Method 1669

Sampling Ambient Water for Trace Metals at EPA Water Quality

Criteria Levels

July 1996

U.S. Environmental Protection Agency

Office of Water

Engineering and Analysis Division (4303)

401 M Street S.W.

Washington, D.C. 20460

Method 1669

Acknowledgements

This sampling method was prepared under the direction of William A. Telliard of the

Engineering and Analysis Division (EAD) within the U.S. Environmental Agency's (EPA's) Office

of Science and Technology (OST). This sampling method was prepared under EPA Contract 68-

C3-0337 by the DynCorp Environmental Programs Division, with assistance from Interface, Inc.

The following researchers contributed to the philosophy behind this sampling method. Their

contribution is gratefully acknowledged:

Shier Berman, National Research Council, Ottawa, Ontario, Canada;

Nicholas Bloom, Frontier Geosciences Inc, Seattle, Washington;

Eric Crecelius, Battelle Marine Sciences Laboratory, Sequim, Washington;

Russell Flegal, University of California/Santa Cruz, California;

Gary Gill, Texas A&M University at Galveston, Texas;

Carlton Hunt and Dion Lewis, Battelle Ocean Sciences, Duxbury, Massachusetts;

Carl Watras, Wisconsin Department of Natural Resources, Boulder Junction, Wisconsin

Additional support was provided by Ted Martin of the EPA Office of Research and

Development's Environmental Monitoring Systems Laboratory in Cincinnati, Ohio and by Arthur

Horowitz of the U.S. Geological Survey.

This version of the method was prepared after observations of sampling teams from the

University of California at Santa Cruz, the Wisconsin Department of Natural Resources, the U.S.

Geological Survey, and Battelle Ocean Sciences. The assistance of personnel demonstrating the

sampling techniques used by these institutions is gratefully acknowledged.

Disclaimer

This sampling method has been reviewed and approved for publication by the Analytical

Methods Staff within the Engineering and Analysis Division of the U.S. Environmental Protection

Agency. Mention of trade names or commercial products does not constitute endorsement or

recommendation for use.

Further Information

For further information, contact:

W.A. Telliard

Engineering and Analysis Division (4303)

U.S. Environmental Protection Agency

401 M Street, SW

Washington, DC 20460

Phone: 202/260–7134

Fax: 202/260–7185

July 1996 ii

Method 1669

Introduction

This sampling method was designed to support water quality monitoring programs authorized

under the Clean Water Act. Section 304(a) of the Clean Water Act requires EPA to publish water

quality criteria that reflect the latest scientific knowledge concerning the physical fate (e.g.,

concentration and dispersal) of pollutants, the effects of pollutants on ecological and human

health, and the effect of pollutants on biological community diversity, productivity, and stability.

Section 303 of the Clean Water Act requires states to set a water quality standard for each body

of water within its boundaries. A state water quality standard consists of a designated use or

uses of a waterbody or a segment of a waterbody, the water quality criteria that are necessary

to protect the designated use or uses, and an antidegradation policy. These water quality

standards serve two purposes: (1) they establish the water quality goals for a specific

waterbody, and (2) they are the basis for establishing water quality-based treatment controls and

strategies beyond the technology-based controls required by Sections 301(b) and 306 of the Clean

Water Act.

In defining water quality standards, the state may use narrative criteria, numeric criteria, or both.

However, the 1987 amendments to the Clean Water Act required states to adopt numeric criteria

for toxic pollutants (designated in Section 307(a) of the Act) based on EPA Section 304(a) criteria

or other scientific data, when the discharge or presence of those toxic pollutants could reasonably

be expected to interfere with designated uses.

In some cases, these water quality criteria are as much as 280 times lower than those achievable

using existing EPA methods and required to support technology-based permits. Therefore, this

sampling method, and the analytical methods referenced in Table 1 of this document, were

developed by EPA to specifically address state needs for measuring toxic metals at water quality

criteria levels, when such measurements are necessary to protect designated uses in state water

quality standards. The latest criteria published by EPA are those listed in the National Toxics

Rule (57 FR 60848) and the Stay of Federal Water Quality Criteria for Metals (60 FR 22228).

These rules include water quality criteria for 13 metals, and it is these criteria on which this

sampling method and the referenced analytical methods are based.

In developing these methods, EPA found that one of the greatest difficulties in measuring

pollutants at these levels was precluding sample contamination during collection, transport, and

analysis. The degree of difficulty, however, is highly dependent on the metal and site-specific

conditions. This method, therefore, is designed to provide the level of protection necessary to

preclude contamination in nearly all situations. It is also designed to provide the procedures

necessary to produce reliable results at the lowest possible water quality criteria published by

EPA. In recognition of the variety of situations to which this method may be applied, and in

recognition of continuing technological advances, the method is performance-based. Alternative

procedures may be used, so long as those procedures are demonstrated to yield reliable results.

Requests for additional copies of this method should be directed to:

U.S. EPA NCEPI

11029 Kenwood Road

Cincinnati, OH 45242

513/489–8190

July 1996 iii

Method 1669

Note: This document is intended as guidance only. Use of the terms "must," "may,"

and "should" are included to mean that EPA believes that these procedures must, may,

or should be followed in order to produce the desired results when using this

guidance. In addition, the guidance is intended to be performance-based, in that the

use of less stringent procedures may be used so long as neither samples nor blanks are

contaminated when following those modified procedures. Because the only way to

measure the performance of the modified procedures is through the collection and

analysis of uncontaminated blank samples in accordance with this guidance and the

referenced methods, it is highly recommended that any modifications be thoroughly

evaluated and demonstrated to be effective before field samples are collected.

July 1996 iv

Method 1669

Sampling Ambient Water for Determination of Metals at EPA Water Quality

Criteria Levels

1.0 Scope and Application

1.1 This method is for the collection and filtration of ambient water samples for subsequent

determination of total and dissolved metals at the levels listed in Table 1. It is designed

to support the implementation of water quality monitoring and permitting programs

administered under the Clean Water Act.

1.2 This method is applicable to the metals listed below and other metals, metals species, and

elements amenable to determination at trace levels.

Chemical Abstract Services

Analyte Symbol Registry Number (CASRN)

Antimony (Sb) 7440-36-0

Arsenic (As) 7440-38-2

Cadmium (Cd) 7440-43-9

Chromium (III) Cr

+3

16065-83-1

Chromium (VI) Cr

+6

18540-29-9

Copper (Cu) 7440-50-8

Lead (Pb) 7439-92-1

Mercury (Hg) 7439-97-6

Nickel (Ni) 7440-02-0

Selenium (Se) 7782-49-2

Silver (Ag) 7440-22-4

Thallium (Tl) 7440-28-0

Zinc (Zn) 7440-66-6

1.3 This method is accompanied by the 1600 series methods listed in Table 1. These methods

include the sample handling, analysis, and quality control procedures necessary for

reliable determination of trace metals in aqueous samples.

1.4 This method is not intended for determination of metals at concentrations normally

found in treated and untreated discharges from industrial facilities. Existing regulations

(40 CFR Parts 400-500) typically limit concentrations in industrial discharges to the mid

to high part-per-billion (ppb) range, whereas ambient metals concentrations are normally

in the low part-per-trillion (ppt) to low ppb range. This guidance is therefore directed

at the collection of samples to be measured at or near the levels listed in Table 1. Actual

concentration ranges to which this guidance is applicable will be dependent on the

sample matrix, dilution levels, and other laboratory operating conditions.

1.5 The ease of contaminating ambient water samples with the metal(s) of interest and

interfering substances cannot be overemphasized. This method includes sampling

techniques that should maximize the ability of the sampling team to collect samples

reliably and eliminate sample contamination. These techniques are given in Section 8.0

and are based on findings of researchers performing trace metals analyses (References 1-

9).

July 1996 1

Method 1669

1.6 Clean and Ultraclean—The terms "clean" and "ultraclean" have been used in other

Agency guidance to describe the techniques needed to reduce or eliminate contamination

in trace metals determinations. These terms are not used in this sampling method due

to a lack of exact definitions. However, the information provided in this method is

consistent with summary guidance on clean and ultraclean techniques (Reference 10).

1.7 This sampling method follows the EPA Environmental Methods Management Council's

"Format for Method Documentation" (Reference 11).

1.8 Method 1669 is "performance-based"; i.e., an alternate sampling procedure or technique

may be used, so long as neither samples nor blanks are contaminated when following the

alternate procedures. Because the only way to measure the performance of the alternate

procedures is through the collection and analysis of uncontaminated blank samples in

accordance with this guidance and the methods referenced in Table 1, it is highly

recommended that any modifications be thoroughly evaluated and demonstrated to be

effective before field samples are collected. Section 9.2 provides additional details on the

tests and documentation required to support equivalent performance.

1.9 For dissolved metal determinations, samples must be filtered through a 0.45 µm capsule

filter at the field site. The filtering procedures are described in this method. The filtered

samples may be preserved in the field or transported to the laboratory for preservation.

Procedures for field preservation are detailed in this sampling method; procedures for

laboratory preservation are provided in the methods referenced in Table 1. Preservation

requirements are summarized in Table 2.

1.10 The procedures in this method are for use only by personnel thoroughly trained in the

collection of samples for determination of metals at ambient water quality control levels.

2.0 Summary of Method

2.1 Before samples are collected, all sampling equipment and sample containers are cleaned

in a laboratory or cleaning facility using detergent, mineral acids, and reagent water as

described in the methods referenced in Table 1. The laboratory or cleaning facility is

responsible for generating an acceptable equipment blank to demonstrate that the

sampling equipment and containers are free from trace metals contamination before they

are shipped to the field sampling team. An acceptable blank is one that is free from

contamination below the minimum level (ML) specified in the referenced analytical

method (Section 9.3).

2.2 After cleaning, sample containers are filled with weak acid solution, individually double-

bagged, and shipped to the sampling site. All sampling equipment is also bagged for

storage or shipment.

NOTE: EPA has found that, in some cases, it may be possible to empty the weak acid solution

from the bottle immediately prior to transport to the field site. In this case, the bottle should be

refilled with reagent water (Section 7.1).

