Installation, Operation and

Maintenance Manual

Table of Contents

I. Introduction ............................................................................. 3

II. Why use AGM

2

batteries? ....................................................... 3

III. Safety....................................................................................... 4

I V. Getting started ........................................................................ 4

A. Installation ..................................................................... 4

B. Battery connections ...................................................... 5

C. Battery cabling .............................................................. 6

D. Torquespecications .................................................... 6

V. Technical details ..................................................................... 8

A. Operating temperature range ....................................... 8

B. Understanding state of charge ..................................... 8

C. Storage and self-discharge ........................................... 8

D. Battery life expectations ............................................... 9

E. Float applications .......................................................... 9

F. Charging ...................................................................... 10

G. Parasitic loads ............................................................. 13

H. Testing .......................................................................... 13

I. Maintenance ................................................................ 14

J. Ventilation .................................................................... 15

K. Winter storage ............................................................. 15

L. Warranty considerations ............................................. 15

VI. Additional information .......................................................... 16

VII. FAQs ...................................................................................... 16

VIII.Denitionsofacronyms ........................................................ 17

View ODYSSEY battery

technical specications

3

AMER-EN-IOM-ODY-0523

www.odysseybattery.com

I. INTRODUCTION

ODYSSEY

®

batteries are manufactured by EnerSys

®

using its unique Absorbed Glass Mat (AGM) Thin

Plate Pure Lead (TPPL) technology to deliver twice the power and three times the life of conventional

AGM batteries.

Bringing together the technologies incorporated into ODYSSEY batteries and NorthStar batteries has

integrated years of intelligence, research and development, resulting in the creation of the next

generation of AGM - TPPL batteries. AGM

2

is a unique design of Valve Regulated Lead Acid (VRLA)

batteries that combines three major technical advancements in one battery: super high-grade

materials + refined chemical formula + TPPL technology. This sets AGM

2

batteries apart in terms of

power, fast-charge acceptance, shelf life, durability and most of all exceptional value for your

investment.

Throughout their design cycle life, AGM

2

batteries can provide engine cranking pulses of up to 2700

amps for five seconds at 77°F (25°C), while delivering over 400 charge/discharge cycles to 80% Depth

of Discharge (DOD). This challenges all typical starting batteries, which are only designed for high cur-

rent for short durations, to perform poorly when deeply discharged repeatedly.

Likewise, a typical deep cycle battery, which is designed to provide relatively low current for a long

duration of time, cannot provide the high current bursts that are needed for starting applications.

AGM

2

technology allows one battery to provide both excellent cycling life and high-power capability

for many applications. AGM

2

batteries excel in both starting and deep cycling without compromising

lifespan or performance, making them an excellent choice for a wide range of applications such as

heavy-duty trucks, recreational vehicles, marine, emergency power and much more.

II. WHY USE ODYSSEY

®

AGM

2

BATTERIES?

• Longservicelife–designlifeof8-12yearsinfloatapplicationsand3-10yearsinnon-float

applications at 77°F (25°C).

• Fastcharging–extremelylowinternalresistanceallowshigh-currentcharging,whichreduces

charge time.

• Excellentcyclelife–provideupto900cycleswhendischarged50%.

• Lowtemperatureperformance–evenatsub-zerotemperaturesdownto-40°F(-40°C),battery

performance allows for quick engine starts or deep discharges.

• Longshelflife–canbestoredforuptotwoyearsat77°F(25°C)andlongeratlowertemperatures.

• Deepdischargerecovery–itispossibletorecoveradeeplydischargedAGM

2

battery. There is

more information on that process later in this manual. However, overall battery life will be affected.

• Virtuallymaintenance-free–noneedtoaddwatertobatteries.

• Superiorvibrationresistance–highcompressiondesignandhigh-strengthplasticconstruction

give these batteries extreme shock and vibration resistance.

• Mountingflexibility–canbemountedinanypositionexceptinverted/upsidedownintypical

starting applications.

• Easyshipping–approvedforshipmentasnon-hazardouscargobytheU.S.Departmentof

Transportation.

• ThemanagementsystemsgoverningthemanufactureofthisproductareIATF16949,ISO9001

andISO14001certified.

AMER-EN-IOM-ODY-0523

www.odysseybattery.com

4

III. SAFETY

Batteries can deliver a large amount of power, which can cause injury or death if not handled safely.

Please follow these guidelines any time you are working around batteries.

• Personalprotectiveequipmentincludingglovesandsafetyglassesshouldbeworn.

• Insulatedtoolsshouldbeused.

• Watches,braceletsorothermetalobjectsshouldberemoved.

• Donotplaceanyobjectsontopofthebattery.

• MakesurethechargingsystemissetforAGMbatteriesandinlinewithadvisedcharging

specifications.

• Donotchargebatteriesifthetemperatureisabove104°F(40°C).

IV. GETTING STARTED

A. INSTALLATION

ODYSSEY

®

AGM

2

batteries are shipped from the factory at a full State of Charge (SOC) and should be

readyforinstallationoutofthebox.Intypicalstartingapplications,measurethebattery’svoltage;ifit

is12.65voltsorhigher,thebatterycanbeinstalled.Ifthevoltageislowerthan12.65volts,thebattery

should be charged. Multiple battery configurations should be matched voltage. Refer to the Charging

section in this manual if needed.

To replace an existing battery, follow the steps below:

1. Besuretoweartheappropriatepersonalprotectiveequipment.

2.Notetheorientationoftheexistingbattery’spositiveandnegativeterminals.

3. Disconnectthecables,negativefirst,fromtheoldbatteryfollowingvehiclemanufacturer

guidelines if applicable. The old battery should be returned to a battery dealer for proper

recycling.

4. Inspectthebatterycablesforcorrosion,aciddamageorinsulationdeteriorationandreplaceif

needed.

5. Position the new ODYSSEY AGM

2

battery in the battery tray and secure it

properlytothevehicle–heightadaptersmaybeneededandareavailableforsomesizes.

