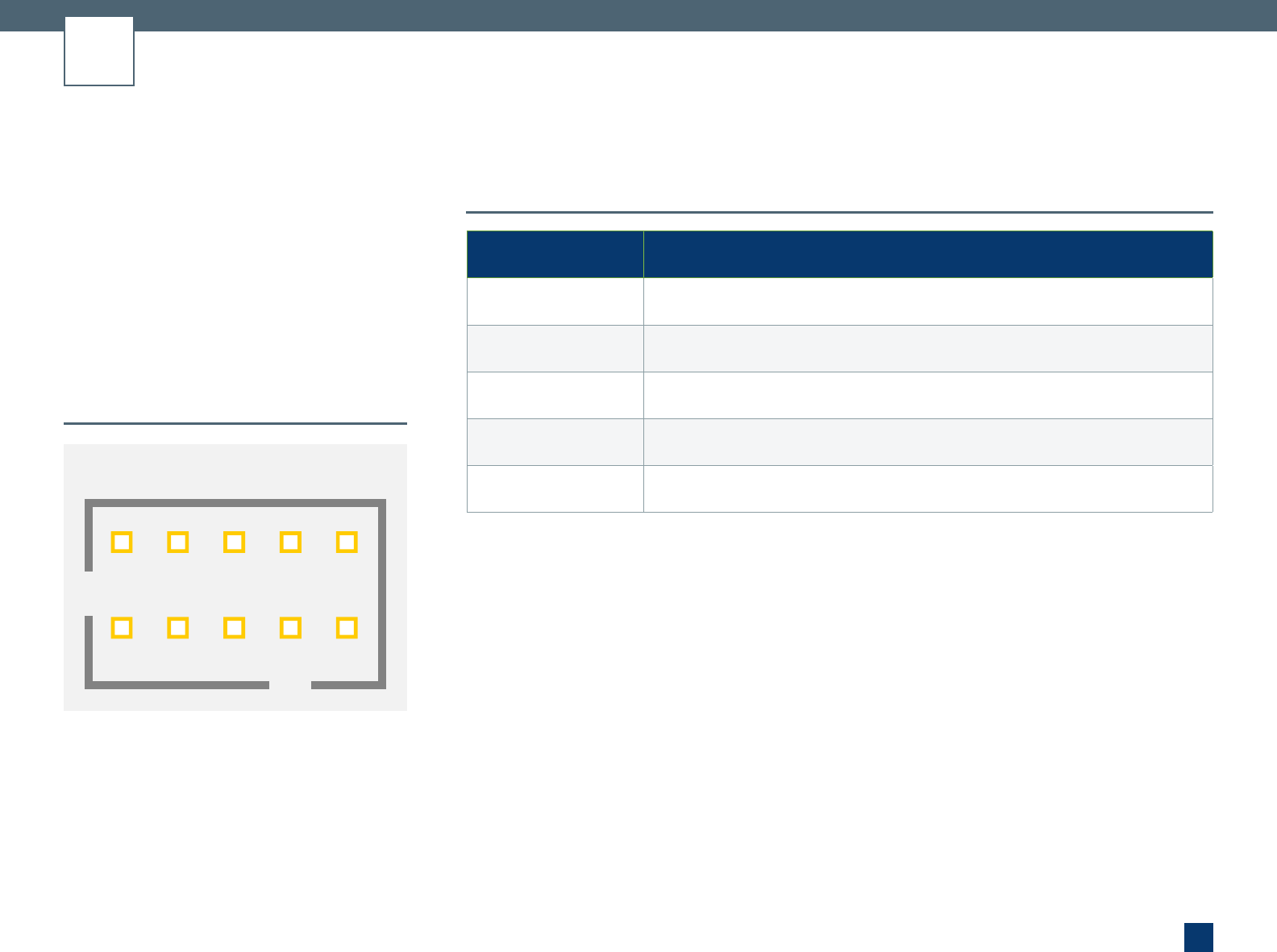

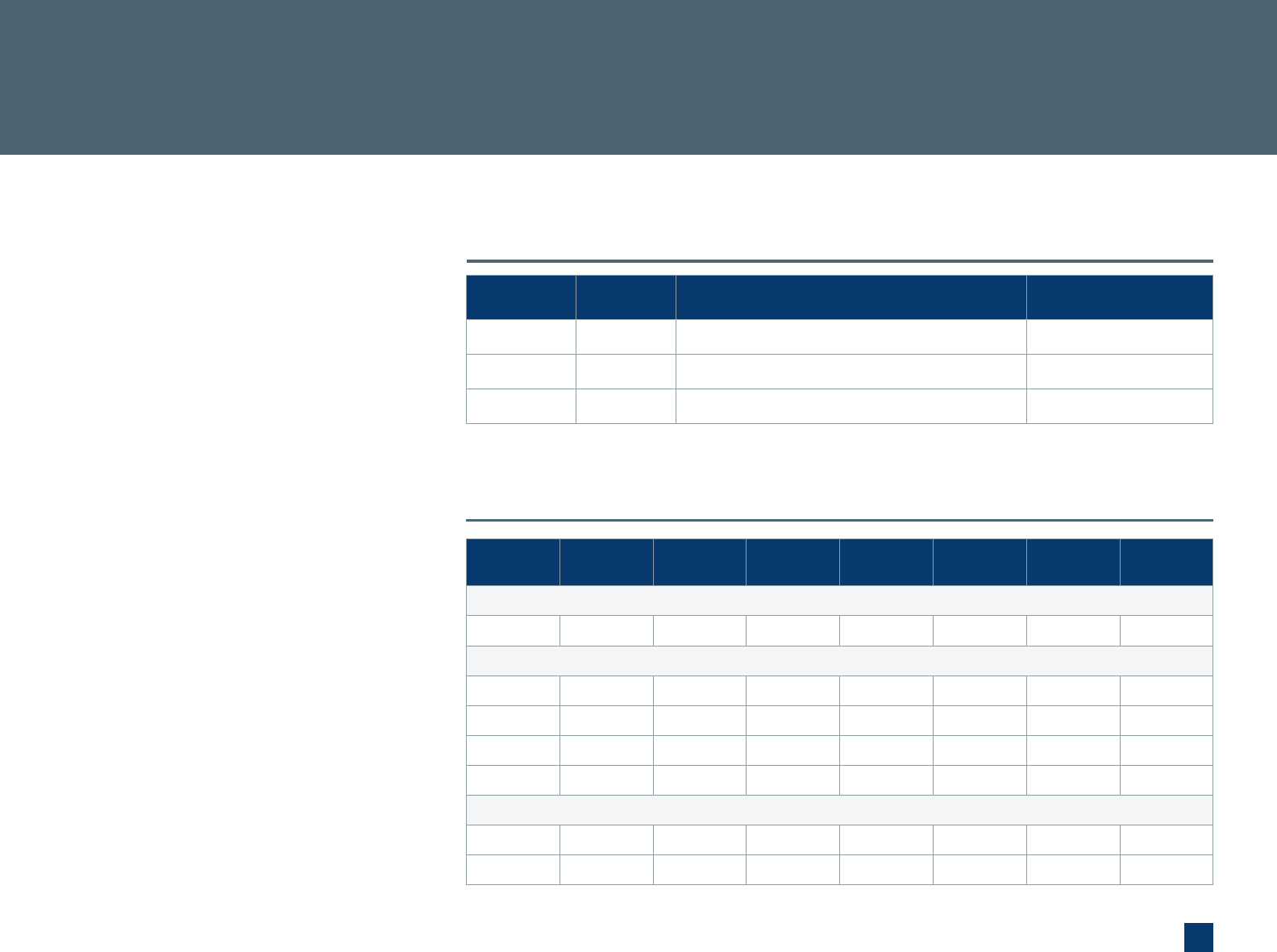

Type of LED Solution Avg. Rebate 2023

Replacement lamps (A19, PAR, MR) $8

TLEDs $4

Pin-based (CFL replacement) $6

Downlights $28

Troer luminaires $33

Troer retrofit kits

(1x4, 2x2, 2x4)

