UNITED STATES DEPARTMENT OF DEFENSE

Data Validation

Guidelines Module 4:

Data Validation

Procedure for Organic

Analysis by GC

Environmental Data Quality Workgroup

03/09/2021

Data Validation Guidelines

Module 4

Digitally signed by

JORDAN.BRIAN.D.1141739820

JORDAN.BRIAN.D.1141739820

Date: 2021.03.11 07:09:34 -06'00'

Brian Jordan Date

Army Principal

GILLETTE.JOHN.S.1123328350

Digitally signed by GILLETTE.JOHN.S.1123328350

Date: 2021.03.10 11:09:04 -06'00'

Seb Gillette, Ph.D. Date

Air Force Principal

ADELSON.JORDAN.M.1268693137

Digitally signed by ADELSON.JORDAN.M.1268693137

Date: 2021.03.11 07:44:17 -05'00'

Jordan Adelson, Ph.D. Date

Navy Principal, EDQW Chair

Department of Defense

Module 4 Data Validation Guidelines: Data Validation Procedure for Organic Analysis by GC

March 2021

Page 1 of 40

Table of Contents

1.0 Purpose ........................................................................................................................................... 2

2.0 Procedure ........................................................................................................................................ 2

2.1 Introduction ................................................................................................................................. 2

2.2 Deliverables ................................................................................................................................. 3

2.3 Validation Stages ......................................................................................................................... 3

3.0 Stage 1 Validation ........................................................................................................................... 3

3.1 Sample Results ............................................................................................................................. 4

3.2 Chain of Custody (CoC) ................................................................................................................ 5

3.3 Field QC ........................................................................................................................................ 7

4.0 Stage 2A Validation ....................................................................................................................... 11

4.1 Surrogate Spikes ........................................................................................................................ 11

4.2 Laboratory Control Sample/Laboratory Control Sample Duplicate (LCS/LCSD) ........................ 13

4.3 Matrix Spike/Matrix Spike Duplicate (MS/MSD) ....................................................................... 13

4.4 Method Blanks ........................................................................................................................... 15

4.5 Sample Dilutions and Reanalysis ............................................................................................... 16

5.0 Stage 2B Validation ....................................................................................................................... 16

5.1 Sequence and Preparation Logs ................................................................................................ 16

5.2 Instrument Performance Checks (Method 8081: Organochlorine Pesticides) .......................... 17

5.3 Initial Calibration ........................................................................................................................ 18

5.4 Initial (Secondary Source) and Continuing Calibration Verification .......................................... 20

5.5 Internal Standards (Optional) .................................................................................................... 21

5.6 Cleanup Procedures for Methods 8081, 8082, 8141, and 8151 ................................................ 21

5.7 Second Column Confirmation/Dissimilar Detector Confirmation ............................................. 23

6.0 Stage 3 Validation ......................................................................................................................... 24

6.1 Samples and Field QC ................................................................................................................ 24

6.2 Method QC ................................................................................................................................. 25

6.3 Instrument QC ........................................................................................................................... 26

6.4 Standards Traceability ............................................................................................................... 28

6.5 Detection/Quantitation Limit Studies (Optional) ...................................................................... 29

7.0 Stage 4 Validation ......................................................................................................................... 29

7.1 Target Compound Identification ................................................................................................ 29

7.2 Retention Time Windows .......................................................................................................... 31

7.3 Manual Integrations .................................................................................................................. 32

Appendix A: Method QC Tables .......................................................................................................... 33

Appendix B: Formulas used in Stage 3 and 4 Data Validation ............................................................ 37

Department of Defense

Module 4 Data Validation Guidelines: Data Validation Procedure for Organic Analysis by GC

March 2021

Page 2 of 40

Module 4: Data Validation Procedure for Organic Analysis

by GC (SW-846 8000 Series)

1.0 Purpose

This document provides guidance on the validation of organic contaminants by SW-846

Series 8000 methods when analyzed on a Gas Chromatograph (GC):

• 1,2-Dibromoethane and 1,2-Dibromo-3-Chloropropane by Microextraction and GC

Method 8011;

• Nonhalogenated Organics by GC Method 8015;

• Aromatic and Halogenated Volatiles by GC Using Photoionization and/or Electrolytic

Conductivity Detectors Method 8021;

• Organochlorine Pesticides by GC Method 8081;

• Polychlorinated Biphenyls (PCBs) by GC Method 8082;

• Organophosphorus Compounds by GC Method 8141; and

• Chlorinated Herbicides by GC Using Methylation or Pentafluorobenzylation

Derivatization Method 8151;

Note: With the exception of EPA 8000D, this document does not identify specific Series

8000 method versions. Consult the project UFP-QAPP to determine specific

requirements for analysis and validation. The language within this document is only to be

used as guidance and the QAPP shall always supersede this document.

The objective of this procedure is to provide the end user with a clear understanding of

the quality and limitations of the data through documented validation procedures and to

encourage consistency in the validation technique and reporting for data generated for

Department of Defense (DoD) projects for organic constituents when analyzed on GC.

This document assumes the user is familiar with data validation conventions and

qualifiers used in the DoD General Data Validation Guidelines Version 1 (2019). This

document is also not intended to obviate the need for professional judgment during the

validation process.

This document references the Uniform Federal Policy for Quality Assurance Project Plans

(UFP-QAPP) Optimized Worksheets (March 2012). Other QAPP formats are equally

acceptable.

2.0 Procedure

This guidance can be applied to organic contaminant data generated in support of DoD

projects that was produced on GC. This guidance should be implemented by personnel

familiar with the methodology contained herein.

Data validation personnel are responsible for implementing this procedure for validation of

data and generation of data validation reports for GC organic contaminant data.

2.1 Introduction

This document was written with primary consideration to the latest SW-846 8000

series GC method versions with Quality Control (QC) criteria identified in the DoD

Quality Systems Manual (QSM). Actual validation should proceed using the acceptance

criteria for the method version specified in the laboratory data deliverable or in the QAPP.

Department of Defense

Module 4 Data Validation Guidelines: Data Validation Procedure for Organic Analysis by GC

March 2021

Page 3 of 40

Appendix A summarizes the QC checks and the required frequency and acceptance criteria

for Method 8000D and the QSM version 5.3 requirements.

2.2 Deliverables

Laboratory data deliverables consist of a combination of forms and raw data. The manner in

which laboratories label their forms is not dictated nor specified. The labeling convention

below is used for simplicity.

• Cover Sheet

• Case Narrative

• Sample Receipt and Conditions Summary

• Sample Results Summary

• Surrogate Recovery Summary

• Laboratory Control Sample/Laboratory Control Sample Duplicate

• Matrix Spike/Matrix Spike Duplicate Recovery Summary

• Method Blank Summary

• Instrument Performance Check Summary (where applicable)

• Initial Calibration Summary

• Initial/Continuing Calibration Verification Summary

• Retention Time/Internal Standard Summary

• Sequence and preparation logs

2.3 Validation Stages

The types of laboratory data deliverables, staged data validation, and the relationship

between the two are outlined in the DoD General Data Validation Guidelines Version 1.

Stage 1 data validation consists of a review of sample results form, associated sample

receipt summaries (chain of custody), and field QC data.

Stages 2A and 2B data validation consist of review of summary forms only.

Stages 3 and 4 data validation require review of both summary forms and all associated raw

data.

Both the laboratory deliverable and the level of validation should be specified in the QAPP or

other planning documents. Data review guidelines and how they apply to the different

validation stages are indicated in the following sections.

Note: Any required stage of validation that reveals significant deviations from project

requirements may require a higher stage of validation to uncover the source. Data validators

are encouraged to communicate with their points of contact identified in the QAPP (such as

the UFP-QAPP Worksheet #6) to resolve discrepancies.

3.0 Stage 1 Validation

The following documents should be reviewed for representativeness (compliance with

required analytical protocols outlined in QAPP), completeness, and project sensitivity needs:

• Cover Sheet

• Table of Contents

• Case Narrative

• Sample results form or equivalent Laboratory Report

Department of Defense

Module 4 Data Validation Guidelines: Data Validation Procedure for Organic Analysis by GC

March 2021

Page 4 of 40

• Chain of Custody (CoC) forms, Laboratory Receipt Checklists, and other supporting

records

• Field QC forms and supporting records

Stage 1 is the validation of investigative and field QC samples.

3.1 Sample Results

Examine the Laboratory Report sample results summary (can be called by many names,

such as Form I) and verify the following information:

• Holding times have been met, as applicable

• All sample identification labels are unique, and match the CoC

• All project GC analytes have been analyzed and are reported

• Second (dissimilar) Column results are consistent with QAPP requirements

• All laboratory reported Limits of Detection (LODs) and Limits of Quantitation (LOQs)

are equal to or less than QAPP required LODs/LOQs

• All project required LOQs have been met and achieved LOQs are less than the

project required action levels

• All reported units (e.g., mg/kg) are accurate and reflect the requirements of the

project, and units are consistent with the type of sample matrix

• All required field QC samples (such as trip blanks, equipment blanks, reagent blanks,

and field duplicates) have been included in the Laboratory Report at the frequency

specified in the QAPP

• Soil samples have been reported on a dry weight basis, unless specified by the QAPP

to report on a wet weight basis

• Each laboratory report has a case narrative that explains non-conformities with the

data

• All sample collection date/time information matches the CoC or any inconsistency is

appropriately documented

The following statements apply to sample results (assuming no other qualifications due to

data quality issues):

Qualification of data is based upon the reporting requirements of the QAPP.

