Packaging & Labeling Requirements

For Aftermarket Parts

PD484 (02/22)

Table of Contents

Preface

Introduction

1.0

Compliance

2.0

Environmental Considerations

3.0

Packaging Responsibilities

3.1

General

3.2

Essential Packaging Functions

3.3

Compliance With Regulatory Requirements

4.0

General Packaging Requirements

4.1

Packaging Costs

4.2

Packaging Material

4.3

Securement

4.4

Ergonomics

4.5

4.6

Part Preservation Requirement

Unique Packaging Requirements

5.0

Shipping Instructions and Documentation

5.1

Destination Label

5.2

Customs Documentation Packets

5.3

Packing List

5.4

Bill of Lading

5.5

Numbering Cartons and Containers

5.6

Handling Instructions

6.0

Shipping Container Specifications

6.1

Definition

6.2

Hand-Handled Container Requirements

6.3

Mechanically-Handled Container Requirements

6.4

Construction of Bulk Containers

6.5

Container Height

6.6

Temperature

6.7

Moisture

6.8

Special Considerations

6.9

Salvaged Packaging Materials

7.0

Corrugated Fiberboard Specifications

7.1

General

7.2

Certificate of Box Manufacturer

8.0

Dunnage Material

9.0

Pallet Specifications

9.1

General

9.2

Pallet Size Requirements

9.3

Constructions Requirements

9.4 Condition

10.0

Loads & Load Containment

10.1

General

10.2

Metallic Strapping

10.3

Plastic Strapping

10.4

Plastic Stretch Film

10.5

Shrink Film

10.6

Unitizing Adhesives

10.7

Stacking & Stackability

10.8

Loading of Cartons

10.9

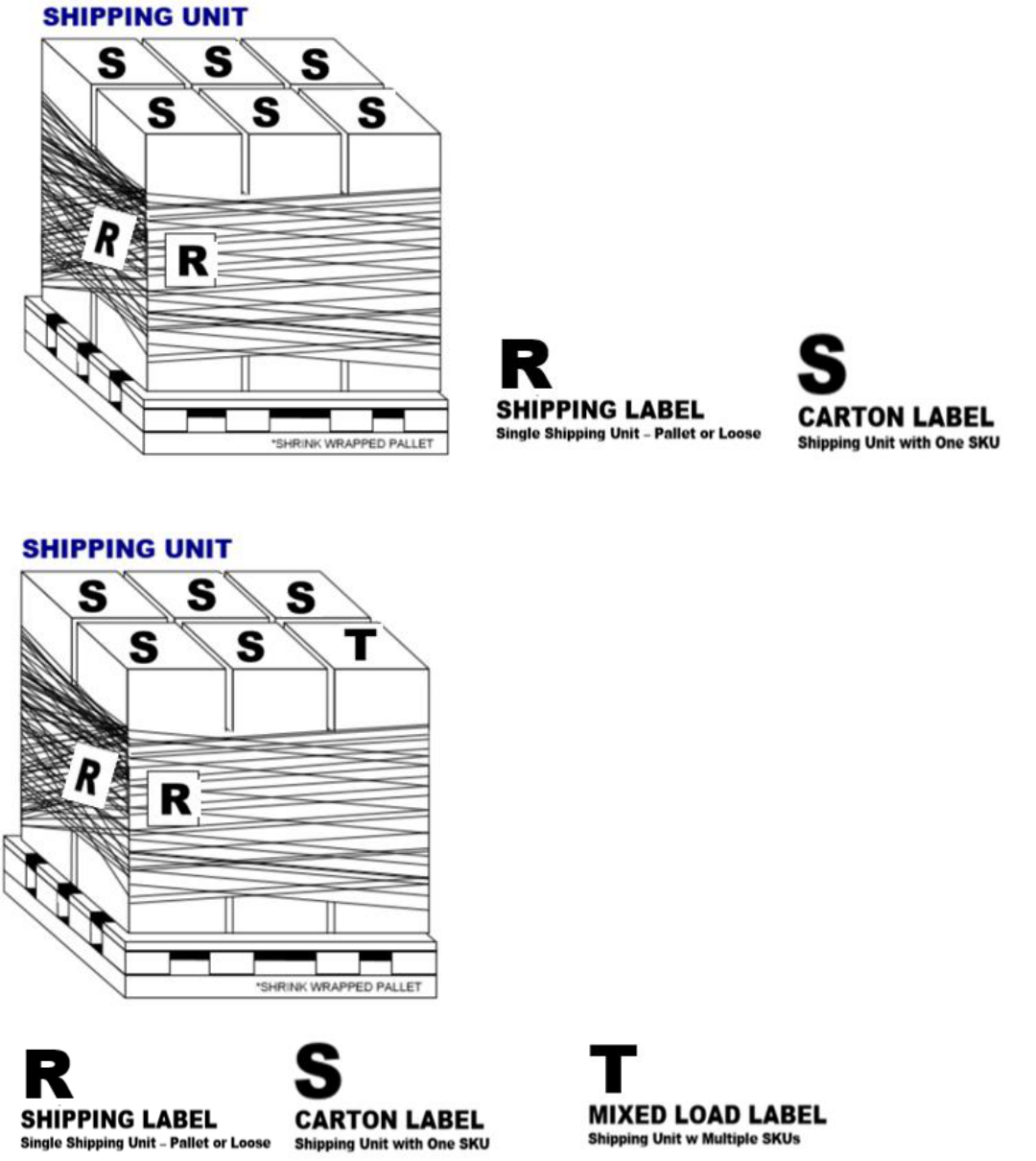

Mixed Load Procedure

11.0

Packaging Testing

12.0

Daimler Trucks North America-Owned Returnable Containers

13.0

Supplier–Owned Returnable Containers

14.0

Mode of Transportation

14.1 Routing Letters

15.0

Hazardous Materials

16.0

Bar Coded Shipping Label Requirements

16.1

General

16.2

Quality

16.3

Label Size and Materials

16.4

Bar Code Symbology

16.5

Shipping (Master) Label Information

16.6

Single Shippable Unit Multiple Container Label

16.7

Label Location and Protection

16.8 Special Labels

17.0

DTNA Individual Salable Unit Bar Coding Requirements

17.1

General

17.2

Quality

17.3

Label Size, Material and Special Requirements

17.4

Required Label Information

17.5

Bar Code Symbology

17.6

Example of Acceptable Bar Codes

17.7

Approval of Bar Code Label by Daimler Trucks North America

Aftermarket Parts Packaging Group

18.0

Advance Shipping Notice

18.1 General

18.2 ASN Information

19.0

Box / Layer / Pallet Quantity Data

20.0

Glossary

21.0

Exhibits

Exhibit A, Plastics Recycling Symbology

Exhibit B, Certificate of Box Manufacturer

Exhibit C, Bill of Lading – Direct to PDC

Exhibit D, Master Bill of Lading

Exhibit E, Bill of Lading – Final Destination

Exhibit F, Bill of Lading – Critical Drop Ship

Exhibit G, Packing Slip

Exhibit H, Types of Expendable Containers

Exhibit I, Fiberboard Box Specifications

Exhibit J, Bulk Container Construction

Exhibit K, Types of Wood Pallets

Exhibit L, Types of Wood Pallets

Exhibit M, Strength of Corrugated Cartons

Exhibit N, Loading of Cartons

Exhibit O, Mixed Load Procedure

Exhibit P, Label Dimensions

Exhibit Q, Label Locations

Exhibit R, Bar Coded Shipping Label

Exhibit S, Single Shippable Unit Multiple Container Label

Exhibit T, Mixed Load Label

Preface

This document is available electronically to insure the latest information is always available to our suppliers.

To view the electronic version please copy the following link into your browser:

https://docmaster.supplier.daimler.com/DMPublic/de/html/M10.01.09.FTPNN02._list.html

Next click on the pdf Download icon associated with “Packaging Guidelines for Aftermarket Parts” to

display the document on screen.

Your feedback is important to us. Questions and suggestions regarding content and recommendations for

future editions should be directed to:

Daimler Trucks North America

Aftermarket Parts Packaging Group

Parts Distribution Operations

515 11

th

Street SE

Canton, OH 44707-3811

Phone: (330) 430-4387

Email: aftermarket-packaging-[email protected]

Introduction

This manual has been prepared to assist aftermarket Suppliers in meeting Daimler Trucks North America’s

packaging, labeling and shipping requirements.

Suppliers are ultimately responsible for the design and testing of all levels of packaging. This includes but not

limited to DTNA salable unit, overpack, dunnage, shippable unit, and required labeling for all items purchased

by DTNA. The Supplier must assure their products arrive, at Daimler Trucks North America’s Parts

Distribution Centers and / or point-of-use, in blemish, scuff, rust, and damage free condition, assuming normal

handling and storage, with appropriate load documentation. In addition, packaging must be economical with

minimum impact to the environment and labeling must be in accordance with DTNA and industry standards.

Sections 1 through 16 contain Daimler Trucks North America’s packaging and shipping label requirements for

aftermarket parts and material, including the use of bar codes. Suppliers are expected to comply with sections 1

through 16.

Section 17 applies exclusively to the use of bar codes for DTNA individual piece part bar coding requirements.

Suppliers are expected to be in compliance with Section 17 upon agreement of accepting business.

Section 18 and 19 discussed EDI, ASNs via API and quantity data requirements of suppliers.

It is essential that Suppliers and Daimler Trucks North America cooperate to achieve acceptable packaging and

labeling at reasonable cost, in our mutual interest and to our customer’s satisfaction.

DTNA reserves the right to change, add, delete or modify any portion(s) of this guideline without notice.

Questions regarding compliance, content, intent, or recommendations for these requirements should

directed to:

Daimler Trucks North America

Aftermarket Parts Packaging Group

Parts Distribution Operations

515 11

th

Street SE

Canton, OH 44707-3811

Phone: (330) 430-4387

Email: aftermarket-packaging-team@daimlertruck.com

1.0 Compliance

Supplier compliance to the requirements in this document is Mandatory. A meeting maybe held with your

company to discuss supplier compliance to this document. Supplier participation in these meetings are

important to maintain supply chain relations. We appreciate your partnership and cooperation in these

meetings.

However, some parts supplied to Daimler Trucks North America may require additional packaging or labeling

not covered in this document. If you supply this type of part, contact Daimler Trucks North America for

assistance in development of a package or label compatible with Daimler Trucks North America’s

requirements.

Any deviation from the requirements listed in this document, or the DTNA Hood Packaging guidelines, must

have written approval from Daimler Trucks North America Aftermarket Parts Packaging group.

Additionally, any changes to supplier packaging / labeling previously approved by Daimler Trucks North America must

also have written approval of the change by Daimler Trucks North America Aftermarket Parts Packaging group prior to

any change implementation.

Ultimate and final determination of all package and labeling adequacy resides with Daimler Trucks North

America.

In addition, Daimler Trucks North America requires a supplier response in 3 business days or less to all

Daimler Trucks North America communications on subjects including, but not limited to, reports and forecasts

and receiving issues and packaging issues. Timely supplier response will ensure resolutions of issues to

support our commitment to our customers and timely payment to our suppliers. E-mail is the preferred method

of communication on most matters.

Questions regarding compliance, intent, request(s) for deviation, or recommendations should be directed to:

Daimler Trucks North America

Aftermarket Parts Packaging Group

Parts Distribution Operations

515 11

th

Street SE

Canton, OH 44707-3811

Phone: (330) 430-4387

Email: aftermarket-packaging-team@daimlertruck.com

2.0 Environmental Considerations

Daimler Trucks North America is participating in industry efforts toward the reuse and recycling of packaging

materials. Successful implementation of waste minimization programs, recycling, and use of returnable

containers has substantially eliminated or reduced the amount of materials sent for disposal. In addition, we are

investigating new technologies, materials and distribution alternatives which will minimize the overall impact

of packaging waste on the environment.

The concept of Product Stewardship, in which industry assumes the responsibility of their products and

packaging from conception to disposal, is vital in achieving an environmentally responsible packaging

strategy.

Daimler Trucks North America requests that Suppliers commit to Product Stewardship and faithfully practice

the 3 R’s principle of Reduce, Reuse and Recycle. By doing so, the elimination and reduction of packaging

related wastes will reduce packaging costs as well as minimize the impact of packaging on the environment

without impacts to quality and product integrity.

3.0 Packaging Responsibilities

3.1 GENERAL

Suppliers are ultimately responsible for the design and testing of all levels of packaging,

including DTNA salable unit, overpack, dunnage, shippable unit, etc…., with required labeling.

All items purchased by DTNA from the supplier must arrive at Daimler Trucks North America’s

Parts Distribution Centers and / or point-of-use, in blemish and scuff and rust and damage free

condition, assuming normal handling and storage, with appropriate load documentation.

All salable unit packaging is to be securely held closed with appropriate type of securement (i.e. glue,

tape, staples, banding, nails, etc…) as needed to insure the product within is secured and contained and

that the packaging is not easily opened without disruption/removal of the securement used.

3.2 ESSENTIAL PACKAGING FUNCTIONS

Packaging must perform a number of essential functions during transportation and storage. Suppliers

should consider the following functions in designing a package for their product:

Protection of the product from physical and environmental damage (e.g. rust, …), blemishes and

scuffing.

Convenience of use, safety and ease of handling.

Compliance to legal and regulatory requirements.

Communication of information (labeling).

Environmental acceptability and ease of disposal or recycling.

Present a clean professional appearance of the product packaging.

“Right Sized” for the salable and shippable unit containing the product (not excessively large or too

small).

Sufficiently robust to provide stackability and protection of packaged product during shipment.

3.3 COMPLIANCE WITH REGULATORY REQUIREMENTS

As a supplier to Daimler Trucks North America, you are required to develop packaging and use

packaging materials which are consistent with regulations established by State, Provincial, or local

governments wherever your package is discarded (recycled, reused, disposed of, etc.). Daimler Trucks

North America will attempt to notify suppliers of any relevant legislation which may apply directly to

containers and packaging shipped to various Daimler Trucks North America locations. However, the

supplier has ultimate responsibility for assuring their packaging is in compliance with regulations.