$34

Accent/track lighting $50

Screw-in high-intensity discharge

(HID) retrofit

$58

Outdoor wall mount $98

Parking garage $101

Outdoor pole $106

High bay fixtures $127

Type of Lighting Control Avg. Rebate 2023

Remote-mounted occupancy sensors $26

Wallbox occupancy sensors $23

Photocells $20

Luminaire-mounted occupancy

sensors

$22

Daylight dimming systems $27

Table 1

Average LED and Lighting Control Rebates in North America*

*LED rebates: BriteSwitch RebatePro for Lighting February 2023

Lighting control rebates: Lighting Controls Association, 2023 Rebate Outlook

Financial Inputs for Lighting Decisions

LED Lighting and Controls Guidance for Federal Buildings

8

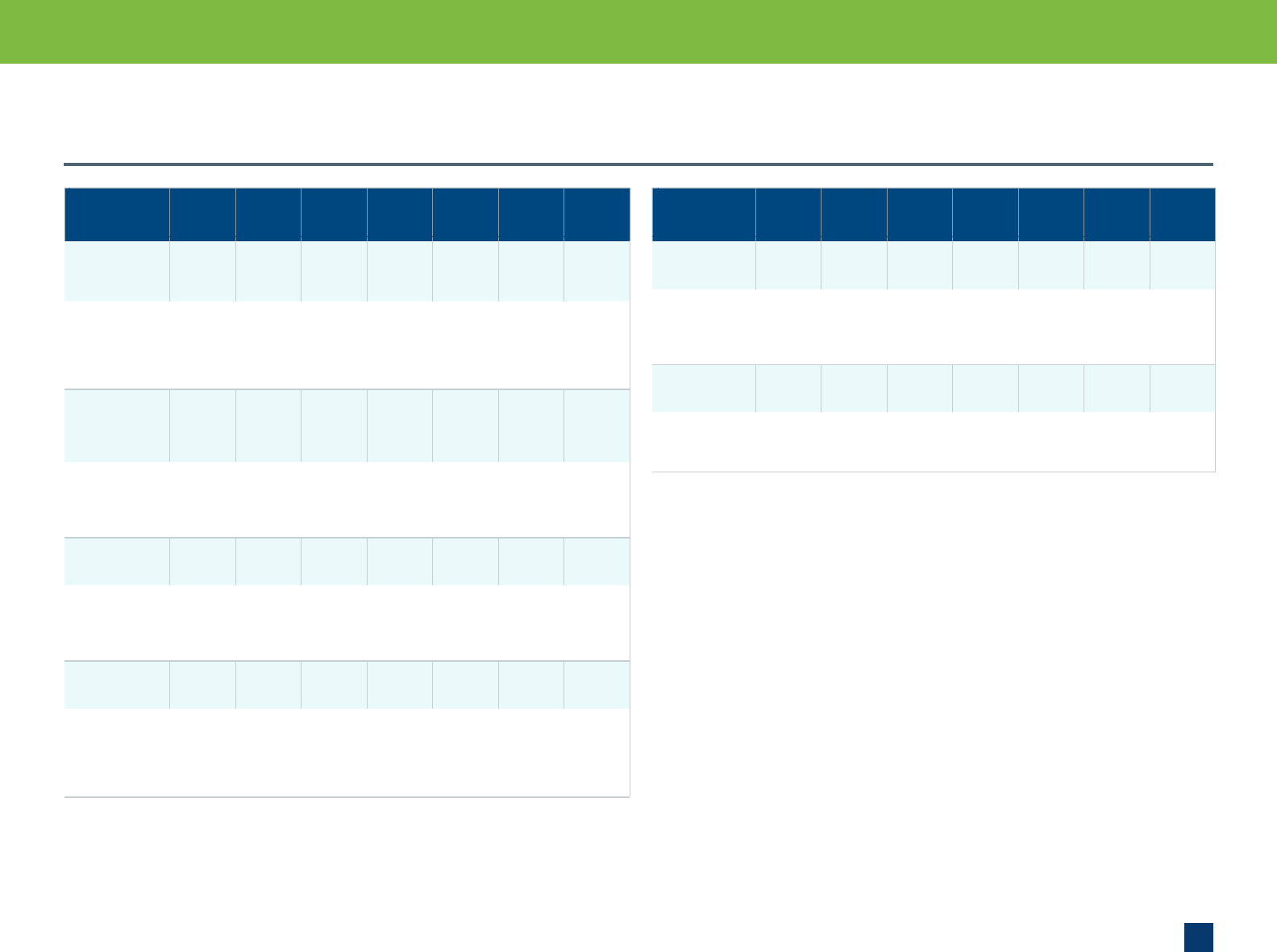

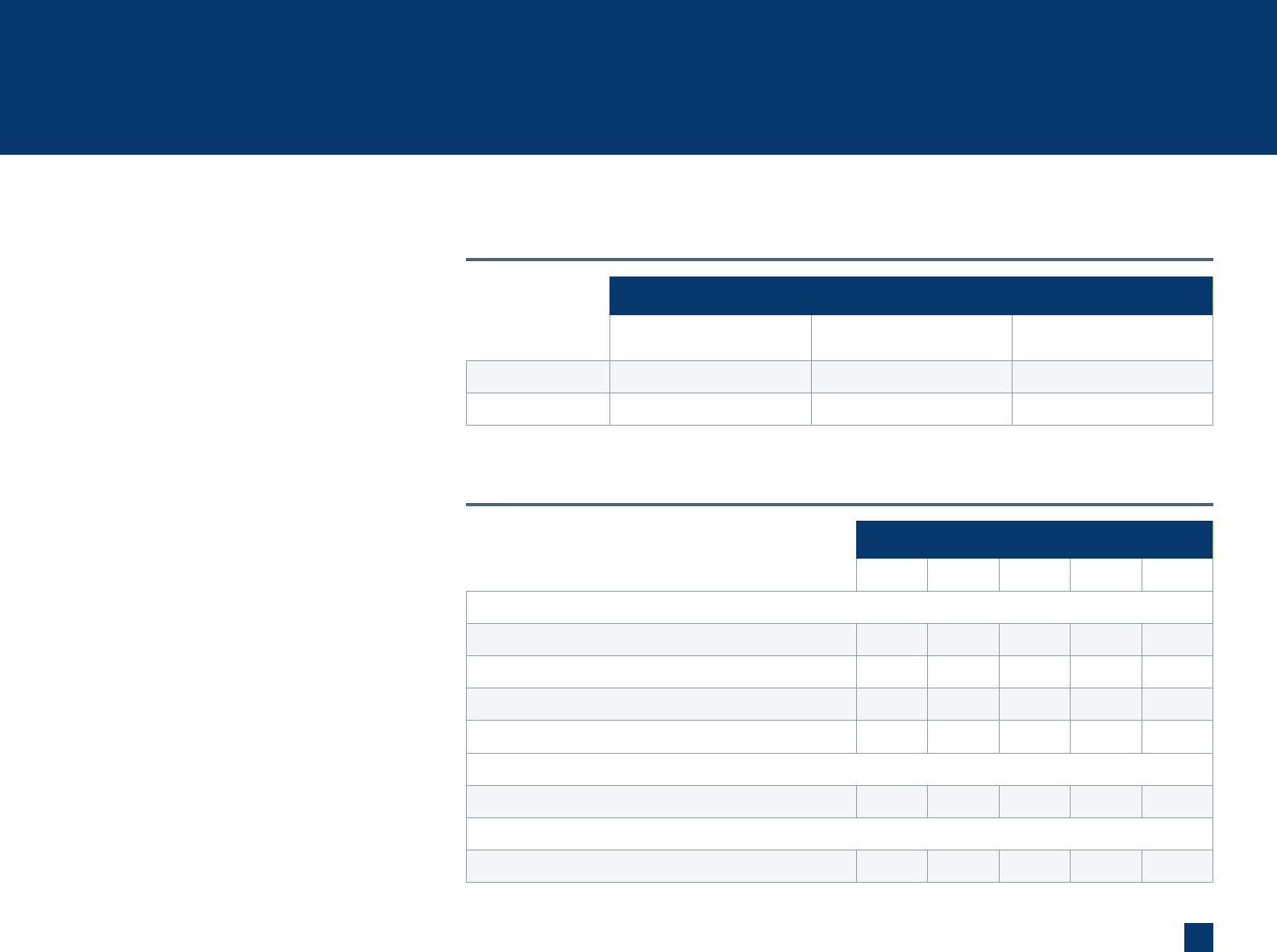

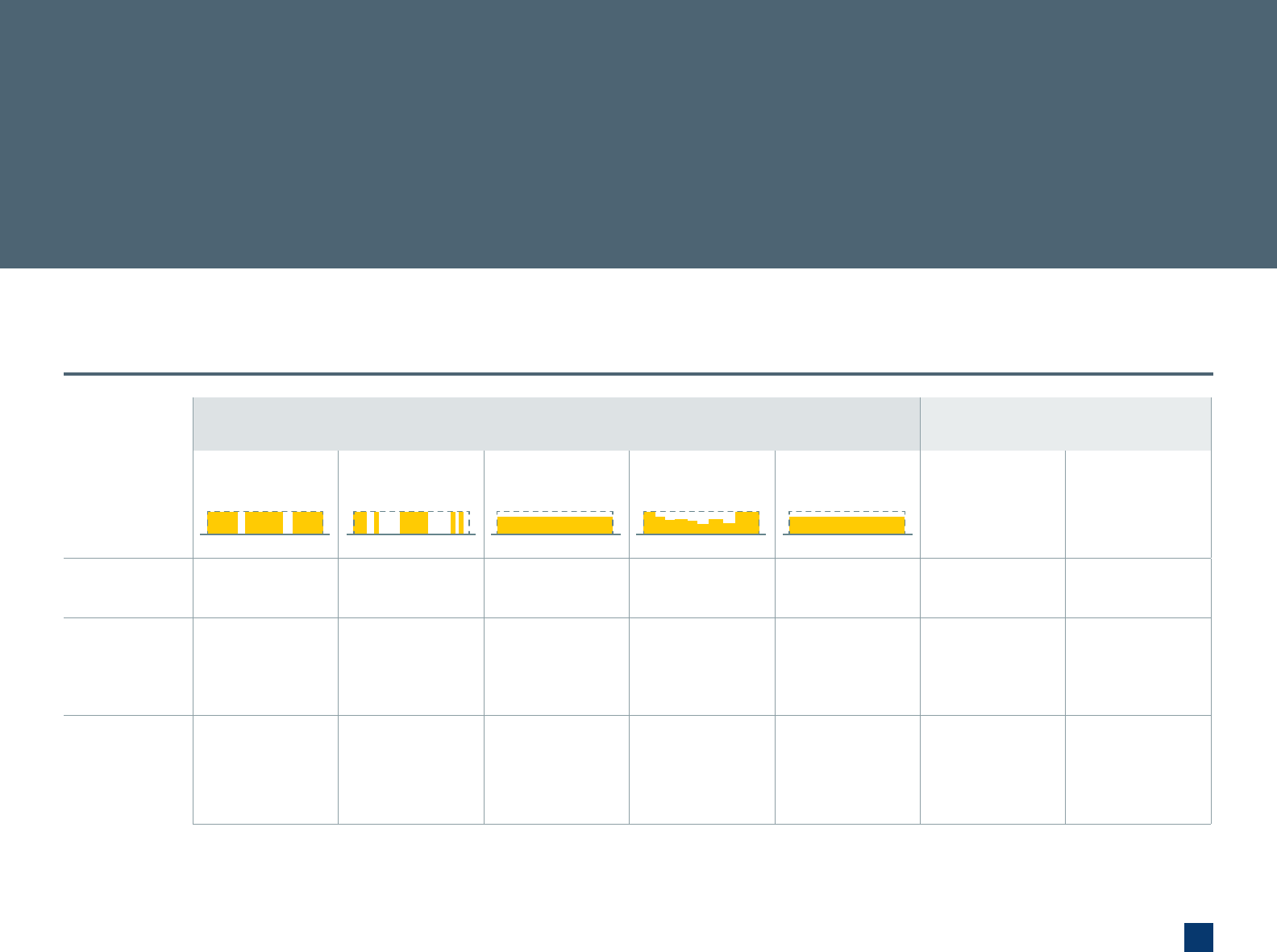

Table 2

5,000 ft

2

Life-Cycle Cost (LCC) Eectiveness for Linear LED Lighting Systems and Controls

*LCC Assumptions: scaled to a 5,000 ft

2

building; baseline 3 lamp 32 W fluorescent fixture; 2900 operating hours;

electricity rate $0.11/kWh

TLEDs

SYSTEM

LIFE

(yrs)

ENERGY

SAVINGS

(%)

ENERGY

SAVINGS

(/ft

2

)

ENERGY

SAVINGS

($ / ft

2

)

FIRST

COST

($ / ft

2

)

PAYBACK

(yrs)

LCC

15-YEAR*

TLED-A

uses existing

fluorescent

ballast

4 35% 1.01 kWh

3.44 kBtu

$0.11 $0.20 1.8 $19,679

• Not recommended because of fluorescent ballast life expectancy. Replacement ballasts will be dicult to

find in the future.

• Less ecient than TLED-B and -C because of the conversion losses of the ballast.

• Type A TLED and fluorescent ballast matching is dicult and makes this technology a challenge.

TLED-B

bypasses

ballast

with direct

wiring

8 35% 1.01 kWh

3.44 kBtu

$0.11 $0.28 2.5 $17,903

• 0-10V communication protocol possible from some manufacturers. May require additional wiring.

• May require replacement of sockets (“tombstones”).

• Requires proper labeling to protect from fire hazards.

TLED-C

incorporates

new LED driver

10 35% 1.01 kWh

3.44 kBtu

$0.11 $0.28 2.5 $17,270

• 0-10V dimming possible from some manufacturers. May require additional wiring.

• Ideal for multi-lamp fixtures; best for 4+ lamp fixtures.

• May require replacement of sockets (“tombstones”).

TLED-C with

zone-based

controls

10 59% 1.42 kWh

4.85 kBtu

$0.16 $0.34 2.2 $14,022

• When possible, combine equipment retrofit with lighting controls.

• Other considerations for Type C TLED, occupancy sensors, and/or daylight sensors.

• Type C TLED’s use of an external driver may allow for easier incorporation of lighting controls compared to

other TLED options.

Stand-Alone

Control

SYSTEM

LIFE

(yrs)

ENERGY

SAVINGS

(%)

ENERGY

SAVINGS

(/ft

2

)

ENERGY

SAVINGS

($ / ft

2

)

FIRST

COST

($ / ft

2

)

PAYBACK

(yrs)

LCC

15-YEAR*

Stand-alone

occupancy

control

15 24% 0.69 kWh

2.36 kBtu

$0.07 $0.03 0.4 $17,4 5 0

• Will require some additional wiring.

• When possible, pair with other technology upgrades.

• Proper sensor selection is important to prevent “false o,” which aects user satisfaction.

Stand-alone

daylight

harvesting

15 28% 0.81 kWh

2.75 kBtu

$0.08 $0.04 0.5 $16,594

• If the existing fixture does not dim, replace it with a device that can dim first.

• Will require some additional wiring.

LED Lighting and Controls Guidance for Federal Buildings

9

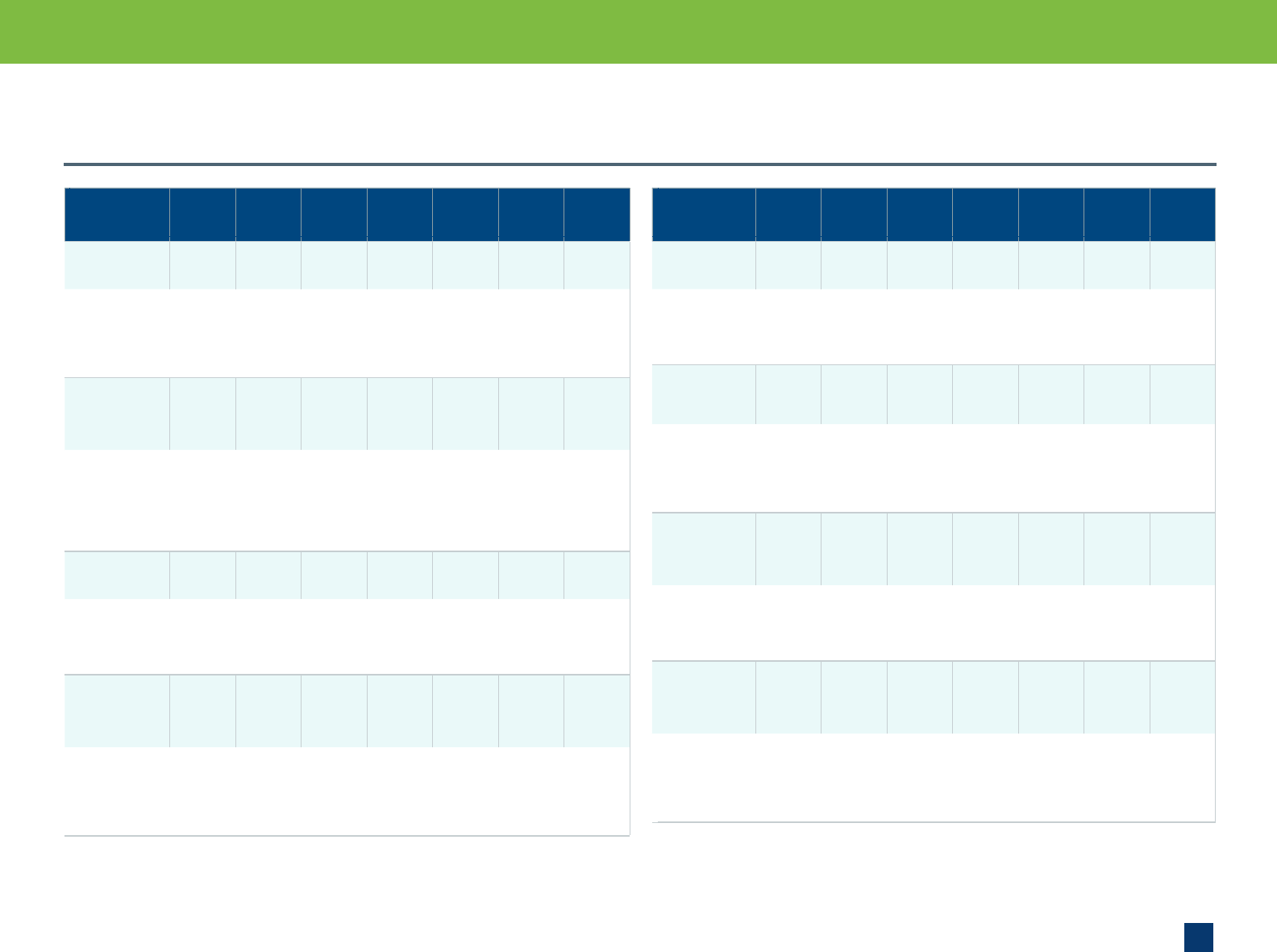

Table 2 (continued)

5,000 ft

2

Life-Cycle Cost (LCC) Eectiveness for Linear LED Lighting Systems and Controls

Retrofit Kits

SYSTEM

LIFE

(yrs)

ENERGY

SAVINGS

(%)

ENERGY

SAVINGS

(/ft

2

)

ENERGY

SAVINGS

($ / ft

2

)

FIRST

COST

($ / ft

2

)

PAYBACK

(yrs)

LCC

15-YEAR*

Retrofit kit with

zone-based

control

15 65% 1.87 kWh

6.38 kBtu

$0.21 $1.72 8.4 $17,288

• Requires either low-voltage wires or wireless communication between the sensor and the luminaires.

• Ideal for low occupancy transitory spaces (e.g., restrooms, corridors, stairs, etc.).

• Spaces with many dierent fixture types and many custom or outlier fixture types may make finding retrofit

kits dicult.

Retrofit kit with

luminaire-level

lighting control

(LLLC),

room-based

15 65% 1.87 kWh

6.38 kBtu

$0.21 $2.45 11.9 $20,988

• Room-based controllers will be sized on both electrical capacity and number of zones—this will aect

control design.

• Requires communication—either wired or wireless—between the controller, sensors, and luminaires.

• Spaces with many dierent fixture types and many custom or outlier fixture types may make finding retrofit

kits dicult.

Retrofit kit with

LLLC, centrally

networked

15 70% 2.03 kWh

6.92 kBtu

$0.22 $4.21 18.9 $28,679

• Economies of scale play a role; technology is more cost eective as the building size increases.

• Allows for more lighting control strategies than other options.

• If a digital system is selected, diagnostics or other information can be queried from the system.

Retrofit kit with

LLLC, centrally

networked

with HVAC

integration

15 70%

lighting

20%

HVAC

4.03 kWh

13.74 kBtu

$0.44 $4.93 11.1 $23,189

• Provides more total energy savings and a shorter cost recovery period than just a lighting control system.

• More cost eective with larger buildings.

• Energy codes are starting to require occupied setback; this option leverages the occupancy sensors in a

lighting system for HVAC integration.

New

Fixtures**

SYSTEM

LIFE

(yrs)

ENERGY

SAVINGS

(%)

ENERGY

SAVINGS

(/ft

2

)

ENERGY

SAVINGS

($ / ft

2

)

FIRST

COST

($ / ft

2

)

PAYBACK

(yrs)

LCC

15-YEAR*

New fixture

with zone-

based controls

20 65% 1.87 kWh

6.38 kBtu

$0.21 $3.18 15.4 $24,713

• New fixtures are optimized for LEDs and will control glare and provide optimal distribution.

• Requires either low-voltage wires or wireless communication between the sensor and the luminaires.

• Ideal for low occupancy transitory spaces (e.g., restrooms, corridors, stairs, etc.).

New fixture

with LLLC

control, room-

based

20 65% 1.87 kWh

6.38 kBtu

$0.21 $3.90 19.0 $28,413

• LLLC includes the sensor as part of the luminaire.

• Room-based controllers will be sized on both electrical capacity and number of zones—this will aect

control design.

• Requires communication—either wired or wireless—between the controller, sensors, and luminaires.

New fixture

with LLLC

control,

centrally

networked

20 70% 2.03 kWh

6.92 kBtu

$0.22 $6.05 27.1 $38,054

• Economies of scale play a role; technology is more cost eective as the building size increases.

• Allows for more lighting control strategies than other options.

• If a digital system is selected, diagnostics or other information can be queried from the system.

New fixture

with networked

controls +

HVAC + IoT

features

20 70%

lighting

20%

HVAC

4.03 kWh

13.74 kBtu

$0.44 $6.77 15.3 $32,564

• Provides more total energy savings and a shorter cost recovery period than just a lighting control system.

• More cost eective with larger buildings.

• Energy codes are starting to require occupied setback; this option leverages the occupancy sensors

in a lighting system for HVAC integration.

*LCC Assumptions: scaled to a 5,000 ft² building; baseline 3 lamp 32 W fluorescent fixture; 2900 operating hours;

electricity rate $0.11/kWh

** 20-year life expectancy of new fixtures exceeds 15-year LCC analysis

LED Lighting and Controls Guidance for Federal Buildings

10

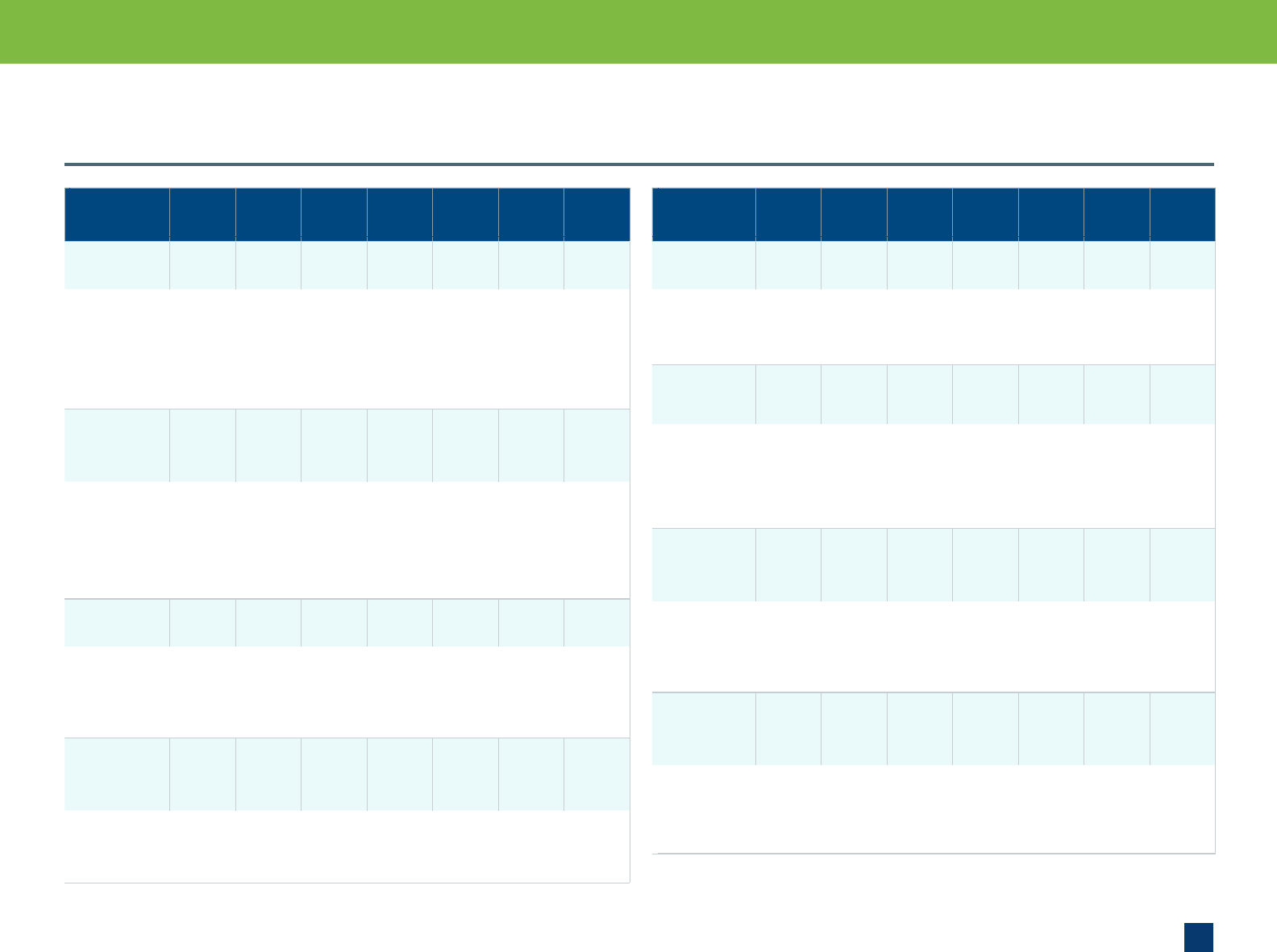

Retrofit

Kits

SYSTEM

LIFE

(yrs)

ENERGY

SAVINGS

(%)

ENERGY

SAVINGS

(/ft

2

)

ENERGY

SAVINGS

($ / ft

2

)

FIRST

COST

($ / ft

2

)

PAYBACK

(yrs)

LCC

15-YEAR*

Retrofit kit with

zone-based

control

15 65% 1.87 kWh

6.38 kBtu

$0.21 $1.67 8.1 $170,182

• As building size increases, a retrofit may involve both a combination of mostly retrofit kits and some TLEDs.

