Environmental Protection (Water) Policy 2009 - Monitoring and Sampling Manual

Sampling design and preparation

Version: February 2018

Quality control for water and sediment sampling

1 Purpose and scope

This document outlines an approach for collecting control samples during a monitoring program—it does not

cover laboratory quality control procedures. The collection of quality control samples is essential in order to

provide confidence in the results of a sampling program, and is part of the overall quality assurance program.

2 Associated documents

Sampling design and preparation: sampling scope and design.

Physical and chemical assessment:

Manual collection of surface water samples (including field filtration)

Background to water quality sampling using automated sampling equipment

Water quality sampling using automated sampling equipment

Chlorophyll a sample collection methods

Collection and preservation of sediment

Guidance on the sampling of groundwaters

Biological assessment: Direct toxicity assessments

3 Introduction

The number and type of quality control samples collected will depend on the type of analysis being undertaken,

the number of samples being collected and the level of contamination expected. For example, blank samples

may be more important when assessing low levels of environmental contamination (e.g. ultra-trace metals in

water) than when assessing industrial waste.

Field quality control samples can be used to assess and estimate:

Whether a contaminant has been introduced into a sample during the sample collection, sample transport

or in the laboratory analysis.

The accuracy of the result. Accuracy refers to how close a result is to its true value.

The precision within the results of a set of analyses. Precision relates to the repeatability of a result—the

closeness of the results of multiple analyses to each other. It gives no indication of a results relationship to

a true value.

The number of quality control samples should be defined during the sampling design process, and acceptance

criteria should be determined during this phase. Acceptance criteria are the agreed upon limits that ensure data

are of acceptable quality. If the quality control results are outside the acceptance criteria, investigations should

be undertaken, and in some cases data will have to be rejected.

Note: The analytical method used for the quality control samples should be exactly the same as used to

analyse other samples from the sampling program.

Quality control for water and sediment sampling

2

4 Quality control samples

4.1.1 Blanks

Blanks are used to trace sources of contamination that may be introduced into a sample from the sampling

process, sample transportation, or from laboratory sources of contamination. The number of blanks collected for

each sampling program will depend upon the programs objectives and size, and the types and concentrations

of analytes being measured. Blanks should analysed for the same analytes as all other samples. Blank water

should be ultra-pure MilliQ water provided by the analytical laboratory, or if from another source routinely tested

to show no contamination is present. Guidance on the number of blank samples is provided in Table 1.Some

types of blanks are outlined below:

Container blank: used to quantify and trace contamination problems associated with the sample

containers and preservation. A bottle is filled with ultra-pure MilliQ supplied by the analytical laboratory,

preservative is added (if required), and the sample is stored for the same time as the samples for analysis.

Trip or transport blanks: used to estimate contamination of a sample from shipping and laboratory

sources of contamination. A bottle is filled with ultra-pure MilliQ, preservative is added (if required), and the

sample is transported using the same procedures as the samples. These blanks are generally used for

assessing volatile contamination; however, it may also be appropriate to include field blanks for all analytes

if using ice for shipping, and there is a chance of melted water coming into contact with sample bottles and

very low levels of contaminants are being measured.

Field blanks: used to estimate contamination of a sample during the collection procedure. Field blanks are

prepared in the field in the same manner as the sample. A bottle is filled in the field with ultra-pure MilliQ

water, preservative is added (if required), and for example, if a sample is field filtered, the field blank will

also be filtered. It is recommended that water is supplied by the testing laboratory, or if produced in house,

undergoes testing to ensure it is contaminant free.

Rinsate/Equipment blank: used where an analyte free liquid is poured over or through decontaminated

field sampling equipment to assess potential contamination from the equipment. Generally, ultra-pure MilliQ

water is used, but other liquids may be more appropriate (e.g. analytical grade hexane if testing for

hydrocarbons or organics).

Note: Distilled water purchased from retailers is not adequate for use as a blank.

4.1.2 Other field quality control samples

Trip spikes. Particularly useful for volatile compounds. Prior to field trip, clean analyte free water spiked

with a known concentration of compound of interest and taken to field and returned unopened for analysis.

Duplicate or triplicates: duplicate or triplicate samples are obtained by splitting a sample into two or by

taking subsamples from the collection container. They may also be collected in the field by sampling at

exactly the same time and place. Duplicate results provide an estimate of the error associated with the

subsampling/splitting process and laboratory analysis, and are a measure of precision. Duplicate samples

should be sent in as blind samples to the laboratory. Depending upon the individual circumstances of the

sampling program, it is recommended that a subset of duplicate or triplicate samples be sent to a second

laboratory to confirm the primary laboratory’s results.

