Chapter 22: Statistical Data Analysis

22.1- Introduction

22.2 - Types of Error

Gross Error

Systematic Error

Random Error

22.3 - Precision vs. Accuracy

22.4 - Statistical Tools

Population vs. Sample

Mean

Standard Deviation and Variance

Standard Error and Error Bars.

Normal Distributions

Confidence Limits

Using Spreadsheets to Determine Confidence Limits

Propagation of Error

Analyzing Data Sets

Identifying Outliers: The Q-Test

Identifying Outliers: The Grubb’s Test

Analyzing Variance: The F-Test

ANOVA: A 2-Dimenstional F-Test

22.5 - Linear Regression Analysis

22.6 - LOD, LOQ and LDR

22.7 - Further Reading

22.8 - Additional Exercises

671

22.1 - Introduction

When we make an instrumental measurement, we want the measurement to be “correct.” So

it makes sense for us to start this discussion with a look at what the word “correct” means to a

scientist. When we make a measurement, there is a fundamental limit to how well we can

“know” the answer

1

. Therefore a real measurement cannot have a single “true” value and to

be complete, must be accompanied by a statement of the uncertainty in the number. In order

for a scientific measurement to be “correct” it must represent the best estimate of the mean of

a set of replicate measurements and be accompanied by an estimate of the uncertainty in the

mean (i.e. error). For example you might see a reported mass as 2.15 ±0.01 grams. The typical

interpretation of this reported value would be that our best estimate of the “true” value is 2.15

grams and the standard deviation of the mean lies in the range of 0.01 above and below the

value of 2.15. Unfortunately the interpretation of the ±0.01 is not consistent throughout all

disciplines of science. Although we have stated here that the ±0.01 typically represents

standard deviation, it is possible that the ±0.01 represents the standard error or the confidence

interval

2

. It is a best practice to always include a statement describing how you are reporting

error in all of your scientific reports.

22.2 - Types of Error

“Nature does not give up her secrets lightly

3

” and in the pursuit of

nature’s secrets it is accepted that the first measurement will yield a false representation of the

truth. In other words, any single data point will inherently contain error

4

. The word error

comes from Latin and loosely translates as “wandering.” For our purposes we define error as

the difference between the experimentally obtained value and the true value. Ironically, if we

knew the true value, we would have no need to conduct the experiment in the first place. This

leads us to a philosophically important conclusion. The goal of an experiment is to obtain a

“true” measured value but since all measured data points contain error, we can never know

with absolute certainty the true value of an experimentally obtained result. All experimentally

obtained results contain uncertainty. Therefore, it is the analyst’s objective to minimize and

quantify error.

It is generally recognized that there are three broad categories of error; gross error,

5

systematic

error

6

and random error.

1

This implied by the Heisenberg Uncertainty Principle: Werner Heisenberg. Z. Phys. 43 (3–4): 172–198. 1927

2

We will define standard error and confidence limits later in this chapter.

3

Brian Greene, The Fabric of the Cosmos: Space, Time, and the Texture of Reality, First Vintage Books (2004)

4

We will use the terms uncertainty and error interchangeably.

5

Also known as human error, operator error, or illegitimate error.

6

Also known as bias.

It is the analyst’s

objective to minimize

and quantify error.

672

Gross Error

Gross error occurs when the analyst makes a mistake. For example the analyst might misread a

balance or strike the wrong button on his/her calculator. These gross errors are often obvious.

However not all mistakes are treated equal. For example, if you were to make replicate

measurements of the volume of your favorite coffee mug and you obtained a set of volumes

such as 298 ml, 302 ml, 299 ml, 80.53 liters, 297 ml, 301 ml, 299ml, 295 ml, 301 ml and 270 ml,

you would immediately recognize that the 80.53 liter measurement was completely WRONG.

You obviously made a mistake! The purist might say that you must keep the 80.53 liter data

point until you can statistically justify the exclusion of that data point. However in practice few

analysts will keep a data point if it is completely obvious that a gross mistake was made. But be

careful. Casually throwing out data points that you do not like is against best practices. There

are good reasons why the purist will always justify an exclusion using statistical tools. Taking

another look at our data you might also wonder about the 270 ml data point? If you exclude

the 80.53 liter data point AND the 270 ml data point you get an average value of 299 ml. It

would appear that the 270 ml data point is ≈ 30 ml “too low”. You might be tempted to ignore

that data point but again, this would be a violation of best practices and in this case it is not so

obvious that the answer is WRONG. Within the precision of your technique, the 270 ml data

point might be legitimate. For example, if you keep the 270 ml data point, you obtain an

average of 295.7 ml and your original data set had a data point of 295 ml. By casually throwing

out the 270 ml data point, you may have artificially raised the mean of your data set. You

would first need to statistically justify the exclusion of the 270 ml data point before you could

ignore it. Data points that statistically fall outside the range of a data set are called outliers.

We will explore the notion of outliers further in section 22.4 when we discuss Q-tests and

Grubb’s-tests.

Systematic Error

Systematic error can be described as a measurement that is always too high or always too low,

and the magnitude of the deviation from the “true” value is constant. Systematic error is often

difficult to identify. The origin of systematic error can be chemical and/or instrumental in

origin. Instrumental systematic errors can result from drift noise

7

, external interference, or

improper calibration of the instrument. For instance an improper ground wire may result in a

bias on the detector that artificially raises or lowers the instrument response to your

measurement. Likewise, if your instrument’s critical components are not properly shielded, an

external magnetic or radio frequency signal can cause your instrument’s response to shift from

its original calibrated value. Instrumental systematic errors are identified by analyzing carefully

constructed standards on a regular basis. For example, baseline drift is a common problem

when conducting AAS analysis. For this reason it is common for AAS methods to incorporate a

blank and a known standard in the analysis after every 5 or 10 samples.

Chemical systematic error occurs in many ways. For instance any error in the construction of

standards used to calibrate an instrument will necessarily impart a systematic error to the

instrumental response. Or a chemical systematic error might result from chemical steps used in

7

See Chapter 5 for a review of noise sources.

673

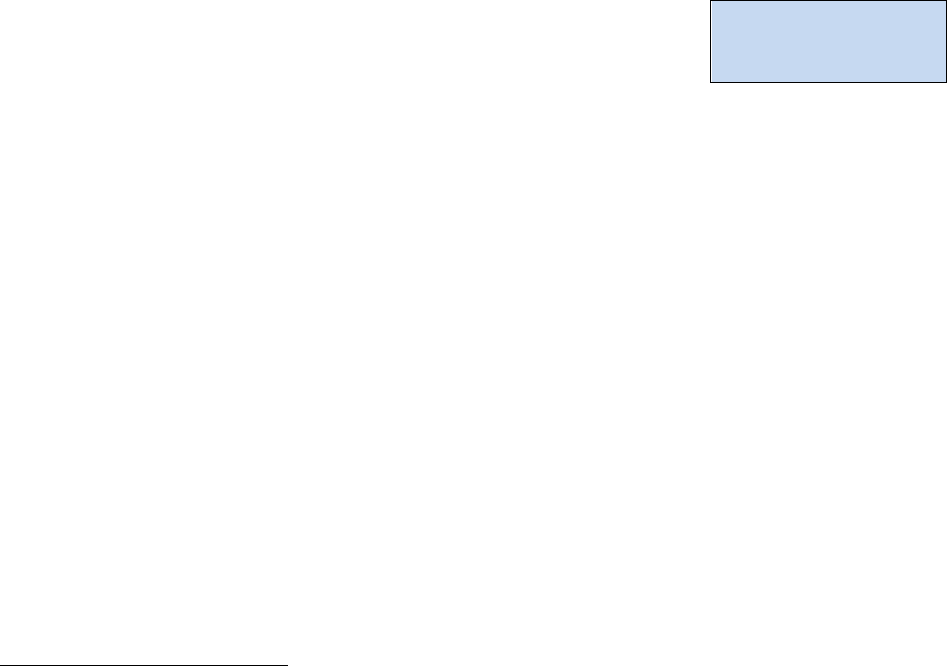

Figure 22.1: Three targets. Target (a)

has relatively high accuracy but

relatively low precision. Target (b)

has relatively low accuracy but

relatively high precision. Target (c)

has relatively high accuracy and

relatively high precision.

preparing the sample for analysis. For example, it is common to esterify carboxylic acids prior

to GC/MS analysis. If the derivatization step had a yield of 85%, the analyst would need to

correct for the 15% loss, otherwise there would be a negative systematic error of 15% in the

final results. Likewise you can imagine a similar loss of sample if there was an inefficient

extraction step in the sample preparation.

Random Error

Random errors are unpredictable high and low

fluctuations in the measurement of physical properties.

These fluctuations can arise from environmental changes

such as moment to moment fluctuations in pressure or

temperature or are the result of slight variation in the

procedural steps. Fortunately, random error can be quantified using statistical tools. Absent

any gross or systematic error, if one repeats an experiment several times, the mean value of a

normally distributed data set will appear close to the true value and the scatter about the mean

can be used to quantify the confidence we have in that mean. We will discuss each of these

ideas in more detail later in this appendix.

22.3 - Precision vs. Accuracy

In the simplest case, accuracy is used to quantify the correctness of an analysis; or how close

the measured value is to the “true” value. Precision is used to quantify the reproducibility of

our technique; or how close to the previous measurements will our next measurement be? A

common analogy used when discussing the terms accuracy and precision is that of hitting a

target. In Figure 22.1 (a) we have a situation in which the reproducibility of each attempt is low

but if we average the distance of each attempt from

the bull’s eye, we get an average value very close to a

perfect bull’s eye. We would say that the precision is

low but the accuracy of the mean can be made

acceptable if enough data is collected and the results

averaged. Conversely in Figure 22.1 (b) we have a

scenario in which the reproducibility of each shot is

relatively high but the shooter consistently failed to hit

the bull’s eye. We would say that the precision is high

but the accuracy is low. Averaging these shots will not

yield a result close to the bull’s eye. Relating these

results to the previous section, we would conclude that

this shooter has a systematic error of shooting high and

to the left in addition to the random error one normally sees with target shooting. Finally in

Figure 22.1 (c) we have a scenario in which the precision and accuracy are both relatively high.

Tying these ideas together we recognize that the precision of an experiment is related to our

ability to minimize random error. In target (b) and (c) of Figure 22.1 we see relatively small

random error. They are both precise but only target (c) is also accurate. The accuracy of an

The precision of an experiment is

influenced most by

our ability to

control random error.

The accuracy

of an experiment is

influenced

most by our ability to

control systematic error.

674

experiment is related to our ability to minimize systematic error. For example, target (b) shows

a systematic error resulting in a high and right pattern resulting in an inaccurate result.

22.4 - Statistical Tools

Population vs. Sample

Before we delve too deeply into specific statistical tools, we need to define some terms. The

term population is used when an infinite sampling occurred or all possible subjects were

analyzed. Obviously we cannot repeat a measurement an infinite number of times so quite

often the idea of a population is theoretical; and in those cases we take a representative sample

of the entire population. For example, if you wanted to know the average height of the human

race, you would have to take a representative sample of people and measure their heights.

Your result would be an estimate and you would necessarily report the uncertainty of your

estimate. However, if the parameters of an experiment are specifically defined, one can

analyze an entire population. For example, if your question was “what is the average height of

your immediate family” then your population has been defined as your immediate family and it

is now possible to measure the height of the entire population. Despite your ability to collect

data on the entire population, you still have random error associated with each measurement.

Be careful to distinguish the statistical use of the word sample from the way a chemist often

uses the word “sample”. For example, if we were analyzing the soil in a field for arsenic

concentration, we might go out to the field and collect 20 representative soil “samples” and

bring them back into the lab. The 20 soil “samples” would give us 20 data points. The

statistician would call the entire set of 20 data points the sample since the 20 data points are

being used to sample the entire population. It can be a confusing tangle of words so take a

moment to think through it.

Mean

The term mean is synonymous with the term average and is obtained by summing all of the

results from an analysis and dividing by the total number of individual results (N). The symbol

for a population mean is

µ

and the symbol for a sample mean is

.

=

Eq. 22.1

=

Eq. 22.2

where

µ

i

and x

i

are the results of the i

th

experiment.

As N ∞,

µ

. How quickly

µ

is dependent upon the relative amount of random error

(precision) associated with each individual measurement, x

i

. We quantify the random error

using two statistical tools called the standard deviation and the variance.

675

Standard Deviation and Variance

The equations for calculating a standard deviation of a population and the standard deviation of

a sample are given in Equations 22.3 and 22.4. The symbol for a population standard deviation

is

σ

and the symbol for a sample standard deviation is s.

=

(

)

Eq. 22.3

=

(

)

Eq. 22.4

If we take a close look at Equations 22.3 we see that the term (x

i

-µ) is nothing more than the

deviation of an individual data point from the population mean. We then square the deviation

values for each data point to get rid of the negative sign. By summing all of the squares,

dividing by N and taking the square root we are left with an average absolute deviation. So for

a population, the standard deviation is simply the absolute value of the average deviation from

the mean. However when determining the standard deviation of a sample, we have a slight

modification to the equation. In Equation 22.4, we use (N-1) in the denominator instead of N.

The term (N-1) is defined as the degrees of freedom for a sample set. Degrees of Freedom

represent the number of repeated measurements (a.k.a. replicates) that are free to vary. Since

the mean of a sample set is constrained by the mean of the population, the last data point is

not “free to vary” since the average of all data points must represent the mean of the

population. Degrees of freedom show up in several other statistical tools so it is important that

you take a moment to learn this term.

On many calculators, the buttons for calculating standard deviation are labeled σ & σ

n-1

, where

σ

n-1

is the sample standard deviation that we have represented here with the symbol “s” as

defined in Equation 22.4. One rarely samples an entire population in a laboratory experiment

so in almost every case you will want to use Equation 22.4 or your σ

n-1

button on your

calculator to calculate “s”.