• As size increases, retrofit installation becomes more ecient.

• Requires either low-voltage wires or wireless communication between the sensor and the luminaires.

• Ideal for low occupancy transitory spaces (e.g., restrooms, corridors, stairs, etc.).

• Spaces with many dierent fixture types and many custom or outlier fixture types may make finding retrofit

kits dicult.

Retrofit kit with

luminaire-level

lighting control

(LLLC), room-

based

15 65% 1.87 kWh

6.38 kBtu

$0.21 $2.27 11.0 $200,882

• Retrofit kits with integrated sensors are a common option.

• Room-based controllers will be sized on both electrical capacity and number of zones—this will aect

control design.

• Requires communication—either wired or wireless—between the controller, sensors, and luminaires.

• Spaces with many dierent fixture types and many custom or outlier fixture types may make finding retrofit

kits dicult.

Retrofit kit with

LLLC, centrally

networked

15 70% 2.03 kWh

6.92 kBtu

$0.22 $2.45 11.0 $196,785

• Economies of scale play a role; technology is more cost eective as the building size increases.

• Recommended for facilities implementing a demand response strategy.

• Allows for more lighting control strategies than other options.

• If a digital system is selected, diagnostics or other information can queried from the system.

Retrofit kit with

LLLC, centrally

networked

with HVAC

integration

15 70%

lighting

20%

HVAC

4.03 kWh

13.74 kBtu

$0.44 $2.82 6.4 $123,889

• Provides more total energy savings and a shorter cost recovery period than just a lighting control system.

• Cost per square foot of integration decreases in large buildings.

• Energy codes are starting to require occupied setback; this option leverages the occupancy sensors in a

lighting system for HVAC integration.

New

Fixtures**

SYSTEM

LIFE

(yrs)

ENERGY

SAVINGS

(%)

ENERGY

SAVINGS

(/ft

2

)

ENERGY

SAVINGS

($ / ft

2

)

FIRST

COST

($ / ft

2

)

PAYBACK

(yrs)

LCC

15-YEAR*

New fixture

with zone-

based controls

20 65% 1.87 kWh

6.38 kBtu

$0.21 $3.12 15.2 $244,432

• Suitable for either new construction or major retrofit projects.

• Requires either low-voltage wires or wireless communication between the sensor and the luminaires.

• Ideal for low occupancy transitory spaces (e.g., restrooms, corridors, stairs, etc.).

New fixture

with LLLC

control, room-

based

20 65% 1.87 kWh

6.38 kBtu

$0.21 $3.73 18 .1 $275,132

• Suitable for either new construction or major retrofit projects.

• LLLC includes the sensor as part of the luminaire.

• Room-based controllers will be sized on both electrical capacity and number of zones—this will aect control

design.

• Requires communication—either wired or wireless—between the controller, sensors, and luminaires.

New fixture

with LLLC

control,

centrally

networked

20 70% 2.03 kWh

6.92 kBtu

$0.22 $4.28 19.2 $290,535

• Economies of scale play a role; technology is more cost eective as the building size increases.

• Recommended for facilities implementing a demand response strategy.

• Allows for more lighting control strategies than other options.

• If a digital system is selected, diagnostics or other information can queried from the system.

New fixture

with networked

controls +

HVAC + IoT

features

20 70%

lighting

20%

HVAC

4.03 kWh

13.74 kBtu

$0.44 $4.65 10.5 $ 217,6 3 9

• Provides more total energy savings and a shorter cost recovery period than just a lighting control system.

• More cost eective with larger buildings.

• Energy codes are starting to require occupied setback; this option leverages the occupancy sensors

in a lighting system for HVAC integration.

*LCC Assumptions: scaled to a 50,000 ft² building; baseline 3 lamp 32 W fluorescent fixture; 2900 operating hours;

electricity rate $0.11/kWh

** 20-year life expectancy of new fixtures exceeds 15-year LCC analysis

Table 3

50,000 ft

2

Life-Cycle Cost Eectiveness for Controls

LED Lighting and Controls Guidance for Federal Buildings

11

LED Lighting

IN THIS SECTION, WE COVER:

LED System Features | 12

Interior LED Retrofit Options | 14

Type A TLED | 15

Type B TLED | 16

Type C TLED | 17

Troer Retrofit Kits | 18

New Troer and Linear Luminaires | 19

PoE Lighting | 20

Other Interior Lighting | 21

Emergency and Egress Lighting | 22

Exterior Lighting | 24

LED Lighting and Controls Guidance for Federal Buildings

12

The following LED system features will help you think

more broadly about the technology. When designing

lighting systems, consider agency design guides and

union standards, which will include requirements for

light output, color, and other aesthetic attributes. GSA’s

LightMatters, which will be released in 2024, will

contain more detailed information on lighting design.

Circadian Lighting

The human body has a circadian rhythm or internal clock

that regulates physical, mental, and behavioral changes

on a 24-hour cycle. Although many factors influence the

circadian system, lighting plays the largest role.

GSA’s PBS-P100 Tier 2 projects require circadian lighting

(i.e., human-centric lighting), which is best managed via

a centrally networked system. To influence the human

circadian system, lighting intensity, spectrum, duration,

and timing of exposure all need to be controlled. The

building science of circadian lighting is still developing.

If you’re considering a circadian lighting system, involve

design experts.

Color Rendering

Color rendering (i.e., throughout Color Rendering Index

[CRI]) measures how light aects the way you see color.

CRI relies on eight standard colors to evaluate color

accuracy. GSA’s PBS-P100 (Tier 2/3) requires interior

lighting to have a CRI greater than 80. Exterior lighting

should have a CRI greater than 70.

Recently, the lighting industry adopted a more

comprehensive color index, TM-30. TM-30 uses

99 colors and includes color fidelity (Rf), color gamut

(Rg-saturation), and gamut shape, a visual description

of hue and saturation. The PBS-P100 requires Tier 1–3

lighting to have an Rf value greater than 85.

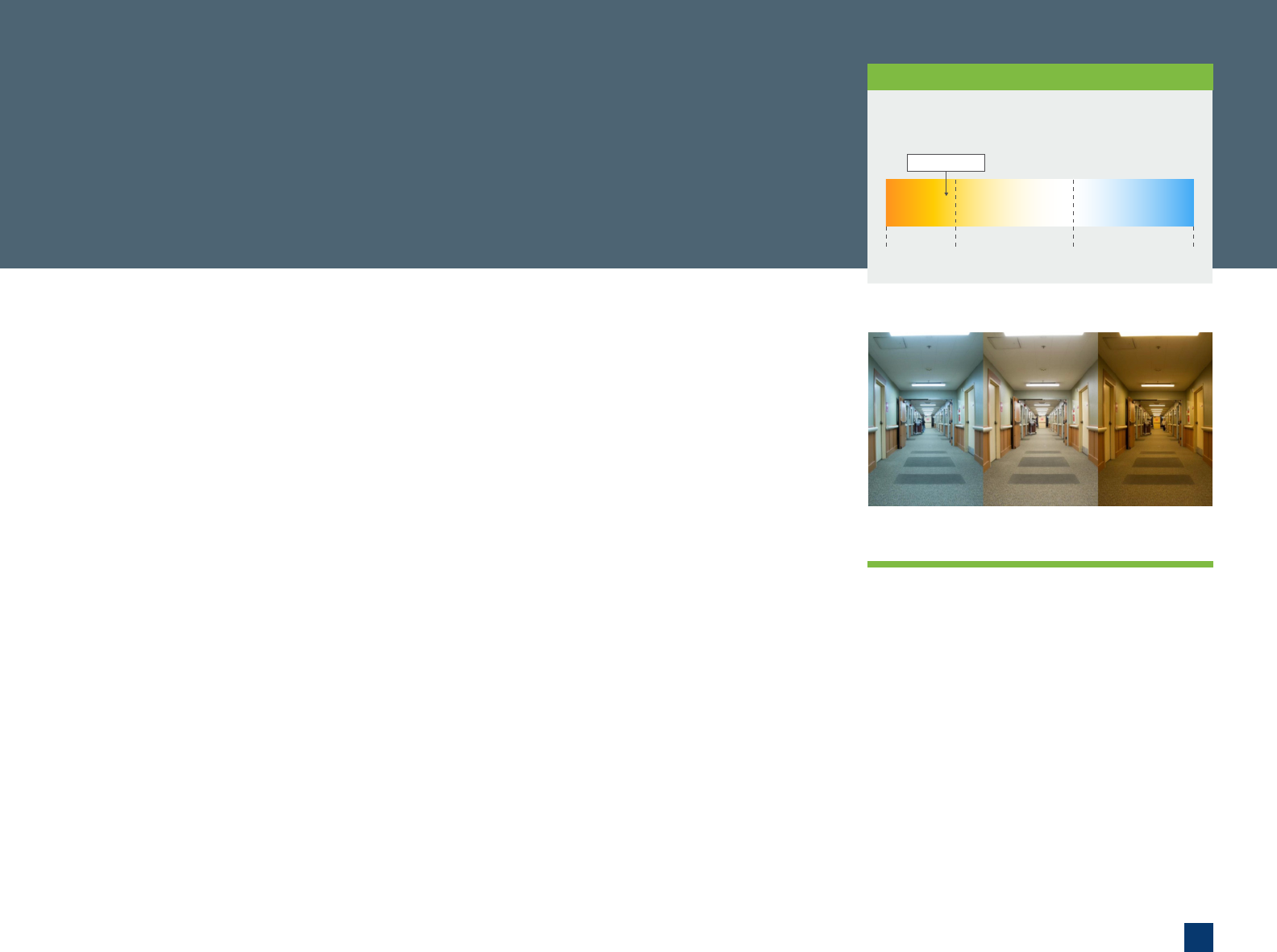

Color Temperature

The correlated color temperature (CCT) is a measure of

the appearance of a light source and is expressed in Kelvin

(K). Low values (1800–2700 K) are warm in appearance,

and high values (4500–6500 K) are cool. A higher or lower

number does not indicate better performance. CCT is an

imprecise metric with multiple structured tolerances per

the American National Standards Institute (ANSI) standard.

As a result, two products can have the same CCT value

and may not appear visually the same.

GSA’s PBS-P100 requires interior lighting to be < 4100 K and

exterior lighting < 3500 K. Some manufacturers oer light

fixtures with multiple CCT values. Electricians can select

from among two or three CCT options in the field using a

dip switch setting at the luminaire. Most occupants prefer

warmer color temperatures in interior applications, with

3000 K and 3500 K being the most common preferences.

Some applications or tasks may require CCT values

greater than 4100 K. These tasks include fine detail work

(e.g., surgery) and precision work (e.g., circuit board

construction). However, for good color, high CRI and ANSI/

IES TM-30 values are more important than CCT values.

