Life Cycle Analysis of Paper Products

1

Dr. Richard A. Venditti

Department of Forest Biomaterials

North Carolina State University

Raleigh, NC 27695-8005

Richard Venditti, Professor, Sabbatical Leave Jan-July 2011, Duke University, Center on

Global Change, Room 109 Phytotron, Duke email: rav16@duke.edu, office 919 681

7180, cell 919 649-4017

Permanent Address: Dept of Forest Biomaterials, North Carolina State University,

Biltmore Hall Rm 1204, 2820 Faucette Drive, Raleigh NC 27695-8005, (919) 515-6185,

richard_ve[email protected], website: go.ncsu.edu/venditti

Outline

• Introduction to LCA

• LCA of Paper

• North American Printing and Writing Grade LCA’s

• Allocation methods in LCA’s

• Recommendations

2

Sustainability?

• How do we supply societies needs without harming the

environment or future generations’ ability to meet their

needs?

– People – Planet - Profit

• We have many options to meet our demands.

• How to choose the “best” option?

• Life cycle assessment (LCA) helps to inform our choices.

• LCA has objective and subjective parts!!!

3

What is a Life Cycle Assessment ?

Life Cycle Assessment (LCA) is a tool to assess the potential

environmental impacts of products, systems, or services at all stages

in their life cycle [ISO 14001:2004].

Types of LCA

•Cradle to Gate: raw materials to finished good (no use or end

life considerations)

•Cradle to Grave: Considers everything from harvesting

materials to the disposal of the finished goods

4

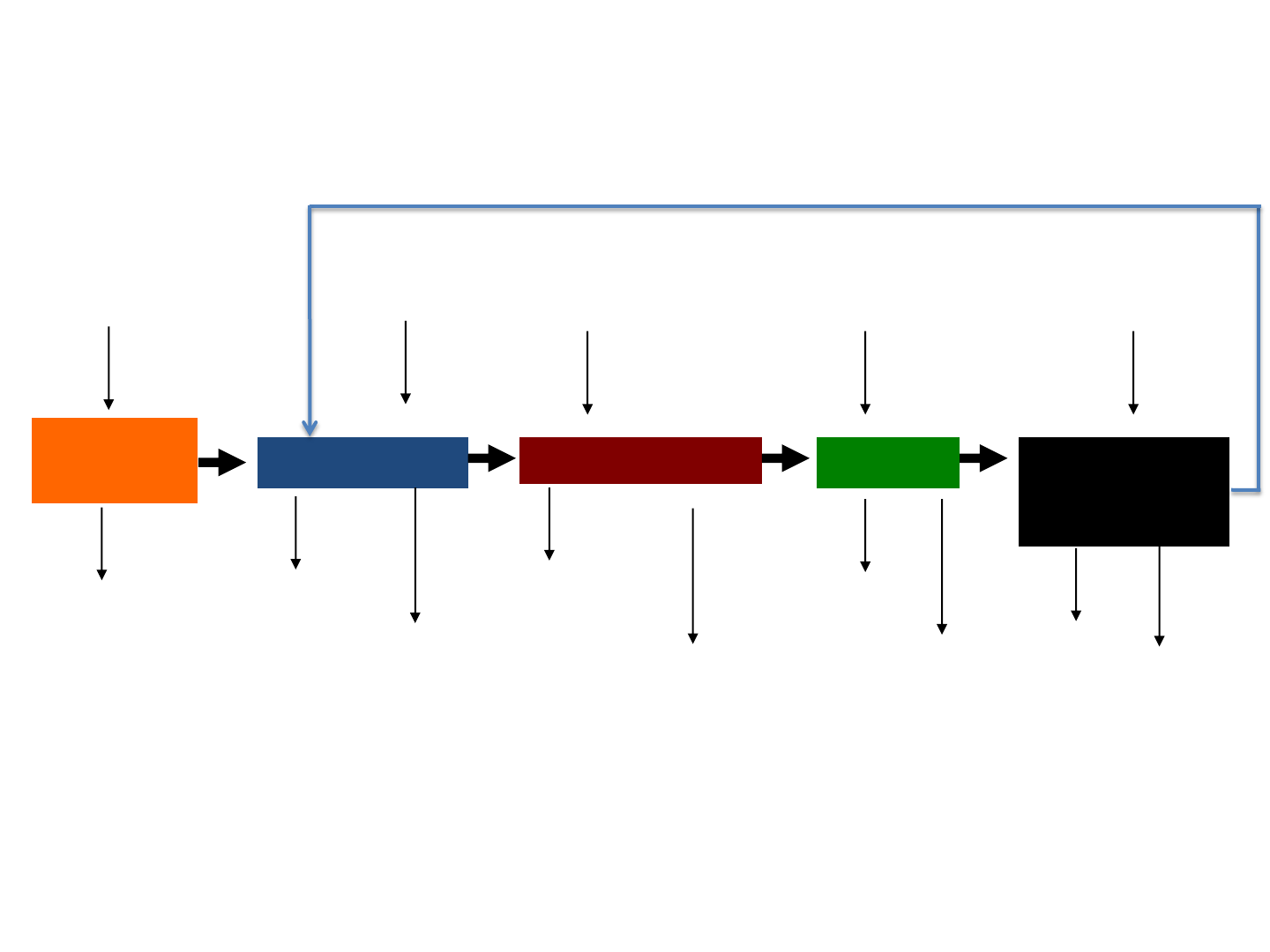

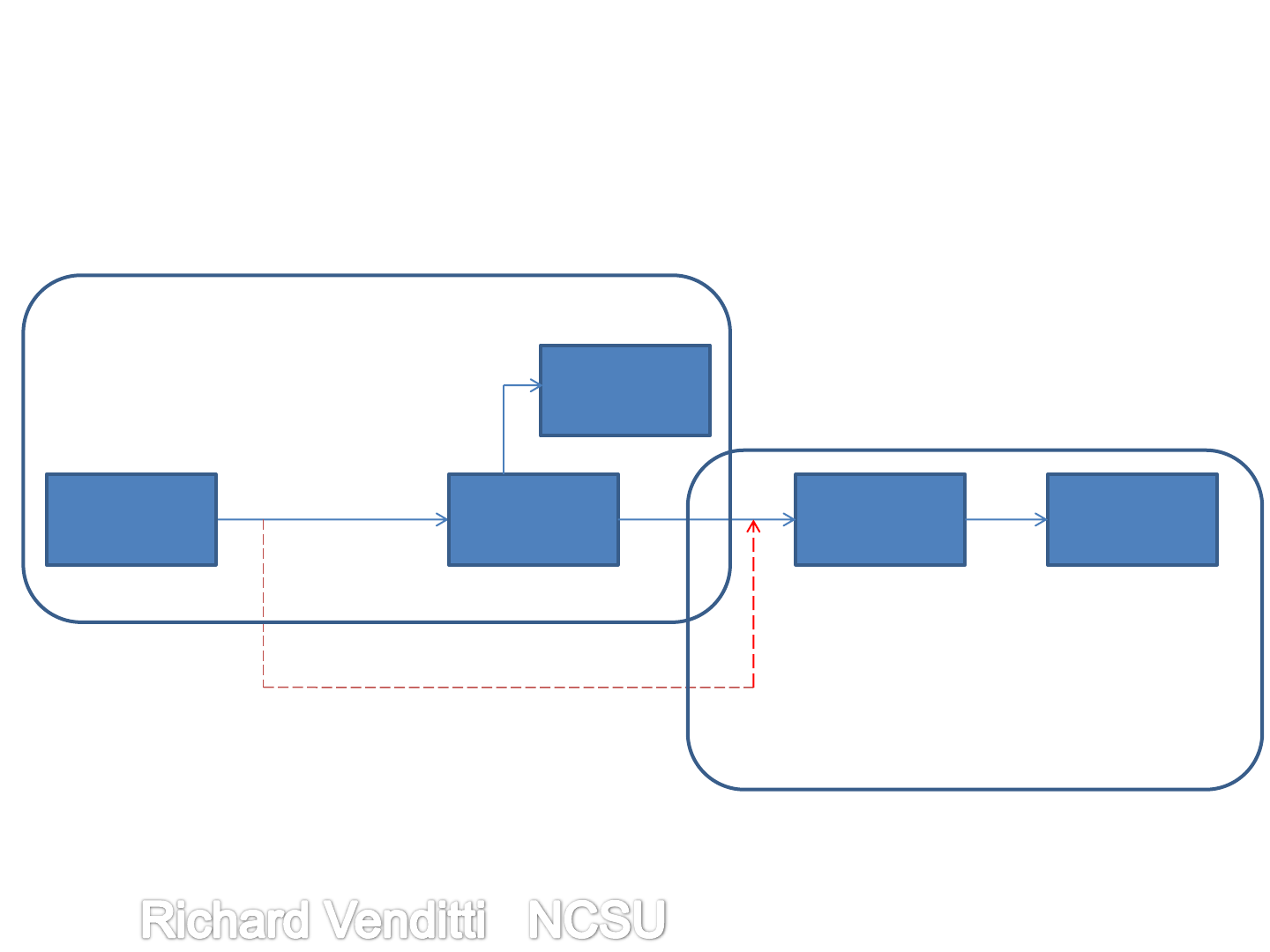

Example LCA Process

5

Production

Transportation

Use Disposal

Recycle

Energy

Energy Energy Energy

Waste

Waste

Waste

Waste

Emissions to

air and water

Emissions to

air and water

Emissions to

air and water

Emissions to

air and water

Recycled Materials

Raw

Materials

Energy

Waste

Why is an LCA Important?