6. ConnectthepositivecablefromtheignitiontothePositive(+)terminalofthebattery.

7. Connect the negative cable from the ignition or chassis to the Negative (-) terminal of the battery.

8. ProperlytorquetheconnectionperthespecificationinTable2onpage6.

Thestepsaboveapplytoasingle,12-voltbattery.Thereareotherapplicationsthatmayrequire

batteriestobeconnectedinparallelorseries.Itisimportanttotakenoteofthebattery’srequired

configurationbeforetheexistingbatteriesareremoved.Ifthereisanyquestionaboutthebattery

configuration, refer to the documentation that was supplied with the device being powered. ODYSSEY

AGM

2

batteries can be installed on their side or end if needed due to space constraints.

NOTE: This is a valve regulated sealed battery and never needs to have water or electrolyte (acid)

added. Warranty will be void if opened!

5

AMER-EN-IOM-ODY-0523

www.odysseybattery.com

ANY OF THE FOLLOWING WILL VOID THE WARRANTY ON YOUR ODYSSEY

®

BATTERY:

•REMOVINGTHELABELEDCOVER

•REMOVINGORDESTROYINGTHEBATTERY’SDATECODE

ODYSSEY

®

EXTREME BATTERY WARNING –DONOTUSEANYTYPEOFOIL,ORGANICSOLVENT,

ALCOHOL,DETERGENT,STRONGACIDS,STRONGALKALIS,PETROLEUM-BASEDSOLVENTOR

AMMONIASOLUTIONTOCLEANTHEBATTERYCOVERSANDBATTERYTOPS.THESEMATERIALS

MAYCAUSEPERMANENTDAMAGETOTHEBATTERYCOVERSANDBATTERYTOPSANDWILL

VOIDTHEWARRANTY.

ODYSSEY

®

PERFORMANCE BATTERY WARNING–PROLONGEDEXPOSUREANDORIMMERSION

INTOANYTYPEOFOIL,ORGANICSOLVENT,ALCOHOL,DETERGENT,STRONGACIDS,STRONG

ALKALIS,PETROLEUM-BASEDSOLVENTORAMMONIASOLUTIONTOCLEANTHEBATTERY

COVERSANDBATTERYTOPSMAYCAUSEPERMANENTDAMAGETOTHEBATTERYCOVERSAND

BATTERYTOPSANDWILLVOIDTHEWARRANTY.

DONOTSHORTCIRCUITYOURODYSSEY

®

BATTERY’STERMINALS!

Remove any metallic items such as watches, bracelets and other personal jewelry.

B. BATTERY CONNECTIONS

Here are some general guidelines regarding different types of battery connections:

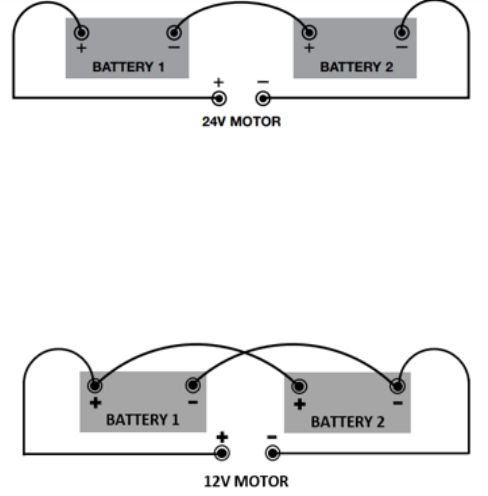

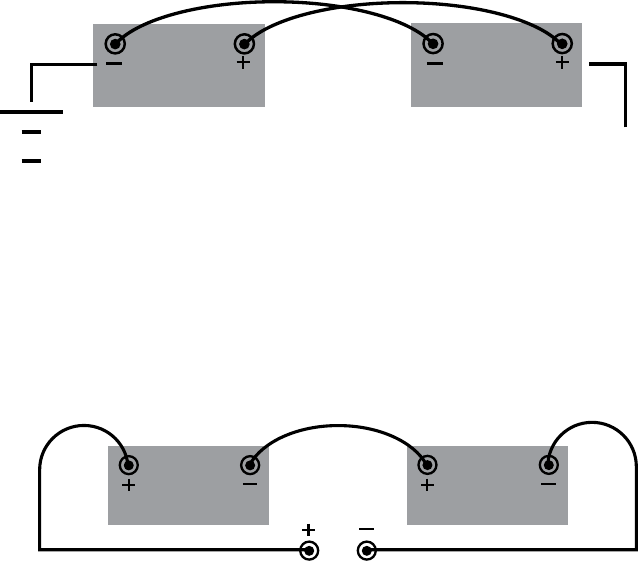

• Seriesconnectionsareusedtoincreasebatteryvoltagebyconnectingthepositiveterminalof

onebatterytothenegativebatteryofanotherbattery.Inthisconfiguration,theoverallcapacityof

the battery is equal to the capacity of one battery. Series systems are wired as shown in Battery

Sketch1.

PLEASE NOTE:Whenreplacingmultiplebatteries,eachbatteryshouldbeofasimilar

SOC.

Battery Sketch 1

• Parallelconnectionsareusedtoincreasethebatterycapacitybyconnectingthepositiveterminal

of one battery to the positive terminal of a second battery. Likewise, the negative terminals are

connected.Inthisconfiguration,thesystemvoltageisthevoltageofonebattery.Parallelsystems

are wired as shown Battery Sketch 2:

Battery Sketch 2

AMER-EN-IOM-ODY-0523

www.odysseybattery.com

6

C. BATTERY CABLING

Since battery cables are the connection between the battery, the charging system and the device

beingpowered,itisimportantthattheyareproperlyinstalled.Improperlyinstalledcablescanresult

inpoorbatteryperformance,terminaldamageorevenfire.Cablesshouldbesizedbasedonthe

amountofcurrenttheyareexpectedtocarryintheapplication.RefertoTable1forcablecurrent

ratingsaccordingtoNECTable310.15(B)16forcoppercablesratedat167°F(75°C).Ifitisnecessary

for a cable to be longer than six feet, a heavier gauge wire should be considered to avoid excessive

voltage drop.