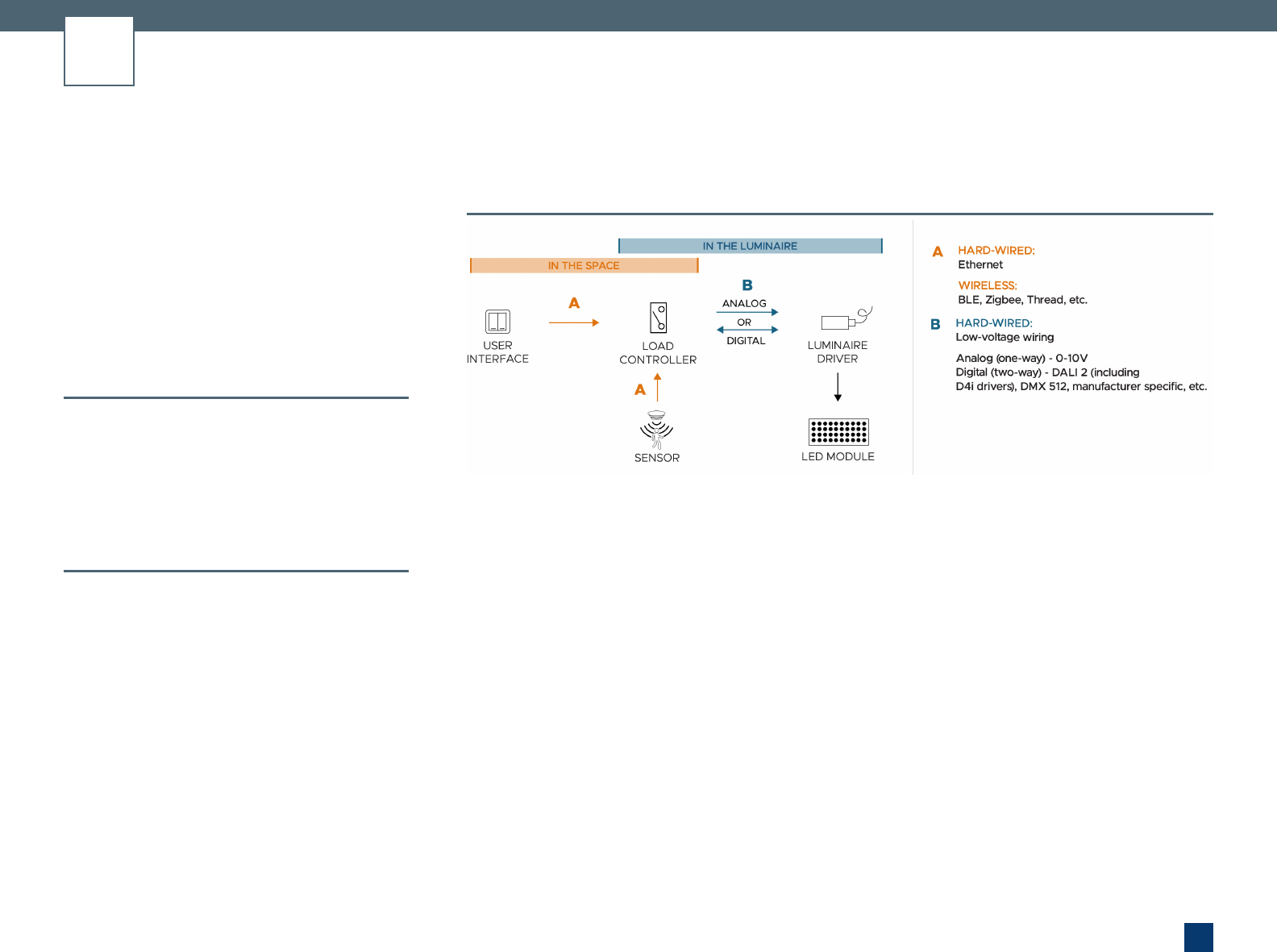

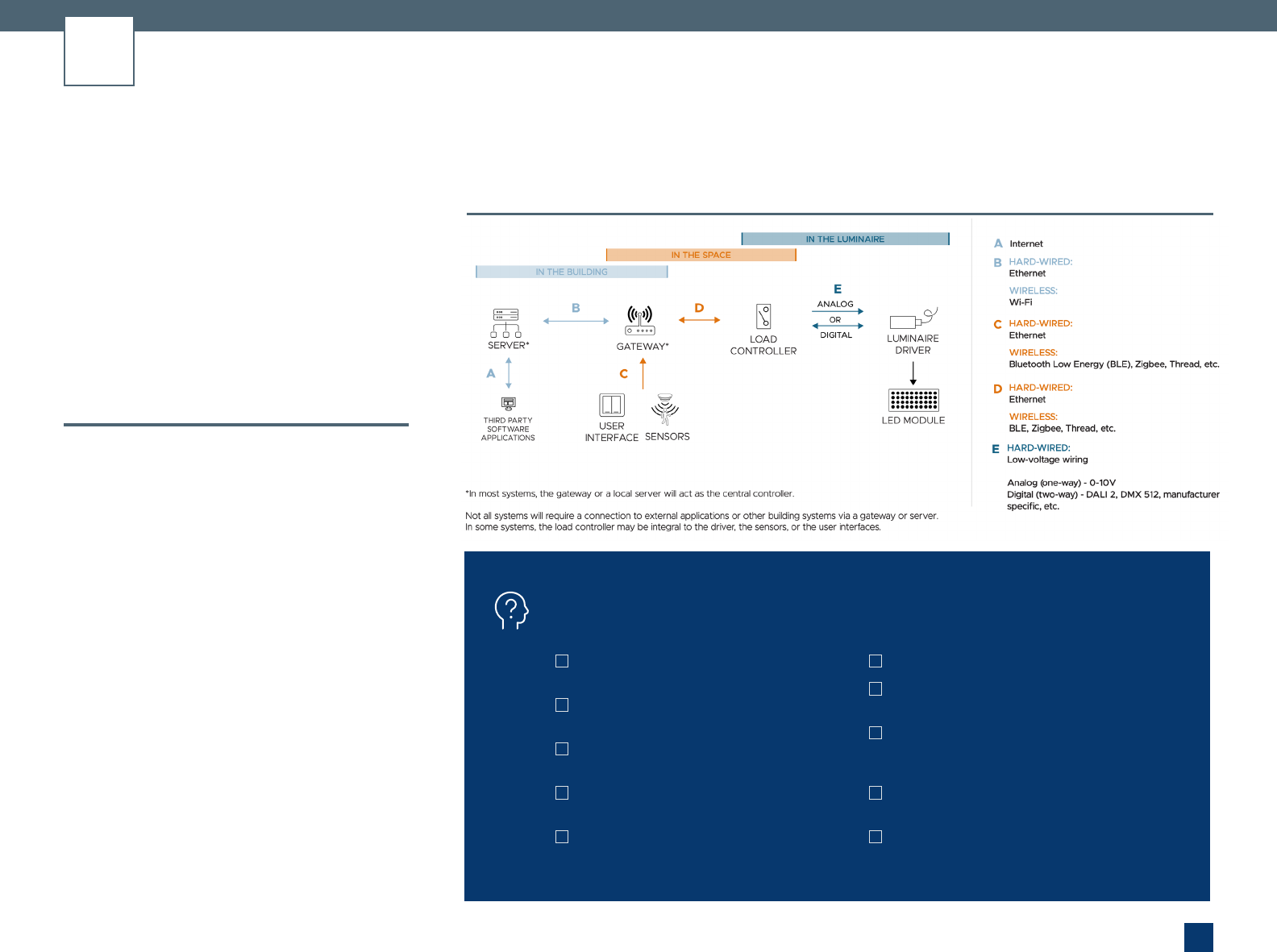

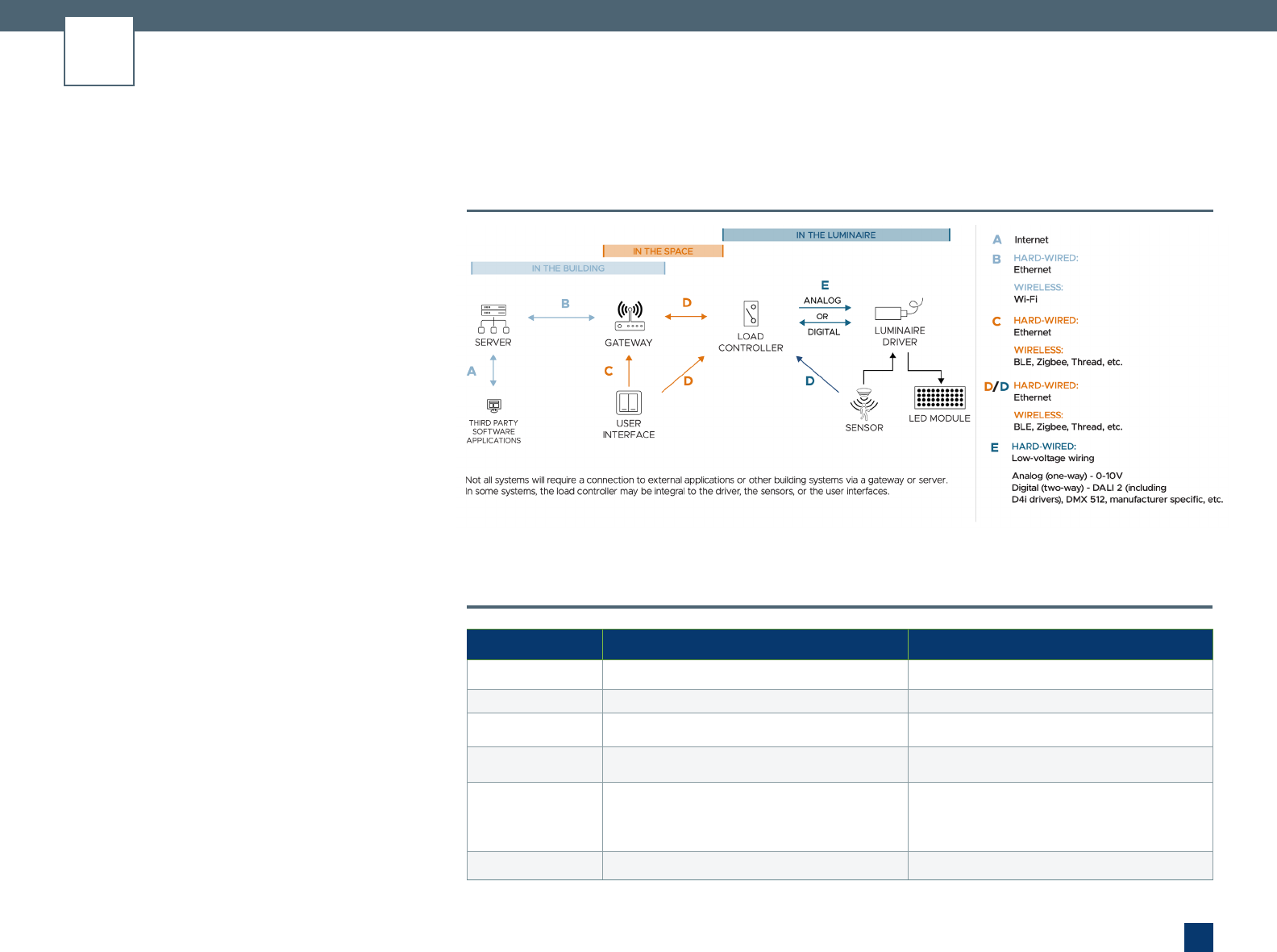

Communication Protocols

Communication protocols are the method by which

devices communicate with each other. Typical

communication protocols include 0–10 V, DALI,

DALI-2, ANSI C137.4 (digital), BacNet, Zigbee,

Bluetooth, Wifi, and Thread.

Controls Interfaces

Controls interfaces are how users interact with the

control system. Explore the controls interface and its

usability before specifying a lighting control system.

PNNL conducted a study and found that vendors

provide dierent means and labeling for increasing

the light level in a space, which can be confusing as

users move between vendors. Inquire about how

the controls work and how easily changes can be

instituted in the system before specifying the full

system. Does the system use an app? Can everything

be controlled or changed at the device? Are the

terms intuitive?

Controls-Ready Fixtures

Controls-ready fixtures include wiring so that the

light fixture can directly support a sensor and/or

communication device after installation. Controls-

ready lamps include a wireless receiver.

Lighting systems have a tremendous impact on building resources. Depending on the building’s

age and lighting system, lighting will consume between 10% and 25% of the electricity in GSA

buildings. Conversions to LED lighting typically save 50% of electricity over a fluorescent baseline.

Furthermore, using less electricity results in lights generating less heat that can allow for reductions

in air-conditioning energy. For this and other reasons, it is a good time to transition to LED.

LED System Features

LED Lighting and Controls Guidance for Federal Buildings

13

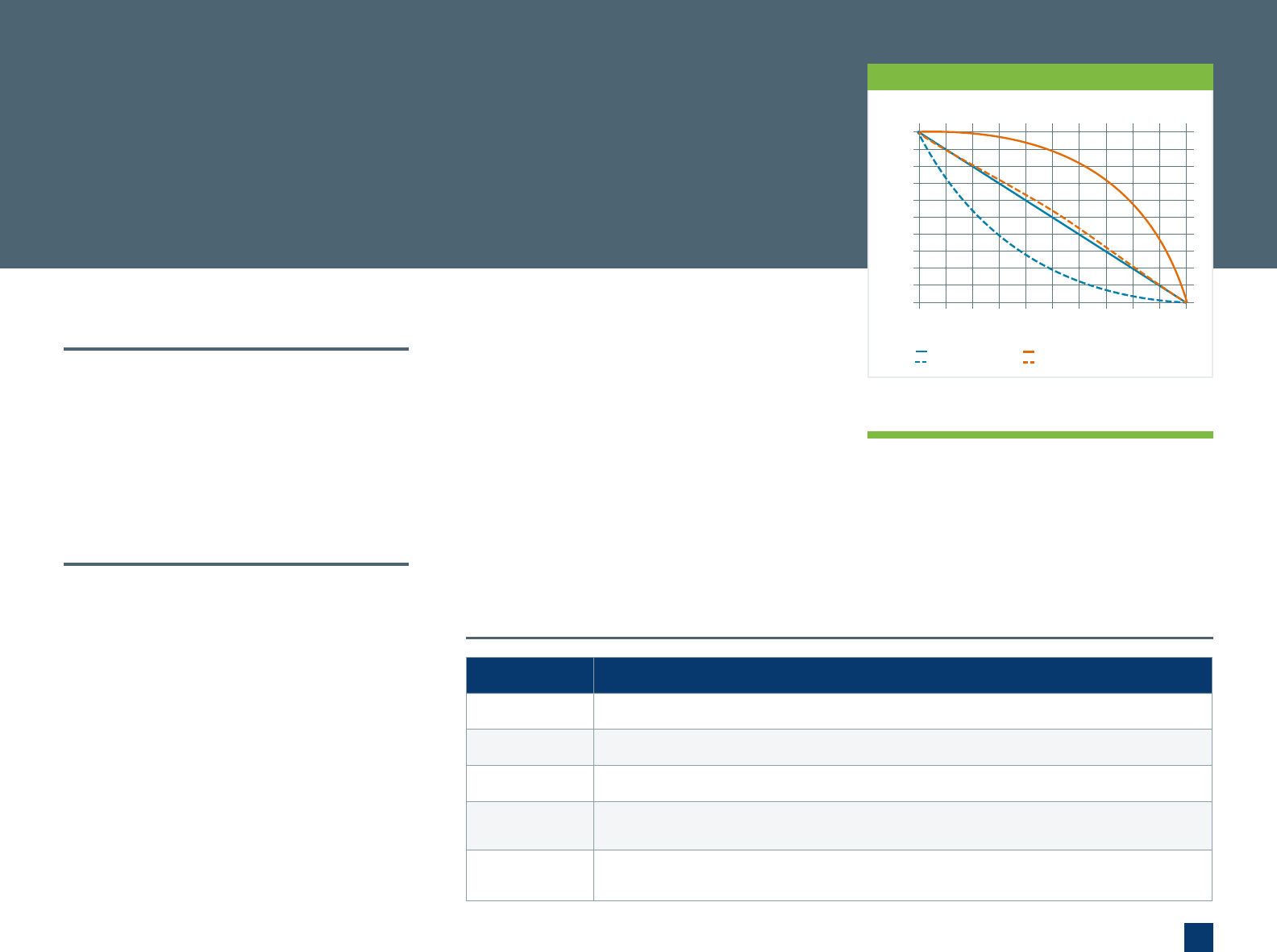

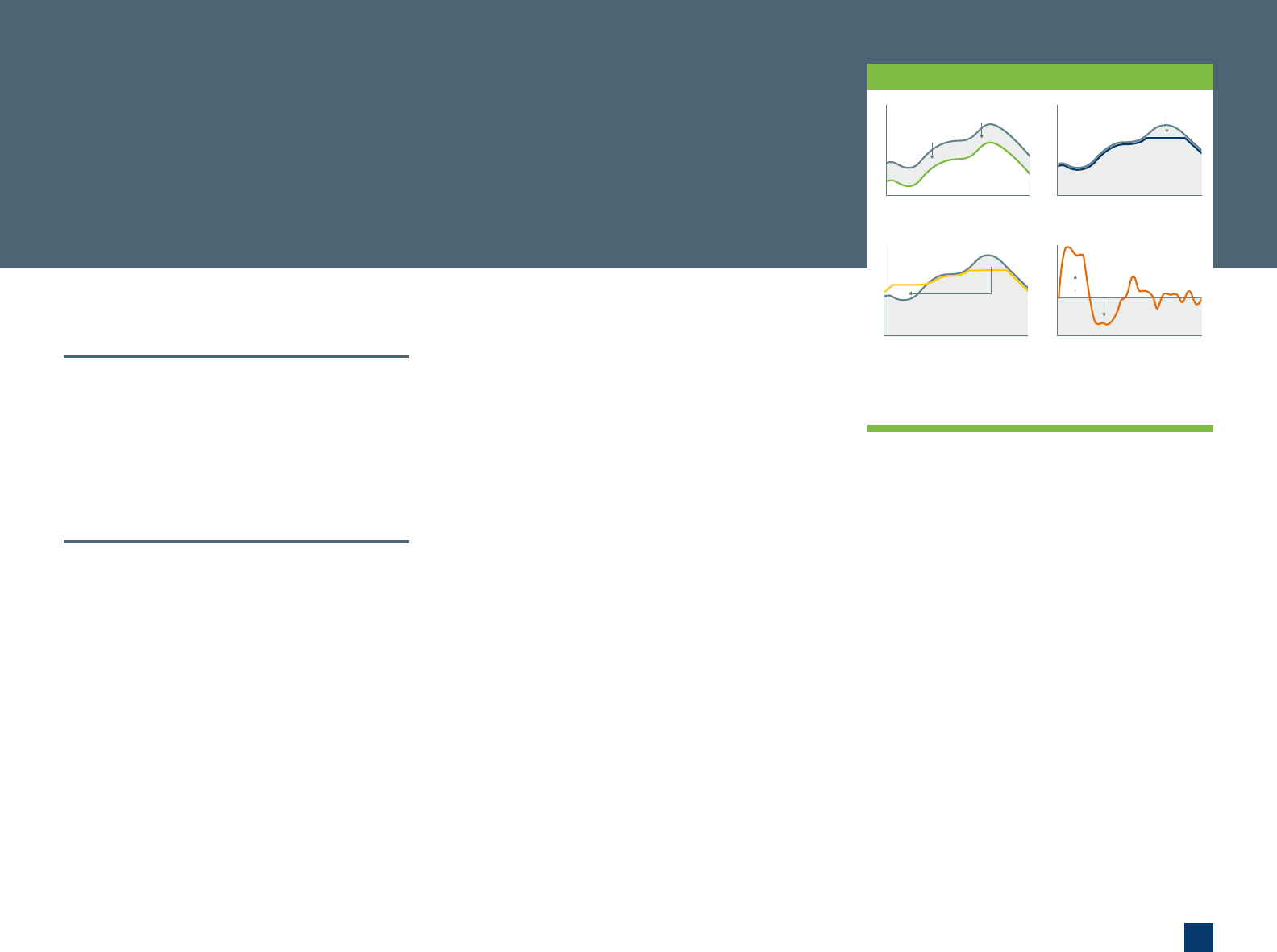

Dimming

Dimming saves energy and is a necessary feature of

multiple energy savings strategies. Drivers use dierent

dimming methods: forward-phase, reverse-phase,

constant current reduction (CCR), and pulse-width

modulation (PWM). All equipment on the same wiring

needs to use the same dimming method. The quality

of dimming (range, curve, consistency, and cost) varies

with drivers and dimming protocols. CCR and PWM

provide smoother dimming and are more common in

commercial fixtures.

Dimming can also be important for occupant satisfaction.

Dimming LED lights does not add additional cost, unlike

with older fluorescent systems. However, not all tubular

LED (TLED) options are dimmable, so if dimming is

required, check the product specifications carefully.

Drivers

A driver is the power supply for LED lighting, fluorescent

lighting like a ballast is for fluorescent. Drivers regulate

current and voltage to the LEDs. It is important to ensure

compatibility between the driver and the controls system.

Some controls manufacturers only interface with specific

drivers (and luminaires).

Distribution

Distribution refers to how light is shaped and directed. It

is represented by beam angles. For example, a light with

a beam angle of 10 degrees is a spotlight; a beam angle

of 25 degrees indicates a narrow flood; a 60-degree beam

angle is a wide flood. An existing lamp and a retrofit lamp

should always have a similar distribution. If they do not,

the combination of the existing fixture and retrofit lamp

will result in an uneven or narrow distribution. Distribution

beam angles can be found in the lamp catalog code and

on the lamp’s datasheet. For a TLED, at least 270-degree

output is necessary.

Ecacy

Lighting ecacy is measured in lumens per watt (lm/W);

the higher the value, the more ecient the lamp. Ecacy

is influenced by luminaire size and type. A downlight

lamp ranges between 50 lm/W and 85 lm/W and a troer

between 85 lm/W and140 lm/W. Parking lot and high

bay luminaires range between 115 lm/W and 150 lm/W.

Section 6.3.2.2 of GSA’s PBS-P100 requires that solid-

state luminaires (LEDs) meet the requirements of the

DesignLights Consortium (DLC).

Eorts to limit glare and improve color, directionality, and

other features can all reduce ecacy. When comparing

two products, ecacy is only one feature to consider.

A luminaire with slightly lower ecacy might be more

desirable because of other luminaire features.