The QSM requires reporting non-detects as U-qualified at the LOD and requires reporting

detects between the DL and LOQ with a J qualification. There are several ways that a project

team may change these reporting requirements for project-specific reasons which are

outlined in the QAPP. Though not recommended for typical projects, these changes include

reporting non-detects as U-qualified at the DL; reporting non-detects and detects below the

LOD as non-detects with U qualification at the LOD; or reporting non-detects and detects

below the LOQ as non-detects with U qualification at the LOQ. These varying reporting

conventions are summarized in the following table:

Department of Defense

Module 4 Data Validation Guidelines: Data Validation Procedure for Organic Analysis by GC

March 2021

Page 5 of 40

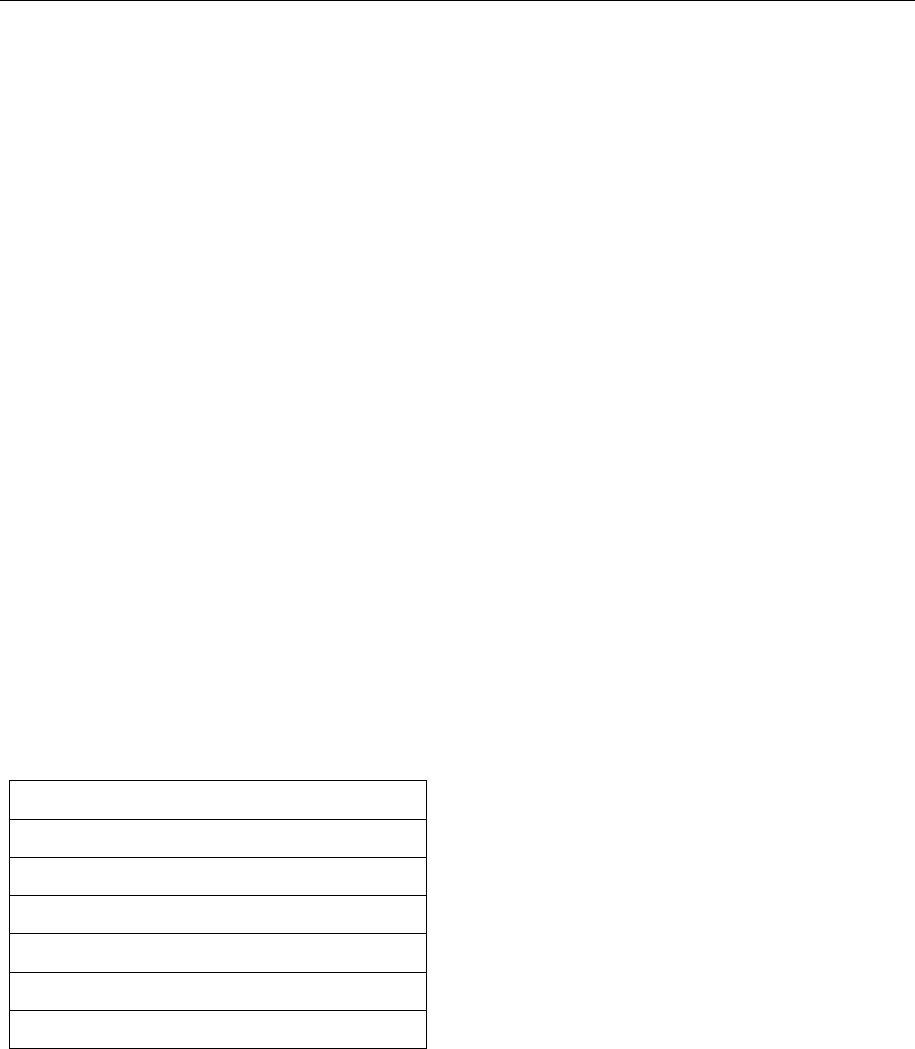

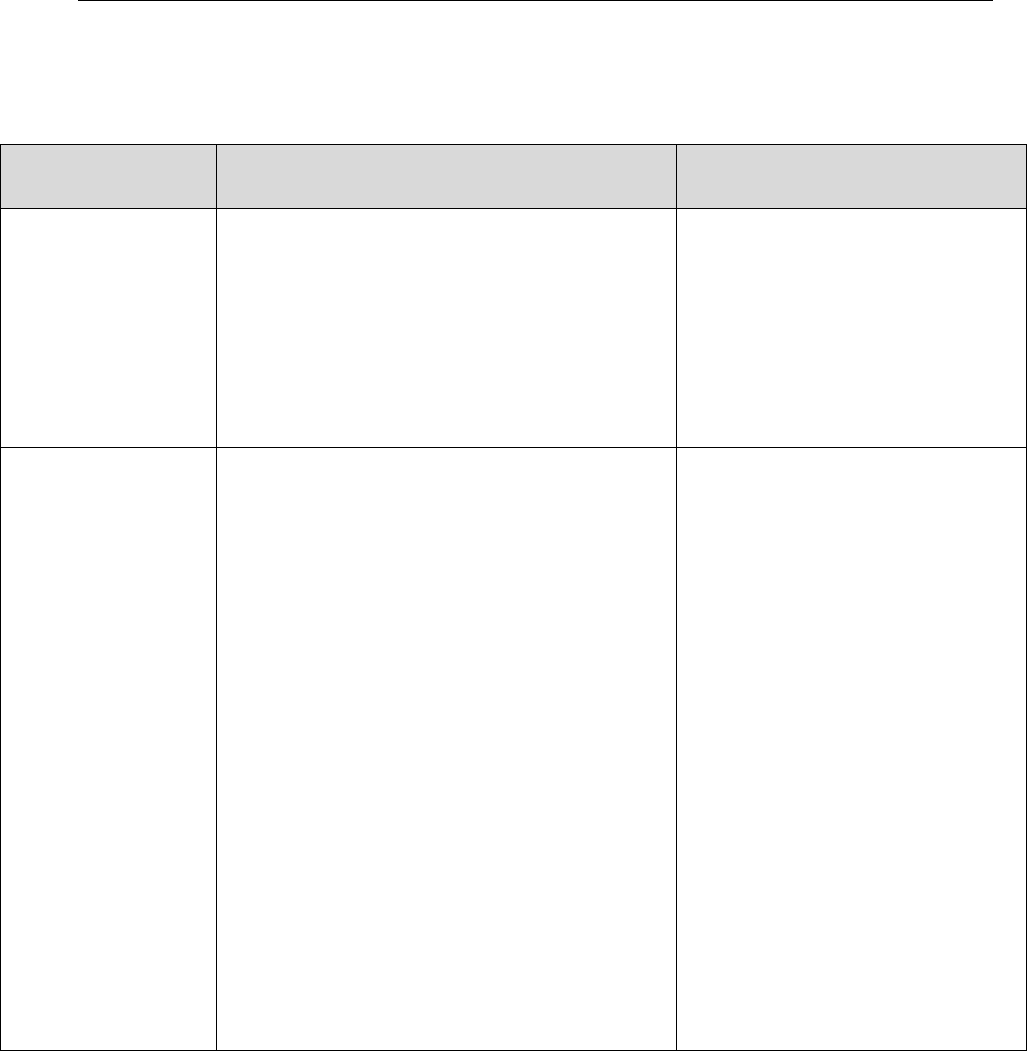

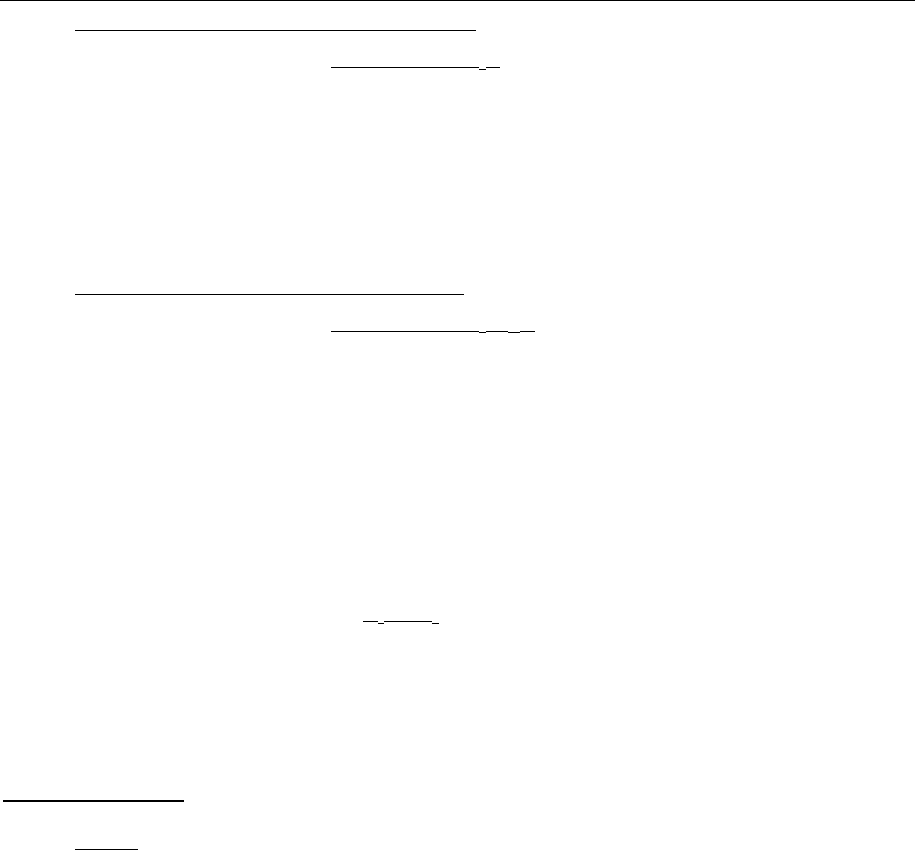

Table I: Reporting Requirements

Reporting

Requirements (listed

below)

Non-detects or

results Below (<) DL

Results Below

(<) LOD

Results Below (<)

LOQ

Standard QSM

Reporting

LOD value U

Reported Result J

Reported Result J

*Reporting results to DL

DL value U

Reported Result J

Reported Result J

Reporting results to

LOD

LOD value U

LOD value U

Reported Result J

Reporting results to

LOQ

LOQ value U

LOQ value U

LOQ value U

*Note: non-detects reported at the DL have a 50% false negative rate. For further discussion

please see Fact Sheet: Detection and Quantitation – What Project Managers and Data Users

Need to Know, DoD Environmental Data Quality Workgroup, October 2017.