2.3 The laboratory or cleaning facility must prepare a large carboy or other appropriate clean

container filled with reagent water (Section 7.1) for use with collection of field blanks

during sampling activities. The reagent-water-filled container should be shipped to the

field site and handled as all other sample containers and sampling equipment. At least

July 1996 2

Method 1669

one field blank should be processed per site, or one per every ten samples, whichever is

more frequent (Section 9.4). If samples are to be collected for determination of trivalent

chromium, the sampling team processes additional QC aliquots are processed as

described in Section 9.6.

2.4 Upon arrival at the sampling site, one member of the two-person sampling team is

designated as "dirty hands"; the second member is designated as "clean hands." All

operations involving contact with the sample bottle and transfer of the sample from the

sample collection device to the sample bottle are handled by the individual designated

as "clean hands." "Dirty hands" is responsible for preparation of the sampler (except the

sample container itself), operation of any machinery, and for all other activities that do

not involve direct contact with the sample.

2.5 All sampling equipment and sample containers used for metals determinations at or near

the levels listed in Table 1 must be nonmetallic and free from any material that may

contain metals.

2.6 Sampling personnel are required to wear clean, nontalc gloves at all times when handling

sampling equipment and sample containers.

2.7 In addition to processing field blanks at each site, a field duplicate must be collected at

each sampling site, or one field duplicate per every 10 samples, whichever is more

frequent (Section 9.5). Section 9.0 gives a complete description of quality control

requirements.

2.8 Sampling

2.8.1 Whenever possible, samples are collected facing upstream and upwind to

minimize introduction of contamination.

2.8.2 Samples may be collected while working from a boat or while on land.

2.8.3 Surface samples are collected using a grab sampling technique. The principle of

the grab technique is to fill a sample bottle by rapid immersion in water and

capping to minimize exposure to airborne particulate matter.

2.8.4 Subsurface samples are collected by suction of the sample into an immersed

sample bottle or by pumping the sample to the surface.

2.9 Samples for dissolved metals are filtered through a 0.45 µm capsule filter at the field site.

After filtering, the samples are double-bagged and iced immediately. Sample containers

are shipped to the analytical laboratory. The sampling equipment is shipped to the

laboratory or cleaning facility for recleaning.

2.10 Acid preservation of samples is performed in the field or in the laboratory. Field

preservation is necessary for determinations of trivalent chromium. It has also been

shown that field preservation can increase sample holding times for hexavalent

chromium to 30 days; therefore it is recommended that preservation of samples for

hexavalent chromium be performed in the field. For other metals, however, the sampling

team may prefer to utilize laboratory preservation of samples to expedite field operations

and to minimize the potential for sample contamination.

July 1996 3

Method 1669

2.11 Sampling activities must be documented through paper or computerized sample tracking

systems.

3.0 Definitions

3.1 Apparatus—Throughout this method, the sample containers, sampling devices,

instrumentation, and all other materials and devices used in sample collection, sample

processing, and sample analysis activities will be referred to collectively as the

Apparatus.

3.2 Definitions of other terms are given in the Glossary (Section 15.0) at the end of this

method.

4.0 Contamination and Interferences

4.1 Contamination Problems in Trace Metals Analysis

4.1.1 Preventing ambient water samples from becoming contaminated during the

sampling and analytical process is the greatest challenge faced in trace metals

determinations. In recent years, it has been shown that much of the historical

trace metals data collected in ambient water are erroneously high because the

concentrations reflect contamination from sampling and analysis rather than

ambient levels (Reference 12). Therefore, it is imperative that extreme care be

taken to avoid contamination when collecting and analyzing ambient water

samples for trace metals.

4.1.2 There are numerous routes by which samples may become contaminated.

Potential sources of trace metals contamination during sampling include metallic

or metal-containing sampling equipment, containers, labware (e.g. talc gloves that

contain high levels of zinc), reagents, and deionized water; improperly cleaned

and stored equipment, labware, and reagents; and atmospheric inputs such as dirt

and dust from automobile exhaust, cigarette smoke, nearby roads, bridges, wires,

and poles. Even human contact can be a source of trace metals contamination.

For example, it has been demonstrated that dental work (e.g., mercury amalgam

fillings) in the mouths of laboratory personnel can contaminate samples that are

directly exposed to exhalation (Reference 3).

4.2 Contamination Control

4.2.1 Philosophy—The philosophy behind contamination control is to ensure that any

object or substance that contacts the sample is nonmetallic and free from any

material that may contain metals of concern.

4.2.1.1 The integrity of the results produced cannot be compromised by

contamination of samples. Requirements and suggestions for controlling

sample contamination are given in this sampling method and in the

analytical methods referenced in Table 1.

4.2.1.2 Substances in a sample or in the surrounding environment cannot be

allowed to contaminate the Apparatus used to collect samples for trace

metals measurements. Requirements and suggestions for protecting the

July 1996 4

Method 1669

Apparatus are given in this sampling method and in the methods

referenced in Table 1.

4.2.1.3 While contamination control is essential, personnel health and safety

remain the highest priority. Requirements and suggestions for personnel

safety are given in Section 5 of this sampling method and in the methods

referenced in Table 1.

4.2.2 Avoiding contamination—The best way to control contamination is to completely

avoid exposure of the sample and Apparatus to contamination in the first place.

Avoiding exposure means performing operations in an area known to be free

from contamination. Two of the most important factors in avoiding/reducing

sample contamination are (1) an awareness of potential sources of contamination

and (2) strict attention to work being performed. Therefore, it is imperative that

the procedures described in this method be carried out by well trained,

experienced personnel. Documentation of training should be kept on file and

readily available for review.

4.2.2.1 Minimize exposure—The Apparatus that will contact samples or blanks

should only be opened or exposed in a clean room, clean bench, glove

box, or clean plastic bag, so that exposure to atmospheric inputs is

minimized. When not being used, the Apparatus should be covered with

clean plastic wrap, stored in the clean bench or in a plastic box or glove

box, or bagged in clean, colorless zip-type bags. Minimizing the time

between cleaning and use will also reduce contamination.

4.2.2.2 Wear gloves—Sampling personnel must wear clean, nontalc gloves

(Section 6.7) during all operations involving handling of the Apparatus,

samples, and blanks. Only clean gloves may touch the Apparatus. If

another object or substance is touched, the glove(s) must be changed

before again handling the Apparatus. If it is even suspected that gloves

have become contaminated, work must be halted, the contaminated gloves

removed, and a new pair of clean gloves put on. Wearing multiple layers

of clean gloves will allow the old pair to be quickly stripped with minimal

disruption to the work activity.

4.2.2.3 Use metal-free Apparatus—All Apparatus used for metals determinations

at the levels listed in Table 1 must be nonmetallic and free of material that

may contain metals. When it is not possible to obtain equipment that is

completely free of the metal(s) of interest, the sample should not come

into direct contact with the equipment.

4.2.2.3.1 Construction materials—Only the following materials

should come in contact with samples: fluoropolymer (FEP,

PTFE), conventional or linear polyethylene, polycarbonate,

polysulfone, polypropylene, or ultrapure quartz. PTFE is

less desirable than FEP because the sintered material in

PTFE may contain contaminants and is susceptible to

serious memory effects (Reference 6). Fluoropolymer or

glass containers should be used for samples that will be

analyzed for mercury because mercury vapors can diffuse

July 1996 5

Method 1669

in or out of other materials, resulting either in

contamination or low-biased results (Reference 3). Metal

must not be used under any circumstance. Regardless of

construction, all materials that will directly or indirectly

contact the sample must be cleaned using the procedures

described in the referenced analytical methods (see Table 1)

and must be known to be clean and metal-free before

proceeding.

4.2.2.3.2 The following materials have been found to contain trace

metals and must not be used to hold liquids that come in

contact with the sample or must not contact the sample,

unless these materials have been shown to be free of the

metals of interest at the desired level: Pyrex, Kimax,

methacrylate, polyvinylchloride, nylon, and Vycor

(Reference 6). In addition, highly colored plastics, paper

cap liners, pigments used to mark increments on plastics,

and rubber all contain trace levels of metals and must be

avoided (Reference 13).

4.2.2.3.3 Serialization—Serial numbers should be indelibly marked

or etched on each piece of Apparatus so that contamination

can be traced, and logbooks should be maintained to track

the sample from the container through the sampling

process to shipment to the laboratory. Chain-of-custody

procedures may also be used if warranted so that

contamination can be traced to particular handling

procedures or lab personnel.

4.2.2.3.4 The Apparatus should be clean when the sampling team

receives it. If there are any indications that the Apparatus

is not clean (e.g., a ripped storage bag), an assessment of

the likelihood of contamination must be made. Sampling

must not proceed if it is possible that the Apparatus is

contaminated. If the Apparatus is contaminated, it must be

returned to the laboratory or cleaning facility for proper

cleaning before any sampling activity resumes.

4.2.2.3.5 Details for recleaning the Apparatus between collection of

individual samples are provided in Section 10.0.

4.2.2.4 Avoid sources of contamination—Avoid contamination by being aware of

potential sources and routes of contamination.

4.2.2.4.1 Contamination by carryover—Contamination may occur

when a sample containing low concentrations of metals is

processed immediately after a sample containing relatively

high concentrations of these metals. At sites where more

than one sample will be collected, the sample known or

expected to contain the lowest concentration of metals

should be collected first with the sample containing the

July 1996 6

Method 1669

highest levels collected last (Section 8.1.4). This will help

minimize carryover of metals from high- concentration

samples to low- concentration samples. If the sampling

team does not have prior knowledge of the waterbody, or

when necessary, the sample collection system should be

rinsed with dilute acid and reagent water between samples

and followed by collection of a field blank (Section 10.3).

4.2.2.4.2 Contamination by samples—Significant contamination of

the Apparatus may result when untreated effluents, in-

process waters, landfill leachates, and other samples

containing mid- to high-level concentrations of inorganic

substances are processed. As stated in Section 1.0, this

sampling method is not intended for application to these

samples, and samples containing high concentrations of

metals must not be collected, processed, or shipped at the

same time as samples being collected for trace metals

determinations.