Flicker

Flicker refers to rapid and repeated changes in the

brightness of a light source over time. Very low flicker

can induce seizures; higher flicker can cause headaches

and migraines. The lighting industry is developing

metrics and better methods to determine and evaluate

flicker. Flicker is also a catch-all term and includes

temporal light modulation, direct flicker, the stroboscopic

eect, and the phantom array eect.

Flicker is a function of the frequency of the electrical

signal and the duty cycle—how quickly the light waves

peak per second (frequency), the width/size of those

peaks, and what happens between the peaks.

Fluorescent lamp sources exhibited flicker with

magnetic ballasts (operating at 120 Hz), but flicker

was significantly reduced when the industry shifted

to electronic ballasts (> 20,000 Hz).

Some LED drivers use low frequencies that can cause

flicker. To reduce the potential for flicker, the LED driver

should be high frequency and not have rectangular or

complex waveforms. These drivers currently tend to be

more expensive and possibly larger than some drivers

on the market. Review the driver information carefully as

you consider options.

There is currently no quick and easy way to assess the

driver’s waveform. This waveform can be analyzed with

dierent meters. Request drivers with noncomplex

waveforms from the manufacturer. As specifiers

require a description of the waveform, it will become

commonplace for it to be reported in the documentation.

LED System Features

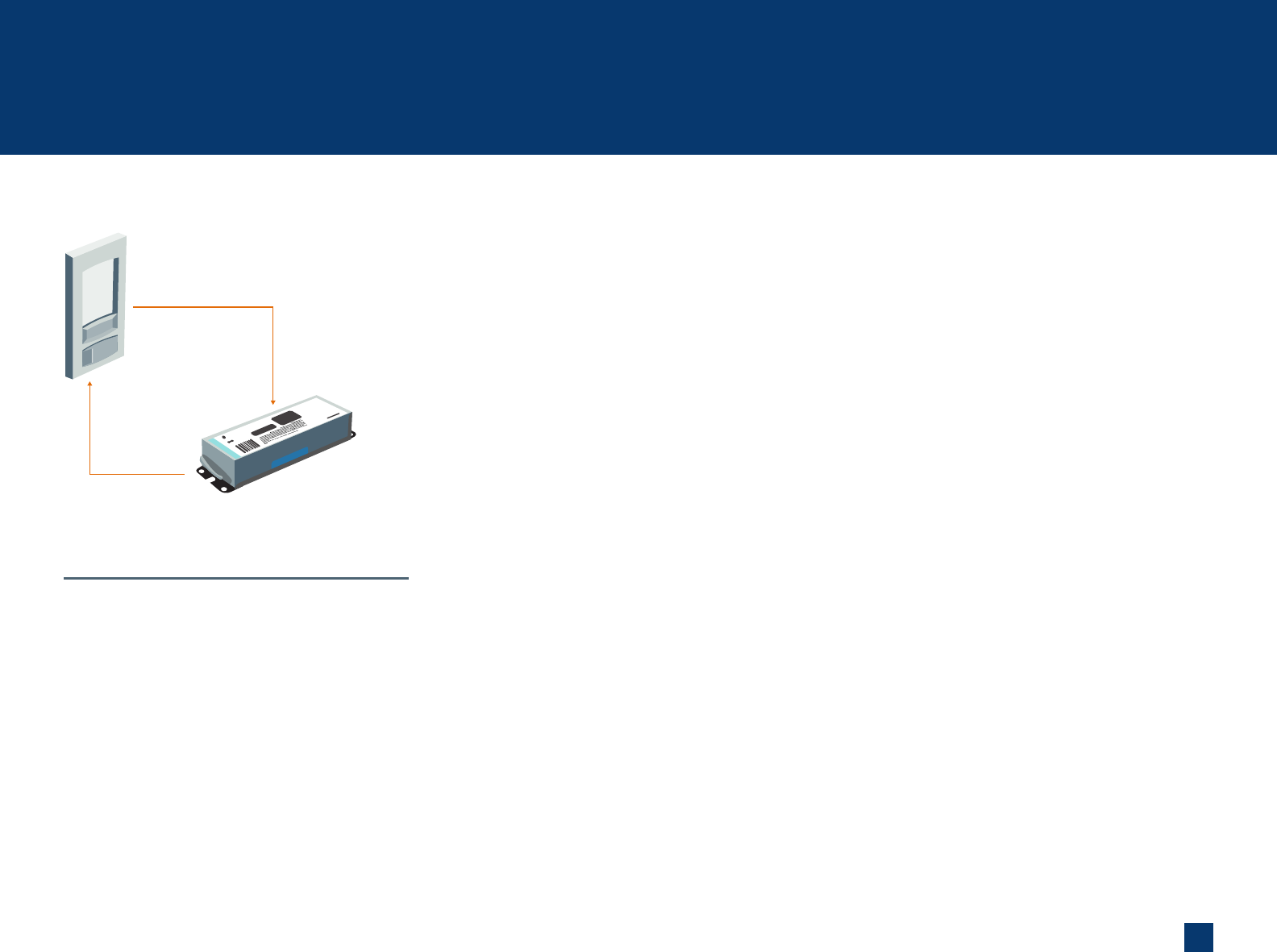

Figure 3

The Driver Determines the Dimming Method

Line Voltage Wire

Communication Protocol

Dimmer

Switch

Driver

Orange

HEX: e36c09

RGB: 227/108/9

CMYK: 7/70/100/1

Yellow

HEX: cb03

RGB: 255/203/3

CMYK: 0/20/100/0

Burnt Orange

HEX: b06928

RGB: 176/105/40

CMYK: 25/63/100/11

Dark Green

HEX: 4d8825

RGB: 77/136/37

CMYK: 74/25/10 0/10

Light Green

Pantone: 376

HEX: 7fbb42

RGB: 127/187/66

CMYK: 56/4/100/0

Dark Blue

HEX: 07386e

RGB: 7/56/110

CMYK: 100/86/31/17

Pale Green

HEX: ecf3d9

RGB: 236/243/217

CMYK: 7/0/17/0

Gray / Blue

HEX: 65848c

RGB: 101/132/140

CMYK: 64/38/38/5

Dark Gray Blue

HEX: 4d6473

RGB: 77/100/115

CMYK: 73/53/42/17

Pale Gray / Blue

HEX: cdd6d3

RGB: 205/214/211

CMYK: 19/9/14/0

Light Gray /Blue

HEX: 8c9ea4

RGB: 140/158/164

CMYK: 48/30/31/0

Warning Red

HEX: ca2c2d

RGB: 202/44/45

CMYK: 14/97/93/4

Bright Blue

HEX: 2574a9

RGB: 37/116/169

CMYK: 85/50/13/1

Dark Gray

HEX: 545454

RGB: 84/84/84

CMYK: 64/56/56/32

reverse link on dk blue body copy color warning online

link blue from - http://colorsafe.co/

11 pt copy on white

Bright Link Blue

HEX: 95dfe0

RGB: 134/218/224

CMYK: 38/0/15/0

Communication Protocol

Dimmer

Switch

Lorem ipsum dolor sit amet, consectetuer adipiscing elit, sed diam nonummy nibh

euismod tincidunt ut laoreet dolore

magna aliquam erat volutpat. Ut wisi enim ad

mi

nim veni

am, quis nostrud exerci tation ullamcorper suscipit lobortis nisl ut aliquip

ex ea comm

odo consequat. Duis autem vel eum iriure dolor in hendrerit in

vulputate velit esse molestie consequat, vel illum dolore eu feugiat nulla facilisis at

vero eros et accumsan et iusto odio dignissim qui blandit

praesent luptatum zzril

delenit augue duis dolore te feugait nulla facilisi

.

Lorem ip

sum dolor sit amet, cons ectetuer adipiscing elit, sed diam

Dimming methods are separate

from communication protocols.

LED Lighting and Controls Guidance for Federal Buildings

14

Replacement Lamps and TLEDs

Replacement lamps are available for 85% of interior light

sources. Tubular LEDs (TLEDs) can be used in linear

fluorescent fixtures (i.e., troers), which are the most

common fixture found in federal government buildings.

TLED replacements have become a popular way to

upgrade lighting systems because they are low cost and

easy to install. They save 25% to 40% lighting energy

compared to fluorescent lamps. The 2016 GSA GPG

study, “Linear LED Lighting Retrofit Assessment,”

found 27% to 29% energy savings by converting

to TLEDs. Since 2016, TLEDs have improved, but

fluorescent lamp performance has remained static since

2012. TLEDs are also longer lasting: TLEDs are typically

rated at 50,000 hours, and fluorescent lamps are rated

at between 25,000 and 40,000 hours. Depending on

the product and control configuration, TLEDs can be

dimmable, which can increase occupant satisfaction. All

TLEDs can create glare problems because the luminous

surface area of TLEDs is much smaller than fluorescent

lamps, and the existing fixture may not eectively

mitigate the glare from TLEDs. Some occupants may

describe TLEDs as too bright, but this may, in fact, be a

problem with glare. To mitigate potential glare issues,

TLEDs should be tested in place.

Retrofit Kits

Retrofit kits are products with a new light source, power

supply, and optics designed to be placed into the shell

of the existing luminaire. By leaving the shell of the

luminaire in place, no new wiring is necessary, and

sensitive spaces (e.g., asbestos above ceiling) do not

have to be disturbed. Kits are also beneficial because

they reduce installation time. The installation time for

kits is a little longer than that for TLEDs and typically

less than half the time for new luminaires. Some kits

may contain integral lighting sensors. Kits (or a similar

name) exist for downlights, troers, linear pendants,

low/high bay fixtures, and in some cases, pole-mounted

luminaires. Retrofit kits have nearly the same life as new

luminaires and may be a partial step to refreshing the

appearance of the space. Kits typically yield 40%

to 60% energy savings before lighting controls are

considered. There is the potential for larger savings

via a redesign and new luminaires, but retrofit kits

can provide maximized energy savings for a reasonable

cost recovery period.

New Fixtures

New fixtures or luminaires are used for new

construction and are the obvious choice for major

renovation or redesign where the ceiling is changed,

but labor costs will be more expensive than retrofit kits.

New luminaires will have a slightly longer life rating

than retrofit kits and similar performance at the device

level as retrofit kits. New luminaires can improve the

appearance of the space.

Interior LED Retrofit Options

GSA Federal Center South Building, Seattle, WA

LED Lighting and Controls Guidance for Federal Buildings

15

Deployment Guidance

Consider if the facility is going to be held < 3 years and

the socket and fixture are in good condition.

Implementation Considerations

Ballast matching can be challenging. A dimming

ballast with a non-dimming lamp will destroy the

ballast. Type A TLEDs will not work with magnetic

ballasts. Magnetic ballasts will be larger and heavier

than electronic ballasts and will emit audible noise.

Ballasts should be labeled (e.g., electronic 2 lamp) to

help with identification. To determine ballast and TLED

compatibility, survey 10% of the fixtures onsite.

After 2025, Type A TLEDs will need to be replaced

with a dierent solution because manufacturers have

stopped making fluorescent ballasts. The fluorescent

ballast has a 10-year life, and most were installed pre-2016.

Assume the ballast reduces the rated eciency

by 20% because of conversion losses.

Dimming is not recommended. There are multiple

issues, including ballast incompatibility, flickering,

and noise.

Cybersecurity scanning is unnecessary unless

a “smart” TLED is installed.

Can be too bright or the diodes are directly

visible and create glare. Because dimming is not

recommended, this can lead to occupant dissatisfaction.

Most utilities do not provide rebates. Incentives

may exist for Type B or Type C TLEDs because those

technologies require electrical modifications to the

luminaires.

Mockups are strongly advised, especially in

courtrooms or high-visibility rooms. GSA has had

experience at several federal sites where Type A

TLEDs did not project light with the same uniformity

as fluorescent bulbs and did not work well in the

existing parabolic or reflective fixtures.

Check the manufacturer’s reputation and warranty

provisions before opting for the lowest-price replacement

bulbs. Low-quality bulbs can flicker and have other

operational issues. Flicker can be disruptive to occupants

and, in extreme cases, induce migraines or headaches.

Type A TLEDs do not require an electrician for

installation. O&M contractors can replace the bulbs

with no extra labor costs.

The tombstone (i.e., socket holder) may have to be

replaced. Type A TLEDs may use shunted tombstones.

Rapid start and dimming fluorescent ballasts use non-

shunted tombstones.

If using a T5 TLED, verify that the length works in

the existing unit since T5s are based on metric lengths

and not units of feet.

Type A TLEDs operate on the existing fluorescent ballast and are a direct replacement for

a fluorescent tube. Type A TLEDs have the shortest simple payback of any retrofit for a

fluorescent lighting system but have a longer ROI over a 15-year analysis.

Type A TLED

Type A TLED installed in the luminaire using the existing ballast.

Photo credit Michael Myer, PNNL

Do not use Type A+B TLED (i.e., dual-mode) because it

introduces more risk.

Remove fluorescent lamps from the site after retrofit

to prevent accidental lamp replacement.

Factor the disposal of lamps into installation costs.

Recycle fluorescent lamps; recycling in bulk costs

~$1.00 per lamp.

Material cost: $10–$20 per lamp; $10–$30 per ballast

Labor time: ~5 minutes per lamp

Low-quality TLEDs show each row of LEDs in the tube and

result in a “pixelated” appearance.

Photo credit Michael Myer, PNNL

LED Lighting and Controls Guidance for Federal Buildings

16

Deployment Guidance

Consider if the facility is going to be held < 5 years and

the socket and fixture are in good condition.

Type B TLED are good for back-of-house and

transitory spaces (e.g., restrooms, storage, mechanical

rooms, and corridors) that typically do not have access

to daylight or need to dim.

An easy option for large projects because they fit

existing sockets and can be delivered “sight unseen.”

The installation team doesn’t need to measure or

identify the existing lighting fixtures.

Avoid using in public spaces, open oces, private

oces, and conference rooms. These spaces

typically have more complex control requirements, and

occupants may have problems with glare or distribution

issues from the Type B TLED retrofit.

Implementation Considerations

Rely on optics of the existing troer, which reduces

the ecacy of lumen output by 10% to 15%.

Can be too bright or the diodes are directly visible and

create glare and lead to occupant dissatisfaction.

Dimming requires a dimming control wire connected

to the fixture. If wires exist, the fixture will need to

be carefully rewired between the line voltage and

communication protocol wires.

May not be eligible for utility rebates.

Remove any magnets used during installation to

hold the tubes in place. Magnets inadvertently left in

the luminaire can cause Type B TLEDs to strobe.

Evaluate a few lamps on site. Some Type B TLEDs

may flicker because the drivers are very small (less

than 1” in width).

Mockups are strongly recommended, especially in

courtrooms or high-visibility rooms.

Select a manufacturer with at least 4 years of

experience. Many TLED manufacturers have limited

experience, and, as a result, some lower-quality products

exist on the market.

Mixing TLED types is not recommended when

transitioning to LEDs. Also, do not use Type A+B TLED

(i.e., dual-mode) because they introduce more risk.

If using a T5 TLED, verify that the length works in the

existing unit since T5s are based on metric lengths and

not units of whole feet.

The tombstone (i.e., socket holder) may have to be

replaced with a non-shunted tombstone to work with

the Type B TLED.

Ensure a qualified electrician disconnects and

removes the ballast. This may add a small recycling/

waste disposal cost, but it is better to remove the ballast

during the retrofit process.

Label each fixture to indicate that fluorescent tubes

should not be installed for safety reasons.

Remove fluorescent lamps from the site after retrofit

to prevent accidental lamp replacement.

Factor recycling lamps and luminaire parts into

installation costs. Bulk lamp recycling costs ~$1.00

per lamp. Recycling costs for PCB-containing ballasts

are ~$1.00/pound and ~$0.50/pound for non-PCB-

containing ballasts.

Material cost: $10–$20 per lamp

Labor time: ~10–15 minutes per lamp

Type B TLEDs include internal LED drivers in the tube and are directly wired to supply line

voltage, thereby reducing the risk of TLED and ballast coordination and eliminating the need to

replace separate ballasts or drivers. Type B TLEDs are the most common, representing more

than 67% of TLED installations.

Type B TLED

Label indicates the fixture was rewired and that fluorescent

tubes should not be installed for safety reasons.

Photo credit Michael Myer, PNNL

Ballast is disconnected. Sockets are wired directly to the

branch circuit and provide line voltage.

Photo credit Michael Myer, PNNL

LED Lighting and Controls Guidance for Federal Buildings

17

Deployment Guidance

Consider if the facility is going to be held < 5 years and

the socket and fixture are in good condition.

Type C TLED are a good choice for high-bay and

low-bay luminaires because one driver can operate

multiple lamps.

Consider when a retrofit kit doesn’t fit and a custom

option is needed.

Avoid using in single-lamp luminaires; a Type A or

Type B TLED will be a better option.

Implementation Considerations

Allows for future driver replacement, whereas Type A

or Type B have to be replaced when the driver fails.

Can include integrated wireless connectivity

(e.g., Wifi, Zigbee, Bluetooth) that will make dimming

and other controls easier.

Depends on existing wiring. If control wiring is not

installed before the Type C TLEDs are installed, additional

wiring or wireless lighting controls will be needed.