4.0 General Packaging Requirements

4.1 PACKAGING COSTS

All part quotations are to include all costs for DTNA defined unit packaging and labeling and shipment

materials. The supplier is responsible for DTNA defined unit packaging and labeling as required by this

document and must include the costs for all materials and labor in the piece-part price at the time of

quotation.

4.2 PACKAGING MATERIAL

Recyclable materials must be used and packaging should consist of recycled materials where possible

and cost effective.

Plastic material must be labeled in accordance with the Society of the Plastics Industry Recycling

Symbology (See Exhibit A and Section 6.8).

Corrugated containers must display a Certificate of Box Manufacturer in a readily visible location on the

container (See Exhibit B and Section 7.2).

The use of salvaged containers, pallets and other packaging material must have written preapproval from

Daimler Trucks North America.

The use of returnable containers and any returnable dunnage must have written preapproval from both

the Daimler Trucks North America Purchasing Department and the Daimler Trucks North America

Aftermarket Parts Packaging group . All returnable containers must be damage free, clean and free of all

prior labeling.

4.3 SECUREMENT

All salable unit packaging is to be securely held closed with appropriate type of securement (i.e. glue,

tape, staples, banding, nails, etc…) as needed to insure the product within is secured and contained and

that the packaging is not easily opened without disruption/removal of the securement used.

4.4 ERGONOMICS

All containers and packaging and necessary dividers and other dunnage must be designed with

consideration given to ease of handling, part removal and employee safety. Appropriate consideration

must be given to height restrictions, weight restrictions, carton disassembly and any other issues which

may affect worker safety.

4.5 PART PRESERVATION REQUIREMENT

DTNA Aftermarket part preservation requirement requires passage of a 96 hour closed chamber fog test

at 100 degrees Fahrenheit and at 100 percent humidity.

4.6 UNIQUE PACKAGING REQUIREMENTS

Unique packaging requirements including, but not limited to, rust prevention, weight, fragility (e.g.

glass, …) surface protection and/or returnables and returnables freight expense(s) which are not covered

by these guidelines are the responsibility of the parts supplier.

5.0 Shipping Instructions and

Documentation

5.1 DESTINATION LABEL

.1 All destination labels shall be machine-printed. Handwritten labels are unacceptable.

.2 Final destination labels shall be located on two adjacent sides of the container or package, where

possible.

.3 Suppliers shall refer to the Daimler Trucks North America Purchase Order for the correct PDC

shipping address.

.4 In addition, Critical Drop Ship orders must also be identified on the same two adjacent sides of the

container or package with a label in large font stating “CRITICAL”.

5.2 CUSTOMS DOCUMENTATION PACKETS

.1 It is a requirement of Daimler Trucks North America that for all International shipments into the

United States and Canada that they be accompanied by a two packet set of the required customs

documentation. The packet contents are different and must consist of the following documents:

Customs Documentation Packet #1

A copy of the commercial invoice

A copy of the packing list which should include shipment date

Original Certificate of Origin and/or Manufacturer’s Affidavit of Origin

A copy of the airway bill (if applicable)

Original bill of lading

Seaway bill (if applicable)

Forwarders Cargo receipt

The above items must be placed in a sufficiently robust envelope and this envelope

must be labeled in large font as:

FOR U.S. CUSTOMS PURPOSES ONLY

Customs Documentation Enclosed

Customs Documentation Packet #2

A copy of the commercial invoice

A copy of the packing list which should include shipment date

A copy of Certificate of Origin and/or Manufacturer’s Affidavit of Origin

A copy of the airway bill (if applicable)

Original bill of lading

Seaway bill (if applicable)

Forwarders Cargo receipt

The above items must be placed in a sufficiently robust envelope and this envelope must

be labeled in large font as:

FOR CUSTOMS BROKER / FORWARDER PURPOSES ONLY

Customs Documentation Enclosed

.2 Further information regarding customs documentation can be found at:

https://docmaster.supplier.daimler.com/DMPublic/de/html/M10.01.09.FTPNN02._list.html

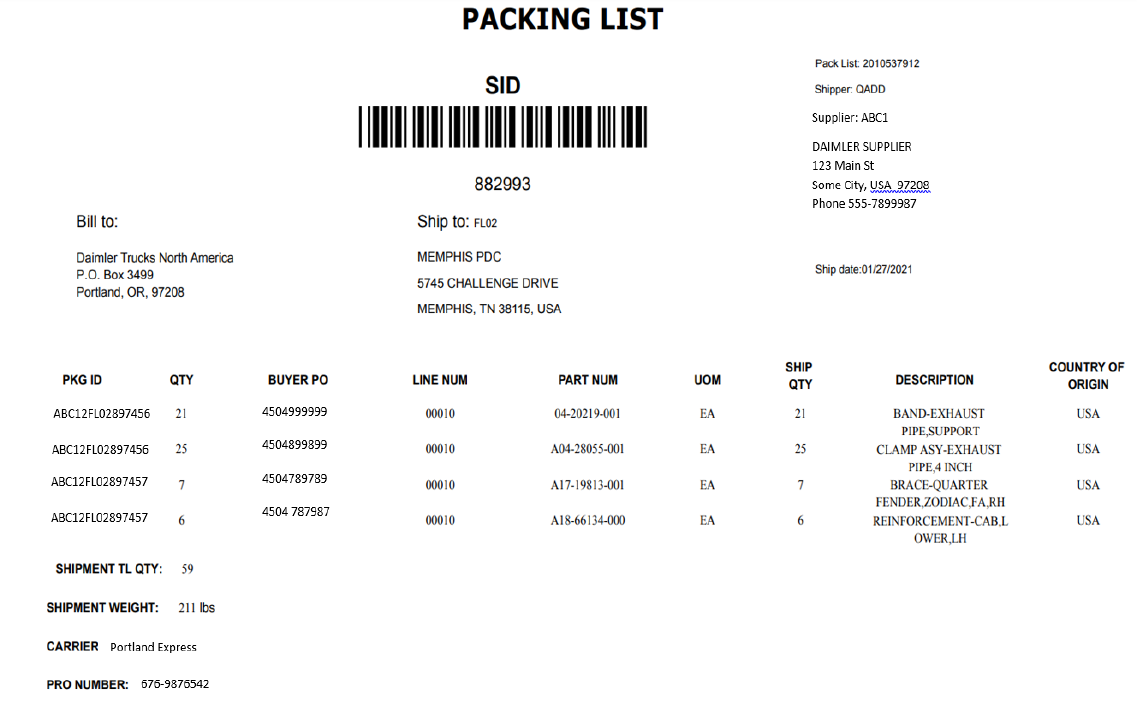

5.3 PACKING LIST

.1 All hardcopy packing lists must be printed as single sided only. No double sided print packing lists are

allowed.

.2 All hardcopy packing lists should be printed with the date of shipment of the load.

.3 All shipments shall contain the required number of copies of the packing list (see exhibit G) as hereby

stated:

Domestic Shipments (including critical drop ships) must include 4 copies of the packing list placed and

contained as follows:

Copy 1 – Copy 1 inside shipment in a separate protective envelope labeled ”Packing List

Enclosed”.

Copy 2 – Copy 2 outside the pallet wrap, in separate protective envelope labeled

“Packaging List Enclosed”.

The location of the packing list shall be labeled or marked stating “Packing List” or “Packing List Inside” on two

adjacent sides of the shipping unit carrying the packing list.

Copy 3 - Copy 3 must be stapled to the Master Bill of Lading.

Copy 4 - Copy 4 must be stapled to the final destination Bill of Lading.

International Shipments (including critical drop ships) must include 6 copies of the packing list placed

and contained as follows:

Copy 1 and Copy 2 – These are the packing slip copies that are contained in Customs

If the entire shipment consists of unpackaged items then both Customs Documentation

Packets #1 and #2 shall be securely attached on top of the parts.

If there is at least one shipping container in the shipment then both Customs

Documentation Packets #1 and #2 shall be securely attached to the outside of the shipping

container.

Copy 3 - inside shipment in a separate protective envelope labeled “Packing List

Enclosed”.

Copy 4 – outside the pallet wrap, in a separate protective envelope labeled “Packing List

Enclosed”.

Copy 5 – this copy should be attached to the Master Bill of Lading which indicates the list

of final destinations included in the trailer.

Copy 6 – this copy should be attached to the Final Destination Bill of Lading

.4 Packing lists shall bear the proper Daimler Trucks North America vendor code.

.5 Packing lists shall contain a Shipment Identification Number (SID).

Packing lists should have a separate location for the SID number.

If there is no separate location for the SID number, then the SID number shall be identified

within the prefix “SID”. For instance, a SID number of 23456 would be shown as “SID

23456”.

SID numbers shall not be repeated within a calendar year.

The SID shall be printed in both human readable text and bar code(see Exhibit G).

The SID shall be a unique number assigned by the supplier (not necessarily in sequential order) that

specifically identifies a shipment. This number shall be referenced on invoices presented to Daimler

Trucks North America for payment. In this way each shipment will have a unique “control” number

that differentiates it from other shipments (for accounting purposes).

Please see section 18.2.1 for additional SID requirements.

Suppliers may use any number (B/L, Work Order, Invoice #, etc.) for the SID number if it

conforms to the above guidelines and is clearly identified as the SID number on the packing

list.

All supplier electronic and hardcopy communications including packing slips, bills of lading,

etc… . must reference a SID number must consistently reflect the full SID number in all

regards, including any leading or trailing characters and/or zeros.

.6 Packing lists shall contain Packing Identification Number(s) (PID).

The Packing Identification Number identifies a shipping unit (box or carton or bag or

crate….) within a shipment.

NOTE - The Packing ID number identifies the shippable unit, excluding the delivery

support (e.g. skid). For example, single cartons would be considered single shippable

units and would each require unique PIDs regardless if they are shipped loose or stacked

together on a skid. However, single cartons stretch wrapped or banded together as a

single unit become a single shippable unit and thus would only require a single PID.

Please see section 18.2.2 for additional PID requirements.

.7 All parts and material in a shipment shall be represented on the packing list by the following:

The unique Shipment Identification Number (SID).

The associated Daimler Trucks North America Purchase Order number.

The appropriate Daimler Trucks North America Purchase order Line Number.

The unique Packing Identification Number(s) (PID) of each individual shipping unit

associated with the shipment.

The appropriate Daimler Trucks North America Part Number.

The quantity shipped by the supplier.

Note - This information in the body of the packing list must be sorted in PID order.

5.4 BILL OF LADING

All shipping units must be clearly tagged / labeled on two adjacent sides showing their specific “final”

destination.

All shipments scheduled to be shipped in one day to one destination must be combined on one B/L (Bill

of Lading) (see exhibits C & E).

If shipping LTL, suppliers are also required to create a Master Bill of Lading. A Master Bill of Lading

must have a combined shipping unit count and combined total weight of each separate Final Destination

Bill of Lading. This document must be clearly marked as “Master Bill of Lading”.

If a shipment is routed via a consolidator, the consolidator is not to be considered the “final” destination

(e.g. for shipments to a PDC the “final” destination is the PDC).

All shipments scheduled to move to a single freight consolidation location on one day must be covered

by a single Master B/L (Master Bill of Lading), (see exhibit D) regardless of the number of “final”

destinations included in the total consignment.

Each separate Bill of Lading must be attached behind the Master Bill of Lading. The “ship to” on the

Master Bill of Lading must read: “(DTNA PDC location) c/o (logistics provider’s name and address

where the material will be cross docked)”.

Final destination Bill of Ladings for Critical Drop Ship orders must include (see exhibit F):

“CRITICAL” printed in the B/L “Consigned To” box.

The DTNA PO#

Final ship-to address

Final shipping instructions per the original purchase order including the carrier and

carrier account number.

5.5 NUMBERING CARTONS AND CONTAINERS

For shipment of multiple cartons or containers, each individual carton or container must be consecutively

numbered and marked on the outside (e.g., 1 of 3, 2 of 3, 3 of 3). This will assist in identifying individual

cartons that may get separated during shipment.

5.6 HANDLING INSTRUCTIONS

Material handling instructions should be marked in bold letters and proportionately sized to the shipping

unit.

Direction of Travel—If a shipping unit is designed to travel in a specific direction, it should be

indicated on two adjacent sides of the shipping unit. Note: Supplier should use “Tip N Tell”

indicators where applicable.

Stacking Instructions—If a shipping unit will not support the weight of other shipping units, it

should be indicated in two visible locations. Note: Supplier should use stacking cones where

applicable.

Fragile—If a product is fragile such that it may be damaged with normal handling or if it

requires special handling, it should be indicated in two visible locations on the shipping unit.

6.0 Shipping Container Specifications

6.1 DEFINITION

Expendable containers are containers that are designed for one-way use. Exhibit H illustrates typical

expendable shipping containers.

6.2 HAND HANDLED CONTAINER REQUIREMENTS

.1 Gross Weight shall not exceed 35 lb.

.2 Corrugated cartons are the most common hand-handled containers, and are acceptable with the

following qualifications:

The container must be expendable (designed for one-way use).

Use a regular slotted carton (RSC) except when other styles may be dictated by part

characteristics.

The unsupported bottom of a carton must be able to hold the contents.

Hand-holds are desirable for bulky packages.

A minimum of 44 lbs. /in edge crush (ECT) or 275 lbs. per square inch burst test is required unless

approved by DTNA.

Construction must be in accordance with the Corrugated Fiberboard Specifications in

Section 7 and Fiberboard Box Specifications in Exhibit I of this document .

6.3 MECHANICALLY HANDLED CONTAINER REQUIREMENTS

.1 Gross Weight shall not exceed 4000 lb.

.2 All shipments of mechanically-handled containers must be on expendable wooden pallets as specified

in Section 9 of this document.

6.4 CONSTRUCTION OF BULK CONTAINERS

The use of wood corner posts is prohibited. Daimler Trucks North America recommends the use of fiber-

based corner supports (Reference Exhibit J).

All corrugated bulk containers are required to utilize a “break away” feature intended to promote recycling

(Reference Exhibit J).