Evaluation of the Laboratory Report

Any samples received for analysis that were not analyzed should be noted in the data

validation report, along with the reason(s) for failure to analyze the samples, if the reason(s)

can be determined; conversely, samples that were analyzed by GC but were not requested

should also be noted.

Analytes that have project action levels less than the laboratory’s LOD may reveal a severe

deficiency in the data and a failure to meet project goals, and such instances should be noted

in the data validation report. Errors in reported units and case narrative non-conformities that

call into question the quality of the data should also be discussed in the data validation

report.

Errors in quantitation limits or missing or misidentified samples may require a higher than

Stage 1 validation. Data validators are encouraged to reach out to their point of contact

(QAPP Worksheet #6) when preparing the data validation report.

3.2 Chain of Custody (CoC)

Examine the CoC form (some information may be included on Laboratory Receipt Checklists)

for legibility and check that all GC analyses requested on the CoC have been performed by

the laboratory. Ensure that the CoC Sample Identification on the laboratory sample results

summary (Form I [or equivalent]) matches the Sample Identification on the CoC. Ensure the

CoC was signed and dated during transfers of custody. Read the laboratory case narrative

for additional information.

Evaluation of the CoC

Any discrepancies in sample identification between the CoC and sample results form should

be noted in the data validation report with the correct sample identification in the report and

on the appropriate summary form, if the correct sample identification can be determined.

These edit corrections should also be verified in any associated electronic data deliverables

(EDDs).

Department of Defense

Module 4 Data Validation Guidelines: Data Validation Procedure for Organic Analysis by GC

March 2021

Page 6 of 40

If the receiving laboratory transferred the samples to another laboratory for analysis, both the

original CoCs and transfer CoCs should be present. Document in the data validation report if

the transfer CoCs are not present or if there is missing information (such as location of the

laboratory). Make note in the data validation report when signatures of relinquish and receipt

of custody were not present.

3.2.1 Sample Preservation, Handling, and Transport

Evaluate sample handling, transport, and laboratory receipt from the CoC and laboratory

receipt checklists to ensure that the samples have been properly preserved and handled.

The project QAPP (such as UFP-QAPP Worksheet #19) should provide specific preservation

requirements. The following are general guidance if project specifications were not stipulated.

Typically, organic samples do not require chemical preservation. An exception is 3 mL 10%

sodium thiosulfate solution is added per gallon (or 0.008%) to aqueous samples with residual

chlorine present. Addition of sodium thiosulfate solution to sample container may be

performed in the laboratory prior to field use. Reference the QAPP for specific preservation

requirements.

• Organic contaminant samples are to be shipped in amber bottles with PTFE-lined lids

• All samples are to be shipped in coolers that are maintained at ≤ 6 degrees Celsius

(°C)

Evaluation of Preservation, Handling, and Transport

If the temperature of receipt is > 6°C but ≤ 15⁰C, detects should be flagged as estimated J-

and non-detects as estimated UJ.

If the temperature of receipt is > 15°C, detects should be flagged as estimated J- and non-

detects as X, exclusion of data recommended.

On occasion, the samples may be delivered to the laboratory within a few hours of collection

and before the temperature of the cooler is able to reach 6⁰C. For those instances, if cooling

has begun, but the temperature is > 6⁰C, special note should be made but no qualification

should be required.

If the temperature is below 0°C, special note should be made but no qualification should be

required.

In the event that both a cooler temperature and a temperature blank were measured, the

temperature blank should be evaluated for temperature compliance as it best represents the

condition of the samples; however, both temperatures shall be noted in the data validation

report.

If the temperature upon receipt at the laboratory was not recorded, note this in the data

validation report and assume that a temperature non-conformance occurred. Detects should

be flagged as estimated J- and non-detects flagged X, exclusion of data recommended.

If the receiving laboratory transferred the samples to another laboratory for analysis, apply

the same temperature criteria to both the transfer CoC and the original CoC.

If aqueous samples known to contain chlorine were not chemically preserved with sodium

thiosulfate, apply professional judgment to qualify the sample results.

Department of Defense

Module 4 Data Validation Guidelines: Data Validation Procedure for Organic Analysis by GC

March 2021

Page 7 of 40

3.2.2 Holding Times

Holding times for organics are measured from the time of collection (as shown on the CoC) to

the time of sample analysis as shown on the sample results summary (Forms I or equivalent)

or extraction log (if applicable). Based on input from the DoD Environmental Data Quality

Workgroup (EDQW) holding time exceedances are calculated as follows:

Total holding time is based on the timeframe (i.e., hours, days, or months) of the

requirement. The following example gives guidance on how holding time exceedances are

measured:

For a test with a recommended maximum holding time measured in days, the holding time is

tracked by the day.

• An exceedance of holding time for a sample with a 14-day holding time will occur

when the 15th day is reached. Therefore, a sample with a 14-day holding time

collected at 8:30 AM on April 4th must be analyzed or extracted before 12:00 AM April

19

th

(midnight, the start of the 15

th

day), or an exceedance has occurred.

Samples and extracts must be stored refrigerated to ≤ 6°C until the time of analysis. The

holding time for aqueous samples is 7 days from the collection date to the beginning of

extraction, and 40 days from extraction to analysis. The holding time for solid samples is 14

days from the collection date to the beginning of extraction, and 40 days from extraction to

analysis. The holding time for aqueous waste samples is 7 days from collection to leaching, 7

days from leaching to the beginning of extraction, and 40 days from extraction to analysis.

The holding time for solid waste samples is 14 days from collection to leaching, 7 days from

leeching to the beginning of extraction and 40 days from extraction to analysis.

There is no specified holding time for PCB Aroclor samples. The QAPP should specify the

holding time requirements.

Evaluation of Holding Time

If the holding time is exceeded, qualify all associated detects as estimated J- and all

associated non-detects as estimated UJ and document that holding times were exceeded.

If holding times are grossly exceeded (defined as > 14 days to extraction for aqueous

samples and > 28 days for solid samples), detects should be qualified as estimated J- and

non-detects as X, exclusion of data recommended.

For PCB Aroclor samples, the above holding times for organic contaminants can be used for

guidance if specific holding times are not listed in the QAPP. Exceedances do not require

qualification of the data but should be noted in the data validation report.

3.3 Field QC

Field QC can consist of various blanks, field duplicates, and field replicates. The purpose of

blanks is to identify potential cross-contamination at different stages of sampling and

cleaning of equipment for reuse. Duplicates and replicates help a project identify

reproducibility among samples at the project site.

3.3.1 Field Blanks

Not every field blank type may be utilized during any given sampling event and there may be

more blank types than described in this document. Field blanks may be varied throughout the

Department of Defense

Module 4 Data Validation Guidelines: Data Validation Procedure for Organic Analysis by GC

March 2021

Page 8 of 40

sampling events of a project. The types of blanks and their collection frequency should be

stipulated in the QAPP. Generally, the blanks are collected once a day or one per twenty field

investigative samples, by each sampling team, and may be matrix dependent.

Below are the common types of field blanks utilized in the collection of organic contaminants

analyzed by GC.

Trip blanks are included for aqueous volatile analytes only. Volatile organic compounds

detected in trip blanks indicate the possibility of contamination of site samples or cross-

contamination between site samples due to sample handling and transport while in the

cooler. A trip blank is usually included for every cooler that transports volatile samples.

An ambient blank is sample collected on site, without the need of equipment, filled directly

into a sample container. Ambient blanks are included for volatile analysis only. Analytes

detected in ambient blanks indicate the possibility of cross-contamination between the air

matrix and the matrix being collected for testing.

An equipment blank (also called a rinse or rinsate blank) is an aliquot of reagent water

subjected to all aspects of sample collection. Analytes detected in equipment blanks indicate

the possibility of cross-contamination between samples due to improper equipment

decontamination. Equipment blanks are usually collected at a frequency of one per twenty

investigative samples, or as specified in the QAPP.

A source blank (also called a reagent blank) may be collected from each source of water

used during each sampling event. This type of field blank may be analyzed to assess

whether the chemical nature of the water used in decontamination may have affected the

analytical results of site samples. A source blank is usually collected once per source prior to

sample collection.

Evaluation of Field Blanks

Check that all coolers containing samples to be analyzed for volatile organic contaminants by

GC contained a trip blank. If a cooler requiring a trip blank did not have an associated trip

blank, no qualification of the samples transported in the cooler is necessary, but the incident

should be discussed in the data validation report along with other required types of field

blanks that were found missing. The point of contact (QAPP Worksheet #6) should be

notified within the required time frame as required by the QAPP.

Determine which field blanks apply to samples in the sample delivery group (SDG) from the

CoC. If the applicability of multiple field blanks cannot be determined, communicate with the

point of contact (QAPP Worksheet #6) to inquire if applicability can be determined.

Note: SDGs can be called by different names such as SEDD Lab Reporting Batch,

depending on the project.

Ensure that units are correct when applying field blank qualifications.

Note: it may not be appropriate to make a direct quantitative comparison for aqueous field

blanks (such as equipment blanks reported as µg/mL) to a solid parent sample (such as a

soil sample reported as mg/kg). At best, only a qualitative comparison can be made.

Generally, when multiple blank type contaminations are present, the evaluation should not

involve a ‘hierarchy’ of one blank type over another. Each blank is evaluated separately and

independently. The final validated result should be assessed on the blank with the highest

value (i.e., greatest effect on sample analyte concentration).

