Battery Replacement and Maintenance – tricks and tips

Thanks to Adrian Hearne (Adrian996) for initiating this DIY and his excellent tips, which I have

incorporated here. I have also extracted information from the workshop manual, courtesy of

Porsche AG. A popular battery choice is the Bosch Silver 7HN (75AH) battery, available from

Euro Car Parts or Costco for around £75. The new Bosch Silver S5 010 85Ah is also a direct

replacement.

Safety Notes:

• All loads must be switched off beforehand!

• Never disconnect battery with engine running!

• Never start engine without securely connected battery!

• The battery terminal clamps should only be attached without force to prevent damage

to the battery housing.

• Battery terminals should not be greased.

• Check that the battery is seated correctly after installation. Other dangers exist with a

loose battery such as: - Reduced service life due to vibration damage. - Damage to the

grid plates of the battery. - Damage to the battery housing through the retaining

bracket (possible acid leak, high subsequent costs). - Inadequate crash safety.

Replacing the Battery

Before you start, if you have a radio prior to the CR-23, make sure you have the radio

code. After reconnection of the battery you will need to re-enter the code. The CR-23 has a

different security system (matched to the car’s ECU) and does not need a code. If you happen

to lose the code for any reason, I have a Becker Radio Decoder, which calculates the code

from the last 4 digits of the serial number. It works in 95% of cases, otherwise it will be an

expensive trip to your OPC.

All UK C16 specification cars are fitted with a tilt sensor and alarm siren – M536 option code.

The alarm siren has a backup battery inside it, and will sense a disconnected battery and will

cause the siren to sound. It is ear-splitting, so you want to avoid this happening! In order to

avoid triggering the alarm siren (installed on right next to the battery) of vehicles with M 536,

the battery must be disconnected with the ignition switched on!

Torque wrench settings are shown in the instructions, but to be honest they aren’t really

necessary IMHO. If you have reasonable car DIY experience, you will know how tight they

need to be by feel.

Removal:

1. Switch ignition on, but do not start the car. Leave the key in this position throughout the

process.

2. Operate luggage compartment release and switch off the air conditioning, radio, and any

other loads.

3. Just to be safe, leave the door open, or make sure

you have a spare key handy. Get out and open the

luggage compartment.

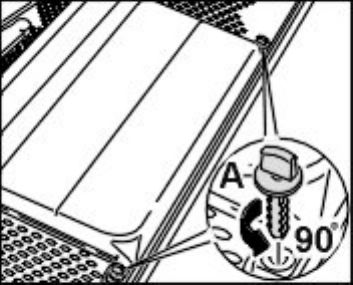

4. Open turn-lock fasteners -A- .

5. Remove battery cover.

6. First disconnect the ground strap of the battery on the

negative battery terminal. Unscrew hexagon nut and

remove terminal. You will need a 10mm open-ended or

ring spanner.

7. Undo hexagon nut on the positive battery terminal

and remove terminal.

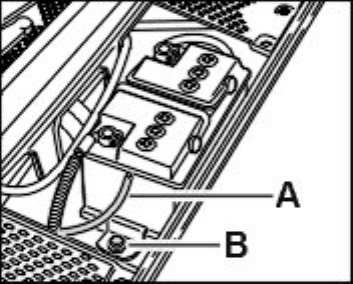

8. Pull off venting hose -A- and fix in a suitable position

with insulating tape.

9. Unscrew fastening screw -B- . You will need a socket

and extension for this.

10. Remove battery.

11. Clean battery platform

Replacement:

1. Insert battery.

2. Screw in fastening screw -B- , position battery and

tighten the fastening screw. Tightening torque: 23 Nm

(17 ftlb.)

3. Push on venting hose -A- .

4. First connect the positive cable then the negative - otherwise there is a danger of a short-

circuit! Tightening torque: 5 Nm (4 ftlb.). When you connect the negative terminal, systems

will spring into life!

5. Put on the battery cover and lock with the turn-lock fasteners.

6 Switch off ignition, or go for a spin!

Checking Acid Level

CAUTION:

• The accident prevention regulations must be observed when handling battery acids.

• Wear suitable protective clothing and protective glasses.

• Only illuminate the inside of the battery with a torch.

• Never illuminate the inside of the battery with a naked flame.

• Do not handle a naked flame or burning cigarettes near to batteries.

• Observe the disposal regulations for batteries when disposing of batteries and sulphuric

acids.

Note

Use commercially available battery filling bottle.

