Department of Fire and Rescue Services

S

tandardized

T

raining

P

rogram

Topic: Electrical Safety

Issue Date: January 2013

STP #: 2013-Q1-T1

Author: Capt. Darrell Hout

Dedication:

This STP is dedicated to FF Fred Dunn of the Silver Spring Fire

Department who was killed in the line of duty on October 2nd, 1964. FF Dunn

received a fatal electrical shock while lowering an aluminum ground ladder on the

scene of a structure fire.

Chapter 1:

Electricity: The Basics

Electrical Injuries

There are four main types of electrical injuries:

Electrocution (death due to electrical shock, average of one worker per day)

Electrical shock

Burns

Falls

Electrical Terminology:

Current – the movement of electrical charge

Resistance – opposition to current flow

Voltage – a measure of electrical force

Conductors – substances, such as metals, that have little resistance to

electricity

Insulators – substances, such as wood, rubber, glass, and bakelite, that have

high resistance to electricity

Grounding – a conductive connection to the earth which acts as a protective

measure

Operating an electric switch is like turning on a water faucet. Behind the

faucet or switch there must be a source of water or electricity with something to

transport it, and with a force to make it flow. In the case of water, the source is a

reservoir or pumping station; the transportation is through pipes; and the force to

make it flow is provided by a pump. For electricity, the source is the power

generating station; current travels through electric conductors (wires); and the

force to make it flow - voltage, measured in volts, is provided by a generator

What affects the flow of electricity?

Electricity flows more easily through some materials than others. Some

substances such as metals generally offer very little resistance to the flow of

electric current and are called “conductors.” A common but perhaps overlooked

conductor is the surface or subsurface of the earth. Glass, plastic, porcelain,

clay, pottery, dry wood, and similar substances generally slow or stop the flow of

electricity. They are called “insulators.” Even air, normally an insulator, can

become a conductor, as occurs during an arc or lightning stroke.

Page 1 of 18

How does water affect the flow of electricity?

Pure water is a poor conductor. But small amounts of impurities in water

like salt, acid, solvents, or other materials can turn water itself and substances

that generally act as insulators into conductors or better conductors. Dry wood,

for example, generally slows or stops the flow of electricity. But when saturated

with water, wood turns into a conductor. The same is true of human skin. Dry

skin has a fairly high resistance to electric current. But when skin is moist or wet,

it acts as a conductor. This means that anyone working with electricity in a damp

or wet environment needs to exercise extra caution to prevent electrical hazards.

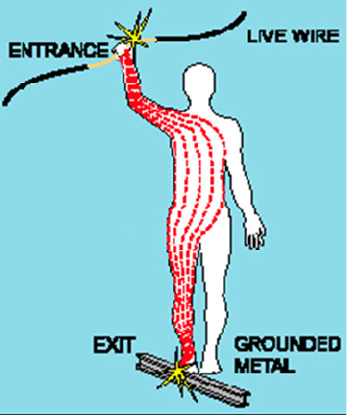

What causes shocks?

Electricity travels in closed circuits, normally through a conductor. But

sometimes a person’s body — an efficient conductor of electricity — mistakenly

becomes part of the electric circuit. This can cause an electrical shock. Shocks

occur when a person’s body completes the current path with:

*Both wires of an electric circuit;

*One wire of an energized circuit and the ground;

*A metal part that accidentally becomes energized due, for example, to a break

in its insulation; or

*Another “conductor” that is carrying a current. When a person receives a shock,

electricity flows between parts of the body or through the body to a ground or the

earth.

What effect do shocks have on the body?

An electric shock can result in anything from a slight tingling sensation to

immediate cardiac arrest. The severity depends on the following:

*The amount of current flowing through the body,

Page 2 of 18

*The current’s path through the body,

*The length of time the body remains in the circuit, and

*The current’s frequency.

This table shows the general relationship between the amount of current

received and the reaction when current flows from the hand to the foot for just 1

second.

Effects of Electric Current in the Human Body

Current Reaction

- Below 1 milliampere Generally not perceptible

- 1 milliampere Faint tingle

- 5 milliamperes Slight shock felt; not painful but disturbing. Average

individual can let go. Strong involuntary reactions can lead to other

injuries.

- 6–25 milliamperes (women) Painful shock, loss of muscular control*

- 9–30 milliamperes (men) The freezing current or “let-go”

range.* Individual cannot let go, but can be thrown away from the

circuit if extensor muscles are stimulated.