Certified reference material (CRM): certified reference materials are available for some analytes in some

matrixes. Certified reference material can be used to assess laboratory accuracy and precision. Samples

should be sent in as a blind sample. The concentration of analytes in the CRM should be in the range of the

analytes expected in the environmental samples.

Note:

A blind sample is a sample named so that it is indistinguishable from the other samples. This means the

source and chemical composition of the samples are not known to the analyst. Blanks, duplicates and CRM are

often used as blind samples. Blind samples can determine variability within a laboratory or bias and variability

between two or more laboratories.

Replicates: replicate samples are obtained by collecting two or more samples across a site at the same time.

Quality control for water and sediment sampling

3

Replicate samples provide estimates of the sample variability, including experimental sampling error and

analytical error. The number of replicate samples collected depends upon the program objectives. See

Sampling design and preparation—sampling scope and design for further information.

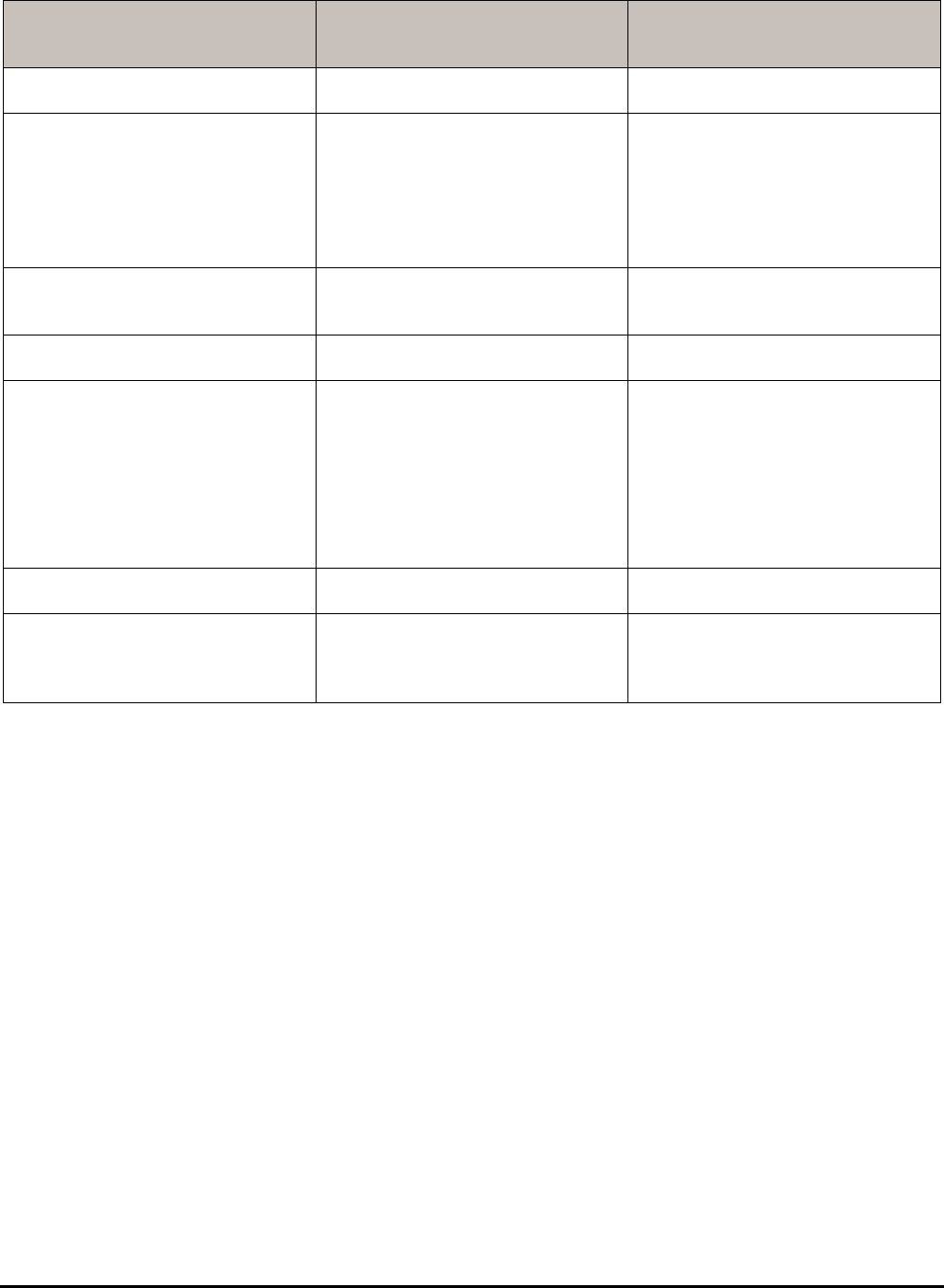

Table 1: Guidance on the frequency of collection and purpose of quality control samples.