676

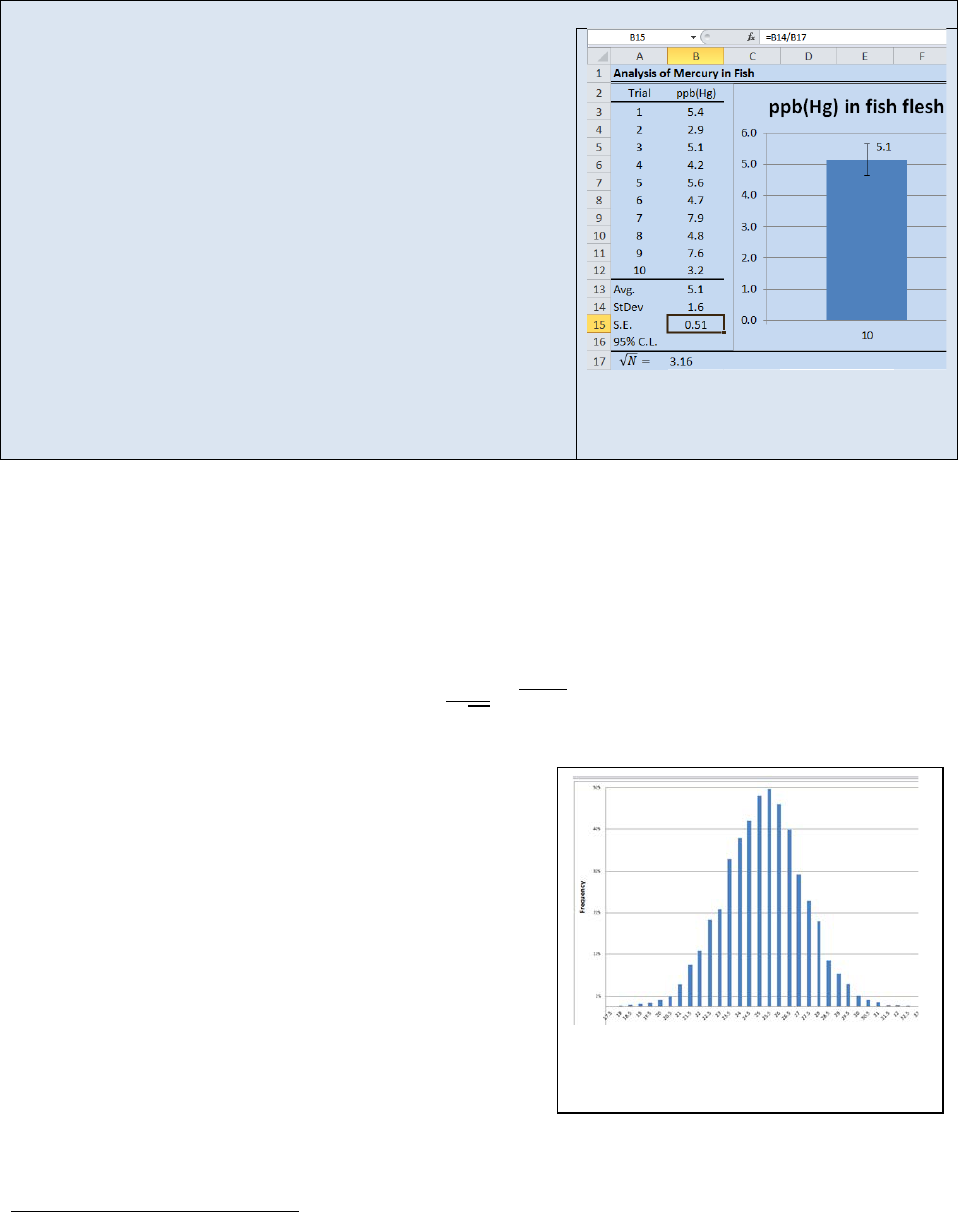

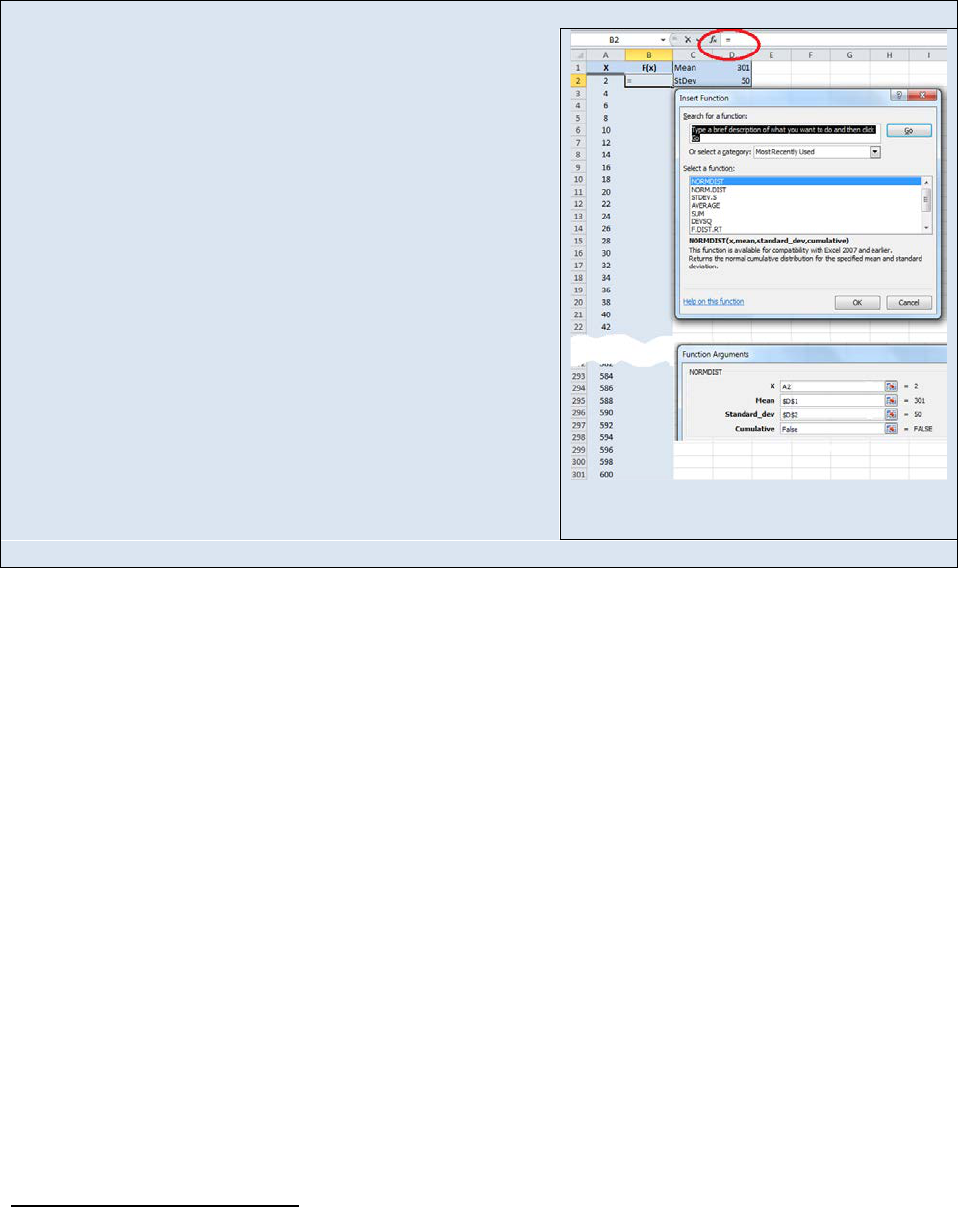

Activity – Using Excel® to generate a mean and standard deviation.

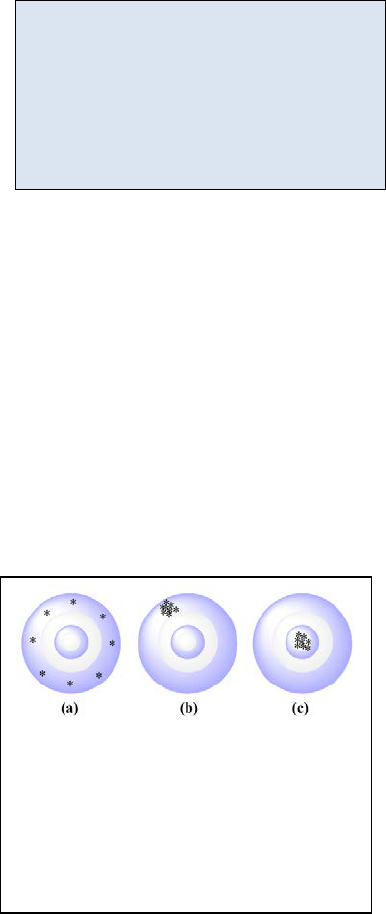

Recreate the spreadsheet seen in Figure 22.2 in Microsoft Excel®. Select

cell B13 and click on the f

x

button to open the Insert Function dialog box

(see Figure 22.3). From the drop down

window in the Insert Function

dialog box, select Statistical. And in the Select Function

window select

AVERAGE. The Function Argument dialog box will open (see Figure 22.4).

The AVERAGE function will use Equation 22.2 to calculate the average of

the data set. In the Number1 field enter the range of addresses for the

numbers you wish to average. In this example the range of addresses is

B3:B12. Or you can click the grid button (cirled in blue in Figure 22.4) and

drag and drop the range of values to be averaged.

Click OK and the

average of cells B3

B12 will be returned in cell B13. Now select cell B14

and repeat the above sequence of steps but this time select the STDEV.S

function instead of the AVERAGE function. STDEV.S uses Equation 22.4 to

calculates the standard deviation of a sample. The Function Arguments

box will open again and you will need to enter the range of values for the

data set (B3:B12) or you can use the drag and drop function. Your final

spread sheet should resemble the one shown in Figure 22.2. We will revisit

this data set when we discuss standard error and confidence limits (CL) so

take a moment to save your spreadsheet as Fish.

Figure 22.2: Spreadsheet

demonstrating the use of

Excel to calculate a mean

and a standard deviation.

Figure 22.3: Insert Function Dialog Box

Figure 22.4: Function Arguments Dialog Box.

Although the key strokes differ from calculator to calculator, most scientific calculators can

perform the statistics function we outlined in the Activity above. The steps typically involve

entering the data points into a data array (often symbolized with a Σ+ button). As you enter

each data point, the total number of points in the array will be displayed as N=#. Once you

have entered your data array, you can press the button to display the average or the σ or σ

(n-

1)

buttons to display the appropriate standard deviation.

677

Exercise 22.1: Using the same data set we examined in the above activity, use the statistical

functions on your calculator to determine the mean and the standard deviation of the data set.

You may need to review your owner’s manual or visit the manufacture’s website for

instructions on using the stats functions on your calculator.

Exercise 22.2: Use Excel® or a similar spreadsheet program to determine the mean and

standard deviation of the following data sample. Repeat the analysis using your

calculator’s statistical functions.

Lead in Drinking Water

Replicate

1

2

3

4

5

6

7

8

9

10

ppm

2.002

1.996

2.000

1.995

1.999

1.987

2.010

2.014

2.007

2.004

Exercise 22.3: Use Excel® or a similar spreadsheet program to determine the mean and

standard deviation of the following data sample. Repeat the analysis using your calculator’s

statistical functions.

Lead in a Paint Chip

Replicate

1

2

3

4

5

6

7

8

9

10

ppm

1001.9

989.0

1020.4

996.1

1002.4

990.0

1019.4

991.3

999.2

1002.4

Standard Error & Error Bars

In the introduction to this chapter we reported a mass as 2.15 ±0.01 grams and mentioned that

the ±0.01 indicated one standard deviation unit above and below the mean and in our activity

above, we reported the concentration of mercury in fish flesh as 5.1 ±1.6 ppb. The

conventional way to report error graphically is to include “error bars". Chemist typically report

error using standard deviation however not all disciplines of science share the same

conventions. Another very common way to represent error is to report a value called the

standard error. The standard error is related to standard deviation as seen in Equation 22.5

. . =

Eq. 22.5

Note that for a given set of measurements, the standard error will always be less than the

standard deviation.

Excel allows the user to report error bars on a graph as either the standard deviation, standard

error, or as a percentage of the mean. Additionally, Excel allows you to add a customized value

for the error bars. It is important that you specify how you are reporting your uncertainty in

your numbers. This is appropriately done in the figure caption.

678

Figure 22.6: Histogram demonstrating

a normal distribution of points about a

mean:

= , = , = .

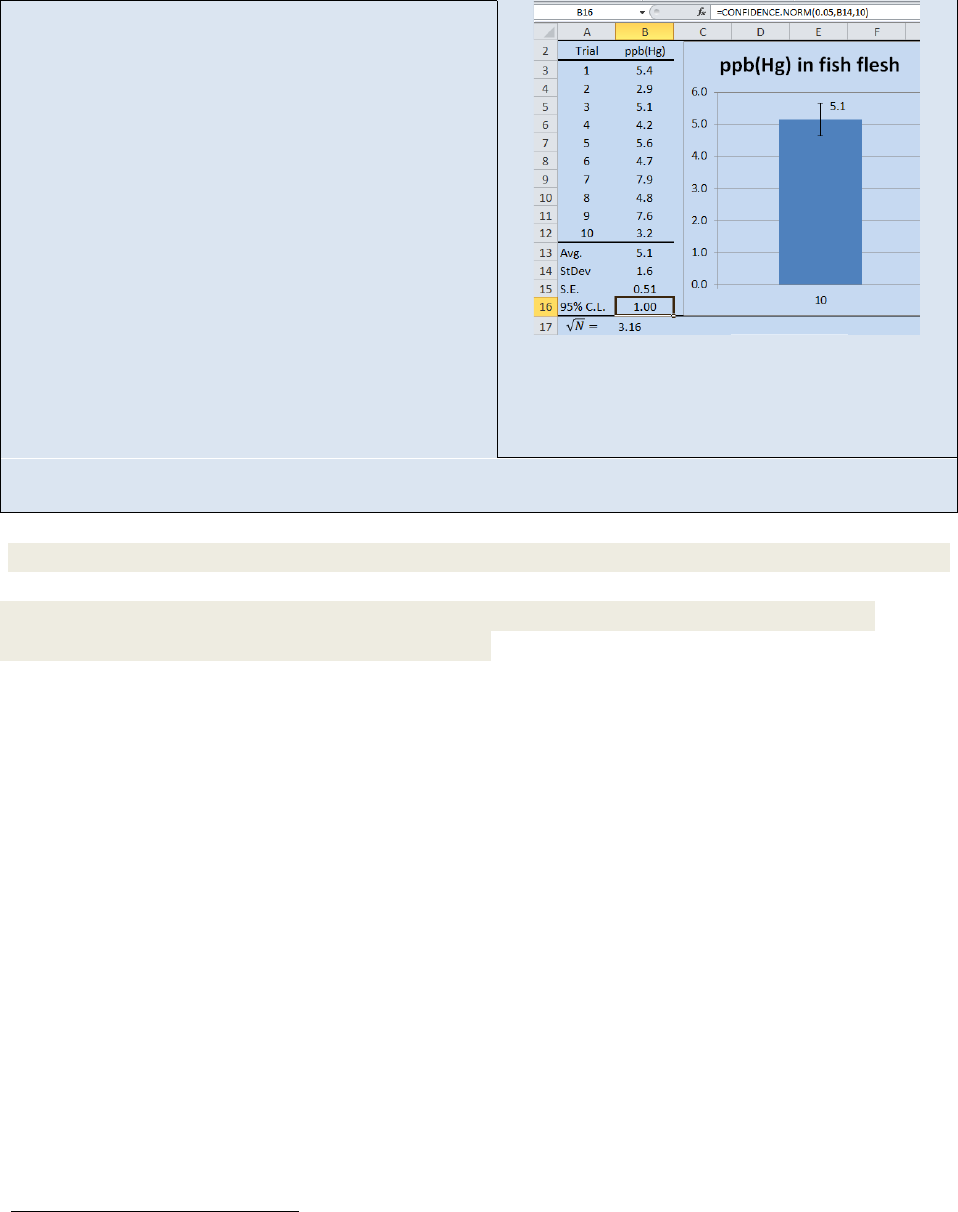

Activity – Using Excel® to calculate standard error and plotting error bars on a bar-graph.