Department of Defense

Module 4 Data Validation Guidelines: Data Validation Procedure for Organic Analysis by GC

March 2021

Page 9 of 40

The source blank water should be analyte free (undetected or as defined by QAPP) and

provided with the sample bottle kit by the contracted laboratory performing the analysis. To

ensure the origin of the water used, consult with the field sampling team leader via

appropriate channels identified in the QAPP (such as UFP-QAPP Worksheet #6). If source

blank water is used as equipment blank water and both are contaminated, the affected

samples are qualified by either the source blank or equipment blank results, whichever has

the higher contaminant concentration.

If analytes (as appropriate) are detected in the field blanks, the procedure for the qualification

of associated sample results is summarized below.

Compare the results of each type of field blank with the associated sample results. The

reviewer should note that the blank analyses may not involve the same units, volumes, or

dilution factors as the associated samples. These factors should be taken into consideration

when applying the 5X and 10X criteria discussed below, such that a comparison of the total

amount of contamination is actually made. Care should be taken to factor in any dilution

factors when doing comparisons between detects in the sample and the blank.

• If an analyte is detected in the field blank, but not in the associated samples, no

action is taken.

• If field blank contamination includes those analytes listed in Table I as common lab

contaminants, then 10X (in lieu of 5X) should be used to determine the qualification of

the sample.

• If field blanks were not collected at the proper frequency required by the QAPP, then

use professional judgment to qualify the data, and make note of this in the data

validation report.

• If an analyte is detected in the field blank (at any concentration) and in the associated

samples, the action taken depends on both the blank and sample concentrations

(Table III).

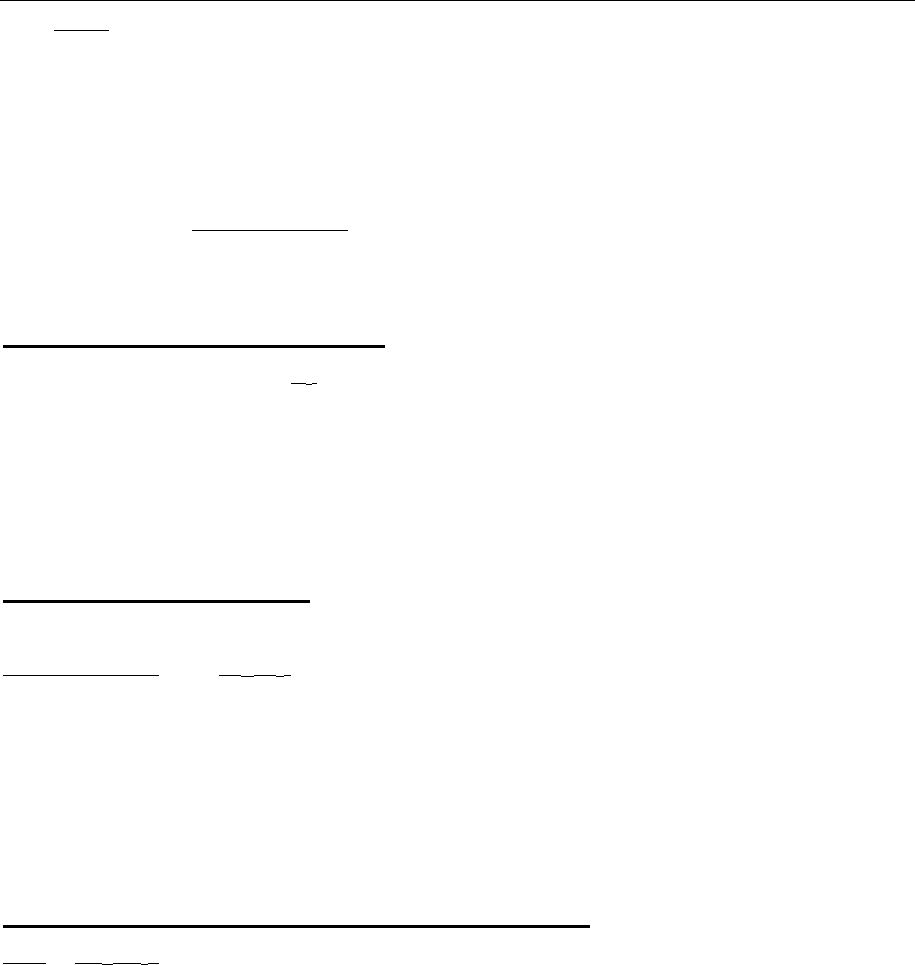

Table II: Common Lab Contaminants

Methylene chloride

Acetone

2-Butanone (MEK)

Phthalate Esters

Toluene

Hexane

2-Propanol

Department of Defense

Module 4 Data Validation Guidelines: Data Validation Procedure for Organic Analysis by GC

March 2021

Page 10 of 40

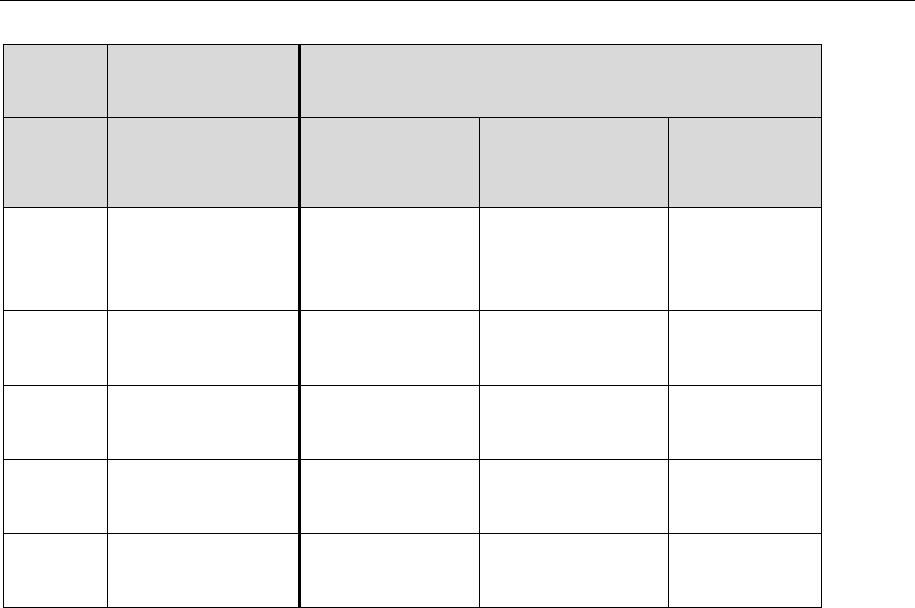

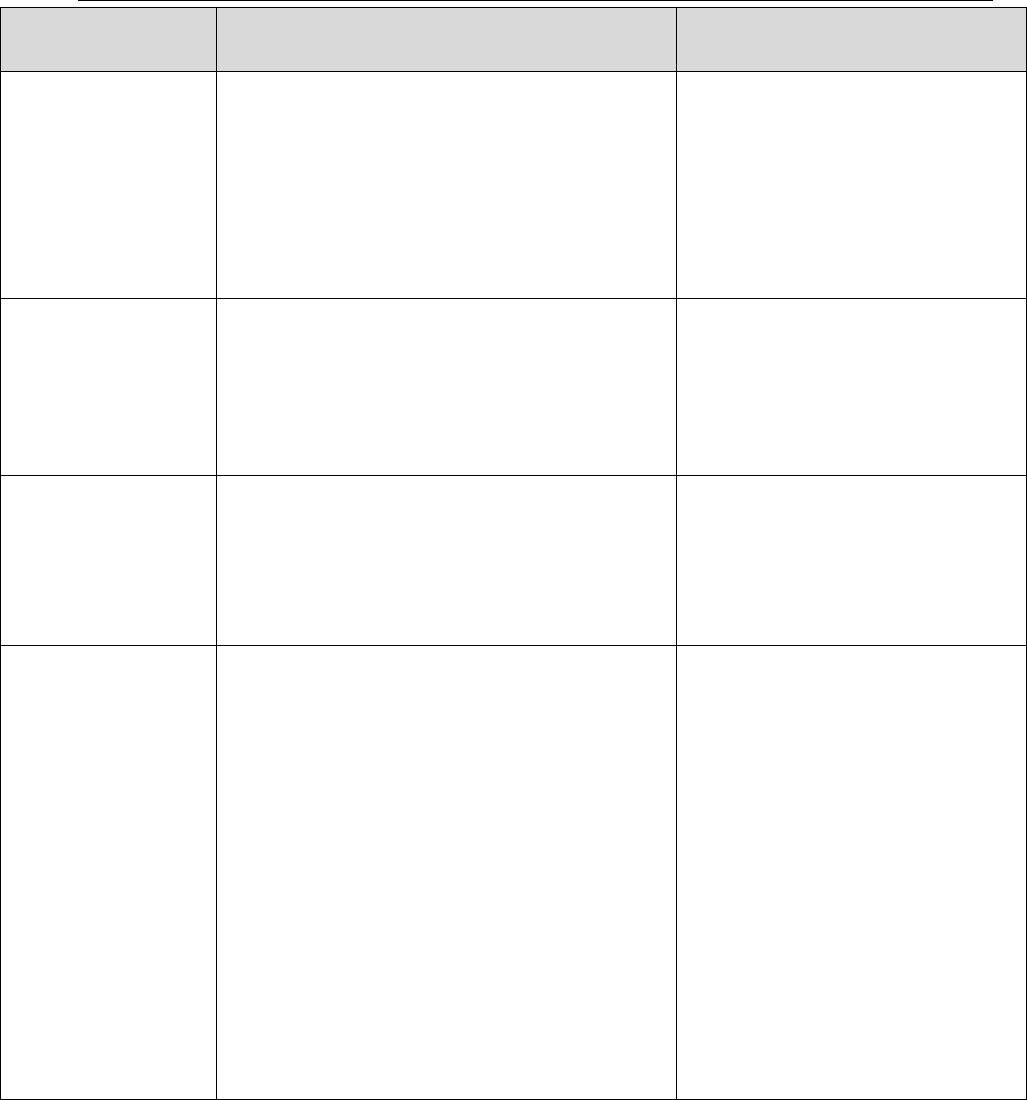

Table III: Blank Qualifications

Blank

Sample

Row

Number

Result

Result

Validated

Result

Validation

Qualifier

1

≤ DL or LOD

≤ DL or LOD

Report as

required by QAPP

(at DL or LOD)