AWG mm2 Amps

14 2.5 20

12 4 25

10 6 35

8 10 50

6 16 65

4 25 85

2 35 115

1 50 130

1/0 55 150

2/0 70 175

4/0 120 230

Table 1

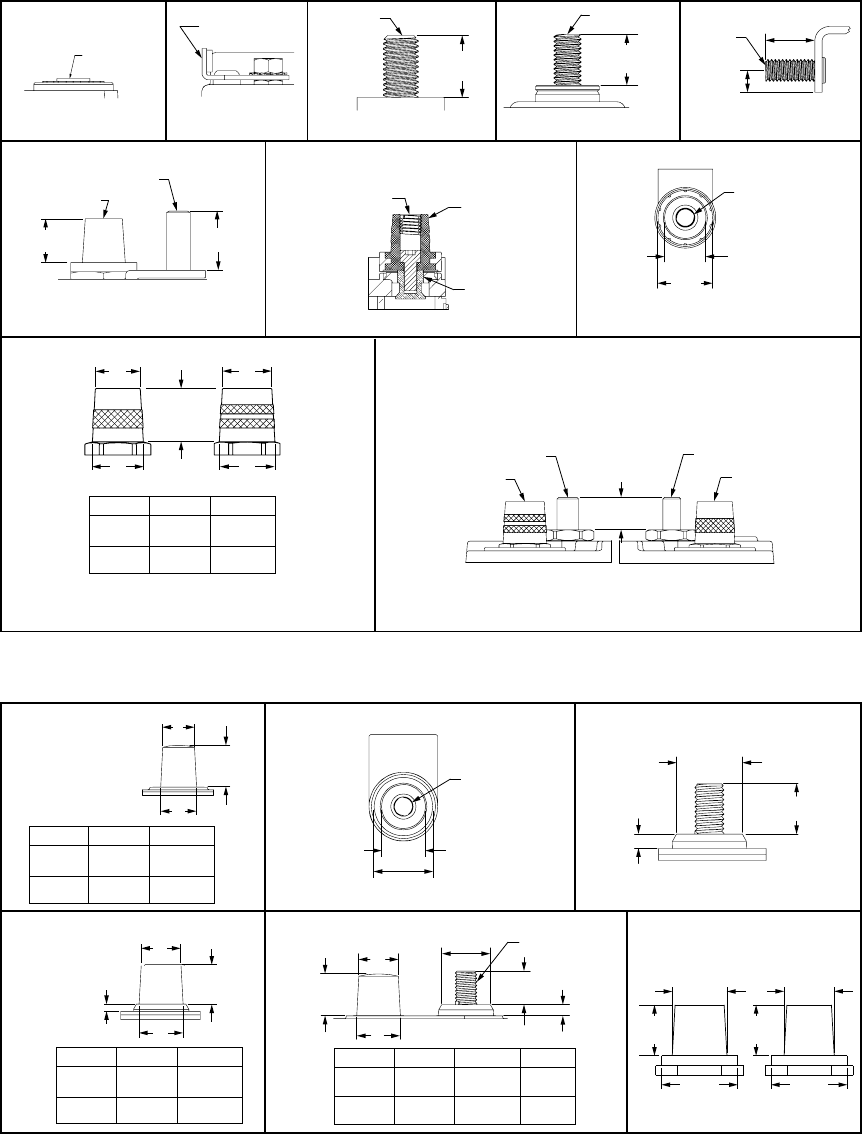

D. TORQUE SPECIFICATIONS

Eachterminaltypehasadifferenttorquespecification.Under-tighteningofconnectionscanleadto

short circuit and electrical damage. Over-tightening can cause physical damage to the battery

terminal. Refer to Table 2 below for the recommended torque specification based on the terminal type.

Terminal Type Details

Maximum Torque

[in-pounds]

Maximum Torque

[Nm]

Stud3/8-16”HD AllG31,Marineand8D 200 22.6

Stud3/8-16” ODS-AGM6M 100 11.3

Stud5/16-18” All Marine 100 11.3

SideTerminal3/8-16”Receptacle G75 G78 60 6.8

M4 Receptacle ODS-AGM8E(PC310) 8.9 1

M6Receptacle ODS-AGM16B,16CL 40 4.5

M6Receptacle ODS-AGM15L,16L 50 5.6

M6Receptacle ODS-AGM28*, 42*, 70* 60 6.8

M6Receptacle ODS-AGM***FT 35 3.9

*ForSAEtorquespecicationrefertovehiclemanufacturer’sspecication.

Table 2

7

AMER-EN-IOM-ODY-0523

www.odysseybattery.com

0.73”

(18.5 mm)

A

B

ODP-AGM34

ODP-AGM34R

ODP-AGM48 H6 L3

ODP-AGM65

ODP-AGM75 86

ODP-AGM94R H7 L4

ODP-AGM49 H8 L5

TERMINAL

0.682” 0.759“

(17.3 mm) (19.3 mm)

0.619” 0.696”

(15.7 mm) (17.7 mm)

POSITIVE

NEGATIVE

DIM A DIM B

SAE TERMINALS

TERMINAL

0.682” 0.759”

(17.3 mm) (19.3 mm)

0.619” 0.696”

(15.7 mm) (17.7 mm)

POSITIVE

NEGATIVE

DIM A DIM B

B

A

0.68”

(17.3 mm)

0.13”

(3.2 mm)

SAE TERMINAL

ODP-AGM31A

A

B

0.20”

(5.1 mm)

0.59”

(15.0 mm)

0.85”

(21.6 mm)

0.73”

(18.6 mm)

TERMINAL

0.682” 0.759”

(17.3 mm) (19.3 mm)

0.619” 0.696”

(15.7 mm) (17.7 mm)

POSITIVE

NEGATIVE

DIM A DIM B

THREAD

3/8-16

5/16-18

THREAD

MARINE (DUAL TERMINAL)

ODP-AGM31M

ODP-AGM34M

ODP-AGM4D

ODP-AGM8D

3/8-16” THREAD

0.34” DEEP

0.85”

(21.6 mm)

1.12”

(28.5 mm)

SIDE TERMINALS

ODP-AGM78

ODP-AGM75 86

0.695” - 0.725”

(17.65 mm - 18.42 mm)

0.85”

(21.6 mm)

0.19”

(4.7 mm)

STUD TERMINALS

ODP-AGM31

NEGATIVE POSITIVE

B

B

0.732”

(18.6mm)

A

A

TERMINAL

0.677” 0.759”

(17.2 mm) (19.3 mm)

0.614” 0.696”

(15.6 mm) (17.7 mm)

POSITIVE

NEGATIVE

DIM A DIM B

ODX-AGM34 ODX-AGM34R ODX-AGM34 78

ODX-AGM65 ODX-AGM31A

SAE TERMINALS

0.76”