Open the spreadsheet Fish that you created in the previous

Activity. We are going to program Eq. 22.5 for the standard

error into cell B15. First we need to calculate the square root

of N. Select cell B17 and type “=sqrt(10)”. Excel will return a

value of 3.16. Next select cell B15 and type “=B14/B17”.

Excel will return a standard error of 0.51.

To display the standard error as error bars on a graph, first

create a graph of your data. In this activity, we have created

a column graph. Next, place your cursor in the graph and

“left-click”

8

. This will display the “Chart Tools” group. From

the “Chart Tools” group, select the “Layout” tab. Next select

“Error Bars” from the “Analysis Group” and fill in the correct

parameters. Your spread sheet should now resemble the one

in Figure 22.5. We will return to this spread sheet when we

discuss confidence limits so be certain to save your work.

Figure 22.5: Determining Standard

Error and displaying it on a graph.

Normal Distributions

For data in which the error is truly random, the probability of obtaining a specified value for an

individual data point (x

i

) is a function of the population mean (µ), and the standard deviation of

the analytical method being employed (σ). Equation 22.6 shows a normal probability

distribution function

()

=

(

)

Eq. 22.6

where x is the value of a particular data point, σ is the

standard deviation, µ is the mean of the population

and f

x

is the probability of obtaining a particular value

of “x”. Stating Equation 22.6 in plain English, the

probability of obtaining a particular value of “x” when

sampling a population is a function of the true value

for that population (µ) and the precision of the

technique used (σ). Equation 22.6 is referred to as a

normal probability function (npf) or a Gaussian

distribution or colloquially as “a bell curve”.

In modern instruments, data is collected digitally so

data is discrete

9

. You do not get a true “bell curve”

but instead you get a histogram of points that fall within the digital resolution of the processor.

8

If you are using an Apple® computer, the “left-click” commands can be obtained by holding down the apple

command key while clicking.

9

See Chapters 4 & 5 for a review of analog to digital converstion.

679

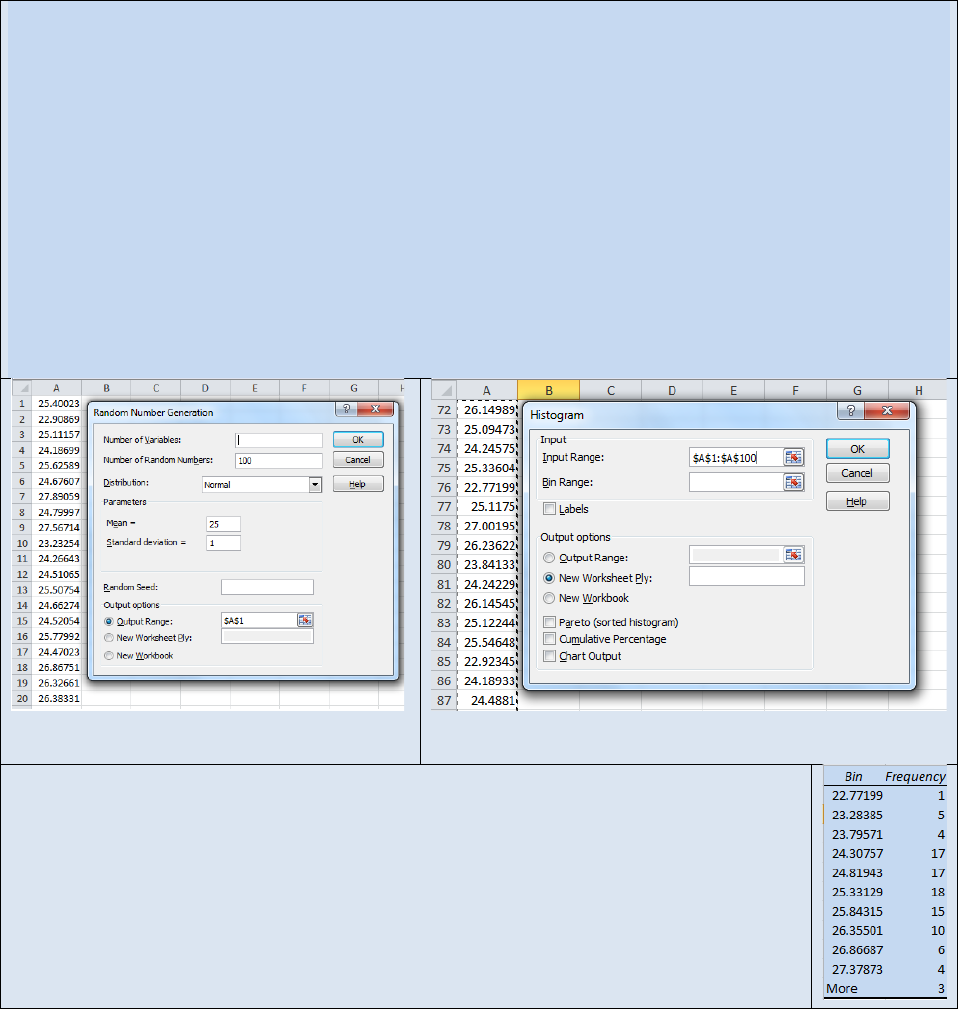

For an npf, the histogram will resemble a bell shaped distribution about the mean. Figure 22.6

shows a histogram for a measurement in which the error followed an npf and the “true” value

was 25. Random error in the analysis returned a range of values with a mean value

approximately centered at 25. If you traced a line through the top of each bar in the graph, the

histogram approximately conforms to a normal distribution function.

Activity – Random Number Generation and Plotting a Histogram in Microsoft Excel®

The point of this activity is to help you visualize how N,

, and

σ

affect the distribution of data points

within a sample set.

Many of the advanced statistical tools available in Excel® are found in the Analysis Tool Pack. The

Analysis Tool Pack is not included in the default installation of Excel® so you may need to “turn it on” if

you have never used advanced statistical tools in your copy of Excel®. Each version of Excel® has

different steps for activating the Analysis Tool Pack. Activate the help screen on your copy of Excel® and

select Analysis Tool Pack and then follow the instructions for your particular version of Excel®

First we will use Excel’s random number generator. Select Random Number Generation from the Data

Analysis Tool Pack. The Random Number Generation dialog box will open (see Figure 22.7). Fill in the

fields as shown. The random number generator will return a string of numbers with a mean of 25 and a

standard deviation of 1.

Figure 22.7: Random Number Generator

Dialog Box

Figure 22.8: Histogram Dialog Box.

Next select Histogram from the data analysis tool pack. The Histogram dialog box will

open (see Figure 22.8). Fill in the Histogram dialog box as shown and select “OK”. Excel

will generate a data table similar to the one shown to the right. To generate a

histogram Plot the Bin # vs. Frequency as a Column Graph. Your graph should resemble

Figure 22.6. You should notice that the histogram has the beginnings of a bell curve but

the existence of random error is visibly evident. Now repeat this activity with a much

larger N values such as 1000 or 2000. Observe how the shape of the histogram has

changed. Repe

at the exercise again and this time decrease the standard deviation.

What affect does N and

σ

have on the shape of the histogram?

680

Figure 22.9

: Normal probability

distribution. The ranges indicate the

percentage of all data points as a

function of the distance from the

mean. The x-

axis is in standard

deviations from the mean.

Exercise 22.4: In your own words, explain how changing N and changing σ affects the

histogram generated in the above Activity.

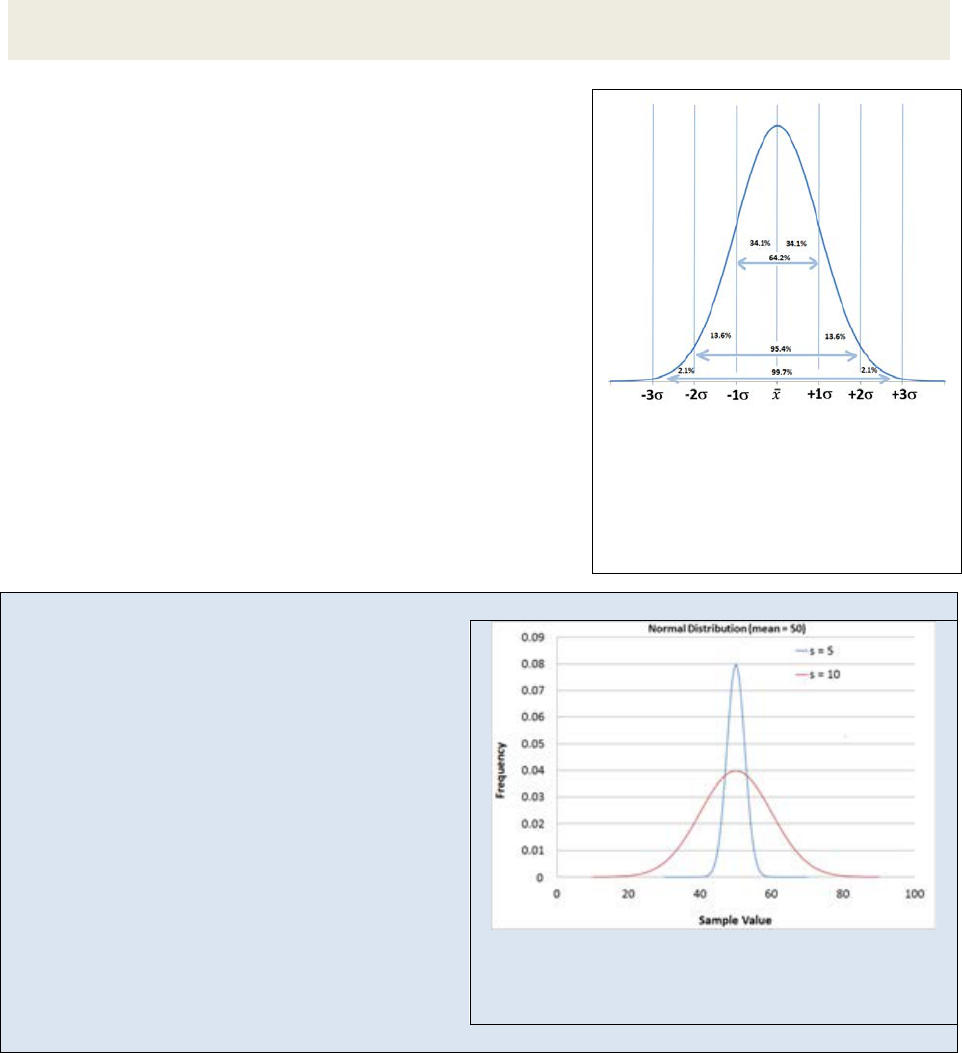

A normal probability function represents the way data is

scattered about a mean when the error in the sampling is

the result of random error. Figure 22.9 shows a normal

probability distribution with the area under the curve

integrated as a function of standard deviation. We see

that 68.2% of all data points fall within a range of ±σ

from the mean, 95.4% of all data points fall within ±2σ of

the mean and by the time we get to ±3σ from the mean

we have incorporated 99.7% of all data points. If we

repeated an analysis 1000 times, we could reasonably

expect that only 3 data points would fall outside the ±3σ

range. Knowing the standard deviation allows us to

predict the likelihood of the next sampled data point

residing within a specified range from the mean.

Example 22.1: The Bell Curve’s shape as a function of the standard deviation

Figure 22.10 shows two different normal

probability functions (npf). Imagine these two npf

curves represent the analysis of a chemical

sample under different experimental conditions.

Each experiment produced a sample mean of 50

however one technique produced a data set with

a standard deviation of 5 while the other data set

had a standard deviation of 10. In the case where

s = 5, nearly 99.7% of all data points fell within

the range of 40 – 60. In the case where s = 10, we

have to expand the range to 20 – 80 in order to

capture 99.7% of all data points. If we could only

afford to repeat the analysis a few times (time =

$) we would have a lot more confidence that our

sample mean is close to the population mean for

Figure 22.10: Two npf curves. The narrow curve

has a standard deviation of 5. The wide curve has a

standard deviation of 10.

the technique where s = 5 than we would for the technique where s = 10.

681

Activity –Plotting a normal distribution function in Excel®

Create the following worksheet in Excel® (See Figure 22.11)

Create a column of numbers from 2 to 600 in intervals of 2

in cells A2

A601. Place a mean value of 301 in cell D1

and your standard deviation of 50 in cell D2. Then select cell

B2 and click the “insert function” link (f

x

) and choose

NORMDIST. The ”Function Arguments” box will open. For

the “x” argument choose cell A2. For the “Mean” argument

box, type $D$1 and for the standard deviation argument

box, type $D$2. The dollar signs in the cell addresses lock

the addresses and prevent them from scrolling. In the

“Cumulative” argument field type the word “FALSE”. The

NORMTDIST function will use Equation 22.

5 to return a

probability value for obtaining a value of “2” in cell B2.

Select cell B2 again and drag and drop it to cell B601. The

“B” column now contains the probability of obtaining the

values listed in the “A” column. Plot an XY scatter plot of

cell

s A2:A601 vs. B2:B601 and insert the graph in your

worksheet. You should see a classic “bell curve”. Now play

with your mean and standard deviation values and observe

Figure 22.11: Example Spreadsheet for

programing a Gaussian Curve.

how the shape of the Gaussian distribution changes as a function of each variable.

Confidence Limits

Earlier we learned how to calculate a standard error. Another common statistical tool for

reporting the uncertainty (precision) of a measurement is the confidence limit (CL). For

example we might report the percent alcohol in a solution as 13% with a 95% CL of ±2%, where

the ±2% represents the CL.

Unless otherwise stated, the reported CL is at the 95% CL and represents the range in which we

are 95% certain the “true” answer lies. The reason the 95% CL is the accepted norm is because

95.4% of all data points in a normal distribution is encompassed by a range of approximately

±2σ. It is reported at 95% instead of 95.4% for purposes of simplicity. However as you will

soon see, it is possible to calculate CL values other than the 95% CL.