- 50–150 milliamperes Extreme pain, respiratory arrest, severe muscular

contractions. Death is possible.

- 1,000–4,300 milliamperes Rhythmic pumping action of the heart ceases.

Muscular contraction and nerve damage occur; death likely.

- 10,000 milliamperes Cardiac arrest, severe burns; death

probable

* If the extensor muscles are excited by the shock, the person may be thrown

away from the power source.

Source: W.B. Kouwenhoven, “Human Safety and Electric Shock,”

Electrical Safety Practices, Monograph, 112, Instrument

Society of America, p. 93. November 1968.

What kind of burns can a shock cause?

Burns are the most common shock-related injury. An electrical accident

can result in an electrical burn, arc burn, thermal contact burn, or a combination

of burns. Electrical burns are among the most serious burns and require

immediate medical attention. They occur when electric current flows through

tissues or bone, generating heat that causes tissue damage. Arc or flash burns

result from high temperatures caused by an electric arc or explosion near the

body. These burns should be treated promptly. Thermal contact burns are

caused when the skin touches hot surfaces of overheated electric conductors,

conduits, or other energized equipment. Thermal burns also can be caused when

clothing catches on fire, as may occur when an electric arc is produced. In

addition to shock and burn hazards, electricity poses other dangers. For

example, arcs that result from short circuits can cause injury or start a fire.

Page 3 of 18

Extremely high-energy arcs can damage equipment, causing fragmented metal

to fly in all directions. Even low-energy arcs can cause violent explosions in

atmospheres that contain flammable gases, vapors, or combustible dusts.

Why do people sometimes “freeze” when they are shocked?

When a person receives an electrical shock, sometimes the electrical

stimulation causes the muscles to contract. This “freezing” effect makes the

person unable to pull free of the circuit. It is extremely dangerous because it

increases the length of exposure to electricity and because the current causes

blisters, which reduce the body’s resistance and increases the current.

The

longer the exposure, the greater the risk of serious injury. Longer exposures at

even relatively low voltages can be just as dangerous as short exposures at

higher voltages. Low voltage does not imply low hazard. In addition to muscle

contractions that cause “freezing,” electrical shocks also can cause involuntary

muscle reactions. These reactions can result in a wide range of other injuries

from collisions or falls, including bruises, bone fractures, and even death.

What should you do if someone “freezes” to a live electrical contact?

If a person is “frozen” to a live electrical contact, shut off the current

immediately. If this is not possible, use boards, poles, or sticks made of wood or

any other no conducting materials and safely push or pull the person away from

the contact. It’s important to act quickly, but remember to protect yourself as well

from electrocution or shock.

How can you tell if a shock is serious?

A severe shock can cause considerably more damage than meets the

eye. A victim may suffer internal hemorrhages and destruction of tissues, nerves,

and muscles that aren’t readily visible. Renal damage also can occur. If you or a

coworker receives a shock, seek emergency medical help immediately.

Page 4 of 18

What is the danger of static electricity?

Static electricity also can cause a shock, though in a different way and

generally not as potentially severe as the type of shock described previously.

Static electricity can build up on the surface of an object and, under the right

conditions, can discharge to a person, causing a shock. The most familiar

example of this is when a person reaches for a door knob or other metal object

on a cold, relatively dry day and receives a shock. However, static electricity also

can cause shocks or can just discharge to an object with much more serious

consequences, as when friction causes a high level of static electricity to build up

at a specific spot on an object. This can happen simply through handling plastic

pipes and materials or during normal operation of rubberized drive or machine

belts found in many worksites. In these cases, for example, static electricity can

potentially discharge when sufficient amounts of flammable or combustible

substances are located nearby and cause an explosion. Grounding or other

measures may be necessary to prevent this static electricity buildup and

the results.

Protection Against Electrical Hazards

What is the best way to protect yourself against electrical hazards?

Most electrical accidents result from one of the following

three factors:

*Unsafe equipment or installation,

*Unsafe environment, or

*Unsafe work practices.

Some ways to prevent these accidents are through the use of insulation,

guarding, grounding, electrical protective devices, and safe work practices.

What protection does insulation provide?

Insulators such as glass, mica, rubber, or plastic used to coat metals and

other conductors help stop or reduce the flow of electrical current. This helps

prevent shock, fires, and short circuits. To be effective, the insulation must be

suitable for the voltage used and conditions such as temperature and other

environmental factors like moisture, oil, gasoline, corrosive fumes, or other

substances that could cause the insulator to fail.