U

2

> DL or LOD

≤ DL or LOD

Report at DL or

LOD

U

3

> DL or LOD

> DL or LOD but

≤ LOQ

Report at LOQ

U

4

> DL or LOD

> LOQ but ≤ 5x

blank

Report at Sample

Result

U

5

> DL or LOD

> LOQ and > 5x

blank

Report at Sample

Result

None

LOD = Limit of Detection LOQ = Limit of Quantitation DL = Detection Limit

Note: The QAPP should specify reporting at either the DL, LOD or both

3.3.2 Field Duplicates (can also be called replicates)

Field duplicates consist of either collocated or subsampled (split) samples. Field duplicates

for groundwater and surface water samples are generally considered to be collocated

samples. Soil duplicate samples may be split samples or collocated, as specified in the

QAPP. Field duplicate results are an indication of both field and laboratory precision; the

results may be used to evaluate the consistency of sampling practices.

Evaluation of Field Duplicates

Check to ensure that field duplicates were collected and analyzed as specified in the QAPP.

If the sampling frequency is less than the frequency stated in the QAPP, no qualification of

the associated sample results is necessary, but the incident should be discussed in the data

validation report.

Relative Percent Differences (RPDs) should be calculated when detected results are

reported for the duplicate(s) and at least one of those results is greater than or equal to the

LOQ. For field duplicate results, if the RPDs or absolute differences are greater than those

stated in the QAPP, qualify the associated sample results as estimated J, and any non-

conformities should be noted in the data validation summary.

Professional judgment may be required in instances where the sample and field duplicate

results are less than the LOQ or project Reporting Limits (RLs). RPD results can be elevated

when low (e.g., <5x the LOQ) or estimated concentrations in the samples and duplicates are

reported. If one or both results in a duplicate pair are <5x the LOQ, the absolute difference

Department of Defense

Module 4 Data Validation Guidelines: Data Validation Procedure for Organic Analysis by GC

March 2021

Page 11 of 40

between the two results can be used as an alternative acceptance criterion, if approved by

the QAPP or project point of contact (QAPP Worksheet #6).

Some sampling schemes, such as Incremental Sampling Methodology (ISM) require specific

replicate calculations, which should be specified in the QAPP.

It should be noted that RPDs or absolute differences for field duplicates are generally not

calculated or reported by the laboratory and should be calculated by the validator.

There are instances where an RPD is not calculable (for example, when one result is a non-

detect and the other is greater than the LOQ). In those cases, the RPDs are not calculated

but the non-conformity should be noted in the data validation report. The reported

concentrations should be carefully examined to determine what conditions would permit one

result to be reported at or above the LOQ/RL and the other to be reported below the LOQ/RL

or as a non-detect.

4.0 Stage 2A Validation

Note: Stage 2A includes all of Stage 1

Stage 2A requires the review and qualification of the following summary documents.

• Surrogate Recovery Summary

• Laboratory Control Sample/Laboratory Control Sample Duplicate

• Matrix Spike/Matrix Spike Duplicate Recovery Summary

• Method Blank Summary Form

• Sample Dilution/Reanalysis Summaries

Stage 2A is the validation of preparation batch specific QC data in addition to any sample

specific parameters included in Stage 1.

Generally, a “preparation batch” of samples consists of up to twenty field samples (maximum)

along with duplicate/replicate (laboratory or field), method blank, and control/matrix type QC

samples. They are meant to be analyzed together on a single instrument. However,

laboratories may choose to split up a batch over multiple instruments to save time. In this

case, if the use of multiple instruments is uncovered in a Stage 2A validation, the validator

should request from their point of contact (QAPP Worksheet #6) a Stage 2B validation to

review sequence logs. The use of multiple instrumentation should be noted in the data

validation report.

4.1 Surrogate Spikes

Extraction efficiency on individual samples is established by means of surrogate spikes. All

samples are spiked with surrogates prior to sample extraction. The evaluation of the results

of these surrogate spikes is not necessarily straightforward. The sample itself may produce

effects due to such factors as interference and high concentrations of analytes. Because the

effects of the sample matrix are frequently outside the control of the laboratory and may

present relatively unique problems, the review and validation of data based on specific

sample results is frequently subjective and demands analytical experience and professional

judgment.

Verify that surrogate percent recoveries and acceptance limits were reported for all field and

batch QC samples.

Department of Defense

Module 4 Data Validation Guidelines: Data Validation Procedure for Organic Analysis by GC

March 2021

Page 12 of 40

Sample and batch QC surrogate recoveries should be within control limits established in the

QAPP or the QSM. Verify that no samples or batch QC have surrogate percent recoveries

outside their criteria.

If any surrogate recovery is out of specification, then a re-extraction (if applicable) and

reanalysis should have been performed and reported. Re-extraction is not required for

surrogates with high bias associated with non-detect sample results. The laboratory should

have reported both runs if the first was unsuccessful.

The laboratory does not have to reanalyze a sample if a matrix spike/matrix spike duplicate

(MS/MSD) was performed on the sample with out-of-control surrogate results showing the

same matrix effects, as long as the batch QC display acceptable surrogate percent

recoveries.

Evaluation of Surrogates

If surrogate percent recoveries are out of specification with no evidence of re-extraction (if

applicable) and reanalysis, justification should be noted in the laboratory case narrative (e.g.,

limited sample volume prevented reanalysis). If justification is not noted, the point of contact

(QAPP Worksheet #6) should be reached for further guidance.

If the surrogate percent recovery control criteria displayed in the deliverable are not the same

ranges stipulated in the QAPP or the DoD QSM, reference the required control ranges for

evaluation instead of the summarized ranges in the deliverable. The project team should be

informed to implement changes to the current deliverables or those to be created in the

future. Please follow the notification protocols outlined in the QAPP (such as the UFP-QAPP

Worksheet #6).

GC Organic Contaminants

If any surrogate percent recovery is < 10%, qualify detects as estimated J-, and non-detects

as X, exclusion of data recommended for all associated target analytes in the sample.

If any surrogate percent recovery is greater than the upper acceptance limit, qualify

associated detects in the sample as estimated with a positive bias J+ and non-detects should

not be qualified.

If any surrogate percent recovery is less than the lower acceptance limit but ≥ 10%, qualify all

associated detects as estimated with a negative bias J- and non-detects as estimated UJ.

For samples that require dilution, surrogates may be reported as “diluted out”, if dilution is

such that the surrogate can no longer be detected above the LOD. If this is the case, note in

the data validation report that surrogate evaluation could not be performed due to a high

dilution factor. A full evaluation (Stage 4 validation) of the sample chromatogram and

quantitation report may be necessary to determine that surrogates are truly “diluted out.”

In the special case of blank analysis with surrogates out of specification, the reviewer should

give special consideration to the validity of associated sample data. The primary concern is

whether the blank failures represent an isolated incident with the blank alone, or whether

there is a systemic problem with the analytical process. For example, if the samples in the

batch show acceptable surrogate recoveries, the reviewer may determine the blank failure to

be an isolated occurrence for which no qualification of the data is required. However, if

surrogate failures occur throughout the field and QC samples, then consideration should be

given to communicate with the QAPP point of contact (QAPP Worksheet #6) to receive a

Department of Defense

Module 4 Data Validation Guidelines: Data Validation Procedure for Organic Analysis by GC

March 2021

Page 13 of 40

revised report. If this cannot be done, then consideration should be given to qualifying all

associated data as X, exclusion of data recommended.

4.2 Laboratory Control Sample/Laboratory Control Sample Duplicate (LCS/LCSD)

An LCS is a sample matrix free from the analytes of interest, spiked with known amounts of

the analytes and taken through all sample preparation, cleanup and analytical steps. LCSs

establish the method precision and bias for a specific batch of samples. Analysis of LCSDs

may be required by the QAPP or may be used as an indication of batch precision in

instances where MSD analysis is not possible (e.g., a limited volume of sample).

LCS (sometimes called a “Blank Spike”) and, if analyzed, LCSD recoveries should be within

the QC limits specified in the QAPP or as listed in the QSM. If an LCSD was analyzed, the

RPDs should be within the QC limits specified in the QAPP or as listed in the QSM.

Evaluation of LCS/LCSD

Verify that results (from appropriate summary form), percent recoveries, RPDs (if applicable)

and acceptance limits were reported for all target analytes and surrogates.

If the LCS/LCSD was not spiked with all target analytes, notify the project team by following

the notification protocols outlined in the QAPP (such as UFP-QAPP Worksheet #6) and

qualify all detects and non-detects for those analytes not spiked as X, exclusion of data

recommended.

If the spike percent recovery control criteria displayed in the deliverable are not the same

range (i.e., outside or wider than) as those stipulated in the QAPP or the DoD QSM,

reference the required control ranges for evaluation instead of the summarized ranges in the

deliverable. The project team should be informed to implement changes to the current

deliverables or those to be created in the future.

In-house control limits are acceptable for any analytes not specified in the QAPP or DoD

QSM. No qualification is necessary for any reported in-house control limit that is within (i.e.,

same or less than) those specified in the QAPP or DoD QSM. If the laboratory’s in-house

control limits are wider than those in the QSM and the results are outside of the DoD QSM

limits, qualify the appropriate data as X, exclusion of data recommended.