Quality Control Sample

Number of quality control

samples to be collected

Notes

Container Blank

One per trip.

Field Blank

One per field team per trip or one

per 20 samples.

If sampling in a particularly dirty

environment and for trace or ultra-

trace concentrations of analytes, it

may be useful to collect more field

blanks (e.g. one per team per

day).

Trip/Transport Blank

For volatile organic contaminants

(VOC) - one per cooler box.

Rinsate/Equipment Blank

One per field team per trip.

Duplicates (triplicates)

For waters: one per 10 samples

for primary laboratory, one per

twenty samples to the second

laboratory (or one per program

when there are less than 20

samples).

For soils: one per 20 samples.

Assesses precision of the results

within a laboratory and between

laboratories.

Trip spike

For VOC – one per trip.

Tests the loss volatile compounds.

Certified Reference Material

Ad hoc. One per large sampling

project.

Evaluates laboratory accuracy and

precision. Should be sent in as a

blind sample.

5 Guidance on assessing quality control data

Quality control data should be assessed immediately upon receipt of data from the laboratory to ensure any

problems indicated from the quality control program can be investigated as soon as possible.

5.1 Blanks

Any reported concentrations of inorganic or organic contaminants in blanks should be investigated immediately.

Collection of adequate blank data should indicate if the source of contamination is the container, equipment,

field, transport or the laboratory.

5.2 Duplicates

The assessment of duplicates is commonly undertaken by expressing the duplicate results as the Relative

Percent Difference (RPD). As a rule of thumb, a RPD of ≤ 20% may indicate an acceptable result for duplicate

aqueous samples (Equation 1), provided the result is five to ten times the limit of reporting (LOR). In those

circumstances where the result is close to the LOR, RPD may exceed 20%. However, the acceptable RPD can

be strongly influenced by the analyte and matrix.

Quality control for water and sediment sampling

4

Therefore, specific acceptance criteria should be discussed with the laboratory prior to the sampling program

commencing. The Australian Standard for Soils (AS 4482.1-2005), which can be applied to sediments, gives an

acceptance criteria RPD of 30-50%, noting that the variation is higher for organic than inorganic analyses.

100

2

21

21

CC

CC

RPD

Equation 1

Where: RPD is relative percentage difference

C

1

is the concentration of analyte from sample 1

C

2

is the concentration of analyte from sample 2

.

5.3 Certified reference material

To assess how far away a result is from a true result using field spikes and certified reference material (CRM),

the percent recovery is typically used (Equation 2).

100

)(

%

K

X

R

Equation 2

Where: %R is recovery as %

X is the measured concentration

K is the known or accepted/true concentration.

For CRM, acceptable recovery ranges are provided by the supplier. Acceptable % recovery ranges for field

spikes are dependent upon the analyte and matrix, and should be discussed with the laboratory.

5.4 Total versus dissolved

A further quality control check can be undertaken by comparing the total concentrations with the dissolved

1

concentrations where applicable. This is most appropriate where the sample used to measure the dissolved

concentration has been subsampled from the one collected to measure total concentration. If samples are

collected separately, there may be variability in environmental conditions at the exact time of collection.

In general, the dissolved concentration should be less than the total concentration. However, as there is a level

of uncertainty associated with any result, the dissolved concentration may exceed the total concentration. An

example is given below in Table 2. The uncertainty of the method can be obtained from the testing laboratory.

1

Dissolved samples are operationally defined as samples that have been filtered through a 0.45µm filter.