How do you inspect different types of insulation?

Before connecting electrical equipment to a power source, it’s a good idea

to check the insulation for any exposed wires for possible defects. Insulation

covering flexible cords such as extension cords is particularly vulnerable to

damage.

Page 5 of 18

What is grounding and what protection does it offer?

“Grounding” a tool or electrical system means intentionally creating a low-

resistance path that connects to the earth. This prevents the buildup of voltages

that could cause an electrical accident. Grounding is normally a secondary

protective measure to protect against electric shock. It does not guarantee that

you won’t get a shock or be injured or killed by an electrical current. It will,

however, substantially reduce the risk, especially when used in combination with

other safety measures discussed in this booklet. 29 CFR, Part 1910.304,

Subpart S, Wiring Design and Protection, requires at times a service or system

ground and an equipment ground in non-construction applications. A service or

system ground is designed primarily to protect machines, tools, and insulation

against damage. One wire, called the “neutral” or “grounded” conductor,

is grounded. In an ordinary low-voltage circuit, the white or gray wire is grounded

at the generator or transformer and at the building’s service entrance.

An equipment ground helps protect the equipment operator. It furnishes a second

path for the current to pass through from the tool or machine to the ground. This

additional ground safeguards the operator if a malfunction causes the tool’s

metal frame to become energized. The resulting flow of current may activate the

circuit protection devices.

What are circuit protection devices and how do they work?

Circuit protection devices limit or stop the flow of current automatically in

the event of a ground fault, overload, or short circuit in the wiring system. Well-

known examples of these devices are fuses, circuit breakers, ground-fault circuit

interrupters, and arc-fault circuit interrupters. Fuses and circuit breakers open or

break the circuit automatically when too much current flows through them.

When that happens, fuses melt and circuit breakers trip the circuit open. Fuses

and circuit breakers are designed to protect conductors and equipment. They

prevent wires and other components from overheating and open the circuit

when there is a risk of a ground fault.

Ground-fault circuit interrupters, or GFCIs, are used in wet locations,

construction sites, and other high-risk areas. These devices interrupt the flow of

electricity within as little as 1/40 of a second to prevent electrocution. GFCIs

compare the amount of current going into electric equipment with the amount of

current returning from it along the circuit conductors. If the difference exceeds 5

milliamperes, the device automatically shuts off the electric power. Arc-fault

devices provide protection from the effects of arc-faults by recognizing

characteristics unique to arcing and by functioning to deenergize the circuit when

an arc-fault is detected.

The basic idea of an overcurrent device is to make a weak link in the

Page 6 of 18

circuit. In the case of a fuse, the fuse is destroyed before another part of the

system is destroyed. In the case of a circuit breaker, a set of contacts opens the

circuit. Unlike a fuse, a circuit breaker can be re-used by re-closing the contacts.

Fuses and circuit breakers are designed to protect equipment and facilities, and

in so doing, they also provide considerable protection against shock in most

situations. However, the only electrical protective device whose sole purpose is

to protect people is the ground-fault circuit-interrupter

Inadequate Wiring Hazards

A hazard exists when a conductor is too small to safely carry the current

Example: using a portable tool with an extension cord that has a wire too small

for the tool The tool will draw more current than the cord can handle, causing

overheating and a possible fire without tripping the circuit breaker The circuit

breaker could be the right size for the circuit but not for the smaller-wire

extension cord.

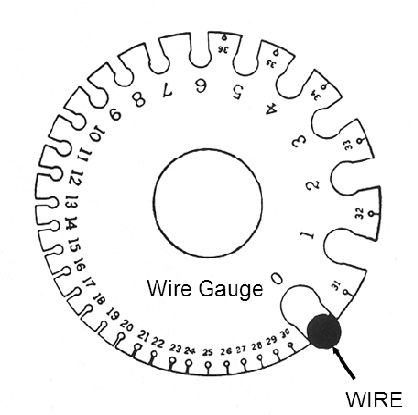

Wire gauges measure wires ranging in size from number 36 to 0 American

wire gauge (AWG) Note that wire-gauge size is inversely related to the diameter

of the wire. For example, a No. 12 flexible cord has a larger diameter wire than a

No. 14 flexible cord.

What work practices help protect you against electrical hazards?