• Helps ensure compliance with government regulations

• Helps decrease the environmental impact of a given product

- Identifies ways to improve sustainability

- Identifies ways to “green” all aspects of product’s life

• Can reshape company strategy

• Can help marketing

- Can reshape company image

- Develop product advantage of competition

6

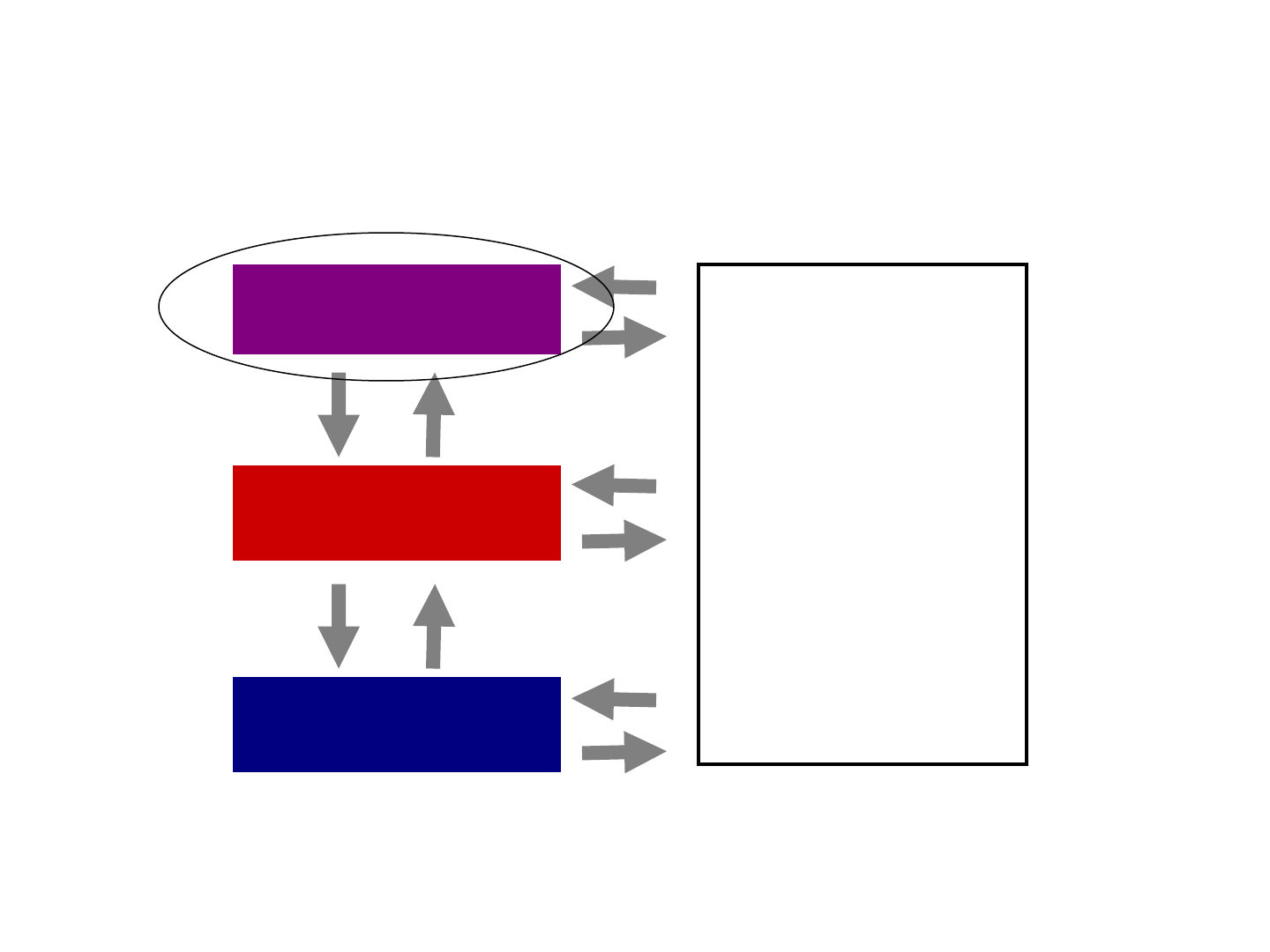

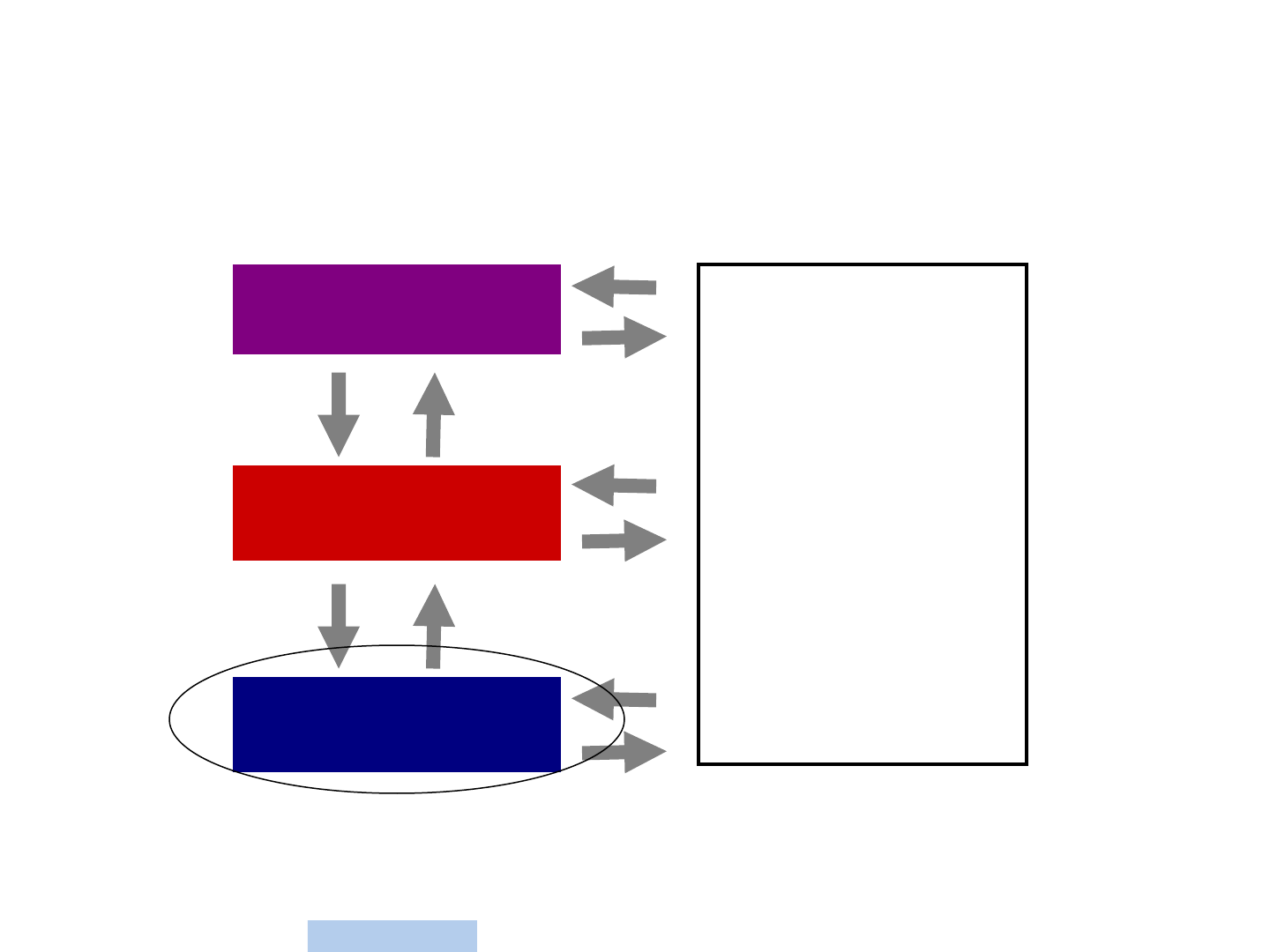

Important Aspects of Life Cycle

Assessment

Interpretation

Impact Assessment

Inventory Analysis

Goal and Scope

Definition

7

Defining Goals

• Should state the intent of the study

– Intended application

– Intended use

– Intended audience

• Should also include reason for the study

8

Defining Scope

• Define functional unit of product

– Example: 100 disposable paper cups vs 1 glass container washed 99 times

• Help establish system boundaries for the LCA

• Determine data collection methods

9

Important Aspects of Life Cycle

Assessment

Interpretation

Impact Assessment

Inventory Analysis

Goal and Scope

Definition

10

Inventory Analysis:

• Definition of the process (flowsheet)

• Definition of all mass and energy inputs to

the process

11

Inventory Analysis: What Needs to be Included?

• All relevant stages of the life of a product

12

Production

Transportation

Use Disposal

Recycle

Energy

Energy Energy Energy

Waste

Waste

Waste

Waste

Emissions to

air and water

Emissions to

air and water

Emissions to

air and water

Emissions to

air and water

Recycled Materials

Raw

Materials

Energy

Waste

Inventory Analysis:

• Foreground data – data specific to the model at hand

• Background data – generic data that can be found in available

databases (examples, generic transportation or electricity)

• Tracking of who is in control of consumption/emissions:

– Scope 1: owned production

– Scope 2: purchased energy sources, like electricity

– Scope 3: non-owned operations such as raw materials production,

transportation in non owned vehicles, or non-owned operations

13

Inventory Analysis:

Example

• Example product: copy paper

• Raw Materials

– Wood, water, various chemicals, energy

– Chemical and Energy Recovery

• Manufacturing

– Machinery, processes, packaging material

• Transportation and Distribution

– Storage of paper in warehouses, selling of it via wholesalers/retailers

• Use

– Products associated with the use of copy paper

• Disposal

– Waste products, Recycling, landfilling

– Energy recovery

14

Important Aspects of Life Cycle

Assessment

Interpretation

Impact Assessment

Inventory Analysis

Goal and Scope

Definition

15

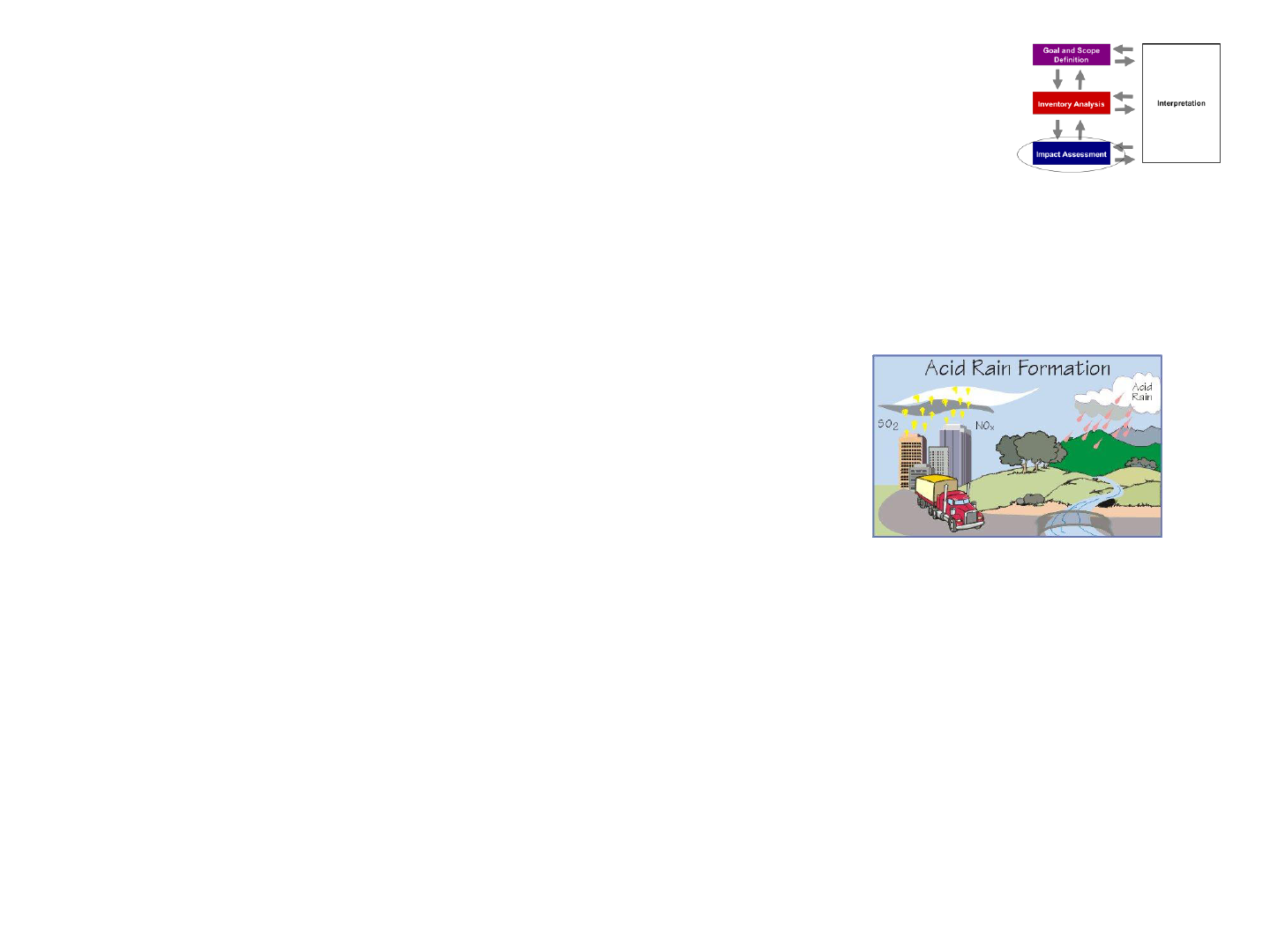

Impact Assessment

16

Definition:

Impact assessment is the process of identifying the future

consequences of a current or proposed action. (cbd.int/impact)

It is used to ensure that projects, programs and policies are

economically viable, socially equitable and environmentally

sustainable. (cbd.int/impact)

Developed with target audience in mind.

Example: Environmental Indices

for given impact categories

17

1. I

GW

– global warming

2. I

SF

– smog formation

3. I

OD

– ozone depletion

4. I

AR

– acid rain

5. I

INH

– human inhalation

6. I

ING

– ingestion toxicity

7. I

CINH

-human carcinogenic inhalation

8. I

CING

– carcinogenic ingestion toxicity

9. I

FT

– fish toxicity

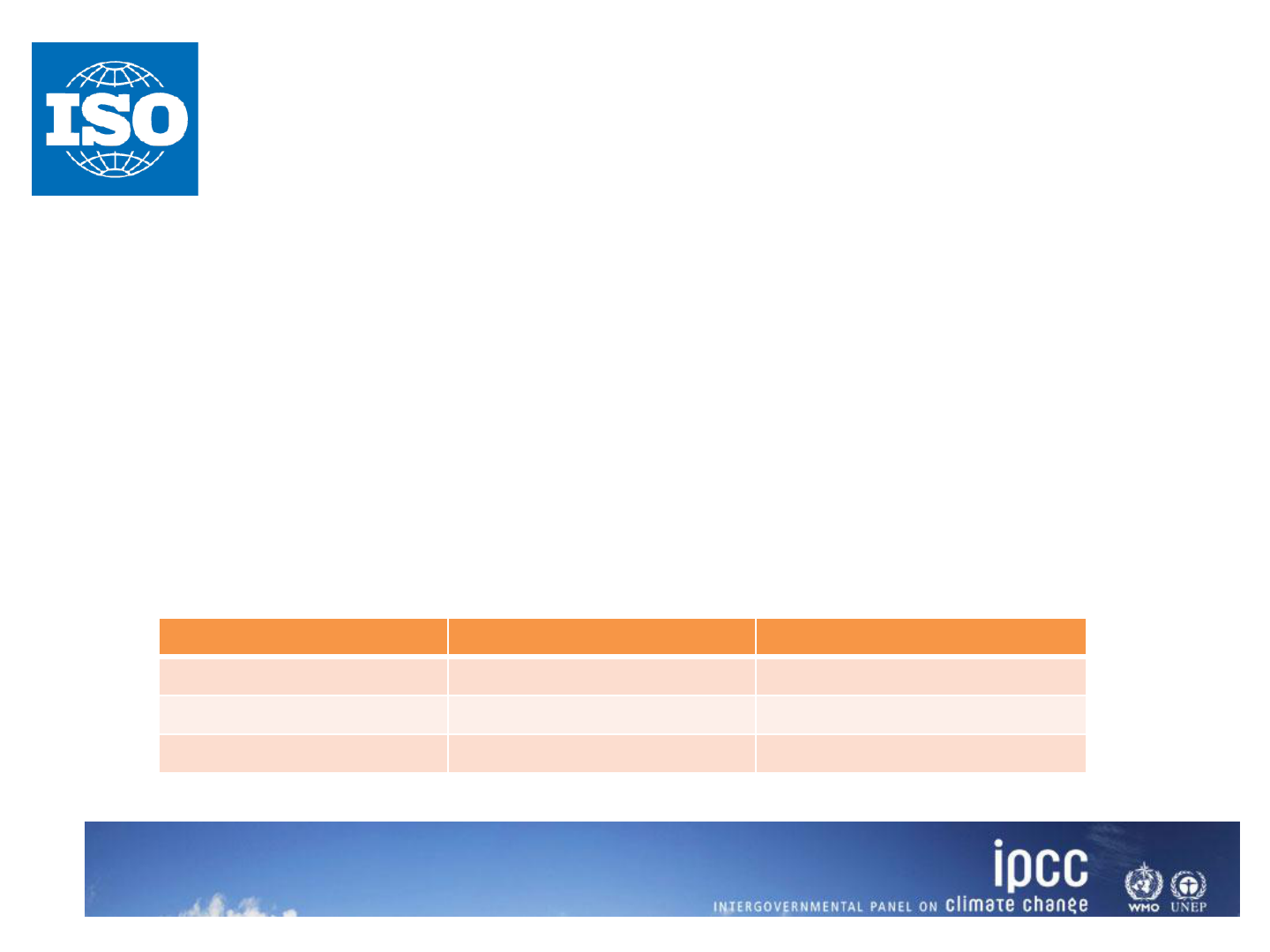

Impact Assessment: ISO Standard

• Characterization factors: determine the relative

contribution of an LCI output to the impact category

• For instance, 1 kg CH4 contributes to global warming 26

times 1 kg of CO2

• If, characterization factor for CO2 =1

• Then, characterization factor for CH4 =26

• From the inventory analysis,

– GWP = 1* kg CO2 + 26*kg CH4

18

Carbon Footprint:

Impact Assessment Method

• Partial life cycle analysis

• A picture of the overall greenhouse gas impact (not

just CO2) of a product over its lifecycle (cradle-to-

grave).