Quality control for water and sediment sampling

5

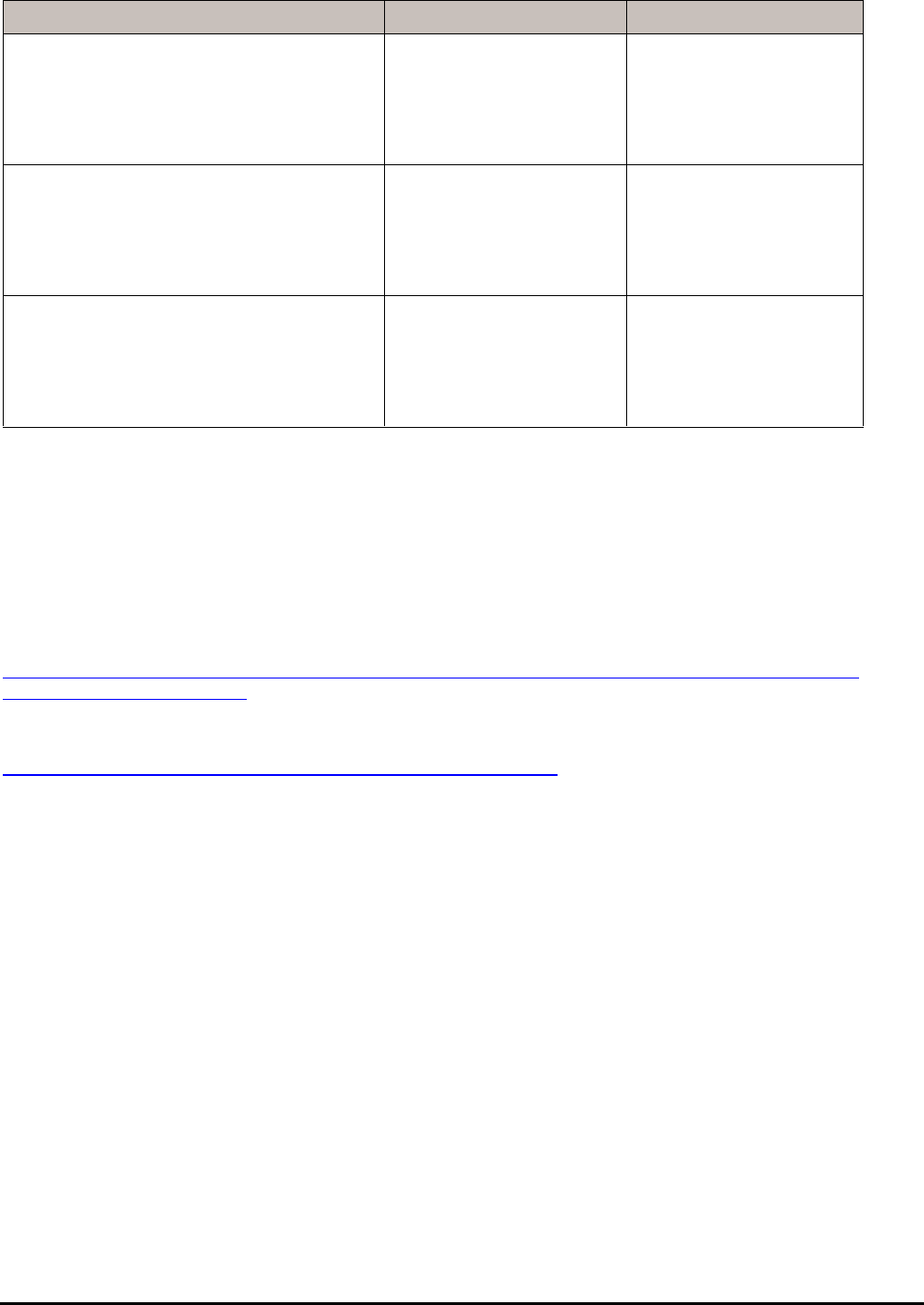

Table 2: Worked examples of total versus dissolved metal check for zinc (based on an example method

uncertainty of 20%). This is only valid if the dissolved metals were subsampled from the same sample

as the total metals.

Results

Notes

Recommended action

Total zinc = 1.4mg/L (1.1–1.7mg/L)

(20% uncertainty is ± 0.3mg/L)

Dissolved zinc = 0.7mg/L (0.6-0.8mg/L)

(20% uncertainty is ± 0.1mg/L)

Total zinc is greater than

dissolved zinc

No investigation required

Total zinc = 1.4mg/L (1.1–1.7mg/L)

(20% uncertainty is ± 0.3mg/L)

Dissolved zinc = 1.6 mg/L (1.3-1.9mg/L)

(20% uncertainty is ± 0.3mg/L)

Total zinc is less than

dissolved zinc, but the

difference is within the

uncertainty of the method.

No investigation required

Total zinc = 1.4mg/L (1.1–1.7mg/L)

(20% uncertainty is ± 0.3mg/L)

Dissolved zinc = 2.2mg/L (1.8-2.6mg/L)

(20% uncertainty is ± 0.4mg/L)

Total zinc is less than

dissolved zinc and the

difference is greater than

the method uncertainty.

Investigation required

6 References and additional reading

AS 4482.1-2005: Guide to the investigation and sampling of sites with potentially contaminated soil – Non-

volatile and semi-volatile compounds.

AS/NZS 5667.1:1998 (R2016). Water quality – Sampling – Guidance on the design of sampling programs,

sampling techniques and the preservation and handling of samples.

National Association of Testing Authorities (NATA) 2004, Technical Note 17 — October 2013, Guidelines for the

validation and verification of quantitative and qualitative test methods. Available from:

http://www.nata.com.au/nata/phocadownload/publications/Guidance_information/tech-notes-information-

papers/technical_note_17.pdf

United States Geological Survey (USGS) 2006, National Field Manual for the Collection of Water-Quality Data,

Chapter 44, Collection of water samples. Available from:

https://water.usgs.gov/owq/FieldManual/chapter4/pdf/Chap4_v2.pdf