The correct acid level of the battery is an important factor for long and efficient operation of

the battery. When the acid level is too low, a capacity loss (performance loss) of the battery

occurs which is caused by the cell plates drying out. If the cell plates are not surrounded by

electrolyte (battery acid), it will lead to corrosion of the lead plates, the plate bridges and the

cell connectors. The result of the corrosion is that the function of the battery cannot be

guaranteed. The battery will become useless. If the acid level is too high, damage can occur

by the battery acid leaking out (sulphuric acid water mixture) outside the battery.

1. Switch ignition off and remove ignition key.

2. Remove battery cover.

3. Unscrew plugs of the battery.

4. Illuminate into the battery using a torch. The electrolyte level of the battery must be at the

protruding lug.

— If the acid level is too low, refill distilled water using the battery filling bottle.

5. Screw in plug of the battery again, ensure that it is seated correctly.

6. Remount battery cover.

Open-circuit voltage measurement

Note

Use a hand-held multimeter to measure the battery voltage.

1. Charge battery fully.

2. Switch ignition on and leave key in ignition as above.

3. Remove battery cover and disconnect ground strap on the battery.

4. Allow a waiting time of at least 2 hours during which the battery should be neither loaded

nor charged.

5. Measure the battery voltage with a hand-held multimeter.

— The battery open-circuit voltage should not fall below 12.5V.

— If the hand-held multimeter shows 12.5V or over, the battery voltage is OK.

— If the hand-held multimeter shows a battery voltage below 12.5V it may be reaching the

end of its life. Check the specific gravity to confirm, and/or have a load test done at a battery

supplier.

Checking the specific gravity of electrolyte

Read safety notes above.

Notes:

Use commercially available battery acid tester. The gravity of electrolyte test provides

information about the state of the battery in connection with a battery load test

The temperature of the battery acid must be at least 10°C .

The gravity of electrolyte must be checked in all battery cells as follows.

1. Switch ignition off and remove ignition key.

2. Unscrew all battery plugs (plugs of the battery cell).

3. Dip into the battery cell using the acid siphon or the pipette and take up the battery acid.

4. Read off the gravity of electrolyte in kg/dm³ on the scale of the battery acid tester and

compare with the following table.

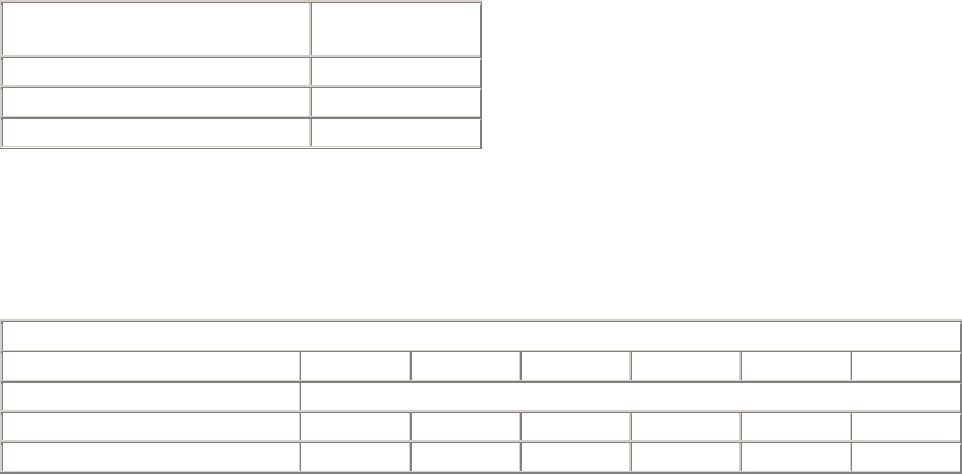

Battery charging condition

in normal climatic zones

Spec. gravity

in kg/dm³

discharge 1.12

half charged 1.20

well charged 1.28

The gravity of electrolyte must be at least 1.24 kg/dm³.

— If the gravity of electrolyte is too low, charge battery.

— After charging the battery, repeat the gravity of electrolyte test.

The measured values for the specific gravity of electrolyte of the individual battery cells should

not deviate by more than 0.03 kg/dm ³ from each other.

Examples of non-permissible specific gravity of electrolyte deviations:

Battery cells: 1 2 3 4 5 6

Gravity of electrolyte per cell in kg/dm³

Example 1: 1.24 1.25 1.25 1.10 1.24 1.25

Example 2: 1.26 1.26 1.25 1.14 1.18 1.24

Example 1: The gravity of electrolyte in cell 4 is too low.

Example 2: The gravity of electrolyte in cells 4 and 5 is too low. The specific gravity of

electrolyte deviations between the battery cells is larger than 0.03 kg/dm³.

— If the nominal values are not achieved, replace battery.

— If the nominal values are achieved, screw the original plug back in.