Electrical accidents are largely preventable through safe work practices.

Examples of these practices include the following:

*Deenergizing electric equipment before inspection or repair,

*Keeping electric tools properly maintained,

*Exercising caution when working near energized lines, and

*Using appropriate protective equipment. Page 7 of 18

How can you protect yourself against metal parts that become

energized?

A break in an electric tool’s or machine’s insulation can cause its metal

parts to become “hot” or energized, meaning that they conduct electricity.

Touching these energized parts can result in an electrical shock, burn, or

electrocution. The best way to protect yourself when using electrical tools or

machines is to establish a low-resistance path from the device’s metallic case to

the ground. This requires an equipment grounding conductor, a low-resistance

wire that directs unwanted current directly to the ground. A properly installed

grounding conductor has a low resistance to ground and greatly reduces the

amount of current that passes through your body. Cord and plug equipment with

a three-prong plug is a common example of equipment incorporating this ground

conductor.

What role do tools play?

Appropriate and properly maintained tools help protect workers against

electric hazards. It’s important to maintain tools regularly because it prevents

them from deteriorating and becoming dangerous. Check each tool before using

it. If you find a defect, immediately remove it from service and tag it so no one will

use it until it has been repaired or replaced. When using a tool to handle

energized conductors, check to make sure it is designed and constructed to

withstand the voltages and stresses to which it has been exposed.

What special training do employees need?

All employees should be trained to be thoroughly familiar with the safety

procedures for their particular jobs. Moreover, good judgment and common

sense are integral to preventing electrical accidents. When working on electrical

equipment,

for example, some basic procedures to follow are to:

*Deenergize the equipment,

*Use lockout and tag procedures to ensure that the equipment remains

deenergized,

*Use insulating protective equipment, and

*Maintain a safe distance from energized parts.

Page 8 of 18

Chapter 2:

Working Safely Around Downed

Electrical Wires

Electrical hazards exist in some form in nearly all occupations. However, those

hazards multiply for workers involved in cleanup and recovery efforts following

major disasters and weather emergencies. One particular life-threatening danger

exists around downed and low-hanging electrical wires.

Safety First

Above all else, always consider all equipment, lines and conductors to be

energized. Be cautious and if you notice downed wires or damaged electrical

equipment, contact appropriate utility personnel. Remember that circuits do not

always turn off when a power line falls into a tree or onto the ground. Even if they

are not sparking or humming, fallen power lines can kill you if you touch them or

even the ground nearby.

Energy

Downed wires can energize other objects, including fences, water pipes,

bushes and trees, buildings, telephone/CATV/fiber optic cables and other electric

utilities. Even manhole castings and reinforcement bars (re/bar)

in pavement can become energized by downed wires. During storms, wind-blown

objects such as canopies, aluminum roofs, siding, sheds, etc., can also be

energized by downed wires.

Page 9 of 18

Backfeed

When electrical conductors are inadvertently energized by other energy

sources, backfeed occurs. Some of those sources include:

*Circuit ties/switch points

*Lightning

*Generators

*Downstream events

Simply testing for energy sources is not sufficient since hazardous electrical

events can happen without warning. Ensure that proper lockout/tagout

procedures are always followed

Rules to live by

*Do NOT assume that a downed conductor is safe simply because it is on the

ground or it is not sparking.

*Do NOT assume that all coated, weatherproof or insulated wire is just

telephone, television or fiber-optic cable.

*Low-hanging wires still have voltage potential even if they are not touching the

ground. So, “don’t touch them.” Everything is energized until tested to be de-

energized.

*Never go near a downed or fallen electric power line. Always assume that it is

energized. Touching it could be fatal.

*Electricity can spread outward through the ground in a circular shape from the

point of contact. As you move away from the center, large differences in voltages

can be created.

*Never drive over downed power lines. Assume that they are energized. And,

even if they are not, downed lines can become entangled in your equipment or

vehicle.

*If contact is made with an energized power line while you are in a vehicle,

remain calm and do not get out unless the vehicle is on fire. If possible, call for

help.

*If you must exit any equipment because of fire or other safety reasons, try to

jump completely clear, making sure that you do not touch the equipment and the

ground at the same time. Land with both feet together and shuffle away in small

steps to minimize the path of electric current and avoid electrical shock. Be

careful to maintain your balance.