• Reports the net amount of GHG’s for a defined

process, in units of kgCO2(equiv)/basis

19

Revision Year CO

2

equivalents for CH

4

CO

2

equivalents for N

2

O

1996 21 310

2001 23 296

2006 25 298

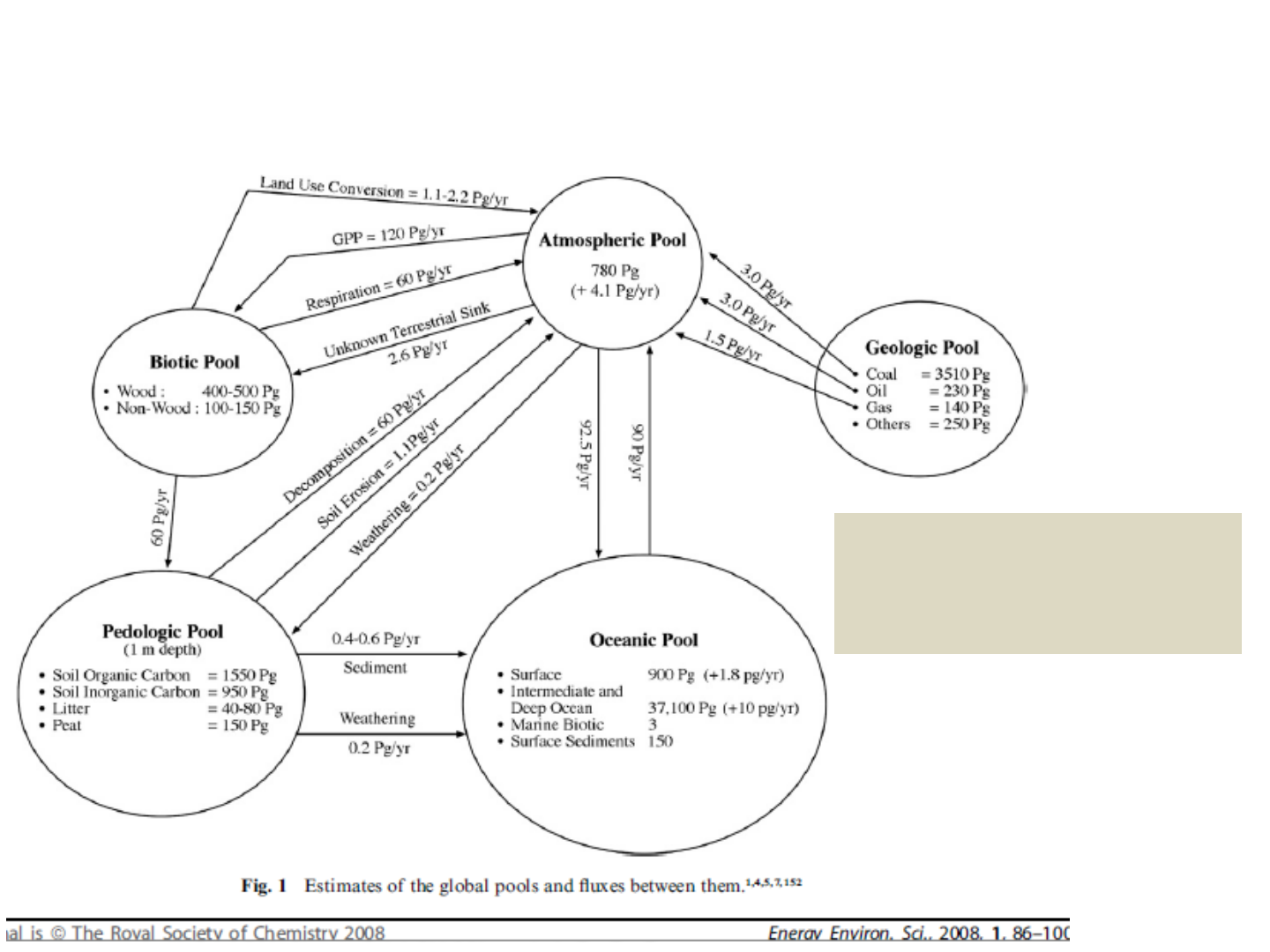

Global Carbon Cycle and Forests?

• Lal, 2008

4.1 Pg C /yr

4.1 billion tonne C / yr

14.7 billion tonne CO2 / yr

40 WW Paper Industries

Paper Production 0.15 billion tonne C/yr

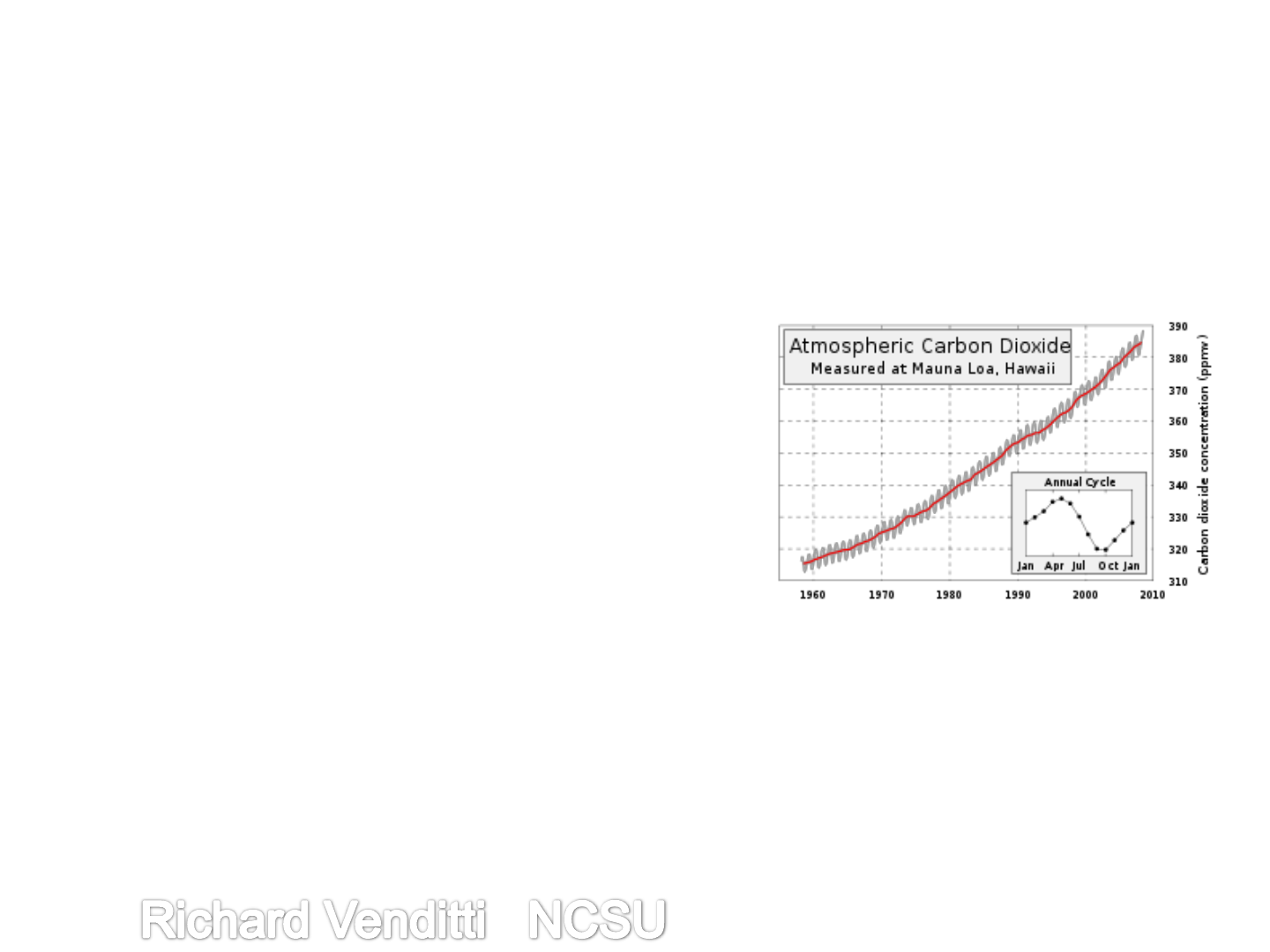

Global Carbon Cycle and Forests?

• Atmospheric concentration of CO2 has

increased by 31% since 1750 (to 390

from 280 ppm) and by 1.5 ppm/yr for

1980-2000 (IPCC 2001)

• Forests are significant in global GHG

(Landsberg & Gower, 1997):

– Cover 65% of the total land

– Contain 90% of the total vegetation

carbon

– 80% of total soil carbon in terrestrial

ecosystems

– Assimilate 67% of the total CO2 removed

from the atmosphere by all terrestrial

ecosystems

Carbon Footprint:

Impact Assessment Method

• Typically, a carbon footprint does not consider biogenic (from

living processes) carbon nor does it consider CO2 emissions

from the burning or decay of the biogenic material (they

balance each other)

• Biogenic material decay/burning that produces methane or N2O

must be considered

22

Tree Growth

100% Decay to CO2 and methane

Tree Growth

Burn to Produce CO2 only Net zero C footprint

+ C footprint

Carbon Footprint:

Impact Assessment Method

• Non renewable resources (coal, oil) are considered since they

have been formed over very long time scales and are not being

formed over time scales of interest

• Materials, transportation, energy often have associated with

them carbon emissions

• Long term storage of carbon away from the atmosphere is

considered a negative C footprint contribution

• When one product with a lower C footprint replaces another

with larger C footprint, an avoided C input to the atmosphere is

claimed, a negative C footprint contribution

23

Tree Growth

Burn to replace coal based electricity

Tree Growth

Book stored in library for long time

- C footprint

- C footprint

Important Aspects of Life Cycle

Assessment

Interpretation

Impact Assessment

Inventory Analysis

Goal and Scope

Definition

24

Interpretation: ISO Standard

25

Goal and

Scope

Interpretation:

1. ID Significant issues

2. Evaluation of

completion, sensitivity,

consistency, other..

3. Conclusions,

recommendations,

limitations

Impact

assessment

Inventory

analysis

Direct

Applications:

Product or

process

development

Public policy

Marketing

Strategic Planning

Other….

Outline

• Introduction to LCA

• LCA of Paper

• North American Printing and Writing Grade LCA’s

• Allocation methods in LCA’s

• Recommendations

26

27

Life Cycle Analysis

for Pulp and Paper Products

• Paper is a measure of the quality of life of a society

• Paper is mainly derived from renewable resources

• Complex furnish and manufacturing

• Extremely efficient manufacturing processes using a

majority of renewable fuels

• Paper manufacturing has air/water/solid emissions

• Paper has several co-products manufactured

• A recyclable product (open loop)

• Paper is the major component in landfills and when

degrades anaerobically forms methane

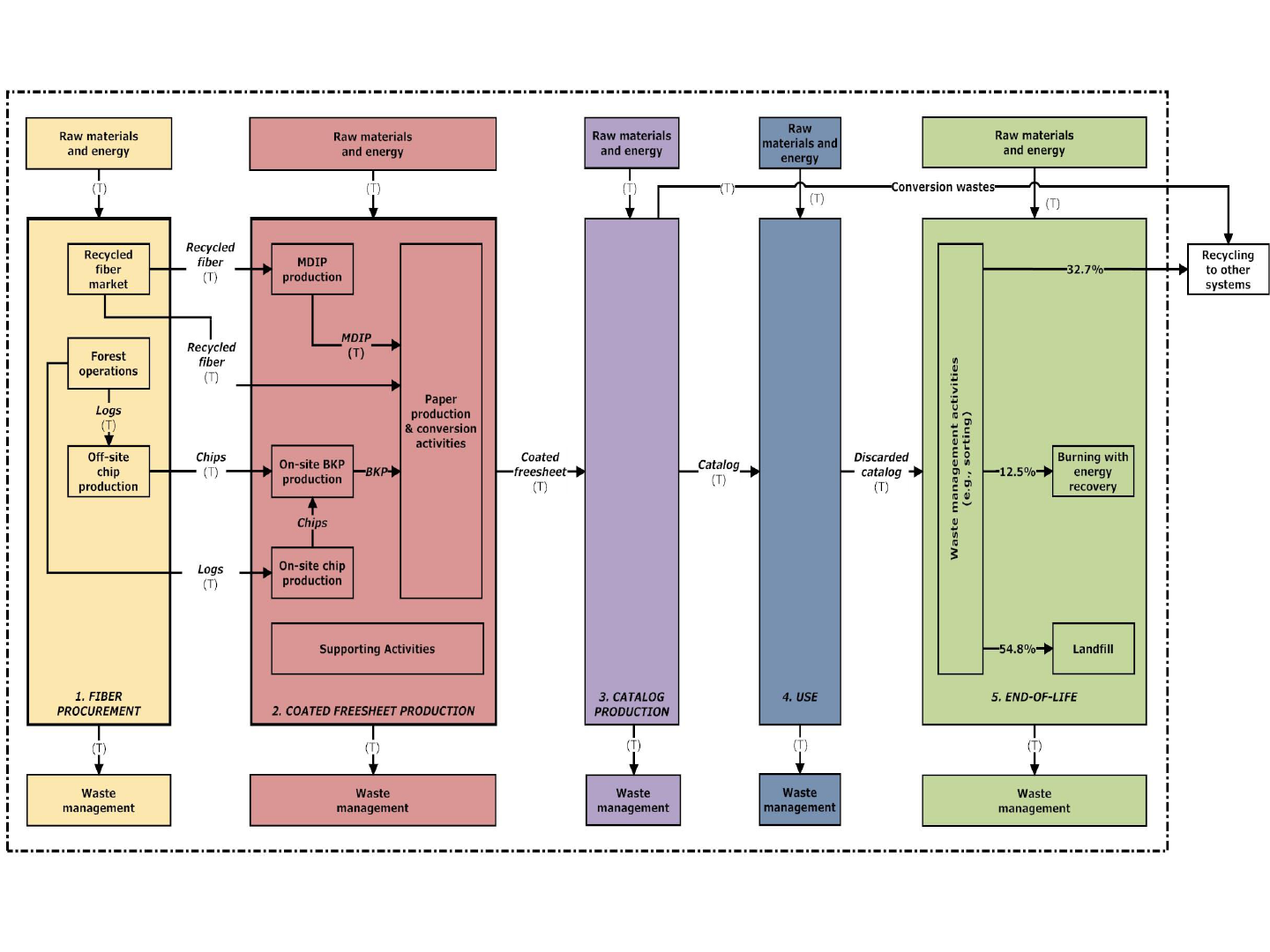

Life Cycle Analysis of Paper: Catalog System Boundary

28

Life Cycle Analysis of Paper: Catalog

29

Table Error! No text of specified style in document.-1. LCIA Results per Functional Unit (TRACI Method, IPCC) –

Catalogs

Impact

category

Unit/

catalog

Total

1-

2-

3-

4-

5-

Storage

use and

landfill

Fiber

procurement

Coated

freesheet

production

Production

of catalogs

Transport

and use

End-

of-life

Global warming

(GW)

kg CO

2

eq.