If the LCS percent recoveries were greater than the upper control limit, qualify detects for the

analyte in associated samples as estimated with a positive bias J+. Non-detects should not

be qualified.

If the LCS percent recoveries were less than the lower control limit, qualify detects for the

analyte in associated samples as estimated with a negative bias J- and non-detects as X,

exclusion of data recommended.

If the LCS/LCSD RPDs were greater than the acceptance limits, qualify detects for the

analyte in the associated sample(s) as estimated J. Non-detects should not be qualified.

Professional judgment should be utilized in qualifying data for circumstances other than

those listed above.

4.3 Matrix Spike/Matrix Spike Duplicate (MS/MSD)

MS/MSD data are used to determine the effect of the matrix on a method’s recovery

efficiency and precision for a specific sample matrix.

Department of Defense

Module 4 Data Validation Guidelines: Data Validation Procedure for Organic Analysis by GC

March 2021

Page 14 of 40

Generally, qualifying action is taken only on the parent sample based on MS/MSD non-

conformities. In instances where it can be determined that the results of the MS/MSD affect

only the sample spiked, then qualification should be limited to that sample alone. Using

informed professional judgment, the data reviewer may use the MS/MSD results in

conjunction with other QC criteria (i.e., surrogates and LCS) and determine the need for

additional qualification beyond that applied to the parent sample when the laboratory is

having a systemic problem in the analysis of one or more analytes, which affects all

associated samples.

If a field blank was used for the MS/MSD, this fact should be included in the data validation

report. Sample matrix effects may not be observed with field blanks; therefore, the recoveries

and precision do not reflect the extraction or analytical impact of the site matrix.

The laboratory should spike and analyze an MS/MSD from the specific project site as

required by the QAPP for each matrix type and analytical batch. The MS and MSD should be

spiked per QSM requirements with all target analytes. If the parent sample for the MS/MSD

was from another site or project (for example, not enough sample collected, or multiple site

samples analyzed within a single batch), the reason should be documented in the data

validation report, and sample results should not be qualified due to any non-conformities

noted in non-site-specific matrices.

Evaluation of MS/MSD

MS/MSD data should be reported on a MS/MSD summary form (or equivalent). Verify that

the MS/MSD were spiked with all target analytes, and that percent recoveries were reported

for all target analytes.

Compare the percent recovery and RPD for each analyte with LCS control limits established

by the QAPP. If the spike percent recovery control criteria displayed in the deliverable are not

the same range (i.e., outside or wider than) as those or stipulated in the QAPP or the DoD

QSM, reference the required control ranges for evaluation instead of the summarized ranges

in the deliverable. The project team should be informed to implement changes to the current

deliverables or those to be created in the future. Please follow the notification protocols

outlined in the QAPP (such as UFP-QAPP Worksheet #6).

If the MS/MSD was not spiked with all target analytes, notify the project team by following the

notification protocols and qualify all detects and non-detects in the parent sample for those

analytes in each batch not spiked as X, exclusion of data recommended.

If the MS/ MSD percent recoveries were greater than the upper control limit, qualify detects

for the analyte in the associated parent sample as estimated J+. Non-detects should not be

qualified.

If the MS/MSD percent recoveries were less than the lower acceptance limit but ≥ 10%,

qualify detects for the analyte in the associated parent sample as estimated J- and non-

detects as estimated UJ. If the percent recoveries were < 10%, qualify detects for the analyte

in the associated parent sample as estimated J- and non-detects as X, exclusion of data

recommended.

If the MS/MSD RPDs were greater than the acceptance limits, qualify detects for the analyte

in the associated sample(s) as J. Non-detects should not be qualified.

If the MS/MSD fail due to the presence of target analytes in the parent sample at > 4X the

spike concentration or if matrix spikes are diluted to less than the LOQ, then MS non-

Department of Defense

Module 4 Data Validation Guidelines: Data Validation Procedure for Organic Analysis by GC

March 2021

Page 15 of 40

conformities should not result in any qualifications. Note the incident in the data validation

report.

4.4 Method Blanks

A method blank is used to identify systemic contamination originating in the laboratory that

may have a detrimental effect on project sample results. The validator should identify

samples associated with each method blank using a method blank summary form (or

equivalent). Verify that the method blank has been reported per batch.

Compare the results of each method blank with the associated sample results. The reviewer

should note that the blank analyses may not involve the same weights, volumes, percent

moistures, or dilution factors as the associated samples.

These factors should be taken into consideration when applying the 5X and 10X criteria

(discussed in section 3.3.1), such that a comparison of the total amount of contamination is

actually made. Care should be taken to factor in the percent moisture or dilution factor when

doing comparisons between detects in the sample and the method blank. If available, raw

data should be used for comparison and evaluation.

Evaluation of Method Blanks

If no method blank was analyzed, qualify detects in samples with no associated method

blank X, exclusion of data recommended. Non-detects do not require qualification.

If gross contamination exists (defined as greater than a Project Action Limit) in the method

blanks, all analytes affected should be qualified X, exclusion of data recommended. due to

interference in all affected samples and this should be noted in the data validation report.

If target analytes other than common laboratory contaminants (see Table II) are found at low

levels in the method blank(s), it may be indicative of a problem at the laboratory and should

be noted in the data validation report.

If an analyte is detected in the method blank, but not in the associated samples, no action is

taken.

If an analyte is detected in the method blank and in the associated samples, the action taken

depends on both the blank and sample concentrations. Table III (Blank Qualifications) and

section 3.3.1 discussions on evaluations of results from the DL/LOD to LOQ is also

applicable to the method blank.

Additionally, there may be instances where little or no contamination was present in the

associated method blanks, but qualification of the sample was deemed necessary.

Contamination introduced through dilution water is one example. Although it is not always

possible to determine instances of this occurring can be detected when contaminants are

found in the diluted sample result but are absent in the undiluted sample result. It may be

impossible to verify this source of contamination. However, if the reviewer determines that

the contamination is from a source other than the sample, the data should be qualified. In this

case, the 5X or 10X rule does not apply. The reason should be documented in the data

validation report. Qualification of the data should be performed as given in Table III.

Multiple blank contaminations (such as a batch with field blanks and a method blank) does

not establish a ‘hierarchy’ of one blank over another. Each blank must be evaluated

individually. Blanks should not be qualified due to the results of other blanks.

Department of Defense

Module 4 Data Validation Guidelines: Data Validation Procedure for Organic Analysis by GC

March 2021

Page 16 of 40

4.5 Sample Dilutions and Reanalysis

Laboratories may dilute samples due to high analyte concentrations or reanalyze samples

due to QC non-conformities, and document both sets of results. Generally, the laboratory will

report the “best” value for a given analyte in the official laboratory report (or equivalent form).

In these instances, the validator should evaluate both the reported and the initial analysis

result. The validator should consider the application of appropriate qualifiers to the reported

results within the scope of the project due to elevated LODs/LOQs or other QC non-

conformities. Qualifiers apply only to the reported results in the official laboratory report.

Evaluation of Sample Dilutions and Reanalysis

When sample results are reported at more than one dilution due to analyte concentrations

exceeding the calibration curve, the lowest LODs are generally used for the non-detects

unless a QC criterion has been exceeded.

Results reported from dilutions leads to elevated LODs for non-detects. The data validation

report should indicate the reason for all reported dilutions (including cases where the

laboratory did not perform an undiluted analysis) resulting in elevated sensitivity limits for

non-detected results.

When reanalysis has occurred due to QC non-conformities, the validator should ensure that

the non-conformity was corrected during the reanalysis. If that is not the case, then the

appropriate qualifier should be placed on the reported results.

In some cases, using professional judgment, the validator may determine that an alternate

result was more appropriate than the one reported. In those cases, explain the rationale for

accepting the alternate result in the data validation report.

In some cases, reanalysis may lead to exceedances of holding time. Use professional

judgment to evaluate the results and apply the appropriate qualifiers (if required).

5.0 Stage 2B Validation

Note: Stage 2B includes all of Stage 1, and Stage 2A

Stage 2B requires the review and qualification of the following summary documents.

• Sequence and Preparation Logs (or equivalent)

• Instrument Performance Check Summary (any equivalent to include Degradation

Checks)

• Initial Calibration Summary (any equivalent to include Initial Calibration, Average

Response Factors, and Regression)

• Initial/Continuing Calibration Verification Summary (any equivalent to include Initial

and Continuing Calibration Verifications)

• Internal Standard Summary (any equivalent to include Internal Standards)

• Cleanup Procedure Summary (any equivalent to include Cleanup Recovery Checks)

• Second Column Summary (or equivalent to show analysis by a Second Column)

Stage 2B is the validation of instrument specific QC data.

5.1 Sequence and Preparation Logs

Sequence logs are reviewed by the data validator to ensure all QC samples (both batch and

instrument specific) were analyzed within a specific batch, in the correct order. Preparation

Department of Defense

Module 4 Data Validation Guidelines: Data Validation Procedure for Organic Analysis by GC

March 2021

Page 17 of 40

logs are reviewed by the data validator to ensure that samples had the proper extraction

performed, within specified holding times. Non-conformities uncovered in the review of the

logs may point the validator to specific samples that require further review. Non-conformities

uncovered in preparation or sequence logs should be noted in the data validation report.

Sequence logs are helpful in identifying when multiple instrumentation is used to analyze a

batch of samples. For example, it is not uncommon to analyze a single batch of twenty

samples at the same time on two or more different instruments. At a minimum, each

instrument should be calibrated independently. Batch QC should be reviewed on each

instrument, as appropriate. Non-conformities involving the use of multiple instruments should

be noted in the data validation report.