4.2.2.4.3 Contamination by indirect contact—Apparatus that may

not directly contact samples may still be a source of

contamination. For example, clean tubing placed in a dirty

plastic bag may pick up contamination from the bag and

subsequently transfer the contamination to the sample.

Therefore, it is imperative that every piece of the Apparatus

that is directly or indirectly used in the collection of

ambient water samples be cleaned as specified in the

analytical method(s) referenced in Table 1.

4.2.2.4.4 Contamination by airborne particulate matter—Less

obvious substances capable of contaminating samples

include airborne particles. Samples may be contaminated

by airborne dust, dirt, particulate matter, or vapors from

automobile exhaust; cigarette smoke; nearby corroded or

rusted bridges, pipes, poles, or wires; nearby roads; and

even human breath (Section 4.1.2). Whenever possible, the

sampling activity should occur as far as possible from

sources of airborne contamination (Section 8.1.3). Areas

where nearby soil is bare and subject to wind erosion

should be avoided.

4.3 Interferences—Interferences resulting from samples will vary considerably from source

to source, depending on the diversity of the site being sampled. If a sample is suspected

of containing substances that may interfere in the determination of trace metals, sufficient

sample should be collected to allow the laboratory to identify and overcome interference

problems.

5.0 Safety

5.1 The toxicity or carcinogenicity of the chemicals used in this method has not been

precisely determined; however, these chemicals should be treated as a potential health

July 1996 7

Method 1669

hazard. Exposure should be reduced to the lowest possible level. Sampling teams are

responsible for maintaining a current awareness file of OSHA regulations for the safe

handling of the chemicals specified in this method. A reference file of Material Safety

Data Sheets should also be made available to all personnel involved in sampling. It is

also suggested that the organization responsible perform personal hygiene monitoring

of each sampling team member who uses this method and that the results of this

monitoring be made available to the member.

5.2 Operating in and around waterbodies carries the inherent risk of drowning. Life jackets

must be worn when operating from a boat, when sampling in more than a few feet of

water, or when sampling in swift currents.

5.3 Collecting samples in cold weather, especially around cold water bodies, carries the risk

of hypothermia, and collecting samples in extremely hot and humid weather carries the

risk of dehydration and heat stroke. Sampling team members should wear adequate

clothing for protection in cold weather and should carry an adequate supply of water or

other liquids for protection against dehydration in hot weather.

6.0 Apparatus and Materials

NOTE: Brand names, suppliers, and part numbers are for illustration only and no endorsement is

implied. Equivalent performance may be achieved using apparatus and materials other than those specified

here. Meeting the performance requirements of this method is the responsibility of the sampling team and

laboratory.

6.1 All sampling equipment and sample containers must be precleaned in a laboratory or

cleaning facility, as described in the methods referenced in Table 1, before they are

shipped to the field site. Performance criteria for equipment cleaning is described in the

referenced methods. To minimize difficulties in sampling, the equipment should be

packaged and arranged to minimize field preparation.

6.2 Materials such as gloves (Section 6.7), storage bags (Section 6.8), and plastic wrap (Section

6.9), may be used new without additional cleaning unless the results of the equipment

blank pinpoint any of these materials as a source of contamination. In this case, either

a different supplier must be obtained or the materials must be cleaned.

6.3 Sample Bottles—Fluoropolymer (FEP, PTFE), conventional or linear polyethylene,

polycarbonate, or polypropylene; 500 mL or 1 L with lids. If mercury is a target analyte,

fluoropolymer or glass bottles should be used. Refer to the methods referenced in Table

1 for bottle cleaning procedures.

6.3.1 Cleaned sample bottles should be filled with 0.1% HCl (v/v). In some cases, it

may be possible to empty the weak acid solution from the sample bottle

immediately prior to transport to the field site. In this case, the bottle should be

refilled with reagent water (Section 7.1).

6.3.2 Whenever possible, sampling devices should be cleaned and prepared for field

use in a class 100 clean room. Preparation of the devices in the field should be

done within the glove bag (Section 6.6). Regardless of design, sampling devices

must be constructed of nonmetallic material (Section 4.2.2.3.1) and free from

material that contains metals. Fluoropolymer or other material shown not to

July 1996 8

Method 1669

adsorb or contribute mercury must be used if mercury is a target analyte;

otherwise, polyethylene, polycarbonate, or polypropylene are acceptable.

Commercially available sampling devices may be used provided that any metallic

or metal-containing parts are replaced with parts constructed of nonmetallic

material.

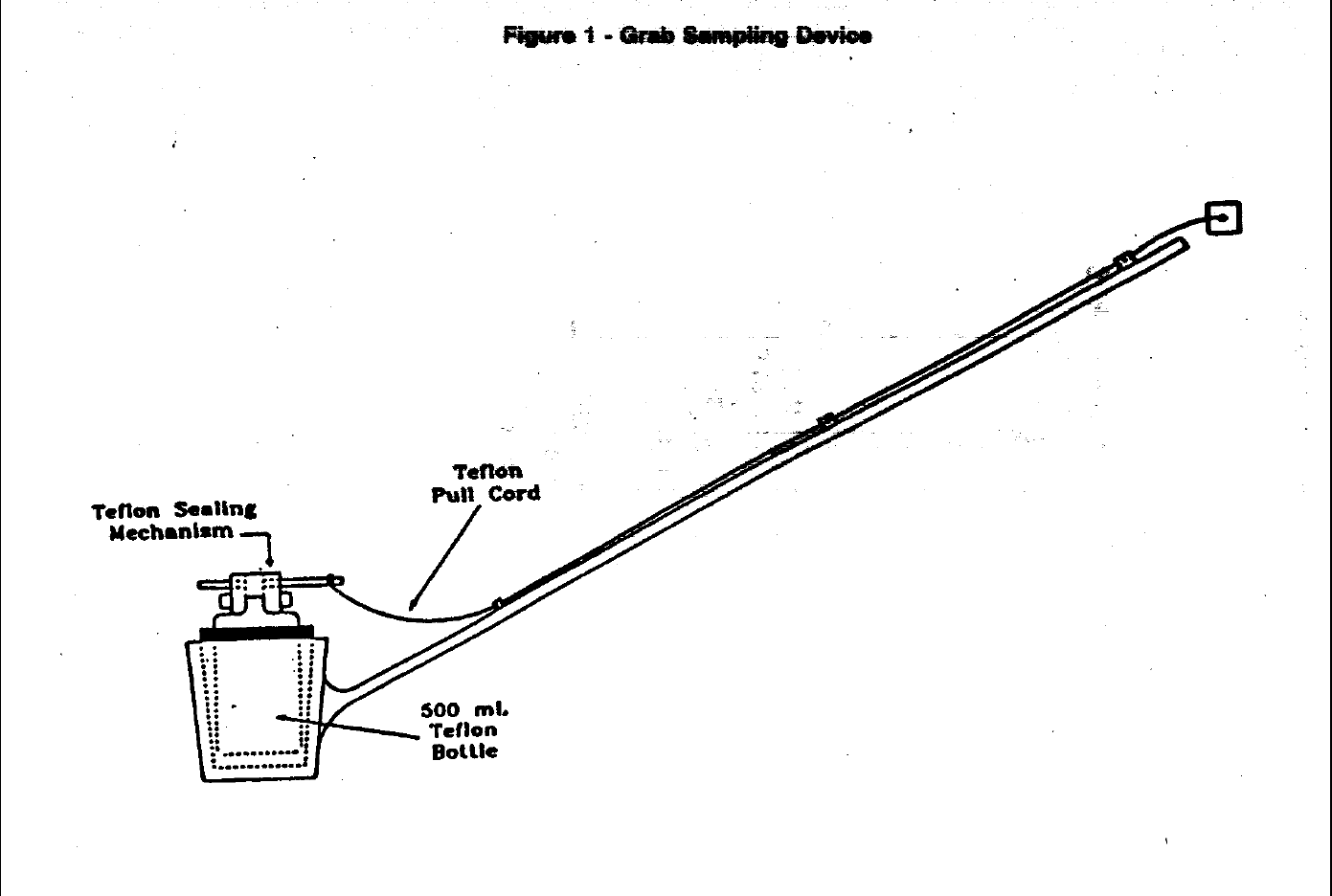

6.4 Surface Sampling Devices—Surface samples are collected using a grab sampling

technique. Samples may be collected manually by direct submersion of the bottle into

the water or by using a grab sampling device. Examples of grab samplers are shown in