We define CL using σ. Recall that σ is the standard deviation of the entire population. When

we do not know σ we use “s” instead and a fudge factor, which we will describe shortly. If we

know the standard deviation for the entire population, then the 95% CL

10

is simply

95% CL = ±2σ Eq. 22.7

and we would report the mean as

10

To be completely accurate, the 95% confidence limit is actually the 95.4% confidence limit because it represents

±2σ from the mean (see Figure 22.5).

682

µ ±2σ

However we seldom know the mean or the standard deviation of an entire population. All

chemical analyses deals with a sampled populations. The CL for a sample is given in Equation

22.8

= ±

Eq. 22.8

and we would report the average as

11

±

were

is the mean of the sample, “s” is the

standard deviation of the sample, N is the number of

data points in the sample and “t” is a “fudge factor”

taken from Table 22.1.

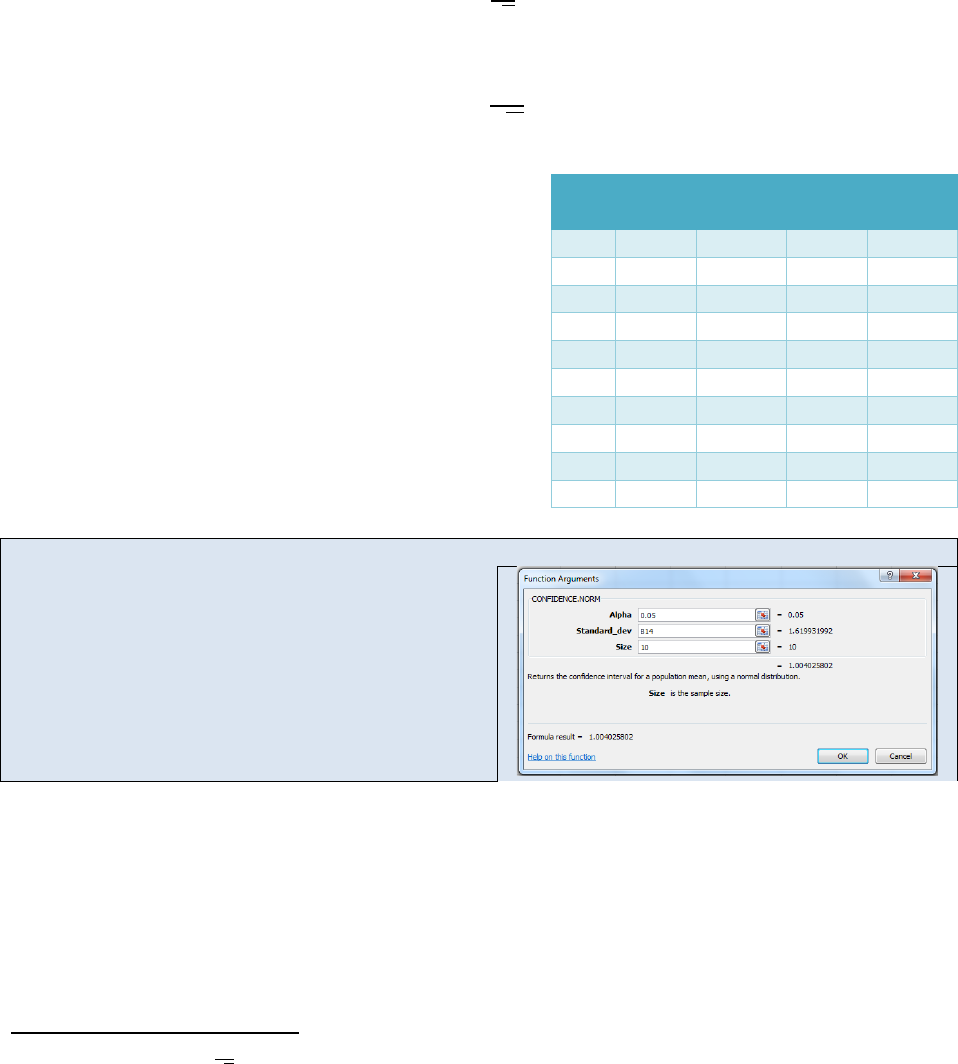

Using Spreadsheets to Determine Confidence Limits

As we have seen, modern spreadsheets such as

Microsoft Excel® are capable of very sophisticated

statistical analysis. The following Activity will walk

you through the steps of calculating the CL for a

sample mean.

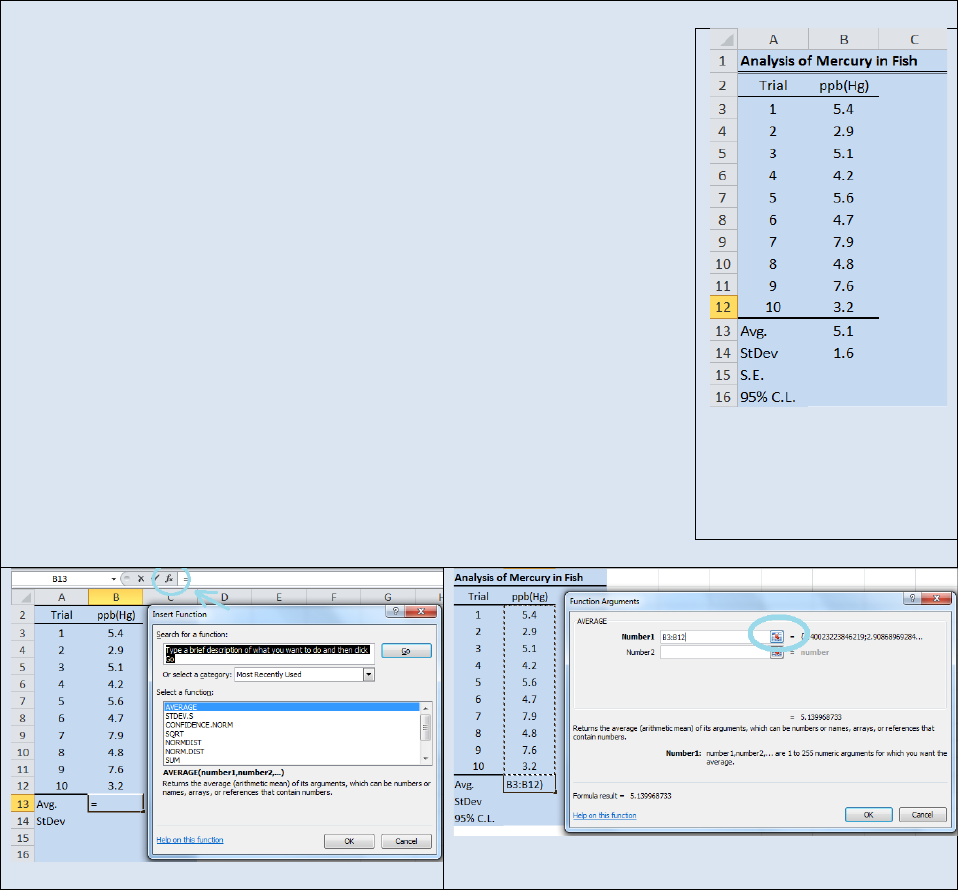

Activity- Using Excel to calculate confidence limits.

Open the spreadsheet Fish that you created in the

previous activities. We are going to use Excel® to

determine the 95% CL of our data set.

Select cell B16 and click on the f

x

button once again.

From the Insert Function dialog box select

CONFIDENCE.NORM. The following dialog box will

appear. To calculate a 95% CL you need to input the

11

Recall that we defined

as the standard error in Equation 22.5.

12

The term (N-1) is the degrees of freedom for the sample set.

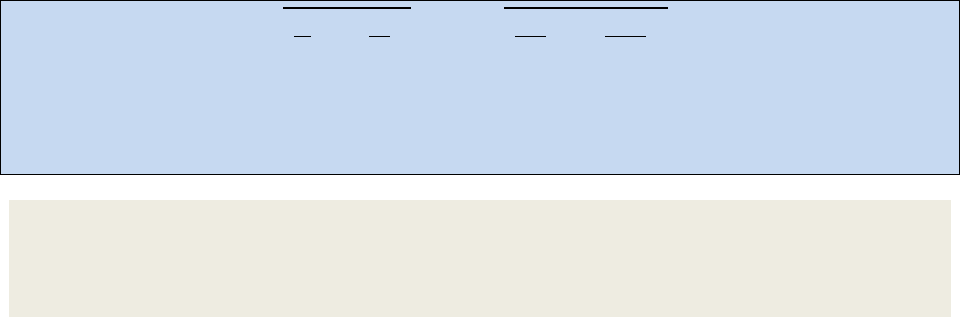

Table 22.1: Confidence Limit t-values as a

function of (N-1)

12

N-1

90%

95%

99%

99.5%

2

2.920

4.303

9.925

14.089

3

2.353

3.182

5.841

7.453

4

2.132

2.776

4.604

5.598

5

2.015

2.571

4.032

4.773

6

1.943

2.447

3.707

4.317

7

1.895

2.365

3.500

4.029

8

1.860

2.306

3.355

3.832

9

1.833

2.262

3.205

3.690

10

1.812

2.228

3.169

3.581

683

uncertainty in the Alpha field as 1.00 – CL You need

to input the CL as a decimal (1.00 –

0.95 = 0.05).

Enter the standard deviation (or the address of the

standard deviation) into the “Standard_dev” field. In

the “Size” field enter the value of “N”; the total

number of data points (10) and click “OK”.

At this point, your spreadsheet should resemble the

one shown in Figure 22.12. You can calculate other

CLs by changing the value of alpha.

In this activity we calculated the 95% CL

for the

analysis of mercury in fish. If we were to report the

answer to the hundredth place we would say that

the average concentration of mercury in fish is 5.10

with a 95% CL of ±1.00. The implication of the CL is

that we are 95% certain that the “true” value lies

Figure 22.12: Data for the analysis of mercury in

fish flesh. The data includes the mean, standard

deviation, standard error, 95% C.L. and a plot of

the data showing the S.E. as error bars.

between 4.1 ppb and 6.1 ppb. Or to state this another way, if we repeated the experiment one more

time, we are 95% confident that the next data point will lie within this range.

Exercise 22.5: For the data set used in the above activity, determine the 90% and the 99% CL

Exercise 22.6: For the data set below, determine the mean, standard deviation and 95% CL

3.06

Propagation of Error

Reporting the standard deviation, or the standard error or the CLs for a measured data point is

an acceptable way of portraying the precision of a measurement. But what do you do if you

use two or more measured values in a computation? How do you report the confidence in the

computed value? For example, imagine you determined the density of an object by

independently measuring the mass and the volume. Each of those measurements contains

error. In other words, you have an error associated with both the volume measurement and

the mass measurement and when we divide the mass by the volume to get density we want to

be able to report the composite error of the resulting density. We need to know how to

propagate the standard deviations through various mathematical manipulations. Table 22.2

outlines this process

13

. The standard deviation of a computed result is given as S

R

where R is

the computed result.

Once you have propagated the standard deviation through the mathematical manipulations,

the 95% CL can be approximated as ±2s. Similarly, the 99.7% CL can be approximated as ±3s

however, if you wish to calculate a CL other than the 95% CL or the 99.7% CL you will need to

13

For more on propagation of error see Data Reduction and Error Analysis for the Physical Sciences 3

rd

ed. by Philip

R. Bevington and K. Robinson. McGraw Hill, 2002 or Math for Chemistry 2

nd

ed. By Paul Monk and J. Munro.

Oxford University Press, 2010.

684

determine the degrees of freedom (df) for the calculated value using Equation 22.9 and then

use Equation 22.8 or Microsoft Excel® to find the CL

Table 22.2: R = Computed Result. S

R

= Standard Deviation of Result

Calculation

Example

Standard Deviation of Result (R)

Multiplication/Division

R =

( )

( )

S

R

= R

+

+

+

Addition/Subtraction

R = α − β + γ + δ

S

R

=

+

+

+

Logarithm

R = log(α)

S

R

=

.

Inv. Log

R = inv-log(α)

S

R

= R(2.303S

α

)

Exponents

R = α

x

S

R

= RX

α

,

β

,

γ

and

δ

are experimentally derived data with standard deviations of s

α

, s

β

, s

γ

&

s

δ

respectively.

df =

(

)

(

)

Eq. 22.9

where N

α

, N

β

, N

γ

and N

δ

are the number of replicate data points for the experimentally

derived data sets α, β, γ and δ with standard deviation of s

α

, s

β

, s

γ

& s

δ

respectively.

Example 22.3 – Let us imagine we were determining the volume of an unknown solid by displacement of

water in a graduated cylinder (∆V = V

f

-V

i

). The initial volume was 23.40ml and the final volume was

24.95ml and ∆V = 24.9 – 23.2 = 1.7ml. You might be tempted to conclude that the uncertainty is ±0.1ml.

However if you were to be rigorous in your propagation of error you would recognize there was an

implied ±0.1ml uncertainty in both the initial and final volume readings. Table 22.2 showed us that the

proper way to estimate error when subtracting two numbers is

S

∆V

=

+

=

. = .

Now let us imagine we determined the mass on a digital balance and obtained a value of 3.003 grams. If

you recall what you were taught about significant figures, the implication is that the uncertainty is in the

thousandth place and a reasonable estimate of the standard deviation would be ±0.001g. What is the

uncertainty in the density?

=

=

.

.

= .

If you simply applied the rules for reporting significant figures, you might assume the uncertainty in this

number were ±0.01, however since we have a calculated data point resulting in measurements made

with different precisions, a more rigorous application of propagation of error is required. Take another

look at Table 22.2. The equation for propagation of errors for multiplication and division is

685

S

d

= R

+

= .

.

.

+

.

.

= .

We would want to report our final density as

= .

± .

Exercise 22.7: Assume you measured the mass of 1.0014 grams of potassium oxalate (K

2

C

2

O

4

)

on a digital balance and placed it in a 1 liter volumetric flask with a rated precision of 0.001

liters. Calculate the molarity of the final solution and report the molarity with a 95% CL using

the appropriate propagation of error equation.

Analyzing Data Sets

In addition to reporting the error associated with an individual data set, the analytical chemist

often needs to compare and analyze the variance in data taken under different circumstances.

The different circumstances can be as benign as collecting data on different days or potentially

more significant such as collecting data using different instruments or data collected by

different technicians. For example, imagine you are perfecting a C-18 reverse phase HPLC

method for the purification of a pharmaceutical product. In the final protocols, how important

is it that you purchase your C-18 columns from the same manufacturer each time you replace

the column? Are the changes you see in the data when you change suppliers statistically

significant? We could ask the same question of the solvent. Is it statistically important that we

use the same supplier of solvent every time we run the procedure? We can investigate these

types of questions by using several different statistical tools.