4.89E-01

5.4%

43.6%

15.7%

1.2%

37.7%

-3.4%

Acidification

(AC)

H

+

moles

eq.

1.67E-01

7.6%

67.4%

21.1%

1.1%

2.9%

N/A

Carcinogenics

(CAR)

kg

benzene

eq.

8.43E-03

0.6%

66.6%

4.2%

0.0%

28.6%

Non-

carcinogenics

(NCAR)

kg toluene

eq.

8.78E+01

0.5%

11.5%

2.4%

0.1%

85.4%

Respiratory

effects (RES)

kg PM

2.5

eq.

6.52E-04

3.5%

77.9%

15.6%

0.3%

2.6%

Eutrophication

(EU)

kg N eq.

8.85E-04

1.9%

19.0%

6.2%

0.2%

72.8%

Ozone depletion

(OD)

kg CFC-11

eq.

1.88E-08

2.8%

66.2%

21.2%

0.4%

9.4%

Ecotoxicity

(ECO)

kg 2,4-D

eq.

2.86E+00

0.9%

14.7%

6.1%

0.1%

78.2%

Smog (SM)

kg NOx

eq.

2.10E-03

7.7%

36.4%

48.7%

1.8%

5.3%

Fossil fuel

depletion (FF)

MJ surplus

3.94E-01

9.3%

52.4%

29.8%

2.6%

5.9%

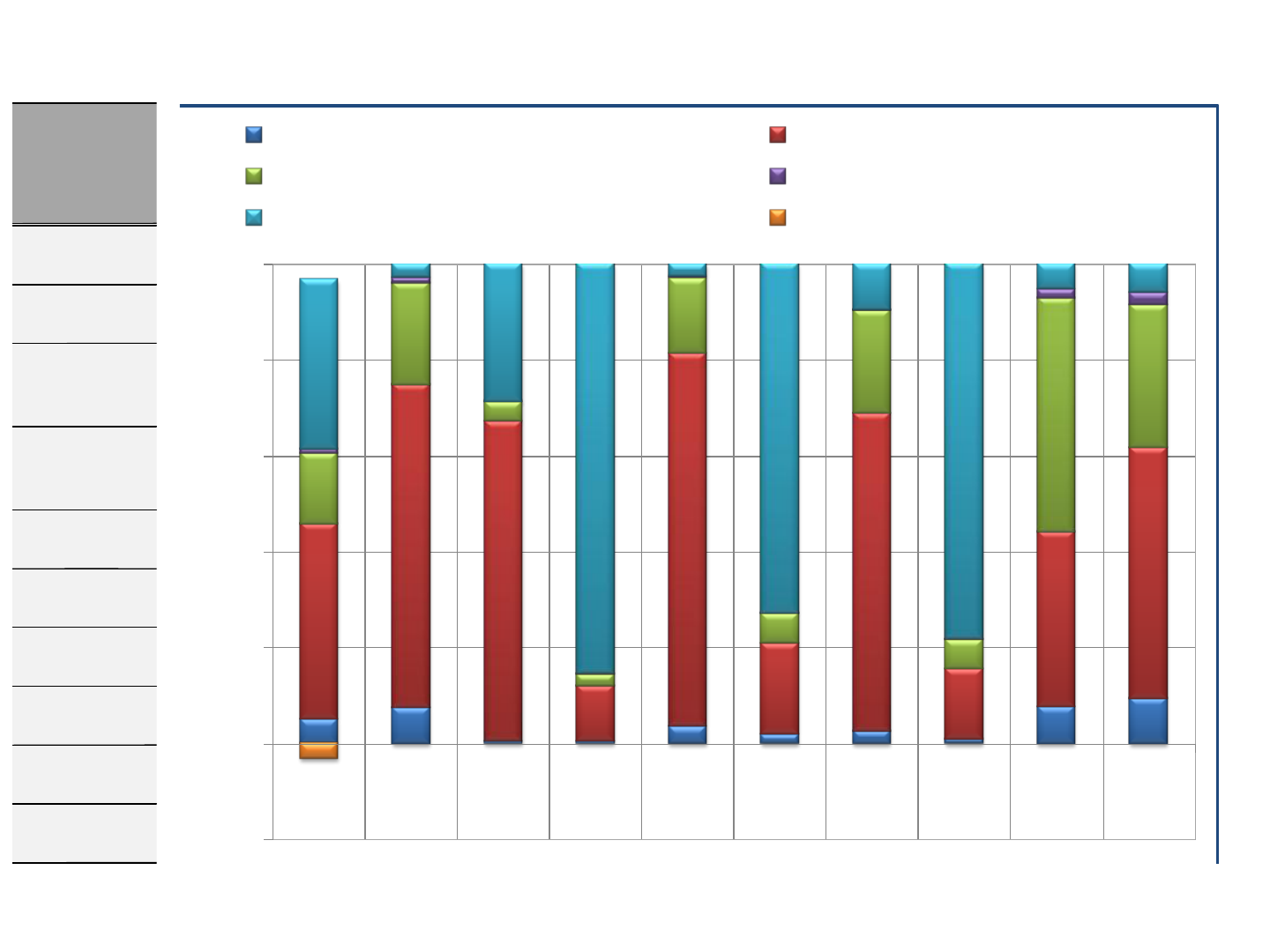

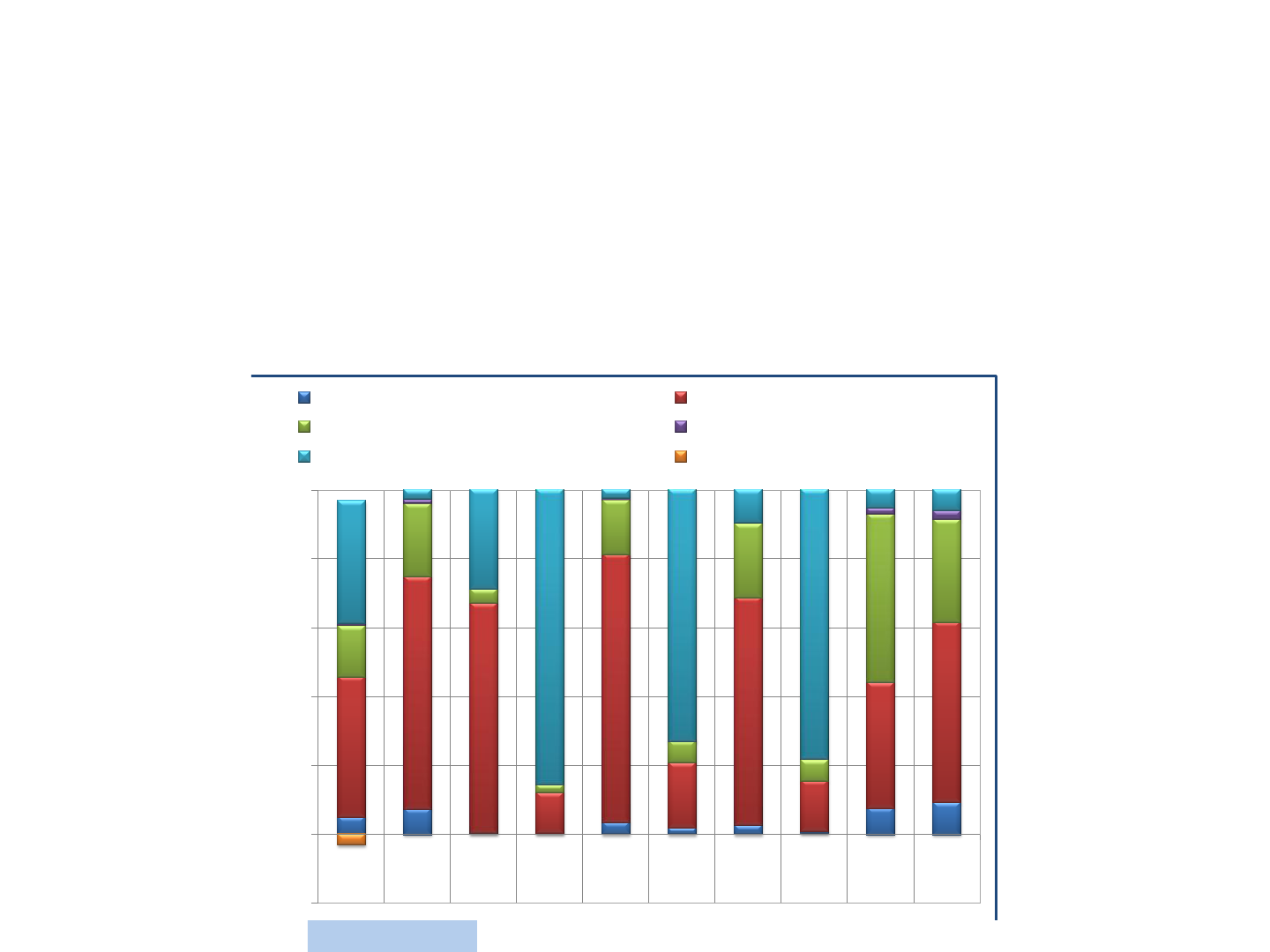

Figure Error! No text of specified style in document.-1. Cradle-to-Grave Contribution analysis – Catalogs Made

Primarily from Coated Freesheet

-20%

0%

20%

40%

60%

80%

100%

GW

AC

CAR

NCAR

RES

EU

OD

ECO

SM

FF

1- Fiber procurement

2- Coated freesheet production

3- Production of catalogs

4- Transport and use of catalogs

5- End-of-life

Storage in use and landfill

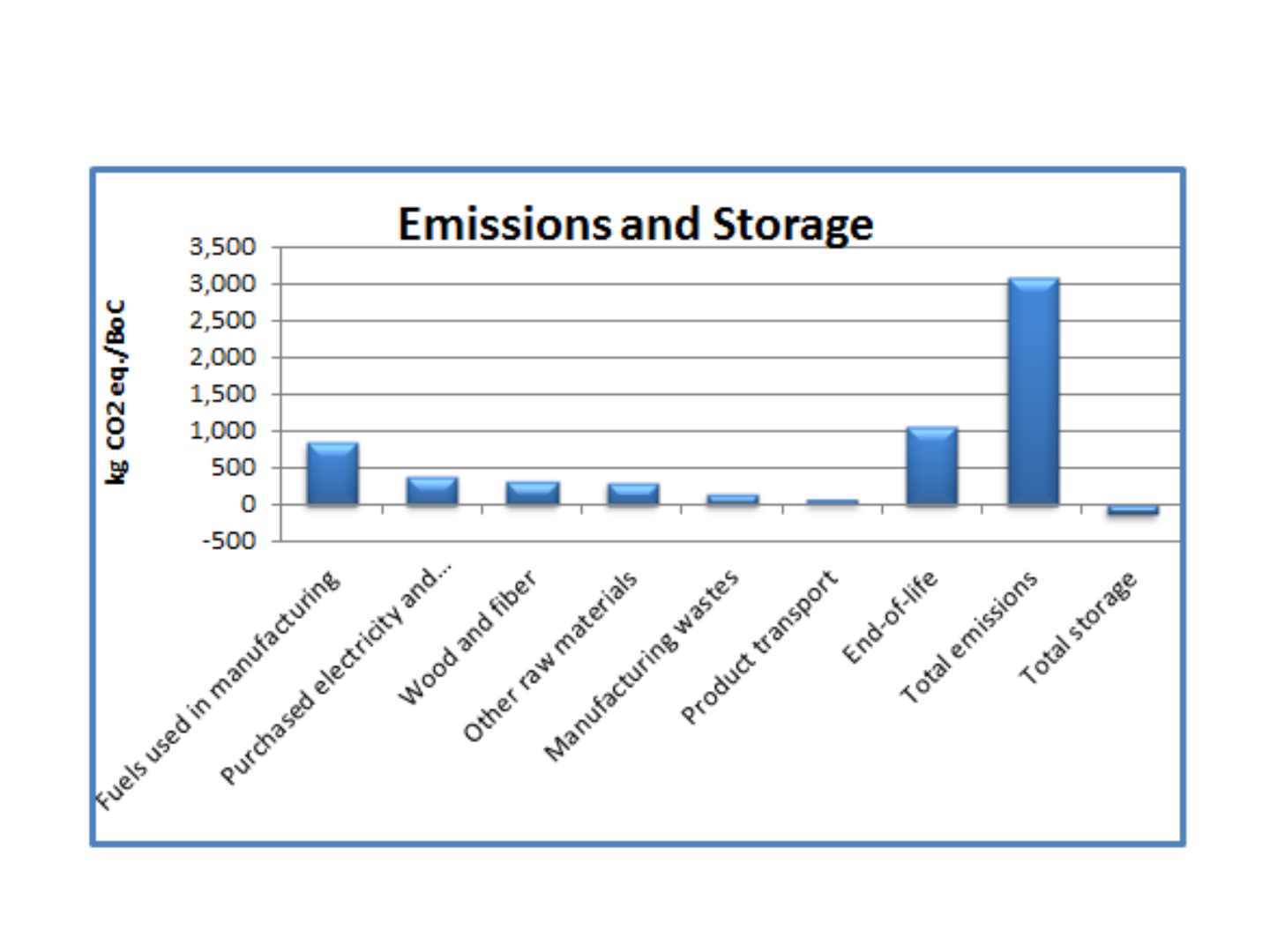

Life Cycle Analysis of Paper: Catalog: Carbon Footprint

30

Outline

• Introduction to LCA

• LCA of Paper

• North American Printing and Writing Grade LCA’s

• Allocation methods in LCA’s

• Recommendations

31

32

Major NA LCA Studies on

Printing and Writing Grades

• Paper Task Force White Paper No. 3 Lifecycle environmental

comparison: virgin paper and recycled paper based systems.