All corrugated bulk containers are required to allow and support stackability and part protection.

6.5 CONTAINER HEIGHT

Containers plus pallet should not exceed 48” in height where part size allows.

6.6 TEMPERATURE

Expendable containers should be designed to withstand temperature variations from -30° F to

+150° F (-34.4° C to 65.6° C).

6.7 MOISTURE

Expendable containers should be designed to withstand 90% humidity at 150°F (65.6°C) exposure

during transit and storage.

6.8 SPECIAL CONSIDERATIONS

The use of non-recyclable wax impregnated and/or polyethylene (PE) coated corrugated fiberboard is

prohibited.

The use of lead and cadmium is prohibited.

The use of asphaltic tape is prohibited.

The use of expanded polystyrene (EPS) is prohibited.

All plastic material must be labeled in accordance with the Society of the Plastics Industry (SPI)

guidelines (See Exhibit A). For more information, contact SPI at 1275 K Street N.W., Suite 400,

Washington, D.C. 20005.

6.9 SALVAGED PACKAGING MATERIALS

Reuse programs may be established in controlled circumstances where packages are designed for

multiple uses and/or distribution environments.

The use of salvaged materials and reuse of cartons, pallets, crates, and other materials must be authorized

by Daimler Trucks North America.

7.0 Corrugated Fiberboard Specifications

7.1 GENERAL

Corrugated fiberboard is the primary material to be used for one-way expendable shipping containers.

Daimler Trucks North America requires Suppliers to use a minimum of 44 lbs. /in edge crush (ECT) or

275 lbs. per square inch burst test, so the parts and container arrive in satisfactory condition until

presented at the point of use. Expendable containers that do not meet this standard will require upgrades

at the Suppliers expense for all future shipments. Alternative Rule 41 of the Uniform Freight

Classification and Item 222 of the National Motor Freight Classification allows packaging engineers to

use edge-crush test (ECT) as an alternative to burst strength (Reference Exhibit I). The resulting

packages have improved stacking strength with less corrugated material as compared to containers

designed using burst strength specifications. Suppliers are encouraged to investigate the use of such

alternatives when designing corrugated cartons in order to:

Provide for improved stacking strength of corrugated containers.

Increase the recycled content of corrugated paper.

Reduce the overall amount of fiber used per shipping container.

7.2 CERTIFICATE OF BOX MANUFACTURER

Daimler Trucks North America LLC requires all corrugated containers be stamped with the certificate of

Box Manufacturer (Reference Exhibit B), as indicated in Item 222-1 of the National Motor Freight

Classification.

8.0 Dunnage Material

Daimler Trucks North America encourages the use of paper-based rather than plastic-based dunnage material.

Paper-based material is easily recycled along with corrugated containers, and does not require intermediate steps

for segregation of materials.

The use of foam or Styrofoam dunnage material must have written approval from Daimler Trucks North America

prior to use.

9.0 Pallet Specifications

9.1 GENERAL

The requirements in this section apply to both new and used/recycled wooden pallets.

Suppliers are to use wooden pallets for “palletable” loads of Aftermarket materials that are destined for

any Daimler Trucks North America facility, unless written approval from Daimler Trucks North

America is received in advance. Hand loaded trailers will be refused and returned freight collect.

The proper use and design and condition of wood pallets is critical to assure part protection and overall

container performance, and to make the most efficient use of storage and trailer space.

9.2 PALLET SIZE REQUIREMENTS

Unless authorized or requested by Daimler Trucks North America and where the part size

permits, standard pallet size of 40” (width) by 48” (length) is required.

If a part dimension is greater than 48”, the pallet should be constructed to accommodate the part

length while maintaining the 40” width requirement.

9.3 CONSTRUCTION REQUIREMENTS

All pallets must provide 4-way fork entry and be of double-face, non-reversible wood

construction (Reference Exhibits K and L).

Pallets constructed of other-than-wooden material must be preapproved by Daimler Trucks

North America.

A minimum 3-1/2” fork opening height must be maintained.

Construction Specifications:

.1 Top and bottom deck board width: minimum 3.5”.

.2 Top and bottom deck board thickness: minimum 1/2”.

.3 Block dimensions: minimum 3.5” x 3.5” x 3.5” (Block type pallets).

.4 Stringer dimensions: standard 2” by 4” (Stringer type pallets).

.5 Annular or ring shank nails with minimum 3 per deck board into each stringer.

Used/recycled pallets are to be Grade 1 or Grade 2 or Grade A or Grade B only.

9.4 CONDITION

Supplier must have a procedure in place to select pallets to be used for transport and/or

storage of any item(s). The procedure must include assessment of the ability of the

pallet to guarantee adequate and safe transport for all item(s) placed upon and/or stacked

above any portion of the pallet to the final destination.

All pallets shipped to DTNA must be fit for reuse/reshipment by DTNA in the same condition

as received.

10.0 Loads & Load Containment

10.1 GENERAL

It is the DTNA supplier’s responsibility to efficiently and economically pack the entire load being

shipped for the method of transportation and type of handling planned for shipment to the final

destination and/or the point-of-use. In this regard:

Unit loads must be properly loaded and stacked and blocked and braced for shipment.

Void space must be filled to prevent load shifting in transit.

The DTNA Consolidation Centers perform break-bulk and reconsolidation services. They do not break

down palletized loads. Therefore, for shipments going through DTNA Consolidation Center facilities the

material destined for multiple DTNA aftermarket locations must be palletized (i.e. no loose cartons) by

each location and not loaded onto a common pallet.

The decision to use strapping, stretch film, shrink film, layer dividers, unitizing adhesives, air pillows,

air bags, blocking and/or bracing for load containment must fully evaluate both performance and

environmental considerations of the chosen material(s). Suppliers must select the load containment

option which provides damage protection and optimum load containment with minimal environmental

impact and safety to those responsible for load depalletization at DTNA and/or point of use.

10.2 METALLIC STRAPPING

The use of metallic strapping is discouraged, but is recognized as the most appropriate material for

certain applications.

10.3 PLASTIC STRAPPING

.1 All plastic strapping must be of either Polypropylene (translucent clear only) or Polyester

(translucent green only) materials. The color requirement aids in material identification for

recycling purposes.

.2 All plastic strapping must be free of metal clips and shall utilize either heat seal or friction weld as a

sealing method.

10.4 PLASTIC STRETCH FILM

Plastic stretch film has a number of performance advantages, particularly for small cartons and parts

shipped loose on pallets. Suppliers should investigate recyclability and adequacy for the application

prior to use. In many cases, stretch film is used when the application calls for strapping.

.1 All stretch film must be of linear low density polyethylene (LLDPE) resin. The use

of polyvinyl chloride (PVC) film is prohibited.

.2 All stretch film must be clear. Tinted or colored film is prohibited.

.3 A stretch wrapped load is to include continuous and adequate wrapping of the

pallet and continuing up to the top of the load.

10.5 SHRINK FILM

Shrink film offers some unique advantages for specific packaging applications and is considered an

acceptable material if used within physical limitations. Suppliers should investigate recyclability and

adequacy for the application prior to the use of shrink film.

10.6 UNITIZING ADHESIVES

Unitizing adhesive is a clear, water-soluble liquid which is applied to the top and sides of corrugated

cartons by spraying or brushing. The liquid forms a fiber bond, which prevents cartons from shifting,

slipping or sliding off the pallet. Daimler Trucks North America encourages suppliers to use unitized

adhesives if recyclability of the cartons is not compromised.

10.7 STACKING & STACKABILITY OF CARTONS / CRATES / CONTAINERS

Suppliers must consider all the conditions under which their dunnage, cartons, crates and containers

must perform.

Compression strength should be a primary consideration. Two-thirds of the stacking strength of a

corrugated fiberboard carton is concentrated at the corners. Failure to properly utilize the corner

strength of the carton(s) frequently leads to carton failure.

Palletized loads must be capable of being double stacked during transportation with minimal distortion

to all levels of packaging (i.e. salable unit, overpack, dunnage, shippable unit, etc……)

Corrugated cartons will lose strength if stacked improperly or under adverse conditions (See Exhibit

M).

10.8 LOADING OF CARTONS

To minimize manual handling and to allow for stacking, all cartons must be “palletized” in individual

layers on the pallet and material storable as received. (See Exhibit N).

The “pyramiding” of cartons is strictly prohibited (See Exhibit N).

The supplier is responsible to assure that packaging is consistent with this policy. If material release

quantities do not permit shipment of individual layers of cartons, Daimler Trucks North America will

assist in establishing consistent release quantities and/or alternative methods of packaging.

10.9 MIXED LOAD PROCEDURE

When stacking cartons on a pallet insure the individual carton labels are facing in the outward

direction.

It is acceptable to mix different part numbers on a pallet only after full pallets of like part

numbers have been built. Exhibit O illustrates when it is acceptable to ship different part

numbers on the same pallet.

When stacking product on a pallet and the shipment consists of more than one part number,

organize the pallet by like part numbers with the part with the greatest quantity of product on

the bottom layer(s) of the pallet and building up accordingly so that the part with the smallest

quantity of product is on the top layer of the pallet load.

For loads containing many different small parts shipped in a single carton, each quantity of

each different part number must be separated from each other using plastic bags and/or

corrugated layering with one part number per layer to facilitate part identification and insure

correct identification by DTNA at time of receipt.

Mixed load shippable units must be labeled with a Mixed Load label (see Exhibit T).

11.0 Package Testing

To assure satisfactory package performance throughout the distribution cycle, the testing of all

packages prior to use is encouraged.

DTNA reserves the right to require suppliers to submit package samples for testing. Sample testing

may result in the sample being damaged/destroyed during the testing process. The samples will not

be returned to you. The testing process may also require additional packaged samples to be sent to us

for additional testing.

For testing, we require loaded samples. The part should be new, but if unavailable, should be a

representative sample in size, shape and weight of the actual part. All sample(s) must be free of

charge and shipped to us freight PREPAID.

The preferred salable unit tests are ISTA Packaging Integrity testing Level 1A Vibration and Drop

testing along with any additional ISTA Level 1A tests as needed due to unique features and/or fragility

of the salable unit being tested.

The American Society for Testing and Materials (ASTM) also has standardized test methods which

govern testing of packaging systems. The standards can be obtained from ASTM at 1916 Race Street,

Philadelphia, PA 19103.

DTNA acceptance or rejection of any supplier submitted packaging test(s) results is at the sole

discretion of DTNA.

12.0 Daimler Trucks North America-

Owned Returnable Containers

The use of Daimler Trucks North America-owned returnable containers must be negotiated

as part of the agreement to supply parts to Daimler Trucks North America.

The Daimler Trucks North America Purchasing Department will maintain an “Authorized Daimler

North America-Owned Returnable Container Listing” for suppliers who are approved to use Daimler

Trucks North America-owned returnable containers.

Returnable containers must be damage free, clean and free of all prior labeling at all times.

13.0 Supplier-Owned

Returnable Containers

The use of Supplier-owned returnable containers for Aftermarket must be preapproved by the Daimler

Trucks North America Aftermarket Parts Packaging group.

The Daimler Trucks North America Purchasing Department maintains an “Authorized Supplier Owned

Returnable Container Listing”. Any use of Supplier-owned returnable containers must be negotiated as

part of the agreement to supply parts to Daimler Trucks North America but only after receiving

preapproval for their use by the Daimler Trucks North America Aftermarket Parts Packaging group.

Return of nonauthorized returnables will be shipped freight collect.

Returnable containers must be damage free, clean and free of all prior labeling at all times.

.

14.0 Mode of Transportation

The Daimler Trucks North America Inbound Logistics Department will designate the most

economical mode of transportation and carrier routes to be used. The determination depends, upon

the volume, weight and quantity of parts to be shipped.

All packaging must be designed to absorb shock and vibration forces incurred in all types of

transportation environments. However, no specific recommendations will be made in this

document due to the variety of packaging and shipping modes.

The DTNA Consolidation Centers perform break-bulk and reconsolidation services. They do

not break down palletized loads. Therefore, for shipments going through DTNA

Consolidation Center facilities the material destined for multiple DTNA aftermarket

locations must be palletized (i.e. no loose cartons) by each location and not loaded onto a

common pallet.

Suppliers are required to use DTNA’s contracted carriers as indicated in the supplier routing

instructions. Failure to use the designated mode and carrier may result in a debit to the supplier

account. Supplier routing may change as directed by DTNA or our logistics partners.

14.1 ROUTING Instructions

With an active Covisint account the “ROUTING LETTER” application is available using the

supplier portal. To bypass the Covisint website and access the “ROUTING LETTER”

application go directly to:

https://secure.freightliner.com/Supplieronline/webapps/suplapps/suplmain.asp

This link will direct to the Daimler Trucks North America login page for Routing

Letters. Please save this URL as a Bookmark/Favorite or create a shortcut to the

address on the desktop for future use.

Login using the Supplier Online Daimler Trucks North America user ID and password.

If you are a Covisint user, this is the second login and password.

If a new supplier or a returning supplier that has not accessed any Daimler Trucks

North America applications in the last 60 days, contact the Daimler Trucks North

America Help Desk at (503) 745-8220, or [email protected] to set up

an account.

With a working Supplier Online account, we strongly suggest logging in to the

Supplier Online address above on a monthly basis to keep the account active and to

check for changes to the routing instructions. The location list will show, at a glance,

when a location was last updated.

Note: Aftermarket routing instructions will migrate to a new location in 2022.

Suppliers will be notified when that change is made.

15.0 Hazardous Materials

The U.S. Department of Transportation has established packaging regulations for materials determined

to be hazardous as defined in two volumes of Title 49, Code of Federal Regulations, parts 100 through

177 and parts 178 through 199. Included in this category are explosives, compressed gases, flammables,

oxidizing materials, poisons, irritating materials, etiologic agents, blasting agents, radioactive materials,

corrosives, and hazardous wastes.

The first volume contains regulations on classification, packaging, marking, labeling, loading,

paperwork, and other issues. The second volume sets forth shipping container specifications for many

types of materials.

All suppliers shipping these type materials to, or on behalf of, Daimler Trucks North America are

required to adhere to these regulations.