Because of random error anytime you repeat an analysis, you expect to obtain different results.

But are the observed differences within the expected variance of the technique? This is a

fundamental question in an analytical lab. You may have a data point that seems significantly

different than the other replicates in the data set and you would like a statistical basis for

keeping or rejecting that data point. Or you may want to know the effect of a particular

experimental parameter on the overall variance of a method. For instance, when comparing

the means of data taken by two different lab technicians, are the observed differences in the

means statistically significant? Or you may want to compare the results of an analysis using

two different instruments (i.e. two different UV-vis spectrometers) or two different techniques.

Again you will want to answer the question “are the observed differences statistically

significant”. In the next few section, we will introduce tools that you can use to help answer

these types of questions.

686

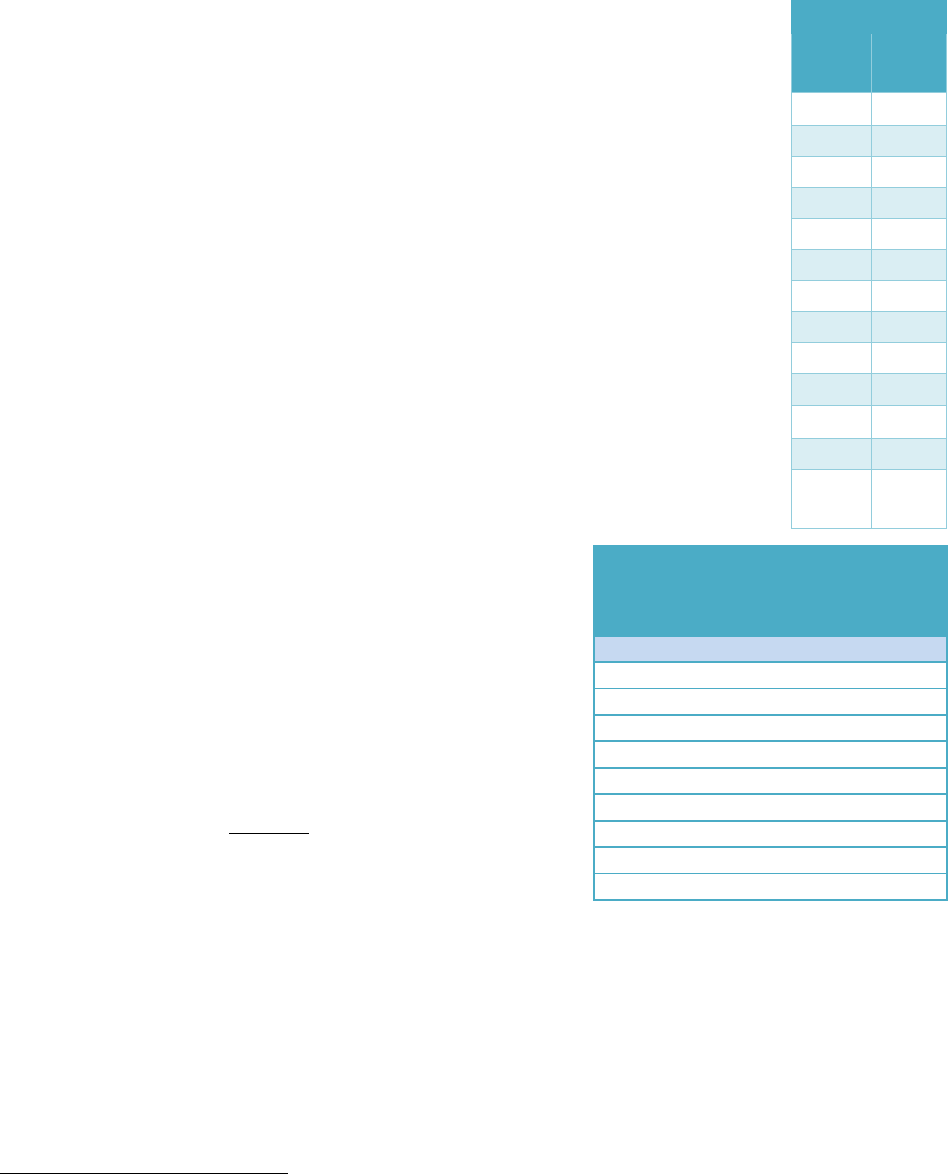

Identifying Outliers: Q-Tests

Although the International Organization of Standardization (ISO) now

recommends that we use the Grubb’s test for identifying outliers, the Q-test

still remains a very commonly used method and we introduce it here because

you are likely to encounter it in your careers. We will examine the Grubb’s test

in the next section.

Sometimes you obtain a set of replicate data and there is one (or more) data

point that just “seems wrong”. For example, Table 22.3 shows the results for

the N = 10 replicate analysis of caffeine in tea. The data points tend to cluster

around 80 ppm with the exception of Cup #5 which had a lower reading of 72

ppm. The sloppy analyst might be tempted to throw out Cup #5’s data based

solely on intuition; however it is quite possible that 72 ppm falls within the

95% confidence interval for this distribution of points. It is unethical to simply

ignore data that you dislike. You should include all data in a report, even

outliers, and if you decide to reject a point in your final analysis, you must have

a statistical justification for that decision. A Q-test is a statistical tool used to

identify an outlier within a data set

14

. To perform a Q-test you must first

arrange your data in a progressive order (low-to-high or high-to-low) and then

using Equation 22.10, you calculate an experimental Q-

value (Q

exp

). If Q

exp

is greater than the critical Q-value

(Q

crit

) found in Table 22.4 then you are statistically justified

in removing your suspected outlier from further

consideration.

15

You then recalculate the mean, standard

deviation and the 95% CL with the outlier removed from

the calculations.

=

Eq. 22.10

X

q

= suspected outlier

X

n+1

= next nearest data point

w = range (largest – smallest data point in the set)

14

R. B. Dean and W. J. Dixon "Simplified Statistics for Small Numbers of Observations". Anal. Chem., 23 (4), 1951,

636–638 // Rorabacher, D.B. "Statistical Treatment for Rejection of Deviant Values: Critical Values of Dixon Q

Parameter and Related Subrange Ratios at the 95 percent Confidence Level". Anal. Chem., 63 (2), 1991, 139–146 //

Table 22.3

Cup

ppm

Caf

1

78

2

82

3

81

4

77

5

72

6

79

7

82

8

81

9

78

10

83

Avg

79.3

StDev

3.3

95%

C.L.

2.0

Table 22.4: Critical Rejection

Values for Identifying an Outlier:

Q-test

Q

crit

N

90% CL

95% CL

99% CL

3

0.941

0.970

0.994

4

0.765

0.829

0.926

5

0.642

0.710

0.821

6

0.560

0.625

0.740

7

0.507

0.568

0.680

8

0.468

0.526

0.634

9

0.437

0.493

0.598

10

0.412

0.466

0.568

687

Example 22.4- Perform a Q-test on the data set from Table 22.3 and determine if you can statistically

designate data point #5 as an outlier within a 95% CL If so, recalculate the mean, standard deviation and

the 95% CL

Strategy – Organize the data from highest to lowest data point and use Equation 22.10 to calculate Q

exp

.

Solution – Ordering the data from Table 22.3 from highest to lowest results in

Substitution into Equation 22.10 yields

=

=

|

|

= .

Using the Q

crit

table, we see that Q

crit

=0.466. Since Q

exp

<Q

crit

, you must keep the data point.

Exercise 22.8: Use the data in Table 22.3 and determine what value (in ppm) would cup #5

have to be before Equation 22.10 would identify it as an outlier. Show your work.

Exercise 22.9: Imagine the following set of 5 replicate data

were collected for the analysis of lead in drinking water.

Trial

1

2

3

4

5

ppm

(Pb)

1.3

1.4

1.0

1.3

1.4

(a) Calculate a mean, standard deviation and 95% CL on the data set (you may want to use

a spread sheet).

(b) Perform a Q-test on the data set. How does the performance of a Q-test alter your

answer in part a?

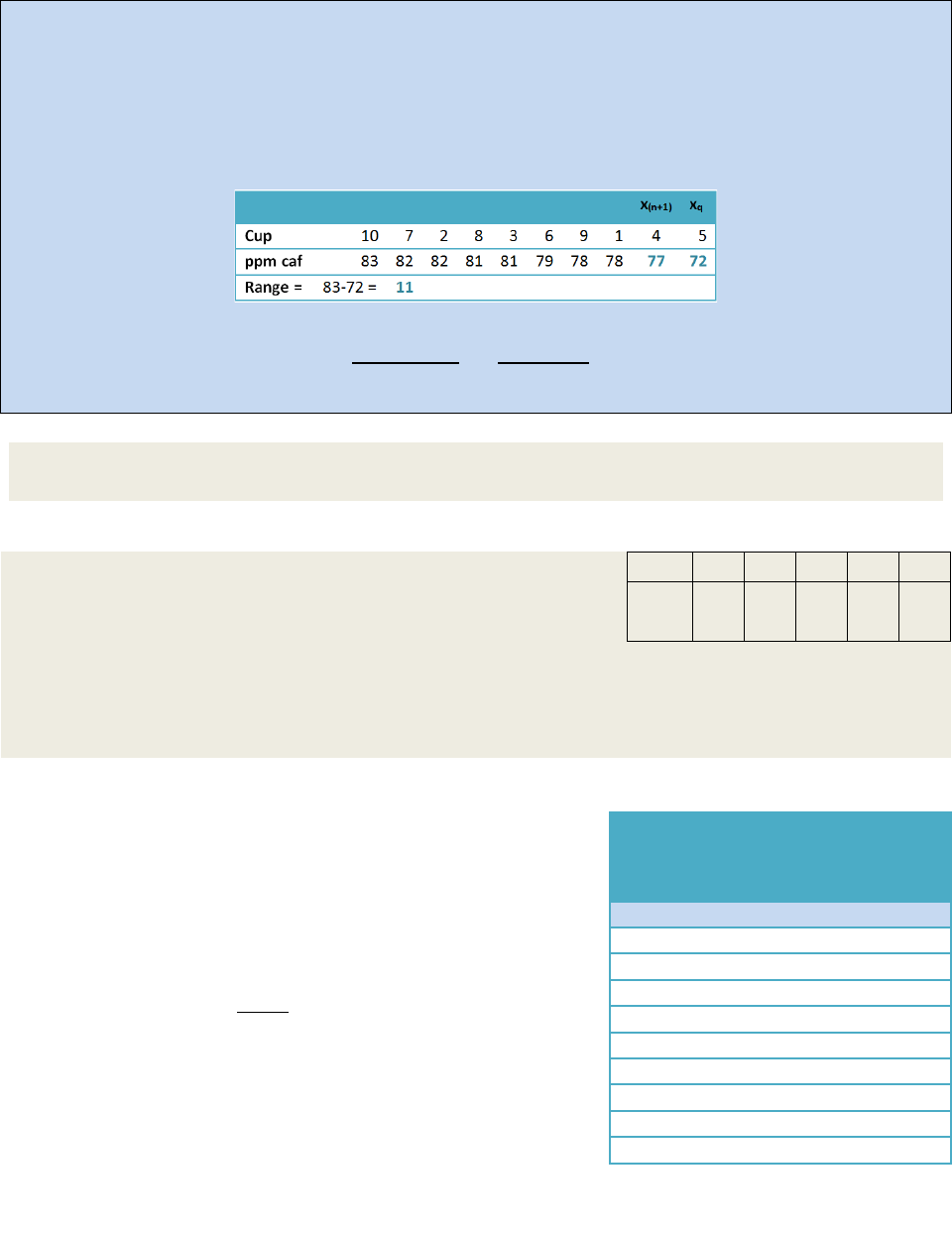

Identifying Outliers: Grubb’s-Tests

The recommended way of identifying outliers is to use the

Grubb’s Test. A Grubb’s test is similar to a Q-test however

G

exp

is based upon the mean and standard deviation of the

distribution instead of the next-nearest neighbor and range

(see Equation 22.11).

=

Eq. 22.11

If G

exp

is greater than the critical G-value (G

crit

) found in

Table 22.5 then you are statistically justified in removing

your suspected outlier from further consideration. You

then recalculate the Mean, Standard Deviation and the 95%

CL with the outlier removed from the calculations.

Table 22.5:

Critical Rejection

Values for Identifying an

Outlier: G-test

G

crit

N

90% C.L.

95% C.L.

99% C.L.

3

1.1.53

1.154

1.155

4

1.463

1.481

1.496

5

1.671

1.715

1.764

6

1.822

1.887

1.973

7

1.938

2.020

2.139

8

2.032

2.127

2.274

9

2.110

2.215

2.387

10

2.176

2.290

2.482

688

Exercise 22.10: Perform a Grubb’s test on the data set found in Exercise 22.9. Report the

mean, standard deviation and the 95% CL based upon the results of your Grubb’s test.