(19.4mm)

0.70”

(17.8mm)

1.06”

(27mm)

1.06”

(27mm)

0.65” - 0.75”

(16.5 - 19.1mm)

3/8-16” THREAD

ODX-AGM31

M6 FEMALE

THREAD

ODS-AGM16B

ODS-AGM16CL

0.43”

(11.0 mm)

M6 THREAD

ODS-AGM30E ODS-AGM40E

M6 FEMALE

THREAD

ALL OTHER MODELS

1.00”

(25.4 mm)

0.53”

(13.5 mm)

3/8-16”

THREAD

ODS-AGM470FTT

(FRONT TERMINAL)

3/8-16” THREAD

0.34” DEEP

0.85”

(21.6 mm)

1.12”

(28.5 mm)

ODX-AGM78 ODX-AGM34 78

SIDE TERMINAL

0.71”

(18mm)

0.71”

(18mm)

DIN TERMINAL

3/8-16” THREAD

0.72”

(18.2 mm)

0.96”

(24.5 mm)

ODS-AGM6M

POSITIVE

SAE

NEGATIVE

SAE

NEGATIVE MARINE

5/16-18” THREAD

POSITIVE MARINE

3/8-16” THREAD

0.568”

(14.4 mm)

ODX-AGM34M ODX-AGM31M

(SEE SAE DIAGRAM

FOR TERMINAL

DETAILS)

POSITIVE NEGATIVE

BRASS SAE

TERMINAL

(SEE SAE

DIAGRAM FOR

DETAILS)

3/8-16” FEMALE

THREAD

BATTERY

TERMINAL

(FEMALE M6)

OPTIONAL SAE TERMINAL

(INSTALLED ON FEMALE M6 TERMINALS)

ODYSSEY

®

EXTREME BATTERIES

ODYSSEY

®

PERFORMANCE BATTERIES

AMER-EN-IOM-ODY-0523

www.odysseybattery.com

8

V. TECHNICAL DETAILS

A. OPERATING TEMPERATURE RANGE

Temperature impacts the life and performance of AGM

2

batteries,asitdoesallbatteries.Ingeneral,

higher temperatures reduce battery life while lower temperatures reduce the available capacity that a

batterycanprovide.RefertoTable3belowfortheoperatingtemperaturerangeforeachmodel.

Battery Model Maximum Operating Temperature Range

ODP-AGM

All models -40°F(-40°C)to140°F(60°C)

ExceptODP-AGMDINsizes

(with or without ODYSSEY

®

Connect battery

monitoring system)

-40°F (-40°C)to113°F(45°C)

ODX-AGM

All models -40°F(-40°C)to176°F(80°C)

ODS-AGM

Powersports (without metal jacket) -40°F(-40°C)to113°F(45°C)

Powersports (with metal jacket) -40°F(-40°C)to176°F(80°C)

Marine and RV -40°F(-40°C)to104°F(40°C)

NSB-AGM

All models -40°F(-40°C)to176°F(80°C)

Table 3

B. UNDERSTANDING STATE OF CHARGE

SOC OCV

100% 12.9

75% 12.6

50% 12.2

25% 11.9

0% 11.5

Table 4

Like all batteries, it is best that AGM

2

batteries be kept at

ahighSOC.Itisimportanttounderstandhowto

determine the SOC of AGM

2

batteries correctly. The

approximate SOC value is found by measuring the

battery’sOpenCircuitVoltage(OCV)withahigh-quality

voltmeter. The voltage reading must be taken at least four

hoursafterthebatteryfinisheschargingoratleast30

minutes after it finishes a discharge. Measurements will

not be accurate if adequate rest time is not allowed.

Table 4 shows the typical relationship between OCV and SOC.

C. STORAGE AND SELF-DISCHARGE

Table 5

Storage

Temperature

Storage

Time (Months)

41°F(5°C) 48

59°F(15°C) 36

77°F (25°C) 24

95°F(35°C) 12

113°F(45°C) 6

Even if batteries are not installed in an

application and are being stored, their SOC

declines over time. The rate at which a

battery loses charge depends on the

temperature. The warmer the temperature

the shorter the storage time before a

freshening charge is required. Cooler

temperatures slow down the rate of

self-discharge. A good rule of thumb to use

isthatforevery18°F(10°C)riseintemperaturethestoragetimeiscutinhalf.Thismeansthatthe

storagetimeat95°F(35°C)ishalfthestoragetimeat77°F(25°C).

Ifstoredat77°F(25°C)orlower,ODYSSEY

®

AGM

2

batteries should be given a freshening charge at

leastonceeverytwoyearsorwhentheOCVdropstoabout12.2volts,whichevercomesfirst.This

9

AMER-EN-IOM-ODY-0523

www.odysseybattery.com

OCV corresponds to a SOC of about 50%. Batteries should always be fully charged before they are

stored. The warmer the temperature the more frequently OCV should be monitored. Table 5 shows

how temperature impacts the rate of self-discharge.

D. BATTERY LIFE EXPECATIONS

Cycling Applications and Depth of Discharge (DOD)

Applications in which the battery is frequently discharged and recharged are called cyclic. A complete

cycle starts with a charged battery that is discharged and then brought back to a full charge. Design

battery life in these applications is stated as the number of cycles the battery will deliver before its

capacitydropsto80%ofitsratedvalue.Forexample,supposeabatteryisratedat100amphours

(Ah) and has a published cycle life of 400. This means that the battery can be cycled 400 times before

its delivered capacity drops to 80Ah.

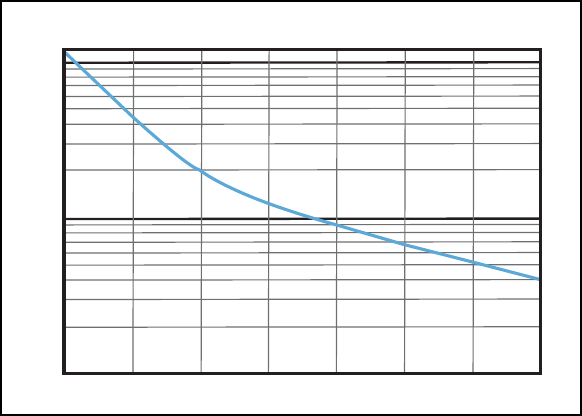

DOD is one of the main factors that determines how many cycles a battery can provide. The DOD is

simply the ratio of capacity extracted from the battery to its rated capacity expressed as a percentage.