It is in violation of Daimler Trucks North America policy to distribute materials defined as hazardous as

detailed above through Daimler Trucks North America parts distribution centers.

Copies of the regulations can be obtained from the Superintendent of Documents, U.S. Government

Printing Office, Washington, D.C. 20402.

16.Bar Coded Shipping

Label Requirements

16.1 GENERAL

These specifications, which apply to bar codes for shipping labels, were developed in

conjunction with the AIAG Shipping / Parts Identification Label Standard (AIAG: B-3,1984).

For more information on AIAG Standards, contact the Automotive Industry Action

Group, 26200 Lahser Road, Southfield, MI 48034.

All human readable text on the labels must be in English.

16.2 QUALITY

The use of bar code systems is intended to increase productivity, reduce costs and improve data

accuracy within the automobile and truck manufacturing industries. An important aspect of any

bar code system is that of quality. When labels cannot be decoded fast and accurately, the

advantages of bar coding are lost.

Suppliers have the responsibility to provide bar code labels that meet the specification of this

document and those of the Print Quality Guideline in Section 4 of AIAG B-1. It is recommended

that verification audits be used in conjunction with statistical process control techniques to assure

shipping label quality.

16.3 LABEL SIZE AND MATERIALS

Label dimensions should be in accordance with the dimensions shown in Exhibit P. All other

exhibits are for illustrative purposes only, and may not be to scale or bar code quality standards.

The recommended label size is 4.0” high by 6.5” wide, which should cover all conditions. The

minimum label size shall be 4.0” high by 5.0” wide.

The label paper shall be white with black printing.

Adhesive labels can be pressure sensitive or dry gummed as long as adherence to the package

substrate is assured, application is wrinkle-free, and for use on expendable packaging only.

Use the methods shown in Exhibit Q to affix the label to the package or container, or use

another method with Daimler Trucks North America's approval.

16.4 BAR CODE SYMBOLOGY

Bar codes shall be the (Code 39) or (Code 128) types as specified by the Automotive

Industry Action Group.

Barcodes should only contain letters from A to Z, numbers from 0 to 9, spaces, or

or dashes “ –“.

.1 Code Configuration

The four (4) characters ($,/,+,%) shall not be used in the bar code labels.

The first two characters of either the SID or PID must exclude 2S, 5S, or V at the

beginning of said number.

.2 Code Density and Dimensions

The bar code heights shall be a minimum of 0.5”.

The element width must be consistent with the standards for the barcode symbology

being used.

The ratio of the nominal width of the wide elements to the nominal width of the narrow

elements shall be 3:1, with an allowable range of 2.8:1 to 3.2:1.

.3 Check Digits

Check digits and /or Checksum calculations should never be used in the bar codes.

16.5 SHIPPING (MASTER) LABEL INFORMATION

.1 Data Areas and Titles

The SID number, PID number and Supplier ID code data shall be displayed in both

human readable characters and bar code symbols (Reference Exhibit R).

Each data area shall be separated by border lines and shall contain the title and data

identifier in the upper left hand corner.

Titles and data identifiers shall be printed in 0.1” high letters.

The Supplier’s name, city, state and zip code shall appear at the bottom of the label,

and shall be in printed in 0.1” high letters.

Human readable data characters shall be a minimum of 0.1” high.

Bar code symbols shall be directly above the human readable data characters and

shall be a minimum of 0.5” high.

.2 Data Identifier Characters

A data identifier character maybe used to identify specific data. This is optional.

The data identifier shall be printed separately in human readable characters under the

title.

The data identifier shall not be included in the human readable characters.

The data identifier shall be included in the bar code symbol.

The data identifier characters are as follows:

V — Supplier Identification Number

2S — Shipment Identification Number (SID)

5S — Packing Identification Number (PID)

.3 Supplier Identification Number

The Supplier Identification number will be the Vendor Code assigned by Daimler Trucks

North America to each supplier location.

The maximum length of the supplier ID is nine (9) alphanumeric characters.

The length of the bar code symbol shall not exceed 5.5”.

.4 Shipment Identification Number

The Shipment Identification Number (SID) is described in section 5.3.4 of this document.

Excluding any data identifiers, the maximum length of the shipment ID is Twenty (20)

alphanumeric characters (A-Z, 0-9, spaces or dashes “-“).

If a data identifier is used, the maximum length is 18 alphanumeric characters.

The length of the bar code symbol shall not exceed 5.5”.

.5 Packing Identification Number

The Packing Identification Number (PID) is described in section 5.3.5 of this document.

Excluding any data identifiers, the maximum length of the packing ID is twenty (20)

alphanumeric characters (A-Z, 0-9, spaces or dashes “-“).

If a data identifier is used, the maximum length is 18 alphanumeric characters.

.6 Label Placement

All shipping labels are to be adhered to the outside of any exterior covering / stretch wrap

on the shippable unit.

16.6 SINGLE SHIPPABLE UNIT MULTIPLE CONTAINER LABELING

When a shippable unit is comprised of multiple containers each containing multiple quantities of

the same part, the multiple containers are required to be labeled as follows:

Example 1 – A pallet contains 4,050 pieces of part number X. Part number X is contained in 45

boxes each containing 90 pieces. Each box of 90 must have a box label as shown in Exhibit S.

Example 2 - A pallet contains 305 pieces of part Y and 20 pieces of part Z. Part number Y is

contained in 30 boxes with each containing 10 pieces and the 31

st

box contains 5 pieces of part

Y and 20 pieces of part Z. Each box of 10 must have a box label as shown in Exhibit S. The 31

st

box must have a Mixed Load label as shown in Exhibit T with an Exhibit S label for each of the

different SKU’s in the box.

.1 Data Areas and Titles

The part number, part description, part quantity and supplier address shall be displayed

in both human readable characters and bar code symbols (Reference Exhibit S).

Each data area shall be separated by border lines and shall contain the title and data

identifier in the upper left hand corner.

Titles and data identifiers shall be printed in 0.1” high letters.

The Supplier’s name, city, state and zip code shall appear at the bottom of the label,

and shall be in printed in 0.1” high letters.

Human readable data characters shall be a minimum of 0.1” high.

Bar code symbols shall be directly above the human readable data characters and

shall be a minimum of 0.5” high.

.2 Data Identifier Characters

A data identifier character maybe used to identify specific data. This is optional.

The data identifier characters are as follows:

P - Part Number

Q - Quantity

.3 Part Number

Part numbers shall be the same part numbers designated on the Daimler Trucks North

America Purchase Order or DTNA Material Release Authorization.

The maximum length of the part number shall be twenty (20) alphanumeric characters.

The length of the bar code symbol shall not exceed 5.5”.

.4

Quantity The maximum length for the quantity is six (6) numeric characters.

16.7 LABEL LOCATION AND PROTECTION

.1 Label Location

Illustrations of the most common shipping packs and recommended label locations are

shown in Exhibit Q. The bottom edge of the label should be parallel to the base of the

shipping unit. To facilitate automatic reading of the bar code symbols, the top edge of the

label, whenever possible, should be 20” from the bottom of the container.

.2 Label Protection

Label protection against moisture, weathering, abrasion, etc. may be required and is

encouraged wherever practical. Laminates, sprays, window envelopes and clear plastic

pouches are examples of possible protection methods. In choosing any protection method,

care must be taken to assure that labels meet reflectivity and contrast requirements and can

be scanned with contact and noncontact devices.

16.8 SPECIAL LABELS

Special labels may be required for mixed item shipments. This label should be used only when authorized

by Daimler Trucks North America.

.1 Mixed Loads

A Mixed Load label, as shown in Exhibit T, shall be used when packages of different items

are shipped together. Each individual package should be identified with a separate bar code

label.

17.0 DTNA Individual Salable Unit

Bar Coding Requirements

17.1 GENERAL

These specifications, which apply to bar codes for DTNA salable units were developed in conjunction

with the TMC RP801C “Bar Code Guidelines.” For more information on TMC Standards, contact the

Maintenance Council of the American Trucking Association, Director of Member Services at (703) 838-

1761.

All individually packaged DTNA salable units are to be labeled as per contained within this document.

There should be no supplier name and/or logo(s) and/or supplier contact information on the labels when

possible.

All subsequent outer carton(s)/crate(s)/bag(s) up to and including the shippable unit must have at

minimum labeling that includes the DTNA part number(s) and quantities contained inside.

All human readable text on labels must be in English.

17.2 QUALITY

The use of bar code systems is intended to increase productivity and data accuracy within the

Automobile and Truck Aftermarket and Manufacturing Industries. Suppliers have the responsibility to

provide bar code labels that meet the specifications of this document and those of the Bar Code Print

Quality Guideline ANSI X3.182. It is recommended that verification audits be used in conjunction with

statistical process control techniques to assure shipping label quality. The thermal printing or laser

method of bar coding generation is preferred by Daimler Trucks North America Customer Support due

to the format flexibility and image quality.

17.3 LABEL SIZE, MATERIAL, AND SPECIAL REQUIREMENTS

.1 Label Size

Labels are to be appropriately sized to the product or package to which it is to be applied. In most cases

the recommended label size is 1 inch high by 3 ½ inches wide. However, in all cases the label information

should be legible and readable from a distance of 3 feet from the label.

.2 Material

The label paper should be white with black printing. Adhesive labels can be pressure sensitive or dry

gummed as long as adherence to the salable unit is assured and application is wrinkle-free.

.3 DTNA Salable Unit Size Limitations

If the recommended 1 inch high by 3 ½ inch wide label cannot be adhered to the DTNA salable unit due

to the size and/or surface coating and/or concern over label removal on the finished surface, the DTNA

salable unit must be tagged or bagged or boxed with the bar coded label attached to the tag or bag or box.

.4 Chargebacks for Non-Compliance

A chargeback fee may be levied for a) unlabeled individual DTNA salable units, and/or b) for not being

labeled in the lowest salable unit of measure.

.5 Individually Packaged DTNA Salable Unit

For those individually boxed, skidded, bagged or tagged DTNA salable units that Daimler Trucks North

America distributes, a bar coded label is required on the exterior of every salable unit box, bag or tag

etc…..

If a DTNA salable unit is individually boxed, it is not necessary to place a 1 inch high by 3½ inch wide

label on the part(s) within the box in addition to the box exterior. The DTNA individual piece bar code

information can be incorporated on the exterior box DTNA salable unit label. The bar code

specifications and human readable information (ref 17.4.1 Data Areas) must be included on each exterior

box label.

.6 Label Location

Placement of the label on the DTNA salable unit package or DTNA salable unit itself should be in the

direction facing outward so that it would be easily visible when the item is in a storage location.

Exceptions to this would be if such label placement would be on a finished surface of the part(s) that

would be difficult to remove and/or which would disfigure and thus render the part unacceptable for sale

or use.

17.4 REQUIRED LABEL INFORMATION

.1 Data Areas

The part number shall be displayed in both human readable characters and bar code symbols. The part

description shall be displayed in human readable characters only. Human readable data characters shall

be a minimum of 0.1” high. The part description shall be displayed below the bar code and the part

number above the bar code (see examples in section 17.6).

.2 Part Number and Part Name

Part numbers and names shall be the same part numbers and names designated on the Daimler Trucks

North America Customer Support Purchase Order or Material Release Authorization.

Vendor part number format (Note: ‘_’ denotes a space required in the bar code)

2 letter Vendor Code: XX _ _ XXXXXX 3 letter Vendor Code: XX X _ XXXXXX 4 letter

Vendor Code: XXXX XXXXXX

Freightliner Proprietary part number format (Note: ‘_’ denotes a space required

in the bar code)

Alpha Characters: A17-12443-000 Alpha Characters: 17-12443-000

Sterling Proprietary part number format (Note: ‘_’ denotes a space required in

the bar code)

Alpha Characters: XXXX _ XXXXXX _ XX

The maximum length of the part number shall be twenty (20) alphanumeric

characters.

.3 Country of Origin

All individual salable unit labels are required to list the country of origin.

The country of origin must be clearly displayed on each label (as pictured in section 17.6) to meet custom

requirements for international trade. Alpha 2 code is an acceptable abbreviation if using the ISO 3166

document.

United States Federal law requires that foreign sourced items must be identified with the Country of

Origin as defined in the U.S. Federal Regulations – title 19 U.S. Customs Service Part 134 as revised. The

identification is to be the English name of the Country of Origin. Markings may not be abbreviated. It is

the suppliers responsibility to assure DTNA salable unit packages are printed with “Country of Origin

(country)” prior to shipment to comply with Federal law.

.4 Salable Unit Quantity

All individual salable unit labels are required to reflect a quantity in the lowest salable unit-of-measure

(also known as the Base Unit of Measure). This unit-of-measure can be different than the vendor invoiced

unit-of-measure.

Example 1– DTNA and supplier agree for supplier to sell DTNA 50-foot rolls of tubing in an agreed

supplier unit-of-measure of ROLLS. Supplier is notified that the lowest salable unit-of-measure is feet.

Supplier would ship, label overpacks, print packing slips and invoice DTNA in unit of ROLLS. Supplier

would label each roll as quantity of 50.

Example 2 – DTNA and supplier agree for supplier to sell DTNA small steel screws in bags of 20 in an

agreed supplier unit-of-measure of EACH. Supplier is notified that the lowest salable unit-of-measure is

EACH. Supplier would ship, label overpacks, print packing slips and invoice DTNA in unit of EACH.

Supplier would label each bag as quantity of 20.

Example 3 – DTNA and supplier agree for supplier to sell DTNA 2-packs of small filters in bags in an

agreed supplier unit-of-measure of EACH. Supplier is notified that the lowest salable unit-of-measure is

PAIR. Supplier would ship, label overpacks, print packing slips and invoice DTNA in unit of EACH.

Supplier would label each bag as quantity of 1.

17.5 BAR CODE SYMBOLOGY

Bar Codes shall be the 3-of-9 (Code 39) type as specified by the TMC (RP801C).

.1 Code Configuration

The four (4) characters ($,/,+,%) of the 3-9 symbology shall not be used in the bar

code labels.