5.2 Instrument Performance Checks (Method 8081: Organochlorine Pesticides)

4,4′-Dichlorodiphenyltrichloroethane (DDT) and Endrin are prone to degradation in the

injection port liner with the presence of high boiling residue from sample injection or when the

injector contains metal fittings. Degradation problems are checked by injecting a standard

containing only DDT and Endrin. Presence of DDE, DDD, Endrin Aldehyde, or Endrin Ketone

indicates breakdown. Unless otherwise specified in an approved project plan, this test should

be performed as a test of the inertness of the analytical system even when DDT and Endrin

are not target analytes for a given project.

Evaluation of Performance Checks

The breakdown of DDT and Endrin should be measured before samples are analyzed at the

beginning of each 12-hour shift. Professional judgment should be applied to qualify results for

samples that were analyzed more than 12 hours after the breakdown standard was analyzed.

Verify that the degradation does not exceed 15% for either DDT or Endrin on both GC

columns.

1. If DDT breakdown is > 15%:

• Flag all associated detects for DDT, DDD, and DDE as J, estimated.

• If DDT was not detected in the breakdown standard, then qualify all results for

DDT as X, exclusion of data recommended. Qualify DDD and DDE detects as

presumptively present at an estimated quantity NJ.

• If DDT is present and passes on one column, but not confirmed on the other

column that has > 15% breakdown, qualify the associated DDT data X,

exclusion of data recommended. Qualify DDE and DDE detects as

presumptively present at an estimated quantity NJ.

2. If Endrin breakdown is > 15%:

• Flag all associated detects for Endrin, Endrin Aldehyde, and Endrin Ketone as

J, estimated.

• If Endrin was not detected, but Endrin Aldehyde or Endrin Ketone are detected

in the breakdown standard, then qualify the Endrin result as X, exclusion of

data recommended. Qualify Endrin Ketone or Endrin Aldehyde detects as

presumptively present at an estimated quantity NJ.

Department of Defense

Module 4 Data Validation Guidelines: Data Validation Procedure for Organic Analysis by GC

March 2021

Page 18 of 40

• If Endrin is present on one column but not confirmed on the other column that

has > 15% breakdown, qualify the associated data X, exclusion of data

recommended. In this case, the reviewer may determine that the compound

needs to be reported as a tentative identification N.

5.3 Initial Calibration

The objective of initial calibration is to ensure that the instrument is capable of producing

acceptable qualitative and quantitative data. Initial calibration demonstrates that the

instrument is capable of acceptable performance in the beginning of the analytical run and of

producing an acceptable calibration curve. The GC system can be calibrated using the

external standard technique or internal standard technique. Because of the difficulty in

selecting suitable internal standards, the external standard technique will most often be the

method of choice.

Evaluation of External Calibration

A minimum of five standards is required for a linear calibration. The lowest calibration

standard concentration should be at or below the LOQ. If the laboratory used more than the

minimum number of standards and must exclude calibration points, only exclusion of the high

or low standard is allowed. The calibration points in between should not be excluded without

sound technical justification.

If reported target analytes were not properly calibrated, make note of this in the data

validation report and qualify the associated data as X, exclusion of data recommended.

If the concentration of the lowest standard in the initial calibration was greater than the LOQ,

qualify all detects between the DL and the lowest standard as X, exclusion of data

recommended. Detects above the low standard do not require qualification. Non-detects do

not require qualification.

Inform the point of contact (QAPP Worksheet #6) for further instruction in those instances of

unwarranted manipulation of calibration curves. As an example, calibration curves that were

run with excessive calibration points that are misapplied to achieve passing criteria (without

any technical justification) require prompt notification of the project team. If the issue cannot

be resolved with the laboratory, make note of this in the data validation report and qualify all

affected data as X, exclusion of data recommended.

Calibration Factor (CF): External standard calibration involves a comparison of instrument

responses from the sample to the target compound responses in the calibration standards.

The ratio of the detector response to the amount of analyte in the calibration standard is

defined as the CF. The instrument should have been calibrated for all target analytes and

surrogates.

Evaluate the percent relative standard deviation (%RSD) for all target compounds. If any

analyte has a %RSD greater than 20%, qualify detects for the affected compounds as J and

non-detects as UJ in the associated samples that correspond to that initial calibration.

If the %RSD is excessively high (defined as > 40%) qualify associated target analyte sample

results as X, exclusion of data recommended.

Linear Regression: The laboratory may employ a linear or weighted linear least squares

regression curve. Evaluate the Correlation Coefficients (r) for all applicable target analytes.

Department of Defense

Module 4 Data Validation Guidelines: Data Validation Procedure for Organic Analysis by GC

March 2021

Page 19 of 40

The r value should be ≥ 0.995. Some instrumentation reports Coefficient of Determination

(r

2

). If the instrument reports r

2

, the value should be ≥ 0.99.

If the r value for any target analyte is < 0.995 (or the r

2

value is < 0.99), qualify detects for the

affected analytes J and non-detects as UJ in the associated samples.

If the r value is excessively low (defined as < 0.95) or the r

2

value is excessively low (defined

as < 0.90), qualify all associated non-detects as X, exclusion of data recommended and

detects as estimated J.

Non-Linear Regression: The laboratory may also generate a higher order curve for the

calibration. The calibration curve should not be more than second order (Quadratic) in

accordance with QSM requirements.

A minimum of six standards is required for a second order (quadratic) curve.

Evaluate the correlation coefficients(r) for all applicable target analytes. The r value should

be ≥ 0.995. Some instrumentation reports coefficient of determination (r

2

). If the instrument

reports r

2

, the value should be ≥ 0.99.

If the required number of calibration standards was not used, qualify detects J. Apply

professional judgment to qualify non-detects based on the concentrations of the standards

used.

If the r value for any target analyte is < 0.995 (or the r

2

value is < 0.99), qualify detects for the

affected analytes J and non-detects UJ in the associated samples.

If the r value is excessively low (defined as < 0.95) or the r

2

value is excessively low (defined

as < 0.90), qualify all associated non-detects as X, exclusion of data recommended and

detects as estimated J.

Calibration curves that are higher than second order (such as a third order polynomial fit) are

not allowed in accordance with QSM requirements. Qualify X, exclusion of data

recommended all associated data based on third order (or higher) calibration curves.

5.3.1 Method 8081: Organochlorine Pesticides & Method 8082: Polychlorinated

Biphenyls (Aroclors)

For Organochlorine Pesticides with multicomponent analytes such as Toxaphene and

Chlordane, quantitation must be performed using a five-point calibration, in accordance with

QSM requirements. Results may not be quantitated using a single point calibration. If

Toxaphene and Chlordane results are reported without a multipoint calibration, then inform

the QAPP point of contact (QAPP Worksheet #6). If the situation cannot be resolved with a

revised laboratory report, then qualify all associated detects as X, exclusion of data

recommended and make note in the data validation report.

For PCB Aroclors, a multipoint calibration employing a mixture of Aroclors 1016 and 1260 at

five different concentrations is sufficient to demonstrate detector linearity because it will

usually include many of the peaks of some of the other Aroclors. Although the method may

be used to demonstrate that a sample does not contain peaks for some of the other Aroclors,

the qualitative identification of the Aroclor is subject to the professional judgment of the

analyst after comparison to standard(s) of that respective Aroclor. If any Aroclor other than

1016 or 1260 is detected, the result must be quantified against a multipoint calibration for the

specific Aroclor mixture of interest prior to reporting a quantitative result for that Aroclor.

Department of Defense

Module 4 Data Validation Guidelines: Data Validation Procedure for Organic Analysis by GC

March 2021

Page 20 of 40

If any Aroclor other than 1016 or 1260 is detected in the associated sample and is not

quantified against a multipoint curve of the identified Aroclor, then inform the QAPP point of

contact (QAPP Worksheet #6). If the situation cannot be resolved with a revised laboratory

report, then qualify all associated detects as X, exclusion of data recommended and make

note in the data validation report.

5.3.2 Method 8151: Chlorinated Herbicides

Herbicide samples undergo a hydrolysis step during extraction and may undergo a

derivatization step. If the calibration standards have undergone these steps as well, then the

calibration curve is directly comparable to the samples. However, if the calibration standards

did not undergo these steps, then then calculation of concentration (quantitation of the

results) should have included a correction of the molecular weight of the methyl ester versus

the acid herbicide.

This calculation may require a Stage 3 validation to determine if the correction factor was

applied appropriately. Inform the point of contact (QAPP Worksheet #6) if sufficient

information cannot be obtained for a Stage 2B validation.

5.4 Initial (Secondary Source) and Continuing Calibration Verification

The initial calibration curve should be verified with a standard that has been purchased or

prepared from an independent source each time initial calibration is performed. This standard

is called the secondary source or Initial Calibration Verification (ICV). The ICV should contain

all of the GC target analytes. Note that multiple ICVs may be analyzed to encompass all of

the target analytes.

After the initial calibration has been verified with a second source, samples may be run

continuously until the initial calibration fails. To verify this, a Continuing Calibration

Verification (CCV) containing all GC target compounds should be analyzed before sample

analysis, after every 10 field samples, and at the end of the analysis sequence. Continuing

calibration checks satisfactory performance of the instrument on a day-to-day basis.

The CCVs for Pesticide multicomponent mixtures Toxaphene and Chlordane by method

8081 and Aroclors other than 1016/1260 by Method 8082 are only required before sample

analysis.

Evaluating the ICV and CCV

Verify the ICV was analyzed following the initial calibration and contained all target analytes.

Verify the CCVs have been run at the proper frequency. When a new initial calibration is

performed, the ICV can serve as the first CCV if samples are being run afterwards. The

CCVs after the first ICV are not required to be a second source.

The ICV percent difference (%D) or percent drift for each target analyte and surrogate should

be ≤ 20%. The CCV %D for each target analyte should also be ≤ 20%.