Ifa100Ahbatterydelivers65Ahandisthenrecharged,itissaidtohavedelivereda65%DODcycle.

ThegeneralrelationshipbetweenDODandnumberofcyclesisshownbelowinFigure1.HigherDODs

results in longer cycle life.

TPPL Cycle Life Graph

10000

1000

100

Cycles

Depth of Discharge %

10 20 30 40 50 60

70

80

*Data based on laboratory testing

Figure 1

E . FLOAT APPLICATIONS

Batteries that are primarily used as a source of backup or emergency power are not frequently cycled.

The life of these types of applications is referred to as float life. Emergency lighting, security alarms

andUninterruptiblePowerSupply(UPS)aregoodexamplesofbatteriesinfloatapplications.In

eachoftheseapplicationsthebatteryisdischargedonlyifthemainutilitypowerislost;otherwise

the battery remains on continuous float or trickle charge.

Since ODYSSEY

®

AGM

2

batteries are dual purpose by design, they offer a long-life battery option in

float applications. At room temperature (77°F (25°C)), these batteries have a design life of 10+years in

float applications. At end of life, an AGM

2

battery will still deliver 80% of its rated capacity.

AMER-EN-IOM-ODY-0523

www.odysseybattery.com

10

F. CHARGING

TherelationshipbetweencyclelifeandDODshowninFigure1holdsonlyifthebatteryisproperly

charged after each discharge. This means that each time the battery is discharged, between

103-105%ofthedischargedamphoursshouldbereturned.Forexample,if100amp-hourswere

dischargedfromthebatterybetween103-105amp-hoursmustbereturnedtothebatteryforafull

recharge. Failure to do so (over or under charging) will result in a loss of cycle life and ultimately a loss

of capacity. There are several ways to recharge batteries and the best way depends on how the

battery is being used.

Charging with an Alternator

Whenusedinstartingapplications,ODYSSEY

®

AGM

2

12-voltbatterieswillbechargedon-boardwith

astandardautomotivealternatorthatgeneratesanywherebetween14.2-14.5voltsat77ºF(25ºC).We

recommendatemperaturecompensationofthechargevoltageat±18mvperbatteryperºCvariation

intemperaturefrom25ºC.Thewarmerthetemperaturethelowerthechargevoltageandthecooler

the temperature the higher the charge voltage.

Charging with an A/C Powered Charger

Whenusedincyclingorstand-bypowerapplications,anA/Cpoweredchargercanbeusedto

recharge ODYSSEY AGM

2

batteries. There are two main types of A/C powered battery chargers on

the market: full recharging ability or maintaining a full SOC.

Inordertorechargeabatterythathasbeendischarged,itisbesttouseanautomaticchargerwithan

AGM setting that has the appropriate charge voltage and current per recommendations. For optimum

charging,thecurrentoutputshouldatleast40%ofthebattery’sC10rating.Thismeansabatterythat

hasa10-hourratingof100amphoursshouldbechargedwith40amps.Chargecurrentshouldnever

belessthan10%ofthebattery’sC10rating.Voltageshigherthan15.0voltswillcauseirreversible

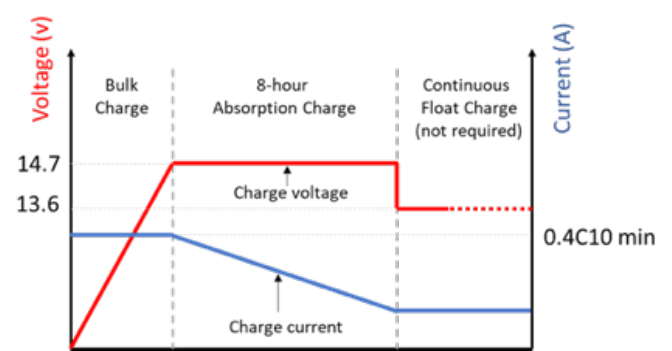

damage to the battery. Please refer to Figure 2 below for a graphical representation of the

recommended charge profile for ODYSSEY AGM

2

batteries used in non-starting applications.

Figure 2

ChargersthataredesignedformaintainingafullSOCareoftencalled“float”or“trickle”chargers

andgenerallysupplycurrentinthe0.5ampto1.5amprange.Thesechargersmightalsobecalled

maintenance chargers and are often used to maintain batteries that are used in seasonal applications

such as boats or RVs. These chargers are not suitable for recharging ODYSSEY AGM

2

batteries that

have been deeply discharged. However, they are suitable for maintaining batteries at a full SOC,

provided the float voltage setting is appropriate. The recommended float voltage for ODYSSEY AGM

2

11

AMER-EN-IOM-ODY-0523

www.odysseybattery.com

batteriesis13.6voltsfora12-voltbatteryat77°F(25°C).

There are also chargers available that charge using constant current. These chargers do not have

multiple charge phases as shown in Figure 2. They simply supply current to the battery, which causes

the battery voltage to rise. Once the battery voltage reaches the setpoint for a fully charged battery,

the charging will terminate. How long it takes to charge a battery with this method depends on how

deeplythebatteryisdischargedandhowmuchcurrentthechargerprovides.SeeTable6belowas

anexampleofrechargingabatteryratedat100Ahfromvariousdepthsofdischargeusinga10-amp

constant current charger.

Open Circuit

Voltage

Depth of Discharge Charge Time

(hours)

12.6 25% 4

12.2 50% 8

11.9 75% 12

11.5 0% 16

Table 6

Temperature Compensation of Charge Voltages

Proper charging of all AGM

2

batteries requires temperature compensation of the charge voltage. This

is especially true in float applications where the batteries are on-charge constantly. The temperature

compensationcoefficientisapproximately±18mVper°Cvariationfrom25°Cper12-voltbattery.

Temperature and charge voltage are inversely related. Therefore, charge voltage must be reduced as

temperatures increase and charge voltage must be increased as temperatures decrease. Regardless

oftemperature,theminimumchargevoltageis13.2voltsaslowervoltageswilldamagethebattery

grids and shorten life.