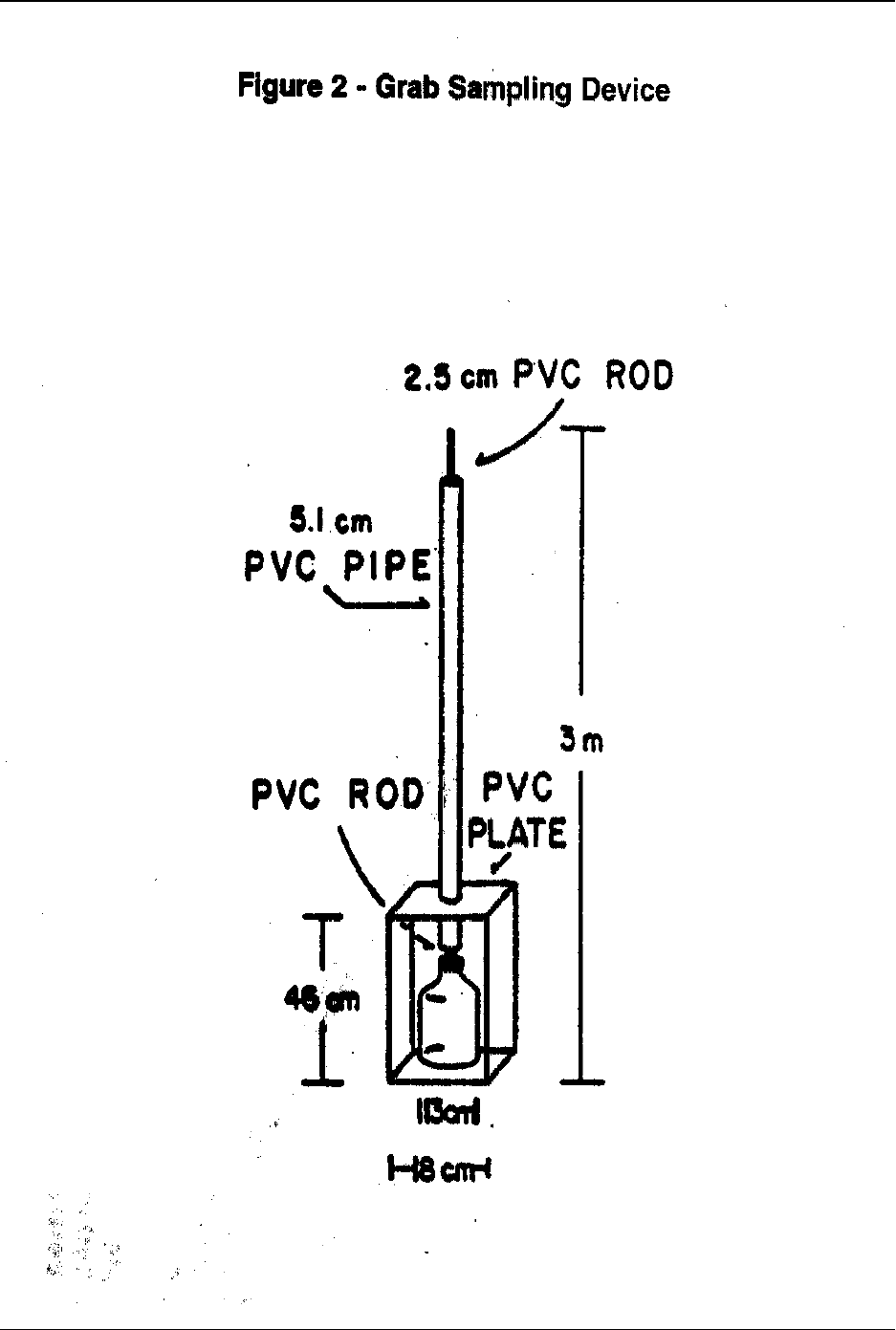

Figures 1 and 2 and may be used at sites where depth profiling is neither practical nor

necessary.

6.4.1 The grab sampler in Figure 1 consists of a heavy fluoropolymer collar fastened

to the end of a 2-m-long polyethylene pole, which serves to remove the sampling

personnel from the immediate vicinity of the sampling point. The collar holds the

sample bottle. A fluoropolymer closing mechanism, threaded onto the bottle,

enables the sampler to open and close the bottle under water, thereby avoiding

surface microlayer contamination (Reference 14). Polyethylene, polycarbonate,

and polypropylene are also acceptable construction materials unless mercury is

a target analyte. Assembly of the cleaned sampling device is as follows (refer to

Figure 1):

6.4.1.1 Thread the pull cord (with the closing mechanism attached) through the

guides and secure the pull ring with a simple knot. Screw a sample bottle

onto the closing device and insert the bottle into the collar. Cock the

closing plate so that the plate is pushed away from the operator.

6.4.1.2 The cleaned and assembled sampling device should be stored in a double

layer of large, clean zip-type polyethylene bags or wrapped in two layers

of clean polyethylene wrap if it will not be used immediately.

6.4.2 An alternate grab sampler design is shown in Figure 2. This grab sampler is used

for discrete water samples and is constructed so that a capped clean bottle can be

submerged, the cap removed, sample collected, and bottle recapped at a selected

depth. This device eliminates sample contact with conventional samplers (e.g.,

Niskin bottles), thereby reducing the risk of extraneous contamination. Because

a fresh bottle is used for each sample, carryover from previous samples is

eliminated (Reference 15).

6.5 Subsurface Sampling Devices—Subsurface sample collection may be appropriate in lakes

and sluggish deep river environments or where depth profiling is determined to be

necessary. Subsurface samples are collected by pumping the sample into a sample bottle.