Page 10 of 18

Chapter 3:

Controlling Electrical Utilities:

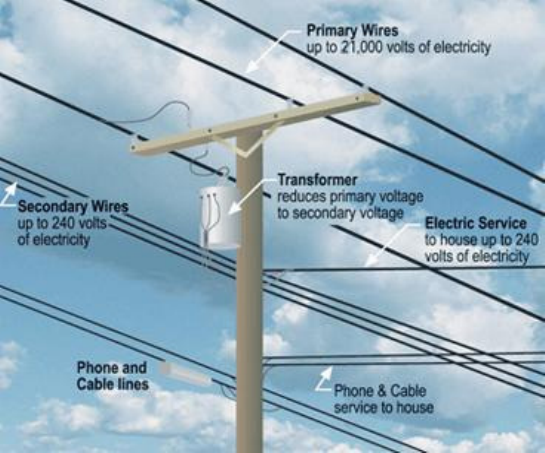

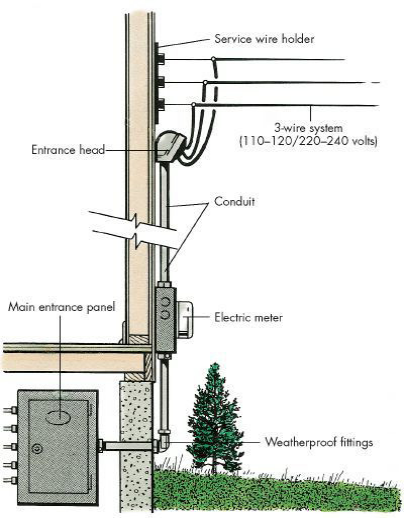

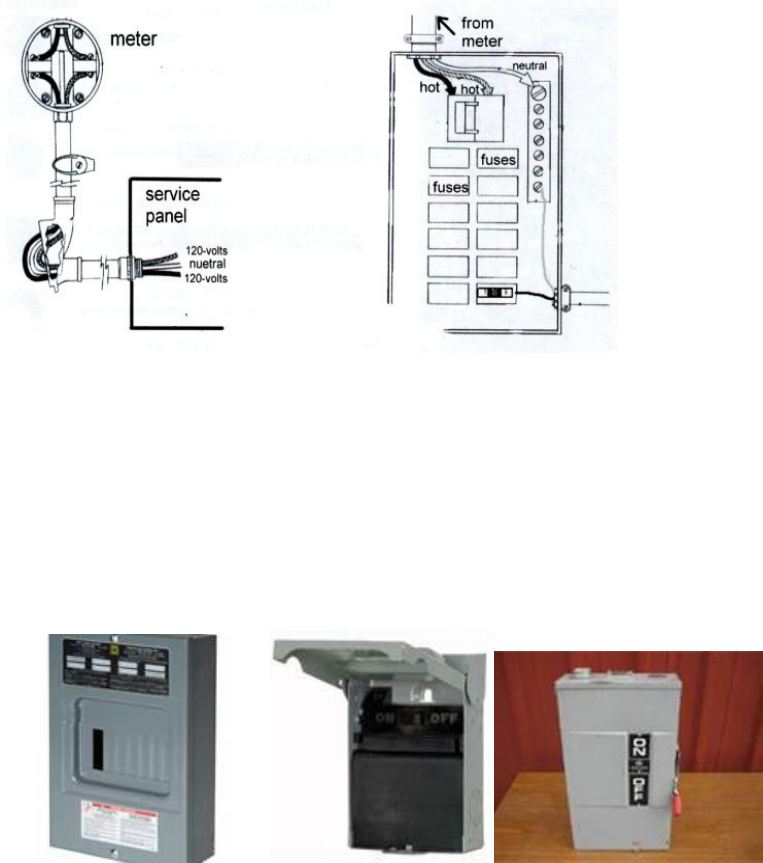

The point at which the electric transmission lines attach to a building is

known as the service entrance. In a residential application this will consist of a

three wire, 240 volt, system including two hot wires and one neutral/ground wire.

A commercial application may add a third hot wire for a 360 volt system. Each

hot wire is supplied by a different phase of the main power generator.

Regardless if this an overhead or underground system, the wires are

attached to the building and run to the meter box. From the meter box, the wires

will enter the building and run to the main circuit breaker panel. By code, the

main circuit breaker panel must be located as close to the meter box as possible.