Can be too bright or the diodes are directly visible and

create glare. As a result, the TLEDs may need to be

dimmed after installation to meet occupant needs. If the

fixture is not wired for controls, this increases costs.

Delamping with parabolic troers can be

problematic. In the GPG assessment of TLEDs

(GPG-030, TLED Lighting Retrofits with Dedicated

Drivers), sta downsized from three linear fluorescent

lamps to two LEDs to augment savings. The parabolic

louver, coupled with directional LED lamps, can heighten

contrast and increase shadowing.

May be eligible for rebates. GSA Region 7 has used

Type C TLED retrofits in most of its major projects

because it was the only TLED that qualified for rebates

as a “permanent LED fixture” in that market.

Flicker is possible, although less likely than Type A or B.

GSA Region 10 had to halt a Type C project because an

employee was extra sensitive to flicker. They have not

had the same issues with retrofit kits or new fixtures.

If using a T5 TLED, verify that the length works in the

existing unit since T5s are based on metric lengths and

not units of whole feet.

Works with multiple emergency power configurations.

Backward compatibility of Type C tubes and drivers

is unknown. Type C TLED drivers are a small market, and

LED technology changes over time. Future Type C TLED

tubes may not be compatible with drivers installed today.

The tombstone (i.e., socket holder) may have to

be replaced. Type C TLEDs typically use non-shunted

tombstones. Rapid start, programmed, and dimming

fluorescent ballasts use non-shunted, but other fluorescent

ballasts will use shunted and will have to be replaced.

Type C TLEDs incorporate an LED driver external to the tube. One driver can operate

multiple TLED lamps (two, four, or six). In some cases, the driver can contain sensors

or receivers for lighting controls.

Type C TLED

Factor recycling lamps and luminaire parts into

installation costs. Bulk lamp recycling costs ~$1.00

per lamp. Recycling costs for PCB-containing ballasts

are ~$1.00/pound and ~$0.50/pound for non-PCB-

containing ballasts.

Ensure a qualified electrician disconnects and

removes the ballast.

Material cost: $25 for the driver; $10–$20 per lamp

Labor time: ~10–20 minutes

Type C TLEDs use an external driver.

Photo credit Keystone Technology

PRIMARY

DAYLIGHT

ZONE

SECONDARY

DAYLIGHT ZONE

H2

H1

Power

Control Signal

Dimmer

Driver

Power

Wireless

Control

Receiver

Driver

Burnt Orange

Dark Blue

HEX: 07386e

RGB: 7/56/110

CMYK: 100/86/31/17

Dark Gray Blue

HEX: 4d6473

RGB: 77/100/115

CMYK: 73/53/42/17

GPG color palette V4 12.05.22

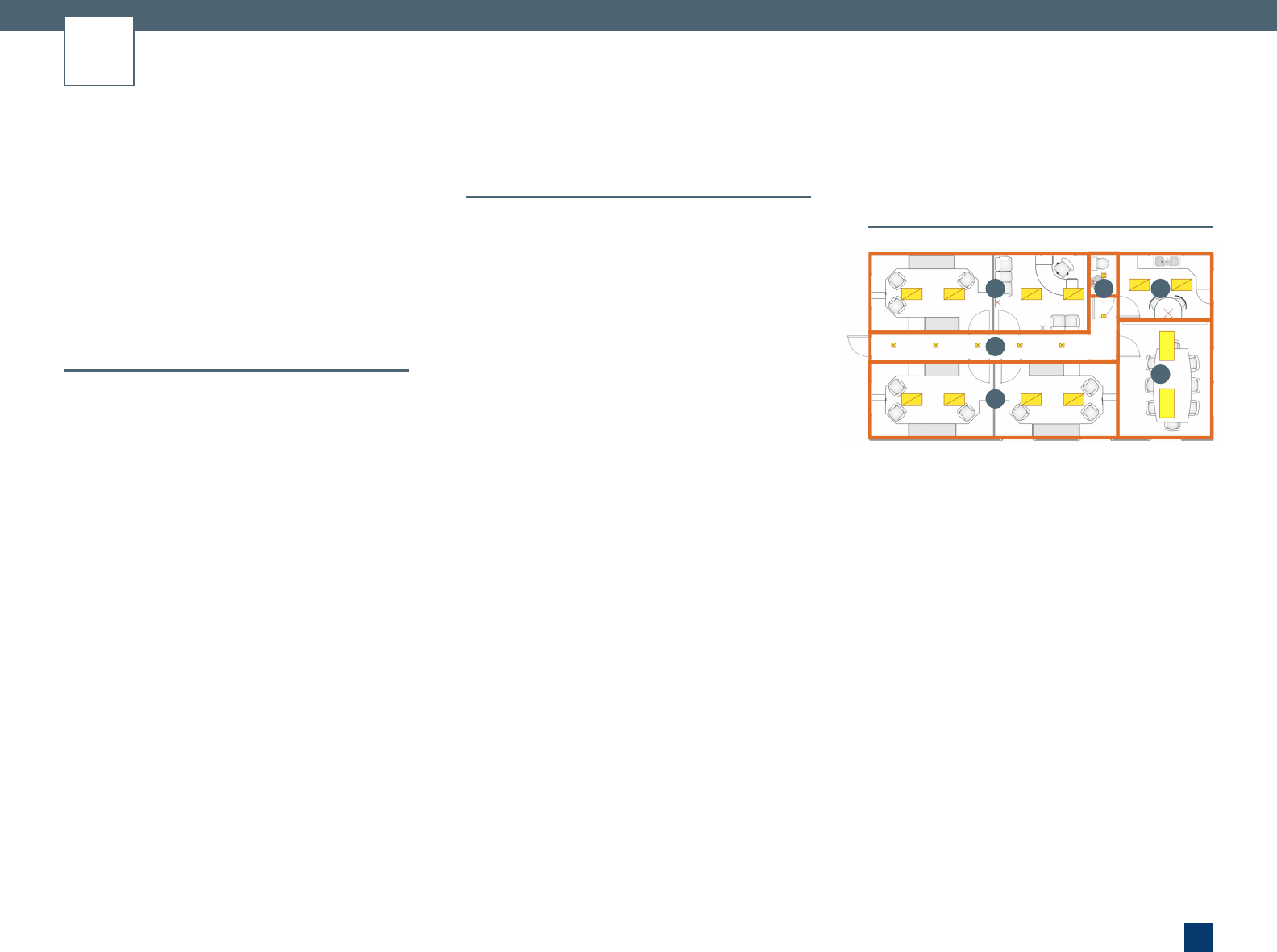

Figure 4

Wired and Wireless Control for Type C TLED

LED Lighting and Controls Guidance for Federal Buildings

18

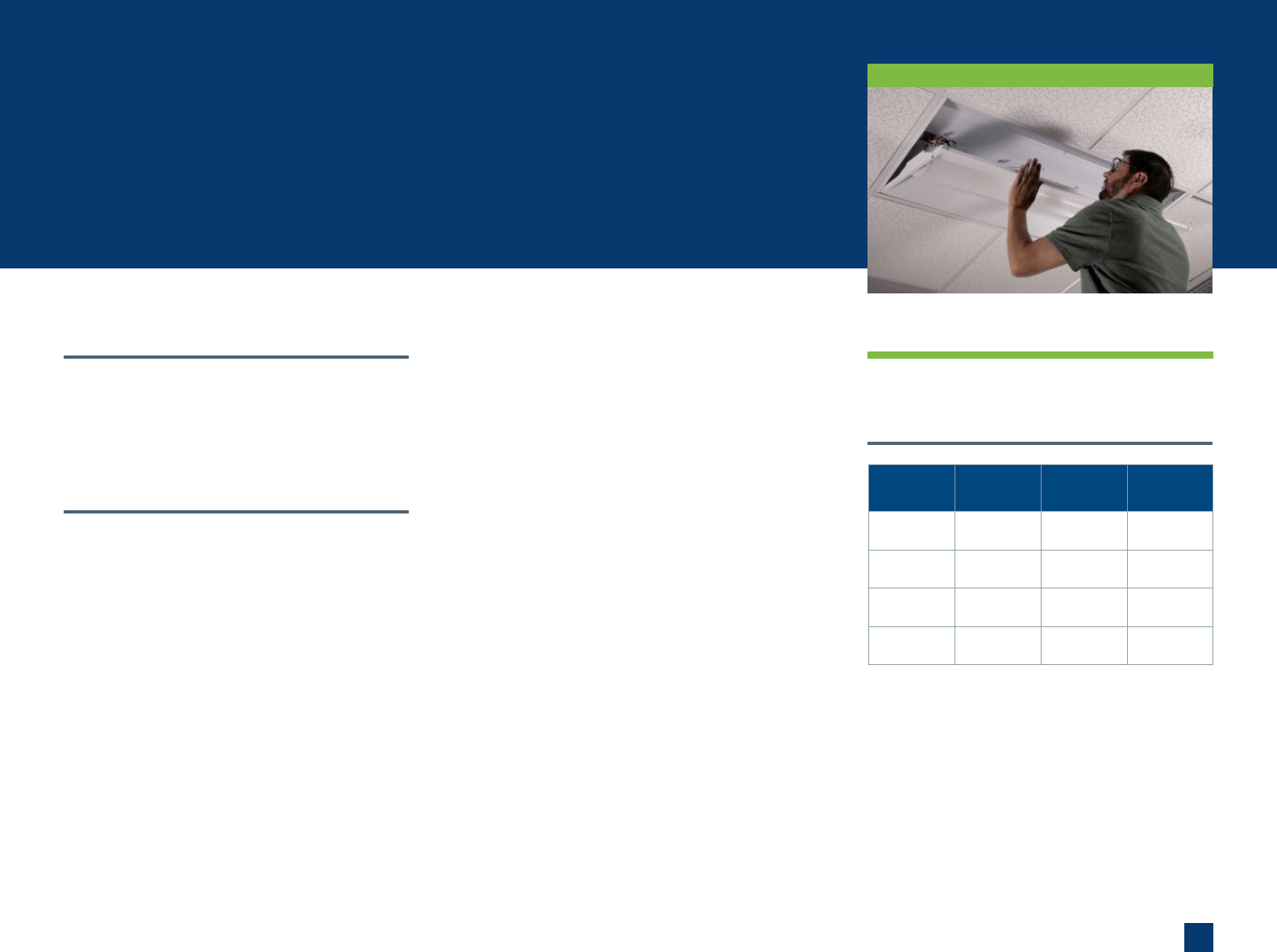

A troer retrofit kit fits within the existing fixture housing (the exterior shell). Most

retrofit kits are designed to be installed from below the ceiling plane. Kits provide

new components for critical elements, so no maintenance is needed for many years.

Troer Retrofit Kits

Deployment Guidance

Focus on buildings that need upgrades in aesthetics

or where tenants have a vested interest in the final look

of lights. Retrofit kits can refresh the look and feel of a

space without having to replace the entire luminaire.

Implementation Considerations

Properly determine retrofit kit light output rather

than matching lumen-for-lumen output. Existing

spaces may be overlit, so correctly sizing light output

can save energy.

Costs can be reduced by working with a team with

varying skill levels rather than requiring a full team of

electricians, particularly on large projects.

Kits are a longer-life option. Heat reduces the life of

LEDs and the driver. Retrofit kits provide more surface

area and heat sinks, reducing the heat on the diodes

and drivers.

Can include integral occupancy and daylight

sensors. This reduces the costs of adding controls

by a factor of two.

If you have lighting fixtures that provide HVAC air

flow through the fixture, look for a retrofit kit that

can accommodate the airflow rather than installing

separate ducting. Otherwise, consider a TLED or new

air-handling LED troer.

Survey existing luminaires onsite to find matching

retrofit kits. Light fixtures vary by manufacturer in

shape and size.

Installing retrofit kits is faster than installing new

fixtures. The GPG technology evaluation at the Fort

Worth Federal Center (GPG-037, Advanced Lighting

Controls and LED) confirmed that installation took less

than 10 minutes.

Install mockups. Lenses and housing often look

dierent in catalogs than in person. Courts have found

several retrofit kit installations that looked “too cheap”

for courthouses. Historic preservation specialists have

not approved some installations in historic buildings.

Time the installation of mockups so the contract can

be based on the actual time rather than an estimated

time. A GPG technology evaluation (GPG-024, LED

Fixtures with Integrated Advanced Lighting Controls)

at the Ralph H. Metcalfe Federal Building in Chicago, IL,

estimated 1 hour per kit for installation. However,

the actual installation time was less than 15 minutes.

Factor the disposal of old luminaire parts into

installation costs.

Rebates may only be available for retrofit kits, which

may make them a better ROI than TLEDs. Rebates for

retrofit kits can be $20–$40 per kit, whereas rebates for

TLEDs are only $1–$4 per lamp.

Material cost: $75–$200

Labor time: ~15 minutes

Most linear retrofit kits can be installed from below the ceiling plane.

Photo credit Lighting Association, Cree Lighting

Retrofit Kit

Applications

Minimum

Light

Output*

Minimum

Ecacy

Standard**

Minimum

Ecacy

Premium**

Troer > 1,500 110 125

Linear

Ambient

> 375 lm/ft 115 130

High-Bay > 10,000 120 130

Low-Bay 5,000–1000 115 130

Table 4

DesignLights Consortium v5.1 Requirements

*Lumens (lm)

**Lumens per watt (lm/W)

LED Lighting and Controls Guidance for Federal Buildings

19

Deployment Guidance

Consider for major interior space retrofit/redesign.

Not only do new fixtures enhance the appearance of

the space, but if the ceiling is being modified in any

way, the existing luminaires will need to be moved or

temporarily removed.

Implementation Considerations

New luminaires will cost more than a replacement

lamp or retrofit kit in labor and materials.

Could require modification to the ceiling system,

either changing the ceiling layout or mitigating

construction materials, such as asbestos.

Ceiling system modifications can optimize lighting

equipment placement (known as a redesign), allow

for new equipment, and refresh the appearance of

the space.

Match the measurement system used in the ceiling

grid to the lighting fixtures (i.e., metric or English).

Document where all parts of the new lighting

system exist, including drivers.

Require a photometric study and design to ensure

proper light distribution. New LED fixture distribution

may dier from the existing fluorescent distribution.

Review plans to ensure that fixtures can be accessed

for maintenance and cleaning.

GSA’s PBS-P100 requires all new interior and exterior

lighting to be high-ecacy LED luminaires that meet

DLC requirements.

EPAct 2005 requires federal agencies to procure

ENERGY STAR or FEMP-designated products,

unless (1) the product is not cost-eective over the life

of the product or (2) no product is reasonably available

that meets the functional requirements of the agency.

FEMP surveys the market and rates the top 25% of the

market as FEMP-designated products (See 42 U.S. Code

§ 8259b). FEMP-designated products are available for

commercial troers, linear ambient luminaires, and low/

high-bay industrial luminaires.

Material cost: Troer: $100–$275; Linear pendant:

$10–$400 (style, materials, and appearance will

aect price)

Labor time: < 1 hour per luminaire

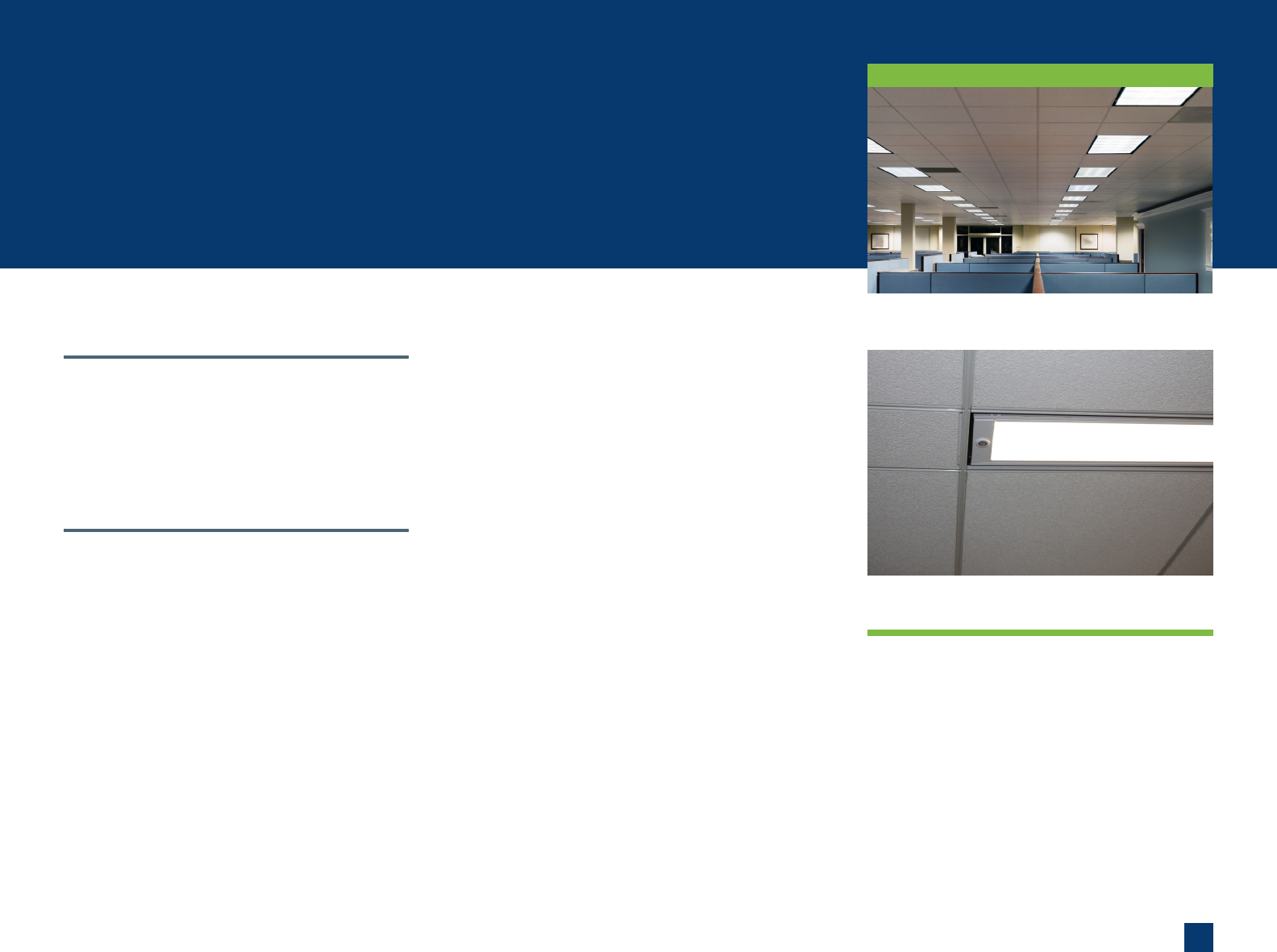

New luminaires are optimized for LED and will control glare and provide optimal

distribution. They will last longer than retrofit kits or replacement lamps. Many new

fixtures are controls-ready out of the box, which can save significant programming

and integration time.