Originally published Dec. 19, 1995, updated February 2002 (Paper

Task Force, 2002)

• The Heinz Center: Following the Paper Trail: The Impact of

Magazine and Dimensional Lumber Grade Production on GHG

Emissions: A Case Study, 2006. (Heinz, 2006)

• National Council for Air and Stream Improvement, Inc. Life Cycle

Assessment of North American Printing and Writing Paper Products

(NCASI, 2010)

•

Paper Task Force (Paper Calculator):

• Data circa 1994

• Synthetic, simplistic separation of virgin and recycled systems

• Mainly indicates preferred disposal method

• Has been extensively mis-marketed and mis-used to promote the use

of recycled fibers in specific products

33

Raw Material

Acquisition (300)

Paper Production (3000) Landfill/Incinerate Virgin

Paper (2500)

Deinking and Paper

Production (3350)

Collection of Recycled

Paper (230)

Net GHG Emissions

Virgin Office Paper

Landfill 6700 (3.4)

Incineration 2500 (1.3)

Waste Management 5800 (2.9)

Recycled Office paper Collect/Process 3580 (1.8)

Paper Task Force (Paper Calculator):

• Producers of manufactured paper products are using national

averages of the industry to represent their product. However, the

range of environmental burdens are very large and using averages to

represent specific products is misleading.

34

-1000

-500

0

500

1000

1500

2000

2500

C50D50EDED D(EO)DED OD(EO)D Industry Average

CO2 from Fossil Fuels, lb/AD ton

Bleaching Sequence

Paper Task Force (Paper Calculator):

35

-2000

-1000

0

1000

2000

3000

4000

5000

Bleached Kraft Pulp Uncoated free

sheet paper

Coated free sheet

paper

Lightweight coated

groundwood virgin

paper

Lightweight coated

paper

Deinked Recovered

Fiber

CO2 from Fossil Fuels, lb/AD ton

Paper Task Force (Paper Calculator):

• Producers of manufactured paper products are using the results to

indicate that more recycled fiber content in a specific product is better,

however, this is not necessarily true

• It is good to recycle in general

• However, in general, it is most efficient to recycle paper products to

lower valued and not higher valued products

• Example:

36

0

0.1

0.2

0.3

0.4

0.5

0.6

0.7

0 5 10 15 20 25 30

Number of

Uses

Cut off

method

Net GHG, kg CO2eq/kg catalog

Utilization Rate (%)

The Heinz Center: Following the Paper

Trail: The Impact of Magazine

• Data circa 2001

• A scope 1 (owned) and 2 (purch power) study for Carbon Footprint

• Omits scope 3 (non-owned) considerations

• Does not follow LCA procedures/fails to document adequately

• Underestimates carbon footprint

37

Forest

Management

and Harvesting

Transport

Paper

Manufacturing

Transport to

Printers and

Printing and to

Distribution

Centers

Final Fate:

Landfill

Recycle

Incinerate

InStyle

(1.11)

Purchased Power

Time

(1.17)

Table 2. Activities in the net GHG Life Cycle tracked in the Heinz Center

Study for the InStyle and Time magazines (ton CO2e/ton product listed)

National Council for Air and Stream Improvement

(NCASI)

• Most modern study

• Robust, scope 1-3 LCA of printing and writing grades

• Follows ISO procedures

• Complex allocation methods for virgin vs recycling products

38

Figure Error! No text of specified style in document.-1. Cradle-to-Grave Contribution analysis – Catalogs Made

Primarily from Coated Freesheet

-20%

0%

20%

40%

60%

80%

100%

GW

AC

CAR

NCAR

RES

EU

OD

ECO

SM

FF

1- Fiber procurement

2- Coated freesheet production

3- Production of catalogs

4- Transport and use of catalogs

5- End-of-life

Storage in use and landfill

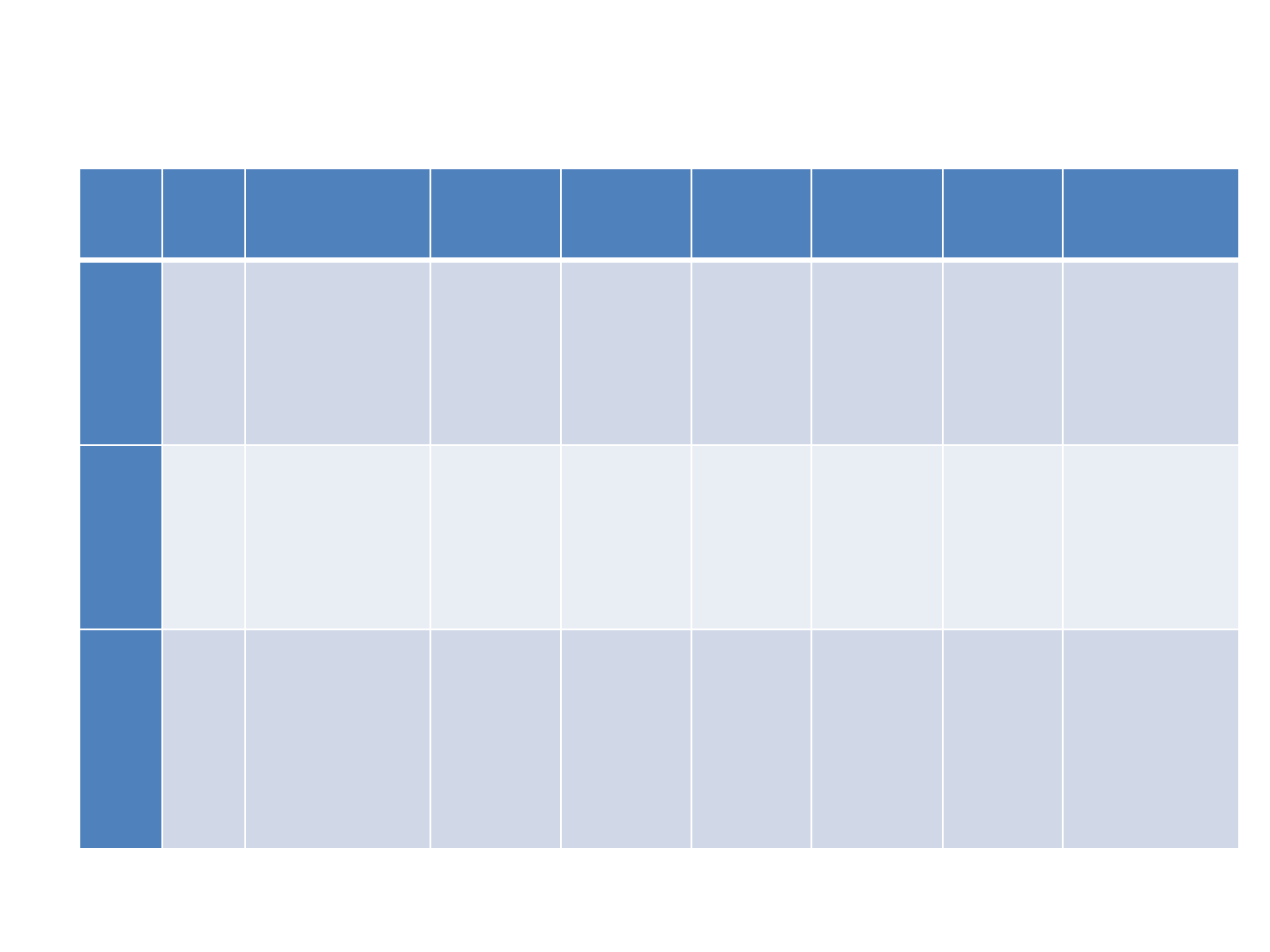

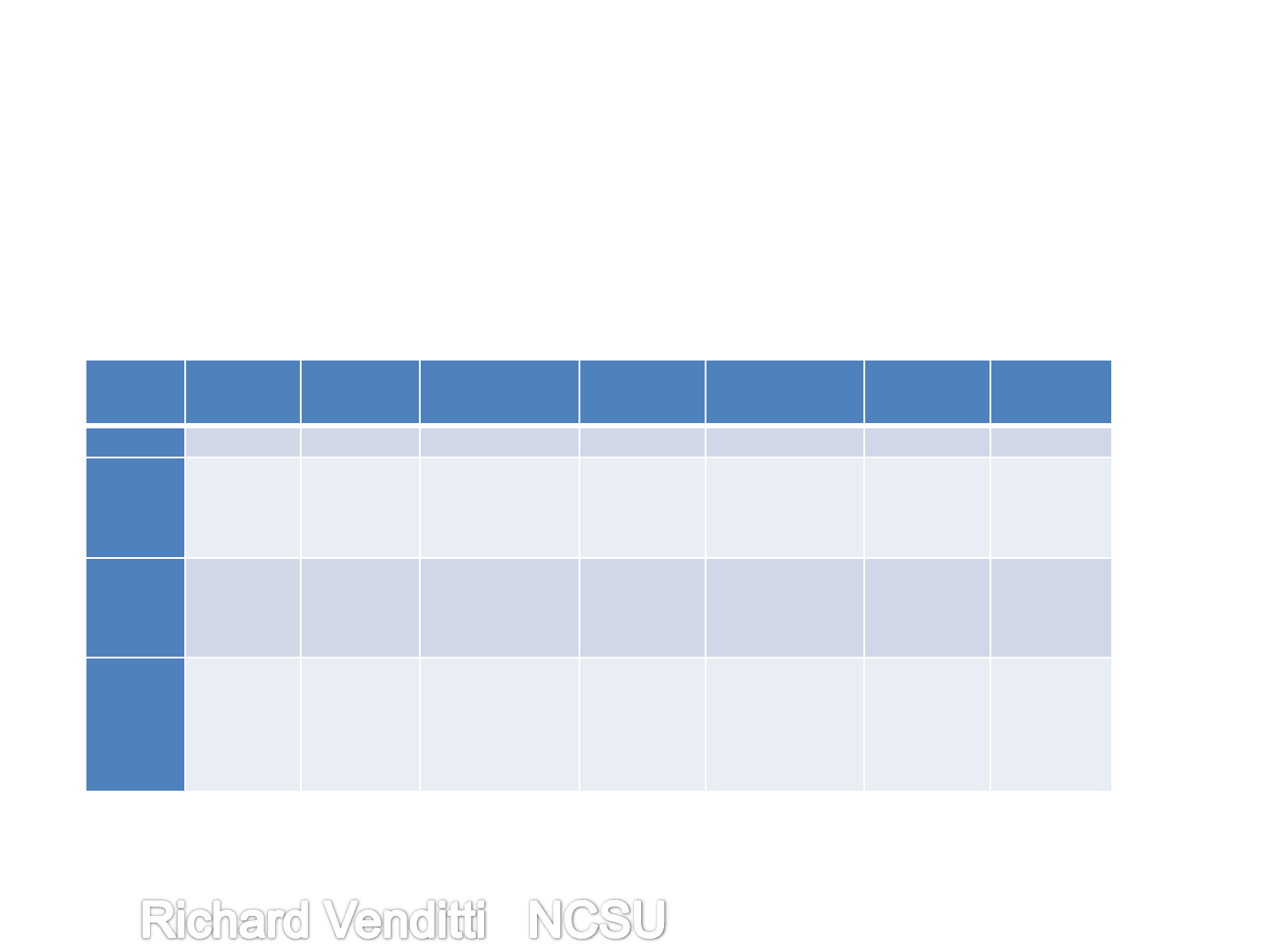

Comparison of Three Studies:

39

Study:

ISO

14040

3

rd

Party Review

Published in a

Peer Reviewed

Journal

Clarity of Data

Impact

Assessment

Uncertainty

Analysis

Sensitivity

Analysis

Allocation methods

Paper

Task

Force

No.

Reviewed by outside

experts. Comments

not provided in the

report.

No.

Extensive

presentation of

the inventory

data.

Net GHG.

None.

None.

Synthetic separation

of virgin and recycled

paper products.

Inconsistent

application of open

loop recycling.

Heinz

No.

None.

No.

Did not define

what data was

included. Data

in inventory

results not

presented.

Only GHG

emissions

reported.

None.

Weaknesses in

study

discussed.

Not done.

Results for

individual

printing

operations

were

presented.

None used for

recycling. Unclear

assumptions on

coproduct allocation

methods.

NCASI

Yes

External peer review

panel. Panelists

comments and the

responses to the

comments appear in

the report

No.

Extensive

flowsheeting of

processes and

lists of data

appear in

report.

SimaPro

software

running

TRACI.

Conducted

with respect to

inventory data.

Sensitivity on

process

conditions,

allocations

methods,

impact

assessment

method,

others

Co

-product and

recycling allocation

methods used.

Comparing Difft LCA’s

• Very Difficult:

• Example, coated paper:

– PTF: .8-1.8 ton CO2e/ton product

– Heinz: 1.11-1.17

– NCASI: 2.36-3.45

– VTT Study (Finland): 1.0-1.6

– Springer/Stora/Canfor (Europe): 0.4-1.9

• Geographical differences, assumptions, data,

calculation methods, scope, …………….