If the ICV (second source) has not been performed successfully after an initial calibration or if

samples have been analyzed prior to a valid ICV, qualify X, exclusion of data recommended

all associated data. No samples should have been analyzed in accordance with QSM

requirements.

Department of Defense

Module 4 Data Validation Guidelines: Data Validation Procedure for Organic Analysis by GC

March 2021

Page 21 of 40

If the CCV has not been analyzed (either continuing or end-of-run), qualify X, exclusion of

data recommended all associated data. No samples should have been analyzed without a

valid CCV.

Verify that the %Ds are within the acceptance criteria. If any target analytes do not meet the

acceptance criteria for the CCV, qualify detects for that analyte as estimated J+ when the

%D is higher than acceptance criteria and J- when below acceptance criteria. Non-detects

are qualified as UJ in all associated samples for %D outside of acceptance criteria.

For gross exceedances of %D (defined as > 50%) qualify all associated data as X, exclusion

of data recommended.

5.5 Internal Standards (Optional)

Internal standard (IS) calibration involves comparison of instrument responses from the target

compounds in the sample to responses of internal standards added to the sample or extract

before injection. A constant amount of the IS is added to all samples extracts and calibration

standards. The peak response ratio of the target compound to the IS in the sample extract is

compared with the same ratio for each calibration standard. This ratio indicates that the

target compound response is calculated relative to that of the IS.

Evaluation of Internal Standards

Each IS area should be within 50-200% (same as QSM criteria of -50 to +100) of the area of

the mid-point standard in the ICAL for associated standards. On days when ICAL is not

performed, the daily initial CCV is used.

The IS retention times for all field and QC samples should be within 30 seconds of the

retention time of the midpoint standard in the ICAL, or on days when ICAL is not performed,

the initial CCV is used.

Detects for analytes quantitated using an IS area count > 200% should be qualified estimated

with a J. Non-detects should not be qualified.

Analytes quantitated using an IS area count < 50% but ≥ 20% should be qualified estimated

with a J for detects. Non-detects should be qualified estimated UJ.

If extremely low area counts are reported (< 20% of the area for associated standards),

detects and non-detects should be qualified X, exclusion of data recommended.

Large retention time variations may call into question peak identifications. If an IS retention

time varies by more than 30 seconds, detects and non-detects should be qualified X,

exclusion of data recommended.

5.6 Cleanup Procedures for Methods 8081 (Organochlorine Pesticides), 8082 (PCBs),

8141 (Ortho phosphorous Compounds), and 8151 (Chlorinated Herbicides)

Cleanup techniques are used to eliminate or minimize chemical and chromatographic

interferences arising from the samples themselves. Most environmental or waste samples

may require one or more cleanup techniques after extraction and prior to analysis. The

specific cleanup performed will be dependent on the nature of the samples.

A summary of recommended cleanup procedures can be found in Table IV. SW-846 method

3600 provides more in-depth guidance on cleanup method selection.

Department of Defense

Module 4 Data Validation Guidelines: Data Validation Procedure for Organic Analysis by GC

March 2021

Page 22 of 40

All associated batch QC samples must undergo the same cleanup procedure(s) as the

samples.

A description of the different cleanup approaches follows:

• Adsorption Chromatography - Florisil (Method 3620), and Silica Gel (Method 3630)

are useful for separating analytes of a relatively narrow polarity range away from

extraneous, interfering peaks of a different polarity. These are primarily used for

cleanup of a specific chemical group of relatively non-polar analytes such as

pesticides and PCBs.

• Gel Permeation Chromatography (GPC) (Method 3640) - This cleanup technique

applies to a broad range of pesticides and is capable of separating high molecular-

weight, high boiling point material from the target analytes. GPC may not be

applicable to elimination of extraneous peaks on a chromatogram which interfere with

the analytes of interest. It is, however, useful for the removal of high boiling point

materials which would contaminate injection ports and improve continuing calibration.

• Acid-base Partitioning (Method 3650) – This technique is useful for separating acidic

or basic organics from neutral organics. It has been applied to analytes such as the

Chlorinated Herbicides.

• Sulfur cleanup (Method 3660) – This technique is useful in eliminating known sulfur

from sample extracts, which may cause chromatographic interference with analytes of

interest.

• Sulfuric Acid/Permanganate Cleanup (Method 3665) – This technique improves

elevated baselines for PCB sample extracts prior to analysis. This method cannot be

used to cleanup extracts for other target analytes, as it will destroy most organic

chemicals, including the pesticides.

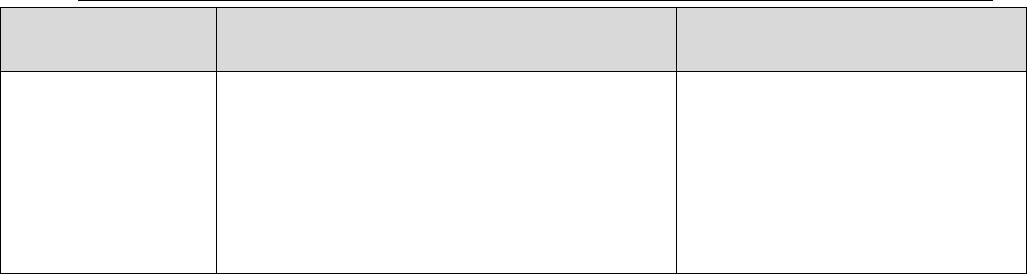

Table IV: Cleanup Methods

Analyte Group

Analytical Method

Cleanup Methods

Organochlorine Pesticides

8081

3620, 3640, 3660

PCBs

8082

3620, 3630, 3665

Organophosphorus Pesticides

8141

3620

Chlorinated Herbicides

8151

3620, 3650

Evaluation of Cleanup Methods (Recovery Checks)

The analyst must demonstrate that the compounds of interest are quantitatively recovered

before applying this method to actual samples. This test applies to both the column cleanup

and cartridge cleanup procedures. A recovery check needs to be performed using standards

of the target analytes at a known concentration near the LOQ for the target analyte. Only lots

of cartridges/columns from which the spiked analytes are quantitatively recovered may be

used to process the samples.

When using Florisil (3620) for pesticides, the lot of Florisil cartridges is acceptable if all

pesticides are recovered at 80 to 110%, the recovery of Trichlorophenol is < 5%, and no

peaks interfere with the target analytes. For Chlorophenoxy acid herbicides, the lot of Florisil

is acceptable if the target analytes are quantitatively recovered, the recovery of

trichlorophenol is < 5%, and no peaks interfere with the target analytes.

For Silica Gel (3630) the recovery of all analytes in the recovery check must be between 85-

115%.

Department of Defense

Module 4 Data Validation Guidelines: Data Validation Procedure for Organic Analysis by GC

March 2021

Page 23 of 40

The GPC (3640) should be calibrated at least once per week. The retention time shift must

be < 5% when compared to retention times in the last calibration UV trace. The UV trace

requirements are as follows: corn oil and Phthalate peaks must exhibit > 85% resolution;

Phthalate and Methoxychlor peaks must exhibit > 85% resolution; Methoxychlor and

Perylene peaks must exhibit > 85% resolution; Perylene and Sulfur peaks must not be

saturated and must exhibit > 90% baseline resolution. GPC elution should continue until after

Perylene has eluted, or long enough to recover at least 85% of the analytes, whichever time

is longer.

Acid-base Partition (3650), Sulfur Cleanup (3660), and Sulfuric acid/Permanganate (3665)

requires only that the batch QC pass the QC limits outlined in the QAPP or the laboratory

Standard Operating Procedure (SOP).

If it is determined that the QC samples were not treated with the same cleanup procedures

as the field samples, inform the point of contact (QAPP Worksheet #6) to receive a revised

laboratory report. If this is not possible, qualify all associated data as, exclusion of data

recommended and make note of this in the data validation report.

If the recovery check standard fails high, qualify detects J+ and no qualification is necessary

for non-detects.

If the recovery check standard fails low, qualify associated positive field sample results as

estimated J and non-detects as estimated UJ.

If the recovery standard fails unusually low (defined as < 10%), qualify positive field sample

results as estimated J and non-detects as X, exclusion of data recommended.

If there is recovery for negative test analytes (Trichlorophenol > 5%) or peak resolution is

less than required, inspect the field sample chromatograms and use professional judgment to

qualify associated results.

5.7 Second Column Confirmation/Dissimilar Detector Confirmation

Second column confirmation of all detects above the QAPP stated DL must be performed for

all GC work, unless an alternate detector was utilized for confirmation. The only exceptions

are for single column methods such as Total Petroleum Hydrocarbon (TPH) by Method 8015

where confirmation is not required. For the purposes of reporting, both columns are

considered equivalent, provided QC evaluations are within acceptance limits on both

columns. Barring chromatographic problems (overlapping peaks, baseline shifts) or QC

anomalies on one column or the other, the result from the column specified in the QAPP

should be reported. Some projects may require the reporting of results from both columns.

Evaluation of Second Column Confirmation

The RPD between columns should be ≤ 40%. The concentrations of both analytical column

peaks must be greater than the stated DL. If one column has a peak that corresponds to a

concentration that is less than the associated DL, then the result must be reported as a non-

detect, and the RPD is noted in the data validation report as “non-calculable”.

If the RPD between columns is > 40%, qualify the results as estimated J.

If second column confirmation is not performed, qualify any reported detect as presumptive

and estimated, NJ. The validator should inform the QAPP point of contact (QAPP Worksheet

#6) to obtain a revised laboratory report, if possible.

Department of Defense

Module 4 Data Validation Guidelines: Data Validation Procedure for Organic Analysis by GC

March 2021

Page 24 of 40

6.0 Stage 3 Validation

Note: Stage 3 validation includes all of Stage 1, Stage 2A and Stage 2B

Stage 3 requires the review of the following documents

• Raw Data (including any laboratory forms, instrument outputs, spreadsheets, or