New Troer and Linear Luminaires

Troers are the most common lighting fixture in GSA buildings.

Photo credit iStock

Troer with embedded occupancy sensor

Photo credit Michael Myer, PNNL

LED Lighting and Controls Guidance for Federal Buildings

20

Deployment Guidance

Consider for major interior space redesign or new

construction. PoE will require new fixtures and new

ethernet cable wiring.

Use with other PoE equipment. If the project is using

other PoE devices (e.g., phones, cameras), consider using

PoE lighting too.

Implementation Considerations

Labor and material savings are expected from PoE.

Low-voltage wiring doesn’t require running copper

conduit, which is expensive. PoE also doesn’t require

skilled electricians and can be installed by less-

expensive technicians. Note: Some jurisdictions require

electricians and conduit even with PoE, which can

negate the potential labor savings of this technology.

Ethernet cable termination can be a weak point

in PoE installations. Each cable requires a termination

and connector.

Heat can degrade ethernet cabling. Individual bundles

should not exceed bundles of 24 to extend the expected

lifespan of cables. Also, select unique PoE cable jacket

colors for quick identification.

Place PoE switch equipment in an IT/telecom closet.

A PoE switch is an ethernet switch-powered box with

multiple ports that allow for communication. PoE

equipment should be located in its own rack. Emergency

lighting devices should be separate and clearly labeled.

PoE requires more planning and design because it

involves more than just power being supplied to the

luminaire like with line-voltage fixtures. PoE network

system architecture can vary between manufacturers,

which should be taken into account in the planning.

Look for vendors with networking experience.

Most PoE oerings are partnerships between lighting

and networking vendors. Focus more on the networking

capabilities than the lighting. GPG tested an early

PoE oering from a lighting vendor that did not have

experience with networking, and the project was

unsuccessful.

PoE will require additional cybersecurity. Each

individual device will need to be scanned. Some PoE

devices have received FedRAMP approval.

O&M will need training to operate more complex

technical lighting control systems.

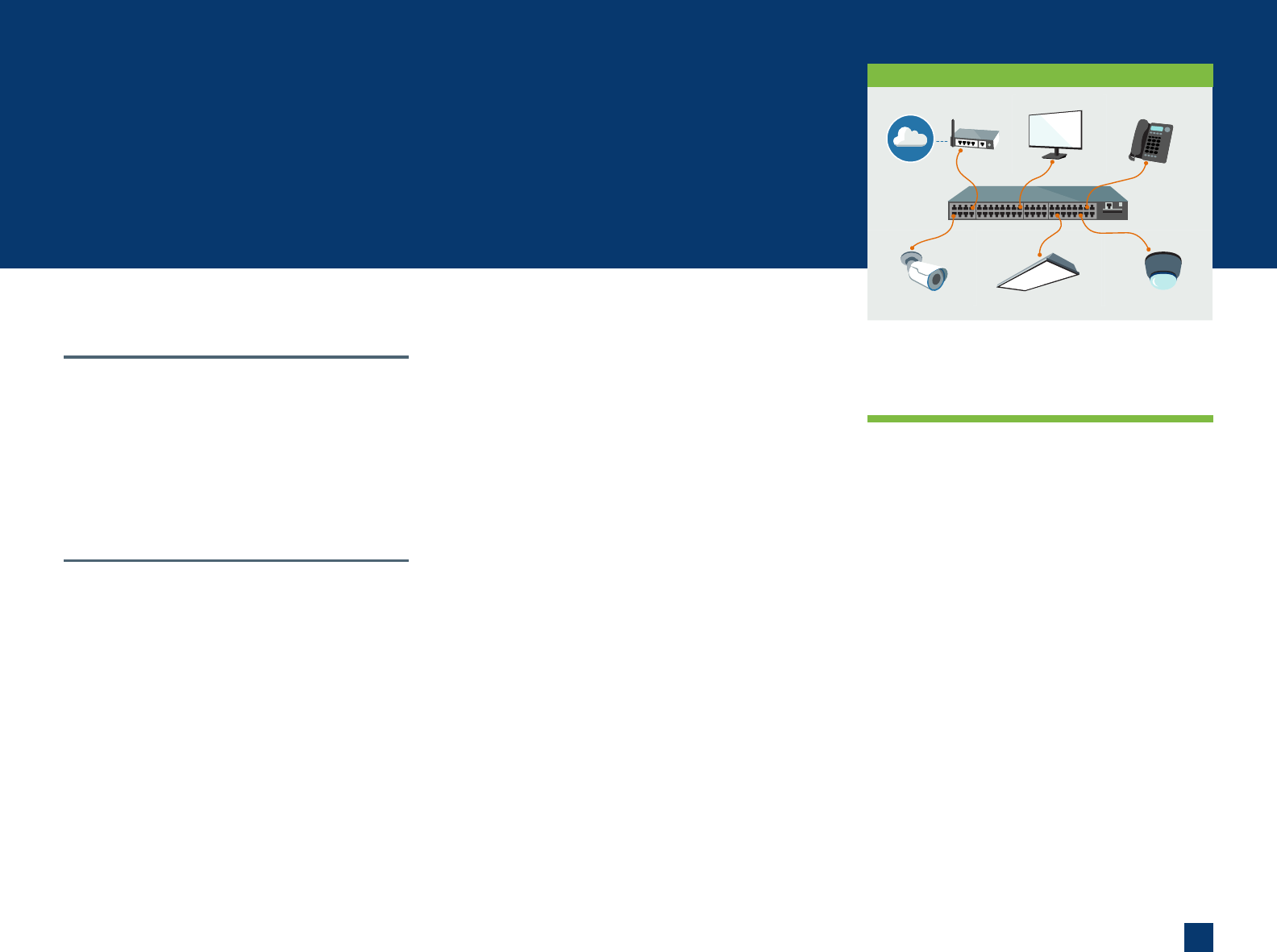

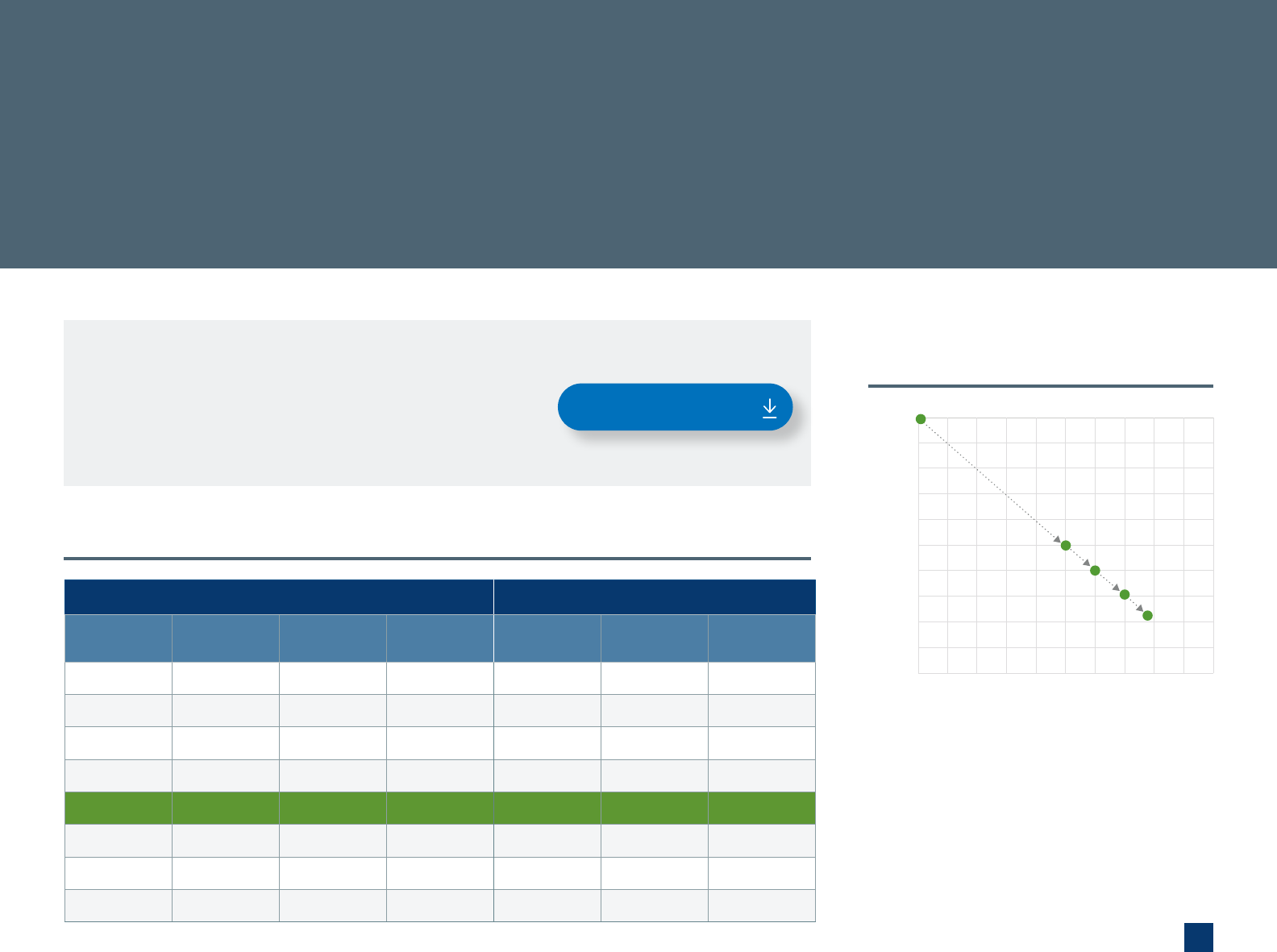

Power-over-Ethernet (PoE) combines power and control signals in a single ethernet cable,

making it ~10%–20% more energy ecient than standard line-voltage light fixtures. Instead of

each light fixture having its own power source, PoE systems use a centralized power supply

to send electricity to multiple light fixtures. Each connected device can send and receive data.

PoE Lighting

luminaire

controller

Figure 5

Power-over-Ethernet networks can combine multiple systems

(e.g., lighting, security, phone, etc.). At the center is a network

switch with ports; orange cables combine power and data.

Material cost: Troer: $100–$275; Linear pendant:

$10–$400 (style, materials, and appearance will aect

price). PoE should have lower wiring material costs

and should be factored into design considerations.

PoE uses CAT 5/6/7 cables that may not require conduit

(dependent on local jurisdiction), and CAT cables are

less expensive than copper wire.

Labor time: < 1 hour per luminaire; savings on wiring

and materials

LED Lighting and Controls Guidance for Federal Buildings

21

Downlights are recessed into the ceiling and include

reflectors designed for the original light source to

provide the necessary distribution for the luminaire. A

GPG technology evaluation (GPG-026, LED Downlight

Lamps for CFL Fixtures) used an LED lamp that was a

direct replacement for pin-based compact fluorescent

lamps. The assessment found up to 50% energy

savings, matching light levels, and payback under

3 years. For better longevity and light distribution than

those of replacement lamps, consider a retrofit kit

because it will contain new optics and a heat sink.

Downlight inserts range in cost between $15–$30.

Low/High Bay spaces are common in industrial,

warehouse, or retail spaces. The tall ceiling heights in

these spaces (e.g., low bay ceilings under 25 feet and

high bay ceilings over 25 feet) make it challenging to

position and power stand-alone lighting control sensors.

• Linear-style fixtures use four, six, or eight fluorescent

T5 or T8 lamps. Since 2010, many linear fixtures have

integrated sensors. Type C TLEDs are a good retrofit

option for linear-style low/high bay luminaires because

they can work with multiple lamps and existing controls.

• Round-style fixtures use either metal halide or high-

pressure sodium lamps, which are not control-friendly

and have very specific optical systems. New luminaires

will have better optics and will allow for integration

with controls.

Linear Pendants are suspended and have two

components: direct (down portion towards task) and

indirect (uplight towards the ceiling). Pendants are

designed around fluorescent lamps and dierent optical

systems. Some retrofit options exist, but they vary and

may be a challenge with more direct pendants. Consider

new luminaires first.

Linear Coves and Wall Slots: Consider new luminaires

because there are few retrofit kits available.

Decorative Lighting: Choose decorative lighting based

on aesthetics; it provides minimal functional lighting.

Manufacturers typically do not measure or state the

ecacy of decorative lighting. Incandescent/halogen

lighting is 10–20 lm/W, and LED decorative lighting is

65–110 lm/W.

Wraparounds: Consider either a TLED or a new

luminaire. TLEDs are a good choice because the

optical systems for wraparounds are not sophisticated,

simply plastic or acrylic diusers. New luminaires

are also a good option because wraparounds can be

quickly replaced (< 0.5 hours). Retrofit kits are not

recommended because wraparounds vary widely

between luminaires.

Strip Lights have exposed lamps that can create glare

with an LED light source. Replace strip lights with a new

wraparound fixture.

This document is primarily focused on linear lighting because it represents the majority of

commercial fixtures. However, there are other interior lighting fixtures to consider. When

designing lighting, don’t locate all of the light fixtures in the same plane. Multiple planes add

visual interest and enhance the space.

Other Interior Lighting

Historically Sensitive Fixtures: Some fixtures may

be considered as historically sensitive and would need

to retain their outward appearance. Because of their

age, the internal wiring should be replaced as part of a

conversion to LED light source(s). Ensure fixtures are

cleaned as part of the conversion process.

Downlights should be replaced rather than retrofitted.

Photo credit iStock

Linear pendants have both an uplight and downlight and can

be challenging to retrofit to LED lighting. New fixtures are best.

Photo credit iStock

LED Lighting and Controls Guidance for Federal Buildings

22

Deployment Guidance

LED lights at entrances and exits must be connected to

an emergency lighting system.

If the building uses emergency ballasts, install either

Type C, LED retrofit kits, or new luminaires with

emergency drivers. The inclusion of emergency drivers

with Type B TLEDs may be more complex.

Occupancy sensors can be used in both stairs and

means of egress as long as the devices meet National Fire

Protection Association (NFPA) 101. Because stairwells are

not used regularly, bi-level occupancy sensors in stairs can

reduce energy use by more than 50%.

Implementation Considerations

Emergency lighting does not need to generate the

same amount of light as normal operations. The

exact parameters need to be verified by photometric

calculations, but in general, an emergency driver

will have ⅓ the rated power of the normal driver. For

example, if the normal driver is rated at 22 W, the

emergency driver may be rated at 8 W.

Discuss emergency lighting options before the final

set of specifications. Although emergency lighting is a

small portion of the overall lighting project, it should not

be an afterthought.

Confirm the control system is wired correctly to

the automatic emergency controls. In a correct

wiring scenario, when lights are manually turned o,

the emergency lighting should not turn on. Emergency

lighting should only turn on when there is a failure of

the branch circuit.

Energy codes require egress lighting to be turned

o when the building is unoccupied. Do not use a

nightlight circuit with egress, emergency, and night

lighting. ASHRAE/IES Standard 90.1 requires most

lighting to be o when the building is unoccupied. A

small portion can remain on if the lighting load does not

exceed 0.02 W/ft

2

multiplied by the gross lighted floor

area of the building.

UL 924-listed relay devices, the Standard for Safety of

Emergency Lighting and Power Equipment, should be

used to enable emergency lighting to turn on quickly.

Check older LED exit signs for light output. LED exit

signs don’t stop working but produce less light over

time. LED exit signs installed earlier than 2010 may not

be producing the necessary amount of light required.