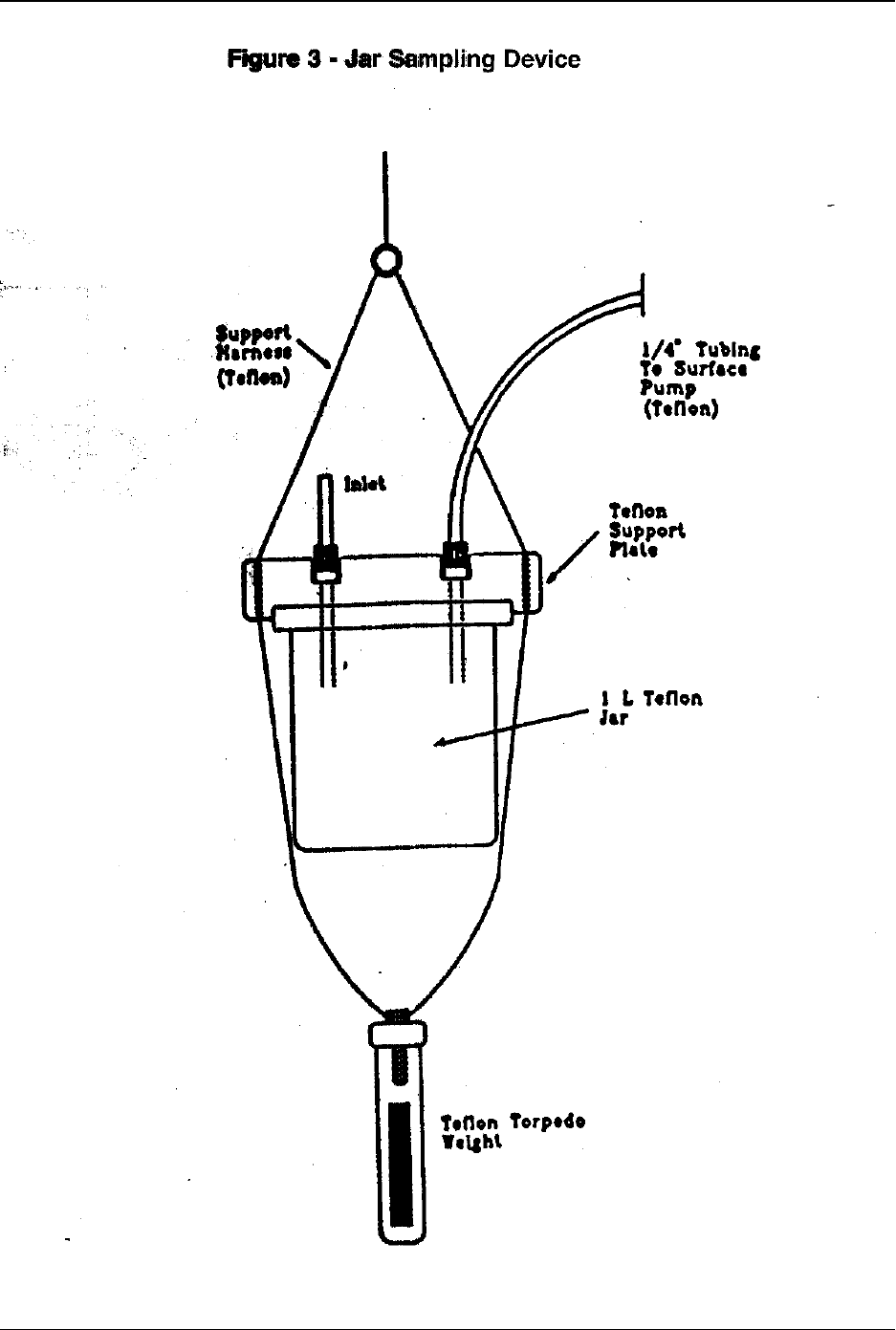

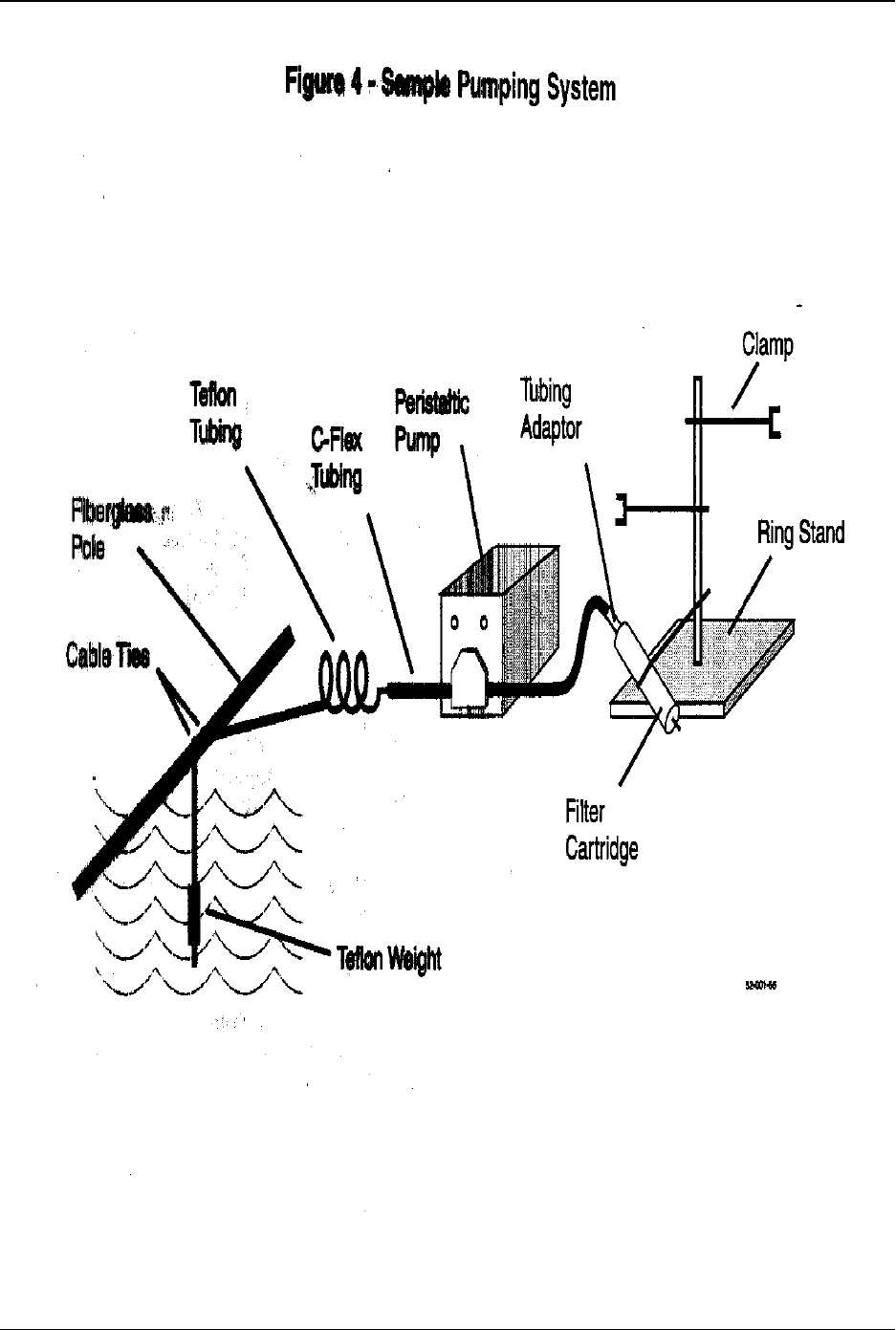

Examples of subsurface collection systems include the jar system device shown in Figure

3 and described in Section 6.5.1 or the continuous-flow apparatus shown in Figure 4 and

described in Section 6.5.2.

6.5.1 Jar sampler (Reference 14)—The jar sampler (Figure 3) is comprised of a heavy

fluoropolymer 1-L jar with a fluoropolymer lid equipped with two 1/4 in.

fluoropolymer fittings. Sample enters the jar through a short length of

fluoropolymer tubing inserted into one fitting. Sample is pulled into the jar by

pumping on fluoropolymer tubing attached to the other fitting. A thick

July 1996 9

Method 1669

fluoropolymer plate supports the jar and provides attachment points for a

fluoropolymer safety line and fluoropolymer torpedo counterweight.

6.5.1.1 Advantages of the jar sampler for depth sampling are (1) all wetted

surfaces are fluoropolymer and can be rigorously cleaned; (2) the sample

is collected into a sample jar from which the sample is readily recovered,

and the jar can be easily recleaned; (3) the suction device (a peristaltic or

rotary vacuum pump, Section 6.15) is located in the boat, isolated from the

sampling jar; (4) the sampling jar can be continuously flushed with

sample, at sampling depth, to equilibrate the system; and (5) the sample

does not travel through long lengths of tubing that are more difficult to

clean and keep clean (Reference 14). In addition, the device is designed

to eliminate atmospheric contact with the sample during collection.

6.5.1.2 To assemble the cleaned jar sampler, screw the torpedo weight onto the

machined bolt attached to the support plate of the jar sampler. Attach a

section of the 1/4 in. o.d. tubing to the jar by inserting the tubing into the

fitting on the lid and pushing down into the jar until approximately 8 cm

from the bottom. Tighten the fitting nut securely. Attach the solid safety

line to the jar sampler using a bowline knot to the loop affixed to the

support plate.

6.5.1.3 For the tubing connecting the pump to the sampler, tubing lengths of up

to 12 m have been used successfully (Reference 14).

6.5.2 Continuous-flow sampler (References 16-17)—This sampling system, shown in

Figure 4, consists of a peristaltic or submersible pump and one or more lengths

of precleaned fluoropolymer or styrene/ethylene/butylene/ silicone (SEBS)

tubing. A filter is added to the sampling train when sampling for dissolved

metals.

6.5.2.1 Advantages of this sampling system include (1) all wetted surfaces are

fluoropolymer or SEBS and can be readily cleaned; (2) the suction device

is located in the boat, isolated from the sample bottle; (3) the sample does

not travel through long lengths of tubing that are difficult to clean and

keep clean; and (4) in-line filtration is possible, minimizing field handling

requirements for dissolved metals samples.

6.5.2.2 The sampling team assembles the system in the field as described in

Section 8.2.8. System components include an optional polyethylene pole

to remove sampling personnel from the immediate vicinity of the

sampling point and the pump, tubing, filter, and filter holder listed in

Sections 6.14 and 6.15.

6.6 Field-Portable Glove Bag—I2R, Model R-37-37H (nontalc), or equivalent. Alternately, a

portable glove box may be constructed with a nonmetallic (PVC pipe or other suitable

material) frame and a frame cover made of an inexpensive, disposable, nonmetallic

material (e.g., a thin-walled polyethylene bag) (Reference 7).

10 July 1996

Method 1669

6.7 Gloves—Clean, nontalc polyethylene, latex, vinyl, or PVC; various lengths. Shoulder-

length gloves are needed if samples are to be collected by direct submersion of the

sample bottle into the water or when sampling for mercury.

6.7.1 Gloves, shoulder-length polyethylene—Associated Bag Co., Milwaukee, WI, 66-3-

301, or equivalent.

6.7.2 Gloves, PVC—Fisher Scientific Part No. 11-394-100B, or equivalent.

6.8 Storage Bags—Clean, zip-type, nonvented, colorless polyethylene (various sizes).

6.9 Plastic Wrap—Clean, colorless polyethylene.

6.10 Cooler—Clean, nonmetallic, with white interior for shipping samples.

6.11 Ice or Chemical Refrigerant Packs—To keep samples chilled in the cooler during

shipment.

6.12 Wind Suit—Pamida, or equivalent.

NOTE: This equipment is necessary only for collection of metals, such as mercury, that are known to

have elevated atmospheric concentrations.

6.12.1 An unlined, long-sleeved wind suit consisting of pants and jacket and constructed

of nylon or other synthetic fiber is worn when sampling for mercury to prevent

mercury adsorbed onto cotton or other clothing materials from contaminating

samples.

6.12.2 Washing and drying—The wind suit is washed by itself or with other wind suits

only in a home or commercial washing machine and dried in a clothes dryer. The

clothes dryer must be thoroughly vacuumed, including the lint filter, to remove

all traces of lint before drying. After drying, the wind suit is folded and stored

in a clean polyethylene bag for shipment to the sample site.

6.13 Boat

6.13.1 For most situations (e.g., most metals under most conditions), the use of an

existing, available boat is acceptable. A flat-bottom, Boston Whaler-type boat is

preferred because sampling materials can be stored with reduced chance of

tipping.

6.13.1.1 Immediately before use, the boat should be washed with water

from the sampling site away from any sampling points to remove

any dust or dirt accumulation.

6.13.1.2 Samples should be collected upstream of boat movement.

6.13.2 For mercury, and for situations in which the presence of contaminants cannot

otherwise be controlled below detectable levels, the following equipment and

precautions may be necessary:

July 1996 11

Method 1669

6.13.2.1 A metal-free (e.g., fiberglass) boat, along with wooden or fiberglass

oars. Gasoline- or diesel-fueled boat motors should be avoided

when possible because the exhaust can be a source of

contamination. If the body of water is large enough to require use

of a boat motor, the engine should be shut off at a distance far

enough from the sampling point to avoid contamination, and the

sampling team should manually propel the boat to the sampling

point. Samples should be collected upstream of boat movement.

6.13.2.2 Before first use, the boat should be cleaned and stored in an area

that minimizes exposure to dust and atmospheric particles. For

example, cleaned boats should not be stored in an area that would

allow exposure to automobile exhaust or industrial pollution.

6.13.2.3 The boat should be frequently visually inspected for possible

contamination.

6.13.2.4 After sampling, the boat should be returned to the laboratory or

cleaning facility, cleaned as necessary, and stored away from any

sources of contamination until next use.

6.14 Filtration Apparatus—Required when collecting samples for dissolved metals

determinations.

6.14.1 Filter—0.45 µm, 15 mm diameter or larger, tortuous-path capsule filters (Reference

18), Gelman Supor 12175, or equivalent.

6.14.2 Filter holder—For mounting filter to the gunwale of the boat. Rod or pipe made

from plastic material and mounted with plastic clamps.

NOTE: A filter holder may not be required if one or a few samples are to be collected. For these cases,

it may only be necessary to attach the filter to the outlet of the tubing connected to the pump.

6.15 Pump and Pump Apparatus—Required for use with the jar sampling system

(Section 6.5.1) or the continuous-flow system (Section 6.5.2). Peristaltic pump; 115 V a.c.,

12 V d.c., internal battery, variable-speed, single-head, Cole-Parmer, portable, "Masterflex

L/S," Catalog No. H-07570-10 drive with Quick Load pump head, Catalog No. H-07021-

24, or equivalent.

NOTE: Equivalent pumps may include rotary vacuum, submersible, or other pumps free from metals and

suitable to meet the site-specific depth sampling needs.

6.15.1 Cleaning—Peristaltic pump modules do not require cleaning. However, nearly

all peristaltic pumps contain a metal head and metal controls. Touching the head

or controls necessitates changing of gloves before touching the Apparatus. If a

submersible pump is used, a large volume of sample should be pumped to clean

the stainless steel shaft (hidden behind the impeller) that comes in contact with

the sample. Pumps with metal impellers should not be used.

12 July 1996

Method 1669

6.15.2 Tubing—For use with peristaltic pump. SEBS resin, approximately 3/8 in. i.d. by

approximately 3 ft, Cole-Parmer size 18, Cat. No. G-06464-18, or approximately

1/4 in. i.d., Cole-Parmer size 17, Catalog No. G-06464-17, or equivalent. Tubing

is cleaned by soaking in 5-10% HCl solution for 8-24 hours, rinsing with reagent

water in a clean bench in a clean room, and drying in the clean bench by purging

with mercury-free air or nitrogen. After drying, the tubing is double-bagged in

clear polyethylene bags, serialized with a unique number, and stored until use.