40

Outline

• Introduction to LCA

• LCA of Paper

• North American Printing and Writing Grade LCA’s

• Allocation methods in LCA’s

• Recommendations

41

Allocation Methods in LCA:

• Allocation: the partitioning of environmental

burdens between two related products

• Controversial:

– ISO methods recommend that allocation is avoided

– ISO does not provide allocation rules, practitioner must decide the

rules and justify their use

– ISO requests that the sensitivity of the LCA results are evaluated

with respect to the allocation methods

• Bottom line: allocation method can determine which

related product in a life cycle is preferred

42

Two Main Allocation Situations:

• Co-products Allocation: a single process produces

multiple products,

– Burdens can be partitioned by mass flows, monetary

values….

– Example for paper production: paper, TOFA, turpentine

– Emissions from pulping are partitioned to the paper, TOFA,

and turpentine using a stated rule

43

Two Main Allocation Situations:

• Recycling Allocation: a virgin product is recycled or

re-used in a subsequent life

– There exists operations that are required by the virgin and

the recycled products (shared operations)

– Example shared operations: virgin raw material production,

final disposal

– Many ways to allocate the burdens of the common

operations

• Open loop recycling allocation is the most

controversial issue in LCA currently!!!!

44

Allocation methods to share burdens reflect

improved environmental efficiency.

• Example: want to understand the burdens of

containing groceries during transport

• Reduce: don’t use a bag, 0 burden/trip

• Re-use (production of bag = 1 burden)

– Use bag once, 1 burden/trip

– Use bag twice, 0.5 burden/trip

• Recycle (to recycle costs 0.4 burdens)

– Then for using the bag and recycling once:

( 1 + 0.4 ) / 2 trips = 0.7 burdens/trip

– (data for example only, not meant to represent an actual

process)

45

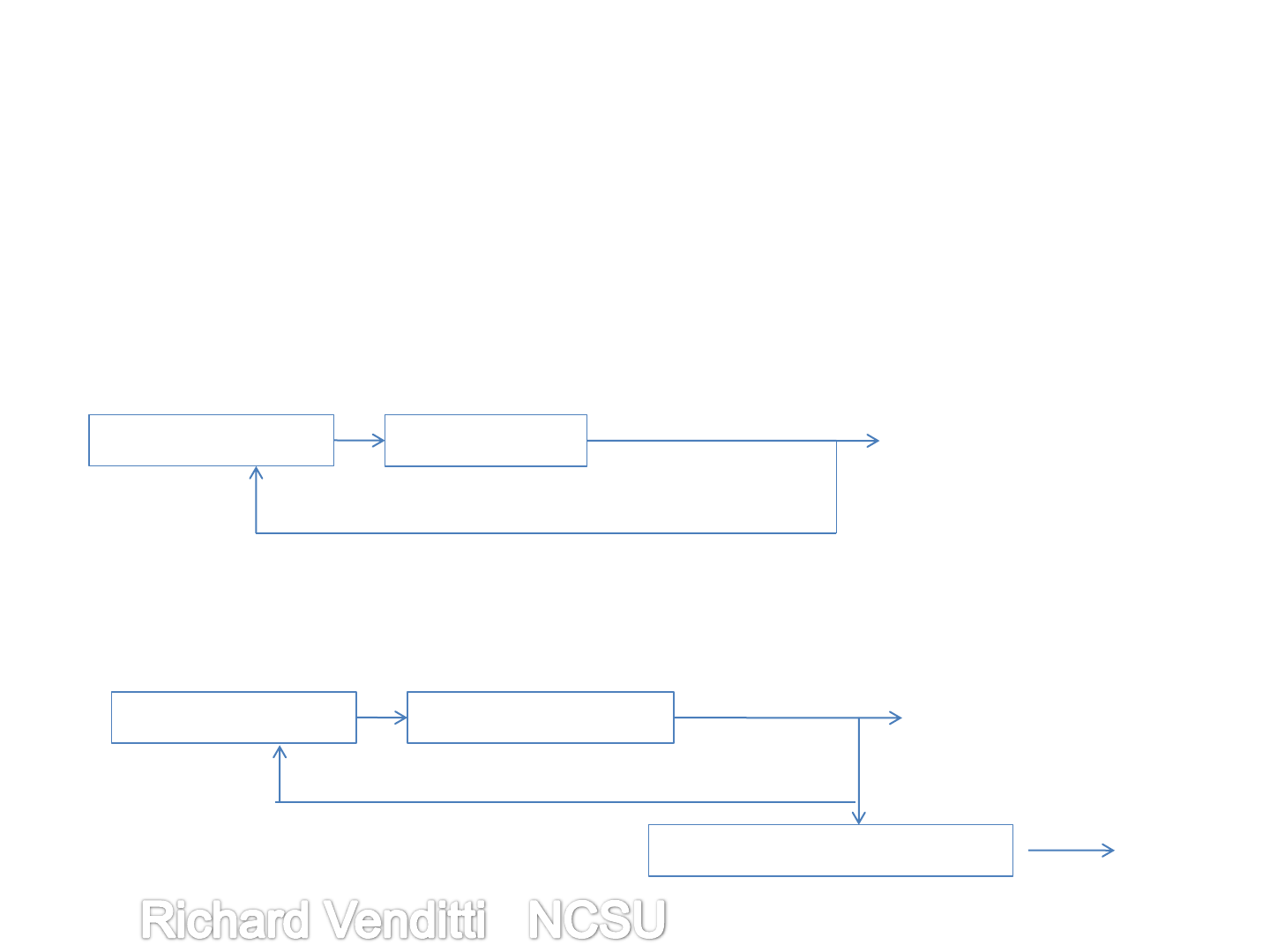

Closed and Open Loop Recycling:

• Closed loop: material or products are returned to

the same system after use and used for the same

purpose again (Baumann, Tillman, 2004)