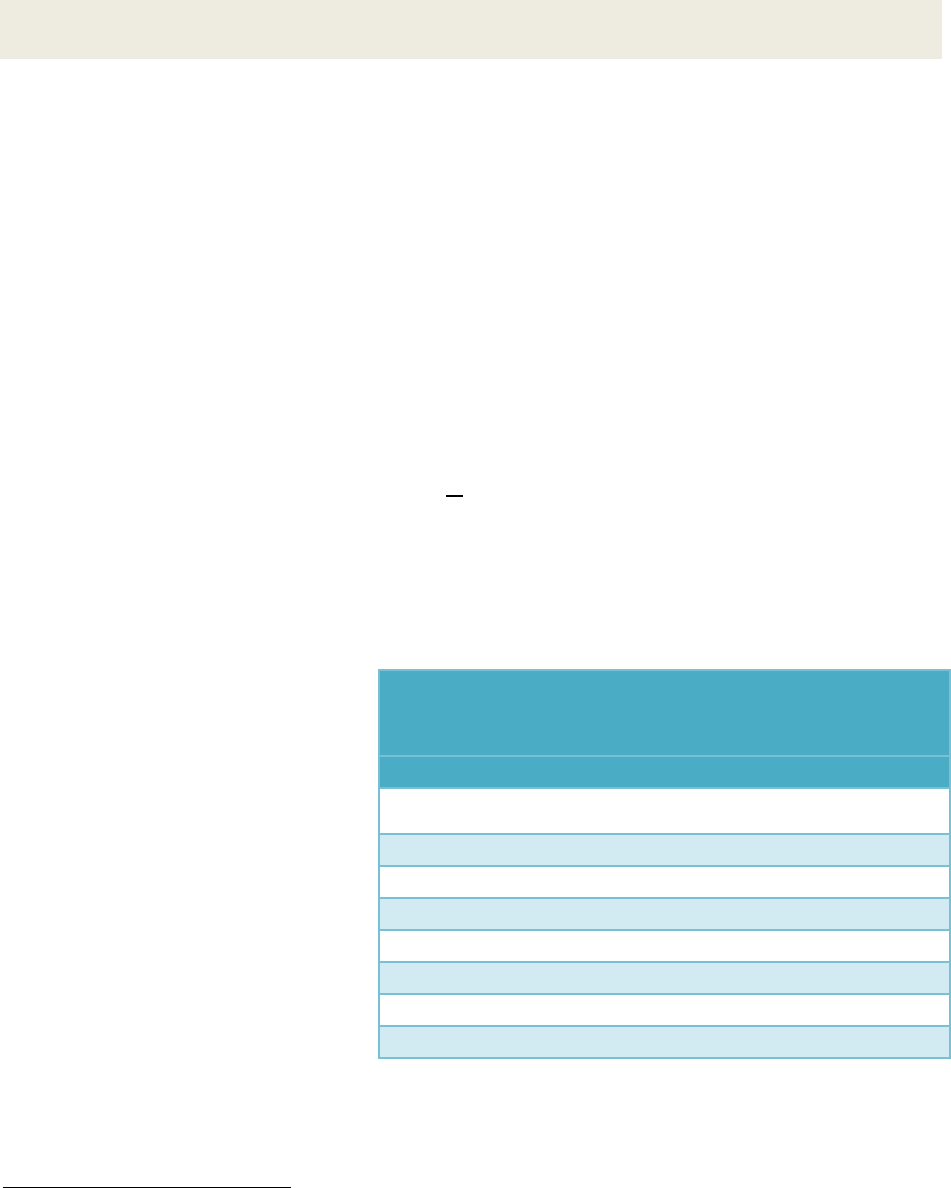

Analyzing Variance: F-Tests

The F-test is named after Ronald Fisher who first developed the test in the 1920’s

16

. The test

allows for the comparison of the variance of two different data sets in order to determine if

there is a statistically significant difference. It is common in a working lab to have data sets that

were obtained under different circumstances. For instance, data may have been collected on

different days, or you may have two different analysts conducting the same measurements.

When the final results vary, you need a way to determine if the difference is statistically

significant. In a manner similar to the Grubb’s test and the Q-test, you perform an F-test by

calculating an experimental F-value (F

exp

) and comparing that to a critical F-value (F

crit

). If

F

exp

>F

crit

then the variance of the two data sets used to calculate F

exp

are statistically different.

F

exp

is determined by the ratio of the sample variances (square of the standard deviations). The

larger variance value goes in the numerator so that F

exp

is always greater than one.

=

Eq. 22.12

In this case, the null hypothesis is that the two variances represent the same population. To

reject (or accept) the null hypothesis, we compare F

exp

to F

crit

. The tables for critical F values

are tabulated as a function of CLs and degrees of freedom for

,

and

. As a result a full set

of F-tables can be extensive. Table

22.6 is an example of critical F-

values at the 95% CL for degrees of

freedom up to 10.

Fortunately we do not need a

complete set of F-tables on hand.

Microsoft Excel

®

can be used to

perform F-tests. Example 22.5

shows an example data set collected

from the HPLC analysis of residual

acrylamide from a batch of

polyacrylamide

17

. In this study two

different analysts performed ten

replicate studies. The results

showed a mean value of 10.1 ppb for analyst #1 and 10.5 ppb for analyst #2 with standard

deviations of 0.9 and 1.5 respectively. The mean values of 10.1 and 10.5 may seem similar

enough with a gross deviation between the two means of only 0.4 but what you really want to

16

R. A. Fisher Statistical Methods, Experimental Design and Scientific Inference. Oxford University Press: New York,

1990, 1991, 1995, 1999.

17

Polyacrylamide is a water absorbent polymer used in diapers. The monomer is a neurotoxin so it is critical that

each batch be tested for residual monomer concentration before it is sent to market.

Table 22.6: 95% C.L. F-Test Critical Values. The degrees of

freedom used to calculate

,

and

represent the column

and row headings respectively

Numerator Degrees of Freedom

Denominator

Deg. Free.

1

2

3

4

5

7

10

1

161.5

199.5

215.71

224.6

230.2

236.8

241.9

2

18.51

19.00

19.164

19.25

19.30

19.35

19.40

3

10.13

9.552

9.2766

9.117

9.014

8.887

8.786

4

7.709

6.944

6.5915

6.388

6.256

6.094

5.964

5

6.608

5.786

5.4095

5.192

5.05

4.876

4.735

7

5.591

4.738

4.3469

4.12

3.972

3.787

3.637

10

4.965

4.103

3.7082

3.478

3.326

3.135

2.978

689

determine is if a gross deviation of 0.4 is within a 95% confidence interval for the standard

deviations of the data sets. Example 22.5 walks you through the performance of an F-test.

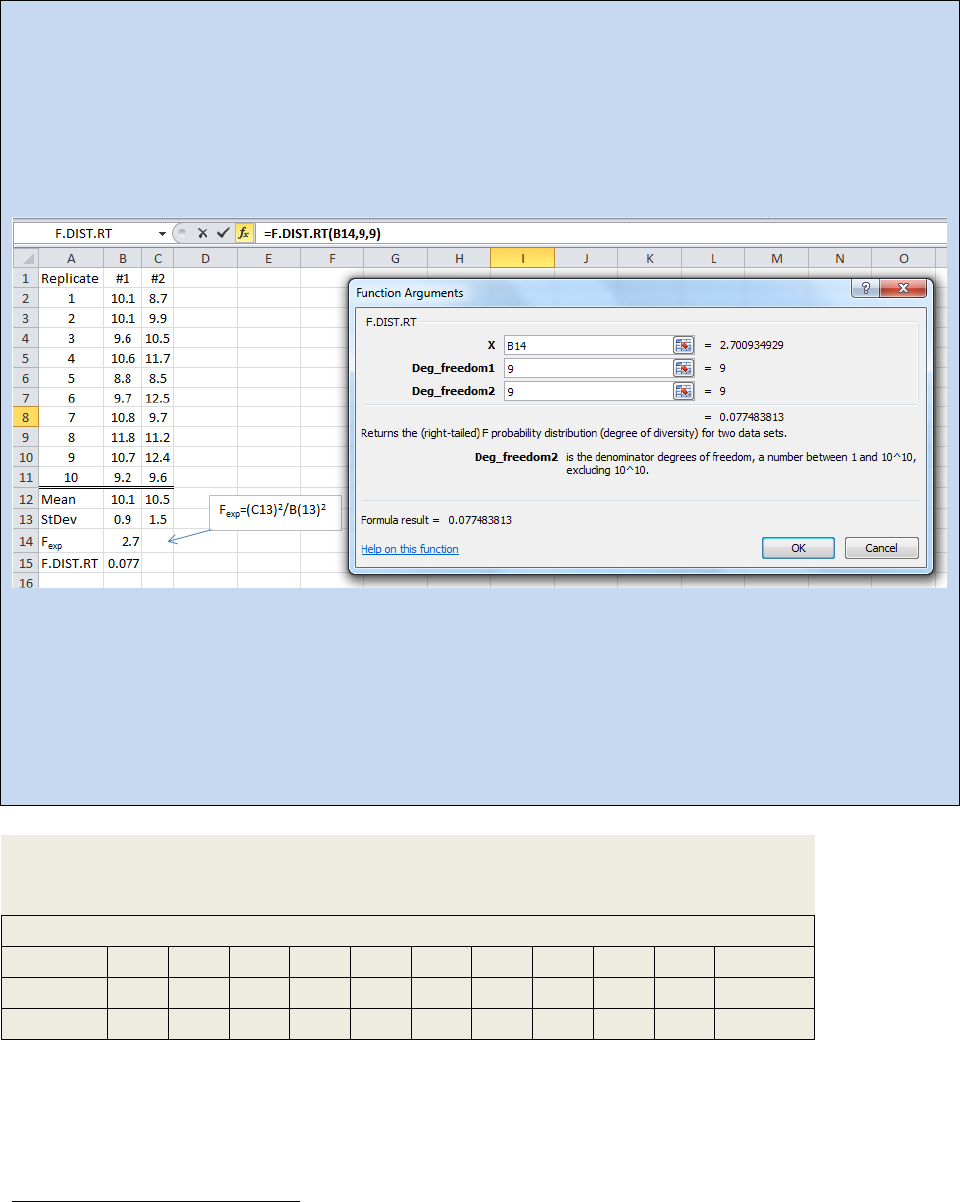

Example 22.5: To perform an F-test using Excel, you need to enter your data as shown in the

spreadsheet below and determine the standard deviation for each data set (for example see cell B13

and C13). Then determine the experimental F-value using Equation 22.12 and put that value into one of

the cells (Here we used B14). Next you need to click on the insert function button (f

x

) and choose

F.DIST.RT. The Function Argument dialog box will open as shown.

______________________________________________________________________________

Spreadsheet 22.1: Right Tailed F-Test comparing the results of two different analysts for the

measurement of residual acrylamide monomer in a batch of polyacrylamide (ppb).

______________________________________________________________________________

Enter your experimentally determined F-value for x and the numerator degrees of freedom

18

for

Deg_fredom1 and the denominator degrees of freedom for Deg_fredom2 and click “OK”.

In the above spreadsheet, the F-test returned a value of 0.077. If we round that to 0.08 then what this

test tells us is the two sets of data can be considered the same if we also accept a CL of 92% (1.00 – 0.08

= 0.92). If we need an 95% CL, we need the F-test to return a value of 0.05 or less.

Exercise 22.11: You have just measured the pH of the water sampled from a local lake.

You have ten replicate measurements with two different pH probes. The data is

presented below. Conduct an F-test on the data set and comment on the results.

pH of Local Lake Water

Replicate

1

2

3

4

5

6

7

8

9

10

Avg. pH

Probe 1

6.74

6.49

6.71

6.62

6.76

6.67

6.99

6.68

6.96

6.52

6.71

Probe 2

6.93

6.83

6.90

6.79

6.88

6.64

7.10

7.18

7.04

6.97

6.93

18

See Equation 22.4 for a review of degrees of freedom.

690

Exercise 22.12: In 2006, the Arundel County Maryland Department of Health tested local wells

for elevated levels of arsenic. They found that 35 out of 71 wells showed elevated levels.

Atomic Absorption Spectroscopy is a very convenient way to measure arsenic in water. Imagine

you are a lab manager and you have given identical arsenic samples to two different

technicians. Conduct an F-test on the two sets of data and comment on the results.

Replicate

1

2

3

4

5

6

7

8

9

10

Avg. ppb (As)

Tech. 1

0.304

0.306

0.301

0.320

0.324

0.276

0.302

0.329

0.304

0.297

0.306

Tech. 2

0.331

0.285

0.317

0.298

0.346

0.239

0.307

0.258

0.308

0.326

0.302

ANOVA: A two dimensional F-test

ANOVA is an acronym for ANalysis Of VAriance. It is very similar in concept to an F-test and in

fact we actually calculate an F-value in the analysis. For example, in Example 22.5 above, we

imagined a scenario where two different analysts performed the same test on the same batch

of polyacrylamide. Let us imagine next that we sent that same batch of polyacrylamide out to

five different labs and upon receiving the data, we wished to statistically compare the results.

We could conduct an F-test on each possible pairing of labs but that would be tedious and the

results hard to interpret. A more sophisticated approach would be to compare the average

variance that occurs as a result of changing labs to the average variance that occurs as a result

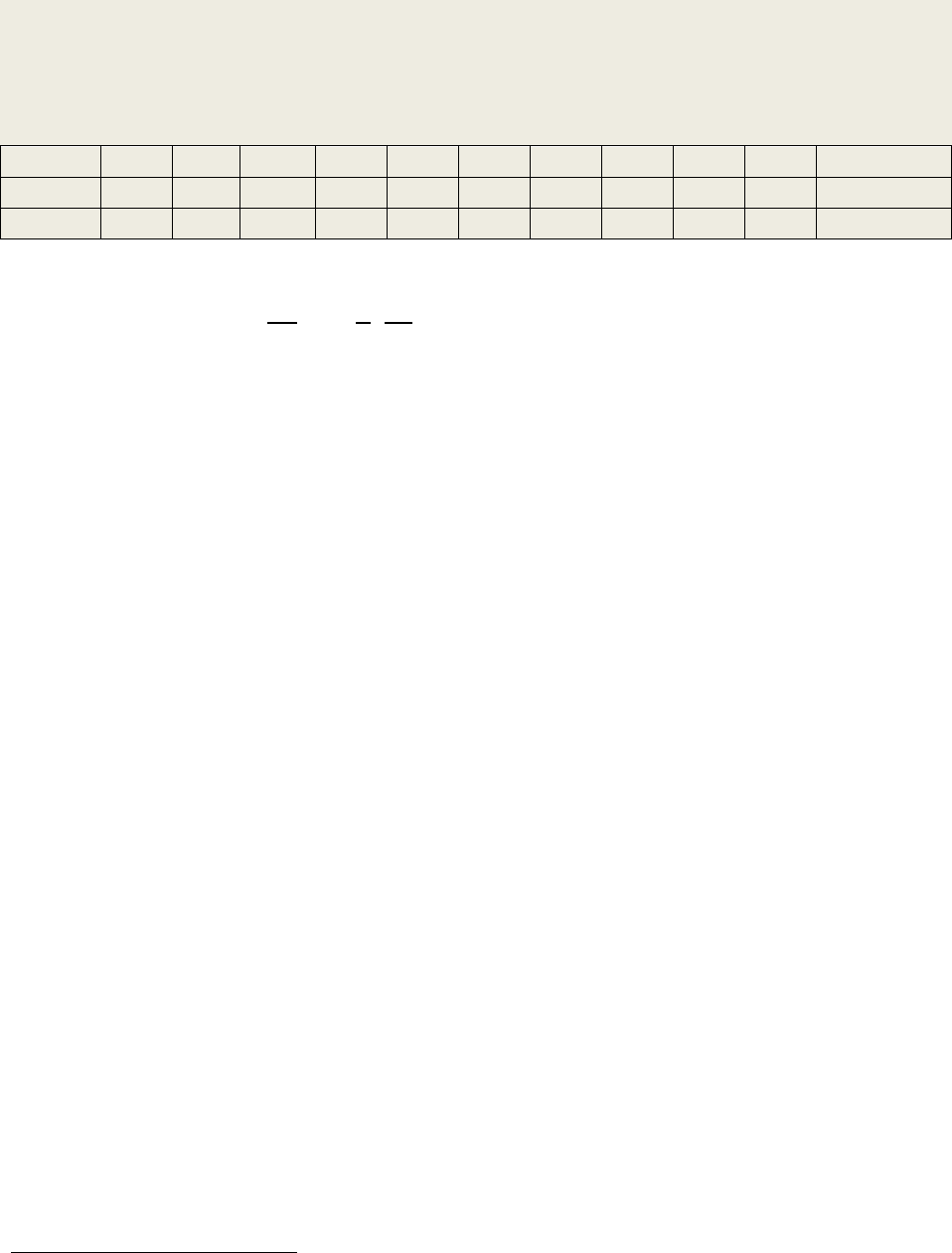

of performing replicate samplings. Spreadsheet 22.2 shows the raw data along with an ANOVA

analysis with inputs conducted by hand for the purposes of demonstration. Fortunately for us,

Excel® will do an ANOVA automatically and you will not need to program each cell manually

(see spreadsheet 22.3).