.2 Code Density and Dimensions

The bar heights shall be a minimum of 3/16”. For each bar code symbol, the average width of narrow elements shall be within

the range of 0.013 to 0.017 inches. The ratio of nominal width of the wide elements to the nominal width of the narrow elements

shall be 2:1.

.3 Check Digits

Check digits shall not be used in the bar codes.

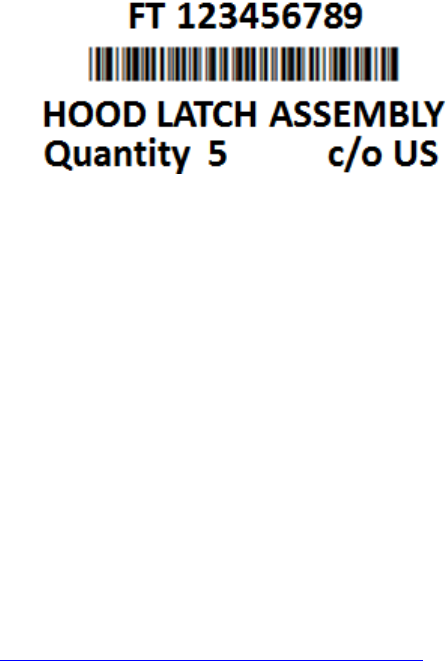

17.6 EXAMPLE OF ACCEPTABLE BAR CODE:

17.7 APPROVAL OF BAR CODE LABEL BY DAIMLER TRUCKS NORTH AMERICA

AFTERMARKET PARTS PACKAGING GROUP

Prior to implementation of the bar coding requirement, the bar code has to be approved by Daimler Trucks North

America. Please send a sample of a bar code label to our Aftermarket Parts Packaging Group for review at the

following address:

Daimler Trucks North America

Aftermarket Parts Packaging Group

Parts Distribution Operations

515 11th Street SE

Canton OH 44707-3811

18.0 – Advance Shipping Notice

18.1 GENERAL

Daimler Trucks North America (DTNA) uses API technology for ASN transmission. All suppliers are expected to

comply with DTNA API ASN requirements. EDI may still be used for other communications, as designated by

DTNA. i.e. Dealer Direct Ship and Critical Drop Ship

Suppliers can send ASN’s by direct API integration with DTNA systems, or through the supplier transportation tool

hosted by our 3PL, Penske Logistics.

To ensure compliance, all ASN’s must have ALL of the following characteristics:

Submitted through the DTNA ASN API, either through direct integration, or the 3PLTransportation Tool

hosted by Penske Logistics

Submitted not more than 30 min after the load leaves the Suppliers dock

Successfully submitted, with a 200 (success return code)

Contains package (pallet) level data for every item node. (excludes Direct Ship and Drop Ship orders)

Shipment ID and Package ID match exactly to what is printed on the shipment label

Chargebacks for Non-Compliance: As of 11/20/2020 ASNs are mandatory on all PDC bound

shipments. Shipments reaching our PDCs without a registered ASN may be subject to a debit for non-compliance.

18.2 ASN Information

.1 Shipment Identification Number (SID)

The Shipment Identification Number plays a vital role in Daimler Trucks North America systems. In order for

proper processing by Daimler Trucks North America, the SID must be on the ASN, Invoice, Shipping label (See

Exhibit R), BOL and Packing Slip printed in human readable and bar coded (see Exhibit G). If the SID number is not

an exact match on all related documents, is missing or is not clearly marked, it disrupts the receiving process at our

PDCs and may ultimately delay supplier payment.

There must only be one SID number per ASN, per shipment, per location, per day. The only time the supplier

should have multiple SID numbers per location on the same day is if shipping material via two different methods:

one by air, one by ground, or one by next day and one by 2

nd

day or multiple trailers. In these cases, Daimler Trucks

North America expects multiple SID numbers because the material may arrive at different times.

SID numbers must not be repeated within a calendar year. Excluding any data identifiers, the SID shall be a

maximum of sixteen (16) alphanumeric characters. For suppliers using Electronic Data Interchange (EDI) for Dealer

Direct Ship or Critical Drop Ship, the same SID is to be used on the advanced shipping notices (type 856 – BGN02)

and invoice (type 810 – REF02(SI)).

.2 Packing Identification Number (PID)

The Packing Identification (PID) number relates the contents of the shipping unit to the ASN. In order for proper

processing by Daimler Trucks North America, the PID must be on the ASN and Shipping Label.

The Packing Identification number must be unique and cannot not be reused within a calendar year. The Daimler

Trucks North America assigned Supplier Code and the PDC ship to must be used as a prefix for the PID. Excluding

any data identifiers, the PID shall be a maximum of twenty (20) alphanumeric characters.

Please see section 5.6.3 for additional PID requirements.

19.0 Box / Layer / Pallet Quantity Data

It is in the best interest of both Daimler Trucks North America and our suppliers to do business at the lowest

possible cost of operation. To this end it is therefore best to optimize the handling both for supplier order processing

and Daimler Trucks North America PDC put-away of the items ordered by Daimler Trucks North America from

their suppliers.

It is therefore required of suppliers to provide, at the time of new supplier sign-on and regular review thereafter, for

each of the part numbers supplied to Daimler Trucks North America, the unit quantities (i.e. the “quantity ordered”

via DTNA fax or 850 transaction) contained within the suppliers shipment overpack, and unit quantities contained

within the suppliers pallet layer, and unit quantities contained within the suppliers full pallet.

This information should be provided in spreadsheet form and transmitted via email to the Daimler Trucks North

America Aftermarket Materials Management group.

20.0 Glossary

For purposes of clarification, the following definitions of terms should be understood when using this document to

avoid confusion.

Packaging – The materials used to support, protect and/or surround the salable unit. In most cases this is the

material that is in direct contact with the salable item.

Pack / Packing – This is another name for the shippable loaded container of packaged item(s) (e.g. the shipping

container/carton). Also, the process or act of properly loading the packaged items into the shippable unit. This term is

used extensively in chapter 16 in reference to Packing ID Number to eliminate confusion with the more generic use

of Packaging ID Number used in industry and to distinguish it from the salable unit part packaging referenced

extensively elsewhere in this guideline.

21.0 Exhibits

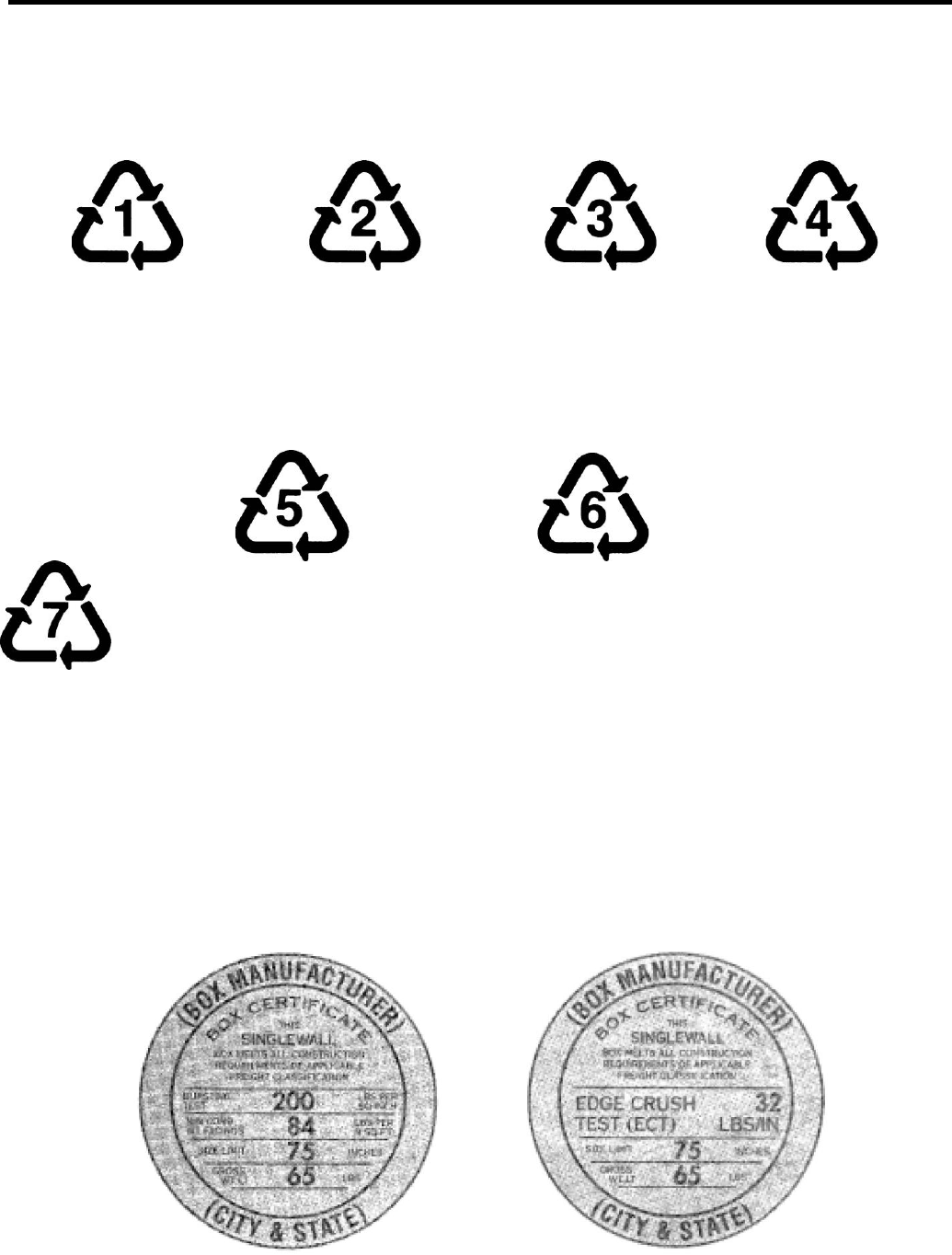

EXHIBIT A, PLASTICS RECYCLING SYMBOLOGY

PETE HDPE V

LDPE

Polyethylene High Density Vinyl

Low Density

Terephthalate Polyethylene

Polyethylene

PP PS OTHER

Polypropylene Polystyrene All Other Resins

EXHIBIT B, CERTIFICATE OF BOX MANUFACTURER

EXHIBIT C, BILL OF LADING – DIRECT TO

PDCDTNA Supplier (insert vendor code)

1234 Main Street

Anywhere, USA 32043

BOL# B22731

(904) 555-1212

Date:

01/11/11

CONSIGNED TO:

DAIMLER TRUCKS - ATLANTA PDC,

2510 MILL CENTER PARKWAY, SUITE 100,

BUFORD,GA,30518, USA

BILL FREIGHT CHARGES:

Inbound collect

Total #

Pkgs

Total Gross Weight

Shipped (& Units)

Packing Slip /

SID#

Freight Description

NMFC #

Final Destination

30

3,205 LBS

039141

Auto Parts NOI

18460

Atlanta PDC

10

1,250 LBS

039142

Auto Parts NOI

18432

Atlanta PDC

40

4,455 LBS

Carrier: Averitt Express (AVRT)

Trailer#:

41998

Seal#:

47620

Supplier Signature:

Carrier Signature:

Date:

EXHIBIT D, MASTER BILL OF LADING

DTNA Supplier (insert vendor code)

1234 Main Street

Anywhere, USA 32043

BOL

No. B22731

(904) 555-1212

Date:

11/11/09

CONSIGNED TO:

DTNA LLC

c/o:

00282 – Excel Logistics (XEXL)

1000 Bond Street

Charlotte, NC 28208

BILL FREIGHT CHARGES

PREPAID WITH 3rd PARTY

BILLING TO:

Daimler Trucks North America

P.O.Box 3499

Portland, OR, 97208

Total

#

Pkgs

Total Gross

Weight

Shipped (&

Units)

Packing

Slip /

SID#

Freight

Description

NMFC

#

Final Destination

30

3,205 LBS

039141

Auto Parts NOI

18460

02A-Memphis PDC

10

1,250 LBS

039142

Auto Parts NOI

18432

19A-Canton PDC

40

4,455 LBS

Carrier: Averitt Express (AVRT)

Trailer#:

41998

Seal#:

47620

Supplier

Signature:

Carrier Signature:

Date:

EXHIBIT E, BILL OF LADING – FINAL DESTINATION

DTNA Supplier (insert vendor code)

1234 Main Street

Anywhere, USA 32043

No. B22731

(904) 555-1212

Date:

01/11/11

CONSIGNED TO:

Daimler Trucks Atlanta PDC LLC

c/o:

00282 – Exel Logistics (XEXL)

1000 Bond Street

Charlotte, NC 28208

BILL FREIGHT CHARGES PREPAID WITH

3

rd

PARTY BILLING TO:

Daimler Trucks North America

P.O.Box 3499

Portland, OR, 97208

Carrier: Averitt Express (AVRT)

Trailer#:

41998

Seal#:

47620

Supplier Signature:

Carrier Signature:

Date:

Total

# Pkgs

Total Gross

Weight

Shipped (& Units)

Packing Slip

/ SID#

Freight

Description

NMFC #

Final

Destination

30

3,205 LBS

039141

Auto Parts NOI

18460

Atlanta PDC

10

1,250 LBS

039142

Auto Parts NOI

18432

Atlanta PDC

40

4,455 LBS

EXHIBIT F, Bill OF LADING – CRITICAL DROP SHIP

DTNA Supplier (insert vendor code) BOL#: No. B22731

1234 Main Street

Anywhere, USA 32043 SID#: 679549402

(904) 555-1212 Date: 01/01/12

CRITICAL

C/O:

Exel Logistics (XEXL)

7802 West Bob Bullock Loop

Laredo, TX 78045

BILL FREIGHT CHARGES PREPAID

WITH 3RD PARTY BILLING TO:

Daimler Trucks North America

P.O. Box 3499

Portland, OR 97208

FINAL DESTINATION:

Truck Centers INC

2280 Formosa RD

Troy, IL 62294

PO#: 4589593519

ROUTING INSTRUCTIONS FROM ORIGINAL PO

CARRIER: UPS Ground

ACCNT #: V7V609

FREIGHT TERMS: 3rd Party Billing

Total #

Pkgs

Total Gross Weight

Shipped (& units)

Packing Slip #

Freight Description

NMFC #

Final Destination

1

50 LBS

039143

Auto Parts NOI

18620

Truck Centers INC

1

50 LBS

Carrier: Averitt Express (AVRT) Trailer#: 41998 Seal#: 47620

Supplier Signature: ________________ Carrier Signature: _________________ Date: ___________

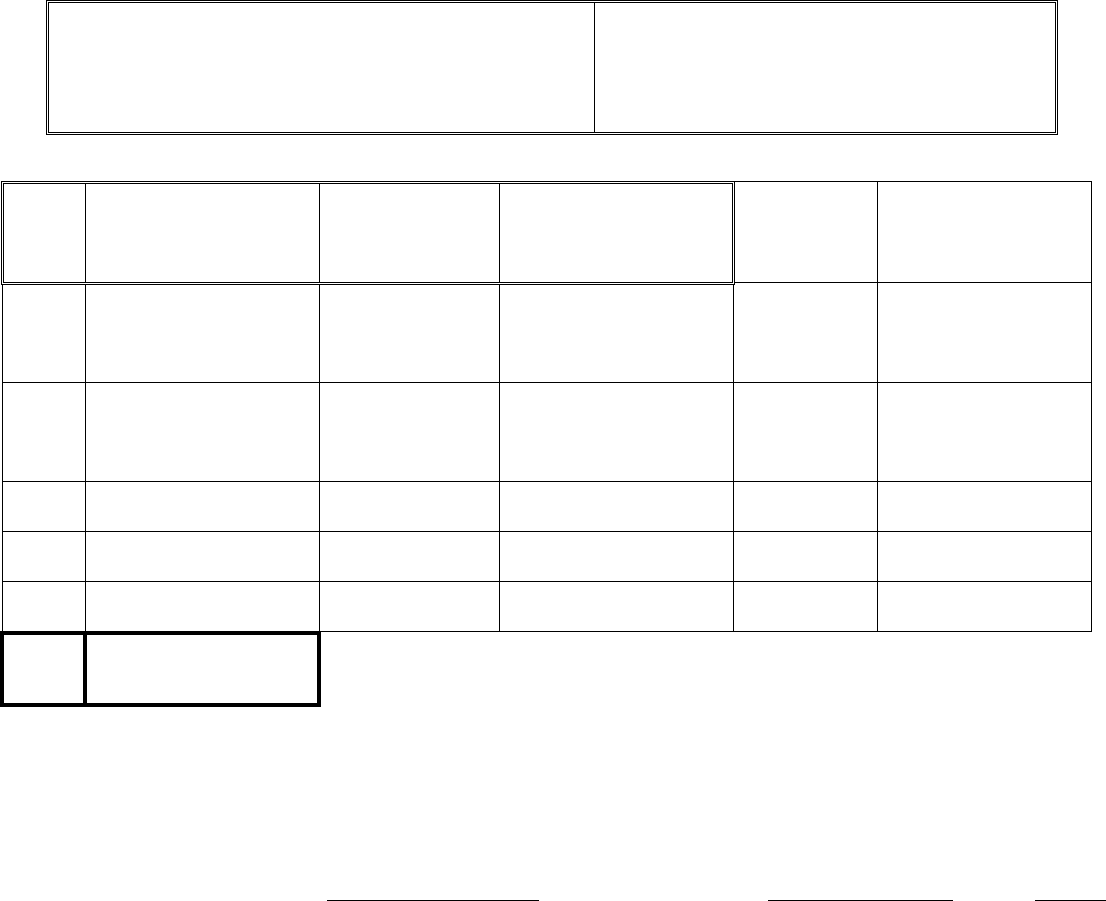

EXHIBIT G, PACKING LIST

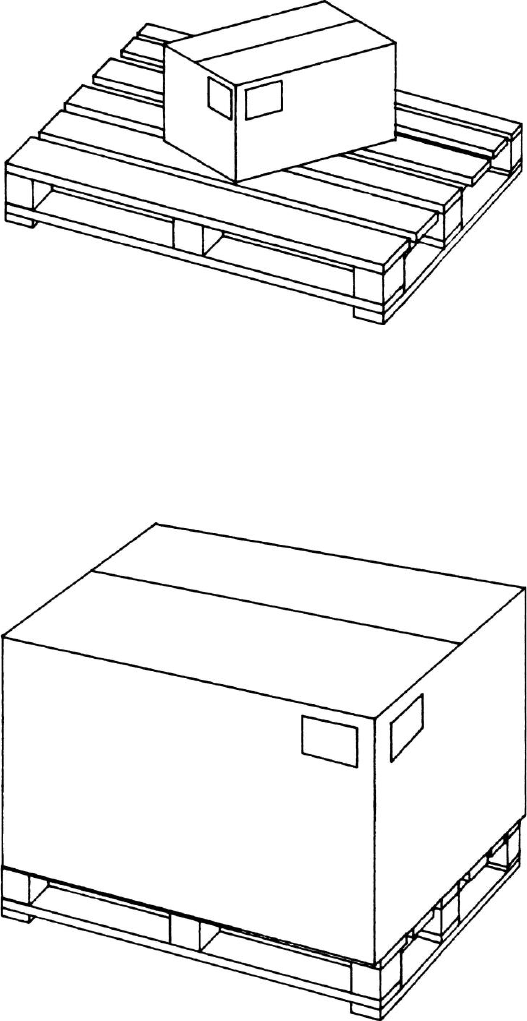

EXHIBIT H, TYPES OF EXPENDABLE CONTAINERS

Hand-Handled Container

Mechanically-Handled Container

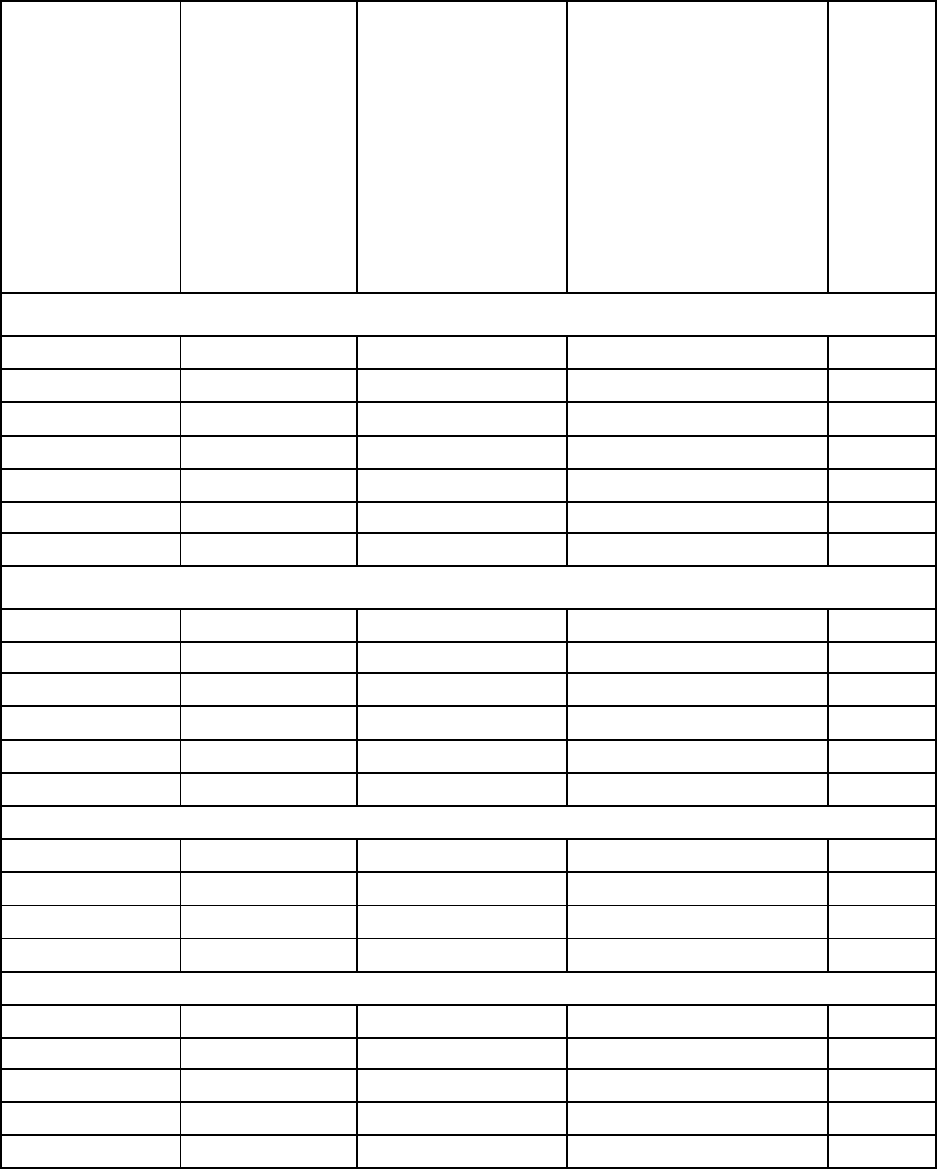

EXHIBIT I, FIBERBOARD BOX SPECIFICATIONS

Maximum Weight

Box/Contents (lbs.)

Maximum Outside

Dimension (L+W+D)

Minimum Burst Test

Single Wall, Double Wall,

or Solid Fiber Board (lbs.

per sq. in.)

Or

Minimum Puncture Test

Triple Wall Board (in oz.

per in. tear)

Minimum Combined Weight of

Facings, Including

Center Facing(s) of

Double Wall and Triple Wall

Board or

Minimum Combined Weight of

Plies, Solid Fiberboard (lbs per

1000 sf)

Minimum

Edge

Crush Test

(lbs per in

width)

SINGLE WALL CORRUGATED FIBERBOARD BOXES

20

40

125

52

23

35

50

150

66

26

50

60

175

75

29

65

75

200

84

32

80

85

250

111

40

95

95

275

138

44

120

105

350

180

55

DOUBLE WALL CORRUGATED FIBERBOARD BOXES

80

85

200

92

42

100

95

275

110

48

120

105

350

126

51

140

110

400

180

61

160

115

500

222

71

180

120

600

270

82

TRIPLE WALL CORRUGATED FIBERBOARD BOXES

240

110

700

168

67

260

115

900

222

80

280

120

1100

264

90

300

125

1300

360

112

SOLID FIBERBOARD BOXES

20

40

125

114

N/A

40

60

175

149

N/A

65

75

200

190

N/A

90

90

275

237

N/A

120

100

350

283

N/A

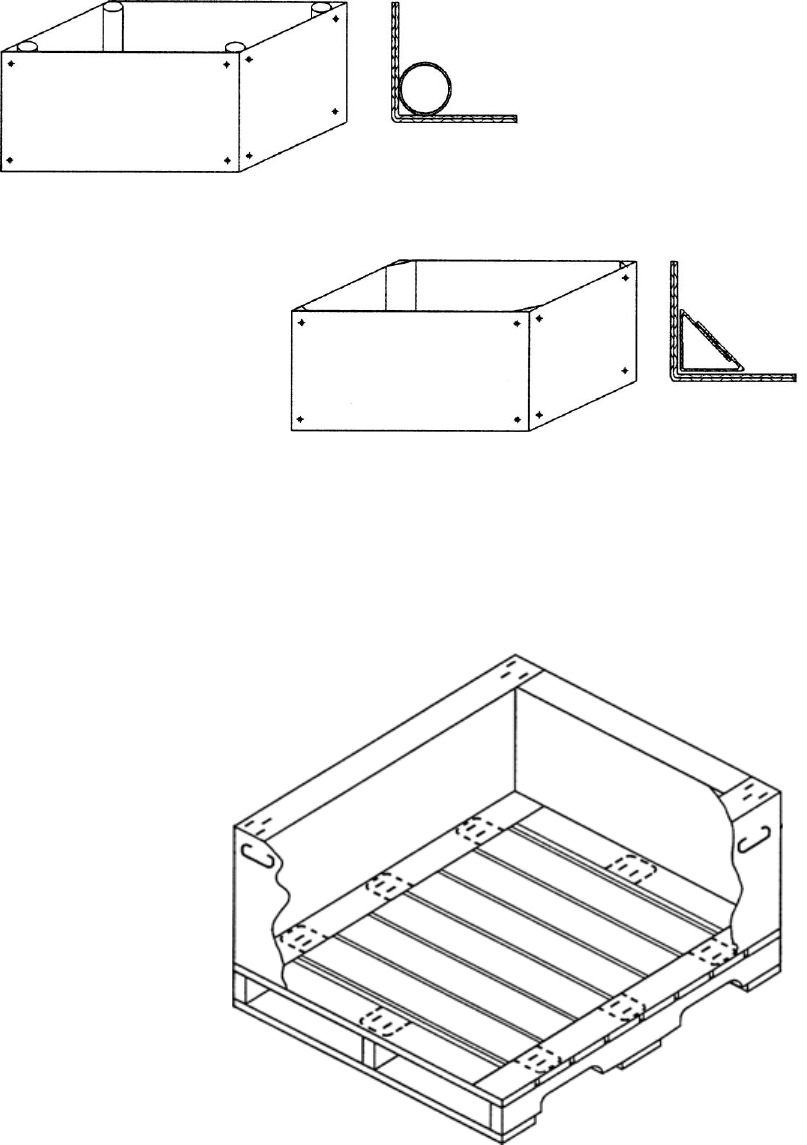

EXHIBIT J, BULK CONTAINER CONSTRUCTION

The Fiber Corner Supports are Designed for Recyclability

Spiral Wound Tube

Corrugated Insert

Break-Away Feature for Bulk Containers

The carton is attached to the pallet by stapling within the perforated areas as shown. When disassembled, the carton easily

separates from the pallet at the perforations.