Recovering a Severely Discharged Battery

Many commercially available chargers must detect a certain minimum voltage for the charging process

tostart.Thisisacommonsafetyfeaturetopreventusinga12-voltchargerona6-voltbattery.

Chargers of this type are unable to charge a battery that has been severely over-discharged. For

example,a12-voltchargermightnotstartthechargingprocessifthebatteryconnectedtoithasan

OCVof5volts.Dependingonthesizeofthebattery,therearetwowaystotrytorecoverthebattery.

• Forbatteriesusedinstartingapplications,thealternatorcanbeusedtorechargethebatteryafter

jump-starting the battery to start the vehicle.

• Forbatteriesnotusedinstartingapplications,asecondbatterythatisknowntobeatahighSOC

can be connected to the discharged battery in parallel. Refer to Section IV, B (Battery Sketch 2)

fordetailsrelatedtoconnectingbatteriesinparallel.Oncethelowbattery’svoltagereaches11.5

volts, the batteries can be disconnected from each other. The standard A/C

charger normally used by the system can then be connected to the battery that needs to be

charged. Please refer to “Procedure to Recover Deeply Discharged ODYSSEY Batteries”found

on www.odysseybattery.com for more details.

Itisimportanttounderstandwhythebatterybecameover-discharged,sothesituationdoesnot

happen again. The most common reasons for batteries to be over-discharged are system issues

relatedtoparasiticloads(seepage13)ormalfunctioning/non-existentlowvoltagedisconnect

equipment.

AMER-EN-IOM-ODY-0523

www.odysseybattery.com

12

Unfortunately,thisrecoveryprocessisnotalwayssuccessful.Whenbatteriesareseverelydischarged,

sulfation develops and can be very difficult to remove depending on how deeply the batteries

are discharged and how long they have been in that state. This condition is not warrantable

since it is the result of abuse or neglect in the application, rather than a manufacturing defect.

Racing Vehicles Using Total Loss (No Alternator)

Standardautomotivetypechargersarenotdesignedtoreturn105-108%oftheenergyremoved.

Theynormallyboostchargeto80-95%andexpectthealternatortocompletethecharge.EnerSys

®

recommendsusingchargersthatprovide105-108%rechargebeforeswitchingtostoragecharge.

Chargers approved by EnerSys are listed on www.odysseybattery.com.

TofullychargeanODX-AGM31andODP-AGM31batterythatareroutinelydischargeddeeply,a

minimumof40ampsarerequiredwithchargervoltagewithintherangeof14.1voltsto14.7volts.

Itisimperativenottoexceed15.0Vasthiswillcausethepressurevalvestoopenandout-gas

hydrogen, oxygen and water from inside the battery. This will shorten the life of the battery and

causeprematurefailure.Someportablechargersexceed15.0volts,especiallytwo-wheelgarage

chargers,sochargingvoltagesshouldbeveriedbymeasuringthechargingvoltageduringthetime

when the charging amperage is reducing from full output. The deep cycle charging voltage must be

within14.1voltsminimumto14.7voltsmaximum.

Ifastandardautomotivechargerisusedtoboostchargeadischargedbatterybecauseofan

accessorylefton,itisimportanttomakesurethechargingvoltagedoesnotexceed15.0volts

during charge. A hand held voltmeter can be used to monitor this periodically.

12V Parallel Connection

BATTERY 1

BATTERY 2

12V MOTOR

GROUND

VEHICLE &

CONNECTION

Battery Sketch 3

24V Parallel Connection

To power a 24-volt trolling motor, you will need to connect two ODYSSEY

®

batteries in a series. As

showninBatterySketch4,thenegativeofBattery1iswiredtothepositiveofBattery2.Hookupthe

positiveterminalofBattery1tothepositiveterminalofyourtrollingmotorandthenegativeterminalof

Battery 2 to the negative terminal of the trolling motor.

BATTERY 1

BATTERY 2

24V MOTOR

Battery Sketch 4

13

AMER-EN-IOM-ODY-0523

www.odysseybattery.com

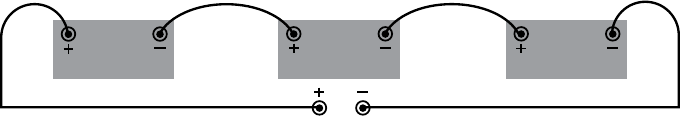

36V Parallel Connection

Topowera36-volttrollingmotor,youwillneedtoconnectthreeODYSSEYbatteriesinseries.As

showninBatterySketch5,thenegativeofBattery1iswiredtothepositiveofBattery2;thenegative

ofBattery2isthenconnectedtothepositiveofBattery3.Finally,hookupthepositiveterminalof

Battery1tothepositiveterminalofyourtrollingmotorandthenegativeterminalofBattery3tothe

negative terminal of the trolling motor.

BATTERY 2

36V MOTOR

BATTERY 3

BATTERY 1

Battery Sketch 5

G. PARASITIC LOADS

Inmanycasesbatteriesthatareapparentlyatrestmaybesupplyingasmallamountofcurrentto

connected equipment such as radios, clocks and security systems, to name just a few examples.

Today’svehicleshavemultipleon-boardelectronicsthatrequiresmallamountsofpower.Thesesmall

currents are collectively referred to as parasitic loads and may be detrimental to the life of a battery if

they are not accounted for in the design of the system.

Overtimethesesmallloads–typicallytensofmilliamps(mA)–willconsumesignificantamphours,

which results in the battery voltage decreasing. Consider a boat that has a parasitic draw of 20mA and

isdockedforfivemonthswiththebatteryconnectedtotheload.Inthat150-dayperiodthatparasitic

load will consume more than 70 amp hours.

There are three ways to ensure that batteries are not being drained by parasitic loads in the system.

1.Physicallydisconnectthebatteryfromtheloadafterfullychargingit.Amasterdisconnect

switch is also an effective countermeasure.

2. Periodically give the battery a freshening charge, using the charging guidelines outlined

onpage10.

3.ConnectatricklechargerforAGMbatterieswhenthebatteryisstored,usingthecharging

guidelinesoutlinedonpage10.