There are a total of 50 replicate data points when you combine the data from all five labs. The

average result of all 50 points is called the Grand Mean. In this case we obtained a value of

10.31 ppb. For each data point the deviation from the grand mean was calculated (columns:

D,G,J,M,P). This value is termed the mean corrected value (d

ij

). Next we squared the mean

corrected values (d

ij

2

) to generate positive numbers (columns: E,H,K,N,Q). Next we summed all

of the d

ij

2

values (SS

c

) and then divided SS

c

by the degrees of freedom

19

to yield

c

. Compare

the derivation of

c

to the derivation of a standard deviation (Equation 22.4). The value

c

is

essentially the grand standard deviation of replicates between labs. Similarly we also

calculated a

r

value.

r

can be thought of as the grand standard deviation of labs between

replicates. The F-value is then determined by dividing

c

by

r.

How one uses an F-value is

demonstrated in the next Activity.

19

See Equation 22.4 for a review of degrees of freedom.

691

Spreadsheet 22.2:-Analysis residual monomer (ppb) found in a batch of polyacrylamide conducted at 5

different independent labs; An ANOVA between 5 independent labs.

692

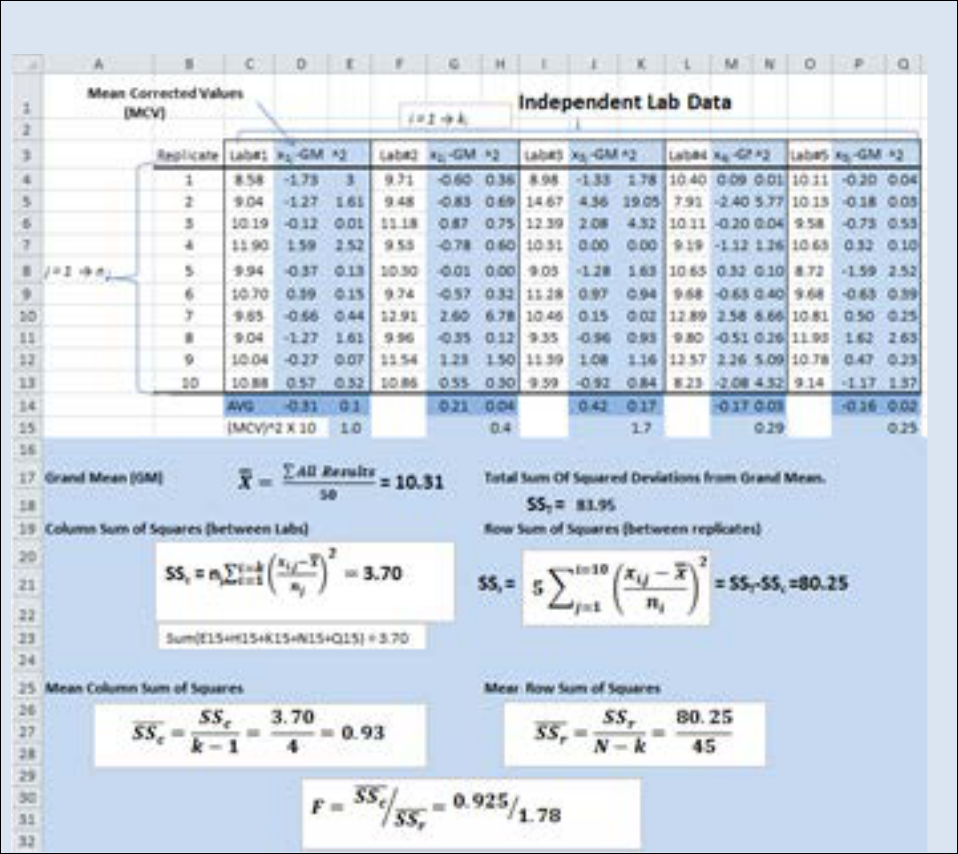

Activity - Letting Excel Perform ANOVA

Using the same data we examined in Spreadsheet 22.2, we will perform an ANOVA using the ANOVA

statistics function in Excel. From the data analysis tool pack, select “ANOVA: Single Factor”. The ANOVA

Single Factor dialog box will open (see Spreadsheet 22.3). The input range is the total 50 data points

obtained between all five labs. In this example, we have the independent labs arranged in columns so

make sure the “Grouped By Columns” radial button is selected. Notice that we have also selected the

“Labels in first row” check box. The default value for α is 0.05 which will calculate a 95% confidence

interval for your ANOVA. You have several options for the output. If you choose to keep your ANOVA

output with your raw data, then

you have to tell Excel where you

want the data table to start. In

this case we began our data table

at cell W16.

The ANOVA table in Spreadsheet

22.3 has a calculated F-value of

0.51897 (the same value we

calculated by hand). The p-value

shown is called the value of

probability. Since we selected an

alpha value of 0.05, we want our

p-value to be above 0.05 in order

for the null hypothesis to hold. In

other words, this ANOVA study did

not find any statistically significant

variance between the five labs.

22.5 – Linear Regression Analysis

The preceding section provides tools useful to the experimenter when working with repetitive

data – that is, measurements that are expected to have essentially the same value every time.

When conducting instrumental analysis, however, it is often the case that we do not know in

advance the actual magnitude of the measurement, but only an estimate of a range in which

the measurement might fall. In such cases, we must prepare and measure standard samples

20

that fall in the expected range in order to calibrate the instrumental response for known

concentrations. The fundamental signal that is obtained from an instrument is either a voltage

or a current, neither of which directly gives us useful information about our sample. In practice

we use standard calibration curves to relate that fundamental signal to one that is more

meaningful, such as pH or absorbance. We then plot that signal as a function of known

concentrations to yield a calibration curve so that the signal from an unknown sample can be

used to determine the analyte concentration. The basic statistical tools outlined above must be

further developed for application to measurements made using a calibration curve.

For an instrument response that is linear with analyte concentration, we would expect to

obtain a series of data points that fall on a straight line as the concentration is varied. However,

20

Recall that a standard sample is one in which the concentration of analyte is known.

Spreadsheet 22.3: A Single Factor ANOVA in Excel.

693

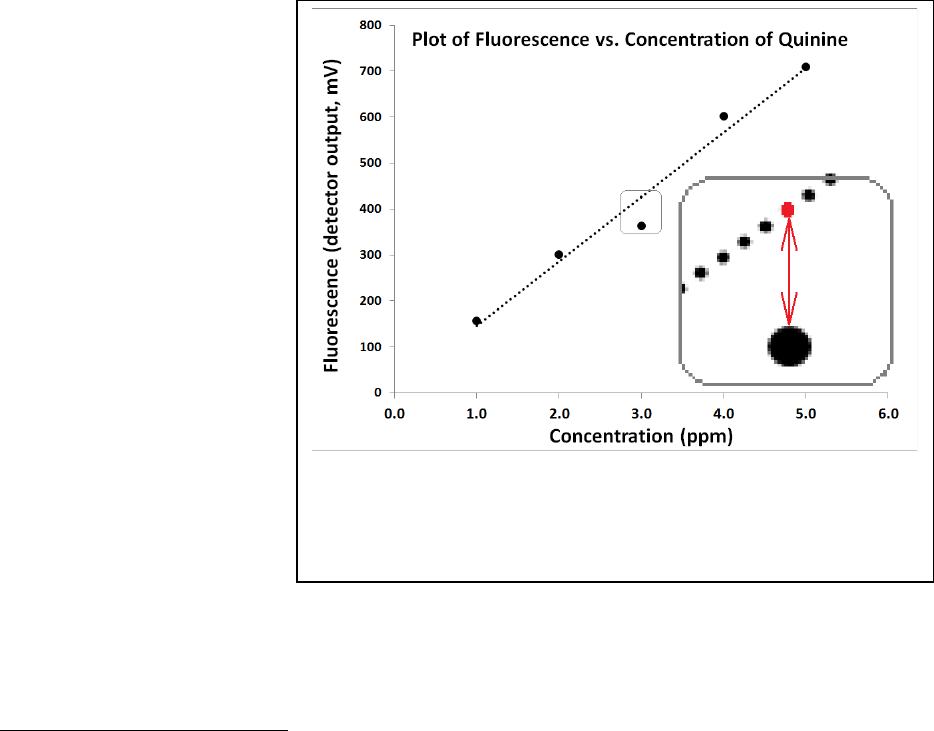

Figure 22.13: Demonstration of the y-residuals. The region around

the third point is expanded in the inset. The red dot represents

y

i,calc

and the large black point represents y

i,act

. The difference

between the two points is (y

i,act

– y

i,calc

) for i=3.

we also expect there to be error in the measured values so the points will have some degree of

variance from the anticipated straight line. If we were to graph those values on paper, we

could use a straightedge to estimate a best fit line for the points. In the modern electronic age,

however, it is more common (and more accurate) to use a method called regression analysis to

discover the best linear approximation from the measured points.

Much of what we need for our analyses can be obtained quickly and easily from Excel™ or

another spreadsheet software package. Using the linest function

21

in Excel™, we can obtain the

slope and intercept for the regression, as well as the standard deviations associated with those

values. Further, we can extract the coefficient of determination, R

2

, also known as the ‘R-

squared’ value and the standard error for the y-estimate (essentially the standard deviation for

the regression), s

y

. The R

2

has a value between zero and 1, and is often referred to as the

“goodness of fit” or a “correlation coefficient”. An R

2

value of 1 indicates a perfect fit between

the actual y-values and those calculated using the linear equation. The farther the R

2

value

deviates from 1, the greater the deviations between the actual and calculated y-values. The s

y

value is used in calculating the standard deviation of results for measurements of unknown

samples obtained using the calibration curve.

It is helpful to understand

how the software goes

about calculating an

equation for the linear

regression. To find a best fit

line (Eq. 22.13), the

software is programmed to

minimize the sum of the

squared differences

(sometimes called residuals)

between the actual y-values

and those calculated by the

linear equation for each x-y

pair. Figure 22.13 provides

a visual depiction of what

we mean by these residuals.

The residuals are squared to

eliminate any negative

values and then the slope of

the line is adjusted until the

sum of the residuals reaches a minimum value. If we call the summed residual values value SS

y-

y

, the software seeks to minimize it in the form of Eq. 22.14.

,

=

+ Eq. 22.13

21

You can accomplish the same thing using the linest function in the function dialog box.

694

=

(

,

,

)

Eq. 22.14

SS

y-y

= sum of the squared residuals

,

= actual (measured) value for y in a given (i) of an x-y pair

,

= y-value calculated from the linear equation Eq. 22.13

Most of what we need for sample analysis can be obtained fairly directly through Excel (see the

Activity on the following page and Example 22.6), but in order to accomplish full statistical

analysis, we need to define one additional quantity, S

x-x

, given in Eq. 22.15. With the

information obtained from the Excel linest function and S

x-x

, we will be able to calculate a

standard deviation for any y-value calculated for a sample of unknown concentration using the

linear regression of the calibration plot (Eq. 22.16).

=

(

)

Eq. 22.15

= value for x in a given (i) of an x-y pair

= the mean of all of the x-values

=

(

)

(

)

+

+

Eq. 22.16

= standard deviation of a calculated y-value for an unknown sample

= standard error in the y-estimate (from Excel linest function)

= slope of the regression line (from Excel linest function)

= mean of all y-values for N

S

replicates of the unknown sample

= mean of all y-values for N

C

samples used in the calibration

= number of samples used in the calibration

= number of replicates of the unknown sample

695

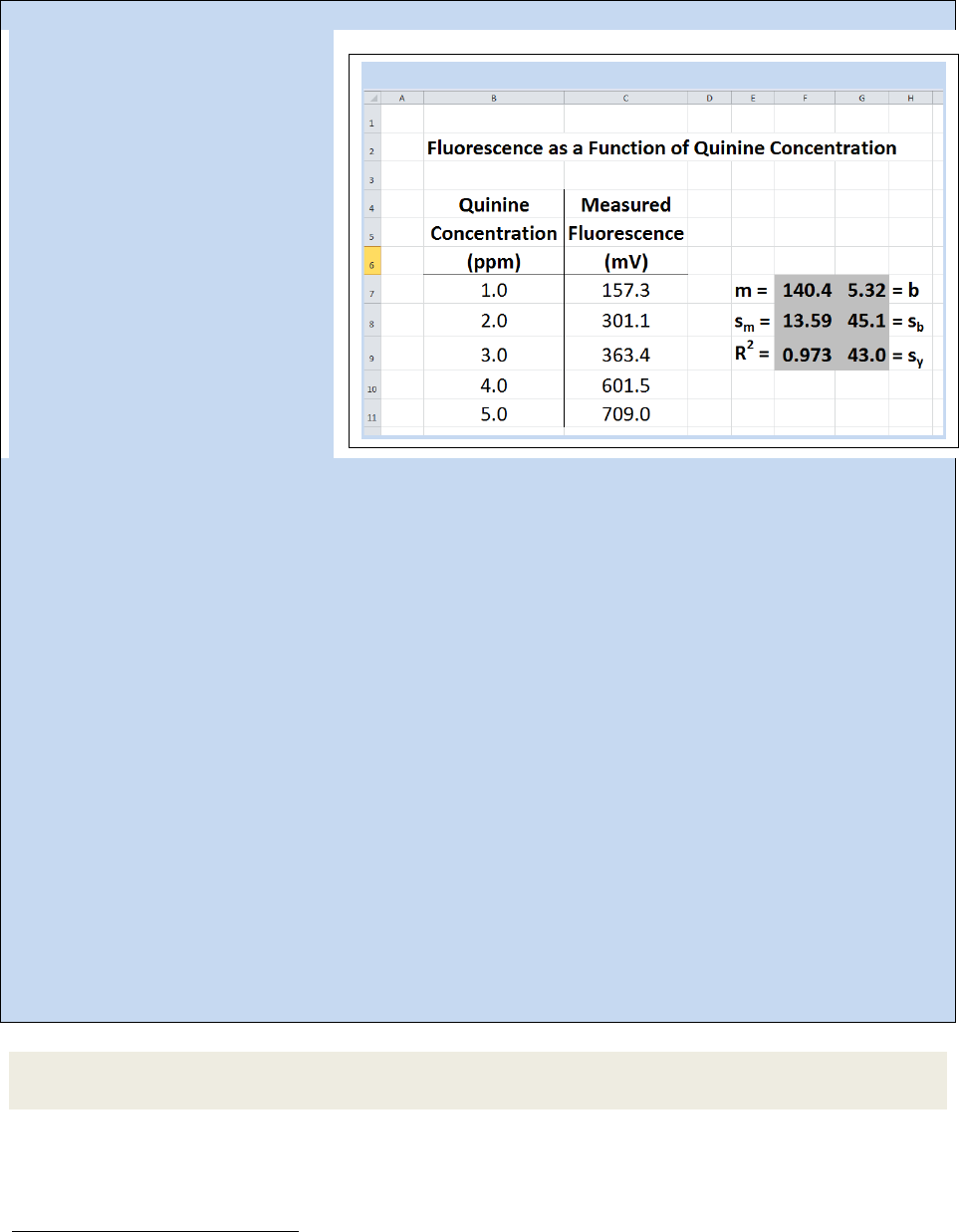

Activity - Letting Excel Perform LINEST to give linear regression data

Set up a calibration data set as

given in Spreadsheet 22.4. To have

Excel calculate the pertinent

analysis data from the calibration

information, we use the linest

function in the following

procedure:

1. Highlight an area encompassing

two columns and three rows

22

(the

highlighted area in Spreadsheet

22.4 is in columns F and G, rows 7-

9).