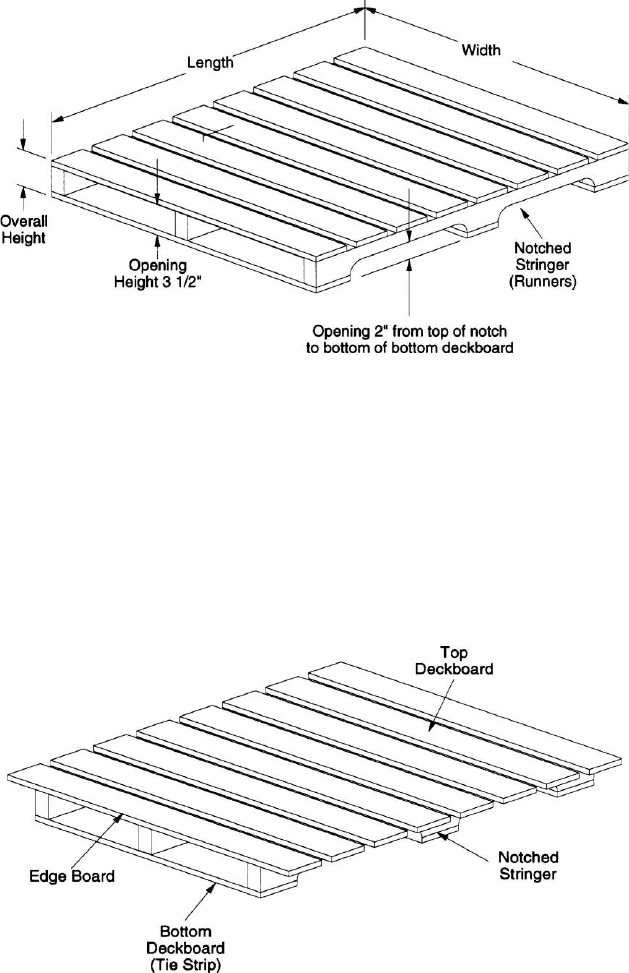

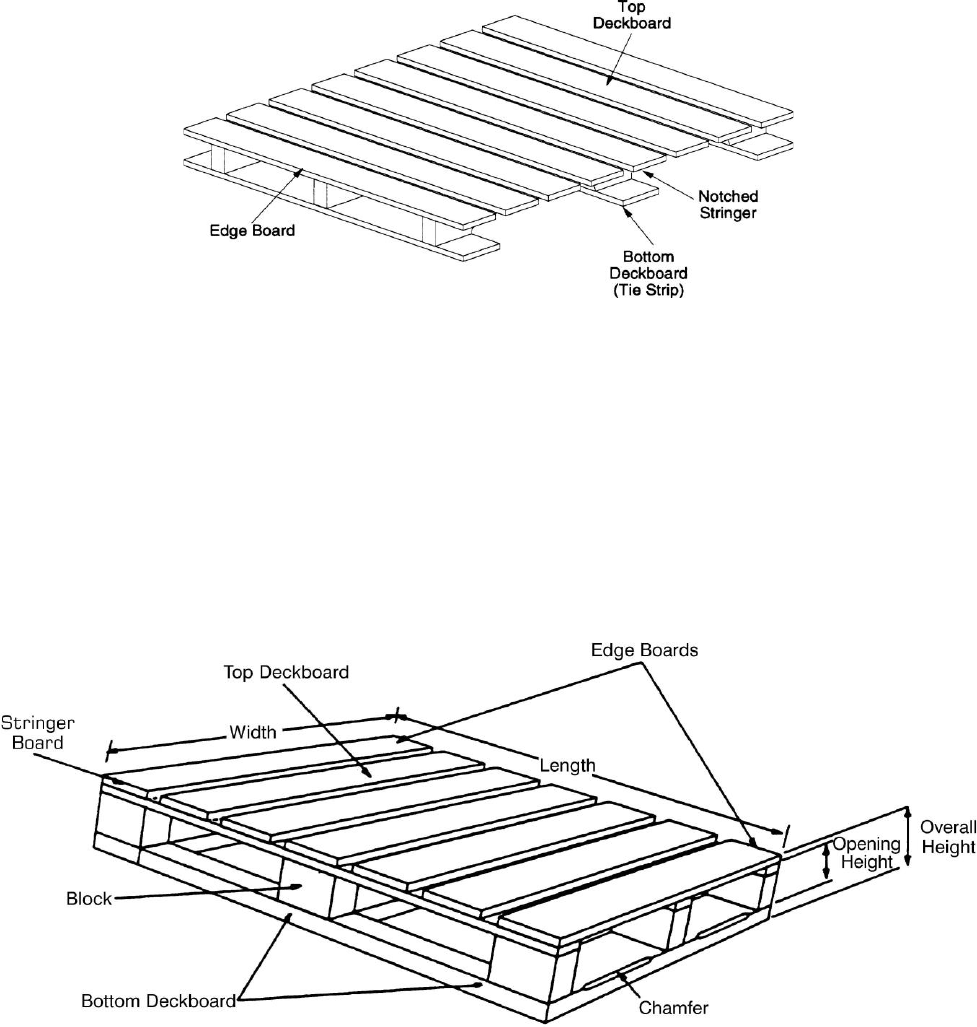

EXHIBIT K, TYPES OF WOOD PALLETS

Notched Stringer Design—Flush Type

f080032

Single Wing Stringer Pallet

EXHIBIT L, TYPES OF WOOD PALLETS

Double Wing Stringer Pallet

Block Style Pallet

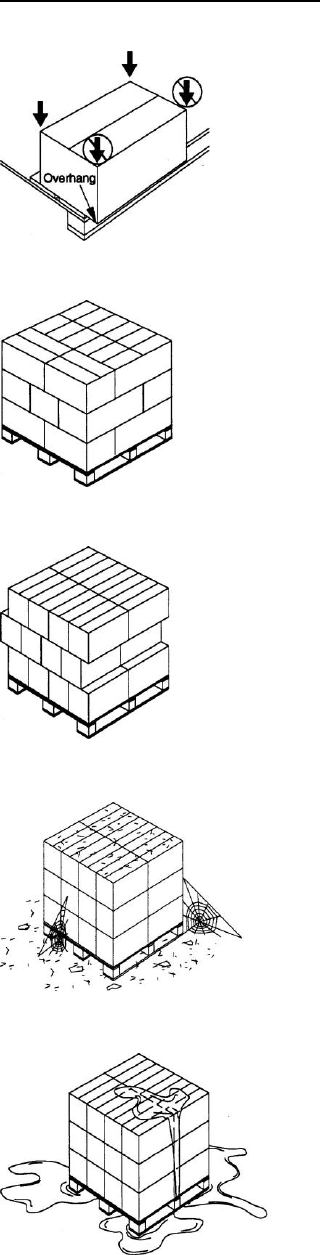

EXHIBIT M, STRENGTH OF CORRUGATED CARTONS

These examples demonstrate the potential loss in top-to-bottom compression strength when corrugated cartons are

stacked improperly or under adverse conditions.

% Loss in Compression Strength

Pallet/Carton Overhang Up to 32%

Interlocked Stacking Pattern Up to 50%

Carton Misalignment Up to 30%

Long-Term Storage Up to 50%

High Humidity (90% RH) Up to 60%

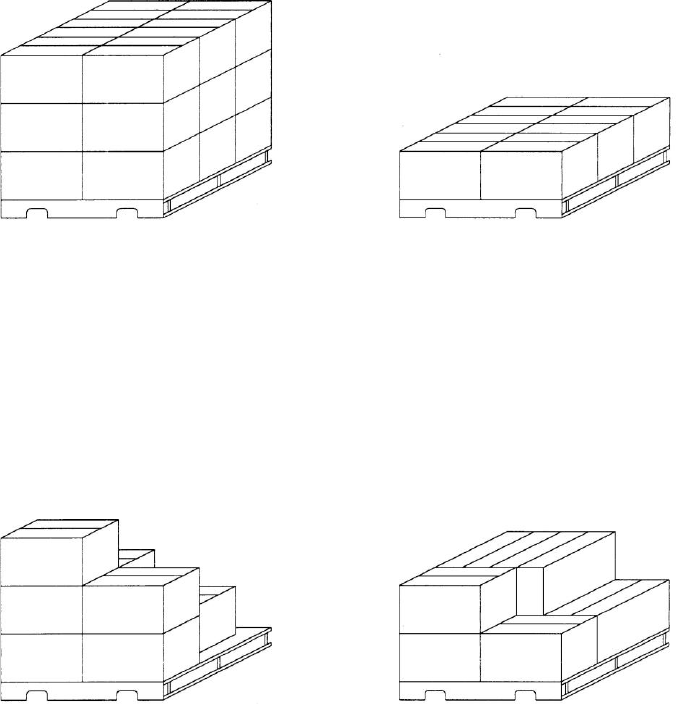

EXHIBIT N, LOADING OF CARTONS

Examples of Properly Palletized Cartons

Acceptable Acceptable

Examples of “Pyramided” Cartons

Unacceptable Unacceptable

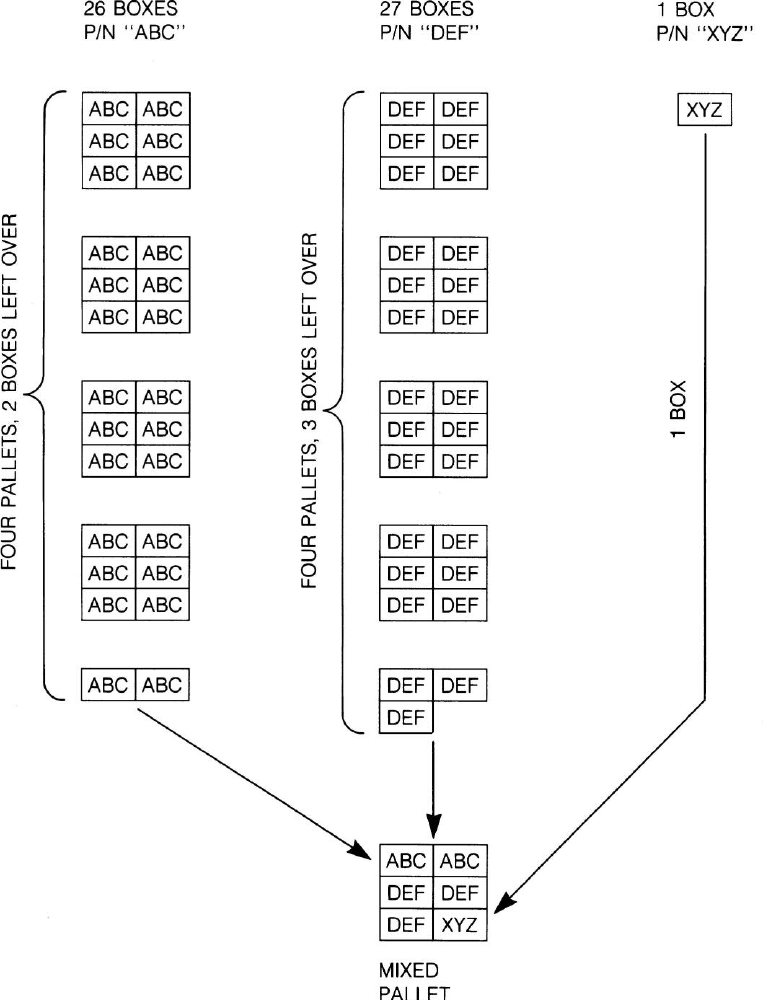

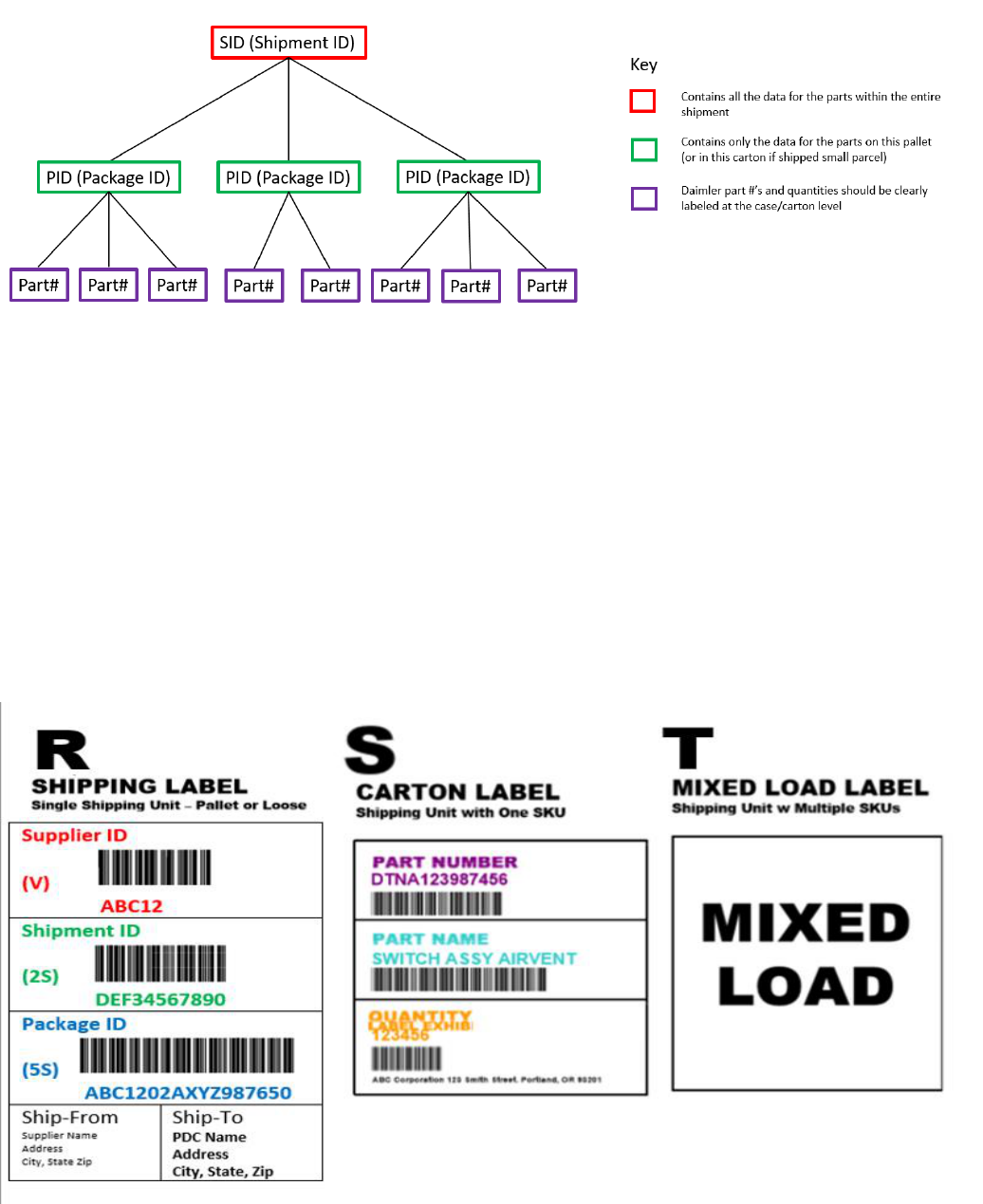

EXHIBIT O, MIXED LOAD PROCEDURE

The following example illustrates when it is acceptable to ship different part numbers on the same pallet.