NFPA 101 power failure requirements include

the following: emergency lighting must turn on

within 10 seconds of power failure to the branch circuit

and provide an average of 1.0 footcandle (fc) (and no

less than 0.1 fc along the path of egress) for at least

90 minutes.

Emergency lighting must turn on within 10 seconds of a power loss and remain on for at

least 90 minutes. Most emergency lighting illuminates pathways and exits that lead out

of the building—the egress paths. Physical limitations onsite may dictate the emergency

power options.

Emergency and Egress Lighting

AC Line In AC Line In

Existing

Sockets

Original

Fluorescent

Ballast

TLED

Replacement

Tubes with

Internal Driver

Emergency

Ballast

Installation

Emergency

Ballast with

High-frequency

AC Output

AC Line In AC Line In

Existing

Sockets

Replacement

AC LED Driver

TLED

Replacement

Tubes without

Internal Driver

Emergency

LED Driver

Installation

Emergency

LED Driver

with DC Output

AC Line In

Existing

Sockets

TLED

Replacement

Tubes with

Internal Driver

Emergency

Inverter

Installation

Emergency

Inverter

AC Line In

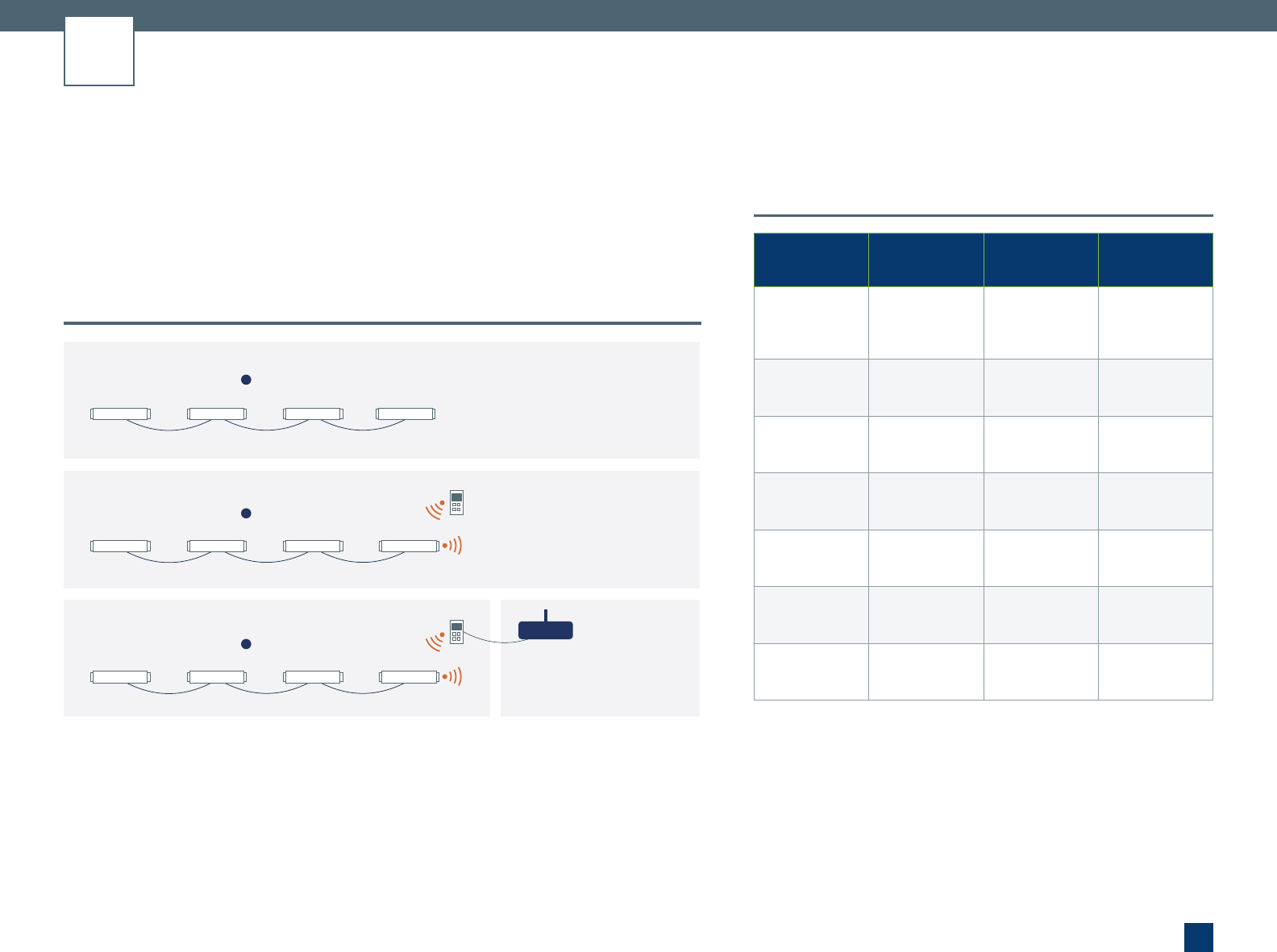

Figure 6

Emergency Power Configurations for TLEDs

Type A TLED with emergency power supplied by

an emergency ballast

Type B TLED with emergency power supplied by

an emergency inverter

Type C TLED with emergency power supplied by

an emergency driver

LED Lighting and Controls Guidance for Federal Buildings

23

NFPA 101 inspection requirements include: Monthly

inspection of every emergency light for a minimum of

30 seconds, and an annual 90-minute test system. With

the appropriate software settings, networked lighting

controls can routinely test and verify emergency lighting

without the need for sta to walk the building. Note

that emergency LED drivers for networked lighting

can be more expensive than standard LED drivers, and

integrating networked lighting controls into emergency

lighting systems can be more complex than stand-alone

lighting systems.

Material cost: Integral battery drivers for digital drivers

(e.g., D4i, ANSI C137.4) cost more than other integral

battery drivers for standard LED luminaires.

Labor time: Monthly and annual tests of emergency

lighting is required, which may require building sta to

test when the space is unoccupied—networked lighting

controls (e.g., D4i, ANSI C137.4) allow for remote testing

rather than physically having to visit each fixture.

Table 5 compares three dierent emergency lighting

power sources, their functional requirements, and

recommendations for deploying each method.

Table 5

Emergency Lighting Power Methods

Emergency Lighting Power Source Requirements Recommendations

Generator • Requires a defined location for the generator

and fuel storage.

• Commonly used at GSA sites. Recent

weather-related issues have demonstrated

generator vulnerabilities.

Centralized battery/inverter • Requires a minimum design life of 10 years.

• Size the system to provide necessary load at

the end of the design life.

• If powering other equipment and non-linear

loads, will need to be a larger size.

• To transform standard lighting into

emergency lighting, use automatic

load-control relays and branch-circuit

emergency lighting transfer switches.

They can bypass the controls in the

event of a power loss.

Batteries integral to the luminaires

(emergency drivers)

• Requires a separate emergency driver that

will be physically attached to the luminaire.

• Unless networked controlled, the maintenance

sta needs to be able to physically push the

test button.

• Suitable solution for small-size projects

< 100 emergency fixtures.

Emergency and Egress Lighting

LED Lighting and Controls Guidance for Federal Buildings

24

Deployment Guidance

Exterior fixtures should be replaced rather than

retrofitted. Moisture and dirt seals on LED luminaires

are dierent (and better) than the seals on fluorescent or

high-intensity discharge (HID) luminaires.

Provide exterior lighting in the following order:

• First, address safety concerns, place lighting at stairs,

where humans and vehicles interact (e.g., parking

lots, crosswalks), and near doors. GSA has used

lighted handrails on ramps and stairs. Although more

expensive, this option can provide better lighting,

aesthetic benefits, and user satisfaction.

• Next, address security. Not all surfaces have to be

lighted. Avoid placing a fixture that lights the area but

makes it harder to see the field of view.

• Finally, selectively provide aesthetic lighting. Consider

lighting the flag pole, vertically washing the building

exterior, or providing lighting that highlights columns.

Aesthetic lighting may need to be bright so the

element stands out and draws your attention, but it

should be used sparingly.

Implementation Considerations

Poles, trenching, and bases to pole-mounted lighting

are significantly more expensive than the actual

lighting fixtures. Lighting design often balances

sucient lighting within a certain budget. For example,

using a 32-ft mounting height for a fixture may result

in fewer poles, bases, and trenching than a 25-ft

mounting height.

Be aware of the directionality and brightness of

new LED lighting and design accordingly.

Planning for maintenance is more important for

exterior applications. A lift truck can be thousands

of dollars per visit.

Replacement of pole lights can provide significant

O&M savings. Region 7 replaced all pole lights at

the Fort Worth Federal Center. The conversion to LED

lighting eliminated a $5,000 lift rental every quarter for

the O&M to replace burnt-out lights.

Surfaces do not need to be continuously lighted.

Lighting recommendations allow for some dark spots.

Brighter is not better in exterior lighting.

Always use either a combination photocell + time

clock or an astronomical time clock. Note that the

schedule can be set to turn on/o closer to sunset/

sunrise than older HID lighting, which required a long

warm-up period.

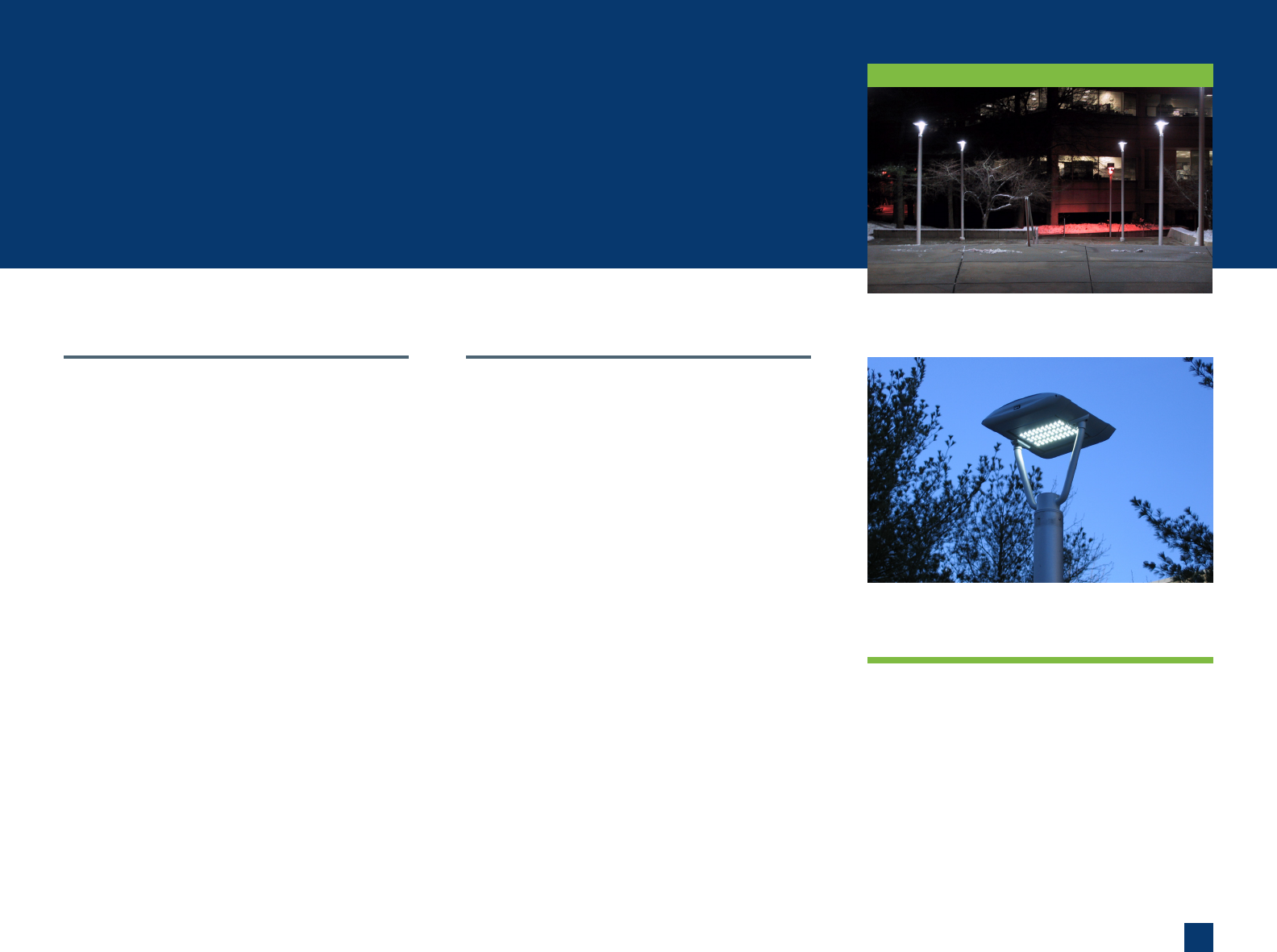

Exterior LED lighting can enhance security and provide increased visibility due to better

distribution and uniformity of light. Exterior lighting is less complex than interior lighting

but it can have greater maintenance costs.

Exterior Lighting

Lighting stairs is more important than continuous walkways.

Photo credit Michael Myer, PNNL

LED exterior fixtures often have opaque tops and produce no

uplight. This fixture has a U0 uplight value.

Photo credit Michael Myer, PNNL

LED Lighting and Controls Guidance for Federal Buildings

25

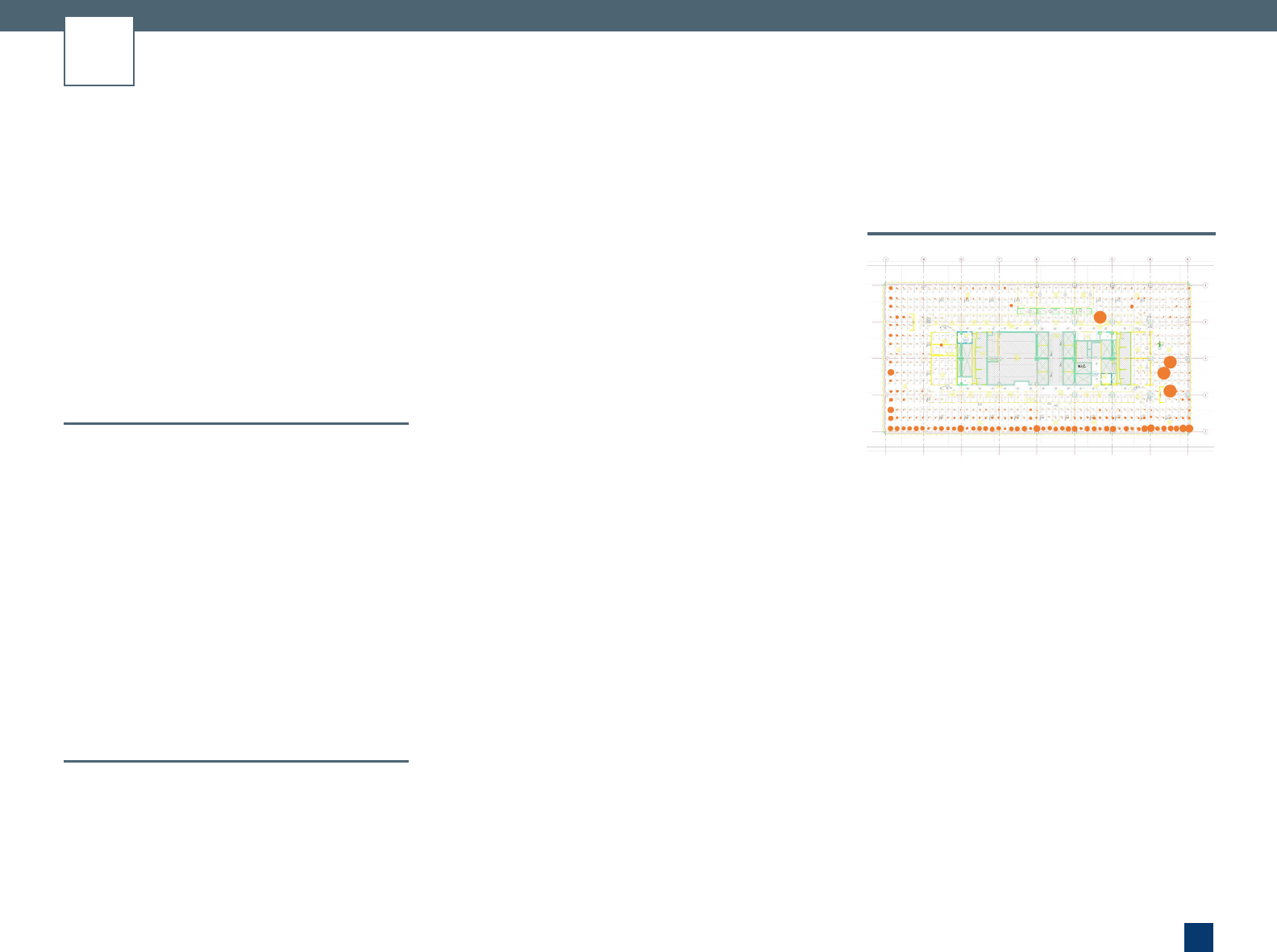

GSA’s P100 requires verification at commissioning

that nighttime setback reduces the lighting power

to 50%.