2. With that area still highlighted,

start typing the function = linest(

3. After the open parentheses,

highlight all the y-values in the

calibration data, then enter a comma.

4. Next, highlight all the x-values in the calibration data, then enter a comma.

5. For the next parameter, you need to make a choice.

a. If you expect that the calibration data should pass through zero (intercept of zero), then enter a zero

followed by a comma.

b. If you want the function to calculate an intercept value, enter a 1, followed by a comma.

6. Now enter a 1, telling Excel to calculate stats beyond just the slope and intercept, close the

parentheses but do not simply press Enter.

7. To complete the calculation, press Ctrl + Shift + Enter (while holding down the Ctrl key, press the Shift

key, and while still holding down both of those, press the Enter key).

In the example given in Spreadsheet 22.4, the completed function looked like this, wherein we allowed

linest to calculate an intercept value:

=LINEST(C7:C11,B7:B11,1,1)

The information that Excel yields from the linest function includes the slope (m, in Cell F-7), the intercept

(b, G-7), the standard deviation in the slope (s

m

, F-8), the standard deviation in the intercept (s

b

, G-8),

the coefficient of determination (R

2

, F-9), and the standard deviation in the y-estimate (s

y

, G-9).

Note that if you need to edit your linest function, you will need to highlight the full 2x3 block again,

make your edits, then press Ctrl + Shift + Enter.

Exercise 22.13: Use Eq. 22.14 to calculate SS

y-y

for the example given in the preceding Activity

(Spreadsheet 22.4).

22

Actually, Excel will provide additional statistics, if we highlight an area that is 2 columns by 5 rows, but the

additional two rows of statistics are not generally as useful as the first 3.

Spreadsheet 22.4: The LINEST function in Excel

696

Exercise 22.14: Repeat Exercise 22.13, but use a slope that is 1% lower and an intercept 1%

higher than that seen in Spreadsheet 22.4. Compare the SS

y-y

you get with that found in 22.13.

Is the result as expected? Explain.

Example 22.6- Following thee calibration represented in Spreadsheet 22.4, three replicates of a quinine

sample of unknown concentration were prepared and the fluorescence measured, yielding the values

406.6, 414.6 and 408.2. Calculate the quinine concentration in the sample and the standard deviation in

the calculated value.

Strategy – Use Eq. 22.13 and the linest data in Spreadsheet 22.4 to calculate the quinine concentration.

Then use Eq. 22.16 to calculate the standard deviation in the calculation.

Solution – The average measured value (

) for the unknown sample is 409.8, so we can calculate the

concentration as

= +

. = . + .

x = 2.8813 = 2.9 ppm

For Eq. 22.16, we will use the following values

s

y

= 43.0 m = 140.4 S

x-x

= 10

= 409.8

= 426.5

N

C

= 5 N

S

= 3

=

(

)

(

)

+

+

=

.

.

(. .)

.

()

+

+

= 0.224 = 0.22 ppm

Exercise 22.15: The following data were obtained for a set of calibration solutions of p-

nitroaniline, measured by absorbance in UV-Visible spectrophotometry.

Concentration (ppm) Absorbance (AU)

19.5 0.980

9.74 0.440

4.87 0.255

0.974 0.101

A p-nitroaniline solution of unknown concentration exhibited an average absorbance of 0.181

for 5 replicate samples. Assuming the intercept is zero for the calibration, calculate the

concentration of the unknown solution and the standard deviation in the calculation.

Exercise 22.16: Repeat Exercise 22.15, but do not assume the intercept is zero for the

calibration. Which set of results do you feel are more accurate? Explain. What additional

information would you need in order to make a more definitive judgment?

697

Exercise 22.17: The following data were obtained for the calibration of an FAA instrument in

the measurement of calcium:

Concentration of Ca (ppm) Absorbance (AU)

0.100 0.010

0.250 0.024

0.500 0.069

1.000 0.093

2.500 0.225

5.000 0.427

7.500 0.628

10.00 0.804

A urine sample was treated to remove interferences, resulting in a dilution factor of 5:2 of the

original urine. The mean absorbance of three replicates of the diluted urine was found to be

0.325. Assuming the intercept is zero for the calibration, calculate the concentration of the

unknown solution and the standard deviation in the calculation.

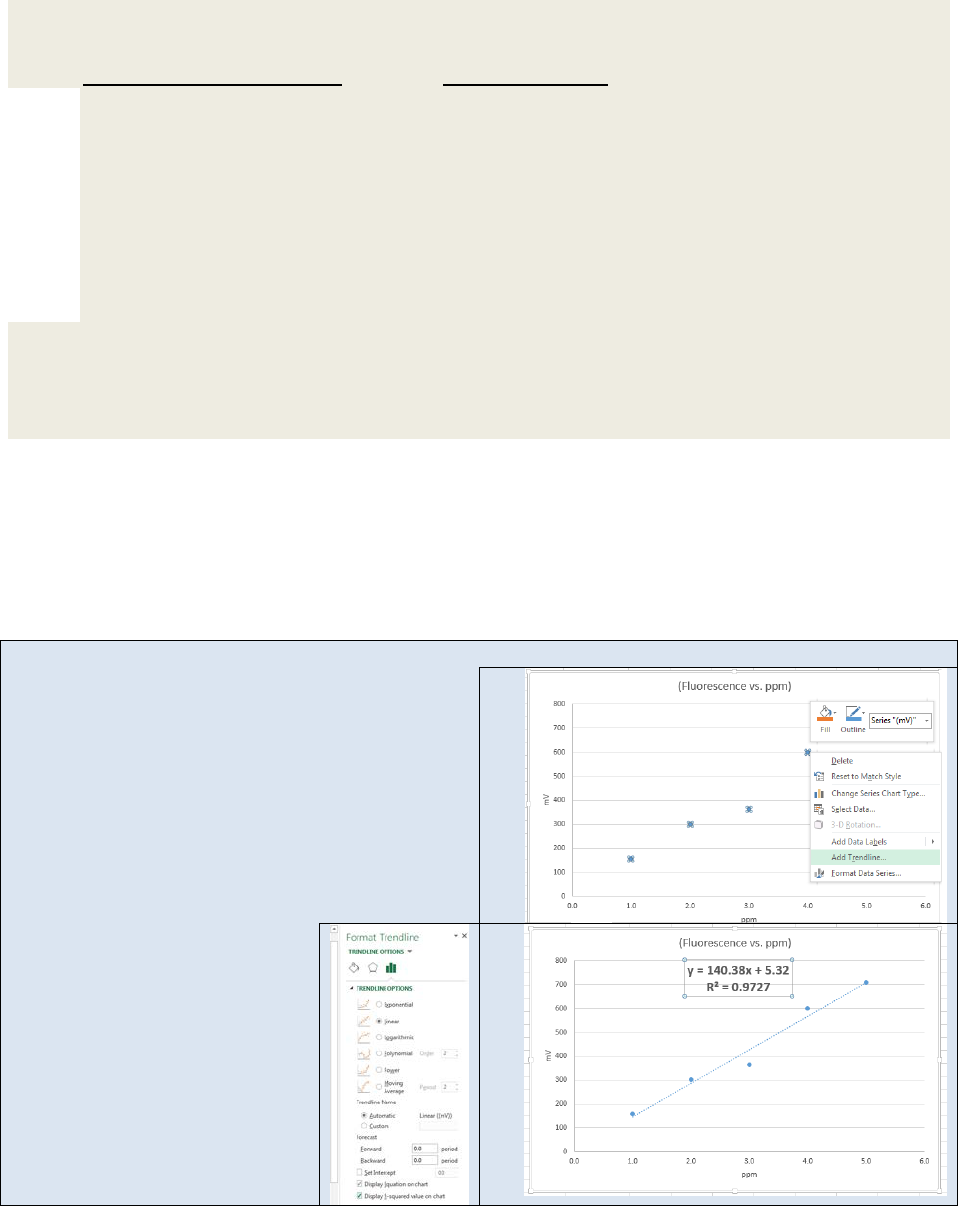

If you don’t need a full statistical analysis of your calibration curve and simply want the y = mx +

b equation and the R

2

value, Excel™ also offers a feature called “add trendline”. The add

trendline feature is accessed by right clicking on the X-Y scatter plot of the calibration data. The

next activity demonstrates the add trendline feature.

Activity – Using Excel™ to add a trend line to a data set.

Using the same data set from our previous activity,

create an X-Y scatter plot as shown here. Highlight

the X-

Y points in the scatter plot and “right click”.

If using an Apple operating system, hold down the

Apple key and click. A dialog box open. Select Add

Trendline. The Format Trendline dialog box will

open (see below).

If you expect your instrument

response to be linear, then select the linear radial

button. Then select Display Equation on Chart

and Display R-squared value on

chart. Hit return. Your graph

should now resemble the one

seen here on the bottom right.

698

22.6 – LOD, LOQ, and LDR

As noted above, we must expect the presence of random error (noise) in every measurement.

Sometimes that noise is clearly visible, but other times it is not obvious. This realization make it

necessary to contemplate the question “At what point can I trust that my measurement is real,

and not just noise?”. Fortunately, statistically sound tools have been developed to help us

make that judgment.

The limit of detection (LOD) is the lowest value measurable above the background noise. At

the LOD, we can be confident that we are measuring some analyte, but we cannot be confident

about the actual amount. The limit of quantitation (LOQ) is the minimum value at which we

can be confident in the quantitative value of the measurement. The IUPAC

23

has demonstrated

the following for any given analytical method:

=

+

Eq. 22.17

LOD

y

= limit of detection of the measurement (y-value)

= mean y-values of a set of blank or baseline measurements

s

blnk

= standard deviation of a set of blank or baseline measurements

k

D

= multiplicative factor. k

D

= 3 at the 99.9% confidence level

=

+

Eq. 22.18

LOQ

y

= limit of quantitation of the measurement (y-value)

and s

blnk

are as above

k

Q

= multiplicative factor. k

Q

= 10 for 10% RSD and k

Q

= 20 for 5% RSD

Note that Equations 22.17 and 22.18 will be relevant for any type of measurement, even if a

calibration plot is not used, as long as we can get a reasonable estimate of the mean blank

signal and its standard deviation.

In many cases involving calibration plots, it is more desirable to think about limits of detection

and quantitation in terms of actual concentrations (the x-value) rather than the measured

quantity (the y-value). Since we know the relationship between x and y for a linear relationship

(y=mx+b), we can derive expressions that give us LOD and LOQ in terms of concentration. Note

that in most instrumental methods, the instrument will be set to a measurement of zero using a

blank solution, so we can assume that in the absence of significant drift, the intercept (b) is

equal to the average blank measurement,

, or

= +

Eq. 22.19

23

Long, GL and Winefordner, JD, “Limit of Detection: A Closer Look at the IUPAC Definition”, Anal. Chem., 55, 1983,

712-724.

699

The “y” in an LOD (or LOQ) calculation is the LOD

y

(or LOQ

y

) from Equation 22.17 (or 22.18), and

the “x” would be the LOD

x

(or LOQ

x

), which is the limit of detection in terms of concentration:

=

+

Eq. 22.20

If we combine Eq. 22.17 and 22.20 (or 22.18 and the LOQ equivalent of 22.20), we can find our

equations for limits of detection and quantitation in terms of concentration (Equations 22.21

and 22.22):

=

Eq. 22.21

LOD

x

= limit of detection of the concentration

s

b

= standard deviation of a set of blank or baseline measurements

k

D

= multiplicative factor. k

D

= 3 at the 99.9% confidence level

=

Eq. 22.22

LOQ

x

= limit of detection of the concentration

s

b

= standard deviation of a set of blank or baseline measurements

k

Q

= multiplicative factor. k

Q

= 10 for 10% RSD and k

Q

= 20 for 5% RSD

Exercise 22.18: Demonstrate that Equations 22.21 and 22.22 can be derived from Equations

22.17 and 22.18, respectively.

Exercise 22.19: Demonstrate that the units of LOD

x

(and thus LOQ

x

) are concentration units.

Assume concentration is in units of molarity and the measurements are made in milliamps from

an arbitrary detector.

Exercise 22.20: In the experiment represented in Exercise 22.17, eight blank measurements

were made: 0.001, 0.000, 0.000, 0.001, 0.002, -0.001, 0.000, -0.001 AU. Calculate the LOD

y

,

LOQ

y

, LOD

x

, and LOQ

x

.

Exercise 22.21: Consider your results from Exercise 22.19 and the data presented in Exercise

22.17. If you were presenting this data for publication, would you need to redo the calculations

you did in Ex. 22.17? Explain.

It is often the case that we do not have available multiple blank measurements for a method

involving a calibration plot. In such a case, two alternatives have been proffered. If, in doing

the linear regression, an intercept is calculated, then we can substitute s

b

(standard deviation of

the intercept) for s

blnk

in the equations presented above. If we set the intercept to zero in the

linear regression, we can use the s

y

(standard deviation of the y-estimate) in place of s

blnk

. In

both cases, we must expect that our estimates for LOD and LOQ will be higher than they would

have been using the formal approach, but it is better to err on the side of caution.

Exercise 22.22: Estimate LOD

x

and LOQ

x

for the data given in Spreadsheet 22.4.

700