6.15.3 Tubing—For connection to peristaltic pump tubing. Fluoropolymer, 3/8 or

1/4 in. o.d., in lengths as required to reach the point of sampling. If sampling

will be at some depth from the end of a boom extended from a boat, sufficient

tubing to extend to the end of the boom and to the depth will be required.

Cleaning of the fluoropolymer can be the same as cleaning the tubing for the

rotary vacuum pump (Section 6.15.1.2). If necessary, more aggressive cleaning

(e.g., concentrated nitric acid) may be used.

6.15.4 Batteries to operate submersible pump—12 V, 2.6 amp, gel cell, YUASA NP2.6-12,

or equivalent. A 2 amp fuse connected at the positive battery terminal is strongly

recommended to prevent short circuits from overheating the battery. A 12 V,

lead-acid automobile or marine battery may be more suitable for extensive

pumping.

6.15.5 Tubing connectors—Appropriately sized PVC, clear polyethylene, or

fluoropolymer "barbed" straight connectors cleaned as the tubing above. Used to

connect multiple lengths of tubing.

6.16 Carboy—For collection and storage of dilute waste acids used to store bottles.

6.17 Apparatus—For field preservation of aliquots for trivalent chromium determinations.

6.17.1 Fluoropolymer forceps—1 L fluoropolymer jar, and 30 mL fluoropolymer vials

with screw-caps (one vial per sample and blank). It is recommended that 1 mL

of ultrapure nitric acid (Section 7.3) be added to each vial prior to transport to the

field to simplify field handling activities (See Section 8.4.4.6).

6.17.2 Filters—0.4 µm, 47 mm polycarbonate Nuclepore (or equivalent). Filters are

cleaned as follows. Fill a 1 L fluoropolymer jar approximately two-thirds full

with 1 N nitric acid. Using fluoropolymer forceps, place individual filters in the

fluoropolymer jar. Allow the filters to soak for 48 hours. Discard the acid, and

rinse five times with reagent water. Fill the jar with reagent water, and soak the

filters for 24 hours. Remove the filters when ready for use, and using

fluoropolymer forceps, place them on the filter apparatus (Section 6.17.3).

6.17.3 Vacuum filtration apparatus—Millipore 47 mm size, or equivalent, vacuum pump

and power source (and extension cords, if necessary) to operate the pump.

6.17.4 Eppendorf auto pipet and colorless pipet tips (100-1000 µL)

6.17.5 Wrist-action shaker—Burrel or equivalent.

July 1996 13

Method 1669

6.17.6 Fluoropolymer wash bottles—One filled with reagent water (Section 7.1) and one

filled with high- purity 10% HCl (Section 7.4.4), for use in rinsing forceps and

pipet tips.

7.0 Reagents and Standards

7.1 Reagent Water—Water in which the analytes of interest and potentially interfering

substances are not detected at the Method Detection Limit (MDL) of the analytical

method used for analysis of samples. Prepared by distillation, deionization, reverse

osmosis, anodic/cathodic stripping voltammetry, or other techniques that remove the

metal(s) and potential interferent(s). A large carboy or other appropriate container filled

with reagent water must be available for the collection of field blanks.

7.2 Nitric Acid—Dilute, trace-metal grade, shipped with sampling kit for cleaning equipment

between samples.

7.3 Sodium Hydroxide—Concentrated, 50% solution for use when field-preserving samples

for hexavalent chromium determinations (Section 8.4.5).

7.4 Reagents—For field-processing aliquots for trivalent chromium determinations

7.4.1 Nitric Acid, Ultrapure—For use when field-preserving samples for trivalent

chromium determinations (Sections 6.17 and 8.4.4).

7.4.2 Ammonium Iron (II) Sulfate Solution (0.01M)—Used to prepare the chromium

(III) extraction solution (Section 7.4.3) necessary for field preservation of samples

for trivalent chromium (Section 8.4.4). Prepare the ammonium iron (II) sulfate

solution by adding 3.92 g ammonium iron (II) sulfate (ultrapure grade) to a 1 L

volumetric flask. Bring to volume with reagent water. Store in a clean

polyethylene bottle.

7.4.3 Chromium (III) extraction solution—For use when field-preserving samples for

trivalent chromium determinations (Section 8.4.4). Prepare this solution by

adding 100 mL of ammonium iron (II) sulfate solution (Section 7.4.2) to a 125 mL

polyethylene bottle. Adjust pH to 8 with approximately 2 mL of ammonium

hydroxide solution. Cap and shake on a wrist-action shaker for 24 hours. This

iron (III) hydroxide solution is stable for 30 days.

7.4.4 Hydrochloric acid—High-purity, 10% solution, shipped with sampling kit in

fluoropolymer wash bottles for cleaning trivalent chromium sample preservation

equipment between samples.

7.4.5 Chromium stock standard solution (1000 µg/mL)—Prepared by adding 3.1 g

anhydrous chromium chloride to a 1 L flask and diluting to volume with

1% hydrochloric acid. Store in polyethylene bottle. A commercially available

standard solution may be substituted.

7.4.6 Standard chromium spike solution (1000 µg/L)—Used to spike sample aliquots

for matrix spike/matrix spike duplicate (MS/MSD) analysis and to prepare

ongoing precision and recovery standards. Prepared by spiking 1 mL of the

14 July 1996

Method 1669

chromium stock standard solution (Section 7.4.5) into a 1 L flask. Dilute to

volume with 1% HCl. Store in a polyethylene bottle.

7.4.7 Ongoing precision and recovery (OPR) standard (25 µg/L)—Prepared by spiking

2.5 mL of the standard chromium spike solution (Section 7.4.6) into a 100 mL

flask. Dilute to volume with 1% HCl. One OPR is required for every 10 samples.

8.0 Sample Collection, Filtration, and Handling

8.1 Site Selection

8.1.1 Selection of a representative site for surface water sampling is based on many

factors including: study objectives, water use, point source discharges, non-point

source discharges, tributaries, changes in stream characteristics, types of stream

bed, stream depth, turbulence, and the presence of structures (bridges, dams, etc.).

When collecting samples to determine ambient levels of trace metals, the presence

of potential sources of metal contamination are of extreme importance in site

selection.

8.1.2 Ideally, the selected sampling site will exhibit a high degree of cross-sectional

homogeneity. It may be possible to use previously collected data to identify

locations for samples that are well mixed or are vertically or horizontally

stratified. Since mixing is principally governed by turbulence and water velocity,

the selection of a site immediately downstream of a riffle area will ensure good

vertical mixing. Horizontal mixing occurs in constrictions in the channel. In the

absence of turbulent areas, the selection of a site that is clear of immediate point

sources, such as industrial effluents, is preferred for the collection of ambient

water samples (Reference 19).

8.1.3 To minimize contamination from trace metals in the atmosphere, ambient water

samples should be collected from sites that are as far as possible (e.g., at least

several hundred feet) from any metal supports, bridges, wires or poles. Similarly,

samples should be collected as far as possible from regularly or heavily traveled

roads. If it is not possible to avoid collection near roadways, it is advisable to

study traffic patterns and plan sampling events during lowest traffic flow

(Reference 7).

8.1.4 The sampling activity should be planned to collect samples known or suspected

to contain the lowest concentrations of trace metals first, finishing with the

samples known or suspected to contain the highest concentrations. For example,

if samples are collected from a flowing river or stream near an industrial or

municipal discharge, the upstream sample should be collected first, the

downstream sample collected second, and the sample nearest the discharge

collected last. If the concentrations of pollutants is not known and cannot be

estimated, it is necessary to use precleaned sampling equipment at each sampling

location.

8.2 Sample Collection Procedure—Before collecting ambient water samples, consideration

should be given to the type of sample to be collected, the amount of sample needed, and

the devices to be used (grab, surface, or subsurface samplers). Sufficient sample volume

July 1996 15

Method 1669

should be collected to allow for necessary quality control analyses, such as matrix

spike/matrix spike duplicate analyses.

8.2.1 Four sampling procedures are described:

8.2.1.1 Section 8.2.5 describes a procedure for collecting samples directly into the

sample container. This procedure is the simplest and provides the least

potential for contamination because it requires the least amount of

equipment and handling.

8.2.1.2 Section 8.2.6 describes a procedure for using a grab sampling device to

collect samples.

8.2.1.3 Section 8.2.7 describes a procedure for depth sampling with a jar sampler.

The size of sample container used is dependent on the amount of sample

needed by the analytical laboratory.

8.2.1.4 Section 8.2.8 describes a procedure for continuous-flow sampling using a

submersible or peristaltic pump.

8.2.2 The sampling team should ideally approach the site from down current and

downwind to prevent contamination of the sample by particles sloughing off the

boat or equipment. If it is not possible to approach from both, the site should be

approached from down current if sampling from a boat or approached from

downwind if sampling on foot. When sampling from a boat, the bow of the boat

should be oriented into the current (the boat will be pointed upstream). All

sampling activity should occur from the bow.

If the samples are being collected from a boat, it is recommended that the

sampling team create a stable workstation by arranging the cooler or shipping

container as a work table on the upwind side of the boat, covering this worktable

and the upwind gunnel with plastic wrap or a plastic tablecloth, and draping the

wrap or cloth over the gunnel. If necessary, duct tape is used to hold the wrap

or cloth in place.

8.2.3 All operations involving contact with the sample bottle and with transfer of the

sample from the sample collection device to the sample bottle (if the sample is not

directly collected in the bottle) are handled by the individual designated as "clean

hands." "Dirty hands" is responsible for all activities that do not involve direct

contact with the sample.

Although the duties of "clean hands" and "dirty hands" would appear to be a

logical separation of responsibilities, in fact, the completion of the entire protocol

may require a good deal of coordination and practice. For example, "dirty hands"

must open the box or cooler containing the sample bottle and unzip the outer

bag; clean hands must reach into the outer bag, open the inner bag, remove the

bottle, collect the sample, replace the bottle lid, put the bottle back into the inner

bag, and zip the inner bag. "Dirty hands" must close the outer bag and place it

in a cooler.