• Open loop: a product is recycled into a different

product

46

Production of P

Use Product

Disposal

Production of P

Use of Product A

Disposal

Production of Product B

Disposal

Recover

Recover

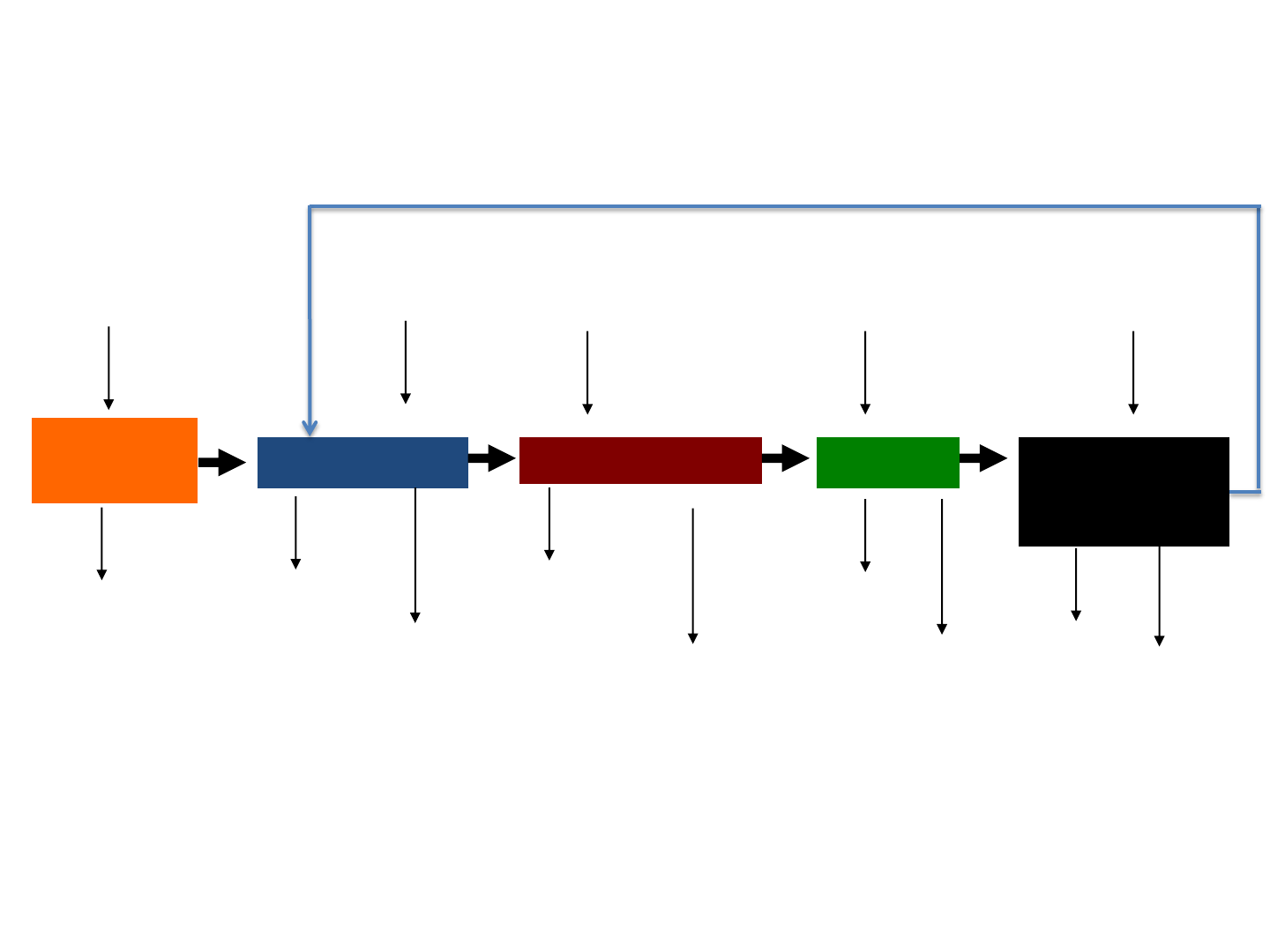

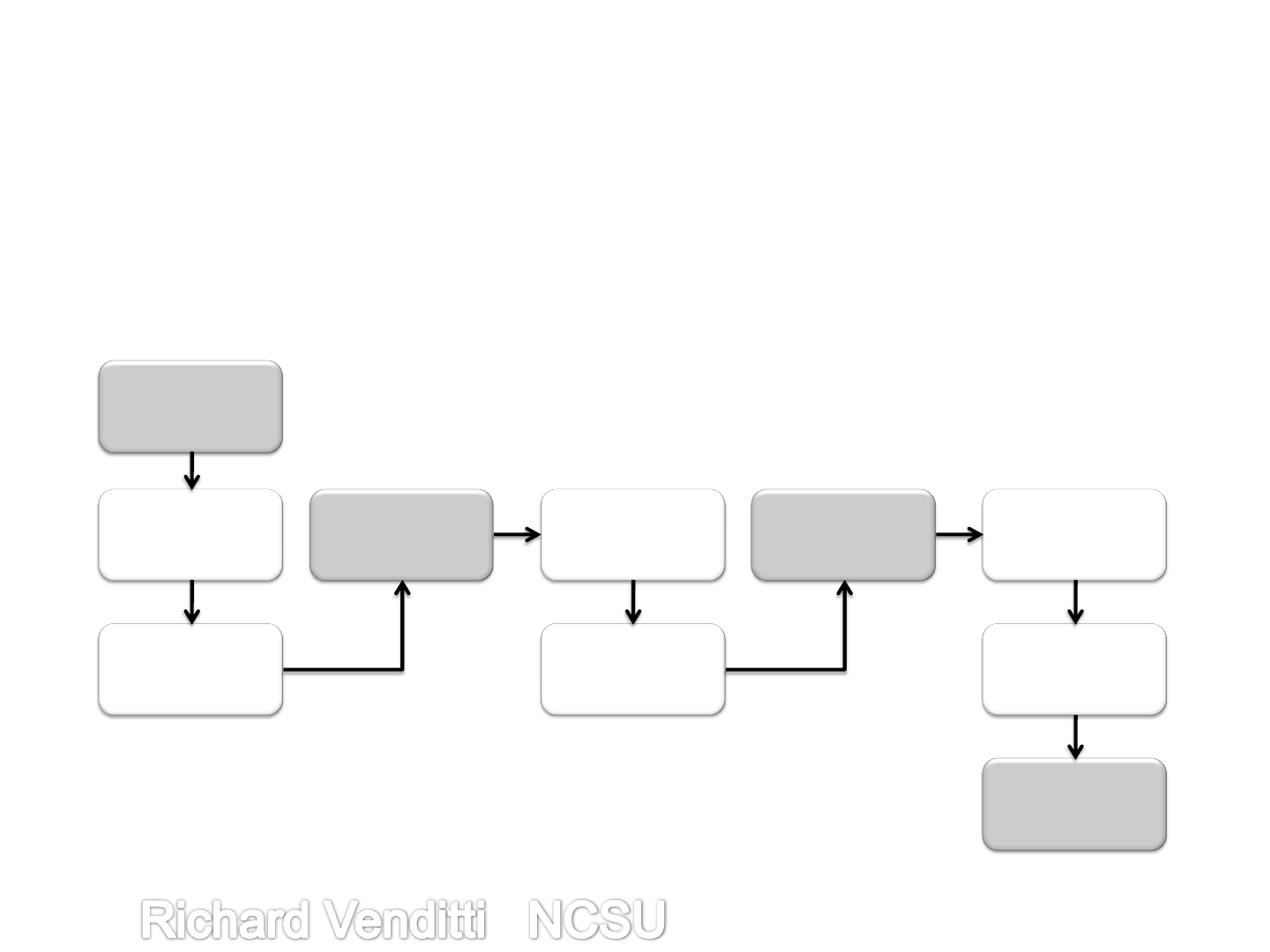

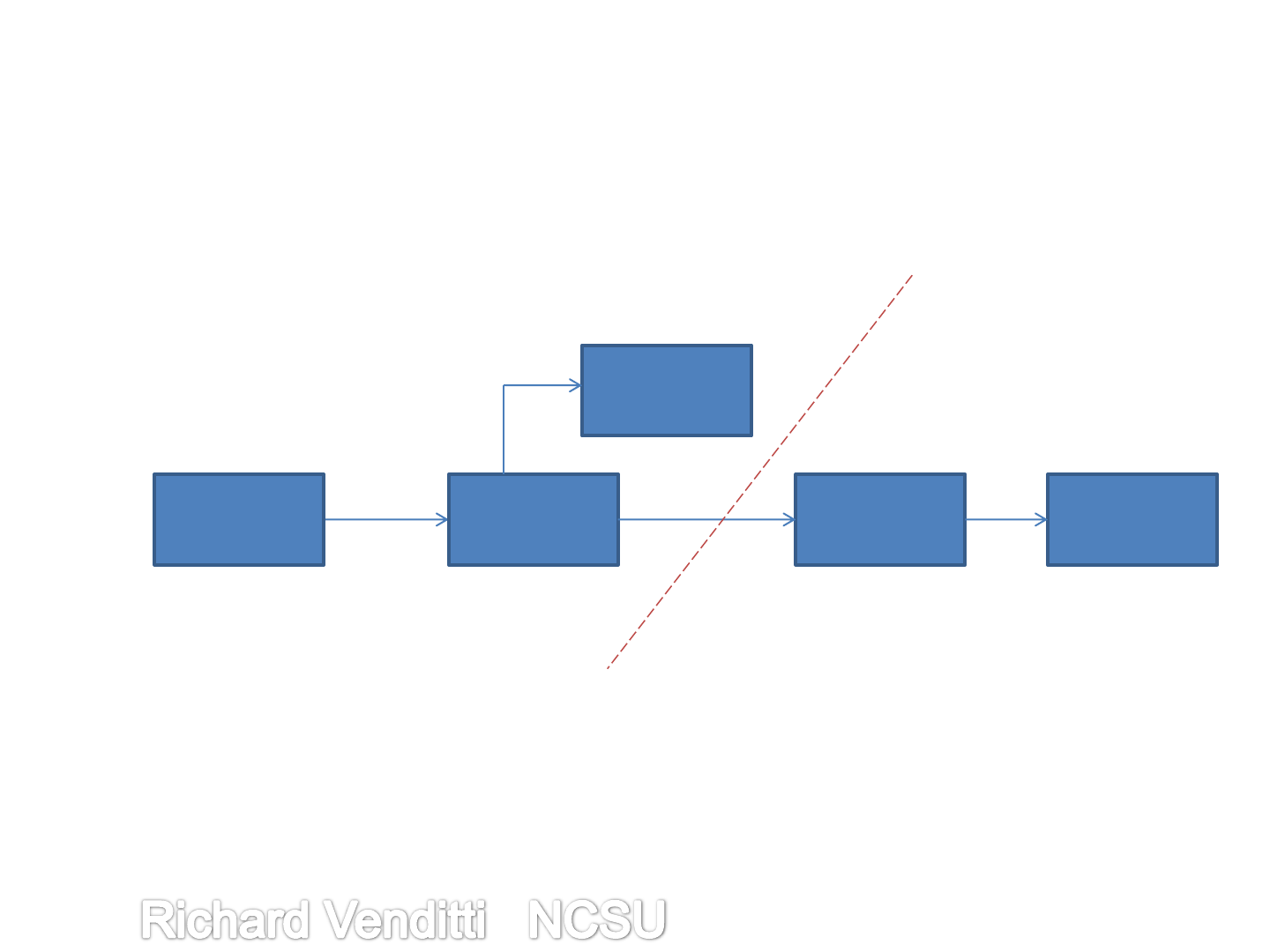

Allocation Methods in LCA:

• Example: virgin paper recycled twice and then

disposed. Closed loop recycling example P1=P2=P3.

47

Primary material

production

(V

1

)

Production of

Product P1

(P

1

)

Use of

Product P1

(U

1

)

Recycling of

Product P1

(R

1

)

Production of

Product P2

(P

2

)

Use of

Product P2

(U

2

)

Recycling of

Product P2

(R

2

)

Production of

Product P3

(P

3

)

Use of

Product P3

(U

3

)

End of life

(W

3

)

Allocation Methods in LCA:

• Example: virgin paper recycled twice and then

disposed. Closed loop recycling example.

48

Raw Matl

Virgin Prod

Collect/transp

Recycle

Process

Collect/transp

Recycle

Process

Waste

Mgmt

V1 P1 R1 P2 R2 P3 W3

Shared

Operation

Potentially

Shared

Operation

Potentially

Shared

Operation

Not Shared

Operation

Potentially

Shared

Operation

Not Shared

Operation

Shared

Operation

CO2e

Lb/ton

product

300 3000 230 3350 230 3350 2500

CO2e

ton/ton

product

.15 1.50 .12 1.68 .12 1.68 1.25

Table 7. Net GHG of office paper from various life cycle stages from the Paper Task Force (2002, pg. 132), waste management is 80/20 landfill/incinerate.

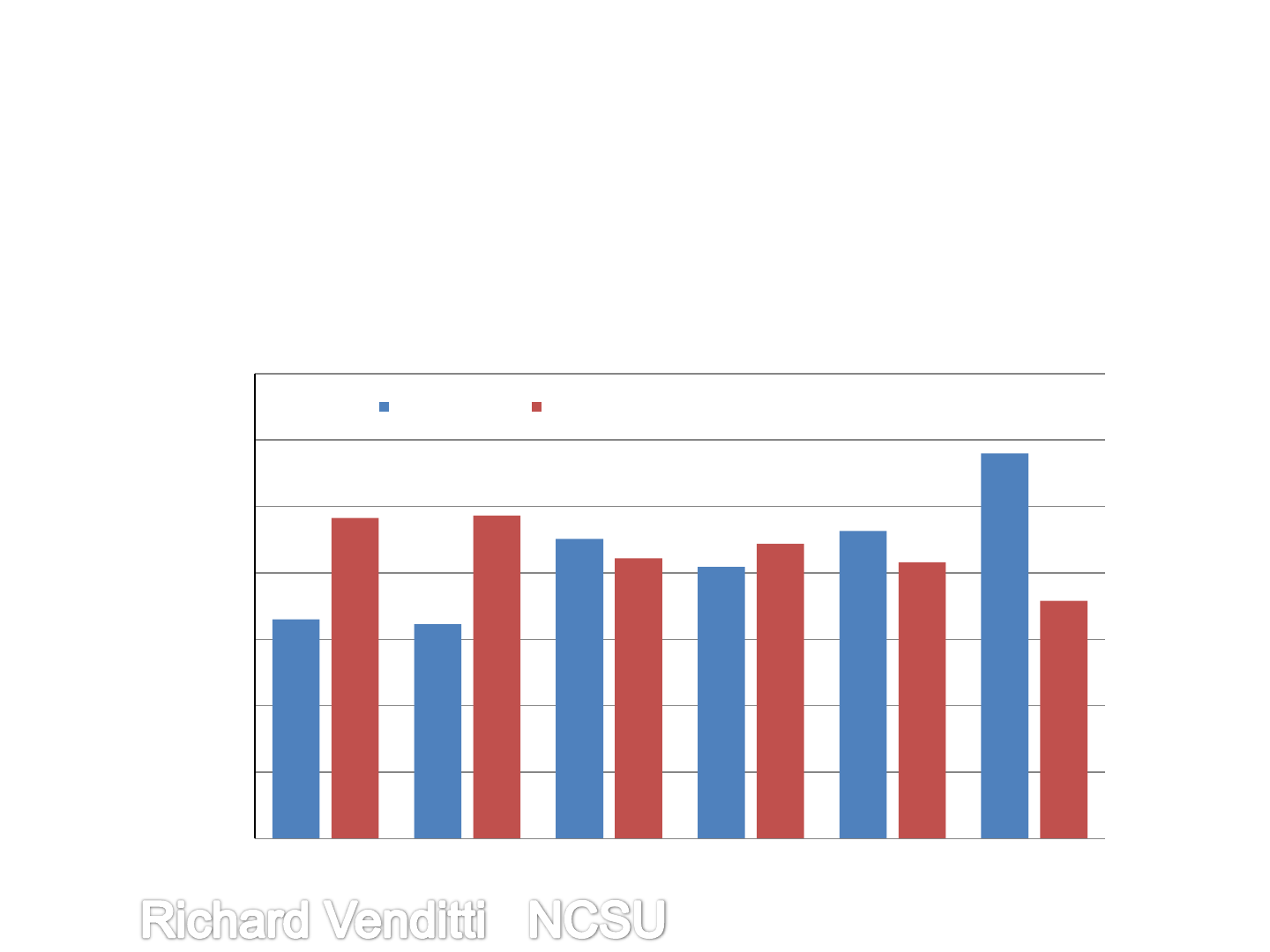

Allocation Methods in LCA:

• Choice of allocation method determines whether

virgin or recycled products are promoted:

49

0

1000

2000

3000

4000

5000

6000

7000

Cutoff MLWMBR 50/50 Closed Loop

Recycling

Quality Loss RMAGWT

Virgin Burden Recycled Burden

Net GHG, lb CO2eq/ton

Paper Task Force

Shared Burden

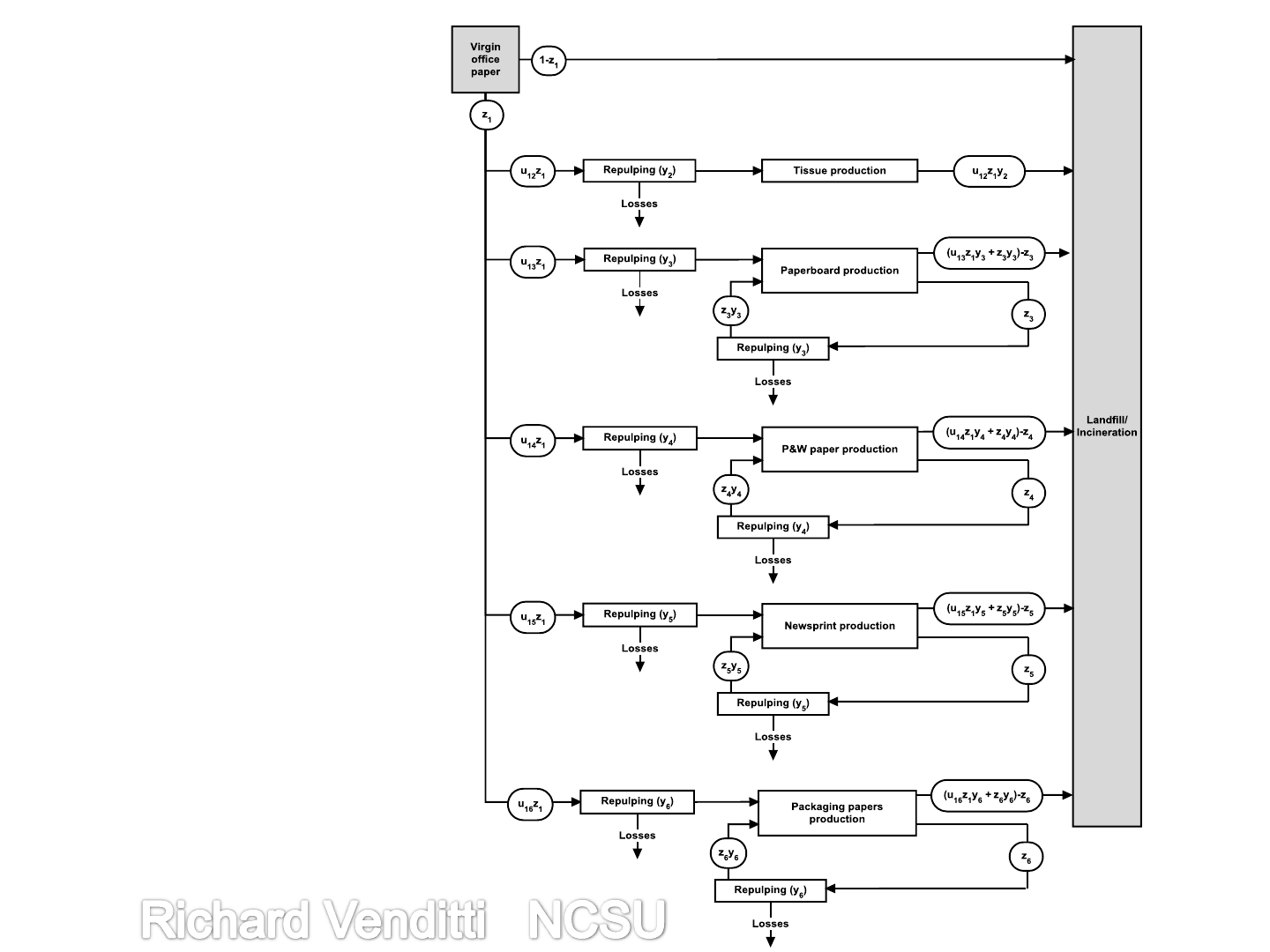

Paper Recycling:

An Open Loop

• Paper products are

recycled into other

products with

different yields upon

recycling, closed

loop recycling not a

good model

50

Allocation Methods in LCA:

• Cut off method: no shared burdens

• Virgin product carries all virgin production burden

• Recycled products aren’t assigned any virgin burdens

• Promotes recycling relative to disposal

• Doesn’t acknowledge the value of recyclable materials

Allocation Methods in LCA:

• Flow sheet of cut off method.

52

GWP =30

Raw

Materials

Disposal

Product 2

Disposal

Product 1

Manuf

Product 2

Manuf.

Product 1

GWP =50

GWP =70 GWP =40

GWP =70

Product 1 Burden = 30 +50 + 70 = 150

Product 2 Burden = 40 + 70 = 110

Cut off Point

Allocation Methods in LCA:

• Number of subsequent uses recycling allocation

method: burdens associated with virgin material

production are shared by all lives of the materials

• Acknowledges benefit to making recyclable materials

Allocation Methods in LCA:

• Number of uses method. Share common burdens.