H. TESTING

There are several different ways to test AGM

2

batteries. Depending on the time and equipment

available, one may choose to perform either a capacity test, a ½CCA Load Test or a Conductance

Test. These options should help determine whether the battery returned by the customer has reached

its end of life or simply needs a full recharge. For all methods, the battery should be fully-charged

before testing. The following includes details related to each test method:

RECOMMENDATION: Testing should be completed on a clean/main battery terminal surface, not

a steel stud. Testing batteries individually in multiple battery situations is best. At minimum, each

battery must be disconnected at one terminal (the same polarity).

1. Capacity Testing: This method tests the performance of the battery based on its Reserve

Capacity (RC) rating, which means the test may be more time consuming, however it is the

preferred test method for a state of health check. The equipment needed to perform this

AMER-EN-IOM-ODY-0523

www.odysseybattery.com

14

type of testing is called a discharger tester. The battery should be fully charged before using

this test method. Discharge testers are designed to apply a constant current load to a fully-

charged batteryuntilthebatteryvoltagereaches1.75voltspercell(10.5voltsperbattery)or

other appropriate end point voltageinlinewithpublishedperformancetables,whichis100%

discharged.Thelengthoftimethedischargetesterrunsuntil1.75voltspercellisreached

shouldbecomparedtothebattery’srated RC. Batteries that do not provide at least 80% of

their rated runtime are considered failed.

2. ½CCA Load Test: This method tests the performance of the battery based on its CCA rating

and is much faster than capacity testing. The equipment needed to perform this type of test is

called a ½CCA load tester. For accurate testing, the battery must be at least 75% charged,

which for AGM

2

batteriesmeanshavinganOCVof12.6voltsorhigher.

To perform the test, the CCA rating of the battery must be programmed into the tester. These

testersapplyhalfofthebattery’sCCAratingtothebatteryfor15seconds.After15seconds,

thebatteryvoltageshouldbeabove9.6voltsifthetemperatureis70°F(21°C)orwarmer;voltage

below 9.6indicatesafailedbattery.Fortemperaturesbelow70°F(21°C), refer to Table 7 on the

next page for voltage. Most of these testers will specify whether the battery passed or failed the

test. This can be an ideal test for batteries used in starter applications.

Temperature End of Test Voltage

70°F(21ºC) 9.60

60°F(16ºC) 9.50

50°F(10ºC) 9.40

40°F(5ºC) 9.30

30°F(-1ºC) 9.10

20°F(-7ºC) 8.90

10°F(-12ºC) 8.70

0°F(-18ºC) 8.50

Table 7

3.Conductance Test: This method tests the performance of the battery based on its level of

conductance. This is a fast test and is generally the type of test that will be used by auto parts

shops. The equipment needed to perform this type of test is a hand-held electronic battery

tester. There are a variety of hand-held testers on the market and most allow the user to

programkeybatteryparameterssuchasCCAandbatterytype.Ifthetesterhasanoptionfor

AGM

2

, it should be used, otherwise AGM is suitable. Like the ½CCA Load Test, the AGM

2

batteryshouldhaveanOCVof12.6voltsorhigherbeforetesting.Aftertheelectronictestingis

complete, the tester will indicate whether the battery passed or failed.

I. MAINTENANCE

ODYSSEY

®

AGM

2

batteries are very different from standard flooded batteries that are openly vented.

These batteries operate as a sealed battery, which depend on internal recombination of battery

gasses under normal operating conditions. This means that there should be minimal corrosion of

terminalsoranypartofthesurroundingarea.Intheeventthatcorrosionispresent,itisbesttoclean

it off thoroughly by using a wire brush on any metal surfaces, and a wet rag anywhere else where there

areresidualsubstances.Itisalwaysrecommendedtouserubbergloveswhencleaningabattery.Do

not use chemicals to clean a battery, as some can damage to the plastic of the battery. There is no

15

AMER-EN-IOM-ODY-0523

www.odysseybattery.com

need to add water to the batteries. Opening the battery cover causes damage to the battery and voids

any warranty.

PLEASE NOTE: Perform periodic inspection for case damage, loose battery hold downs, loose

connections, corrosion and container swelling.

J. VENTILATION

ODYSSEY

®

AGM

2

batteries are part of a broader category of lead acid batteries called VRLA. This type

of battery depends on the internal recombination of battery gasses for proper operation. The internal

valveallowsfornearly100%recombinationofgasses,whichmeansthereisnoneedtoperiodically

add water.

WARNING: Any battery producing an odor or visibly venting should be removed from service.

Physically disconnect only after the area has been ventilated.

The high recombination efficiency of ODYSSEY AGM

2

batteries makes them safe for installation in

humanenvironments.Itisnotuncommontoseethesebatteriesinaircraft,hospitaloperatingrooms

and computer rooms. The only requirement is that these batteries must not be stored, operated or

charged in a sealed or gastight enclosure. However, local regulations regarding ventilation must also

be followed.

K. Winter Storage

The ODYSSEY battery does not lose its charged energy during cold storage temperatures, so there

isnoneedtotrickleoroatchargeduringwintermonths.Tostoreo-season,measurethebattery

voltagetomakesureitisfullycharged,12.84voltsorgreater;rechargeifnecessary.Disconnectthe

negative battery cable to prevent any applied electrical load during storage. The ODYSSEY battery

cannotfreezedownto-40°F(-40°C),soitcanbeleftinthevehicle.Itcanbestoredfortwoyearsor

morebelow77°F(25°C).Chargingisrequiredattwoyearsor12.2volts,whichevercomesrst.

A12-volttricklechargercanalsobeleftconnectedtothebatteryifitiskeptinstorageforextended

periods or if the battery is subject to parasitic loads during storage. The trickle charge voltage

measuredatthebatteryterminalsmustbebetween13.5voltsand13.8volts.Itisrecommendedto

use the ODYSSEY battery charger for your battery. Additional information on ODYSSEY battery

chargers, where to buy ODYSSEY battery chargers and ODYSSEY battery charging in general can

be found at www.odysseybattery.com.

L. WARRANTY CONSIDERATIONS

ODYSSEY AGM

2

batteries are covered by warranty against defects in material and workmanship for at

least two years. Some models and applications are covered for longer. Please note that the following

actions will void any warranty coverage:

• Removingthelabeledcover

• Removingoralteringthebattery’sdatecode/serialnumber

• Removingoralteringthebatteryterminal(s)

• Openingthebatterycase

The complete warranty statement can be found on our website, www.odysseybattery.com, for more details.