16 July 1996

Method 1669

To minimize unnecessary confusion, it is recommended that a third team member

be available to complete the necessary sample documentation (e.g., to document

sampling location, time, sample number, etc). Otherwise, "dirty hands" must

perform the sample documentation activity (Reference 7).

8.2.4 Extreme care must be taken during all sampling operations to minimize exposure

of the sample to human, atmospheric, and other sources of contamination. Care

must be taken to avoid breathing directly on the sample, and whenever possible,

the sample bottle should be opened, filled, and closed while submerged.

8.2.5 Manual collection of surface samples directly into the sample bottle.

8.2.5.1 At the site, all sampling personnel must put on clean gloves (Section 6.7)

before commencing sample collection activity, with "clean hands" donning

shoulder-length gloves. If samples are to be analyzed for mercury, the

sampling team must also put their precleaned wind suits on at this time.

Note that "clean hands" should put on the shoulder-length polyethylene

gloves (Section 6.7.1) and both "clean hands" and "dirty hands" should put

on the PVC gloves (Section 6.7.2).

8.2.5.2 "Dirty hands" must open the cooler or storage container, remove the

double-bagged sample bottle from storage, and unzip the outer bag.

8.2.5.3 Next, "clean hands" opens the inside bag containing the sample bottle,

removes the bottle, and reseals the inside bag. "Dirty hands" then reseals

the outer bag.

8.2.5.4 "Clean hands" unscrews the cap and, while holding the cap upside down,

discards the dilute acid solution from the bottle into a carboy for wastes

(Section 6.16) or discards the reagent water directly into the water body.

8.2.5.5 "Clean hands" then submerges the sample bottle, and allows the bottle to

partially fill with sample. "Clean hands" screws the cap on the bottle,

shakes the bottle several times, and empties the rinsate away from the site.

After two more rinsings, "clean hands" holds the bottle under water and

allows bottle to fill with sample. After the bottle has filled (i.e., when no

more bubbles appear), and while the bottle is still inverted so that the

mouth of the bottle is underwater, "clean hands" replaces the cap of the

bottle. In this way, the sample has never contacted the air.

8.2.5.6 Once the bottle lid has been replaced, "dirty hands" reopens the outer

plastic bag, and "clean hands" opens the inside bag, places the bottle

inside it, and zips the inner bag.

8.2.5.7 "Dirty hands" zips the outer bag.

8.2.5.8 Documentation—After each sample is collected, the sample number is

documented in the sampling log, and any unusual observations

concerning the sample and the sampling are documented.

July 1996 17

Method 1669

8.2.5.9 If the sample is to be analyzed for dissolved metals, it is filtered in

accordance with the procedure described in Section 8.3.

8.2.6 Sample collection with grab sampling device—The following steps detail sample

collection using the grab sampling device shown in Figure 1 and described in

Section 6.4.1. The procedure is indicative of the "clean hands/dirty hands"

technique that must be used with alternative grab sampling devices such as that

shown in Figure 2 and described in Section 6.4.2.

8.2.6.1 The sampling team puts on gloves (and wind suits, if applicable). Ideally,

a sample bottle will have been preattached to the sampling device in the

class 100 clean room at the laboratory. If it is necessary to attach a bottle

to the device in the field, "clean hands" performs this operation, described

in Section 6.4.2, inside the field-portable glove bag (Section 6.6).

8.2.6.2 "Dirty hands" removes the sampling device from its storage container and

opens the outer polyethylene bag.

8.2.6.3 "Clean hands" opens the inside polyethylene bag and removes the

sampling device.

8.2.6.4 "Clean hands" changes gloves.

8.2.6.5 "Dirty hands" submerges the sampling device to the desired depth and

pulls the fluoropolymer pull cord to bring the seal plate into the middle

position so that water can enter the bottle.

8.2.6.6 When the bottle is full (i.e., when no more bubbles appear), "dirty hands"

pulls the fluoropolymer cord to the final stop position to seal off the

sample and removes the sampling device from the water.

8.2.6.7 "Dirty hands" returns the sampling device to its large inner plastic bag,

"clean hands" pulls the bottle out of the collar, unscrews the bottle from

the sealing device, and caps the bottle. "Clean hands" and "dirty hands"

then return the bottle to its double-bagged storage as described in Sections

8.2.5.6 through 8.2.5.7.

8.2.6.8 Closing mechanism—"Clean hands" removes the closing mechanism from

the body of the grab sampler, rinses the device with reagent water

(Section 7.1), places it inside a new clean plastic bag, zips the bag, and

places the bag inside an outer bag held by "dirty hands." "Dirty hands"

zips the outer bag and places the double-bagged closing mechanism in the

equipment storage box.

8.2.6.9 Sampling device—"Clean hands" seals the large inside bag containing the

collar, pole, and cord and places the bag into a large outer bag held by

"dirty hands." "Dirty hands" seals the outside bag and places the double-

bagged sampling device into the equipment storage box.

18 July 1996

Method 1669

8.2.6.10 Documentation—After each sample is collected, the sample number is

documented in the sampling log, and any unusual observations

concerning the sample and the sampling are documented.

8.2.6.11 If the sample is to be analyzed for dissolved metals, it is filtered in

accordance with the procedures described in Section 8.3.

8.2.7 Depth sampling using a jar sampling device (Figure 3 and Section 6.5.1)

8.2.7.1 The sampling team puts on gloves (and wind suits, if applicable) and

handles bottles as with manual collection (Sections 8.2.5.1 through 8.2.5.4

and 8.2.5.6 through 8.2.5.7).

8.2.7.2 "Dirty hands" removes the jar sampling device from its storage container

and opens the outer polyethylene bag.

8.2.7.3 "Clean hands" opens the inside polyethylene bag and removes the jar

sampling apparatus. Ideally, the sampling device will have been

preassembled in a class 100 clean room at the laboratory. If, however, it

is necessary to assemble the device in the field, "clean hands" must

perform this operation, described in Section 6.5.2, inside a field-portable

glove bag (Section 6.6).

8.2.7.4 While "dirty hands" is holding the jar sampling apparatus, "clean hands"

connects the pump to the to the 1/4 in. o.d. flush line.

8.2.7.5 "Dirty hands" lowers the weighted sampler to the desired depth.

8.2.7.6 "Dirty hands" turns on the pump allowing a large volume (>2 L) of water

to pass through the system.

8.2.7.7 After stopping the pump, "dirty hands" pulls up the line, tubing, and

device and places them into either a field-portable glove bag or a large,

clean plastic bag as they emerge.

8.2.7.8 Both "clean hands" and "dirty hands" change gloves.

8.2.7.9 Using the technique described in Sections 8.2.5.2 through 8.2.5.4, the

sampling team removes a sample bottle from storage, and "clean hands"

places the bottle into the glove bag.

8.2.7.10 "Clean hands" tips the sampling jar and dispenses the sample through the

short length of fluoropolymer tubing into the sample bottle.

8.2.7.11 Once the bottle is filled, "clean hands" replaces the cap of the bottle,

returns the bottle to the inside polyethylene bag, and zips the bag.

"Clean hands" returns the zipped bag to the outside polyethylene bag

held by "dirty hands."

8.2.7.12 "Dirty hands" zips the outside bag. If the sample is to be analyzed for

dissolved metals, it is filtered as described in Section 8.3.

July 1996 19

Method 1669

8.2.7.13 Documentation—After each sample is collected, the sample number is

documented in the sampling log, and any unusual observations

concerning the sample and the sampling are documented.

8.2.8 Continuous-flow sampling (Figure 4 and Section 6.5.2)—The continuous-flow

sampling system uses peristaltic pump (Section 6.15) to pump sample to the boat

or to shore through the SEBS-resin or PTFE tubing.

8.2.8.1 Before putting on wind suits or gloves, the sampling team removes the

bags containing the pump (Section 6.15), SEBS-resin tubing (Section 6.15.2),

batteries (Section 6.15.4), gloves (Section 6.7), plastic wrap (Section 6.9),

wind suits (Section 6.12), and, if samples are to be filtered, the filtration

apparatus (Section 6.14) from the coolers or storage containers in which

they are packed.

8.2.8.2 "Clean hands" and "dirty hands" put on the wind suits and PVC gloves

(Section 6.7.2).

8.2.8.3 "Dirty hands" removes the pump from its storage bag, and opens the bag

containing the SEBS-resin tubing.

8.2.8.4 "Clean hands" installs the tubing while "dirty hands" holds the pump.

"Clean hands" immerses the inlet end of the tubing in the sample stream.

8.2.8.5 Both "clean hands" and "dirty hands" change gloves. "Clean hands" also

puts on shoulder length polyethylene gloves (Section 6.7.1).

8.2.8.6 "Dirty hands" turns the pump on and allows the pump to run for

5-10 minutes or longer to purge the pump and tubing.

8.2.8.7 If the sample is to be filtered, "clean hands" installs the filter at the end of

the tubing, and "dirty hands" sets up the filter holder on the gunwale as

shown in Figure 4.

NOTE: The filtration apparatus is not attached until immediately before sampling to prevent

buildup of particulates from clogging the filter.

8.2.8.8 The sample is collected by rinsing the sample bottle and cap three times

and collecting the sample from the flowing stream.

8.2.8.9 Documentation—After each sample is collected, the sample number is

documented in the sampling log, and any unusual observations

concerning the sample and the sampling are documented.

8.3 Sample Filtration—The filtration procedure described below is used for samples collected

using the manual (Section 8.2.5), grab (Section 8.2.6), or jar (Section 8.2.7) collection

systems (Reference 7). In-line filtration using the continuous-flow approach is described

in Section 8.2.8.7. Because of the risk of contamination, it is recommended that samples

for mercury be shipped unfiltered by overnight courier and filtered when received at the

laboratory.

20 July 1996

Method 1669

8.3.1 Set up the filtration system inside the glove bag, using the shortest piece of pump

tubing as is practicable. Place the peristaltic pump immediately outside of the

glove bag and poke a small hole in the glove bag for passage of the tubing. Also,

attach a short length of tubing to the outlet of the capsule filter.