54

GWP =30

Raw

Materials

Disposal

Product 2

Disposal

Product 1

Manuf

Product 2

Manuf.

Product 1

GWP =50

GWP =70 GWP =40

GWP =70

Product 1 Burden = 30 -15 +50 + 70 = 135

Product 2 Burden = 15 + 40 + 70 = 125

GWP =15

Transferred shared burden

GWP =15

Allocation Methods Comparison:

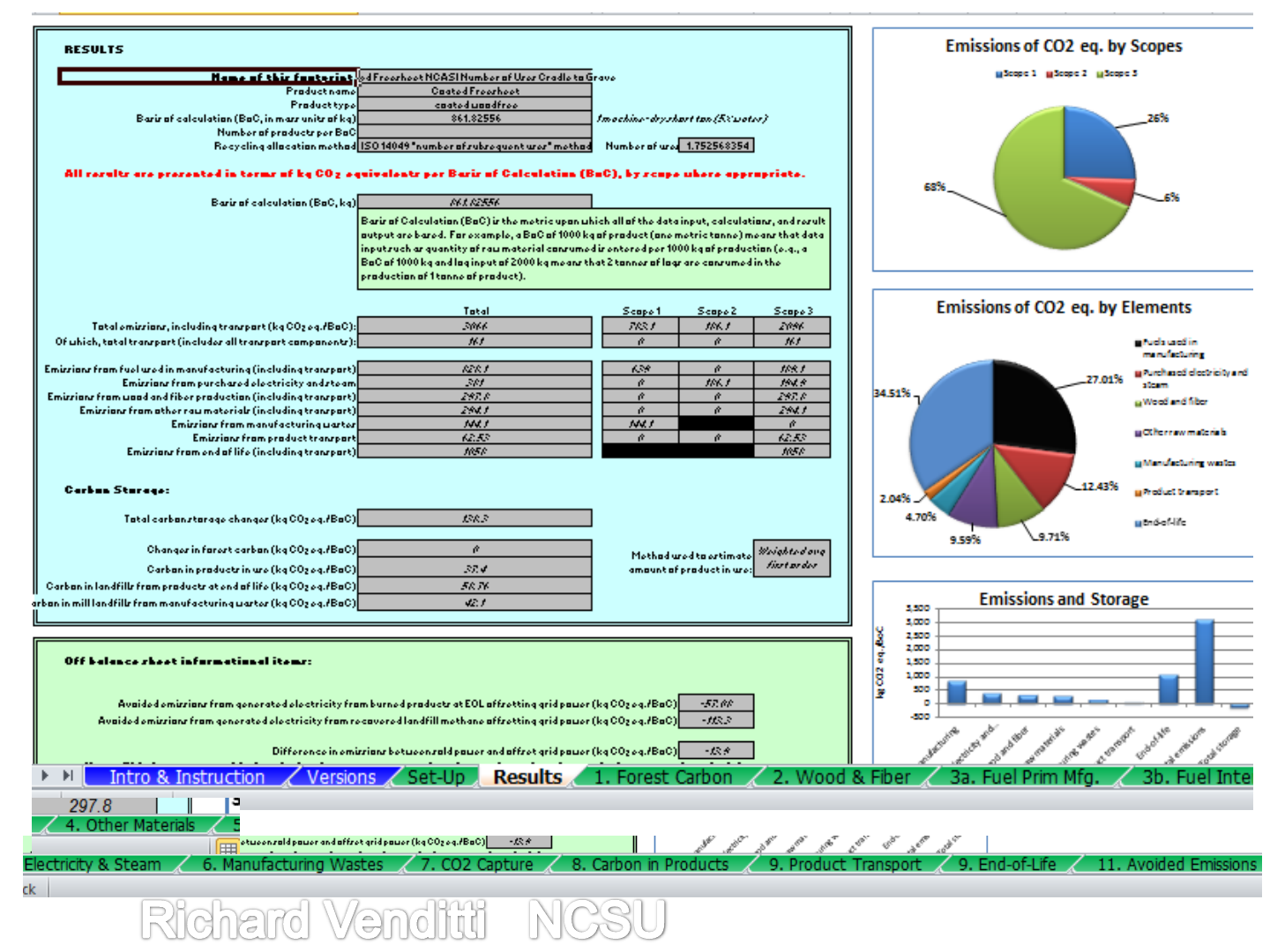

• Used FEFPro carbon footprint tool for paper products

• Determined carbon footprint for both number of uses

and cut off method as a function of

– Recovery rate of product

– Utilization rate of recycled fibers in product

FEFPro:

Allocation Methods Comparison:

• Recovery Rate:

– Increased RR decreases carbon footprint

– Number of uses carbon footprint much less than cutoff

0.000

0.100

0.200

0.300

0.400

0.500

0.600

0.700

0 20 40 60 80 100

Cut off Number of Uses

Recovery Rate (%)

Net GHG, kg CO2eq/kg catalog

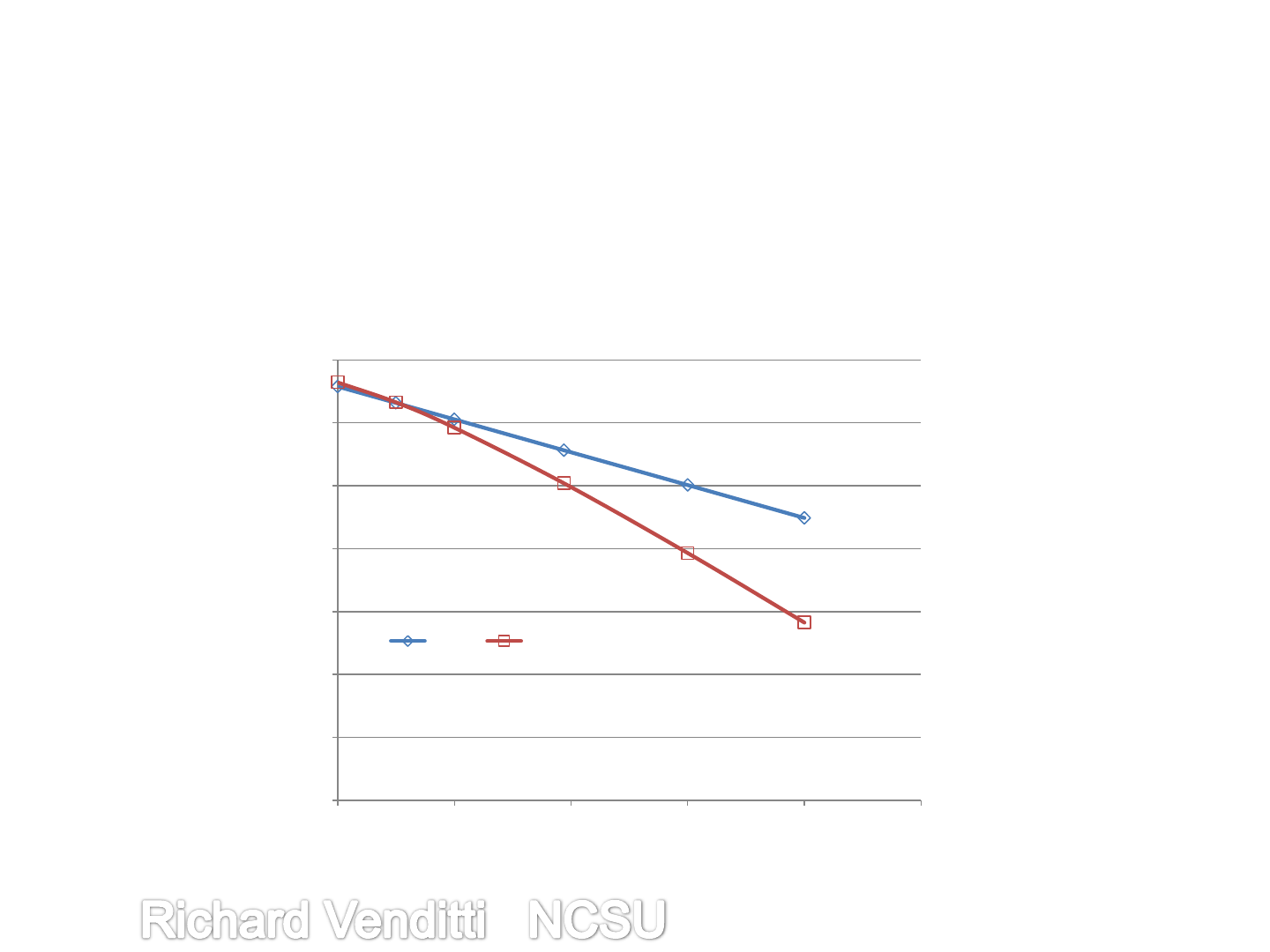

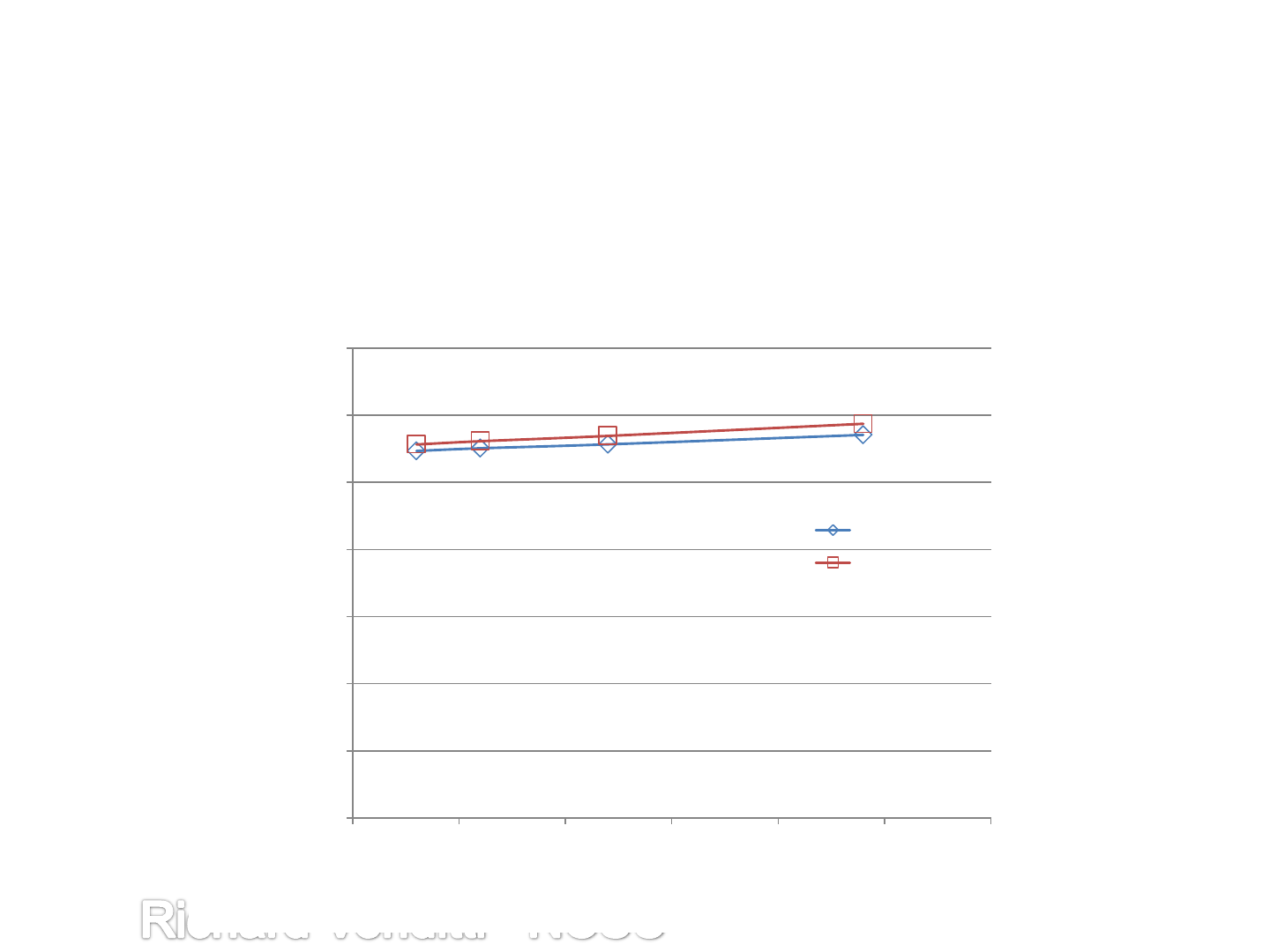

Allocation Methods Comparison:

• Utilization Rate:

– UR does not significantly impact carbon footprint

– Number of uses carbon footprint similar to cutoff

0

0.1

0.2

0.3

0.4

0.5

0.6

0.7

0 5 10 15 20 25 30

Number of Uses

Cut off method

Net GHG, kg CO2eq/kg catalog

Utilization Rate (%)

Outline

• Introduction to LCA

• LCA of Paper

• North American Printing and Writing Grade LCA’s

• Allocation methods in LCA’s

• Recommendations

59

Recommendations:

• The comparisons of different LCA studies can be extremely

difficult.

• The authority and reasonableness of LCA studies are not

consistent.

Recommendations:

• When considering two related products in the same life cycle

such as virgin or recycled materials, the choice of available

allocation methods can determine whether virgin or recycled

material is promoted.

• The number of uses method is an appropriate model for the life

cycle analysis of paper products, which is most reasonably

modeled as an open loop recycling process.

Recommendations:

• As based on data in this paper, the recovery of used paper for

manufacture of new materials or use in incineration to create

energy is more desirable than landfilling.

• With respect to the utilization of recovered paper in specific

products, the data in this paper demonstrate that a blanket

statement that all paper products should maximize use of

recovered paper is not substantiated.

• Increased recycling of paper products and the design of paper

products that are recyclable is environmentally beneficial.

Recommendations:

• Industry average data are useful for an industry to benchmark

its overall performance.

• The use of industrial averages of environmental impacts to

promote a specific paper product relative to other similar paper

products is not reasonable.