AMER-EN-IOM-ODY-0523

www.odysseybattery.com

16

VI. ADDITIONAL INFORMATION

Should you need additional information, please contact your local Sales Representative or battery

supplier.OurTechnicalSupportgroupisalsoavailablebyphoneat+1-800-964-2837andby

submittingaTechnicalInquirythroughtheContactUslinkonourwebsite.

VII. FAQS

Are ODYSSEY

®

AGM

2

batteries the same as Gel batteries?

No, these are not Gel batteries. These are absorbed electrolyte batteries, which means there is no

freeacidinsidethebattery;alltheacidisabsorbedintheglassmatseparators.Theseseparators

servetokeepthepositiveandnegativeplatesapart.InGelbatteries,theelectrolyteisinagelform.

What is the Ah rating?

Theamperehour(Ah)ratingdefinesthecapacityofabattery.Abatteryratedat100Ahatthe

10-hourrateofdischargewilldeliver10Afor10hoursbeforetheterminalvoltagedropstoa

standardvaluesuchas10.5voltsfora12-voltbattery.

Does mishandling the battery void the warranty?

The warranty applies to manufacturing defects and workmanship issues and does not cover

damages caused by customer mishandling.

What is the CCA rating?

Per SAE standard, the Cold Cranking Ampere (CCA) rating is the number of amperes a battery can

deliverfor30secondsatatemperatureof0°F(-18°C)beforethevoltagedropsto1.2voltspercell

or7.2voltsfora12-voltbattery.A12-voltbatterythathasaratingof550CCAwilldeliver550amps

for30secondsat0°F(-18°C)beforethevoltagefallsto7.20.

What is the MCA rating?

The Marine Cranking Ampere (MCA) rating refers to the number of amperes a battery can deliver for

30secondsatatemperatureof32°F(0°C)untilthebatteryvoltagedropsto7.20fora12-volt

battery.A12-voltbatterythathasanMCAratingof725willdeliver725amperesfor30seconds

at32°F(0°C)beforethevoltagefallsto7.20.TheMCAissometimescalledthecrankingamperes

or CA.

What is the HCA rating?

TheabbreviationHCAstandsforHotCrankingAmps.ItisthesameasMCA,CAorCCA,except

thatthetemperatureatwhichthetestisconductedis80°F(26.7°C).

What is the PHCA rating?

UnlikeCCAandMCA,thePulseHotCrankingAmpere(PHCA)ratingdoesnothavean“official”

definition;however,itissuggestedthatfortrueautomotiveandmarinepurposes,a30-second

dischargeisunrealistic.ThePHCA,ashortduration(about3-5seconds)highratedischarge,ismore

realistic. Because the discharge is for such a short time, it is more like a pulse. The low impedance

of ODYSSEY battery technology allows them to maintain a higher voltage for more starter pulses,

resulting in less heating of starter motors and cables. Higher power output results in a faster start.

What is impedance?

The impedance of a battery is a measure of its internal resistance. The lower the battery impedance

the more the available power. The impedance of ODYSSEY

®

AGM

2

batteries is considerably

lower than that of a conventional automotive or marine battery. The high rate discharge capability

of ODYSSEY AGM

2

automotive and marine batteries is significantly higher than that of conventional

automotive and marine batteries.

17

AMER-EN-IOM-ODY-0523

www.odysseybattery.com

What is Reserve Capacity (RC) rating?

The RC of a battery is the number of minutes it can support a 25-ampere load at 80°F (27°C) before

itsvoltagedropsto10.50fora12-voltbattery.A12-voltbatterywithareservecapacityratingof100

willdeliver25ampsfor100minutesat80°F(27°C)beforeitsvoltagedropsto10.5.

What is the short-circuit current of these batteries?

Typically thousands of amps. As mentioned before, the AGM

2

batteries have a very low internal

resistance, which means that the short circuit current is very high. Precautions should be taken to

avoid short circuits as equipment and battery damage will occur.

What is the operating temperature range of these batteries?

Theoperatingrangevariesbasedonthebatterytype.RefertoTable3onpage8fordetails.

Is the battery ruined if it is dropped?

Itispossibletodamagetheinternalconnectionsaswellastheexternalcontainer,leadingtoa

damaged the battery. Batteries with visible external damage should not be used. Dropped batteries

should be tested prior to use.

VIII. DEFINITIONS OF ACRONYMS

AGM–AbsorbedGlassMatbattery.ThisisatypeofVRLAbatteryinwhichalltheelectrolyteinthe

battery is absorbed into the glass mat separator material.

TPPL – Thin Plate Pure Lead. This refers to the fact that these batteries are made of very thin plates,

which do not contain any calcium or other typical impurities that deplete battery voltage over time.

VRLA Battery – Valve Regulated Lead Acid Battery. These lead acid batteries are designed to include

pressurereliefvalvesthatallowfornearly100%recombinationofthegassesthatwouldventin

traditional flooded batteries. Because of this very efficient recombination process, there is no need

to periodically add water to these batteries.

OCV – Open Circuit Voltage. This is a voltage reading obtained from a battery that is not charging or

discharging. To get an accurate OCV on AGM

2

batteries, it is important to wait at least four hours after

chargingor30minutesafterdischargingtotakethevoltagereading.

DOD – Depth of Discharge. This is the measure of how many amp hours were taken out of a battery

comparedtothebattery’srating.Forexample,a100amp-hourbattery,whichhas40amp-hours

removed during discharge is said to be at 40% DOD.

SOC – State of Charge.Thelevelofchargeofabattery.Itcanbeapproximatedbyevaluatingthe

battery’sOCV.

www.enersys.com

EnerSys World Headquarters

2366 Bernville Road

Reading, PA 19605, USA

Tel: +1-800-964-2837

EnerSys EMEA

EH Europe GmbH

Baarerstrasse 18

6300 Zug, Switzerland

EnerSys Asia

152 Beach Road

#11-08 Gateway East Building

Singapore 189721

Tel: +65 6431 3700

© 2023 EnerSys. All rights reserved. Trademarks and logos are the property of EnerSys and its affiliates unless otherwise noted. Subject to revisions without prior notice. E.&O.E.

AMER-EN-IOM-ODY-0523

Want more info?

Scan code to access

the ODYSSEY

®

Battery

Literature Library