8.3.2 "Clean hands" removes the water sample from the inner storage bag using the

technique described in Sections 8.2.5.2 through 8.2.5.4 and places the sample

inside the glove bag. "Clean hands" also places two clean empty sample bottles,

a bottle containing reagent water, and a bottle for waste in the glove bag.

8.3.3 "Clean hands" removes the lid of the reagent water bottle and places the end of

the pump tubing in the bottle.

8.3.4 "Dirty hands" starts the pump and passes approximately 200 mL of reagent water

through the tubing and filter into the waste bottle. "Clean hands" then moves the

outlet tubing to a clean bottle and collects the remaining reagent water as a blank.

"Dirty hands" stops the pump.

8.3.5 "Clean hands" removes the lid of the sample bottle and places the intake end of

the tubing in the bottle.

8.3.6 "Dirty hands" starts the pump and passes approximately 50 mL through the

tubing and filter into the remaining clean sample bottle and then stops the pump.

"Clean hands" uses the filtrate to rinse the bottle, discards the waste sample, and

returns the outlet tube to the sample bottle.

8.3.7 "Dirty hands" starts the pump and the remaining sample is processed through the

filter and collected in the sample bottle. If preservation is required, the sample

is acidified at this point (Section 8.4).

8.3.8 "Clean hands" replaces the lid on the bottle, returns the bottle to the inside bag,

and zips the bag. "Clean hands" then places the zipped bag into the outer bag

held by "dirty hands."

8.3.9 "Dirty hands" zips the outer bag, and places the double-bagged sample bottle into

a clean, ice-filled cooler for immediate shipment to the laboratory.

NOTE: It is not advisable to reclean and reuse filters. The difficulty and risk associated with

failing to properly clean these devices far outweighs the cost of purchasing a new filter.

8.4 Preservation

8.4.1 Field preservation is not necessary for dissolved metals, except for trivalent and

hexavalent chromium, provided that the sample is preserved in the laboratory

and allowed to stand for at least two days to allow the metals adsorbed to the

container walls to redissolve. Field preservation is advised for hexavalent

chromium in order to provide sample stability for up to 30 days. Mercury

samples should be shipped by overnight courier and preserved when received at

the laboratory.

July 1996 21

Method 1669

8.4.2 If field preservation is required, preservation must be performed in the glove bag

or in a designated clean area, with gloved hands, as rapidly as possible to

preclude particulates from contaminating the sample. For preservation of

trivalent chromium, the glove bag or designated clean area must be large enough

to accommodate the vacuum filtration apparatus (Section 6.17.3), and an area

should be available for setting up the wrist-action shaker (Section 6.17.5). It is

also advisable to set up a work area that contains a "clean" cooler for storage of

clean equipment, a "dirty" cooler for storage of "dirty" equipment, and a third

cooler to store samples for shipment to the laboratory.

8.4.3 Preservation of aliquots for metals other than trivalent and hexavalent

chromium—Using a disposable, precleaned, plastic pipet, add 5 mL of a 10%

solution of ultrapure nitric acid in reagent water per liter of sample. This will be

sufficient to preserve a neutral sample to pH <2.

8.4.4 Preservation of aliquots for trivalent chromium (References 8-9).

8.4.4.1 Decant 100 mL of the sample into a clean polyethylene bottle.

8.4.4.2 Clean an Eppendorf pipet by pipeting 1 mL of 10% HCl (Section (7.4.4)

followed by 1 mL of reagent water into an acid waste container. Use the

rinsed pipet to add 1 mL of chromium (III) extraction solution (Section

7.4.3) to each sample and blank.

8.4.4.3 Cap each bottle tightly, place in a clean polyethylene bag, and shake on

a wrist action shaker (Section 6.17.5) for one hour.

8.4.4.4 Vacuum-filter the precipitate through a 0.4 µm pretreated filter membrane

(Section 6.17.2), using fluoropolymer forceps (Section 6.17.1) to handle the

membrane, and a 47 mm vacuum filtration apparatus with a precleaned

filter holder (Section 6.17.3). After all sample has filtered, rinse the inside

of the filter holder with approximately 15 mL of reagent water.

8.4.4.5 Using the fluoropolymer forceps, fold the membrane in half and then in

quarters, taking care to avoid touching the side containing the filtrate to

any surface. (Folding is done while the membrane is sitting on the filter

holder and allows easy placement of the membrane into the sample vial).

Transfer the filter to a 30 mL fluoropolymer vial. If the fluoropolymer vial

was not pre-equipped with the ultrapure nitric acid (Section 7.4.1), rinse

the pipet by drawing and discharging 1 mL of 10% HCl followed by 1 mL

of reagent water into a waste container, and add 1 mL of ultrapure nitric

acid to the sample vial.

8.4.4.6 Cap the vial and double-bag it for shipment to the laboratory.

8.4.4.7 Repeat Steps 8.4.4.4-8.4.4.6 for each sample, rinsing the fluoropolymer

forceps and the pipet with 10% high-purity HCl followed by reagent water

between samples.

8.4.5 Preservation of aliquots for hexavalent chromium (Reference 20).

22 July 1996

Method 1669

8.4.5.1 Decant 125 mL of sample into a clean polyethylene bottle.

8.4.5.2 Prepare an Eppendorf pipet by pipeting 1 mL of 10% HCl (Section 7.4.4)

followed by 1 mL of reagent water into an acid waste container. Use the

rinsed pipet to add 1 mL NaOH to each 125 mL sample and blank aliquot.

8.4.5.3 Cap the vial(s) and double-bag for shipment to the laboratory.

9.0 Quality Assurance/Quality Control

9.1 The sampling team shall employ a strict quality assurance/ quality control (QA/QC)

program. The minimum requirements of this program include the collection of

equipment blanks, field blanks, and field replicates. It is also desirable to include blind

QC samples as part of the program. If samples will be processed for trivalent chromium

determinations, the sampling team shall also prepare method blank, OPR, and MS/MSD

samples as described in Section 9.6.

9.2 The sampling team is permitted to modify the sampling techniques described in this

method to improve performance or reduce sampling costs, provided that reliable analyses

of samples are obtained and that samples and blanks are not contaminated. Each time

a modification is made to the procedures, the sampling team is required to demonstrate

that the modification does not result in contamination of field and equipment blanks.

The requirements for modification are given in Sections 9.3 and 9.4. Because the

acceptability of a modification is based on the results obtained with the modification, the

sampling team must work with an analytical laboratory capable of making trace metals

determinations to demonstrate equivalence.

9.3 Equipment Blanks

9.3.1 Before using any sampling equipment at a given site, the laboratory or equipment

cleaning contractor is required to generate equipment blanks to demonstrate that

the equipment is free from contamination. Two types of equipment blanks are

required: bottle blanks and sampling equipment blanks.

9.3.2 Equipment blanks must be run on all equipment that will be used in the field.

If, for example, samples are to be collected using both a grab sampling device and

the jar sampling device, then an equipment blank must be run on both pieces of

equipment.

9.3.3 Equipment blanks are generated in the laboratory or at the equipment cleaning

contractor's facility by processing reagent water through the equipment using the

same procedures that are used in the field (Section 8.0). Therefore, the "clean

hands/dirty hands" technique used during field sampling should be followed

when preparing equipment blanks at the laboratory or cleaning facility. In

addition, training programs must require must require sampling personnel to

collect a clean equipment blank before performing on-site field activities.

9.3.4 Detailed procedures for collecting equipment blanks are given in the analytical

methods referenced in Table 1.

9.3.5 The equipment blank must be analyzed using the procedures detailed in the

July 1996 23

Method 1669

referenced analytical method (see Table 1). If any metal(s) of interest or any

potentially interfering substance is detected in the equipment blank at the

minimum level specified in the referenced method, the source of

contamination/interference must be identified and removed. The equipment

must be demonstrated to be free from the metal(s) of interest before the

equipment may be used in the field.

9.4 Field Blank

9.4.1 To demonstrate that sample contamination has not occurred during field

sampling and sample processing, at least one field blank must be generated for

every 10 samples that are collected at a given site. Field blanks are collected

before sample collection.

9.4.2 Field blanks are generated by filling a large carboy or other appropriate container

with reagent water (Section 7.1) in the laboratory, transporting the filled container

to the sampling site, processing the water through each of the sample processing

steps and equipment (e.g., tubing, sampling devices, filters, etc.) that will be used

in the field, collecting the field blank in one of the sample bottles, and shipping

the bottle to the laboratory for analysis in accordance with the method(s)

referenced in Table 1. For example, manual grab sampler field blanks are

collected by directly submerging a sample bottle into the water, filling the bottle,

and capping. Subsurface sampler field blanks are collected by immersing the

tubing into the water and pumping water into a sample container.

9.4.3 Filter the field blanks using the procedures described in Section 8.3.

9.4.4 If it is necessary to acid clean the sampling equipment between samples (Section

10.0), a field blank should be collected after the cleaning procedures but before

the next sample is collected.

9.4.5 If trivalent chromium aliquots are processed, a separate field blank must be

collected and processed through the sample preparation steps given in

Sections 8.4.4.1 through 8.4.4.6.

9.5 Field Duplicate

9.5.1 To assess the precision of the field sampling and analytical processes, at least one

field duplicate sample must be collected for every 10 samples that are collected

at a given site.

9.5.2 The field duplicate is collected either by splitting a larger volume into two

aliquots in the glove box, by using a sampler with dual inlets that allows

simultaneous collection of two samples, or by collecting two samples in rapid

succession.

9.5.3 Field duplicates for dissolved metals determinations must be processed using the

procedures in Section 8.3. Field duplicates for trivalent chromium must be

processed through the sample preparation steps given in Sections 8.4.4.1 through

8.4.4.6.

24 July 1996

Method 1669

9.6 Additional QC for Collection of Trivalent Chromium Aliquots

9.6.1 Method blank—The sampling team must prepare one method blank for every ten

or fewer field samples. Each method blank is prepared using the steps in Sections