Inside the main circuit breaker panel, the two hot wires are connected to

different sides the main disconnect and the neutral/ground is connected to the

neutral bus bar. From here, the current passes through the main disconnect and

supplies the individual circuit breakers/fuses. Both 120 & 240 volt circuits can be

supplied by this panel. For a 120 volt circuit, a single circuit breaker supplies one

hot wire and the neutral wire is attached to the neutral bus bar. A 240 volt system

utilizes a double breaker which connects to two hot wires.

Page 11 of 18

Do not rely on the color of the wires to determine which wire is the hot

wire. Usually, the black and red wires are hot, the white wire is neutral, and the

bare wire is the ground. However, there are applications such as a switch leg on

a lighting circuit where the white wire is used as a hot wire.

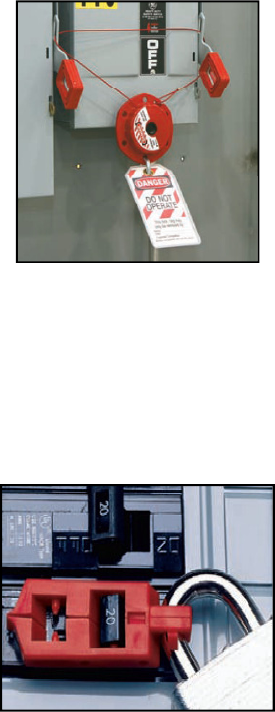

Small circuit load centers and remote electric disconnects may also be

used in addition to the main circuit breaker panel. A small circuit load center is

basically a scaled down version of the main breaker panel. As seen in the

example below, many do not contain a main disconnect. These will be found in

locations where multiple circuits are run. Examples include garages, additions,

laundry rooms, and utility rooms. A remote electric disconnect is required for high

hazard appliances such as hot tubs and exterior HVAC units. Don’t assume that

the power to these devices is controlled by the disconnect in the main circuit

breaker panel. Always confirm that power is removed with a voltage tester!

l

Small circuit load center Remote electric disconnects

Page 12 of 18

.

It is not uncommon to find wiring that is out dated or not up to code. Always test before

starting work near electrical equipment!

The first step to controlling electric to a house should be at the disconnect

in the main circuit breaker panel. However, as previously stated, always confirm

that the electric is shut off locally before starting work. Care should be used if it

becomes necessary to shut off individual breakers. Record any breaker numbers

which were shut off and do not disturb breakers which were “tripped” to assist the

fire marshals’ with their investigation.

Directive 06-03 prohibits fire/rescue personnel from removing electric

meters from their sockets. PEPCO should be utilized to either remove the meter,

or cut power at the pole, if there is an incident which electric power must be cut

off prior to the main disconnect.

Page 13 of 18

Chapter 4:

Making Sure The Electric Stays Off:

Proper lockout/tagout procedures protect you from the dangers of the

accidental or unexpected startup of electrical equipment. These procedures

ensure that electrical equipment is de-energized before it is repaired or inspected

and protects you against electrocution or shock.

The first step before beginning any inspection or repair job is to turn the

current off at the switch box and padlock the switch in the OFF position. This

applies even on so-called low-voltage circuits. Securely tagging the switch or

controls of the machine or equipment being locked out of service clarifies to

everyone in the area which equipment or circuits are being inspected or repaired.

Only qualified personnel who have been trained in safe lockout procedures

should maintain electrical equipment. No two of the locks used should match,

and each key should fit just one lock. In addition, one individual lock and key

should be issued to each maintenance worker authorized to lock out and tag the

equipment. All employees who repair a given piece of equipment should lock out

its switch with an individual lock. Only authorized workers should be permitted

to remove it.

Brady Electrical Lockout / Tagout Toolbox

1 Mini Cable Lockout (50940)

2 120V Snap-On Breaker Lockouts (65387)

2 120/277V Clamp-On Breaker Lockouts w/cleats (65396)

2 480/600V Clamp-On Breaker Lockouts w/cleats (65397)

2 Universal Multi-Pole Breaker Lockouts (66321)

Page 14 of 18

1 Oversized Breaker Lockout (65329)

1 3-in-1 Plug Lockout (PLO23)

1 Wall Switch Lockout (65392)

1 Small Fuse Blockout (65390)

1 Large Fuse Blockout (65691)

2 RED Padlocks

Mini Cable Lockout 50940

●Cable lockout perfect for use on disconnect switches, small gate valves, etc.