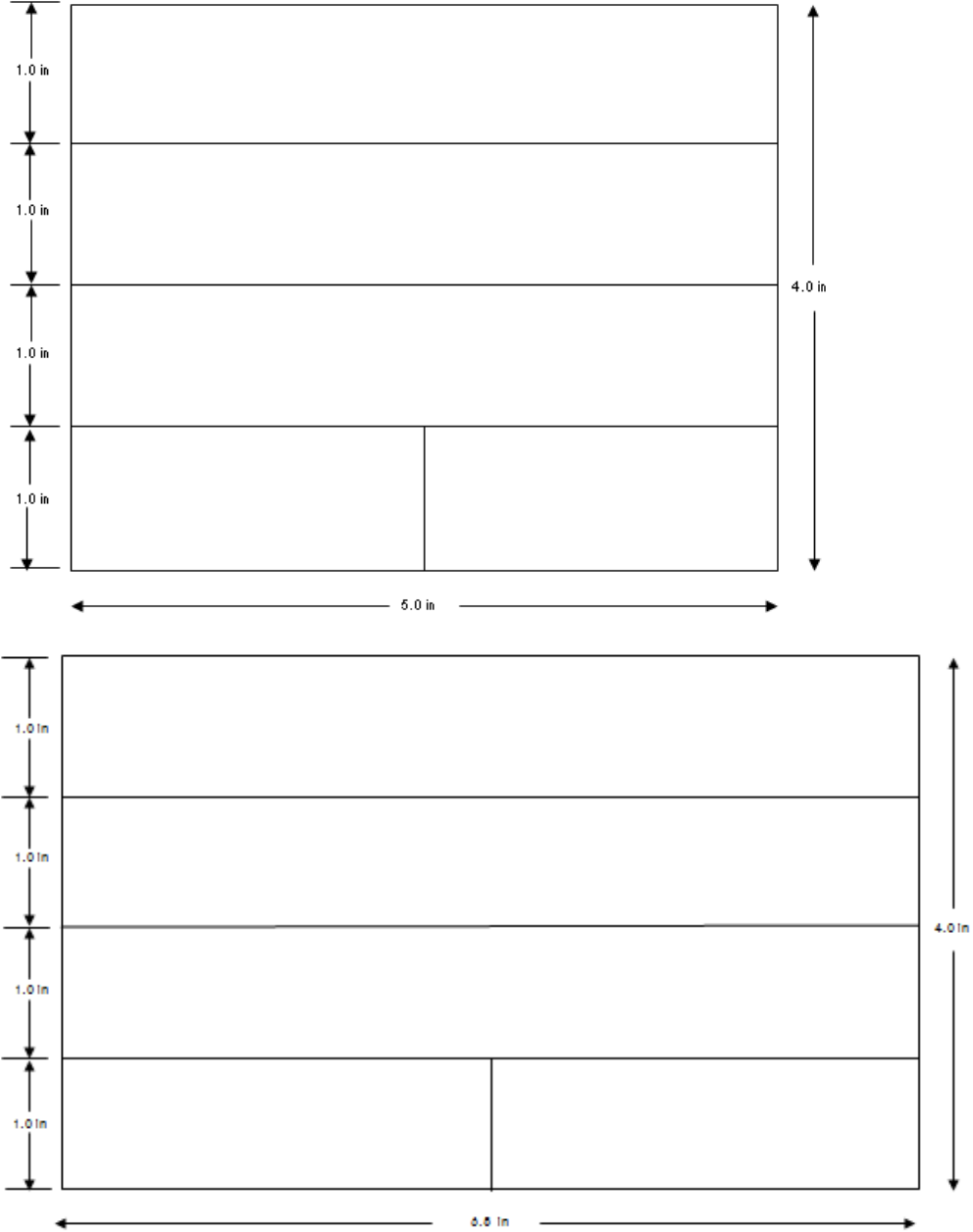

EXHIBIT P, LABEL DIMENSIONS

EXHIBIT Q, LABEL LOCATIONS

Loose Box or Carton

Identical labels should be located on two adjacent

sides. (Wrap around label acceptable.) The upper edges

of the labels should be as high as possible up to 20"

from the bottom of carton.

Cartons on Pallet

One master label may be used as described in

section 16.5, or one mixed load label as

described in section 16.8.1.

Rack

Tag one visible piece near top, or use a label holder.

Telescopic or Set-up Containers

Identical labels should be located on two

adjacent sides of the outer box. Some

applications may also require identification of

the inner box.

Roll

Hand one tag 2” (51 mm) from end of the material.

Bundle

Identical tags should be located at each end.

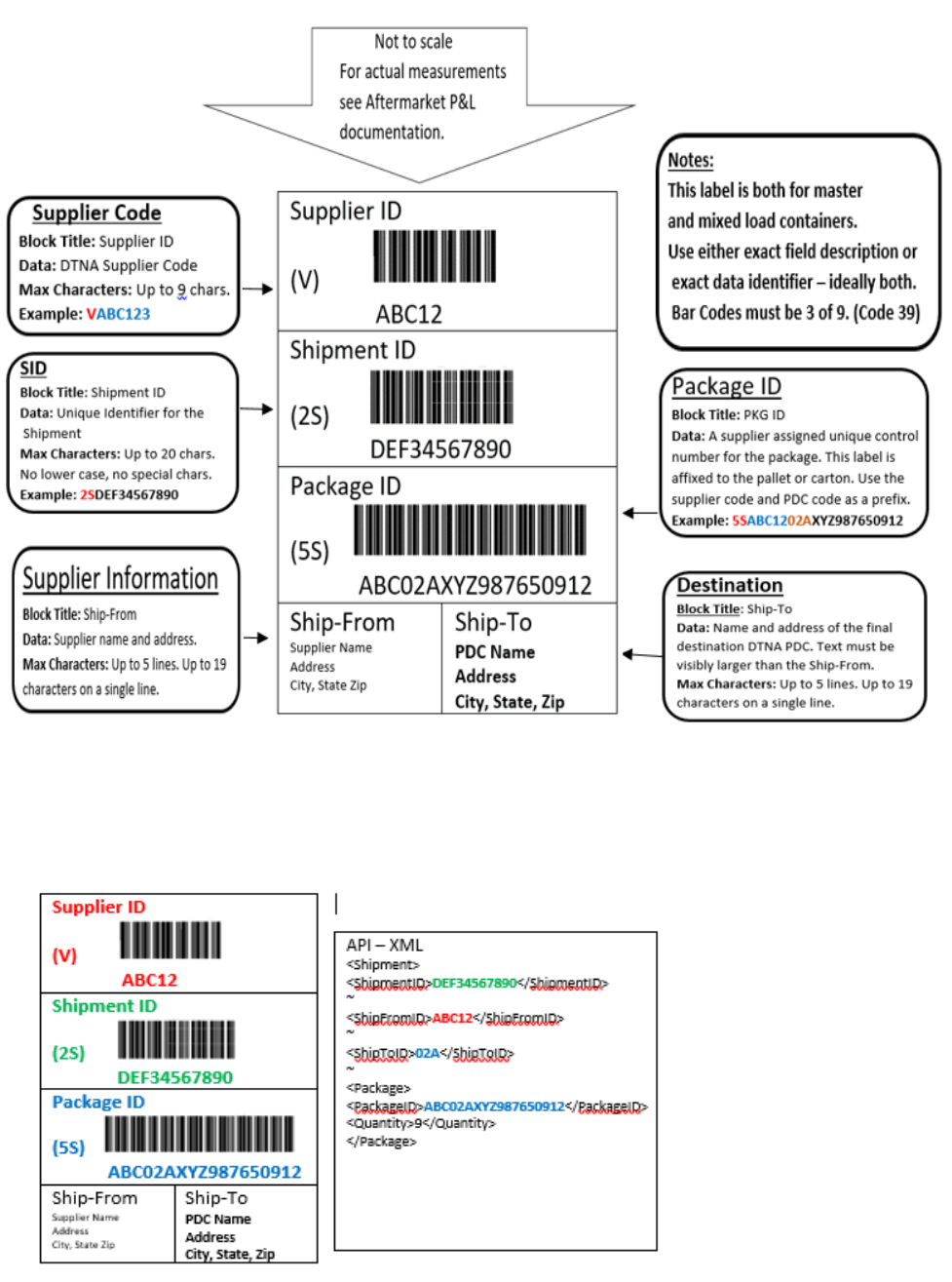

EXHIBIT R, BAR CODED SHIPPING LABEL

NOTE: Label NOT to Scale

Bar Code Receiving – Label to API ASN Document Synchronization

Shipment ID (SID) and Package ID (PID) on the label must match exactly to what is transmitted via the ASN.

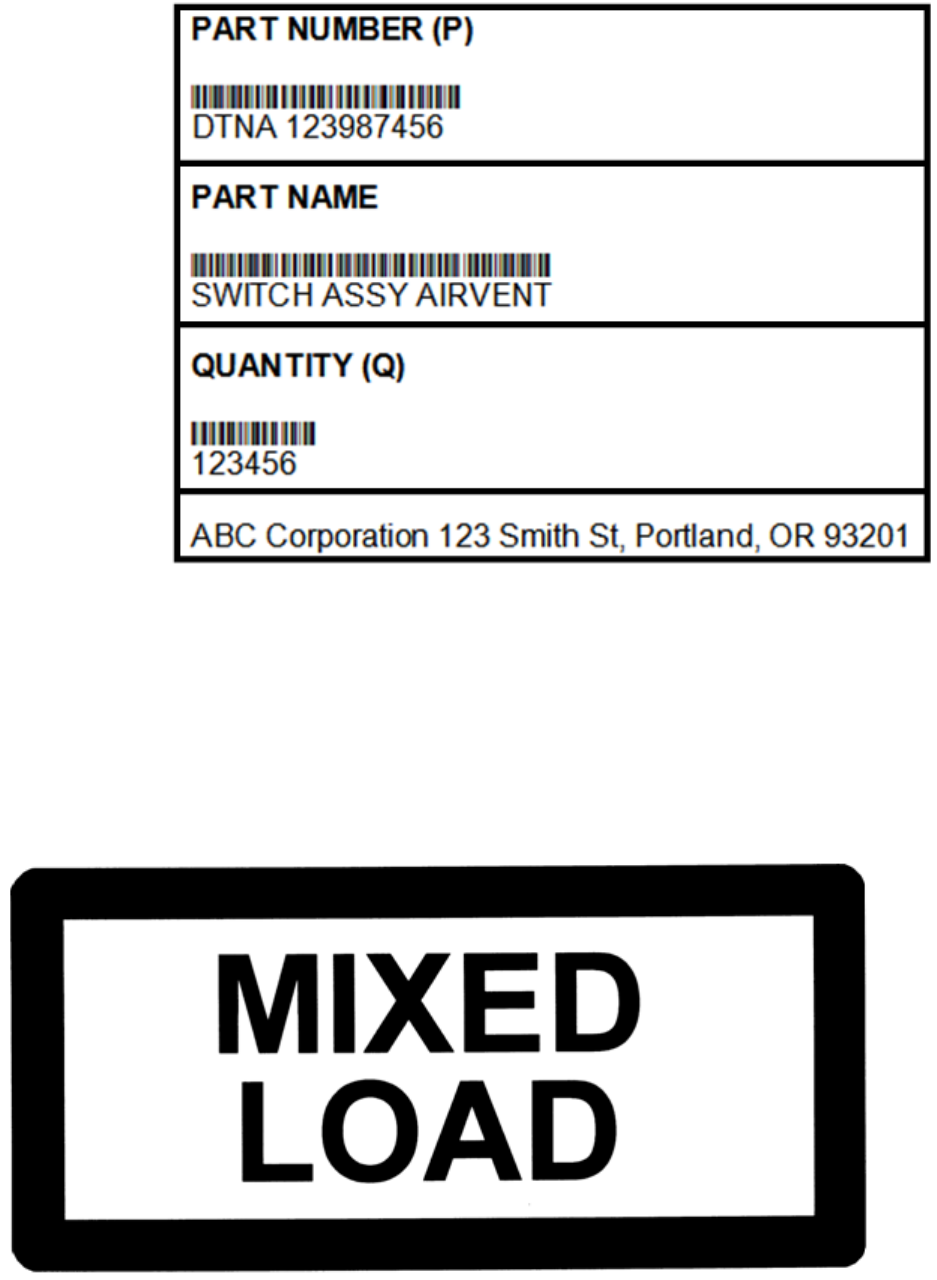

EXHIBIT S, SINGLE SHIPPABLE UNIT MULTIPLE CONTAINER LABEL

EXHIBIT T, MIXED LOAD LABEL

Label Exhibits

Carton label - the DTNA part number must match the DTNA part number from the PO.

Example 1: Multiple cartons per pallet, one SKU per carton.

Example 2: Multiple cartons per pallet. Five cartons with one SKU, one carton with multiple SKUs.