●Cable stored internally – works just like a tape measure

● Push-button self-winding mechanism automatically cinches cable tight

● Comes with vinyl-coated steel cable or nonconductive nylon cable

●6 lock holes accommodate most padlock shackles and hasps

●Cable length: 8’

120V Snap-On Breaker Lockout 65387

●Designed for 120V breakers that have holes in the switch tongue

●Quick and easy – just snap in place and apply lock

●Dual cavities accommodate different size switch tongues

Page 15 of 18

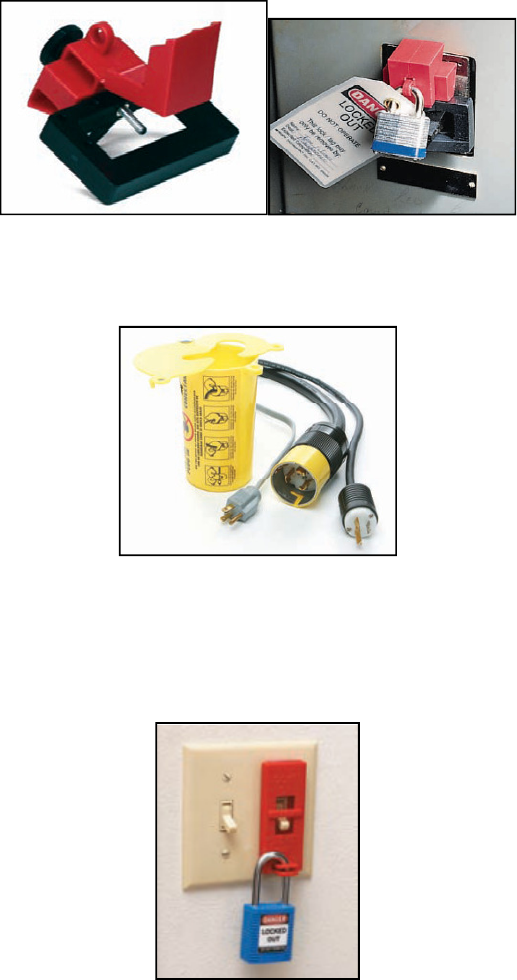

Clamp-On Breaker Lockouts 65396 / 65397

●Works on wide range of single-pole and internal-trip multi-pole breakers

●Two sizes, one for 120/277V breakers and one for 480/600V breakers

●Use thumbscrew to clamp lockout securely onto switch tongue, then pull cover

over thumbscrew and lock in place to prevent clamp from being loosened

●Detachable cleats (included) expand the range of applicable breakers

Cleats for Clamp-On Breaker Lockouts 65396 / 65397

Step1 Step 2 Step 3

●Use in conjunction with clamp-on breaker lockouts

●Easily clips onto the bottom of the lockout body

● Assures positive restraint for breakers with long, sliding switch throws

Universal Multi-Pole Breaker Lockout 66321

●Single device works with most major multi-pole breakers that employ a tie-bar

●Use thumbscrew to clamp lockout securely over tie bar, then insert lock to

prevent clamp from being loosened

●Universal Multi-Pole Lockout works with most two or three pole breakers

utilizing a tie-bar

Page 16 of 18

Oversized Breaker Lockout 65329

●Oversized 480/600V frame lockout fits breaker switches up to 2 1/4" wide and

7/8" thick

PRINZING 3-In-1 Plug Lockout PL023

● Accommodates high and low-voltage plugs up to 3" in diameter and 5 1/2" in

length

● 2 sliding top lids can be used individually or together to accommodate small,

medium and large-diameter cords up to 1 1/4

Wall Switch Lockouts 65392

● Device may be used with most wall-mounted switches

● Easy to install using existing screws

● Locks switch in "on" or "off" position

Page 17 of 18

Fuse Blockout Devices 65690 / 65691

● Block out 1/4" to 11/16" and blade type fuses

● Use these highly visible devices in conjunction with Brady Lockout Tags to

comply with OSHA's Lockout / Tagout Standard

References:

Controlling Electrical Hazards

U.S. Department of Labor/ O.S.H.A.

Electrical

(power-point presentation)

U. S. Department of Labor / O.S.H.A.

Working Safely Around Downed Power Lines

O.S.H.A. Fact Sheet

U.S. Department of Labor / O.S.H.A.

Brady Electrical Lockout/Tagout Toolbox

(power-point presentation supplied by FS 31C)

.

Page 18 of 18